Swegon GOLD RX Series, GOLD RX 120, GOLD RX 100, GOLD CX Series, GOLD CX 100 Instructions For Installation Manual

...Page 1

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 1

Instructions for Installation

GOLD RX/CX, sizes 100/120

The document was originally written in Swedish.

Page 2

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

2

www.swegon.com

1. Installation ............................................... 3

1.1 General .................................................................. 3

1.2 Transport within the site ......................................... 3

1.3 Parts packed together with the unit ........................ 3

1.3.1 Hand-held micro terminal .................................. 3

1.3.2 Supply air sensor ............................................... 3

1.3.3 Document pocket ............................................. 3

1.4 Location ................................................................. 3

1.5 Method of delivery ................................................. 3

1.5.1 GOLD RX .......................................................... 3

1.5.2 GOLD CX .......................................................... 3

1.6 Lifting .................................................................... 4

1.6.1 With a fork-lift truck ......................................... 4

1.6.2 With a crane ..................................................... 4

1.6.2.1 Complete units ............................................ 4

1.6.2.2 Heat exchanger section, supplied split into two

casing sections and rotor (GOLD RX only) ................. 5

1.7 To assemble the heat exchanger unit section,

if required (GOLD RX only) ........................................... 7

1.7.1 Alternative 1 ..................................................... 7

1.7.2 Alternative 2 ................................................... 11

1.7.3 Common for Alternatives 1 and 2 ................... 15

1.7.3.1 To adjust the rotor’s inclination ................... 15

1.7.3.2 Sealing plates/purging sector ...................... 16

1.7.3.3 Pressing roller ............................................. 16

1.7.3.4 Vinyl-coated fabric seal .............................. 16

1.7.3.5 Sealing ....................................................... 17

1.7.3.6 Decorative fittings ...................................... 18

1.8 Transport locking devices, fans ............................. 19

1.9 Version and fan arrangement ............................... 19

1.9.1 GOLD RX ........................................................ 19

1.9.2 GOLD CX ........................................................ 19

1.10 The docking of unit sections ............................... 20

1.10.1 Fan/filter sections .......................................... 20

1.10.2 Fixation, front of the unit .............................. 20

1.10.3 Fixation, rear of the unit ................................ 21

1.10.4 Decorative fittings ......................................... 22

1.10.5 Electrical quick-fit connectors ........................ 23

1.10.6 To connect air tubes to filter pressure sensors 24

1.11 Duct connection ................................................. 25

1.12 To install the supply air sensor ............................. 25

1.13 Electrical connections, protective motor switch and

communication cables (GOLD CX only) ....................... 26

1.13.1 Protective motor switch ................................ 26

1.13.2 Communication cables ................................. 26

1.14 To connect the electric power supply .................. 27

1.15 To Connect external cables ................................. 28

1.15.1 GOLD RX ...................................................... 28

1.15.2 GOLD CX ...................................................... 28

1.16 Installation of pipework package

(GOLD CX only) .......................................................... 29

2. Dimensions ............................................29

2.1 GOLD RX 100/120 ............................................... 29

2.2 GOLD CX 100/120 ............................................... 30

3. Explanation – wiring terminals,

control unit ................................................ 31

Content

Page 3

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 3

3440

1070

1070

1868

1170 2350

1861

2930

1.1 General

All staff concerned must acquaint themselves with these

instructions before beginning any work on the unit. Any

damages to the unit or parts of it due to improper handling or misuse by the purchaser or the fitter cannot be

considered subject to guarantee if these instructions have

not been followed correctly.

The product identification plates are located on the

inspection side of the air handling unit and inside the

electric equipment cubicle of the unit. Refer to the particulars on the product identification plate when you contact

Swegon.

The air handling unit is supplied in packaged condition.

Possible ordered accessories are supplied in separate pack-

aging with the unit.

Remove the air handling unit’s protective plastic foil pack-

aging when you have completed the installation.

1.2 Transport within the site

Before removing the transport pallet/transport cradle, if

used, determine whether a forklift truck or a pallet transporter will be used for further transporting the unit within

the site to the spot where it will be installed.

1.3 Parts packed together with the unit

Individually packaged components such as the hand-held

micro terminal, decorative fittings, commissioning plates,

bolts, supply air sensor and document pocket are inside

the air handling unit when it is delivered.

1.3.1 Hand-held micro terminal

The hand-held micro terminal is equipped a 3 m long

cable and a quick-fit connector. For particulars of the electrical connections, see 1.15. A holder for wall-mounting

is supplied with the hand-held micro terminal. The holder

can be secured to the outside of the air handling unit

(does not apply to the outdoor units) or another appropriate place. An extension cable (8 metres long) is available

as an accessory.

1.3.2 Supply air sensor

The sensor is equipped with a 10 m long cable and a

quick-fit connector. For particulars regarding installation,

see 1.12. For particulars of the electrical connections, see

1.15.

1.3.3 Document pocket

Secure the document pocket to the exterior of the air

handling unit or another appropriate place.

1.4 Location

The air handling unit must be mounted horizontally on a

flat and firm supporting surface and this surface must be

constructed in a way enabling it to support the weight of

the unit.

1. Installation

When installing the air handling unit and connecting pipework and electric cables, make sure that adequate free

space is provided for opening the inspection doors and

covers and withdrawing functional sections, such as filter

cassettes and fan assemblies, clear of the unit casing.

Inspection space required

A clear space of 1,000 mm should be provided in front of

the unit for opening the inspection doors.

1.5 Method of delivery

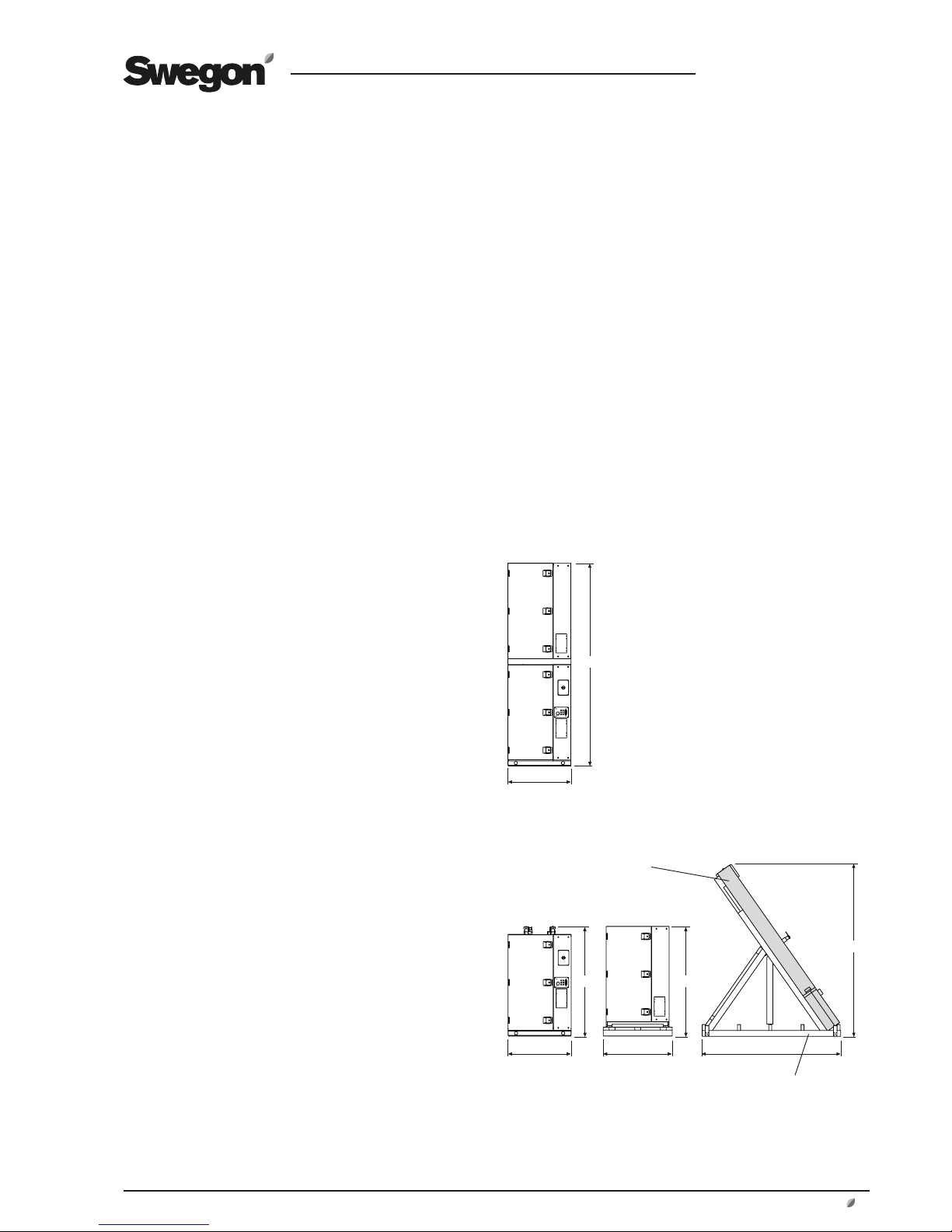

1.5.1 GOLD RX

The GOLD RX 120 is normally supplied in five separate

sections: two fan sections, two filter sections and one

heat exchanger section.

The heat exchanger section can also be supplied split into

two casing sections and rotor, in which case the rotor is

supplied tilted in a transport cradle (transport height =

2,930 mm, minimum transport width = 2,350 mm). See

Section 1.7 for installation particulars.

For other dimensions and weights, see Section 2.1.

Heat exchanger section supplied as a separate unit

Heat exchanger section, supplied split

into two casing sections and rotor

Rotor, Ø 3150

Transport cradle

3440

1070

1.5.2 GOLD CX

The GOLD CX 120 is supplied as six separate units:

Two fan sections, two filter sections and two coil heat

exchanger sections.

For dimensions and weights, see Section 2.2.

Page 4

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

4

www.swegon.com

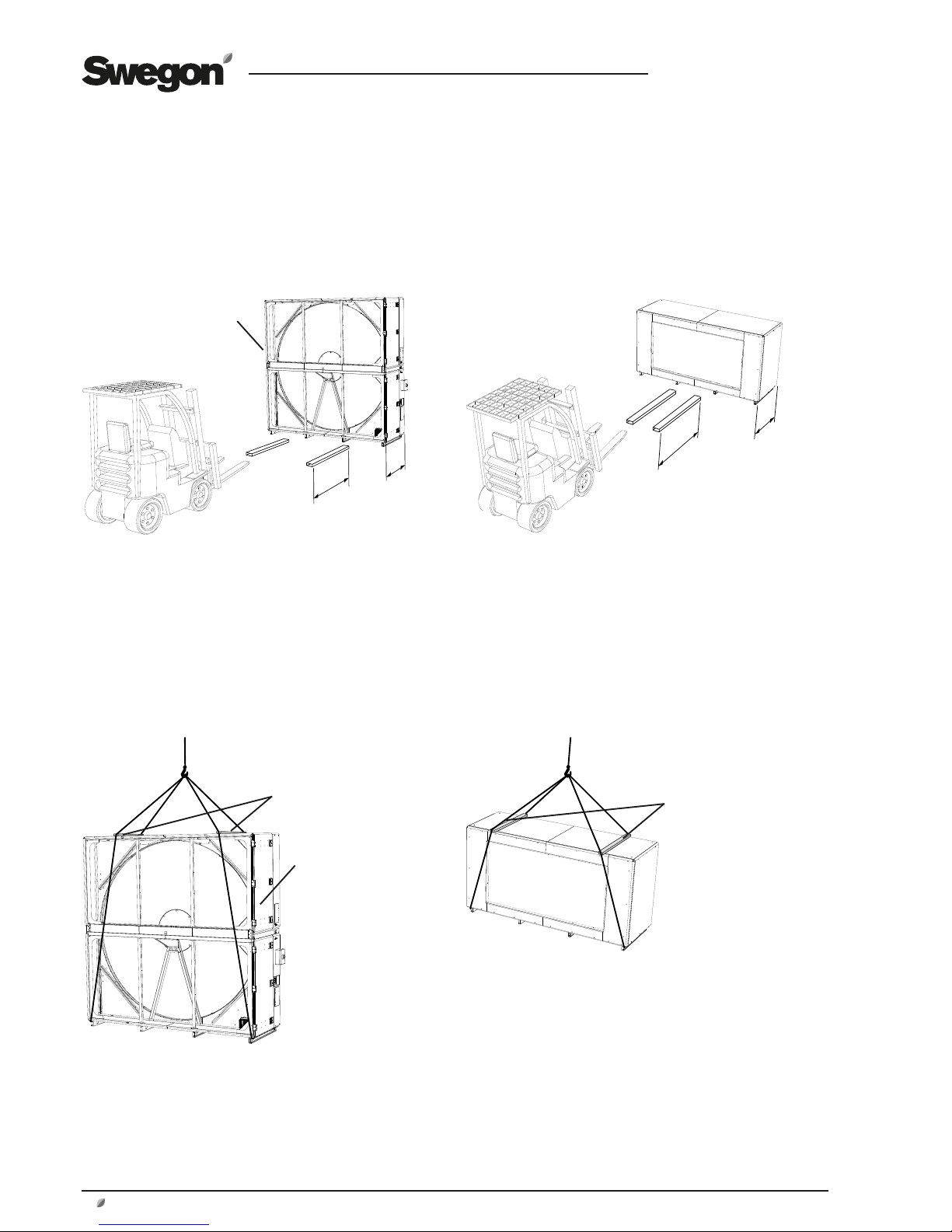

1.6 Lifting

1.6.1 With a fork-lift truck

L

L

NOTE! Make sure that

forks of the fork-lift truck

are sufficiently long!

Other sections

L

L

Rotary heat exchanger (GOLD RX only).

NOTE! Make sure that

forks of the fork-lift truck

are sufficiently long!

NOTE! High centre of gravity!

1.6.2 With a crane

1.6.2.1 Complete units

Other sections

NOTE! A line spreader must

be used!

NOTE! High centre of

gravity!

NOTE! A line spreader must

be used!

Rotary heat exchanger (GOLD RX only).

Page 5

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 5

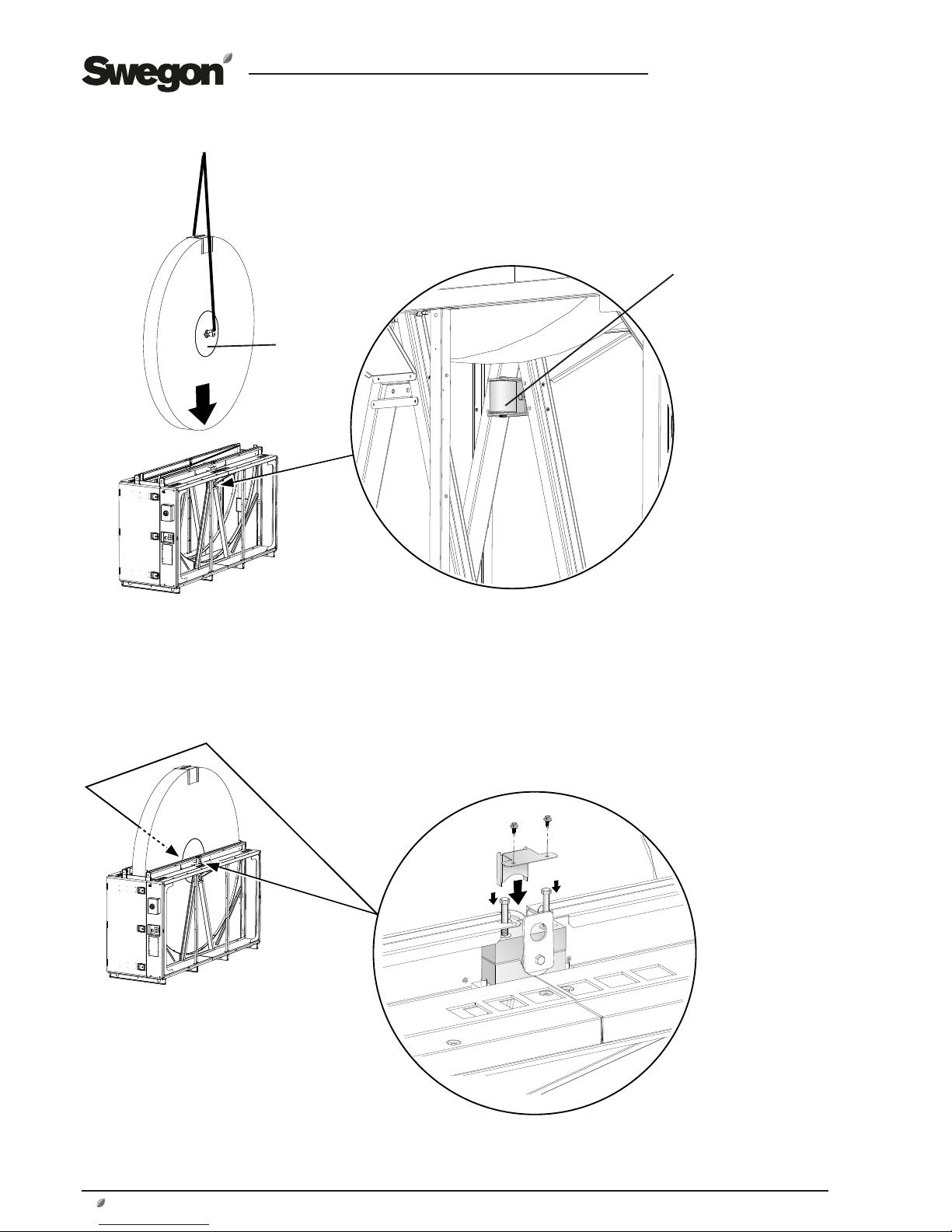

Lower casing section

NOTE! A line spreader must

be used!

Upper casing section

1.6.2.2 Heat exchanger section, supplied split into two casing sections and rotor (GOLD RX only)

Page 6

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

6

www.swegon.com

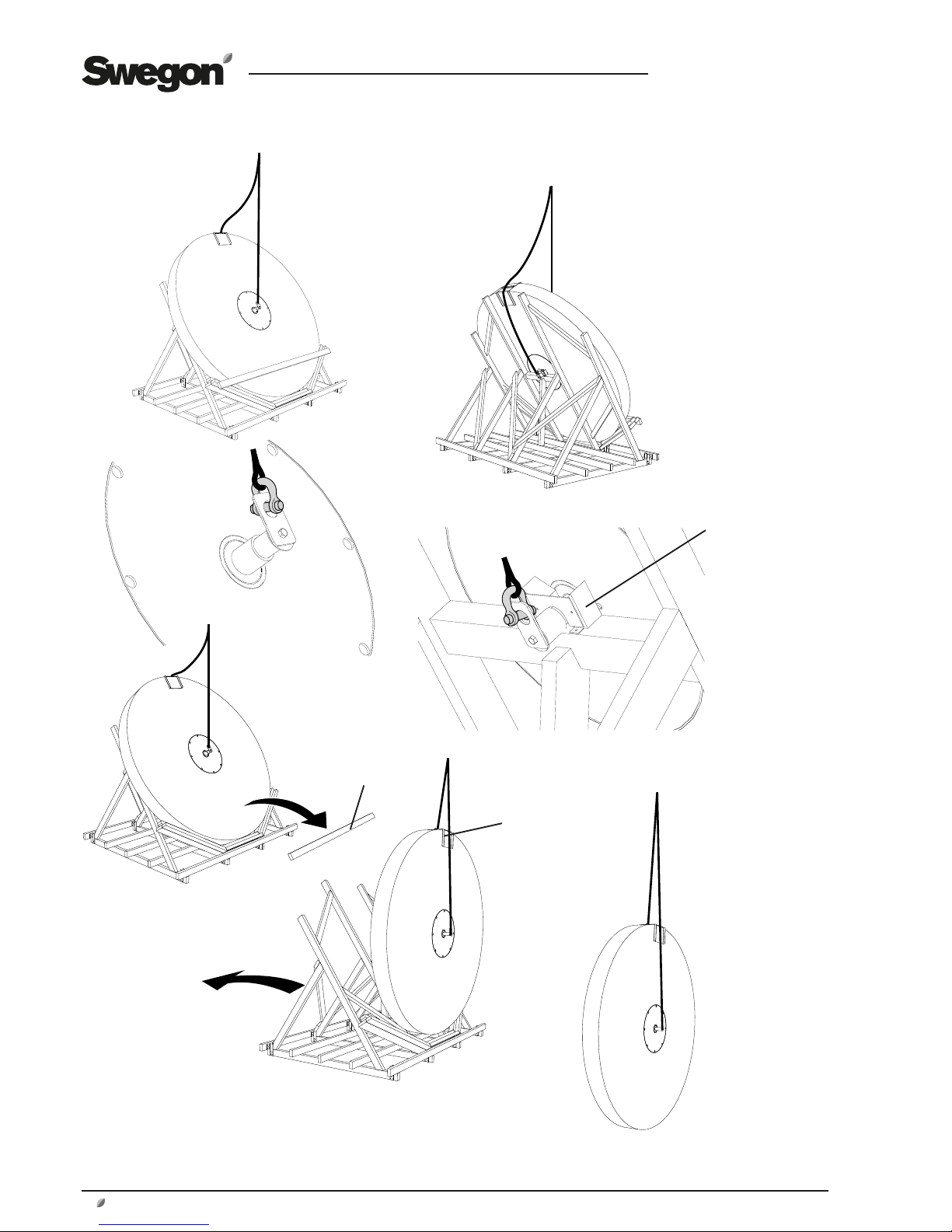

Rotor

Remove the

wooden stud

NOTE! Carefully raise the rotor so that it

will not be damaged! Make sure that the

lifting device rests against the protecting

plate at the top edge.

Protecting plate

Remove the anchor

plate

Page 7

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 7

1.7 To assemble the heat exchanger unit

section, if required (GOLD RX only)

If the heat exchanger unit section is supplied in parts, they

must be jointed together. This can be done in two ways:

Alternative 1 is appropriate for use if there is sufficient free

space upward since this alternative is simpler. If sufficient

space is not available, Alternative 2 should be used.

If the heat exchanger unit section is supplied as one unit,

go on to Section 1.8.

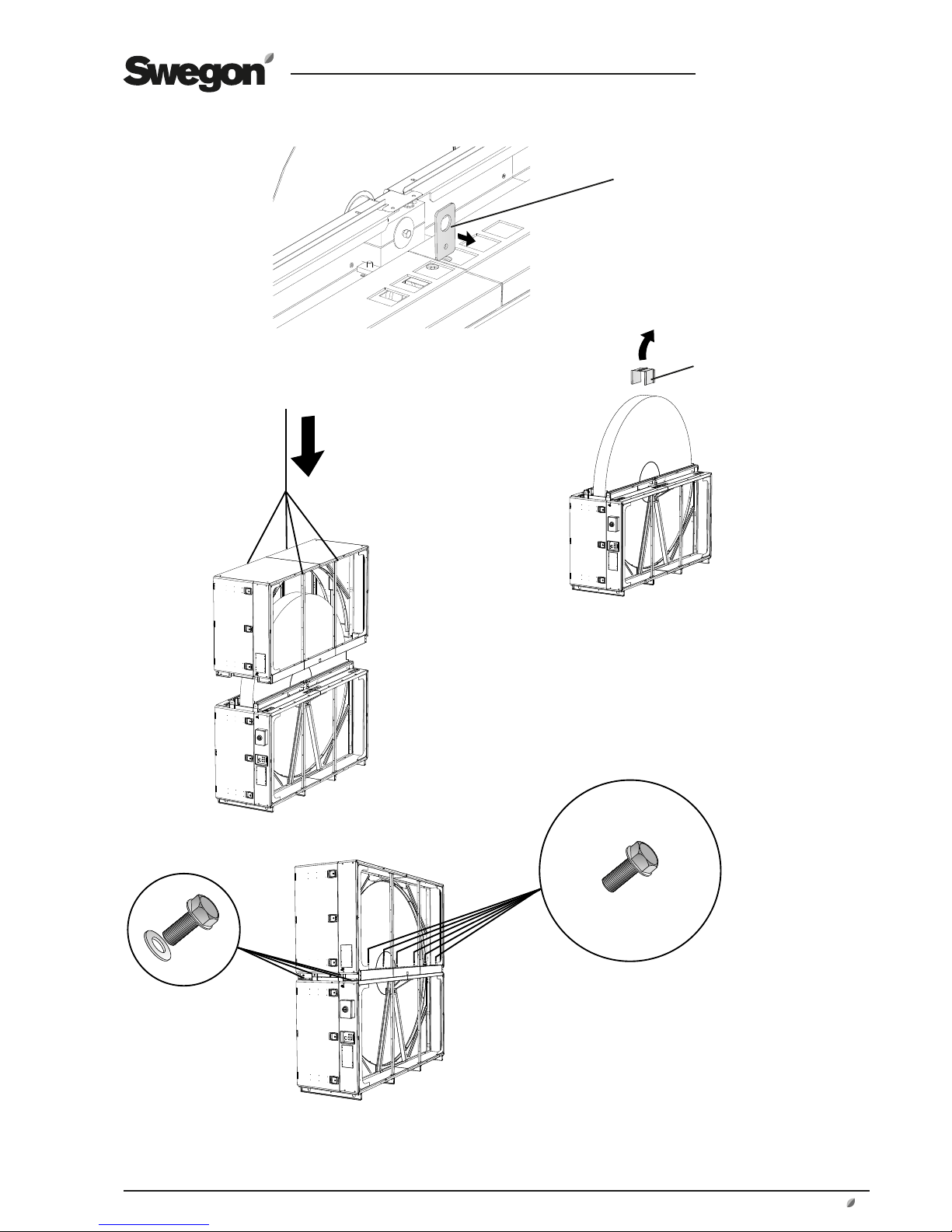

1.7.1 Alternative 1

Lower casing section

Shaft mounting brackets

Remove the upper shaft bracket and

the sealing plate (2x)

Page 8

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

8

www.swegon.com

Lift the rotor into the lower casing section (see Section 1.6).

NOTE! IMPORTANT! The smooth side of the rotor hub (without holes) should face the pressing roller!

Be careful not to damage the rotor!

Hub side

Pressing roller

Mount the upper shaft bracket

and the sealing plate (2x)

Page 9

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 9

Remove the lifting lugs. Refit the bolts

and washers to the shaft end (2x).

Remove the protecting plate

of the rotor.

Lift the upper casing section

onto the lower casing section

(see Section 1.6).

2 x 6

Fix the upper casing section to the lower casing

section with the bolts supplied, screwing them

into the pre-fitted rivet nuts (a total of 20 pcs.).

2 x 4

Page 10

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

10

www.swegon.com

Slacken off the two screws

holding the motor + mounting bracket. Move the motor +

mounting bracket back to their

original positions. Secure the

motor + mounting bracket with

bolts (6 bolts).

Unfasten the electrical equipment cubicle

and move it to the side.

Disconnect the electrical quick-fit connectors

from the fan motors and

the heat exchanger drive

motor.

NOTE! Do not disconnect

the cables from the electrical equipment cubicle

to the main switch.

Dismantle the heat exchanger motor + mounting bracket (6 bolts).

Move the motor + mounting bracket into position

shown in the illustration

and temporarily secure

them with two screws

Place the rotor drive belt

around the motor belt

pulley.

Reconnect the electrical quick-fit

connectors to the fan motors and

the heat exchanger drive motor.

Move the electrical equipment

cubicle back into position and

secure it with the appropriate

bolts.

See also Section 1.7.3 Common for Alternatives 1 and 2

Page 11

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 11

1.7.2 Alternative 2

Unfasten the electrical equipment cubicle and move it to the

side. Disconnect the electrical quick-fit connectors from the fan

motors and the heat exchanger drive motor.

NOTE! Do not disconnect the cables from the electrical equipment cubicle to the main switch.

Dismantle the heat exchanger motor + mounting bracket

(6 bolts). Remove the sealing plate and tube.

Lower casing section

Shaft mounting brackets

Remove the upper shaft bracket

and the sealing plate (2x)

Page 12

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

12

www.swegon.com

Lift the rotor from the side into the lower casing section (see

Section 1.6).

NOTE! IMPORTANT! The smooth side of the rotor hub (without holes) should face the pressing roller!

Be careful not to damage the rotor!

Hub side

Pressing roller

Mount the upper shaft bracket

and the sealing plate (2x)

Page 13

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 13

Remove the lifting lugs. Refit the bolts

and washers to the shaft end (2x).

Remove the protecting plate of

the rotor.

Slacken off the two screws holding the motor + mounting

bracket. Move the motor + mounting bracket to the position

shown in the illustration. Secure the motor + mounting bracket

with bolts (6 bolts).

Move the motor + mounting bracket into position shown in the

illustration and temporarily secure them with two screws Place

the rotor drive belt around the motor belt pulley.

Reconnect the electrical quick-fit connectors to the fan motors

and the heat exchanger drive motor. Move the electrical equipment cubicle back into position and secure it with the appropriate bolts.

Fit the sealing plate

and tube.

Page 14

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

14

www.swegon.com

Upper casing section

Remove the cover panel on the rear

side. Remove the sealing plates (2 pcs.).

Lift the upper casing section from the side onto the

lower casing section (see

Section 1.6).

Mount the cover panel and

the sealing plates (2 pcs.).

2 x 6

Fix the upper casing section to the lower casing

section with the bolts supplied, screwing them

into the pre-fitted rivet nuts (a total of 16 pcs.).

2 x 2

See also Section 1.7.3 Common for Alternatives 1 and 2

Page 15

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 15

1.7.3 Common for Alternatives 1 and 2

1.7.3.1 To adjust the rotor’s inclination

L

L

≈ 0,5xL

≈ 0,5xL

The illustration shows an appropriate rotor inclination

setting for Fan Arrangement 1. The inclination must always be toward the filter, which means that the inclination for Fan Arrangement 2 is in the other direction.

The rotor’s inclination may need to be greater in applications that involve high airflows with associated high

pressure.

Slightly back off the locking bolts.

Do not dismantle the shaft bracket.

Adjust the inclination of the rotor by means

of the adjusting bolts. Tighten the adjusting

bolts equally.

When you have adjusted the inclination,

tighten the locking bolts.

Page 16

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

16

www.swegon.com

1.7.3.2 Sealing plates/purging sector

Back off the screws

for the sealing plates/

purging sector. Arrange

the sealing plates/

purging sector so that

the bristles are against

the rotor. Tighten the

screws.

1.7.3.3 Pressing roller

Tension the pressing roller against the rotor hub until you no

longer can roll the pressing roller with your hand.

1.7.3.4 Vinyl-coated fabric seal

Slip the vinyl-coated fabric seal of the rotor (blue) over the rim

all the way around on both sides of the rotor.

Page 17

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 17

1.7.3.5 Sealing

Apply appropriate sealing

compound/putty to corners

by the sealing plates/purging

sector (4 plates).

Apply appropriate sealing compound/

putty around the sealing plate of the

rotor shaft (2 plates).

Apply appropriate sealing compound/

putty to the joints between the upper casing section and the lower casing section

(front and rear).

Page 18

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

18

www.swegon.com

1.7.3.6 Decorative fittings

Mount the decorative fittings with self-tap-

ping screws in the pre-punched holes.

Mount the decorative fittings with the pre-fitted M5

bolts in the pre-fitted rivet nuts.

Page 19

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 19

Right-hand version

Left-hand version

Fan arrangement 1 Fan arrangement 2

Fan arrangement 1 Fan arrangement 2

1.9 Version and fan arrangement

1.9.1 GOLD RX

The GOLD RX 120 is supplied in the right-hand or a lefthand version and with fan arrangement 1 or 2, see the

illustration below.

For particulars of the delivery configuration and installation of the relevant air handling unit, see the decal on the

lower section of the heat exchanger.

Outdoor air Supply air Extract air Exhaust air

1.8 Transport locking devices, fans

The fans are equipped with transport locking devices (4x2

devices/fan, a total of 48 pcs.). All these must be removed,

see illustration.

1.9.2 GOLD CX

The GOLD CX 120 is supplied in the right-hand or a lefthand version and with fan arrangement 1, 2, 4 or 5, see

the illustrations below.

For particulars of the delivery configuration and installation of the relevant air handling unit, see the decal on the

lower section of the heat exchanger.

N.B.! Coil heat exchangers with control unit are always

located in the lower level. The supply air fan is marked 1;

the extract air fan is marked 2. These identifying decals are

affixed to the inner wall of the fan sections.

N.B.! If extract air flows through the lower level: The air

handling unit must be raised at least 50 mm (higher than

the upper edge of the base beams) to provide space for

the water trap. This can be done by mounting adjustable

feet (accessories, a minimum of 24 feet).

Right-hand version

Fan arrangement 1 Fan arrangement 2

Fan arrangement 5,

supply air upper

Fan arrangement 5,

supply air lower

Left-hand version

Fan arrangement 1 Fan arrangement 2

Fan arrangement 4,

supply air – upper level

Fan arrangement 4,

supply air - lower level

x 32, GOLD 100

x 48, GOLD 120

Page 20

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

20

www.swegon.com

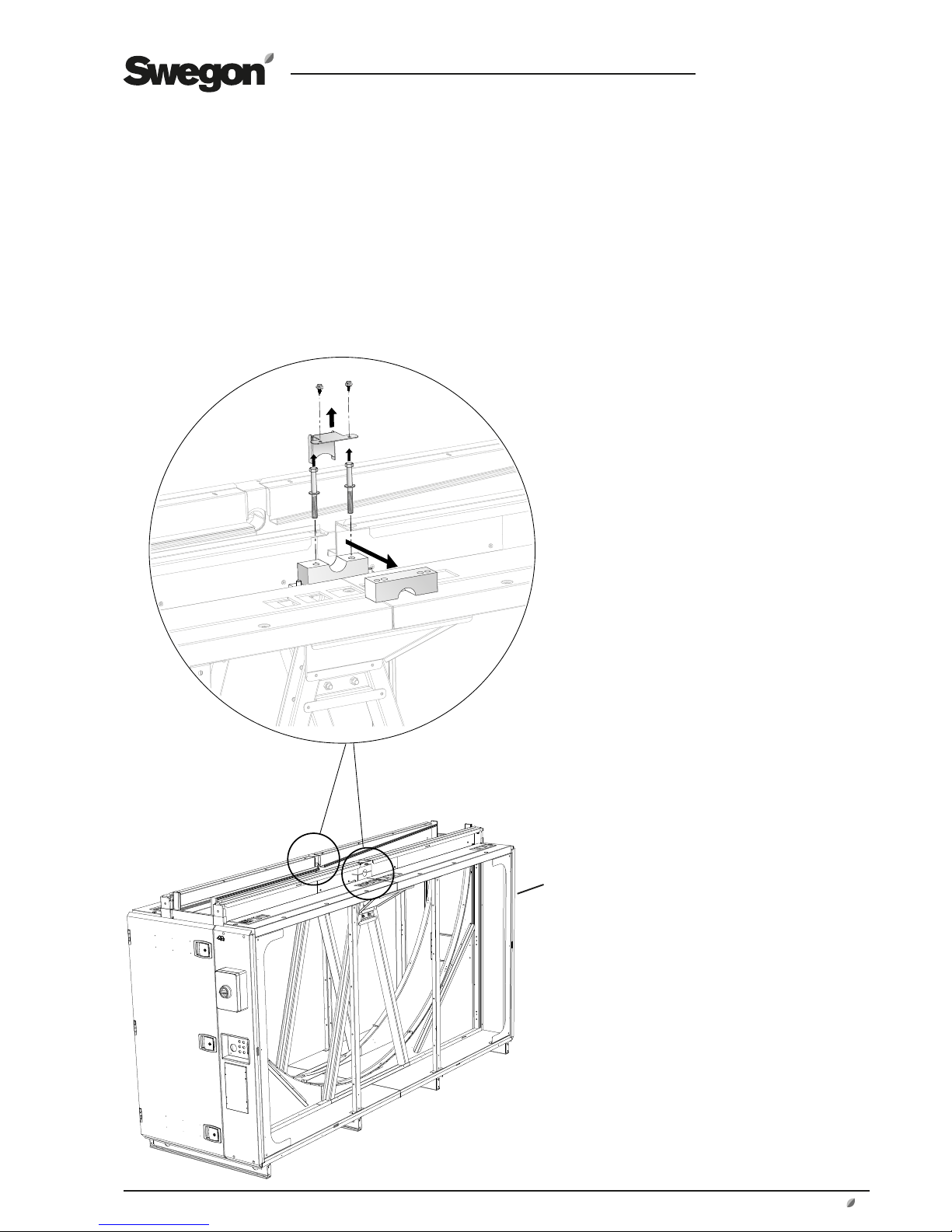

1.10 The docking of unit sections

Locate the fan/filter sections by the heat exchanger

section according to the delivery configuration (see

Section 1.9). Fix the fan/filter sections at thefront side

of the air handling unit to the heat exchanger section

with the bolts supplied, screwing them into the prefitted rivet nuts (a total of 2x4 pcs.).

The illustrations in Section 1.10 show a GOLD RX air handling unit with fan arrangement 2. The principle is however the same for the other air handling units.

1.10.1 Fan/filter sections

1.10.2 Fixation, front of the unit

Place the fan, filter and possible coil heat exchanger

sections on top of one another, according to the

delivery configuration (see Section 1.9). Fix the upper

section to the lower section with the bolts supplied,

screwing them into the pre-fitted rivet nuts (a total of

4 pcs.).

Page 21

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 21

Alt. 1

External fixing.

Dismantle the blanking plate and insulation inside the

cover on the rear side of the air handling unit. Fix the

fan/filter sections to the heat exchanger section with

the bolts supplied, screwing them into the pre-fitted

rivet nuts (a total of 2x4 pcs.). Refit the blanking plate

and the insulation.

Securing with screws at the rear of the air handling unit

can be done in two ways, internally or externally. External

fixing (Alt. 1) is appropriate for use if there is sufficient free

space behind the air handling unit, since this alternative

is simpler. If sufficient space is not available, Alt. 2) can be

used.

Alt. 2

Internal installation.

Fix the fan/filter sections to the heat exchanger section

with the bolts supplied, screwing them into the prefitted rivet nuts (a total of 2x4 pcs.). The anchoring

points inside the unit are shown in the illustration.

In order to access the anchor points in the fan section,

you must unfasten the flexible connections and the

fan assemblies and move them outward toward the

inspection door. You can then tighten the screws from

the opening of the duct connection.

NOTE! You do not need to remove the fan assemblies

completely!

1.10.3 Fixation, rear of the unit

Blanking

plate

Page 22

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

22

www.swegon.com

x2 (RX)

x3 (CX)

x2

x2

Press the decorative fittings firmly into the base

beam to engage them.

GOLD CX: Fit the decorative plate with cable

grommets on the heat exchanger section.

Joint together two decorative fittings with

screws as shown in the illustration. Then

secure the decorative fittings to the ends of

the base beams with screws.

Press the decorative against the base

beam to engage it firmly.

Joint together two decorative

fittings with screws as shown in

the illustration. Then secure the

decorative fittings to the ends

of the base beams with screws.

1.10.4 Decorative fittings

Page 23

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 23

1A

2A

1A

2A

1B

1B

2B

GOLD 100

1A

2A

3A

1A

2A

3A

1B

2B

3B

1B

2B

3B

GOLD 120

2B

1A

2A

1A

2A

1B

1B

2B

GOLD 100

1A

2A

3A

1A

2A

3A

1B

2B

3B

1B

2B

3B

GOLD 120

2B

1.10.5 Electrical quick-fit connectors

Connect the electric cables with

quick-fit connectors between the

electrical equipment cubicle and

the fans.

The illustration shows the GOLD

RX, fan arrangement 2.

The principle is however the

same for the other air handling

units.

Cap. var. 1, 2

Cap. var. 2

Cap. var. 1, 2

Cap. var. 2

Cap. var. 1, 2

Cap. var. 2

Cap. var. 1, 2

Cap. var. 2

Page 24

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

24

www.swegon.com

- +

Connect the air tube from the air nipple below the filter

to the + connection on the filter pressure sensor as

shown in the illustration. The air tubes are connected to

each air nipple (below the filter) and are rolled up inside

each fan/filter section.

The illustration shows the GOLD RX, fan arrangement 2.

The principle is however the same for other air handling

units.

1.10.6 To connect air tubes to filter pressure sensors

Page 25

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 25

1.12 To install the supply air sensor

The supply air temp. sensor must be mounted inside the

supply air duct.

The sensor must be positioned at a spot that is at least 1.5

metres from the air handling unit.

NOTE! If an air heater and/or air cooler, if required, is

installed in the system, the sensor must be positioned 1.5

metres from the unit measured from this component.

1. Measure and mark where the sensor is to be placed.

2. Drill an 11 mm dia. hole in the supply air duct.

3. Apply sealing compound around the hole and secure

the sensor by means of 2 self-tapping screws.

4. Connect the sensor's quick-fit connector to the appropriate socket on the control circuit board of the air

handling unit. See Section 1.15.

1.11 Duct connection

The air handling unit’s connection frames are rectangular

and can be jointed to ducts by means of slip-clamps.

The ducts should be insulated according to local regulations and customary trade standards.

A >= 1500 mm

B = 10000 mm

C = Ø 11 mm

B

A

B

C

A

Page 26

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

26

www.swegon.com

SD

WLAN

CPU 1

CPU 2

1A2B3

GND4+5-6+7-8+9-

10+11-12+13

-

SA TempCom 5Com 4Com 3Com 2Com 1

14+15-16+17-18+19

-

Heat Cool

20C21NO22C23NO24C25NO26C27NO28P29G30G031G32

G0

24V AC

Sensor 1 Sensor 2 Sensor 4Sensor 3 Com 6 Com 7 Com 8 Com 9 Com 10 Com 11

+33-34G35G036Y37U

38 39 40

24V AC In

41 42

18V AC In

45 46

230V AC In

4743 44

230V AC Out

1.13 Electrical connections, protective motor

switch and communication cables

(GOLD CX only)

The electrical connections should be wired by a qualified

electrician in accordance with local electrical safety regulations.

Dismantle the Cover panels and blanking plate in front of

the electrical equipment cubicles.

Connect the cables for the protective motor switch and

the communication cables between the upper and lower

electrical equipment cubicles, see the illustration below.

1.13.1 Protective motor switch

GOLD CX 100 and 120, capacity variant 1

Cables from the lower electrical equipment cubicle (connected at the factory) should be connected in the upper

electrical equipment cubicle as illustrated below. Run

the cables into the upper electrical equipment cubicle

through the grommets on the cover panel and in the

electrical equipment cubicle.

Upper electrical equipment cubicle

GOLD CX 120, capacity variant 2

Cables from the lower electrical equipment cubicle (connected at the factory) should be connected in the upper

electrical equipment cubicle as illustrated below. Run the

cables into the upper electrical equipment cubicle through

the grommets on the cover panel and in the electrical

equipment cubicle.

Upper electrical equipment cubicle

Cover panel Blanking plate

Upper electrical

equipment cubicle

Lower electrical

equipment cubicle

Communica-

tion cables

Cables for

the protec-

tive motor

switch

1.13.2 Communication cables

There are 2 or 3 communication cables from the upper

electrical equipment cubicle (connected at the factory)

which should be connected in the lower electrical equipment cubicle, depending on the variant selected.

Run the cables into the lower electrical equipment cubicle

through the grommets on the cover panel and in the

electrical equipment cubicle.

One of the communication

cables is always marked

COM6-11 and should be

connected in an optional

bus contact marked COM6-

11.

One or two of the communication cables is/are

marked Sensor 1, 2, 3 or 4

and should be connected

to the corresponding bus

contact.

Control circuit card in the lower electrical equipment cubicle

Page 27

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 27

1.14 To connect the electric power supply

The electrical connections are to be wired by a qualified

electrician in accordance with local electrical safety regulations.

Wire the incoming power supply cable to the air handling

unit’s external safety isolating switch. Remove the cover

of the safety isolating switch to gain access to its wiring

terminals.

N.B.! Make sure that you have done Item 1.13

before you connect the power (GOLD CX only). Risk

of personal injury!

Wiring terminals,

safety isolating switch

L1 L2 L3 N PE

L1 L2 L3 N PE

Safety isolating switch

GOLD RX 100, capacity variant 1:

3-phase, 5-wire cable, 400V -10/+15%, 50/60 Hz, 50 AT.

GOLD CX 100, capacity variant 1:

3-phase, 5-wire cable, 400V -10/+15%, 50/60 Hz, 63 AT.

GOLD RX/CX 100, capacity variant 2:

3-phase, 5-wire cable, 400V -10/+15%, 50/60 Hz, 80 AT.

GOLD RX/CX 120, capacity variant 1:

3-phase, 5-wire cable, 400V -10/+15%, 50/60 Hz, 80 AT.

GOLD RX/CX 120, capacity variant 2:

3-phase, 5-wire cable, 400V -10/+15%, 50/60 Hz, 125 AT.

Page 28

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

28

www.swegon.com

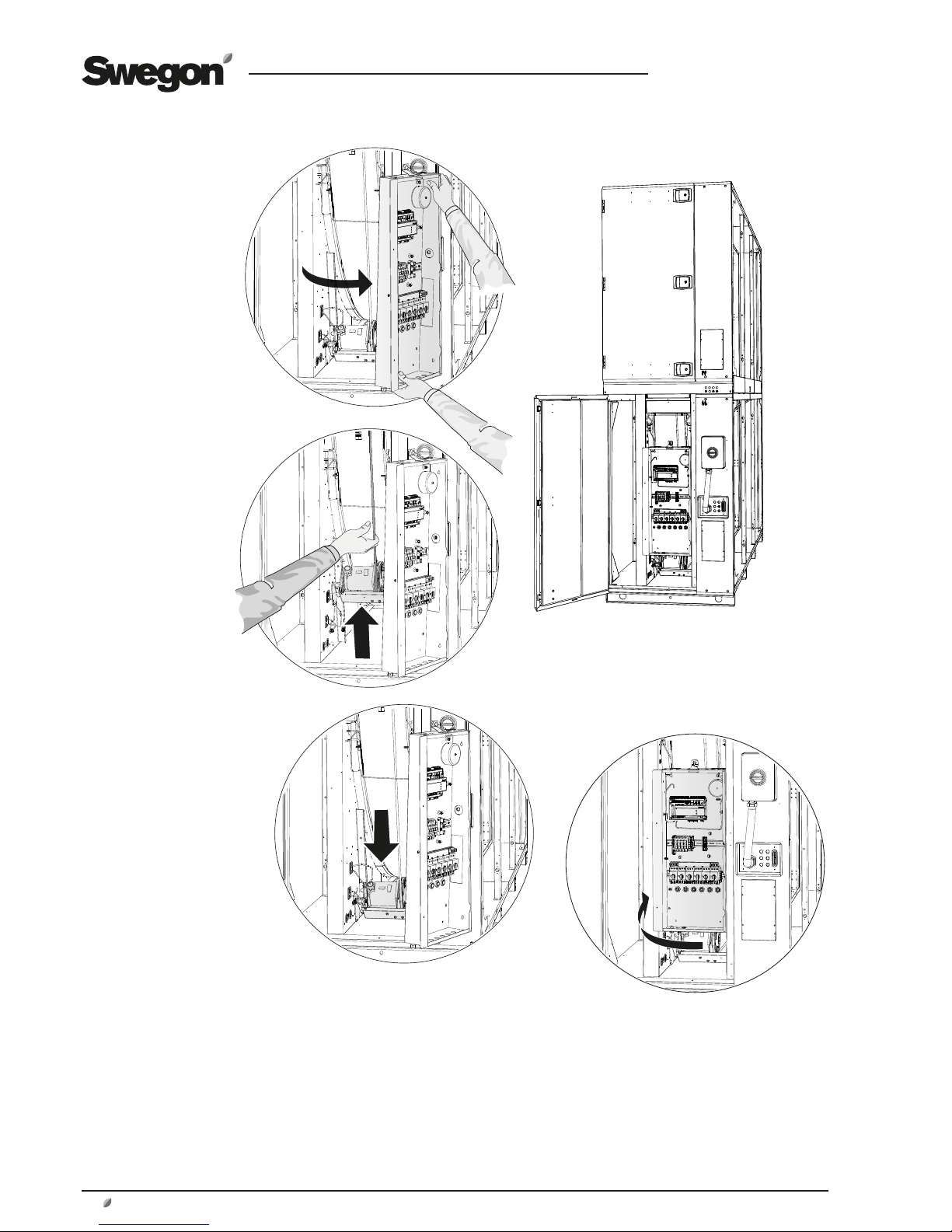

1.15 To Connect external cables

1.15.1 GOLD RX

To make the control unit accessible, open the inspection

door in front of the heat exchanger.

The decorative fitting can be used as a cable trough if you

need to run external cables. Dismantle the decorative fittings and fold back an appropriate number of ”tongues”

in the ends of the decorative fittings and run cables

through cable grommets in the decorative fitting of the

heat exchanger section. Refit the decorative fittings. Run

the cables further in to the electrical equipment cubicle

through the rubber diaphragm in front of the cubicle on

the heat exchanger section. Dismantle the service hatch to

enable you to run the cables. See illustration.

NOTE! External communication cables outside the air

handling unit should be positioned at a min. distance of

100 mm from energized cables.

Decorative fitting

Cable Service hatch

Control circuit board inside the

electrical equipment cubicle

1.15.2 GOLD CX

To gain access to the control unit, remove the cover panel

on the lower part of the coil heat exchanger and the

blanking plate of the electrical equipment cubicle.

The decorative fitting can be used as a cable trough if you

need to run external cables. Dismantle the decorative fittings and fold back an appropriate number of ”tongues”

in the ends of the decorative fittings and run cables

through cable grommets in the decorative fitting of the

heat exchanger section. Refit the decorative fittings. Run

the cables further into the electrical equipment cubicle

through the rubber diaphragm in front of the electrical

equipment cubicle on the heat exchanger section. See

illustration.

N.B.! External communication cables outside the air handling unit should be positioned at a min. distance of 100

mm from energized cables.

Decorative fitting

Cable Blanking plate, electri-

cal equipment cubicle

Cover panel

Control circuit board inside the

electrical equipment cubicle

Page 29

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 29

2. Dimensions

2.1 GOLD RX 100/120

56* NO

56

M

N

P

P

77 3186

77

1048

1000 10481048122

45

137

Power connection

* The air handling unit is supplied without end connection panel if a duct accessory housed in an insulated casing will be connected.

Individual weights

Filter section

GOLD 100/120: 529 kg/pc.

Fan section

GOLD 100: 834 kg/pc.

GOLD 120: 968 kg/pc.

Heat exchanger section, mounted

GOLD 100/120: 1,174 kg .

Heat exchanger section, supplied in two casing sections + rotor

Lower casing section = 494 kg

Upper casing section = 270 kg

Rotor = 410 kg)

Transport cradle = 190 kg

Size A B D E F G H I J K L M N O P Weight, kg

100 1126 3340 1070 191 120 0 2400 3440 520 210 470 3322 800 170 2500 172 0 3900

120 112 6 3340 1070 191 120 0 2400 3440 520 210 470 3322 800 170 2500 1720 416 8

1.16 Installation of pipework package

(GOLD CX only)

For details on how to install the pipework package, see

separate instructions for the TBXZ-42 pipework package.

Page 30

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

30

www.swegon.com

2.2 GOLD CX 100/120

Filter section

GOLD 100/120: 529 kg/pc.

Fan section

GOLD 100: 834 kg/pc.

GOLD 120: 968 kg/pc.

Heat exchanger section

GOLD 100/120: 880 kg /pc.

Power connection

Size A B D E F G H I J K L M N O P Weight, kg

100 1126 3340 1070 191 120 0 2400 3440 520 210 470 3322 800 170 2500 172 0 4486

120 112 6 3340 1070 191 120 0 2400 3440 520 210 470 3322 800 170 2500 1720 4754

56*

56

M

P

P

NO

N

137

77 3186 77

1048

1000 10481048122

45

Individual weights

Page 31

GB.GOLDINE120.130915

Swegon reserves the right to alter specifications.

www.swegon.com 31

3. Wiring terminals, control unit

SD

WLAN

CPU 1

CPU 2

1A2B3

GND4+5-6+7-8+9-

10+11-12+13

-

SA TempCom 5Com 4Com 3Com 2Com 1

14+15-16+17-18+19

-

Heat Cool

20C21NO22C23NO24C25NO26C27NO28P29G30G031G32

G0

24V AC

Sensor 1 Sensor 2 Sensor 4Sensor 3 Com 6 Com 7 Com 8 Com 9 Com 10 Com 11

+33-34G35G036Y37U

38 39 40

24V AC In

41 42

18V AC In

45 46

230V AC In

4743 44

230V AC Out

Digital inputs, terminals 4-17, are of extra-low voltage type. Analogue inputs, terminals 18-19 have an input impedance of 66 kΩ.

Wiring

terminal

Function Remarks

1,2,3 Connections for EIA -485 1= Communication connection A/RT+, 2= Communication connection B/RT–, 3= GND/COM.

4,5 External stop Stops the air handling unit by opening the circuit. On delivery, this function is fitted with a jumper. If

the connection is interrupted, the air handling unit will stop.

6,7 External fire/smoke function 1 External fire and smoke function. On delivery, this function is fitted with a jumper. If the connection is

interrupted, the function will trip and initiate an alarm.

8,9 External fire/smoke function 2 External fire and smoke function. On delivery, this function is fitted with a jumper. If the connection is

interrupted, the function will trip and initiate an alarm.

10,11 External alarm 1 External contact function. Optional: Normally open/normally closed.

12,13 External alarm 2 External contact function. Optional: Normally open/normally closed.

14,15 External low speed External contact function. Overrides the time switch from stop to low speed operation.

16,17 External high speed External contact function. Overrides the time switch from stop or low speed to high speed operation.

18,19 Demand control Input for 0-10 VDC. The input signal influences the supply air/extract airflow setpoint if the unit is

operating in the demand control mode. For connection of a sensor, for example CO

2

, CO and VOC

20,21 Circulation pump, heating circuit Independent contact, max. 5 A/AC1, 2 A/AC3, 250 VAC. Closes on a heating load.

22,23 Circulation pump, cooling circuit or

cooling on/off, 1-step operation

Independent contact, max. 5 A/AC1, 2 A/AC3, 250 VAC. Closes on a cooling load.

24,25 Cooling, on/off, 2-step operation Independent contact, max. 5 A/AC1, 2 A/AC3, 250 VAC. Closes on a cooling load.

26,27 In-service indication Independent contact, max. 5 A/AC1, 2 A/AC3, 250 VAC. Closes when the unit is operating.

28,29,30 Damper control 24 VAC. 28= Controlled 24 VAC (G), 29= 24 VAC (G), 30= 24 VAC (G0).

31,32 Control voltage

1)

24 VAC control voltage. Terminals 31-32 are loaded with a total of 16 VA. Opened by means of the

safety isolating switch.

33,34 Reference voltage Output for constant 10 VDC. Max. permissible load: 8 mA.

35,36,37,38 Control, recirculation damper The recirculation damper can be loaded with max. 2 mA at 10 VDC. 35= 24 V AC (G), 36= 24 V AC (G0),

37= 0-10 V DC control signal, 38= 0-10 VDC feedback signal.

The max permissible common load on terminals 31-32, outputs for Heat/Cool and damper output (terminals 28-30) is 50 VA.

1)

GOLD 100/120: If more than 16 VA is required, use wiring terminals 201 (G) and 202 (G0). Terminals 201-202 can be loaded

with a total of max. 48 VA.

The max. permissible load on the

corresponding connection is 16 VA.

Page 32

GB. GOLDINE120.130915

Swegon reserves the right to alter specifications.

32

www.swegon.com

Loading...

Loading...