Swegon ELQZ-2-504 series, ELQZ-2-504 GOLD, ELQZ-2-504 COMPACT Installation Instructions Manual

Page 1

3. Push the intermediate plate together with cover

upward and hold firmly against the base plate.

GB.ELQZ504480.110202

Specifications are subject to alteration without notice.

www.swegon.com 1

Installation Instructions for theELQZ-2-504 Air Quality Sensor

GOLD/COMPACT

1. General

The carbon dioxide content of the indoor air is an effective

indicator of how many occupants are in a room and the

degree of ventilation required to maintain the air quality

we need. Ventilation control based on CO2 measurements

guarantee the adequate supply of fresh air, and at the

same time keeps energy costs as low as possible.

2. Function

Demand Control

Set the air handling unit to “DEMAND REGULATION”

under the “FAN REGULATION” (CONTROL) function menu

(see the Operation and Maintenance Instructions).

Set the setpoint required as a percentage of the sensor’s

operating range.

If a setpoint of 1000 ppm is required, for instance, set

the setpoint to 50%. Enter the setting under the “FLOW/

PRESSURE” menu group (see the Operation and Maintenance Instructions).

ReCO

2

Set the GOLD unit to ”CO2” under the ”ReCO2” Function

menu (see the Operation and Maintenance Instructions).

Set the setpoint required as a percentage of the sensor’s

operating range.

If a setpoint of 1000 ppm is required, for instance, set

the setpoint to 50%. Enter the setting under the “FLOW/

PRESSURE” menu group (see the Operation and Maintenance Instructions).

3. Mounting

Locate the sensor where the indoor climatic conditions are

typical for the premises. Avoid any spot where the sensor

would be exposed to direct draught or poor air mixture. We

advise locating the sensor at least 2 metres above the

floor to minimize the risk of physical damage or inaccurate

readings due to direct exposure to exhaled air. Access to

the sensor is needed for checking its function and servicing only.

1. Route the cable to where the sensor is to be located.

The cable can be recessed in the wall or other surface and

should then be passed into the air quality sensor through

its bottom section. If the wire is surface-mounted, it can

be passed into the sensor through one of the knockout

lead-throughs in the top of the sensor.

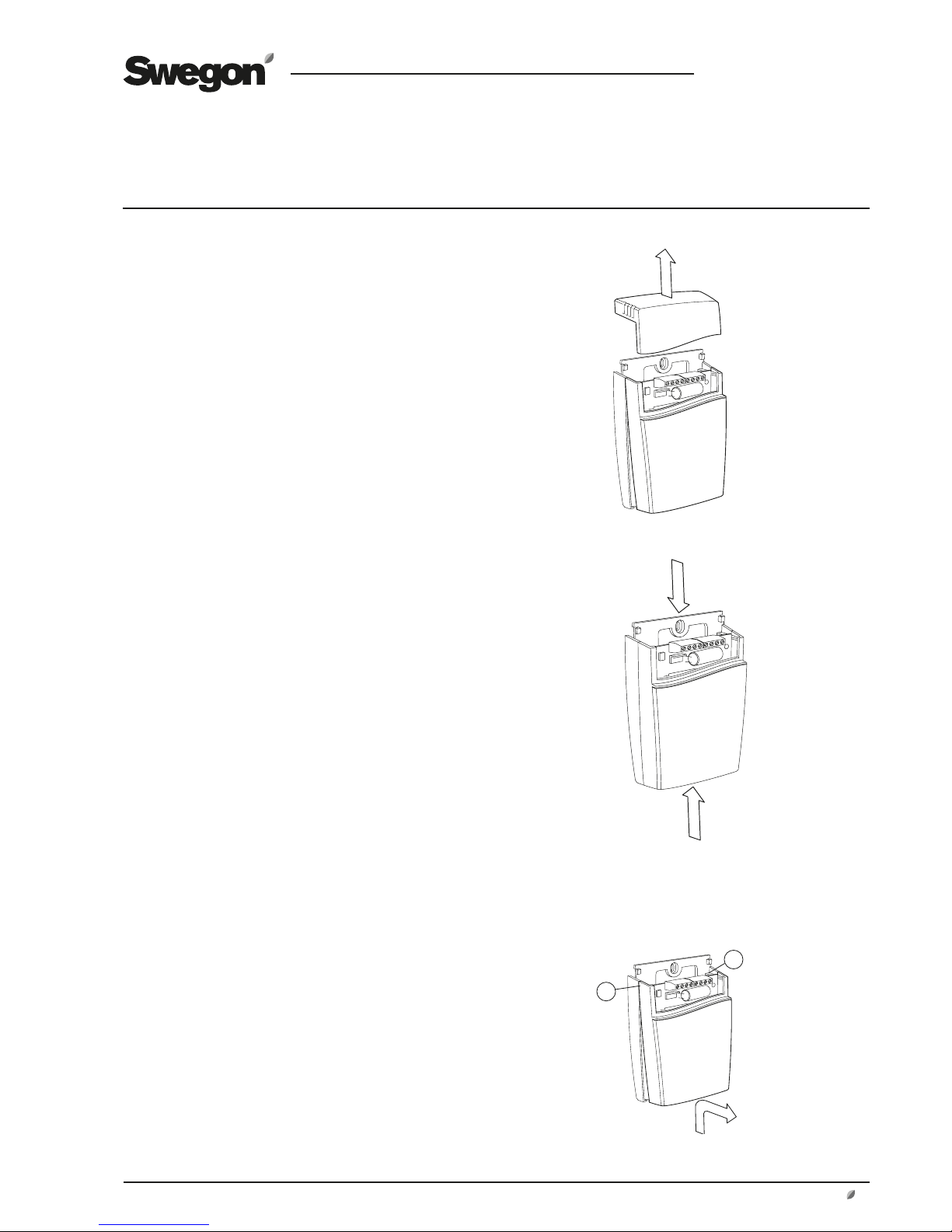

2. Back off the screw and pull the top section straight

upward.

4. Bend the intermediate plate with cover obliquely

outward and detach it from the hooks. 1

1

1

Page 2

GB.ELQZ504480.110202

Specifications are subject to alteration without notice.

2

www.swegon.com

4. Technical Data

Supply voltage 24 V AC ± 20%

Frequency 50/60 Hz

Power consumed 3 W

Output signal 0–10 VDC

Measuring range 500–1500 ppm

Accuracy* ± 1% of the measuring range

± 5% of the reading

Warm-up period < 1 min.

Response time < 2 min.

Wiring nuts for max. 1,5 mm²

Enclosure Class IP 20

Operating temperature 0 till +50 °C

Storage temperature -20 till +70°C

Dimensions (H×W×D) 120×82×30

*The accuracy is defined for continuous operation (at least three weeks

after installation).

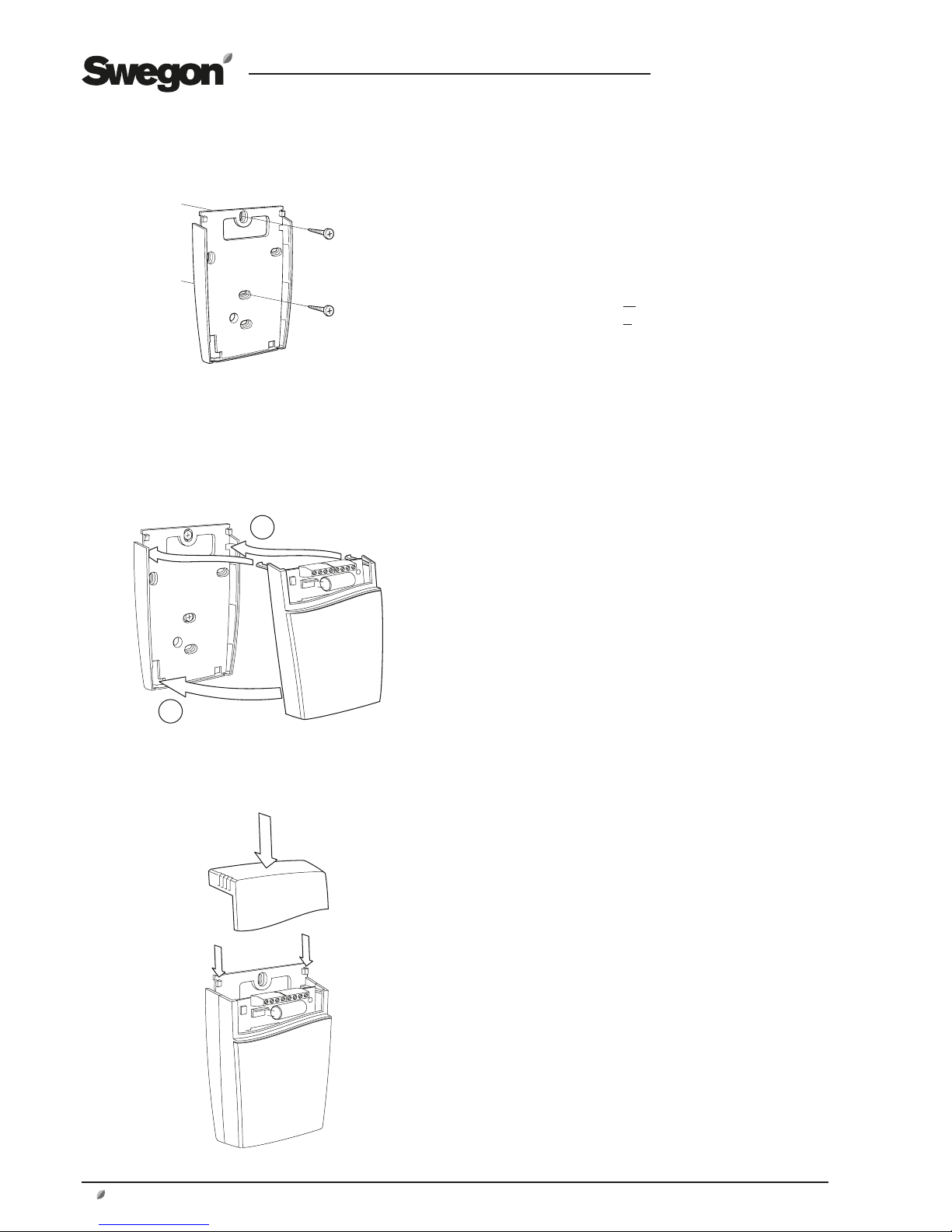

5. Secure the base plate by means of screws to the wall.

The screw head should be max. 4 mm.

A

B

6. A Insert the hooks into the holes in the upper

section of the base plate.

B Press the front against the base plate until its

hooks lock into the bottom edge of the front.

7. Push in the top section under the locking hooks in the

base plate and secure it in position by means of the screw.

Page 3

GB.ELQZ504480.110202

Specifications are subject to alteration without notice.

GOLD RX/PX/CX/SD

www.swegon.com 3

5. Electrical Connections

A qualified electrician should wire electrical connections in

accordance with local regulations.

Demand Control

G+ 1

2

3

G0

20% 0%

Out 1

Out 2

1

G0

G

2

3

20

19

Air quality sensor

IQnomic control unit

GOLD RX/CX

ReCO

2

IQnomic Plus

Air quality sensor

G+ 1

2

3

G0

20% 0%

Out 1

Out 2

1

31

61 G0

60 G+

33

2

A

B

31

33

3

3

Exhaust air fan

Supply air fan

IQnomic control unit

Starting

point

Current

Voltage

Current

Voltage

GOLD RX/PX/CX/SD

A = Control of supply air fan

B = Control of extract air fan

Starting

point

Current

Voltage

Current

Voltage

Applies to GOLD size 100/120 only:

If the total load on wiring terminals

58-59 and 60-61 is higher than 16

VA,you should wire the leads to terminals 201 (G) and 202 (G0). Wiring

terminals 201-202 can be loaded with

a total of max. 48 VA.

Page 4

GB.ELQZ504480.110202

Specifications are subject to alteration without notice.

Demand Control

G+ 1

2

3

G0

20% 0%

Out 1

Out 2

1

35

10 G0

9 G+

37*

2

3

IQnomic control unit

GOLD LP/COMPACT

GOLD LP/COMPACT

*Demand regulation (control) should be selected for

the one fan and slave control should be selected to the

other fan if so desired.

4

www.swegon.com

Air quality sensor

Starting

point

Current

Voltage

Current

Voltage

Loading...

Loading...