Page 1

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

www.swegon.com 1

GOLD version E/F, Function Guide,

SMART Link/AQUA Link

1. General

The SMART Link function is intended for use in controlling

the times, temperatures, etc. as well as reading the alarms

and settings of a Swegon chiller/heat pump via a handheld micro terminal and web page in a GOLD air handling

unit.

For electrical wiring and functionality at connection with

Nestor, see separate documentation.

1.1 Energy-saving functions

1.1.1 Control of the supply air temperature/supply

flow temperature

By comparing the supply air temperature downstream of

the fan with the supply flow temperature to the coil, the

equipment makes sure that the valve for the coil opens

only if the water has a temperature that conveys energy to

the air.

This means that if there is a heat load and the water temperature is lower than the supply air temperature, which

can occur during defrosting cycles, the valve is not allowed

to open. If there is a cooling load, the reverse applies.

1.1.2 Optimisation function

A cooling unit/heat pump will be more effective if the difference between the outdoor temperature and the water

temperature is as small as possible. This reduces energy

consumption.

The supply air energy to a water coil is controlled by a

valve. Optimisation of the valve position so that it always

strives to be fully open, and instead control the water

temperature, saves energy.

1.1.3 AQUA Link

The AQUA Link provides both air handling units and

comfort modules with cooling power. Even here energy

savings are obtainable by allowing the need to control the

water temperature.

Depending on whatever the specific need is (dehumidification, cooling of the supply air, cooling of the room via

comfort modules), the temperature of the chilled water

can be varied and the control system ensures that the

chiller will not produce chilled water that is colder than

necessary.

1.1 Installation

The installation work is fast and simple compared with

that of other systems. It requires only hydraulic and electric connection between the GOLD unit, chiller/heat pump

and possible AQUA Link.

All the necessary control functions are ready to activate.

One supplier of all the equipment.

The IQlogic

+

module TBIQ-3-1 is included in the AQUA

Link equipment cubical.

2. Material Specification

Air handling unit GOLD RX/PX/CX/SD

Cable adapter TBLZ-1-64

IQlogic

+

module,

extra regulation sequence (SMART link) TBIQ-3-2

Chiller/heat pump manufactured by Swegon that uses

glycolic water as cooling or heating media (not evaporative media).

Other equipment to the extent required:

Set of valves, air heater, air cooler, dual-purpose coil,

AQUA Link.

Page 2

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

2 www.swegon.com

BT1

BT50BT40

MF2

BT30

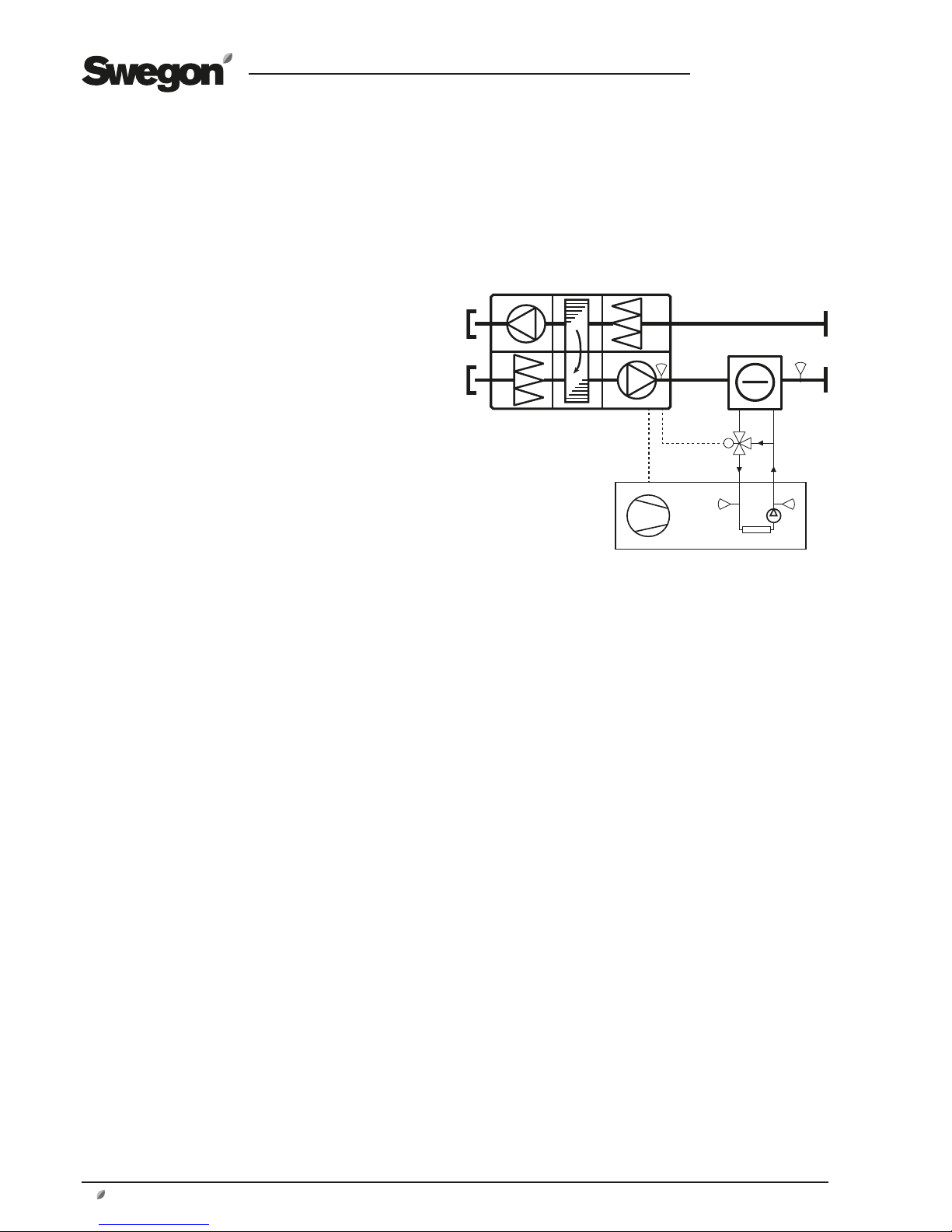

3. Operation

See below and the following pages for diagrammatic

descriptions of the function.

3.1 Control of cooling/heating to the GOLD

via Swegon chiller/heat pump

3.1.1 Chiller

The cooling capacity of the supply air is controlled via an

IQlogic+ module (extra regulation sequence function, see

separate instructions for the TBIQ IQlogic+ module) preset

for cooling (0-10 V). The function can be activated in the

hand-held terminal of the GOLD air handling unit (see the

Operation and Maintenance Instructions for the GOLD).

Communication with the chiller can be activated under

Functions in the hand-held micro terminal of the GOLD

unit. See Section 5.

If temperature sensor BT1 calls for cooling, the function

transmits a refrigerant setpoint (12°C*) to the chiller via

Modbus.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function allows valve MF2 to regulate the flow.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function does not allow valve MF2 to regulate the flow

(forces it to close).

Optimisation function active:

To ensure the best functionality when the optimisation

function is activated, the value for cooling diff. (2 K*)

should be set to the same value as that set in the chiller,

see Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 2K* from the refrigerant temperature

setpoint and if it has been so during a continuous period

of more than 60 seconds* the optimisation function is

allowed.

If the optimisation function is allowed and valve MF2 is

fully open (100%*) the controller decreases the refrigerant temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF2 is

open less than 80%*, the controller increases the refrigerant temperature setpoint at a rate of 0.6K/minute*.

* Factory setting. The value can be changed.

** Estimated temperature in the GOLD RX.

Modbus

0-10 V

GOLD

Supply

air

Swegon chiller

A pump and accumulator tank can be

added and, depending on the size of

the system, can be located inside or

outside the chiller.

Page 3

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

www.swegon.com 3

BT1

BT50

MF1

BT30

BT40

Modbus

0-10 V

GOLD

Supply

air

Swegon heat pump

A pump and accumulator tank can be

added and, depending on the size of

the system, can be located inside or

outside the heat pump.

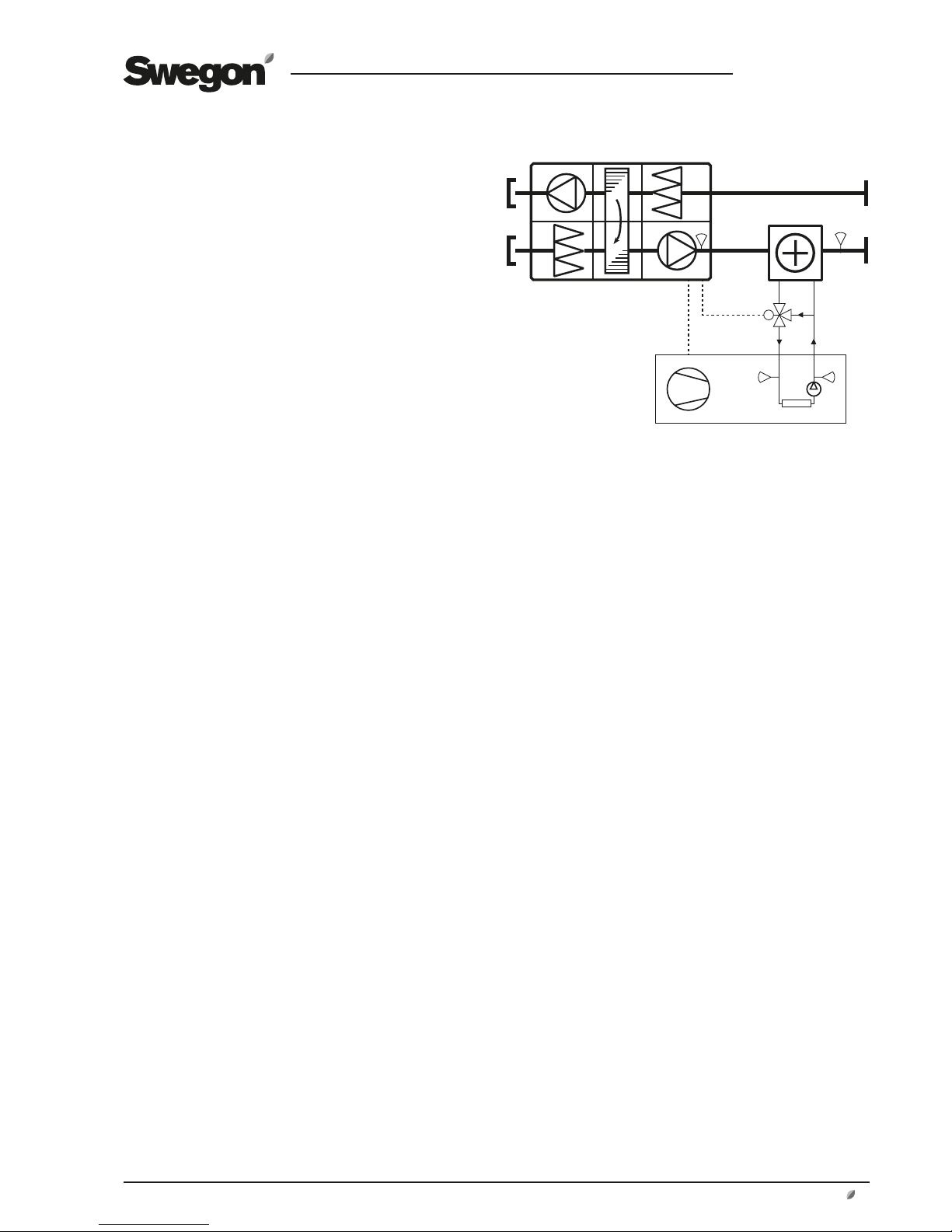

3.1.2 Heat pump

The heating capacity of the supply air is controlled via an

IQlogic+ module (extra regulation sequence function, see

separate instructions for the TBIQ IQlogic+ module) preset

for heating (0-10 V). The function can be activated in the

hand-held terminal of the GOLD air handling unit (see the

Operation and Maintenance Instructions for the GOLD).

Communication with the heat pump can be activated

under Functions in the hand-held micro terminal of the

GOLD unit. See Section 5.

If temperature sensor BT1 calls for heating, the function

transmits a start signal and heating medium setpoint

(40°C*) to the heat pump via Modbus.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function allows valve MF1 to regulate the flow.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function does not allow valve MF1 to regulate the flow

(forces it to close).

Optimisation function active:

To ensure the best functionality when the optimisation

function is activated, the heating diff. value (3 K*) should

be set to the same value as that set in the heat pump. See

Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 3K* from the heating medium temperature setpoint and if it has been so during a continuous

period of more than 60 seconds* the optimisation function is allowed.

If the optimisation function is allowed and valve MF1 is

fully open (100%*) the controller increases the heating

medium temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF1 is

open less than 80%*, the controller decreases the refrigerant temperature setpoint at a rate of 0.6K/minute*.

* Factory setting. The value can be changed.

** Estimated temperature in the GOLD RX.

Page 4

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

4 www.swegon.com

BT1

BT50

BT40

MF1

BT30

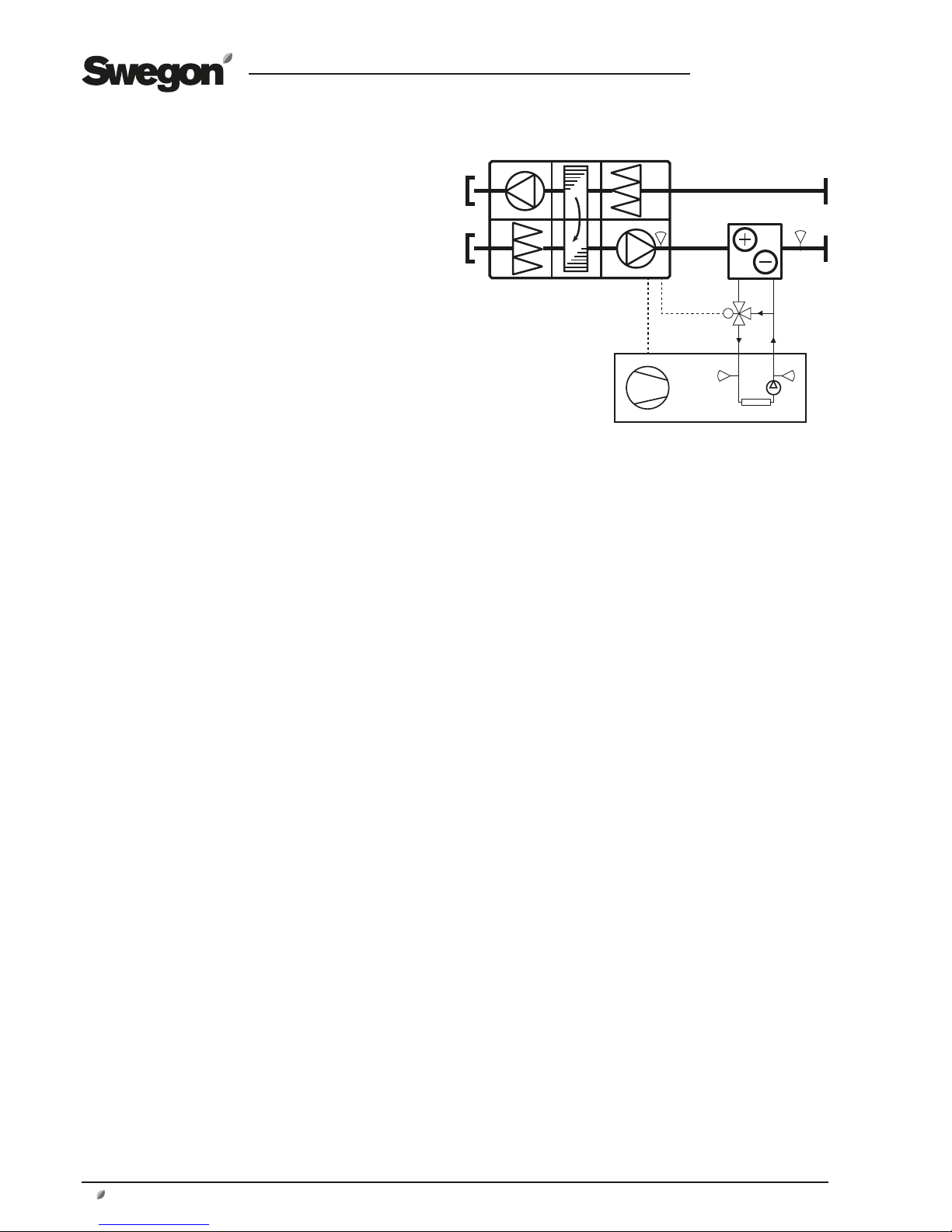

3.1.3 Reversible chiller/heat pump

The heating or cooling capacity of the supply air is controlled via an IQlogic+ module (extra regulation sequence

function, see separate instructions for the TBIQ IQlogic+

module) preset for heating and cooling (0-10 V). The

function can be activated in the hand-held terminal of the

GOLD air handling unit (see the Operation and Maintenance Instructions for the GOLD).

Communication with the reversible chiller/heat pump

can be activated under Functions in the hand-held micro

terminal of the GOLD unit. See Section 5.

Cooling

If temperature sensor BT1 calls for cooling, the function

transmits a start signal for cooling and a refrigerant setpoint (12°C*) to the reversible chiller/heat pump via Modbus.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function allows valve MF1 to regulate the flow.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function does not allow valve MF1 to regulate the flow

(forces it to close).

Optimisation function active:

To ensure the best functionality when the optimisation

function is activated, the value for cooling diff. (2 K*)

should be set to the same value as that set in the reversible

chiller/heat pump. See Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 2K* from the refrigerant temperature

setpoint and if it has been so during a continuous period

of more than 60 seconds* the optimisation function is

allowed.

If the optimisation function is allowed and valve MF1 is

fully open (100%*) the controller decreases the refrigerant temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF1 is

open less than 80%*, the controller increases the refrigerant temperature setpoint at a rate of 0.6K/minute*.

Heating

If temperature sensor BT1 calls for cooling, the function

transmits a start signal for heating and a heating medium

setpoint (40°C*) to the reversible chiller/heat pump via

Modbus.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function allows valve MF1 to regulate the flow.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function does not allow valve MF1 to regulate the flow

(forces it to close).

Modbus

0-10 V

GOLD

Supply

air

Swegon chiller/heat pump

A pump and accumulator tank can be

added and, depending on the size of

the system, can be located inside or

outside the chiller/heat pump. For more

information, see the Swegon product

brochure.

Optimisation function active:

To ensure the best functionality when the optimisation

function is activated, the heating diff. value (3 K*) should

be set to the same value as that set in the reversible

chiller/heat pump. See Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 3K* from the heating medium temperature setpoint and if it has been so during a continuous

period of more than 60 seconds* the optimisation function is allowed.

If the optimisation function is allowed and valve MF1 is

fully open (100%*) the controller increases the heating

medium temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF1 is

open less than 80%*, the controller decreases the heating

medium temperature setpoint at a rate of 0.6K/minute*.

* Factory setting. The value can be changed.

** Estimated temperature in the GOLD RX.

Page 5

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

www.swegon.com 5

BT1

BT50BT40

MF2

MF1

BT30

3.1.4 Chiller and external heating

The cooling capacity of the supply air is controlled via an

IQlogic+ module (extra regulation sequence function, see

separate instructions for the TBIQ IQlogic+ module) preset

for cooling (0-10 V). The function can be activated in the

hand-held terminal of the GOLD air handling unit (see the

Operation and Maintenance Instructions for the GOLD).

The function controls external heating (waterborne or

electric) via the GOLD unit’s ordinary output for heating (0-10 V). The air heater for heated water has a frost

monitor function and is automatically activated when it is

connected.

Communication with the chiller can be activated under

Functions in the hand-held micro terminal of the GOLD

unit. See Section 5.

If temperature sensor BT1 calls for cooling, the function

transmits a refrigerant setpoint (12°C*) to the chiller via

Modbus.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function allows valve MF2 to regulate the flow.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function does not allow valve MF2 to regulate the flow

(forces it to close).

If dehumification is active, the function allows valve MF1

to regulate the flow.

Optimisation function active:

To ensure the best functionality when the optimisation

function is activated, the value for cooling diff. (2 K*)

should be set to the same value as that set in the chiller,

see Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 2K* from the refrigerant temperature

setpoint and if it has been so during a continuous period

of more than 60 seconds* the optimisation function is

allowed.

If the optimisation function is allowed and valve MF2 is

fully open (100%*) the controller decreases the refrigerant temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF2 is

open less than 80%*, the controller increases the refrigerant temperature setpoint at a rate of 0.6K/minute*.

* Factory setting. The value can be changed.

** Estimated temperature in the GOLD RX.

Modbus

0-10 V

The external air heater can be

of water-coil or electric type.

GOLD

Supply

air

Swegon chiller

A pump and accumulator tank

can be added and, depending

on the size of the system, can

be located inside or outside the

chiller.

Page 6

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

6 www.swegon.com

BT1

BT50

MF1

MF2

BT30

BT40

Modbus

0-10 V

GOLD

Supply

air

Swegon heat pump

A pump and accumulator tank

can be added and, depending

on the size of the system, can

be located inside or outside the

heat pump.

The external air heater can be

of water-coil or electric type.

3.5 Heat pump and external heating

The heating capacity of the supply air is controlled via an

IQlogic+ module (extra regulation sequence function, see

separate instructions for the TBIQ IQlogic+ module) preset

for heating (0-10 V). The function can be activated in the

hand-held terminal of the GOLD air handling unit (see the

Operation and Maintenance Instructions for the GOLD).

The function controls external heating (waterborne or

electric) via the GOLD unit’s ordinary output for heating (0-10 V). The air heater for heated water has a frost

monitor function and is automatically activated when it is

connected.

Communication with the heat pump can be activated

under Functions in the hand-held micro terminal of the

GOLD unit. See Section 5.

If temperature sensor BT1 calls for heating, the function

transmits a start signal and heating medium setpoint

(40°C*) to the heat pump via Modbus.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function allows valve MF1 to regulate the flow.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function does not allow valve MF1 to regulate the flow

(forces it to close).

Optimisation function active:

To ensure the best functionality when the optimisation

function is activated, the heating diff. value (3 K*) should

be set to the same value as that set in the heat pump. See

Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 3K* from the heating medium temperature setpoint and if it has been so during a continuous

period of more than 60 seconds* the optimisation function is allowed.

If the optimisation function is allowed and valve MF1 is

fully open (100%*) the controller increases the heating

medium temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF1 is

open less than 80%*, the controller decreases the heating

medium temperature setpoint at a rate of 0.6K/minute*.

* Factory setting. The value can be changed.

** Estimated temperature in the GOLD RX.

Page 7

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

www.swegon.com 7

BT1

BT50

MF1

MF2

BT30

BT40

3.1.6 Reversible chiller/

heat pump and external heating

The heating or cooling capacity of the supply air is controlled via an IQlogic+ module (extra regulation sequence

function, see separate instructions for the TBIQ IQlogic+

module) preset for heating and cooling (0-10 V). The

function can be activated in the hand-held terminal of the

GOLD air handling unit (see the Operation and Maintenance Instructions for the GOLD).

The function controls external heating (waterborne or

electric) via the GOLD unit’s ordinary output for heating (0-10 V). The air heater for heated water has a frost

monitor function and is automatically activated when it is

connected.

Communication with the reversible chiller/heat pump

can be activated under Functions in the hand-held micro

terminal of the GOLD unit. See Section 5.

Cooling

If temperature sensor BT1 calls for cooling, the function

transmits a start signal for cooling and a refrigerant setpoint (12°C*) to the reversible chiller/heat pump via Modbus.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function allows valve MF1 to regulate the flow.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function does not allow valve MF1 to regulate the flow

(forces it to close).

Optimisation function active:

To ensure the best functionality when the optimisation

function is activated, the value for cooling diff. (2 K*)

should be set to the same value as that set in the reversible

chiller/heat pump. See Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 2K* from the refrigerant temperature

setpoint and if it has been so during a continuous period

of more than 60 seconds* the optimisation function is

allowed.

If the optimisation function is allowed and valve MF1 is

fully open (100%*) the controller decreases the refrigerant temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF1 is

open less than 80%*, the controller increases the refrigerant temperature setpoint at a rate of 0.6K/minute*.

Heating

If temperature sensor BT1 calls for heating, the function

transmits a start signal for heating and a heating medium

setpoint (40°C*) to the reversible chiller/heat pump via

Modbus.

If the temperature by temperature sensor BT50 is higher

than the temperature by temperature sensor BT30**, the

function allows valve MF1 to regulate the flow.

Modbus

0-10 V

GOLD

Supply

air

Swegon chiller/heat pump

A pump and accumulator tank can be

added and, depending on the size of the

system, can be located inside or outside

the chiller/heat pump.

The external air heater can be

of water-coil or electric type.

If the temperature by temperature sensor BT50 is lower

than the temperature by temperature sensor BT30**, the

function does not allow valve MF1 to regulate the flow

(forces it to close).

Optimisation function active:

Optimisation is not carried out if temperature regulation is

selected for extract air regulation.

To ensure the best functionality when the optimisation

function is activated, the heating diff. value (3 K*) should

be set to the same value as that set in the reversible chiller/

heat pump. See Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 3K* from the heating medium temperature setpoint and if it has been so during a continuous

period of more than 60 seconds* the optimisation function is allowed.

If the optimisation function is allowed and valve MF1 is

fully open (100%*) the controller increases the heating

medium temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF1 is

open less than 80%*, the controller decreases the heating

medium temperature setpoint at a rate of 0.6K/minute*.

* Factory setting. The value can be changed.

** Estimated temperature in the GOLD RX.

Page 8

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

8 www.swegon.com

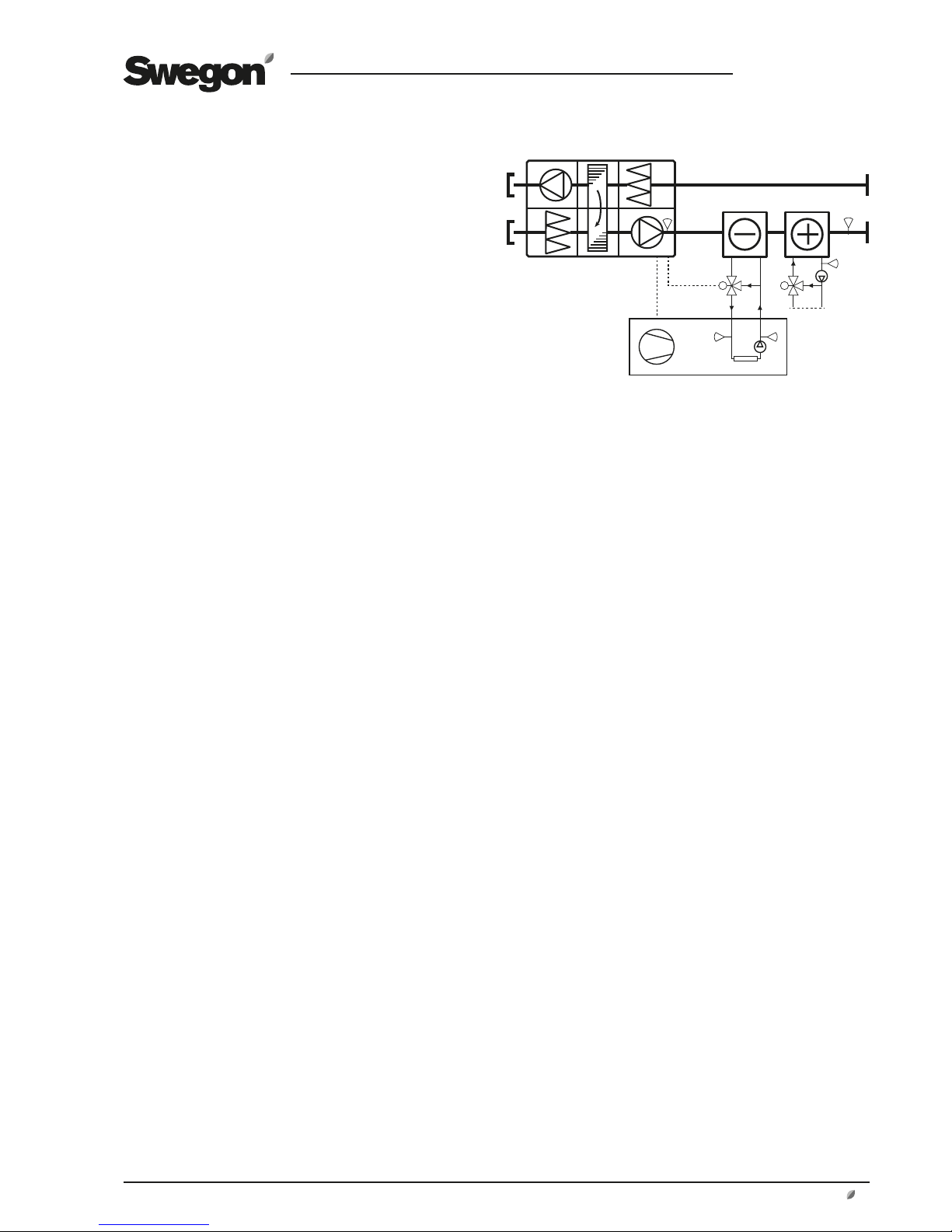

BT1

MF2

BT40

BT50

G20 G10

BT10

MF10

Modbus

0-10 V

GOLD

Supply

air

Swegon

chiller

AQUA Link

AYC

See the function guide for

the AYC.

Comfort

modules

3.2 Control of cooling energy to the GOLD

and comfort modules via the Swegon

chiller and AQUA Link

3.2.1 Control of cooling energy to the GOLD

The cooling capacity of the supply air is controlled via valve

actuator MF2 and an IQlogic+ module (extra regulation

sequence function, see separate instructions for the TBIQ

IQlogic+ module) preset for cooling (0-10 V). Cooling can

be activated in the hand-held terminal of the GOLD air

handling unit (see the Operation and Maintenance Instruc-

tions for the GOLD).

3.2.2 Control of cooling energy

to the comfort modules

See the function guide for All Year Comfort (AYC).

3.2.3 Swegon chiller and AQUA Link

Communication with the chiller can be activated under

Functions in the hand-held micro terminal of the GOLD

unit. See Section 5.

Communication with AQUA Link takes place via the

IQlogic

+

module (function selector switch set to 5) which

controls and manages alarms from pump G20. The

module is located in the AQUA Links cubicle.

The chiller’s water temperature setpoint is controlled by

the GOLD unit and is determined by the cooling load in

the ventilation system. The temperature setpoint from

the AYC function is compared with the ordinary cooling

supply air setpoint and the lowest value of these is transmitted as a setpoint to the chiller.

Circulation pump G20 located inside the AQUA Link is

started and stopped via the GOLD unit. When the GOLD

unit is in operation and valve MF2 or MF10 is open more

than 5%, circulation pump G20 starts up.

Optimisation function active:

Applies to the supply air cooling setpoint.

To ensure the best functionality when the optimisation

function is activated, the value for cooling diff. (2 K*)

should be set to the same value as that set in the chiller,

see Section 5.

If the temperature by temperature sensor BT40 (reference

water) is within 2K* from the refrigerant temperature

setpoint and if it has been so during a continuous period

of more than 60 seconds* the optimisation function is

allowed.

If the optimisation function is allowed and valve MF2 is

fully open (100%*) the controller decreases the refrigerant temperature setpoint at a rate of 0.3K/minute*.

If the optimisation function is allowed and valve MF2 is

open less than 80%*, the controller increases the refrigerant temperature setpoint at a rate of 0.6K/minute*.

* Factory setting. The value can be changed.

Page 9

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

www.swegon.com 9

GND

+-

J25 BMS2

4. Electrical connections.

4.1 SMART Link

Connect the bus cable (supplied) between the bus contact, marked COM4, on the control unit of the GOLD unit

and an optional bus contact on the cable adapter.

The communication cable between the chiller/heat pump

control equipment and TBLZ-64 cable adapter should be

wired according to one of the alternatives below.

The cables are not included in the supply. Twisted-pair

cables are recommended.

4.1.1 Alternative 1. Connection to the chiller's/heat

pump's controller

1

2

3

4

Wiring terminals, pC05+

chiller/heat pump

Wiring terminals for the

TBLZ-64 cable adapter

pC05+

Cable adapter (TBLZ-64)

Page 10

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

10 www.swegon.com

-+GNDGG0

-+GND

serial card 1J1

J8

727170

4.1.2 Alternative 2. Connection via external SMART

Link communications interface

Wiring terminals, SMART Link

communications interface

Wiring terminals for the

TBLZ-64 cable adapter

1

2

3

4

Wiring terminals, junction box,

chiller/heat pump

24 VAC

A4 A2

Communications interface (SMART Link) A4 (RS485) A2 (mC2)

Cable connected at the factory

Cable adapter (TBLZ-64)

Page 11

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

www.swegon.com 11

-+GND

serial card

4.1.3 Alternative 3. Connection via built-in SMART

Link communications interface

Wiring terminals for the

TBLZ-64 cable adapter

1

2

3

4

A4 A2

Wiring terminals, SMART Link

communications interface

Communications interface (SMART Link)

A4 (RS485) A2 (mC2)Cable adapter (TBLZ-64)

Cable connected at the factory

Page 12

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

12 www.swegon.com

4.1.4 Alternative 4. Connection via internal iPro-link

communications interface

ASM1 (iPro-link) SERI1 (485/TTL) A2 (IC208CX)

Wiring terminals for

the cable adapter

1

2

3

4

SERI1 A2

ASM1

+

Cable adapter (TBLZ-64)

Cable connected at the factory

6

7

8

9

Page 13

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

www.swegon.com 13

4.1.5 Alternative 5. Connection via external A2 communications interface (RS485 slave)

Wiring terminals for the

TBLZ-64 cable adapter

1

2

3

4

A2

A2 (RS485 slave)

97 (-)

98 (+)

99 (GND)

Cable adapter (TBLZ-64)

Page 14

GB.BlueBox.180415

Swegon reserves the right to alter specifications.

14 www.swegon.com

4.2.1 All Year Comfort

If All Year Comfort is included in the system (together with

AQUA Link), a modular cable must be connected between

the IQlogic+ module in the AQUA Link electrical distribution box and the IQlogic+ module in the All Year Comfort

electrical equipment cubicle.

Other connections between AQUA Link and All Year Comfort is carried out on terminal blocks.

See sketch.

4.2 AQUA Link

If an AQUA Link is included in the system, the modular

cable between the IQlogic+ module integrated into the

AQUA Link electric cubicle, and the modular connection

marked ”COM3” on the GOLD AHU control unit should

be connected. See illustration.

SD

WLAN

CPU 1

CPU 2

1A2B3

GND4+5-6+7-8+9-

10+11-12+13

-

SA TempCom 5Com 4Com 3Com 2Com 1

14+15-16+17-18+19

-

Heat Cool

20C21NO22C23NO24C25NO26C27NO28P29G30G031G32

G0

24V AC

Sensor 1 Sensor 2 Sensor 4Sensor 3Com 6Com 7Com 8Com 9Com 10 Com 11

+33-34G35G036Y37U

38 39 40

24V AC In

41 42

18V AC In

45 46

230V AC In

4743 44

230V AC Out

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

P1

IQlogic

+

COM POWER

1234 5678

-+-+-

S - S

C9NO

10+11-12

Com 1Com 2

IQlogic+ module

AQUA Link

GOLD Control unit

Modular cable

The function selector

switch must be set to

position 5.

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

P1

IQlogic

+

COM POWER

1234 5678

-+-+-

S - S

C9NO

10+11-12

Com 1Com 2

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

P1

COMPOWER

IQlogic

+

1234 5678 9101112

-+-+-

++--S - S

C13NO14C15NO

16

+17-

18

+19-

20

G21G0

22

Com 1Heat/CoolCom 2

101 102PE 104 105103 107 108 110109106

102 103101 104 G MXG0

105 106 107 108 109 110

X1 G1

-BTT

All Year Comfort electrical equipment cubicle

Modular cable

The function selector switch

must be set to position 7.

AQUA Link electric cubicle

The function selector switch

must be set to position 5.

Brown

White

Page 15

GB.BlueBox.180415

Swegon reserves the right to alter specifi cations.

www.swegon.com 15

SMART Link

Function

5. Settings

For basic facts on how to use the hand-held terminal, see

the Operation and Maintenance Instructions for the GOLD

air handling unit.

The chiller/heat pump functions must be manually activated under Functions/SMART Link.

The function can be activated, under Function.

Set the type supplied (water, heat pump/water, chiller/water, reversible/DX, heat pump/DX, chiller/DX, reversible.

Set the required set point for cooling and/or heating water

as well as the permissible deviation under Settings. The set

points represent the reference temperature of the refrigerant and heating medium returning to the chiller/heat

pump. Set the limit for the outdoor temperature (minimum permitted operating temperature).

The function for the optimization of the set point heating

and cooling can be activated under Optimize.

Other chiller/heat pump settings can be entered in the

chiller/heat pump.

If required, AQUA Link can be activated under AQUA Link.

Select alarm on open contact, alarm on closed contact or

contactor function for the pump alarm.

SMART Link

Settings

Optimize

AQUA Link

6. Status

The chiller/heat pump readings can be viewed under

Status.

No values can be changed in this menu group.

7. Manual test

The actual input and output values on the circulation

pump in the cooling circuit can be manually controlled

under INSTALLATION – MANUAL TEST - SMART Link.

Status

SMART Link

Manual test

Loading...

Loading...