Page 1

CONDUCTOR W4

Installation instruction for W4.1 and W4.2

Controller

4

3

5

2

8

Figure 1. Overview of the Controller.

Pos 1. Product marking.

Pos 2. Termination resistance.

1 = The unit is the last node in the network

2 = The unit is the first node in the network

3 = The unit is situated between the first and last nodes

Pos 3. Modular Contact / ModBUS RTU units (pressure sensor and room unit)

Pos 4. Inputs: Wiring terminals for the connection of sensors.

Pos 5. DIP switch for ModBUS RTU.

1 (=on) boosts the controller to Modbus address 1

2 (=on) access to Modbus register via BMS system

(requires a restart of the controller)

Pos 6. LED, indicates the status of the controller.

Pos 7. Input and output for signal to external relay.

Pos 8. Outputs: Wiring terminals for the connection of valve and

damper actuators.

1

Product Identification Label

1

Conductor RE W4

Modbus Adress 2

Artnr: 942334001

RF id: 00350

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

Figure 2. Product identification label on the controller.

Pos 1. Name of the product.

Pos 2. ModBus RTU address default from factory.

Pos 3. Part number.

Pos 4. Controller ID number.

6

7

2

3

4

To be installed above a false ceiling

If a DIN rail is NOT available pre-mounted or is not available, the controller can be appropriately mounted above the false ceiling (not on the

module).

1

2

Figure 4. To mount the controller.

Pos 1. Supporting surface, NOT for the comfort module or climate beam.

Pos 2. Screws.

a. Secure the controller by means of screws in the upper left-hand and the

lower right-hand corners. Use screws suitable for the supporting surface.

To mount the controller.

Mounting on a DIN rail

1

2

3

4

Figure 3. To mount the controller.

Pos 1. Plastic hooks

Pos 2. Supporting surface

Pos 3. DIN rail

Pos 4. Snap-on fastener.

Page 2

CONDUCTOR W4

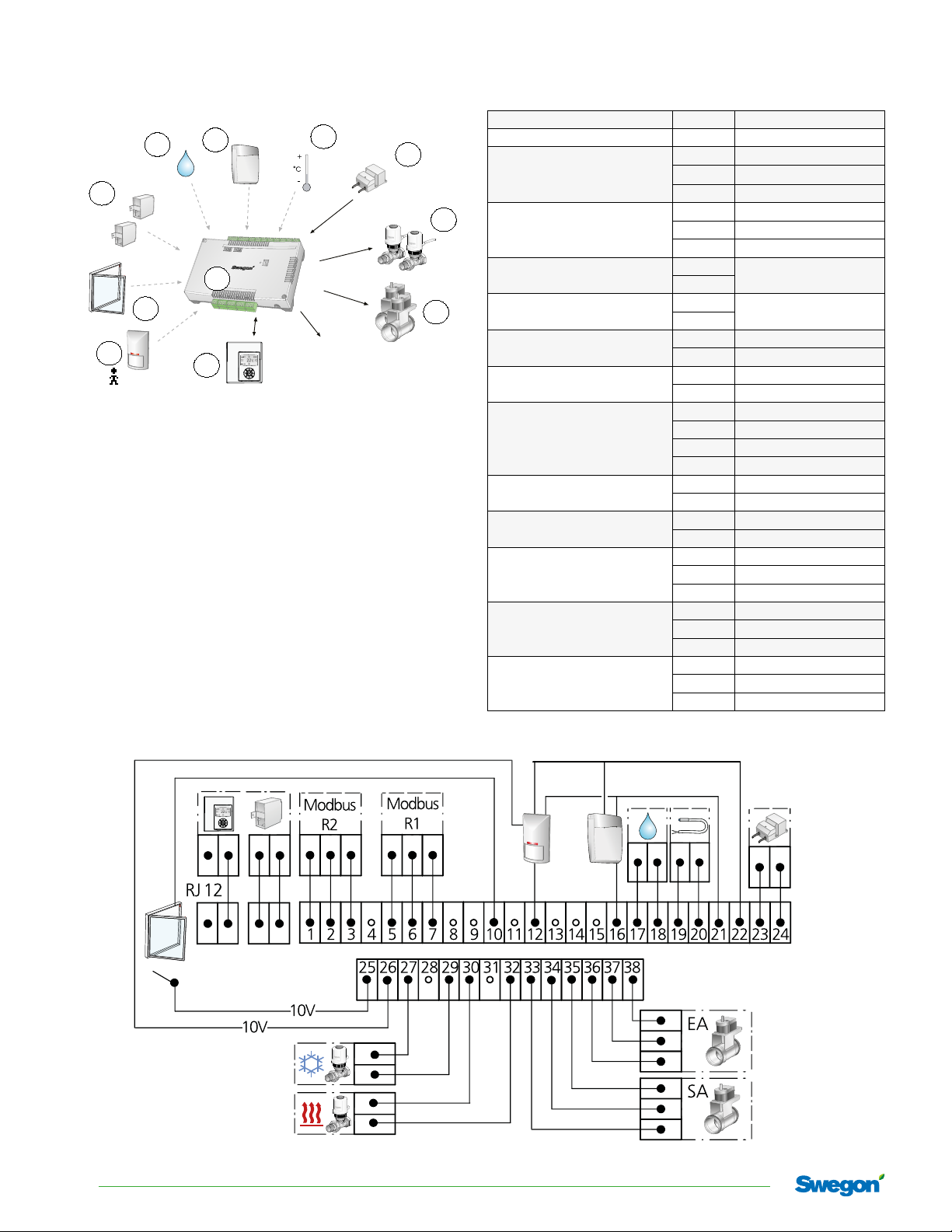

W4.1 (Hotel/Office)

6

7

5

1

4

3

Figure 5. CONDUCTOR W4.1: Integral Components

1

Controller

2

Room unit

3

Presence detector

4

Window contact

5

Pressure sensor

6

Condensation sensor

7

CO2-sensor

8

External temp. sensor

9

Transformer

10

Valve actuator

11

Ventilation damper

incl. damper actuator

• Connect the presence sensor, check application parameter P_1910

• Connect the window contact, check application parameter P_1909

• Connect the pressure sensor to the Modular contact.

Set the address on sensor: SA1 = 3, EA = 4

• Check application parameters P_1929, P_1930 and P_1931. (P_1930

allways 0 in appl W4.1)

2

Conductor RE

Conductor RU

DETECT Occupancy

SYST PS

SYST CG

DETECT Quality

CONDUCTOR T-TG

SYST TS-1

ACTUATOR b 24V NC

CRTc -aaa-2

(aaa = dimension)

8

9

10

11

Monitoring

system via ModBus

Room unit RJ12 Modular contact

Pressure sensor RJ12 Modular contact

1 Data (B)

MODBUS RS2

MO DBUS RS1

Condensation sensor

Temperature sensor

Transformer

Window contact

Presence detector

Valve actuator, cooling

Valve actuator, heating

Damper, supply air (SA)

Damper, extract air ( EA)

-sensor

CO

2

2 Data (A)

3 Earth

5 Data (B)

6 Data (A)

7 Earth

17

Resistance

18

19

KTY

20

23 + 24V AC

24 -G0

25

10V

10 10V

26 10V

12 0-10V

21 +24V AC

22 -G0

27 -G0

29 +24V

30 -G0

32 +24V

33 -G0

34 0-10V

35 +24V

36 -G0

37 0 -10V

38 +24V

16 0-10V Signal

21 +24V AC

22 -G0

Figure 6. Wiring diagram,

CONDUCTOR W4.1

2

Swegon reserves the right to alter specications. 15-03-2017

Page 3

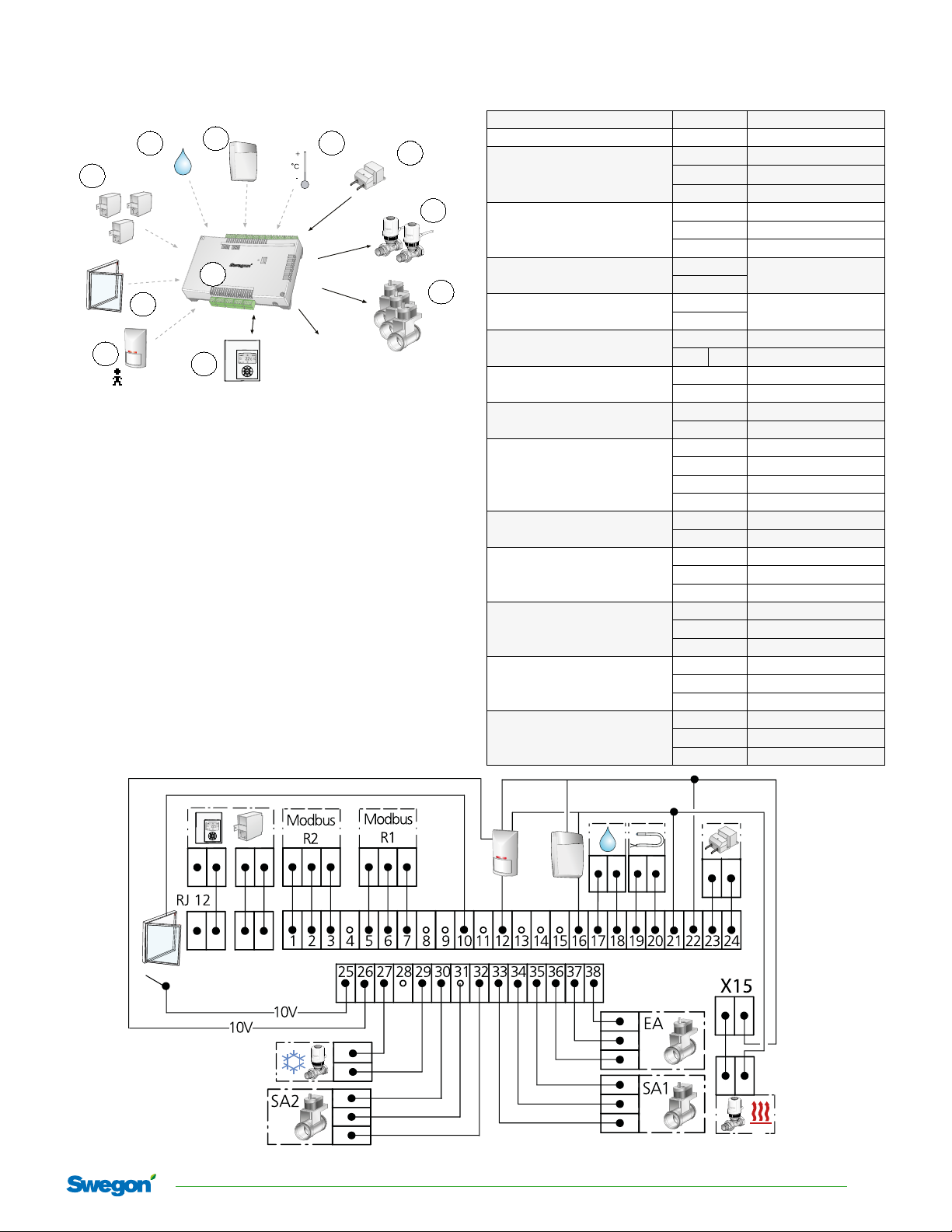

W4.2 (Conference)

6

7

5

1

4

3

Figure 7. CONDUCTOR W4.2: Integral Components

1

Controller

2

Room unit

3

Presence detector

4

Window contact

5

Pressure sensor

6

Condensation sensor

7

CO2-sensor

8

External temp. sensor

9

Transformer

10

Valve actuator

11

Ventilation damper

incl. damper actuator

• Connect the presence sensor, check application parameter P_1910

• Connect the window contact, check application parameter P_1909

• Connect the pressure sensor to the Modular contact.

Set the address on sensor: SA1 = 3, SA2 = 6, EA = 4

• Check application parameters P_1929, P_1930 and P_1931.

2

Conductor RE

Conductor RU

DETECT Occupancy

SYST PS

SYST CG

DETECT Quality

CONDUCTOR T-TG

SYST TS-1

ACTUATOR b 24V NC

CRTc aaa-2

(aaa = dimension)

8

Monitoring

system via ModBus

9

10

11

CONDUCTOR W4

Room unit RJ12 Modular contact

Pressure sensor RJ12 Modular contact

1 Data (B)

MODBUS RS2

MO DBUS RS1

Condensation sensor

Temperature sensor

Valve actuator, heating

Transformer

Window contact

Presence detector

Valve actuator, cooling

Damper 2, supply air (SA2)

Damper 1, supply air (SA1)

Damper, extract air ( EA)

-sensor

CO

2

2 Data (A)

3 Earth

5 Data (B)

6 Data (A)

7 Earth

17

18

19

20

21 +24V

22 X15 -G0

23 + 24V AC

24 -G0

25

10 10V

26 10V

12 0 -10 V

21 +24V AC

22 -G0

27 -G0

29 +24V

30 -G0

31 0 -10V

32 +24 V

33 -G0

34 0-10 V

35 +24V

36 -G0

37 0-10V

38 +24V

16 0-10V Signal

21 +24V AC

22 -G0

Resistance

KTY

10V

Figure 8. Wiring diagram,

CONDUCTOR W4.2

15-03-2017 Swegon reserves the right to alter specications

3

Page 4

CONDUCTOR W4

Main me nu

Setup

Enter code

1

1 9 1 9

Service menu

2

3b

3a

Figure 9. Wireless: 3xAAA, (pos 3a),

Cable: RJ12 (pos 3b).

1

2

3

Regulator adjust

k-factor SA1

Norm SA1 l/s

Boost SA1 l/s

k-factor SA2

Boost SA2 l/s

k-factor EA

Off set l/s

Tem p C

Tem p H

Settings

Room unit no.

RF pair-up

Language

FirstTime func

RF Quality

Temp.calibration

Energy saving

Backlight

Basescreen mode

System info

Room temp

Serial Number

Battery Level

Application

Sw. ver. RE

Sw. ver. RU

.

General Param.

Enter code

3 7 4 9

Parameter

P_10 1

ModBus address

Min 0

value

2

Max 79

Appl. Param.

Enter code

9 4 7 3

Parameter

P_19 02

1 or 2 room un its

Min 0

values

1

Max 2

Alarms

Figure 10. To mount the room unit (thermostat).

Pos 1. Front piece.

Pos 2. Back piece.

Pos 3. Screws suitable for the supporting surface.

• Recommended installation height RU

= standard height for light switches

• RU should not be exposed to direct

sunlight, or other disturbing heat

sources

• Room air should be able to circulate

around the front and sides of the RU.

4

Swegon reserves the right to alter specications. 15-03-2017

Set point step

Commissioning

Figure 11. Overview over the menu system of the room unit.

Page 5

CONDUCTOR W4

Room unit overview

5

4

3

2

1

Figure 12. Overview of the main image of the room unit.

Pos 1. Cursor key for moving DOWN.

Pos 2. Cursor key for moving to the LEFT.

Pos 3. Heating/cooling.

Pos 4. Battery charge status/Window status.

Pos 5. Current airflow.

Pos 6. Operating mode.

Pos 7. Current temperature.

Pos 8. Carbon dioxide content.

Pos 9. Occupancy status

Pos 10. Cursor key for moving UP.

Pos 11. Cursor key for moving to the RIGHT.

Pos 12. OK key.

6

7

8

9

10

11

12

RF pair-up (When RJ12 not used)

OK 3 sek.

Main menu

Setup

<Exit Select>

▲▼

Press code

1

919

▲▼

<Exit >

ModBUS

RF pair-up

RF Quality

<Exit Select>

▲▼

RF pair-up

0000

0

▲▼

<Exit Select>

......................

Conductor RE W4

Modbus Adress 2

Artnr: 942334001

RF id: 00350

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

Product identification label

on the controller.

15-03-2017 Swegon reserves the right to alter specications

5

Page 6

CONDUCTOR W4

Conductor to BMS and SuperWise

First and

middle zone

Last RE in zone

Last zone

Last RE in zone

6

Swegon reserves the right to alter specications. 15-03-2017

Page 7

CONDUCTOR W4

FCC ID: ZIW-COND02

This device complies with part 15 of the FCC rules and RSS-210 of IC rules. Operation is subject to the following

two conditions: (1) This device may not cause harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Cet équipement est conforme au chapitre 15 des directives FCC et RSS-210 des directives IC. Son fonctionnement

est soumis aux deux conditions suivantes: (1) cet appareil ne doit pas causer d'interférences nuisibles, et (2) cet

appareil doit accepter toute autre interférence reçue, y compris celles pouvant entraîner un dysfonctionnement.

Changes or modification not expressly approved by the partly responsible for compliance could void the user’s

authority to operate the equipment.

Toute transformation ou modification non expressément autorisée par l'autorité responsable de l'appareil est

susceptible de faire perdre à l'utilisateur son droit d’utiliser l’équipement.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference in a

residential installation. This equipment generates, uses, and can radiate radio frequency energy and if not installed

and used in accordance with the instructions, may cause harmful interference to radio communications. However,

there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

- Reorient or relocate the receiving antenna. – Increase the separation between the equipment and receiver. –Connect the equipment into an outlet on a circuit different from that to which the receiver is connected. –Consult the

dealer or an experienced radio /TV technician for help.

"The term "IC" before the equipment certification number only signifies that the industry Canada technical

specifications"

"Le terme « IC » figurant devant le numéro de certification de cet équipement signifie uniquement le respect des

spécifications techniques de Canada Industrie."

For US and Canada market

WARNING:

All electrical installation, including wiring the actuators, valve actuators and various sensors is to be

carried out by the electrical contractor or the systems contractor.

The power feeding shall be a Low Voltage class 2 circuit.

Safety precautions / Responsibility

It is the responsibility of the user to do the following:

• Assess all the risks involved in the activities which are related to this instruction.

• Make sure that all necessary safety precautions are made be-fore starting the activities which are

related to this instruction.

15-03-2017 Swegon reserves the right to alter specications

7

Page 8

CONDUCTOR W4

8

Swegon reserves the right to alter specications. 15-03-2017

Loading...

Loading...