Page 1

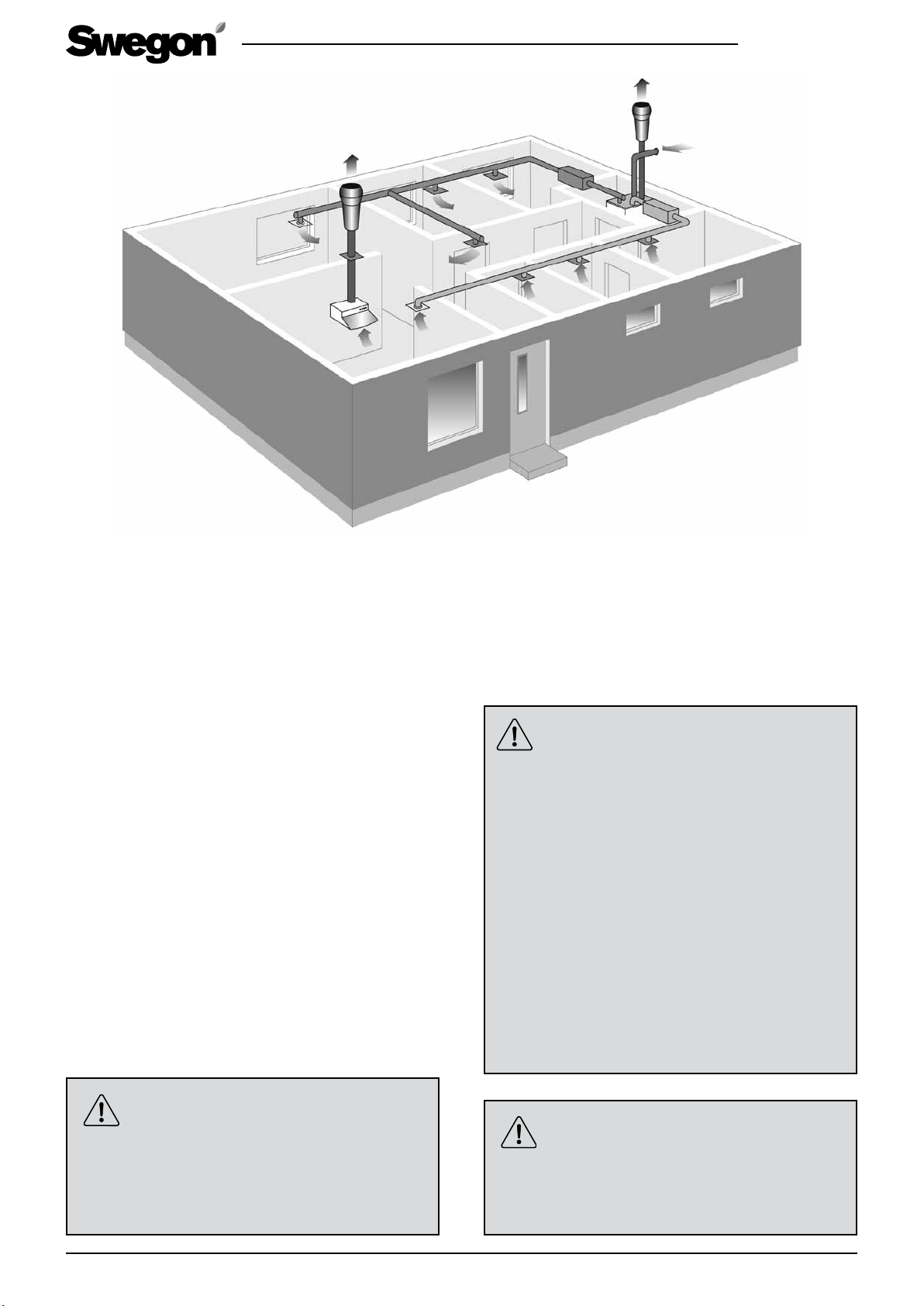

Swegon CASA® R120

Instructions for installation, operation and maintenance

R120_g_EN-m

Page 2

Content

Instructions for Use

For the user

Important information ����������������������������������������� 3

Control from a Premium control panel ����������������� 4

Control from a Premium cooker hood ������������������ 4

To replace the filters ��������������������������������������������� 5

Alarms ����������������������������������������������������������������� 5

Installation, operation and maintenance

R120.211112

For fitters and service personnel

1. Installation instructions ........................................ 6

Important information �����������������������������������������������������������6

1�1 General ����������������������������������������������������������������������������7

1�2 To install the ventilation unit ��������������������������������������������7

1�3 Ceiling installation �����������������������������������������������������������7

1�4 Installation in ceiling mounting frame ������������������������������8

1�5 Condensate discharge ������������������������������������������������������8

1�6 To connect the cooker hood ���������������������������������������������9

1�7 Electric and control cables ������������������������������������������������9

1�8 Ducts ����������������������������������������������������������������������������� 10

1�9 Moisture barrier against cold timber frames �������������������10

2. Operation ............................................................ 11

2�1 Basic functions ��������������������������������������������������������������� 11

2�1�1 Fans ���������������������������������������������������������������������������� 11

2�1�2 Temperature ���������������������������������������������������������������11

2�1�3 Protective functions ����������������������������������������������������11

2�2 Optional items of equipment – automated control system

��������������������������������������������������������������������������������������������11

3. Application .......................................................... 12

3�1 To set the airflows ����������������������������������������������������������12

3�2 Premium control panel ���������������������������������������������������12

3�3 Premium cooker hood ����������������������������������������������������12

3�4 Start menu ���������������������������������������������������������������������14

3�4�1 Fireplace switch function ���������������������������������������������14

3�4�2 Fan speed �������������������������������������������������������������������14

3�5 Main menu �������������������������������������������������������������������� 14

3�5�1 Language ��������������������������������������������������������������������14

3�5�2 Installation and service ������������������������������������������������ 14

3�5�3 Clock �������������������������������������������������������������������������� 14

3�5�4 Summer night cooling� ������������������������������������������������14

3�5�5 Temperature ���������������������������������������������������������������14

3�5�6 Basic display ����������������������������������������������������������������14

3�5�7 To switch off the unit ��������������������������������������������������14

3�5�8 Fireplace switch function ���������������������������������������������14

3�5�9 Weekly timer ��������������������������������������������������������������14

3�5�10 Ventilation unit model �����������������������������������������������15

3�6 Installation and service ��������������������������������������������������� 15

3�6�1 Sensor fault ����������������������������������������������������������������15

3�6�2 Service reminder/alarms ����������������������������������������������15

3�6�3 Clock �������������������������������������������������������������������������� 15

3�6�4 Temperature ���������������������������������������������������������������15

3�6�5 Measurement �������������������������������������������������������������15

3�6�6 Control �����������������������������������������������������������������������15

3�6�7 Fan speeds ������������������������������������������������������������������ 15

3�6�8 To switch off the unit ��������������������������������������������������15

3�6�9 Factory settings ����������������������������������������������������������� 15

3�6�10 Actuators ������������������������������������������������������������������ 15

3�6�11 Functions ������������������������������������������������������������������ 15

3�6�12 Electric air heater ������������������������������������������������������15

4. Servicing .............................................................. 16

4�1 Service reminder ������������������������������������������������������������16

4�2 To open the ventilation unit �������������������������������������������16

4�3 Filter change ������������������������������������������������������������������ 16

4�3 Other servicing ���������������������������������������������������������������16

5. Alarms and troubleshooting .............................. 17

5�1 Alarms ��������������������������������������������������������������������������� 17

5�1�1 Alarms from a Premium control panel �������������������������17

5�2 Troubleshooting: ������������������������������������������������������������17

5�2�1 The supply air is not sufficiently heated ����������������������� 17

6. List of components ............................................. 18

7. Technical data ...................................................... 19

7�1 Sizing �����������������������������������������������������������������������������19

7�2 Wiring diagram, ventilation unit ������������������������������������� 21

7�3 Power consumption ������������������������������������������������������� 21

7�4� Wiring diagram, optional equipment ����������������������������22

7�5 Control diagram ������������������������������������������������������������24

7�6 Dimensions �������������������������������������������������������������������� 25

7�7 Weight ��������������������������������������������������������������������������25

7�8 Optional equipment ������������������������������������������������������� 25

8. Commissioning .................................................... 26

Plant data to be given when requesting service

Project planning

See separate project planning instructions, www�swegon�com�

N.B.! The manual was originally written in Finnish.

2 www�swegon�com

Swegon reserves the right to alter specifications.

Page 3

Instructions for Use

Important information!

R120.211112

Airflows

The air in the home should be changed at a

continuous and sufficient rate to ensure a pleasant indoor climate and avoid damage to building

elements caused by dampness� The ventilation

unit should be stopped only while service work

is in progress�

The airflow from the ventilation unit can be

controlled to generate the various airflows from

a Premium control panel or a Premium cooker

hood�

• Away = a low airflow, which can be utilized

when no one is in the home and there is no

need for the same ventilation that is normally

in use, e�g� for moisture-removal�

• Home = normal airflow�

• Boost = a high airflow, used in connection

with cooking, taking a sauna bath, showering,

drying laundry and similar activities�

The Away/Home operating modes and the temperature of the supply air can be controlled with

the ventilation unit’s built-in weekly timer; however the operating mode can always be changed

from the Premium control panel or the Premium

cooker hood�

A low airflow when the home is unoccupied

means economical operation� This saves on fan

energy and the home heating system does not

have to heat as much air during the cold season�

The most important function of the ventilation system is to ensure that the indoor

air will be continuously fresh and to remove impurities and moisture from the air.

You should therefore make an appraisal of

whether a low airflow is sufficient while the

home is unoccupied. The low airflow mode

must absolutely not be used when someone

is in the home.

If the load on the home is greater than

you’ve anticipated, then you should increase

the normal airflow to a correspondingly

higher rate.

Drying laundry

A tumbler dryer of extract air type or a drying

cabinet must not be connected to the system

due to the high moisture content in the air leaving them� We recommend a condensing tumbler

dryer without duct connection�

Freeze protection

During periods of cold weather, the heat exchanger is liable to freeze if the extract air is

humid� A protective function then automatically

reduces the speed of the supply air fan� Under

such conditions, variations in the fan speed are

therefore normal�

Filters

The ventilation unit must not be operated without filters� Use only filters recommended by

Swegon in the ventilation unit�

Commissioning

The ventilation should not be commissioned until

all work that produces large quantities of grinding dust or other impurities has been completed�

Swegon reserves the right to alter specifications.

www�swegon�com 3

Page 4

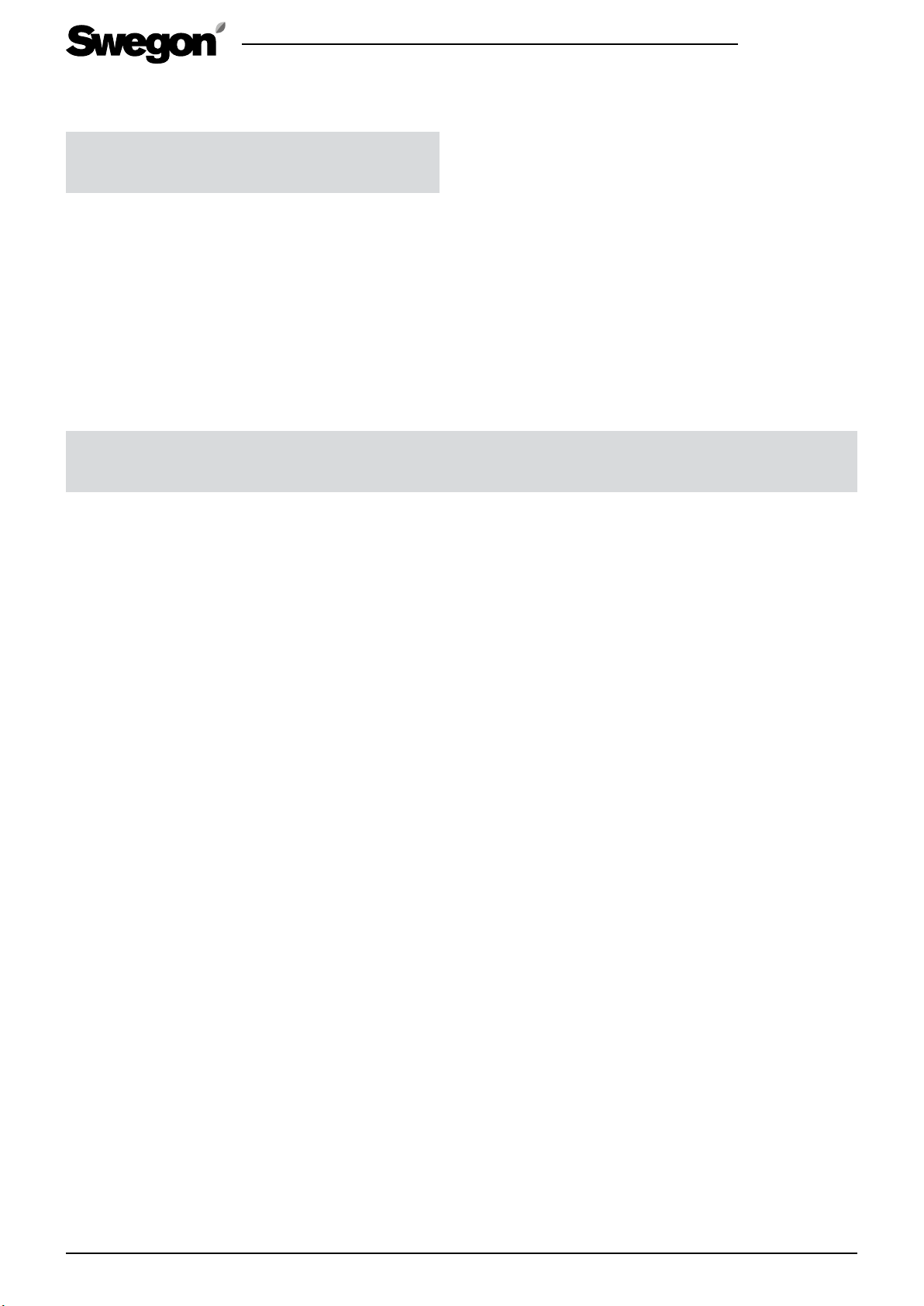

Control from a Premium control panel

When the power is switched on, the ventilation unit

starts up in the Home operating mode� The start time

is approx� 1 minute� After that, the control panel can

be used� Likewise after a power failure, the ventilation

unit starts up in the Home operating mode, if the power

failure has cleared the memory�

The functions of the push buttons are described in the

image to the right�

R120.211112

Fireplace switch function

The speed of the extract air fan decreases and the speed

of the supply air fan increases for a few minutes� This

produces excess pressure in the home and in this way

"creates" an updraught in the chimney, which makes it

easier to light the log-fire�

Selection of fan speed

The fans inside the unit can be controlled to operate at

three speeds: Home/Away/Boost� Select the required fan

speed from the control panel�

You can select an airflow boost time of 30, 60 or 120

minutes, or continuous boosted airflow�

The operating mode can be manually changed, even

when the fan speed is controlled by the weekly timer�

Menu/Installation and service

You can enter settings that affect the operation and

functions of the ventilation unit from the Installation

and service menu and submenu� You should normally

enter these settings when you install the ventilation sys-

tem� The settings are described in Sections 3�5 and 3�6�

Signal lamp

The indicating lamp on the control panel indicates the

functions and alarms of the ventilation unit with various

colours� This is described in Section 5�

Signal lamp

Fireplace switch function

Return to previous menu

level

Move to the left

Menu structure

Selection of fan speed

Move upward/downward

Entering values

Fireplace switch

function

Installation and service

(See Section 3.6)

Menu

Move to the right

Setting function

Start menu

Fan speed

Menu

(See Section 3.5)

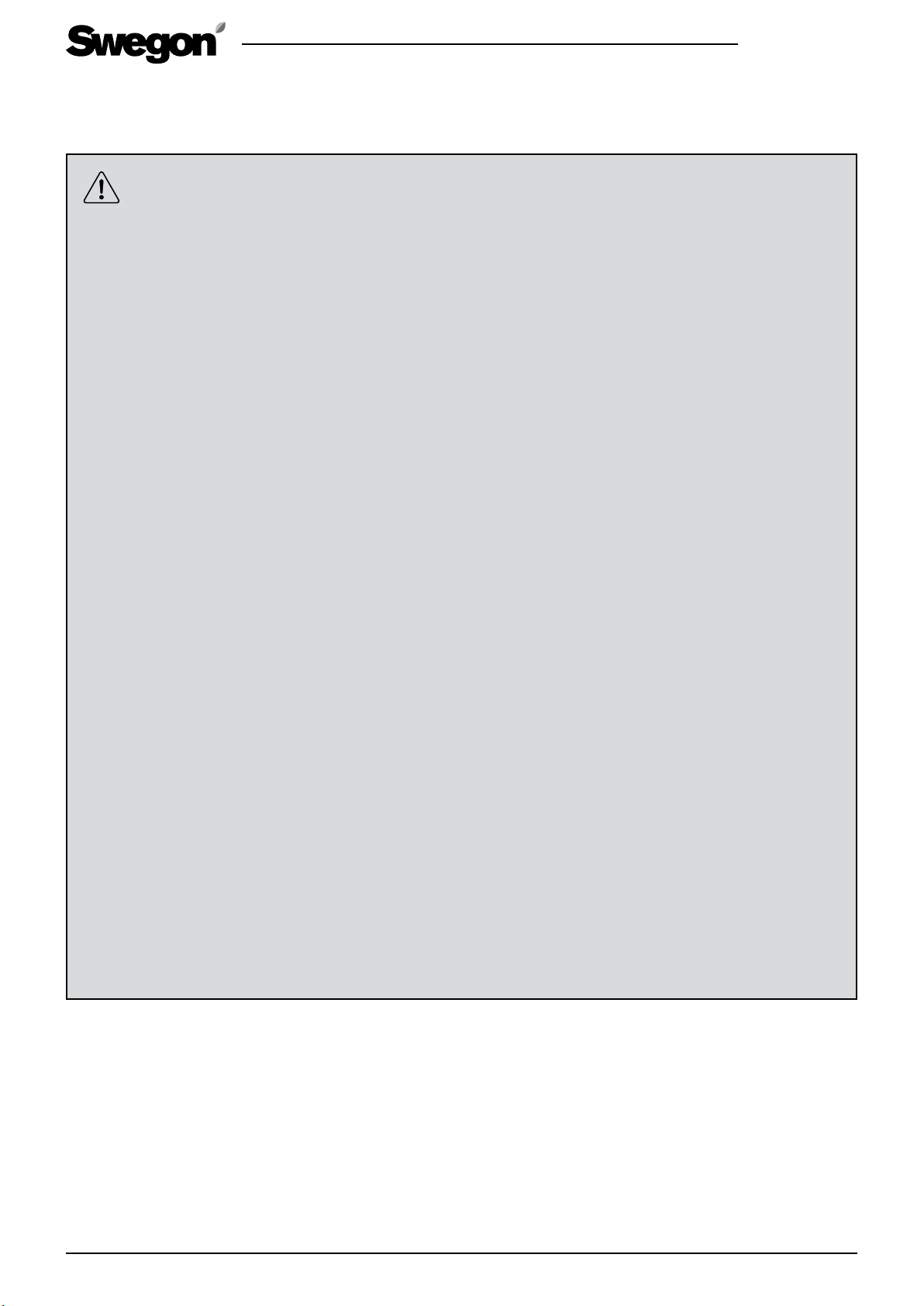

Control from a Premium cooker hood

The ventilation unit fan speeds and other settings

should be entered via the Premium control panel� When

you have entered these settings, the functions below

will be available from the cooker hood control panel�

• The cooker hood damper� When preparing food or

carrying out a similar activity, a 30, 60 or 120 minute

damper-open period can be selected� One single

press of the button will change the setting to the

next damper-open period� The fourth press of the

button cancels the setting and closes the damper�

• The cooker hood lighting� On/Off�

• The ventilation unit fan speed� The fans inside the

unit can be controlled to operate at three speeds:

Away/Home/Boost� One single press of the button

will increase the fan speed one step� The period for

the boost speed is preset to 60 minutes, after which

the ventilation unit will return to normal airflow�

4 www�swegon�com

Control of the cooker hood shutoff damper

Indication: 30/60/120 min�

The control panel of the Premium cooker hood

Lighting Ventilation unit fan speed

Away, home, boost

Swegon reserves the right to alter specifications.

Page 5

R120.211112

To replace the filters

The home owner can change the fil-

ters himself or herself. Other service work

must be carried out by qualified service

personnel.

Extract air filter

The filter should be cleaned every six months and should

be replaced at least once per year� It may be necessary

to clean or replace the filter more often in homes where

there is considerable dust�

Supply air filter

The filter should be cleaned every six months and should

be replaced at least once per year� If the air is highly

polluted, e�g� due to heavy traffic, the filter should be

replaced more often�

Service reminder

The ventilation unit’s control system is normally preset

for displaying a service reminder every six months� This

time setting can be changed by qualified service personnel�

The locations of the filters in a ventilation unit in

the right-hand version.

The locations of the filters are mirror-inverted in a

ventilation unit in the left-hand version.

Wide-meshed filters

and fine filter

Fine filter

Alarms

Alarms from a Premium control panel

• The indicating lamp is flashing red: The automated

protection system has stopped the fans due to a

malfunction� The alarm text is shown in the display�

Contact service!

• The indicating lamp is lit with a steady red glow:

Alarm or a service reminder� The alarm text is shown

in the display� Contact service!

• The indicating lamp indicates certain unit functions

with other colours� See Section ”3�2 Premium control

panel”

The ventilation unit must not be op-

erated without filters!

Use only filters recommended by Swegon

in the ventilation unit.

Find the correct filters in Section 6.

List of components

.

Swegon reserves the right to alter specifications.

www�swegon�com 5

Page 6

1. Installation instructions

Important information!

R120.211112

Qualified personnel only

The installation work, the entering of settings

and commissioning should be carried out by

qualified personnel only�

Standards and requirements

The pertinent national standards and regulations dealing with installation, the entering of

settings and commissioning must be followed if

the equipment is to operate correctly�

You will find the document entitled “Project

design instructions for ventilation” at the web

address www�swegon�com/casa, in which

requirements on electric power, noise, airflows

and duct systems are presented� Each country

has specific national requirements which must

be observed�

Right-hand or left-hand version

Check whether the ventilation unit has been

supplied in the right-hand or left-hand version

to make certain that you are connecting the air

ducts to the correct duct connection spigots on

the unit� See also the dimensional drawings in

Section 7, Technical data�

Drying laundry

A tumbler dryer of extract air type or a drying

cabinet must not be connected to the system

due to the high moisture content in the air leaving them� We recommend a condensing tumbler dryer without duct connection�

The covered duct connection spigots

The duct connection spigots of the ventilation

unit must be covered by lids during transport,

storage and installation�

Filters

The ventilation unit must not be operated

without filters� Use only filters recommended by

Swegon in the ventilation unit�

Commissioning

The ventilation should not be commissioned

until all work that produces large quantities

of grinding dust or other impurities has been

completed�

6 www�swegon�com

Swegon reserves the right to alter specifications.

Page 7

1.1 General

You can install the ventilation unit in a scullery, storage space, attic, etc� If the ventilation unit is located

in a cold space, it should be have thermal insulation, if

required�

The ventilation unit conforms to enclosure class IP 44

when the cover is closed�

Connect the extract air from the Premium cooker hood,

if the need arises, via a duct to the extra duct connection spigot on the top side of the ventilation unit�

Otherwise, blank off the connection spigot�

To make it easier to lift the ventilation unit, the inspection cover can be removed and the heat exchanger

can be dismantled from the unit� The fans can also be

removed if necessary� See Section 4, Service�

1.2 To install the ventilation unit

Secure the ventilation unit to the wall using the wall

mounting bracket supplied with the unit�

R120.211112

Horizontal stud for the ventilation unit’s mounting bracket

Acoustic insulation

On delivery, the package containing

the wall mounting bracket is inside the

bypass duct.

The ventilation unit should not be secured to a

wall that borders to a living room or a bedroom.

If the wall is composed of vertical studs and building

boards, the wall must be reinforced with horizontal

studs to enable it to support the weight of the unit�

Swegon also recommends that the wall be insulated

with mineral wool or similar insulation for preventing

sound from propagating to other rooms�

Secure the mounting bracket horizontally to the wall

with screws, using a suitable means of anchoring that

can support the weight of the ventilation unit�

Lift the ventilation unit into place, so that the wall

bracket tips engage into the corresponding slots on the

backside of the ventilation unit�

Make sure that the electric and control cables are

visible. See also Section 1.7 Electric and control

cables.

Wall mounting bracket’s dimensions

Horizontal reinforcement

Wall mounting bracketInsulated wall

The ventilation unit can also be mounted in a mounting

frame on the ceiling� See Optional Equipment�

1.3 Ceiling installation

Fasten the ceiling mounting frame with four M8 threaded rods in the ceiling anchor sleeves so that at least

three of the threaded rods are aligned with the corners

of the ceiling mounting frame� To avoid a possible collision with the ducts, one of the threaded rods can be

located in the hole next to the corner� Screw in the M8

nuts onto the threaded rods to such a height that the

Swegon reserves the right to alter specifications.

The points on the locking hooks on

the edge of the ceiling mounting frame

should be bent back.

The bottom of the ceiling mounting frame

should be positioned approx. 15 mm below the ceiling surface. If ceiling moulding

is fitted around the frame, it should be

mounted after the unit has been installed.

www�swegon�com 7

Page 8

R120.211112

ceiling mounting frame will be horizontal when the top

of the frame goes against the nuts� Fit the mounting

frame through the selected holes against the nuts on

the threaded rods and lock the frame into position with

nuts from below� The ends of the threaded rods are permitted to stick out max� 3 cm from the ceiling mounting

plate� If they stick out farther, they will protrude against

the unit’s upper casing section�

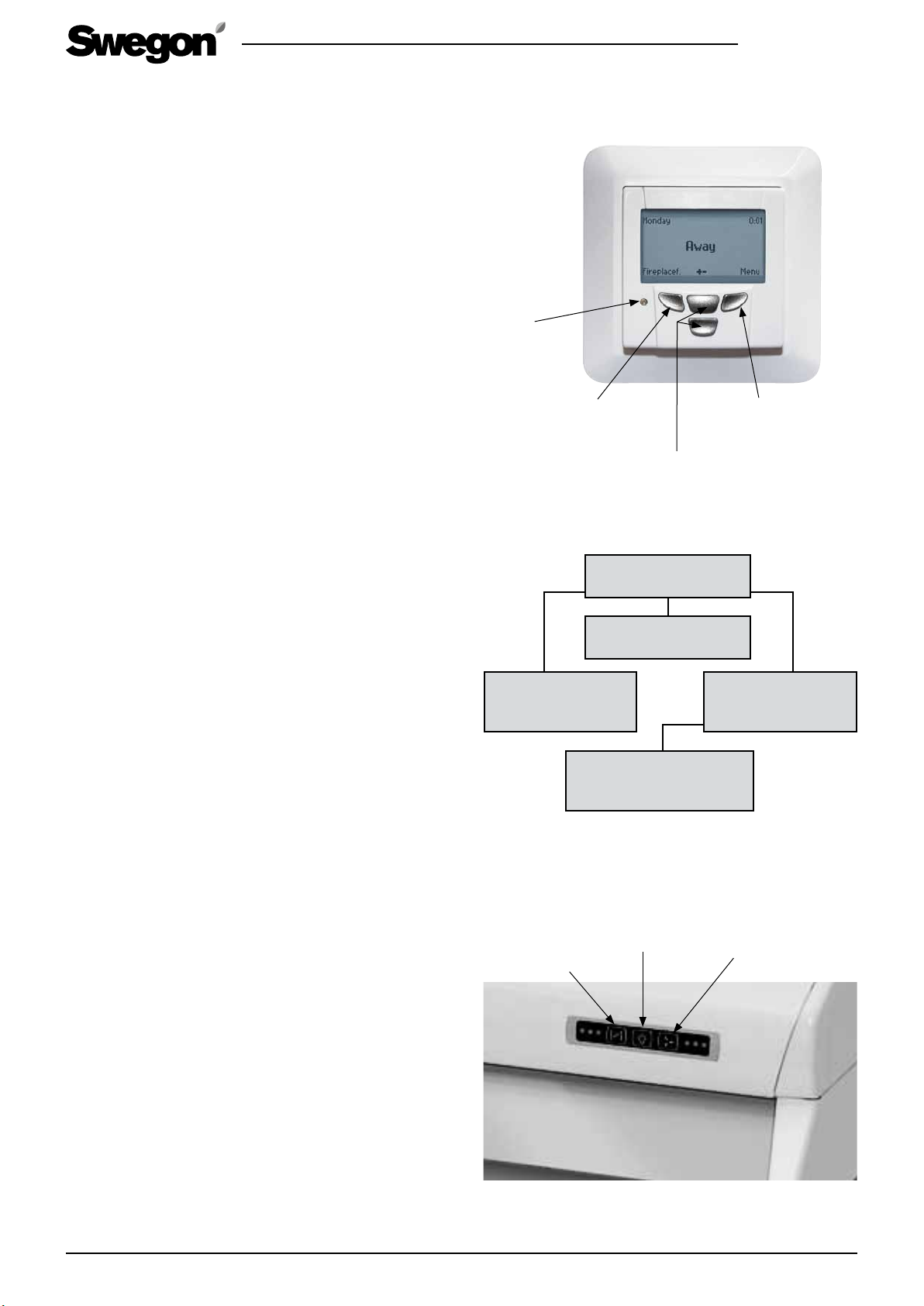

1.4 Installation in ceiling mounting frame

Run the power supply and data cable through the ceiling mounting frame before you lift the unit into position� Lift the ventilation unit into the ceiling mounting

frame so that all four locking hooks will fit correctly in

the notches at the top of the unit� The locking hooks

have two catches; the lower one locks the unit to

facilitate connection to the ducts and the wiring of the

electric cables� When the unit is at the correct position

in relation to the duct and the electric cables have been

run inside the unit, lift up the upper catches� When

the catches are locked the screws of the upper section

spring out� Finish by ensuring that the ventilation unit is

mounted at its location by tightening the screws in the

upper casing section�

Make sure that no wires

or the like come to rest

between the ventilation

unit and the mounting

bracket.

The R120 lifted up on

the lower catches.

Lock the R120 into

place by tightening

the screws in the front.

1.5 Condensate discharge

As a rule, no condensate discharge is needed under dry

ambient conditions and in combination with a rotary

heat exchanger� A certain amount of humidity load is

common in homes� If substantial moisture is produced

in the home, connect the ventilation unit’s condensate

drain connection to discharge piping�

Connect the condensate discharge hose to the condensate discharge connection of the unit (3/8”, Male

threads)� The condensate must be channelled to a floor

gulley, the water trap of a sink or the equivalent by

means of a stiff hose or a pipe having an inner diameter

of at least 12 mm� The water must not be led away

directly to the sewer�

Vertically mount the water trap on the hose supplied

with the unit and fill it with water� The hose must not

have a second water trap or be run horizontally� The

damming height of the water trap should be at least

100 mm�

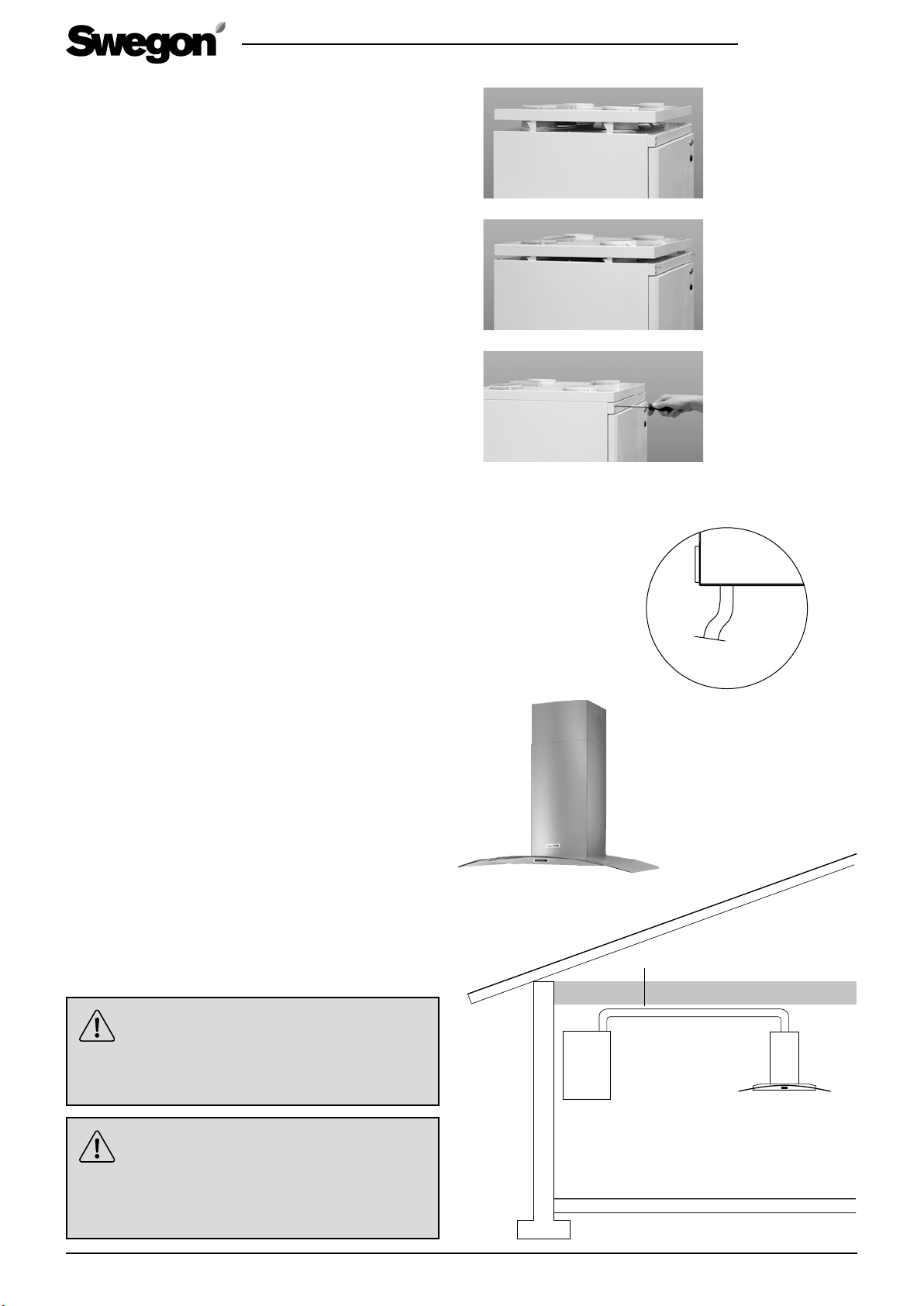

Do not use the cooker hood for basic

kitchen ventilation; use it only when you

prepare food.

Condensate discharge

Ø 125 mm

The electric and control cables of the

ventilation unit are located on the top side

of the unit. Make sure that the electric cable can be connected to a wall outlet.

8 www�swegon�com

Swegon reserves the right to alter specifications.

Page 9

1.6 To connect the cooker hood

Connect a duct from the cooker hood duct connection spigot to the connection spigot on the top side

of the ventilation unit, which is intended for separate

extract air and which conveys the air to bypass the heat

exchanger�

The duct between the cooker hood and the ventilation

unit must be mounted in such a way that makes it possible to clean it�

R120.211112

If the bypass from the kitchen is not used, the outlet

spigot must be blanked off�

1.7 Electric and control cables

The unit has an earthed plug contact for connection to

the mains power� The mains plug serves as the ventilation unit’s main switch and it should be connected to an

electric socket at an easily accessible spot�

The room unit is equipped a 1�5 m long cable with plugin contact, installed from the topside of the ventilation

unit� Arrange the wall outlet at an easy-to-reach location� For power requirement particulars, see Section 7,

Technical data�

Connect the ventilation unit to the Premium control

panel via a modular cable� Install the Premium control

panel at a place of your choice� Two modular cables are

included in the supply: one approx� 3 m long cable and

one 20 m long cable�

When installing the unit, make sure that you provide

adequate access to the connector of each cable (loose

ones as well), e�g� for servicing and adjusting the unit, if

and when the need arises�

The diameter of the modular cable wiring tube should

be 20 mm�

To dismantle the front plate on a Premium control panel.

To connect the modular cable. The extra contact is used for

connection of an extra control panel.

The electric and control cables are

located on the top side of the ventilation

unit. Make sure that the electric cable can

be connected to a wall outlet without obstruction.

The connection of possible optional equipment is

described in the wiring diagram in Section 7, Technical

data� The cables for the optional items of equipment are

not included in the supply�

If you lengthen the modular cable

within some building element (e.g. in a

wall), you should lengthen the cable in a

20 mm dia. conduit, anticipating a possible

later change of cabling.

Swegon reserves the right to alter specifications.

www�swegon�com 9

Page 10

R120.211112

1.8 Ducts

Install the air ducts, sound attenuators, supply air diffusers, air intake grilles and exhaust air ducts as shown in

the ventilation drawings� To prevent the propagation of

sound, do not install the ducts directly against structural

building elements�

Insulate the air ducts in order to reduce loss of heat or

cooling energy and to prevent water from condensing

on surfaces�

In general, ventilation ducts are insulated in the following manner:

• Outdoor air ducts are insulated in warm spaces and

in attics that are used�

• Exhaust air ducts should always be insulated in accordance with national regulations� See separate project planning instructions (for example Fire resistance

classification requirements)�

• Insulate supply air ducts in cold spaces�

• Insulate extract air ducts in cold spaces�

• If the air inside the duct is colder than the air in the

surroundings, the insulation should be protected by

a moisture barrier (e�g� outdoor air and exhaust air in

interior spaces, or chilled supply air)�

1.9 Moisture barrier against cold timber

frames

It is important that the moisture barrier between cold

stud work and the warm ceiling maintains its tightness

at duct penetration points� A duct penetration piece

(optional extra) will facilitate this�

The thickness of the insulation and

the nature of the surface layer of the ventilation ducts vary depending on insulation

material, climate zone and national standards in force. For this reason, Swegon does

not offer any general recommendations.

Most manufacturers of insulation material

offer calculation programs for the calculation of sufficient and correct insulation.

In renovation projects, it is advisable to

examine the existing ducts to determine

whether they are sufficiently and correctly

insulated.

It is essential that the ventilation

ducts are clean in order for the ventilation

unit to operate as it should. The ventilation ducts should be cleaned regularly

and always when the home is renovated.

10 www�swegon�com

Insulating in the right way is necessary for

the ventilation unit to operate correctly.

When the freeze protection function

is activated, you cannot change the ventilation unit fan speeds from the control

panel.

Swegon reserves the right to alter specifications.

Page 11

R120.211112

This item is available in sets of 5 for size 100, 125 and

160 mm dia� ducts� It can be fastened with tape in the

moisture barrier�

We recommend the use of a mounting frame (optional

extra) for sealing the moisture barrier in the attic tie

beams�

Cut up the openings with approx� 10 mm smaller

diameter than that of the ducts� Secure the mounting

frame in the ceiling with screws through the holes on

the sides� The plastic film of the moisture barrier should

either be stretched and fastened between the mounting

frame and the structural element of the building, or be

taped tightly against the mounting frame�

2. Operation

2.1 Basic functions

How to activate and set the functions is described in

Section 3, Application.

2.1.1 Fans

The fans can be controlled to different operation modes

from a control panel or a Premium cooker hood�

• Away = a low airflow, which can be utilized when no

one is in the home and there is no need for the same

ventilation that is normally in use, e�g� for moistureremoval�

• Home = normal airflow�

• Boost = a high airflow, used in connection with cook-

ing, taking a sauna bath, drying laundry and similar

activities�

The Away/Home operating modes are controllable with

the ventilation unit’s built-in weekly timer; however the

operating mode can always be changed from a Premium control panel (or from the control panel on a cooker

hood�

The airflow boost time can be selected manually to 30,

60 or 120 minutes, or for continuous boosted airflow,

from a Premium control panel� When the unit is controlled from a Premium cooker hood, the fan’s boost

time is 60 minutes and the time that the damper is open

can be selected to 30, 60 or 120 minutes�

2.1.2 Temperature

The user sets the desired temperature, and the ventilation unit then strives to reach this temperature if

possible� In general, the user should set a temperature

between 13 and 20 °C� The temperature should be

lower than the room temperature, so that the supply air

will thoroughly mix with the room air� Note that a high

temperature setting will increase the ventilation unit’s

consumption of electric power� The factory-preset supply air temperature is 17 °C�

When the heat exchanger’s heating capacity is insufficient for reaching the preset supply air temperature, the

speed of the supply air fan will decrease and the supply

air temperature will rise� The fan will stop if the supply

air temperature drops despite this measure�

If there is an electric air heater inside the ventilation

unit, it will be activated when the heat exchanger’s

heating power is insufficient, and the air heater will

strive to reach the supply air temperature setting� If no

heating is required, the air heater can be switched off

from a Premium control panel�

The function for summer night cooling can be used

for utilising the cool night air to cool down the home�

The automatic function for summer night cooling stops

the rotary heat exchanger when heat recovery is not

needed� The heat exchanger starts up and makes use of

the extract air if the indoor air is cooler than the outdoor air� The limit values of the function are adjustable

from a Premium control panel�

2.1.3 Protective functions

The electric air heater has two protective functions�

One automatic excess temperature cutout switches off

the air heater if a fault situation arises� This protective

function automatically resets itself when the air heater

has cooled down�

The excess temperature cutout with manual reset can

be reset by pressing a button inside the ventilation unit�

The location of the button is marked in the adjacent

illustration� The excess temperature cutout is reset when

you sense a click on pressing the button�

The heat exchanger is equipped with a freeze protection� The speed of the supply air fan decreases when

cold weather involves risk that the heat exchanger will

freeze� If the supply air temperature drops further, the

controller switches off the supply air fan� This protective

function automatically resets itself when the temperature rises�

The fans have a thermal overload cutout, which stops

them if the temperature rises too high� The controller

also stops the fans if a serious malfunction occurs in the

ventilation unit� The protective function resets itself automatically when the temperature drops or the malfunction has been remedied�

2.2 Optional equipment – automated

control equipment

How to activate and set the functions is described in

Section 3, Application. The connection of optional

equipment is described in the wiring diagram in Section

7, Technical data.

The optional items of equipment can be used

for achieving the type of control required in the following way:

• Boost timer. The boosted operation mode can be

switched in from a control panel or a Premium cooker

hood� A separate boost timer (push button) can be

installed in another place, e� g� in a sauna, bathroom,

scullery, etc�

• Humidity sensor. Detects whether a preset limit

Swegon reserves the right to alter specifications.

www�swegon�com 11

Page 12

R120.211112

value, e�g� 60 % relative humidity (RH), is exceeded

and switches the fan to operate in the boosted flow

mode� It can be placed in a sauna, a bathroom, a

scullery, etc� The sensor voltage is 24 V DC�

• Separate fireplace switch. The function can be

switched in from a control panel or a Premium cooker

hood� A separate fireplace switch (push button) can

be installed in another place, e� g� next to an open

fireplace� The speed of the extract air fan decreases

and the speed of the supply air fan increases for a

few minutes� This produces excess pressure in the

home and in this way "creates" an updraught in the

chimney, which prevents smoke from entering the

room when you light the log-fire�

• Occupant detection sensor. The sensor detects

movement in the home and increases the fan speed

to the Home value�

• Carbon dioxide sensor. It is suitable for use when-

ever the number of occupants varies� The sensor

increases the fan speed to the Boost value, when a

preset maximal value is exceeded, e�g� 900 ppm�

• Negative pressure compensation. Negative pres-

sure arises in the home when a separate cooker hood

or central vacuum cleaner is used, since the extract

airflow becomes substantially higher than the supply

airflow� A separate sensor (e�g� one that senses the

difference in pressure) can transmit a signal to the

controller to increase the supply air flow from the

ventilation unit to restore balance�

• Supervision (DDC). Certain functions can be con-

trolled from the automated building management

system of the building� See the connection schedule

for optional items of equipment in Section 7, Technical data�

• Home/Away switch.

from a cooker hood, generally have a separate Home/

Away switch (optional extra) by the front door� The

switch starts the Away function in the ventilation unit�

The switch can be a standard switch of optional type�

See Section 7�

For example, systems controlled

3. Application

3.1 To set the airflows

The home should have continuous air change to ensure

a pleasant indoor climate and avoid damage to building

elements due to humidity� The ventilation unit should be

stopped only while service work is in progress�

The airflows should be set according to the ventilation

plan and applicable regulations� For estimated values,

use the sizing curves in Section 7, Technical data� A

qualified person should set the ventilation unit’s and the

ventilation equipment’s airflows using appropriate measurement equipment�

A low airflow when the home is unoccupied means

economical operation� This saves on fan energy and the

home heating system does not have to heat as much

air during the cold season� An assessment of whether a

low airflow is sufficient for removing emissions, moisture, etc� from the air should be made�

3.2 Premium control panel

When the power is switched on, the ventilation unit

starts up in the Home operating mode� The start time

is approx� 1 minute� After that, the control panel can

be used� Likewise after a power failure, the ventilation

unit starts up in the Home operating mode, if the power

failure has cleared the memory�

The functions of the push buttons are described in the

image�

The indicating lamp on the control panel shows the various functions of the ventilation unit in different colours�

1� Steady green glow: The ventilation unit is operating

normally�

2� Flashing green glow: The freeze protection has been

activated�

3� Orange flashing glow: The electric air heater has been

activated� (Reheating is optional equipment�)

12 www�swegon�com

4� Flashing red glow: The automated protection system

has stopped the fans due to a malfunction�

5� Steady red glow: Alarm or a service reminder�

3.3 Premium cooker hood

The ventilation unit fan speeds and other settings

should be entered via the Premium control panel� When

you have entered these settings, the functions below

will be available from the cooker hood control panel�

• The ventilation unit fan speed� The fans inside the

unit can be controlled to operate at three speeds:

Away/Home/Boost� One single press of the button

will increase the fan speed one step� The period for

the boost speed is preset to 60 minutes, after which

the ventilation unit will return to normal airflow�

• The cooker hood damper� When preparing food or

carrying out a similar activity, a 30, 60 or 120 minute

damper-open period can be selected� One single

Swegon reserves the right to alter specifications.

Page 13

R120.211112

press of the button will change the setting to the

next damper-open period�

• The cooker hood lighting� On/Off�

Before commissioning the ventilation

system, check that the ventilation unit, filters and ducts are clean and that there are

no loose objects inside them.

Premium control panel

Signal lamp

Fireplace switch function

Return to previous menu

level

Move to the left

Selection of fan speed

Move upward/downward

Entering values

Menu

Move to the right

Setting function

Control panel, Premium cooker hood

Control of the cooker hood shutoff damper

Indication: 30/60/120 min�

Lighting Ventilation unit fan speed

Away, home, boost

Swegon reserves the right to alter specifications.

www�swegon�com 13

Page 14

R120.211112

3.4 Start menu

3.4.1 Fireplace switch function

The fireplace switch function decreases the extract air

fan speed and increases the supply air fan speed for

approx� 10 minutes� This produces excess pressure in

the home and in this way "creates" an updraught in the

chimney, which prevents smoke from entering the room

when you light the log-fire�

An unnecessary or longterm use of the fireplace switch

function in the wintertime may easily activate the frost

protection function during an unnecessarily long time,

which creates negative pressure in the house and smoke

can be drawn into the house via the chimney� You can

cancel the fireplace switch function by pressing the

fireplace switch function button once again within 10

minutes after you pressed it the first time�

N.B.! The ventilation unit is no source for necessary replacement air while a fire is burning in the

fireplace.

The function is shown in the display only if the value is

On in Menu 3.5.8.

3.4.2 Fan speed

Select the appropriate fan speed� Timer-controlled

airflow boost is available� The operating mode can be

manually changed, even when the fan speed is controlled by the weekly timer�

Menu structure

3.4.1

Fireplace switch

function

3.6 Installation

and service

See next page!

3.4 Start menu

3.4.2 Fan speed

• Away

• Home

• Boost

3.5 Main menu

• Language

• Installation and service

Time switch clock

(timer)

Summer night

cooling

Temperature

Base display

Fireplace switch

function

Switch off

3.5 Main menu

You can enter settings that affect the operation and

functions of the ventilation unit from the menu�

N.B.! A number of functions are available in the

Main menu as well as in the Installation and Service submenu.

From the Montage and service menu, you select whether the function should be used and certain settings�

The function must be activated from the main menu�

3.5.1 Language

Select the appropriate language�

3.5.2 Installation and service

See Section 3�6, Installation and service�

3.5.3 Clock

Select date and time of day�

3.5.4 Summer night cooling.

This function utilises the cool night air to cool down the

home� The rotary heat exchanger stops�

Conditions for start:

• The reheating function is not active�

• The extract air temperature is above 22 °C� The

outdoor temperature is above 16 °C, but at least 1

°C lower than the extract air temperature� It is possible to change the temperature limits and select fan

speeds�

Weekly timer

Unit model

3.5.5 Temperature

Set the desired supply air temperature (factory setting:

17 °C)� The ventilation unit’s heat exchanger and an air

heater, if included, are automatically activated so that

the desired temperature will be reached� The supply air

temperature should be lower than the room temperature,

so that the supply air will thoroughly mix with the room

air� Note that a high temperature setting will increase the

ventilation unit’s consumption of electric power�

3.5.6 Basic display

Basic display 1 is selected when the fan speeds in the

Away/Home/Boost steps are to be changed�

Basic display 2 is selected when the fan speeds are to be

changed in five different steps�

3.5.7 To switch off the unit

The ventilation unit fans, the heat exchanger and an air

heater, if fitted, are stopped� The circuit card is however still energised and the settings are preserved in the

memory�

3.5.8 Fireplace switch function

Select ON as the value for this function, if you wish to

use the function from the control panel display, otherwise select Off� See also 3�4�1 above�

3.5.9 Weekly timer

Four different programs can be selected on the weekly

14 www�swegon�com

Swegon reserves the right to alter specifications.

Page 15

R120.211112

timer, with the Away–Home–Boost fan speeds� Manual

operation from the control panel bypasses (overrides)

the weekly timer functions�

3.5.10 Ventilation unit model

Shows the model of the ventilation unit�

3.6 Installation and service

The menu is can be opened by entering code 1234�

3.6.1 Sensor fault

Contact a service company�

3.6.2 Alarms/Service reminder

The service reminder appears on the screen at six-month

intervals� On completed service, the reminder is set to

zero from the menu and a new period of six months

begins� The time period can be altered from the Functions menu�

Alarms for malfunctions are displayed in the display�

3.6.3 Clock

”On” or ”Off”�

The clock is displayed in the start menu�

3.6.4 Temperature

”On” or ”Off”�

The supply air temperature control function is displayed

in the start menu� Select ON in order to use the function

for setting the supply air temperature, otherwise select

Off� (The models with reheat�)

3.6.5 Measurements

Depending on the accessories connected, the following can be measured: the carbon dioxide content (CO

temperature, pressure differential, the speed of the fans

and relative humidity (RH)�

3.6.6 Control functions

Carbon dioxide content (CO

), supervision (DDC) or

2

timer can be selected as a control means�

3.6.7 Fan speeds

N.B.! The Summer night cooling function should be

deactivated whenever you change the fan speeds.

One of five fan modes (1–5) can be selected for each

operating mode (Away, Home, Boost etc�)�

The various fan mode speeds (expressed as a percentage: 10–100) can then be selected (separate for supply

air and extract air)�

3.6.8 To switch off the unit

The ventilation unit fans, the heat exchanger and an air

heater, if fitted, are stopped� The circuit card is however still energised and the settings are preserved in the

memory�

),

2

3.6 Installation and service

(code 1234)

• Alarm/Service reminder

• Time switch clock (timer)

• Temperature

• Measurements

• Control functions

• Fan speeds

• Switch off

• Factory settings

• Controller

• Functions

• Air heater

3.6.9 Factory settings

All settings except the fan speeds are reset to factory

values�

3.6.10 Actuators

It is possible to select settings for duct equipment, the

valve actuators or circulation air regulation�

3.6.11 Functions

• Select ON as the value for Low pressure compensation, e�g� if the cooker hood has a differential pressure guard in the extract air duct of the cooker hood

for this function, otherwise select OFF�

• Select ON as the value for Service reminder, if the

function is to be used, otherwise select Off� The time

interval (6 months) can be changed�

• Select ON as the value for Summer night cooling, if

you wish to select the function in the menu, otherwise select Off�

• Select On as the value for Heating, if an air heater

is installed, otherwise select Off� The limit value for

high temperature is 50 °C� The temperature can be

changed� Supply air fan ctrl is selected as the control

means, this can be changed to Room controlled�

• Select On as the Fireplace switch function setting,

if a fireplace switch has been installed, otherwise

select Off� The fireplace switch function decreases the

extract air fan speed and increases the supply air fan

speed� The freeze protection works in the reverse

manner: It stops the supply air fan and only allows

the extract air fan to run�

• Select On as the value for Boost, if a boost timer or a

presence detector is installed, otherwise select Off�

3.6.12 Electric air heater

If the ventilation unit has an air heater for reheating,

select the ”In operation” setting� The air heater is not

activated when the outdoor air temperature is above 11

°C� The temperature limit can be changed�

Swegon reserves the right to alter specifications.

www�swegon�com 15

Page 16

4. Servicing

4.1 Service reminder

The ventilation unit’s control system is normally preset

for displaying a service reminder every six months� If

required, this function can be altered in the Installation

and Service menu� From same menu you set to zero the

service reminder after performed service�

4.2 To open the ventilation unit

Isolate the power supply voltage to the ventilation unit

(pull out the mains plug from the wall socket)� Wait a

few minutes before you open the inspection covers on

the ventilation unit, so that the fans will have time to

stop and the air heaters can cool down�

4.3 Filter change

• To open the front inspection cover�

• Wait a few minutes, so that the fans have time to

stop and the air heaters, if fitted, have time to cool

down�

• Change the filters�

• Close the inspection cover�

The filters should be vacuum cleaned every six

months and should be replaced at least once per

year.

R120.211112

The ventilation unit must not be op-

erated without filters!

Use only filters recommended by Swegon

in the ventilation unit.

Find the correct filters in Section 6. List of

components.

The locations of the filters in a ventilation unit in

the right-hand version.

The locations of the filters are mirror-inverted in a

left-hand model.

Wide-meshed filters and fine filter

4.3 Other servicing

To be carried out at least once per year.

• Withdraw the heat exchanger for inspection� If you

withdraw the entire heat exchanger, you must also

disconnect the quick-fit connector� Then remove the

front panel�

Check that the drive belt is not worn� Replace it if it

is worn�

Check that the heat exchanger passages are not

clogged� Clean with a soft brush, vacuum cleaner or

under running water, if needed� If you find it necessary to use detergent, choose one that does not

corrode aluminium� Protect the heat exchanger drive

motor to prevent contact with liquid�

N.B.! The passages of the heat exchanger should

be dry before you refit it.

• Clean the inner surfaces of the ventilation unit, if

needed�

• Check that the condensate discharge outlet is not

clogged and check its outflow by pouring water on

the bottom of the ventilation unit�

Fine filter

16 www�swegon�com

Swegon reserves the right to alter specifications.

Page 17

R120.211112

5. Alarms and troubleshooting

5.1 Alarms

5.1.1 Alarms from a Premium control panel

• The indicating lamp is flashing red: The automated

protection system has stopped the fans due to a

malfunction� The alarm text is shown in the display�

Remedy the malfunction�

• The indicating lamp is lit with a steady red glow:

Alarm or a service reminder� The alarm text is shown

in the display� Remedy the malfunction or perform

service on the ventilation unit�

• The indicating lamp indicates certain unit functions

with other colours� See Section ”3�2 Premium control

panel”

5.2 Troubleshooting:

Eventual malfunctions are shown by alarm texts in accordance with 5�1�1� Investigate the components related

to the malfunction and remedy the malfunction�

5.2.1 The supply air is not sufficiently heated

Low temperature setting for the supply air

Investigate and, if needed, increase the temperature

from the menu�

The electric air heater is faulty (optional equipment)

The air heater has one excess temperature and one

overheating protection functions� The alarm is initiated

in accordance with Section 5�1�1� if either of these are

activated�

the command with the highest priority, e�g� the freeze

protection�

Priority 1: Commands from outer sensor or the ventilation unit’s protective functions�

Priority 2: External supervision (DDC)�

Priority 3: A normal control panel or the operation of

the cooker hood�

Freeze protection

During periods of cold weather, the heat

exchanger is liable to freeze if the extract

air is humid. A protective function then

automatically reduces the speed of the

supply air fan. Under such conditions,

variations in the fan speed are therefore

normal.

The LED on a Premium control panel

flashes green when the freeze protection

is activated.

The over temperature protection resets itself automatically when the temperature decreases� The overheating

protection must be reset by pressing a push button on

the air heater� If you hear a click when you press in the

button, this indicates that the overheating protection

has been reset�

Excessively high temperature may be due to too low an

air flow through the air heater� The cause can be that

a filter, outer wall grille or supply air device is clogged�

Replace and clean, if needed�

Tip: In most models, the outer wall grill has an insekt

net� If the net has small mesh, dust and insects can clog

it� During certain conditions it it is also liable to freeze�

Remove the net or replace it with a net with larger

mesh�

An excessively high temperature can also be due to the

supply air fan having stopped or that the temperature

sensor has been shaken loose from its position in the

fan intake�

Badly isolated ventilation ducts

If the unit emits warm air but the supply air discharged

from the air diffuser feels cold, this may be due to

poorly insulated ventilation duct�

The ventilation unit does not obey commands

If two overlapping commands are issued, the unit obeys

Swegon reserves the right to alter specifications.

www�swegon�com 17

Page 18

6. List of components

R120.211112

Position Component Data Order no.

1 Circuit card 603012

2 Reheating cassette 10212RVM

3 Fan motor G3G146-ED23-06 119 W (R) 60842

3 Fan motor G3G146-ED23-56 119 W (L) 60844

4 Heat exchanger (complete) 61052

5 Modular cable, 20 m PMK20

6 Premium control panel PSP148

7 Temperature sensors

8/9 Set of filters 2 class F7 fine filters

1 class G3 wide-mesh filter

10 Front access panel DR120RL

10212RSS

18 www�swegon�com

Swegon reserves the right to alter specifications.

Page 19

0

50

100

150

200

250

300

350

400

450

500

020406080100 120140

100%

87%

81%

76%

71%

67%

63%

60%

57%

54%

50%

46%

7. Technical data

0

50

100

150

200

250

300

020406080 100 120 140

100%

87%

81%

76%

71%

67%

63%

60%

57%

54%

50%

46%

7.1 Sizing

R120.211112

Supply air

500

100 %

450

400

87 %

350

81 %

300

76 %

250

71 %

67 %

200

63 %

60 %

150

57 %

54 %

Available pressure, Pa

100

50 %

46 %

50

0

0 20 40 60 80 100 120 140

Airflow, l/s

Extract air

Power consumption

Total power consumption, W

Airflow, l/s

Available pressure, Pa

Airflow, l/s

Thick line = SFP 2.0 or lower.

Acoustical performance

Sound emitted to supply air duct

Fan setting

%

54 67 60 55 50 48 42 36 22 54

57 67 63 57 52 51 45 39 27 56

60 67 63 58 53 52 46 41 29 57

63 67 65 60 54 53 48 43 32 58

67 71 66 61 56 55 50 45 35 60

71 72 68 62 57 56 52 46 36 61

76 74 70 64 59 57 54 48 38 63

81 75 71 65 59 57 54 48 40 64

87 77 73 67 61 59 56 50 42 65

100 78 75 69 63 60 58 52 44 67

Swegon reserves the right to alter specifications.

Sound power level broken down into octave bands, L

63

Hz

125

Hz

250

Hz

, dB

wokt

500Hz1000Hz2000Hz4000Hz8000

Hz

Weighted sound

power level,

, dB(A)

L

WA

www�swegon�com 19

Page 20

Sound emitted to extract air duct

R120.211112

Fan setting

%

Sound power level broken down into octave bands, L

63

Hz

125

Hz

250

Hz

500Hz1000Hz2000Hz4000Hz8000

wokt

, dB

Hz

54 64 46 48 43 37 33 23 8 45

57 64 48 49 45 38 34 24 9 46

60 62 58 51 46 39 35 26 11 49

63 64 61 51 48 40 36 27 13 50

67 63 63 53 49 41 38 29 15 52

71 63 63 55 50 43 40 31 17 53

76 66 66 56 52 44 41 32 19 55

81 63 66 57 54 45 42 33 20 55

87 66 68 58 55 46 43 35 22 57

100 66 68 59 55 46 43 35 22 57

Sound emitted to extract air duct of the cooker hood

Fan setting

Sound power level broken down into octave bands, L

%

63

Hz

125

Hz

250

Hz

500Hz1000Hz2000Hz4000Hz8000

54 63 - 49 44 33 31 25 13 45

57 65 - 51 45 34 32 27 15 47

60 63 53 53 46 35 33 28 17 48

63 59 47 53 47 37 35 30 18 48

67 61 59 55 48 37 36 31 20 50

71 64 57 56 49 39 37 32 22 51

76 69 59 57 51 40 39 34 24 53

81 68 61 59 52 41 40 36 26 54

87 66 64 60 52 43 41 37 27 55

100 67 65 61 53 43 42 38 29 56

wokt

, dB

Hz

Weighted sound

power level,

, dB(A)

L

WA

Weighted sound

power level,

, dB(A)

L

WA

Sound emitted to the surroundings

Fan setting

Sound power level broken down into octave bands, L

%

63

Hz

125

Hz

250

Hz

500Hz1000Hz2000Hz4000Hz8000

54 44 46 37 28 23 12 - - 30

57 46 46 38 29 24 13 - - 35

60 46 46 39 30 25 14 - - 35

63 44 47 40 30 26 14 - - 36

67 45 47 42 33 28 17 - - 37

71 44 48 43 34 29 19 10 - 38

76 46 49 44 34 29 20 11 - 39

81 47 50 45 36 32 21 12 - 40

87 49 52 46 37 33 22 14 - 42

100 51 54 48 39 34 24 15 - 43

20 www�swegon�com

wokt

, dB

Hz

Weighted sound

power level,

, dB(A)

L

WA

Swegon reserves the right to alter specifications.

Page 21

R120.211112

7.2 Wiring diagram, ventilation unit

The ventilation unit conforms to enclosure class IP 44�

Excess temperature sensor

Exhaust air sensor

Extract air sensor

Suppy air/frost protection sensor

Control panel

Room air sensor

Supply air sensor

Outdoor air sensor

7.3 Power consumption

Max. total power consumption

Ventilation unit: 250 W, 1�1 A (with optional equipment

800 W, 4�6 A)

Premium Classic cooker hood: 15 W, 0�1 A

Premium Swing cooker hood: 45 W, 0�2 A

Supervision (DDC)

X11 = Supply air fan’s plug contact

X12 = Extract air fan’s plug contact

X21 = Supply air fan’s EC contact

X22 = Extract air fan’s EC contact

X13 = Plug-in contact for heat exchanger motor

Accessories

Air heater with quick-fit con-

nector

800 W

Power supply: 230 V, 10 A

Swegon reserves the right to alter specifications.

www�swegon�com 21

Page 22

CO2 INPUT

TEMP INPUT

G+G0OUT1

OUT2MRelay

Relay

OUT4

G+

G0

OUT1

OUT2

M

Relay

Relay

OUT4

24V AC/DC

C

NC

NO

1

NC

2

3

NO

L

N

230V AC 50Hz

NC

NO

P

N

C

P

2

1

3

2

1

3

105TK

102TKC

117PK2

117HDL

117HDL

102LT

117KHH

105A1

2 x 0,5

2 x 0,5

2 x 0,5

2 x 0,5

2 x 0,5

3 x 0,5

4 x 0,5

5 x 0,5

2 x 1,5

230V AC 50Hz

2 x 1,5

2 x 0,5

2 x 0,5

M

24 VDC 2W (3,5VA)

M

24 VDC 2W (3,5VA)

1

2

3

4

5

6

7

8

9

10

R120.211112

7.4. Wiring diagram, optional equipment

Priority 1: Commands from outer sensor or the ventilation unit’s protective functions�

Priority 2: External supervision (DDC)�

Priority 3: A normal control panel or the operation of

the cooker hood�

Control priority 1

To connect the modular cable.

Control priority 3

To cooker hood,

control panel or

Modbus gateway

To the cooker

hood or the

control panel

1� Fireplace switch

2� Boost timer*

3� Humidity sensor

4� Timer

5� Sensor for negative pressure compensation*

6� CO

7� CO

sensor with relay

2

sensor

2

8� Presence detector

9� Damper actuator for duct damper – A outdoor air

duct**

10� Damper actuator for duct damper – B exhaust air

duct**

22 www�swegon�com

*) Connect any of the functions, negative pressure compensation or boost to the BOOST/COMP contact� One

of the separate functions can also be wired to Input 4

on the DDC wiring terminal row� See DDC�

**) The use of the duct damper should be judged

on the basis of the specific case� The use of the duct

damper is recommended at least in the outdoor air

duct, especially on the Econo models�

Swegon reserves the right to alter specifications.

Page 23

R120.211112

Supervision (DDC)

Control priority 2

• The functions of wiring terminals 2-5 can be activated/deactivated from the control panel service menu�

• The status outputs (terminals 6 and 7) can always be

used

8: 0 V (GND)

7: The supply air temperature actual value: 0-10 V DC

(corresponds to 10–30 °C)

6: Actual value for fan speed: 0–10 V DC

5: The supply air temperature 0-10 V DC control

(corresponds to 10–30 °C)

4: 0–10 VDC fan speed control*

3: Alarm – signal from the ventilation unit

(earthed contact)

2: Emergency stop (if contact between terminals 1-2 is

broken, the ventilation unit will stop)�

1: 0 V (GND)

*) Voltages for fan speed control

Separate function via DDC terminal row

(e.g. Home/Away switch)

The following changes should be made in the functional

parameters of the ventilation unit using the Premium

control panel:

• Change the fan speed in the Boost mode from speed

5 to speed 4 from the menu: Installation and service/Fan speeds/Situations�

• Set the separate supply and extract airflow functions

to speed5 from the menu: Installation and service/

Fan speeds/Speeds�

• Activate control of the fan speed via DDC from the:

Installation and service/Control/DDC/Fan control

system�

Speed 1 = 1–2�9 VDC

Speed 2 = 3–4�9 VDC

Speed 3 = 5–6�9 VDC

Speed 4 = 7–8�9 VDC

Speed 5 = 9–max� 24 V DC

Control priority 3

0-0�9 V DC

Alarm output

max 40V, 500mA

Close = alarm

Open = no alarm

24VDC

max 500mA

A2

Delivery demarcation

DDC CONTROL

1 2 3 4 5 6 7 8

1 2 3 24V P2 P1 0

A1

Closed contact = Activation of

the separate function

Open contact = Normal use

of the separate

function

Swegon reserves the right to alter specifications.

www�swegon�com 23

Page 24

7.5 Control diagram

Group electrical distribution box

Electrical cubicle

Power supply: 230 V, 10 A with

plug-in connection

Modular cable with

RJ9 connector

R120.211112

Control panel

Outdoor

air

G 3

Exhaust air

Supply demarcation of the ventilation unit

The damming height of the

water trap, 100 mm

SYMBOL DESIGNATION EXPLANATION

TC01 TEMPERATURE CONTROLS Electric air reheater temperature thermostat/overhea-

T1 TEMPERATURE SENSOR Temperature sensor, outdoor air

T2 TEMPERATURE SENSOR Temperature sensor, supply air / freeze protection

T3 TEMPERATURE SENSOR Temperature sensor, extract air

T4 TEMPERATURE SENSOR Temperature sensor, supply air

T5 TEMPERATURE SENSOR Temperature sensor, exhaust air

T6 TEMPERATURE SENSOR Excess temperature sensor for the reheating air heater

T8 TEMPERATURE SENSOR Temperature sensor for room air

TZ03 OVERHEATING PROTEC-

TION

HSx�1 MANUAL TIMER SWITCH Control of the fans + cooker hood damper

ting protection

Overheating protection with manual reset

800 W

(optional

equipment)

Supply air

Extract air

Extraction, cooker hood

Kitchen

24 www�swegon�com

Swegon reserves the right to alter specifications.

Page 25

7.6 Dimensions 7.7 Weight

Ventilation unit: 78 kg�

7.8 Optional equipment

• Filter set (1 pc� G3 + 2 pcs� F7

• Premium control panel

• 20 metre long modular cable (an extention contact is

600

60

10

119

supplied with it)�

• Separate extension contact

• Premium Design cooker hoods for separate location

(bypass for kitchen on the top side)

• Roof mounting frame

• Mounting frame with moisture barrier

• Optional equipment for Premium control system (see

Item 2�2)

Each item of optional equipment is supplied with its

own instructions for use�

R120.211112

604

597

598

126

457

108

Model R Model L

5

2

1

1 2 3 4 5

Supply air

Ø 160

Extract air

Ø 160

4

3

119

299

479

Duct Connections

Outdoor air

Ø 160

Exhaust air

Ø 160

4

Separate

extract air

Ø 125

5

2

13

Wall mounting bracket

Swegon reserves the right to alter specifications.

www�swegon�com 25

Page 26

R120.211112

8. Commissioning

Operation Factory setting Setting value

Temperature, supply air

Base display 1

Time switch clock (timer) On

Temperature On

Fan speeds (situations)�

Away 1

Home 3

Boost 5

Cool off 4

Cooling 4

Heating 3

Fan speeds

Speed 1, supply air fan 40 %

17

°C

Speed 1, extract air fan 60 %

Speed 2, supply air fan 65 %

Speed 2, extract air fan 65 %

Speed 3, supply air fan 75 %

Speed 3, extract air fan 75 %

Speed 4, supply air fan 85 %

Speed 4, extract air fan 85 %

Speed 5, supply air fan 100 %

Speed 5, extract air fan 100 %

Negative pressure compensation Off

Service reminder On

Interval 6 months

Summer night cooling On

Start temperature (in start menu)

Fan speed (in start menu) No change

neutral zone (in Installation and service menu)

Temperature limiting (in Installation and service menu)

Heating Off

22

1

16

°C

°C

°C

Temp� limitation

Control Supply air controlled

Filter guard

Fireplace switch function (with fireplace switch) Off

Boost (with extra timer or presence detector) On

Input, heat exchange limit

Min� temperature 11 °C

Neutral zone 3 °C

Outdoor temperature limit, for activation of air heater 10 °C

26 www�swegon�com

(Not available for R120)

50

°C

On

Swegon reserves the right to alter specifications.

Page 27

R120.211112

Airflows Project planning values Setting value

Supply air, total l/s l/s

Away

Home

Boost

Extract air, total l/s l/s

Away

Home

Boost

N.B.! All the fan modes should be preset.

Other comments

Data for the ventilation unit

Write down the unit-specific data here (on the identification plate of the ventilation unit) for use when you contact a

service company�

Preset by: Date:

Remember to explain the use of the item of optional equipment and how to ser-

Swegon reserves the right to alter specifications.

vice it to the user/caretaker!

www�swegon�com 27

Page 28

R120.211112

Guarantee Conditions

GUARANTOR

Swegon ILTO Oy

Asessorinkatu 10, FI-20780 S:t Karins�

GUARANTEE PERIOD

The product has a two (2) year guarantee as from the date of purchase�

SCOPE OF THE GUARANTEE

The guarantee covers defects that have arisen during the guarantee period, which have been reported to the manufacturer, or been

declared by the guarantor or a representative of the guarantor, and which refers to design, manufacture or material defects as well

as consequential defects that have arisen on the product itself� The above mentioned defects are to be cleared by putting the product in working order�

GENERAL GUARANTEE LIMITATIONS

The guarantor’s guarantee liability is limited in accordance with these guarantee conditions and the guarantee does not cover damages to property or personal injury� The guarantor is not bound to comply with verbal promises in addition to this guarantee�

LIMITATIONS ON GUARANTEE LIABILITY

This guarantee is granted on condition that the product is used in a normal way or under comparable circumstances for the intended

purpose, and that the instructions for use have been observed�

The guarantee does not cover faults that have been caused by the following:

- Transport of the product�

- Careless use or overloading the product�

- Failure to follow the instructions dealing with installation, operation, maintenance and care�

- Incorrect installation of the product or incorrect location at the place where it is used�

- Circumstances which are not the fault of the guarantor, such as excessive variations in voltage, damage by lightning and fire or

other accidents�

- Repairs, maintenance or design modifications that have been done by unauthorized parties�

- The guarantee does not cover insignificant defects from an operational standpoint such as scratches on surfaces�

- Parts, which through handling or normal wear are exposed to a greater than normal risk of failure, such as lamps, glass, porcelain,

paper and plastic parts as well as fuses are not covered by the guarantee�

- The guarantee does not cover settings, information about usage, maintenance, service or cleaning which is normally described in

the instructions for use or the work required to rectify faults caused by the user neglecting to observe the warning or installation

instructions, or investigation of such�

CHARGES DURING THE GUARANTEE PERIOD

The authorized service partner will not charge the client for repairs, replaced parts, repair work, transport or travelling expenses

necessary for carrying out the repair work that are within the scope of the guarantee�

This however assumes the following:

- The defective parts are handed over to the authorized service partner�

- that the repair begins and the work is carried out during normal working hours� The authorized service partner has the right to

charge the client for extra costs for urgent repairs, or repairs carried out outside of normal working hours� However if the defects

may cause a health risk or substantial economic losses, the defects will be repaired immediately without extra charge�

- A service vehicle or public means of transportation that follows a timetable (boats, airplanes or snow vehicles are not considered

public means of transportation) can be used in conjunction with the repair of the product or replacement of defective parts�

- that the costs for dismantling and installation of equipment, which is securely mounted to the place where it is used, cannot be

considered abnormal�

REMEDIAL MEASURES WHEN A FAULT HAS BEEN DISCOVERED

If a defect is discovered, the client must without delay report the defect to the distributor or to an authorized service partner (www�

swegon�com)� Specify which product has a fault (product model, type designation on the guarantee card or on the product identification plate, serial number); describe the type of fault as accurately as possible, and the circumstances under which the fault has

arisen� If there is risk that the fault may have consequential impact on the environment, steps must be immediately taken to prevent

this from occurring� A prerequisite for valid guarantee liability is that the manufacturer or a representative of the manufacturer is

given opportunity to inspect the defects reported in the guarantee claim before the repair work begins� A prerequisite for repair

under guarantee is also that the client, in a satisfactory manner, can prove that the guarantee is valid (= written receipt of purchase)�

After the guarantee period has expired, guarantee claims, which have not been submitted in writing prior to the expiration date of

the guarantee, are not valid�

Swegon ILTO Oy, Asessorinkatu 10, FIN-20780 Kaarina, www�swegon�com, unit�warranty@swegon�fi

28 www�swegon�com

Swegon reserves the right to alter specifications.

Page 29

R120.211112

EG Compliancy Declaration

We at:

Swegon ILTO Oy

Asessorinkatu 10

20780 S:t Karins, Finland

FINLAND

We hereby affirm that

the Swegon CASA ventilation units

comply with the following EC Directives:

The machinery Directive (2006/42/EC)

Low Voltage Directive (2006/95/EC)

The EMC Directive (2004/108/EC)

and that the following harmonised standards have been applied:

EN 60335-1:2002 +A1:2004 +A11:2004 +A12:2006 +A13:2008 +A14:2010 +A15:2011 +A2:2006

EN 60204-1:2006 +A1:2009

EN 60034-5:2001 +A1:2007

EN 55014-1:2006 +A1:2009

EN 55014-2:1997 +A1:2001 +A2:2008

EN 61000-3-2:2006 +A1:2009 +A2:2009

EN 61000-3-3:2008

Person authorised to compile the technical documentation:

Name: Rami Wiberg

Address: Asessorinkatu 10, 20780 S:t Karins, Finland

E-mail: rami�wiberg@ilto�fi

Date: Kaarina 02�07�12

Signature:

Peter Stenström

CEO

Swegon ILTO Oy

N�B�! The document’s original language is English�

Swegon reserves the right to alter specifications.

www�swegon�com 29

Page 30

R120.211112

30 www�swegon�com

Swegon reserves the right to alter specifications.

Page 31

R120.211112

Swegon reserves the right to alter specifications.

www�swegon�com 31

Page 32

www�swegon�com

Loading...

Loading...