Swegon CASA R3 Smart, CASA R2 Smart Installation, Commissioning And Maintenance Instructions

R3_g_EN-t

Installation, commissioning and maintenance instructions

CASA® R3 Smart

2

R2.060219

All rights to changes reserved.www.swegon.com

NOTE! The manual’s original language is

English.

Contents

Technical Guide

for design engineers, installation engineers and service personnel

The section 1 describes the high lights of the unit.

All information for mechanical installation is found from section 2.

Instructions for basic commissioning is found from section 3.

Units external connections to the systems or devices like Modbus, DI, DO, AI, etc. is found from section 4.

Units functions description and usage is found from section 5.

Units periodically maintenance and service is described in section 6.

If a malfunction or alarm occurs the instructions are found from section 7.

All technical data is found from section 8.

Important information ............................................. 3

1. General Description .............................................. 4

1.1 Enclosure .........................................................................4

1.2 Fans ................................................................................. 4

1.3 Demand ventilation control ..............................................5

1.4 Filter ................................................................................5

1.5 Heat exchanger ................................................................5

1.6 Temperature ....................................................................5

1.7 External connections ........................................................ 5

1.8 Protective functions .........................................................5

2. Installation ............................................................. 6

2.1 Ventilation unit’s installation site ......................................6

2.1.1 Wall mounting ........................................................6

2.1.2 Ceiling mounting ....................................................6

2.1.3 Installation of the cooker hood directly on the

ventilation unit ................................................................. 7

2.1.4 Installation of the cooker hood separately from the

ventilation unit ................................................................. 7

2.2 Condensate discharge ......................................................8

2.3 Ducts ............................................................................... 8

2.3.1 Commissioning the bypass for the kitchen...............9

2.4 Electric and control cables ..............................................10

2.5 Installation of the Smart control panel ............................10

2.6 Accessories ....................................................................11

2.6.1 Smart sensor package ...........................................11

3. Basic commissioning ........................................... 12

3.1 Air flows ........................................................................ 12

3.1.1 Setting the basic airflows.......................................12

3.1.2 Travelling ...............................................................12

3.1.3 Maximum automatic boost....................................12

3.1.4 General notifications ............................................. 12

3.2 Cooker hood function ....................................................13

4. Units external connections................................. 14

4.1 Modbus ......................................................................... 14

4.2 Switch inputs (DI) ........................................................... 15

4.3 Voltage inputs (AI) .........................................................15

4.4 Relay outputs ................................................................. 16

4.5 Voltage outputs (AO) .....................................................16

4.6 Smart Access .................................................................16

5. Functions and use ............................................... 18

5.1 Functions ....................................................................... 18

5.1.1 Shortcuts ..............................................................18

5.1.2 Summer night cooling ........................................... 18

5.1.3 Cooker hood function ........................................... 19

5.1.4 Central vacuum function ....................................... 19

5.1.5 Fireplace function ..................................................19

5.1.6 Automatic Home/Away/Boost function ..................19

5.1.7 Automatic humidity control ...................................20

5.1.8 Automatic air quality control .................................20

5.1.9 Weekly program ....................................................20

5.2 Supply air temperature control .......................................21

5.2.1 Temperature control settings ................................21

5.2.2 Temperature measurement ....................................21

5.2.3 External heating and cooling units ......................... 21

5.3 Anti-frost protection ......................................................22

5.4 Restoring factory settings ............................................... 22

5.6 Changing settings password ..........................................22

5.7 Use ................................................................................ 22

6. Service .................................................................. 23

6.1 Service reminder ............................................................23

6.2 To open the ventilation unit ...........................................23

6.3 Filters ............................................................................. 23

6.4 Heat exchanger ..............................................................23

6.5 Fans ............................................................................... 24

6.6 Other servicing ............................................................... 24

6.7 Diagnostics ....................................................................24

7. Alarms and Troubleshooting .............................. 26

7.1 Alarm indication, cooker hood ....................................... 26

7.2 Alarm indication, control panel ......................................26

7.3 Troubleshooting ............................................................. 26

7.4 Alarm descriptions .........................................................27

8. Technical data ...................................................... 28

8.1 List of components ........................................................28

8.2 Air flows (EN 13141-4) ...................................................29

8.3 Connection outputs ....................................................... 29

8.4 Acoustic data ................................................................. 30

8.5 Electrical wiring diagram ................................................ 31

8.5.1 Ventilation unit .....................................................31

8.5.2 R3, CASA Jazz cooker hood and control panel ......31

8.6 Control diagram ............................................................32

8.7 Measurements ...............................................................33

8.8 Weights .........................................................................34

8.9 Ventilation unit’s codes ..................................................34

8.10 Accessories for installation ...........................................34

Commissioning form ............................................... 35

R2.060219

All rights to changes reserved.

3

www.swegon.com

Important information

Installation and commissioning

Only qualified personnel should carry out installation,

configuration and commissioning. Only a qualified

electrician is allowed to make electrical installations in

accordance with national regulations.

The national standards and regulations dealing with

unit installation, configuration and commissioning

must be followed.

Do not use the ventilation unit until all work that

produces large quantities of dust or other impurities

has been completed.

The duct connections of the ventilation unit must be

covered by lids until it is mounted at its final location.

Make sure that the ventilation unit, filters and ducts

are clean and that there are no loose objects in them

before you commission the ventilation system.

Electrical work and connections

If you carry out voltage tests, measure the electrical

insulation resistance at various points or perform

other remedial measures that could damage sensitive

electronic equipment, you must first isolate the

ventilation unit from the electrical supply grid.

It is recommended that all Smart ventilation units

should be equipped with a surge protection device.

It is recommended that all Smart ventilation

units should be equipped with a residual current

circuit breaker. Comply with local electrical safety

regulations when you install electrical equipment.

Drying laundry

A tumbler dryer of extract air type or a drying cabinet

must not be connected to the system due to the high

moisture content in the air it discharges.

Models with water-based air heater

When there is a water-based post heater in the

ventilation system the system should be equipped

with damper in outdoor air duct so that the air

heater cannot freeze during a power failure and unit

freezing protection works correctly.

Separate extract air

(bypass for cooker hood)

The separate extract air duct runs past the heat

exchanger. The separate extract air duct should only

be used while cooking and the extract air from the

kitchen should be conducted to the ventilation unit’s

extract air duct. Note that separate extract air flow

affects the ventilation unit’s annual efficiency.

Condensation

The surface temperature of the ventilation unit can

drop down to 12 °C during periods of low outdoor

temperature and depending on the moisture content

of the air surrounding the unit, moisture may condense on the surface. Condensation should be taken

into account when choosing furnishings that are to

be installed in the vicinity of the ventilation unit.

Balancing functions

It is recommended to use external preheater when

balancing functions are used at temperatures below

-10 °C.

To open the ventilation unit for service

Always isolate the ventilation unit’s power supply cable

before you open the inspection door! Wait a few minutes before you open the inspection door so that the

fans are stopped and electrical heaters are cooled.

There are no components inside the electrical box

that can be serviced by the user. In case of malfunction, do not restart the ventilation unit before the cause

of the fault is identified and fixed.

Filters

The ventilation unit must not be operated without

filters! Use only original Swegon filters. Find the correct filter in the section ”Technical data”.

Warranty conditions

Warranty conditions are included in delivery of the

unit as a separate document.

Declaration of conformity

Link to the declaration of conformity:

www.swegonhomesolutions.com

(Toolbox/Find a pdf)

!

This document is intended for everyone involved in the installation work for or the use of a Swegon CASA ventilation unit. Read this Instructions for Use before you use the ventilation unit. Save the Instructions for Use for

future use. This document is available in our website.

The ventilation unit is not designed to be used by children (below 8 years old) or by persons whose senses, physical or mental capacity or a lack of knowledge and experience limits safe use of the ventilation unit. Such persons

may use the ventilation unit if supervised by a person who is responsible for their safety, or according to the

instructions.

4

R2.060219

All rights to changes reserved.www.swegon.com

1. General Description

The most important function of the ventilation system

is to ensure clean and fresh indoor air and to remove

moisture. The air in the home should be changed at

a continuous and sufficient rate to ensure a pleasant

indoor climate and avoid damage to building elements

caused by dampness.

Swegon CASA R3 is designed for detached houses,

multi-dwelling houses and holiday cottages less than

150 m

2

. The ventilation unit can be used both for new

construction and renovation projects. The R3 ventilation

unit can also be installed together with a cooker hood

instead of a spice rack above the cooker.

• Air flow interval: 25–80 l/s

• Heat exchanger temperature efficiency up to 86 %

(EN 308)

• Built-in humidity sensor as standard.

• Continuous control of the supply air temperature

• Energy-efficient and quiet EC fans

• Available in right and left hand design (supply air)

• Can be installed directly above the cooker together

with the cooker hood.

• The ventilation unit has modular dimensions and

can be mounted together with a standard kitchen

cabinet.

• CASA Smart control system

• The ventilation unit can be controlled from a control

panel, from the cooker hood, via external switches or

Modbus.

• Energy class A according to the Ecodesign directive

1.1 Enclosure

The ventilation unit conforms to enclosure class IP34

when the cover is closed.

1.2 Fans

Swegon CASA R3 is equipped with energy efficient EC

fans.

The fans can be controlled in four operating modes and

steplessly with Smart functions:

• Boost = maximum commissioned air flow is used

when the ventilation requirement increases, e.g. for

cooking, showering or drying laundry.

• Home = normal air flow. In normal cases guarantees

healthy indoor air quality.

• Away = low air flow. Reduces power consumption

when no one is in the house.

• Travelling = very low air flow and lower supply air tem-

perature. Used when house is empty long period. (Can

only be selected from a Smart control panel.)

The unit’s weekly timer can change operation modes

and temperature setpoint at the preset times. It is always

possible to override the weekly timer and change the

operation mode from a control panel or a Smart cooker

hood.

The delivery includes:

• Ventilation unit, R3

• Wall mounting bracket

• Cover plate for locks (2 pcs.)

• Instructions for Use (FI, SE, EN, NO, DE)

• Installation, commissioning and maintenance

instructions (FI, SE)

• Warranty Conditions

• “Remember to change the filter” decal

• Product information sheet

Standard connections:

• Power cord with earthed plug (2 m)

• Modular cable with RJ9 connector (2 pcs., 1.5 m)

• Freely configurable I/O contacts for connection of

accessories (2 pcs.)

Accessories:

• Modular cable, 20 m, adapter

• Smart control panel

• Roof mounting frame

• Mounting frame with vapour barrier

• Water trap

• Condensate discharge hose

• Cover plate for inspection door (white or stainless

steel):

• SEC: IO extension cable with Modbus RTU

• SEM: IO extension module with relay and Modbus

RTU (input and output connections)

• Waterborne air heater/air cooler for installation in

ducts

• Electric air heater for installation in ducts

• Smart sensor (RH, RH+CO

2

, RH+VOC)

• Set for constant duct pressure

• Smart Access mobile user interface

R2.060219

All rights to changes reserved.

5

www.swegon.com

You can select an air flow boost time of 30, 60 or

120 minutes or continuous boost from a Smart control

panel. When the unit is controlled from a cooker hood,

the fan’s air flow boost time is 60 minutes.

1.3 Demand ventilation control

Ventilation can be controlled by demand with following

Smart functions:

• Stepless Home/Away/Boost Control = ventilation

level is controlled according to the CO

2

level.

• Humidity Control = ventilation is boosted steplessly

according to the moisture load caused by people.

• Air Quality Control = ventilation is boosted steplessly

according to VOC level.

• Smart Balancing Functions = supply and extract air

flow balance is controlled to maintain room pressure

level constant. i.e. cooker hood, fireplace or central

vacuum cleaner functions.

• Smart Cooling Boost = ventilation is boosted

according to cooling need.

1.4 Filter

The ventilation unit is equipped with supply and extract

air filters according to filter class ISO ePM1 55 % (F7).

The need of filter replacement is indicated on the

control panel and on a CASA Smart cooker hood.

1.5 Heat exchanger

The ventilation unit is equipped with a efficiency controlled rotary heat exchanger. Heath exchanger is

controlled either to maintain constant supply air temperature or to achieve maximum energy efficiency.

1.6 Temperature

The supply air temperature is controlled with heat exchanger and if needed with heating or cooling element.

In Comfort mode constant supply air temperature is

maintained by rotor efficiency control and heating and

cooling control.

In Eco mode maximum heating / cooling efficiency is

maintained. Supply air temperature is controlled only in

heating or cooling period.

The temperature control setpoint can be adjusted from

user panel, weekly timer, by operating mode or by room

temperature.

Automatic summer night cooling detects the need

for cooling. Function lowers supply air temperature setting and controls the rotor to achieve the best possible

cooling effect.

1.7 External connections

All connections can be made without opening the

electrical box. Plug-in modules are available for external

connections. Wide variety of IO functions are available.

The ventilation unit is equipped with In-build Modbus.

Modbus cabling can be made easily with external cable

(SEC) or module (SEM). Unit can be fully controlled

with Modbus and all external IO´s can be configured to

Modbus usage.

1.8 Protective functions

The heat exchanger freeze protection

The defrosting function guarantees continuous ventilation and maintains units performance even during

extreme conditions.

The fan overheating protection

The fan overheat protection stops the fan if the temperature rises too high and is reseted automatically. If protection stops the fans an alarm is generated.

Rotor quard

Rotor quard detects that the rotor is working.

Malfunction generates an alarm.

Electric air heaters

The electric heater is equipped with automatic and

manual overtemperature protection. Overheat cuts the

heating circuit and generates an alarm.

Water-based air heaters

The ventilation unit with water-based air heater/cooler

has a temperature sensor that protects the coil from

freezing. Protection generates the alarm and starts

freezing prevention. If freezing prevention is not enough

the unit is stopped and demanded shut-off dampers are

closed. Freezing prevention is reseted automatically.

Cold supply air

The ventilation unit has built-in condensation protection.

If the supply air is too cold, the ventilation unit stops and

an alarm is generated

High temperature

If supply air or units internal temperature is detected

dangerously high the unit is stopped and an alarm is

generated.

Temperature sensors

If a sensor fault is detected, the ventilation unit runs in

restricted mode. The ventilation unit’s returns to normal

mode once the fault has been corrected.

6

R2.060219

All rights to changes reserved.www.swegon.com

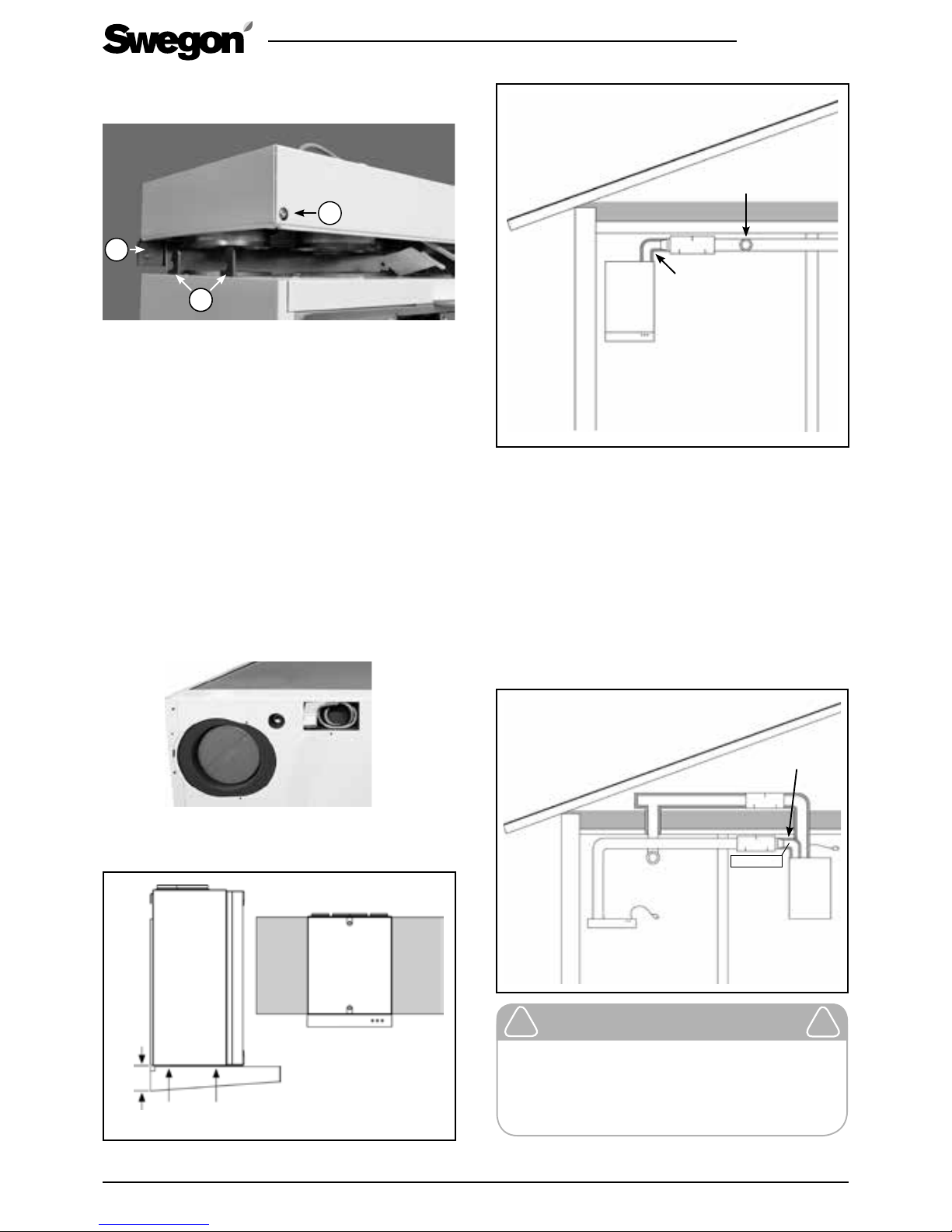

2.1.2 Ceiling mounting

The ventilation unit can also be mounted in a ceiling

mounting frame on the ceiling (can be ordered as an

accessory).

Fasten the ceiling mounting frame in ceiling anchor

sleeves with four M8 threaded rods. The length of rods

must be adjusted so that they will be positioned approx.

15–20 mm under the inner surface of the ceiling

mounting frame. Install the ceiling mounting frame

approx. 35–55 mm below a suspended ceiling.

The ceiling mounting frame must not be used as

part of a support structure for the ducts, the duct

support must be sufficient even without the support

effect provided by the ceiling mounting frame.

Secure the locking hooks in mounting openings on

the ventilation unit’s top side by means of pop rivets.

Position the hooks so that the sharp point is facing the

rear side of the ventilation unit.

The hooks must absolutely not be secured with

rivets directly above the ventilation unit.

The points of the hooks face the rear part of the ventilation

unit and they are to be slipped into the unit’s notches before

you secure them with rivets.

Hang the ventilation unit up in the mounting frame

so that the rear of the unit engages in the suspension

plate. Lift the ventilation unit up against the ceiling

mounting frame so that the locking hooks on both sides

engage into position. The unit is firmly secured if the

screw heads on the front part of the ceiling mounting

frame return to their original positions. The ventilation

2.1 Ventilation unit’s installation site

The temperature in the space where the unit will be

installed must be more than +10 °C. The ventilation unit

can be installed in a machine room, laundry room, store

room, etc.

The ventilation unit can also be mounted in the kitchen

above the cooker. Swegon CASA Jazz cooker hood can

be connected directly to/below the ventilation unit.

Due to the risk of disruptive noise, the ventilation unit

should not be installed on the wall towards the living

room or bedroom.

Make sure it is easy to access the power and control

cables as well as accessories.

The ventilation unit can be mounted either on the wall

with a wall mounting bracket included in the supply or

on the ceiling with a ceiling mounting frame which is

available as an optional extra.

The unit should be mounted as near as possible to a

wall or ceiling. The space between the ventilation unit

and the wall/ceiling must be insulated to prevent the

transmission of sound through the wall behind the unit

to the adjacent room.

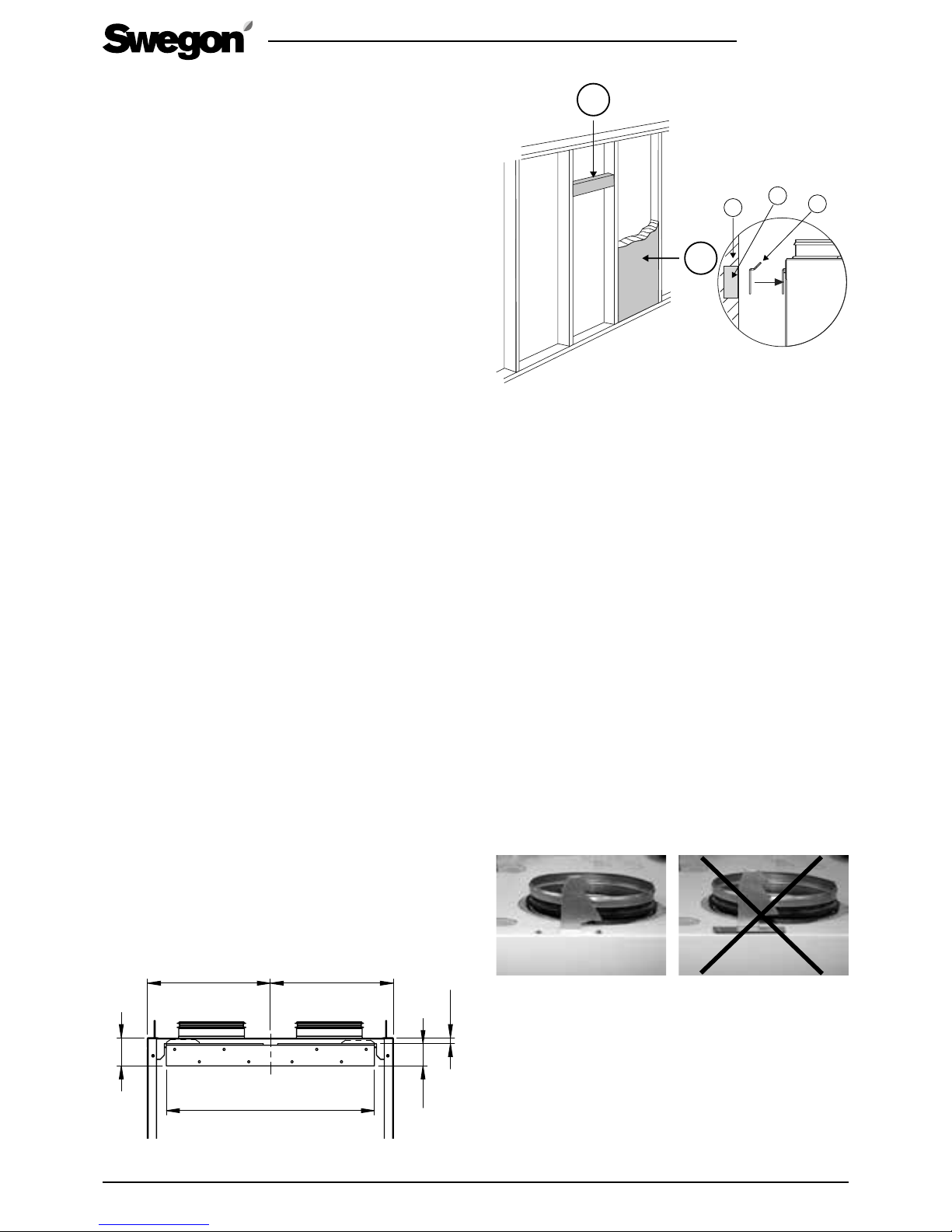

2.1.1 Wall mounting

A wall mount is supplied together with the ventilation

unit.

If it is a question of a light partition wall, the wall must

be reinforced with horizontal studs that support the

weight of the ventilation wall. In addition, Swegon also

recommends that the wall be insulated with mineral

wool or similar insulation for preventing sound from

propagating to other rooms.

Screw the wall mount firmly in horizontal position onto

the wall where a wall stud will support the weight

of the unit. Lift up the ventilation unit onto the wall

mounting bracket so that the ears on the bracket

engage in the corresponding notches at the top on the

backside of the unit.

The door of the ventilation unit and the fans can be

dismantled to facilitate lifting the ventilation unit. See

the ”Servicing” Section.

2. Installation

1

2

1. Horizontal stud for the ventilation

unit’s mounting bracket

2. Acoustic insulation

1

2

3

1. Insulated wall

2. Horizontal stud

3. Wall mounting

bracket

Wall mounting bracket’s dimensions

299 299

505

68

54

14

R2.060219

All rights to changes reserved.

7

www.swegon.com

unit can then be secured into position by screwing in

the locking screws to their end positions.

1

2

3

1. Suspension plate

2. Locking hooks

3. Lock screw

2.1.3 Installation of the cooker hood directly on

the ventilation unit

Swegon CASA Jazz cooker hood can be connected

directly below the ventilation unit. In this case, a twosocket socket is required. Make sure that the spacing

between the cooker hood and cooker corresponds with

local regulations.

Connect the control and power cables that come out

of the bottom of the ventilation unit to the connector

on the cooker hood. Secure the cooker hood to the

ventilation unit with the screws supplied.

The ventilation unit can be controlled from the cooker

hood control panel.

The electric and control cables as well as the connection

for the cooker hood’s extract air are located under the

cover plates in the bottom of the unit.

99 mm

The fan’s

mounting screws

The kitchen airflow from the

cooker hood during operation in

the boosted flow mode

Condensation/sound

insulation

The kitchen’s general

ventilation via extract air

register

∅ 125 mm

2.1.4 Installation of the cooker hood separately

from the ventilation unit

All compatible Swegon CASA cooker hoods can be

mounted separately from the ventilation unit, the

extract air is then led from the cooker hood via a duct to

an extra duct connection on the top of the ventilation

unit. The duct between the cooker hood and the

ventilation unit must be installed in such a way that

makes it possible to clean it.

The ventilation unit can be controlled from the cooker

hood control panel.

∅ 100 mm

∅ 125 mm

∅ 125 mm

The kitchen’s general

ventilation via extract

air register

The kitchen airflow from

the cooker hood during

operation in the boosted

flow mode

Condensation/sound

insulation

Important

The 100 mm duct outlet on the kitchen

bypass should be fitted with a taper piece

for transition to 125 mm as near to the unit

as possible.

!

!

8

R2.060219

All rights to changes reserved.www.swegon.com

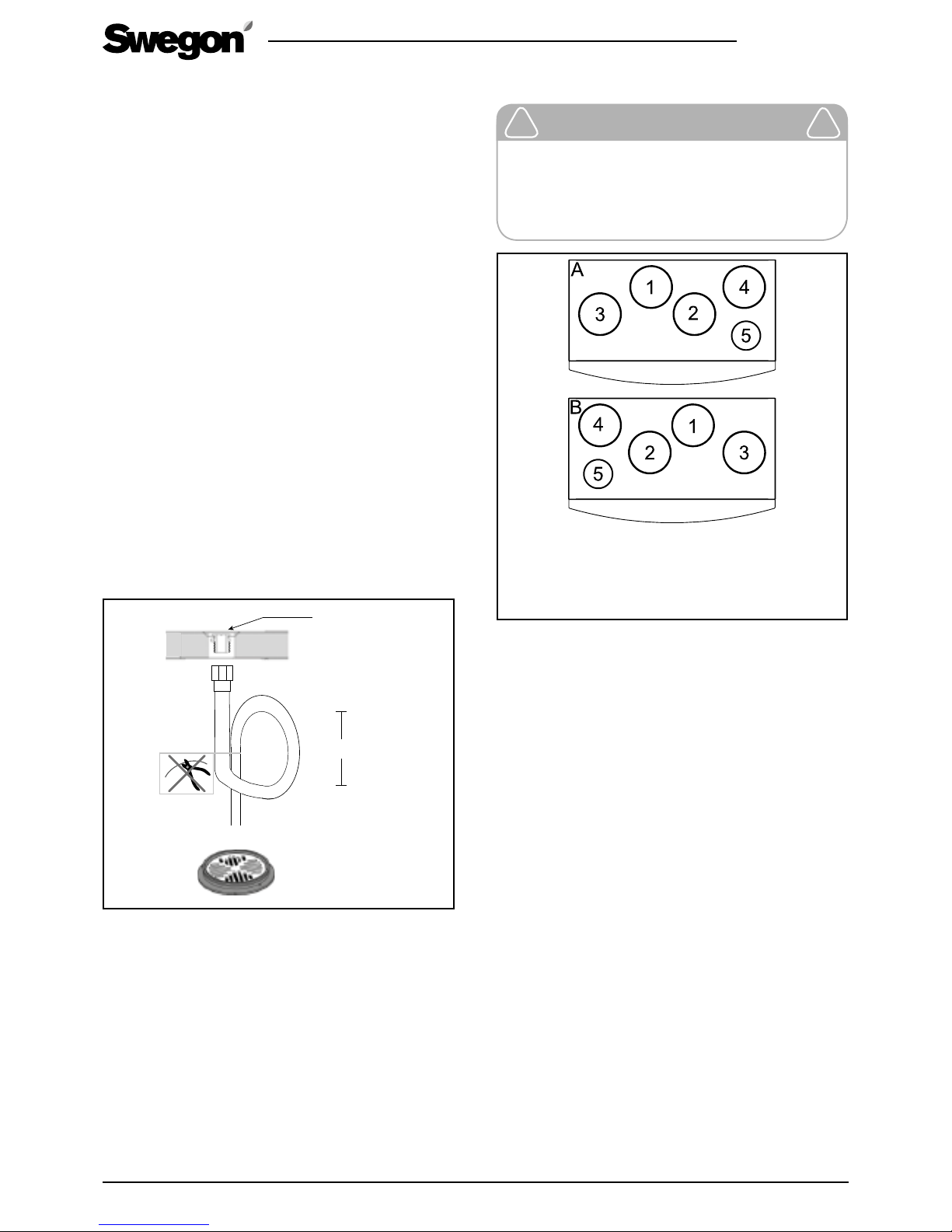

2.2 Condensate discharge

As a rule, no condensate discharge connection

is needed under dry ambient conditions and in

combination with a rotary heat exchanger. A certain

humidity load exists in homes and a condensate

discharge line should be connected to the ventilation

unit, if considerable moisture is produced in the home.

Connect the discharge hose to the ventilation unit’s

condensate discharge connection (3/8” male threads).

The condensate must be channelled to a floor drain,

the water trap of a sink or the equivalent by means of

a tube or a pipe having an inner diameter of at least 12

mm. The tube must not be connected directly to the

sewer. The tube must not have a second water trap or

be run horizontally. The damming height of the water

trap should be at least 100 mm.

The condensate discharge connection is plugged

from the outside of the ventilation unit. Remove

the plug when you begin using the condensate

discharge connection. Check that the condensate

discharge outlet is not clogged and check its outflow

by pouring water on the bottom of the ventilation unit.

The condensate discharge connection is located on the

rear of the unit under the rotary heat exchanger.

A hose to lead off the condensate is available as an

accessory (product: CDH3). The hose has a ready-made

loop that serves as a water trap.

200 mm

3/8" male

thread

There is a metal water trap available as an accessory

(UVL).

2.3 Ducts

Important

Check whether the ventilation unit is in

a left or right-hand version, to be sure to

connect the ventilation ducts to the correct

duct connections.

!

!

A. Right-hand version

B. Left-hand version

1. Supply air

2. Extract air

3. Outdoor air

4. Exhaust air

5. Extract air from the cooker hood

Install the ducts according to the ventilation drawings.

Do not mount ducts directly against structural elements

to avoid the propagation of sound.

Insulate the ventilation ducts to prevent leakage of heat,

cold and sound, as well as water condensing. Fire insulate

the ducts according to national regulations. Pay particular

attention to insulate cold ducts without gaps in the

insulation, so that moisture cannot condense.

The thickness of the insulation must be sufficient for the

insulation material, for the climate area and according

to local regulations. Most manufacturers of insulation

material offer calculation programs for the calculation of

correct and sufficient insulation.

Supply air duct should be fitted with acoustic insulation

along the stretch between the unit duct outlet and

the sound attenuator, so that fan sound will not be

propagated out into the room.

Generally, ventilation ducts should be insulated as follows:

• Insulate the outdoor ducts that pass through warm

spaces.

• Exhaust air ducts should always be insulated in

accordance with national regulations.

• Insulate supply air ducts in cold spaces.

• Insulate extract air ducts in cold spaces.

• If the air inside the duct is colder than in the

surroundings; the insulation should be protected by a

vapour barrier.

R2.060219

All rights to changes reserved.

9

www.swegon.com

It is important to the ensure the tightness of the vapour

barrier at the penetration collars. We recommend the

use of a mounting frame with vapour barrier designed

for the ventilation unit (accessory, PR085YP) for sealing

the vapour barrier.

2.3.1 Commissioning the bypass for the kitchen

The ventilation unit has extra duct connections for

extract air from the cooker hood on its top and

bottom sides. The extract air from the cooker hood

flows directly out through the unit’s extract air fan and

does not pass the heat exchanger. For this reason, the

kitchen's general ventilation must not take place via the

cooker hood. On delivery, both of the duct outlets that

bypass the heat exchanger are fitted with covers.

If the duct connection designed for bypass from the

kitchen is used, the duct between the cooker hood and

the unit must be installed in such a way that makes it

possible to clean it.

Important

The kitchen bypass is intended for use

when the air flows from the cooker hood/

kitchen are boosted. The kitchen’s general

ventilation must take place via the extract

air duct. If the general ventilation takes

place continuously via the cooker hood, the

supply air and extract air flows through the

heat exchanger will be out of balance, and

this will lower the efficiency and impair

the ventilation unit’s anti-freeze protection

functions during the winter.

!

!

Dismantle the cover panel on the top of the

ventilation unit

How to open the ventilation unit and remove the guard

plates are described in the section entitled: ”Service”.

• Open the ventilation unit’s inspection door and

remove the guard plates in front of the heat

exchanger.

• Remove the screws of the guard plate that covers the

duct connection.

• Pull out the cover together with its insulation.

• Secure the guard plates for the extract air fan and

the heat exchanger with screws at their positions

and close the inspection door. The duct connection

spigots are now ready for connection to ducting.

Dismantle the cover panel on the bottom of the

ventilation unit

How to open the ventilation unit as well as how to

remove the guard plates and heat exchanger are

described in the Section entitled: ”Service”.

• Open the ventilation unit’s inspection door and

remove the heat exchanger guard plates. Withdraw

the heat exchanger from the unit.

• Remove the screws of the guard plate that covers the

duct connection.

• Pull out the cover together with its insulation.

• Push the heat exchanger back into the unit, secure

the guard plate with screws at its position and close

the inspection door.

10

R2.060219

All rights to changes reserved.www.swegon.com

2.4 Electric and control cables

The ventilation unit has a power cable with earthed plug.

The plug serves as the ventilation nit’s main switch and

should be connected to an easily accessible wall socket.

There is a modular cable on top of the ventilation unit

to control the unit. The modular cable for the cooker

hood is located under the cover plate at the bottom

of the ventilation unit. The maximum length of the

modular cable is 40 metres. If you route the modular

cable within a building element, the cable must be

routed in a ∅ 20 mm conduit, bearing in mind any

subsequent cable replacement.

Ensure during the installation of the ventilation unit that

it is easy to access the cable connectors, among others,

for servicing and setting up.

Accessories are either connected to the ventilation

unit’s four-way connector (2 extra functions) or to the

external connection modules (3 extra functions). The

cables are routed through the cable entries that are

inside and on top of the ventilation unit. The connection

of accessories is described in the section “External

connections”. Connection cables to connection modules

and accessories are not included in the supply.

A. Cable entry for accessory cables.

B. Terminal blocks for connection of accessories.

B

A

Important

According to national regulations only a

qualified electrician may carry out electrical

installations.

!

!

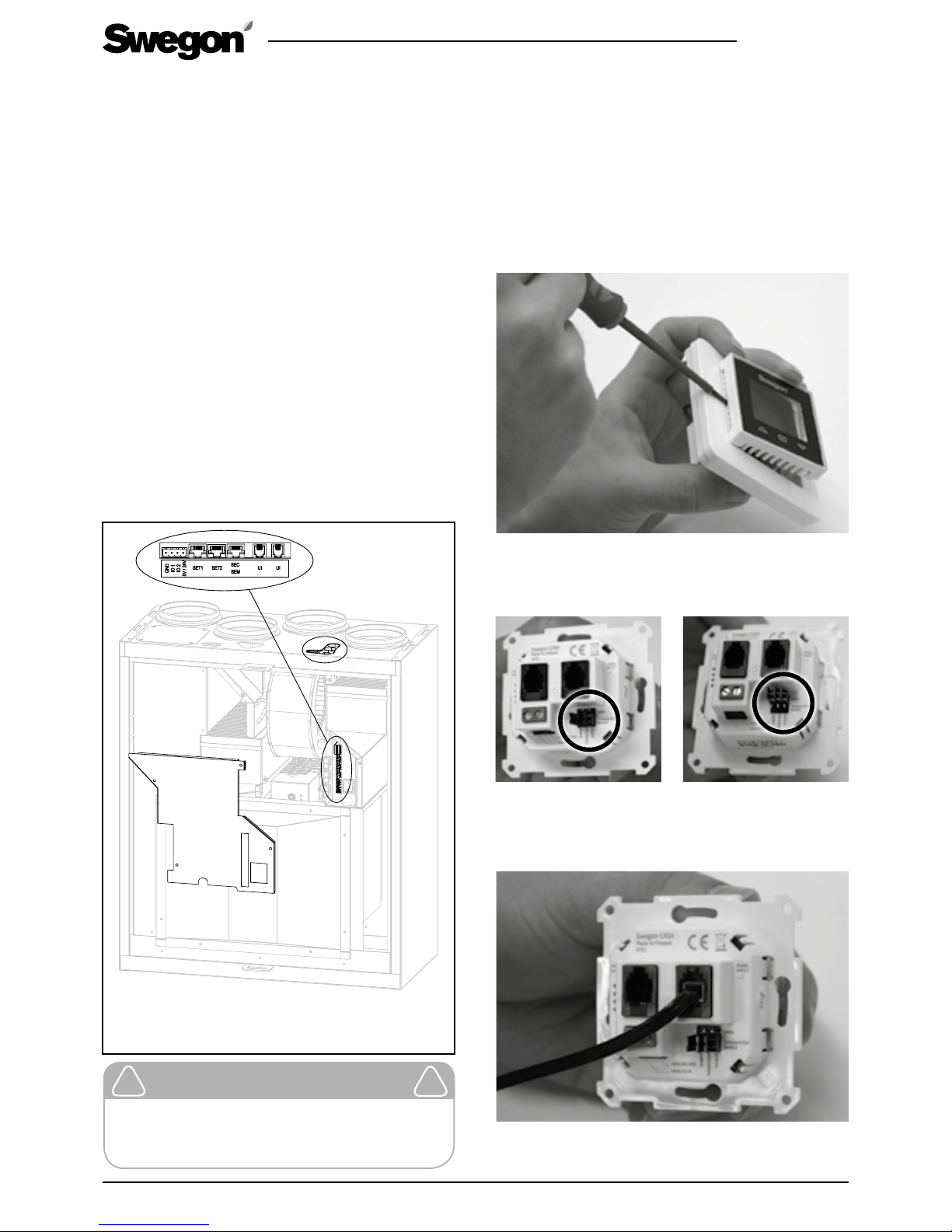

2.5 Installation of the Smart control panel

A maximum of two Smart control panels can be connected to the ventilation unit. These should be configured with different ID numbers (Settings/Display/

Display ID). A Smart control panel can be mounted up

to 40 metres from the unit (using 2 x 20 metre long

modular cables).

The front panel on the Smart control panel is released

using a screwdriver to push the retaining clips through

the holes on either side.

If several control panels are connected in chain, the

middle panel’s bus termination is moved to the “Open”

position. The jumpers do not need to be adjusted if only

one control panel is used.

The modular cable can be connected to any outlet

socket on the panel.

Finally, refit the front panel.

Bus termination: OpenBus termination: Terminated

R2.060219

All rights to changes reserved.

11

www.swegon.com

2.6 Accessories

Installation instructions for accessories are included in

the delivery of the each product.

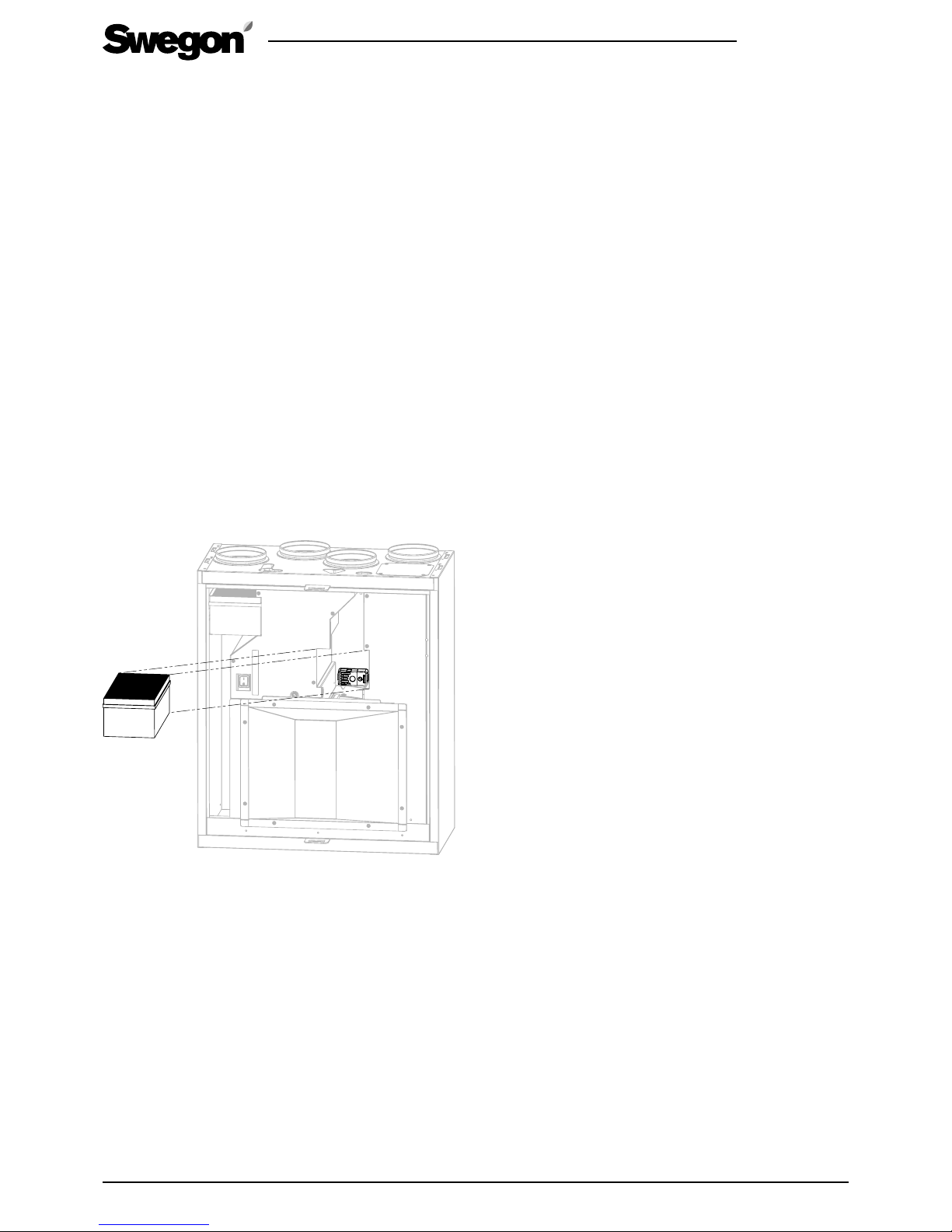

2.6.1 Smart sensor package

Smart Sensor package is a combination sensor:

• Humidity sensor (SRH)

• Humidity and carbon dioxide sensor (SRHCO2)

• Humidity sensor and VOC sensor (SRHVOC).

The ventilation unit has a connection cable for the

sensor package. The sensor package is attached using

the supplied screw. On the R3 ventilation unit, the

installation position for the Sensor package is located

under the extract air filters in the extract air chamber.

The position of the sensor package in the ventilation

unit is shown in the image below. The extract air filter

must be dismantled from the ventilation unit while the

installation is performed.

All sensor combinations are encapsulated in the same

way. If there is a sensor package version installed in the

ventilation unit, you can replace it with an optional

sensor package. See the section Functions and use for

information about the sensor functions.

Loading...

Loading...