Swegon CoolDX 08-1, CoolDX 20-1, CoolDX 08-2, CoolDX 12-2, CoolDX 20-2 Installation And Maintenance Instructions Manual

...Page 1

GB.COOLDX.INST.090301

CoolDX COOLING UNIT

Installation and Maintenance Instructions

Sizes 08-60

Page 2

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

2

www.swegon.com

CONTENTS

1. General Survey 3

1.1 General 3

1.2 Basic function diagram 4

2 Safety instructions 5

2.1 Safety switch/mains power switch 5

2.2 Risks 5

2.3 Electrical equipment 5

2.4 Authorisation 5

2.5 Identification decals 5

3 Installation 6

3.1 Unloading/transport within the building site 6

3.1.1 Lifting using a forklift truck 6

3.1.2 Lifting using a crane 6

3.2 Arrangement 6

3.3 Docking configurations 7

3.3.1 Height adjustment to height of GOLD/water trap 8

3.3.2 Connection to GOLD Units, CoolDX Size 08-12 8

3.3.3 Connection to GOLD Units, CoolDX Size 20-60 9

3.3.4 Duct connection, CoolDX size 08-12 9

3.3.5 Duct connection, CoolDX sizes 20-60 9

3.3.6 Condensate drainage from cooling coil 9

5 Commissioning 12

5.1 Preparations 12

5.1.1 Before initial start up 12

5.1.2 Starting up 12

5.1.3 In-service pressure switches 12

5.1.4 Phase-sequence monitor 12

5.1.5 Remedial action if wrong phase sequence 12

6 Alarms 12

7 Maintenance 13

7.1 Cleaning 13

7.2 Handling of refrigerant 13

7.3 Annual inspection 11

7.4 Servicing 13

8 Troubleshooting and leakage tracing 14

8.1 Troubleshooting Schedule 14

9 Dimensions 15

9.1 CoolDX 08 15

9.2 CoolDX 12 15

9.3 CoolDX 20-40 15

9.4 CoolDX 60 15

3.3.7 Supply air filter 9

3.3.8 Condensation barrier mat 10

4 Electrical connections 11

4.1 Connection to power supply 11

4.2 To connect the communication cable 11

10 General technical data 16

11 Electrical equipment 17

12 Internal Wiring Diagram 18

12.1 CoolDX 08-40, all capacity variants, and size 60,

capacity variant 1 18

12.2 CoolDX 60 Capacity variant 2 19

12.3 CoolDX 60 Capacity variant 3 20

13 Commissioning Record 21

Page 3

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

3

1. GENERAL SURVEY

1.1. General

Cooling unit CoolDX

Cooling unit CoolDX is a complete cooling unit for comfort cooling in air handling systems. All the components

are fully wired, have fully connected refrigeration circuits

and are collected inside a common casing. The casing is

fabricated of aluminium profiled sections held together by

plastic corner pieces. The panels are of sandwich design

and consist of a 0.7-1 mm thick galvanized sheet steel

outer skin with painted visible surfaces (colour: NCS 2005

Y 30R), 1 mm thick aluminium-zinc plated sheet steel

inner skin and 35 mm thick intervening expanded polyurethane isolation.

The cooling coil and condenser are fabricated of copper

tubes and profiled aluminium fins; the casing is made of

galvanized sheet steel.

The cooing units are tested prior to delivery.

The CoolDX is available in 16 output variants which are

divided into six physical sizes, specially suited for the size

08-60 GOLD units.

Compressors

Size 60 units in output variant 2 and 3, contain a piston

compressor and a scroll compressor, all other sizes/output

variants contain two piston compressors each.

Completely direct-acting system

The CoolDX has a completely direct-acting system. It has

an evaporation coil for direct-evaporating refrigerant on

the cold side and a condenser coil on the hot side.

Refrigerant

The CoolDX has double refrigerant circuits separated from

each other. Type R407C refrigerant is used. The refrigerant

circuits are charged on the delivery. At present, this refrigerant has no known influence on the ozone layer and no

known future restrictions are anticipated.

Refrigerant volume

See section 10. General technical data.

Duty to report

If the total volumetric weight of the refrigerant filled into

the cooling system exceeds 10 kg, a report must be submitted to the local supervisory authority.

Annual inspection

If the volumetric weight of the refrigerant in the cooling

unit exceeds 3 kg, an annual inspection by an accredited

inspectorate is required. All the CoolDX units (except size

8, output variant 1) should be checked once a year.

ISO 9001 Quality Management and ISO 14001 Environmental Management Systems

We at Swegon are deeply involved in the maintenance of

our certified quality management system defined by ISO

9001 and our certified environmental management system defined by ISO 14001.

Page 4

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

4

www.swegon.com

1.2 Basic function diagram

COND

VSH2

FD1FD2

HP

HP

BP1-3

IPL1IPL2

M1 M2

VET1VET2

EVAP

VSL1

LP

BP1

VSL2

COND Condenser

VSH1 Overpressure protection

VSH2 Overpressure protection

BP1-3 Pressure limiting switch for high pressure 26 bar

BP1 Pressure limiting switch for low pressure 2,5 bar

BP2-3 Pressure limiting switch for high pressur 26 bar

BP2 Pressure limiting switch for low pressure 2,5 bar

BP1-2 Alarm pressure switch for high pressure 28 bar

BP2-2 Alarm pressure switch for high pressure 28 bar

M1 Compressor

M2 Compressor

VSL1 Underpressure protection

VSL2 Underpressure protection

EVAP Evaporator

VET1 Expansion valve with thermostat

VET2 Expansion valve with thermostat

IPL1 Sight glass, refrigerant circuit 1

IPL2 Sight glass, refrigerant circuit 2

FD1 Filter drier

FD2 Filter drier

Operation

There are two refrigerant circuits in the cooling unit. The

circuits are separate from one another.

Each circuit is equipped with a finned condenser, a finned

evaporator and a compressor.

The two compressors have different capacity, which enables control in 3 steps.

The gaseous refrigerant is compressed by compressors M1

and M2 and from there moves on to condenser COND,

where it is chilled by the extract air and is condensed to

liquid form.

The pressure and the temperature decrease as the refrigerant in fluid form flows through expansion valves VET1

and VET2.

HP

BP2-2BP1-2

HP

BP2-3

LP

BP2

From the expansion valves the refrigerant moves on to

evaporator EVAP, where the refrigerant evaporates and

chills the outdoor air.

From evaporator EVAP, the evaporated refrigerant is conveyed further to the suction side of the compressors where

it is again compressed.

Control

The cooling capacity is regulated in three binary steps by

having one or two compressors in operation.

The cooling compressors are controlled from the GOLD

unit via relays on the IQnomic Plus module mounted in the

CoolDX.

Step 1: When cooling is needed, Compressor M1 is started.

Step 2: If more cooling is needed, Compressor M2 starts

and at the same time Compressor M1 stops. An adjustable time delay (a step duration of 300 seconds) ensures

that Compressor M2 will not start until Compressor M1 is

operating at full capacity.

Step 3: If even more cooling is needed, Compressor M1 is

restarted and is run at the same time as Compressor M2.

This third cooling step is also delayed by a preset time delay setting. In addition, the restarting time (480 seconds)

for Compressor M1 shall have expired.

If less cooling is needed and the compressors are subsequently switched out step-by-step, there will be no delay

between compressors. The restarting time (480 seconds)

for Compressor M1 shall have expired to enable it to start

again in Step 1 after it has been operated in Step 3.

If any compressor is stopped, the restarting time must

expire before a restart can take place. The restart time is

calculated from one start to the next start.

Low pressure switches BP1/BP2 and high pressure switches

BP1-3/BP2-3 (in-service pressure switches for the respective circuit) ensure that the system pressure is within predetermined limits.

If the pressure in the cooling circuit becomes too low, or

if the pressure in the condenser circuit becomes too high,

the compressor is stopped and the text PRESSURE LIMITING is displayed alternately in the hand-held micro terminal of the GOLD air handling unit.

When the restart time has expired, the compressors will try

to restart.

If the pressure increases more, high pressure switches

BP1-2 and BP2-2 will trip and stop the GOLD unit and the

CoolDX cooling unit.

Alarms 85 and 86 will be displayed in the hand-held micro

terminal of the GOLD unit.

Pressure switches BP1-2 and BP2-2 can be manually reset

by pressing a button under each protective sock on the

upper side of the pressure switch. This can be done without removing the protective sock.

Page 5

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

5

2 SAFETY INSTRUCTIONS

2.1 Safety switch/mains power switch

The safety isolating switch is positioned on the inspection

side of the cooling unit.

The safety isolating switch should not be used for starting

or stopping of the cooling unit.

To ensure that the CoolDX is switched off: stop the air

handling unit or briefly switch off the cooling unit via the

hand-held micro terminal. See the GOLD Operation and

Maintenance Instructions.

On completing the above, the safety isolating switch can

be used for switching off the power supply.

Caution!

Always switch off the safety switch whenever you

service the unit, unless otherwise stated in relevant

instructions

2.2 Risks

Warning

Always isolate the power supply before starting any

work in the refrigerant circuit or the electrical system.

Warning

The inspection door of the GOLD unit may not be opened while the unit is in operation. Positive pressure inside the unit will cause the door to fly open and possibly

cause personal injury.

2.3 Electrical equipment

The electrical equipment of the cooling unit is housed in

a separate cubicle located behind one of the inspection

doors.

2.4 Authorisation

Only qualified and authorised electricians shall be permitted to install electrical wiring in the unit.

Only an accredited refrigeration company shall be permitted to modify or repair the refrigeration circuits.

Other modifications in the unit should only be made by

service personnel trained by Swegon.

2.5 Identification decals

The unit identification decal indicating type designation,

serial number, refrigerant volume, etc. is affixed to the

door of the cooling unit.

Type designation: COOLDX-aa-A-c-d-e

GOLD size

Warning

Under no circumstances may the refrigerant circuits be

opened by unauthorised personnel, since they contain

gas under high pressure.

Risk areas where exposure to refrigerant could occur

Practically the whole area inside the cooling unit is a risk

area. For particulars on how to deal with leakage, see

Section 7.2.

Type R 407C refrigerant is used.

Capacity variant

Page 6

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

6

www.swegon.com

3 INSTALLATION

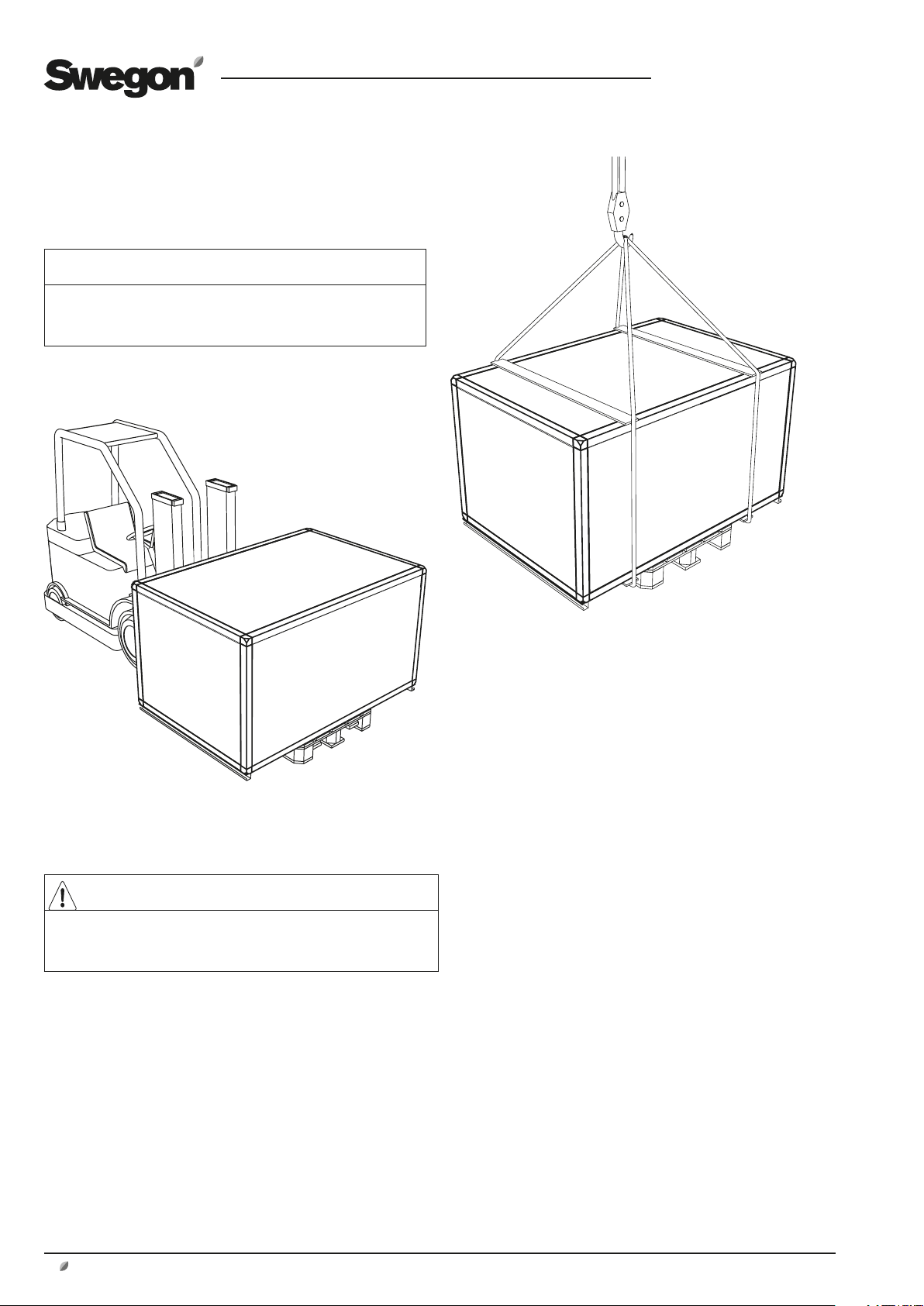

3.1 Unloading/transport

within the building site

Important!

All transport should be carried out with the cooling unit

in the horizontal position.

3.1.1 Lifting using a forklift truck

Warning

The unit has a high centre of gravity! Carefully lift the

cooling unit!

3.1.2 Lifting using a crane

Position two line spreaders at the upper side of the cooling

unit and two under the underside of the pallet or under

the cooling unit and lift in the pallet (or in the base frame

of the cooling unit if the unit is not delivered on a pallet).

3.2 Arrangement

Position the CoolDX cooling unit at suitable place in the

fan room.

Allow an open space around the safety isolating switch/

mains power switch for servicing in accordance with applicable electrical safety regulations.

The unit can be positioned with its backside against a wall;

however it is advisable to position it at a distance of approx. 1 metre away from a wall to make it easier to service

the rear compressor.

See sketch.

Page 7

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

7

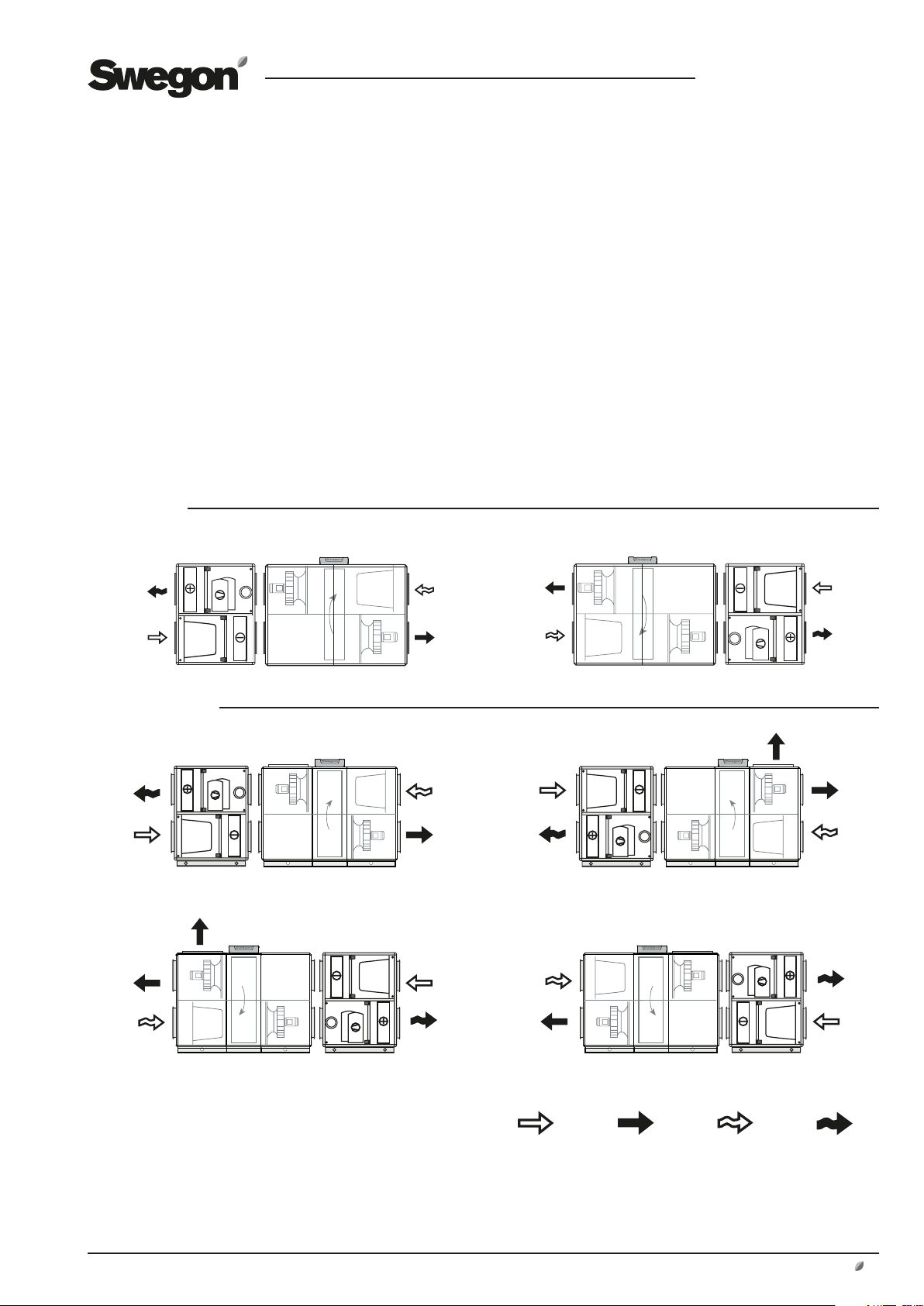

3.3 Docking configurations

The design of the CoolDX cooling unit enables it to be

docked to the outdoor air and exhaust air side of the

GOLD air handling unit. See sketch!

The dimensions and capacities of the CoolDX are designed

for connection to size 08-60 GOLD air handling units.

For a list of the cooling unit sizes and capacities that

match a given size of GOLD unit, see Section 10. General

Technical Data.

CoolDX 08

CoolDX 12-60

Cooling coil in lower level/GOLD fan arrangement 1 Cooling coil in upper level/GOLD fan arrangement 2

Right hand version Left hand version

Right hand version

Left hand version

Cooling coil in upper level/GOLD fan arrangement 1 Cooling coil in lower level/GOLD fan arrangement 2

Outdoor air Supply air Extract air Exhaust air

Page 8

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

8

www.swegon.com

50

3.3.1 Height adjustment to height of GOLD/

water trap

CoolDX, size 08

In combination with GOLD RX 08

The design of the GOLD unit makes it necessary to mount

it on a stand or some other form of support, so that its

inspection doors can be opened. The stand is available as

an accessory.

A corresponding stand is also available as accessory for the

CoolDX.

The heights of the stands are matched to one another and

also provide space for a water trap, if required, for connection at the lower section (right-hand version).

In combination with the GOLD PX 08

The air handling unit is supplied on a 180 mm high base

frame.

A corresponding base frame is also available as an accessory for the CoolDX. The heights of the base frames

are matched to one another and also provide space for a

water trap, if required, for connection at the lower section

(right-hand version).

CoolDX, sizes 12-40

The GOLD air handling unit and the cooling unit CoolDX

are supplied with 100 mm high base beams.

Applicable to cooling coil in lower level:

If a water trap (accessory) is fitted, the GOLD unit and

the cooling unit must be raised at least 50 mm to provide

space for the water trap. Adjustable support feet (accessories) can be appropriately fitted to the base beams for

this purpose.

3.3.2 Connection to GOLD Units, CoolDX Size 08-12

Insert rubber ring seals (2 rings, not included in the supply)

into the circular outdoor air and exhaust air connections of

the GOLD unit respectively. See the installation instructions

for the GOLD, as well.

If the CoolDX is to be docked directly against the GOLD

unit:

Use a forklift truck or a hand truck to position the CoolDX

against the GOLD unit as described in Section 3.3 Docking Configurations. Make sure that the rubber seals on

the GOLD unit engage into the duct connections on the

CoolDX unit. See sketch!

Important! Be careful to prevent damage to the unit and

the rubber ring!

Rubber ring seal

CoolDX

GOLD

Distance, GOLD/CoolDX

CoolDX, sizes 60

The GOLD air handling unit and the cooling unit CoolDX

are supplied with 100 mm high support feet. The support

feet can be removed or left on the unit.

Applicable when cooling coil in lower level:

If a water trap (accessory) is fitted, the GOLD unit and the

cooling unit must be raised at least 50 mm above the base

beams to provide space for the water trap. This can appropriately be done by leaving the factory-fitted support feet

on the base beams. Or you can replace them with adjustable feet (accessory).

CoolDX

GOLD

If the CoolDX is to be located at another place:

Position the CoolDX at an appropriate place in the fan

room. Insert rubber ring seals (2 rings, not included in the

supply) into the relevant circular duct connections on the

CoolDX. See Section 3.3 Docking Configurations.

Connect the ducts between the GOLD unit and the

CoolDX unit.

It may be necessary to extend the communication cable

and necessary tubing (not included in the supply) depending on the distance between the GOLD unit and the

CoolDX unit.

Page 9

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

9

71

3.3.3 Connection to GOLD units, CoolDX Sizes 20-60

Fit the sealing strip onto the GOLD unit’s outdoor air and

exhaust air connections respectively. See the installation

instructions for the GOLD, as well.

If the CoolDX is to be docked directly against the GOLD

unit:

Use a forklift truck or a hand truck to position the CoolDX

against the GOLD unit as described in Section 3.3 Docking

Configurations. Make sure that the connections on the

GOLD unit and the CoolDX unit are in alignment and are

close to one another.

Important! Be careful to prevent damage to the unit!

Joint the connections together with slip clamps (accessories: TBLZ-2-aa-08 slip clamps ). See the installation

instructions for the GOLD.

Distance, GOLD/CoolDX

CoolDX

The condensate discharge pipework shall be connected

across a water trap (accessory) to the drain connections of

the cooling unit and shall run with continuous slope to a

drain gulley.

Nipples in the

intermediate deck

Pressure

transducer

Interconnection nipples

White hose

Blue hose

CoolDX

GOLD

Extract air fan

Existing hoses for measuring

the pressure drop across the

filter in the GOLD

Duct connection

GOLD

If the CoolDX is to be located at another place:

Position the CoolDX at an appropriate place in the fan

room. Connect ducts between the GOLD unit and the

CoolDX unit, arranging the connections as described in

Section 3.3 Docking Configurations.

Joint the ducts and connection spigots together with slip

clamps (accessories: TBLZ-2-aa-08 slip clamps ). See the

installation instructions for the GOLD.

It may be necessary to extend the communication cable

and necessary tubing (not included in the supply) depending on the distance between the GOLD unit and the

CoolDX unit.

3.3.4 Duct connection, CoolDX Size 08-12

Fit rubber ring seals (not included in the supply) to the

CoolDX for connection to circular ducting. See the installation instructions for the GOLD, as well.

3.3.5 Duct connection, CoolDX Sizes 20-60

The size 20-60 CoolDX cooling units have rectangular connections. Use slip clamps (accessories: TBLZ-2-aa-08 slip

clamps) for jointing to ducts.

3.3.6 Condensate drainage from cooling coil

The cooling unit is equipped with a drain tray below the

cooling coil for collecting condensate that drips from coil

surfaces.

3.3.7 Supply air filter

The CoolDX is supplied with its own supply air filter. Consequently, the supply air filter in the GOLD unit should be

dismantled.

The hoses for measuring air pressure drop across the

supply air filter are supplied in the CoolDX and are connected inside the CoolDX at the factory. These hoses must

however be connected to supply air filter pressure drop

measurement hoses inside the GOLD unit. To do this,

proceed as follows:

Extend the hoses from the CoolDX unit, through the duct

connections of both units to the extract air fan space inside the GOLD unit. Disconnect the existing filter pressure

drop hoses from the pressure drop measurement nipples

in the intermediate deck of the GOLD. To prevent leakage,

use an appropriate sealant to seal the nipples in the intermediate deck.

IMPORTANT! Do not disconnect the hoses from the pressure transducer as doing so is likely to damage the hose

connections on the pressure transducer.

Connect the blue hose from the CoolDX to the blue hose

from the pressure transducer of the GOLD unit using the

interconnection nipples supplied. Connect the white hoses

in the same way. See above sketch.

IMPORTANT! There are other variants besides those

shown in the sketch. See Section 3.3 Docking Configurations.

Position and secure the hoses by means of bundling straps,

for example.

Page 10

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

10

www.swegon.com

3.3.8 Condensation barrier mat

Install condensation barrier mats (supplied) on the interior

surfaces of the connections between the GOLD air handling unit and the CoolDX as illustrated below, to prevent

condensate from reaching metallic surfaces.

The condensation barrier mats are self-adhesive. Open the

inspection doors on the GOLD air handling unit and install

the mats from this side.

A

Cross section A-A

A

Open the inspection doors. Fit the condensation barrier mat

onto the interior surfaces of the

connections between the GOLD

unit and the CoolDX.

Page 11

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

11

4 ELECTRICAL CONNECTIONS

Important

Electrical installations must be carried out by an authorised electrician.

4.1 Connection to power supply

Connection to the mains power supply must be wired

across the safety isolating switch on the front panel of the

cooling unit. Remove the four screws on the safety switch

enclosure and remove the lid. There are knockout holes on

the sides of the enclosure serving as cable lead-throughs.

Connect the 400 V power supply (5-conductor system,

except for the size 60 CoolDX in capacity variant 3 that has

a 4-conductor system) directly to the safety isolating switch,

which has four normally-closed contact functions (three for

the size 60 CoolDX, capacity variant 3). The terminal for the

incoming earth conductor is situated right next to the safety

switch. See sketch.

The ambient temperature and the way the cable is placed

must be taken into account when sizing the power cable.

Technical data, see Section 10.

Connect power

supply here

Factory

mounted

cables

4.2 To connect the communication cable

Only one communication cable is required for transferring

information between the controls of CoolDX and the GOLD.

All operating status and other information can be accessed

and read in the hand-held micro terminal of the GOLD unit.

The communication cable is pre-wired to the electrical

equipment inside the CoolDX unit and is coiled up behind

the inspection door.

The communication cable is to be lead out through the

predrilled hole in the cover plate on the inspection side of

CoolDX. First fit the rubber sleeve, supplied, into the predrilled hole to serve as a cable gland. Then lead the communication cable in a secure manner through the rubber sleeve

and from the CoolDX to the junction (wiring) hood of the

GOLD.

To connect the cable to the GOLD

Connect the communication cable to any of the bus connections on the control unit. See encircled area in sketch.

.

Use one of the holes in the oblong rubber clad cable

gland on the back side of the junction hood of the electrical cubicle, to extend the cable to control unit. See

sketch.

Push aside part of the cable gland to insert the communication cable through it. Connect the cable to an

optional bus connection on the control unit. Adjust the

length of cable inside the electrical cubicle and adjust its

position through the cable gland. Refit the cable gland

back to its correct position.

An extra outdoor air temperature sensor is required if

any of the following functions are activated in the GOLD

air handling unit: outdoor compensation, cooling step

blocking, cooling boost, summer night cooling, CoolDX

comfort control and pump control for the heating coil.

Use the TBLZ-1-30 accessory for mounting an outdoor

air temperature sensor in the ductwork upstream of the

CoolDX. Use the TBLZ-1-24/25 for installing the outdoor

air temperature sensor outdoors.

If outdoor air temperature readings are obtained via

communication to the GOLD air handling unit, then no

extra temperature sensor is needed.

Page 12

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

12

www.swegon.com

1

1

2

3

4

5

6

7

8

9

0

P1 L1 L2

632457 12981011

13 181514 1617 19 242120 22 23

Rsf 077

CAREL

ok

alarm

5 COMMISSIONING

5.1 Preparations

5.1.1 Before initial start up

• The power supply must be connected.

• The communication cable to the GOLD air handling

unit should be connected to one of the connections

marked Internal EIA-485.

• Check that all fuses and protective motor switches are

on.

The control system of the GOLD has a pre-programmed factory

setting, which makes the cooling unit ready to use after basic

settings have been entered. The CoolDX function should be

activated. See the Operation and Maintenance Instructions for

the GOLD dealing with managing the menus in the hand-held

micro terminal.

5.1.2 Starting up

• Set the safety isolating switch of the cooling unit to

position ON.

• Check that light-emitting diode L2 on the IQnomic

Plus module steadily shines (24 V supply), and that

light-emitting diode L1 is flashing (communication).

The function selector switch should be in position 6.

• Check in the hand-held micro terminal of the GOLD

unit that Auto Operation has been selected as the air

handling unit’s cooling function (under Operation

Mode), and that CoolDX Economy or CoolDX Comfort

has been selected under Cooling Regulation.

• Go to the Manual Test Menu in the hand-held micro

terminal of the GOLD unit. See the Operation and

Maintenance Instructions for the GOLD unit.

Navigate to IQnomic Plus and CoolDX.

• Check: Start one compressor at a time. If any

compressor doesn’t start, an alarm will be initiated.

For the size 60, capacity variants 2 and 3, CoolDX

units, the rotation direction of compressor no. 2 is

important. See Section 5.1.4 Phase sequence monitor.

• Set the compressors to 0 (stop).

• Go back to the main menu.

• CoolDX is now ready for operation and will start when

there is a cooling load.

5.1.4 Phase-sequence monitor

The size 60 CoolDX, capacity variants 2 and 3, are equipped with

a phase sequence monitor for compressor 2.

The phase sequence monitor for capacity variant 2 is installed in

the electrical equipment cubicle, see illustration.

The phase sequence monitor for capacity variant 3 is integrated

with the compressor and is installed in its connection box. It lacks

visible indication LEDs.

Alarm 86, CoolDX K2 tripped, is displayed in the hand-held micro terminal of the GOLD unit. In the event that Alarm 86 trips,

this may be due to several causes: incorrect phase sequence,

tripped protective motor switch, tripped high pressure switch

(BP2-2) or the absence of control voltage.

Electrical equipment in the CoolDX

1

Applicable to size 60, capacity variant 2 only:

When LED 1 is lit, there are at least two phases.

When LED 2 is lit, the phase sequence is correct..

2

5.1.5 Remedial action if wrong phase sequence

Warning

May only be carried out by an authorised electrician or

trained service personnel.

• Stop the CoolDX by selecting SHUT OFF in the menu SETTINGS.

• Set the safety switch to position OFF on the CoolDX.

• Isolate the power supply to the CoolDX.

5.1.3 In-service pressure switches

The CoolDX has two in-service pressure switches in each cooling

circuit, one for low pressure and one for high pressure.

If the operating pressure, in any of the circuits, exceeds or drops

below a limit value, the relevant compressor is switched off. The

text CoolDX PRESSURE LIMITING is displayed in the hand-held

terminal until the pressure comes within the limit values again.

The compressor is permitted to restart when the restart delay has

expired.

Important

Check that the incoming power supply to the CoolDX is

isolated by measuring.

• Transpose the two phase wires on the incoming power

supply cable in order to obtain correct phase sequence

(direction of rotation).

• Reconnect on power supply to the CoolDX.

• Set the safety isolating switch to the ON position.

• Start the CoolDX as described in Section 5.1.2 Starting up.

6 ALARMS

For a description of the alarms, see the Operation and Maintenance Instructions for the GOLD.

Page 13

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

13

7 MAINTENANCE

7.1 Cleaning

Use a vacuum cleaner and a damp cloth to clean the interior of the cooling unit, if needed.

Inspect the unit at least twice a year.

7.2 Handling refrigerant

Type R 407C refrigerant is used.

The refrigerant circuit is already charged when the unit is

delivered.

Warning

Under no circumstances shall unauthorised personnel be

permitted to open the refrigerant circuits, as long as gas

under high pressure is present in the circuits. Only the

technicians of an accredited refrigeration company shall

be permitted to modify or repair the refrigerant circuit s.

The CoolDX is equipped with a safety valve to prevent

excessively high pressure in the system if high temperatures caused by a fire, for example.

Important

Charging with refrigerant must be carried out according

to the recommendations of the refrigerant producer.

Avoid direct skin contact with the refrigerant.

Use close-fitting protective eyeglasses, protective gloves

and protective work clothing that cover the whole body.

Provide adequate ventilation/local extraction.

In the event of eye contact

Flush the eyes using an emergency eye-wash shower

(alternating with lukewarm water) for 20 minutes. Seek

a doctor.

In the event of skin contact

Thoroughly wash with soap and lukewarm water.

In the event of frostbite

Seek a doctor.

Important

Contact Swegon Service if you detect any refrigerant

leakage.

Warning

If refrigerant is exposed to fire or in some other way

becomes superheated in the atmosphere, poisonous

gases can form.

7.3 Annual inspection

An annual check carried out by an accredited inspectorate

is required if the volume of refrigerant in the cooling unit

exceeds 3 kg. See 10, General technical data.

Obligation to report

You are obligated to file a report with the local supervisory

authorities only if the total volume of refrigerant charged

in refrigerating units at a given company exceeds 10 kg.

7.4 Servicing

Only service personnel trained by Swegon shall be permitted to modify the cooling unit.

Page 14

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

14

www.swegon.com

8 TROUBLESHOOTING AND

LEAKAGE TRACING

8.1 Troubleshooting Schedule

Symptom Possible cause Remedial measure

Compressor is not operating

Too low cooling capacity

The low pressure switch switches

off the compressor.

The high pressure switch switches

off the compressor.

Significant freezing on the

evaporator.

The voltage has been isolated.

Size 60, capacity variants 2 and 3: Incorrect phase

sequence.

The compressor safety circuit has been broken.

Defective compressor.

The voltage has been isolated.

Size 60, capacity variants 2 and 3: Incorrect phase

sequence.

No airflow or too low airflow across the evaporator.

Thermostat/control equipment incorrectly set or defective.

Inadequate refrigerant.

No airflow or too low airflow across the evaporator.

The expansion valve is defective.

The low pressure switch is defective.

No airflow or too low airflow across the condensor.

Excessively high exhaust air temperature

The high pressure switch is defective.

The expansion valve is defective or incorrectly set.

No airflow or too low airflow across the evaporator.

Check the operating/safety switch. Check the condition of the fuses.

Check and change the phase sequence.

Check, reset if needed.

Replace the compressor.

Check the operating/safety switch. Check the condition of the fuses. .

Check and change the phase sequence.

Check the airflow.

Adjust the setting or replace faulty components.

The cooling system is leaking. Tighten the leak and

charge with refrigerant.

Check the airflow.

Check, replace.

Check, replace.

Check the airflow.

Check the exhaust air temperature.

Check. replace.

Check. Replace or adjust setting

Check the airflow.

8.2 Leakage Tracing

As a preventive measure, the cooling system should be

inspected at least once per year to detect possible leakage.

The leakage tracing inspection must be documented.

If the cooling system is leaking, this will become apparent

firstly by impaired cooling performance, or if the leakage is

substantial, when the cooling unit does not operate at all.

If you suspect that the cooling system is leaking refrigerant, check the level of refrigerant in the sight glass located

on the liquid line of the cooling unit.

If you see continuous and a substantial amount of bubbling in the sight glass and the cooling unit operates at appreciably lower capacity than normal, the system is probably leaking. One or several bubbles appearing when the

cooling unit is started up, operation at reduced capacity or

normal operation need not necessarily indicate a refrigerant deficiency.

If it is bubbling in the sight glass and the cooling unit operates at appreciably lower capacity, call for qualified service

help.

N.B.! Maintenance work in the refrigerant system is permitted to be carried out only by an accredited inspectorate

(a company with requisite authorisation).

Page 15

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

15

9 DIMENSIONS

46 46 5050 K

46 46

50

50

K

46 465050 K

9.1 CoolDX 08

9.2 CoolDX 12

9.3 CoolDX 20-40

CoolDX,

size

08 1250 990 1086 Ø 400

CoolDX,

size

12 1250 1199 1394 935 Ø 500

CoolDX,

size

20

30

40

L

(length)

mm

L

(length)

mm

L

(length)

mm

1250

1250

1250

B

(width)

mm

B

(width)

mm

B

(width)

mm

1294

1595

1886

H

(height)

mm

H

(height)

mm

H

(height)

mm

1394

1696

1986

Duct connection

K

mm

connection

K

mm

connection

1036

1000 x 400

1336

1200 x 500

1706

1400 x 600

mm

Duct

mm

Duct

mm

9.4 CoolDX 60

Supplied on 100 mm high support feet. Can be removed or left on when

the unit is in place. Has provision for adjustable support feet

CoolDX,

size

60 1250 2253 2353 2075 1600 x 800

L

(length)

mm

B

(width)

mm

H

(height)

mm

K

mm

Duct

connection

mm

Page 16

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

16

www.swegon.com

10 GENERAL TECHNICAL DATA

Cooling system CoolDX

CoolDX Capacity Rated Rated Refrigerant Minimum Power supply Weight

Size variant cool. power power req. data R407c (kg) airflow (kg)

(kW) 1) (kW) Circuit 1 Circuit 2 (m3/s)

08-1 1 10 3,69 1,2 1,6 0,46 3-phase, 400V, 16A 247

08-2 2 14 5,02 1,2 2,2 0,46 3-phase, 400V, 16A 257

12-1 1 14 4,95 1,3 2,7 0,68 3-phase, 400V, 16A 305

12-2 2 20 6,94 1,4 2,9 0,9 3-phase, 400V, 20A 332

20-1 1 14 4,95 1,3 2,7 0,68 3-phase, 400V, 16A 323

20-2 2 20 6,94 1,4 2,9 0,9 3-phase, 400V, 20A 351

20-3 3 26 9,88 2,3 3,3 0,9 3-phase, 400V, 25A 373

30-1 1 27 9,00 2,0 4,2 1,25 3-phase, 400V, 25A 440

30-2 2 32 10,66 2,2 4,7 1,5 3-phase, 400V, 32A 486

30-3 3 45 16,47 3,4 5,6 1,5 3-phase, 400V, 40A 527

40-1 1 39 12,24 2,6 5,3 1,8 3-phase, 400V, 40A 572

40-2 2 45 14,54 2,9 5,9 2,1 3-phase, 400V, 40A 605

40-3 3 58 21,42 5,1 8,1 2,1 3-phase, 400V, 63A 672

60-1 1 58 18,94 4,9 8,0 2,6 3-phase, 400V, 50A 720

60-2 2 69 20,20 4,9 8,0 3,2 3-phase, 400V, 63A 819

60-3 3 95 33,18 7,9 11,9 3,2 3-phase, 400V, 80A 944

1)

For an outdoor temperature of 28°C, 50% RH and an extract air temperature of 25°C.

Sizing

There are many factors that influence what size of cooling

unit is required.

The CoolDX units have been designed to enable them to

meet many different prerequisites.

For correct sizing we refer to our ProUnit unit selection

program.

Page 17

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

17

11 ELECTRICAL EQUIPMENT

1

2

3

4

5

6

7

8

9

0

P1 L1 L2

632 457 1298 1011

13 181514 1617 19 242120 2223

1

2

3

4

5

6

7

8

9

0

P1 L1 L2

632 457 1298 1011

13 181514 1617 19 242120 2223

1

1

2

3

4

5

6

7

8

9

0

P1 L1 L2

632 457 1298 1011

13 181514 1617 19 242120 2223

The electric equipment in the CoolDX is located behind

the inspection door.

For a diagrammatic description, see the wiring diagram.

Sizes 08-20, all capacity variants

Size 30, capacity variant 1

2

1

5

3

6

4

Size 30, capacity variant 2 ands 3

Size 40, all capacity variants

Size 60, capacity variant 1 and 2

2

1

5

3

6

Size 60, capacity variant 3

85

2

1

3

9

4

1. Protective motor switch with auxiliary contact for compressor 1.

2. Protective motor switch with auxiliary contact for compressor 2.

3. Contactor with auxiliary contact for compressor 1.

4. Contactor with auxiliary contact for compressor 2.

5. Control circuit fuse.

6. IQnomic Plus, control unit.

7. Phase sequence monitor, applies to size 60, capacity variant 2 only.

8. Transformer, 400/230 V for control voltage

9. Fuse, 230 V, operating voltage.

6

4

7

Page 18

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

18

www.swegon.com

12 INTERNAL WIRING DIAGRAM

12.1 CoolDX 08-40, all capacity variants, and size 60, capacity variant 1

Q = Electrical circuit load separator, connection point for supply voltage

Mx = Compressor

PSC = Controls for phase sequence

BPx = Low and high pressure switch

BPx-x = High pressure switch

Hx = Crankcase heater

Page 19

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

19

12.2 CoolDX 60 Capacity variant 2

Q = Electrical circuit load separator, connection point for supply voltage

Mx = Compressor

PSC = Controls for phase sequence

BPx = Low and high pressure switch

BPx-x = High pressure switch

Hx = Crankcase heater

TP = Thermal overload protection for scroll compressor

Page 20

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

20

www.swegon.com

12.3 CoolDX 60 Capacity variant 3

Q = Electrical circuit load separator, connection point for

supply voltage

Mx = Compressor

PSC = Controls for phase sequence

BPx = Low and high pressure switch

BPx-x = High pressure switch

Hx = Crankcase heater

TP = Thermal overload protection for scroll compressor

Page 21

GB.COOLDX.INST.090301

We reserve the right to alter specifications.

www.swegon.com

21

13 Commissioning Record

Company

Our reference

Client Date SO No.

Plant Project/Air handling unit Subject No.

Plant address Type/Size

Installation/Connections

Inspection measure

Installation according to instructions

Condensate drain correctly connected, water trap filled with water

Supply air filter in GOLD unit dismantled

Air hoses for filter in CoolDX fitted according to instructions

Electrical connections installed according to instructions

Control cable from CoolDX to GOLD connected according to instructions

Direction of rotation of compressor 2 checked

(Applicable to CoolDX, size 060, capacity variants 2 and 3)

Approved/

Done Remarks

Page 22

GB.COOLDX.INST.090301

Item inspected CoolDX, size Factory-preset amperage Factory-preset value

Protective motor switch, Compressor 1 08-1 5,0 A

Protective motor switch, Compressor 2 7,5 A

08-2 6,0 A

10,0 A

12-1 5,0 A

10,0 A

12-2 7,5 A

12,0 A

20-1 5,0 A

10,0 A

20-2 7,5 A

12,0 A

20-3 10,0 A

15,5 A

30-1 9,5 A

15,5 A

30-2 9,5 A

22,0 A

30-3 15,5 A

27,0 A

40-1 12,0 A

22,0 A

40-2 12,0 A

27,0 A

40-3 22,0 A

36,0 A

60-1 15,5 A

36,0 A

60-2 22 A

60-3 36,0 A

Function selector switch, IQnomic Plus Position 6

22

www.swegon.com

35,0 A

50,0 A

We reserve the right to alter specifications.

Loading...

Loading...