Swegon CASA series Installation, Operation And Maintenance Instructions

Installation, operation and maintenance instructions

for design engineers, installation engineers and service personnel

PTH_a_EN–m

Swegon CASA® Regulation for

constant duct pressure

Important information

Only qualified personnel

Only qualified personnel should carry

out installation, configuration and

commissioning.

Important details to consider

during installation

The installation point affects the

measurement result. The sensor must be

installed at a point where the airflow is as

even as possible.

Commissioning

The pressure sensor may not be installed

until all work that produces large quantities

of sanding dust or other impurities has been

completed.

Make sure that the ducts are clean and that

there are no loose objects in them before

commissioning.

NOTE! The manual’s original language is Finnish.

!

Included in the delivery:

• Pressure sensor

• Measuring tube

• Measurement tapping

• Instructions

2

PTH.191017

Swegon reserves the right to make changes.www.swegonhomesolutions.com

3.1. Installation of the sensor in the duct

system

Install the pressure sensor close to the measurement

point. When measuring the (positive) pressure on the

supply air duct, connect the measuring tube to the tapping on the pressure sensor (+). When measuring the

(negative) pressure on the extract air duct, connect the

measuring tube to the tapping on the pressure sensor (-).

3.2. Electric and control cables

Connect the 3-wire cable from the pressure sensor to

the ventilation unit’s I/O connection according to the

wiring diagram.

NOTE! Make sure that the strain relief is arranged

for the connections according to the electrical

safety directives.

3. Installation

The constant duct pressure function on the Smart ventilation unit attempts to regulate the fan speeds to maintain the duct pressure at the set value. Individual setting

values for the duct pressure should be determined for

each operating mode (away, home, boost). The operating mode can be switched as normal when the constant

duct pressure function is used.

1. General Description

2. Planning

Select the position of the measurement tapping point

in the duct with care, so that as far as possible it represents the pressure in the entire duct system. For example, a suitable location is close to the ventilation unit,

yet so the airflow is still uniform in the measurement

point. The measurement is based on the pressure difference, and therefore the other measurement sensor must

be positioned so it represents the air that surrounds the

duct, and where the air is stable.

Important

Only a qualified electrician may make the

electrical connections.

!

!

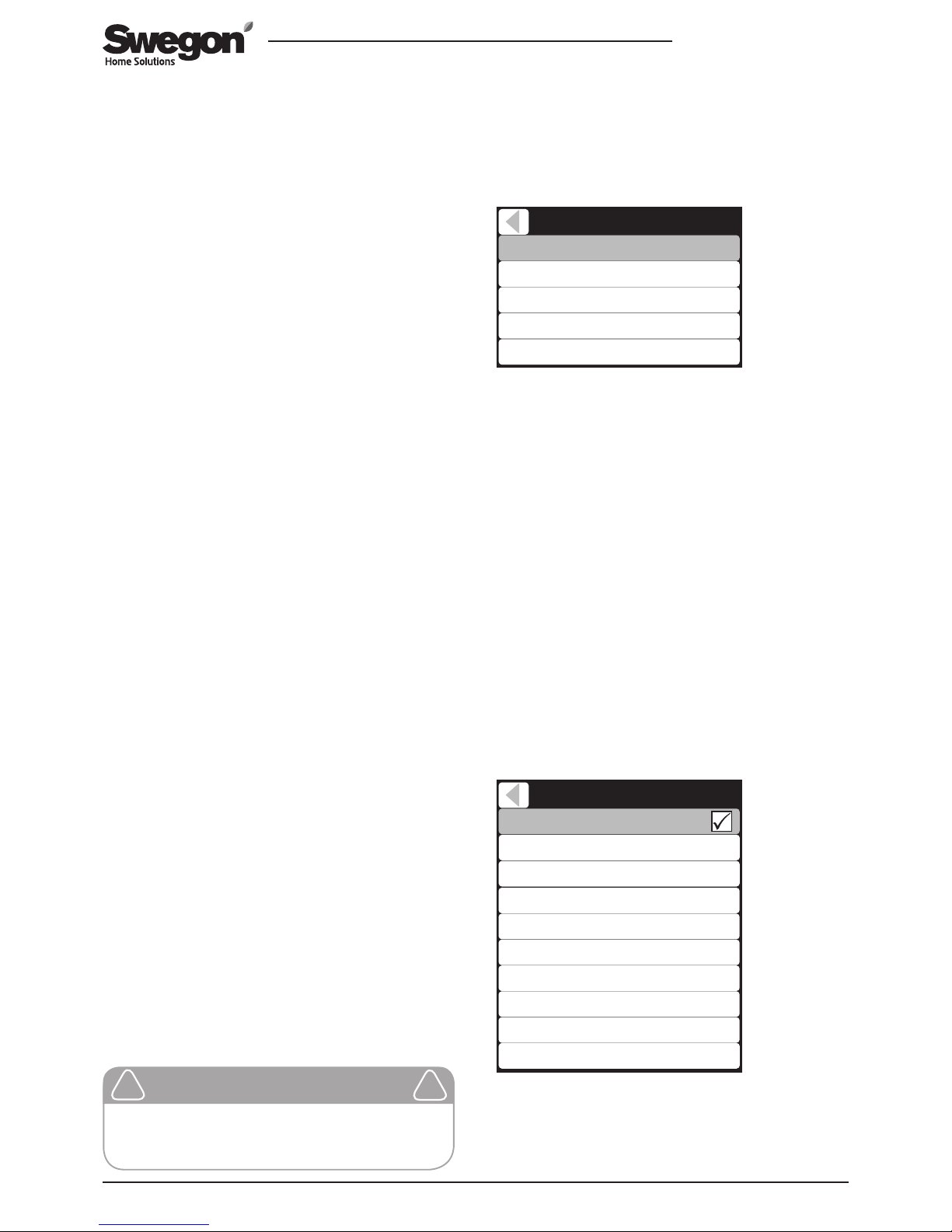

4. Commissioning

The commissioning of regulation for constant air pressure is performed with a Smart control panel. Main

menu/Settings/(1234)/IO controls

IO controls

IO 1

IO 2

IO 3 (ext.)

IO 4 (ext.)

Pa Extract - AI

Away - DI

Emg.Stop_NO - DI

Pa Supply - AI

IO 5 (ext.)

DDC control - AI

Select connections that correspond to the IO-points Pa

Supply - AI / Pa Extract - AI. Example: “Pa Supply - AI”

as a function for IO 1 and “Pa Extract - AI” as a function

for IO 2.

The pressure setting values and airflows must be adjusted for all operating modes (Home, Away, Boost), so that

the ventilation unit functions in all conditions.

NOTE! The constant duct pressure function is not

activated until you have set the values for all operating modes.

The control type for the ventilation unit is selected and

the airflow is set from the menu Main menu/settings/

(1234)/Airflow adjustments.

Airflow adjustments

Commissioning mode

Home (exhaust)

Away (supply)

Away (exhaust)

Boost (supply)

Boost (exhaust)

Travelling (supply)

Max Smart boost (supply)

50 Pa

35 Pa

38 Pa

90 Pa

92 Pa

35 Pa

82 Pa

Control type Pa

Home (supply) 48 Pa

Select “Pa” as the control type of both ducts that are to

be regulated for a constant duct pressure. If the control

type is set to “Pa Supply” or “Pa Extract”, the selected

duct is solely regulated for constant duct pressure and

5. Settings

Loading...

Loading...