Page 1

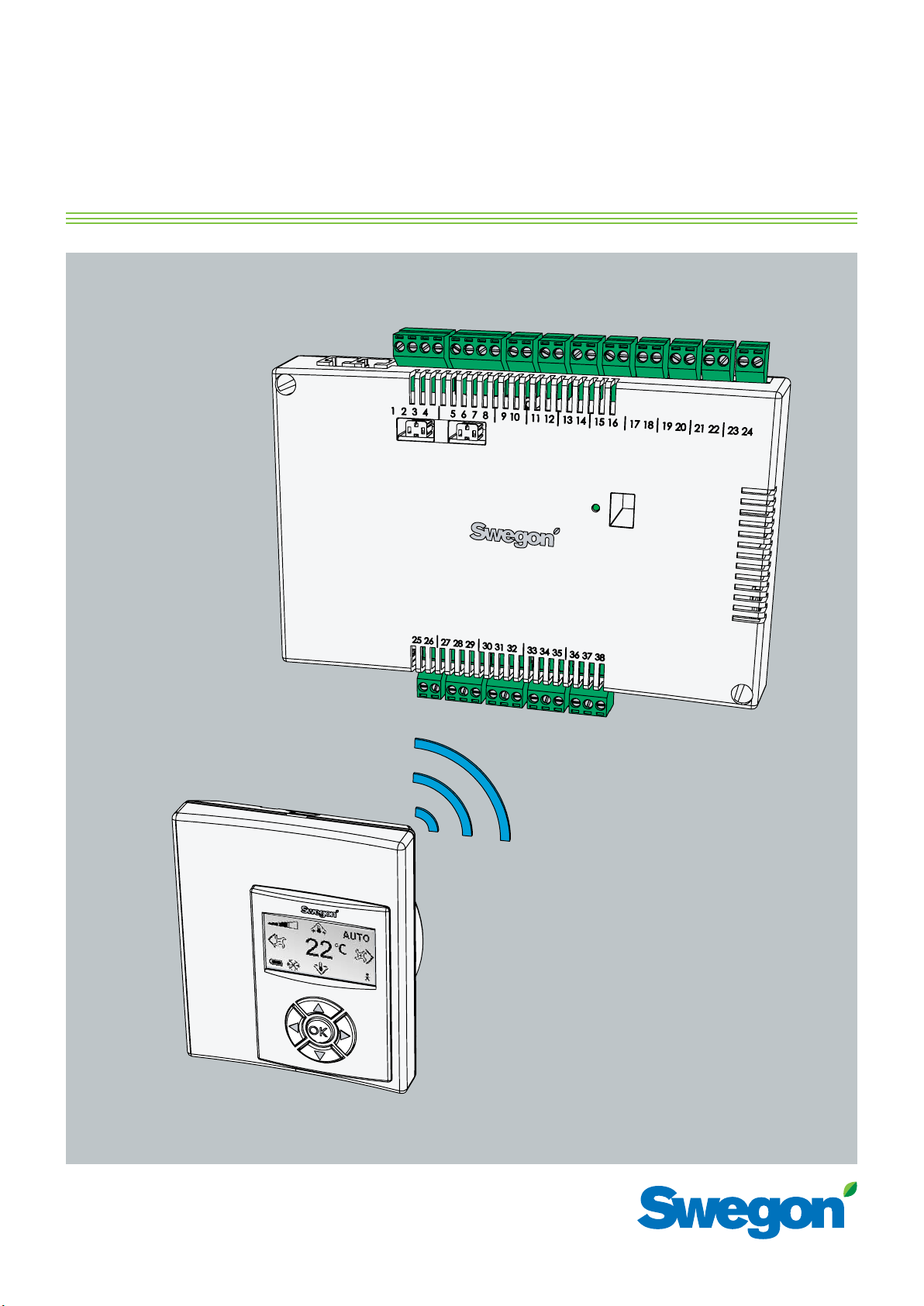

CONDUCTORTM W1/W3

Technical Manual

Updated : 2012-11-16

SW version 0.76

Page 2

Page 3

Contents

Contents

Introduction and Safety .....................................5

About this Manual .................................................. 5

Product Design Changes ......................................... 5

Safety Precautions .................................................. 5

Technical Description ......................................... 7

About Conductor W1/W3 ...................................... 7

Controller and Room Unit (thermostat) ................... 7

Installation Examples .............................................10

Operating Mode .................................................... 11

Operating Modes ..................................................13

Functions ...............................................................14

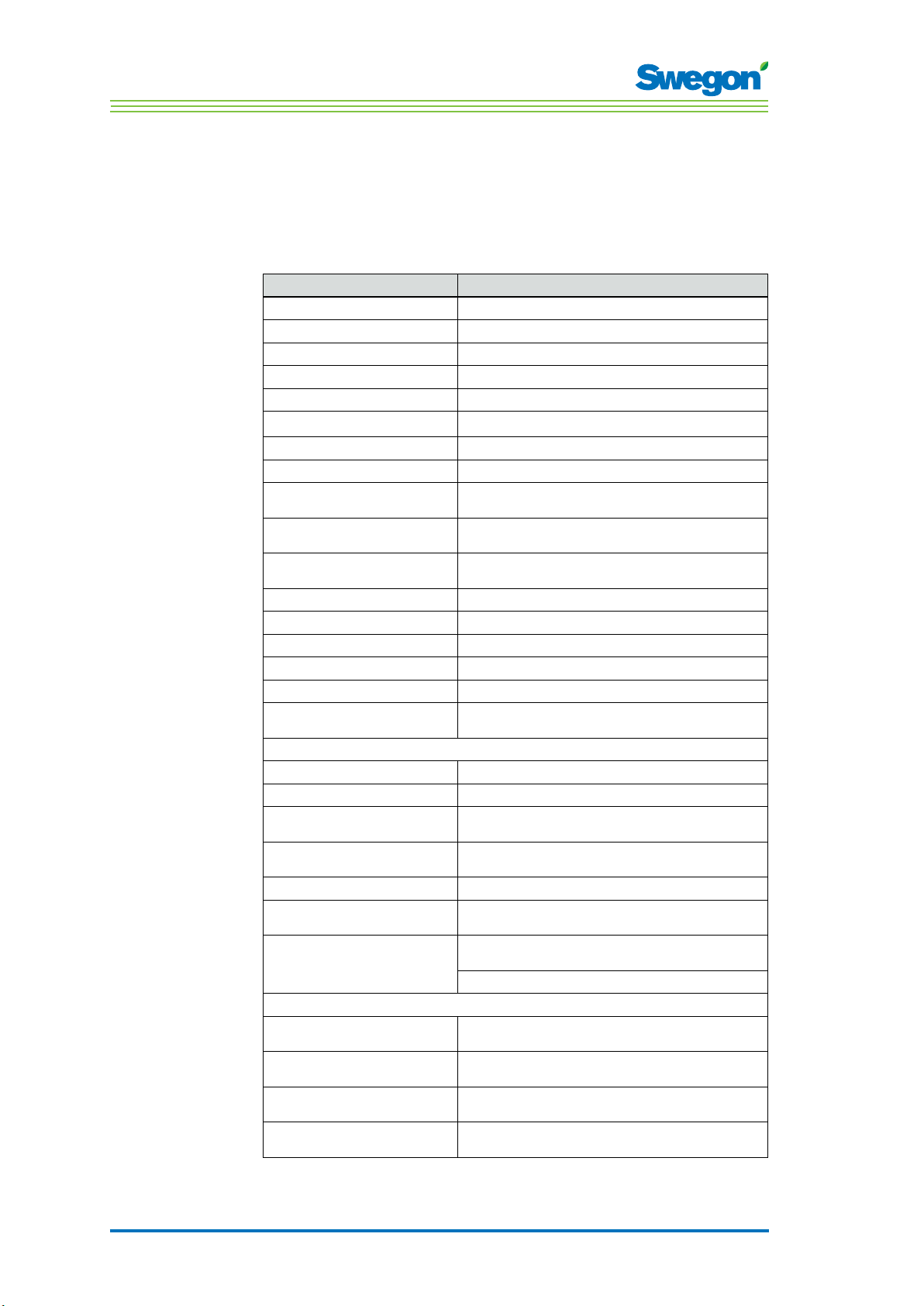

Technical Data RE Controller ..................................16

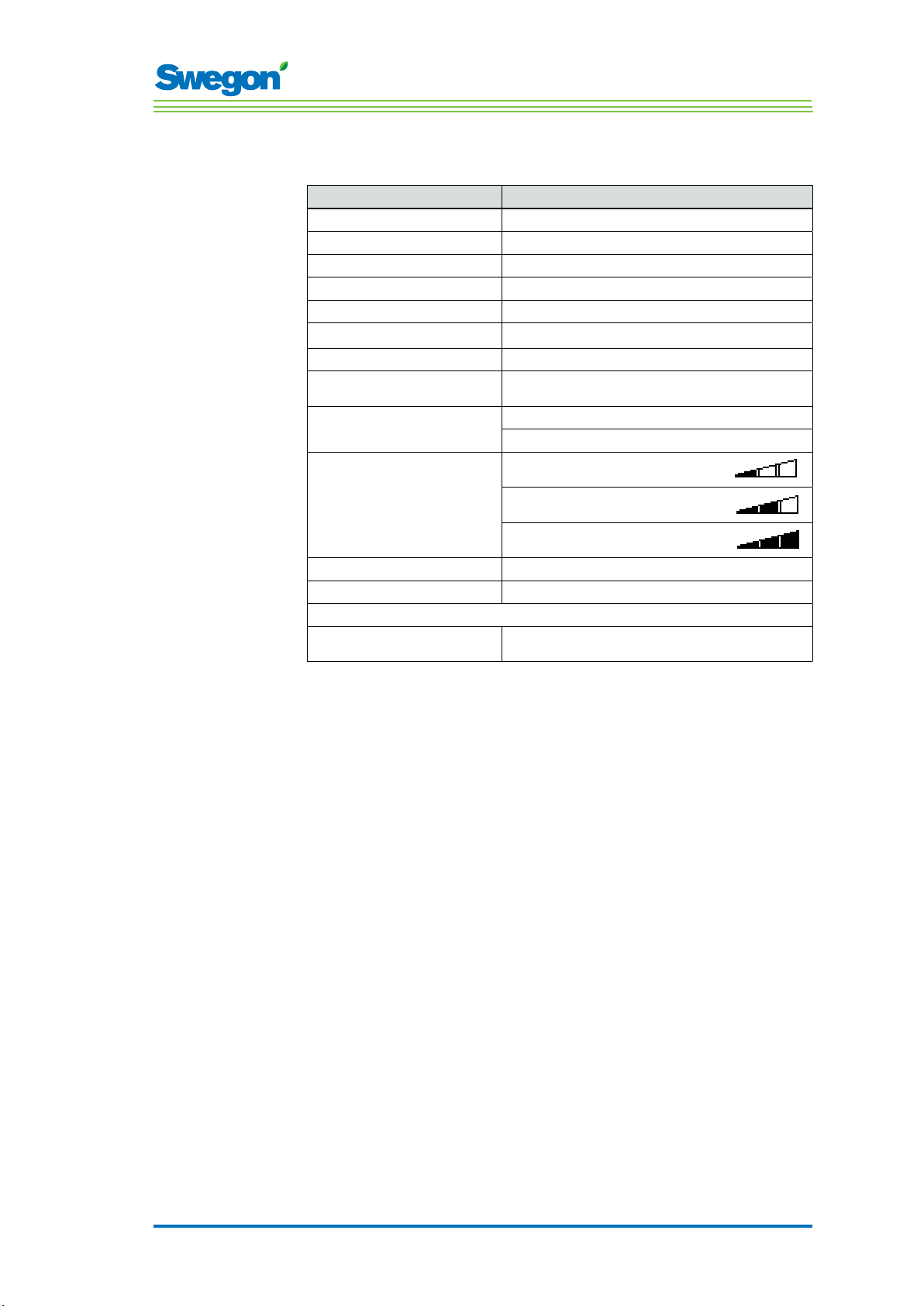

Technical Data RU room unit..................................17

Installation ....................................................... 19

Ordering, Delivery and Electrical Installation ...........19

Preparations ..........................................................20

Step 1, To Mount the Controller. ............................21

Step 2, To Connect the Units .................................23

Step 3, Commissioning ..........................................24

Step 4, To Install the Room Unit (thermostat) .........26

The Menus of the Room Unit RU (thermostat) ... 27

The Main Image and the Key Pad of the RU ...........27

Overview of the Menu System of the RU ...............29

Navigating in the Menus of the Room Unit ........... 30

Changes in the Main Image ...................................31

Changes and Settings in the Service Menu ............32

Service ............................................................. 41

Parameters ............................................................41

System Parameters.................................................41

Application Parameters

W1 ........................................................................43

W3 ........................................................................45

Indications on the Controller ..................................49

Troubleshooting ................................................... 50

ModBus Register W1 .............................................52

ModBus Register W3 ........................................... 58

3

Page 4

Contents

4

Page 5

Introduction and safety

About this manual

This manual is intended for use by the members of the staff who are

responsible for maintenance of the climate system and it contains the

following information:

• Technical description of the CONDUCTOR W1/W3 controller.

• Installing and commissioning the CONDUCTOR W1/W3 controller .

• Instructions on how the various settings should be entered in the room

unit (thermostat).

The Service section is intended for personnel who are specially trained by

Swegon.

Product design changes

Swegon reserves the right to change the specifications in the manual and

change the design of the product without notice.

Safety precautions

Introduction and Safety

Responsibility

It is the responsibility of the user to do the following:

• Assess all the risks involved in the activities which are related to this

manual.

• Make sure that all necessary safety precautions are made before

starting the activities which are related to this manual.

Safety levels

The following levels of safety warnings are used in this manual:

WARNING:

Used when there is risk of damage to persons or

equipment.

N.B.!

Used to point out important information.

1 : 5

Page 6

Introduction and Safety

1 : 6

Page 7

Technical Description

About Conductor W1/W3

CONDUCTOR W1/W3 is a controller application in the CONDUCTOR series.

The W designation indicates that the application is applicable to waterborne climate systems.

CONDUCTOR is a control system for the individual control of room

temperature and airflow (W3)., especially adapted for partitioned offices

and hotel rooms. It can operate independently or in combination with a

central system.

Controller and Room Unit (thermostat)

The main components in the CONDUCTOR W1/W3 control system are a

controller and a room unit (thermostat).

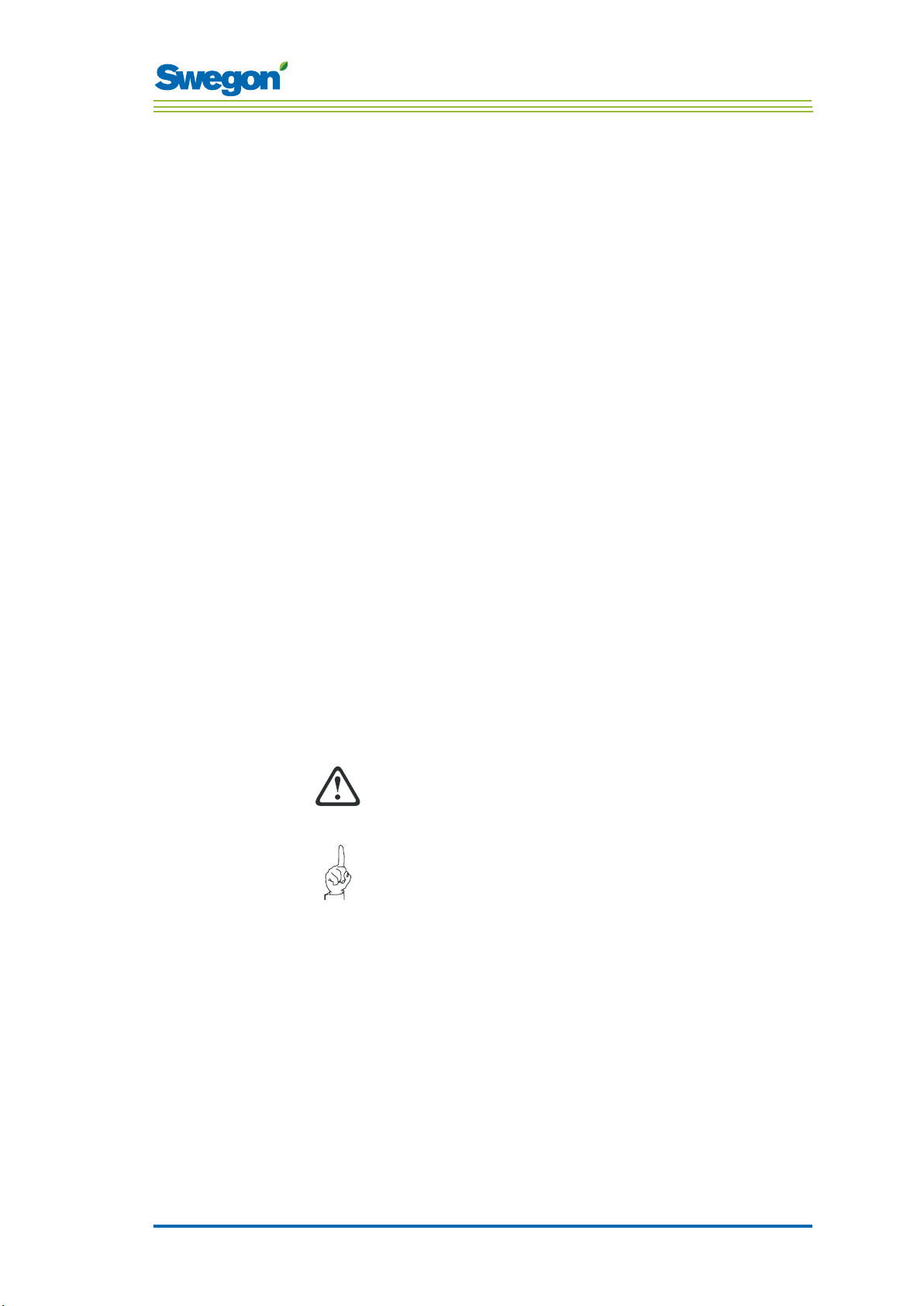

Controller

4

Technical Description

3

5

6

2

7

8

1

Figur 1. Overview of the Controller.

Pos 1. Product marking.

Pos 2. Termination resistance.

Pos 3. Modbus RTU units.

Pos 4. Inputs: Wiring terminals for the connection of sensors.

Pos 5. DIP switch for ModBUS RTU.

Pos 6. LED, indicates the status of the controller.

Pos 7. Input and output for signal to external relay.

Pos 8. Outputs: Wiring terminals for the connection of valve and damper actuators.

2 : 7

Page 8

Technical Description

The controller is equipped with inputs for connection of a condensation

sensor, carbon dioxide sensor, window switch, presence detector and

outputs for the connection of actuators for valves and air dampers.

Up to twelve pairs of actuators (twelve for cooling + twelve for heating) can

be wired to each controller. Or you can connect up to four complete units

per controller for controlling both the airflow (supply air and central extract

air, 5 damper actuators) and cooling and heating (cooling and heating

circuit, valve actuators).

The controller provides proportional and integral (PI) control. Through

so-called PWM control (pulse width modulation), the I section senses both

the size and the duration of the control deviation and adjusts the actuator

opening time accordingly. It is possible to switch over from PWM control to

0-10 V control, if needed.

The user can easily configure the controller functions and parameters by

means of the room unit (thermostat).

The controller has a built-in communication port that enables connection to

an RS 485 network with ModBus RTU for supervising and override control

via a main control system.

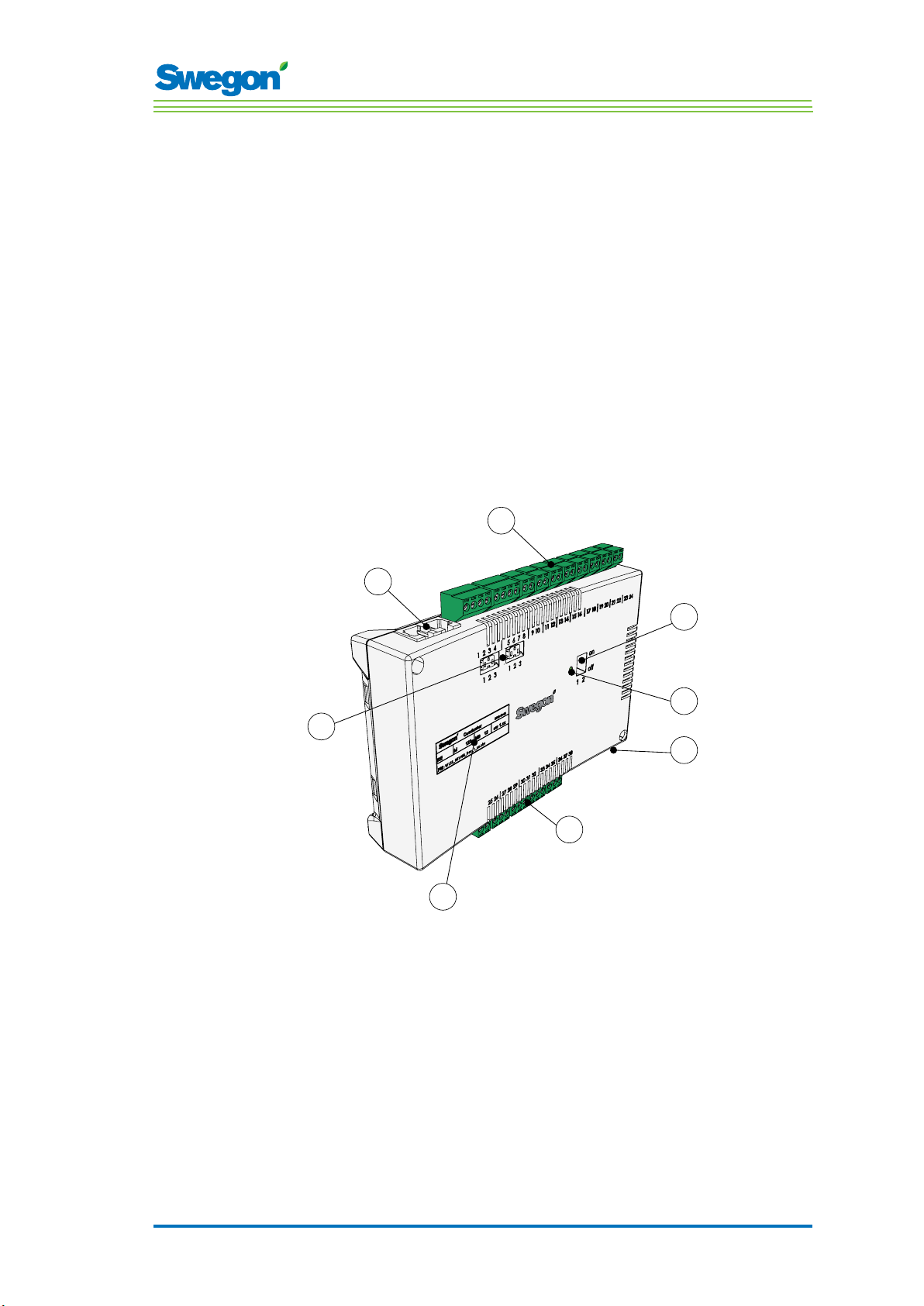

Product Identification Label

The product identification label affixed to the front of the controller,

indicates rated data, the controller ID-number, which you will need when

you install the CONDUCTOR.

1

2

Conductor RE W1

Modbus Adress 2

Artnr: 942334001

3

RF id: 00350

IIIIIIIIIIIIIIIIIIIIIIIIIIIIIII

4

Figur 2. Product identification label on the controller.

Pos 1. Name of the product.

Pos 2. ModBus RTU address.

Pos 3. Part number.

Pos 4. Controller ID number.

2 : 8

Page 9

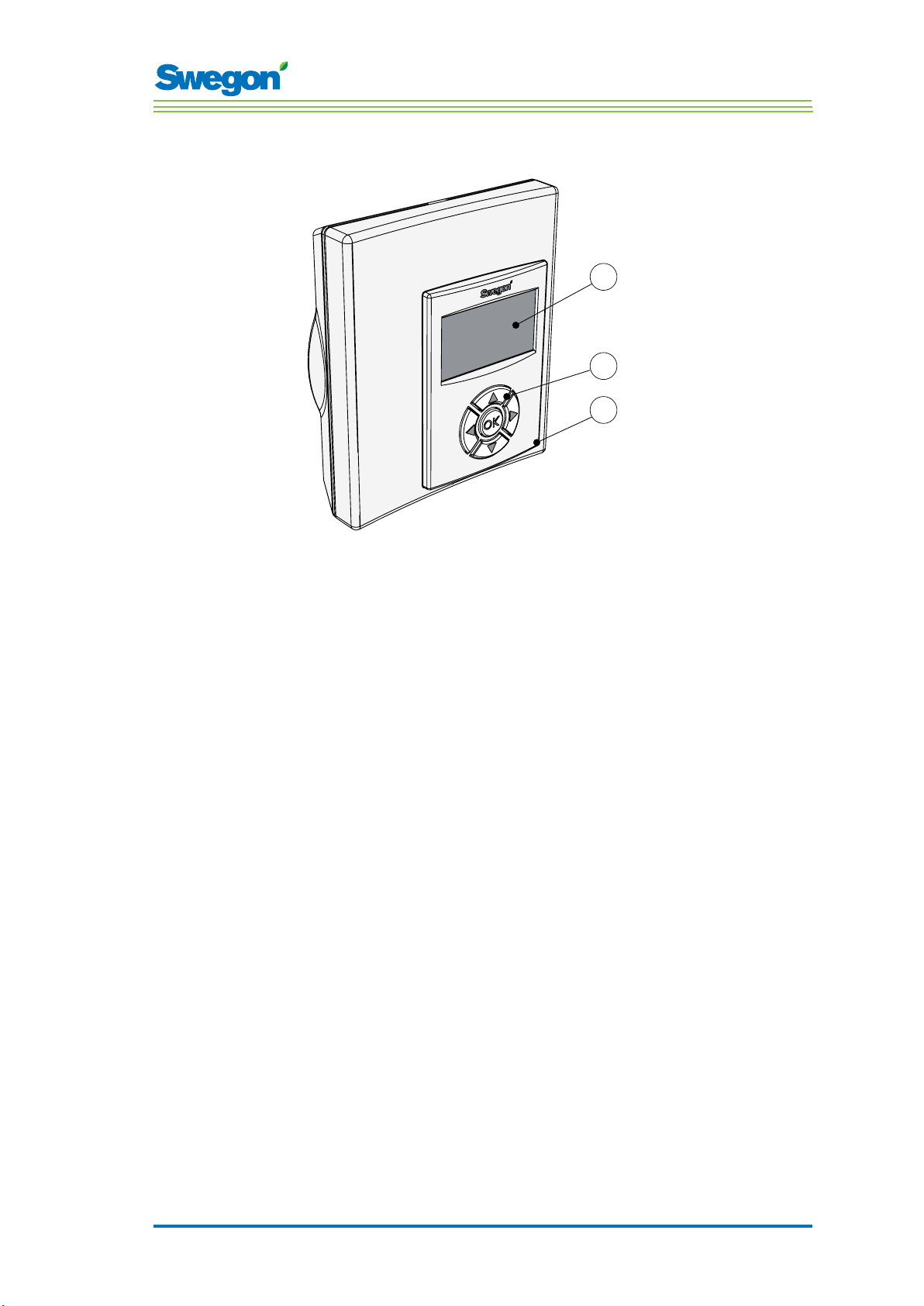

Room Unit

Technical Description

1

2

3

Figur 3. Overview of the room unit (thermostat).

Pos 1. Display

Pos 2. Keypad.

Pos 3. Temperature sensor.

The room unit is simple to use and has an easy-to-interpret design

that makes it user-friendly. The digital display shows the current preset

temperature and airflow settings.

The function of the room unit is to measure the temperature in the room,

communicate with the controller and to serve as a tool for adjusting the

climate in the room.

The internal communication between the controller and the room unit is

wireless, which makes it easier to find an appropriate spot in the room

where the room unit can be installed.

If requested, the room unit can be wire-connected with a RJ12 cable to the

controller.

2 : 9

Page 10

Technical Description

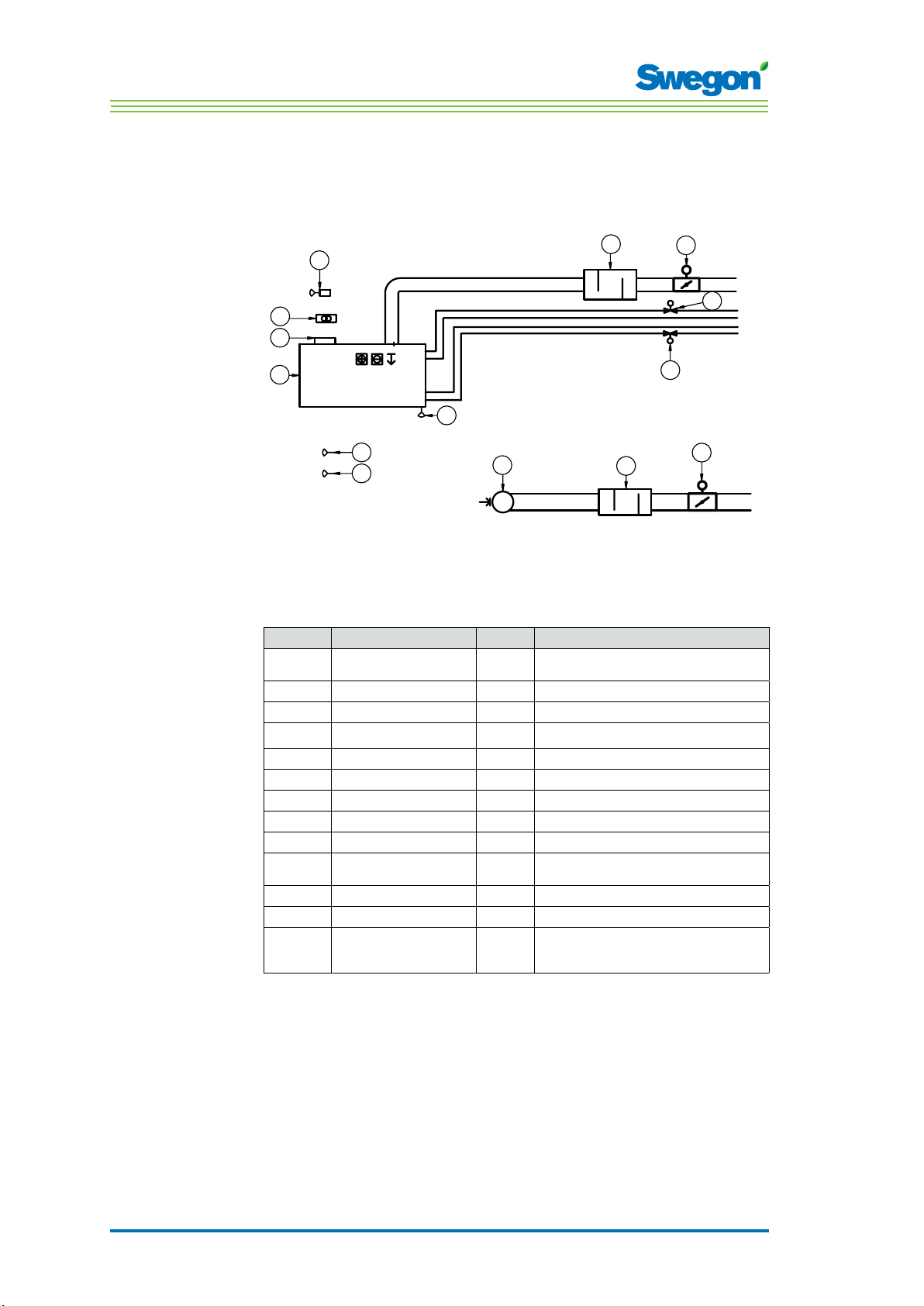

Installation Examples

The illustration below shows a typical arrangement of a complete

installation with the CONDUCTOR W1/W3 control system.

3

RU

GT

24V AC

4

RE

2

1

5

GX

GX

GX

7

6

12

Figur 4. Example of a CONDUCTOR W1/W3 installation.

Item Component Quantity Description

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

Accessories

PARASOL 1192-B-HF

CONDUCTOR RE W1/W3

CONDUCTOR RU

SYST TS-1

SYST CG

DETECT Occupancy 1 Presence detector

External

LUNA a AT-2

SYST VD 115-CLC

SYST CRTc 9-125-2 CM 24

CLA 125-500

Extract air register

SYST MS

Comfort module including cooling, heating and

1

ventilation

Controller

1

Room unit

1

Transformer

1

Condensation sensor

1

Window contact, not supplied by Swegon (W3)

1

Valve actuator

2

Control valve

2

Supply air damper 1 including motor (W3)

1

Extract air damper 1 including motor (W3)

Sound attenuator

1

Extract air register with given C-Factor

1

Assembly part for suspending the PARASOL

4

Not necessary if the product is mounted directly

against the ceiling.

11

10

9

8

10

11

2 : 10

Page 11

Operating Mode

Applications

These instructions deal with two different applications: W1 and W3. W

indicates that both the applications are applicable to waterborne climate

systems.

A waterborne system provides the room with waterborne heating and

cooling. The air-based systems which can be controlled in the W3 by means

of connected damper actuators are only used to satisfy the demands on

air quality, while the temperature of the supply air and extract air is kept

constant.

Depending on the status of connected sensors, the controller adjusts the

outputs from any of several possible operating conditions. The various

operating conditions described here are based on occupancy in the room

and the status of the window switch and condensation sensor.

W1

Technical Description

W1 is a standard solution for offi ces, mainly designed for partitioned offi

ces, but which also can be used in large rooms, as with open-plan offi ces.

The application is suitable for so called CAV systems (Constant Air Volume),

which means that the airfl ow in the room is constant and that no damper

actuators are needed. Only two outputs are used, one for actuators that

control cooling and one for actuators that control heating. There is provision

for connecting a condensation sensor, a temperature sensor and an

presence detection sensor.

Table 1. Operating conditions for application W1

Condensation Cooling Heating

Yes Off Normal

No Normal Normal

2 : 11

Page 12

Technical Description

W3

The W3-application can be used either for offi ces or for hotel rooms. It is

well-suited for systems with variable airfl ow (VAV) with both supply air and

extract air. Four outputs are used to control heating, cooling, supply and

extract air. The damper motors are adjusted depending on the generated

airfl ow and duct pressure in both the supply and extract air ducts.

Three inputs are used; for condensation sensors, window switches and

presence detectors. The principle is to use minimal, normal or high airfl ow,

depending on occupancy and sensor status.

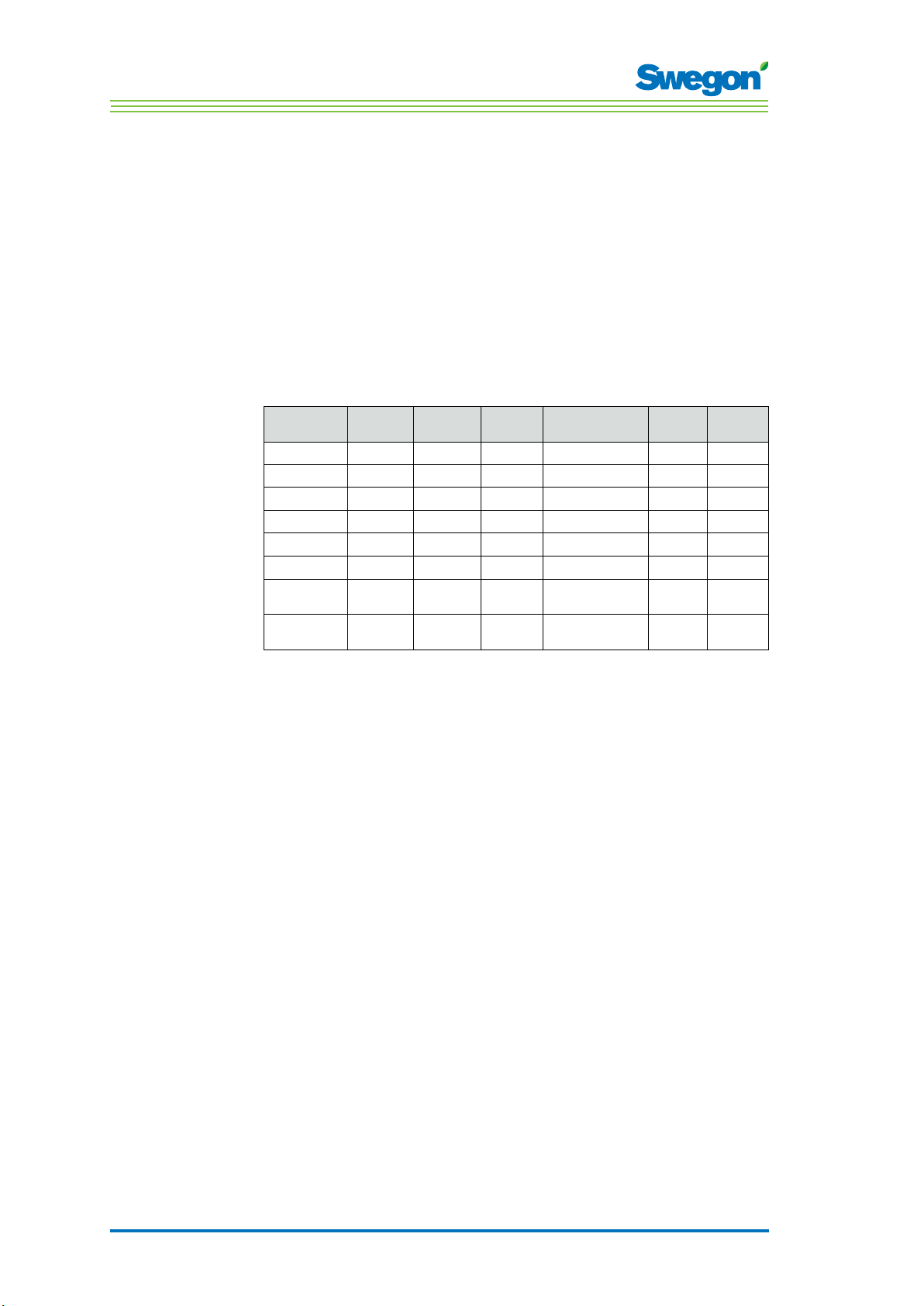

Table 3: Operating conditions for application W3

Occupancy Window Conden-

sation

Yes Yes Yes Off Frost protection Min. Min.

Yes Yes No Off Frost protection Min. Min.

Yes No Yes Off Normal Max. Max.

Yes No No Normal Normal Normal Normal

No Yes Yes Off Frost protection Min. Min.

No Yes No Off Frost protection Min. Min.

No No Yes Off

No No No Normal

Cooling Heating Supply

Normal/Energy

saving

Normal/Energy

saving

air

Min. Min.

Min. Min.

Extract

air

2 : 12

Page 13

Operating Modes

There are a variety of functions built into the CONDUCTOR:

• MAN, manual mode.

• AUTO, automatic mode.

• ECON, energy-saving mode.

• Stand-by mode.

• EMERG, emergency mode.

MAN, Manual operating mode.

Whenever the CONDUCTOR registers occupancy in the room in response

to signals from a presence detector, the user can regulate the temperature

and airflow rate by entering settings in the room unit. When the user enters

a new desired setting, the controller switches over to the manual operating

mode (MAN).

AUTO, Automatic operating mode.

When the CONDUCTOR no longer registers occupancy in the room, the

controller automatically decreases the supply air flow to the low airflow

setting and the system automatically returns to the AUTO mode.

Technical Description

The controller also switches automatically to the AUTO mode after a

predefined number of minutes after the most recent change, manually

entered on the room unit.

When the controller is set to the automatic mode, the valve actuators for

chilled water and hot water respectively and the supply air damper and

extract air damper respectively are adjusted in response to occupancy in the

room and the level of carbon dioxide as well as the status of the window

contact and the condensation sensor.

The automatic control system controls the airflow, cooling and heating until

the user manually enters a new airflow or temperature setting.

ECON, energy-saving mode.

When the energy-saving function is enabled, the system switches

automatically to the ECON energy-saving mode, when no occupancy has

been registered for a predefined number of minutes. The system returns to

the AUTO mode when occupancy is registered again.

In the energy-save mode, the valve actuator is controlled for chilled water

and hot water respectively according to the status on other sensors in the

room, but with a greater permissible difference between actual value and

setpoint than in the AUTO mode.

2 : 13

Page 14

Technical Description

Stand-by mode.

When the control system registers a signal indicating that a window is open,

the controller switches over to the standby mode. When the window is

closed, the controller switches to the AUTO operating mode.

While the controller is in the Stand-by mode, the room temperature is

maintained above the predefined level for the Frost protection function.

EMERG, emergency mode.

In the event of a fire alarm, the air damper in the extract air duct is opened

or closed, depending on the setting entered in the control system. The

cooling and heating functions are shut off while the system is in the EMERG

mode. The supply air is normally shut off.

The EMERG mode can only be managed in control systems that are

connected to a main control system via ModBus RTU.

Functions

There are a variety of functions built into the CONDUCTOR W1/W3:

• Exercising of valves

• First open

• Frost protection

• Change over

• Night cool

• Time-set setpoint restoration

Exercising of valves

The function involves regularly exercising the water valves by utilising

automated functions in order to prevent them from becoming sluggish or

jamming. During the exercising period, all the valves that are wired to the

controller are opened for a maximum of 6 minutes and are then closed.

The valves for the cooling system are exercised first. Then the valves for the

heating system are exercised.

First open

The function means that the water valves are open when the system is

installed, which makes it easier to fill, pressure test and vent the water

system.

The function will be automatically disabled after the actuator has been

energized for approx. 6 minutes. A clicking noise will be heard when the

valves and the dampers change over to the NC mode (=normally closed)

and the normal control function is enabled.

2 : 14

Page 15

Technical Description

Frost protection

The function involves the following: Heating operation is started at a

predefined room temperature in order to counteract the risk of damage that

otherwise can arise due to freezing.

Change over

The function involves the use of only one valve actuator which should be

wired to the cooling output terminal. This actuator then controls both the

heating water and the cooling water, which are transported in the same

pipe.

In winter, when heating is required, the valve opens if the water in the pipe

is warmer than the temperature setpoint. If the water is colder, the valve

does not open.

In summer, when cooling is required, the valve opens if the water in the pipe

is colder than the temperature setpoint.

In order to be able to use this function, you are required to mount an

external temperature sensor onto the water pipe through which supply

water circulates continuously. Wire the sensor according to the general

wiring diagram shown in the section entitled: Installation

Night cool

The function involves using cold air from outdoors for cooling the room at

night to the predefined level.

The function can only be managed in control systems that are connected to

a main control system via ModBus RTU.

Time-set setpoint restoration

The function involves adjusting the room temperature to the predefined

level when the controller switches to the AUTO operating mode.

The controller also switches automatically to the AUTO mode after a

predefined number of minutes after the most recent change, manually

entered on the room unit.

2 : 15

Page 16

Technical Description

Technical Data

CONDUCTOR RE Controller

Technical data applicable to the CONDUCTOR RE controller (W1/W3) is

specified below.

Item Data

Designation CONDUCTOR RE (W1/W3)

Storage temperature -40 °C to +80 °C

Operating temperature -20 °C to +50 °C

Degree of protection IP 32

Dimensions 121 x 193 x 44 mm

Supply voltage 24V AC ± 10%

Power consumption 1 VA

Control function PI

P-band, cooling/heating

increments

Dead band, occupancy in

room

Dead band, no occupancy Depends on switching in cooling and switching in

Frost protection 10 °C

Valve installation 1 time/48h period (fully open for 3 minutes)

Installation Mounting holes in enclosure or onto DIN rail

Connections Wiring terminal for 2.5 mm² multicore cable

Data communication ModBus RTU

Wireless communication 433 MHz band radio modem with room unit

Inputs

Condensation sensor Resistance

Temperature sensor Resistance

Presence detector No occupancy/NO/NC (optional), default = NC for

Window contact

Carbon dioxide sensor 2 - 10 V, or 24 V

Pressure sensor / ModBus RTU

sensor

Modular contact RJ12 6-pole for connecting up to the room unit

Outputs

Actuator, heating 24 V AC, PWM (on/off or 0 - 10 V) max load: 72

Actuator, cooling 24 V AC, PWM (on/off or 0 - 10 V) max load: 72

Supply air damper

Extract air damper

(W3) No occupancy/NO/NC (optional), default = NC for

(W3) 0 - 10 V DC (low/normal/high) max load 25 VA =

(W3) 0 - 10 V DC (low/normal/high) max load 25 VA =

1 K

Depends on switching in cooling and switching in

heating

heating

(thermostat)

occupancy

closed window

2 - 10 V / RJ12 cable

(thermostat)

RJ12 6-pole for connecting up to ModBus RTU

VA = 12 actuators

VA = 12 actuators

5 actuators.

5 actuators.

2 : 16

Page 17

Technical Description

CONDUCTOR RU room unit (thermostat)

Item Data

Designation: CONDUCTOR RU

Storage temperature -40 °C to +80 °C (*)

Operating temperature 0 °C to +50°C

Degree of protection IP 20

Dimensions 86 x 100 x 32 mm

Supply voltage 12 V, 4 size AAA batteries

Actual value, range +10 °C to +32°C

Installation Against a wall or in a 70 mm standard junction

In-operation LED, temperature Cooling load

In-operation LED, air Low airflow:

In-operation LED, enabled Lit LED, AUTO

In-operation LED, disabled Dimmed display, AUTO

Input

Modular contact RJ12 6-pole for connecting up to the controller

(*) = Specified storage temperature appies to a room unit WITHOUT batteries.

(**) = Used only if wireless communication is not desired.

box. Must not be exposed to direct sunlight

Heating load

One LED lit

Normal airflow:

Two LEDs lit

High airflow:

Three LEDs lit

(**)

2 : 17

Page 18

Technical Description

2 : 18

Page 19

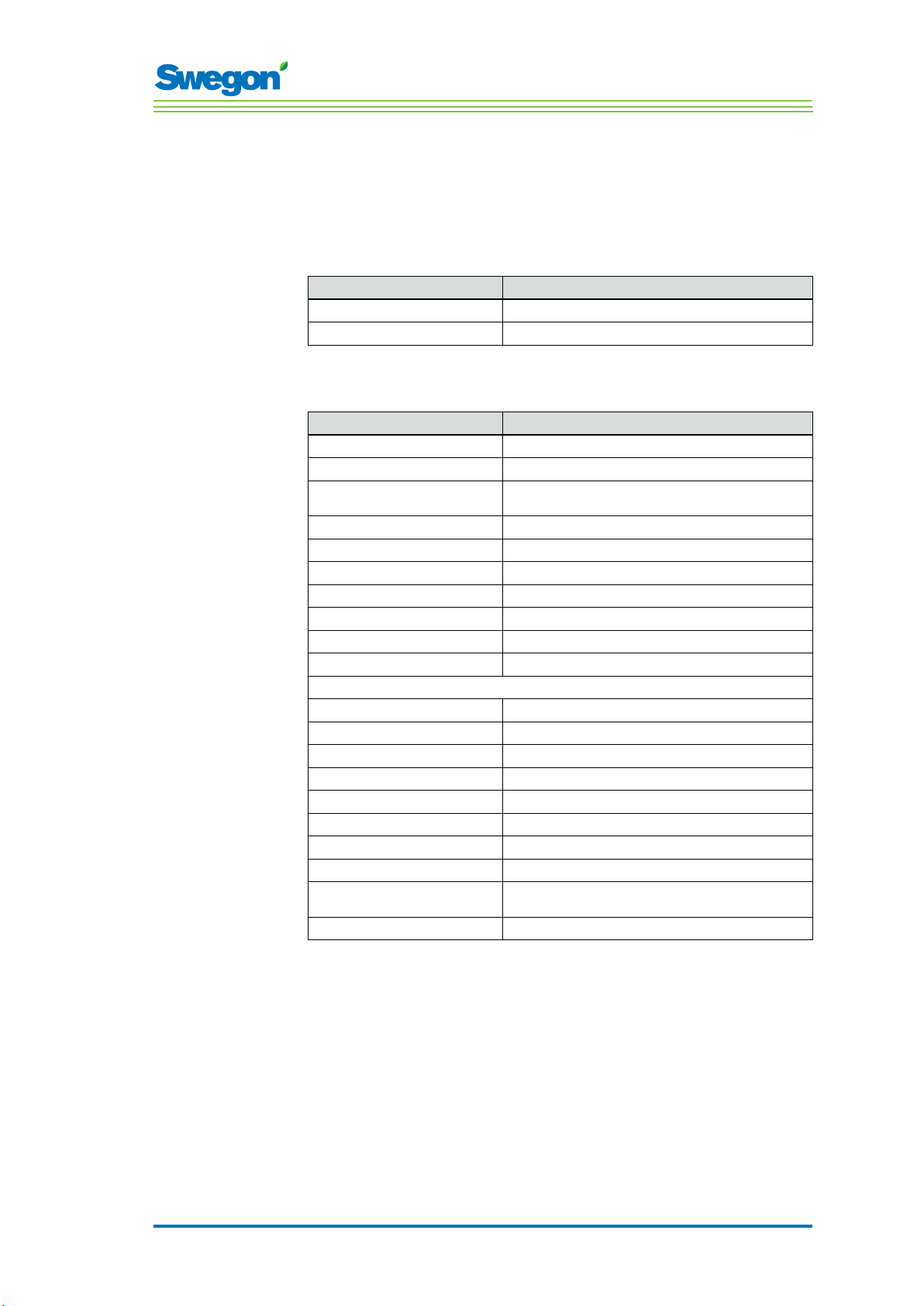

Installation

Ordering, delivery and electrical installation

Ordering key, Control equipment

Item Data

Controller W1/W3 CONDUCTOR RE (aa)

Room unit (Thermostat) CONDUCTOR RU

Ordering Key, Accessories

Item Data

Valve SYST VD 115-CLC

Valve actuator LUNA a AT-2

Ventilation damper incl.

damper actuator

Adapter, actuator/valve LUNA a T-VA-(aa)

Condensation sensor SYST CG

Carbon dioxide sensor DETECT Quality

Presence detector DETECT Occupancy

Modular cable RJ12 6/6, 5 metres long

Transformer SYST TS-1

External temperature sensor CONDUCTOR T-TG

SYST CRTc 9 (aaa)-2-CM-24

Installation

(aa) = Fitted to valve type:

32 Tour & Andersson

39 Oventrop

50 Honeywell, Reich, MNG, Böhnisch (H), Cazzaniga

54 Certain MMA-valves

59 Danfoss RAV/L

72 Danfoss RAV

78 Danfoss RA

80 Siemens and more (always included in the LUNA a

(aaa) = 125 or 160

AT-2 actuator)

3 : 19

Page 20

Installation

Ordering

Specify the desired number of ordered components or refer to drawing.

Delivery

• The valves are delivered to the plumbing contractor for installation in

the system.

• The room controller is delivered to the electrical contractor, systems

contractor or other contractor for installation onto the junction box.

• Controller is normally delivered factory fitted on the comfort module

or climate beam. The controller is delivered to electrical contractor,

systems contractor or other contractor for installation by means of

screws at some other suitable place, if separate components are

supplied.

WARNING:

All electrical installation, including wiring the actuators,

valve actuators and various sensors is to be carried out by

the electrical contractor or the systems contractor.

The electrical contractor or the systems contractor provides a 230 V earthed

outlet for transformer, a fitted junction box for the room unit (thermostat)

and possible external cables.

Preparations

The CONDUCTOR W1/W3 should be installed in steps as follows:

1. To mount the controller.

2. To connect units.

3. Commissioning.

4. To mount the room unit (thermostat).

Check the following before installing the CONDUCTOR W1/W3:

• The comfort module, with pre-fitted valve actuators for chilled and hot

water, are mounted in the ceiling.

• The required sensors (e.g. presence detector, window contact and

condensation sensor) are installed in the room.

• Required actuators are installed.

• Cables from all the units are marked and run up to the comfort

module, or alternative location for the controller.

The following are required for installation:

• ordinary screwdriver or electric screwdriver

• Electric drill.

3 : 20

Page 21

Step 1, To mount the controller.

Mounting on a DIN rail

If a DIN rail is mounted on the comfort module or at another suitable

location, the controller should be fastened to this rail.

Installation

1

2

3

4

Figur 1. To mount the controller.

Pos 1. Plastic hooks

Pos 2. Supporting surface, for example a comfort module or climate beam.

Pos 3. DIN rail

Pos 4. Snap-on fastener.

1. Fasten the two plastic hooks on the backside of the controller on the

upper control edge on the DIN rail.

2. Press to fasten the snap-on fasteners on the backside of the controller

against the lower control edge on the DIN rail.

3 : 21

Page 22

Installation

To be installed above a false ceiling

If a DIN rail is NOT available pre-mounted or is not available, the controller

can be appropriately mounted above the false ceiling (not on the module).

1

2

Figur 2. To mount the controller.

Pos 1. Supporting surface, NOT for the comfort module or climate beam.

Pos 2. Screws.

1. Secure the controller by means of screws in the upper left-hand and

the lower right-hand corners. Use screws suitable for the supporting

surface.

3 : 22

Page 23

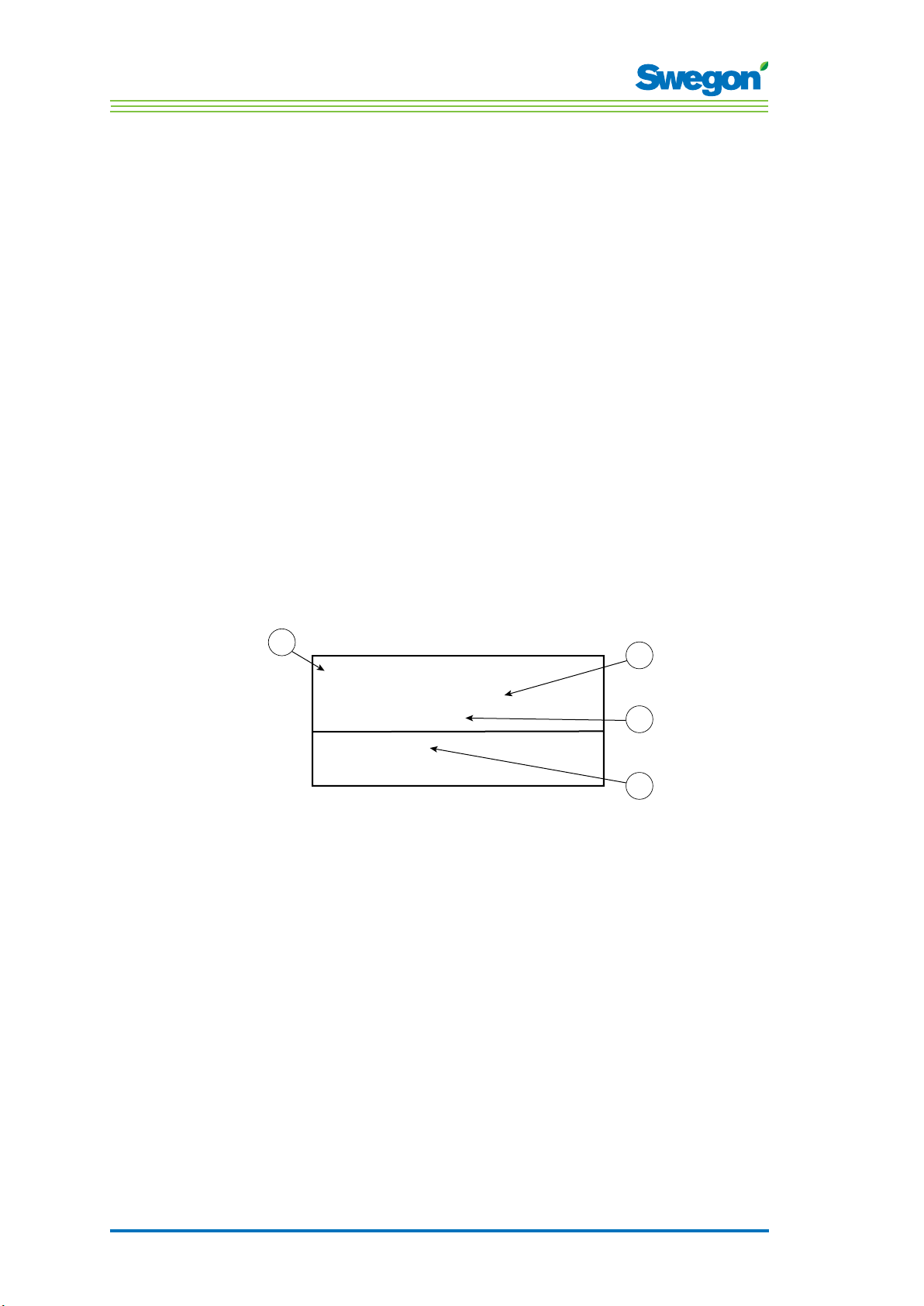

Step 2, Installation of units

The following units should be connected to the detachable wiring terminals

of the controller:

Installation

5

4

3

1

Figur 3. Overview of the units.

Pos 1. Valve actuator for cooling water.

Pos 2. Valve actuator for heating water

Pos 3. Presence detector.

Pos 4. Window contact.

Pos 5. Condensation sensor.

Pos 6. External temperature sensor

Pos 7. Transformer.

Pos 8. Damper motor for extract air. (W3)

Pos 9. Damper motor for supply air. (W3)

(W3)

6

24 V AC

7

8

S

9

2

1. Connect the valve actuator for cooling water to wiring terminals 27 (blue

cable) and 29 (brown cable) respectively.

2. Connect the valve actuator for heating water to wiring terminals 30 (blue

cable) and 32 (brown cable) respectively.

3. Connect the presence sensor to wiring terminals 12 and 26 respectively.

4. Connect the window contact (normally closed or normally open) to wiring

terminals 10 and 25 respectively.

5. Connect the wires of the condensation sensor to wiring terminals 17 and 18

respectively.

6. Connect the wires of the temperature sensor to wiring terminals 30 and 32

respectively.

7. Connect the secondary side cables of the transformer to wiring terminals 23

(G) and 24 (GO) respectively.

8. Connect the damper motor for extract air G0 (blue cable) to wiring terminal no.

36. 0-10 V signal (red cable) to no. 37. and 24 V (brown cable) to no. 38.

9. Connect the damper motor for supply air G0 (blue cable) to wiring terminal no.

33. 0-10 V signal (red cable to no. 34 and 24 V (brown cable) to no. 35.

3 : 23

Page 24

Installation

Step 3, Commissioning

To connect the mains power supply cable

1. Connect the transformer’s mains power supply cable to an electric

outlet.

To insert batteries in the room unit (thermostat)

The room unit is normally supplied with electric current from four size AAA

batteries.

As an alternative to batteries, the room unit can be energized from the

controller, via a 6-pole cable with RJ12 modular connectors.

N.B.!

If the room unit is energized via a controller, the cable must be

connected at this point.

1

2

3

Figur 4. To insert batteries in the room unit (thermostat).

Pos 1. To open the snap-on fastener.

Pos 2. Remove the back piece.

Pos 3. To insert batteries.

2. Insert the batteries in the room unit (thermostat) as follows:

• Open the snap-on fastener by pressing a screw driver in the notch

between the front piece and back piece of the room unit.

• Press on the snap-on fastener and remove the back piece.

• Insert the batteries with the poles turned according to the relief

markings in the battery compartment.

3 : 24

Page 25

Installation

Booting

As soon as the controller and the room unit have been energized, the

system boots up and the main view is shown in the display of the room unit.

The controller is in the AUTO operating mode when the system has finished

booting.

Figur 5. Main view in the display of the room unit.

1. Check that the main view is shown in the display.

Selection of Language

On delivery, the room unit has factory-preset English language settings.

2. Change to desired language in accordance with instructions in the

section: Room unit menus.

Check the factory settings

3. Make sure that the current application setting is in agreement with

units connected to the controller. Check in accordance with instructions

in the section: Room unit menus.

To connect units

In order for the controller to be able to properly communicate with the

room unit, they must be connected up to one another.

N.B.!

If the room unit is operated via the controller, you need not

connect it.

4. Connect the controller and the room unit to one another in accordance

with the instructions in section: Room unit menus. The ID or serial

number of the controller should be given as address when connecting

up.

3 : 25

Page 26

Installation

Step 4, To install the room unit (thermostat)

The room unit contains a temperature sensor used for measuring the current

room temperature. In order for the controller to regulate the temperature in

relation to the preset setting, the room unit must be installed in such a way

that enables it to correctly measure the temperature. The room unit should,

for example, not be exposed to direct sunlight.

1

2

3

Figur 6. To mount the room unit (thermostat).

Pos 1. Front piece.

Pos 2. Back piece.

Pos 3. Screws suitable for the supporting surface.

1. Select a suitable location in the room for installing the room unit. The

recommended height above the floor is standard height for of a light

switch.

2. Remove the back piece from the room unit.

N.B.!

Tighten the back piece only in the right-hand and the left-hand

fastening holes.

3. Then secure the back piece to the wall by means of two countersink

screws, appropriate for the supporting surface.

3 : 26

Page 27

The menus of the room unit

The menus of the room unit (thermostat)

The main image and the key pad of the room unit

5

6

7

8

4

9

10

3

11

2

12

1

Figur 1. Overview of the main image of the room unit.

Pos 1. Cursor key for moving DOWN.

Pos 2. Cursor key for moving to the LEFT.

Pos 3. Heating/cooling.

Pos 4. Battery charge status/Window status.

Pos 5. Current airflow.

Pos 6. Operating mode.

Pos 7. Current temperature.

Pos 8. Carbon dioxide content.

Pos 9. Occupancy status

Pos 10. Cursor key for moving UP.

Pos 11. Cursor key for moving to the RIGHT.

Pos 12. OK key.

Heating/Cooling

The field shows whether the climate system is heating or cooling.

Symbol for heating.

Symbol for cooling.

Battery charge status/Window status

The field shows the battery level. If a window is open in the room this will

be visible on the screen.

Symbol for fully charged batteries.

Symbol for half charged batteries.

Symbol for empty batteries.

Symbol for an open window.

4 : 27

Page 28

The menus of the room unit

Current airflow

The field shows the present airflow setting.

Operating mode

The field shows the current operating mode. The field is empty if the unit is

operating in the manual mode.

AUTO Automatic.

ECON Economy.

STOP Standby.

EMERG Emergency.

Symbol for low airflow.

Symbol for normal airflow.

Symbol for high airflow.

Current temperature

The field shows the current temperature setting. The temperature is

specified in°C.

Level of carbon dioxide

The symbol is shown in the field when the carbon dioxide content in the

room exceeds the pre-defined content.

Symbol for carbon dioxide content.

Occupancy status

The symbol is shown in the field when someone is in the room.

Symbol for occupancy.

4 : 28

Page 29

The menus of the room unit

Overview over the menu system of the room unit.

The menu system of the room unit consists of the following menus with

associated submenus.

• Main menu

• Service menu

Main menu and Service menu

Main me nu

Setup

Enter c ode

Service menu

Regul ator adju st

Econ SA % 20

Norm SA % 5 0

Boost SA % 80

Econ EA % 2 0

Norm E A % 50

Boost E A % 80

Temp C

Sett ings

ModBU S

RF pair -up

RF Quality

Langu age

FirstT ime func

Temp. cali bratio n

Info

Room te mp

Serial Number

Batt ery Level

Appli cation

Sw. ver. RE

SW. ver. RU

General Param.

.

Paramet er

P_101

Min 0

Enter c ode

ModBus ad dress

value

2

Max 79

Appl. P aram.

Enter c ode

Paramet er

P_1902

1 or 2 room uni ts

Min 0

values

1

Max 2

Alar ms

4 : 29

Page 30

The menus of the room unit

Navigating in the menus of the room unit

Go to the main menu

<Exi t

Figur 2. Main image and Main menu.

1. Press on the OK key while the main image is shown in the display and

hold the key pressed down for 3 seconds.

Go to the Service menu

A authorization code must be entered in order to reach the Service menu.

Main menu

Setup

..

Selec t>

Main menu

Setup

<Exi t

Figur 3. The image for selecting Setup and to enter the code.

Selec t>

<Exi t

Press code

9 1 9

1

>

1. Go to the Main menu.

2. Highlight Setup.

3. Press OK or on the ►Right key.

4. Enter the first digit in the code by pressing the ▲ UP or ▼ DOWN key.

5. Mark the next digit position by pressing the ► Right key.

6. Enter the remaining three digits in the code.

7. Press OK to confirm the code.

If you have entered the correct code, the Service menu will be shown.

Otherwise the Main menu will be shown.

4 : 30

Page 31

Changes in the Main image

To set the desired room temperature

Figur 4. The Main image

1. Check that the main image is shown in the display.

2. Press on:

• The ▲ UP key to raise the temperature.

• The ▼ DOWN key to lower the temperature.

3. Press OK or wait 3 seconds to confirm the setting.

To set the desired airflow

The menus of the room unit

Figur 5. Main image.

1. Check that the main image is shown in the display.

2. Press on:

• The ► Right key to increase the airflow.

• The ◄ Left key to decrease the airflow.

3. Press OK or wait 3 seconds to confirm the setting.

Low airflow corresponds to the ECON operating mode. Normal airflow

corresponds to th AUTO operating mode. High airflow corresponds to the

BOOST operating mode.

4 : 31

Page 32

The menus of the room unit

Changes and settings in the Service menu

To set the air damper for supply air and to change the

K-factor

..... ............... ..

Service Menu

Regulator adjust

<Exi t

Figur 6. Image for selecting Regulator adjustment settnings and view for setting the K-factor

and the damper for supply air in air duct 1.

..

..

Settings

..

Selec t>

1. Go to the Service menu.

2. Highlight the Regulator adjustment settings.

3. Press OK or on the ►Right key.

4. Highlight the line of the value you want to change by pressing the

▲ UP key or the ▼ DOWN key.

Econ SA % 20

Norm SA % 50

Boost SA % 80

<Exi t

..

OK sele ct

Next>

5. Press OK to highlight the value.

6. To change the value:

• K-factor.

• Norm = the value applicable to normal airflow.

• Boost = the value applicable to high airflow.

7. Press OK to confirm the change.

8. Press the ►Right key for advancing further and changing the values of

K-factor and supply air in air duct 2.

9. Press the ◄ Left key twice to return to the Service menu.

4 : 32

Page 33

The menus of the room unit

Adjust the air damper for extract air and change the

value for offset

..... ............... ..

Service Menu

Regulator adjust

..

..

Settings

<Exi t

Figur 7. Image for selecting Regulator adjustment settings and image for setting the air

damper for extract air and the value for offset.

Selec t>

1. Go to the Service menu.

2. Highlight the Regulator adjustment settings.

3. Press OK or on the ► Right key.

4. Press the ► Right key twice for showing the image for setting the air

damper for extract air and offset.

5. Highlight the line of the value you want to change by pressing the

▲ UP key or the ▼ DOWN key.

Econ EA % 20

Norm EA % 50

Boost EA % 80

<Previ ous

OK sele ct

Next>

6. Press OK to highlight the value.

7. Change to desired value.

8. Press OK to confirm the change.

9. Press the ◄ Left key twice to return to the Service menu.

4 : 33

Page 34

The menus of the room unit

To set the existing room temperature

Service Menu

Regulator adjust

<Exi t

Figur 8. Image for selecting Regulator adjustment settings and image for setting the existing

room temperature.

1. Go to the Service menu.

2. Highlight the Regulator adjustment settings.

3. Press OK or on the ►Right key.

4. Press the ► Right key three times to show the image for setting the

existing room temperature.

5. Press OK to highlight and to be able to change the room temperature.

6. Change the room temperature by pressing the ▲ UP key or ▼ DOWN

key.

..

..

Settings

Selec t>

..... ............... ..

<Prev.

Temp C

OK sele ct

20

Next>

7. Press OK to confirm the change.

8. Press the ◄ Left key four times to return to the Service menu.

4 : 34

Page 35

The menus of the room unit

Change ModBus address in room unit for RU

Selec t>

..... ............... ..

<Exi t

ModBUS

..

[First]

Settings

ModBUS

RF pair-up

<Exi t

Figur 9. Image for selecting to change the ModBus address and the MB address image.

The unit must be assigned an adress to enable connecting it up to ModBUS,

when the room unit is connected via cable to the controller.

1. Go to the Service menu.

2. Highlight Settings

3. Press OK or on the ►Right key.

4. Highlight ModBus.

5. Press OK.

6. Make one of the following selections:

• Select First whether the room unit is the first one in the room.

• Select Second if the room unit is the second one in the room.

7. Press OK in order to confirm the selection and return to the Service

menu.

4 : 35

Page 36

The menus of the room unit

Connect units room unit (RU) to controller (RE)

<Exi t

Figur 10. Image for selecting RF pair-up and the RF pair-up image.

The units must be connected together in order to control the controller by

means of a hand-held micro terminal. This is done by entering the RF (radio

frequency) ID of the controller, which is specified on the identification plate

of the controller.

1. Go to the Service menu.

2. Highlight Settings.

3. Press OK or on the ► Right key.

4. Mark Connect units.

ModBUS

RF pair-up

RF Quality

Selec t>

..... ............... ..

<Exi t

RF pair-up

0

0 0 0 0

>

5. Press OK or on the ► Right key.

6. Enter the first digit in the RF ID number by pressing the ▲ UP key or

▼ DOWN key.

7. Highlight the next digit position by pressing the ► Right key.

8. Enter the remaining four digits in the RF ID number.

9. Press OK to confirm the RF ID number and connect the room unit to

the controller.

If the connection is successful, the text: Connected will be shown.

10. Return to the Settings menu by pressing the ◄ Left key.

11. Return to the Service menu by pressing the ◄ Left key.

4 : 36

Page 37

The menus of the room unit

Test the radio connection

..... ............... ..

ModBUS

RF pair up

.

Language

<Exi t

Figur 11. Imaage for selecting the RF pair-up and the RF connection image.

Selec t>

If no cable is connected between the controller and the room unit, the two

will communicate with one another via radio signals.

1. Go to the Service menu.

2. Highlight Settings.

3. Press OK or on the ►Right key.

4. Highlight RF pair up

5. Press OK or on the ►Right key.

6. Start the test by the ► Right key.

During the test, 100 messages are sent between the controller and

the room unit. The room unit calculates the number of successful

transmissions and displays them in the image.

• The test can be cancelled by pressing the ► Right key.

RF connection

RF pair up: 100

<Exi t

Star t

7. Press the ◄ Left key when the test is finished to return to the Settings

menu.

8. Return to the Service menu by pressing the ◄Left key.

4 : 37

Page 38

The menus of the room unit

Change language

..

FirstTime func

<Exi t

Figur 12. Image for selecting Language and the Language image.

1. Go to the Service menu.

2. Highlight Settings.

3. Press OK or on the ► Right key.

4. To highlight Language.

5. Press OK or on the ► Right key.

6. Select between the languages Swedish, English and Finnish by pressing

the ▲ UP or ▼ DOWN key.

7. Press OK in order to confirm the change and return to the Settings

menu.

RF Quality

.

Language

Selec t>

..... ............... ..

<Exi t

Language

.

[Swedish]

8. Return to the Service menu by pressing the ◄ Left key.

To enable/disable the ”first open” function

Selec t>

..... ............... ..

FirstTime func

[Off]

<Exi t

Language

..

.

..

FirstTime func

Temp. calibration

<Exi t

Figur 13. Image for selecting FirstTime function and the FirstTime function function image.

1. Go to the Service menu.

2. Highlight Settings.

3. Press OK or on the ► Right key.

4. Highlight FirstTime function.

5. Press OK or on the ► Right key.

6. Enable the function by selecting [On], disable by selecting [Off].

7. Press OK in order to confirm the selection and return to the Settings

menu.

8. Return to the Service menu by pressing the ◄ Left key.

4 : 38

Page 39

The menus of the room unit

Calibrate temperature

..... ............... ..

Language

FirstTime func

Temp. calibration

<Exi t

Figur 14. Image for selecting calibrate temperature and the Temp. calibration image .

Selec t>

The purpose of the Calibrate temperature action is to ensure that the

temperature reading is in agreement with the actual room temperature.

1. Go to the Service menu.

2. Highlight Settings

3. Press OK or press on the ► Right key..

4. Highlight Temp. calibration.

5. Press OK or on the ► Right key.

6. Change the number of degrees to which the temperature reading

should be adjusted.

• Increase the number of degrees by pressing the ▲ UP key.

• Decrease the number of degrees by pressing the ▼ DOWN key.

Temp. calibration

[0,0]

<Exi t

7. Press OK to confirm the calibration and return to the Settings menu.

8. Return to the Service menu by pressing the ◄ Left key.

Show system information

..... ............... ..

Settings

Room temp.

RE RF id

Info

Battery Level

General Param.

<Exi t

Figur 15. Image for selecting Info and the first image in System information.

Selec t>

<Exi t

1. Go to the Service menu.

2. Highlight Info.

3. Press OK or on the ► Right key.

Current information for the application is shown in the System

information images. Navigate between the images by pressing the ▲UP

or ▼ DOWN key.

4. Return to the Service menu by pressing the ◄ Left key.

22,0 C

23456

5.2V

.

4 : 39

Page 40

The menus of the room unit

Change parameters

<Exi t

Figur 16. Image for selecting changes in the application parameters and typical parameter

1. Go to the Service menu.

2. Depending on which parameters you want to change, highlight the

3. Press OK or on the ► Right key.

4. Enter the authorization code for General parameters or Application

5. Select the parameter to be altered by pressing the ▲ UP or ▼ DOWN

General param.

..... ............... ..

Appl. Param.

Alarms

Selec t>

image.

Param eter

P_1902

1 or 2 room u nits

Min 0 M ax 2

<Exi t

Value

1

appropriate General parameter or Application parameter.

parameters.

key.

Chang e>

6. Highlight the value by pressing the ► Right key.

7. Highlight the value by pressing the ▲ UP or ▼ DOWN key.

8. Press OK to confirm the new value.

9. Press the ◄ Left key to exit the parameter change image.

10. Highlight:

• Yes to save the changes you’ve made.

• No to not to save the changes.

• Cancel to return to parameter change image.

11. Press OK to return to the Service menu.

Show Alarms

Selec t>

..... ............... ..

Alarms

No alarms

<Exi t

General Param.

Appl. Param.

Alarms

<Exi t

Figur 17. Image for selecting Show Alarms and the Alarm image.

1. Go to the Service menu.

2. Highlight Alarms.

4 : 40

3. Press OK or on the ► Right key.

All active alarms are shown in the image.

4. Return to the Service menu by pressing the ◄ Left key.

Page 41

Service

Parameters

Service

This section is intended only for use by personnel who are specially trained

by Swegon.

In order to control the functions in the CONDUCTOR W1/W3, there are

a number of parameters, which can be changed in order to optimize the

current installation. In the display of the room unit (thermostat) every

parameter is shown in accordance with the figure below.

P_xxx

Figur 1. Main image in the display of the room unit

Pos 1. Minimal value.

Pos 2. Parameter number.

Pos 3. Factory-preset value

Pos 4. Maximum value.

Pos 5. Parameter text.

System parameters

System parameters are basic parameters which are common for several

applications.

Display image Description

P_101 set 2 ID

min 1 max 247

Min xx

2

xxxxxx

1

5

xxxxxx

Max xx

3

4

Indicates the ModBus address.

Modbus Address

P_102 set 3

BMS Baudrate, 9.6 19.2 38.4

min 1 max 3

P_103 set 2

BMS Parity 0=Od. 1=Ev. 2=None

min 0 max 2

P_104 1

BMS Stop bits

min 1 max 2

P_105 3

Component type, 2=DC, 3=RC

min 2 max 3

Indicates the transmission speed

for connecting up to a Building

Management System (BMS).

1 = 9.6

2 = 19.2

3 = 38.4

Parity setting for connection

to BMS.

0 = Uneven

1 = Even

2 = None

Number of stop bits for

connection to BMS.

1 = 1 bit

2 = 2 bits

Indicates the current type of

controller.

5 : 41

Page 42

Service

Display image Description

P_106 2

Application type

Indicates which application the

controller is set to run.

1 = W3

2 = W1

min 1 max 14

P_107 1

Relay at emer. 0=Op. 1=Cl. 2=No act.

min 0 max 2

P_108 48 hour

Valve exercise (h) 0=Not used

min 0 max 96

P_109 20 min

Motion timer delay (min)

min 0 max 60

P_110 60 min

Warning delay from start-up (min)

min 0 max 720

P_111 120 min

Warning delay, PI-overload (min)

min 0 max 720

P_112 120 min

Warning delay, Set point (min)

min 0 max 720

Indicates the status of the relay

for the EMERG mode.

0 = Open

1 = Closed

2 = No action

Indicates how often the valves

should be exercised (how many

hours shall pass between two

exercise runs).

Indicates the number of

minutes after which the

controller should switch from

AUTO to ECON after the last

occupant has left the room.

Indicates the number of

minutes after which the

controller shall be permitted

to initiate an alarm following a

start up.

Indicates the number of

minutes after which the system

should initiate an alarm for

a +100% or -100% output

signal.

Indicates the number of

minutes after which the system

should initiate an alarm, if the

temperature, flow or pressure

setpoint has not been reached.

P_113 30 min

Warning delay, pressure sensor (min)

min 0 max 720

P_114 0

Room Number (optional)

min 0 max 32000

P_118 0 h

Zero calibration (h) 0=not used

min 0 max 720

P_119 3 min

Zero calibration wait (min)

min 1 max 6

P_120 set 2 ID

MBS Modbus Address

min 1 max 247

Indicates the number of

minutes after which the system

should initiate an alarm if no

signal is received from the

pressure sensor or flow sensor.

Indicates the room number.

Zero point calibration of the

Modbus-pressure sensor.

Indicates hours between

calibration.

Indicates the delay before the

calibration starts. (The damper

blade should have time to

close)

Modbus address for the pipe

work contractor in BMS mode

(Modbus 1)

5 : 42

Page 43

Application parameters W1

Application parameters are parameter-specific for the selected application.

Display image Description

P_1101 4

System1=H,2=C,3=ChOv,4=HC

min 1 max 4

P_1102 1

0=ext.temp, 1 or 2 room units

min 0 max 2

P_1103 10 C

min 5 max 12

Frost guard temp.

Service

Indicates how the climate

system should operate for

heating and cooling.

1 = Heating only

2 = Cooling only

3 = Change-over function

4 = Heating/Cooling

Indicates whether one or

two room units are used. If 2

units are used they should be

connected with a cable.

0 = The controllers temp.

sensor is used, 1 = 1 unit

2 = 2 units

Indicates at which temperature

the frost protection should

switch in.

P_1108 1

Economy mode available

min 0 max 1

P_1109 1

ActuatorCool 1=NC, 2=0-10V, 3=NO

min 1 max 3

P_1110 1

ActuatorHeat 1=NC, 2=0-10V, 3=NO

min 1 max 3

P_1111 0

Window 0=NP

min 0 max 0

P_1112 0

Occupancy 0=NP

min 0 max 0

P_1113 5000

P term Change over

min 1 max 10000

Indicates whether the Economy

mode is available.

0 = No

1 = Yes

Indicates which sort of valve

actuator is installed in the

cooling water circuit

(1=24V-NC, 2=0-10V, 3=24VNO)

Indicates which sort of valve

actuator is installed in the

heating water circuit..

(1=24V-NC, 2=0-10V, 3=24VNC)

Indicates whether a window

contact is installed and if so

how it is installed.

0 = No contact installed

Indicates whether a presence

detector is installed and if so

how it is installed.

0 = No contact installed

Indicates the value for P for the

Change Over function. A high

value denotes faster control.

A low value denotes slower

control.

P_1114 50

I term Change over

min 1 max 10000

Indicates the value for I for the

Change Over function. A high

value denotes faster control.

A low value denotes slower

control.

5 : 43

Page 44

Service

Display image Description

P_1119 16 C

Room unit’s min temperature

min 0 max 20

Indicates which lowest

temperature is possible to

adjust manually on the room

unit in the MAN operating

mode.

P_1120 28 C

Room unit’s max temperature

min 25 max 50

P_1121 20 C

Night cool temp set point

min 10 max 20

P_1122 480

RU back to auto state

min 0 max 1200

P_1123 3500

P term Cooling Scale 1:100

min 1 max 10000

P_1124 10

I term Cooling Scale 1:100

min 1 max 10000

P_1125 3500

P term Heating Scale 1:100

min 1 max 10000

Indicates which highest

temperature is possible to

adjust manually on the room

unit in the MAN operating

mode.

Indicates the temperature

setpoint applicable to the Night

cool function.

Indicates how long after the

most recent manual room

temperature adjustment that

the controller should return to

the AUTO mode.

0 = Not used

Indicates the value for P for

cooling. A high value denotes

faster control. A low value

denotes slower control

Indicates the value for I for

cooling. A high value denotes

faster control. A low value

denotes slower control.

Indicates the value for P for

heating. A high value denotes

faster control. A low value

denotes slower control.

P_1126 10

I term Heating Scale 1:100

min 1 max 10000

P_1127 23

TC_Normal

min 15 max 30

P_1128 21

TH_Normal

min 15 max 30

P_1129 25

TC_Economy

min 10 max 30

P_1130 19

TH_Economy

min 10 max 30

Indicates the value for I for

heating. A high value denotes

faster control. A low value

denotes slower control.

Switch in cooling for normal

operation.

Switch in heating for normal

operation.

Switch in cooling for economic

operation

Switch in heating for economic

operation.

5 : 44

Page 45

Application parameters W3

Application parameters are parameter-specific for the selected application.

Display image Description

P_1001 4

System1=H,2=C,3=ChOv,4=HC

min 1 max 4

P_1002 1

0=ext.temp, 1 or 2 room units

min 0 max 2

P_1003 10 C

min 5 max 12

Frost guard temp.

Service

Indicates how the climate

system should operate for

heating and cooling.

1 = Heating only

2 = Cooling only

3 = Change-over function

4 = Heating/Cooling

Indicates whether one or

two room units are used..

(0=The controllers temp. sensor

is used, 1=1 unit, 2=2 units If 2

units are used they should be

connected with a cable.

Indicates at which temperature

the frost protection should

switch in.

P_1008 90 %

Boost flow SA %

min 0 max 1

P_1010 0

Emergency func SA damper

min 0 max 1

P_1011 10 %

Stand-by flow SA %

min 0 max 100

P_1012 90 %

Boost flow EA %

min 0 max 100

P_1014 0

Emergency func exhaust damper

min 0 max 1

P_1015 10 %

Stand-by flow EA %

min 0 max 100

Indicates the supply airflow for

BOOST.

Indicates which blade position

the damper in the supply air

duct should have in event of

fire.

0 = Closed

1 = Open

Indicates the supply airflow for

STOP.

Indicates the extract airfl ow for

BOOST.

Indicates whether the damper

in the extract air duct should be

open or closed in the EMERG

mode.

(0=Closed, 1=Open)

Indicates the extract airflow

for STOP.

P_1016 50 %

Normal flow SA %

min 0 max 100

P_1017 50 %

Normal flow EA %

min 0 max 100

Indicates the supply airflow for

AUTO.

Indicates the extract airflow for

AUTO.

5 : 45

Page 46

Service

Display image Description

P_1018 0 mV

SA mV at 0% output

Offset voltage for 0% supply

airflow.

(Dissolution=50mV)

min 0 max 5000

P_1019 10000 mV

SA mV at 100% output

min 5000 max 10000

P_1020 0 mV

EA mV at 0% output

min 0 max 5000

P_1021 10000 mV

EA mV at 100% output

min 5000 max 10000

P_1022 1

Economy mode available?

min 0 max 1

P_1023 1

ActuatorCool 1=NC,2=0-10V,3=NO

min 1 max 3

P_1024 1

ActuatorHeat 1=NC,2=0-10V,3=NO

min 1 max 3

Offset voltage for 100% supply

airflow.

(Dissolution=50mV)

Offset voltage for 0% extract

airflow.

(Dissolution=50mV)

Offset voltage for 100% extract

airflow.

(Dissolution=50mV)

Indicates whether the Economy

mode is available.

0 = No

1 = Yes

Indicates which sort of valve

actuator is installed in the

cooling water circuit.

(1=24V-NC, 2=0-10V, 3=24VNO)

Indicates which sort of valve

actuator is installed in the

heating water circuit.

(1=24V-NC, 2=0-10V, 3=24VNO)

P_1025 0

Window 0=NP,1=NC,2=NO

min 0 max 2

P_1026 0

Occupancy 0=NP,1=NC,2=NO

min 0 max 2

P_1027 5000

P term Change over

min 1 max 10000

P_1028 50

I term Change over

min 1 max 10000

Indicates whether a window

contact is installed and if so

how it is installed.

0 = No contact installed

1 = Normally closed

2 = Normally open

Indicates whether a presence

detector is installed and if so

how it is installed.

0 = No contact installed

1 = Normally closed

2 = Normally open

Indicates the value for P for the

Change Over function. A high

value denotes faster control.

A low value denotes slower

control.

Indicates the value for I for the

Change Over function. A high

value denotes faster control.

A low value denotes slower

control.

5 : 46

Page 47

Display image Description

P_1029 2 K

Boost at temp. over setpoint (K)

min 1 max 10

Indicates by how much the

room temperature actual value

should rise above the setpoint

in order for the controller to

switch from AUTO to BOOST.

Service

P_1034 1

Timer function available?

min 0 max 1

P_1035 5 min

Timer function time (min)

min 1 300

P_1038 16 C

Room unit’s min set point

min 0 max 20

P_1039 28 C

Room unit’s max set point

min 25 max 50

P_1040 10 %

Room unit’s min air flow

min 5 max 50

P_1041 100 %

Room unit's max air flow

min 50 max 100

Indicates whether time-adjusted

fl ow boost is accessible.

(0=No, 1=Yes)

Indicates how long the timeadjusted fl ow boost should

be on ON when occupancy is

activated

The lowest possible room

temperature setpoint for the

MAN operating mode

The highest possible room

temperature setpoint for the

MAN operating mode.

The lowest possible airflow

setpoint for the MAN operating

mode.

The highest possible airflow

setpoint for the MAN operating

mode.

P_1042 1 K

Boost temp. below setpoint (K)

0 max 10

P_1043 20 %

Economy flow SA %

min 0 max 100

P_1044 20 %

Economy flow EA %

min 0 max 100

P_1045 480 min

RU back to auto state

min 0 max 1200

Indicates how much the current

room temperature should differ

from the setpoint in order for

the controller to switch from

BOOST to AUTO.

Indicates the supply airflow for

ECON.

Indicates the extract airflow for

ECON.

Indicates how long time after

the latest manual adjustment of

room temperature or airfl

ow that the controller should

return to AUTO.

(0=Is not used)

5 : 47

Page 48

Service

Display image Description

P_1046 18 C

Night cool temp set point

Indicates the temperature

setpoint applicable to the Night

cool function.

min 10 max 20

P_1047 80 %

Night cool flow SA %

min 50 max 100

P_1048 80 %

Night cool flow EA %

min 50 max 100

P_1049 5000

P term Cooling Scale 1:100

min 1 max 10000

P_1050 10

I term Cooling Scale 1:100

min 1 max 10000

P_1051 5000

P term Heating Scale 1:100

min 1 max 10000

P_1052 10

I term Heating Scale 1:100

min 1 max 10000

Indicates the supply airflow for

“night cool”.

Indicates the extract airflow for

“night cool”.

Indicates the value for P for

cooling. A high value denotes

faster control. A low value

denotes slower control.

Indicates the value for I for

cooling. A high value denotes

faster control. A low value

denotes slower control.

Indicates the value for P for

heating. A high value denotes

faster control. A low value

denotes slower control.

Indicates the value for I for

heating. A high value denotes

faster control. A low value

denotes slower control.

P_1053 23

TC_Normal

min 15 max 30

P_1054 21

TH_Normal

min 15 max 30

P_1055 25

TC_Economy

min 10 max 30

P_1056 19

TH_Economy

min 10 max 30

Switch in cooling for normal

operation.

Switch in heating for normal

operation.

Switch in cooling for economic

operation.

Switch in heating for economic

operation.

5 : 48

Page 49

Indication on the controller

There are two indicating LEDs on the controller, one on the front (No.1) and

under the lid (No.2). The indications that can be shown, their importance

and their relation to the DIP switches (DIP) is as follows:

No. 1st 2nd DIP 1 DIP 2 Explanation Remarks

1. Green

flashing

for 1

second.

2. Red and

green

flashing.

3. Red

flashing

for 1

second.

4. Orange

flashing

for 1

second.

5. - - Off. On. BMS mode. The mode is

6. Light

orange.

7. Green. Green. - - The controller has

8. Orange. Green. On. - The controller has

9. Fast

green

flashing.

10. - Red. - - The voltage is low

11. - Very rapid

12. - Very

None. Off. Off. Normal operation. -

None. Off. Off. Normal operation, but:

None. Off. Off. External memory error.

None. On. Off. Service position. All MB ports are

Light

orange.

Green. - - The parameter file is

green

flashing.

rapid red

flashing.

The room unit or

pressure sensor is

missing.

The temperature sensor

in the room unit is

defectiveive.

KTY sensor missing.

AC output signals are

incorrect.

MB-ID = 0 or higher

than 247.

- - The controller lacks

bootloader or is in reset.

bootloader but lacks

software.

bootloader but lacks

software.

being processed.

(Supply voltage is <13V).

- - Radio Frequency

communication.

- - Further transmission

of MB.

Service

-

X1 and X2 are “slaves”

and X3 is a “master”.

MB-ID is 1.

Set DIP 1 and DIP 2

to On.

“slaves”, 38400n1.

Room unit does not

operate in the service

mode.

automatically activated

when required.

-

MB-ID is same as in the

parameter file.

MB-ID is forced to 1.

See to it that the power

supply is maintained.

Safety measure for the

AC output signals. All

signals are Off.

-

-

5 : 49

Page 50

Service

Trouble shooting

An alarm is initiated when an error arises in the control system. There are

two types of alarms:

• General alarms.

• Application alarms.

Trouble shooting of the control system should always begin with

investigating whether any alarm has been initiated and if so which.

Certain alarms are automatically reset (Auto) after the cause of the error has

been remedied, while other alarms have to be manually (Man) reset.

If the control system is connected to a ModBus system, the alarms can be

read within the 10100 – 10139 range.

Alarm

No.

Alarm text Description /

Cause

0. No active alarms No active alarms present. No measure required. -

1. No room unit 1 The controller has not

2. No room unit 2 The controller has not

3. No pressure sensor Pressure sensor is missing

4. No supply flow sensor Flow sensor is missing or

5. No exhaust flow sensor Flow sensor is missing or

6. Room unit 1

temperature

7. Room unit 2

temperature

8. Controller KTY short

circuit

9. Controller KTY open

circuit

10. Room unit low battery The level on the battery in

11. PT-controller overload The output signal has

12. Set point not reached Set temperature, set flow

13. TBD - - -

14. TBD - - -

15. No device list - - -

16. AC overload The supply voltage is too

17. System fault Component error. Replace the controller! -

18. No serial number Program error. Replace the controller! -

received any signal from

the room unit 1 within

the given time (P_110).

received any signal from

the room unit 2 within

the given time (P_110).

or is defectiveive. Alarm is

initiated after given time

(P_113).

is defectiveive. Alarm is

initiated after given time

(P_113).

is defectiveive. Alarm is

initiated after given time

(P_113).

No temperature from

room unit 1.

No temperature from

room unit 2.

KTY sensor defectiveive. Replace the KTY

KTY sensor missing. Check connection of

the room unit is low.

been +100% or -100%

during given time

(P_111).

or pressure has not been

reached within given time

(P_112).

high.

Remedial

measure

Make a new

connection – Radio

Frequency mode.

Check the cable.

Check the cable. Auto

Install or replace the

sensor.

Install or replace the

sensor.

Install or replace the

sensor.

Change room unit! Auto

Change room unit! Auto

sensor.

the KTY sensor.

Replace the batteries

in the room unit!

Check water the

temperature and the

water flow.

Check the water

temperature, the

water flow and the

airflow.

Check the voltage

source.

Resetting

Auto

Auto

Auto

Auto

Auto

Auto

Auto

Auto

Auto

Auto

5 : 50

Page 51

Service

Alarm

No.

Alarm text Description /

Cause

19. TBD - - -

20. Short circuit X11 Connected component is

21. Short circuit X12 Connected component is

22. Short circuit X13 Connected component is

23. Short circuit X14 Connected component is

24. SPI flash broken Component error. Replace the controller! Man.

25. Radio chip broken Component error. Replace the controller! Man.

26. Parameter file revision Parameter file is incorrect. Update with new

27. Parameter file format Parameter file is incorrect. Update with new

28. No Modbus ID Parameter file is incorrect. Update with new

29. No application Parameter file is incorrect. Update with new

30. No parameters Parameter file is incorrect. Update with new

31. Parameter missing Parameter file is incorrect. Update with new

32. Parameter value error Parameter file is incorrect. Update with new

33. Parameter file size Parameter file is incorrect. Update with new

34. Wrong parameter file Parameter file is incorrect. Update with new

35. Check duct group SM - -

36. Check duct group DC - - -

37. Previous parameters

are lost

38. Factory parameters

take up

39. TBD - - -

40. TBD - - -

41. No supply pressure

from AHU

42. No exhaust pressure

from AHU

43. Supply duct 100%

open

44. Exhaust duct 100%

open

45. Low voltage detect The voltage for the

46. TBD - - -

47. Duct group member

missing

48. Negative pressure - - -

defectiveive.

defectiveive.

defective.

defective.

Changes in parameter file

has been lost.

Changes in parameter file

have not been approved.

- - -

- - -

- - -

- - -

controller is low.

- - -

Remedial

measure

Troubleshoot to find

the faulty component

and replace the

component.

Troubleshoot to find

the faulty component

and replace the

component.

Troubleshoot to find

the faulty component

and exchange the

component.

Troubleshoot to find

the faulty component

and exchange the

component.

parameter file.

parameter file.

parameter file.

parameter file.

parameter file.

parameter file.

parameter file.

parameter file.

parameter file.

To restart the

controller.

To restart the

controller.

Check the voltage

source.

Resetting

Man.

Man.

Man.

Man.

Man.

Man.

Man.

Man.

Man.

Man.

Man.

Man.

Man.

-

Man.

Man.

Auto

5 : 51

Page 52

Service

Modbus-register W1

The information listed below applies when the CONDUCTOR W1 is connected to a so-called ModBus system.

ModBus-register W1 applies to software after 076

Input Status

Modbus Name Min/Max Remarks Default

0x0001 Not used

0x0002 Not used

0x0003 Not used

0x0004 Not used

0x0005 Economy mode 0/1 0=Unavailable, 1= Available 1

0x0006 Not used

0x0007 Not used

ModBus-register W1 applies to software after 0.76

Input Status

Modbus Name Min/Max Remarks Default

1x0001 Condensation 0/1

1x0002 Relay state 0/1

1x0003 Occupancy switch 0/1

1x0004 Window switch 0/1

1x0005 Motion 0/1

1x0006 No active alarms 0/1 ALARM INFO

1x0007 No Room Unit 1 0/1 ALARM, resets automatically

1x0008 No Room Unit 2 0/1 ALARM, resets automatically

1x0009 No Pressure sensor 0/1 ALARM, resets automatically

1x0010 No Supply Flow sensor 0/1 ALARM, resets automatically

1x0011 No Exhaust Flow sensor 0/1 ALARM, resets automatically

1x0012 Room Unit 1 Temperature 0/1 ALARM, resets automatically

1x0013 Room Unit 2 Temperature 0/1 ALARM, resets automatically

1x0014 Regulator KTY short circuit 0/1 ALARM, resets automatically

1x0015 Regulator KTY open circuit 0/1 ALARM, resets automatically

1x0016 Room Unit Low Battery 0/1 ALARM, resets automatically

1x0017 PI-controller overload 0/1 ALARM, resets automatically

1x0018 Setpoint not reached 0/1 ALARM, resets automatically

1x0019 Not used

1x0020 Not used

1x0021 No device list 0/1 ALARM, resets automatically

1x0022 AC overload 0/1 ALARM, resets automatically

1x0023 System fault 0/1 ALARM

1x0024 No serial number 0/1 ALARM

1x0025 Not used

Discrete Input (1 bit) Read

only

Discrete Input (1 bit) Read

only

5 : 52

Page 53

Service

ModBus-register W1 applies to software after 0.76

Holding

register

Modbus Name Min/Max Remarks Default

1x0026 Short circuit X11 0/1 ALARM, requires HW reset

1x0027 Short circuit X12 0/1 ALARM, requires HW reset

1x0028 Short circuit X13 0/1 ALARM, requires HW reset

1x0029 Short circuit X14 0/1 ALARM, requires HW reset

1x0030 SPI Flash broken 0/1 ALARM, requires HW reset

1x0031 Radio chip broken 0/1 ALARM, requires HW reset

1x0032 Parameter file revision 0/1 ALARM, requires HW reset

1x0033 Parameter file format 0/1 ALARM, requires HW reset

1x0034 No ModBus ID 0/1 ALARM, requires HW reset

1x0035 No Application 0/1 ALARM, requires HW reset

1x0036 No parameters 0/1 ALARM, requires HW reset

1x0037 Parameter missing 0/1 ALARM, requires HW reset

1x0038 Parameter value error 0/1 ALARM, requires HW reset

1x0039 Parameter file size 0/1 ALARM, requires HW reset

1x0040 Wrong parameter file 0/1 ALARM, requires HW reset

1x0041 Check Duct Group SM 0/1 ALARM, resets after right parameters

1x0042 Check Duct Group DC 0/1 ALARM, resets after right parameters

1x0043 Previous parameters are lost 0/1 ALARM, requires HW reset

1x0044 Factory parameters take up 0/1 ALARM, requires HW reset

1x0045 Not used

1x0046 Not used

1x0047 No supply pressure from AHU 0/1 ALARM, resets automatically

1x0048 No exhaust pressure from AHU 0/1 ALARM, resets automatically

1x0049 Supply duct 100% open 0/1 ALARM, resets automatically

1x0050 Exhaust duct 100% open 0/1 ALARM, resets automatically

1x0051 Low voltage detect 0/1 ALARM, resets automatically

1x0052 Not used

1x0053 Duct group member missing 0/1 ALARM, resets automatically

1x0054 Negative pressure 0/1 ALARM, resets automatically

16 bit integer register R/W

5 : 53

Page 54

Service

ModBus-register W1 applies to software after 0.76

Holding

register

Modbus Name Min/Max Remarks Default

4x0001 Relay in Emergency 0/1 0=Close, 1=Open, 2=No Action

4x0002 Application transition 1/8 1=Normal, 3=Manual, 4=Stand-by,

4x0003 Room number

4x0004 Valve exercise 0/72 Valve exercise 0=Not used (hours) 48

4x0005 Motion Timer 0/20 Motion timer (minutes) 20

4x0006 General warning time 0/60 Warning delay, general (minutes) 60

4x0007 PI-overload warning time 0/60 Warning delay, PI-overload (minutes) 120

4x0008 Set-point warning time 0/60 Warning delay, Set point (minutes) 60

4x0009 Not used

4x0010 Not used

4x0011 Not used

4x0012 Not used

4x0013 Not used

4x0014 System type 1/4 1= Heat, 2= Cool, 3= Change Over,

4x0015 Number of Room units 1/2 1=One room unit, 2= Two room units 1

4x0016 Window switch 0/2 0=Not used 1=Normaly Closed

4x0017 Occupancy switch 0/2 0=Not used 1=Normaly Closed

4x0018 Actuator Type Cool 1/3 ActuatorCool 1=NC,2=0-10V,3=NO 1

4x0019 Actuator Type Heat 1/3 ActuatorHeat 1=NC,2=0-10V,3=NO 1

4x0020 Not used

4x0021 Not used

4x0022 Not used

4x0023 Frost guard temp. 5/15 10

4x0024 TC1 Normal 15/30 (degC) 23

4x0025 TH1 Normal 15/30 (degC) 21

4x0026 TC2 Economy 10/30 (degC) 25

4x0027 TH2 Economy 10/30 (degC) 19

4x0028 Night cool temp set point 10/20 20

4x0029 Room unit's min set point 0/20 only when room unit is manual state

4x0030 Room unit's max set point 25/50 only when room unit is manual state

4x0031 Not used

4x0032 Not used

4x0033 Not used

4x0034 Not used