Swegon GLOBAL PX, GLOBAL RX, GLOBAL PX TOP FW, GLOBAL RX TOP, GLOBAL LP FW Operation And Maintenance Instructions

...Page 1

GLOBAL RX TOP

Operation and maintenance instructions

GLOBAL PX/RX/LP

Applicable to program versions TAC5 – Version DT 2.8.8 & DG 2.7.3

GLOBAL PX

GLOBAL LP

FW

GLOBAL PX TOP

FW

GLOBAL RX

GLOBAL PX

FW

Page 2

2

1.0 Safety precautions

2.0 Symbols and abbreviations

3.0 Product Overview

4.0 Wiring Overview

5.0 Functions

6.0 Commissioning

6.1 Commissioning with Touchscreen interface

7.0 Preventive maintenance

8.0 Troubleshooting

9.0 Parameters/Commissioning Sheet

10.0 CE Declaration

GLOBAL PX/RX/LP

Table of content

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 3

3

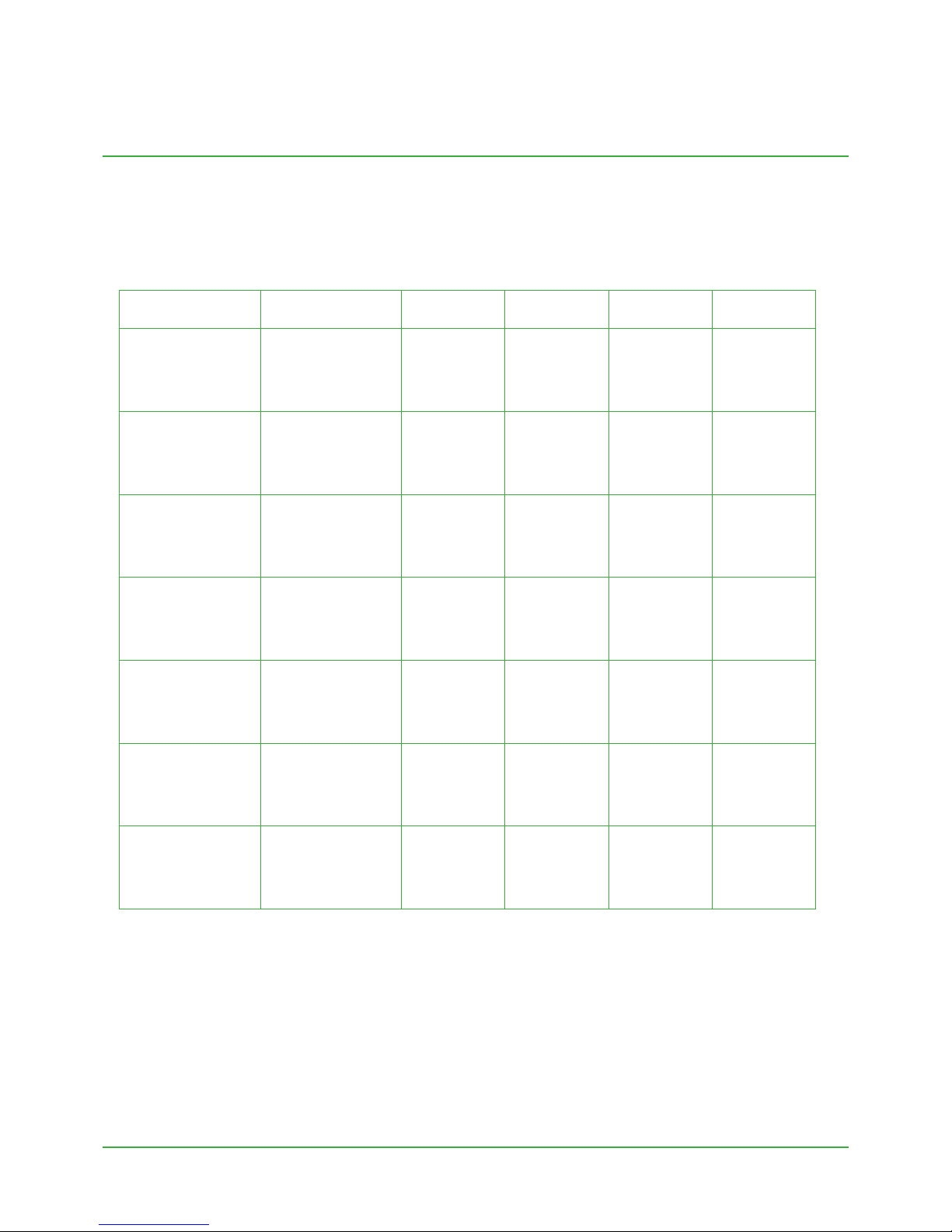

1.0 Installation manual

Applicable for the following units

EXCHANGER SIZES

INTEGRATED

PREHEATING

INTEGRATED

POSTHEATING

HANDING FAN

GLOBAL PX

FW

Counterow

800/1200/2000/

3000/4000/6000

Yes, electrical

Yes, electrical

or water

Le / Right Forward (FW)

GLOBAL PX

Counterow

800/1200/2000/

3000/4000/6000

Yes, electrical

Yes, electrical

or water

Le / Right Backward

GLOBAL PX TOP

FW

Counterow

800/1200/2000 Yes, electrical

Yes, electrical

or water

Right Forward (FW)

GLOBAL RX

Rotary

05/08/10/12/13/

14/16/18/20/24/26

No

Yes, electrical

or water

Le / Right Backward

GLOBAL RX TOP

Rotary

05/08/10/12/

13/14/16

No

Yes, electrical

or water

Le / Right Backward

GLOBAL LP

FW

Counterow

450/600/ 1000/

1600/2000

Yes, electrical No Le / Right Forward (FW)

GLOBAL LP

Counterow

02/04/06/08

10/12/13/14/16/20

Yes, electrical

Yes, electrical

or water

Le / Right Backward

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 4

4

Disclaimer

Danger/Warning/Caution

• All sta concerned shall acquaint themselves with

these instructions before beginning any work on the

unit. Any damages to the unit or its components

caused by improper handling or misuse by the

purchaser or the installer cannot be considered

subject to guarantee if these instructions have not

been followed correctly.

• Make sure that the power supply to the unit is

disconnected before performing any maintenance or

electrical work!

• All electrical connections must be carried out by an

authorized installer and in accordance with local

rules and controls.

• Although the mains supply to the unit has been

disconnected there is still risk for injury due to

rotating parts that have not come to a complete

standstill.

• Beware of sharp edges during mounting and

maintenance. Make sure that a proper liing device

is used. Use protective clothing.

• Unit should always be operated with closed doors

and panels.

• If the unit is installed in a cold place make sure that

all joints are covered with insulation and are well

taped.

• Duct connections /duct ends should be covered

during storage and installation, in order to avoid

condensation inside of the unit.

• Check that there are no foreign objects in unit,

ducting system or functional sections.

• The unit is packed to prevent damage of the

external and internal parts of the unit, dust and

moisture penetration. If the unit is not to be installed

immediately, it should be stored in a clean, dry

area. If stored externally, it should be adequately

protected from the weather inuence.

RANGE OF APPLICATION

The GLOBAL units are designed for use in comfort

ventilation applications.

Depending on the variant selected, GLOBAL units can be

utilised in buildings such as oce buildings, schools, day

nurseries,public buildings, shops, residential buildings, etc.

GLOBAL units equipped with plate heat exchangers (PX)

can also be used for the ventilation of moderately humid

buildings; however not where the humidity is continuously

high, such as in indoor swimming baths, saunas, spas or

wellness centres.

Please do contact us if you have a need for a unit that is

suited for such an application.

HOW TO READ THIS DOCUMENT

Please make sure that you have read and understood the

safety precautions below.

Please read chapter 2 where the Symbols and

Abbreviations used for GLOBAL are listed and Chapter 5

where the operating principles of a GLOBAL air handling

unit are described. The commissioning of the unit is

described in chapter 6.

The commissioning chapter is divided based on what

device (Remote Control, Graphical Remote Control or

App) is used to control the unit. Simply go to the sub

chapter, relevant for your device and the base setup for

the operating mode which will be used to control the

unit.

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 5

5

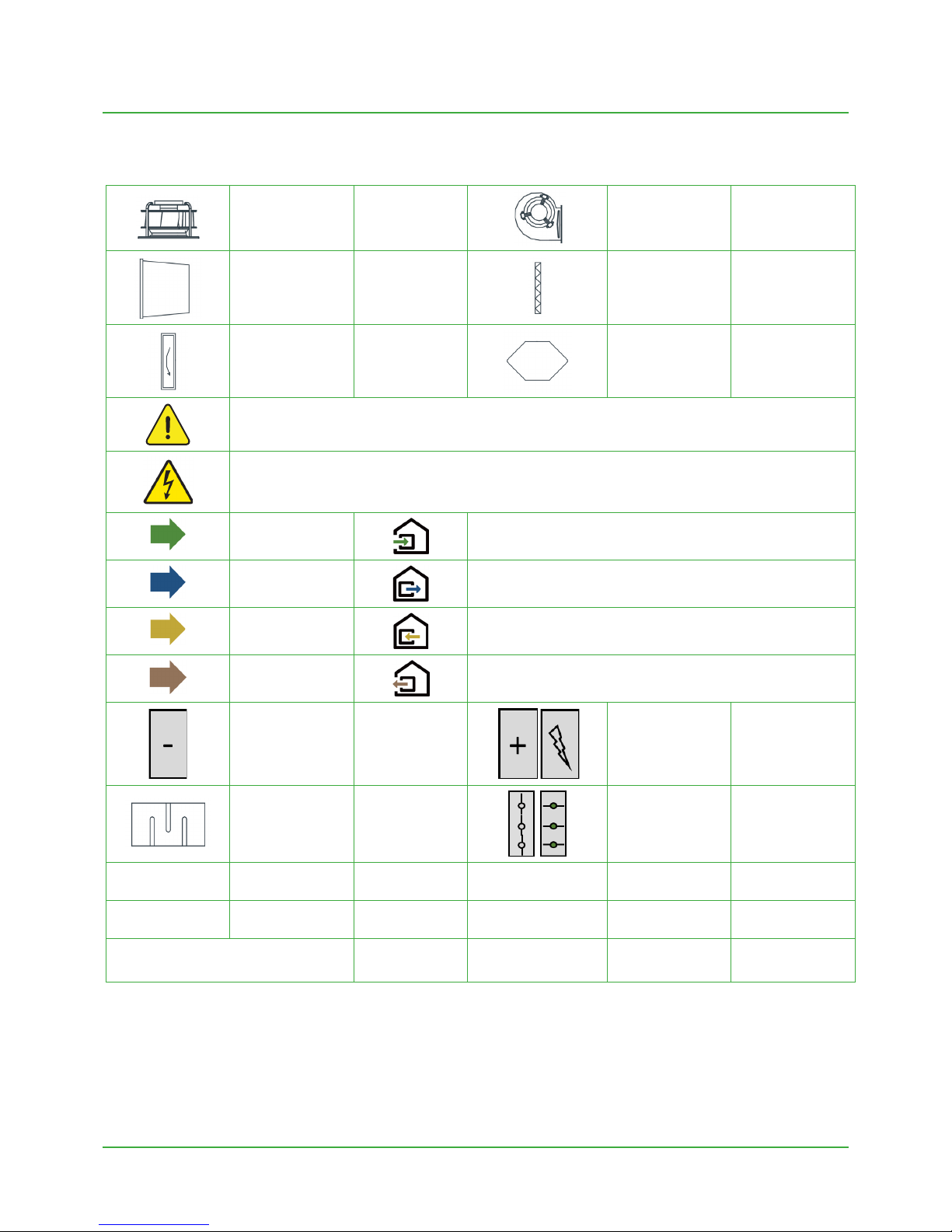

2.0 Symbols and abbreviations

BW

BACKWARD

CURVED FAN

FW

FORWARD

CURVED FAN

BF BAG FILTER PF PLEATED FILTER

RX

ROTARY HEAT

EXCHANGER

PX

PLATE HEAT

EXCHANGER

WARNING

Must be connected by a qualied Electrician.

Warning! Hazardous voltage.

OUTDOOR AIR Air from outdoor to the AHU

SUPPLY AIR Air from the AHU to the building

EXTRACT AIR Air from the building to the AHU

EXHAUST AIR Air from the AHU to outdoor

COOLING COIL BA-

IBA / KW

HEATING COIL

(WATER / ELECTRICAL)

SILENCER GD CTm

MOTORIZED

DAMPER

PRESSURE SENSOR P Tx

TEMPERATURE SENSOR

Nr = x (1,2,3…)

SLIP CLAMP SC MS

FLEXIBLE

CONNECTION

CIRCULAR DUCT CONNECTION ER For inlet SR For outlet

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 6

6

3.1 GENERAL OVERVIEW

ATTENTION

Right and le hand units have dierent article numbers and should be ordered accordingly.

It is however possible to change the direction aerwards but only by an accredited

Service technician. Main version described in the manuals is always the hand right version.

3.0 Product Overview

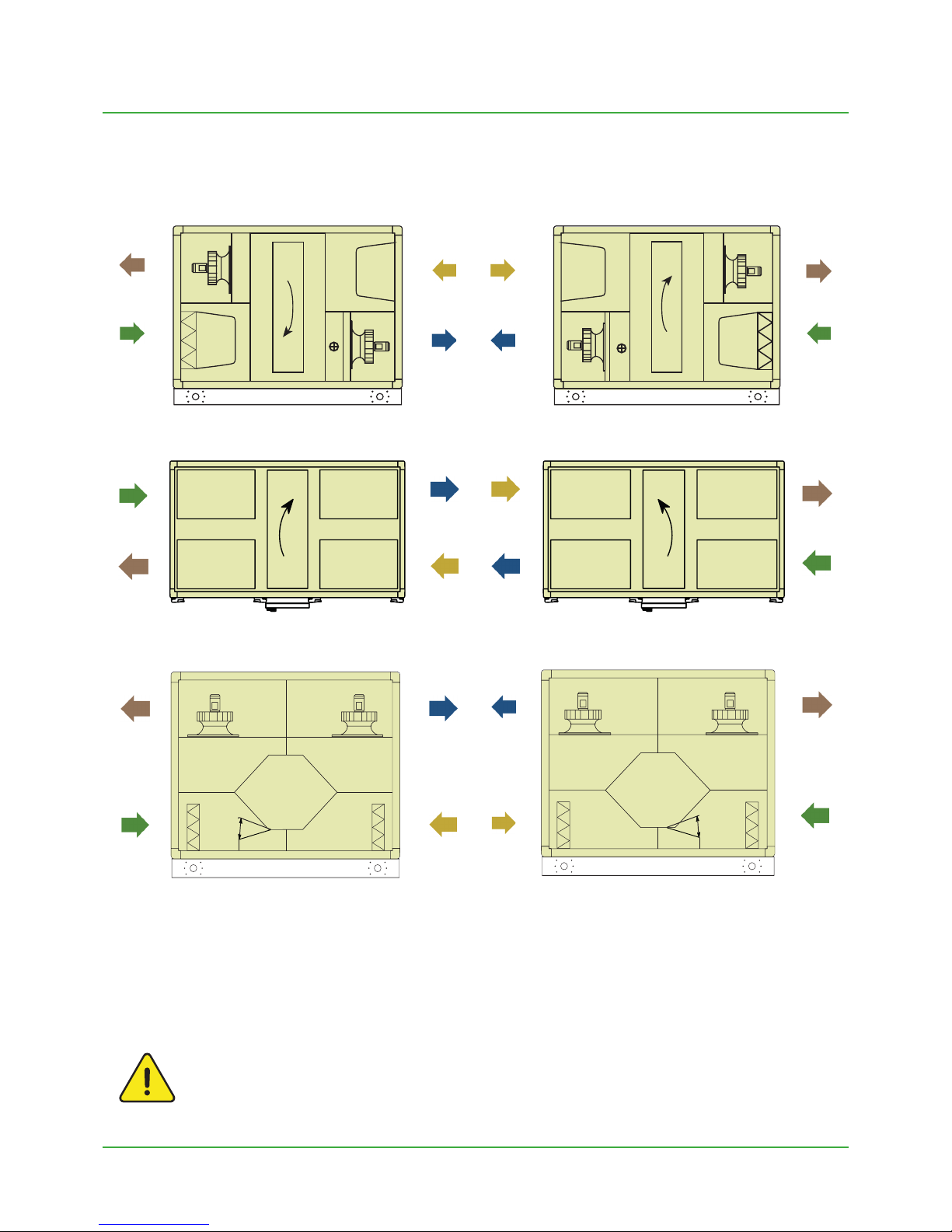

RIGHT HAND UNIT SUPPLY AIR TO THE RIGHT LEFT HAND UNIT SUPPLY AIR TO THE LEFT

GLOBAL RX GLOBAL RX

GLOBAL RX TOP GLOBAL RX TOP

GLOBAL PX (FW) GLOBAL PX (FW)

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 7

7

ATTENTION

Right and le hand units have dierent article numbers and should be ordered accordingly.

It is however possible to change the direction aerwards but only by an accredited

Service technician. Main version described in the manuals is always the hand right version.

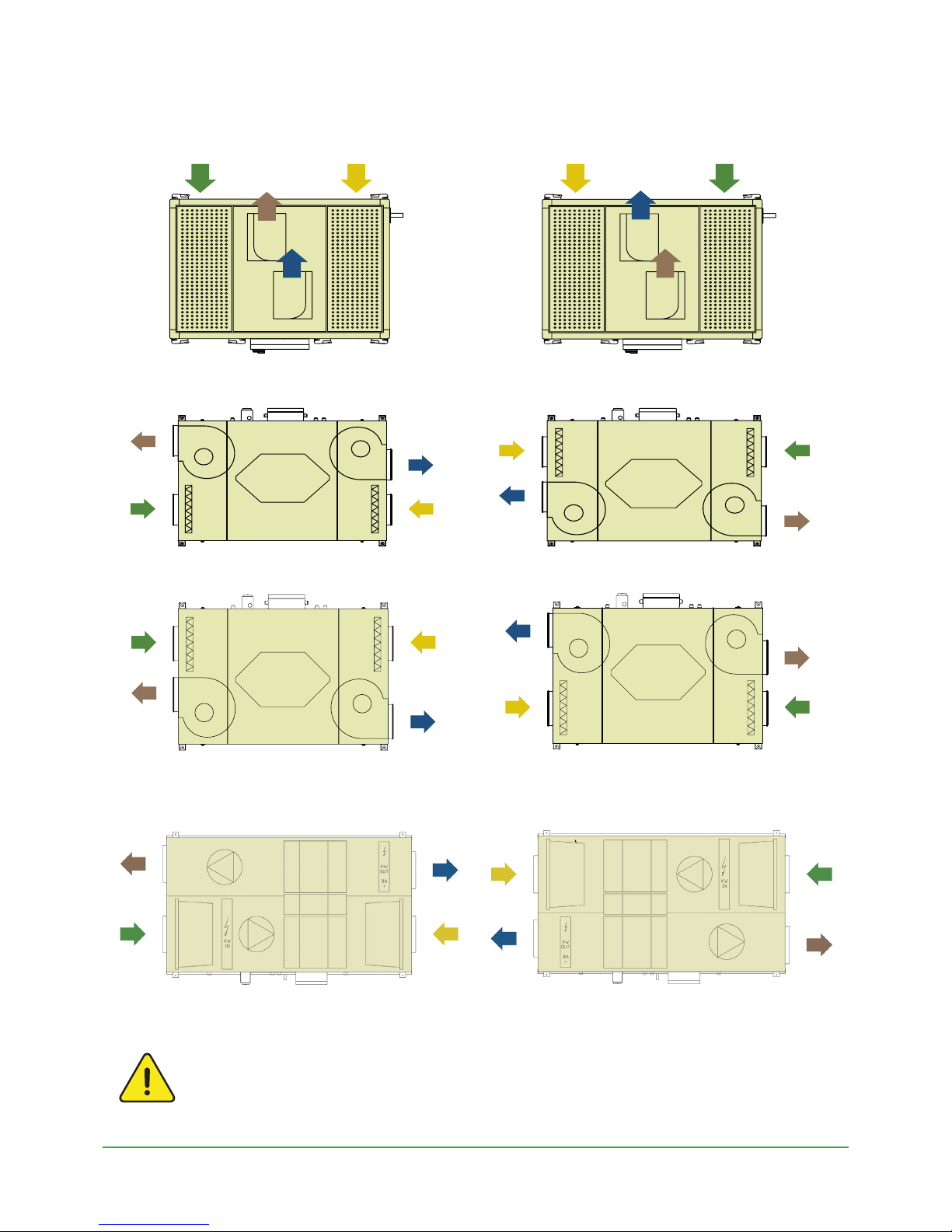

RIGHT HAND UNIT SUPPLY AIR TO THE RIGHT LEFT HAND UNIT SUPPLY AIR TO THE LEFT

Attention: The dierence between le and right LP units is the factory placement of the controls box on opposite sides.

GLOBAL LP (TOP view)

GLOBAL LP (TOP view)

GLOBAL PX TOP FW GLOBAL PX TOP FW

GLOBAL LP 450FW (BOTTOM view)

GLOBAL LP 450FW (BOTTOM view)

GLOBAL LP 600/1000/2000 FW (BOTTOM view)

GLOBAL LP 600/1000/2000 FW (BOTTOM view)

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 8

8

5

4

3

2

6

7

8

9

9

10

11

19

13

20

20

18

18

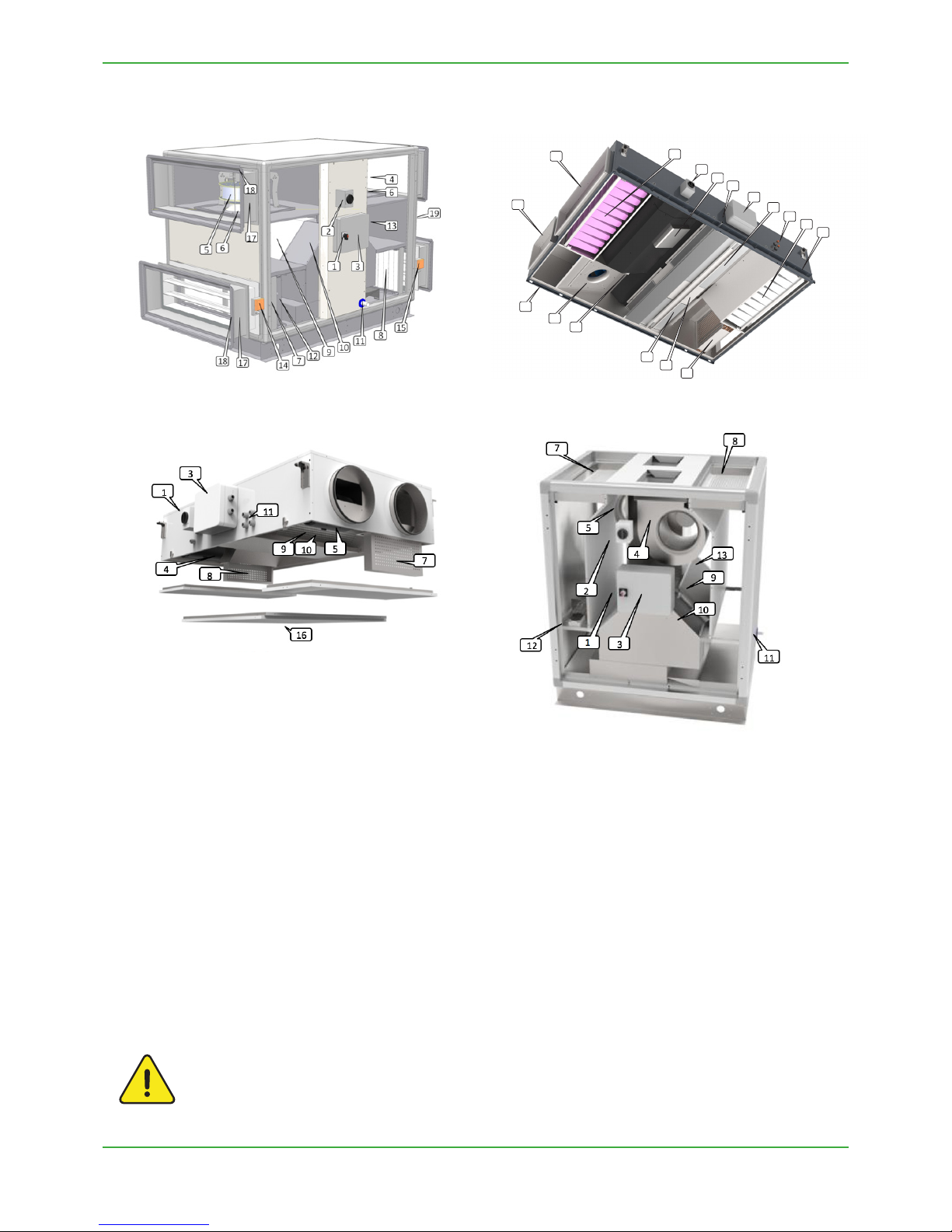

1. Main power switch for AHU

2. Main power switch for electrical coils

(both internal pre-hating and post-heating)

3. Wiring box TAC5 controller

4. Supply fan

5. Extract fan

6. Kit CA -airow measurement (option)

7. Outdoor air lter (bag or pleated)

8. Extract air lter (bag or pleated)

9. Heat exchanger (Plate or Rotary)

10. Modulating 100% by-pass (PX only)

11. Drain pan and drain pipe (PX only)

12. Pre-heating electrical antifrost coil (PX only)

13. Internal post-heating water or electrical coil (accessory)

14. Motorized damper (at outdoor air side - accessory)

15. Motorized damper (at exhaust air side - accessory)

16. Access panel (LP only)

17. Flexible connection(accessory)

18. Slip Clamps (accessory)

19. Water connection for postheating (accessory)

1, 2 and 3 must be installed by an accredited electrician

Note: internal electrical coils, motorized dampers, internal fan-pressure sensors, exible connections and

slip-clamps have to be ordered initially and are all pre-mounted and factory wired. Internal heating watercoil accessory is pre-mounted but has to be hydraulically and electrically connected by the installer.

GLOBAL PX FW

GLOBAL LP

FW

GLOBAL PX TOP

FW

GLOBAL LP

3.2

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 9

9

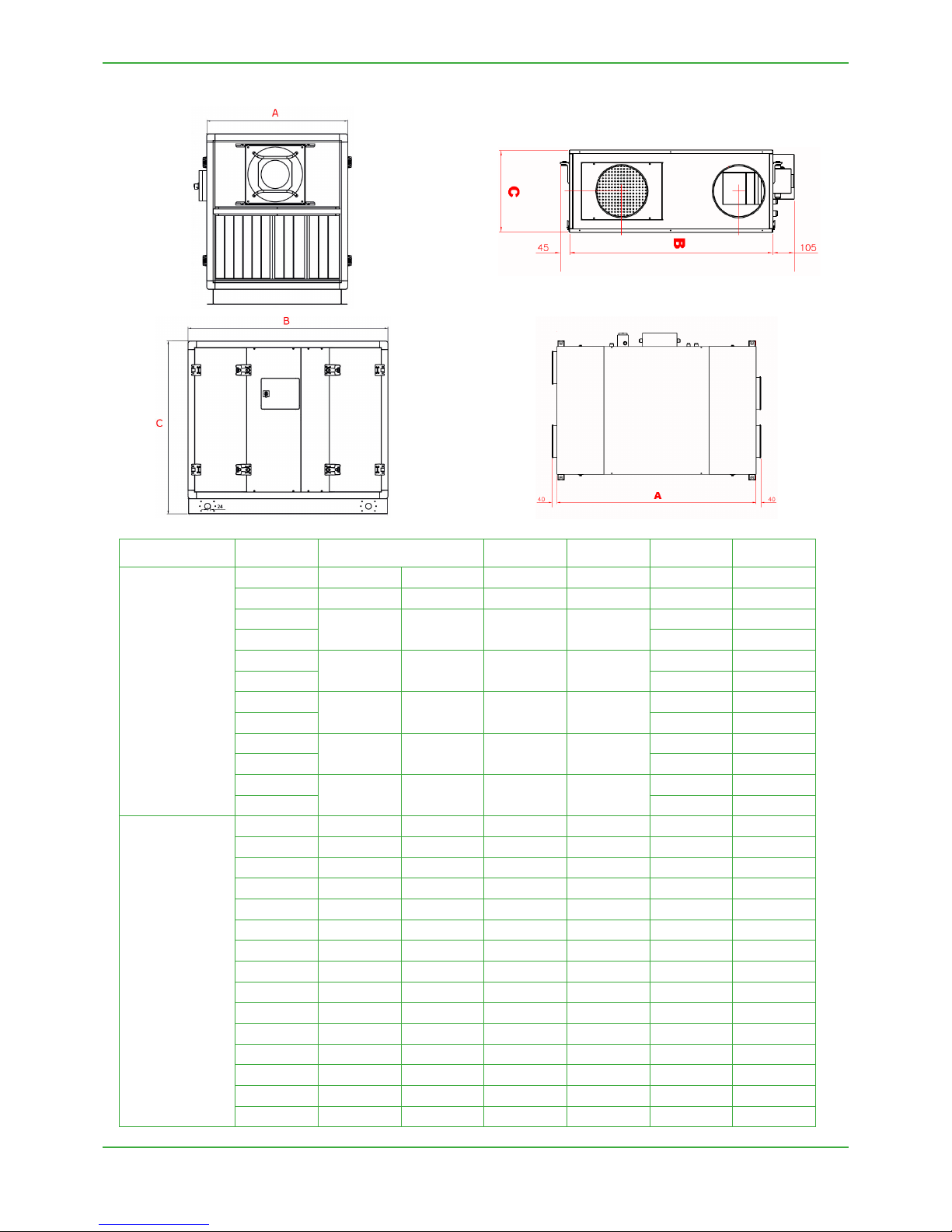

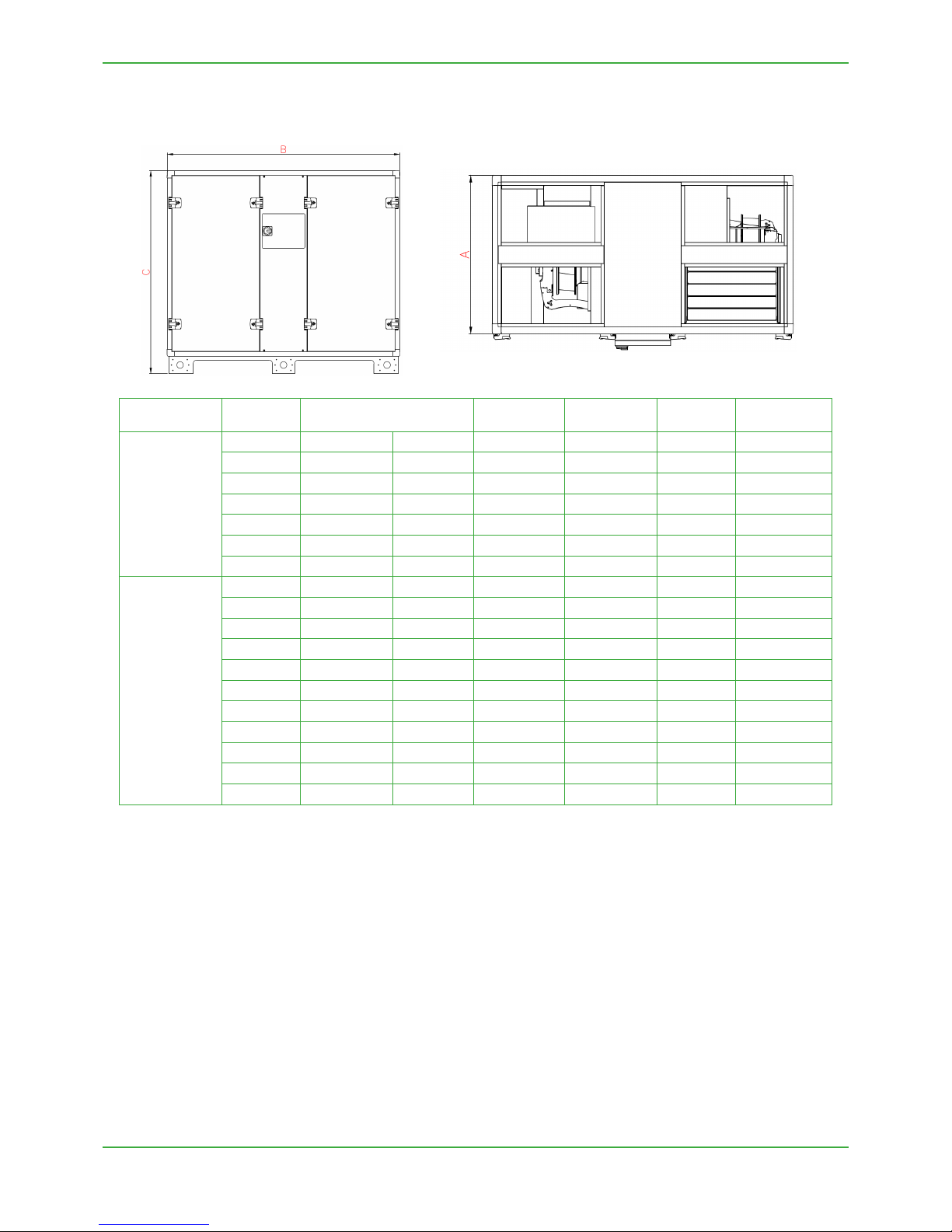

EXCHANGER SIZE AIR VOLUME A [mm] B [mm] C [mm] Weight [kg]

GLOBAL PX

Counterow

800

(FW)

800 m³/h 222 l/s 575 1210 1235 195

1200

(FW)

1200 m³/h 333 l/s 940 1210 1235 245

2000

FW

2000 m³/h 560 l/s 1105 1635

1230 325

2000 1360 375

3000

FW

3000 m³/h 833 l/s 1475 1635

1230 370

3000 1360 420

4000

FW

4000 m³/h 1111 l/s 1845 1635

1230 540

4000 1360 545

5000

FW

5000 m³/h 1389 l/s 2135 1635

1600 690

5000 1760 690

6000

FW

6000 m³/h 1667 l/s 2135 1635

1600 715

6000 1760 715

GLOBAL LP

Counterow

450

FW

450 m³/h 125 l /s 1100 560 360 75

600

FW

600 m³/h 167 l/s 1490 850 320 110

1000

FW

1000 m³/h 278 l/s 1550 1000 400 160

1600

FW

1600 m³/h 444 l /s 1550 1640 400 225

2000

FW

2000 m³/h 556 l/s 1700 1940 400 270

02 580 m³/h 160 l/s 1300 890 350 105

04 650 m³/h 180 l/s 1300 1100 350 125

06 1050 m³/h 290 l/s 2100 1050 435 195

08 1450 m³/h 400 l/s 2100 1300 435 230

10 1850 m³/h 510 l/s 2100 1600 435 270

12 2200 m³/h 610 l/s 2250 1700 510 325

13 2600 m³/h 720 l/s 2250 1700 510 325

14 2900 m³/h 800 l/s 2250 1940 510 360

16

20

3.3 AIR VOLUMES AND DIMENSIONS

GLOBAL PX

(FW)

GLOBAL LP

(FW)

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 10

10

1, 2 and 3 must be installed by an accredited electrician

Note: internal electrical coils, motorized dampers, internal fan-pressure sensors, exible connections and

slip-clamps have to be ordered initially and are all pre-mounted and factory wired. Internal heating watercoil accessory is pre-mounted but has to be hydraulically and electrically connected by the installer.

GLOBAL RX TOP

GLOBAL RX

1

2

3

4

5

6

6

7

8

9

13

15

14

17

17

18

18

19

3.2

1. Main power switch for AHU

2. Main power switch for electrical coils

(both internal pre-hating and post-heating)

3. Wiring box TAC5 controller

4. Supply fan

5. Extract fan

6. Kit CA -airow measurement (option)

7. Outdoor air lter (bag or pleated)

8. Extract air lter (bag or pleated)

9. Heat exchanger (Plate or Rotary)

10. Modulating 100% by-pass (PX only)

11. Drain pan and drain pipe (PX only)

12. Pre-heating electrical antifrost coil (PX only)

13. Internal post-heating water or electrical coil (accessory)

14. Motorized damper (at outdoor air side - accessory)

15. Motorized damper (at exhaust air side - accessory)

16. Access panel (LP only)

17. Flexible connection(accessory)

18. Slip Clamps (accessory)

19. Water connection for postheating (accessory)

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 11

11

Duct connections: see drawings downloadable on our website.

EXCHANGER SIZE AIR VOLUME A [mm] B [mm] C [mm] Weight [kg]

GLOBAL RX TOP

Rotary

05 1100 m³/ h 305l /s 815 1530 1315 295

08 1500 m³/h 416l/s 815 1530 1315 310

10 1600 m³/h 440l/s 885 1680 1465 365

12 2000 m³/h 555l/s 885 1680 1465 365

13 2300 m³/h 640l/s 995 1680 1465 390

14

2800 m³/h

780l/s 1182

1680

1465 400

16

3200 m³/h 830l/s 1182 1680 1465 410

GLOBAL RX

Rotary

05 1200 m³/ h 330 l/s 815 1530 1315 295

08 1600 m³/h 440 l/s 815 1530 1315 310

10 1800 m³/h 500 l/s 885 1680 1465 355

12 2300 m³/h 640 l/s 885 1680 1465 340

13 2900 m³/h 805 l /s 995 1680 1465 365

14 3100 m³/h 860 l/s 1182 1680 1465 390

16 3400 m³/ h 940 l/s 1182 1680 1465 400

18 4500 m³/ h 1250 l /s 1382 1880 1725 535

20 5500 m³/h 1525 l/s 1382 1880 1725 535

24 6700 m³/h 1860 l/s 1640 1880 1725 575

26 7200 m³/h 2000 l/s 1640 1880 1725 575

3.3 AIR VOLUMES AND DIMENSIONS

GLOBAL RX TOP

This document is an overview of technical specifications. Please do refer to our selection software for detailed and up-to-date information.

Page 12

12

Operation and maintenance instructions – v2.8.8 & 2.7.3

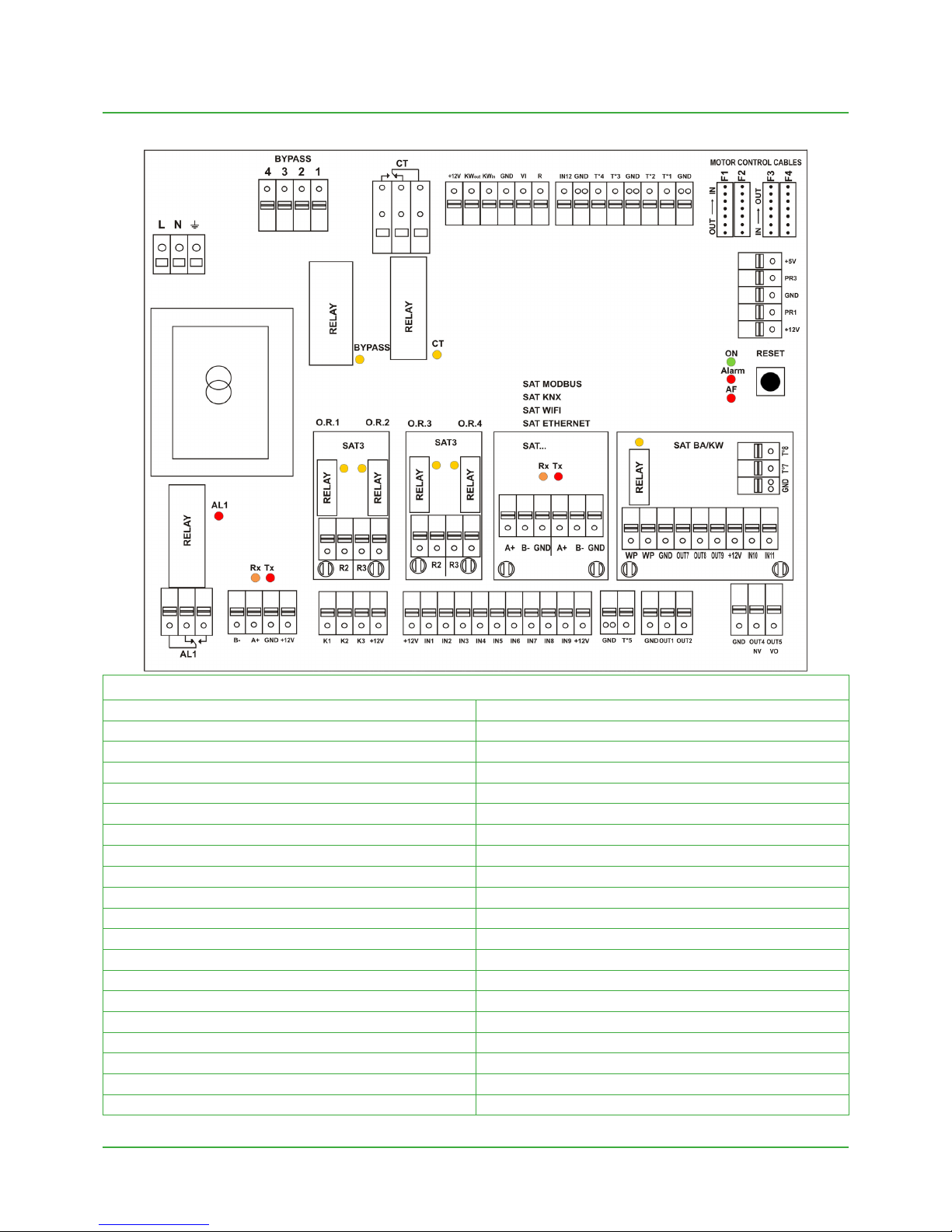

MAIN CONTROL BOARD TAC5 DG CID025000

TAC5 DG: GLOBAL PX & LP

FW

CT = output to CT actuator(s) (option - prewired) IN1 = Master selection

BYPASS = output to bypass actuator (prewired) IN2 = dPa (pressostat digital input)

AL1 = ALARM OUTPUT (230V/5A) IN3 = Fire alarm input

B- / A+ / GND / +12V = connection to HMI IN4 = Bypass open / Stop heat recovery

K1: Airow MODE = m³/h K1 IN5 = Real time clock auto/manu

Demand/Pressure control = START/STOP IN6 = ON/OFF post heating (IBA/KWout)

Torque MODE = %torque K1 IN7 = ON/OFF SUPPLY if re alarm

K2: Airow control = m³/ h K2 IN8 = ON/OFF EXHAUST if re alarm

Demand/Pressure control = 0-10V INPUT IN9 = BOOST Airow

Torque control = %torque K2 IN12 = PWM input bypass position

K3: Airow control = m³/h K3 OUT1 = 0-10V OUTPUT (airow / pressure)

Demand/Pressure control = % ON K3 or 0-10 V INPUT OUT2 = 0-10V OUTPUT (airow / pressure)

Torque control = %torque K3 OUT4 = 0-10V OUTPUT internal post heating (IBA)

T1 = from outdoors T° sensor (prewired) OUT5 = 24VDC / 1A

T2 = from indoors T° sensor (prewired) O.R.1 (output relay 1 - SAT3) = PRESSURE ALARM

T3 = to outdoors T° sensor (prewired) O.R.2 (output relay 2 - SAT3) = FAN ON

T4 = IBA anti freeze protection T° sensor (option - prewired) O.R.3 (output relay 3 - SAT3) = HEATING DEMAND OUTPUT

T5 = supply T° sensor for IBA/KWout coil (option - prewired) O.R.4 (output relay 4 - SAT3) = BYPASS STATUS

PR1 = Pa from supply inlet fan (only on PX - option) KWin = output for KWin capacity control (option - prewired)

PR3 = Pa from exhaust inlet fan (only on PX - option) KWout = output for KWout capacity control (option - prewired)

4.0 Wiring Overview

Page 13

13

Operation and maintenance instructions – v2.8.8 & 2.7.3

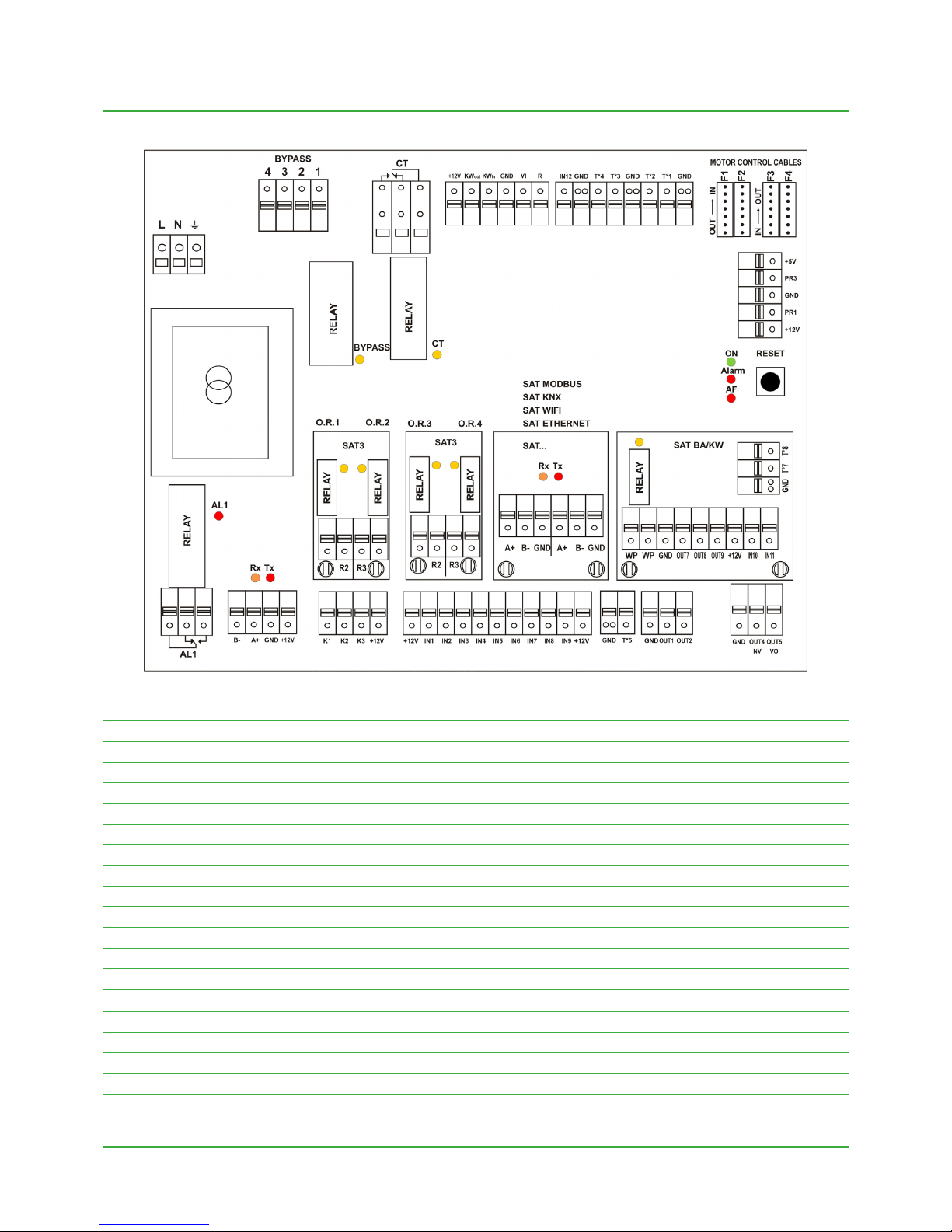

TAC5 DT: GLOBAL RX (TOP) & LP

(FW)

CT : output to CT actuator(s) (option - prewired) IN1 = Master selection

KWout = output for KWout capacity control (option - prewired) IN2 = dPa (pressostat digital input)

AL1 = ALARM OUTPUT (230V/5A) IN3 = Fire alarm input

B- / A+ / GND / +12V = connection to HMI IN4 = Bypass open / Stop heat recovery

K1: Airow control = m³/h K1 IN5 = Real time clock auto/manu

Demand/Pressure control = START/ STOP IN6 = ON/OFF post heating (IBA/KWout)

Torque control = %torque K1 IN7 = ON/OFF SUPPLY if re alarm

K2: Airow control = m³/ h K2 IN8 = ON/OFF EXHAUST if re alarm

Demand/Pressure control = 0-10V INPUT IN9 = BOOST Airow

Torque control = %torque K2 IN12 = input pulse from heat exchanger magnet (prewired)

K3: Airow control = m³/h K3 OUT1 = 0-10V OUTPUT (airow / pressure)

Demand/Pressure control = % ON K3 or 0-10 V INPUT OUT2 = 0-10V OUTPUT (airow / pressure)

Torque control = %torque K3 OUT4 = 0-10V OUTPUT internal post heating (IBA)

T1 = from outdoors T° sensor (prewired) OUT5 = 24VDC / 1A

T2 = from indoors T° sensor (prewired) O.R.1 (output relay 1 - SAT3) = PRESSURE ALARM

T4 = IBA anti freeze protection T° sensor (option - prewired) O.R.2 (output relay 2 - SAT3) = FAN ON

T5 = supply T° sensor for IBA/KWout coil (option - prewired) O.R.3 (output relay 3 - SAT3) = HEATING DEMAND OUTPUT

PR1 = Pa from supply inlet fan (only on RX - option) O.R.4 (output relay 4 - SAT3) = BYPASS STATUS

PR3 = Pa from exhaust inlet fan (only on RX - option) R-GND: output for heat exchanger wheel speed command (prewired)

MAIN CONTROL BOARD TAC5 DT CID026001

Page 14

14

Operation and maintenance instructions – v2.8.8 & 2.7.3

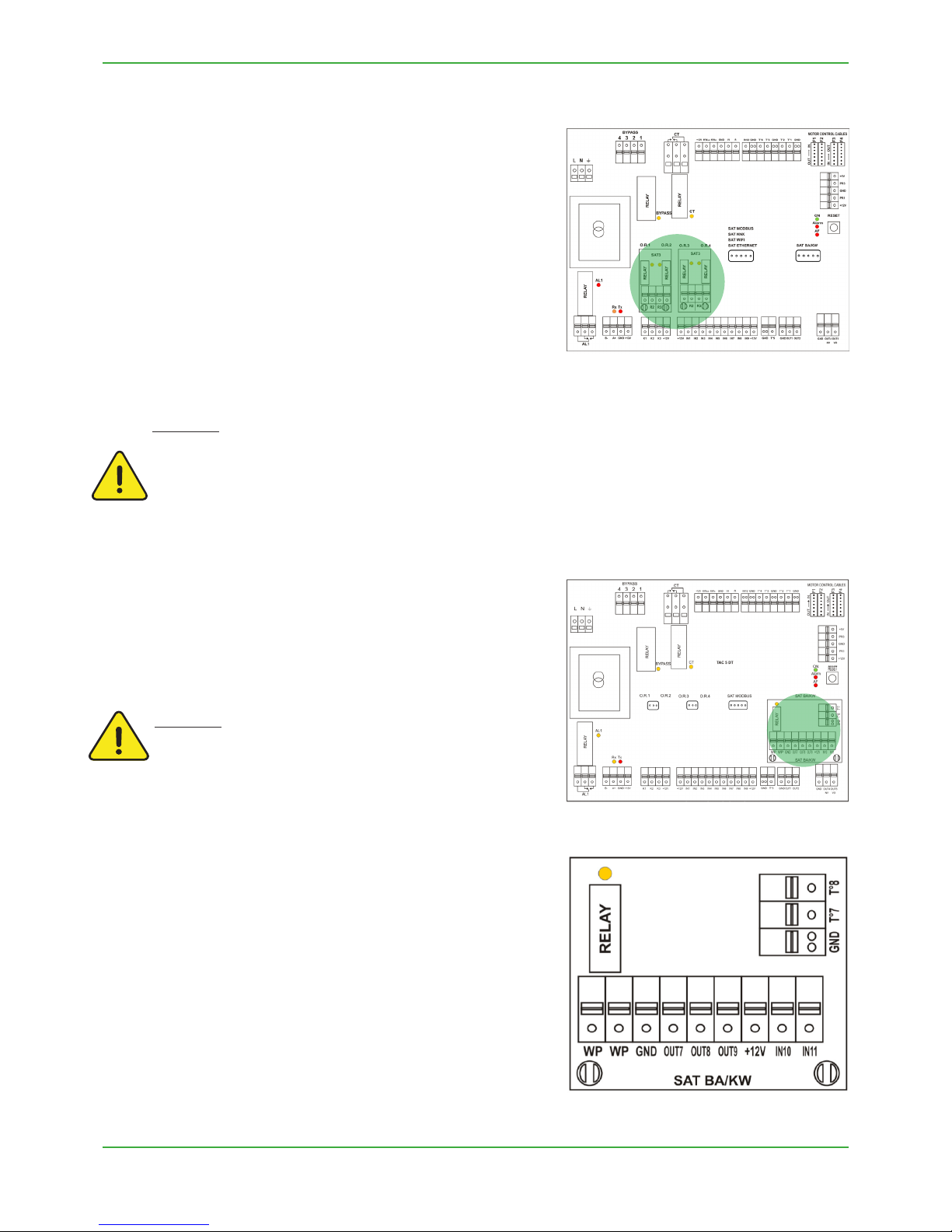

4.1 CIRCUIT BOARD SAT 3 CID372005

The SAT3 circuit board is used for extra functions for

which inputs and outputs are not included as standard

in the control unit of the air handling unit. All outputs

are normally open (N.O.). Maximal load: 230VAC – 4A.

The circuit board SAT3 allows for signalling of the

following by means of a potential-free contact:

• Fan status - O.R. 1

• Dierential pressure alarm - O.R. 2

• Heating demand - O.R.3

• Bypass status - O.R.4

Installation

SAT3 must be plugged onto the control board circuit

(see g.1).

Attention: The SAT3 must be plugged in before

the circuit is powered. SAT must be plugged in

correctly, wrong positioning can damage both

circuits permanently.

Fig. 3

4.2 CIRCUIT BOARD SAT BA/KW CID372004

SAT TAC5 BA/KW is a satellite circuit designed to be tted on the main

control board. It permits control of external coils.

Installation

The SAT BA/KW must be plugged onto the control board circuit

(se e Fig.2).

Attention: The SAT TAC5 BA /KW must be plugged in before

the circuit is powered. SAT must be plugged in correctly, wrong

positioning can damage both circuits permanently.

Wiring

The terminals of the SAT BA/KW are displayed in g.3

WP WP = Cooling demand (max. 30 V-2 A)

OUT7 = 0-10 V output to control heating- or change over capacity.

OUT8 = 0-10 V output to control cooling capacity

OUT9 = PWM output to control electrical coil

T°7 = Heating coil frost protection sensor (T7)

T°8 = Cooling coil frost protection sensor (T8)

IN10 = boosted cooling OFF, (to boost external post heating coil use IN6)

IN11 = Input cooling/ heating (open = heating, closed = cooling)

Fig. 1

Fig. 2

Page 15

15

Operation and maintenance instructions – v2.8.8 & 2.7.3

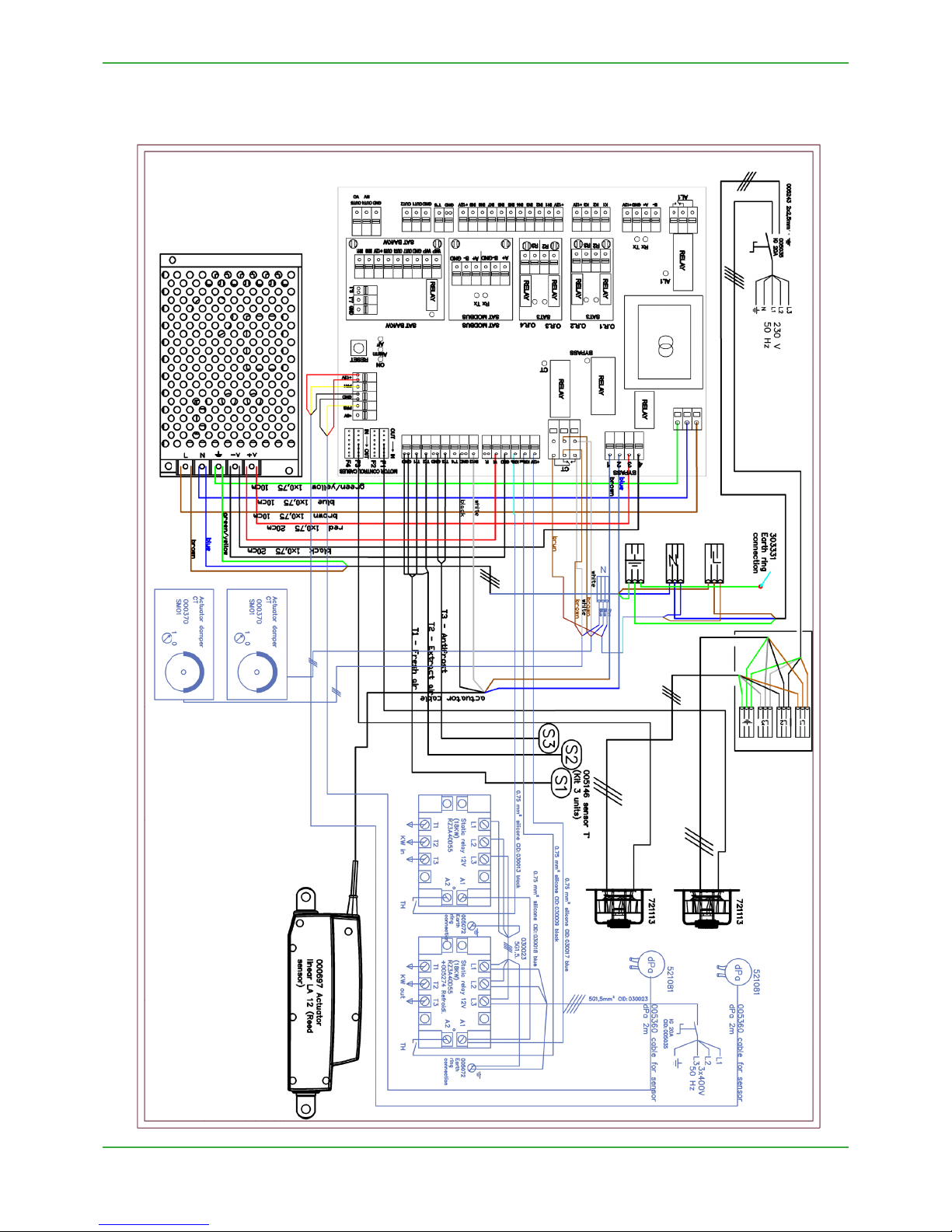

4.3 INTERNAL WIRING DIAGRAM GLOBAL PX

Page 16

16

Operation and maintenance instructions – v2.8.8 & 2.7.3

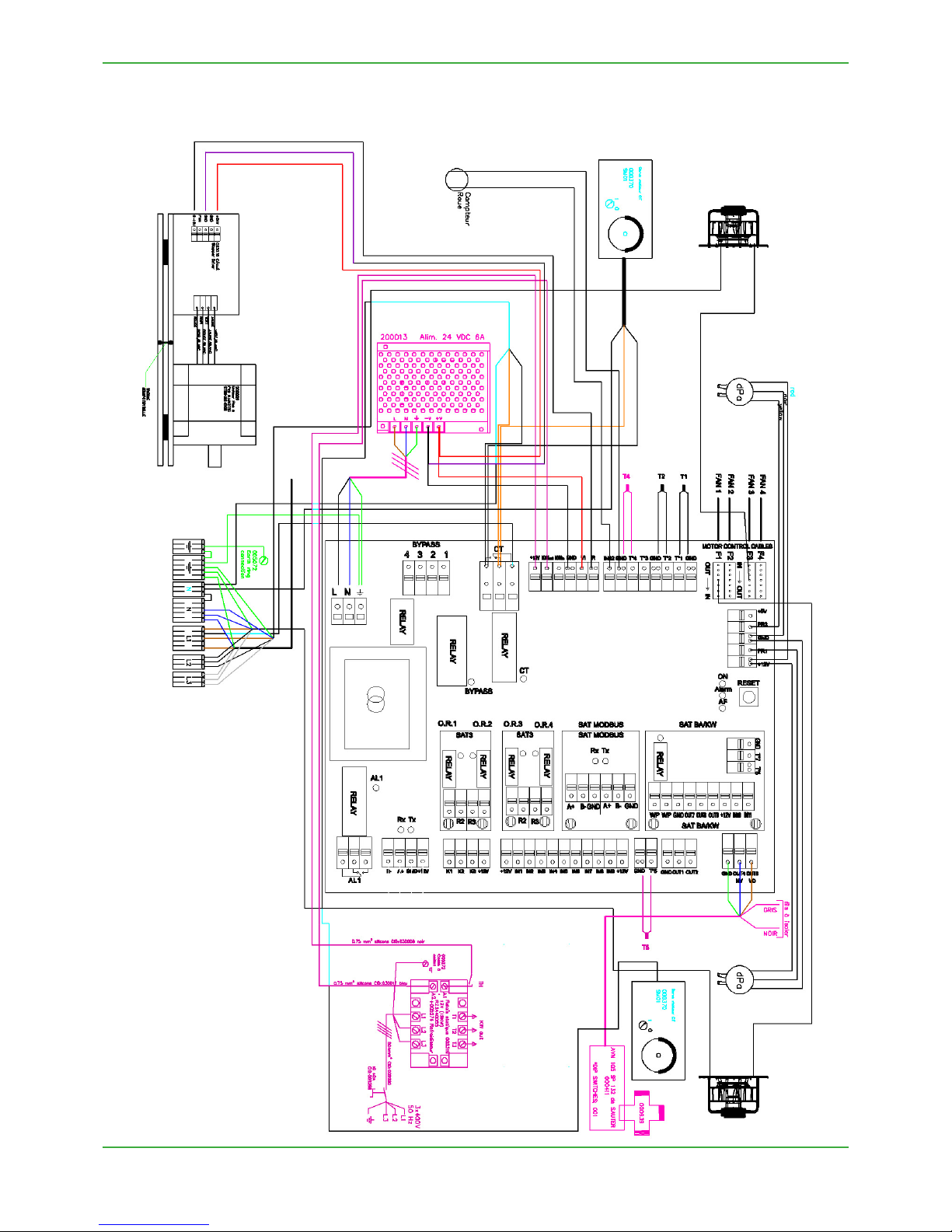

4.4 INTERNAL WIRING DIAGRAM GLOBAL RX TOP

Page 17

17

Operation and maintenance instructions – v2.8.8 & 2.7.3

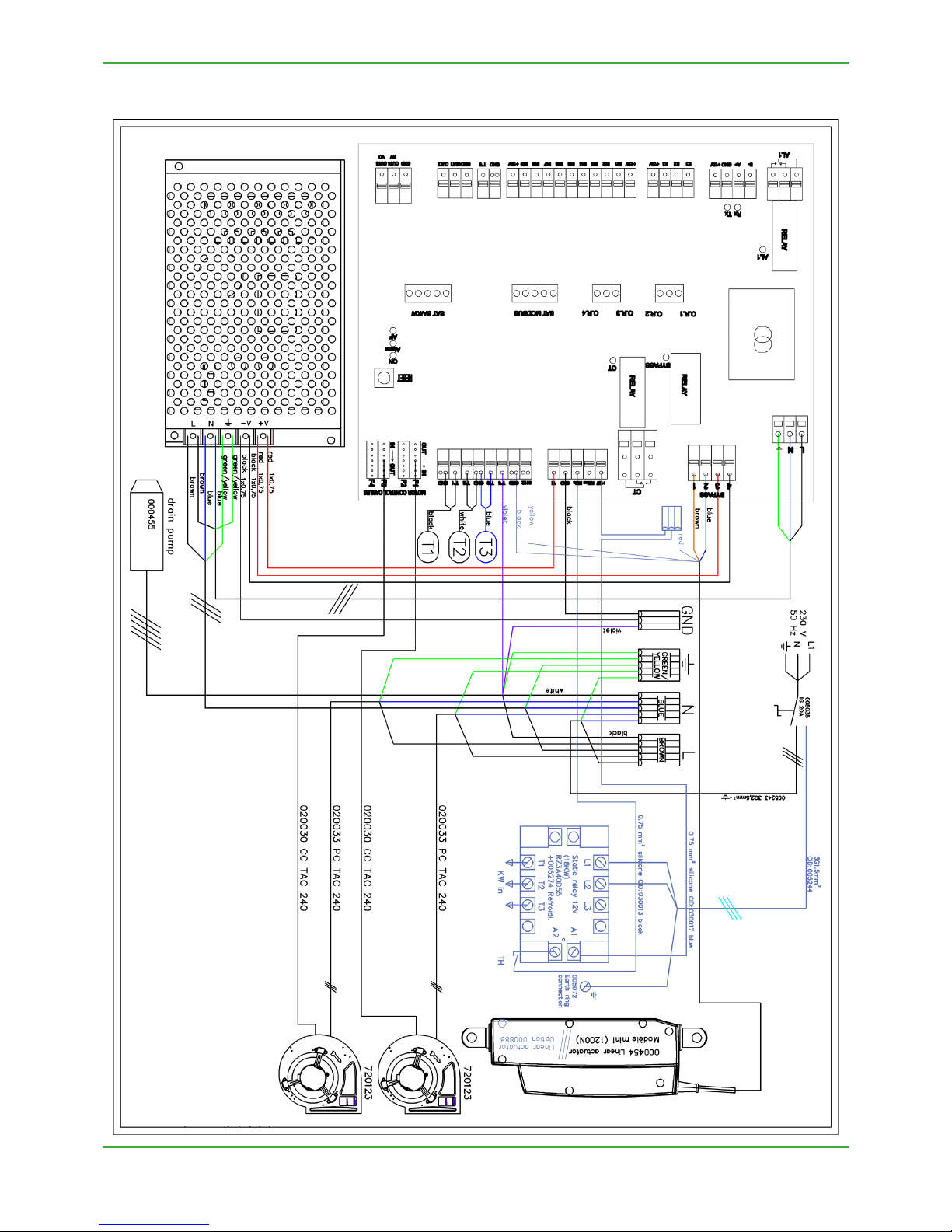

4.5 INTERNAL WIRING DIAGRAM GLOBAL LP

FW

Page 18

18

Operation and maintenance instructions – v2.8.8 & 2.7.3

5.1 OPERATING MODE

There are ve main operating modes. The operating

mode determines how the airow or the fan torque

is modulated. The default operating mode is Airow

control. Exceptions are units equipped with backwards

fans without the Constant Air Kit or if Constant Torque

mode has been selected in the product setup menu, in

both cases it is the fan torque that will be controlled and

modulated.

5.0 Functions

In all the operating modes, the supply fan(s) will operate

as per the assigned mode and parameters. The exhaust

fan(s) will operate according to the chosen percentage

of the supply fan (%EXH/SUP ratio). The ve main

operating modes are:

• 1 - Airow control:

Flow control involves operating the air handling unit to keep the pre-set airow constant. The speed of the

fans is automatically regulated to provide correct airow even if the lters begin to become clogged, air

terminals are blocked, etc. Airow control mode is advantageous, since the airow always is exactly as it was

from the beginning. It should however be noted that everything that increases the pressure drop in the

ventilation system, such as blocking of air terminals and dust accumulating in lters, causes the fans to run at

a higher speed. This results in higher power consumption and may also cause discomfort in the form of noise.

There are three airow setpoints to be congured by the user (m³h K1, m³h K2, m³h K3).

• 2 - Torque control:

3 torque setpoints to be congured by the user (%TQ K1, %TQ K2, %TQ K3). The setpoint is congured

in % of the maximal torque. The torque control allows to vary the fan speed automatically, to

provide a variable airow for demand controlled systems (DCV). This allows for demand controlled fan operation

or fan optimisation by a BMS system, mostly used in multi zone systems. This operation mode can partially

replace the constant pressure control when a duct pressure sensor hasn’t been installed.

• 3 - Demand control 0-10V:

The airow is controlled by a 0-10 V signal. The control signal is connected to terminals K2&GND. The assigned

supply airow is set as a percentage of a linear 0-10 V signal. The user denes the link with 4 parameters: Vmin,

Vmax, m³h Vmin and m³h Vmax, applied to the following diagram. The demand control mode is also

available for modulating fan torque instead of airow (relevant for backwards fans units without Kit CA).

The principle is identical to the demand control mode operation with the dierence that Vmin and Vmax are

connected to a %TQ instead of m³/h.

• 4 - Pressure control:

The airow automatically varies to provide constant pressure in the ducting system. This type of control is

also called VAV control (Variable Air Volume).

Pressure on supply: the airow of the supply fan(s) is modulated to maintain a certain pressure Setting

constant. The pressure is measured by a pressure sensor located in the supply air duct.

Pressure on exhaust: the airow of the exhaust fan(s) is modulated to maintain a certain pressure Setting

constant. The pressure is measured by a pressure sensor located in the extract air duct.

• 5 - MODE OFF :

This stops the AHU

Page 19

19

Operation and maintenance instructions – v2.8.8 & 2.7.3

5.2 TEMPERATURE CONTROL

5.3 FREE COOLING RX AND PX

There are several options available on GLOBAL units to ensure a comfortable temperature.

The options are controlled either via supply or extract air temperature.

The free cooling function uses the lower temperature of the outside air to cool the building.

Free cooling is realized by means of the integrated 100% modulating bypass of the heat exchanger (PX) or the stepless

motor control of the rotary heat exchanger (RX). The optional output O.R.4 on the SAT3 relay indicates the position of

the bypass. The contact will open if the bypass is fully closed, or close if the bypass is fully or partially open.

The bypass (PX) or the rotary heat exchanger (RX) can be congured as on/o or modulating. This is congured

in ADVANCED SETUP. In modulating mode, the temperature is congured in the base setup and the position of

the bypass/stepless motor will modulate in order to maintain the setpoint. The free cooling function is activated

automatically. An on/o bypass / stepless motor operates according to the logic below:

Free cooling STARTS if the following conditions are TRUE :

These Settings can be congured in ADVANCED SETUP

Free cooling STOPS if one of the following conditions is TRUE :

Extract Air Temperature

The default temperature control can be changed to Extract temperature control via the advanced setup.

The extract air temperature is measured on sensor T2. Extract air control involves keeping a constant temperature in

the extract air duct (premises), by controlling the supply air temperature. This provides a uniform temperature in the

premises regardless of the load. The internal sensor T2 can be replaced with the optional external room temperature

sensor (CID370042).

Temperature sensor positioning :

• The outdoor temperature (sensor T1) is lower

than the extract air temperature (sensor T2)

• The outdoor temperature (sensor T1) is

higher than 15°C.

• The extract air temperature (sensor T2) is

higher than 22°C.

• The outdoor temperature (sensor T1) is higher

than the extract air temperature (sensor T2).

• The outdoor temperature (sensor T1) is

lower than 14°C.

• The extract air temperature (sensor T2) is

lower than 20°C.

Supply Air Temperature

Supply temperature control is the default setting. This involves keeping a constant supply air temperature without

consideration to the load in the premises. The supply air temperature is measured on sensor T5.

Page 20

20

Operation and maintenance instructions – v2.8.8 & 2.7.3

5.5 CHANGE OVER FUNCTION

The TAC5 controller allows for the control of both cooling and heating coil. Both coils are equipped with their motorised

3-way valves. The oset between the measured temperature (supply air or extract air, to be congured) and the

setpoint will determine if heating or cooling is automatically activated. When the unit is equipped with both a cooling

and a heating coil, only one setpoint has to be congured: Comfort temperature. The neutral band prevents the cooling

and heating systems from counteracting each other. The high neutral band is added to the comfort setpoint for the

activation of the cooling function and the low neutral band is subtracted from the comfort setpoint for the activation of

the heating function. Both high and low neutral bands have to be congured in the advanced setup.

4 PIPE AUTOMATIC CHANGE OVER

5.4 COOLING RECOVERY RX ONLY

Cooling recovery STARTS if the following condition is TRUE :

• The outdoor temperature (sensor T1) is higher than the extract air temperature (sensor T2).

The cooling recovery function uses the lower extract air temperature to cool down the fresh air. The function is not

congurable. If there is a cooling load in the building and the temperature in the extract air is lower than the outdoor

air temperature, the heat exchanger shall be automatically controlled to operate at maximal speed. The temperature

setpoint is congured in the base setup and the rotary heat exchanger will modulate in order to maintain the setpoint.

The cooling recovery operates according to the logic below:

Page 21

21

Operation and maintenance instructions – v2.8.8 & 2.7.3

• 1 - Reduced supply air ow :

The heat exchanger is supplied with a frost protection sensor on the exhaust air (T3). If the exhaust air

temperature (T3) is >1°C and <+5°C :

• In airow control mode and demand control, the supply air ow will modulate between 100% and 33%

(AFlow)of the setpoint (AFn)

• In pressure control mode, the supply air pressure will modulate between 100% and 50% (AFlow) of the setpoint

(AFn)

If the exhaust air temperature (T3) is <1°C, the supply air fans will stop until the exhaust air temperature (T3) is

>2°C for 5 minutes.

• 2 - Modulating bypass :

The modulating bypass is controlled by the exhaust temperature sensor (T3). If:

• Exhaust temperature (T3) >+1°C: bypass closed or controlled by free cooling function

• Exhaust temperature (T3) ≤ +1°C: bypass will modulate for the exhaust temperature (T3) to exceed +1°C.

The corresponding supply air temperature will drop due to a lower airow through the heat exchanger

• 3 - Electrical preheating coil (accessory) :

If an electrical pre-heating coil (KWin) is installed and congured, the pre-heating coil (KWin)

will modulate so the exhaust temperature is +1°C.

• 4 - Dierential pressure measurement (Cold climate option) :

For cold climate conditions (≥-20C), the unit is equipped with a dierential pressure sensor mounted on the

heat exchanger. The pressure sensor detects when the pressure drop, due to frost, has become too high. In

critical conditions, the supply air ow will be paused for a short time, to allow for defrosting.

The frost protection strategy (down regulation supply airow, modulating bypass or electrical pre-heating) will

still be used as a rst step. The defrost function will only be active if the frost protection strategy is not sucient.

5.6 FROST PROTECTION

The frost protection function is always active if the

heating coil has been correctly congured in the product

setup. The monitoring function uses the temperature

sensor T4 for the integrated coil (IBA) or the temperature

sensor T7 for the external coil (EBA). The function is

In order to protect the rotary heat exchanger from

freezing, the strategy for frost protection consists of

modulating the speed of the rotating heat exchanger,

which is linked to the outdoor air temperature (sensor T1).

There are three strategies to protect the plate heat exchanger from freezing :

These Settings can be congured in ADVANCED SETUP

activated when the surface temperature of the coil drops

below 5°C. Under these conditions the pump output is

activated and the three-way valve output will be 100%.

If aer 15 minutes the surface temperature has not risen,

the unit will shut down and generate a frost alarm.

If the outdoor air temperature < T°AF (default -9°C): the

rotation speed of the heat exchanger is reduced to avoid

the risk of icing. To exit this anti-frost protection: T°(T1) ≥

T°AF for 5 minutes.

These Settings can be congured in ADVANCED SETUP.

HEATING COIL

ROTARY HEAT EXCHANGER RX

PLATE HEAT EXCHANGER PX

Page 22

22

Operation and maintenance instructions – v2.8.8 & 2.7.3

• In airow control mode: the airow by selecting m³h K1 / m³h K2 / m³h K3 / OFF (stop)

• In torque control mode: the torque by selecting %TQ K1 / %TQ K2 / %TQ K3 / OFF (stop)

• In demand control mode :

• with only one 0-10 V signal (default) or with 2 signals to control the

supply airow: the link LS (percentage of the nominal link, cfr m³/h Vmin

and m³/h Vmax in setup OR cfr %TQ Vmin and %TQ Vmax in setup) and

the rate of the exhaust airow by the supply airow.

• with one 0-10 V signal for supply and one 0-10 V signal for exhaust (via

advanced setup): one link LS (percentage of the nominal link) for supply

and one for exhaust.

• In pressure control mode :

• Constant pressure on supply or exhaust: the pressure setpoint (percentage of the

nominal setpoint) and the rate of the exhaust airow by the supply airow.

• Constant pressure on supply and exhaust: one pressure setpoint (percentage of the

nominal setpoint) for supply and one for exhaust.

For each time slot select :

5.7 TIME SCHEDULE

The controller allows 4 time slots (channels) to be congured. For each day of the week,

the operation mode can be either AUTO (operate according to time slots) or OFF.

Page 23

23

Operation and maintenance instructions – v2.8.8 & 2.7.3

6.0 Commissioning

As a human machine interface (HMI), several options are available. The HMI will enable access to the control parameters

in the integrated controller. The HMI as such does not contain any programming and therefor is not mandatory.

The possible HMIs are:

TACtouch touchscreen - CID372096

This 4.3” touchscreen display is used when there is a need for

a graphical HMI. The Touchscreen touchscreen is a complete

graphic monitoring system where the screens are designed to be

intuitive and complete, ensuring a userfriendly experience.

Position switch (COM4) - CID010007

The most basic interface to control a GLOBAL air handling unit

is the 4 position swich. This swith will allow to control the unit

to its three congured airow (low, medium and high) and as

a fourth position, the unit is switched o.

Application Eole

An application for Windows, Android and iPhone is available.

In order to connect to the AHU, a SAT Ethernet or SAT Wi is

mandatory.

Page 24

24

Operation and maintenance instructions – v2.8.8 & 2.7.3

6.1 COMMISSIONING WITH TACtouch INTERFACE

The hand-held terminal consists of a .” touch screen with a , metre long cable for connection to the air handling

units control circuit board.

If the hand-held terminal is not used for minutes, it switches over to the sleep mode.

The Touchscreen controller can be used outdoors, but it must be kept at a weatherproof place.

Data:

Operating temperature: ... °C

Maximum length of the cable: metres

Protection class: IP

Dimensions [mm]: ,x,x,

Power consumption: mA

IMAGE MANAGEMENT

Start-up image

At the rst start up, the basic setup menu will be activated automatically. See section ..

Main menu. See Section ...

The main menu is presented as a rotary menu. Aer

pressing the “menu”-button at the bottom le corner of

the Home Screen, the rotary menu will be shown.

Home Screen. See Section ...

By default, the home screen will be shown if no other

menu is opened by the user or if selected in the main

menu.

N.B.! The appearance of the image varies depending on

the type of air handling unit and functions selected.

LANGUAGE

UNIT

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

Page 25

25

Operation and maintenance instructions – v2.8.8 & 2.7.3

6.1.1 HOME SCREEN

The home screen displays the current key data for the air handling unit and is shown is normally displayed if no other menu

has been selected or if selected from the main menu. The

touch screen switches to the sleep mode aer minutes. To

leave the sleep mode, press on the touchscreen.

On the main screen, the elds are:

• Current operation mode

The operation modes are: STOP, Heating, Cooling, Post

ventilation, Freecooling, Frost protection.

• Current date and time

• Active alarms

This elds shows the number of current alarms. By clicking

on this eld, more detailed information about the dierent

alarms is available

• Menu

Accessing the main menu, see section 6.1.2

• Flow Chart

The ow chart is not editable by the user, the conguration

of the activated options and functions is done throught the

product setup (menu). A code and a special training are

desired for access to this menu. The appearence of the image varies depending on the type of air handling unit and

its selected functions and/or options. Flow chart symbols:

Bypass (closed/open)

Water heating coil

Cooling coil

Number of current alarms

Current operation status

Main menu button

Electrical heating coil

Change over coil

Motorised damper

(open/closed/opening)

Flow charts:

Plate heat exchanger Rotary heat exchanger

Page 26

26

Operation and maintenance instructions – v2.8.8 & 2.7.3

Time and date

The current date and time can be set and adjusted

if needed. The timer automatically takes leap years

into consideration. The system is preset for automatic

changeover between summer time/winter time according to EU Standard.

Control

The control menu will allow for the user to change basic

parameters and operation status of the unit.

The unit can be switched on/o

The fan speed can be selected; three manual speeds one

auto speed

Post heating, post cooling and free cooling setpoints can be

changed.

Time schedule

The built-in timer enables you to control the AHU’s operating mode/time. Certain other oversteering functions such as

external timer, communication, etc. aect the preset operating modes.

Alarm

Alarms are displayed on the main screen of the HMI. Active

alarms can be viewed in this menu. All the alarms can be reset.

A fault can be traced by examining the function or functional

component indicated in the alarm text. More information

about the individual alarms, see section .

If the fault cannot be immediately remidied:

Consider whether the air handling unit can continue to operate

until the fault has been remedied.

Time schedule

Times and days can be set when the air handling unit is

to run in the high speed mode, medium speed mode, low

speed mode or be switched o. For each day (Monday Sunday), four dierent time slots can be congured. The

time slots are subsequent.

Seasonal management

The seasonal management menu allows for the deactivation of heating coils, cooling coils and bypass freecooling function based upon a year calendar. In between the

programmed interval, the selected function is OFF.

.. Main menu

The main menu consists of a rotary menu with icons.

Page 27

27

Operation and maintenance instructions – v2.8.8 & 2.7.3

Basic Setup

The basic setup menu will guide the user through the

most critical settings of the air handling unit. This setup

procedure is described in detail, section ..

LANGUAGE

UNITS

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

Readings

The operating status and the Settings can be read. Used

for performance checks and for generally checking Settings, settings, power consumption, etc. No Settings can

be altered in this menu group.

Maintenance

Conguration of service related settings. A maintenance

warning interval can be congured as wel as the lter

clogging alarm.

Advanced setup

A code and a special training are desired for access to this

menu.

Page 28

28

Operation and maintenance instructions – v2.8.8 & 2.7.3

BASIC SETUP

.. BASIC SETUP

When the air handling unit is started up for the rst time, the

commissioning menu is automatically displayed. At the very end

of the commissioning (menu) the commissioning of the unit has

to be conrmed by the service technician. Once the commissioning has been conrmed, the commissioning menu will not

be displayed as rst menu any more. The commissioning menu,

however, will remain accessible through the advanced setup. See

Section ...

Language

The language desired can be set here. The language setting can

be changed at any time in the basic setup menu.

Setting Settings

range

Factory

setting

Language Languages as

displayed

English

LANGUAGE

UNITS

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

Units

The desired unit can be set here. The unit setting can be changed

at any time in the basic setup menu.

Setting Settings

range

Factory

setting

Unit m³/h

l/s

m³/h

LANGUAGE

UNITS

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

LANGUAGE

UNITS

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

Airow regulation

The desired control mode can be set here. The setting can be

changed at any time in the basic setup menu. Depending on

the selected function, ows can be set as (l/s, m³/h), pressure

(Pa), input signal strenght (%) or torque (%). For both “Airow

control” and “Torque control”, three setpoints are available: Low,

medium and high.

Setting Settings

range

Factory

setting

Operating mode OFF

Airow

Demand control

Pressure

Torque

Airow

Page 29

29

Operation and maintenance instructions – v2.8.8 & 2.7.3

Constant airow

Flow control involves operating the air handling unit to

keep the preset airow constant. The speed of the fans is

automatically regulated to provide correct airow even if

the lters become clogged, diusers are blocked, etc. The

exhaust air fan is controlled as a slave. A ratio between

exhaust and supply pressure can be congured in order

to create over, under or balanced pressure. For units with

backward fans, constant airow can only be selected if

the “constant air kit” has been ordered as an option. The

desired setpoint is preset in (l/s, m³/h).

Setting Range Factory set-

ting

Airow K1/K2/K3 0...max

Ratio exhaust/supply 5...999% 100%

Enable pressure alarm No

Yes

Yes

DP Supply/Exhaust

for pressure alarm

25...999Pa 200Pa

Initialisation airow (l/s, m³/h)

Pressure alarm initialisation

No

Yes

Yes

Torque control

The constant torque operating mode allows to vary the

fan speed automatically, to provide a variable airow for

demand controlled systems. This operating mode can

partially replace the constant pressure control when a

duct pressure sensor hasn’t been installed. The exhaust air

fan is controlled as a slave. A ratio between exhaust and

supply pressure can be congured in order to create over,

under or balanced pressure. The desired setpoint is preset

in %. The Torque control mode can be deactivated in the

advanced setup.

Setting Range Factory setting

Airow K1/K2/K3 0...100%

Ratio exhaust/supply 5...999% 100%

Demand control

The airow desired is regulated in response to - V

input signals from an external sensor, such as a carbon

dioxide or a humidity sensor. The function can be congured with a positive or a negative logic. A ratio between

exhaust and supply pressure can be congured in order to

create over, under or balanced pressure. The desired setpoint is preset in (l/s, m³/h). The “sleep factor” is a lower

operating rate for the unit (due to e.g. low occupancy)

that will be activated by speed “III “

Setting Range Factory

setting

Vmin 0...10V 1,0V

Vmax 0...10V 10,0V

m³/h ~Vmin (l/s, m³/h)

m³/h ~Vmax (l /s, m³/h)

Ratio exhaust/supply 5...999% 100%

Sleep factor on K3 10...100% 100%

Enable pressure alarm No

Yes

Yes

DP Supply/Exhaust

for pressure alarm

10...999Pa 200Pa

Initialisation airow (l/s, m³/h)

Pressure alarm initialisation

No

Yes

Yes

Constant pressure

The airow automatically varies to provide constant

pressure in the ducting. The duct pressure is measured by

an external in-duct pressure sensor which is connected

to the control unit’s BUS communication or the an analogue ...V input. The function can be congured on

supply air, extract air or supply and extract air. The rst

two congurations will have the second set of fans be

controlled as a slave. A ratio between exhaust and supply

pressure can be congured in order to create over, under

or balanced pressure. The initialisation will allow for an

automatic calculated pressure setpoint, determined by

the nominal airow. The “sleep factor” is a lower operating rate for the unit (due to e.g. low occupancy) that will

be activated by speed “III “

Setting Range Factory

setting

Control Supply

Exhaust

Supply+Exhaust

Supply

Ratio exhaust/supply 5...999% 100%

Sleep factor on K3 10...100% 100%

Pressure initialisation Via Airow

Via Pressure

Airow

Start reference initialisation

Yes

No

Yes

Page 30

30

Operation and maintenance instructions – v2.8.8 & 2.7.3

Temperature

The temperature control can be congured as a supply air control or an extract

air control. By default, this function is congured as a supply air temperature

control. Changes to this conguration are done in the advanced setup; see

Section ..

Setting Settings

range

Factory

setting

T° heating 0...45°C 20,0°C

T° Cooling 0...99°C 24,0°C

T° Freecooling 0...99°C 15°C

Fire Alarm

An external re detection system is used to control the air handling unit in case

of emergency. The re alarm function is activated by means of digital input

IN.

Setting Settings

range

Factory

setting

Input Normally open

Normally closed

Normally

closed

Supply airow 0...max

Extract airow 0...max

Periodic maintenance

Built-in timer for maintenance warning; if the maintenance interval is

exceeded, a maintenance reminder will be displayed.

Setting Settings

range

Factory

setting

3 monthly warning Ye s

No

No

12 monthly warning Yes

No

No

Commissioning completed

When the commissioning has been successfull and this is conrmed in this

menu, the commissionig menu will not be activated automatically anymore.

Setting Settings

range

Factory

setting

Conrmation of

successfull commissioning

Yes

No

No

LANGUAGE

UNITS

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

LANGUAGE

UNITS

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

UNITS

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

AIRFLOW REGULATION

TEMPERATURE

FIRE ALARM

BASIC SETUP

PERIODIC MAINTENANCE

PERIODIC MAINTENANCE

COMMISSIONING COMPLETED

Page 31

31

Operation and maintenance instructions – v2.8.8 & 2.7.3

.. ADVANCED SETUP

N.B.! The appearance and content of this menu varies depending on the

type of air handling unit and functions and/or options selected. A code

and a special training are needed to access this menu.

Attention: The settings range for most of the functions

is dened for maximal exibility. The factory setting is the

advised setting, deviating from this setting requires carefull

consideration.

Stop fan with ...V

Function only availalbe if “demand control” function has been selected

in basic setup. With this function, the fans can be stopped if the ...V

control signal is below or above a specied setpoint. The control signal is

connected to the analogue input K.

Setting Settings

range

Factory

setting

Stop if <Vlow No

Yes

Yes

Vlow 0...10V 0,8V

Stop if >Vhigh No

Yes

Yes

Vhigh 0...10V 10,0V

Second ...V control signal

Function only availalbe if “demand control” function has been selected in

basic setup. With this function, a separate ...V control signal for the

extract air can be activated. The control signal is connected to the analogue input K.

Setting Settings

range

Factory

setting

0...10V on K3? No

Yes

No

Control Exhaust

Supply

Exhaust

Pressure control

Function only availalbe if “pressure control” function has been selected

in basic setup. The reaction speed of the fans for the balancing of the

constant pressure system can be modied. A higher Setting will result in a

faster reaction speed; a lower Setting will result in a slowerreaction speed.

The system can be dened as a negative or a positive logic. A negative

logic airow drops when analogue signal on K is than the setpoint.

Setting Settings

range

Factory

setting

Reaction speed 0...10 10

Logic Positive

Negative

Negative

ADVANCED SETUP

STOP FAN WITH 0...10V

2ND 0...10 CONTROL SIGNAL

CONSTANT PRESSURE

SOFT STOP

START TORQUE

ADVANCED SETUP

STOP FAN WITH 0...10V

2ND 0...10 CONTROL SIGNAL

CONSTANT PRESSURE

SOFT STOP

START TORQUE

ADVANCED SETUP

STOP FAN WITH 0...10V

2ND 0...10 CONTROL SIGNAL

CONSTANT PRESSURE

SOFT STOP

START TORQUE

ADVANCED SETUP

Page 32

32

Operation and maintenance instructions – v2.8.8 & 2.7.3

Stop fan when pressure alarm

Possibility to stop the fans automatically in case of a pressure

alarm.

Setting Settings

range

Factory

setting

Stop fans No

Yes

No

Start torque

Possibility to change the fans’s starting torque.

Setting Settings

range

Factory

setting

Start Torque 0...100% 2%

Deactivate sostop

With this function, the “OFF” function is deactivated.

Setting Settings

range

Factory

setting

Sostop Yes

No

No

Temperature

In this menu advanced temperature control parameters can be

modied.

Supply air involves keeping a constant supply air temperature

without consideration to the load in the premises.

Extract air involves keeping a constant temperature in the

extract air duct (premises), by modulating the supply air temperature.

The reaction speed of capacity control signal can be modied.

A higher Setting will result in a smoother control; a lower Setting will result in a faster reaction speed. but also greater risc of

oscillations.

Setting Settings

range

Factory

setting

Supply or Extract temperature control?

Supply

Extract

Supply

Reaction speed 1...10 1

Supply air, min 0...20°C 15,0°C

Supply air, max 16...50°C 28,0°C

Stop fan if T°Supply <5°C No

Yes

No

2ND 0...10 CONTROL SIGNAL

CONSTANT PRESSURE

STOP FAN

START TORQUE

DEACTIVATE SOFTSTOP

ADVANCED SETUP

CONSTANT PRESSURE

STOP FAN

START TORQUE

DEACTIVATE SOFTSTOP

TEMPERTURE

ADVANCED SETUP

CONSTANT PRESSURE

DEACTIVATE SOFTSTOP

TEMPERATURE

BOOST

POST VENTILATION

ADVANCED SETUP

Page 33

33

Operation and maintenance instructions – v2.8.8 & 2.7.3

Boost

The boost mode can be used to force the supply and extract

airow to a higher setpoint, when specic conditions are met.

The boost mode can be activated with a contact connected to

the digital input IN or by an analogue ...V control signal

connected to input K. The boost setpoint is preset in (l/s,

m³/h).

Setting Settings

range

Factory

setting

Supply / Extract airow 0...max

Boost activation on Contact

RH

Contact

RH on / o 0...100% 60% / 40%

Vmin/max RH on K3 0...10V 2,0V / 9,5V

RH ~Vmin/max 0...100% 2% / 95%

Post ventilation

The post ventilation function is used to keep the fans running

during a specied laps of time. This function is activated automatically when an electrical heating coil is activated.

Setting Settings

range

Factory

setting

Activation No

Yes

No

Time 0...9999sec 90sec

DEACTIVATE SOFTSTOP

TEMPERATURE

BOOST

POST VENTILATION

EXTERNAL COILS

ADVANCED SETUP

TEMPERATURE

BOOST

POST VENTILATION

INTERNAL COILS

EXTERNAL COILS

ADVANCED SETUP

Page 34

34

Operation and maintenance instructions – v2.8.8 & 2.7.3

Internal coils

Water preheating coil

By preheating the outdoor air, it is possible to prevent moisture precipitation in the AHU’s outdoor air lter, to reduce

the risk of frosting in the heat exchanger and to eliminate

the risk that pressure sensors and motor control systems are

operating in too low ambient temperature. The setpoint is of

the exhaust air temperature.

Setting Settings

range

Factory

setting

Setpoint -9,9...99,9°C 1,0°C

Electrical preheating coil

By preheating the outdoor air, it is possible to prevent

moisture precipitation in the outdoor air lter of the air

handling unit, to reduce the risk of frosting in the heat

exchanger and to eliminate the risk that the ambient temperature will drop lower than minimum permissible. The

electrical preheating coil is installed and congured in factory. The electrical preheating coil will always have its separate power supply and main switch.

Setting Settings

range

Factory

setting

Setpoint -9,9...99,9°C 1,0°C

PID - Proportional Band 0...100 5

PID - Integral 0...100 30

PID - Derivate 0...100 11

Electrical postheating coil

The electrical postheating coil is installed and congured in

factory. The electrical postheating coil will always have its

separate power supply and main switch. The capacity of the

coil will be controlled proportionally in order to keep a temperature as dened by the selected operating mode.

Setting Settings

range

Factory

setting

Control mode Exhaust

Supply

Supply

Setpoint -9,9...99,9°C 21,0°C

PID - Proportional Band 0...100 5

PID - Integral 0...100 30

PID - Derivate 0...100 11

Water postheating coil

The water postheating coil is installed and congured

in factory. The -way valve is not installed and will have

to be installed and wired on site. The capacity of the

coil will be controlled proportionally in order to keep a

temperature as dened by the selected operating mode.

The output O.R. on the optional “SAT” output relay, is

activated whenever heating is desired.

Setting Settings

range

Factory

setting

Control mode Exhaust

Supply

Supply

Setpoint -9,9...99,9°C 21,0°C

Reaction Speed 1...10 5

BOOST

POST VENTILATION

INTERNAL COILS

EXTERNAL COILS

INTERNAL COILS

ADVANCED SETUP

Page 35

35

Operation and maintenance instructions – v2.8.8 & 2.7.3

External coils

Conguration of the coils

This menu will allow for the conguration of any combination of external heating and or cooling coil(s).

Setting Settings

range

Factory

setting

Type None

Hot water

Cold water

Hot & Cold water

Reversible water

Electric PWM

Electric PWM + Cold water

Water preheating

Water preheating+postheating

Water preheating+reversible

Electric 0...10V

Electric 0...10V + Cold water

None

Water post heating

The external post heating coil is delivered seperately from

the air handling unit and will not be pre congured in

factory. Both the coil and the -way valve will have to be

installed and wired on site. The capacity of the coil will be

controlled proportionally in order to keep a temperature

as dened by the selected operating mode. The reaction

speed can be set. A higher Setting will result in a faster

reaction speed; a lower Setting will result in a slower reaction speed.

Setting Settings

range

Factory

setting

Control mode Exhaust

Supply

Supply

Setpoint 0...99,9°C 21,0°C

Reaction Speed 1...10 5

Water cooling coil

The external post cooling coil is delivered seperately from

the air handling unit and will not be pre congured in

factory. Both the coil and the -way valve will have to be

installed and wired on site. The capacity of the coil will be

controlled proportionally in order to keep a temperature

as dened by the selected operating mode.

Setting Settings

range

Factory

setting

Control mode Exhaust

Supply

Supply

Setpoint 0...99°C 17,0°C

Reaction Speed 1...10 5

Electrical postheating coil

The external post heating coil is delivered seperately from

the air handling unit and will not be pre congured in factory. The coil will have to be installed and wired on site.

The capacity of the coil will be controlled proportionally

in order to keep a temperature as dened by the selected

operating mode.

Setting Settings

range

Factory

setting

Control mode Exhaust

Supply

Supply

Setpoint 0...+99°C 21,0°C

PID - Proportional Band 0...100 5

PID - Integral 0...100 30

PID - derivate 0...100 11

Combi coil

The external change over coil is delivered seperately from

the air handling unit and will not be pre congured in factory. The coil will have to be installed and wired on site.

The capacity of the coil will be controlled proportionally

in order to keep a temperature as dened by the selected

operating mode.

Setting Settings

range

Factory

setting

Activate change over No

Yes

No

Neutral band High 0...+50°C 4K

Neutral band Low 0...+50°C 2K

BOOST

POST VENTILATION

EXTERNAL COILS

FROST PROTECTION

FREECOOLING

ADVANCED SETUP

Page 36

36

Operation and maintenance instructions – v2.8.8 & 2.7.3

Frost protection heating and cooling coils

The water coils are always protected against freezing by

an anti-frost temperature sensor. This sensor is monted

on the surface of the water coil. When the anti-frost

protection temperature of the hydraulic coil detects a

tempeature lower than °C (default), the pump contact

is closed and the way valve is opened % during

minutes. If the unit is running, the alarm is activated

immediately. For a water preheating coil, the frost alarm

is delayed by minutes. If frost protection conditions

occur when the air handling unit is OFF, the alarm is

delayed by minutes.

Setting Settings

range

Factory

setting

Internal heating coil -10...+10°C +4,0°C

External heating coil -10...+10°C +4,0°C

External cooling coil -10...+10°C +4,0°C

Internal preheating coil -10...+10°C +4,0°C

Freecooling

The bypass on the GLOBAL product range, can be congured for freecooling. The main parameters to activate the

free cooling function are the outside temperature (T)

and the extract (room) air temperature (T). When there

is maximal freecooling possibility the bypass will be %

open. The % opened bypass can activate the congurable freecooling airow.

Setting Settings

range

Factory

setting

Outdoor T° 0...27°C 0,0°C

Extract /Room T° 6...28°C 22,0°C

Supply airow (l/s, m³/h)

Extract airow (l/s, m³/h)

Bypass control Frost protection

Freecooling

Frost protection &

free cooling

Freecooling

Frost protection

Frost protection plate heat exchangers (PX)

In environments where the extract air can occasionally

be humid, the defrosting function can be activated to

protect the heat exchanger from frosting. There are four

strategies: down control of the supply air volume, modulating by-pass control, modulation of capacity of a preheating coil, dierential pressure measurement (cold climate option). If non of these measures are eective, the

air handling unit can be stopped by limting the minimal

supply air temperature. When the Frost protection cycle

is active, it will be indicated on the HMI. The congurable

temperatures are outdoor temperatures.

Setting Settings

range

Factory

setting

T° Low 1...3°C +1,0°C

T° High 1...5°C +5,0°C

Stop supply airow No

Yes

Yes

Frost protection rotary heat exchangers (RX)

In environments where the extract air can occasionally be humid, the defrosting function can be activated

to protect the heat exchanger from frosting. The speed

of the rotating heat exchanger is linked to the temperature of the supply (sensor T). When the Frost protection cycle is active, it will be indicated on the HMI.

Setting Settings

range

Factory

setting

Activate Frost protection -10...+99°C -9°C

RX rotation speed 2...10RPM 2RPM

Frost protection cycle active

Frost protection alarm

Frost protection Nominal

Rotation speed

Page 37

37

Operation and maintenance instructions – v2.8.8 & 2.7.3

Modbus conguration

The MODBUS RTU communication requires an additional

satellite circuit (CID) which is used as communication interface. The communication protocol used is

MODBUS RTU, RS.

Setting Settings

range

Factory

setting

Adress 1...247 1

Baudrate 1200

4800

9600

19200

9600

Parity No

Yes

No

LAN conguration

The MODBUS TCP/IP communication requires an additional satellite circuit (CID ) which is used as communication interface. The communication protocol used

is Modbus TCP/IP on Ethernet network over twisted pair

BASE T/Base-TX IEEE ..

Setting Settings

range

Factory

setting

IP conguration DHCP

Manual

Manual

IP adress 192.168.1.1

Netmask 255.255.255.0

Gatway 0.0.0.0

Operating time

For maintenance purposes, operating timers can be activated. If the “service alarm time” or the “Stop fan” timers

are triggered, the according alarm will be shown and the

unit will switch to “OFF”-mode.

Setting Settings

range

Factory

setting

Reset timer No

Yes

No

Fan run time activation No

Yes

No

Display time No

Yes

No

Service alarm time 0...999999h 0h

Stop fan 0...999999h 0h

-V output

The controller has as a standard feature two congurable analogue ...V outputs. The outputs represent the

actual airow (or torque) or the actual pressure delivered

by one of the selected fans.

Setting Settings

range

Factory

setting

Output 1 Flow Fan 1

Pressure Fan 1

Flow Fan 2

Pressure Fan 2

Flow Fan 3

Pressure Fan 3

Flow Fan 4

Pressure Fan 4

Torque Fan 1

Torque Fan 2

Torque Fan 3

Torque Fan 4

Flow Fan 1

Output 2 Flow Fan 1

Pressure Fan 1

Flow Fan 2

Pressure Fan 2

Flow Fan 3

Pressure Fan 3

Flow Fan 4

Pressure Fan 4

Torque Fan 1

Torque Fan 2

Torque Fan 3

Torque Fan 4

Pressure Fan 1

Page 38

38

Operation and maintenance instructions – v2.8.8 & 2.7.3

Attention : before handling and/or opening the access panels it is compulsory to shut down the unit and

disconnect the power supply using the general switch located on the front panel.

Do not isolate the power supply whilst the unit is running. If KWin and\or KWout are installed, then isolate the

corresponding power supplies.

Regular maintenance is essential to guarantee good operation of the air handling unit and a long service life. The

maintenance frequency will depend on the application and on the actual environment conditions but the following are

general guidelines:

Replace the lters with a kit of replacement lters.

- Check for any alarms indicated on the control device. In case of an alarm refer to troubleshooting section.

- Check the state of lter clogging. The control device allows a pre-dened ‘lter alarm’ threshold to be set.

Replace lters if necessary. Filters that are too clogged can generate the following problems:

- Insucient ventilation

- Excessive increase of fan rotation speed

- Excessive sound levels

- Excessive power consumption (power consumption will increase exponentially to an increase

in pressure drop, for a constant airow)

- Unltered air passing through the heat exchanger (risk of clogging) and into ventilated rooms.

The list of replacement lter kits for each unit can be downloaded from our website.

- Inspection and cleaning of the inside of the unit:

• Vacuum clean any accumulations of dust in the unit.

• Inspect and gently vacuum clean the heat exchanger if necessary. Use a brush to protect the ns.

• Clean any condensation stains

• For PX units, clean any accumulations in the drain pan.

7.1 ONCE THE UNIT OPERATES IN NORMAL CONDITION

7.2 EVERY 3 MONTHS

7.0 Preventive maintenance

Page 39

39

Operation and maintenance instructions – v2.8.8 & 2.7.3

1. For rotary heat exchanger (RX) units, check the brush seals on the rotary heat exchanger along the

perimeter in contact with the frame:

If necessary, bring the brush seals closer to the exchanger to ensure good sealing.

2. For RX units, check the tension of the driving belt on the rotating heat exchanger. If there is no tension or if

the belt is damaged, please, contact the service department for a belt replacement.

Ideally the heat exchanger should be cleaned using vacuum cleaner with a so nozzle to prevent damaging the air

passages in the rotor. Turn the rotor by hand to enable you to vacuum clean its entire surface. If the heat exchanger is

substantially fouled, it can be blown clean with compressed air.

3. For plate heat exchanger (PX) units:

• Clean the drain pan

• Clean the inside of the bypass. To access the interior of the bypass it is necessary to force it open, proceed as follows:

place a jumper between terminals IN4 and +12V on the TAC5 circuit board. The bypass is now open, regardless of the

temperature conditions.

• Remember to remove the jumper between terminals IN4 and +12V once cleaning of bypass is done.

• Always clean against the direction of the airow.

• Cleaning must only be done by blowing with compressed air, vacuum cleaning with a so nozzle or through

wet cleaning with water and/or solvent. Before you begin cleaning, cover adjacent functional sections to protect them.

If cleaning solvent is used, do not use solvent that will corrode aluminium or copper.

4. Fan maintenance:

Check again whether the power supply is shut down and fans are not running.

Inspect and clean the fan impellers to remove any dirt deposits, be careful not to alter the impeller balance

(do not remove balancing clips). Check the impeller to make sure that it is not out of balance. Clean or brush o the

fan motor. It can also be cleaned by carefully wiping it with a damp cloth that has been dipped in a solution of water and

detergent. Clean the fan space, if needed. Remove the fans if necessary.

5. Check seals on the unit:

Ensure that the side access panels are fully closed and that the seals are intact. Replace if necessary.

7.3 EVERY 12 MONTHS

Page 40

40

Operation and maintenance instructions – v2.8.8 & 2.7.3

8.0 Troubleshooting

- Conditions:

- Causes:

•

Failure of fan Fx. This problem is usually caused by the fan motor.

If not, the failure may be caused by an internal cable (control or power) or by the TAC5 circuit.

- Eects:

The TAC5 control board generates and reports 18 types of alarms.

The alarms are subdivided into auto resetting and non-auto resetting alarms. For the latter, a reset will be

necessary once the problem has been resolved.

For each type of alarm, a full text description will be displayed on the user interface depending on the alarm type:

- Activation of contact relay (NC or NO contact)- AL 1

- Activation of SAT3 OR1 in case of pressure alarm, provided that the optional module SAT 3 is installed on the control board.

- “Alarm”, “Pa” and “AF” activated LED’s on control board

- Alarm on user interface.

- Alarm communication with networking modules provided that an optional communication module

(Modbus RTU, MODBUS TCP/IP, and KNX) is installed on the TAC5 control board.

8.1 TYPE 1: ALARM INDICATING A FAN FAILURE

Displayed on HMI

Text displayed LED ALARM LED Pa

B.11 Fan 1 failure

RED /

B.12 Fan 2 failure

B.13 Fan 3 failure

B.14 Fan 4 failure

TAC5 control board

AL1 relay O.R.1 LED ALARM LED AF Fans

Alarm / ON / stopped

Auto reset: yes

Page 41

41

Operation and maintenance instructions – v2.8.8 & 2.7.3

- Conditions:

• Mode airow control or demand control. Unit must have forward fans or backward fans with kit CA.

• External pressostat connected on IN2 input

- Causes:

• Pressure alarm setup in airow control or demand control mode

• External pressostat connected on IN2 input has triggered

- Eects:

* unless the status has been changed in advanced setup

8.2 TYPE 2: ALARM ON THE PRESSURE VARIATION

Displayed on HMI

Text displayed LED ALARM LED Pa

P.1 0 Pressure alarm - Supply air

/ REDP. 2 0 Pressure alarm - Extract air

S.40 Pressure variation too great

TAC5 control board

AL1 relay O.R.1 LED ALARM LED AF Fans

/ Closed ON / Run*

Auto reset: yes

Page 42

42

Operation and maintenance instructions – v2.8.8 & 2.7.3

- Conditions:

•

Mode Airow control or Demand control: during the initialization of the pressure alarm. In this case, the unit must have

forward fans or backward fans with kit CA.

•

Mode Pressure control: during the initialization of the pressure reference via airow

- Causes:

The reference pressure (Paref) cannot be identied and the fans are stopped. 4 possibilities:

1. Actual airow < requested airow: The requested working point is ‘too high’ (too high pressure loss)

for the maximal available pressure at the requested airow for this fan.

2. Actual airow > requested airow: the nominal airow requested to initialize the pressure alarm

cannot be reached because the lower limit of the fan’s operating zone has been reached.

3. Very unstable pressure (pumping).

4. Assigned airow not reached aer 3 minutes.

If this occurs during initializing an alarm pressure, there are 2 options:

1. No action is taken: the control will operate without a pressure alarm.

2. Corrective action is taken (change the working point to one located in the working

zone of the fan, by reducing the pressure system, modifying the nominal airow…) and restart the setup operation.

If this occurs during initializing of the assignment pressure in pressure control mode: Corrective action must be taken

(change the working point to one located in the working zone of the fan, by reducing the pressure system,

modifying the nominal airow …) and restart the setup operation.

- Eects:

8.3 TYPE 3: ALARM REPORT DURING REFERENCE PRESSURE INITIALIZATION

Displayed on HMI

Text displayed LED ALARM LED Pa

P. 2 0 Initialisation of the reference pressure - Unstable supply air pressure

RED /

P. 2 1 Initialisation of the reference pressure - Unstable extract air pressure

P. 2 2 Initialisation of the reference pressure - Supply air ow too low

P. 2 3 Initialisation of the reference pressure - Extract air ow too low

P. 2 4 Initialisation of the reference pressure - Supply air ow not reached

P. 2 5 Initialisation of the reference pressure - Extract air ow not reached

P. 2 6 Initialisation of the reference pressure - Supply air ow too high - Min. limit of the motor

P. 2 7 Initialisation of the reference pressure - Extract air ow too high - Min. limit of the motor

TAC5 control board

AL1 relay O.R.1 LED ALARM LED AF Fans

ALARM / ON / Stopped

Auto reset: no

Page 43

43

Operation and maintenance instructions – v2.8.8 & 2.7.3

- Conditions:

- Causes:

•

The setpoint cannot be fullled because the upper or lower limit of the fan’s working zone has been reached

- Eects:

- Conditions:

- Causes:

•

Crucial data from the circuit board has been lost

- Eects:

- Solutions:

•

Try a TOTAL RESET of the data using the advanced setup. If still not resolved, order a new circuit board.

8.4 TYPE 4: ALARM INDICATING THE SYSTEM CANNOT FULFIL THE SETPOINT

8.5 TYPE 5: ALARM INDICATING A DATA FAILURE IN THE CONTROL CIRCUIT

Displayed on HMI

Text displayed LED ALARM LED Pa

S.11 “Constant Pressure” fan 1 - Pressure too low - Maximum air ow reached

RED /

S.12 “Constant Pressure” fan 1 - Pressure too high - Minimum air ow reached

S.13 “Constant Pressure” fan 3 - Pressure too low - Maximum air ow reached

S.14 “Constant Pressure” fan 3 - Pressure too high - Minimum air ow reached

S.20 “Demand control” fan 1 - Air ow too low - Reduce the pressure on this fan

S.21 “Demand control” fan 1 - Air ow too high - Minimum limit of the motor reached

S.22 “Demand control” fan 2 - Air ow too low - Reduce the pressure on this fan

S.23 “Demand control” fan 2 - Air ow too high - Minimum limit of the motor reached

S.24 “Demand control” fan 3 - Air ow too low - Reduce the pressure on this fan

S.25 “Demand control” fan 3 - Air ow too high - Minimum limit of the motor reached

S.34 “Constant Air Flow” fan 3 - Air ow too low - Reduce the pressure on this fan

S.35 “Constant Air Flow” fan 3 - Air ow too high - Minimum limit of the motor reached

Displayed on HMI

Text displayed LED ALARM LED Pa

D.10 Programme Error

RED /

D.20 Data Error

TAC5 control board

AL1 relay O.R.1 LED ALARM LED AF Fans

/ / ON / /

Auto reset: yes

TAC5 control board

AL1 relay O.R.1 LED ALARM LED AF Fans

Alarm status / ON / Stopped

Auto reset: no

Page 44

44

Operation and maintenance instructions – v2.8.8 & 2.7.3

- Conditions:

•

Fire alarm input must be connected to a re detection system

- Causes:

•

Activation of re alarm input, IN3, connected to a re detection system.

IN3 can be congured to work as NO open contact by default or as NC if congured so in the advanced setup.

- Eects:

* The fans are stopped by default in the event of a re alarm but, via the advanced setup, it is

possible to congure a xed airow for supply (contact IN7 needs to be closed) and for exhaust

(contact IN8 needs to be closed).

8.6 TYPE 6: FIRE ALARM

Displayed on HMI

Text displayed LED ALARM LED Pa

F.1 0 FIRE ALARM

RED /

F.1 1 End of the re alarm

TAC5 control board

AL1 relay O.R.1 LED ALARM LED AF Fans

Alarm status / ON / *

Auto reset: no

Page 45

45

Operation and maintenance instructions – v2.8.8 & 2.7.3

- Conditions:

•

the running hours feature must be enabled in advanced setup

- Causes:

• SERVICE ALARM: the fan operating time (in hours) has exceeded the congurable threshold

• STOP FAN: the fan operating time (in hours) has exceeded the congurable threshold. This alarm stops the fans

- Eects:

* unless the status has been changed in advanced setup

- Conditions:

•

User interface is connected

- Causes:

•

Communications failure between the TAC5 circuit and the HMI

- Eects:

8.7 TYPE 7: MAINTENANCE ALARM

8.8 TYPE 8: ALARM INDICATING A COMMUNICATION BREAKDOWN

BETWEEN THE TAC5 CIRCUIT AND THE HMI

Displayed on HMI

Text displayed LED ALARM LED Pa

M.10 Maintenance 3 months

RED /

M.11 Maintenance 6 months

M.21 Operating hours

M.22 Operating hours - AHU o

Displayed on HMI

Text displayed LED ALARM LED Pa

CB COM ERROR Red /

TAC5 control boards

AL1 relay O.R.1 LED ALARM LED AF Fans

Alarm status / ON /

Stopped if SERVICE STOP FAN*

Reset via “fan run time” (HMI) or “alarm menu” (App)

TAC5 control board

AL1 relay O.R.1 LED ALARM LED AF Fans

Alarm status / / / /