Page 1

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 1

INSTALLATION AND MAINTENANCE INSTRUCTIONS FOR

COMPACT AIR & COMPACT HEAT

Applicable to program version 1.04 and newer versions

COMPACT Heat

COMPACT Air

Page 2

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

2

www.swegon.com

Content

1 GENERAL .................................... 3

1.1 Field of Application ..................................3

1.2 Mechanical Design ...................................3

1.3 Control System ........................................3

1.4 Environmental Documentation .................3

1.5 The Components of the

Air Handling Units ..........................................4

1.5.1 COMPACT Air ....................................4

1.5.2 COMPACT Heat ..................................5

2 SAFETY PRECAUTIONS ..............6

2.1 To Start/Stop the Air Handling Unit ...........6

2.2 Risks .......................................................6

3 INSTALLATION ........................... 7

3.1 General ....................................................7

3.2 Transport Within the Site/Sectionalizing ....7

3.2.1 To Split the Air Handling Unit into

Separate Sections to Facilitate Transport

Within the Building Site. ..............................7

3.3 Location ...................................................8

3.4 To Fit the Kick-protection Base ..................8

3.5 To Install the Air Recirculation Section/

Louvre Damper

(applies to COMPACT Heat only) .... 8

3.6 Duct Connection ......................................8

3.7 Exterior Wall Hood ...................................9

3.8 Existing Ventilation ...................................9

3.9 Serving More than One Room ..................9

3.9.1 Extract Air Intake ................................9

3.9.2 Transfer Air ........................................9

3.10 Connection to the Electric Power Grid ....9

3.11 To Connect External Cables ....................9

3.12 To Adjust the Supply Air Discs ...............10

4 COMMISSIONING ....................11

4.1 General ..................................................11

5 CONTROL DISPLAY AND

USING THE MENU ....................... 12

5.1 Control display .......................................12

5.1.1 General: ...........................................12

5.1.2 The Buttons ......................................12

5.1.3 Display screen ...................................12

5.1.4 Abbreviations Used ...........................12

6 MAIN MENU 1 .......................... 13

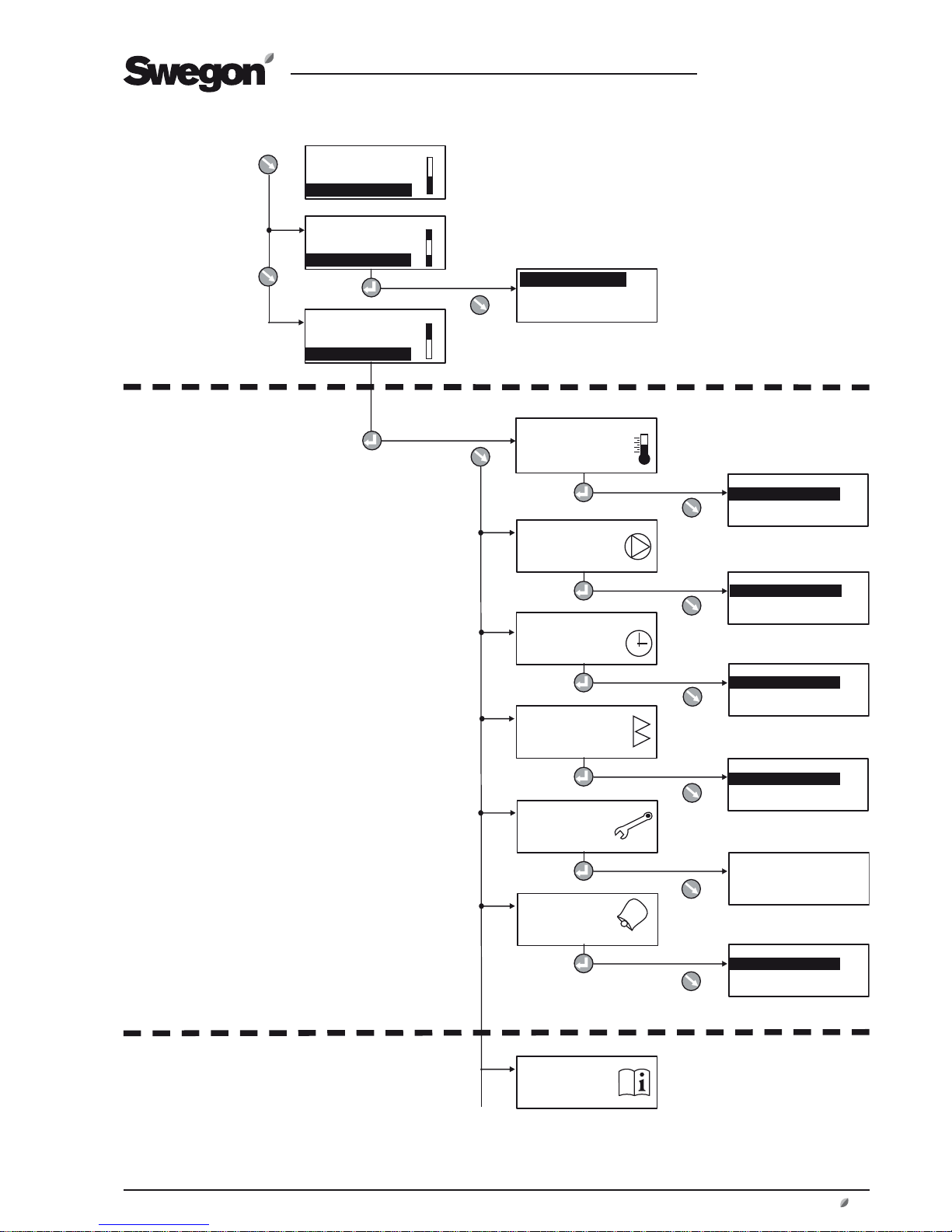

6.1 The Menu Tree .......................................13

6.2 General ..................................................14

6.3 Selection of Language ............................14

6.4 Normal Operation ..................................14

6.5 Extended operation ................................14

6.6 Airing ....................................................14

6.7 Heating(applies to COMPACT Heat only) 14

6.8 Heating + Recirculation(applies to

COMPACT Heat only) ...................................14

6.9 Main Menu 2 .........................................14

7 MAIN MENU 2 .......................... 15

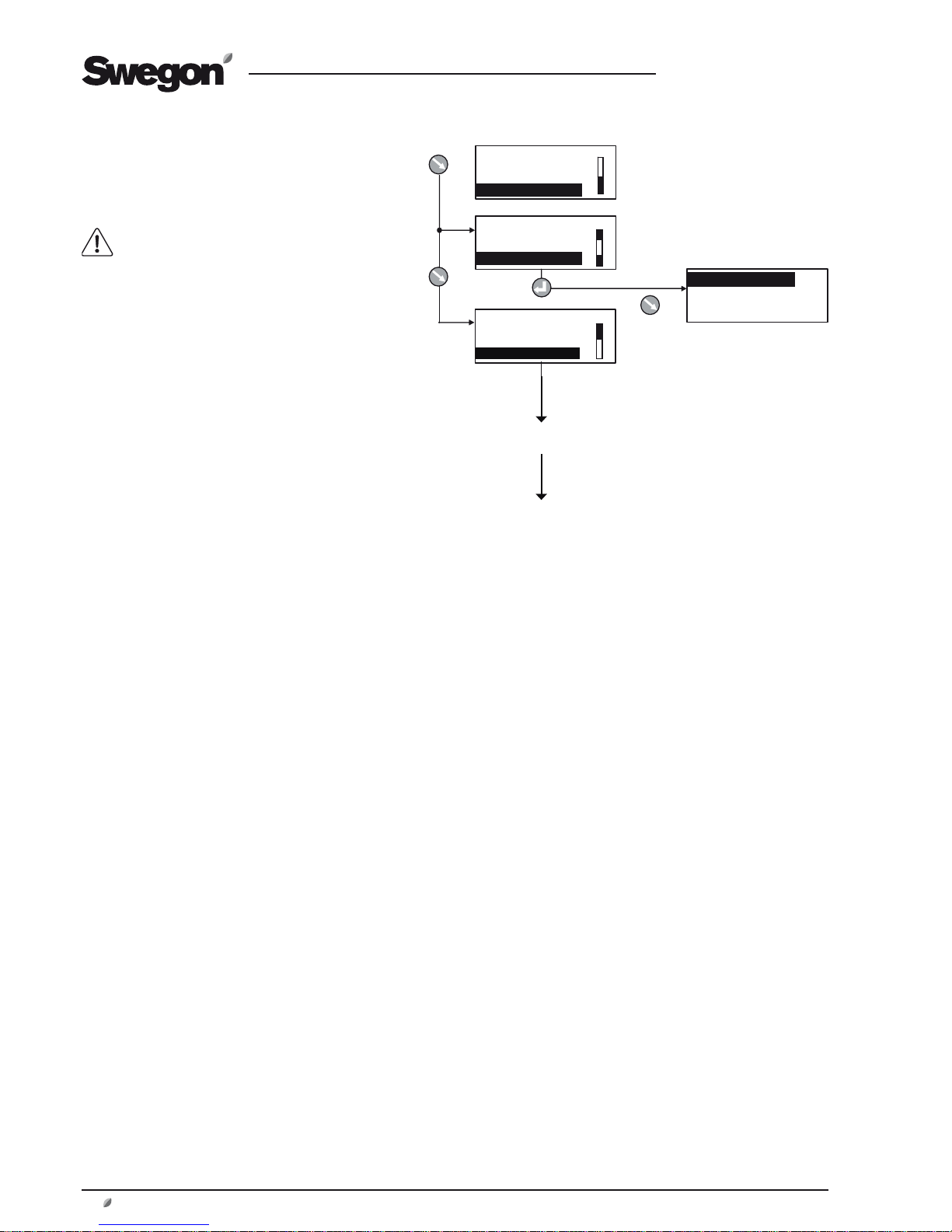

7.1 Menu tree ..............................................15

7.2 Changing Operating Mode ....................16

7.3 Settings .................................................16

8 USER LEVEL ..............................17

8.1 Temperature...........................................17

8.1.1 Readings ..........................................17

8.1.2 Settings ............................................17

8.2 Air fl ow/Pressure ....................................18

8.2.1 Readings ..........................................18

8.2.2 Settings ............................................18

8.3 Switch clock ...........................................19

8.4 Filters .....................................................19

8.4.1 Readings ..........................................19

8.4.2 To Calibrate the Filters ......................19

8.4.3 Calibration - Rotary Heat Exchanger ..19

8.5 Air Adjustment .......................................20

8.6 Alarms ...................................................20

9 INSTALLATION LEVEL ..............21

9.1 Menu Survey ..........................................21

10 FUNCTIONS ............................ 22

10.1 Temperature.........................................22

10.2.1.1 ERS Regulation ............................23

10.2.2 Airing Function ...............................24

10.2.2.1 Automatic Airing .........................24

10.2.2.2 Manual Airing .............................24

10.2.3 Summer Night Cooling ...................25

10.2.4 Intermittent Night-time Heating

(applies to COMPACT Heat only) ................26

10.2.5 Morning BOOST

(applies to COMPACT Heat only) ................27

10.2.6 Heating

(applies to COMPACT Heat only) ................27

10.2.7 External Temperature Sensors .........28

10.3 Flow/Pressure .......................................29

10.3.1 Fan Regulation ...............................29

10.3.1.1 Flow Regulation ...........................29

10.3.1.2 Demand Regulation (Control) ......29

10.3.1.3 Slave Control ...............................29

10.3.1.4 Clean Air Control .........................30

10.3.2 Outdoor Temperature

Compensation ...........................................31

10.3.3 Downspeed Control of Fan

Speed to Min. Set Point, Airfl ow ................32

10.4 To Activate the Filter

Monitoring Function ....................................32

10.5 Operation ............................................33

10.5.1 Switch clock ...................................33

10.5.2 Extended Operation ........................33

10.5.3 Summer time/Winter time ..............33

10.6 Heating ................................................34

10.6.1 Heat exchanger ..............................34

10.6.1.1 Defrosting the rotary heat

exchanger .................................................34

10.6.1.2 Heating BOOST

(applies to COMPACT Heat only) ................35

10.7 Cooling (Applies to an air cooler installed

in the outdoor air duct only) .........................36

10.7.1 Operation .......................................36

10.7.2 Temperature Regulation (Control) ...36

10.7.3 Periodic Operation ..........................37

10.7.4 Regulation Speed ...........................37

10.7.5 Outdoor Temperature Limit .............37

10.7.6 Restart Time ...................................37

10.7.7 Cooling Min Air Flow ......................37

10.7.8 Neutral Zone ..................................37

10.7.9 Cooling BOOST ..............................37

10.8 Input/output connections .....................38

10.9 IQnomic Plus ........................................39

11 AUTOMATIC FUNCTIONS ......40

11.1 General ................................................40

11.1.1 Starting Sequence ..........................40

11.1.2 Cooling Recovery ............................40

11.1.3 Zero Point Calibration .....................40

11.1.4 Additional cooling –

Electric Air Heater ......................................40

11.1.5 Additional running -

Heat Exchanger .........................................40

11.1.6 Density-corrected Airfl ow ...............40

11.1.7 BOOSTER-function

(Applies to COMPACT Heat only) ...............40

12 READINGS .............................. 41

13 MANUAL TEST ....................... 41

14 ALARM SETTINGS ..................42

14.1 Fire Alarms ...........................................42

14.2 External Alarms ....................................42

14.3 Alarm Limits .........................................42

14.4 Alarm Priority .......................................42

15 CONTROL DISPLAY ................43

15.1 Language .............................................43

15.2 Air fl ow unit .........................................43

15.3 Min/Max Adjustment ...........................43

15.4 Base Settings ........................................43

16 COMMUNICATION ................. 44

16.1 EIA-485 ...............................................44

16.2 Ethernet ...............................................44

17 SERVICE LEVEL .......................44

18 MAINTENANCE ...................... 45

18.1 Filter Change .......................................45

18.1.1 To remove the Filters .......................45

18.1.2 To fi t new fi lters ..............................45

18.2 Cleaning and Inspection .......................45

18.2.1 General ..........................................45

18.2.2 Filter Space .....................................45

18.2.3 Heat exchangers .............................45

18.2.4 Fans and Fan Space ........................45

18.3 Performance Checks ............................45

18.4 Damper Actuator for the Change-over

Damper .......................................................45

19 ALARMS AND

FAULT TRACING ..........................46

19.1 General ................................................46

19.1.1 A and B Alarms ...............................46

19.1.2 To reset the alarm ...........................46

19.1.3 To Change the Alarm Settings .........46

19.2 Alarm Descriptions with

Factory Settings ...........................................47

20 INFORMATIVE MESSAGES .... 51

21 TECHNICAL DATA ..................52

21.1 Dimensions, COMPACT Air...................52

21.2 Dimensions, COMPACT Heat ................52

21.3 Electrical Equipment Cubicle ................53

21.3.1 Internal Connections,

COMPACT Air ...........................................54

21.3.2 Internal Connections,

COMPACT Heat .........................................55

21.3.3 Connection to Terminal Blocks ........56

21.4 Electrical Data ......................................57

21.4.1 Air Handling Unit ............................57

21.4.2 Fans ...............................................57

21.4.3 Electrical equipment cubicle ............57

21.4.4 Heat Exchanger Motor ....................57

21.4.5 Control Inaccuracy ..........................57

22 APPENDICES ........................... 58

22.1 Compliancy Declaration .......................58

22.2 Commissioning Record .........................59

Page 3

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 3

1 GENERAL

1.1 Field of Application

The COMPACT Air and COMPACT Heat units are complete

air handling units that can be installed directly in the room

to be ventilated. The ducts for outdoor air and exhaust air

should be connected to the top of the unit and should be

arranged to lead out through the wall. Other than that,

you need only connect the unit to the mains electric supply.

The installation work can be carried out very quickly and

easily and if the task of cutting openings through the wall

is not complicated, the unit can be operational in just a

few hours. It is also simple to relocate the air handling

unit if the nature of the activities conducted in the room

changes.

The ventilation is very effective thanks to the displacement

air distribution method used. The built-in control equipment has several functions for economic operation.

The COMPACT Air and COMPACT Heat units are designed

for comfort ventilation and can be used in classrooms, day

nurseries, conference halls, smaller offi ces, workrooms,

shops, restaurants and similar public premises.

The difference between the COMPACT Air and the COMPACT Heat units is that the COMPACT Heat units can also

be used for heating.

It is important keep all the special characteristics of the

air handling units in mind when planning them into the

project, installing, adjusting and operating them to fully

obtain all the benefi ts the COMPACT system has to offer.

The unit must be installed indoors.

Important!

Always read the safety precautions in Section 2 that

explain the risks involved in running the unit and

designate who shall be permitted to operate and

service the unit, and carefully follow the installation

instructions provided in each paragraph.

The product identifi cation plates are located inside the

room unit and on the unit’s rear side. See Sections 1.5.1

and 1.5.2 respectively. Refer to the particulars on the

product identifi cation plate when you contact Swegon.

1.2 Mechanical Design

The COMPACT is available in one physical size and for two

airfl ow ranges.

Its sheet steel exterior is painted white, NCS S 0502-G.

The decorative strips and cover plate around the control

display are dark grey, NCS S6010-R90B. The inner skin is

predominantly made of aluminium-zinc plated sheet steel.

The casing has 30 mm thick intervening mineral wool

insulation; the inspection doors have 50 mm thick insulation.

The COMPACT Air and the COMPACT Heat are equipped

with pleated, Class F7 fi lters.

The type RECOnomic rotary heat exchanger is variable

speed controlled and has a peak temperature effi ciency of

85%.

The supply air and extract air fans are direct-driven plug

fans. The fans are equipped with EC motors that provide

high effi ciency across the entire operating range.

1.3 Control System

The IQnomic control system is microprocessor-based and is

integrated into the unit. It controls and regulates the fans,

heat exchanger, temperatures, airfl ows, operating times

and a large number of internal and external functions as

well as alarms.

1.4 Environmental Documentation

Environmental Documentation with the Dismantling

Instructions for recycling and the Environmental Declaration can be downloaded from our home page: wwww.

swegon.com.

The air handling unit is design in such a way that it can

be dismantled into its natural parts for scrapping. When

the unit has ended its useful product life, the services of

an accredited recycling company should be utilized for

disposal.

Approximately 94% of the parts in COMPACT air handling

units is recyclable.

Swegon AB is associated with the REPA Register, No.

5560778465.

Contact Swegon AB, Phone: +46 (0)512-322 00, if you

have any questions regarding the dismantling instructions

or the air handling unit’s impact on the environment.

Page 4

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

4 www.swegon.com

1.5 The Components of the

Air Handling Units

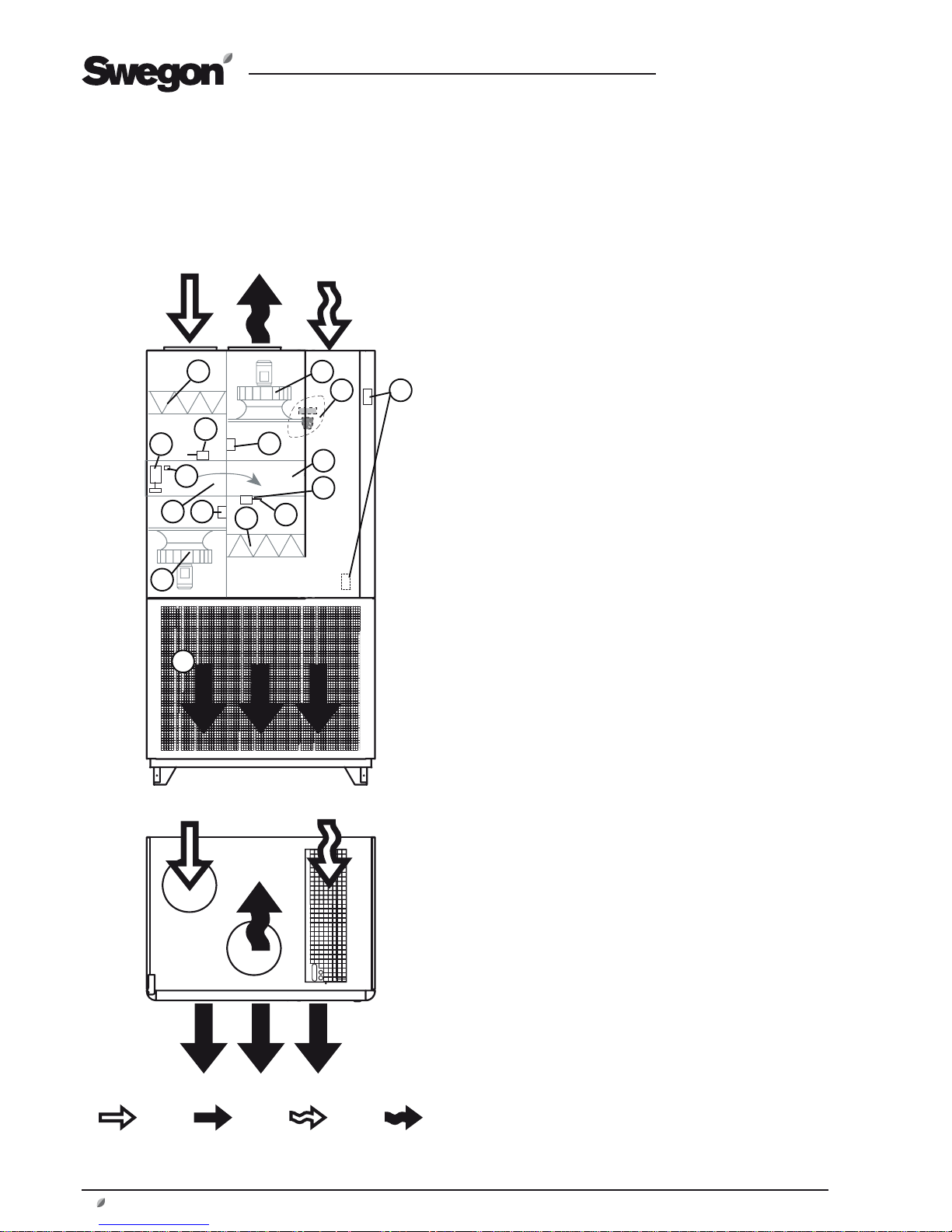

1.5.1 COMPACT Air

The individual components each specifi ed below in a simplifi ed and diagrammatical description.

The arrangement of the components

and their designations

1 Extract air fan with motor and built-in controller

2 Control display (on the inspection door)

3 Product identifi cation plate

4 Pressure sensor, extract air fan

5 Electrical equipm. cubicle with control unit

6 VOC sensor

7 Sensor, extract air temperature

8 Extract air fi lter

9 Sensor, supply air temperature (inside the lower section)

10 Supply air fan with motor and built-in controller

11 Heat exchanger

12 Pressure sensor, supply air fan

13 Sensor, rotation monitor

14 Drive motor, heat exchanger

15 Sensor, outdoor temperature

16 Supply air fi lter

Outdoor air Supply air Extract air Exhaust air

1

4

5

2

8

9

16

15

11

14

13

12

7

10

3

6

Page 5

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 5

1.5.2 COMPACT Heat

The individual components each specifi ed below in a simplifi ed and diagrammatical description.

The arrangement of the components

and their designations

1 Extract air fan with motor and built-in frequency inverter

2 Control display (on the inspection door)

3 Product identifi cation plate

4 Pressure sensor, extract air fan

5 Electrical equipm. cubicle with control unit

6 VOC sensor

7 Sensor, extract air temperature

8 Extract air fi lter

9 Electric air heater, (inside the lower section)

10 Sensor, supply air temperature (inside the lower section)

11 Change-over damper with actuator (inside the lower section)

12 Supply air fan with motor and built-in controller

13 Heat exchanger

14 Pressure sensor, supply air fan

15 Sensor, rotation monitor

16 Drive motor, heat exchanger

17 Sensor, outdoor temperature

18 Supply air fi lter

19 Recirculation section with actuator

20 Louvre damper

Outdoor air Supply air Extract air Exhaust air

1

4

5

2

8

18

13

16

15

14

12

3

19 20

10

17

7

11

9

6

Page 6

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

6 www.swegon.com

2 SAFETY PRECAUTIONS

All staff concerned must acquaint themselves with these

instructions before beginning any work on the unit. Any

damages to the unit or parts of it due to improper handling or misuse by the purchaser or the fi tter cannot be

considered subject to guarantee if these instructions have

not been followed correctly.

Warning

Only an authorised electrician or qualifi ed service

personnel trained by Swegon shall be permitted to

carry out electrical installation on the air handling

unit or wire external functions to it.

2.1 To Start/Stop the Air Handling Unit

The air handling unit should normally be started and

stopped via the control display. Note that the control

equipment of the air handling unit is still electrifi ed after

the unit has been switched off via the control display.

Pull out the plug connector before servicing the unit if not

otherwise specifi ed in the pertinent instructions or in the

event of an emergency.

2.2 Risks

Warning

Before carrying out any work, make sure that the

power supply to the air handling unit has been

isolated.

Risk areas with moving parts

Typical moving parts are fan impellers and drive pulleys of

the rotary heat exchanger. Safety guards are provided in

front of these components. If the ducts are not connected

to the fan outlet, these must be fi tted with a safety guard

(wire mesh screen).

Only a qualifi ed electrician or trained service technicians

shall be allowed to remove the safety guards.

Page 7

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 7

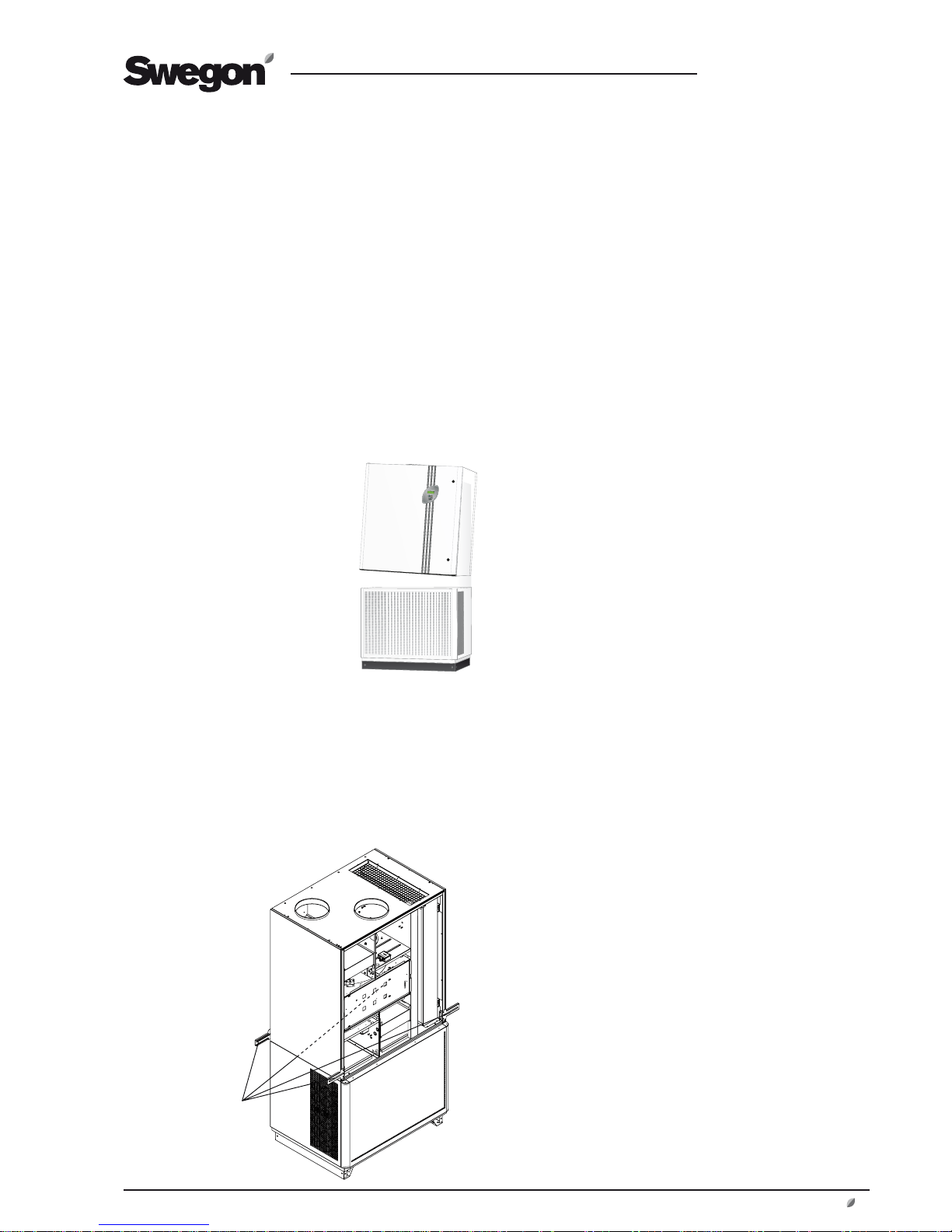

3.1 General

The air handling unit is delivered with packaging, standing

on a wooden pallet. The kick-protection base is supplied

in kit form laying inside a carton placed in the extract air

duct of the air handling unit. The recirculation section and

louvre damper, if ordered, are supplied unmounted. For

assembly instructions see Section 3.5.

Any accessories that have been ordered with the unit are

supplied in unmounted condition.

3.2 Transport Within the Site/Sectionalizing

The Compact Air unit is always supplied as one complete air handling unit. If transporting the unit within the

site proves diffi cult, the unit can be split into sections as

described below:

1. Open the inspection door using the spanner supplied with

the unit.

2. Dismantle the safety guard in front of the heat exchanger.

Disconnect the communication cable of the control display

by removing the quick connector on the control unit connection (marked HMI) and bundling strap. Pull the communication cable out all the way to the inspection door.

3.2.1 To Split the Air Handling Unit into Separate Sections to Facilitate Transport

Within the Building Site.

3 INSTALLATION

3. Remove the screws of the upper hinge and lift off the

inspection door.

4. Fasten the lifting handle (supplied, located below the extract

air fi lter) with screws, see illustration.

5. Remove the insulation and the safety guard from the supply

air fan.

6. Pull the quick connectors of the cables to the supply air fan

apart to disconnect them.

7. Dismantle the supply air fan by backing off the two screws

in the rear part of the fan suspension bracket. Do not

unscrew them completely. Unscrew and remove the screws

in the front part of the suspension bracket. Withdraw the

entire fan package. The suspension bracket will then let go

from the rear screws.

8. Slightly turn the fan package and withdraw it from the unit.

9. If you need to further reduce the weight of the upper section, you can also dismantle the extract air fan by repeating

Items 5-8 above.

10. Remove the cable protection on the bottom of the fan compartment.

11. If the air handling unit is fi tted with an electric air heater,

unscrew the screws of this component, lift it up and place it

loosely inside the air handling unit.

12. Remove the screws that secure the mounting bracket of

the supply air sensor. Lift up the mounting bracket and the

supply air sensor and place them to rest unsecured inside

the unit.

13. Remove the four screws (M8) in the bottom of the upper

section. These screws hold both sections together.

14. Lift off the upper section.

15. Now each section can be individually transported.

16 Reassembly should be carried out following the above steps

in the reverse order.

3.2.2 To Remove the Door and Front Grille

1. Remove the safety guard in front of the heat exchanger.

2. Disconnect the communication cable of the control display

by removing the quick connector on the control unit connection (marked HMI) and bundling strap. Pull the communication cable out all the way to the inspection door.

3. Remove the screws of the upper hinge and lift off the

inspection door.

4. Remove the four screws that hold the front grille of the

upper section, using a 6 mm Allen wrench.

5. Reassembly should be carried out following the above steps

in the reverse order.

Lifting handles,

(set of 4)

Page 8

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

8 www.swegon.com

3.5 To Install the Air Recirculation Section/

Louvre Damper

(applies to COMPACT Heat only)

The room temperature sensor supplied with the unit must

be mounted, see special instructions for the TBLZ-1-24-2

room sensor.

The air recirculation section and louvre damper are supplied loose.

The damper actuator for the air recirculation section is

supplied resting on the extract air intake mesh on top of

the unit. This part must be mounted on the air recirculation section’s damper spindle as follows:

1. Remove the damper actuator from the mesh of the extract

air intake. It is advisable to mount the damper

actuator while the air recirculation section is at fl oor level

before the former is mounted.

2. Disconnect the electric quick connector on the damper

actuator.

3. Secure the mounting rail by means of the screws provided,

in the redrilled holes on the air recirculation section. See

illustration.

3. Mount the damper actuator with the damper blade in the

outdoor air position, that is: the damper blade must be

located against the grille. See illustration.

4. Tighten the screws holding the damper actuator with the

clamp on the damper spindle. Set the actuating direction

according to the direction arrow towards 0. See illustration.

5. Mount the air recirculation section on the top side of the air

handling unit for outdoor air and connect the electric quick

connector.

6. Fit the louvre damper on the top side of the air handling

unit for exhaust air.

3.6 Duct Connection

Connect 250 mm dia. spiral ducts to the outdoor air and

exhaust air connections on the top side of the air handling

unit.

Run the ducts through the external wall and have the duct

end edge-to-edge with the façade of the building if Swegon’s external wall hood is used.

The ducts can also be run through the ceiling (the ducts

for the COMPACT Heat cannot be run straight up from

the air handling unit. However this makes more complicated modifi cations necessary and among others places

greater demands on sealing around the arrangement to

achieve air tightness.

The ducts must be insulated with at least 30 mm thick

insulation and be provided with a damp-proof outer layer.

3.3 Location

To achieve optimal operating economy it is important to

design the duct system with as low a pressure drop as possible. Therefore the designer should focus on arranging

the duct runs as short as possible so that there will not be

more duct bends than necessary. The duct connections on

the Compact Air/Heat units are arranged to enable ducts

to be run in any direction without being in the way of one

another.

The design of the hoods, grilles, etc. for outdoor air/exhaust air are also important. The specially constructed

exterior wall hood for the Compact Air/Heat units is designed in such a way that minimizes pressure losses.

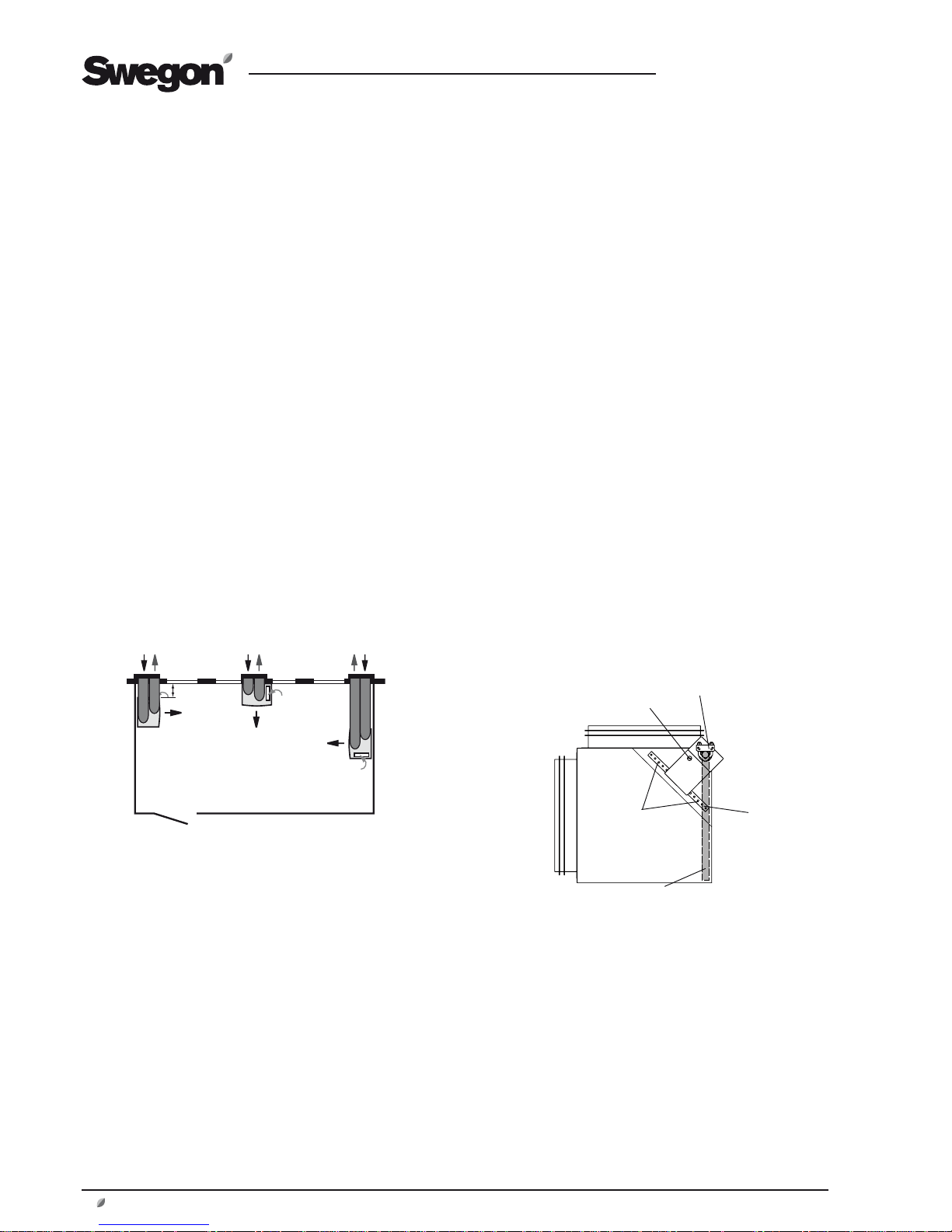

Examples of alternative locations of the Compact Air/Heat

unit in a room are shown below.

Important! The air handling unit should be located

at least 400 mm on either side from a wall to avoid

acoustic problems. See the illustration below.

For the sake of comfort, the nearest workplace should be

1 metre from the unit. However note that at least 1,200

mm open space is required in order to be able to open the

inspection door.

In the case of a COMPACT Heat unit, make sure that you

provide open space in front of the air handling unit to enable long throw lengths when the unit is operating in the

BOOSTER mode (fl ow Boost).

3.4 To Fit the Kick-protection Base

Secure the 6 screws supplied halfway into the tapped

holes on the base beam of the air handling unit.

Then fi t the side plates of the kick protection base (the

two short plates) by pushing the keyhole fasteners over

the screws from the front side of the unit. Now the side

plate should hang loosely on the screws.

Fit the front side of the kick protection plate (the long

plate) on the two screws on the front side. Now the front

plate should hang loosely on the screws.

Adjust the position of the plates and tighten the screws.

Fasten the cover plugs, supplied, in the holes over the

screws.

Important! If the unit is to be installed with its right-hand

or left-hand side near a wall (min. of 400 mm), the base

plate that is to face this way should be fi tted before the

unit is positioned at its fi nal location.

Mounting rail

Damper blade must be in the outdoor air position (grey-shaded)

Clamp for the damper spindle must be in this position

Actuating direction in Position 0

Air recirculation

section

Min.

400 mm

Predrilled

holes

Page 9

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 9

3.7 Exterior Wall Hood

The CACZ-1-03 External wall hood accessory is specially

designed for low pressure drop and for preventing shortcircuiting between the outdoor air and the exhaust air.

The standard hood is painted grey black, NCS 8502-B. See

special instructions.

3.8 Existing Ventilation

The existing ventilation in the room for supply air and

extract air should be blanked off or sealed. This is an

important prerequisite for satisfactory ventilation and heat

recovery.

3.9 Serving More than One Room

The COMPACT Air units are designed for installation and

connection according the instructions in Sections 3.3, 3.6

and 3.7.

Swegon recommends this procedure.

Nevertheless it is possible to completely or partially take

extract air from adjacent rooms or also to ventilate a space

other than the room where the air handling unit is standing.

The problems, which one must observe in this case, are

specifi ed below. Always engage the services of a professional in this fi eld.

3.9.1 Extract Air Intake

If the extract air is completely or partially taken from an

adjacent room, note that the duct pressure drop must not

exceed available pressure.

Also note that the supply air temperature is regulated in

relation to the extract air temperature. If the extract air

comes from another room with a different temperature,

the temperature of the supply air may cause short-circuit

airfl ows or give rise to draught problems. Pay special attention to where the extract air sensor is located.

3.9.2 Transfer Air

Transfer air grilles to adjacent rooms have a strong infl uence on the system’s performance.

Air transfer grilles positioned low, cause the transfer of

”unused” air to adjacent rooms and impair the ventilation

performance in the room where the unit is installed.

Air transfer grilles positioned high involve the risk that

”used” air will be transferred to adjacent rooms. Ventilation is however not impaired in the room where the unit is

installed.

Important! If the doors are open, the adjacent room will

also be ventilated due to the displacing air supply.

3.10 Connection to the Electric Power Grid

The COMPACT air handling unit is supplied with a power

cable with mains plug, from the factory.

COMPACT Air

Cable: 3 x 1.5 mm2. Mains plug, 10 AT, single-phase 230V.

COMPACT Heat

Cable: 5 x 2.5 mm2. Mains plug, 5-wire Perilex, 16 AT,

3-phase 400V.

Important! The power supply connection to the COMPACT Heat unit is not of an electrical safety design that

prevents children from inserting objects into the socket. It

is recommended that it be positioned 2 metres above the

fl oor above the air handling unit by the duct connections

for instance.

If the air handling unit is instead to be connected with a

fi xed extension, an external main switch must be fi tted.

3.11 To Connect External Cables

The electrical cubicle in the COMPACT Air and the COMPACT Heat units is located by the heat exchanger. When

access to the control unit is required, the safety guard

in front of the heat exchanger must fi rst be dismantled.

When access to the power unit is required, the cover plate

in the unit’s extract air duct must fi rst be dismantled.

Cables from external sources can be run into the air handling unit through the rubber diaphragm by the extract air

intake, located on the top of the unit.

The external cables can be extended in the existing cable

protection together with the power supply cable in the

extract air duct of the unit. Insert the cable in the opening

in the end of the cable protection or press it in between

the cable protection and the insulation.

Cables can be run in to the electric cubicle according to

appropriate hole instructions in the rubber diaphragm.

N.B.! Cables for external communication outside the air

handling unit must be arranged at a minimum distance of

100 mm from any current-carrying (live) cable.

Electrical equipment cubicle

Extract air duct of the

air handling unit

Extract Air Intake

Cable protection

Cover plate

Page 10

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

10 www.swegon.com

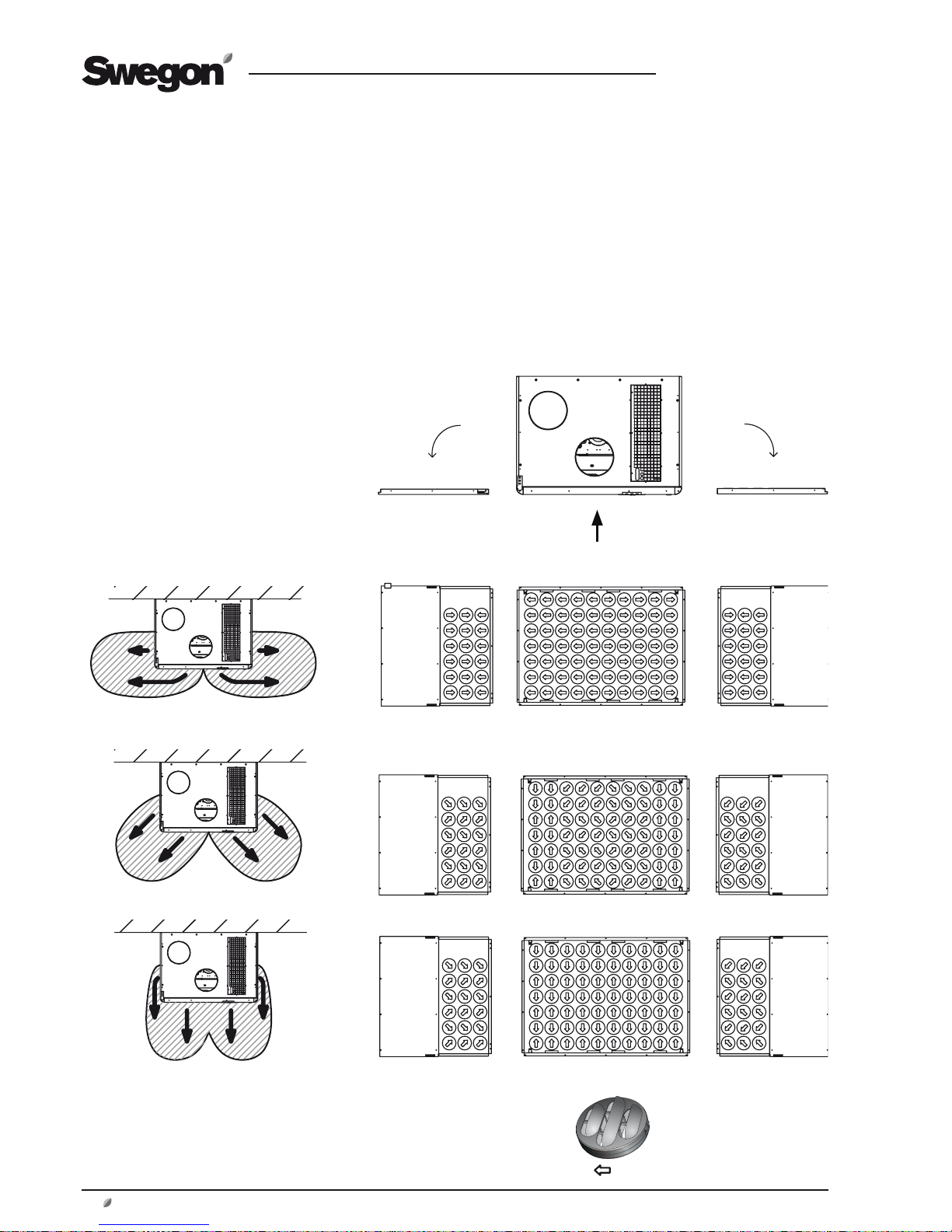

3.12 To Adjust the Supply Air Discs

The positions of the supply air discs can be adjusted after

dismantling the front grille of the lower section of the

unit. Use a 6 mm Allen key. The screws are located within

the outer holes in the corners.

When the front grille has been removed, the air discharge

direction of the front discs can be adjusted from the

backside of the front grille. Turn the discs by hand to the

appropriate setting.

The side discs can now also be adjusted without any further dismantling. The discs are accessible by putting your

hand inside the air handling unit.

Air handling unit viewed from above.

The front discs and side discs are

shown from this view below.

The factory-preset supply air distribution pattern and two

examples of possible modifi ed distribution patterns are

shown below.

Since each disc is individually adjustable, the possibilities

for modifying the air distribution pattern are practically

endless.

The arrows shown above

indicate the position of

each disc.

Discs in factory-preset position

Distribution pattern

Example 1

Example 2

Front discs and side discs

Page 11

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 11

4 COMMISSIONING

4.1 General

Commissioning sequence:

1. Check that there are no foreign objects inside the unit,

duct system or functional sections.

COMPACT Heat: air recirculation section, louvre

damper and room temperature sensor shall be installed,

see Section 3.5.

2. Connect the mains plug. Note that the air handling

unit starts up immediately and operates in the normal

mode.

3. Select the appropriate language, if you have not already

done so. See Section 15.1.

4. The air handling unit has a factory setting that makes

it ready to operate. See Section 22.2 Commissioning

Record.

However, in many cases, these settings need to be

adjusted to suit the current installation.

Program the timer (switch clock), operating mode,

temperatures, airfl ows and functions according to the

procedures in Sections 6-17.

Select whether the airfl ow unit of measurement shall

be l/s, m3/s or m3/h. (INSTALLATION LEVEL in the CONTROL DISPLAY menu).

Fill out the Commissioning Record and save it in the

document pocket of the air handling unit.

5. Activate, if needed, manual or auto operation (MAIN

MENU 2) or lock the speed of the fans (AIR ADJUSTMENT menu).

6. Finish off with a fi lter calibration as described in Section

6.4.2.

Page 12

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

12 www.swegon.com

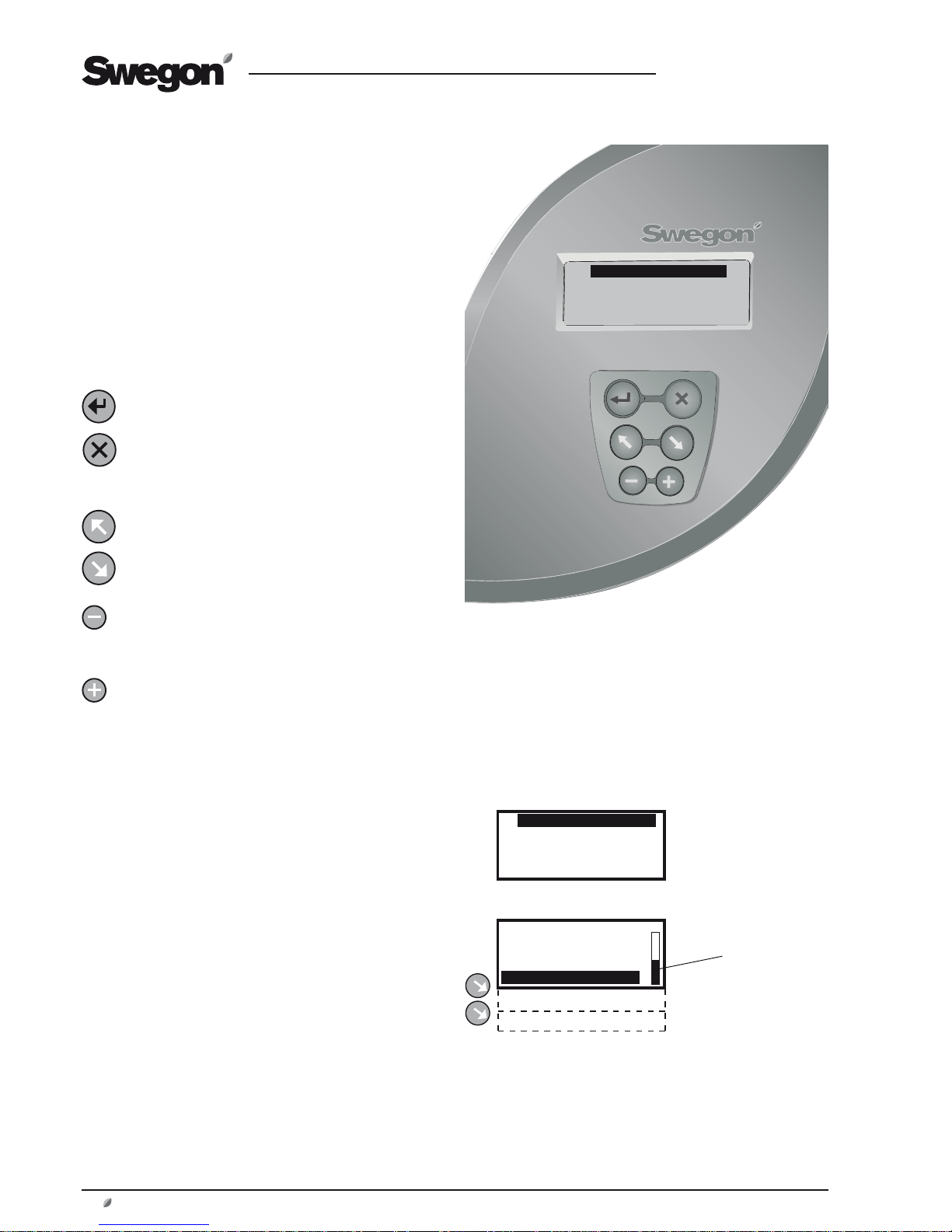

5 CONTROL DISPLAY AND

USING THE MENU

5.1 Control display

5.1.1 General:

The control display has an illuminated display, 6 pushbuttons and a red LED for indicating alarms.

5.1.2 The Buttons

The buttons have the following functions:

ENTER confi rms your selection of the highlighted

function and proceeds to next deeper menu level.

ESCAPE changes the display back to the previous

menu. For menus with REMAIN.TIME display, the

image changes automatically back to the previous

menu after approx. 10 seconds.

ADVANCE UPWARD or to the LEFT.

ADVANCE DOWNWARD or to the RIGHT.

DECREASES the value of the highlighted setting.

Changes are registered immediately and need not

be confi rmed by pressing Enter.

INCREASES the value of the highlighted setting.

Changes are registered immediately and need not

be confi rmed by pressing Enter.

5.1.3 Display screen

The display screen has 4 lines. Many of the menus however have more lines and these are shown line for line as

you press the ADVANCE DOWNWARD button. The position indicator shows where you are in the menu.

5.1.4 Abbreviations Used

The following abbreviations are generally used in the

menus:

SA = Supply air (Ex: SA FAN = Supply air fan)

EA = Extract air

OUTD = Outdoor air

ROOM = Room

ANTI-FROST MON = Anti-frosting monitor

HEAT EXCH = Heat exchanger

The control display is mounted on the

inspection door of the air handling unit.

Position indicator

√ NORMAL OPERATION

EXTENDED OPERATION

AIRING

>>

COMPACT-A TUE 14:40

STOP

MANUAL OPERATION

STOP?

MAN/AUTO.OP

SETTINGS

√ NORMAL OPERATION

EXTENDED OPERATION

AIRING

>>

Page 13

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 13

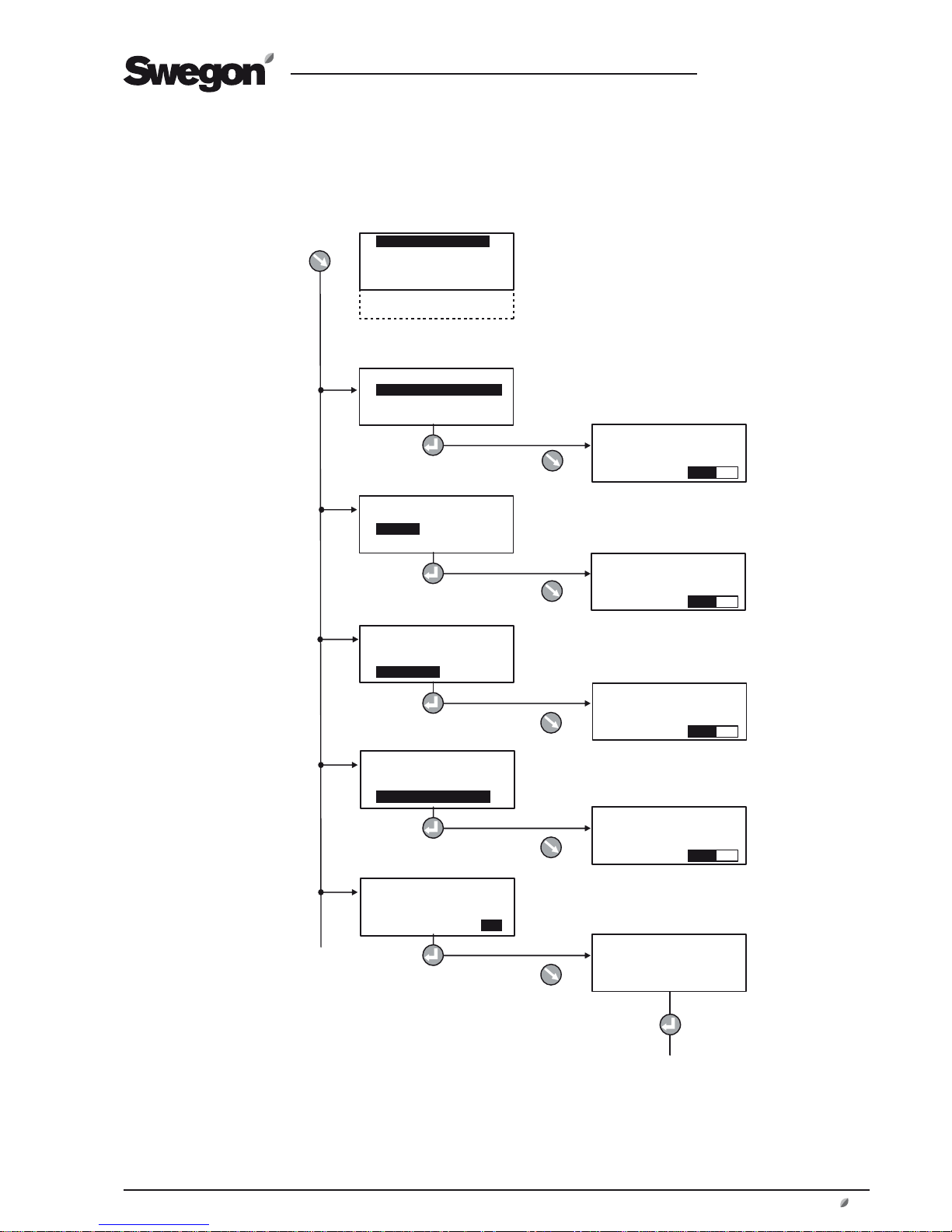

6 MAIN MENU 1

6.1 The Menu Tree

Code = 1110*

To Main Menu 2

* The code can be changed under Service Level.

√ NORMAL OPERATION

EXTENDED OPERATION

AIRING

HEATING

HEATING + RECIRC.

>>

NORMAL OPERATION

√ EXTENDED OPERATION

AIRING

HEATING

NORMAL OPERATION

EXTENDED OPERATION

√ AIRING

HEATING

NORMAL OPERATION

EXTENDED OPERATION

AIRING

√ HEATING

EXTENDED OPERATION

AIRING

HEATING

√

HEATING + RECIRC.

Applies to COMPACT Heat only

Applies to COMPACT Heat only

AIRING

HEATING

HEATING + RECIRC.

>>

EXTENDED

LOW SPEED

REM.TIME

AIRING

REM.TIME

VÄRMNING

HEATING

REM.TIME

VÄRMNING

HEATING + RECIRC.

REM.TIME

VÄRMNING

CODE: 0000

Page 14

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

14 www.swegon.com

6.2 General

The main menu is normally shown if no other menu has

been selected.

The display automatically returns to the main menu after

30 minutes.

The content in the menu changes depending on the

operating mode selected, other functions that affect the

present operating mode and possible tripped alarms.

6.3 Selection of Language

When the air handling unit is started up for the fi rst time,

a language selection menu is displayed. Select the appropriate language.

If you want to change language at a later opportunity – or

if you’ve selected the wrong language – you can change

the language at INSTALLATION LEVEL under CONTROL

DISPLAY. See Section 15.1.

6.4 Normal Operation

NORMAL OPERATION is highlighted in the display when

the air handling unit is operated in the selected operating mode under Main Menu 2. Alternatives to operation

are: stop (appears alternately in the menu when selected),

auto operation, manual low speed or manual high speed

operation, see Section 7.2.

The type of operation selected can be checked under Main

Menu 2.

Normal operation indicates that the air handling unit is not

being operated in any of the time-limited manually activated functions. See Sections 6.5, 6.6, 6.7 and 6.8.

6.5 Extended operation

When EXTENDED OPERATION has been activated, the

unit operates in the high speed airfl ow mode preset under

User Level, see Section 8.2.

For particulars of the times for extended operation, see

Section 10.5.2.

The function can be cancelled by pressing the escape

button on the control display and then selecting Normal

Operation.

6.6 Airing

When AIRING is activated, the unit operates in the max

speed airfl ow mode preset under User Level, see Section

8.2.

For particulars on how to set the appropriate supply air

temperature and period for airing, see Section 10.2.2.

The function can be cancelled by pressing the escape

button on the control display and then selecting Normal

Operation.

6.7 Heating

(applies to COMPACT Heat only)

The COMPACT Heat can be used for heating the room.

When HEATING is activated, the electric air heater (7.5

kW) heats up the air. A change-over damper in the lower

section of the air handling unit is reset and the air is led to

the air discharge outlets at the bottom of the unit. The air

is discharged at high velocity and follows the fl oor surface

by means of the so-called coanda effect. This enables long

throw lengths and quickly heats the entire premises.

The function can also be manually selected under HEATING. The air handling unit then operates According to the

preset conditions and times, see Section 10.2.6.

The function can be cancelled by pressing the escape

button on the control display and then selecting Normal

Operation.

6.8 Heating + Recirculation

(applies to COMPACT Heat only)

The COMPACT Heat can be used for heating the room.

When the HEATING + RECIRC. function is activated, the

extract air fan and the heat exchanger are switched off.

The damper in the air recirculation section is reset and

room air is circulated. The louvre damper for exhaust air

closes to prevent any cold down draught.

The electric air heater (7.5 kW) heats up the air. A changeover damper in the lower section of the air handling unit

is reset and the air is led to the air discharge outlets at the

bottom of the unit. The air is discharged at high velocity

and follows the fl oor surface by means of the so-called

coanda effect. This enables long throw lengths and quickly

heats the entire premises.

When HEATING + RECIRC. is activated the air handling

unit operates according to the preset conditions and

times, see Section 10.2.6.

The function can be cancelled by pressing the escape

button on the control display and then selecting Normal

Operation.

6.9 Main Menu 2

You can access to Main Menu 2 by highlighting >> the

line farthest down and acknowledge by pressing the Enter

button.

Enter the code. (Factory-preset code: 1110) The code can

be changed under Service Level.

Page 15

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 15

7 MAIN

MENU 2

7.1 Menu tree

USER LEVEL

(Section 8)

INSTALLATION LEVEL

(Section 9-17)

COMPACT-A TUE 14:40

STOP

MANUAL OPERATION

STOP?

COMPACT-A TUE 14:40

MANUAL OPERATION

STOP?

MAN/AUTO.OP

COMPACT-A TUE 14:40

STOP?

MAN/AUTO.OP

SETTINGS

TEMPERATURE

FLOW/PRESSURE

SWITCH CLOCK

FILTERS

AIR ADJUSTMENT

ALARMS

INSTALLATION

AUTO OPERATION

MANUAL LOW SPEED

MANUAL HIGH SPEED

*SWITCH CLOCK*

TIME/DATE

TIME CHANNEL

YEAR CHANNEL

*FILTERS*

READINGS

CALIBRATION

*AIR ADJUSTMENT*

LOCKS FAN SPEED

TIME SETTING: 0 h

*ALARMS*

ACTIVE ALARMS

ALARM HISTORY

*FLOW/PRESSURE*

READINGS

SETTINGS

Important! The appearance of

the menus varies depending

on the type of air handling

unit and functions selected.

*TEMPERATURE*

READINGS

SETTINGS

Page 16

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

16 www.swegon.com

COMPACT-A TUE 14:40

STOP

MANUAL OPERATION

STOP?

COMPACT-A TUE 14:40

MANUAL OPERATION

STOP?

MAN/AUTO.OP

AUTO OPERATION

MANUAL LOW SPEED

MANUAL HIGH SPEED

COMPACT-A TUE 14:40

STOP?

MAN/AUTO.OP

SETTINGS

USER LEVEL

INSTALLATION LEVEL

7.2 Changing Operating Mode

You can start and stop the air handling unit or

change over to manual or automatic operation

from the main menu.

The air handling unit should normally be

started and stopped from the hand-held

micro terminal; not by switching the safety

isolating switch on and off.

When the air handling unit is started up, menus

for the various delays that are part of the starting

sequence are shown.

See also Section 11.1.1, Starting Sequence.

7.3 Settings

When selecting SETTINGS in the main menu, you

will advance to User Level and Installation Level.

See Section 8.

Page 17

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 17

8 USER LEVEL

8.1 Temperature

The basic functions can be preset at INSTALLATION LEVEL and the values can be read and set at USER LEVEL.

See also Section 10.2 in which the functions for

temperature are described in detail.

IMPORTANT! If you intend to substantially alter the tempera-

ture settings, you should fi rst stop the air handling unit before

doing so.

8.1.1 Readings

Used for checking the performance.

8.1.2 Settings

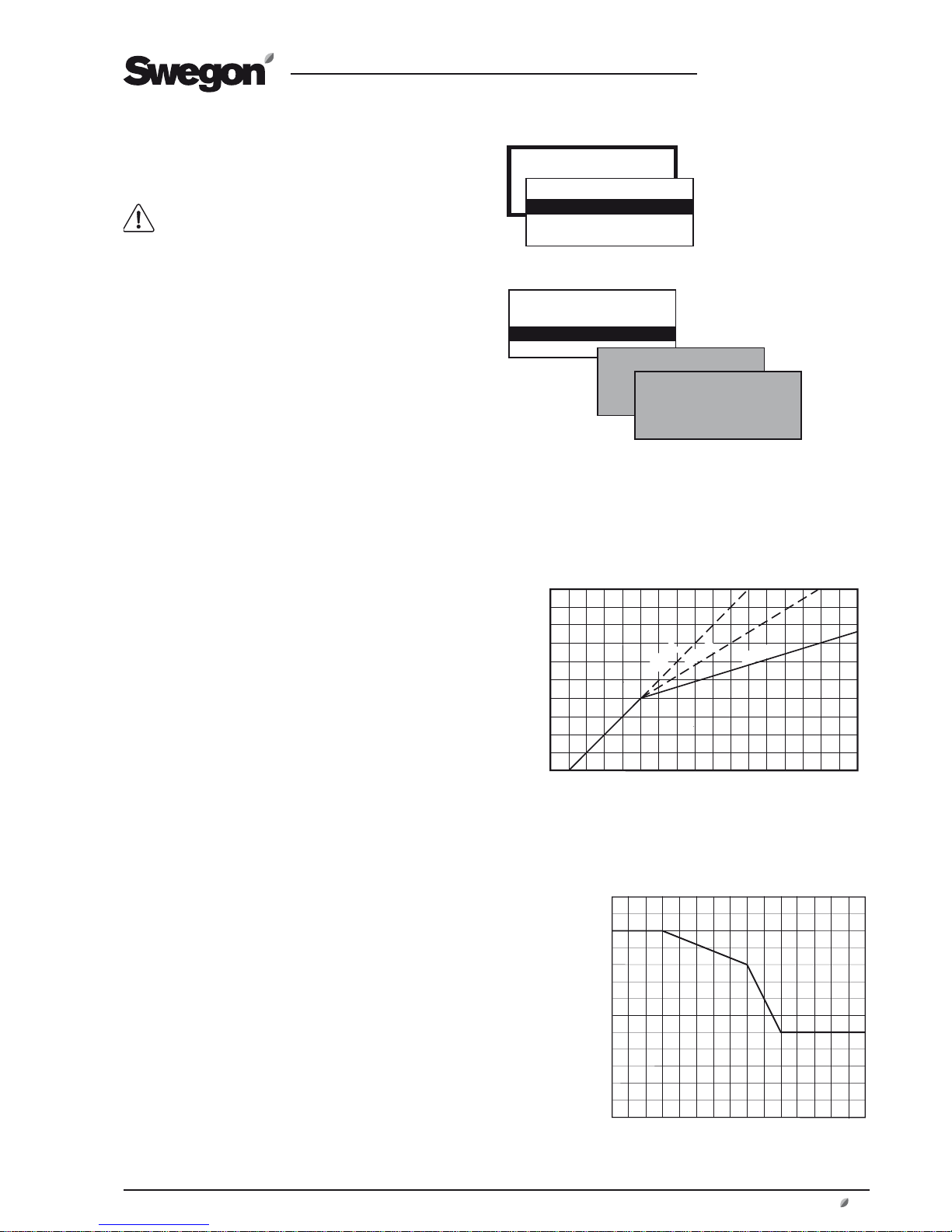

ERS REGULATION 1

The control unit regulates the relationship between the supply air and the extract air temperatures according to a factory

preset curve.

Settings (see the chart to the right as well):

Value Setting Factory

range settings

Step 1 - 3 1

EA/SA Differential 1-5 °C* 2 °C

Breakpoint (refers to 15-23 °C* 20 °C

extract air temperature)

*) The setting range can be changed. See Section 15.3, Min./

Max. Setting.

ERS REGULATION 2

The control unit regulates the relationship between the supply

air and extract air temperatures according to a custom-plotted

curve. The curve has three adjustable breakpoints.

Settings (see the chart to the right as well):

Value Setting Factory

range settings

Extract air temperature

X1 10-40 °C 15 °C

X2 10-40 °C 20 °C

X3 10-40 °C 22 °C

Supply air temperature

Y1 10-40 °C 20 °C

Y2 10-40 °C 18 °C

Y3 10-40 °C 14 °C

ERS Regulation 1

TEMPERATURE

*TEMPERATURE*

READINGS

SETTINGS

*TEMPERATURE*

READINGS

SETTINGS

ERS REGULATION 1

ERS REGULATION 2

Important! The

appearance of the menus

varies depending on the

type of air handling unit

and functions selected.

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

15

16

17

18

19

20

21

22

23

24

14

Supply air temperature setpoint °C

Extract air temperature °C

Step 3

Step 2

Step 1

1

2

3

15

20

22

9

10

12 15 20 25 27

X = Extract air temperature °C

Y = Supply air temperature setpoint °C

ERS Regulation 2

Page 18

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

18 www.swegon.com

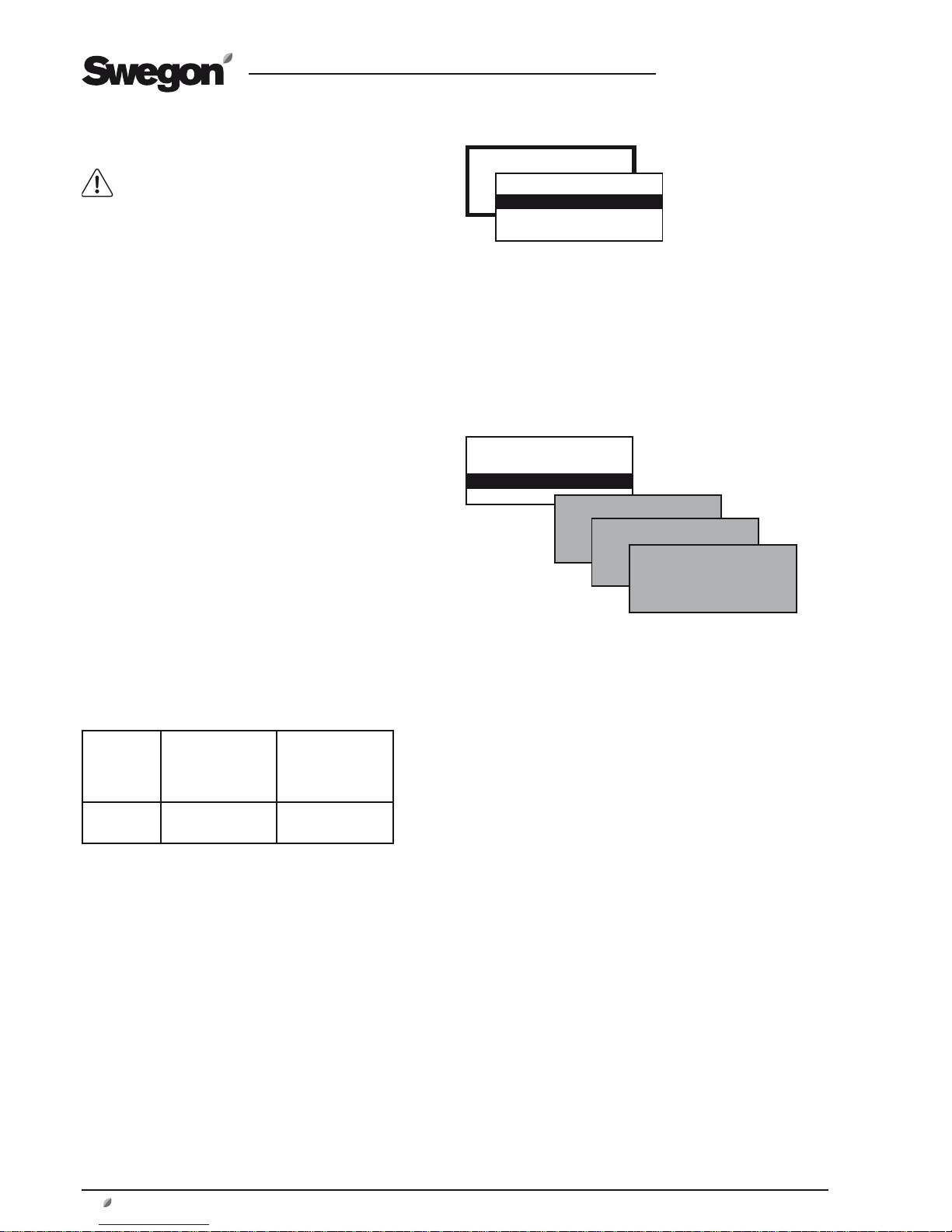

8.2 Air fl ow/Pressure

Basic functions are set at INSTALLATION LEVEL

and values are read and set at USER LEVEL.

Therefore see also Section 10.3, in which the func-

tions for fl ow/pressure are described in detail.

8.2.1 Readings

Used for performance checks.

8.2.2 Settings

The functions selected at INSTALLATION LEVEL and the

min. and max. airfl ows of each unit size (see the table

below) determine which values can be set.

Values for airfl ow (l/s, m3/s, m3/h), pressure (Pa) or input

signal strength (%) can be preset depending on the function selected.

LOW SPEED

Must always be preset! The value for low fan speed cannot be higher than the value for high speed.

Low speed can be set as 0, which means that the air handling unit stops.

HIGH SPEED

Must always be preset! The value for high speed cannot

be lower than the value for low speed.

MAX SPEED

Is only appropriate for the airing function. The value for

max speed cannot be lower than the value for high speed.

AIRFLOW MIN FLOW

COMPACT AIR AND

COMPACT HEAT

MAX FLOW

COMPACT AIR AND

COMPACT HEAT

SIZE

m3/h * m3/s m3/h m3/s

02 300 0.08 800 0.23

03 300 0.08 1300 0.36

* When you adjust the value, round off the value to the nearest

adjustable step.

Min/Max Airfl ows

AIR FLOW/PRESSURE

*FLOW/PRESSURE*

READINGS

SETTINGS

*FLOW/PRESSURE*

READINGS

SETTINGS

LOW SPEED

HIGH SPEED

MAX. SPEED

Page 19

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 19

8.3 Switch clock

Basic functions for the switch clock can be preset

at INSTALLATION LEVEL under FUNCTIONS/OPERATION and the values can be read and set at USER

LEVEL.

TIME/DATE

The current date and time can be set and adjusted whenever

required.

The switch clock automatically takes leap years into consideration.

Automatic changeover between summer time/winter time to EU

Standard has been preset.

This changeover function can be blocked at INSTALLATION LEVEL

under FUNCTIONS/OPERATION

.

TIME CHANNEL

Times and days can be set when the unit is to run at high speed,

low speed or be stopped.

Eight different time channels can be set. If the same in-operation

times are to apply every day of the week (Mon-Sun), you need

only program one time channel. Different operation times for

each day of the week can be programmed by programming a

time channel for each day (Mon-Fri, Sat-Sun or Mon, Tues, Wed,

etc)

The time can be set as 00:00-00:00 if the deviating in-operation

period is desirable for the entire 24 hours period.

YEAR CHANNEL

The year channels make it possible to set deviating in-service

times for parts of the day during certain parts of the year. Eight

different year channels (yearly time schedules) can be set. The

year channels over-modulate the time channel during the hours

of the day and the days that the year channel is active. The year

channel dates indicate the dates between which the year channel shall apply and the year channel hours indicate the hours of

the day between which the year channel will steer the controller

to operate the rotary heat exchanger at a specifi ed speed. Other

times within the year channel still apply to that time channel.

The time can be set as 00:00-00:00 if the deviating in-operation

period is desirable for the entire 24 hours period.

Functions for summer night cooling, prolonged operation, etc.,

operate also when the year channel is active.

8.4 Filters

(and anti-frosting function of rotary heat exchanger)

There are two types of fi lter monitoring:

Calculated fi lter monitoring (preset at factory) monitors the fan’s

speed increase conditional on the degree of fouling in the fi lter.

The calibration involves taking airfl ow and fan speed readings.

An alarm is initiated when the fan speed has increased by 10%

above the preset alarm limit.

Filter monitoring with a pressure sensor (accessory) measures

the pressure drop across the fi lter. The alarm limit is preset in Pa.

8.4.1 Readings

When reading the fi lter status, the fi rst value shows current value

and the second value shows current alarm limit.

8.4.2 To Calibrate the Filters

The fi lters must be calibrated for the fi rst time during commissioning, when the duct system has been installed and adjusted.

After that every time fi lters are replaced.

Calibration should be activated for both the supply air and the

extract air if both fi lters are changed or for only for one airfl ow

direction if only one fi lter has been changed.

When fi lter calibration has been activated, the unit runs at high

speed for about 3 minutes.

After the fi lter has been calibrated, a speed increase of 10%, or

a pressure rise (= fouling of the fi lters) of 100 Pa is permissible,

after which an alarm is initiated indicating a fouled fi lter.

The alarm limit can be changed at INSTALLATION LEVEL under

ALARM SETTINGS.

8.4.3 Calibration - Rotary Heat Exchanger

If the anti-frosting function accessory for heat exchanger is installed (see 10.6.1.1) calibration can be selected from this menu.

When calibration R-HX is activated the fans are accelerated to

high speed for about 3 minutes.

SWITCH CLOCK

*SWITCH CLOCK*

TIME/DATE

TIME CHANNEL

YEAR CHANNEL

Settings:

Value Setting Factory

range setting

TIME/DATE

Day Mon-Sun Automatic

Time 00:00-23:59 Current

Date Day/Month/Year Current

TIME CHANNEL 1-8

Operation Low speed/High speed* High speed

Time 00:00-23:59 00:00-00:00

Period Not active Not active

Mon, Tues, Wed etc

Mon-Fri

Mon-Sun

Sat-Sun

YEAR CHANNEL 1-8

Operation Not active Not active

Stop/Low sp./High sp.

Time 00:00-23:59 00:00-00:00

Period From Day/Month/Year 01/01/2005

To Day/Month/Year 01/01/2005

*) Shows Stop/Low speed/High speed if this function is selected

at INSTALLATION LEVEL under FUNCTIONS/OPERATION.

FILTERS

*FILTERS*

READINGS

CALIBRATION

*FILTERS*

READINGS

CALIBRATION

*FILTER CALIBRATION*

STD.FILTER

HEAT EXCHANGER

Page 20

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

20 www.swegon.com

8.5 Air Adjustment

The speed of the fans can be locked for up to 72 hours.

This is practical in conjunction with adjusting the airfl ow in

the duct system.

The period desired is preset but can be interrupted earlier

by selecting STOP in the menu or by changing the time

setting to 0.

8.6 Alarms

If an alarm is initiated, this is shown in the hand-held terminal both as clear text and by a blinking red diode.

This menu enables you to read alarms quickly.

ACTIVE ALARMS

Shows alarms that are active but have not initiated an

alarm signal in the display. This applies to alarms that have

a long delay, i.e. airfl ow or temperature alarms.

ALARM HISTORY

The 10 most recent tripped alarms are shown.

Alarm settings can be entered at INSTALLATION

LEVEL under ALARM SETTINGS.

For complete description of alarms, see Section 19.

AIR ADJUSTMENT

*AIR ADJUSTMENT*

LOCKS FAN SPEED.

TIME SETTING: 0 h

ALARMS

*ALARMS*

ACTIVE ALARMS

ALARM HISTORY

Page 21

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 21

Section 10

Section 12

Section 13

Section 14

Section 15

Section 16

Section 17

FUNCTIONS

READINGS

MANUAL TEST

ALARM SET

CONTROL DISPLAY

COMMUNICATION

SERVICE LEV.

*MANUAL TEST*

TEMPERATURE

FANS

HEAT EXCHANGE

REHEAT

IN/OUTPUTS

IQnomic Plus

*READINGS*

TEMPERATURE

FANS

HEAT EXCHANGE

REGULATION SIGNALS

IN/OUTPUTS

IQnomic Plus

OPERATION TIME

PROGRAMVERSIONS

*ALARM SETTINGS*

FIRE ALARM

EXTERNAL ALARMS

ALARM LIMITS

ALARM PRIORITY

*CONTROL DISPLAY INST*

LANGUAGE

AIR FLOW UNIT

MIN/MAX SETTING

BASE SETTINGS

*COMMUNICATION*

EIA-485

ETHERNET

*SERVICE LEV.*

CODE: 0000

INSTALLATION

9 INSTALLATION LEVEL

9.1 Menu Survey

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

Section 11

Automatic functions

*INSTALLATION*

CODE: 0000

Code = 1111

Important! The appearance of

the menus varies depending

on the type of air handling

unit and functions selected.

Page 22

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

22 www.swegon.com

10 FUNCTIONS

10.1 Temperature

Basic functions can be set at INSTALLATION LEVEL

and values are read and set at USER LEVEL.

IMPORTANT! If you intend to substantially alter the temperature settings, you should fi rst stop the air handling

unit before doing so.

10.2 Temperature Regulation (Control)

Select ERS Regulation. Then select ERS Regulation 1 or 2.

Control sequence for ERS regulation:

1. The temperature effi ciency of the air handling unit’s

heat exchanger is modulated to provide max. heat

recovery.

2. After that the air heater, if installed, will begin to

generate heat.

3. If a downstream heating coil is not installed, or if the

its output is not adequate, the supply air fan will be

automatically and variably downspeed-regulated to

convey air at a lower fl ow rate.

A neutral zone can be preset, which allows a lower supply

air temperature setpoint before regulation to a lower fl ow

rate begins. See 10.3.3.

When the supply airfl ow is regulated to a lower rate, the

heat exchanger will have ”excess heat”, i.e. warm extract

air, giving it capacity to maintain the supply air temperature required.

As the supply airfl ow is regulated to a lower rate, the air

pressure in the premises will become negative and this

will instead cause outdoor air to be sucked in through

leakage spots such as doors and windows. This outdoor

air will then be heated by the usual heating system of the

premises.

Downspeed regulation to lower the airfl ow rate occurs

from the current preset fl ow (high speed or low speed),

down to half of this fl ow rate. The degree of regulation

to a lower rate is also limited by the min fl ow setting of

the unit. When preset fl ow for low speed is near the min

fl ow rate, the effect of this regulation to a lower rate will

be small.

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

* Applies to COMPACT Heat

only

Important! The appearance

of the menus varies

depending on the type of air

handling unit and functions

selected.

* TEMPERATURE *

TEMPERATURE REG

AIRING FUNCTION

SUMMER NIGHT COOL

INTERM. NIGHT HEAT

MORNING BOOST

HEATING

EXT. SENSORS

*

*

*

Page 23

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 23

10.2.1.1 ERS Regulation

ERS regulation means Extract air temperature-Related

Supply air temperature regulation. This means that the

temperature of the supply air is regulated in relation to the

temperature of the extract air. Under normal circumstances, the supply air temperature is regulated to be a few degrees lower than the extract air temperature. In this way,

the heat exchanger will provide optimal performance, and

this means excellent operating economy. ERS regulation is

suitable for use when there is excess heat in the premises

generated, for example, by machinery, lighting or people

and the supply air devices in the premises are suitable for

diffusing air below room temperature.

ERS REGULATION 1

The control unit regulates the relationship between the

supply air and extract air temperatures according to a factory-preset curve.

See the chart to the right.

The steps, breakpoint and EA/SA differential plotted in

the curve can be changed at USER LEVEL under TEMPERATURE/SETTINGS.

Settings:

Value Setting Factory

range setting

Step 1 – 3 1

Breakpoint 15-23 °C 20 °C

(refers to extract air temp.)

EA/SA-Differential 1-5 °C 2 °C

The setting range for the Break Point and EA/SA difference is limited by Min. and Max. settings at INSTALLATION

LEVEL under CONTROL DISPLAY.

ERS REGULATION 2

This is used when special needs and conditions are such

that the factory preset ERS regulation 1 curve cannot provide the results required. Conditional on which settings are

made, it may be necessary to install a post-heating coil.

An individually adapted curve regulates the relationship

between the supply air and extract air temperature.

See the chart to the right.

The following settings are possible at USER LEVEL under

TEMPERATURE/SETTINGS:

Value Setting Factory

range setting

Extract air temperature

X1 10-38 °C 15 °C

X2 11-39 °C 20 °C

X3 12-40 °C 22 °C

Supply air temperature setpoint

Y1 10-40 °C 20 °C

Y2 10-40 °C 18 °C

Y3 10-40 °C 14 °C

Factory setting means:

If the extract air temperature is below 20 °C (breakpoint),

the supply air temperature setpoint will be automatically

regulated to be 2 °C (EA/SA differential) lower.

If the extract air temperature is above 20 °C, the supply

air temperature setpoint will follow the curve according to

Step 1.

Breakpoints according to factory setting means:

If the extract air temperature is below 15 °C (X1) the setpoint for supply air temperature is constant 20 °C (Y1).

If the extract air temperature is 20 °C (X2) the supply air

temperature set point will be 18 °C (Y2).

If the extract air temperature is above 22 °C (X3), the supply air temperature setpoint will be constantly 14 °C (Y3).

15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

15

16

17

18

19

20

21

22

23

24

14

Supply air temperature setpoint °C

Extract air temperature °C

Step 3

Step 2

Step 1

ERS regulation 1

1

2

3

15

20

22

9

10

12 15 20 25 27

X = Extract air temperature °C

Y = Setpoint supply air temperature °C

ERS regulation 2

Page 24

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

24 www.swegon.com

10.2.2 Airing Function

The airing function means that the air handling unit will

operate in the max. speed mode and temperature during

the preset period.

The function requires either a presence detector or has to

be manually activated in Main Menu 1.

10.2.2.1 Automatic Airing

The presence detector shall be connected to the external

input, selected for external high speed.

Conditions that must be met for automatic airing to start:

• Presence of occupant(s) has been indicated during at

least 10 minutes.

• Occupant(s) are no longer present and the preset time

period for high speed airfl ow has expired.

Conditions that must be met for automatic airing to stop:

• Airing has taken place during the preset time period.

• The presence of occupant(s) is indicated via input for

externally actuated high speed airfl ow.

10.2.2.2 Manual Airing

The Airing function can be started from Main Menu 1 and

will then operate during the preset time period.

The Airing function can be manually cancelled by setting

the air handling unit to Normal Operation in the control

display.

Settings:

Value Setting range Factory setting

Function, Off/On Inactive/Active Inactive

Supply air temperature 10 - 20 °C 10 °C

Time period 10-60 min. 15 min.

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

* Applies to COMPACT Heat

only

* TEMPERATURE *

TEMPERATURE REG

AIRING FUNCTION

SUMMER NIGHT COOL

INTERM. NIGHT HEAT

MORNING BOOST

HEATING

EXT. SENSORS

*

*

*

Page 25

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 25

10.2.3 Summer Night Cooling

The lower temperature at night is utilized to cool down

the building structure. This reduces the cooling load during the fi rst hours of the day. If a cooling unit is installed,

its in-operation hours will be minimized, thus offering savings. If no cooling unit is installed, a certain cooling effect

will still be realized.

When summer night cooling function is activated, the unit

fans operate at high speed, with a supply air setpoint of

10°C, from the preset time until the conditions necessary

for stop are satisfi ed.

Conditions to be met to start summer night cooling at the

preset time:

• The extract air temperature should be higher than the

preset value

• The extract air should be at least 2°C warmer than the

outdoor air.

• The outdoor temperature should be above the preset

value.

• Heating has not been required between 12.00–23.00

hours.

• The unit must not operate in the high speed mode or

be stopped from an external source or manually from the

control display.

Conditions to be met to stop summer night cooling at the

preset time:

• The extract air temperature drops below the preset

value.

• The outdoor temperature drops below the preset value.

• Switch clock or external input calls for high speed.

• The extract air is less than 1 °C warmer than the outdoor

air.

The function starts once per set time period.

Settings:

Value Setting Factory

range setting

Extract air temperature for start 17 - 27 °C 22 °C

Extract air temperature for stop 12 - 22 °C 16 °C

Outdoor temperature for stop 5 - 15 °C 10 °C

Supply air setpoint 10 - 20 °C 10 °C

Operating period 00:00-00:00 23:00-06:00

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

* Applies to COMPACT Heat

only

* TEMPERATURE *

TEMPERATURE REG

AIRING FUNCTION

SUMMER NIGHT COOL

INTERM. NIGHT HEAT

MORNING BOOST

HEATING

EXT. SENSORS

*

*

*

Page 26

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

26 www.swegon.com

If the extract airfl ow is set to 0 and the output to the

damper is inactive, the following will take place:

When conditions for start are met, outdoor air and exhaust air shut-off dampers remain closed. The damper in

the air recirculation section is opened. The extract air fan

is idle.

The supply air fan operates according to the preset supply

airfl ow and the heating coil downstream of the air handling unit operates according to the supply air temperature setpoint, until the conditions for stop are met.

10.2.4 Intermittent Night-time Heating

(applies to COMPACT Heat only)

The unit is utilized to heat the premises when it is normally

stopped by the switch clock.

The function requires connection of an external room

sensor. Connect the TBLZ-1-24-2 Room sensor by means

of the modular cable supplied, to an optional connection

marked Internal BUS 1.

When the function is activated, the air handling unit detects when the room temperature drops below the preset

start temperature. The unit starts with preset fl ows and

the supply air temperature setpoint.

If extract air fan operation is not desirable, the extract

airfl ow can be set to 0.

The damper output can be set to be Inactive. This means

that the connected dampers (such as shut-off dampers

for outdoor air and extract air) will not be affected. These

dampers are normally closed when the air handling unit is

stopped and they also remain closed. The damper in the

air recirculation section opens at the same time.

Intermittent night-time heating does not affect a possible

extra temperature zone (Xzone) that regulates according

to its ordinary set point, if intermittent night-time heating

is in operation.

Conditions to be met for intermittent night-time heating

to start:

• The unit should operate in a time channel/switch clock

stop.

• The room temperature should be below set start tem-

perature.

Conditions to be met for intermittent night-time heating

to stop:

• High speed or external/manual stop should be activated.

• Room temperature should be above the preset stop

temperature.

• Alarm with preset stop priority has tripped.

If the needed, the air handling unit fans will continue to

operate to cool the electric air heater although other conditions for stop have been met.)

Settings:

Value Setting Factory

range setting

Room temperature for start 5 - 25 °C 16 °C

Room temperature for stop 5 - 25 °C 18 °C

Supply air temperature setpoint 10 - 40 °C 28 °C

Supply airfl ow *) m3/s/Pa **) m3/s/Pa

Extract airfl ow *) m3/s/Pa 0 m3/s/Pa

Damper output Inactive/Active Inactive

*) The setting range is the same as the min/max settings of the

air handling unit.

**) According to the setting for low speed at USER LEVEL under

FLOW/PRESSURE.

Intermittent night-time heating with air recirculation section:

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

RUMSLUFT

SUPPLY AIR

* Applies to COMPACT Heat

* TEMPERATURE *

TEMPERATURE REG

AIRING FUNCTION

SUMMER NIGHT COOL

INTERM. NIGHT HEAT

MORNING BOOST

HEATING

EXT. SENSORS

*

*

*

Page 27

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 27

10.2.5 Morning BOOST

(applies to COMPACT Heat only)

The unit is utilised to heat the premises during a preset

period prior to the switch-in time set on the switch clock.

The unit starts early and uses the separate settings for

operation and temperature regulation.

The preset time is the time difference between the start of

Morning BOOST to the start of ordinary operation.

Damper output can be set to be inactive. This means that

connected dampers (e.g. outdoor air and exhaust air shutoff dampers) are not affected. Normally these dampers

are closed when the unit is stopped and thus they remain

closed. The damper in the air recirculation section opens

at the same time.

The extract airfl ow can be set to Inactive if it is not desirable for the extract air fan to operate.

Settings:

Value Setting Factory

range setting

Time for start prior to regular

start time according to switch clock hour, min.

00:00

Damper output Inactive Inactive

Extract air fan Inactive Inactive

EA/Room temp* 10 - 30 °C 22 °C

SA-min* 8 - 20 °C 15 °C

SA-max* 16 - 50 °C 28 °C

* If these values are changed, the corresponding values

under Heating will also change.

10.2.6 Heating

(applies to COMPACT Heat only)

The air handling unit is utilised for heating the room during a preset time period. The function must be activated

manually.

The air handling unit switches over to extract air/room

regulation (control) of the temperature. The air heater, air

recirculation section and BOOSTER function are activated.

Settings:

Value Setting range Factory setting

Time for manual heating hour:min 00:45

EA/Room Temp* 10 - 30 °C 22 °C

SA min* 8 - 20 °C 15 °C

SA max* 16 - 50 °C 28 °C

* If these values are changed, the corresponding values

under Morning BOOST will also change.

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

* Applies to COMPACT Heat

only

* TEMPERATURE *

TEMPERATURE REG

AIRING FUNCTION

SUMMER NIGHT COOL

INTERM. NIGHT HEAT

MORNING BOOST

HEATING

EXT. SENSORS

*

*

*

* Applies to COMPACT Heat

only

* TEMPERATURE *

TEMPERATURE REG

AIRING FUNCTION

SUMMER NIGHT COOL

INTERM. NIGHT HEAT

MORNING BOOST

HEATING

EXT. SENSORS

*

*

*

Page 28

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

28 www.swegon.com

10.2.7 External Temperature Sensors

An external room sensor and external outdoor sensor can

be connected to the IQnomic control unit. The sensor can

be used when the internal sensor of the unit does not

provide representative values.

External Extract air/Room can measure the extract air

temperature in a larger room instead of the temperature

inside the air handling unit.

External Outdoor measures the outdoor air temperature

outdoors, instead of the temperature inside the air handling unit.

Connect the TBLZ-1-24-2 sensor by means of the modular

cable supplied, to an optional connection marked Internal

BUS 1.

Sensor TBLZ-1-24-2 can be used both as a room sensor

and an outdoor sensor. They must therefore be addressed

according to function using the function selector switch

on the sensor. The function selector switch must be in

Position 0 when the room sensor is used and in Position A

when an outdoor sensor is used.

If the TBLZ-1-24-2 sensor is installed outdoors, it must be

mounted inside an air-tight enclosure.

As an alternative, a temperature reading can be communicated to the air handling unit from a supervisory system,

for instance.

Settings:

Value Setting range Factory setting

External Extract air/Room Inactive//IQnomic

Communication

Inactive

External Outdoor Inactive//IQnomic

Communication

Inactive

Alarms 0 - 9990 min. 5 min.

INSTALLATION

FUNCTIONS

*FUNCTIONS*

TEMPERATURE

AIR FLOW/PRESSURE

FILTER

OPERATION

HEATING

COOLING

IN/OUTPUTS

IQnomic Plus

* Applies to COMPACT Heat

only

* TEMPERATURE *

TEMPERATURE REG

AIRING FUNCTION

SUMMER NIGHT COOL

INTERM. NIGHT HEAT

MORNING BOOST

HEATING

EXT. SENSORS

*

*

*

Page 29

GB.COMPACTAH.101110

Registered design. The company reserves the right to make design changes without prior notice.

www.swegon.com 29

10.3 Flow/Pressure

Basic functions are set at INSTALLATION LEVEL and

the values are read and set at USER LEVEL.

10.3.1 Fan Regulation