Page 1

LUNA d

Instructions for Use

Contents

Introduction ....................................................... 2

1.1 Introduction .......................................................... 2

1.2 Selection of room temperature ............................. 2

1.3 LED status lamp .................................................... 2

System overview and installation ..................... 2

2.1 System overview ................................................... 2

2.2 Terminal functions ................................................ 2

2.3 Invert heating outputs ........................................... 3

2.4 Resetting .............................................................. 3

2.5 Hand-held terminal LUNAb T-CU .......................... 3

Control functions ................................................ 4

3.1 Operating modes .................................................. 4

3.2 Setting room temperatures ................................... 4

3.3 Deadband ............................................................. 4

3.4 Control process ..................................................... 4

3.5 P-function ............................................................. 4

3.6 I-function .............................................................. 4

Inputs and sensors .............................................. 5

4.1.1 Sens or t ype ........................................................ 5

4.1.2 Average value measurement ............................... 5

4.2 Occupancy sensor ................................................. 6

4.2.1 Switch-on delay ................................................. 6

4.2.2 Switch-off delay ................................................. 6

4.2.3 Inverting the occupancy signal ........................... 6

4.3 Overriding the operating mode ............................. 6

4.3.1 Forced output when external contact function

is activated ...................................................................6

4.4 Condensation sensor ............................................ 6

4.4.1 Select effect of output A1 ................................. 6

13 /11 / 2018

Article xxxxxxxx

Outputs and actuators ....................................... 7

5.1 Actuator ............................................................... 7

5.2 Output signals ...................................................... 7

5.3 Heating, cooling or direct temperature .....................

control of output .................................................. 7

5.4 Limitation of control range .................................... 8

5.5 Temperature limits for

“direct temperature control” (see 5.3)...................... ..8

5.6 Setting the voltage limits for outputs A1 and A2 ... 8

5.7 Inverting the output .............................................. 8

5.8 Periodic valve operation ........................................ 8

Menu functions with hand-held unit ................ 9

6. Hand-held terminal ................................................. 9

6.1.1 Restoring the factory settings ............................. 9

6.1.2 Quick guide: ....................................................... 9

6.2 Hand-held terminal’s different modes ................. 10

6.2.1 Local mode (the settings are made in the tool) . 10

6.2.2 Read mode ...................................................... 10

6.3 LUNAd T-CU buttons .......................................... 10

6.4 Display symbols ...................................................11

6.5 Navigation under the main menu .........................11

6.6 Navigation under the settings menu .....................11

6.7 Change values .....................................................11

6.8 Display overview ................................................ 12

6.9 Week program .................................................... 14

6.10 Log function ..................................................... 14

6.11 Control settings ................................................. 14

6.12 Outputs, settings ............................................... 15

6.13 Outputs, Settings ...............................................17

6.14 Occupancy ........................................................ 18

6.15 Calibration of temperature sensors .................... 19

6.16 Button functions ............................................... 20

6.17 Test Menu ......................................................... 21

6.18 Type designations .............................................. 23

The document was originally written in Swedish.

Page 2

LUNA d

Introduction

1.1 Introduction

LUNAd is a room controller that gives a stable and

comfortable room temperature through efficient and

accurate control and regulates the different heating and

cooling actuators. The room controller has four outputs

that can individually be adjusted to suit most requirements.

In the supplied version the room controller is set to control

heating and cooling actuators with 24 V AC and 0–10 V DC.

The room controller has a built-in temperature sensor for

detection and setting of the room temperature.

Different types of sensors can be connected to the room

controller.

If you need to change the settings on a room controller

a special hand-held terminal with display (LUNAd T-CU)

is required. The hand-held terminal is then connected

temporarily to the room controller’s 4-way connector. The

connector is located behind the room controller’s cover.

If you wish to install an external sensor in the room or

e.g. in the air duct, the sensor is connected to the screw

terminals in the room controller. The external sensor is then

activated automatically.

Even different types of sensors can be connected to the

controller, for example, occupancy sensor, condensation

sensor, extra temperature sensor or an external contact.

The external sensor’s functions can be set on the menus

on the hand-held terminal with display.

The room controller has three different operating modes

(day, night and save) that can activate different room

temperatures.

1.2 Selection of room temperature

The temperature is set by adjusting by turning the adjuster

knob. The adjuster knob always controls the required

temperature in DAY operating mode, irrespective of whether

any other operating mode is active. It is not possible to

see which operating mode is currently active, but with the

help of the large LED you can see whether the controller is

in heating mode, cooling mode or in standby (dead zone).

The scale of the adjuster knob is not graduated (i.e. no

numbers), so that it is possible to change the adjuster

knob’s temperature range. On delivery the adjust knob’s

range is 19–25 °C with the set point 22 °C in the middle

of the set point scale. Turn the adjuster knob up (clockwise) you increase the temperature and vice versa.

System overview and

installation

2.1 System overview

The room controller can be configured in a variety of

ways. The controller has been especially developed to

facilitate customisation without the need making and

changes to the hardware. The room controller can be

directly connected to numerous different control systems

without the need to make any settings. These are

described in this chapter.

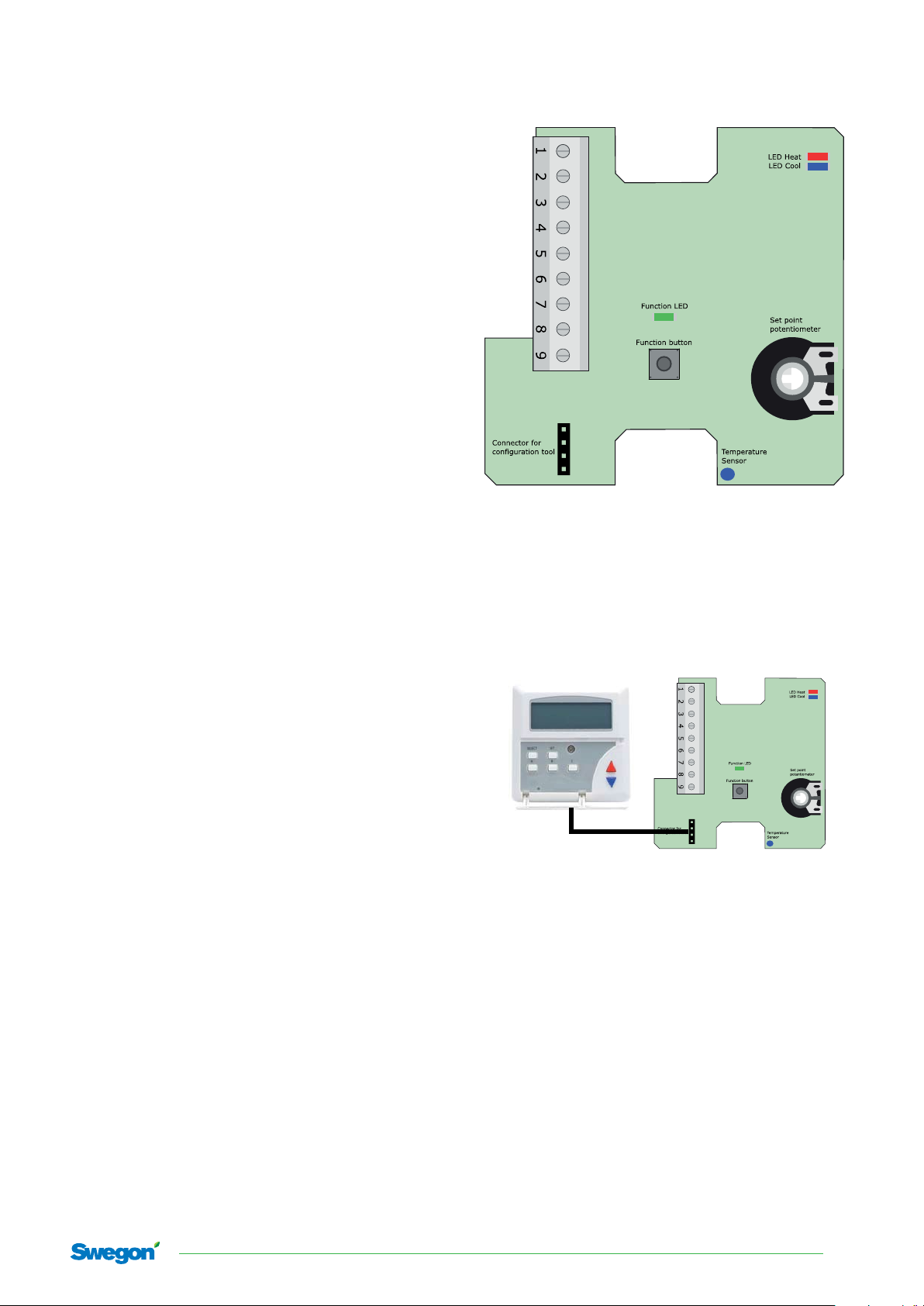

2.2 Terminal functions

The screw terminals on the controller have different markings

and placements. The following figure describes the screw

terminals in a factory set room controller:

1. Output D1 - 24 V Cooling actuator (0 V)

2. Common phase 24V AC for actuator

3. Output D2 - 24 V heating actuator (0 V)

4. Analogue output A1, 0–10 V DC, cooling

1.3 LED status lamp

The room controller is equipped with a LED status lamp

that indicates the current output signal. The LED lamp can

also display other operating modes. In normal mode the

LED lamp displays the following:

1. Blue = cooling requirement

2. Red = heating requirement

3. Flashing blue = condensation (only when the condensation function is active in the room controller and the

operating mode is cooling requirement.

2

Swegon reserves the right to alter specications. 13/11/2018

5. G, phase 24V AC from transformer

6. G0, 0V from transformer

7. Analogue output A2, 0–10 V DC, heating

8. Input for external temp. sensor

9. Input for condensation sensor

Page 3

2.3 Invert heating outputs

There is a button under the cover on the controller. The

button can be used to invert all the heating outputs.

1. Set the temperature potentiometer to its lowest position.

2.

3.

Press and hold the button for about 12 seconds.

The room controller now inverts all the heating outputs.

Repeat the procedure to remove all the inverted heating

outputs.

2.4 Resetting

There is a button under the cover on the controller.

The button can be used to reset the memory according to

the customer’s configuration.

1. Switch off the power to the controller.

2.

3.

Press and hold the button while you switch on the

controller.

Release the button, the controller now performs a

customer reset.

LUNA d

2.5 Hand-held terminal LUNAb T-CU

On the room controller’s PCB, behind the cover, is a 4-way

outlet where the hand-held terminal can be connected.

Using this it is possible to configure different settings in

the room controller.

All the settings are described in the manual, chapter 6

13/11/2018 Swegon reserves the right to alter specications.

3

Page 4

LUNA d

Control functions

The room controller regulates the temperature in the

room with the help of a heating elements and/or chilled

beams. The room controller compares the set temperature

with the current measured room temperature and controls

via its outputs the heating or cooling to the room.

3.1 Operating modes

The room controller has three operating modes each with

its setting values for room temperature and “deadband”.

Other functions can also be connected to the different

operating modes. The operating modes can be controlled

by the following functions in priority order:

1. External contact

2. Occupancy

3.2 Setting room temperatures

The room temperature is adjusted individually for the

three operating modes with the help of the hand-held

terminal LUNAd T-CU.

Using the adjuster knob on the room controller you

can only adjust the desired temperature for DAY mode.

The desired temperature is also called the “set point”.

The measured room temperature is also called the “actual

value”.

3.4 Control process

A slightly simplified control works as follows, step by step:

1. The room controller selects the right temperature and

deadband taking into consideration the enabled

operating mode.

2. The controller calculates the regulated setpoints for

cooling and heating that are equal to the setpoint ±

half the deadband.

3. If the temperature has been higher than the regulated

set point for cooling, the controller is set to cooling

mode and uses the regulated set point for cooling when

regulating.

4. The deviation between the desired temperature and

the measured temperature can be calculated.

5. The capacity value for heating or cooling is calculated.

6. The room controller’s i-function detects if the temperature deviation has not been corrected for a long

period, and if necessary adds an extra “boost” to the

capacity values.

7. The capacity values are converted to output signals and

are sent to the different outputs.

3.5 P-function

The room controller’s method of control is known as “PI”,

which is an abbreviation of proportional and integral. The

proportional function (p-function) means that the controller

calculates a capacity requirement that is proportional to

the temperature deviation.

3.3 Deadband

The room controller has a neutral zone between heating

and cooling control that is called the deadband. This

function is used to prevent both the heating and cooling

outputs from being connected at the same time, and

to save energy. However, the room controller permits

the temperature to deviate a half degree up or down

compared to the set point temperature, before a control

signal is sent to the heating elements or chilled beams.

This applies in DAY operating mode.

In NIGHT mode and SAVE mode the deadband is wider, to

give an economy function when you are not in the room.

When the hand-held terminal is connected it is possible to

adjust the three different deadbands under menu 3.

For DAY operating mode: function “DB.D”

For NIGHT operating mode: function “DB.N”

For SAVE operating mode: function “DB.S”

When high climate comfort is required, the deadband

should be relatively small. However, the deadband should

be wider to save energy.

If the room controller is set to only control heating or

only cooling, then the deadband has not function, and

the room temperature is then controlled directly to the

temperature set for each operating mode.

The P-band can be configured under menu 3.

P-band for heating: function “P.H”

P-band for cooling: function “P.C”

3.6 I-function

The integral function (i-function) means that the room

controller continuously monitors the capacity requirement

that the p-function gives. This helps to smooth out the

deviation more accurately than what the p-function can

sometime achieve, for example, due the heating element

or chilled beam needing a higher control signal to be able

to reach the right temperature in the room.

The I-function can be configured under menu 3.

I-time for heating: function “I.H”

I-time for cooling: function “I.C”

4

Swegon reserves the right to alter specications. 13/11/2018

Page 5

Inputs and sensors

The room controller has a fixed input for the condensation

sensor and a programmable input for the external sensor.

Depending on the selected function, a sensor can be of

the thermistor type for temperature monitoring (resistive),

condensation detection (resistive) or a contact (0 V or no

contact).

The condensation sensor is connected between terminal

block 9 (input) and terminal block 6 (G0).

An external sensor (resistive or contact) is connected

between terminal block 8 (input) and terminal block 6 (G0).

The configuration tool can be used to select the type of

sensor you wish to connect.

There are four different sensor functions:

Type Input

1. Condensation sensor 9. Condensation

2. External temperature sensor 8. Termistor,NTC,10K

3. Presence sensor 8. Contact:

4. Operating mode contact 8. Contact:

LUNA d

4.1.1 Senso r t yp e

Two types of sensor can be used for temperature control:

a) in-built sensor

b) external resistive sensor (NTC, 10 kOhm at 25°C)

The built-in sensor in the room controller is always used

automatically by the room controller if no other sensor

is connected to the terminal. When an external, resistive

sensor is connected, the room controller selects this

sensor automatically instead of the built-in sensor.

4.1.2 Average value measurement

In order to connect the average value measurement with

both an external sensor and the built-in sensor in the

room controller, set the following on menu 5 (input):

Function “R1+R2” can be set to 1, 2 or 3

1 = internal sensor only

2 = external sensor only

3 = average value between internal and external sensors

If value 3 is used and if no other sensor is connected to

the terminal, the room controller only reads the internal

sensor.

13/11/2018 Swegon reserves the right to alter specications.

5

Page 6

LUNA d

4.2 Occupancy sensor

It’s possible to connect an occupancy sensor that enables

the DAY operating mode when occupancy is detected

and which enables NIGHT operating mode when the

occupancy indication ceases. A switching on and off delay

for the DAY operating mode can be set.

The presence sensor can have a contact output (normally

open or normally closed) which is connected between

terminal block 8 (input) and terminal block 6 (G0). G0 is the

signal that the sensor switches on and off to the input.

The presence sensor is activated with the help of the

configuration tool, under menu 6 and the function

“ACTIVE” (enable).

Då närvarogivare är aktiverad, inkopplas driftläget NATT i

stället för DAG när närvaro indikeras. Då närvaro indikeras

inkopplas driftläge DAG.

4.2.1 Switch-on delay

When occupancy has been indicated at some time

both during the first and second half of the delay time,

the DAY operating mode is enabled after the time has

expired. This operating mode remains enabled as long as

there is an occupancy indication.

The switch-on delay for occupancy is selected under

menu 6:

Function “TIME1”: select the delay time for switching on

4.3 Overriding the operating mode

With the 0 V-signal from an external contact you can force

any of the room controller’s four outputs. the contact is

connected between terminal 8 (input signal) and 6 (G0).

Enabling the external contact function is selected under

menu 5 with the help of the hand-held terminal LUNAd

T-CU.

Function “EXT.”:

0 = external contact function disabled

1 = external contact function enabled

4.3.1 Forced output when external contact

function is activated

When the external contact function is enabled it is possible to select which of the outputs is to be forced to open

(0 V to terminal 8).

Activation of forcing output is selected under menu 4,

OUTP”:

First select the output under the function “OPno”:

D1 = 24 V output terminal 1

D2 = 24 V output terminal 3

A1 = 0–10 V output terminal 4

A2 = 0–10 V output terminal 7

4.2.2 Switch-off delay

The switch-off delay delays the disabling of DAY operating

mode when occupancy indication from the sensor ceases. The

time is adjustable between 0 and 990 minutes. The resolution is

10 minutes over 100 minutes.

The switch-off delay for occupancy is selected under menu 6:

Function “TIME0”: select the delay time for switching off

4.2.3 Inverting the occupancy signal

The input function can be inverted to select either an

occupancy sensor that has a normally open or normally

closed contact for occupancy indication.

Inverting the occupancy signal is selected under menu 6:

Function “NO”: 0 = (NC, normally closed) is

opened when occupancy is

detected

1 = (NO, normally open) closes

when occupancy is detected.

Select the function “FORC.”:

0 = forcing of output disabled

1 = forcing of output enabled (when the external

contact is enabled with 0 V to the input on

terminal 8).

4.4 Condensation sensor

It is possible to connect a condensation sensor to input I1

(between terminal 8 and terminal 6) to disable all cooling

outputs and generate an alarm for high condensation of

output A1.

The condensation input is designed for resistive condensation sensors, with resistance values between 50 K and

900 kΩ (for condensation).

The condensation function is set under menu 5 with the

help of the hand-held terminal LUNAd T-CU.

Function “COND” 0 = condensation disabled

1 = condensation enabled

4.4.1 Select effect of output A1

If this function is enabled, the controller activates the 10 V

DC output on Y3 (terminal 4) when condensation occurs.

Function “CALRM” 0 = alarm signal disabled

1 = alarm signal enabled

6

Swegon reserves the right to alter specications. 13/11/2018

Page 7

LUNA d

Outputs and actuators

The room controller has two 24 V outputs (d1 and d2) and two

analogue 0–10 V outputs (A1 and A2).

Actuators are connected to the following terminal blocks:

• d1: terminal block 1 and 2.

• d2: terminal block 3 and 2.

• A1: terminal block 4 (+), terminal block 6 (G0) and to G

(phase 24 V AC).

• A2: terminal block 7 (+), terminal block 6 (G0) and to

G (phase 24 V AC).

An output can be affected by the following functions (the

uppermost has the highest priority):

1. Output affected by the condensation sensor

2. Output “active” for test activation

3. Output “active” if the function “FORC.”=1 under

menu 4 when input I2 is set to the contact

function “EXT.” = 1.

Under menu 4 (“OUTP”) you can select the type of

regulation outfeed and other settings for each output.

Select the output to be set:

Function “OPno” select d1, d2, A1 or A2.

5.1 Actuator

In this context an actuator is an electro-mechanical unit

that is governed by an electrical signal from the controller

and manoeuvres, e.g. a valve or damper to close.

5.2 Output signals

Different actuators require different output signals from

the room controller. The outputs are therefore adjustable

for different types of actuator.

Pulse regulating (24V or 0-10V)

Normally used to control thermal actuators or for electrical

heating control.

ON/OFF control (24V or 0-10V)

Normally used for the control of 2-position damper

motors or electrical heaters via contactors.

3-p regulating (24V)

Normally used to control increase/decrease actuators.

0-10 V regulation (0-10 V)

Normally used to control 0-10 V actuators.

5.3 Heating, cooling or direct temperature

control of output

You can choose whether an output should control a

heating actuator, a cooling actuator or an actuator for

both heating and cooling.

The setting of functions that follow “OPno” only apply to

the selected output.

When “3P” has been selected for output D1, the settings

refer to both outputs d1 and d2, as this outfeed uses both

the digital outputs.

The room controller outputs a heating and cooling

capacity values between 0–100 % to the outfeed logic.

A capacity value is calculated for each individual output

based on this value (and depending on the following

settings for each output).

A cooling actuator is only activated when the controller

outputs a capacity value for cooling. A heating actuator

is only activated when the controller outputs a capacity

value for heating.

An actuator that is directly controlled by the room

temperature is not affected by the controller’s fed capacity,

but only by the selected limit value for the room temperature.

Go to the function “HC” under menu 4, and set the

following selections for the required output:

COOL: for the regulation of cooling

HEAT: for the regulation of heating

HC: for the regulation of both cooling and heating

dIFF: for direct temperature control

In “HC” mode, 0–5 V is fed with a cooling requirement

100–0 % and 5–10 V for a heating requirement 0–100 %

on outputs A1 and A2.

It is possible to set the controller so that the 0–10 V outfeed to output A1 is available both for heating and cooling

requirement to control of an actuator on a 6-way valve.

13/11/2018 Swegon reserves the right to alter specications.

7

Page 8

LUNA d

5.4 Limitation of control range

(does not apply if “direct temperature regulation of

output” is selected)

The room controller calculates a capacity value between

0–100 % which is sent to the outfeed logic. You can

choose, for each output, whether it should regulate

within the whole or part of this range.

Example:

If, for example, you have selected an output that regulates

within the range 20–50 %, the capacity to the actual

output will be regulated as follows:

Capacity from the controller Capacity outfeed to the output

0–20 % 0%

20–50 %0 –100%

50 –100 %100 %

This function can be used, for example, to control output

in sequence.

5.6 Setting the voltage limits for outputs

A1 and A2

The voltage on outputs A1 and A2 are normally between

0–10 V, but the values can be limited upwards or downwards.

The voltage from output A1 and A2 does not drop below

the selected minimum value in the function “LIML V” and

does not exceed the selected max value in the function

“LIMH V”.

Exceptions For the condensation indication the voltage is

set to 0 V, irrespective of the value for the function “LIML

V”.

5.7 Inverting the output

Inverting means that the outputs D1 and D2 close instead

of open and vice versa.

For an increase/decrease outfeed the outputs with work

in reverse so that the actuator changes rotation direction.

Go to menu 4, and set the following selections for the

required output:

LIML%: the low capacity limit in %

LIMH%: the high capacity limit in %

5.5 Temperature limits for “direct tem-

perature control” (see 5.3)

When “dIFF” is selected in the function “HC”, the output

is not regulated to the capacity value from the controller,

but directly by the selected room temperature limits.

Set a temperature range with the functions “LIM.-1” and

“LIM.-0”. When the temperature is within the range and

“PULS”-, “3P”-, “OnOff” or “0-10” regulation is selected,

the capacity is outputted to output by the temperature

value in relation to these limit values.

When the temperature reaches “LIM.-1” or is outside of

this value, 100 % of the capacity is fed to the output.

Output A1 and A2 give 10–0 V instead of 0–10 V, for

example 7 V becomes 3 V instead.

Inverting of the output signal is set under menu 4:

Function “INV.” select 0 (not inverted)

select 1 (inverted)

5.8 Periodic valve operation

Some valves need to be “test run”, i.e. periodically

opened and closed to not jam or seize.

Test running occurs at optional daily intervals:

D1 and A1 open at 01:00–01:03.

D2 and A2 open at 01:30–01:33.

The setting for test running is set under menu 4:

The function “MOT” select the number of days between

test running. The value 0 disables test running.

When the temperature reaches “LIM.-0” or is outside of

this value, 0 % of the capacity is fed to the output.

8

Swegon reserves the right to alter specications. 13/11/2018

Page 9

Menu functions with

hand-held unit

6. Hand-held terminal

The hand-held terminal/tool is used to read and change

the settings in the controller. The tool communicates with

the controller with the help of a cable that is connected

to the 4-way outlet on the controller’s circuit board. All

settings in the controller are shown under different menus

in the tool.

The settings can be changed and stored locally in the

unit’s own memory and then downloaded to the controller.

Alternatively the values in the controller can be transferred

to the tool and in this stage any changes are stored in the

settings both in the tool and the controller.

6.1.1 Restoring the factory settings

Prior to use it is usual to make a factory reset of the tool so

that old configured values are not accidentally fed into the

controller. A reset is performed with the power switched

off by holding down the buttons A, B and C and at the

same time powering up the unit (for example, by connecting

it to the controller. When you release the buttons A, B and

C the tool is reset to the factory settings.

LUNA d

6.1.2 Quick guide:

a) Factory reset

Hold down the three buttons (A, B and C) and power up.

The tool’s memory is reset to the factory

settings when the buttons are released.

b) Change the values in the tool’s local memory

Press the A button under the tool’s cover (activates

local mode). The settings are only stored in the local

memory and are not transferred to the controller.

c) Transfer settings from the controller to the tool

Press the B button under the tool’s cover.

When a “one” is shown it is possible to read the controller’s

values on the tool’s display. Note that the values are not

stored in the tool’s permanent memory.

The tool only reads the values from the controller and

shows them on the display. The downloaded values in the

tool cannot be transferred to another controller once the

tool’s power has been switched off as the unit loses all

data that has been downloaded.

d) Changed settings from the tool

Download data from the controller by pressing the B

button under the tool’s cover. If changes are made in

the settings, the settings are downloaded to the controller and are saved in the tool’s memory at the same time

(data is stored in tool).

e) Download the settings to the controller

Press and hold the C-button under the tool’s cover for

3 seconds until a zero is shown. After a few seconds a

“one” is shown and all settings have been downloaded and stored in the controller’s memory.

13/11/2018 Swegon reserves the right to alter specications.

9

Page 10

LUNA d

6.2 Hand-held terminal’s different modes

6.2.1 Local mode

(the settings are made in the tool)

This is the start-up mode after a power failure.

A sun or moon symbol is not displayed.

Any changes in the settings are only made in the

permanent memory. To change the mode to read mode,

press the A-button, so that “LOCAL 1” is shown.

6.2.2 Read mode

This mode is activated when you press the B-button or

the C-button.

B-button (activates read mode).

When you press the B-button, “READ 0” is shown.

After a few seconds “READ 1” is shown when the

settings in the controller are copied to the tool. The

copied settings are NOT saved in the permanent memory

in the tool. These settings cannot be copied to another

controller. When the power to the tool is switched off,

the unit loses the settings that have been copied.

6.3 LUNAd T-CU buttons

The figure shows the placement of the different buttons

on the hand-held terminal for LUNAd T-CU. All functions

and settings in H202 can be accessed using the buttons.

The buttons have the following functions:

A P(0) reset must be performed to copy the settings from

the volatile memory to the permanent memory. This is

done from the RESET function under the TEST menu.

Settings made in “Read mode” are transferred to the

controller and are also copied to the permanent memory

in the tool.

C-button (activates read mode).

When you press the C-button for three seconds,

“PRO! 0” is shown.

After a few seconds “PRO! 1” is shown, where the settings

from the permanent memory in the tool are downloaded

to the permanent memory in the controller. A sun or

moon symbol is shown (this denotes that the tool is

connected to the controller and that read mode is active).

SELECT = Menu selection under the main menu (goes

through the principle menu functions)

SET = change display values

Arrow up = increase the value, alternatively go to the

next function in the menu

Arrow down = decrease the value, alternatively go to the

previous function in the menu

A = Activates local mode in LUNAd T-CU

B = Activates read mode in LUNAd T-CU

Transfer all settings from LUNAd RE to

LUNAd T- CU

C = Activates read mode. Download all settings

from LUNAd T-CU to LUNAd RE.

10

Swegon reserves the right to alter specications. 13/11/2018

Page 11

operating

mode

Output

Text eld Numerical eld

Tools Menu symbol

6.4 Display symbols

The display symbols have the following functions:

1. Sun, Day operating mode

2. Moon, Night operating mode

3. Sun + Moon = Save operating mode

4. HEAT = output signal for heating is activated

5. COOL = output signal for cooling is activated

A flashing cooling symbol indicates condensation if

this function is activated and the output signal for

cooling is activated.

6. Tool = the setting menu

7. MENU = main menu

LUNA d

6.5 Navigation under the main menu

Press the SELECT button to go to the main menu.

Each menu option has four different functions and are

described in this manual. Some menus are based on

submenus below a master menu. Here you always move

sideways by pressing one of the arrow keys.

6.6 Navigation under the settings menu

Press the SELECT button until the tool symbol is displayed

to navigate

between the different settings menus. The current

active settings menu is shown with the name and menu

number. Pres the SET button and the menu number will

start to flash. You can now select the menu you wish to

navigate to by pressing the arrow up or down. Once you

have selected the menu you wish to navigate to, press the

SET button again to confirm the choice (the value stops

flashing). You can now navigate in this menu and its

functions by pressing the arrow up or down.

If you press the SELECT button when in a menu, the tool

returns to its standard view (shows the room temperature).

If you wish to return to the settings menu just press

the SELECT button several times until the tool symbol is

shown. When you have navigated to the active settings

menu you can navigate through its functions with arrow

up or down.

6.7 Change values

To change the value on the display, press the SET button.

The selected setting on the display starts to flash. This

indicates that the value can be changed. Change the

value by pressing arrow up or down.

Change grouped values

Sometimes a group of values is shown and the SET button

goes through these values one at a time. If a group of

values shows “0 0 0” and the middle value needs to be

changed, press the SET button twice to access the middle

number (the middle number starts to flash) use arrow

up to increase or arrow down to decrease the value.

Complete the change by pressing the SET button again to

leave “change value mode”. The value stops flashing.

13/11/2018 Swegon reserves the right to alter specications.

11

Page 12

LUNA d

6.8 Display overview

Basic view

HEAT HEAT

ROOM MON.

HEAT

TIMER

SUB MENU

RED

BLUE

°C

21.0 12:25 01:01 17:01 100

MENU

HEAT HEAT HEAT

DATE Y:W %OUT

MENU MENU MENU

0:00

MAIN MENU

SETTINGS

MENU

SELECT

RED

SET

BLUE

HEAT

DAY

HEAT

NITE

HEAT

SAVE

Week

program

HEAT

W.PR.

Log

HEAT

LOG

Controller

functions

HEAT

REGUL

Output

HEAT

OUTP

Inputs

HEAT

INPUT

Type menu

HEAT

OCC.

Modbus

HEAT

CAL.

Button functions

HEAT

BUT.F

Times and

measurements

HEAT

TEST

Set point

HEAT

TYPE

22.0

22.0

22.0

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

MENU

7

MENU

8

MENU

9

MENU

10

°C

°C

°C

1

HEAT

2

TIME

HEAT

3

DB.D

HEAT

4

OPNO

HEAT

5

R1+R2

HEAT

6

ACTIV.

HEAT

R1

HEAT

CODE:

HEAT

IN:

HEAT

PROG.

1.0

0.0

0000

01

2727

60

D1

1

0

MENU

°C

SUB MENU

RED

BLUE

HEAT HEAT

NV.NO MEAS

HEAT

DB.N

HEAT

TYPE

HEAT

COND

HEAT

NO

HEAT

4.0

PULS

1

HEAT

DB.S

HEAT

HC:

HEAT

CALRM

0

HEAT

TIME0

1

0.0

GRND

OUT:

VER

HEAT

HEAT

010

HEAT

25.5

HEAT

MEAS.

1

HEAT

TST.R

HEAT

SER.1

0.0

8.0

COOL

0000

°C

HEAT

P.H

FORC.

EXT.

0

TIME1

0

SEL.F

1

RESET

0

SER.2

1.5

HEAT

0

HEAT

0

HEAT

0

HEAT

3

HEAT

ACP0

HEAT

0000

All function values are organised in a

menu system as set out above. There is

1 main menu, 10 settings menus with a

number of functions under each menu.

12

Swegon reserves the right to alter specications. 13/11/2018

Page 13

LUNA d

REGUL

OUTP

BUT.F

TEST

HEAT

P.C

HEAT

LIML%

HEAT

SEL.T

HEAT

ADDRE

1.0

724

HEAT

I.H

20.0

HEAT

LIMH%

0

HEAT

MAX.T

5

HEAT

DATA

100

255

250

HEAT

I.C

20.0

Only for analogue output A1, A2 Only for analogue output A1, A2

HEAT

LIML V

HEAT

MINSP

HEAT

INT.

0.0

HEAT

LIMH V

MX SP

CODEG CODES LIGHT

0

10.0

HEAT

30.030.0

HEAT HEAT HEAT

6076 0000 0

HEAT

PTIME

20.0

HEAT

°C°C

LOCK

HEAT

INV

HEAT

MOT

HEAT

ENG

0

0

1

1

13/11/2018 Swegon reserves the right to alter specications.

13

Page 14

LUNA d

6.9 Week program

This menu and its functions are not used in this version.

6.10 Log function

The room controller features an integrated log function,

where it saves all current room temperatures at predetermined intervals. As standard the log interval is set

to once per hour.

The room controller has space for 75 log values.

The log interval can be set on the “TIME” display and be

set in minutes in the range 0–75. Zero deactivates the log

function.

To red logged values set the required log point 1–75 on

the display “MV.no”, where point 1 is the last saved log.

The actual log value is read on the “MEAS.” display.

6.11 Control settings

This menu includes the controller’s adjustable control

parameters for temperature control.

The following parameters are available:

a) Deadband, day mode “DB.D”0.5 - 30.0 K

b) Deadband, night mode “DB.N”0.5 - 30.0 K

c) Deadband, save mode “DB.S”0.5 - 30.0 K

d) P-band, heating “P.H”0.5 - 99.5 K

e) P-band, cooling “P.C”0.5 - 99.5 K

f) I-time, heating “I.H”0 - 99.5 min

g) I-time, cooling “I.C”0 - 99.5 min

HEAT

W.P R

HEAT

WPno

HEAT

LOG.

HEAT

TIME

HEAT

MV. no

HEAT

MEAS.

REGUL

DB.D

DB.N

DB.S

P. H

P. C

I.H

I.C

HEAT

HEAT

HEAT

HEAT

HEAT

HEAT

HEAT

HEAT

MENU

MENU

MENU

22.0

1.0

4.0

8.0

1.5

1.0

20.0

20.0

1

0

2

60

1

°C

MENU

3

a)

b)

c)

d)

e)

f)

g)

14

Swegon reserves the right to alter specications. 13/11/2018

Page 15

6.12 Outputs, settings

On this menu you can select the function of all outputs

on the room controller. There are two 24 V outputs

and two 0–10 V outputs. These are called “d1”, “d2”,

“A1” and “A2”, where “d” stands for 24 V regulated digital

output (outputs Y1 and Y2) and “A” means analogue

0–10 V output (outputs Y3 and Y4).

To select the output you wish to see or change in the

menu, select this on the display “OPno”. Press the SET

button so that “d1” starts flashing and then select with the

INC/DEC buttons. Press the SET button again to confirm

the selection. The displays in this view, i.e. “TYPE”, now

shows the current settings for the selected output.

a) Type of output (“TYPE”)

Here you can choose from the following types:

- Increase/decrease “3p”

- On /off “OnOF”

- Time proportional on/off (PWM “PULS”

- 0–10 V “0-10”

- No signal “-”

Depending which output is selected, only the applicable

signal types are displayed for each output.

HEAT

OUTP

HEAT

OPno

HEAT

TYPE

HEAT

HC

HEAT

FORC.

HEAT

LIML%

HEAT

LIMH%

HEAT

LIML V

HEAT

LIMH V

HEAT

P.TIME

HEAT

INV.

HEAT

MOT

MENU

4

d1

PULS

COOL

0

0

100

-

-

20.0

0

1

LUNA d

a)

b)

c)

d)

d)

e)

e)

f)

g)

h)

b) Selection of heating and/or cooling output signal

(“HC”)

Here you state if you want the output to work as a

cooling output or a heating output. You also have the

possibility to allow the output to control both heating and

cooling, for e.g. a mixing damper or the like.

Furthermore, you can allow the output to be regulated

directly by the room temperature. You then set the

desired limit values on “LIML” and “LIMH” (see point c).

- Cooling output signal “COOL”

- Heating output signal “HEAT”

- Heating/Cooling signal “HC”

- Absolute temperature “dIFF”

The controller automatically detects on all outputs, if it is

only cooling outputs or heating outputs or if there are

both. This determines how the controller’s set point works.

If, for example, there are no outputs set as a cooling stage

the controller then regulates without a deadband, i.e.

directly on the set point.

The deadband is used as soon as the controller detects

that both heating and cooling outputs are being used.

13/11/2018 Swegon reserves the right to alter specications.

15

Page 16

LUNA d

c) Select forced outputs

Forcing means that the outputs are activated by the timer.

0= Forced deactivated

1 = Forced activated

d) Setting of the regulation range (“LiML%” /

“LIMH%”)

The controller has a PI function the calculates the room’s

capacity need. This signal is then connected with different

outputs. Normally, for example, the outputs “d1” and

“A1” are set to regulate between 0 to 100 % of the cooling

capacity requirement, i.e. the whole cooling output signal.

If you want to reset the outputs to give e.g.

two step cooling in sequence, you can state that the

output “d1” must work between 0 and 50 % of the

cooling capacity requirement and output “d2” is reset for

cooling control and set to the range 50–100 %. These

outputs will then work in sequence.

In the example above the outputs “d1” and “d2” are set

to the following values:

”d1” HC = COOL

”d1” LiML% = 0%

”d1” LiMH% = 50%

”d2” HC = COOL

”d2” LiML% = 50%

”d2” LiMH% = 100%

If the output’s type is set to “dIFF”, these values are

changed to “LIM.-1” and “LIM.-0”.

On the display “LIM.-1” the room temperature is set that

should give full output signal on the output, and on

“LIM.-0” the temperature is set that should give a zero

signal on the output.

f) Setting of period time or running time for the

increase/decrease actuator (“PTIME”)

The period time is set here if the output has the type

“PULS”, i.e. time proportional on/off. The period time

is set to 20.0 minutes by default. The time proportional

function is sometimes called “PWM”,

i.e. pulse width modulation. This means that the controller

converts an output signal between 0 and 100% to pulses

with varying times.

If, for example, the output signal is 50 % the output then

gives out 24 V in 50 % of the period time (i.e. 10 minutes)

and is then closed for the rest of the period (i.e. 10

minutes).

g) Inverting of output signal (“INV.”)

Here you can choose that the output signal shall invert

the output. This works for all output types.

For example, a thermal actuator is usually used

with a normally open function, which means the output

signal must be inverted.

h) Automatic valve test running (“MOT”)

A function that is normally activated is automatic valve

test running. This means the actuator switches to open

mode for 3 minutes once a day, irrespective of the normal

output signal. This is to prevent the valves from seizing

up, as some times they remain closed for long periods,

e.g. during the summer.

Here you state in which interval the actuator shall test run

the valve, from 0 to 30 days. If 0 is stated the function is

deactivated.

e) Setting of the voltage limits for analogue outputs A1 and A2.

For example, “LIML V” is set to 2.0 volt and “LIMH V” is

set to 7.4 volt. The outfeed value to the control output is

“rescaled” so that it modulates between 2.0 and 7.4 volt

for the whole of the selected control range.

For forcing or test running the voltage is set to the value

in “MAX” and for the signal “Output off” the voltage is

set to the value in “LIML V”. “LIML V” and “LIMH V”

can also be used to calibrate the output voltage.

The minimum voltage limitation does not apply for the

SAVE operating mode or when the output is switched off

due to the condensation

function.

16

Swegon reserves the right to alter specications. 13/11/2018

Page 17

6.13 Outputs, Settings

MENU

On this menu you can select the temperature sensor

that will be available for the regulation loop, active the

condensation sensor also activate an external operating

mode switch. There is an input for condensation (I1) and

an input (I2) for an external temperature sensor, presence

sensor or external contact function.

a) Select active temperature sensor

The room controller can control the temperature with a

built-in sensor or with an external sensor, connected to

terminal 8 (+) and terminal 6 (-). The external sensor shall

be of the type NTC 10 KOhm @ 25°C

The built-in sensor in the room controller is always used

automatically by the room controller if no other sensor is

connected to the terminal block in the room controller.

When an external, resistive sensor is connected, the room

controller selects this sensor automatically instead of the

built-in sensor.

In order to connect the average value measurement with

both an external sensor and the built-in sensor in the

room controller,

set “R1+R2 to the value 3. If value 3 is used and if no

other sensor is connected to the terminal, the room

controller only reads the internal sensor.

Function “R1+R2” can be set to 1, 2 or 3

1 = internal sensor only

2 = external sensor only

3 = average value between internal and

external sensors

b) Condensation sensor

It is possible to activate an input for a condensation

sensor (1= activated). If condensation occurs, the controller

blocks the cooling outputs and if the controller still has a

need to cool the LED lamp flashes blue.

Once the condensation has disappeared, the cooling outputs regulate as usual and the LED lamp stops flashing.

LUNA d

HEAT

INPUT

HEAT

R1+R2

HEAT

COND

HEAT

CALRM

HEAT

EXT.

As the room controller has a programmable input, you

can activate more than one function at a time for input I2.

Input I1 is intended for the condensation sensor.

Input I1 Condensation

Input I2 External temperature sensor

External contact

Presence sensor

Make sure you deactivate other functions for input I2

before setting a new function. Setting for the presence

sensor are made via menu 6.

d) External contact, override operating mode

This function can activate an operating mode by connecting a relay with a normally open/closed function.

Relay open = Activate override function

Relay closed = Deactivate override function

Value 1 = Activate “DAY” operating mode

Value 2 = Activate “NIGHT” operating mode

Value 3 = Activate “SAVE” operating mode

5

a)

1

b)

0

c)

0

d)

0

Function “Cond” can be set to 0 or 1.

0 = Condensation function off.

1 = Condensation function on.

c) Condensation alarm

If this function is enabled, the controller activates the 10 V

DC output on the analogue output Y3 when condensation

occurs.

13/11/2018 Swegon reserves the right to alter specications.

17

Page 18

LUNA d

MENU

6.14 Occupancy

The controller has functions to override the operating mode

with an occupancy sensor. A basic passive IR-detector can

be used if it has a potential-free relay or equivalent.

a) Activation of occupancy function

Set this value to 1 to activate this function. If overriding is

not affected by the timer or an external override function,

the operating mode switches from “DAY” to “NIGHT”.

When occupancy is detected, the operating mode

switches to “DAY”.

b) Normally-open contact

The contact function can be selected to suit most

common IR detectors.

NO = 0 relay open at detection

NO = 1 relay closed at detection

HEAT

OCC.

HEAT

ACTIV

HEAT

NO

HEAT

TIME0

HEAT

TIME1

6

60

a)

0

b)

0

c)

d)

0

c) Switch-off delay

A switch-off delay can be set for the occupancy input.

The value can be set from 0 to 990 minutes, with

increments of 1 up to 100 minutes. These increment then

change to 10 minute increments.

When the occupancy contact stops indicating, the switchoff delay starts to count down.

When the delay countdown stops, the controller switches

operating mode back to “NIGHT”.

d) Switch-on delay

The switch-on delay is set as a delay before the controller

activates the “DAG” operating mode when occupancy

is detected. The value can be set from 0 to 99 minutes.

When occupancy is detected the controller receives a

pulse from the detector and the countdown for the

switch-on delay starts. If no new pulses are received, the

current operating mode does not change.

If the controller receives one or more pulses, the “DAY”

operating mode is activated when the controller has

completed its countdown of the set switch-on delay.

This function is useful if you wish to prevent the controller

from changing the operating mode from “NIGHT” when

you quickly pass through a room.

18

Swegon reserves the right to alter specications. 13/11/2018

Page 19

6.15 Calibration of temperature sensors

MENU

The controller has functions to override the operating

mode with an occupancy sensor. A basic passive IRdetector unit can be used if it has a potential-free relay or

equivalent.

a) Internal temperature sensor

Calibration of the internal sensor.

The value can be set from -9.9 to 9.9

b) External temperature sensor

Calibration of the external sensor if connected to input I2.

The value can be set from -9.9 to 9.9

CAL.

R1

R2

HEAT

HEAT

HEAT

LUNA d

7

a)

0

b)

0

13/11/2018 Swegon reserves the right to alter specications.

19

Page 20

LUNA d

MENU

6.16 Button functions

On this menu you can set the controller’s set point range,

access protection and timer functions.

a) Access code

An access code can be set to prevent unauthorised access

to the controller A system code can be set to prevent

unauthorised access to the setting menu.

The default code is set to “0000”. This code also

deactivates the code function.

b) not used

c) not used

d) not used

e) not used

f) Maximum timer time

A contact function can be selected for the IR detector’s

relay to suit the most common IR detector units.

NO = 0 relay open at detection

NO = 1 relay closed at detection

g) Minimum set point scale

This is the lowest set point for the set point scale, the

default value is 19 °C.

The value can be selected from 5.0 °C to 30.0 °C

HEAT

BUT.F

HEAT

CODE:

HEAT

GRND

HEAT

MEAS

HEAT

SEL.F

HEAT

SEL.T

HEAT

MAX.T

HEAT

MINSP

HEAT

MX SP

HEAT

COVER

HEAT

ENG

8

0000

255

°C

19.0

°C

25.0

a)

b)

1

c)

1

d)

0

e)

5

f)

g)

h)

i)

0

j)

1

g) Maximum set point scale

is the highest set point for the set point scale,

the default value is 25 °C.

The value can be selected from 5.0 °C to 30.0 °C

i) Lock values

A lock function can be activated for different values on

the main menu. If a value of 1 is set the whole menu view

is still visible, but the following values cannot be changed:

- Day, time, date, year

- NIGHT operating mode set point

- SAVE operating mode set point

j) Language setting

Set the language:

0 = Swedish

1 = English

The value is also saved in the controller the next time you

connect the hand-held terminal.

20

Swegon reserves the right to alter specications. 13/11/2018

Page 21

6.17 Test Menu

MENU

On this menu you can set temporary test parameters and

see the input and output functions.

a) Input status

Reading of the input status IN1 and IN2.

0 = inactive, 1 = active

If IN2 is used for an external sensor the number 1 is

shown if the sensor is connected.

b) Output status

In this view you can see the status of the controller’s two

24 V outputs. The number to the right denotes the status

of output “d2” and the number in the middle denotes the

status of output “d1”

The number to the left can be set to 1 if you wish to

force any of the outputs to active, by pressing the SET

button and then the UP button (the control functions are

switched off automatically). Now press the SET button

again to go to the next number (output). The value can

be set to 1 or 0 to force the outputs.

If any of the outputs have been activated through forcing,

the AUTO symbol flashes. The function is automatically

deactivated after 2 hours or in the event of a power failure.

HEAT

TEST

HEAT

IN:

HEAT

OUT:

HEAT

TST.R

HEAT

RESET

HEAT

ADDRE

HEAT

DATA :

HEAT

INIT

HEAT

CODEG

HEAT

CODES

HEAT

LIGHT

9

00

000

0

ACP0

724

250

3385

0000

0

LUNA d

a)

b)

c)

d)

e)

f)

g)

0

h)

i)

j)

c) Override room temperature

In order to make simulations and test the control functions

in the controller the room temperature sensors’ reading

can be deactivated. Instead it’s possible to state

(simulated temperature) values manually in the main

menu view, by first activating override in view “TST.R” to

then return to the main menu and press the SET button

and state a simulated temperature value. The function is

automatically deactivated after 2 hours or in the event of

a power failure.

d) Resetting

The controller’s resetting functions can reset the controller’s

software or all the controller’s values to the factory

settings.

The resetting functions are:

ACP0

A = Reset all (all values are reset to the factory settings)

Note! This can only be performed with a special code.

C = Reset all, except important system parameters.

P = “Standard” reboot. Values read from the controller are

copied to the hand-held terminal’s permanent memory.

0 = Not used. Must be 0!

Press the SET button to move between the resetting

functions and confirm your selection by pressing the UP

button.

13/11/2018 Swegon reserves the right to alter specications.

21

Page 22

LUNA d

e+f) Read values from the hand-held terminal’s RAM.

In or to perform specific types of fault finding, you may

need to read certain values from the RAM memory.

The address is stated in the view “Addri” and the value

can then be read in the view “DATA”. When in the menu

view (“Addri”) you can press the SET button twice and

then use the UP button to switch to the menu view

(“Addre”).

This denotes that it is reading the controller’s RAM

directly, instead of the hand-held terminal’s RAM. Press

the SET button again to confirm the selection.

g) Only used by Swegon to program customer

specific original values.

h+i) Special code to protect system functions

Specific functions are protected to prevent any hardware

related settings from being made incorrectly, however,

sometimes access to these may be necessary

View “CODEG” generates a temporary code.

Note down the code and then contact Swegon to receive

an access code. The access code is then entered in the

display view “CODES”.

j) Invert colours for status LED

It is possible to invert the LED colours by changing the

setting “LIGHT” to 0 or 1.

0 = not inverted LED indication

1 = inverted LED indication

22

Swegon reserves the right to alter specications. 13/11/2018

Page 23

6.18 Type designations

MENU

This menu identifies product and software versions and

shows the product’s serial number if this needs to be

specified.

a) Software number

Normally shows the software number or specially developed

adapted program numbers.

b) Software version

Shows the software version.

c) Serial number 1

To read the serial number, the digits must be interpreted

from right to left on “SER.1”. The digits to the far right

are singular and are followed by ten, hundred and

thousand. The digits in the menu “SER.2” are, from right

to left, ten thousand, hundred thousand, million and ten

millions.

HEAT

TYPE

HEAT

PROG

HEAT

VER.

HEAT

SER.1

HEAT

SER.2

10

2727

25.5

0000

0000

LUNA d

a)

b)

c)

d)

d) Serial number 2

To read the serial number, the digits must be interpreted

from right to left on “SER.1”. The digits to the far right

are singular and are followed by ten, hundred and

thousand. The digits in the menu “SER.2” are, from right

to left, ten thousand, hundred thousand, million and ten

millions.

13/11/2018 Swegon reserves the right to alter specications.

23

Loading...

Loading...