Page 1

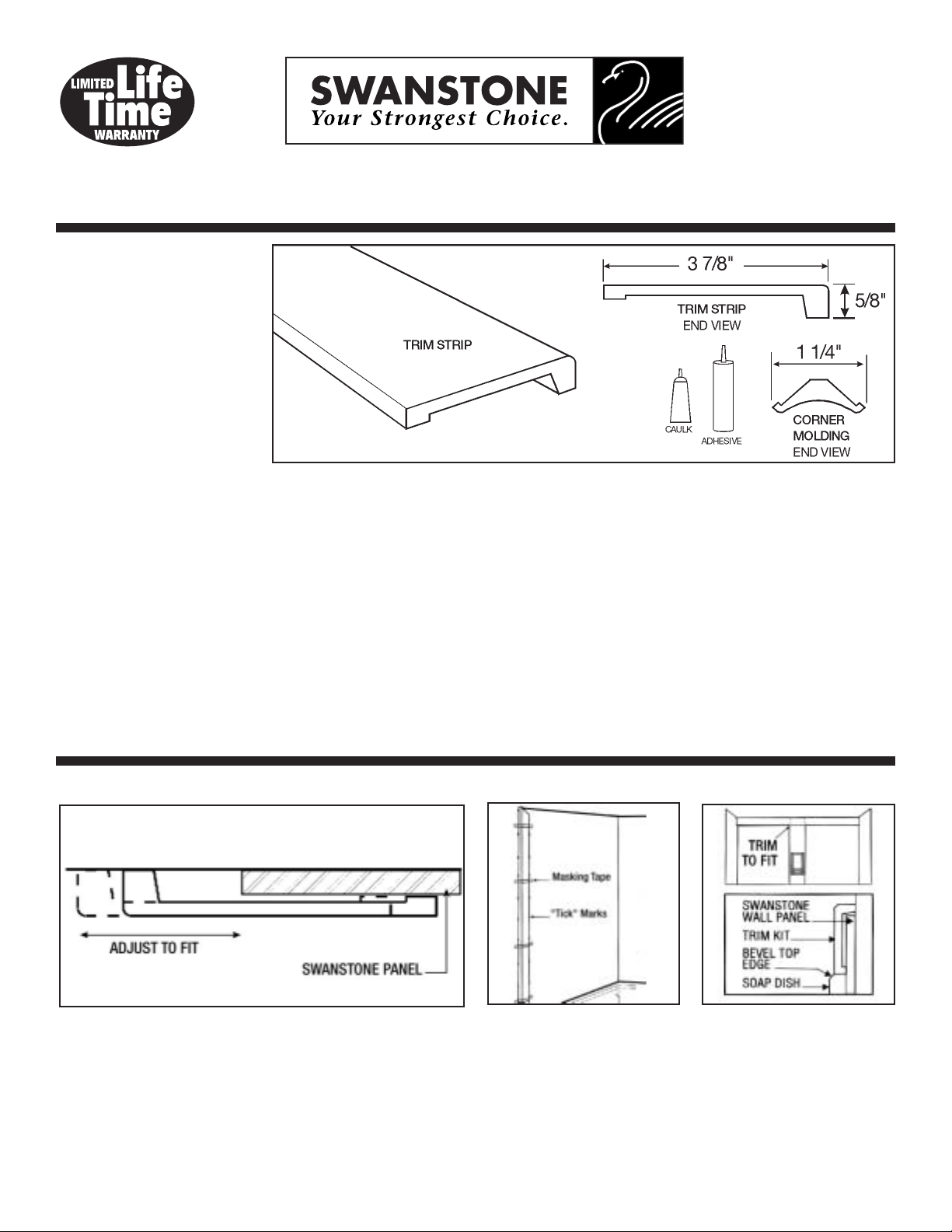

TK-6072 & TK-105 Wall Panel Trim Kits

An adjustable trim kit unit will

accommodate 30⬙ to 32⬙ bath-

tub depths. Designed to fit over

Swanstone Model SS bathtub

panels or Model SS shower

panels only.

INCLUDED IN CARTON:

TK-6072

Four 3-7/8⬙ x 74⬙ trim strips and

two 1-1/4⬙ x 7/8 ⬙ x 72⬙ corner

moldings designed to fit

Swanstone 60⬙ and 72⬙ high x 5⬘

wide (or smaller) bathtub and

shower wall panel systems.

TK-105

Two 3-7/8⬙ x 105⬙ trim strips,

two 3-7/8⬙ x 74⬙ trim strips and

two 1-1/4⬙ x 7/8⬙ x 96⬙ corner

moldings. All are designed to fit

Swanstone 96⬙ high x 5⬘ wide

(or smaller) shower wall panel

systems including 96⬙ NEO

walls.

NOTE

All Trim Kits include one 11 oz.

tube of adhesive and one 6 oz.

tube of color coordinated caulk.

Installation Procedure for

TOOLS REQUIRED

TO INSTALL

Tools needed are a carbide tip

saber saw, drill, ruler, level,

masking tape, and caulking gun.

For best results and extended

tool life, we recommend professional or industrial rated power

tools. All routing and cutting

tools should have a minimum

rating of 10 AMPS.

CUTTING AND ROUTING

TOOLS

Dependent on the type of cut or

edge detail required, one or

more of the following tools may

be required.

• Circular saw: Minimum 40tooth carbide blade (triple chip

grind, 60-tooth will give a

smooth, clean cut)

• Portable power plane with carbide blades or cutter heads.

• Saber Saw (straight up/down

blade travel). Fine plywood

carbide blade or blade with no

tooth over-hang (14 teeth per

inch)

• Miter saw

IMPORTANT

If you are installing the TK-6072

bathtub wall panel trim kit over a

Swanstone SS-60 bathtub wall

panel unit, trimming of the center

soap dish panel will be required.

You must follow the procedure

shown in step #3.

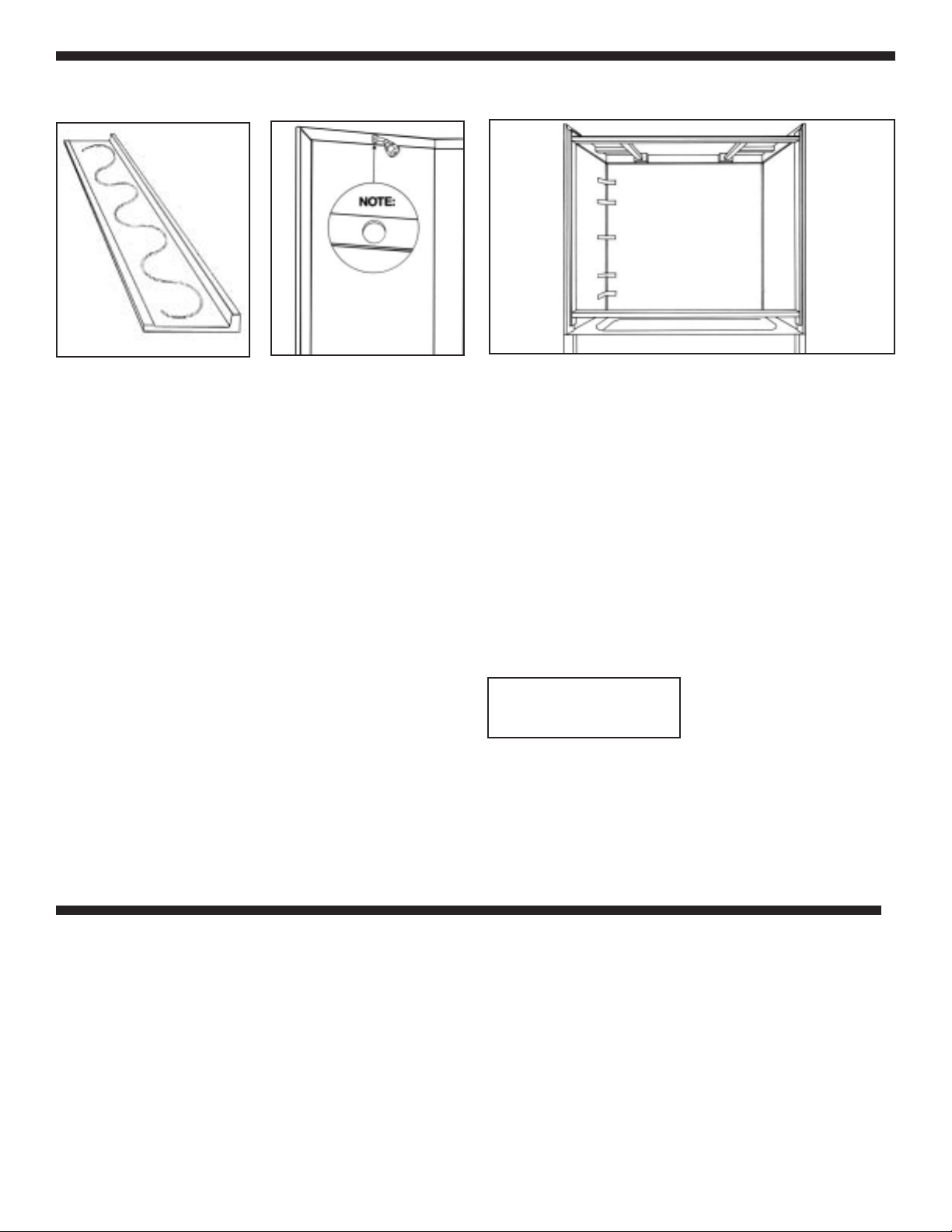

TRIAL FIT BEFORE YOU START

1

1. VERTICAL TRIM STRIP

Select any two of the trim strips. A 45⬚ mitered cut is recommended

for seaming the vertical and horizontal strips. The outside, or long,

measurement of the vertical trim strip should be approximately 7/8⬙

greater than the vertical measurement of the wall panel. Set each vertical trim strip into position. The most desirable placement will line up

the front edge of the trim strip with the front edge of the bathtub or

shower floor. Trial fit all pieces before final application.

2

2. VERTICAL FIT

For a proper vertical fit, check

with a level. Temporarily secure

trim strip to the wall with masking tape. Mark the location of the

vertical trim strips with “tick”

marks. These “tick” marks will be

used for final fit.

3

3. IMPORTANT

If you are installing the TK-6072

bathtub wall panel trim kit over a

Swanstone SS-60 bathtub wall

panel unit, it will be necessary to

trim the center soap dish panel.

Using the proper cutting tools

(see Cutting and Routing Tools),

measure and trim as needed.

(continued)

Page 2

INSTALLATION INSTRUCTIONS CONTINUED

4

4. BACK WALL-HORIZONTAL

TRIM STRIP

Transfer measurement from the

back wall onto either one of the

two remaining trim strips. Using

the proper cutting tools (see

“Cutting and Routing Tools”) trim

as needed. Following the pattern

illustrated, run a 1/8⬙ bead of

adhesive along the entire length

of the trim strip. Final fit by setting into position.

5

5. SIDE WALLS-HORIZONTAL

TRIM STRIPS

Transfer measurements from the

side walls onto the remaining

trim strip. Using the proper cutting tools (see “Cutting and

Routing Tools”) trim as needed.

Follow the adhesive pattern in

step #4 and final fit trim strips

into place.

NOTE

It may be necessary to cut one

of the side wall trim strips to

allow for the location of the

shower arm. Measure and locate

the position of the desired cut.

Use router, spade bit, twist drill,

or hole saw only. DO NOT USE

AUGER BITS. Cut hole 1/2⬙

larger than the diameter of the

pipe. Drill from the finished side

of the panel.

6 & 7

6. FINAL FIT

You are now ready to final fit the

vertical trim strip. Repeat the

adhesive pattern used in both

steps #4 and #5. Using the “tick”

marks from step #2, position the

vertical trim strips into place.

NOTE

To promote contact until adhesive sets, use temporary bracing

and allow adhesive to cure

overnight. Temporary bracing

may be constructed and wedged

into position as illustrated by

using lengths of 1 x 2s, 2 x 2s,

1x3s. Lumber should be cut as

needed.

POSITIVELY NO

HAMMERING OR NAILING

IS TO BE DONE.

7. CORNER MOLDING

Locate the placement of the

corner moldings and measure

the vertical areas of the corner

seam. Trim corner molding to

desired length and trial fit. If

installing corner moldings around

an SS-7211 Swanstone soap

shelf, multiple measurements

and cuts will be required.

Apply a 3/16⬙ bead of adhesive

(included in kit) along the corner

seam where the corner molding

is to be placed. Press corner

molding firmly into position.

Immediately remove any excess

adhesive with a damp cloth.

Temporarily secure corner molding to the wall with masking tape.

Allow adhesive to cure overnight.

CAULKING

Following instructions on the

caulking tube...apply a bead of

caulk along the bottom and to

edge of the back and side

walls. Also make caulk applications to all vertical seams

and edges.

CLEANING

Clean your Swanstone bathtub panels as you would any other fine bath fixture, using normal household detergents and cleansers.

Just wiping the wall surfaces quickly removes watermarks and residues. Occasional scrubbing with household abrasive cleansers

ensures that the original luster is maintained, similar to tile and other permanent type bath fixture materials.

REPAIRING

Use 400 grit sandpaper to remove scratches and gouges in the surface. A Scotchbright pad can be used to blend in the area.

The Swan Corporation

St. Louis, MO 63101

FORM #528-4-98-5M

Loading...

Loading...