Page 1

20190329 We reserve the right to alter specifi cations.

GOLD

1

Description of the air handling unit

General, Range of Application, Certifi cation ................................................................... 2

Mechanical Design ............................................................................................................. 3

Electrical and Control Equipment ..................................................................................... 9

Hand-Held Micro Terminal and How to Use the Menus ................................................ 10

Control Schedule ............................................................................................................... 11

Delivery Version ................................................................................................................ 16

Possible combinations for fi lter/fan sections, RX, size 014-030 .................................... 17

Possible combinations for fi lter/fan sections, PX, size 004-008 .................................... 19

Possible combinations for fi lter/fan sections, PX, size 011-030 .................................... 21

Installation Tips ................................................................................................................ 23

Contents

GOLD PX GOLD RX

GOLD SD

GOLD CX

Page 2

GOLD

We reserve the right to alter specifi cations. 20190329

2

Description of the Air Handling Unit

The GOLD RX/PX/CX air handling units are complete with

direct-driven supply air and extract air fans, supply air and

extract air fi lters and heat exchanger. The heat exchanger

is either a rotary heat exchanger (RX), counterfl ow heat

exchanger (PX) or coil heat exchanger (CX).

The GOLD SD single-direction units are supply air/extract

air handling units with one direct-driven supply air or

extract air fan. A fi lter is available as an option for all

sizes. The coil heat exchanger and unmounted pipework

package can be selected for the size 004-120 units.

The GOLD has built-in control equipment that can be

operated from the hand-held micro terminal in the form

of a touchscreen.

The electrical and control system is completely integrated

into the air handling unit. The microprocessor-based

equipment controls and regulates temperatures, airfl ows

and other functions. A large number of functions are built

into the system and are simple to activate.

If supplementary functional sections such as dampers

and air coolers are required, they must be installed in the

ductwork (uninsulated duct accessories) or be docked to

the air handling unit (insulated duct accessories). Unit sections such as e.g. the multisection and air bypass section

can be installed in the air handling unit arrangement of

the size 004-120 RX/PX/CX units.

With provision for cooling and heating

The GOLD is also well suited for cooling and heating.

Control functions are ready to activate in the control

system and the equipment for cooling as well as for preheating and reheating are available as accessories.

Field of Application

The GOLD units are designed for use in comfort ventilation applications. Depending on the variant selected,

GOLD units can be utilized in buildings such as offi ce

buildings, schools, day nurseries, public buildings, shops,

residential buildings, etc.

GOLD units equipped with counterfl ow-/coil heat

exchanger (PX/CX) and separate supply air and extract air

handling units (SD) can also be used for the ventilation

of moderately humid buildings; however not where the

humidity is continuously high, such as in indoor swimming

baths.

The separate GOLD supply air and extract air handling

units (SD) are designed for applications in which the

supply air and extract air fl ows need to be completely

separated from one another or where, due to limited

available space, separate units for supply air and extract

air are needed. They can also be used individually if only

one of the variants is needed.

GOLD units equipped with the roof, air intake section and

exhaust air hood accessories can be installed outdoors.

The GOLD is designed and tested for temperatures, in the

surroundings and the air stream, from -40°C to +40°C.

However, for GOLD RX the temperature difference

between the outdoor air and extract air must not exceed

70°C.

GOLD conforms to the requirements set out in the

hygiene design regulations VDI 6022, see the separate

guide.

Certifi cation

Swegon has a certifi cated quality management system

that conforms to ISO 9001 and an environmental management system that conforms to ISO 14001 Standards.

The GOLD air handling system is also certifi cated by

Eurovent, No. AHU-06-06-319 and the Passive House

Institute.

General

Sensor designations and colours of arrows in

this publication conform to IEC 81346-1

www.eurovent-certifi cation.com

N° 06.06.319

Range: GOLD

Page 3

20190329 We reserve the right to alter specifications.

GOLD

3

Description of the Air Handling Unit

Mechanical Design

Casing of the GOLD RX/PX/CX

Composed of flush-mounted cover panels and inspection doors. The outer skin is made of galvanized sheet

steel, re-painted in Swegon’s own grey metallic paint

(closest comparable RAL colour: 9007). The inner skin is

made of aluminium-zinc plated sheet steel. The entire air

handling unit conforms to Environmental Class C4. CE

marked. Conform to the provisions of EN 61000-6-2 and

EN 61000-6-3 Standards. Panel thickness of 52 mm with

intervening insulation consisting of mineral wool.

The inspection doors are hung on hinges and are fitted

with flush-mounted door handles. The door handles must

be opened in two steps to equalise the pressure before

the door can be opened completely.

Casing performance

Air leakage, class: L1(M).

Thermal bridges: TB2.

Thermal transmission: T2.

Mechanical strength D1.

Applicable to sizes 004/005

and 007/008 inside a common casing:

Common casing with two inspection doors. One of the

door handles of each inspection door can be locked.

The safety isolating switch is located on the outside of the

connection hood.

Circular duct connections for insertion joints fitted with a

rubber seal ring as standard.

The GOLD RX with rotary heat exchanger can be

mounted on base beams, a foundation or on a stand. Prefitted base beams are obtainable as optional equipment; a

stand supplied unmounted is available as an accessory.

GOLD PX units with counterflow heat exchanger are

supplied with base beams. A set of legs (four legs) to be

screwed into the base beams is available as an accessory.

Applicable to sizes 004/005

and 007/008 in split version as well as size 011-120:

The basic arrangement of the size 004-080 units consists

of three unit sections (two fan/filter sections and one

heat exchanger section). The size 100/120 units consist of

five (RX) or six (CX) sections.

Each section/unit section has one or two inspection

doors. One of the handles for each one of both outer

inspection doors is lockable. On the size 120 units, the

inspection door of the heat exchanger section (GOLD RX)

is also lockable.

The size 014-120 units are equipped with rectangular duct

connections for slip-clamp jointing as standard. The size

004-012 units are equipped with circular duct connections for insertion joints fitted with a rubber seal ring as

standard.

The unit is equipped with base beams.

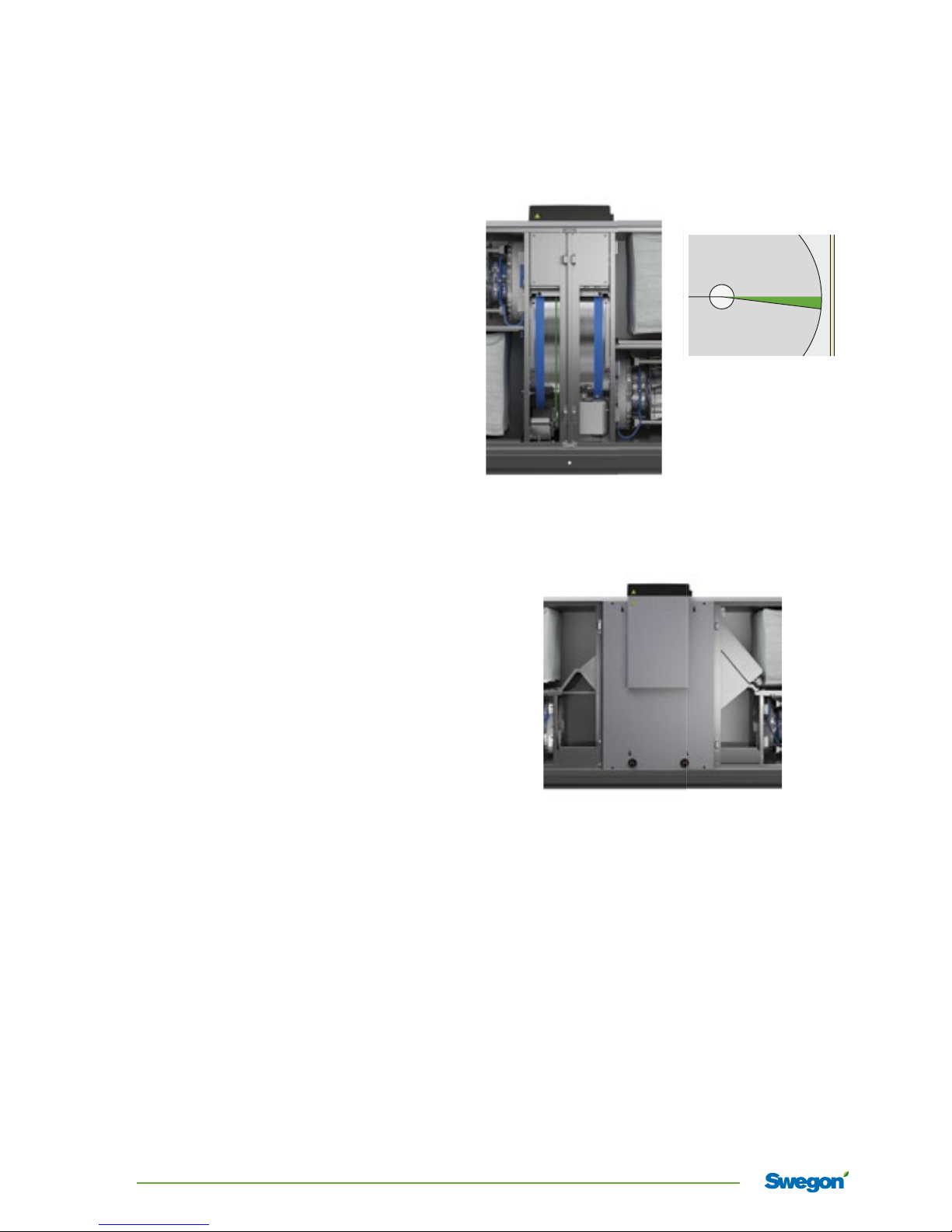

GOLD RX, size 030

GOLD RX, size 008

GOLD PX, size 012, full face end connection panel

On the size 004-020 units, the safety isolating switch is

externally located on the connection hood.

On the size 025-120 units, the safety isolating switch is

externally located on the heat exchanger section of the

unit.

Page 4

GOLD

We reserve the right to alter specifi cations. 20190329

4

Description of the Air Handling Unit

Mechanical Design

Sizes 004/005 and 008

Sizes 014-080

Shows the variant with functions: fi lter + coil heat exchanger + fan.

Casing of the GOLD SD

Composed of fl ush-mounted cover panels and inspection doors. The outer skin is made of galvanized sheet

steel, re-painted in Swegon’s own grey metallic paint

(closest comparable RAL colour: 9007). The inner skin is

made of aluminium-zinc plated sheet steel. The entire air

handling unit conforms to Environmental Class C4. CE

marked. Conform to the provisions of EN 61000-6-2 and

EN 61000-6-3 Standards. Panel thickness of 52 mm with

intervening insulation consisting of mineral wool.

The inspection doors are hung on hinges and are fi tted

with fl ush-mounted door handles. The door handles must

be opened in two steps to equalise the pressure before

the door can be opened completely.

Casing performance

Air leakage, class: L1(M).

Thermal bridges: TB2.

Thermal transmission: T2.

Mechanical strength D1.

Applicable to sizes 004-012, common casing:

Composed of one or two sections depending on the variant selected. Possible variants are fan (with space for a

fi lter) or fan (with space for a fi lter) + coil heat exchanger.

The fan section casing has one (sizes 004-008) or two

(sizes 012) inspection doors. The handles are lockable.

Space for a pleated fi lter of fi lter class ePM10 60% (M5)

or ePM1 50% (F7) is available and can be ordered as an

accessory.

The safety isolating switch is located on the inspection

side by the inspection door of the fan section.

Circular duct connections for insertion joints fi tted with a

rubber seal ring as standard.

The GOLD SD size 004-008 without coil heat exchanger

can be mounted on base beams, a foundation or on a

stand. Prefi tted base beams are obtainable as optional

equipment; a stand supplied unmounted is available as an

accessory.

GOLD SD size 004-008 with coil heat exchanger and

GOLD SD size 11/12 is equipped with base beams.

Applicable to sizes 004-012, split version and size

014-120 :

Composed of one to three sections depending on the

variant selected. Possible variants are fan, fi lter + fan or

fi lter + coil heat exchanger + fan.

The sections for fan and fi lter have their own inspection

door. One of the door handles of the outer inspection

door can be locked.

The safety isolating switch is located on the inspection

side.

The size 004-012 units are equipped with circular duct

connections for insertion joints fi tted with a rubber seal

ring as standard. The size 014-120 units are equipped

with rectangular duct connections for slip-clamp jointing

as standard.

The unit is equipped with base beams.

Page 5

20190329 We reserve the right to alter specifications.

GOLD

5

Filters

The filter material is glass fibre. The filter holder has a

filter locking system designed for effective sealing and

complies with the requirements for bypass leakage to

Class ePM1 85% (F9). All filters can be selected as ePM10

60% (M5) or ePM1 50% (F7) filters.

GOLD RX Top size 004-012 is equipped with pleated

filters.

The separate GOLD SD supply air and extract air handling

units in sizes 004-012 in a common casing can have

pleated filters as an option.

The units in other sizes/variants have bag filters of ample

proportions on both the supply air and outdoor air sides.

Pressure sensors for measuring the pressure drop across

the filters are incorporated into the control system.

Pre-filter inside air handling units

Prefilters installed inside air handling units can be ordered

as optional extras (does not apply to the type RX Top

units).

Fans

The direct-driven fans are of GOLD Wing+ type, unique

axial-centrifugal fans with the focus on excellent power

efficiency, uniform airflow and low noise level. The GOLD

Wing is patented. Functional sections such as air coolers

and bends can be connected directly against the air handling unit without appreciable pressure losses. This saves

space in the fan room.

The fans are driven by high-efficiency EC motors, which

together with a motor control system especially developed for the GOLD, perform with extremely high efficiency.

The fans are approved for continuous operation in temperatures of up to 40°C.

The fans are tested for, and can manage operation for

one hour at 70°C.

The fan motors have a motor control system for variable

speed regulation and the fans have measurement tappings for continuous measurement and regulation of the

airflow.

The fans are effectively vibration-isolated from the casing

by means of rubber bushings/flexible connections.

The fans are fixed in their positions by means of locking

knobs/screws and clamping bands. These fasteners can

easily be loosened, after which the entire fan package can

be withdrawn for inspection and maintenance.

Description of the air handling unit

Mechanical Design

Prefilters are used in ventilation systems, in which the

extract air and/or the outdoor air is/are heavily polluted

and it is desirable to prevent the fine filters inside the

GOLD unit from becoming clogged after a short period of

use.

the filters are of woven aluminium type or Class Coarse

65% (G4) compact filters.

Pressure sensors for measuring the pressure drop across

the filters are incorporated into the control system.

Page 6

GOLD

We reserve the right to alter specifi cations. 20190329

6

Description of the Air Handling Unit

Heat exchanger

Rotary heat exchanger

RECOnomic/RECOsorptic rotary heat exchanger with a

temperature effi ciency of up to 85%. The need for heat

is dealt with by automatically and variably regulating the

speed of the rotor.

The rotary heat exchanger effectively recovers cooling

energy as well.

It is available in a sorption version (RECOsorptic) for moisture recovery, which reduces operating and investment

costs for cooling and improves indoor comfort levels in

the winter, as well as in an epoxy-treated version.

Purging sector, commissioning plates and pressure measurement tappings as standard, ensure that the extract air

will not be carried over to the supply air.

The RECOnomic/RECOsorptic heat exchanger is patented.

Mechanical Design

Purging sector

Counterfl ow heat exchanger

The counterfl ow heat exchanger is as standard equipped

with centre-mounted bypass dampers and two heat

exchanger dampers for variable and automatic regulation

of the heat exchanger’s effi ciency on heat recovery.

The counterfl ow heat exchanger is available in two versions: Normal effi ciency (MPE, Maximum Pressure Effi ciency) and high effi ciency (MTE, Maximum Temperature

Effi ciency) respectively. In the MPE version, the focus is on

low pressure drop across the heat exchanger. In the MTE

version, priority is given to high temperature effi ciency.

Internal leakage between air streams conforms to the

provisions of Ductwork leakage class L2.

In cold weather, and when the extract air is humid, there

is risk of frosting inside the plate heat exchanger. The

GOLD PX is therefore equipped with anti-frost protection.

RECOfrost anti-frost protection

The pressure drop across the heat exchanger, extract air

temperature, moisture content in the extract air and outdoor air temperature are measured.

With consideration given to the pressure drop across the

heat exchanger, the extract air temperature, the moisture

content in the extract air and the outdoor air temperature, the control system individually regulates dampers

for bypass and the heat exchanger for section-by-section

defrosting without the formation of frost. This enables

high annual effi ciency, smaller air heaters and pressuredrop-optimized operation during the spring and autumn.

Page 7

20190329 We reserve the right to alter specifi cations.

GOLD

7

Coil heat exchanger

The coil heat exchanger in the one-piece units, GOLD

CX, sizes 035-080, are supplied complete from the factory; including mounted pipework package with all the

necessary components. The system is normally fi lled with

liquid, vented, adjusted and performance-tested prior

to delivery, but can also be ordered in unfi lled condition

e.g. for housing improvement projects or if the application requires fi lling with another mixture instead of 30 %

ethylene glycol. On the size 100/120 GOLD CX one-piece

unit, the pipework package (accessory) including separate

control unit are supplied in unmounted condition.

Coil heat exchangers and pipework packages are available

as unmounted accessories for the separate size 004-120

supply air and extract air handling units (SD) A separate

control unit for the coil heat exchanger is always included

in the supply.

The pipework package's valve variably regulates the coil

heat exchanger's effi ciency on heat recovery and the

circulation pump is demand-controlled.

In cold weather, and if the extract air is humid, there is

risk of frosting in coil heat exchangers. The GOLD CX/SD

is equipped with an extremely effective anti-frost protection that measures the temperature of the liquid in the

extract air coil and also the humidity in the extract air.

Taking the humidity into consideration, the IQlogic control

system calculates the lowest permissible liquid temperature without risk of frosting inside the coil. The valve in

the pipework package is then controlled to prevent the

temperature from dropping below this limit.

Description of the Air Handling Unit

Mechanical Design

Page 8

GOLD

We reserve the right to alter specifi cations. 20190329

8

Duct Connections

Are for sizes 004/005, 007/008 and 011/012 circular and

designed for connection to ducts with insertion joints

fi tted with a rubber seal ring. A duct bend fi ts directly

into the connection. The duct connections are horizontally and vertically offset to enable ducts to be run in any

direction without blocking one another.

The size 014-120 units have rectangular duct connections

with a securely mounted connection frame for slip-clamp

joint connection. Type METU connection frames are available as an accessories.

GOLD RX /PX are also available in a top-fed variant, GOLD

RX/PX Top, with all the duct connections upward. GOLD

RX/PX Top is available in sizes 004-030.

To further reduce pressure losses, a full face end connection with larger rectangular duct connection is also

offered as an accessory (all sizes).

The air handling unit's GOLD Wing+ fans provide a

uniform airfl ow immediately downstream of the outlet

making it possible to connect duct bends and functional

sections, for example cooling coils, directly to the unit

without appreciable pressure losses.

If insulated duct accessories are selected, they should be

docked directly against the air handling unit. The air handling unit is then supplied without end connection panel

for the relevant inlet/outlet.

Pressure Adjusting Plates

(applicable to air handling units with rotary heat

exchanger only)

The unit is equipped with pressure adjusting plates

to ensure that the purging air fl ow through the heat

exchanger will be as it was designed to be. These plates

make it possible to achieve correct pressure balance in the

unit so that the purging airfl ow will pass in the correct

direction.

The pressure adjusting plates are supplied in unmounted

condition and shall be positioned by the extract air inlet of

the air handling unit.

Environment Declaration

Swegon AB has a certifi cated environmental management

system that conforms to ISO 14001 Standard and is registered on the REPA Register, no. 5560778465.

A Building Material Declaration with a complete list of

constituent materials is available on Swegon's home page.

Description of the Air Handling Unit

Mechanical Design

Circular duct connections

Rectangular duct connections

Circular duct connections

GOLD RX Top

Rectangular duct connection

GOLD RX Top

Page 9

20190329 We reserve the right to alter specifi cations.

GOLD

9

General

The electrical and control system is completely integrated

into the air handling unit. The microprocessor-based

equipment controls and regulates temperatures, airfl ows

and other functions. A large number of functions are built

into the system and are simple to activate.

The air handling unit can be automatically controlled in

several ways via the built-in timer or main control system,

however it can also be demand-controlled e.g. via a

CO

2

sensor. Manual control is also possible.

A large number of functions and settings can be activated/entered via a main control system.

Control Inaccuracy:

Temperature ± 1

o

C.

Airfl ow ± 5%.

Power Effi ciency

The design and performance of the air handling unit are

optimized for achieving excellent power effi ciency.

Standards

The unit meets the provisions of the ELSÄK-FS 1999:5

and SS-EN 60204-1 electrical safety standards. Protection

class IP 54.

Interference Level

The unit meets the requirements defi ned in the EMC

Directive and has been tested according to the provisions in EN 61000-6-2 and 61000-6-3 (electromagnetic

emissions in dwellings, offi ce buildings, shops and similar

environments as well as for immunity in industrial environments).

Use of an earth fault circuit breaker

The earth fault circuit breaker, if required, should only

serve the air handling unit and must be of a type

designed for use with the control system of the EC motor.

Control Unit – GOLD SD

If both GOLD SD supply air and extract air handling units

are used in a ventilation system, the supply air unit is

fi tted with a control unit and the extract air unit is without. A communication cable is used to connect them to

one another making it possible to control both units.

Electrical and Control Equipment

On the smaller unit sizes, the electrical and control equipment must be connected via the junction hood.

Connection cables for hand-held micro terminal, supply

air temperature sensor, air heater and air cooler have

modular connectors.

Other accessories and external functions can be connected to an easy-to-access row of terminal connections.

Description of the Air Handling Unit

All electrical and control equipment is collected inside a special

enclosure in the centred section of the air handling unit.

Electrical and Control Equipment

An extra terminal for a single phase 230 V supply is also

provided after the safety switch on the GOLD unit. This

terminal can be used for external functional sections and

can be loaded with max. 1.5 A.

The extra functional sections such as a cooling unit and

an electric air heater, must have a separate power supply.

GOLD RX/PX/CX

On the size 004-020 GOLD RX and the GOLD PX units,

electrical and control equipment must be wired via the

junction hood. On the size 025-070 and 080 GOLD RX

and the size 035-080 GOLD CX units, electrical and

control equipment must be wired via the panel on the

centre section of the air handling unit. On the size 080

GOLD RX, capacity variant 2, and the size 100/120 GOLD

CX units, electric power is connected across an external

safety switch and the electrical and control equipment

must be wired via the panel on the centre section of the

air handling unit.

GOLD SD

On the size 004-080 GOLD DS units, the electrical and

control equipment must be wired via the panel by the fan

inspection door. On the size 100/120 units, electric power

is connected across an external safety switch and the

electrical and control equipment must be wired via the

panel on the centre section of the air handling unit.

Page 10

GOLD

We reserve the right to alter specifi cations. 20190329

10

Description of the Air Handling Unit

The IQnavigator hand-held micro terminal, has 7" touchscreens and is very simple and user friendly. Commissioning and the entering of settings can be carried out

intuitively and in steps. Flow images and help texts are

always at hand.

The hand-held terminal is equipped with a three metre

long connection cable that can be connected via quick-fi t

connector to the air handling unit's control unit (standard). Wireless communication between the hand-held

terminal and the GOLD unit can also take place via WLAN

(requires the IQnavigator hand-held terminal accessory

with WLAN).

Communication between the hand-held micro terminal

and the GOLD air handling unit can also transpire wirelessly via WLAN (accessory). It is just as simple to use a

computer, tablet pc or cell phone via WiFi. Double Ethernet ports and USB connection are available as standard.

The preset values are stored and will not be unaffected in

the event of a power failure.

Hand-held micro terminal IQnavigator and image management

Page 11

20190329 We reserve the right to alter specifications.

GOLD

11

BT3 Temperature sensor, outdoor air.

BT1 Temperature sensor, supply air. Positioned in

the ductwork

BT2 Temperature sensor, extract air.

T1/T2 Motor control system for variable speed

control of the fan motors.

BF1/BF2 Pressure transducer. Indicates for controlling

the fan speed so that the preset airflow will be

maintained.

BP1/BP2 Pressure transducer for checking the filter

status.

BP3 Pressure sensor for checking the heat

exchanger.

BG1 Rotation monitor for checking the rotation of

the heat exchanger.

E1 Electrical equipment cubicle containing the

control circuit card and other electrical

equipment for controlling internal and external

functions, etc.

P1 Hand-held micro terminal for setting airflows,

temperatures, control functions, in-operation

periods, etc. as well as alarms.

VVX Variable speed-controlled rotary heat

exchanger with air purging operation.

T3 Drive motor for the rotary heat exchanger

Diagrammatic description of the control functions, GOLD RX

The built-in control system controls and regulates temperatures, airflows, in-operation periods and a large number

of internal and external functions.

In that it is a microprocessor-based system, it can solve

highly complicated tasks. The specific components are

outlined below each individually in a simplified and schematic specification.

When you use the AHU Design air handling unit selection

program for calculating data, you receive a project-specific flow

chart with complete description of pertinent unit functions.

Control Schedule

Description of the Air Handling Unit

T2

BF2

E1

BT3

BT2

T3

VVX

T1

BF1

BT1

P1

BP1

BP2

BG1

BP3

Page 12

GOLD

We reserve the right to alter specifications. 20190329

12

Description of the Air Handling Unit

BT3 Temperature sensor, outdoor air.

BT1 Temperature sensor, supply air. Positioned in

the ductwork

BT2/BM2 Extract air temperature sensor/Extract air

humidity sensor.

For RECOfrost anti-frost protection.

T1/T2 Motor control system for variable speed

control of the fan motors.

BF1/BF2 Pressure transducer. Indicates for controlling

the fan speed so that the preset airflow will be

maintained.

BP1/BP2 Pressure transducer for checking the filter

status.

BT6 Heat exchanger pressure sensor.

For anti-frost protection.

MG6 Actuator for by-pass and shut-off dampers.

E1 Electrical equipment cubicle containing the

control circuit card and other electrical

equipment for controlling internal and external

functions, etc.

P1 Hand-held micro terminal for setting airflows,

temperatures, control functions, in-operation

periods, etc. as well as alarms.

VVX Counterflow heat exchanger with bypass and

shut-off dampers.

BT20/BT30

Temperature sensor for density-corrected

airflow.

Diagrammatic description of the control functions, GOLD PX

The built-in control system controls and regulates temperatures, airflows, in-operation periods and a large number

of internal and external functions.

In that it is a microprocessor-based system, it can solve

highly complicated tasks. The specific components are

outlined below each individually in a simplified and schematic specification.

Control Schedule

When you use the AHU Design air handling unit selection

program for calculating data, you receive a project-specific flow

chart with complete description of pertinent unit functions.

T2

BF2

MG6

BT3

BT2/BM2

VVX

T1

BF1

BT1

BP1

BP2

BT6

E1

P1

BT20 BT30

BT7

Page 13

20190329 We reserve the right to alter specifications.

GOLD

13

Description of the Air Handling Unit

BT3 Temperature sensor, outdoor air.

BT1 Temperature sensor, supply air. Positioned in

the ductwork.

BT2/BM2 Temperature sensor, extract air/Humidity

sensor, extract air. For anti-frost protection.

T1/T2 Motor control system for variable speed

control of the fan motors.

BF1/BF2 Pressure transducer. Indicates for controlling

the fan speed so that the preset airflow will be

maintained.

BP1/BP2 Pressure transducer for checking the filter

status.

BT6 Temperature sensor, coil heat exchangers. For

anti-frost protection.

G6 Circulation pump, coil heat exchangers.

MF6 Valve actuator, coil heat exchangers.

E1 Electrical equipment cubicle containing the

control circuit card and other electrical

equipment for controlling internal and external

functions, etc.

P1 Hand-held micro terminal for setting airflows,

temperatures, control functions, in-operation

periods, etc. as well as alarms.

VVX Coil heat exchanger with pipework package.

BT20/BT30

Temperature sensor for density-corrected

airflow.

BP3 Differential pressure sensor.

Diagrammatic description of the control functions, GOLD CX

The built-in control system controls and regulates temperatures, airflows, in-operation periods and a large number

of internal and external functions.

In that it is a microprocessor-based system, it can solve

highly complicated tasks. The specific components are

outlined below each individually in a simplified and schematic specification.

Control Schedule

When you use the AHU Design air handling unit selection

program for calculating data, you receive a project-specific flow

chart with complete description of pertinent unit functions.

GOLD CX, sizes 100/120: Pipework package including control box are supplied in unmounted condition for floor or wall mounting (accessories).

T2

BF2

E1

BT3

BT2/

BM2

VVX

T1

BF1

BT1

P1

BP1

BP2

MF6

G6

BT6

BT20

BT30

BP3

Page 14

GOLD

We reserve the right to alter specifications. 20190329

14

Description of the air handling unit

Diagrammatic description of the control functions,

GOLD SD sizes 004-012, common casing

The built-in control system controls and regulates temperatures, airflows, in-operation periods and a large number

of internal and external functions.

Because the system is microprocessor-based, it can solve

highly complicated tasks. The individual components

each specified below in a simplified and diagrammatical

description.

Control Schedule

When you use the AHU Design AHU selection program for

calculating performance data, it provides you with a project-

specific flow chart with complete descriptions of pertinent

functions.

BT3 Outdoor air temperature sensor.

(Applicable to air handling units with coil heat

exchanger)

BT2 Outdoor air temperature sensor/supply air density

sensor (In extract air units: Extract air

temperature sensor/exhaust air density sensor)

BT1 Supply air temperature sensor. Positioned in the

ductwork. (Not used in extract air units)

BF1 Supply air fan pressure sensor. Indicates for

control of the fan speed so that the preset

airflow will be obtained. (In extract air handling

units: Extract air fan pressure sensor)

BP1 Supply air filter pressure sensor, if applicable. For

checking the status of the filter (In extract air

handling units: Extract air filter pressure sensor)

T1 Motor control system for variable speed control

of the fan motor.

E1 Electrical equipment cubicle containing a control

circuit card, if included, and other electrical

equipment for controlling internal and external

functions, etc.

E2 Control unit, if applicable, for controlling the

pipework package.

P1 Hand-held micro terminal, if specified, for setting

airflows, temperatures, control functions,

in-operation periods, etc. as well as alarms.

BT2

BP1

BF1

P1

BT1

E1

T1

E2

BT3

Page 15

20190329 We reserve the right to alter specifications.

GOLD

15

Description of the air handling unit

Diagrammatic description of the control functions,

GOLD SD, sizes 004-012 in split version and sizes 014-120

The built-in control system controls and regulates temperatures, airflows, in-operation periods and a large number

of internal and external functions.

Because the system is microprocessor-based, it can solve

highly complicated tasks. The individual components

each specified below in a simplified and diagrammatical

description.

Control Schedule

When you use the AHU Design AHU selection program for

calculating performance data, it provides you with a project-

specific flow chart with complete descriptions of pertinent

functions.

BT3 Outdoor air temperature sensor.

(Applicable to air handling units with coil heat

exchanger)

BT2 Outdoor air temperature sensor/supply air density

sensor (In extract air units: Extract air

temperature sensor/exhaust air density sensor)

BT1 Supply air temperature sensor. Positioned in the

ductwork. (Not used in extract air units)

BF1 Supply air fan pressure sensor. Indicates for

control of the fan speed so that the preset

airflow will be obtained. (In extract air handling

units: Extract air fan pressure sensor)

BP1 Supply air filter pressure sensor, if applicable. For

checking the status of the filter (In extract air

handling units: Extract air filter pressure sensor)

T1 Motor control system for variable speed control

of the fan motor.

E1 Electrical equipment cubicle containing a control

circuit card, if included, and other electrical

equipment for controlling internal and external

functions, etc.

E2 Control unit, if applicable, for controlling the

pipework package.

P1 Hand-held micro terminal, if specified, for setting

airflows, temperatures, control functions,

in-operation periods, etc. as well as alarms.

BT2

BP1

BF1

P1

BT1

E1

BT3

T1

E2

Page 16

GOLD

We reserve the right to alter specifications. 20190329

16

Delivery Version

RX/PX/CX, sizes 004-080

The GOLD RX/PX/CX units are composed of unit sections.

The unit sections are as follows:

• Fan/filter section

• Heat exchanger section (RX, PX, CX and RX/HC

respectively)

• Air recirculation section

• Air bypass section

• Multisection

• Duct crossover section (PX)

The basic arrangement of the GOLD RX/PX/CX units

consists of two fan/filter sections and one heat exchanger

section. The other air handling unit sections are optional,

see also the section entitled Complements and Accessories.

The unit sections in an air handling unit arrangement are

delivered separately or already fitted together with one or

several other unit sections as specified below:

• The fan/filter section with the fan in the upper section is always supplied already fitted together with

another unit section, with the exception of CX (all

sizes) and RX/HC size 014-080.

• The heat exchanger section, RX, is always supplied

already fitted together with another unit section.

• The air recirculation, air bypass, multi and duct

crossover sections are always supplied already fitted

together with another unit section, with the exception of size 035/040.

• The max. length of a delivery unit is 3,000 mm.

• An air handling unit arrangement may at most be

divided into four delivery units (sizes 004-060).

See also Swegon's air handling unit software: AHU

Design.

Description of the air handling unit

Page 17

20190329 We reserve the right to alter specifications.

GOLD

17

Filter/fan sections for basic variants of standard RX and

RX Top can be combined in a number of different ways,

see below and the next page.

Description of the unit

Standard

Top

Outdoor air Supply air Extract air Exhaust air

Right-hand versionLeft-hand version

Basic variants

Possible combinations for filter/fan sections, RX, size 014-030

Option Option Option Option

outdoor air supply air extract air exhaust air

Supply air fan, left, upper level

Supply air fan, right-hand, lower level

Left-hand version

Right-hand version

Supply air fan, right, lower level

Supply air fan, right-hand, upper level

Note that performance, dimensions and weight are different depending on whether the filter/fan section is

RX standard or RX Top, see section Sizing, installation,

dimensions and weights for GOLD RX.

Supply air fan, left, upper level

Supply air fan, right-hand, lower level

Supply air fan, right, lower level

Supply air fan, right-hand, upper level

Page 18

GOLD

We reserve the right to alter specifications. 20190329

18

Combinations

Possible combinations for filter/fan sections, RX, size 014-030

Description of the unit

Left-hand version Right-hand version

Top Standard

Standard Top

Top Standard

TopStandard

Top Standard

Standard Top

Top Standard

TopStandard

Outdoor air Supply air Extract air Exhaust air

Option Option Option Option

outdoor air supply air extract air exhaust air

Page 19

20190329 We reserve the right to alter specifications.

GOLD

19

Top

Basic variant

PX Top size 004-008 has, from PX standard side fed air

handling units, a deviating height measurement.

However, it is possible to order a side-fed filter/fan section

with a height measurement adapted to each size of PX

Top.

Description of the unit

Possible combinations for filter/fan sections, PX, size 004-008

Right-hand version

Left-hand version

These side fed filter/fan sections have the same performance as a PX standard side fed filter/fan section, see the

section Sizing, installation, dimensions and weights for

GOLD PX.

Dimensions and weight deviate, see the following page.

Combinations

Top Side fed filter/

fan section

Side fed filter/

fan section

Top

Top Side fed filter/

fan section

Side fed filter/

fan section

Top

Left-hand version Right-hand version

Outdoor air Supply air Extract air Exhaust air

Page 20

GOLD

We reserve the right to alter specifications. 20190329

20

Possible combinations for filter/fan sections, PX, size 004-008

Description of the unit

Dimensions

The diagrams show side fed filter/fan sections with a

height measurement adapted to each size of PX Top and

centre section.

Filter/fan section to the left of the centre section Filter/fan section to the right of the centre section

GOLD A B C D E F G H I K Ø kg*

004 617 825 240 130 0 181 230 460 1085 238 345 315 93 -115

005 617 825 240 130 0 181 230 460 1085 238 345 315 93 -119

007 647 995 278 1517 230 271 543 1295 278 440 400 112-15 0

008 647 995 278 1517 230 271 543 1295 278 440 400 119 -15 4

C K

D

PX

B

F

G

CK

B

F

G

D

ø

E

ø

E

I

I

ø

ø

ø

ø

C K

D

PX

B

F

G

ø

E

I

ø

ø

* Only filter/fan section

Page 21

20190329 We reserve the right to alter specifications.

GOLD

21

Standard

Top

Basic variants

Filter/fan sections for basic variants of standard PX and PX

Top can be combined in a number of different ways, see

below and the next page.

Description of the unit

Outdoor air Supply air Extract air Exhaust air

Possible combinations for filter/fan sections, PX, size 011-030

Option Option

outdoor air extract air

Right-hand version

Left-hand version

Right-hand version

Left-hand version

Note that performance, dimensions and weight are different depending on whether the filter/fan section is PX

standard or PX Top, see section Sizing, installation, dimensions and weights for GOLD PX.

Page 22

GOLD

We reserve the right to alter specifications. 20190329

22

Top Standard

Standard Top

Top Standard

Standard Top

Description of the unit

Possible combinations for filter/fan sections, PX, size 011-030

Left-hand version Right-hand version

Combinations

Outdoor air Supply air Extract air Exhaust air

Option Option

outdoor air extract air

Page 23

20190329 We reserve the right to alter specifications.

GOLD

23

Sizing the Duct System

The preset flow is automatically kept at a constant rate

if this function has been selected in the hand-held micro

terminal. Lower air velocity in ducts and air diffusers

mean lower pressure drop and consequently lower energy

consumption and a quieter ventilation system.

To achieve optimal operating economy and low noise

level it is important to design the ventilation system with

as low pressure drop as possible. The hoods for outdoor

air and extract air, designed especially for the GOLD, are

optimized in this respect.

If the use of a common outdoor air duct is still desirable, every branch

duct for each GOLD air handling unit must be equipped with a non-

return damper or a motorized damper (also applies to a common

exhaust air duct/hood).

Examples of how air deflectors and extruded inlets minimize pressure

losses in Swegon accessories for the GOLD.

A duct or non-return damper of its own.

Zero calibration is an integrated function in the GOLD air

handling units. Every individual GOLD air handling unit

in a ventilation system must be equipped with its own

outdoor air and exhaust air hood/duct in order for this

function to operate correctly. Or else, every individual

air handling unit must be equipped with a non-return

damper or a motorized damper in the outdoor air duct

and/or exhaust air duct.

Every GOLD air handling unit must have its own outdoor air duct (and

its own exhaust air duct/hood).

Description of the Air Handling Unit

Installation Tips

Page 24

GOLD

We reserve the right to alter specifications. 20190329

24

Loading...

Loading...