Swegon CONDUCTOR W1, CONDUCTOR W3 Technical Manual

CONDUCTORTM W1/W3

Technical Manual

Updated : 2012-11-16

SW version 0.76

Contents

Contents

Introduction and Safety .....................................5

About this Manual .................................................. 5

Product Design Changes ......................................... 5

Safety Precautions .................................................. 5

Technical Description ......................................... 7

About Conductor W1/W3 ...................................... 7

Controller and Room Unit (thermostat) ................... 7

Installation Examples .............................................10

Operating Mode .................................................... 11

Operating Modes ..................................................13

Functions ...............................................................14

Technical Data RE Controller ..................................16

Technical Data RU room unit..................................17

Installation ....................................................... 19

Ordering, Delivery and Electrical Installation ...........19

Preparations ..........................................................20

Step 1, To Mount the Controller. ............................21

Step 2, To Connect the Units .................................23

Step 3, Commissioning ..........................................24

Step 4, To Install the Room Unit (thermostat) .........26

The Menus of the Room Unit RU (thermostat) ... 27

The Main Image and the Key Pad of the RU ...........27

Overview of the Menu System of the RU ...............29

Navigating in the Menus of the Room Unit ........... 30

Changes in the Main Image ...................................31

Changes and Settings in the Service Menu ............32

Service ............................................................. 41

Parameters ............................................................41

System Parameters.................................................41

Application Parameters

W1 ........................................................................43

W3 ........................................................................45

Indications on the Controller ..................................49

Troubleshooting ................................................... 50

ModBus Register W1 .............................................52

ModBus Register W3 ........................................... 58

3

Contents

4

Introduction and safety

About this manual

This manual is intended for use by the members of the staff who are

responsible for maintenance of the climate system and it contains the

following information:

• Technical description of the CONDUCTOR W1/W3 controller.

• Installing and commissioning the CONDUCTOR W1/W3 controller .

• Instructions on how the various settings should be entered in the room

unit (thermostat).

The Service section is intended for personnel who are specially trained by

Swegon.

Product design changes

Swegon reserves the right to change the specifications in the manual and

change the design of the product without notice.

Safety precautions

Introduction and Safety

Responsibility

It is the responsibility of the user to do the following:

• Assess all the risks involved in the activities which are related to this

manual.

• Make sure that all necessary safety precautions are made before

starting the activities which are related to this manual.

Safety levels

The following levels of safety warnings are used in this manual:

WARNING:

Used when there is risk of damage to persons or

equipment.

N.B.!

Used to point out important information.

1 : 5

Introduction and Safety

1 : 6

Technical Description

About Conductor W1/W3

CONDUCTOR W1/W3 is a controller application in the CONDUCTOR series.

The W designation indicates that the application is applicable to waterborne climate systems.

CONDUCTOR is a control system for the individual control of room

temperature and airflow (W3)., especially adapted for partitioned offices

and hotel rooms. It can operate independently or in combination with a

central system.

Controller and Room Unit (thermostat)

The main components in the CONDUCTOR W1/W3 control system are a

controller and a room unit (thermostat).

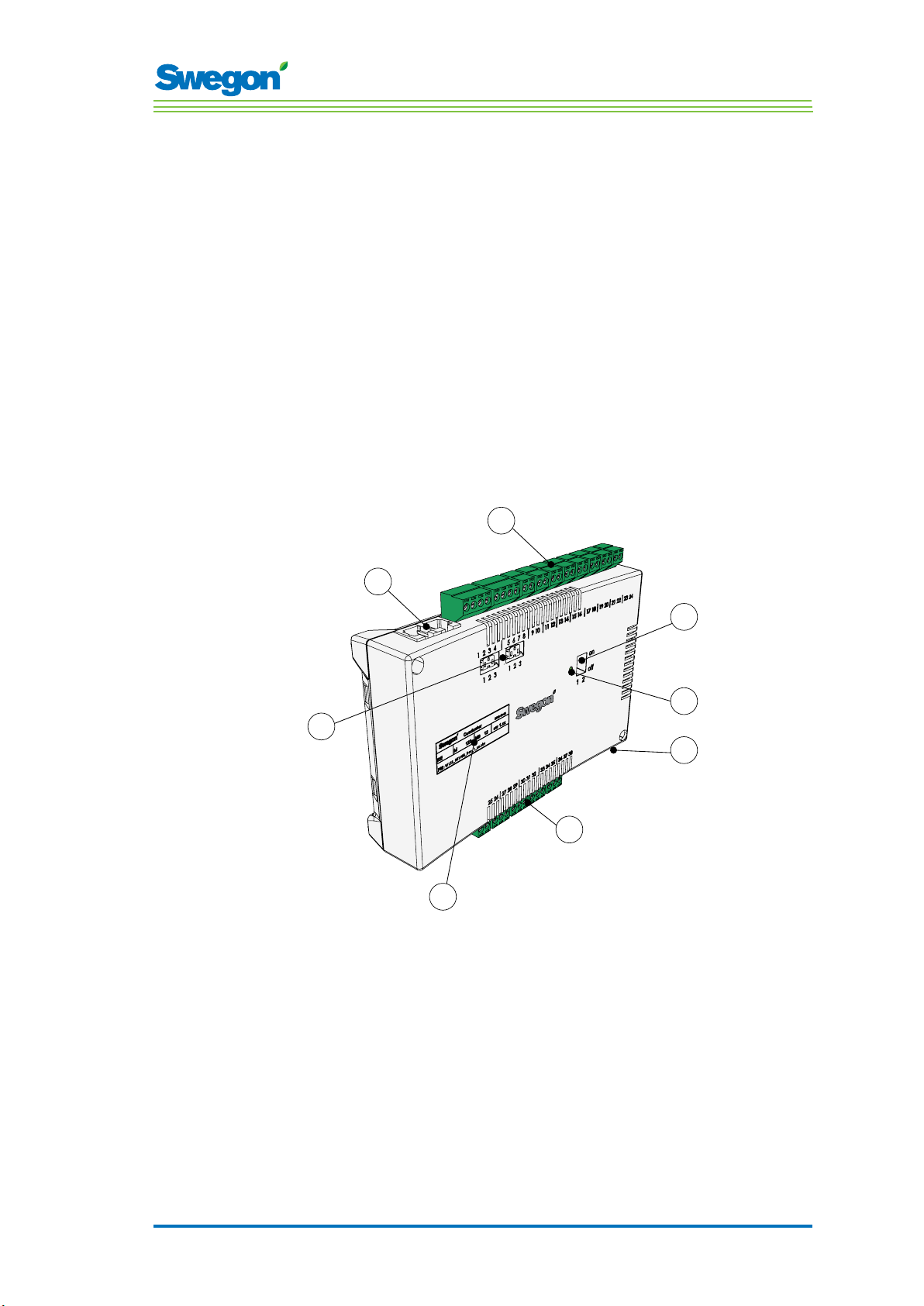

Controller

4

Technical Description

3

5

6

2

7

8

1

Figur 1. Overview of the Controller.

Pos 1. Product marking.

Pos 2. Termination resistance.

Pos 3. Modbus RTU units.

Pos 4. Inputs: Wiring terminals for the connection of sensors.

Pos 5. DIP switch for ModBUS RTU.

Pos 6. LED, indicates the status of the controller.

Pos 7. Input and output for signal to external relay.

Pos 8. Outputs: Wiring terminals for the connection of valve and damper actuators.

2 : 7

Technical Description

The controller is equipped with inputs for connection of a condensation

sensor, carbon dioxide sensor, window switch, presence detector and

outputs for the connection of actuators for valves and air dampers.

Up to twelve pairs of actuators (twelve for cooling + twelve for heating) can

be wired to each controller. Or you can connect up to four complete units

per controller for controlling both the airflow (supply air and central extract

air, 5 damper actuators) and cooling and heating (cooling and heating

circuit, valve actuators).

The controller provides proportional and integral (PI) control. Through

so-called PWM control (pulse width modulation), the I section senses both

the size and the duration of the control deviation and adjusts the actuator

opening time accordingly. It is possible to switch over from PWM control to

0-10 V control, if needed.

The user can easily configure the controller functions and parameters by

means of the room unit (thermostat).

The controller has a built-in communication port that enables connection to

an RS 485 network with ModBus RTU for supervising and override control

via a main control system.

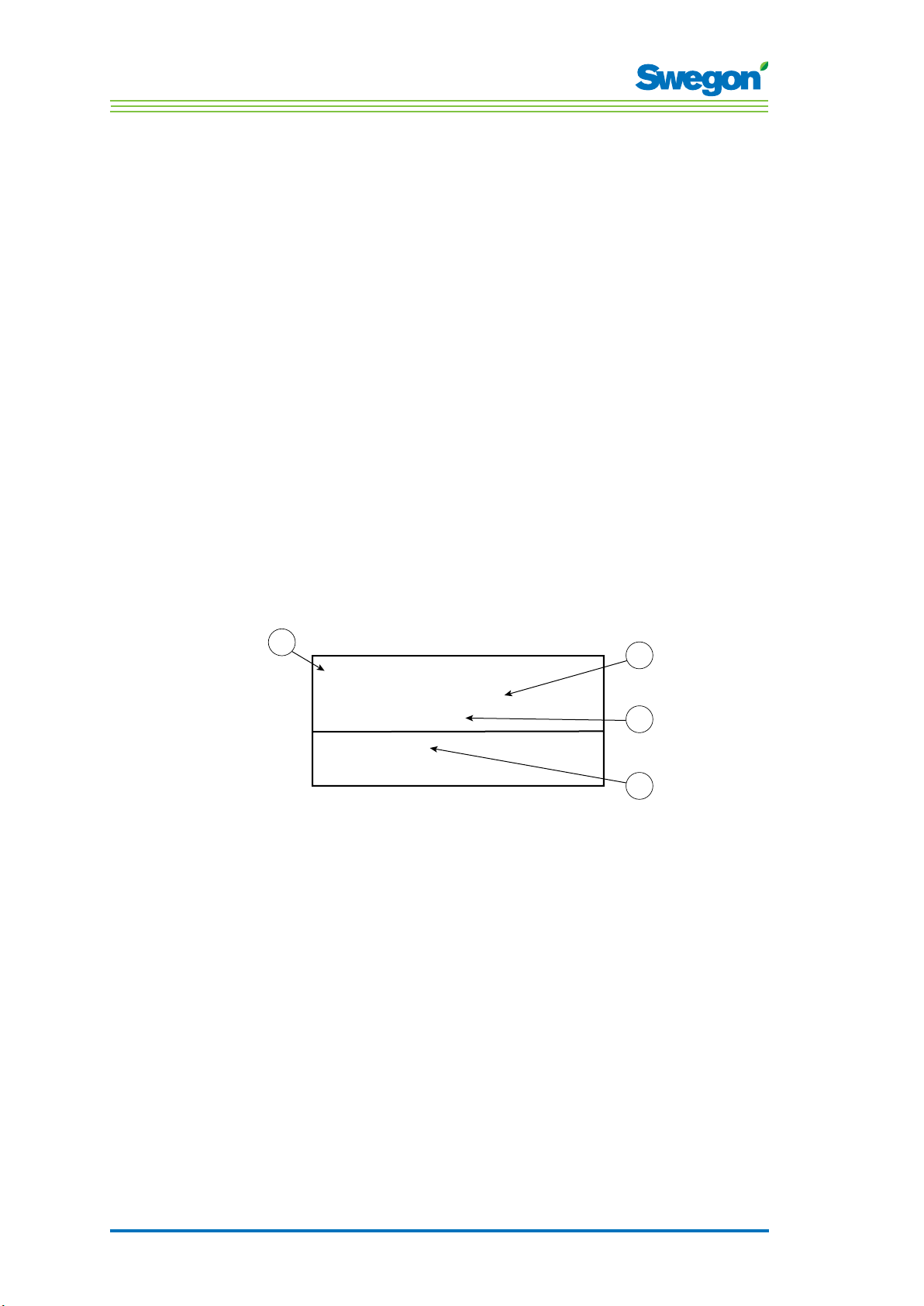

Product Identification Label

The product identification label affixed to the front of the controller,

indicates rated data, the controller ID-number, which you will need when

you install the CONDUCTOR.

1

2

Conductor RE W1

Modbus Adress 2

Artnr: 942334001

3

RF id: 00350

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

4

Figur 2. Product identification label on the controller.

Pos 1. Name of the product.

Pos 2. ModBus RTU address.

Pos 3. Part number.

Pos 4. Controller ID number.

2 : 8

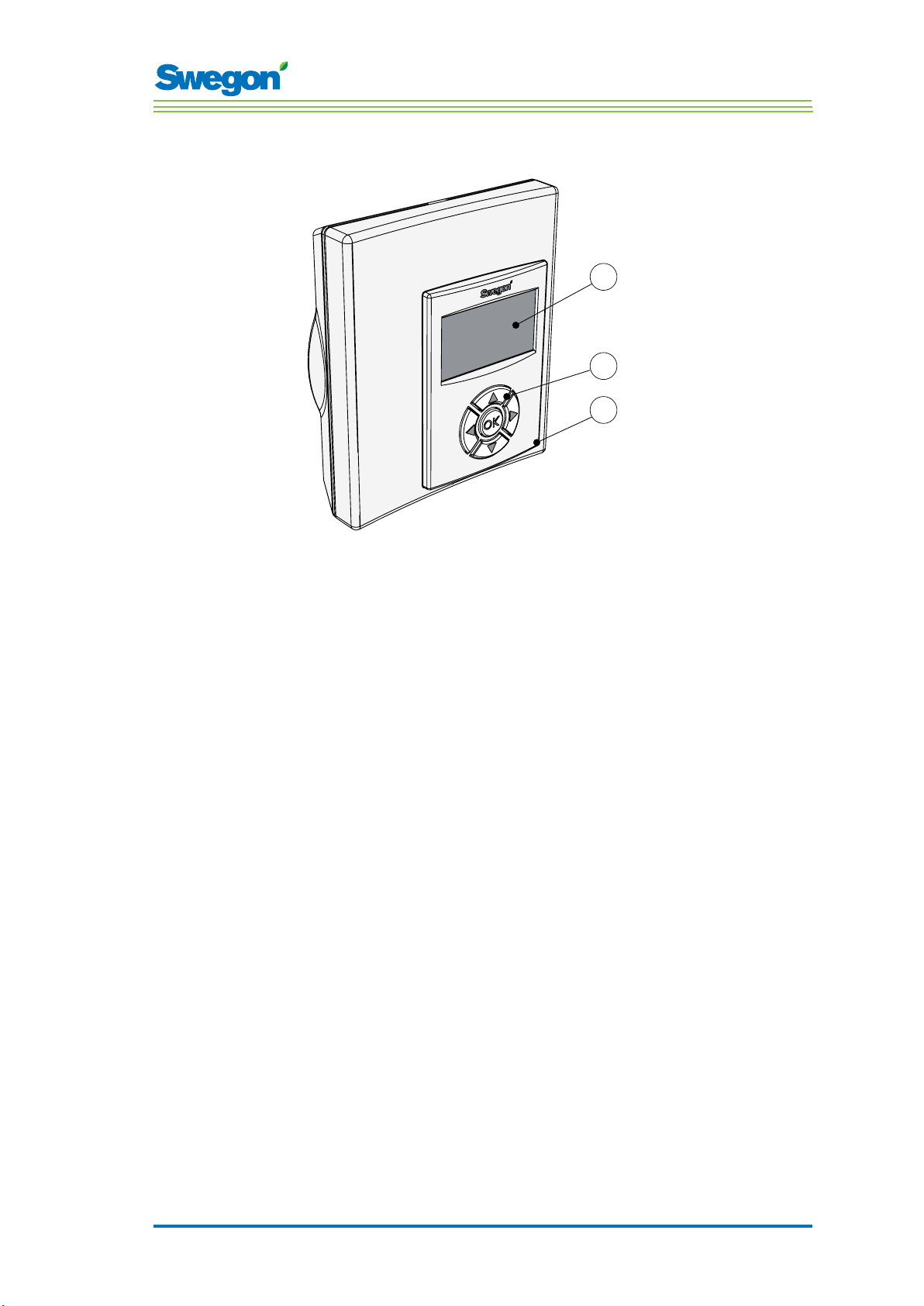

Room Unit

Technical Description

1

2

3

Figur 3. Overview of the room unit (thermostat).

Pos 1. Display

Pos 2. Keypad.

Pos 3. Temperature sensor.

The room unit is simple to use and has an easy-to-interpret design

that makes it user-friendly. The digital display shows the current preset

temperature and airflow settings.

The function of the room unit is to measure the temperature in the room,

communicate with the controller and to serve as a tool for adjusting the

climate in the room.

The internal communication between the controller and the room unit is

wireless, which makes it easier to find an appropriate spot in the room

where the room unit can be installed.

If requested, the room unit can be wire-connected with a RJ12 cable to the

controller.

2 : 9

Technical Description

Installation Examples

The illustration below shows a typical arrangement of a complete

installation with the CONDUCTOR W1/W3 control system.

3

RU

GT

24V AC

4

RE

2

1

5

GX

GX

GX

7

6

12

Figur 4. Example of a CONDUCTOR W1/W3 installation.

Item Component Quantity Description

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Accessories

PARASOL 1192-B-HF

CONDUCTOR RE W1/W3

CONDUCTOR RU

SYST TS-1

SYST CG

DETECT Occupancy 1 Presence detector

External

LUNA a AT-2

SYST VD 115-CLC

SYST CRTc 9-125-2 CM 24

CLA 125-500

Extract air register

SYST MS

Comfort module including cooling, heating and

1

ventilation

Controller

1

Room unit

1

Transformer

1

Condensation sensor

1

Window contact, not supplied by Swegon (W3)

1

Valve actuator

2

Control valve

2

Supply air damper 1 including motor (W3)

1

Extract air damper 1 including motor (W3)

Sound attenuator

1

Extract air register with given C-Factor

1

Assembly part for suspending the PARASOL

4

Not necessary if the product is mounted directly

against the ceiling.

11

10

9

8

10

11

2 : 10

Operating Mode

Applications

These instructions deal with two different applications: W1 and W3. W

indicates that both the applications are applicable to waterborne climate

systems.

A waterborne system provides the room with waterborne heating and

cooling. The air-based systems which can be controlled in the W3 by means

of connected damper actuators are only used to satisfy the demands on

air quality, while the temperature of the supply air and extract air is kept

constant.

Depending on the status of connected sensors, the controller adjusts the

outputs from any of several possible operating conditions. The various

operating conditions described here are based on occupancy in the room

and the status of the window switch and condensation sensor.

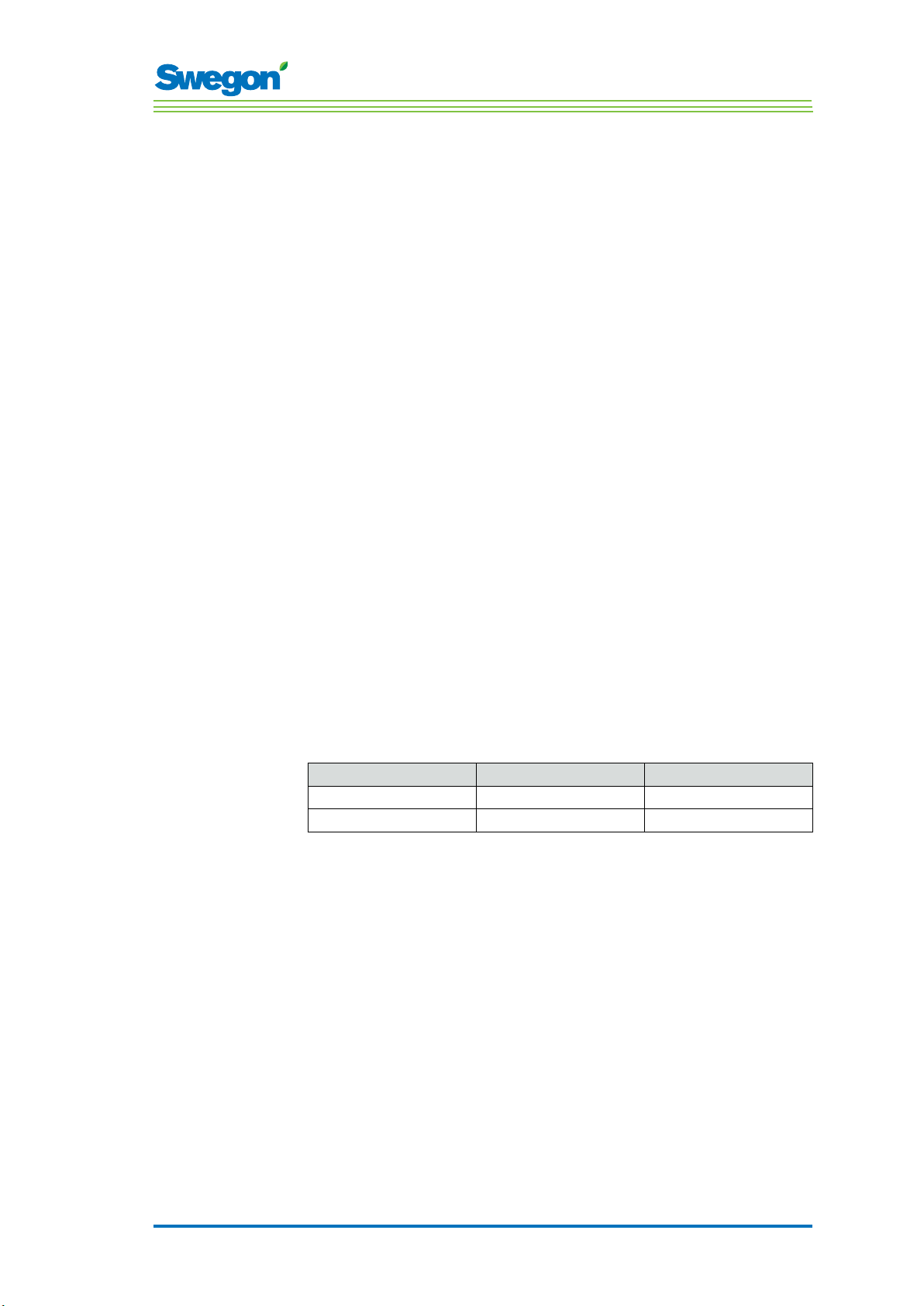

W1

Technical Description

W1 is a standard solution for offi ces, mainly designed for partitioned offi

ces, but which also can be used in large rooms, as with open-plan offi ces.

The application is suitable for so called CAV systems (Constant Air Volume),

which means that the airfl ow in the room is constant and that no damper

actuators are needed. Only two outputs are used, one for actuators that

control cooling and one for actuators that control heating. There is provision

for connecting a condensation sensor, a temperature sensor and an

presence detection sensor.

Table 1. Operating conditions for application W1

Condensation Cooling Heating

Yes Off Normal

No Normal Normal

2 : 11

Technical Description

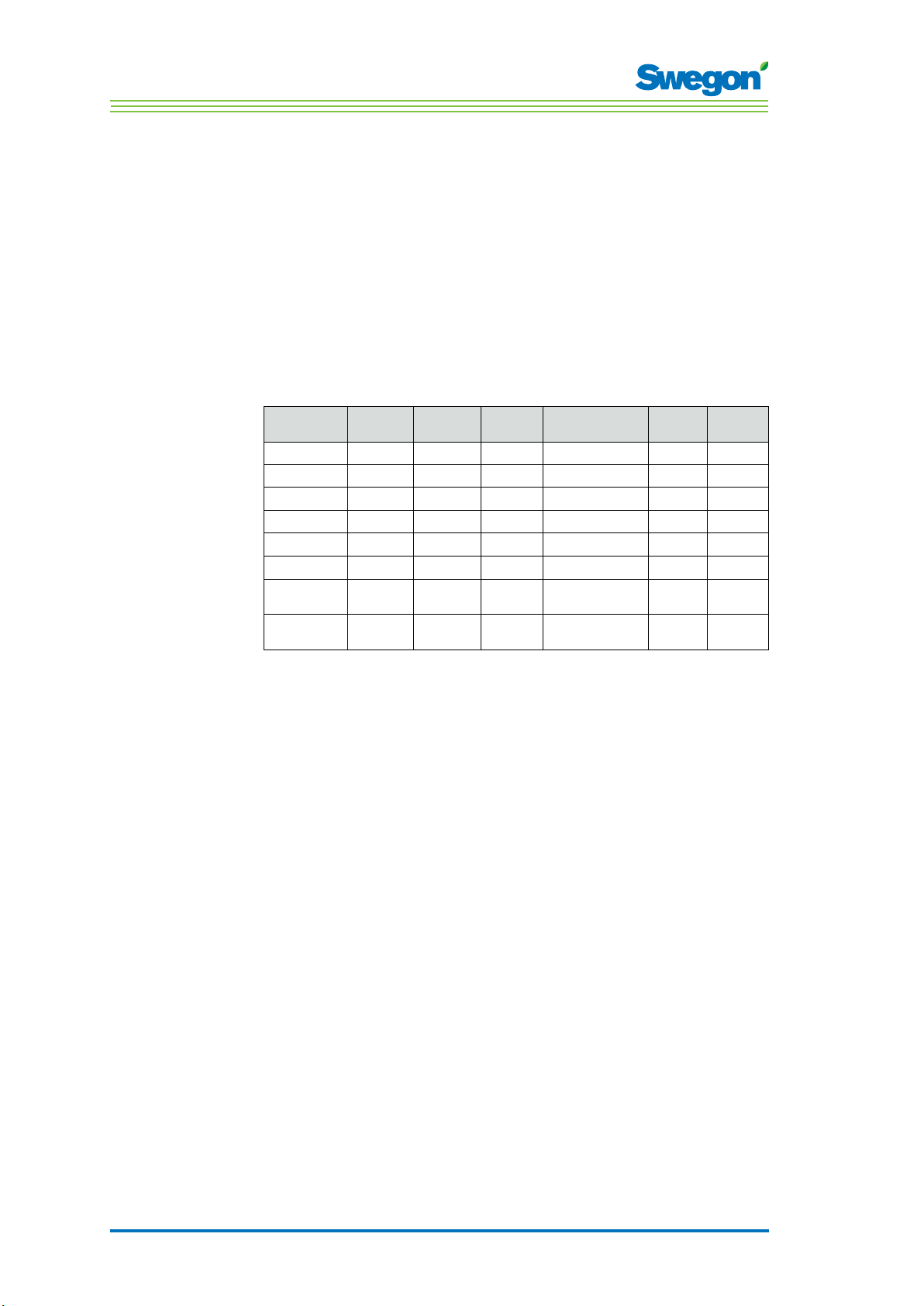

W3

The W3-application can be used either for offi ces or for hotel rooms. It is

well-suited for systems with variable airfl ow (VAV) with both supply air and

extract air. Four outputs are used to control heating, cooling, supply and

extract air. The damper motors are adjusted depending on the generated

airfl ow and duct pressure in both the supply and extract air ducts.

Three inputs are used; for condensation sensors, window switches and

presence detectors. The principle is to use minimal, normal or high airfl ow,

depending on occupancy and sensor status.

Table 3: Operating conditions for application W3

Occupancy Window Conden-

sation

Yes Yes Yes Off Frost protection Min. Min.

Yes Yes No Off Frost protection Min. Min.

Yes No Yes Off Normal Max. Max.

Yes No No Normal Normal Normal Normal

No Yes Yes Off Frost protection Min. Min.

No Yes No Off Frost protection Min. Min.

No No Yes Off

No No No Normal

Cooling Heating Supply

Normal/Energy

saving

Normal/Energy

saving

air

Min. Min.

Min. Min.

Extract

air

2 : 12

Operating Modes

There are a variety of functions built into the CONDUCTOR:

• MAN, manual mode.

• AUTO, automatic mode.

• ECON, energy-saving mode.

• Stand-by mode.

• EMERG, emergency mode.

MAN, Manual operating mode.

Whenever the CONDUCTOR registers occupancy in the room in response

to signals from a presence detector, the user can regulate the temperature

and airflow rate by entering settings in the room unit. When the user enters

a new desired setting, the controller switches over to the manual operating

mode (MAN).

AUTO, Automatic operating mode.

When the CONDUCTOR no longer registers occupancy in the room, the

controller automatically decreases the supply air flow to the low airflow

setting and the system automatically returns to the AUTO mode.

Technical Description

The controller also switches automatically to the AUTO mode after a

predefined number of minutes after the most recent change, manually

entered on the room unit.

When the controller is set to the automatic mode, the valve actuators for

chilled water and hot water respectively and the supply air damper and

extract air damper respectively are adjusted in response to occupancy in the

room and the level of carbon dioxide as well as the status of the window

contact and the condensation sensor.

The automatic control system controls the airflow, cooling and heating until

the user manually enters a new airflow or temperature setting.

ECON, energy-saving mode.

When the energy-saving function is enabled, the system switches

automatically to the ECON energy-saving mode, when no occupancy has

been registered for a predefined number of minutes. The system returns to

the AUTO mode when occupancy is registered again.

In the energy-save mode, the valve actuator is controlled for chilled water

and hot water respectively according to the status on other sensors in the

room, but with a greater permissible difference between actual value and

setpoint than in the AUTO mode.

2 : 13

Technical Description

Stand-by mode.

When the control system registers a signal indicating that a window is open,

the controller switches over to the standby mode. When the window is

closed, the controller switches to the AUTO operating mode.

While the controller is in the Stand-by mode, the room temperature is

maintained above the predefined level for the Frost protection function.

EMERG, emergency mode.

In the event of a fire alarm, the air damper in the extract air duct is opened

or closed, depending on the setting entered in the control system. The

cooling and heating functions are shut off while the system is in the EMERG

mode. The supply air is normally shut off.

The EMERG mode can only be managed in control systems that are

connected to a main control system via ModBus RTU.

Functions

There are a variety of functions built into the CONDUCTOR W1/W3:

• Exercising of valves

• First open

• Frost protection

• Change over

• Night cool

• Time-set setpoint restoration

Exercising of valves

The function involves regularly exercising the water valves by utilising

automated functions in order to prevent them from becoming sluggish or

jamming. During the exercising period, all the valves that are wired to the

controller are opened for a maximum of 6 minutes and are then closed.

The valves for the cooling system are exercised first. Then the valves for the

heating system are exercised.

First open

The function means that the water valves are open when the system is

installed, which makes it easier to fill, pressure test and vent the water

system.

The function will be automatically disabled after the actuator has been

energized for approx. 6 minutes. A clicking noise will be heard when the

valves and the dampers change over to the NC mode (=normally closed)

and the normal control function is enabled.

2 : 14

Technical Description

Frost protection

The function involves the following: Heating operation is started at a

predefined room temperature in order to counteract the risk of damage that

otherwise can arise due to freezing.

Change over

The function involves the use of only one valve actuator which should be

wired to the cooling output terminal. This actuator then controls both the

heating water and the cooling water, which are transported in the same

pipe.

In winter, when heating is required, the valve opens if the water in the pipe

is warmer than the temperature setpoint. If the water is colder, the valve

does not open.

In summer, when cooling is required, the valve opens if the water in the pipe

is colder than the temperature setpoint.

In order to be able to use this function, you are required to mount an

external temperature sensor onto the water pipe through which supply

water circulates continuously. Wire the sensor according to the general

wiring diagram shown in the section entitled: Installation

Night cool

The function involves using cold air from outdoors for cooling the room at

night to the predefined level.

The function can only be managed in control systems that are connected to

a main control system via ModBus RTU.

Time-set setpoint restoration

The function involves adjusting the room temperature to the predefined

level when the controller switches to the AUTO operating mode.

The controller also switches automatically to the AUTO mode after a

predefined number of minutes after the most recent change, manually

entered on the room unit.

2 : 15

Technical Description

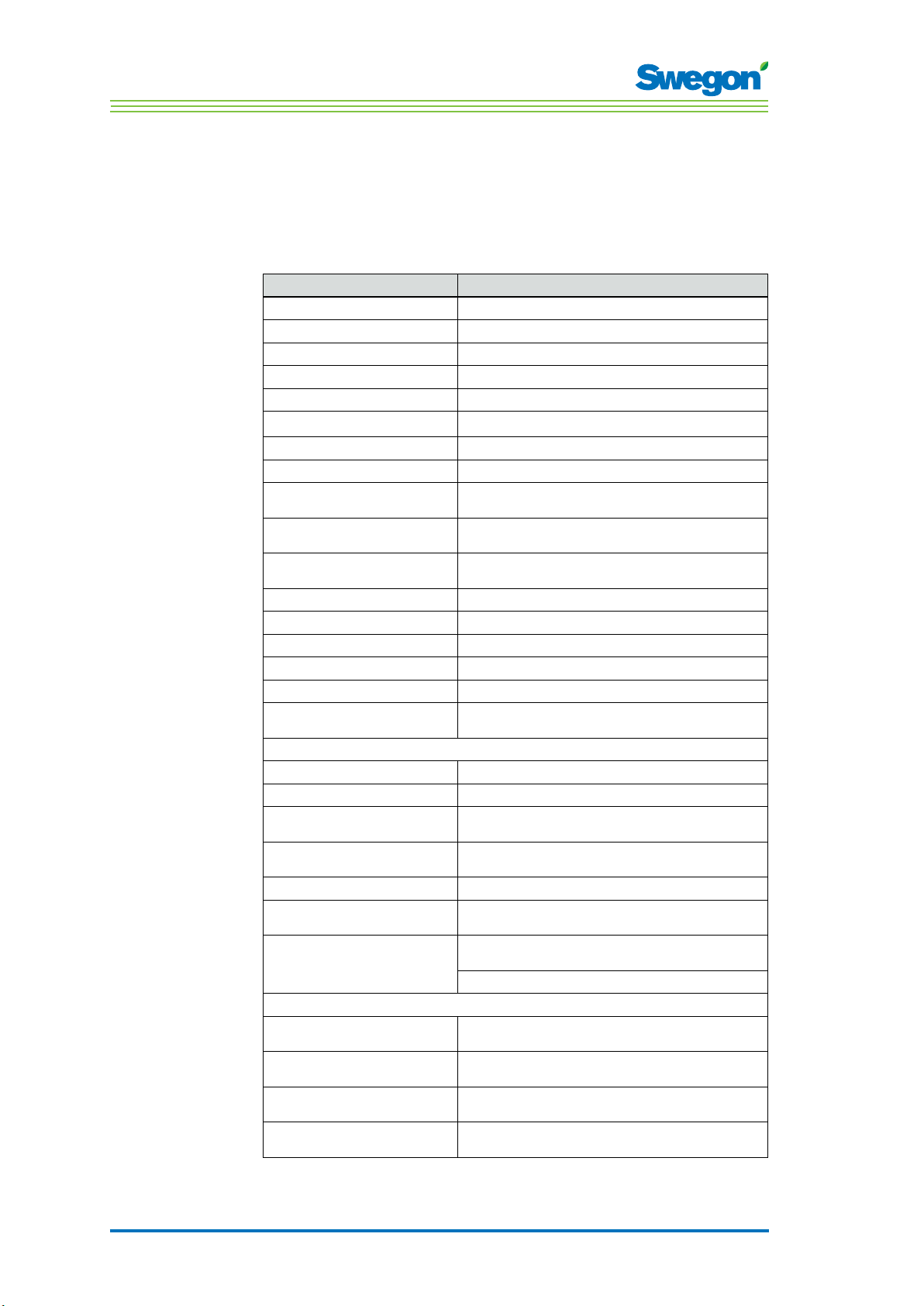

Technical Data

CONDUCTOR RE Controller

Technical data applicable to the CONDUCTOR RE controller (W1/W3) is

specified below.

Item Data

Designation CONDUCTOR RE (W1/W3)

Storage temperature -40 °C to +80 °C

Operating temperature -20 °C to +50 °C

Degree of protection IP 32

Dimensions 121 x 193 x 44 mm

Supply voltage 24V AC ± 10%

Power consumption 1 VA

Control function PI

P-band, cooling/heating

increments

Dead band, occupancy in

room

Dead band, no occupancy Depends on switching in cooling and switching in

Frost protection 10 °C

Valve installation 1 time/48h period (fully open for 3 minutes)

Installation Mounting holes in enclosure or onto DIN rail

Connections Wiring terminal for 2.5 mm² multicore cable

Data communication ModBus RTU

Wireless communication 433 MHz band radio modem with room unit

Inputs

Condensation sensor Resistance

Temperature sensor Resistance

Presence detector No occupancy/NO/NC (optional), default = NC for

Window contact

Carbon dioxide sensor 2 - 10 V, or 24 V

Pressure sensor / ModBus RTU

sensor

Modular contact RJ12 6-pole for connecting up to the room unit

Outputs

Actuator, heating 24 V AC, PWM (on/off or 0 - 10 V) max load: 72

Actuator, cooling 24 V AC, PWM (on/off or 0 - 10 V) max load: 72

Supply air damper

Extract air damper

(W3) No occupancy/NO/NC (optional), default = NC for

(W3) 0 - 10 V DC (low/normal/high) max load 25 VA =

(W3) 0 - 10 V DC (low/normal/high) max load 25 VA =

1 K

Depends on switching in cooling and switching in

heating

heating

(thermostat)

occupancy

closed window

2 - 10 V / RJ12 cable

(thermostat)

RJ12 6-pole for connecting up to ModBus RTU

VA = 12 actuators

VA = 12 actuators

5 actuators.

5 actuators.

2 : 16

Technical Description

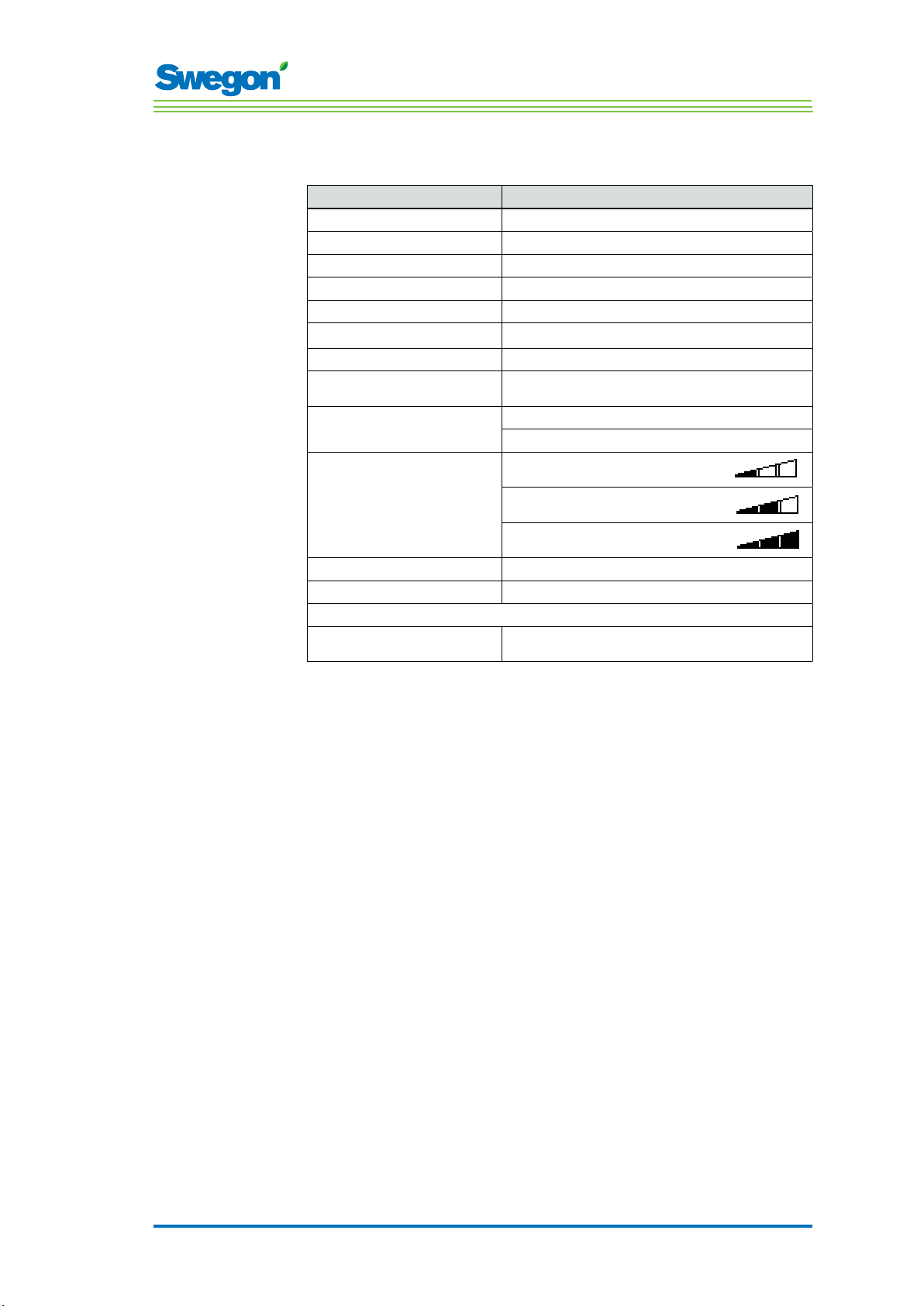

CONDUCTOR RU room unit (thermostat)

Item Data

Designation: CONDUCTOR RU

Storage temperature -40 °C to +80 °C (*)

Operating temperature 0 °C to +50°C

Degree of protection IP 20

Dimensions 86 x 100 x 32 mm

Supply voltage 12 V, 4 size AAA batteries

Actual value, range +10 °C to +32°C

Installation Against a wall or in a 70 mm standard junction

In-operation LED, temperature Cooling load

In-operation LED, air Low airflow:

In-operation LED, enabled Lit LED, AUTO

In-operation LED, disabled Dimmed display, AUTO

Input

Modular contact RJ12 6-pole for connecting up to the controller

(*) = Specified storage temperature appies to a room unit WITHOUT batteries.

(**) = Used only if wireless communication is not desired.

box. Must not be exposed to direct sunlight

Heating load

One LED lit

Normal airflow:

Two LEDs lit

High airflow:

Three LEDs lit

(**)

2 : 17

Technical Description

2 : 18

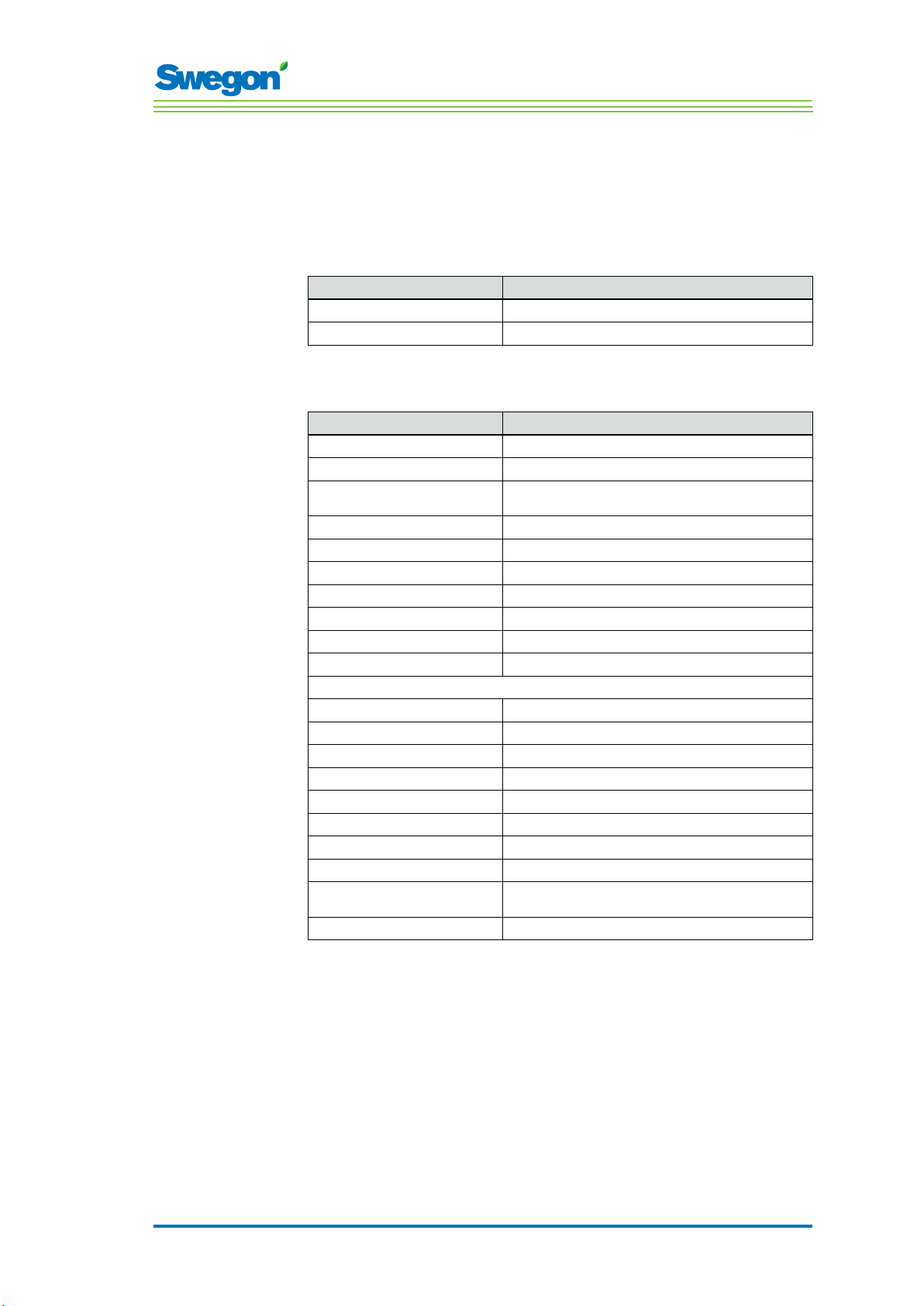

Installation

Ordering, delivery and electrical installation

Ordering key, Control equipment

Item Data

Controller W1/W3 CONDUCTOR RE (aa)

Room unit (Thermostat) CONDUCTOR RU

Ordering Key, Accessories

Item Data

Valve SYST VD 115-CLC

Valve actuator LUNA a AT-2

Ventilation damper incl.

damper actuator

Adapter, actuator/valve LUNA a T-VA-(aa)

Condensation sensor SYST CG

Carbon dioxide sensor DETECT Quality

Presence detector DETECT Occupancy

Modular cable RJ12 6/6, 5 metres long

Transformer SYST TS-1

External temperature sensor CONDUCTOR T-TG

SYST CRTc 9 (aaa)-2-CM-24

Installation

(aa) = Fitted to valve type:

32 Tour & Andersson

39 Oventrop

50 Honeywell, Reich, MNG, Böhnisch (H), Cazzaniga

54 Certain MMA-valves

59 Danfoss RAV/L

72 Danfoss RAV

78 Danfoss RA

80 Siemens and more (always included in the LUNA a

(aaa) = 125 or 160

AT-2 actuator)

3 : 19

Loading...

Loading...