Swegon CASA W100B Instructions For Installation, Operation And Maintenance

Swegon CASA® W100, version B

Instructions for installation, operation and maintenance

For design engineers, installation engineers and service personnel

Suomenkielinen Asennus-, käyttö- ja huolto-ohje löytyy osoitteesta www.swegon.com/casa

(Tukimateriaali > Etsi PDF-tiedosto “W100”)

En svenskspråkig Montering, drif och underhåll anvisning finns på adressen www.swegon.com/sv

(Resurser > Hitta PDF “W100”)

En norskspråklig Montering, drift og vedlikehold anvisning finnes på adressen www.swegon.com/no

(Ressurser > Finn PDF “W100”)

En dansk Vejledninger til montering, drift og vedligeholdelse findes på adressen www.swegon.com/da

(Ressourcer > Find PDF-dokumenter “W100”)

Eine Deutsch Sprachversion der Anleitung für Montage, Betrieb und Wartung ist verfügbar unter www.

swegon.com/de (Ressourcen > PDF-Suchmaschine “W100”)

W100B_c_EN-t

Contents

Installation, operation and maintenance

for design engineers, installation engineers and service personnel

W100B.021014

Important information ............................................. 3

1. General Description .............................................. 4

1.1 Enclosure .........................................................................4

1.2 Fans ................................................................................. 4

1.3 Filters ............................................................................... 4

1.4 Heat exchanger ................................................................4

1.5 Temperature ....................................................................4

1.6 Protective functions .........................................................5

2. Installation ............................................................. 6

2.1 Ventilation unit installation site ........................................6

2.1.1 Wall mounting ..............................................................6

2.1.2 Ceiling mounting .......................................................... 7

2.2 Condensate discharge ......................................................7

2.3 Ducts ............................................................................... 8

2.4 To connect the cooker hood .............................................8

2.5 To seal around duct penetration collars ............................8

2.6 Electric and control cables ................................................9

2.7 To connect water pipes in the Econo model .....................9

3. Commissioning .................................................... 10

3.1 To set the airflows ..........................................................10

3.2 Functions in the ’Install. and service’ menu in the Premium

control panel. .................................................................10

3.2.1 To open the menu .......................................................10

3.2.2. Alarm ........................................................................10

3.2.3 Clock .......................................................................... 10

3.2.4 Temperature ...............................................................10

3.2.5 Measurement .............................................................10

3.2.6 Control functions .......................................................10

3.2.7 Fan settings ................................................................10

3.2.8 Shutdown ................................................................... 10

3.2.9 Factory settings ........................................................... 10

3.2.10 Controllers ................................................................10

3.2.11 Functions .................................................................. 10

3.2.12 Electric air heater ......................................................11

3.3 Application ....................................................................11

6. List of components ............................................. 15

7. Technical data ...................................................... 16

7.1 Fan Diagrams ................................................................. 16

7.2 Outputs of the components .......................................... 17

7.3 Acoustic data ................................................................. 17

7.4 Sizing of the water-heated air heater .............................19

7.5 Pressure loss in the air heater for reheating ....................19

7.6 Electrical wiring diagram ................................................ 20

7.6.1 Ventilation unit ...........................................................20

7.6.2 Control functions with accessories ..............................20

7.7 Control diagram ............................................................23

7.7.1 W100 EC .................................................................... 23

7.7.2 W100 EC Econo ..........................................................24

7.8 Dimensions .................................................................... 25

7.9 Weights .........................................................................25

7.10 Ventilation unit codes ..................................................25

7.11 Accessories for installation ...........................................25

8. Commissioning form ........................................... 26

Warranty Conditions .............................................. 28

EC Declaration of Conformity ................................ 29

4. Servicing .............................................................. 12

4.1 Service reminder ............................................................12

4.2 To open the ventilation unit ...........................................12

4.3 Filters ............................................................................. 12

4.4 Heat exchanger ..............................................................12

4.5 Fans ............................................................................... 12

4.6 Other servicing ...............................................................12

5. Alarms and troubleshooting .............................. 14

5.1 Alarms from a Premium control panel ............................14

5.2 Troubleshooting: ............................................................14

5.2.1 The supply air is not sufficiently heated ....................... 14

5.2.2 Badly isolated ventilation ducts ...................................14

5.2.3 The ventilation unit does not obey commands ............14

2

Swegon reserves the right to alter specifications.www.swegon.com/casa

W100B.021014

!

Important information

Qualified personnel only

The installation work, the entering of settings and commissioning should be carried

out by qualified personnel only.

Standards and requirements

The pertinent national standards and regulations dealing with installation, the entering of

settings and commissioning must be followed

if the equipment is to operate correctly.

You will find the document entitled “Project

planning instructions for ventilation” at the

www.swegon.com/casa web address, in

which requirements on electric power, sound,

airflows and duct system are presented.

Measurement and electrical work

Isolate the ventilation unit from the electrical supply grid before you carry out voltage

tests, measure the electrical insulation resistance at various points or perform other

remedial measures that could damage sensitive electrical equipment.

Surge protection

Swegon recommends that all ventilation units

equipped with Premium automatic control be

equipped with a surge protection device.

Earth fault circuit breaker

It is not certain that an earth fault circuit

breaker will operate faultlessly in combination with the ventilation unit, since the

unit's regulation and control equipment can

cause leakage currents. Comply with local

electrical safety regulations when you install

electrical equipment.

To open the ventilation unit for service

Always ensure that the ventilation unit’s

power supply has been isolated before you

open the inspection door! Wait a few minutes before you open the inspection door

on the ventilation unit so that the fans have

time to stop and air heaters, if fitted, have

time to cool down.

There are no components inside the electrical equipment cabinet that can be serviced

by the user. Leave the servicing or these

components to service personnel. Do not

restart the ventilation unit before you’ve

identified the cause of the fault and service

personnel have serviced the ventilation unit.

Separate extract air (bypass for

kitchen)

If there is an extract air duct connected from

a cooker hood to the ventilation unit, keep

in mind that the separate extract air duct

bypasses the heat exchanger and that use of

it will affect the ventilation unit’s annual efficiency. The separate extract air duct should

only be used while cooking is in progress

and the ordinary extract air register in the

kitchen should be connected to the ventilation unit’s extract air duct.

The Econo models (water-heated

air heater)

The Econo model ventilation unit should be

equipped with shut-off damper so that the

water-heated air heater cannot freeze during a power failure.

Drying laundry

A tumbler dryer of extract air type or a drying cabinet must not be connected to the

system due to the high moisture content in

the air it discharges. However, we recommend the use of a condensing tumbler dryer

without duct connection.

Commissioning

Do not commission the ventilation unit until

all carpentry work that produces large quantities of sanding dust or other impurities has

been completed.

The duct connection spigots of the ventilation unit must be covered by lids while the

unit is being transported, kept in storage

and mounted at its final location.

Make sure that the ventilation unit, filters

and ducts are clean and that there are no

loose objects in them before you commission the ventilation system.

N.B.! The manual’s original language is Finnish.

Swegon reserves the right to alter specifications. 3www.swegon.com/casa

1. General Description

W100B.021014

steers the extract air to bypass the heat exchanger when

heating is not needed.

The most important function of the ventilation system is

to ensure fresh indoor air and to remove moisture. The

air in the home should be changed at a continuous and

sufficient rate to ensure a pleasant indoor climate and

avoid damage to building elements caused by dampness. The ventilation unit should be stopped only while

service work is in progress.

1.1 Enclosure

The ventilation unit’s enclosure class is IP X4 when the

inspection door is closed.

1.2 Fans

The Swegon CASA W100 is equipped with energy-efficient fans with EC motors, advantageous in that their

speed is variably controllable and their efficiency is high

even when they operate in the lower speed range. The

power supply and control cables of the fans have quickfit connectors making the fans easily removable from

the unit, if required.

The fans can be controlled from a control panel or a

Premium cooker hood to operate at three different

speeds.

• Away = a low airflow, which can be used when no

one is present in the home.

• Home = normal airflow.

• Boost = a high airflow, used in connection with cook-

ing, taking a sauna bath, drying laundry and similar

activities.

The unit’s weekly timer has four programs that can

switch in the various fan modes at the preset times.

On the unit with electric reheating, you can also

select the required temperature of the supply air. Even

when the ventilation unit is being controlled with the

weekly timer, it is always possible to change the fan

mode from a Premium control panel or a Premium

cooker hood.

1.5 Temperature

The user sets the required value for supply air temperature, and, during the heating season, the ventilation

unit then strives to reach this temperature if possible.

In general, the user sets a temperature in the 13-20 °C

range. The supply air temperature should be lower than

the room temperature, so that the supply air will mix

thoroughly with the room air. Note that a high temperature setting will also increase the consumption of

electric power. The factory setting for supply air temperature is 17 °C.

In the Econo models, the setpoint can be set with

a thermostat inside the ventilation unit. You can

turn the thermostat dial to the minimum setting if

heating is not required.

When the heat exchanger’s heating power is not sufficient for reaching the preset supply air temperature, the

electric air heater is activated to heat the air to the supply air setpoint. If no heating is required, the air heater

can be switched off from a Premium control panel.

If the bypass shutter for summer ventilation is

open, the electric air heater is automatically put

out of operation.

You can select an airflow boost time of 30, 60 or 120

minutes from a Premium control panel. When the unit

is controlled from a Premium cooker hood, the fan’s airflow boost time is 60 minutes. You can select a damper

open time of 30, 60 or 120 minutes.

1.3 Filters

The ventilation unit has class G3 wide-meshed filters for

the supply air and extract air. There is also a class F7 fine

filter for the supply air.

1.4 Heat exchanger

Inside the ventilation unit, there is a plate heat exchanger fabricated out of aluminium foil. The heat exchanger

operates according to the counter-flow principle. The

airflows conveyed to the heat exchanger and flowing

from it pass through separate channels and are not

mixed together. The unit’s mechanical bypass damper

4

Swegon reserves the right to alter specifications.www.swegon.com/casa

1.6 Protective functions

The heat exchanger’s anti-freeze protection

The heat exchanger is equipped with anti-freezing

protection. When cold weather involves risk that the

heat exchanger will freeze, the air heater for reheating

is switched on and the supply air fan runs at a lower

speed. This protective function automatically resets itself

when the temperature rises.

Electric air heater

An automatic overtemperature protection (thermal overload cutout) switches off the air heater if a fault situation arises. This protection device automatically resets

itself when the air heater has cooled down.

The overheating protection that requires manual resetting can be reset by pressing a button inside the ventilation unit. The location of the button inside the air

heaters is marked in the illustrations below. When you

press the reset button and feel it click, the overtemperature protection (thermal overload cut out) has then been

reset.

W100B.021014

Reset button for the overtemperature protection on

the preheating air heater

Reset button for the overtemperature protection on

the preheating air heater

(Only models with electric

air heater)

Econo model’s water-heated air heater

On the Econo models, there is a temperature sensor

that protects the water-heated air heater from freezing.

If the air heater’s temperature has dropped to a risky

level, the red signal lamp on the control panel will flash,

but the ventilation unit will operate normally.

If the air heater’s temperature drops further, the controller will stop the ventilation unit to prevent the air

heater from freezing. The anti-freeze protection alarm

is acknowledged from the ’Install. and service’ menu’s

’Alarm’ point.

The overheating protection of the fans

The fans have overheating protection. The fans stop

them if the temperature rises too high. They also stop

if a serious malfunction occurs in the ventilation unit.

The protective function resets itself automatically when

the temperature drops or the malfunction has been

remedied.

Swegon reserves the right to alter specifications. 5www.swegon.com/casa

2. Installation

2

2.1 Ventilation unit installation site

The temperature in the installation space for the unit

should be more than +10 °C, and there should be a

drain in the installation space for draining off condensate. The ventilation unit can be installed in a machinery

room, laundry room, storeroom, etc. The ventilation unit

should not be secured to a wall that borders to a living

room or a bedroom.

During installation, arrange electric and control cables to

make them easily accessible.

The ventilation unit can be mounted either on the wall in

a wall mounting bracket or on the ceiling with a ceiling

mounting frame. The required mounting frame can be

purchased as an accessory (on the Dou model the wall

mounting bracket is included in the supply).

The unit should be mounted as near as possible to a wall

or ceiling. The space between the ventilation unit and the

wall/ceiling must be insulated to prevent the transmission

of sound through the wall behind the unit to the adjacent room.

W100B.021014

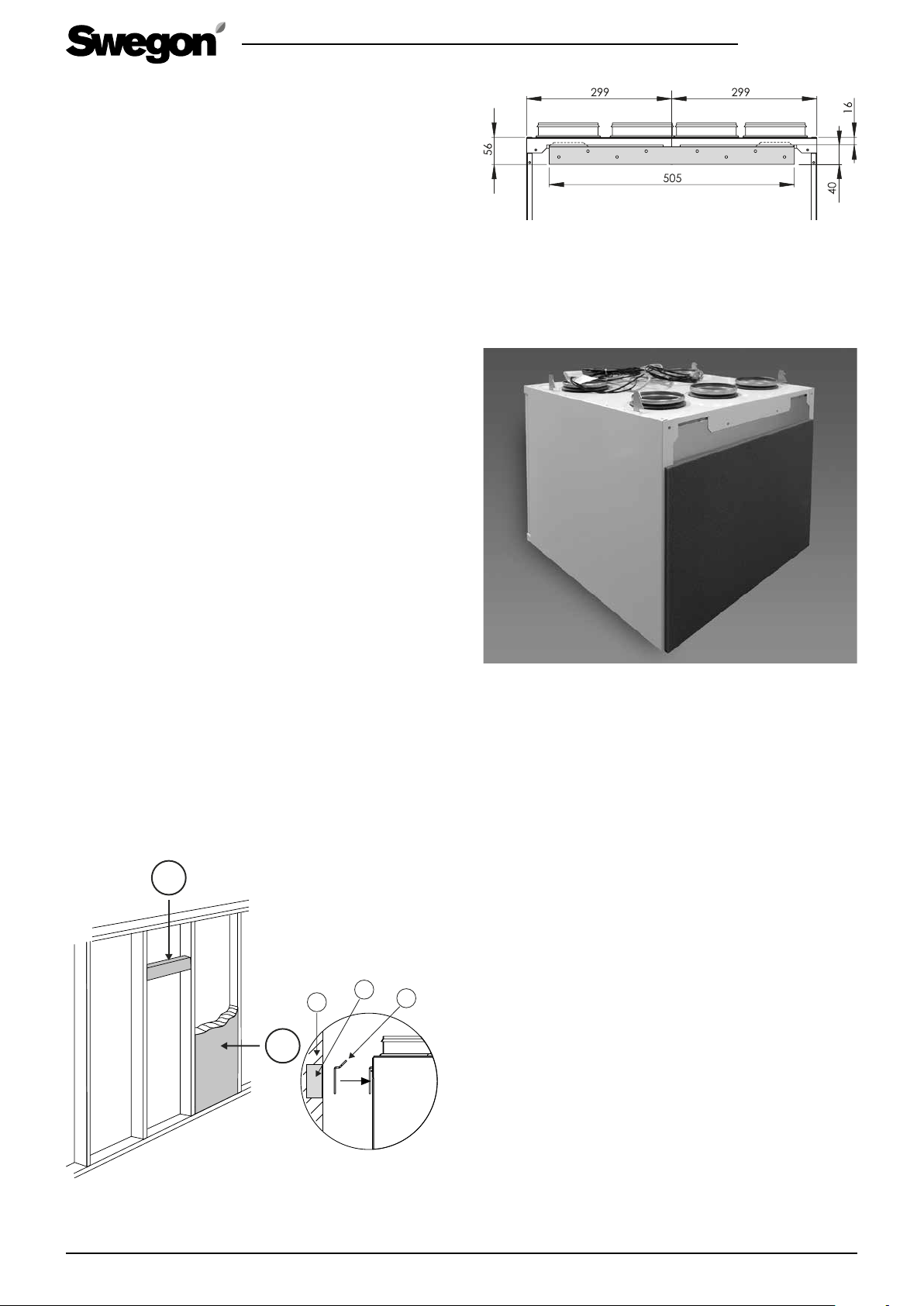

Wall mounting bracket’s dimensions

Screw the wall mounting firmly in horizontal position

onto the wall where a wall stud will support the weight

of the unit.

Connect the extract air from a Premium cooker hood, if

installed, via a duct to the extra duct connection spigot

on the top side of the ventilation unit, which on delivery

is plugged.

2.1.1 Wall mounting

Mount the ventilation unit on a wall by means of a wall

mounting bracket which is available as an accessory

(standard on the Duo models).

If the wall is composed of vertical studs and wall boards,

the wall must be reinforced with horizontal studs that

will support the weight of the unit. Swegon also recommends that the wall be insulated with mineral wool or

similar insulation for preventing sound from propagating to other rooms.

1

1

3

Fasten the insulation, supplied with the wall mounting

bracket, behind the ventilation unit.

Before you lift the ventilation unit into place, attach

the insulation supplied with the wall mounting bracket

onto the back side of the ventilation unit. Lift up the

ventilation unit onto the wall mounting bracket so that

the ears on the bracket engage in the corresponding

notches at the top on the backside of the unit. The ventilation unit’s inspection door and heat exchanger can

be removed to make it easier to lift the unit. The fans

can also be removed if necessary. See the ”Servicing”

Section.

1. Horizontal stud for the ventilation

unit’s mounting bracket

2. Acoustic insulation

6

2

1. Insulated wall

2. Horizontal stud

3. Wall mounting

bracket

Swegon reserves the right to alter specifications.www.swegon.com/casa

W100B.021014

2.1.2 Ceiling mounting

The ventilation unit can also be mounted in a ceiling mounting frame (available as an accessory) on the

ceiling.

Fasten the ceiling mounting frame in ceiling anchor

pieces with four size M8 threaded rods. Adjust the

length of rods so that they will extend no more than

30 mm below the inner surface of the ceiling mounting

frame. If they extend further, they will interfere with the

upper section of the ventilation unit. Install at least three

threaded rods in the corners of the ceiling mounting

frame. To avoid a possible collision with the ducts, one

of the threaded rods can be located in the hole next to

the corner.

Screw in the M8 nuts onto the threaded rods to such a

height that the ceiling mounting frame will be horizontal when the top of the frame goes against the nuts. Fit

the ceiling mounting frame through the selected holes

towards the nuts of the threaded rods and lock the

frame into position with nuts from underneath. Adapt

the installation height so that the locking screws in the

ceiling mounting frame’s front section will extend sufficiently far below the ceiling.

Lift the ventilation unit up against the ceiling mounting

frame so that all four locking hooks engage into position. There are two catches on each locking hook. The

purpose of the upper one is to secure the ventilation

unit to facilitate connection to the ducts and the wiring

of the electric cables.

When the unit is in the correct position in relation to the

duct and the electric cables and water pipes, if required,

have been run into the ventilation unit, lift up the unit

to rest on the lower hooks. When the hooks are locked,

the spring-loaded screws of the front section of the

ceiling mounting frame extend outward. Finally, lock the

ventilation unit into position by tightening the screws.

Be careful not to press on the screws, because doing so will disengage the ventilation unit.

!

Important

!

If you improperly tighten the ceiling

mounting frame, this could turn the frame

and the ventilation unit will not have room

inside the frame.

Run the mounting hooks through the assembly openings above the ventilation unit and secure them with

tension rivets. Position the hooks so that the sharp point

is facing the rear side of the ventilation unit.

The hooks must absolutely not be secured with rivets directly above the ventilation unit.

The points of the hooks face the rear part of the ventilation

unit and they are to be slipped into the unit’s notches before

you secure them with rivets.

Before you lift the ventilation unit into position, back

off the two screws at the front of the ceiling mounting

frame so much that the screw heads stick out approx. 2

cm. Also run the power supply and data cables, and on

the Econo model the water pipes, through the ceiling

mounting frame.

The ventilation unit’s inspection door and heat exchanger can be removed to make it easier to lift the

unit. The fans can also be removed if necessary. See the

”Servicing” Section.

Finally, lock the ventilation unit at its final location by

lightly tightening the locking screws.

The pipe connections of the Econo model should be arranged inside the ventilation unit. The connection work

will be facilitated if you temporarily remove the heat

exchanger and filter from the unit. Connect the inlet

flow pipes to the thermostat (3/8” female threads) and

the return pipe in the coupling with ∅ 15 mm on the

ball valve.

2.2 Condensate discharge

Connect the condensate discharge tube to the ventilation unit’s condensate discharge connection (3/8"

male threads). The condensate must be channelled to

a floor drain, the water trap of a sink or the equivalent

by means of a tube or a pipe having an inner diameter

of at least 12 mm. The tube must not be connected

directly to the sewer.

Vertically mount the water trap on the tube supplied

with the unit and fill it with water. The tube must not

have a second water trap or be run horizontally. The

damming height of the water trap should be at least

100 mm.

Swegon reserves the right to alter specifications. 7www.swegon.com/casa

W100B.021014

2.3 Ducts

Install the air ducts, sound attenuators, supply air diffusers, air intake grilles and exhaust air ducts as shown in

the ventilation drawings. To prevent the propagation of

sound, do not install the ducts directly against structural

building elements.

Insulate the air ducts according to the ventilation plan in

order to reduce the losses of heat or cooling and to prevent water from condensing on surfaces. The applicable

fire resistance insulation requirements are also specified

in the ventilation plan. It is of greatest importance to

insulate cold ducts without gaps in the insulation,

so that moisture cannot condense.

!

Important

!

Check whether the ventilation unit has

been supplied in the right-hand or lefthand version to make certain that you are

connecting the air ducts to the correct duct

connection spigots on the unit. Check the

ventilation plans to make sure that the

duct connections are correctly installed.

See also the dimensional drawings in the

Section entitled: “Technical data”.

2.4 To connect the cooker hood

The cooker hood is usually connected to the ordinary

extract air duct. However the cooker hood can be

connected to the ventilation unit’s separate extract air

connection, in order to meet national regulations or for

achieving a more effective than normal extract airflow.

The duct between the cooker hood and the ventilation

unit must be installed in such a way that makes it possible to clean it.

On delivery, the connection for separate extract air is

blanked off.

If you connect the cooker hood to a separate extract air duct it is important to keep in mind that

the airflow will then bypass the heat exchanger

and this could cause an activation of the antifreeze protection function earlier than normal.

!

The bypass for a kitchen is intended for use

when the airflows from the cooker hood/

kitchen are boosted. The kitchen’s general

ventilation must take place via the extract

air duct. If the general ventilation takes

place continuously via the cooker hood, the

supply air and extract air flows through the

heat exchanger will be out of balance, and

this will lower the efficiency and impair

the ventilation unit’s anti-freeze protection

functions during the winter.

Important

!

2.5 To seal around duct penetration collars

We recommend the use of a mounting frame designed

for the ventilation unit (accessory) for sealing the vapour

barrier in the loft ceiling beams.

Cut up the openings with approx. 10 mm smaller

diameter than that of the ducts. Secure the mounting

frame in the ceiling with screws through the holes on

the sides. Tighten the plastic of the moisture barrier

between the mounting frame and the structural element of the building or fix it in position with tape tightly

against the mounting frame.

It is also important to the preserve the tightness of the

vapour barrier at the duct system’s other penetration

collars that run through the attic joists. A building element penetration seal (accessory) will facilitate this. This

item is available in sets of 5 pieces, for diameters: 100,

125 and 160 mm.

The thickness of the insulation and the nature of the

surface layer of the ventilation ducts vary depending on

insulation material, climate zone and national standards

in force. For this reason, Swegon does not offer any

recommendations. Most manufacturers of insulation

material offer calculation programs for the calculation of

sufficient and correct insulation.

In renovation projects, it is advisable to examine the

existing ducts to determine whether they are sufficiently

and correctly insulated. Insulating in the right way is

necessary for the ventilation unit to operate correctly..If

the ducts are uninsulated, even across a small area,

there is a high degree of risk of condensation and

indirect damage.

The supply air and extract air ducts should be fitted

with acoustic insulation along the stretch between the

ventilation unit’s duct outlet and the sound attenuator,

so that fan sound will not be propagated out into the

room.

In general, ventilation ducts should be insulated in the

following manner:

• Insulate outdoor air ducts run through warm spaces.

• Exhaust air ducts should always be insulated in accordance with national regulations. See separate

project planning instructions (e.g.e ”Fire resistance

requirements”).

• Insulate supply air ducts in cold spaces.

• Insulate extract air ducts in cold spaces.

• If the air inside the duct is colder than in the surroundings; the insulation should be protected by a

vapour barrier.

8

Swegon reserves the right to alter specifications.www.swegon.com/casa

2.6 Electric and control cables

The electric and control cables are located on the upper

side of the ventilation unit.

A 1.5 m long cable with earthed plug-in contact is fitted

to the ventilation unit for measuring the voltage. The

mains plug serves as the ventilation unit’s main switch

and it should be connected to an electric socket at

an easily accessible spot. For power required, see the

Section entitled: “Technical data”.

Connect the ventilation unit to the Premium control

panel (accessory) via a modular cable. A 20 metre long

modular cable is included in the supply of the control

panel. Run the cable to the desired place where the

panel will be mounted. If the modular cable is run inside

some building element (e.g. a wall), run the cable in a ∅

20 mm conduit bearing in mind a possible later change

of cabling.

When installing the unit, make sure that you provide

adequate access to the connector of each cable (loose

ones as well), e.g. for servicing and adjusting the unit, if

and when the need arises.

In multi-storey buildings, a control panel can be used as

a so-called hand-held micro terminal in conjunction with

service and installation work.

The connection of possible accessories is described in

the wiring diagram in the Section entitled: ”Technical

data”. The cables for accessories are not included in the

supply.

!

If any further electrical wiring is required,

only a qualified electrician shall be allowed

to carry out this work.

The electric and control cables are located

on the upper side of the ventilation unit.

Make sure that the electric cable can

be connected to a wall outlet without

obstruction.

Important

!

W100B.021014

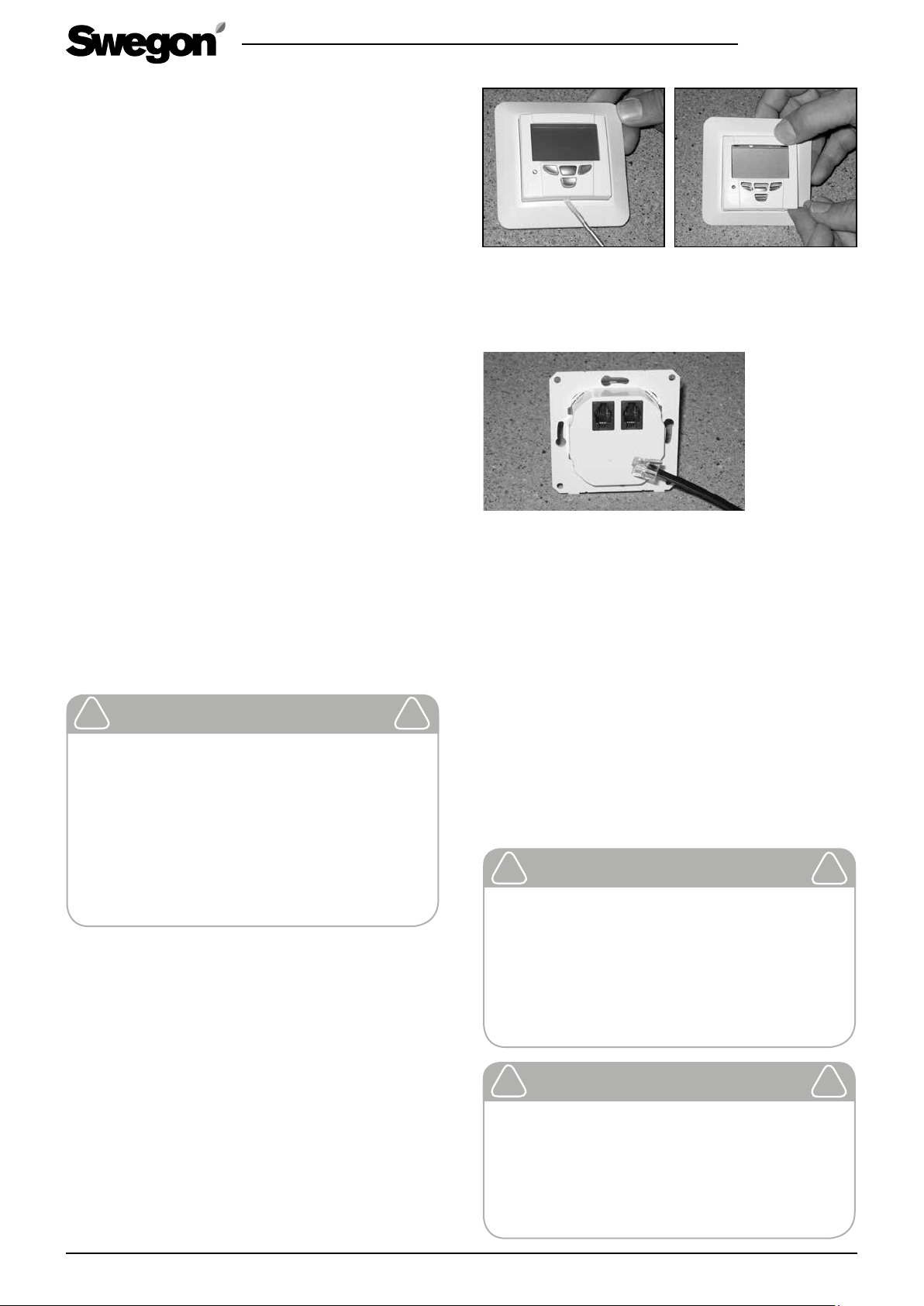

The front plate on the Premium control panel can be done

using a small screwdriver as shown in the figure. Put the front

plate back into place by first placing the upper edge of the

front plate in position and then pressing the plate firmly into

place.

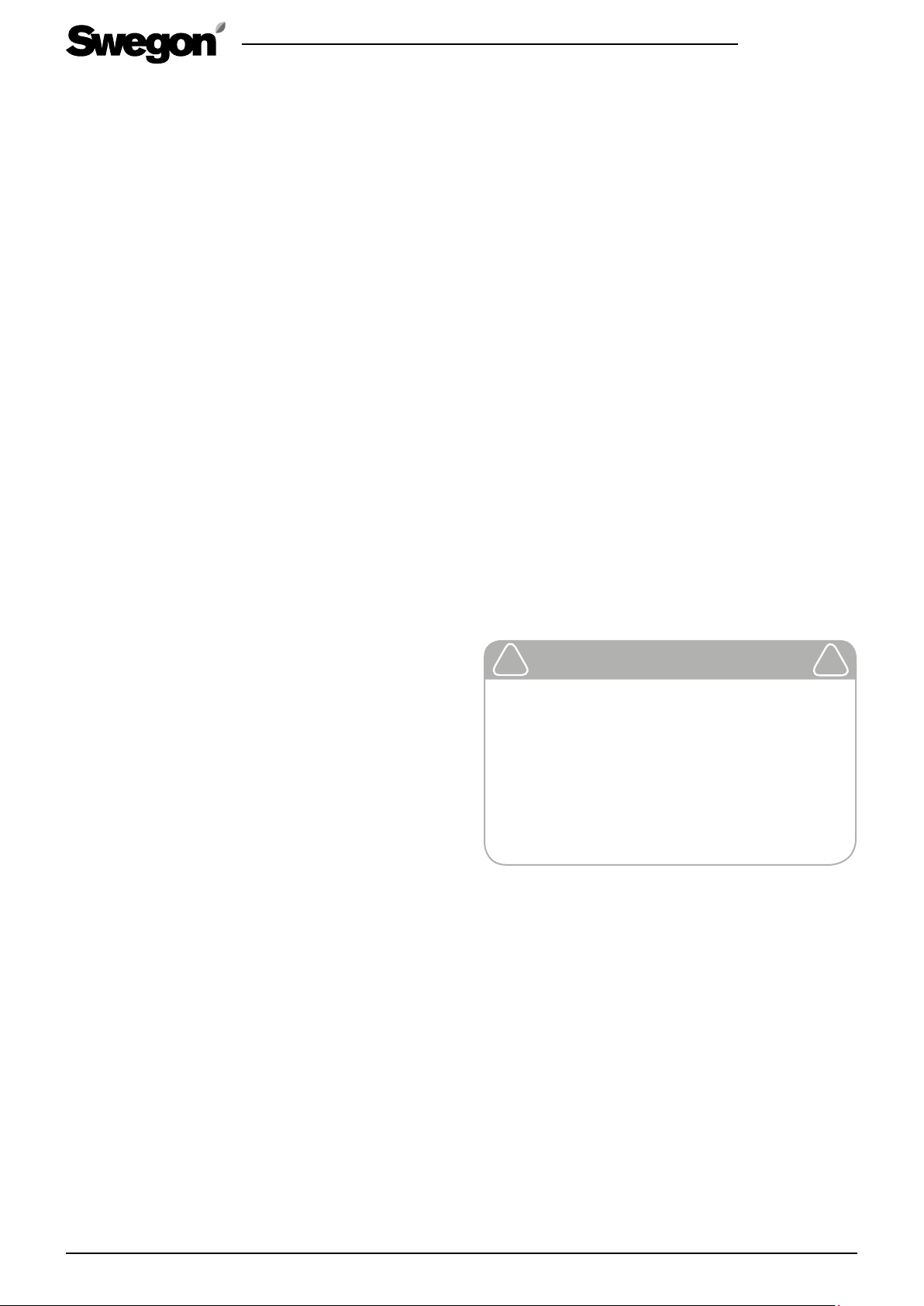

To connect the modular cable. The extra plug terminal is used

for an extra control cable.

2.7 To connect water pipes in the Econo

model

The pipe connections of the Econo model should be arranged inside the ventilation unit. The connection work

will be facilitated if you temporarily remove the heat

exchanger and filter from the unit. Connect the inlet

flow pipe to the thermostat (3/8” female threads) and

the return pipe in the coupling with ∅ 15 mm on the

ball valve.

The Econo model requires a continuous circulation

of hot water during the heating season.

!

Check that the ventilation unit, filters and

ducts are clean and that there are no loose

objects in them before commissioning the

ventilation system.

The ventilation ducts should be cleaned

regularly and always when the home is

renovated.

Important

!

!

It is absolutely forbidden to operate the

ventilation system during the construction

period or if dust-raising work is carried out.

Before installing the unit, the ducts should

be blanked off with covers to prevent the

entry of impurities.

Swegon reserves the right to alter specifications. 9www.swegon.com/casa

Important

!

3. Commissioning

3.1 To set the airflows

For estimated values for setting the airflows, use the

sizing curves in the Section entitled: ”Technical data”. A

qualified person should set the ventilation unit’s and the

ventilation equipment’s airflows using appropriate measurement equipment.

As an initial value for ventilation planning, you can use

the ventilation value 0.5 times the volume of the building per hour + 6 l/s supply air per person, when the unit

is operating in the Home mode. (Initial values can vary

in different countries.)

As a guideline in the Away fan mode, you can use 0.7 x air

volume in the Home mode. Scope for boosting should be

provided in accordance with regulations that apply in the

relevant country.

W100B.021014

3.2.4 Temperature

The supply air temperature is displayed in the main

menu if you select ”On”. (The models with electric

reheating.)

3.2.5 Measurement

Depending on the accessories connected, the following

values can be measured: carbon dioxide content (CO2),

temperature, pressure differential, the speed of the fans

and relative humidity (RH) as well as the light contact

(not on the R100).

3.2.6 Control functions

The carbon dioxide content (CO2), supervision (DDC)

weekly timer or RH control are selectable as control

means. With exception of the weekly timer, all the

control means require you to connect the accessory to

the system.

All the fan modes must be preset so that the ventilation unit will operate correctly. Fill in your entered

settings in the commissioning report.

3.2 Functions in the ’Install. and service’

menu in the Premium control panel.

From this menu, you can decide which functions you

want to be able to use from the main menu. From the

’Install. and service’ menu, you can also enter settings

that affect the ventilation system’s operation while you

commission or service the unit. Possible alarms and the

service reminder can also be acknowledged from this

menu.

3.2.1 To open the menu

To open the menu, enter code 1234.

3.2.2. Alarm

Sensor error

Alternative setting ”On” should be selected as the value

for the temperature sensors. If a possible sensor error

occurs, contact a service company. Sensor errors can

also be acknowledged from this menu.

Service reminder

After servicing, acknowledge the service reminder from

this menu with ”Service OK”. As factory setting, the service reminder is activated and the time interval for the

service reminder is sex months. The service reminder can

be deactivated and the time interval can be changed

from the Functions menu.

The freeze risk warning on the Econo models

If the air heater’s temperature drops to a risky level, the

“Freeze risk” alarm text will appear on the control panel

display. The air heater’s freeze risk warning can be acknowledged from the Freeze risk point. One prerequisite

for acknowledgement is that the temperature by sensor

T6 exceeds 16 °C.

3.2.3 Clock

The clock is displayed in the main menu if you select ”On”.

3.2.7 Fan settings

Situations

Select one of the five fan modes (1–5) for each operating

mode (Away, Home, Boost, Cool, Refresh and Heating).

The factory setting is Away 1, Home 3, Boost 5.

Speeds

For each fan mode(1–5), select fan speeds as percentage of the fan capacity (10–100 %). Enter the settings

separately for supply air and extract air.

!

Important

!

Set the fan speeds in accordance with national regulations when you commission

the ventilation system. The system should

be commissioned by a qualified person,

and the airflows must not be changed on

one’s own responsibility, since doing so

could disrupt the way the ventilation system operates.

3.2.8 Shutdown

The ventilation unit fans and the air heater, if fitted,

are switched off. The circuit card however is still being

supplied with voltage and the settings are retained in

the memory. The same function is also given in the main

menu.

3.2.9 Factory settings

All settings except the fan speeds are restored to the

factory settings.

3.2.10 Controllers

There is provision for using duct controls and valve motor if such accessories have been installed.

3.2.11 Functions

Negative pressure compensation

Put into operation if a cooker hood is connected to a

10

Swegon reserves the right to alter specifications.www.swegon.com/casa

Loading...

Loading...