SweetHome SH450, SH650 Repair Manual

Sw ee tHom e SH 4 50SS

SweetHome Pellet Grill

Repair Manual

Models SH450 & SH650

The S w eetHom e Service Kit P/N 1122 2 in cludes:

a. F an M otor, Feed Motor

b. M ain C ircuit Bo ard

c. M ain P o wer S w itch

d. Ign iter

e. T h ree (3) (5A) M ain fuses

f. The rmo-Sens or

h. E P R O M - Operating Software Chip

GENER AL T R O U B LESHOOT IN G

The following flo w charts will a ssist in ide ntifying basic

diagnos is and rep airs .

FO RWAR D

This m anua l is intende d for u se by tec hnician prop erly

tra in ed to service and repair electrical appliances .

Disc ussion s in cluding the use o f electric m ulti-m eters,

Ohm m eters, a nd general electric troub le shooting will

not be included. P lease refe r to g eneral rep air hand

books fo r these ins tructions.

WARNING - ELECTRIC SHOCK POTENTIAL

All repairs must be accomplished with the

120VAC power disconnected from grill.

PR O DUCT DESCRIPTIO N

The S w eetHom e Pellet Grill cons is ts of a m ain cab inet

(bod y), ba se assem bly with legs, h ood ass em bly, and

hoppe r asse m bly. C o nstru ction is form ed an d w elded

galv. stee l provid ing long life. B oth in terior an d exterior

finishes are high temperature m etallic b la ck.

By des ign m ost key electric co m p onen ts are housed in

the ho pper assem bly. The three co m ponents for service

conside ration in the m a in c hassis is the ignite r, fan

motor, and therm o-s enso r. F or this rea son the m anua l

will d ivide repairs into fo ur se ctions.

TOOLS & S ERVIC E K IT

The tools an d equipm ent nee ded for se rvicing the

Sw eetHom e Pellet Grill a re as follows:

a. G o od shop vacu um with blower capa bilities.

b. S et o f sock et drivers which must in clude 11 /32,

1/2 & 7/16 so ckets or n ut drivers.

c. P hillips and plastic coated slot screw drivers

d. F la shlight

e. E xtension cord with gro und

f. Allen wrenc h s et (long handle)

g. W ire strip per a nd cutter

h. E lectrical continu ity tes te r with light or LE D

i. A ssorted crim p conn ectors with crim p tool

j. Digital re ad out volt m ulti m eter

GENER AL T ESTING PR O CE D U R E S

Grill operation and function is pro vided b y the m a in

control bas ed on a m ic rop roc esso r con tainin g the

operatin g instruction or p rog ram . In general the te stin g of

the co ntroller is functiona l alon g with ba sic output

electrical te sting. Field repair of the contro ller is not

practical and b est a ccom plishe d by factory.

To as sist the technician in g eneral trouble s hooting the

controller h as a “test” func tion which displays the current

therm o -senso r te m pera ture alon g w ith the ta rge t

tem perature. This fu nction is reac hed by PRESS ING

BO TH THE UP A N D D O W N BUTTONS AND HO LDIN G

FO R 5 SECONDS. You will no t be able to cha nge

display o utput back and forth . A standa rd display will be

restored whe n cyclin g the m ain po wer off.

Onc e in the test d is play m od e, the info rmatio n pro vided

by dire ct read therm o -se nsor tem perature will be

valuab le . The following is a sum m ary of testin g m ethods

and corre ctive actions:

CONTROL FUNCTIO N TESTING

1) Turn m a in p ower O N .

Initia l disp la y - Mod el d esignation - (450) or (650 )

* Confirm s pro per EP R O M (compu ter chip) m odel

program ming. If m odel is incorrect re place EPR O M.

* Displa y shou ld p rov id e three lighted characters an d

three dots under the ch ara cters . Damag ed display

would have missing o r fragm e nted cha rac ters.

2) Control set to Tes t Function d is plays dual te m p.

* Displa y both ta rge t temp. 3 25° a nd actual sensor

temp. based on cabinet a nd surro unding a ir.

* Confirm atio n of co ntrol and s oftware statu s in cluding

thermo-sensor.

3) The rmo-S ensor Input test ca n be acc om plis hed with

a co m mon he at so urc e held und er se nsor hood .

* Onc e tes t function displa ys add he at un der s enso r

hood and c onfirm display ed te m perature increase.

* CAU T ION - Do not overhea t sensor w ith dire ct

flame.

4) A Com plete System Test Run can be achieved b y

The rmo-S ensor hea ting .

* To confirm a c omplete system test run, rem ove all

fuel from hopper, remove grills, tray, flam e baffle,

and burn tray.

* Tu rn main pow e r O N , ad vanc e to Test Fun ctio n

display. P ress O N bu tton.

* Confirm feed s ta rt, fan start, and igniter start. All

thes e functio ns beg in immediately with the igniter

taking s everal m inu te s to reach full h eat.

* Carefully apply heat to sensor c onfirming rise o n

display th rou gh 330 °.

* Ma in ta in heat a bove 3 30° for s everal m in utes to

confirm “Run Mod e” is achieved by flas hing display

and th ree b eeps fro m co ntroller. Fan speed will

change, feed s w ill chan ge, a nd you c an reduce

target tem pera tu re to 230°.

* Onc e target te m peratu re is re duced rem ove hea t

fro m senso r area and confirm s lo w ly falling sensor

tempe ratures.

* Onc e tem peratu re falls b elow 140° or falls rapid ly

enoug h the C oL m ode will be dis played . Feed w ill

stop , igniter off, an d fan s peed incre ased to clean

burn tra y.

This co m pletes the system test. At any po in t a fa ilure is

note d reg ard in g fan motor, fe ed m o to r, o r ignite r

operatio ns refer to the Flow Charts for further testing.

-2 -

IF THE C O N T R O L PA S S ES 325° A N D DOES NOT

ADV A N C E TO RUN MO D E W HICH IS CONFIR MED B Y

FL A S H ING DIS PLAY A N D T H R E E B E E PS PLUS THE

ABILITY T O CHA N G E TARGET TEMPERATURE TH IS IN D ICATES A THERMO -SENSOR PROBLEM.

TE S TIN G AND PO SSIB L E R E PLACEMEN T OF

SE N S O R IS B EST TROUBLE SHOO TIN G

PR O CED U R E .

TES T ING & SE R VIC ING T H ERM O -SENSOR

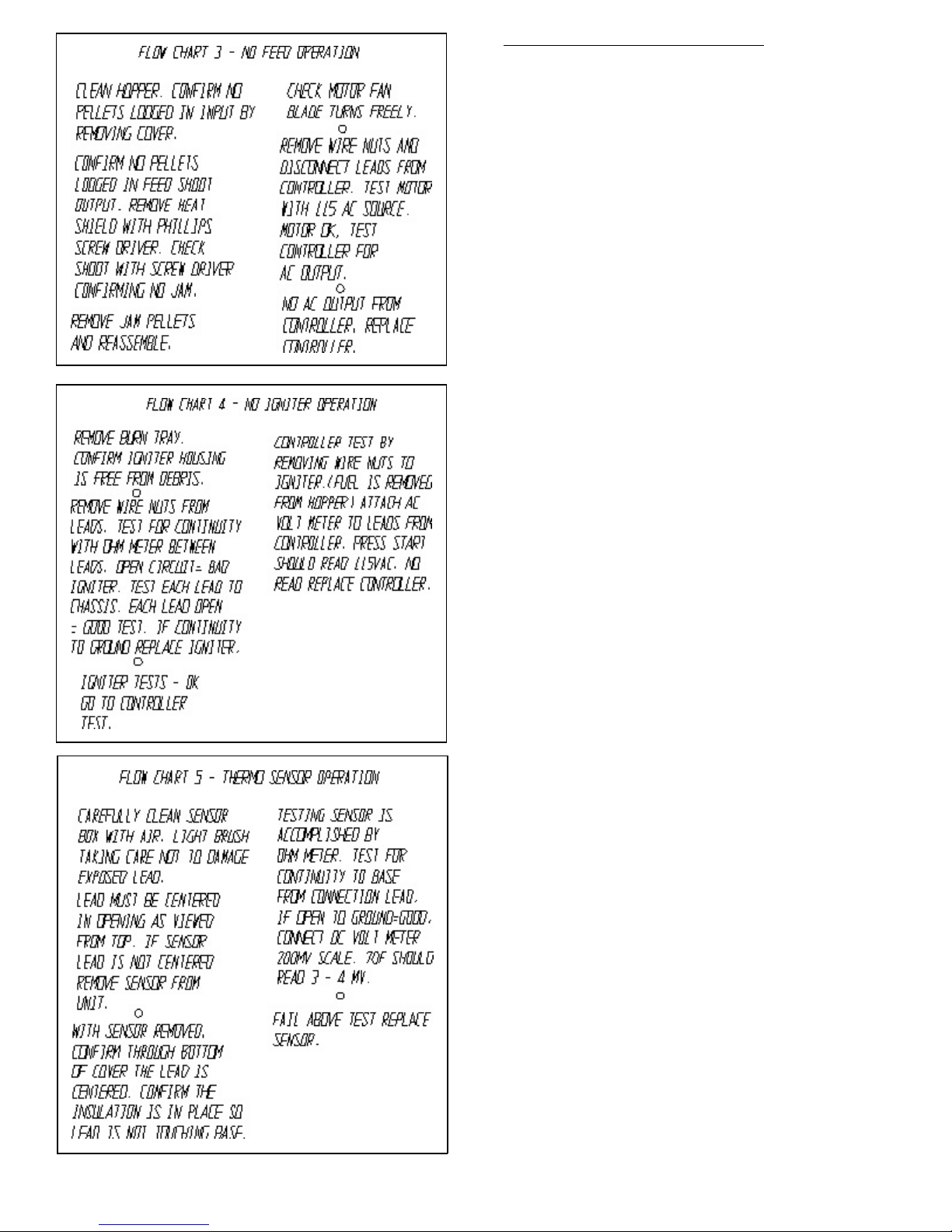

The therm o-sensor is loc ate d on the le ft s ide in te rior of

the chassis. It is protected by a steel hood and is

designe d for s ta nda rd grill operations . The sensor does

not require reg ular se rvic e e xcept to confirm it is free

from cook in g debris.

It m ay be poss ible however to dam age the se nsor if

som e item is pushed through the hood acc ess or is hit

hard enoug h to dis place the lead e nd. T e stin g of ths

senso r is the refore as im portant as the m ain control test.

Outline of the basic control test will provide gene ral

operation of the sensor an d fee d back to the c ontro ller. If

the sensor o peratio n w arran ts furthe r eva lu atio n

com p le te the following tests:

1) Check sensor physical d am age or d ebris in ho od or

hood ve nt hole.

* Clean with a ir or soft b rus hing action to rem o ve

build u p. Care sho u ld be taken not to bend or

da m a ge le ad end.

Therm o -Se nsor - L o cated le ft inside bas e

2) Check sensor lea d attac hm e nt to th e controlle r by

accessing m ain co ntrol th rough front pan el.

* Confirm the screw s that hold the leads are tight.

Care sho u ld be taken no t to over tig hte n a s the

ba se is m ad e o f plastic .

* Loose attachm en t cou ld c ause e rratic s enso r reads

by con troller.

* Leads have sp ecific polarity and m us t be attache d to

the prope r lug. R efer to the colo rs no te d on th e

board base, RED & YELLO W .

* Reversing the polarity will cause the grill to read a

reducing te m pe rature when the a ctual tem pe rature is

increasing. T he ope rating result is to start the g rill

and a run o f less than 5 m in utes with a C o L shut

down.

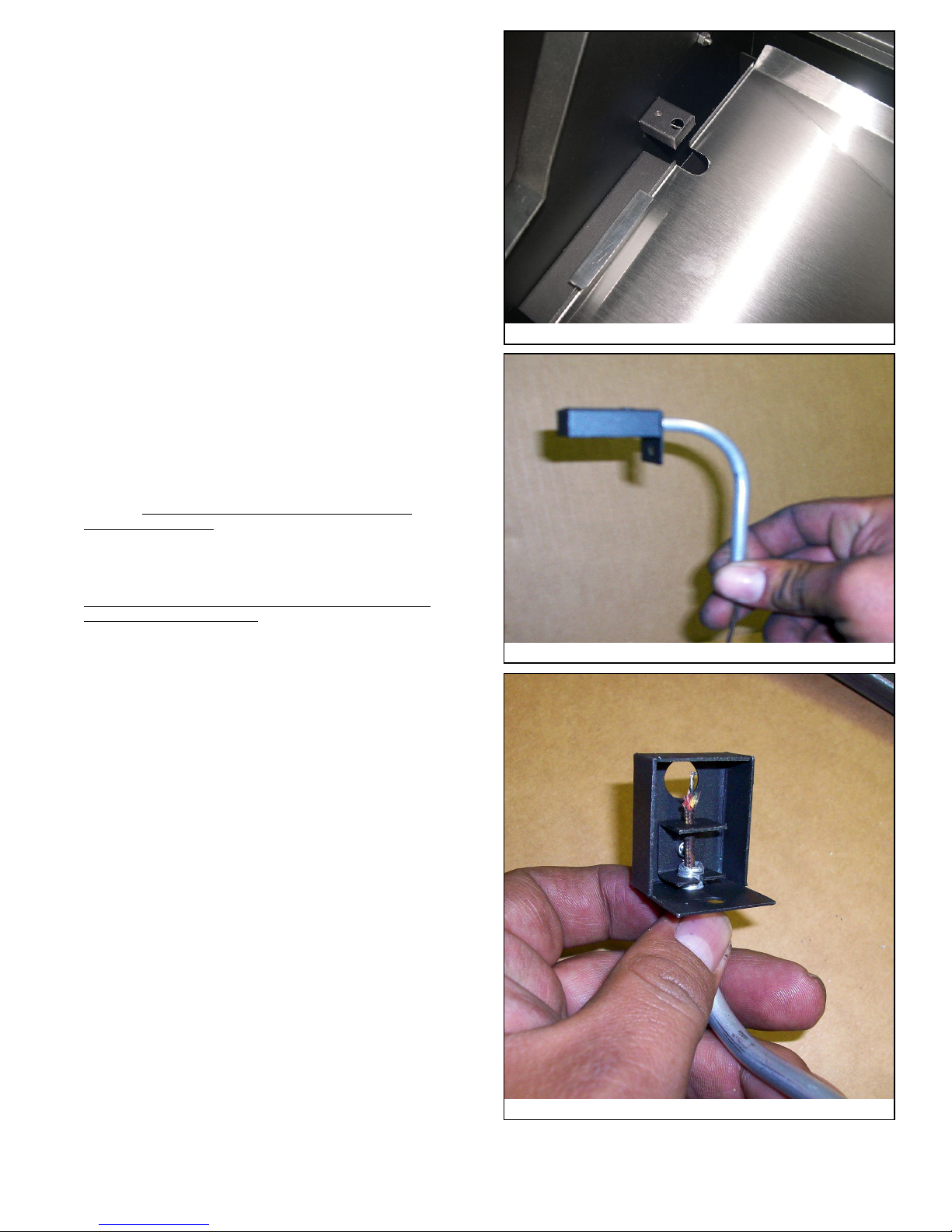

3) Se nsor G rounding to Chassis cau sing con trol

function problem s and m issed s tarts.

* The s enso r leads sh ould not come in c ontact with

the chassis to a c ause a ground con dition . This will

cause the co ntroller to act erratic.

* Starts tha t continu e beyond the 32 5° target w ithout

run m o de initiation and e rratic sh ut downs leading to

fast C o L cycles are direc tly caus ed by grounde d

sensors.

* Testing for g rou nding requires th e sens or lead s to be

disconnected from the c ontrolle r and a O HM m e ter

applied to c hass is a nd one s ensor lead. If c ontinuity

is fo und the se nsor is groun ded an d shou ld b e

rem oved for insp ection and possible replacem e nt.

Therm o-sensor Assem bly

TES T ING & SE R VIC E AUG ER, FAN , AN D IGNIT E R

Tes t proce dures for th ese co m ponen ts a re sign ificantly

the sam e as they are basic 115VAC lo ads . Eac h

com p onent can be re m oved for electric testing an d or

tested in place. The following is an ite m spe cific

description :

Therm o-sensor lead p lacement

-3 -

Loading...

Loading...