Sweepster 205 Series Operator And Parts Manual

OPERATOR’S AND PARTS MANUAL

205 Series

SB Hopper Broom

Cold Planer Special

Serial Number: ___________________

Model Number: ___________________

800-456-7100 I www.paladinattachments.com 2800 N. Zeeb Rd., Dexter, MI. 48130, United States of America Copyright ©

Manual Number: 51-4178

Release Date: January 2014

Serial Number: 0913001 & Up

Rev. 1

1

Notes

2

TABLE OF CONTENTS

INTRODUCTION ..........................................................................................................................................4

SAFETY STATEMENTS ...............................................................................................................................4

GENERAL SAFETY PRECAUTIONS........................................................................................................5-6

SAFETY SIGNS & LABELS .........................................................................................................................7

SERVICE & REPAIR - SAFETY ...................................................................................................................8

OPERATION .................................................................................................................................................8

STORAGE ..................................................................................................................................................10

PRODUCT INFORMATION ........................................................................................................................11

MAINTENANCE .........................................................................................................................................12

REPLACING BRUSH SECTIONS ..............................................................................................................13

MAINTENANCE SCHEDULE .....................................................................................................................14

MAINTENANCE RECORD .........................................................................................................................15

TROUBLESHOOTING ..........................................................................................................................16-17

ADJUSTING THE GUTTERBROOM ..........................................................................................................18

CORE ASSEMBL Y .....................................................................................................................................20

MOTOR ASSEMBL Y ..................................................................................................................................21

BEARING ASSEMBL Y .......................................................................................................................... 22-23

HOOD ASSEMBL Y .....................................................................................................................................24

CUTTING EDGE KIT ..................................................................................................................................25

GUTTERBROOM ..................................................................................................................................26-27

DUST SUPPRESSION KIT ................................................................................................................... 28-29

BOL T T ORQUE SPECIFICATIONS ...........................................................................................................30

HYDRAULIC TORQUE SPECIFICA TIONS ...........................................................................................31-32

WARRANTY ...............................................................................................................................................33

3

INTRODUCTION

SAFETY STATEMENTS

Purpose of Sweeper

This sweeper is designed solely for the use in

construction cleanup, road maintenance and similar

operations. Use in any other way is considered

contrary to the intended use. Compliance with and

strict adherence to operation, service and repair

conditions, as specied by the manufacturer, are

also essential elements of the intended use.

Contacting Sweepster

If you have any questions about information in this

manual or need to order parts, please call, write, fax

or e-mail SWEEPSTER.

Sweepster

2800 North Zeeb Road

Dexter, Michigan 48130

Phone: (734)-996-9116 - (800)-456-7100

Fax: (734) 996-9014

e-mail: sweepster@paladinbrands.com

DANGER! THIS STATEMENT IS USED

WHERE SERIOUS INJURY OR

DEATH WILL RESULT IF THE

INSTRUCTIONS ARE NOT

FOLLOWED PROPERLY.

WARNING! THIS STATEMENT IS USED

WHERE SERIOUS INJURY OR

DEATH COULD RESULT IF

THE INSTRUCTIONS ARE NOT

FOLLOWED PROPERLY.

CAUTION! THIS STATEMENT IS USED

WHERE MINOR INJURY COULD

RESULT IF THE INSTRUCTIONS

ARE NOT FOLLOWED PROPERLY.

NOTICE! THIS STATEMENT IS USED

WHERE EQUIPMENT OR

PROPERTY DAMAGE COULD

RESULT IF THE INSTRUCTIONS

ARE NOT FOLLOWED PROPERLY.

For help with installation, operation or maintenance

procedures, contact our Technical Service

Department. Direct product questions and parts

orders to our Sales Department.

When ordering parts or accessories, be prepared to

give the following information:

• Sweeper model, serial number and date of

purchase

• Prime mover, make and model

• Part number, description and quantity

Terms Used in Manual

Right-hand, left-hand, front and rear are determined

from the operator’s perspective (either the

operator’s seat or standing behind a walk-behind

unit), facing forward in the normal operating

position.

Warranty

THIS SYMBOL BY ITSELF OR

USED WITH A SAFETY SIGNAL

WORD THROUGHOUT THIS

MANUAL IS USED TO CALL YOUR

ATTENTION TO INSTRUCTIONS

INVOL VING YOUR PERSONAL

SAFETY OR THE SAFETY OF

OTHERS. FAILURE TO FOLLOW

THESE INSTRUCTIONS CAN

RESULT IN INJURY OR DEATH.

To validate the warranty for this unit, ll out the

warranty card or warranty pages located in the

back of this manual. Then send this information to

SWEEPSTER.

4

GENERAL SAFETY PRECAUTIONS

GENERAL SAFETY PRECAUTIONS

WARNING! READ MANUAL PRIOR TO

INSTALL

Improper installation, operation,

or maintenance of this equipment

could result in serious injury or

death. Operators and maintenance

personnel should read this

manual as well as all manuals

related to this equipment and the

prime mover thoroughly before

beginning installation, operation,

or maintenance. FOLLOW ALL

SAFETY INSTRUCTIONS IN

THIS MANUAL AND THE PRIME

MOVERS MANUAL.

WARNING! READ AND UNDERSTAND ALL

SAFETY STATEMENTS

Read all safety decals and safety

statements in all manuals prior

to operating or working on this

equipment. Know and obey all

OSHA regulations, local laws

and other professional guidelines

for your operation. Know and

follow good work practices when

assembling, maintaining, repairing,

mounting, removing or operating this

equipment.

KNOW YOUR EQUIPMENT

Know your equipment’s capabilities,

dimensions and operations before

operating. Visually inspect your

equipment before you start, and

never operate equipment that is not

in proper working order with all safety

devices intact. Check all hardware to

assure it is tight. Make certain that all

locking pins, latches, and connection

devices are properly installed and

secured. Remove and replace any

damaged, fatigued or excessively

worn parts. Make certain all safety

decals are in place and are legible.

Keep decals clean, and replace them

if they become worn and hard to

read.

WARNING! PROTECT AGAINST FLYING

DEBRIS

Always wear proper safety glasses,

goggles or a face shield when driving

pins in or out or when operation

causes dust, ying debris, or any

other hazardous material.

WARNING! LOWER OR SUPPORT RAISED

EQUIPMENT

Do not work under raised booms

without supporting them. Do not use

support material made of concrete

blocks, logs, buckets, barrels or any

other material that could suddenly

collapse or shift positions. Make

sure support material is solid,

not decayed, warped, twisted, or

tapered. Lower booms to ground

level or onto blocks. Lower booms

and attachments to the ground

before leaving the cab or operator’s

station.

WARNING! USE CARE WITH HYDRAULIC

FLUID PRESSURE

Hydraulic uid under pressure can

penetrate the skin and cause serious

injury or death. Hydraulic leaks

under pressure may not be visible.

Before connecting or disconnecting

hydraulic hoses, read your prime

movers operator’s manual for

detailed instructions on connecting

and disconnecting hydraulic hoses or

ttings.

•Keep unprotected body parts,

such as face, eyes, and arms as

far away as possible from a

suspected leak. Flesh injected with

hydraulic uid may develop

gangrene or other permanent

disabilities.

• If injured by injected uid, see a

doctor at once. If your doctor is not

familiar with this type of injury, ask

him to research immediately to

determine proper treatment.

5

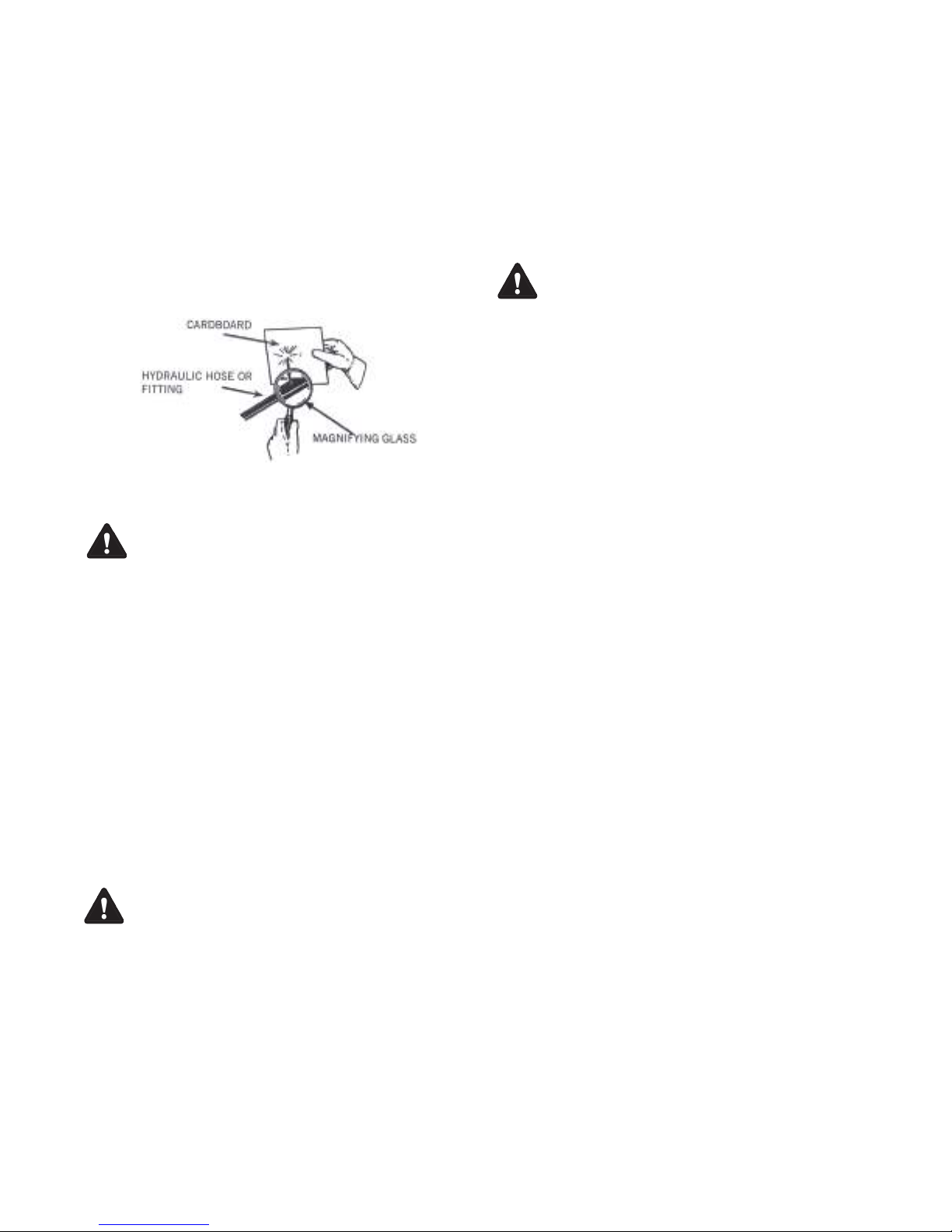

GENERAL SAFETY PRECAUTIONS

GENERAL SAFETY PRECAUTIONS

CONTINUED

• Wear safety glasses, protective

clothing, and use a sound piece of

cardboard or wood when

searching for hydraulic leaks.

DO NOT USE YOUR HANDS!

SEE ILLUSTRATION.

WARNING! DO NOT MODIFY MACHINE OR

ATTACHMENTS

Modications may weaken the

integrity of the attachment and may

impair the function, safety, life and

performance of the attachment.

When making repairs, use only

the manufacturer’s genuine parts,

following authorized instructions.

Other parts may be substandard

in t and quality. Never modify

any ROPS (Roll Over Protection

System) equipment or device. Any

modications must be authorized in

writing by the manufacturer.

CONTINUED

• W e a r t h e p r o t e c t i v e c l o t h i n g

equipment specied by the tool

manufacturer.

WARNING! SAFELY OPERATE EQUIPMENT

Do not operate equipment until you

are completely trained by a qualied

operator in how to use the controls,

know its capabilities, dimensions,

and all safety requirements. See

your prime movers manual for these

instructions.

• Keep all step plates, grab bars,

pedals, and controls free of dirt,

grease, debris, and oil.

• Never allow anyone to be around

the equipment when it is operating.

• Do not allow riders on the

attachment or the prime mover.

• Do not operate the equipment

from anywhere other than the

correct operators position.

• Never leave equipment unattended

with the engine running or with this

attachment in a raise position.

• Do not alter or remove any safety

feature from the prime mover or

this attachment.

• Know your work site safety rules as

well as trafc rules and ow. When

in doubt on any safety issue,

contact your supervisor or safety

coordinator for an explanation.

WARNING! SAFELY MAINTAIN AND REPAIR

EQUIPMENT

• Do not wear loose clothing, or any

accessories that can catch in

moving parts. If you have long hair,

cover or secure it so that it does

not become entangled in the

equipment.

• Work on a level surface in a well-lit

area.

• Use properly grounded electrical

outlets and tools.

• Use the correct tool for the job at

hand. Make sure they are in good

condition for the task required.

6

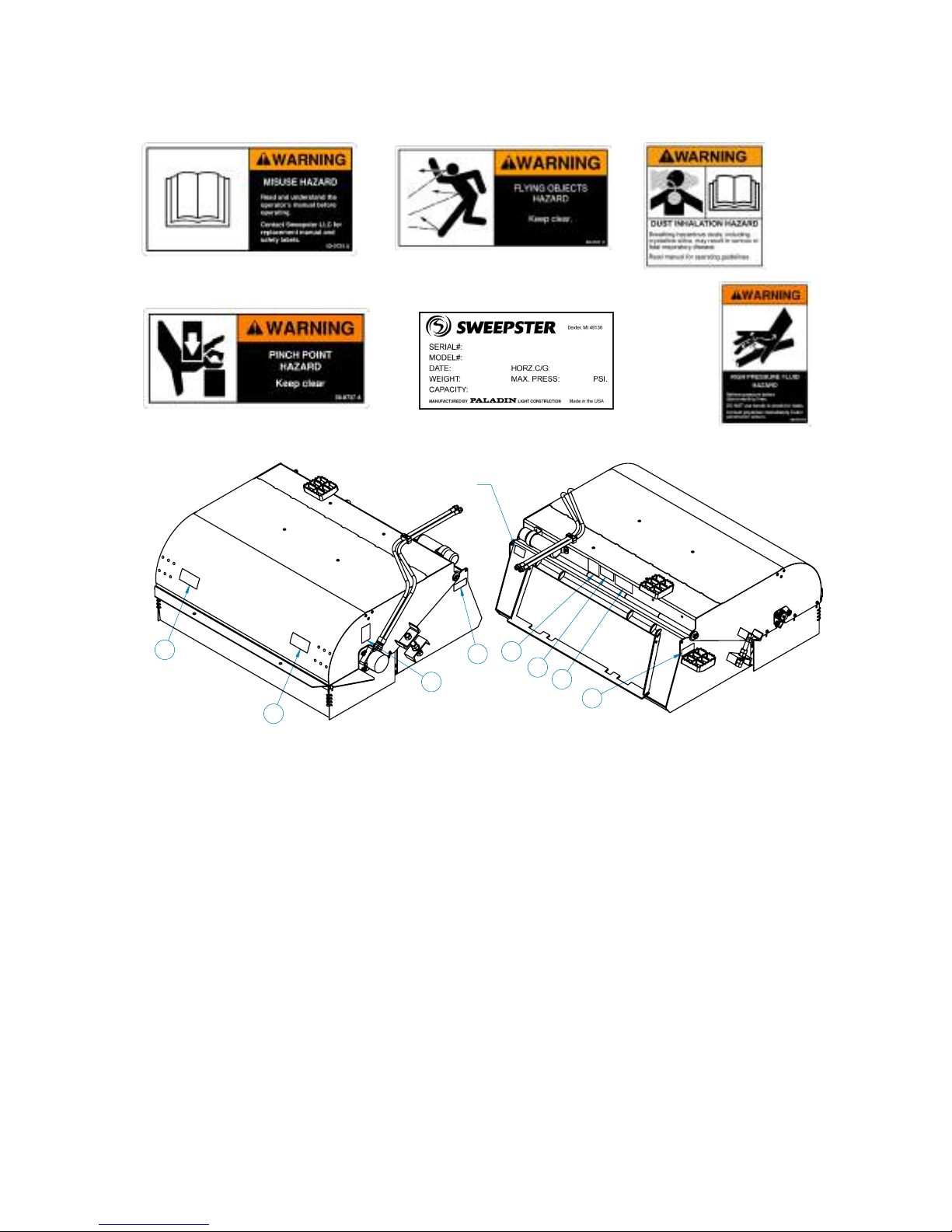

SAFETY SIGNS & LABELS

50-0723

50-0737

3

50-0727

50-0634

Serial Number

2

3

6

4

1

3

4

41043

50-0724

SAFETY SIGNS & LABELS

There are several specic signs on this sweeper.

The exact location of the hazards and description of

the hazards are reviewed.

Placement or replacement of Safety Signs

1. Clean the area of application with nonammable

solvent, and then wash the same area with soap

and water.

2. Allow the surface to fully dry.

3. Remove the backing from the safety sign,

exposing the adhesive surface.

4. Apply the safety sign to the position shown in

the diagram above and smooth out any bubbles.

Item Part Qty Description

1. 50-0723 1 Label, Read Manual

2. 50-0724 1 Label, Warning, High Pressure Fluid

3. 50-0727 3 Label, Warning, Flying Objects

4. 50-0737 2 Label, Warning, Pinch Point Hazard

5. 50-0634 1 Label, Serial Number

6. 41043 1 Decal, Warning, Hazardous “Dust

Instructions

1. Keep all safety signs clean and legible.

2. Replace all missing, illegible, or damaged safety

signs.

3. Replacement parts, for parts with safety signs

attached, must also have safety signs attached.

4. Safety signs are available, free of charge, from

your dealer or from SWEEPSTER.

7

SERVICE & REPAIR - SAFETY

OPERATION

CAUTION! DO NOT MODIFY THE SWEEPER

IN ANY WAY . Personal injury could

result. If you have questions, contact

your dealer or SWEEPSTER.

Repair or adjust the sweeper in a safe area, away

from trafc and other hazards.

Before adjusting or servicing the sweeper, lower

the sweeper to the ground, stop the prime mover

engine, set the brakes and remove the key from the

ignition.

When working on or around the sweeper, lower it

to the ground or secure it with transport chains or

cylinder-stop locks.

Stop the prime mover engine and cycle control

levers to release hydraulic pressure before servicing

or adjusting sweeper hydraulic systems.

WARNING! ESCAPING HYDRAULIC FLUID

CAN HAVE ENOUGH PRESSURE

TO PENETRATE THE SKIN, causing

serious personal injury.

Do not bend high pressure lines. Do not strike high

pressure lines. Do not install bent lines, bent tubes,

or kinked hoses. Do not install damaged lines,

tubes, or hoses.

Repair damaged or loose lines, tubes and hoses.

Leaks can cause res. See your SWEEPSTER

dealer for repair or replacement parts.

Replace the parts if any of the following conditions

are present:

• The end ttings are damaged or leaking.

• The outer covering is chafed or cut.

• The reinforcing wire layer is exposed.

CAUTION! A SWEEPER IS A DEMANDING

MACHINE. Only fully trained

operators or trainee operators under

supervision of a fully trained person

should use this machine.

Before operating sweeper:

•Learn sweeper and prime mover controls in an

off-road location.

•Be sure that you are in a safe area, away from

trafc or other hazards.

•Check all hardware holding the sweeper to the

host machine, making sure it is tight.

•Replace any damaged or fatigued hardware

with properly rated fasteners.

•Make sure all hydraulic hardware and hydraulic

ttings are tight.

•Replace any damaged or fatigued ttings or

hoses.

•Check all tire pressures before sweeping.

•Check tire ratings to be sure they match the

prime mover load. Weigh the sweeper end of

the prime mover, if necessary, to insure proper

tire rating.

•Remove from the sweeping area all property

that could be damaged by ying debris.

•Be sure all persons not operating the sweeper

are clear of the sweeper discharge area.

•Always wear proper apparel such as a long

sleeved shirt buttoned at the cuffs; safety

glasses, goggles or a face shield; ear

protection; and a dust mask.

• The outer covering is ballooning locally.

• The hose is kinked or crushed.

• The hose has been pulled or stretched.

Make sure that all clamps, guards, and shields are

installed correctly.

8

While operating sweeper:

•When operating sweeper, adhere to all

government rules, local laws and other

professional guidelines for your sweeping

application.

•Before leaving the operators area for any

reason, lower the sweeper to the ground. Stop

the prime mover engine, set the brakes and

remove the key from the ignition.

Run the prime mover and sweeper at a low idle.

Check for hydraulic leaks or other problems and

make corrections, if necessary, before using the

sweeper.

•Minimize ying debris - use the slowest rotating

speed that will do the job.

•Keep hands, feet, hair and other loose clothing

away from all moving parts.

•Leave the brush hood (shield) and all other

shields and safety equipment in place when

operating the sweeper and primer mover.

•Be aware of extra weight and width a sweeper

adds. Reduce travel speed accordingly.

•When sweeping on rough terrain, reduce speed

to avoid “bouncing” the sweeper. Loss of

steering can result.

•Never sweep toward people, buildings, vehicles

or other objects that can be damaged by ying

debris.

•Only operate the sweeper while you are in the

seat of the prime mover. The seat belt must be

fastened while you operate the prime mover.

Only operate the controls while the engine is

running. Protective glasses must be worn while

you operate the prime mover and while you

operate the sweeper.

•While you operate the sweeper slowly in an

open area, check for proper operation of all

controls and all protective devices. Note any

repairs needed during operation of the sweeper.

Report any needed repairs.

WARNING! AVOID SERIOUS INJURY. Check

for large objects that could harm the

operator or others if thrown by the

sweeper. Remove these items before

operating.

During Use

Carry the sweeper low to the ground so that the

operator has good visibility and stability. Avoid any

sudden movements from one side to the other side

when you carry a sweeper.

Avoid excessive downward pressure on the brush

sections to prevent excessive wear. A two to four

inch wide pattern is sufcient for most applications.

Ensure that the motor and bearing plates are

equally adjusted in order to prevent an uneven wear

pattern.

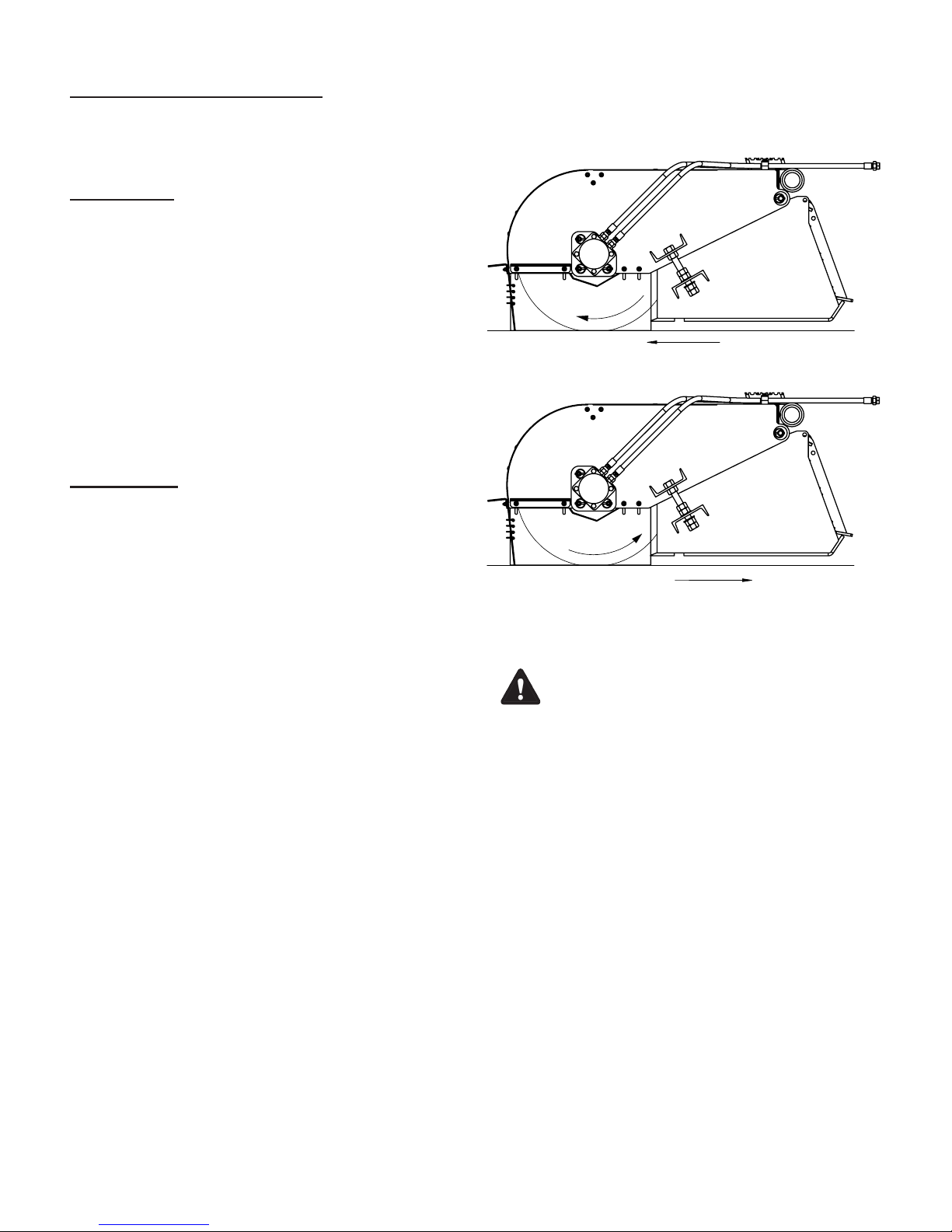

Directing Debris

Observe wind direction. Sweeping with the wind

makes sweeping more effective and helps keep

debris off the operator.

The terms swing and angle are used

interchangeably.

NOTICE! AVOID SWEEPER DAMAGE.

Reduce travel speed to avoid

hitting immovable objects.

Before Each Use

Perform daily maintenance as indicated in

Maintenance Schedule.

9

Brush, Engine & Travel Speeds

Vary brush, engine and travel speeds to match

sweeping conditions.

Dirt & Gravel

To keep dust at a minimum, plan sweeping for days

when it is overcast and humid or after it has rained.

Also, sweep so the wind blows at your back.

Low brush speeds and moderate travel speeds work

best for cleaning debris from hard surfaces. Brush

speeds that are too fast tend to raise dust because

of the aggressive sweeper action.

To sweep gravel, use just enough brush speed to

“roll” the gravel, not throw it.

Heavy Debris

BRUSH

ROTATION

TRAVEL

Travel slowly - 5 mph (8 kph).

Sweep a path less than the full width of the

sweeper.

Increase engine speed if debris becomes very

heavy.

STORAGE

NOTICE! Do not store the sweeper with

weight on the brush. Weight will

deform the bristles, destroying the

sweeping effectiveness.

Do not store polypropylene

brushes in direct sunlight. The

material can deteriorate and

crumble before the bristles are

worn out.

BRUSH

ROTATION

TRAVEL

WARNING! EXPOSURE TO RESPIRABLE

CRYSTALLINE SILICA

DUST ALONG WITH OTHER

HAZARDOUS DUSTS MAY

CAUSE SERIOUS OR FATAL

RESPIRATORY DISEASE.

It is recommended to use dust

suppression, dust collection and

if necessary personal protective

equipment during the operation of

any attachment that may cause high

levels of dust.

Keep polypropylene brush

material away from intense heat or

ame.

10

Loading...

Loading...