Swegon COOL DX 008, COOL DX Series, COOL DX 012, COOL DX 040, COOL DX 030 Installation And Maintenance Instructions Manual

...Page 1

Chiller COOL DX version G

Installation and Maintenance Instructions

SILVER C, size 008-080

COOL DX

GB.COOLDX.SI.G.190603

The document was originally written in Swedish.

Page 2

CONTENTS

GB.COOLDX.SI.G.190603

1. Overview 3

1.1. General 3

1.2 Basic function diagram 4

2 Safety Instructions 5

2.1 Safety Isolating Switch/Main Switch 5

2.2 Risks 5

2.3 Electrical equipment 5

2.4 Authorisation 5

2.5 Decals 5

3 Installation 6

3.1 Unloading/site transport 6

3.1.1 Handling with truck 6

3.1.2 Handling with crane 6

3.2 Arrangement 6

3.3 Basic Installation Diagram COOL DX 7

3.3.1 Height adaptation to SILVER C/water trap 8

3.3.2 Connection to SILVER C air handling unit,

COOL DX, sizes 008-012 9

3.3.3 Connection to SILVER C air handling unit,

COOL DX, sizes 020-040 10

3.3.4 Connection to SILVER C air handling unit,

COOL DX, sizes 060-080 11

3.3.5 Stand-alone COOL DX 11

3.3.6 Supply air filter 11

6 Alarms 14

7 Maintenance 15

7.1 Cleaning 15

7.2 Handling of refrigerant 15

7.3 Leakage tracing interval/Obligation to report 15

7.4 Service 15

8 Trouble shooting and leakage tracing 16

8.1 Troubleshooting Schedule 16

8.2 Leakage Tracing 16

9 Dimensions 17

10 General technical data 18

11 Internal wiring diagram 19

12 Commissioning Record 23

4 Power connection 12

4.1 Supply connection 12

4.2 Connection of signal, 0 – 10 V 12

5 Commissioning 13

5.1 Preparations 13

5.1.1 Before initial start up 13

5.1.2 Control functions 13

5.1.3 Pressure sensor 13

5.1.4 Phase sequence monitor 14

5.1.5 Measure whether the phase-sequence is wrong 14

2 www.swegon.com

We reserve the right to alter specifications.

Page 3

1. OVERVIEW

1.1. General

GB.COOLDX.SI.G.190603

COOL DX Chiller

Chiller COOL DX is a complete chiller for comfort cooling

in the air handling system. All the components refrigeration engineering-wise and electrically pre-wired and collected inside a common casing. The outer skin is made

of galvanized sheet steel, pre-painted in Swegon’s grey

metallic colour (closest comparable: RAL, 9007). The inner

skin material is aluminium-zinc coated sheet steel. Environmental class C4. Panel thickness of 52 mm with intervening insulation consisting of mineral wool.

The cooling coil and condenser are fabricated of copper

tubing and profiled aluminium fins; the casing is made of

galvanized sheet steel.

The chillers are test run prior to delivery.

The COOL DX is available in 19 capacity variants spread

on nine physical sizes, designed for use with the size 008 080 SILVER C air handling units.

Compressors

The compressor in the COOL DXchiller is of scroll compressor type and/or rotary compressors.

Refrigerant

The COOL DX has double refrigerant circuits, which are

separate from each other. Type R410A refrigerant is used.

The refrigerant circuits are charged with refrigerant on

delivery. At present, this refrigerant has no known influence on the ozone layer and no known future restrictions

are anticipated.

Refrigerant volume

See section 10. General technical data.

Installation check/Obligation to report/

Leakage tracing interval

Must be carried out according to the F-Gas Regulation

EU/517/2014 and associated local legislation.

Quality System to ISO 9001

and Environmental Management System to ISO

14001

Swegon AB works to a certified quality system that conforms to ISO 9001 standard and a certified Environmental

Management System that conforms to ISO 14001.

Completely direct-acting system

The COOL DX has a completely direct-acting system. It has

an evaporation coil for direct-evaporating refrigerant on

the cold side and a condenser coil on the hot side.

We reserve the right to alter specifications.

www.swegon.com 3

Page 4

GB.COOLDX.SI.G.190603

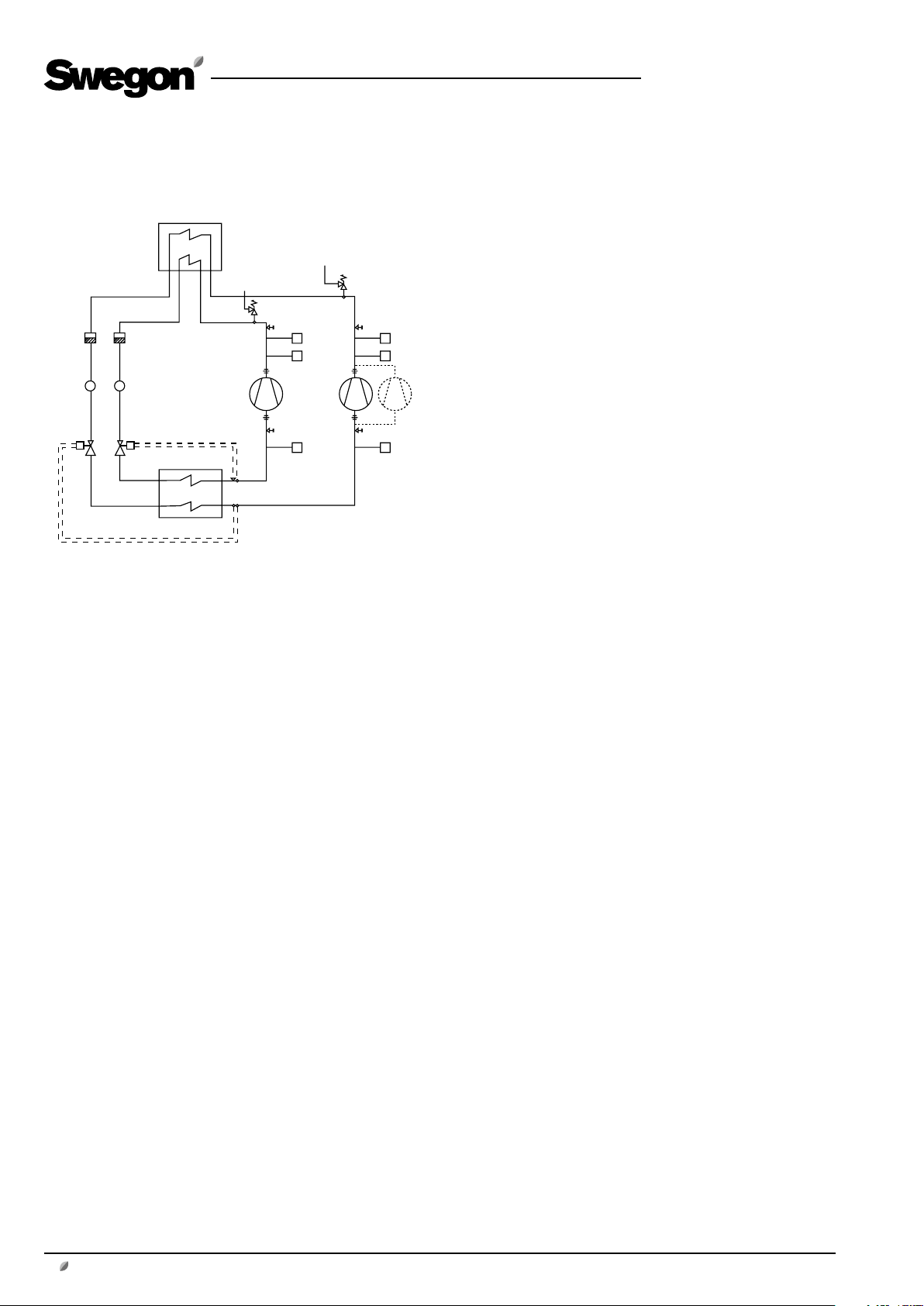

1.2 Basic function diagram

COND

VSH1

FD1FD2

IPL1IPL2

VET1VET2

EVAP

COND Condenser

VSH1 Overpressure protection

VSH2 Overpressure protection

B1-1 High pressure sensor

B2-1 Low pressure switch

B1-2 High pressure sensor

B2-2 Low pressure switch

BP1-2 High pressure switch, alarming

BP2-2 High pressure switch, alarming

M1 Compressor

M2 Compressor

M3 Compressor (size 80, cap. var. 3)

EVAP Evaporator

VET1 Expansion valve with thermostat

VET2 Expansion valve with thermostat

IPL1 Sight glass, cooling medium circuit 1

IPL2 Sight glass, cooling medium circuit 2

FD1 Filter dryer

FD2 Filter dryer

HP

HP

B1-1

M1 M2

LP

B2-1

VSH2

HP

HP

M3

LP

BP2-2BP1-2

B1-2

B2-2

The gaseous refrigerant is compressed by cooling compressors M1 and M2 and from there flows to condenser

COND, where it is cooled by the extract air and is condensed to liquid form.

The gaseous refrigerant flows through expansion valve

VET1 and VET2, where the pressure and the temperature

decrease.

From the expansion valves, the refrigerant advances to

evaporator EVAP, where the refrigerant evaporates and

cools down the outdoor air.

The evaporated refrigerant flows from evaporator EVAP

further to the suction side by the compressors to once

again be compressed.

Regulation

The cooling capacity is regulated in three binary steps by

having one or two compressors in operation.

COOL DX is controlled via a signal, 0 – 10 V.

Step 1: When cooling is needed, Compressor M1 is started.

Step 2: If more cooling is needed, Compressor M2 starts

and at the same time Compressor M1 stops. An adjustable time delay (a step duration of 250 seconds) ensures

that Compressor M2 will not start until Compressor M1 is

operating at full capacity.

Step 3: If even more cooling is needed, Compressor M1 is

restarted and is run at the same time as Compressor M2.

This third cooling step is also delayed by a preset time delay setting. In addition, the restarting time (300 seconds)

for Compressor M1 shall have expired.

If less cooling is needed and the compressors are subsequently switched out step-by-step, there will be no delay

between compressors. The restarting time (300 seconds)

for Compressor M1 shall have expired to enable it to start

again in Step 1 after it has been operated in Step 3.

If any compressor is stopped, the restarting time must

expire before a restart can take place. The restart time is

calculated from one start to the next start.

If the pressure in the cooling circuit becomes too low, or

if the pressure in the condenser circuit becomes too high,

the compressor is stopped.

When the restart time has expired, the compressors will try

to restart.

Function

There are two refrigerant circuits in the chiller. The circuits

are separated from one another.

Each circuit is equipped with its own finned condenser,

finned evaporator and compressor.

The two compressors are of different capacity, which

makes it possible to regulate the capacity in 3 steps.

4 www.swegon.com

If the pressure increases more, high pressure switches BP12 and BP2-2 will trip and stop the chiller.

Alarms are shown on the hand-held terminal, see separate

instructions for IC208CX control.

Pressure switches BP1-2 and BP2-2 can be manually reset

by pressing a button under each protective sock on the

upper side of the pressure switch. This can be done without removing the protective sock.

We reserve the right to alter specifications.

Page 5

GB.COOLDX.SI.G.190603

2 SAFETY INSTRUCTIONS

2.1 Safety Isolating Switch/Main Switch

The safety isolating switch is positioned on the inspection

side of the chiller.

The safety switch should not be used for start or stop of

the chiller.

Ensure that COOL DX is shut-off by turning off the chiller

via the display.

When this has been carried out, the current can be isolated with the safety switch. The safety switch must be

switched off in order to make it possible to open the

inspection door.

Important:

Always switch off the safety isolating switch before servicing the unit if not otherwise specified in the pertinent

instructions.

2.3 Electrical equipment

The machine’s electrical equipment is housed in a separate

cabinet inside one of the inspection doors.

2.4 Authorisation

Only authorized electricians shall be permitted to install

electrical wiring in the unit.

Only an accredited refrigeration company shall be permitted to modify or repair the refrigeration circuit.

Other service work in the unit should only be performed

by service personnel trained by Swegon.

2.5 Decals

The type number mark with type designation, serial number, refrigerant volume and more is affixed on the chiller’s

door.

Type designation: COOLDX-aa-F-c-d-e-f-g

SILVER C size

2.2 Risks

Warning

Before carrying out any work, make sure that the power

supply to the air handling unit has been switched off.

Warning

Under no circumstances may the refrigerant circuit be

opened by unauthorised personnel, since it contains gas

under high pressure.

Risk areas with refrigerant

Risk area for refrigerant is in principal inside the entire

chiller.

For handling when leakage, see section 7.2.

Refrigerant used is R 410A.

Capacity variant

Warning

The unit’s inspection door must not be opened when

the SILVER C air handling unit is operational. The door

can open and injure personnel. (The safety switch on the

COOL DX must be switched off in order to make it possible to open the inspection door of the chiller.)

We reserve the right to alter specifications.

www.swegon.com 5

Page 6

GB.COOLDX.SI.G.190603

3 INSTALLATION

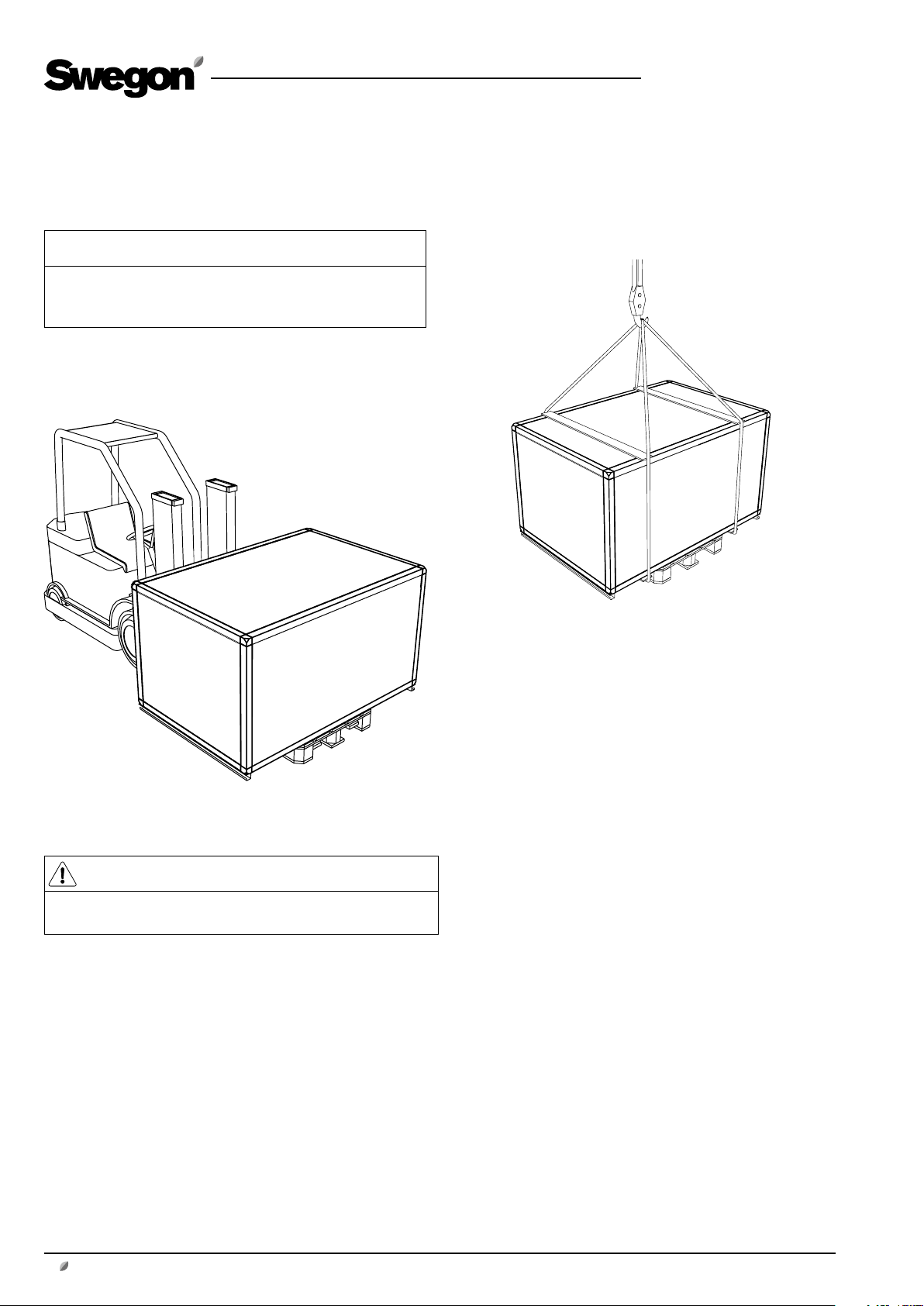

3.1 Unloading/site transport

Important:

All transport should take place with the chiller in horizontal position.

3.1.1 Handling with truck

3.1.2 Handling with crane

Place two line spreaders on top of the chiller and two on

the underside of the pallet or below the chiller and lift in

the pallet (or the chiller if the pallet is not to be included).

See the illustration.

Warning

High centre of gravity! Lift the chiller carefully.

3.2 Arrangement

Place the COOL DX at a suitable location.

Safety isolating switch/main switch must have the requisite space to serve according to applicable electrical regulations.

The unit can stand with the back against the wall, but to

facilitate any service of the rear compressor, a distance of

about 1 metre is recommended.

6 www.swegon.com

We reserve the right to alter specifications.

Page 7

3.3 Basic Installation Diagram COOL DX

Locate the COOL DX chiller against the outdoor air and

exhaust air side of the SILVER C air handling unit. COOL

DX can also be installed as a stand-alone unit, if you order

a stand-alone COOL DX, select the variant with end connection panels.

The dimensions and capacity of the chiller COOL DX is

matched for connection to the SILVER C air handling unit

in sizes 008-080.

For a list of the capacity sizes of chillers matched to respective unit size,

see section 10. General technical data.

COOL DX 008

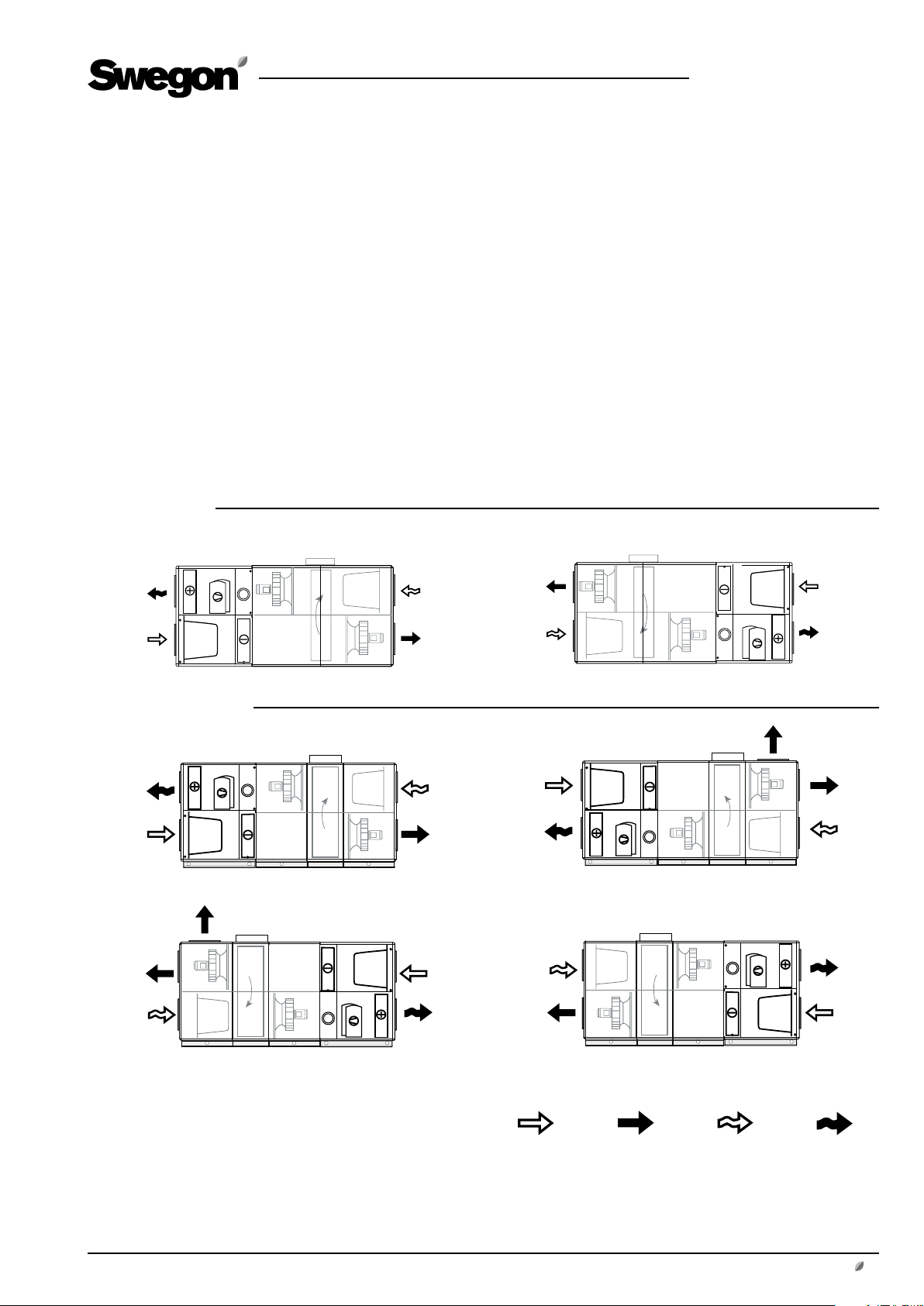

GB.COOLDX.SI.G.190603

Right-hand version Left-hand version

COOL DX 012-080

Cooling coil in lower level/SILVER C fan arrangement 1

Right-hand version

Cooling coil in upper level/SILVER C fan arrangement 2

Left-hand version

Cooling coil in upper level/SILVER C fan arrangement 1

We reserve the right to alter specifications.

Cooling coil in lower level/SILVER C fan arrangement 2

Outdoor air Supply air Extract air Exhaust air

www.swegon.com 7

Page 8

3.3.1 Height adjustment to the height of the SILVER C/water trap

COOL DX, size 008

In combination with the SILVER C RX 08

The SILVER C air handling unit can be mounted on base

beams, a stand or some other form of foundation. Base

beams and stands are available as accessories.

Appropriate base beams and stands are also available as

accessories for the COOL DX. The base beams/stands are

matched to one another in terms of height. The stands

also provide space for accommodating a possible water

trap in the lower level (right-hand unit version).

In combination with the SILVER C PX 008

The air handling unit is supplied with base beams. A set of

legs (accesssory) can be mounted in the base beams.

Appropriate base beams and set of legs are also available

as accessories for the COOL DX. The base beams/sets of

legs are matched to one another in terms of height. The

sets of legs also provide space for accommodating a possible water trap in the lower level (right-hand unit version).

GB.COOLDX.SI.G.190603

COOL DX, sizes 012-080

The SILVER C air handling unit and the COOL DX cooling

unit are supplied with a 100 mm high base beam.

Applicable to a cooling coil in the lower level:

If a water trap (accessory) is fitted, the SILVER C air handling unit and the cooling unit must be raised at least 50

mm to provide space for the water trap. Adjustable support feet (accessories) can be appropriately fitted to the

base beams for this purpose.

8 www.swegon.com

We reserve the right to alter specifications.

Page 9

3.3.2 Connection to SILVER C air handling unit,

COOL DX, sizes 008-012

The sealing strips are factory-fitted to the unit.

The chiller is connected directly to the air handling unit by

means of the supplied bolts + pre-fitted rivets nut and 2

expansion locking devices, see the figure.

Secure the chiller to the air handling unit from inside the

unit via the inspection door. It may be necessary to remove

the fan assembly or filter cassettes in order to reach the

expansion-type locking device.

Expansion-type locking device

GB.COOLDX.SI.G.190603

COOL DX Chiller

In this case, fastening is done with the bolts and

pre-fitted rivet nuts.

We reserve the right to alter specifications.

www.swegon.com 9

Page 10

GB.COOLDX.SI.G.190603

3.3.3 Connection to SILVER C air handling unit,

COOL DX, sizes 020-040

The sealing strips are factory-fitted to the unit.

Dock the chiller directly to the SILVER C air handling unit

by means of the supplied bolts (4 bolts) + pre-fitted rivet

nuts.

To secure accessories to the rear edge

Alternative 1, External installation

Illustration 1

The SILVER C air handling unit, rear

Remove the cover and insulation. Secure the chiller to the SILVER C air handling unit

with the bolts supplied and pre-fitted rivet nuts. Refit the blanking plate and the

insulation.

Option 1

If there is sufficient space for working from the rear of the

air handling unit, the simplest way to secure the chiller at

the rear edge of the SILVER C air handling unit is by externally jointing it, see Illustration 1.

Secure the chiller to the front edge of the SILVER C air

handling unit within the unit via the inspection cover, see

Illustration 3.

Option 2

The chiller is secured to the back edge of the SILVER C

air handling unit within the casing, see Illustration 2. This

requires removal of the fan assembly and filter cassettes.

Secure the chiller to the front edge of the SILVER C air

handling unit within the unit via the inspection cover, see

Illustration 3.

COOL DX chiller, rear

Alternative 2, Internal installation

Illustration 2

To secure accessories to the front edge

Illustration 3

COOL DX Chiller

In this case, fastening is done with the bolts supplied and pre-fitted rivet nuts in

predrilled holes.

COOL DX Chiller

In this case, fastening is done with the bolts supplied and pre-fitted rivet nuts in

predrilled holes.

10 www.swegon.com

We reserve the right to alter specifications.

Page 11

3.3.4 Connection to SILVER C air handling unit,

COOL DX, sizes 060-080

The sealing strips are factory-fitted to the unit.

Dock the chiller directly to the SILVER C air handling unit

by means of the supplied bolts (4 bolts) + pre-fitted rivet

nuts, see the illustration.

You may need to remove the filter cassettes.

COOL DX Chiller

In this case, fastening is done with the bolts supplied and pre-fitted rivet nuts in

predrilled holes.

GB.COOLDX.SI.G.190603

3.3.5 Stand-alone COOL DX

The variant with end connection panel should be selected.

Ducts connect between the SILVER C air handling unit and

COOL DX chiller, see section 3.3 Basic Installation Diagram

COOL DX.

3.3.6 Supply air filter

The supply air filter in the SILVER C air handling unit should

be dismantled and moved to the COOL DX unit.

We reserve the right to alter specifications.

www.swegon.com 11

Page 12

4 POWER CONNECTION

The cross sectional dimension of the power supply cable

should take into consideration the ambient temperature

and way the cable is run.

Important:

Installation must be carried out by a authorised electrician.

4.1 Power connection

Incoming power supply

Sizes 008-020, all capacity variants, and size 030, capacity

variant 1:

5-core system, 400 V ±10%.

GB.COOLDX.SI.G.190603

Size 030, capacity variants 2 and 3 and size 040-080 all

capacity variants:

4-core system, 400 V ±10%.

COOL DX, sizes 008-040, 060-1/2

Open the inspection door in front of the electrical equipment cubicle.

Open the inspection door of the electrical equipment

cubicle.

Pull the incoming cable for power supply through predrilled hole in the cover panel of the chiller (supplied cable

gland is mounted), through the space for compressors

and through the cable gland of the electrical equipment

cubicle. Locate the cable in a safe way. Make sure that the

cable does not touch the compressors or other components, since surfaces could be hot or vibrate.

Connect the incoming power supply to the safety switch

situated in the electrical equipment cubicle, see the illustration. The wiring terminal for incoming earth is situated

right next to the safety switch.

See section 10, Technical data.

Sizes 060–3, 080

Remove the cover on the external safety switch.

Safety switch block.

Supply is connected here

Connect the incoming power supply to the safety switch,

see the illustration. The wiring terminal for incoming earth

is situated right next to the safety switch.

See section 10, Technical data.

4.2 Connection signal 0-10 V

Terminals 103 and 104 are connected to give a signal,

0-10 V. For more information, also see the electrical wiring

diagram supplied separately.

12 www.swegon.com

Factory-fitted

cables

We reserve the right to alter specifications.

Page 13

GB.COOLDX.SI.G.190603

5 COMMISSIONING

5.1 Preparations

5.1.1 Before initial start up

• The power supply should be connected.

• Terminals 105 and 106 in COOL DX electrical cabi-

net must be connected (closed switch), otherwise

the cooling machine will not start despite the signal

0 – 10 V, and no compressors are activated. (These

terminals can be used to connect an external thermostat to activate/deactivate signal 0 – 10 V for a specific

temperature).

• Terminals 103 and 104 shall be connected to give a

signal, 0-10 V.

A free contact for a general alarm is located on terminals

100, 101 and 102.

5.1.2 Control functions

Silver Cool DX is equipped with two controls:

• IC208CX Dixell, hardware version 7.3 or 4.2

• Siemens (model: 12/24 RC 6ED1052-1MD08-0BA0)

Signal 0-10 V is received by the Siemens control which

converts it to digital output signals (see below) and forwards these to control IC208CX.

Control IC208CX is set at the factory to moto-condenser

mode and starts or stops the compressors via the digital

output signals from the Siemens control. All control and

safety functions for the refrigerant circuit are regulated by

control IC208CX.

For conversion of the signal, 0 – 10 V to digital output

signals, see below.

5.1.3 Pressure sensor

The chiller has two in-service pressure switches in each

cooling circuit, one for low pressure and one for high pressure.

If the operating pressure, in any of the circuits, exceeds

or drops below a limit value, the relevant compressor is

switched off. See separate instructions for IC208CX control for further information.

The compressor is permitted to restart when the restart

delay has expired.

Pressure sensor settings:

Value Setting Factory

range settings

Compressor 1

Low pressure limitation 1-10 bar 4.5 bar

High pressure limitation 25-50 bar 39.0 bar

High pressure alarm limit 25-50 bar 42 bar

Compressor 2

Low pressure alarm limit 1-10 bar 4.5 bar

High pressure limitation 25-50 bar 39.0 bar

High pressure alarm limit 25-50 bar 42 bar

When the 0-10 V increases:

• Point 1: Q1 and Q2 = OFF

• Point 2: signal increases to above 1 V, then Q1= ON

and Q2 = OFF

• Point 3: signal increases to above 4 V, then Q1= OFF

and Q2 = ON

• Point 4: signal increases to above 7 V, then Q1= ON

and Q2 = ON

When the 0-10 V decreases:

• Point 4: signal decreases to below 7 V, then Q1= OFF

and Q2 = ON

• Point 3: signal decreases to below 4 V, then Q1= ON

and Q2 = OFF

• Point 2: signal decreases to below 1 V, then Q1= ON

and Q2 = OFF

• Point 1: Q1 stops when the signal reaches 0 V

Q1 and Q2 are the digital output signals that are sent to

control IC208CX to activate compressor 1 and 2.

Q1= compressor with lower cooling capacity

Q2 = compressor with higher cooling capacity

For more information about control and safety functions,

see separate instructions for IC208CX control.

We reserve the right to alter specifications.

www.swegon.com 13

Page 14

GB.COOLDX.SI.G.190603

5.1.4 Phase sequence monitor

The COOL DX unit is equipped with phase sequence

guard for compressors (not size 008 capacity variant 1).

The phase sequence monitor is installed in the electrical

cabinet.

Phase sequence monitor

The phase sequence is correct when LED 1 is lit.

The voltage is connected when LED 2 is lit.

PSC

DPA51 3-Phase monitoring relay

1

1

2

5.1.5 Measure whether the phase-sequence is

wrong

6 ALARMS

For an alarm description, see the separate instructions for

IC208CX control.

Warning

May only be performed by authorised or trained service

personnel.

• Stop the COOL DX by selecting SHUT OFF in the

menu SETTINGS.

• Set the safety switch to position OFF on the COOL

DX.

• Switch the power supply to COOL DX.

Important:

Check that the incoming power supply to the COOL DX

is isolated by measuring.

• Transpose the two phase wires on the incoming

power supply cable in order to

obtain correct phase sequence (direction of rotation).

• Switch on the power supply to COOL DX.

• Set the safety switch to ON.

• Start COOL DX as described in the section dealing

with starting up, see Section 5.1.2.

14 www.swegon.com

We reserve the right to alter specifications.

Page 15

GB.COOLDX.SI.G.190603

7 MAINTENANCE

7.1 Cleaning

If needed, clean the inside cleaning of the unit by vacuum

cleaning and wiping surfaces with a damp cloth.

Inspections should be performed twice a year.

7.2 Handling of refrigerant

The refrigerant used is R 410A.

The refrigerant circuit is completely charged when the unit

is delivered.

Warning

Under no circumstances may the refrigerant circuit be

opened by unauthorised personnel, since it contains

gas under high pressure. Only an accredited refrigeration company shall be permitted to modify or repair the

refrigeration circuit.

The COOL DX is equipped with a safety valve to prevent

excessively high pressure in the system caused by e.g. a

fire.

Important:

Contact Swegon Service in the event of leakage of

refrigerant.

Warning

Important:

Filling of refrigerant must be performed in accordance

with the recommendations of the refrigerant manufacturer.

Avoid direct skin contact with refrigerant and lubricant.

Use tightly sitting protective glasses, protective gloves

and covering work clothes.

Arrange ventilation/point extraction.

In the event of eye contact

rinse the eyes using an eye-wash shower (or with lukewarm water) for 20 minutes. seek a doctor.

In the event of contact with skin

carefully wash with soap and lukewarm water.

In the event of frostbite

seek a doctor.

7.3 Leakage tracing interval/

Obligation to report

Must be carried out according to the F-Gas Regulation

EU/517/2014 and associated local legislation.

7.4 Service

Only service personnel trained by Swegon should be permitted to modify the chiller.

If refrigerant is exposed to fire or in some other way

becomes superheated in the atmosphere, poisonous

gases can form.

We reserve the right to alter specifications.

www.swegon.com 15

Page 16

8 TROUBLE SHOOTING AND

LEAKAGE TRACING

8.1 Troubleshooting Schedule

Symptoms Possible cause Action

Compressor is not operating The voltage has been isolated.

Incorrect phase sequence.

The compressor safety circuit has been broken.

Defective compressor.

Too low cooling capacity The voltage has been isolated.

Incorrect phase sequence.

No air flow or too low air flow across the evaporator.

Thermostat/control equipment incorrectly set or defective.

The compressor switches off

because the low pressure sensor

has measured an excessively low

value.

The compressor switches off

because the high pressure sensor

has measured an excessively high

value.

Significant freezing on the

evaporator.

Inadequate refrigerant.

No air flow or too low air flow across the evaporator.

The expansion valve is defective.

The low pressure switch is defective.

No air flow or too low air flow across the condenser.

Excessively high exhaust air temperature.

The high pressure sensor is defective.

The expansion valve is defective or incorrectly set.

No air flow or too low air flow across the evaporator.

Check the operating/safety switch. Check the condition of the fuses.

Check and change the phase sequence.

Check, reset if needed.

Replace the compressor.

Check the operating/safety switch. Check the condition of the fuses.

Check and change the phase sequence.

Check the air flow.

Adjust the setting or replace faulty components.

The cooling system is leaking. Tighten the leak and

charge with refrigerant.

Check the air flow.

Check, replace.

Check, replace.

Check the air flow.

Check the exhaust air temperature.

Check, replace.

Check. Replace or adjust setting.

Check the air flow.

GB.COOLDX.SI.G.190603

8.2 Leakage Tracing

Leakage tracing should be carried out at least once per

year as a precaution. The leakage tracing inspection must

be documented.

If the cooling system is leaking, this will become apparent

firstly by impaired cooling performance, or if the leakage is

substantial, when the chiller does not operate at all.

If you suspect that the cooling system is leaking refrigerant, check the level of refrigerant in the sight glass located

on the liquid line of the chiller.

If you see continuous and a substantial amount of bubbling in the sight glass and the chiller operates at appreciably lower capacity than normal, the system is probably

leaking. One or several bubbles appearing when the chiller

is started up, operation at reduced capacity or normal

operation need not necessarily indicate a refrigerant deficiency.

If it is bubbling in the sight glass and the chiller operates at

appreciably lower capacity, call for qualified service help.

NOTE! Maintenance work in the refrigerant system is permitted to be carried out only by an accredited inspectorate

(a company with requisite authorisation).

16 www.swegon.com

We reserve the right to alter specifications.

Page 17

9 DIMENSIONS

5050

16

K

1)

1)

16

1)

M

1)

5050 K

454521 K

1)

M

1)

COOL DX 008

GB.COOLDX.SI.G.190603

Base beams are accessories.

1)

End connection panel, optional.

COOL DX 012

M

1)

End connection panel, optional.

Size L B H K M Duct connection

008 900 995 1085 749 709 Ø 400

2)

For the locations of the duct connections, see the corresponding

SILVER C air handling unit

Size L B H K M Duct connection

012 900 1199 1395 953 709 Ø 500

2)

For the locations of the duct connections, see the corresponding

SILVER C air handling unit

2)

2)

COOL DX 020, 030, 040, 060, 080

Size L B H K M Duct connection

020

030

040

060

080

2)

For the locations of the duct connections, see the corresponding

900

900

1100

1100

1100

1400

1600

1990

2318

2637

1551

1811

2159

2288

2640

1154

1354

1744

2072

2395

709

709

884

884

884

1000 x 400

1200 x 500

1400 x 600

1600 x 800

1800 x 1000

SILVER C air handling unit

1)

End connection panel, optional.

2)

We reserve the right to alter specifications.

www.swegon.com 17

Page 18

10 GENERAL TECHNICAL DATA

Cooling system COOL DX

GB.COOLDX.SI.G.190603

Refrigerant

(kg)

Nom.

COOL

DX

Size

008 1 0.55 0.22 9.8 2.39 1,20 1.30 3-phase+N, 400 V ±10%, 16 A 194 8

012 1 0.85 0.35 15.4 3.95 1,50 1.70 3-phase+N, 400 V ±10%, 20 A 260 10

020 1 1.1 0.45 15.4 4.06 1,20 1,50 3-phase+N, 400 V ±10%, 25 A 243 11

030 1 1.8 0.7 25,0 6.33 1,80 2.00 3-phase+N, 400 V ±10%, 32 A 322 17

040 1 2.9 1.1 38.6 8.40 3.30 4.00 3-phase, 400 V ±10%, 25 A 468 22

060 1

080 1

Cap.

flow

var-

(m

iant

2 0.70 0.3 13.9 4.33 1,20 1.30 3-phase+N, 400 V ±10%, 20 A 215 8

2 1.05 0.4 20.9 6.53 1,50 1.70 3-phase+N, 400 V ±10%, 25 A 287 10

2 1.3 0.5 23.3 5.73 2,50 2,80 3-phase+N, 400 V ±10%, 25 A 283 11

3 1.6 0.6 31.0 9.15 2,10 2.40 3-phase+N, 400 V ±10%, 40 A 314 11

2 2.0 0.8 35.8 9.34 3.00 3,20 3-phase, 400 V ±10%, 25 A 374 17

3 2.4 1.0 46.2 13.5 2.90 3.30 3-phase, 400 V ±10%, 40 A 414 17

2 3.1 1.3 48.4 12.3 3.30 4.50 3-phase, 400 V ±10%, 40 A 476 22

3 3.6 1,5 67.0 17.5 5.50 4.50 3-phase, 400 V ±10%, 50 A 529 22

2

3

2

3

air

3

3.9

4.1

5,0

5.2

6.0

7.0

/s)

Min

air

flow

(m

1,5

1.6

2.0

2.0

2.4

2.8

3

/s)

Nom.

cooling

1)

cap.

(kW)

56.2

66.7

97.5

67.0

96.5

134.0

Nom.

Power

required

(kW)

11.8

17.1

26.3

13.3

24.8

36.4

Circuit 1Circuit

2

4.50

5,00

6.00

6,60

6,50

9.00

5.50

5.20

7,50

7,30

9.00

11.50

Power

supply

3-phase, 400 V ±10%, 40 A

3-phase, 400 V ±10%, 50 A

3-phase, 400 V ±10%, 80 A

3-phase, 400 V ±10%, 50 A

3-phase, 400 V ±10%, 80 A

3-phase, 400 V ±10%, 100 A

Weight

excl. end

conn.

panel

(kg)

708

779

852

852

979

1035

Weight

of each

end conn.

panel, if

required

(kg)

31

31

31

38

38

38

2)

1)

For an outdoor temperature of 26°C, 50% RH (capacity variant 1), 27°C, 50% RH (capacity variant 2) or 28°C, 50% RH (capacity variant 3), and

an extract air temperature of 26°C.

2)

The first weight applies to a small end connection panel; the second weight applies to a large end connection panel. COOL DX can be supplied

completely without end connection panels or with a maximum of 2 small and two large end connection panels depending on the variant selected.

Sizing

There are many factors that influence what size of chiller is

required.

COOL DX is designed to handle very different prerequisites.

For correct sizing we refer to our ProUnit air handling unit

selection program.

18 www.swegon.com

We reserve the right to alter specifications.

Page 19

11 INTERNAL WIRING DIAGRAM

2R

L3

11.1 COOL DX, size 08, capacity variant 1

1

5

2

-RM2

M2.2

RM2.1

-CS2

-CM2

GB.COOLDX.SI.G.190603

5

6

3

4

br

1

2

blue

/3.7

-QF3

-QF2

/3.3

/3.2

-KM2

1

2

-RM1

RM1.1

RM1.

-CS1

-CM1

5

6

3

4

bl

1

2

blue

/3.6

-KM1

/2.0

10

10

21

-KM2

10

21

-KM1

4G1,5 mm²

-W2

5

4G1,5 mm²

-W1

04

22

-X1

/3.7

03

22

-X1

/3.6

S

bl

RC

M

br

C2 R2 S2

-X1

C1 R1 S1

-X1

1~

blue

S

br

RC

bl

blue

-PE

-M2

M

-M1

-PE:2

1~

-PE

-PE:1

/2.0

00

00

-X1

00

-R1 -R2

-X1

/2.31/2.3

0

-QF01

7

-QF1

grey

black

brown

blue

-Q

N

L2

L1

3

230V

2

-TC1

24V 230V

LINIE KUNDENS. GESCHUEZT

LIGNE PROTEGEE PAR LE CLIENT

LINE PROTECTION BY CUSTOMER

LINEA PROTETTA A CURA DEL CLIENTE

0

4

-PE:3

We reserve the right to alter specifications.

10

1

-QF02

Cx = Condenser

QFx = Fuse

KMx = Contactor

Q = Load separator

Rx = Crankcase heater

www.swegon.com 19

Page 20

GB.COOLDX.SI.G.190603

L3

11.2 The COOL DX size 08, capacity variants 2, size 12 and 20, all capacity

variants and size 30, capacity variant 1

/3.332/3.3

L3

-L3:

L2

-L2:

L1

L1:

-PSC

brown

grey

black

/3.3

13

14

5

6

I>

3

4

I>

1

2

I>

grey

black

brown

5

6

3

4

1

2

/3.7

-KM2

-QM2

1

2

-RM1

RM1.2

RM1.1

29

14

11

WVU

grey

M

black

-W2

brown

3~

PE

-PE:2

-M2

5

grey

-CS1

-CM1

5

6

3

4

black

1

2

blueblue

/3.6

-QF2

/3.2

-KM1

/2.0

10

10

21

-KM2

10

21

-KM1

C1 R1 S1

-X1

04

22

-X1

/3.7

03

22

-X1

/3.6

S

black

RC

M

brown

1~

-W1

-PE

-M1

-PE:1

/2.0

/2.31/2.3

00

0

00

-X1

00

-R1 -R2

-X1

-QF01

7

-QF1

brown

black

blue

-Q

N

L2

L1

3

230V

2

-TC1

24V 230V

-PE:3

0

4

10

1

-QF02

20 www.swegon.com

LINIE KUNDENS. GESCHUEZT

LIGNE PROTEGEE PAR LE CLIENT

LINE PROTECTION BY CUSTOMER

LINEA PROTETTA A CURA DEL CLIENTE

LIMITE FORNITURA

Cx = Condenser

QFx = Fuse

KMx = Contactor

PSC = Control system for phase sequence

Qmx = Motor protection

Q = Load separator

Rx = Crankcase heater

We reserve the right to alter specifications.

Page 21

GB.COOLDX.SI.G.190603

L3

13

14

11.3 COOL DX, size 30, capacity variants 2 and 3, size 40, all capacity variants and size 60,

capacity variants 1 and 2, size 80, capacity variant 1

/3.3

5

6

I>

3

4

I>

1

2

I>

-QM2

/3.2

13

14

5

6

I>

3

4

I>

1

2

I>

-QM1

grey

black

brown

grey

black

brown

5

6

3

4

1

2

-W2

/3.7

-KM2

5

6

3

4

1

2

-W1

/3.6

-KM1

/3.332/3.3

L3

-L3:

L2

-L2:

L1

L1:

29

14

11

grey

black

brown

grey

black

brown

WVU

M

3~

PE

-PE:2

-M2

WVU

M

3~

PE

-PE:1

-M1

grey

-PSC

/2.0

10

10

21

-KM2

grey

black

brown

10

21

-KM1

black

brown

5

6

I>

3

4

I>

1

2

I>

3

400-415V

2

-TC1

-Q

L2

L1

-QF1

LINIE KUNDENS. GESCHUEZT

LIGNE PROTEGEE PAR LE CLIENT

LINE PROTECTION BY CUSTOMER

LINEA PROTETTA A CURA DEL CLIENTE

24V 230V

-PE:3

7

0

4

04

22

-X1

/3.7

03

22

-X1

/3.6

-R1 -R2

-QF01

10

-QF02

/2.0

/2.31/2.3

00

0

00

-X1

00

-X1

1

Cx = Condenser

QFx = Fuse

KMx = Contactor

PSC = Control system for phase sequence

Qmx = Motor protection

Q = Load separator

Rx = Crankcase heater

We reserve the right to alter specifications.

www.swegon.com 21

Page 22

11.4 COOL DX size 60, capacity variant 3 to size 80, capacity variant 2

L3

13

14

M2M1 /3.7

/3.3

5

5

6

I>

3

4

I>

1

2

I>

-QM2

/3.2

13

14

5

6

I>

3

4

I>

1

2

I>

grey

black

brown

grey

black

brown

6

3

4

1

2

-W2

/3.7

-KM2

5

6

3

4

1

2

-W1

/3.6

-KM1

-QM1

/3.332/3.3

L3

-L3:

L2

-L2:

L1

L1:

29

14

11

grey

black

brown

grey

black

brown

WVU

M

3~

PE

-PE:2

-M2

WVU

M

3~

PE

-PE:1

-M1

GB.COOLDX.SI.G.190603

grey

-PSC

/2.0

10

10

L

N

-X1

/2.0

00

00

-X1

/2.31/2.3

0

-FTM2

10

21

-KM2

grey

black

brown

10

21

-KM1

black

brown

5

6

I>

3

4

I>

1

2

I>

3

400-415V

2

-TC1

24V 230V

-PE:3

7

0

4

-QF1

04

22

-X1

/3.7

03

22

-X1

/3.6

-R1 -R2

-QF01

10

-QF02

00

-X1

00

-X1

1

L2

L1

22 www.swegon.com

-Q

LINIE KUNDENS. GESCHUEZT

LIGNE PROTEGEE PAR LE CLIENT

LINE PROTECTION BY CUSTOMER

LINEA PROTETTA A CURA DEL CLIENTE

Cx = Condenser

QFx = Fuse

KMx = Contactor

PSC = Control system for phase sequence

Qmx = Motor protection

Q = Load separator

Rx = Crankcase heater

We reserve the right to alter specifications.

Page 23

12 Commissioning Record

Company

Our reference

Client Date SO No.

Plant Project/Air handling unit Subject no:

Plant address Type/size

GB.COOLDX.SI.G.190603

Installation/connections

Inspection measure

Installation according to instructions

Condensate drain correctly connected, water trap filled with water

The supply air filter in the SILVER C air handling unit has been moved

to the COOL DX unit.

Electrical connections installed according to instructions

Control cable from COOL DX connected according to instructions

Appr./Exec.

Remarks

We reserve the right to alter specifications.

www.swegon.com 23

Page 24

GB.COOLDX.SI.G.190603

Checks COOL DX, size Factory-preset value Checked value

Safety switch, Compressor 1 08-1 D10

Safety switch, compressor 2 D13

Safety switch, Compressor 1

08-2 D10

Protective motor switch, Compr. 2 8.5 A

12-1 D10

8.5 A

12-2 D16

14.4 A

20-1 D10

13.0 A

20-2 D16

14.4 A

20-3 D16

18.0 A

30-1 D16

14.4 A

Protective motor switch, Compressor 1

Protective motor switch, compressor 2

30-2 13.0 A

18.0 A

30-3 14.4 A

21.0 A

40-1 13.0 A

18.0 A

40-2 14.4 A

21.0 A

40-3 18.0 A

27.0 A

60-1 14.4 A

21.0 A

60-2 18.0 A

27.0 A

60-3 21.0 A

45.0 A

80-1 14.4 A

27.0 A

80-2 21.0 A

45.0 A

80-3 27.0 A

33.0 A

Protective motor switch, Compr. 3 33.0 A

24 www.swegon.com

We reserve the right to alter specifications.

Loading...

Loading...