SWASH SFF1000CSA series, SFF1001CSA series, SFF1002CLN series, SFF1002CSA series, SFF1001CLN series Technical Education

TECHNICAL EDUCATION

L-86

SWASH™ Clothing Care System

SFF1000CSA*

SFF1001CSA*

SFF1002CSA*

SFF1001CLN*

SFF1002CLN*

* Denotes Engineering Revision

JOB AID W10713431

FORWARD

This Whirlpool Job Aid, "SWASH™ Clothing Care System” (Part No. W10713431), provides the In-Home

Service Professional with informaon on the operaon and service of the “SWASH Clothing Care

System."

GOALS AND OBJECTIVES

The goal of this Job Aid is to provide informaon that will enable the In-Home Service Professional to

properly diagnose malfuncons and repair the "SWASH™ Clothing Care System.”

The objecves of this Job Aid are to:

• Understand and follow proper safety precauons.

• Successfully troubleshoot and diagnose malfuncons.

• Successfully perform necessary repairs.

• Successfully return the clothing care system to its proper operaonal status.

WHIRLPOOL CORPORATION assumes no responsibility for any repairs made on our

products by anyone other than authorized In-Home Service Professionals.

Copyright © 2014, Whirlpool Corporaon, Benton Harbor, MI 49022

Whirlpool®/™ is a trademark of Whirlpool U.S.A. Tide®/™ is a trademark of The Procter & Gamble Company. Swash®/™ is a

trademark of Go Unlimited LLC. © 2014. All Rights Reserved. The WHIRLPOOL and TIDE trademarks are used by Go Unlimited

LLC under license. Product manufactured under license for, and warranty provided by, Go Unlimited LLC, Cincinna, OH 45202

ii n

SWASH™ Clothing Care System

SWASH™ Clothing Care System

SECTION 1 — GENERAL INFORMATION

SWASH™ SYSTEM SAFETY ..................................................................................................................1-2

MODEL & SERIAL NUMBER LABEL .....................................................................................................1-3

TECH SHEET LOCATION .......................................................................................................................1-3

SWASH™ SYSTEM................................................................................................................................1-4

SWASH™ SYSTEM OVERVIEW.............................................................................................................1-5

SWASH™ SYSTEM SPECIFICATIONS ....................................................................................................1-5

SECTION 2 — OPERATION

CONNECTING THE SWASH™ SYSTEM .................................................................................................2-2

BUTTONS AND STATUS LIGHTS ..........................................................................................................2-3

HOW DOES THE SWASH™ SYSTEM WORK? ........................................................................................2-4

HOW TO USE SWASH™ SYSTEM .........................................................................................................2-5

HANGING CLOTHES ............................................................................................................................2-6

EMPTYING THE RESERVOIR ................................................................................................................2-8

CONSUMER TROUBLESHOOTING .......................................................................................................2-9

SWASH™ SYSTEM TIPS .......................................................................................................................2-9

TABLE OF CONTENTS

SECTION 3 — COMPONENT ACCESS

SWASH™ SYSTEM EXPLODED VIEW ...................................................................................................3-2

SWASH™ SYSTEM PARTS LIST .............................................................................................................3-3

REMOVING THE REAR PANEL .............................................................................................................3-4

REMOVING THE TOP COVER & CONTROL HOUSING .........................................................................3-5

REMOVING THE USER INTERFACE ......................................................................................................3-6

REMOVING THE DISPENSING SYSTEM ...............................................................................................3-6

REMOVING THE PUMP ASSEMBLY .....................................................................................................3-7

REMOVING THE APPLIANCE CONTROL UNIT (ACU) ..........................................................................3-7

REMOVING THE THERMISTOR ...........................................................................................................3-7

REMOVING THE DOOR ASSEMBLY .....................................................................................................3-8

REMOVING THE CLIPS & ROLLER ASSEMBLY .....................................................................................3-9

REMOVING THE BASE COMPONENTS ..............................................................................................3-10

REMOVING THE SIDE PANELS ..........................................................................................................3-12

SECTION 4 — DIAGNOSTICS & TROUBLESHOOTING

SAFETY FIRST ......................................................................................................................................4-2

CUSTOMER TROUBLESHOOTING .......................................................................................................4-3

CUSTOMER ERROR CODES .................................................................................................................4-3

CONTROL PANEL .................................................................................................................................4-4

DIAGNOSTIC GUIDE ............................................................................................................................4-4

SERVICE DIAGNOSTICS .......................................................................................................................4-4

SERVICE DIAGNOSTIC FUNCTIONS ....................................................................................................4-5

FAULT / ERROR CODES ........................................................................................................................4-6

TROUBLESHOOTING GUIDE ...............................................................................................................4-8

WIRING DIAGRAM ............................................................................................................................4-10

APPLIANCE CONTROL UNIT (ACU) ...................................................................................................4-11

USER INTERFACE (UI) ASSEMBLY .....................................................................................................4-12

STRIP CIRCUITS .................................................................................................................................4-13

SWASH™ Clothing Care System

n

iii

PRODUCT SPECIFICATIONS & WARRANTY INFORMATION SOURCES (inside back cover)

iv n

SWASH™ Clothing Care System

GENERAL INFORMATION

Section 1:

General Information

This secon provides general safety, parts, and informaon for

the “SWASH™ Clothing Care System.”

Q SWASH™ System Safety

Q Model & Serial Number Label

Q Tech Sheet Locaon

Q SWASH™ System

Q SWASH™ System Overview

Q SWASH™ System Specicaons

Q Notes

SWASH™ Clothing Care System

n

1-1

GENERAL INFORMATION

SWASH™ System Safety

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual and on your appliance. Always read and obey all safety

messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately

DANGER

WARNING

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

follow instructions.

You

can be killed or seriously injured if you don't

instructions.

follow

STATE OF CALIFORNIA PROPOSITION 65 WARNINGS:

WARNING: This product contains one of more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals know to the State of California to cause birth defects or other

reproducve harm.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: To reduce the risk of re, electric shock, or injury to persons when using the SWASH™ system, follow basic

precauons, including the following:

n Read all instrucons before using the SWASH™ system.

n Use the SWASH™ system only for its intended use.

n To reduce the risk of electric shock, do not immerse any

part of SWASH™ system in water or other liquids.

n Never yank cord to disconnect from outlet; instead, grasp

plug and pull to disconnect.

n Do not allow cord to touch hot surfaces. Let SWASH™

system cool completely before pung away. Loop cord

loosely around SWASH™ system when storing.

n Always disconnect SWASH™ system from electrical outlet

when not in use, or when cleaning SWASH™ system.

n Do not operate SWASH™ system with a damaged cord, or

if it has been dropped or damaged. To reduce the risk of

electric shock, do not disassemble or aempt to repair

SWASH™ system. Contact a qualied service person for

examinaon and repair. Incorrect reassembly or repair

could cause a risk of re, electric shock, or injury to

persons when SWASH™ system is used.

n Close supervision is necessary for any appliance being

used near children.

n Use care when interrupng a cycle; interior surfaces may

be hot if SWASH™ system is opened when in use.

n To reduce the likelihood of circuit overload, do not

operate other high-waage hardware (i.e. refrigeraon,

air condioner, etc) on the same circuit.

n The SWASH™ system is intended for household use only.

Do not use outdoors.

n Do not use in garages or near any ammable liquids.

n Do not use an extension cord.

n The use of accessories other than those supplied with

the SWASH™ system is not recommended and may cause

injury.

n Use and store SWASH™ system out of regularly traveled

paths to reduce the possibility of p-over.

n Keep the area clear around the base of SWASH™ system

to make sure venlaon openings in the boom of

SWASH™ system are not blocked.

n Do not modify SWASH PODS™ cups or use any alternate

formulas. The SWASH™ system was designed to work

safely using only the unique SWASH PODS™ cups. Any

modicaons could reduce user safety.

n Burns could occur from touching hot metal parts.

SAVE THESE INSTRUCTIONS

1-2 n

SWASH™ Clothing Care System

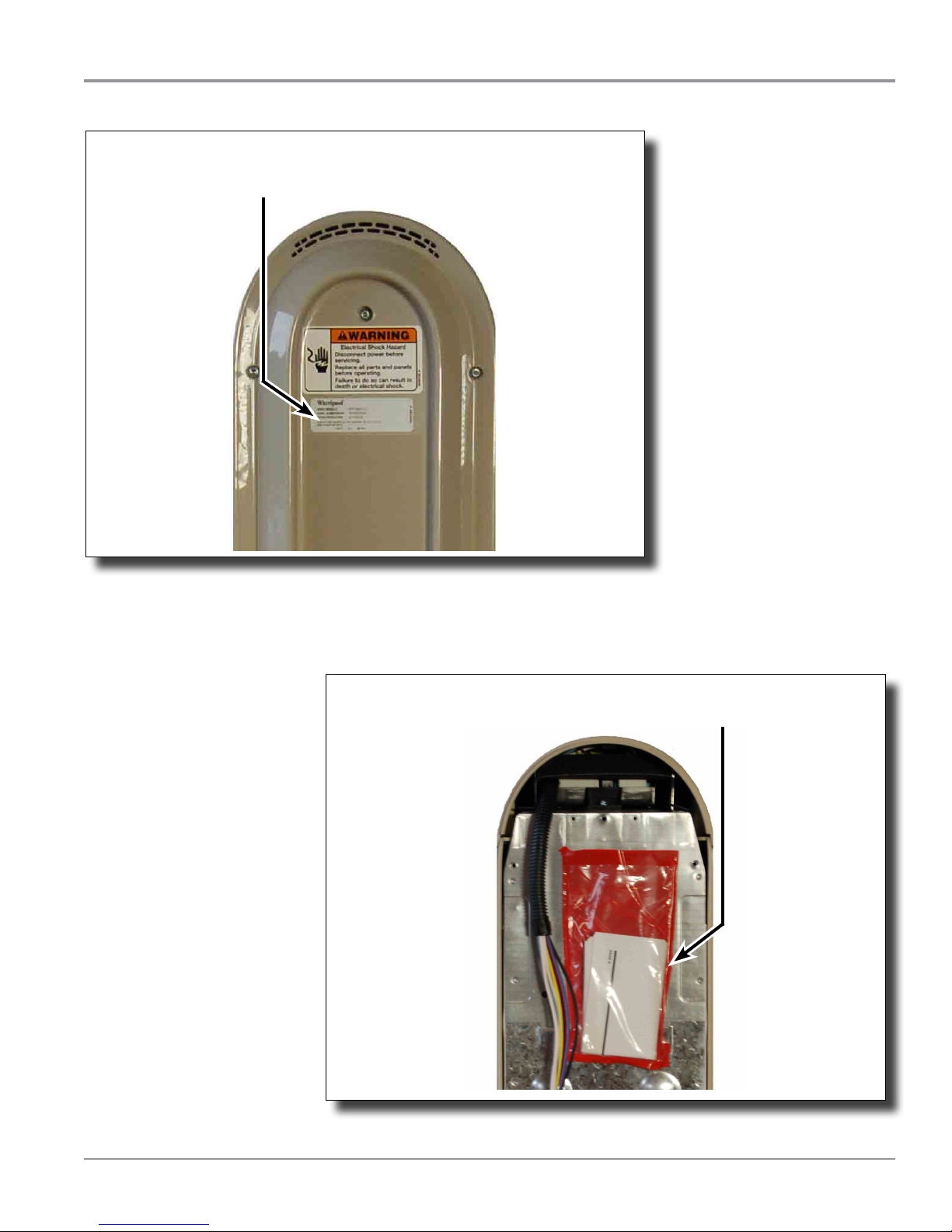

Model & Serial Number Label

Model & Serial Number

Label Location

GENERAL INFORMATION

Figure 1 - Located on back panel of SWASH™ system

Tech Sheet Location

Tech Sheet Location

Figure 2 - Located behind the back panel of SWASH™ system

SWASH™ Clothing Care System

n

1-3

GENERAL INFORMATION

SWASH™ System

SWASH PODS™ BAY

CONTROL PANEL

ADJUSTABLE

HANGER

RESERVOIR

SLEEVE

WRAPS

DOOR

SMOOTHING

CLIPS

SWASH PODS™ CUPS

1-4 n

SWASH™ Clothing Care System

POCKET

SMOOTHER

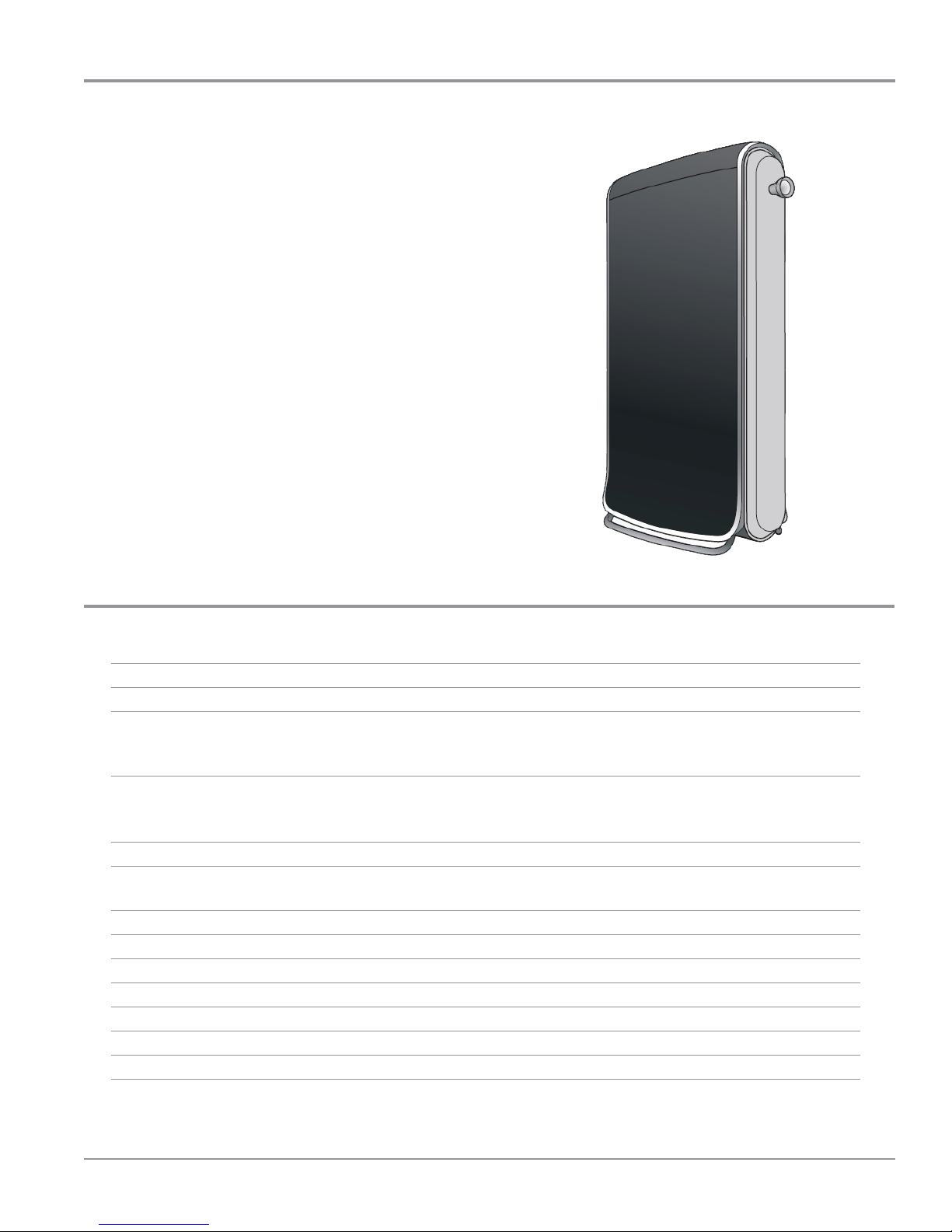

SWASH™ System Overview

SWASH™ Clothing Care System

The SWASH™ system gets clothes looking and feeling their

best. De-wrinkle, Refresh, Restore, and Preserve clothes for

results never before achievable at home with the SWASH

system’s 10 minute express clothing care. The SWASH system,

an all-in-one, in-home, convenient clothing care system, has

elements of a clothes steamer and an iron. Designed to t in

any life-style, the consumer can put the SWASH system almost

anywhere, like their bedroom or closet. It uses a standard wall

outlet, so all they have to do is plug it in and start living life

unhampered.

The SWASH system works with a few key technologies. The

Smoothing Clips provide the right amount of tension; a

superne mist of the SWASH PODS™ formula is sprayed onto

both sides of the hanging clothes, and circulated heat removes

light wrinkles and restores the t to clothes that’s lost aer

wear by ghtening bers without shrinking.

Using the SWASH system is as easy as plugging it into a

standard 120 VAC wall outlet. No water, plumbing, pipes,

vents, special hook-ups, or professional installaon assistance

is needed.

GENERAL INFORMATION

SWASH™ System Specifications

Voltage: 120 VAC, 60 Hz

Heater Waage: 1300 W

Countdown and Display Status: LED Countdown Time Remaining - White LEDs

Cycle Done - Blue LED

Cup Missing - Orange LED

Cycles: Normal - 10 minutes

Heavy Duty - 15 minutes

Cancel

Number of Cycles: 3

Number of Garments: 2-Sided Treatment of 1 Garment

1-Sided Treatment of 2 Garments

Number of Smoothing Clips: 6

Number of Sprays: 4

Pocket Smoother 1

Height: 51 in.

Width: 16 in.

Depth: 30 in.

Depth with door open: 54 in.

SWASH™ Clothing Care System

n

1-5

GENERAL INFORMATION

Notes

1-6 n

SWASH™ Clothing Care System

OPERATION

Section 2:

Operation

This secon provides operaonal use and care informaon for

the “SWASH™ Clothing Care System.”

Q Connecng the SWASH™ System

Q Buons and Status Lights

Q How Does the SWASH™ System Work?

Q How to Use SWASH™ System

Q Hanging Clothes

Q Emptying the Reservoir

Q Consumer Troubleshoong

Q SWASH™ System Tips

Q Notes

SWASH™ Clothing Care System

n

2-1

OPERATION

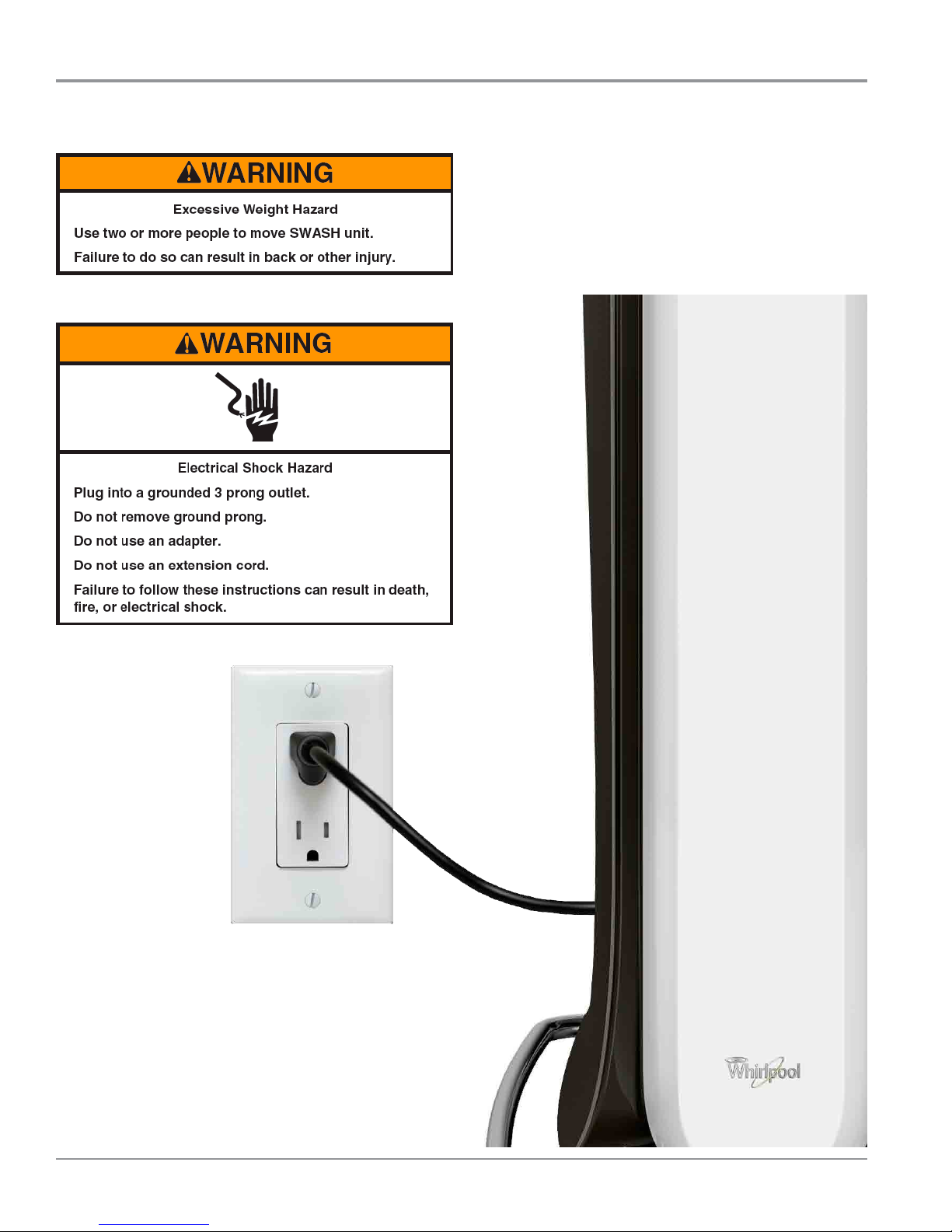

Connecting the SWASH™ System

Connecng the SWASH™ System

Plug your SWASH™ system into a standard grounded electrical

outlet (110v). No plumbing, pipes, or vents needed.

2-2 n

SWASH™ Clothing Care System

Figure 1

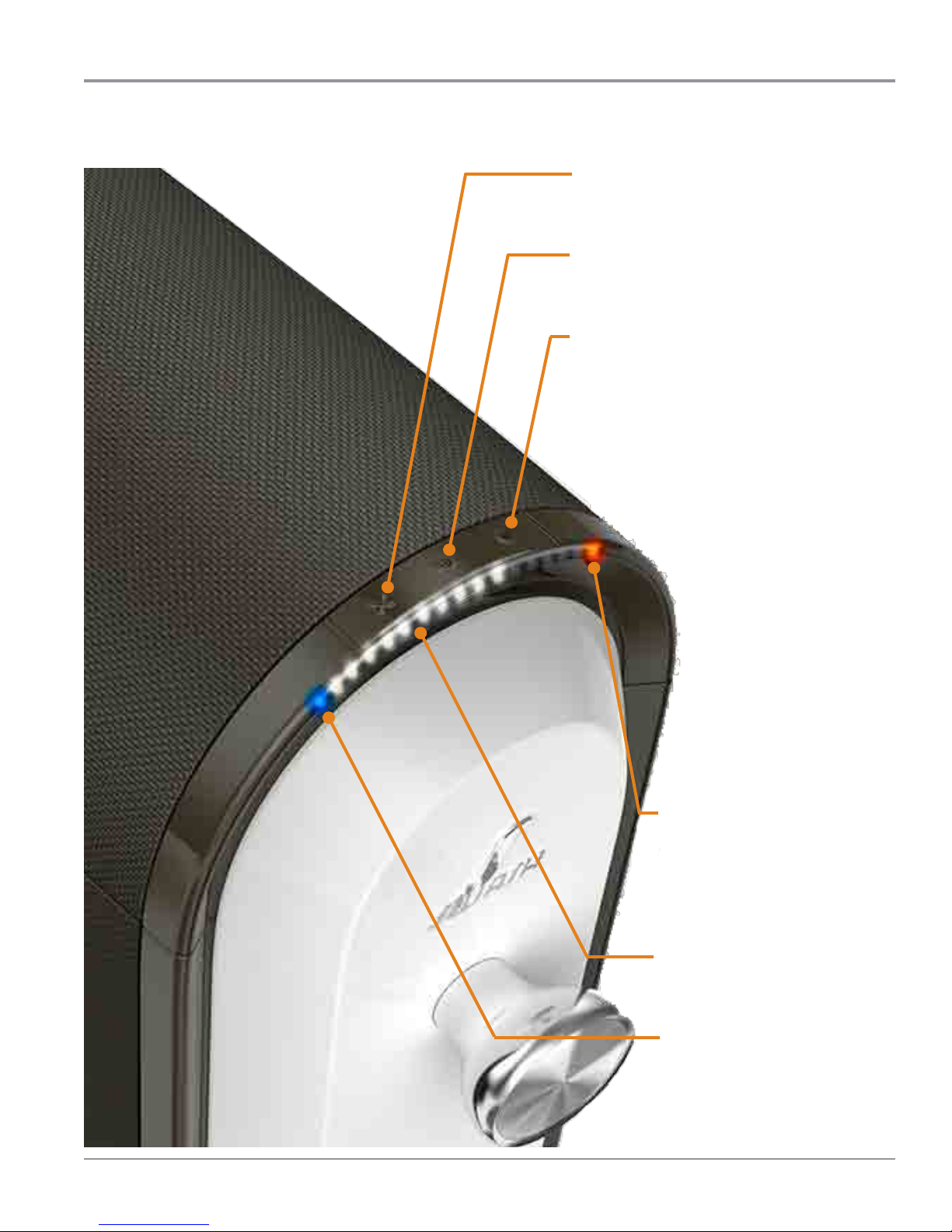

Buttons and Status Lights

X BUTTON

cancels the cycle

10 MINUTE BUTTON (STANDARD CYCLE)

use for most clothing

15 MINUTE BUTTON (EXTENDED CYCLE)

extends drying me for heavier clothing

OPERATION

ORANGE LIGHT

ashes if you try to start SWASH™

system without a cup or if the door

is not completely closed. If other

lights are on with the orange light

(see troubleshoong)

WHITE LIGHTS

count down the minutes remaining

BLUE LIGHT

turns on when your cycle is nished

Figure 2

SWASH™ Clothing Care System

n

2-3

OPERATION

How Does the SWASH™ System Work?

The SWASH™ system works with a few key technologies. A superne mist of the SWASH PODS™ formula is sprayed onto both

sides of the hanging clothes. The smoothing clips (oponal) pull clothes ght, and heat is circulated.

Superne mist circulaon

2-4 n

SWASH™ Clothing Care System

Warm air circulaon

Figure 3

Operang Basics

OPERATION

How to Use SWASH™ System

Hang

1. Pull out drawer and hang clothes in machine. See pages

6-7 for more informaon on how to hang clothes.

Load

2. Load a SWASH POD™ cup in top of drawer and close

drawer rmly (see Figure 4). Do not remove lm from cup

as it will get pierced when you push the drawer in. Only

use SWASH PODS™ cups.

Start

3. Select cycle buon to Start. Tap on “10” for standard

cycle, “15” for extended cycle, or “X” to cancel. See page 3

for more informaon.

10

Cancel

15

Figure 5

4. White LEDs will count down the minutes remaining and

a blue light will let you know when the cycle is done (see

Figure 6).

White Lights

(me remaining)

Figure 4

Figure 6

5. Remove the empty SWASH PODS™ cup.

6. Remove garment from SWASH™ system and enjoy.

SWASH™ Clothing Care System

n

2-5

OPERATION

Hanging Clothes

Hanging Your Clothes

Smoothing clips aren’t needed for refreshing. You can get great results with minimal eort. For smoothing wrinkles, try

experimenng with a few clips.

IMPORTANT: The SWASH™ system is not recommend for silk, leather, velvet, suede, and fur. Some temporary spots may occur.

If this happens, clean per clothing manufacturer’s instrucons.

CREASED PANTST-SHIRT / POLO SHIRT

Figure 7

SWEATER DRESS

Figure 8

2-6 n

SWASH™ Clothing Care System

OPERATION

Hanging Clothes (Continued)

Buon Down Shirt

Place sleeves through sleeve wraps and clip. Use the remaining 4 clips to pull at and hold ght to get maximum wrinkle release.

Finally put pocket smoother in pocket.

Pants or Jeans

Hang legs over the top of hanger rst and then clip. Pull waist down and clip

to get the most area exposed to the SWASH PODS™ formula.

Figure 9

Shorts or Skirts

Pull a couple of smoothing clips through the

hanger for shorts and skirts.

Figure 10

SWASH™ Clothing Care System

n

2-7

OPERATION

Emptying the Reservoir

Emptying the Reservoir

The SWASH™ system is designed to collect any excess mist for

easy disposal. If the orange and blue lights are both ashing,

you will need to empty the reservoir that collects the excess

mist.

1. Locate reservoir at rear base of SWASH™ system.

Blue Light

Figure 11

2. Remove reservoir and take to sink (see Figure 12).

Orange Light

3. Pull plug and empty out liquid in sink (see Figure 13).

Figure 13

4. Replace plug and insert reservoir back into SWASH™

system (see Figure 14).

Figure 12

2-8 n

SWASH™ Clothing Care System

Figure 14

Consumer Troubleshooting

Troubleshoong

Nothing happens when you push the 10 or 15

minute button

¾ Check to make sure the SWASH™ system is plugged into a

power outlet.

¾ If SWASH™ system is plugged in, unplug it and plug it back

in to reset.

SWASH™ system does not work as well as expected

¾ Select the recommended cycle based on your clothing type.

¾ Keep longer clothes from laying on the boom of the

device.

¾ SWASH™ system is only recommended for 2 lightweight

items. For best results, refresh only one item at a me.

¾ Do not operate, install, or store the SWASH™ system where

it will be exposed to water, weather, or at temperatures

below 50° F (10° C). Let the SWASH™ system and SWASH

PODS™ cups warm up to room temperature before use.

OPERATION

1. Orange light is blinking - SWASH™ system will

not start

¾ Make sure door is closed properly.

¾ Make sure cup is loaded in bay. If cup is empty or missing,

replace with new cup. Use only SWASH PODS™ cups in your

SWASH™ system.

2. Orange and blue lights are blinking

¾ The reservoir is full and needs to be emped, or is missing

and needs to be replaced. See emptying the reservoir on

page 2-8.

You have a spot on your clothing after a cycle.

¾ The SWASH PODS™ formula may leave a spot on some

fabrics. These spots are easily removed when clothes

are washed or dry-cleaned according to clothing

manufacturer’s care label.

SWASH™ System Tips

Multiple Clothing Items

The SWASH™ system works best on one item. If refreshing

2 items at a me, hang them back-to-back for best results.

Addional SWASH™ hanger required. You can order addional

hangers at SWASH.COM.

Reducing Wrinkles

To maximize wrinkle release, buon or zip up your clothing.

Use the smoothing clips for non-stretchy fabrics. Make sure

your clothes are ght and smooth.

Smoothing Clips

Experiment with the smoothing clips to nd what gives you

the best results for your clothes. You may not need all of the

provided smoothing clips to get great results.

3. Orange and white lights on

¾ If orange and me remaining lights are solid. SWASH™

system is paused. Close door and cycle will resume.

4. Orange light blinking and white lights on

¾ If orange light is blinking and at least two white lights

are solid, SWASH™ system is not working. See Secon 4,

“Diagnoscs and Troubleshoong.”

Temperature Use

If your SWASH™ system or SWASH PODS™ cups have just come

inside from very cold weather, allow them to sit for a while to

get to room temperature before using.

Cleaning SWASH™ system

Use a so, damp cloth or sponge to wipe your SWASH™

system to help keep it looking new.

Wash Hands after Cleaning

If eye contact occurs, rinse well with water. If irritaon

persists, get medical aenon.

Visit swash.com/setup for addional informaon and video demonstraons.

SWASH™ Clothing Care System

n

2-9

OPERATION

Notes

2-10 n

SWASH™ Clothing Care System

COMPONENT ACCESS

Section 3:

Component Access

This secon provides service parts access, removal, and

installaon instrucons for the “SWASH™ Clothing Care

System.”

n SWASH™ System Exploded Views

n SWASH™ System Parts List

n Removing the Rear Panel

n Removing the Top Cover & Control Housing

n Removing the User Interface

n Removing the Dispensing System

n Removing the Pump Assembly

n Removing the Appliance Control Unit (ACU)

n Removing the Thermistor

n Removing the Door Assembly

n Removing the Clips & Roller Assembly

n Removing Base Components

n Removing the Side Panels

n Notes

SWASH™ Clothing Care System

n

3-1

COMPONENT ACCESS

SWASH™ System Exploded View

NOTE: The SWASH™ System Exploded View was not available

at the me of publicaon. Please refer to PartSmartweb

Online Parts Catalog for product related parts informaon.

This page is a place-holder for future revision.

Reference Parts List on page 3

3-2 n

SWASH™ Clothing Care System

COMPONENT ACCESS

SWASH™ System Part List

NOTE: The SWASH™ System Parts List was not available

at the me of publicaon. Please refer to PartSmartweb

Online Parts Catalog for product related parts informaon.

This page is a place-holder for future revision.

SWASH™ Clothing Care System

n

3-3

COMPONENT ACCESS

Removing the Rear Panel

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

1. Unplug the SWASH™ Clothing Care System.

2. Locate the reservoir at the rear base of the unit.

3. Remove the reservoir and set aside.

4. Remove back cover. Using a T-20 TORX driver, remove the

9 screws securing the back cover to the SWASH system

(see Figure 2).

Reservoir

Figure 2

3-4 n

SWASH™ Clothing Care System

Figure 2

5. Set aside back panel for reinstallaon.

Removing the Top Cover & Control Housing

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

1. First, perform procedure on page 3-4, “Removing the Rear

Panel” prior to performing the following steps.

2. Remove the top cover by sliding the cover back “slightly”

towards the rear of the unit (see Figure 1).

COMPONENT ACCESS

4. Using a 1/4” socket, remove the six (6) screws (3 on each

side) securing the control housing to the unit (see Figure 3).

Control Housing

Cover Slots

Figure 3

5. Remove harness shield from back of the control housing

(see Figure 4).

Slide cover towards rear

Figure 1

3. Li the top up and away from the unit—starng from the

back (see Figure 2). Remove cover and set aside.

Li up cover and remove

Harness Shield

Figure 4

6. Remove control housing and set aside (see Figure 5).

Figure 2

Figure 5

SWASH™ Clothing Care System

n

3-5

COMPONENT ACCESS

Removing UI and Dispensing System

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

Removing the User Interface

1. First, perform procedure on page 3-4, “Removing the Rear

Panel” prior to performing the following steps.

2. Next, perform procedure on page 3-5, “Removing Top

Cover and Control Housing.

3. Slide open door.

4. Disconnect harness from UI PCB. See Figure 1.

5. Using a 1/4” nut driver, remove the

securing the User Interface to the control bracket as

illustrated in Figure 1.

door switch and remove from unit.

Pull UI Assembly forward over the

two (2) screws

Removing the Dispensing System

1. First, perform procedure on page 3-4, “Removing the Rear

Panel” prior to performing the following steps.

2. Next, perform procedure on page 3-6, “Removing Top

Cover and Control Housing.

3. Disconnect hose from Dispensing System.

4. Disconnect harness from Dispensing System micro-switch.

See Figure 1.

5. Using a 1/4” nut driver, remove the

securing the Dispensing System to the control bracket as

illustrated in Figure 1.

unit.

Remove Dispensing System from the

Switch Harness

two (2) screws

Pump Hose

Figure 1 - User Interface

Figure 1 - Dispensing System

UI Harness

3-6 n

SWASH™ Clothing Care System

Removing Pump, ACU, and Thermistor

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

Removing the Pump Assembly

1. First, perform procedure on page 3-4, “Removing the Rear

Panel” prior to performing the following steps.

2. Next, perform procedure on page 3-5, “Removing Top

Cover and Control Housing.

3. Disconnect hose from Pump Assembly (see Figure 1).

4. Disconnect hoses from “T” ng (see Figure 1).

5. Disconnect harness from Pump Assembly (see Figure 1).

6. Using a 1/4” nut driver, remove the four (4) screws

securing the Pump Assembly to the control bracket (see

Figure

1).

Remove Pump Assembly from the unit.

“T” Fing Hoses

Pump Hose

COMPONENT ACCESS

Removing the Appliance Control Unit (ACU)

1. First, perform procedure on page 3-4, “Removing the Rear

Panel” prior to performing the following steps.

2. Next, perform procedure on page 3-5, “Removing Top

Cover and Control Housing.

3. Disconnect the four (4) harnesses from the Appliance

Control Unit (ACU).

4. Using a 1/4” nut driver, remove the one (1) screw securing

the ACU to the control bracket (see Figure

ACU from unit.

Figure 1 - ACU

Removing the Thermistor

1. First, perform procedure on page 3-4, “Removing the Rear

Panel” prior to performing the following steps.

2. Next, perform procedure on page 3-5, “Removing Top

Cover and Control Housing.

3. Disconnect the two (2) wires going to the Thermistor

Assembly (see Figure 1).

4. Using a 1/4” nut driver, remove the two (2) screws

securing the Thermistor to the control bracket (see Figure

1).

Remove Thermistor from unit.

1).

Remove

Pump Harness

Figure 1 - Pump Assembly

Thermistor

Wires

Figure 1 - Thermistor

SWASH™ Clothing Care System

n

3-7

COMPONENT ACCESS

Removing the Door Assembly

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

Removing the Door Assembly

1. Unplug the SWASH™ Clothing Care System.

2. Slide open the door assembly as far as possible (see

Figure 1).

3. Lay SWASH™ system on its side to access the boom of

the door assembly (see Figure 2).

4. Separate the lower slide from the door frame. Using a

#2 Phillips screwdriver, remove the

screws and using a #15 TORX driver, remove the four (4)

‘boom-mounted’ screws as illustrated in Figure 2.

Phillips Screws

TORX Screws

Figure 2

NOTE: When reassembling the door frame to the lower slide,

be sure to place the tab of the lower slide assembly into the

slot located under the door frame as shown in Figure 3.

two (2) ‘side-mounted’

Figure 1

Frame Slot

Slide Tab

Figure 3

connued . . .

3-8 n

SWASH™ Clothing Care System

COMPONENT ACCESS

Removing the Clips & Roller Assembly

5. Set SWASH™ system upright. Using a #15 TORX driver,

remove the two (2) screws securing the top door cover as

illustrated in Figure 4. Remove cover to expose the upper

slide assembly.

Phillips Screws

Figure 4

6. Separate the upper slide from the door frame. Using a #1

Phillips screwdriver, remove the

securing the upper door to the slide assembly. See Figure 4.

Door assembly can now be removed from

three (3) bolts and nuts

SWASH™

system.

Removing the Clips & Roller Assembly

1. First, perform procedure on page 3-8, “Removing the Door

Assembly” prior to performing the following steps.

2. Using a #2 Phillips screwdriver, remove the door knob

from door assembly.

3. Remove door cover from door frame. The door cover is

aached to the frame by six (6) clips (see Figure 1). Slowly

pull the door cover from the frame 1 clip at a me starng

from the boom and working to the top.

Figures 1 & 2

4. Remove Clip and Roller Assembly. Using a #2 Phillips

screwdriver, remove the four (4) screws (2 on each side)

securing the clips & roller assembly to the upper door

frame. See Figure 3.

Figure 4

Phillips Screws

(each side)

Figure 3

SWASH™ Clothing Care System

n

3-9

COMPONENT ACCESS

Removing Base Components

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

1. Unplug the SWASH™ Clothing Care System.

2. Locate the reservoir at the rear base of the unit. (Refer to

page 3-4 for locaon of reservoir.)

3. Remove the reservoir and set aside.

4. Lay SWASH™ system on its back (see Figure 1).

5. Using a 1/4” nut driver, remove the ve (5) screws

securing the boom plate to the unit (see Figure 1).

Remove boom plate and set aside.

6. Using a #20 TORX driver, remove the four (4) screws

securing the reservoir housing to the unit (see Figure 2).

Boom Plate

Figure 2

7. Remove the reservoir housing by sliding two at bladed

screwdrivers in-between the housing and side panel of

unit. Gently, move the side panel away from the housing

unl it pops free from base. See Figure 3.

Figure 1

3-10 n

SWASH™ Clothing Care System

Figure 3

Removing Base Components (continued)

8.

Disconnect the blower and heater connectors (see Figure 4).

9. Using a 1/4 nut driver, remove the screw securing the

ground wire coming from the blower motor (see Figure 4).

10. Using a 1/4” nut driver, remove the seven (7) screws

securing the blower/heater assembly to the unit (see

Figure 4).

Blower

Connector

COMPONENT ACCESS

11.

To remove the heater from the blower/heater

assembly, use a 1/4” nut driver to remove the two

screws securing the heater to the blower housing (see

Figure 5 below).

12.

Remove heater assembly from blower housing. The

heater assembly contains the heater coil, thermal

cuto, and high limit thermostat. (See Figure 6.)

Blower Wheel

GND Screw

Figure 6

IMPORTANT: The fan motor and blower wheel cannot be

replaced individually. The fan motor, blower wheel, and

blower housing must be replaced as an assembly.

Heater

Connector

Figure 4

Heater Assembly

Fan Motor

Heater Screws (2)

Figure 5

SWASH™ Clothing Care System

n

3-11

COMPONENT ACCESS

Removing the Side Panels

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

1. First, perform procedure on page 3-6, “Removing the Rear

Panel” prior to performing the following steps.

2. Next, perform steps 1 - 3 on page 3-7, “Removing Top

Cover and Control Housing.

3. Side panels are held in place with tabs (see Figure 2). To

remove side panel, grasp top of panel on each side and li

up (see Figure 1). Set aside for reassembly.

Side Panel Tabs (4)

Li up panel and remove

Figure 2

5. SWASH™ system with side panels removed (see Figure 4).

NOTE: Two (2) sprayers on each side of cabinet.

Sprayers

Tabs Slots (4)

Figure 1

4. Repeat process for other side.

3-12 n

SWASH™ Clothing Care System

Figure 3

Notes

COMPONENT ACCESS

SWASH™ Clothing Care System

n

3-13

COMPONENT ACCESS

Notes

3-14 n

SWASH™ Clothing Care System

DIAGNOSTICS & TROUBLESHOOTING

Section 4:

Diagnostics &

Troubleshooting

This secon provides diagnosc, fault codes, and

troubleshoong informaon for the “SWASH™ Clothing Care

System.”

n Safety First

n Customer Troubleshoong

n Customer Error Codes

n Control Panel

n Diagnosc Guide

n Service Diagnoscs

n Service Diagnosc Funcons

n Fault / Error Codes

n Troubleshoong Guide

n Wiring Diagram

n Appliance Control Unit (ACU)

n User Interface (UI) Assembly

n Strip Circuits

n Notes

SWASH™ Clothing Care System

n

4-1

DIAGNOSTICS & TROUBLESHOOTING

WARNING

For Service Technician Use Only

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

Electrical Shock Hazard

Voltage Measurement Safety Information

When performing live voltage measurements, you must do the following:

n Verify the controls are in the off position so that the appliance does not start when energized.

n Allow enough space to perform the voltage measurements without obstructions.

n Keep other people a safe distance away from the appliance to prevent potential injury.

n Always use the proper testing equipment.

n After voltage measurements, always disconnect power before servicing.

IMPORTANT: Electrostatic Discharge (ESD) Sensitive Electronics

ESD problems are present everywhere. Most people begin to feel an ESD discharge at approximately

3000V. It takes as little as 10V to destroy, damage, or weaken the main control assembly. The new

main control assembly may appear to work well after repair is nished, but a malfunction may occur

at a later date due to ESD stress.

n Use an anti-static wrist strap. Connect wrist strap to green ground connection point or unpainted

metal in the appliance

n Touch your nger repeatedly to a green ground connection point or unpainted metal in the

appliance.

n Before removing the part from its package, touch the anti-static bag to a green ground

connection point or unpainted metal in the appliance.

n Avoid touching electronic parts or terminal contacts; handle electronic control assembly by

edges only.

n When repackaging main control assembly in anti-static bag, observe above instructions.

IMPORTANT SAFETY NOTICE — “For Technicians only”

This service data sheet is intended for use by persons having electrical, electronic, and mechanical

experience and knowledge at a level generally considered acceptable in the appliance repair trade.

Any attempt to repair a major appliance may result in personal injury and property damage. The

manufacturer or seller cannot be responsible, nor assume any liability for injury or damage of any

kind arising from the use of this data sheet.

4-2 n

SWASH™ Clothing Care System

-OR-

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Customer Troubleshoong

Nothing happens when you push the 10 or 15

minute button

¾ Check to make sure the SWASH™ system is plugged into a

power outlet.

¾ If SWASH™ system is plugged in, unplug it and plug it back

in to reset.

SWASH™ system does not work as well as expected

¾ Select the recommended cycle based on your clothing type.

¾ Keep longer clothes from laying on the boom of the

device.

¾ SWASH™ system is only recommended for 2 lightweight

items. For best results, refresh only one item at a me.

¾ Do not operate, install, or store the SWASH™ system where

it will be exposed to water, weather, or at temperatures

below 50° F (10° C). Let the SWASH™ system and SWASH

PODS™ cups warm up to room temperature before use.

You have a spot on your clothing after a cycle.

¾ The SWASH PODS™ formula may leave a spot on some

fabrics. These spots are easily removed when clothes

are washed or dry-cleaned according to clothing

manufacturer’s care label.

Customer Error Codes

1. Orange light is blinking - SWASH™ system will

not start

¾ Make sure door is closed properly.

¾ Make sure cup is loaded in bay. If cup is empty or missing,

replace with new cup. Use only SWASH PODS™ cups in your

SWASH™ system.

2. Orange and blue lights are blinking

¾ The reservoir is full and needs to be emped, or is missing

and needs to be replaced. See emptying the reservoir on

page 2-8.

3. Orange and white lights on

¾ If orange and me remaining lights are solid. SWASH™

system is paused. Close door and cycle will resume.

4. Orange light blinking and white lights on

¾ If orange light is blinking and at least two white lights

are solid, SWASH™ system is not working. See Secon 4,

“Diagnoscs and Troubleshoong.”

SWASH™ Clothing Care System

n

4-3

DIAGNOSTICS & TROUBLESHOOTING

FOR SERVICE TECHNICIAN’S USE ONLY

For Service Technician Use Only

Control Panel

White LEDs (15)

X

“10” key

10 15

“X” key

Control Panel, Viewed From Above Control Panel, Viewed From Front

“15” key

Diagnosc Guide

Before servicing, check the following:

n Make sure there is power at the wall outlet.

n Has a household fuse blown or circuit breaker tripped? Was a

regular fuse used? Inform the customer that a me delay fuse

is required.

n All tests/checks should be made with a VOM (volt-ohm-

milliammeter) or DVM (digital-voltmeter) having a sensivity

of 20,000 Ω per volt DC or greater.

n Check all connecons before replacing components. Look for

broken or loose wires, failed terminals, or wires not pressed

into connecons far enough.

n A potenal cause of a control not funconing is corrosion on

connecons. Observe connecons and check for connuity

with an ohmmeter.

n Connectors: Look at top of connector. Check for broken or

loose wires. Check for wires not pressed into connector far

enough to engage metal barbs.

n Resistance checks must be made with power cord unplugged

from outlet, and with wiring harness or connectors

disconnected.

Blue LED

LED 8

LED 6

LED4

Figure 1

LED 10

LED 12

LED 14

Service Diagnoscs

NOTE: THE ONLY WAY TO ENTER SERVICE DIAGNOSTICS IS

FROM THE OFF MODE.

The SWASH™ system should be able to enter service

diagnoscs mode regardless of the state of door switch and

reservoir switch.

Right aer powering up (plugging in the SWASH™ system), you

will have 30 seconds to press the three dierent keys in any

sequence three mes within 10 seconds to place the SWASH™

system in service diagnosc mode. If the key sequence is not

completed within the 10 second me period, entrance to

service diagnosc mode will not occur. If entrance to service

diagnosc mode is successful, the following sequence of

events will occur:

1. If the reservoir switch is ON, all 15 white LEDs will ash

ON and OFF. The tester must verify that no LED is missing.

If the reservoir switch is OFF, all 15 White LEDs will be OFF.

2. The service technician will instruct the tester to “Press

and hold the <15> key”. If the tester veries that the fan

relay turned ON, this step passed. Releasing the <15> key

will turn the relay OFF.

3. Next the service technician will instruct the tester to

“Press and hold the <10> key”. If the tester veries that

the pump relay turned ON by detecng a waage change

of approximately 60W, this step passed. Releasing the

<10> key will turn the relay OFF. Verify that the power

consumpon decreased.

4. Next the service technician will instruct the tester to

“Press and hold the <X> key”. If the tester veries that

the heater reads approximately 1300W, this step passed.

Releasing the <X> key will turn the relay OFF.

5. The blue LED will ash ON and OFF if the thermistor is

operang correctly.

6. The blue LED will turn ON if the thermistor is OPEN or

SHORTED.

7. Open the door and the orange LED will turn OFF.

8. Shut the door and the orange LED will ash ON and OFF.

9. Service diagnoscs will end aer two minutes or if power

is cycled.

Orange LED

4-4 n

SWASH™ Clothing Care System

NOTE: Refer to table on page 4-5 for diagnosc test funcons.

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Service Diagnosc Funcons (see page 4-4 for instrucons)

Right aer powering up (plugging in the SWASH™ system), you will have 30 seconds to press the three dierent keys in any

sequence three mes within 10 seconds to place the SWASH™ system in service diagnosc mode. If entrance to service

diagnosc mode is successful, the following funcons will be available.

COMPONENT KEY STATUS LEDs

RESERVOIR SWITCH ON

OFF

FAN RELAY “15” Acvates Fan* N/A

All 15 White LEDs ash ON and OFF

All 15 White LEDs OFF

PUMP RELAY “10”

HEATER RELAY “X”

THERMISTOR Funconal

DOOR SWITCH Open

NOTES:

* Press and hold the <15> key to turn on the Fan. Release the <15> key to turn o the Fan.

† Press and hold the <10> key to turn on the Pump. Release the <10> key to turn o the Pump.

‡ Press and hold the <X> key to turn on the Heater. Release the <X> key to turn o the Heater. (You will hear the heater

solenoid on the ACU “click” when the heater turns on and o.)

Acvates Pump†

Acvates Heater‡

Open/Shorted

Closed

N/A

N/A

Blue LED Flash ON and OFF

Blue LED will turn ON

Orange LED will turn OFF

Orange LED Flash ON and OFF

SWASH™ Clothing Care System

n

4-5

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Fault / Error Codes

DISPLAY ERROR CODE MALFUNCTION EXPLANATION AND RECOMMENDED PROCEDURE

LED ON:

12, 14

LED FLASHING:

ORANGE

LED ON:

10, 12, 14

LED FLASHING:

ORANGE

LED ON:

8, 10, 12, 14

LED FLASHING:

ORANGE

F3E1 Open Thermistor Condion Connually monitor temperature sensor for an invalid

resistance value based on the thermistor reading value out

of the range of 35.42kΩ (32°F/0°C) and 719Ω (212°F/100°C).

This error will show if reading more than 35.42kΩ for more

than 30 seconds.

1. Review the ambient temperature of the room; if the

temperature of the sensor is less than 32°F (0°C), the

error will remain.

2. Verify the wire harness connecon. Any open

connecon will create a resistance higher than 35.42kΩ

and the error will remain.

3. Reset the ACU by unplugging the SWASH™ system for

more than 5 seconds.

4. Enter the service diagnoscs mode (see page 2) and

review the operaon of the thermistor.

5. Verify the resistance value of the thermistor (J3-5 to J3-

6); if it is open or shorted, replace the thermistor.

F2E2 Shorted Thermistor Condion Connually monitor temperature sensor for an invalid

resistance value based on the thermistor reading value out

of the range of 35.42kΩ (32°F/0°C) and 719Ω (212°F/100°C).

This error will show if reading less than 719Ω for more than

30 seconds.

1. Review the ambient temperature of the room; if the

temperature of the sensor is more than 212°F (100°C),

the error will remain.

2. Verify the wire harness connecon. Any shorted

connecon will create a resistance lower than 719Ω

and the error will remain.

3. Reset the ACU by unplugging the SWASH™ system for

more than 5 seconds.

4. Enter the service diagnoscs mode (see page 2) and

review the operaon of the thermistor.

5. Verify the resistance value of the thermistor (J3-5 to J3-

6); if it is open or shorted, replace the thermistor.

F2E1 Shorted Key Event If the control detects an invalid key press (one or more keys

pressed for more than 5 seconds), the UI will generate an

error code (F2E1) to the ACU.

1. Disconnect the WIDE Connector of the UI and reset the

SWASH™ system by unplugging the power for more

than 5 seconds. By doing this, the capacive buons

will recalibrate.

2. Make sure that the UI PCB Assembly is not aected by

extreme ambient condions like temperature (185°F

[85°C] max.) and humidity (95% non condensate).

3. Verify 5V input from WIDE connector between lines

P1-1 and P3-1.

4. Inspect the keypad area to conrm that there are no

liquids, moisture, or any other foreign materials on the

capacive buon area.

4-6 n

SWASH™ Clothing Care System

Connued . . .

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Fault / Error Codes (connued)

DISPLAY ERROR CODE MALFUNCTION EXPLANATION AND RECOMMENDED PROCEDURE

LED ON:

6, 8, 10, 12, 14

LED FLASHING:

ORANGE

LED ON:

4, 6, 8, 10, 12, 14

LED FLASHING:

ORANGE

F6E1 WIDE Communicaon The failure will be shown if: Communicaon

• The ACU has not received a valid WIDE serial

communicaon message within 30 seconds.

• The ACU has detected connuous problems with

messages transmied over the WIDE bus.

• If communicaon is resumed at any me, the display

will funcon normally.

1. Check the wire harness connecon between the ACU

and the UI, and measure connuity between all wires.

2. Make sure that the UI PCB Assembly and the ACU

board are not aected by extreme ambient condions

like temperature (185°F [85°C] max.) and humidity

(95% non condensate).

3. Reset the SWASH™ system by disconnecng the power

for more than 5 seconds.

4. Verify 5V output from the WIDE connector between

lines P1-1 and P3-1 and the P19 connector.

5. Enter the service diagnoscs mode (see page 2) and

review the operaon of the thermistor.

F1E1 Microcontroller Fault If a corrupted microcontroller or communicaon error has

occurred, the ACU will generate this error code.

1. Review input voltage from lines P12 and P9. It should

be 120 VAC/60 Hz.

2. Make sure that the ACU board is not aected by

extreme ambient condions like temperature (185°F

[85°C] max.) and humidity (95% non condensate).

3. Remove the ACU board from the plasc chassis and

perform a visual inspecon of the back of the board.

4. Verify 5V and 12V output on the P19 connector

between pins P19-2 and P19-3 for 5V, and P19-1 and

P19-3 for 12V.

5. If no voltage is detected in step 4, replace the ACU.

SWASH™ Clothing Care System

n

4-7

DIAGNOSTICS & TROUBLESHOOTING

WARNING

For Service Technician Use Only

Troubleshoong Guide

DANGER

Electrical Shock Hazard

Only authorized technicians should perform

diagnostic voltage measurements.

After performing voltage measurements,

disconnect power before servicing.

Failure to follow these instructions can result in

death or electrical shock.

Disconnect power before servicing.

Replace all parts and panels before operating.

Failure to do so can result in death or

electrical shock.

PROBLEM POSSIBLE CAUSE /TEST

NOTE: Possible Causes/Tests must be performed in the sequence show for each problem.

WON’T POWER UP

(buons do not respond

when pressed)

WON’T START A CYCLE 1. Verify that there is a cup inside the SWASH™ system.

WON’T DISPENSE 1. Verify that the cup inside the SWASH™ system is new.

1. Verify that the SWASH™ system is plugged into a working outlet and that there are no blown fuses or

tripped circuit breakers.

2. Verify that the plug does not have two adapters aached to it.

3. Unplug the SWASH™ system or disconnect the power.

4. Reconnect the power.

5. Check the voltage available (120V) at the ACU terminals (CON2-P12 and CON1-P9). If there is voltage,

go to step 10.

6. If there is no voltage at the ACU, disconnect the power cord from the harness and check if there is

voltage (120V) at the connector that plugs into the harness. If there is voltage at the power cord

connector, go to step 8.

7. Replace the power cord if there is no voltage at the connector.

8. Check the connuity between power cord connector terminal 1 on the harness and CON2-P12. Check

the connuity between terminal 2 and CON1-P9.

9. Replace the harness if there is no connuity in any line.

10. Check that there is 5V DC between pin 2 and pin 3 at connector P19 inside the ACU.

11. If there is no voltage between pin 2 and pin 3 at connector P19 on the ACU, replace the ACU.

12. If there is voltage between pin 2 and pin 3 at connector P19 on the ACU, replace the UI.

2. Check if the orange LED on the UI is ashing at a rate of 3 Hz.

3. If the orange LED is ashing and a cup is inserted in the SWASH™ system, verify that the piercing

mechanism is funconing properly.

4. Verify that the pump harness is connected to the ACU at connector J1-10.

5. Disconnect the pump, aempt to start a cycle, and verify that there is voltage at the pump terminals

on the harness during the dispensing phase.

6. If there is no voltage at the pump terminals on the harness, check the connuity of the harness

between the pump and the ACU. If connuity is OK, replace the ACU.

2. Disconnect the pump, aempt to start a cycle, and verify that there is voltage at the pump terminals

on the harness during the dispensing phase. If there is voltage, go to step 4.

3. If there is no voltage at the pump terminals on the harness, check the connuity of the harness

between the pump and the ACU. If connuity is OK, replace the ACU.

4. If there is voltage at the pump terminals on the harness, replace the pump.

Electrical Shock Hazard

4-8 n

SWASH™ Clothing Care System

Connued . . .

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

Troubleshoong Guide (connued)

PROBLEM POSSIBLE CAUSE /TEST

NOTE: Possible Causes/Tests must be performed in the sequence show for each problem.

GARMENT IS WET 1. Disconnect the fan motor and verify that there is voltage of 120V at the fan motor connector on the

THERE IS A PUDDLE OF

WATER BENEATH THE

SWASH™ SYSTEM

CUP IS NOT COMPLETELY

EMPTY

SWASH™ SYSTEM STARTS

BY ITSELF

SWASH™ SYSTEM VIBRATES

OR IS NOISY

harness during the running/drying mode. If there is voltage, go to step 5.

2 If there is no voltage at the fan motor connector on the harness, check the connuity between fan

motor connector terminal 1 and CON1-P11 and also between fan motor connector terminal 2 and

CON1-P9.

3. Replace the harness if there is no connuity in any line.

4. Replace the ACU if the harness is OK and if voltage was not found at the fan motor connector on the

harness in step 1.

5. If there is voltage at the fan motor connector on the harness, replace the fan motor.

1. Empty the reservoir tray.

2. Disconnect the reservoir sensor switch.

3. Check the connuity (J3-3 to J3-4) in the reservoir sensor switch connector to the SWASH™system

when the reservoir tray is inserted. If there is connuity, go to step 5.

4. If there is no connuity, replace the reservoir sensor switch.

5. Check the connuity in the harness between reservoir sensor switch connector terminal 1 and

CON3-P4 and also between sensor switch connector terminal 2 and CON3-P3.

6. Replace the harness if there is no connuity in any line.

7. If none of these steps indicate an electrical problem, the problem is mechanical and the reservoir tray

must be replaced.

1. Verify that the piercing mechanism is properly piercing the cup.

2. Remove the needle and make sure that liquid can pass through it.

3. Inspect the hoses to verify that they are not kinked.

4. Replace the pump.

1. Check for an error code on the SWASH™ system display.

2. Verify that there is voltage of 5V DC between pin 2 and pin 3 at connector P19 on the ACU.

3. If there is no voltage between pin 2 and pin 3 at connector P19 on the ACU, replace the ACU.

4. If there is voltage between pin 2 and pin 3 at connector P19 on the ACU, replace the UI.

1. Verify that the pump is properly aached.

2. Make sure that the impeller is not touching the lower blower.

3. Verify that the motor is properly aached.

4. Verify that the motor sha is not damaged.

SWASH™ Clothing Care System

n

4-9

DIAGNOSTICS & TROUBLESHOOTING

FOR SERVICE TECHNICIAN’S USE ONLY

For Service Technician Use Only

CUP

SWITCH

SENSOR

IMPORTANT: Electrostac discharge may cause damage to control electronics. See page 5-1 for ESD informaon.

Figure 2

Wiring Diagram

4-10 n

SWASH™ Clothing Care System

For Service Technician Use Only

Appliance Control Unit (ACU)

DIAGNOSTICS & TROUBLESHOOTING

J3 - Thermistor, Cup &

Reservoir Switches

J1 - Neutral, Pump, & Fan Motor

APPLIANCE

CONTROL

UNIT

ACU CONNECTOR PIN-OUTS

CONNECTOR J1

(Neutral, Pump, and Fan Motor)

J1-9 Neutral from plug

J1-10 Pump

J1-11 Fan Motor

CONNECTOR J2

(L1 and Heater)

J2-7 Heater Assembly

J2-12 L1 from plug

P19 - User Interface J2 - L1 & Heater

Figure 3

CONNECTOR J3

(Pod Switch, Reservoir Switch, and Thermistor)

J3-2 Switch, Cup Sensor

J3-3 Switch, Reservoir Sensor

J3-4 Switch, GND

J3-5 Thermistor (Temp 2)

J3-6 Thermistor (Temp 1)

CONNECTOR P19

(User Interface)

P19-2 +5 VDC

P19-3 Ref GND

P19-4 DATA

SWASH™ Clothing Care System

n

4-11

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

User Interface (UI) Assembly

Figure 3 - User Interface Assembly

Flex PCB

Rigid PCB

P3 - Flex PCB

UI CONNECTOR PIN-OUTS

CONNECTOR J1

(Appliance Control Unit)

J1-1 +5 VDC

J1-2 DATA

J1-3 Ref GND

User Interface

Rigid PCB

J1 - Appliance Control Unit

Figure 3 - Rigid PCB

CONNECTOR P3

(Flex PCB)

P3 - Ribbon Connector

4-12 n

SWASH™ Clothing Care System

Strip Circuits

L1

N

FAN MOTOR

L1

N

HEATER

L1

N

PUMP

Heater

DIAGNOSTICS & TROUBLESHOOTING

For Service Technician Use Only

BK

Fan Motor

Pump

J2-12

ACU BOARD

BK

BK

J2-12

HEATER

J2-12

RELAY

J2-7

ACU BOARD

FAN MOTOR

RELAY

ACU BOARD

PUMP

RELAY

V

P6-1

J1-11

J1-10

THERMAL

CUTOFF

BOTTOM TRAY

NOTE: Check TCO & High Limit if open circuit is detected.

THERMAL

FUSE

LBU

P7-1

BOTTOM TRAY

NOTE: Check Thermal Fuse if open circuit is detected.

HEATER

ELEMENT

11.5 Ω

FAN

MOTOR

13.1 Ω

M

PUMP

V

P5-1

NOTE: Check pump resistance if open circuit is detected.

??? Ω

P

P5-2

HIGH LIMIT

THERMOSTAT

W

P7-2

W

P6-2

W

W

W

W

Pod / Reservoir Switches

CUP SENSOR SWITCH

POD SENSOR SWITCH

RESERVOIR SENSOR SWITCH

ACU BOARD

Thermistor

ACU BOARD

TEMP1

J3-6

POD SWITCH

CUP SWITCH

J3-2

J3-3

B

Y

RESERVOIR

SWITCH

THERMISTOR

R/W R/W

10k Ω ∗

* Approximate value measured

at room temperature

R

J3-4

R

GND

ACU BOARD

ACU BOARD

J3-5

TEMP 2

SWASH™ Clothing Care System

4-13

n

DIAGNOSTICS & TROUBLESHOOTING

Notes

4-14 n

SWASH™ Clothing Care System

PRODUCT SPECIFICATIONS &

WARRANTY INFORMATION SOURCES

IN THE UNITED STATES:

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL:

PHONE: 1-866-333-4195

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-832-7174

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED IN-HOME SERVICE PROFESSIONAL

FOR LITERATURE ORDERS (CUSTOMER EXPERIENCE CENTER):

PHONE: 1-800-851-4605

FOR TECHNICAL INFORMATION AND SERVICE POINTERS:

www.servicemaers.com

IN CANADA:

FOR PRODUCT SPECIFICATIONS AND WARRANTY INFORMATION CALL

PHONE: 1-800-461-5681

FOR TECHNICAL ASSISTANCE WHILE AT THE CUSTOMER’S HOME CALL:

THE TECHNICAL ASSISTANCE LINE: 1-800-488-4791

HAVE YOUR STORE NUMBER READY TO IDENTIFY YOU AS AN

AUTHORIZED IN-HOME SERVICE PROFESSIONAL

SWASH™

Clothing Care System

W10713431

Loading...

Loading...