Page 1

Indesit Company UK Ltd

© 2015 Reg. Office: Peterborough PE2 9JB Registered in London: 106725

Service

Information

SWAN brand

Entry Level

ELECTRONIC

CONDENSER

TUMBLE DRYERS

Models Covered:

STCL407WUK 87207

STCL407BUK 87208

STCL408WUK 87209

STCL408BUK 87210

5407837 Issue 2 July 2015

SM003992 ~ C00307711

PLEASE NOTE:

These models do not

display Fault Codes if a

Fault occurs.

Refer to the Fault Finding

details on page 6.

Page 2

2 of 34

Service Manual UK

Indesit Company

English

SAFETY NOTES & GENERAL SERVICING ADVICE

1. This manual is NOT intended as a comprehensive repair/maintenance guide to the appliance.

2. It should ONLY be used by suitably qualified persons having technical competence applicable

product knowledge and suitable tools and test equipment.

3. Servicing of electrical appliances must b e undertaken with the applia nce disconnected (unplugge d)

from the electrical supply.

4. Servicing must be preceded by Earth Continuity, Earth Resistance and Insulation Resistance

checks.

5. Personal safety precautions must be taken to protect against accidents caused by sharp edges on

metal and plastic parts.

6. After servicing the appliance must be rechecked for Electrical Safety. In the case of appliances

which are connected to a water supply (i.e.: Washing Mach ines, Dishwashers & Foo d Centres etc.)

checks must be made for leaks from seals gaskets and pipe work and rectification carried out where

necessary.

7. It can be dangerous to attempt 'DIY' repairs / maintenance on complex equipment and the Company

recommends that any problem with the appliance is referred to its own Service Organisation.

8. Whilst the Company has endeavou red to ensure the accuracy of the data within thi s publication they

cannot hold themselves responsible for any inconvenience or loss occasioned by any error within.

SERIAL NUMBER / INDUSTRIAL CODE EXPLANATION

Serial Number Example

1 10 02 0895

Four remaining digits = Build number that day 895

th

built

Third two digits = Day of manufacture 2

nd

of month

Second two digits = Month of manufacture October

First digit = Year of manufacture 2011

Industrial Code Example

37 24455 0010

Last four digits = 0000 original production.

Second five digits = COMMERCIAL CODE*

First two digits = Factory of origin

* Vital for correct model information and system identification

Other numbers denote major production changes

Page 3

3 of 34

Indesit Company

Service Manual UK English

INDEX

Safety & Servicing Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Serial Number / Industrial Code Explanation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Production Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Model Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Energy Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Fault Finding / Test Cycles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 10

Thermistor Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Heater Connection Details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Dryer Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 - 16

Dryer Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 - 19

Dryer Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 - 23

Component Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 - 25

Programme Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Control Board Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27 - 28

Dismantling - Condenser . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29 - 33

Production Changes

February 2015 Settings File updated to fix Dryer not heating when used in locations with a low

ambient temperature (Garages / Outhouses etc.)

Thermistor Resistance value chart added to this document (Issue 3 ) .

Page 4

4 of 34

Service Manual UK

Indesit Company

English

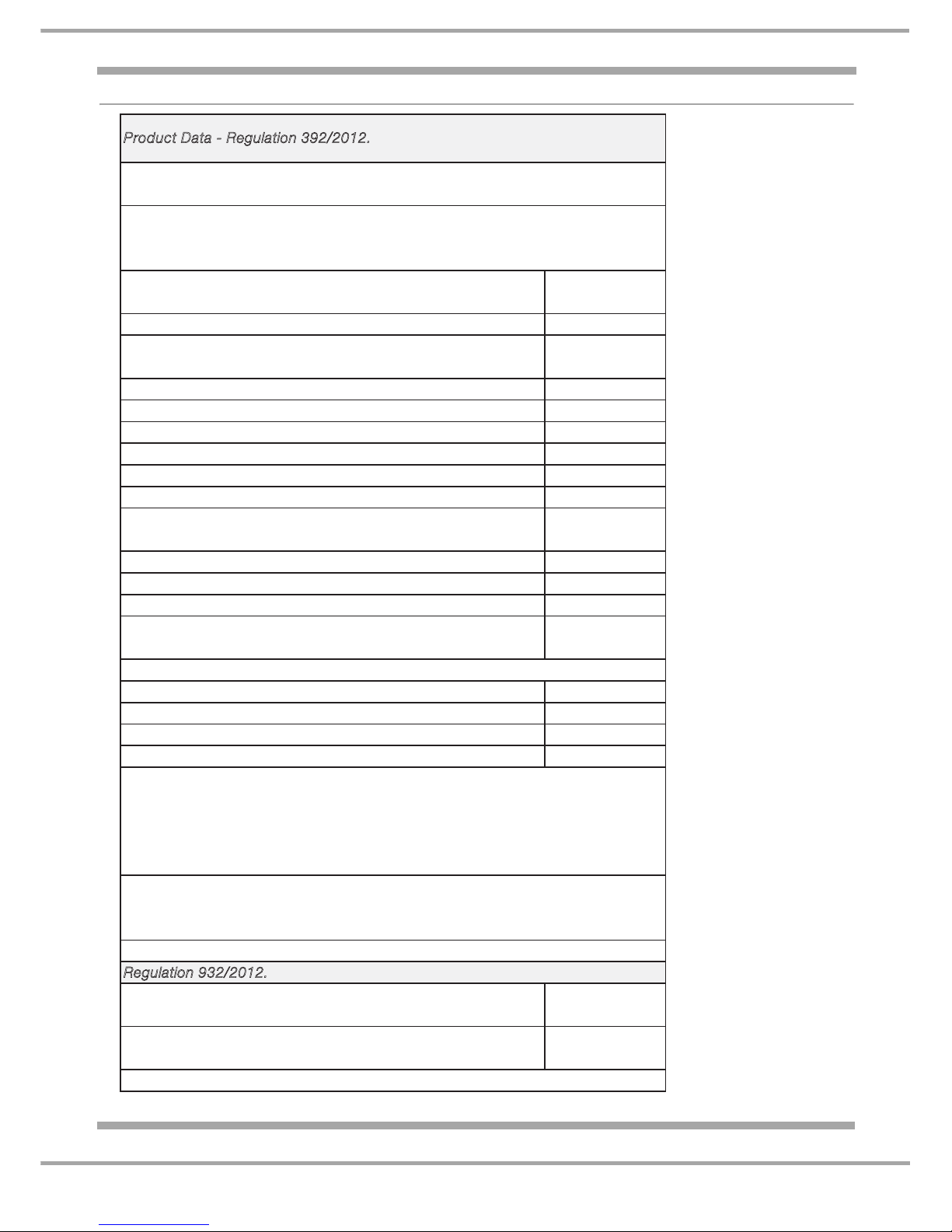

Example Energy Information - STCL408W / STCL408B

This household tumble drier is a Condenser

The weighted Annual Energy Consumption (AEc)* kWh 1) 627.8

This household tumble drier is a Automatic

Energy consumption full load; Edry - kWh 2) 5.33

Energy consumption partial load; Edry½ - kWh 2) 2.83

Power consumption: o-mode (Po) - Watts 0.42

Power consumption: left-on mode (Pl) - Watts 2.24

Prog. Time - weighted (Tt) full & partial load - minutes 3) 112

Full load (Tdry) - minutes 151

Partial load (Tdry½) - minutes 82

weighted (Ct) full & partial load 3) 71

full load (Cdry) 71

partial load (Cdry½) 71

Airborne acoustical noise emissions - dB(A) re 1 pW 68.0

Programme time in minute, for program “Synthetics” full load 85

Partial load for program “Synthetics” N/A

Average condensation eciency - %

1) "Standard cotton” at full and partial load is the standard programme to which the

information in the label and the che relates. The standard cotton program is

suitable to dry at cupboard level (0%) cotton laundry and is the most ecient

programme in terms of energy consumption. Partial load is half the rated load.

2) based on 160 drying cycles of the standard cotton programme at full and partial

load, and the consumption of the low-power modes. Actual energy consumption

will depend on how the appliance is used.

3) Weighted average of 3 cycles at full load and 4 cycles at half load.

R

egulation 93 2 /2 0 12.

Energy consumption in kWh, for program “Synthetics” full load 1.93

Energy eciency class on a scale from A+++ (low consumption)

to D (high consumption)

C

Duration of the 'left-on mode' for power management system minutes

30

Condensation eciency class on a scale from G (least ecient) to

A (most ecient)

C

P

roduct Data - R egulation 392/2012.

Brand

Swan

Model

STCL 408W (UK) STCL 408B (UK)

Rated capacity of cotton laundry for the "standard cotton

programme" at full load - kg

8.0

Page 5

5 of 34

Indesit Company

Service Manual UK English

SPECIFICATIONS

Introduction Date August 2014

Features Electronically controlled tumble dryer comprising an combined interface

and control module fitted to the rear of the dashboard.

Country of Origin UK

Dimensions

Height 850 mm

Width 595 mm

Depth 623 mm

Net Weight 36.87 kg

Colour White

Energy Class B or C Depending on model (2012 Energy Label Regulations)

Noise Level 69db

Power Consumption

Left On 2.24 watts

Off Mode 0.42 watts

Drum Volume 112 Litres

Electronics Stripped Arcadia

Heater High Heat 2.3 kW

Heater Controls Variable using Electronic Controls and sensors

Sensing Levels 3 or 5 depending on model.

Control Thermostats Cycling Thermostat 120

°C

One Shot Thermostat 143 °C

Motor Type 362/363-Single Phase Capacitor run 2 pole Induction Motor 2800 rpm

Capacitor 8.5uF

Approvals CE, IMQ

Page 6

6 of 34

Service Manual UK

Indesit Company

English

FAULT FINDING

FAULT CODES

These models DO NOT display Fault Codes when the dryer develops a fault.

However an Auto Test feature is available to help diagnose faults.

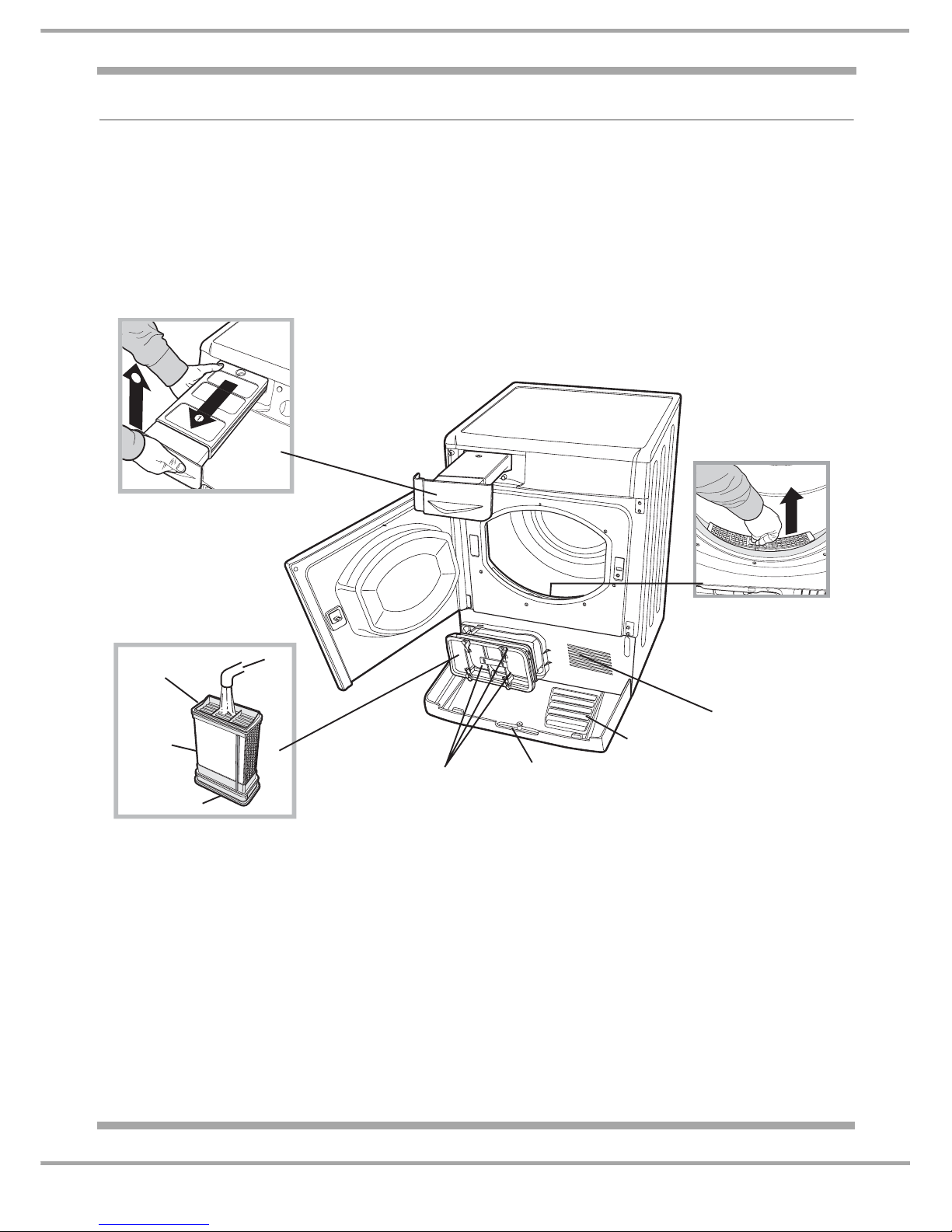

Preliminary Checks:

Before performing any tests ALW AYS check that the W ater Cont ainer is empty and that the Condenser

Unit and the Drum Filter are NOT blocked with fluff or lint, as this may be the cause or partial cause of

the of the fault.

Auto Test

If a Fault is detected the dryer will not move on to the next phase of the test, but will perform the

following sequence:

> Beep Once

> Pause for 30 Seconds

> Beep 3 Times

> The End LED will display

This will Indicate the dryer has a Fault, but it will not indicate the exact cause of the problem.

Observing at which phase the auto test ends gives an indication of the type of fault and cause.

See the information on the following pages.

2

Water container

Condenser Unit

Condenser cover

Catches

Filter

Handle

Air intake

Ta p

Rear

Front

Condenser

unit

Page 7

7 of 34

Indesit Company

Service Manual UK English

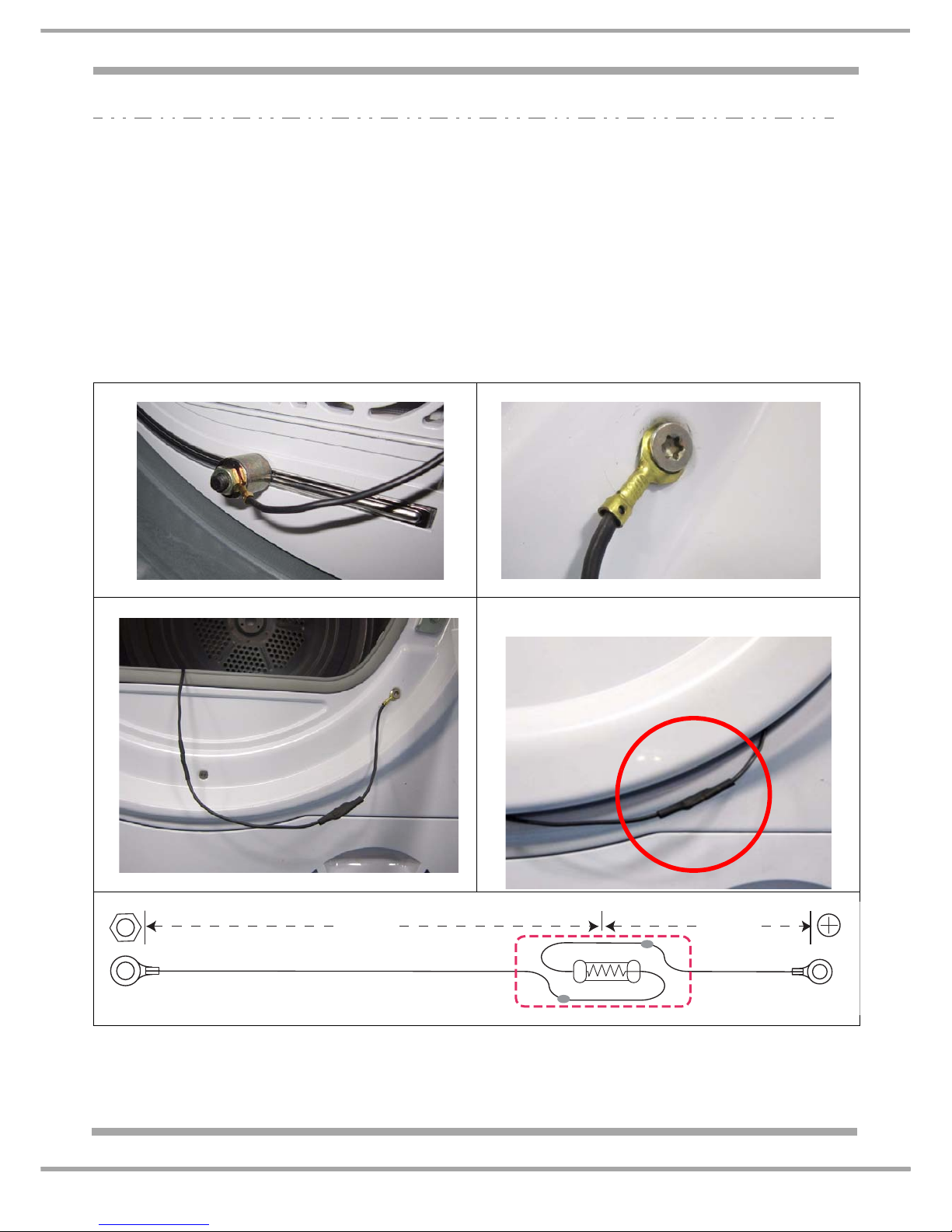

Auto Test Sequence

Before Starting the Auto Test, make sure the Water Container is empty, the Filter and

Condenser are Clear of fluff or lint.

Auto Test - Preparation:

If you are including the Conductivity Sensor Test when running the test procedure:

1. Attach the magnetic end of the 270 K ohm test lead to the metal strip conductivity sensor inside

the drum.

2. Connect the ring terminal end to an earth point on the cabinet of the machine. (The Ai r Duct fixing

screw is recommended).

3. After attaching, check Earth Continuity between this ring terminal and the mains power plug Earth

pin on or the metal rear panel of the dryer, using a multimeter.

The continuity resistance reading should be 1 ohm or less.

Magnet fixed to sensing strip inside the drum Ring terminal end fixed under air duct screw

Routing of wire and resistor. Safe position of 270K ohm resistor

assembly with door closed

270K

2W

450 mm

180 mm

Magnet Screw fixing

Page 8

8 of 34

Service Manual UK

Indesit Company

English

AUTO TEST - CONDENSER DRYERS

SAFETY WARNING !

When performing the Auto Test you will need to remove the top cover of the Dryer while

Electrical power is still applied.

To avoid the risk of electric shock, during this sequence you MUST make certain no

persons have any contact with the LIVE area around the Mains Terminal Block (cable entry

position) or main Power module behind the Console.

Preparation:

1. Remove the 2 screws securing the top cover to allow its removal when required during the test

sequence.

2. If necessary fit the Magnetic Test resistor. See page 7 for details.

To Enter Auto Test Mode - Condenser Models

1. The dryer must be plugged into the electricity supply with the Programme Selector set to the

“OFF” Position.

2. Turn the Selector Clockwise to Programme 1. Wait for the LED’s to turn OFF.

3. Push the Delay Option Button once.

4. Turn the Selector Clockwise to Programme 2.

5. Push the Delay Option Button once.

6. Turn the Selector Anti-Clockwise to Position 15.

7. Push the Start Button once.

This starts the test, indicated by the drum rotating clockwise fo r a short period - approximately

7 -8 seconds.

Note: If after starting the Auto Tes t and the drum has not Pause d within 15 seconds, the a uto test

has not been entered successfully, turn the control Knob to OFF, and repeat the above sequence.

TEST SEQUENCE - for a CONDENSER DRYER which has no detectable Faults

1. The Drum Rotates Clockwise for about 7 or 8 seconds.

Pause.

At this point remove the top cover. Remove the Water Bottle and pour 300 ml of water into the

Water Bottle support. (This will operate the Float Switch at the base of the dryer).

2. Refit the Water Bottle (if the Water Bottle is not replaced the test will fail at this point).

3. The dryer will pause until the Float Switch has moved to the full position.

The drain pump will turn on and the drum will rotate Clockwise for about 15 seconds.

The water that was poured into the support (filling the pump) will be pumped into the water bottle.

Pause for 5 seconds.

4. The Drum Rotates Anti-Clockwise with the Heater On (both elements) until the Rear Thermistor

detects a temperature Rise, - the heater then turns OFF and the drum continues to rotate.

Pause for 5 seconds.

5. The Drum Rotates Clockwise with the Heater On until the Front Thermistor detects a temperature

change, the Heater turns Off and the drum continues to rotate.

Long Pause.

6. 3 Beeps then the END LED Illuminates.

7. Test Ends.

Page 9

9 of 34

Indesit Company

Service Manual UK English

TEST SEQUENCE - for a CONDENSER DRYER which has a Fault,

1. The Drum rotates clockwise for about 7 to 8 seconds

Step Phase: Float switch operation and Drain Pump operation

At this point remove the top cover. Remove the Water Bottle and pour 300 ml of water into the

Water Bottle support. This will operate the Float Switch at the base of the dryer.

2. Refit the Water Bottle (if the Water Bottle is not replaced the test will fail at this point).

3. The dryer will pause until the Float Switch has moved to the full position.

The drain pump will turn on and the dr um wi ll r otate Clockwi se for abou t 15 se conds - ac tual Ti me

depends on quantity of water in the base reservoir.

The water that was poured into the support (filling the pump) will be pumped into the water bottle.

Pause 5 seconds.

Step Phase: Heater Operation and Rear Thermistor Temperature Check

4. Drum Rotates Anti-Clockwise with the Heater On (both elements) until the Rear The r mistor

detects a temperature Rise, - the heater then turns OFF and the drum continues to rotate for a

short period.

Pause for 5 seconds.

Step Phase: Heater Operation and Front Thermistor Temperature Check

5. Drum turns Clockwise with Heater On (both elements), until the Front Thermistor detects a

temperature change.

6. Heater will Turn Off, the Drum will continue for a few minutes..

Step Phase: Conductivity Sensor Check (only applies if magnetic resistance is being used)

8. Test Ends

If the pump is faulty or a there is a blockage in the hose or a pump wiring fault, the

Water container will not fill with water at this point, and the drum wil l continue to turn

for approx. 3 minutes, then the dryer beeps, paus es fo r 30 se con ds , bee ps 3 times

then the Test Ends.

If the Rear Thermistor, Thermostat or Heater is Open Circuit (both Elements) or

disconnected the Test Cycle will finish at this point - then the dryer beeps, pauses

for 30 seconds, beeps 3 times then the Test Ends.

If the Front Thermistor, is Open Circuit or disconnected the Test Cycle will finish at

this point - then the dryer beeps, pauses for 30 seconds, beeps 3 times then the

Test Ends.

7.

With Magnetic test resistor fitted

and Sensor Circuit OK

Without Magnetic test resistor fitted

OR fitted but Sensor Circuit not OK

Long Pause,

3 Beeps,

End LED is Illuminated.

Pause,

Beep,

Long Pause,

3 Beeps,

End LED is Illuminated.

Page 10

10 of 34

Service Manual UK

Indesit Company

English

DRYER OPERATION CHECK - Condenser Models

When Checking Heater, Drum Action or Thermistor Operation, you are advised to use a Timed

Programme.

When Sensor Programmes are used, after the module has estimated the weight of the clothes and the

cycle time required to dry the clothes, the Dryer will start to reverse tumble.

Note: This weight and estimated drying time are calculated by the module which monitors the front

thermistor temperature increase in the Front Air Duct over a period of time.

For example, a small load will allow a faster temperature rise at the front thermistor.

A large load would cause the temperature to rise more slowly.

Drum

When set to a Timed Programme the machine will reverse for a short period approximately every 5

minutes.

Heater

Faulty or Disconnected Thermistors (Front and Rear) and the associated wiring will cause the

machine not to heat. (If an Auto Cycle is used the dryer may operate at ½ Heat, depending on cycle

used).

In these instances the machines will complete the Cycle without Heating with no indication to the user,

other than the load will be cold and wet at the end of the cycle.

One Element Open Circuit - Dryer works at 1.15 kW and dries normally taking slightly longer to

complete the cycle.

Thermistors

Rear Thermistor (Located on Heater Frame) next to the Cycling and One-Shot cut-outs.

Page 11

11 of 34

Indesit Company

Service Manual UK English

Thermistor Tables

When testing these Thermistors make sure you have selected the CORRECT resistance range on

your test meter for the value you expect to see. The resistance value varies with temperature.

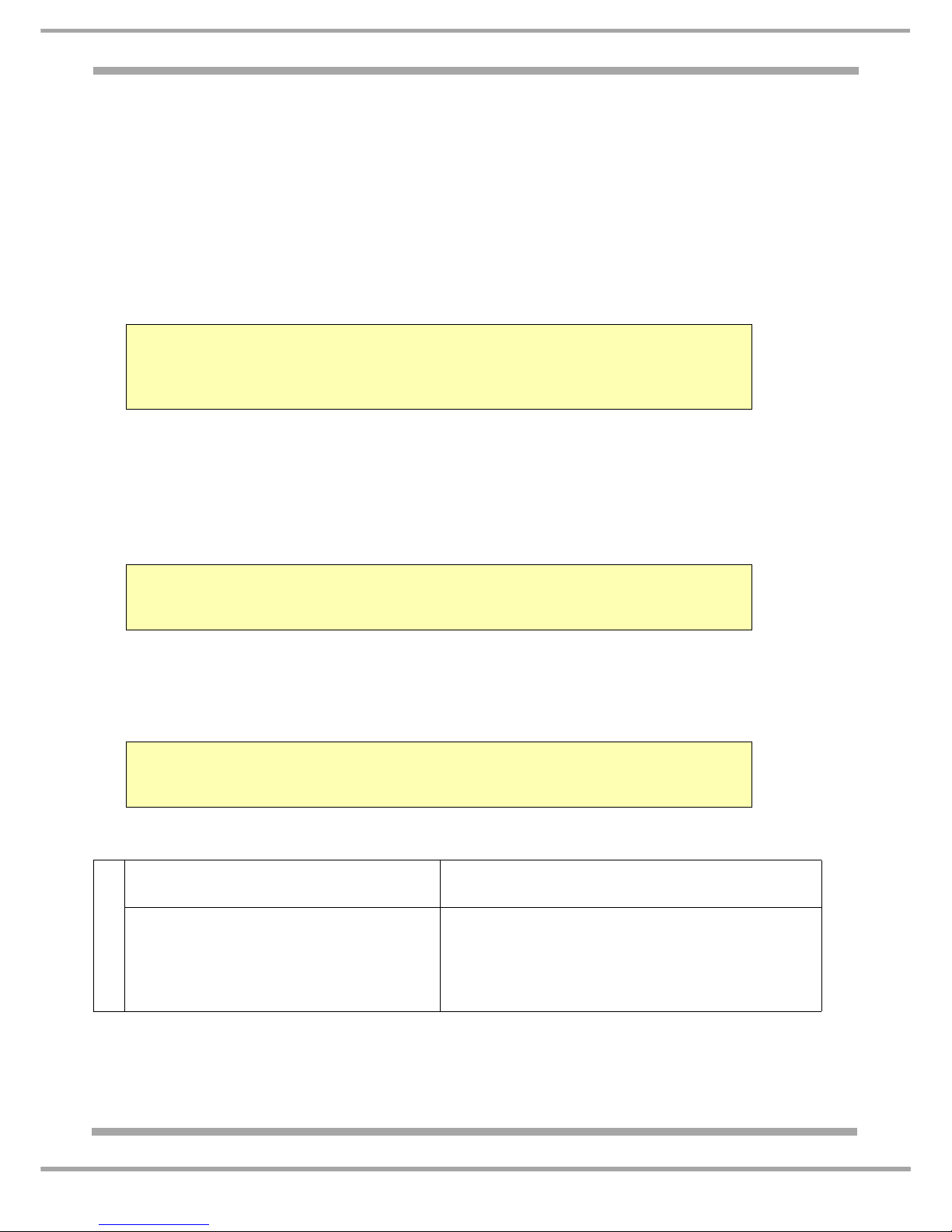

FRONT THERMISTOR REAR THERMISTOR

Temperature

°C

Resistance

KΩ

Temperature

°C

Resistance

KΩ

-20 462.89 -20 958.78

-10 268.29 -10 549.14

0 160.39 0 324.98

10 98.66 10 198.37

20 62.32 20 124.37

25 50.00 25 100.00

30 40.35 30 80.544

40 26.73 40 53.173

50 18.096 50 35.878

60 12.496 60 24.768

70 8.792 70 17.418

80 6.296 80 12.442

85 5.361 85 10.582

90 4.583 90 9.0436

100 3.388 100 6.6843

110 5.0111

Example: Front Thermistor

If the ambient temperature where

you are testing is 15°C you would expect to get a

reading of approximately 80.40KΩ.

(If the thermistor has warmed up because of

handling or operation of the dryer then the meter

reading will be a lower value)

The Rear Thermistor is a different component wi th

a different specification - refer to the chart

120 3.8064

125 3.3330

130 2.9262

140 2.2754

150 1.7891

Page 12

12 of 34

Service Manual UK

Indesit Company

English

Heater Connection Details

Cable Colours

Heater / Thermistor Connector Plug

Always fit a cable

tie to secure the

Heater connectors

together.

dynamic/upper heater

brown

orange

orange

orange

white

link

hot/rear NTC

5

4

3

2

1

red

red

static/lower heater

one shot

cycling

cut-out

thermostat

cycling one shotthermistor

Page 13

Indesit Company

13 of 34

Service Manual UK English

WIRING DIAGRAM - Entry Level CONDENSER Models

231

65321

4

blue

red

black

1

2

cycling

thermostat

one shot

cut-out

door switch

brown

brown

orange

orange

orange

231

231

front NTC

hot/rear NTC

float switch

drain pump

PSC Motor

with protector

3

4

blue

red

red

red

black

Capacitor

main connection

with suppressor

L

N

E

brown

blue

54321

red

red

white

red

blue

white

Drum assy

sensing

strip

1

2

3

132

orange

blue

blue

red

red

CONNECTOR

ON BOARD WAYS WIRES DESCRIPTION

CN1 5 5 I2C

CN2 4 4 UART BPM motor

CN3 1 1 earth

CN4 1 1 sensi ng

strip

CN5 6 4 drain pump

- Ňoat switch

CN6 3 2 hot/rear NTC

CN7 3 2 front NTC

CN9 3 3 PSC motor

CN10 3 3 heate r

CN11 4 4 suppressor - doorsw itch

1

2

HARNESS INDESIT CODE DESCRIPTION

H1 21023259100 motor

drain pump

Ňoat

switch

front NTC

hot

NTC

H2 16002965300 Sensingstrip

H3 16002965200 Earth

H4 16002974000 Heater

H5 16002973900 s

uppressor -

door sw itch

green/yellow

static/lower heater

dynamic/upper heater

Heater cover assy

cw

ccw

4,8

160029741

160029743

160029744

160029742

black

160029653

160029652

160029739

160029738.00

CN1CN2

CN3

CN4

CN5CN9 CN6

CN7

CN10

CN11

CONDENSER DRYER

Page 14

14 of 34

Service Manual UK

Indesit Company

English

INSTALLATION

The dryer MUST be located away from gas stoves,

hobs or heaters.

If the dryer is located under a work surface, there

must be a 10 mm gap around any top or above the

dryer and a minimum 15 mm space along each side.

This is to ensure correct air circulation.

CONDENSER DRYERS

Draining the dryer into an Internal Drain

If the dryer drains into an external drain, the water container will not need to be regularly emptied.

The height of the drain must be less than 1 metre from the bottom of the dryer.

Remove the existing hose from the position shown, Fig. 1. Fit a suitable length of hose (Part No.

C00279043) to the location shown in the photo (Fig. 2).

Confirm the hose is not squashed or kinked when the dryer is in its installed position.

15 mm

15 mm

10mm

Remove this hose

Fig.1

Outlet Spigot

Fig.2

New drain hose fitted

Fig.3

Page 15

15 of 34

Indesit Company

Service Manual UK English

LOOKING AFTER THE DRYER

FLUFF FILTER

The fluff filter MUST be cleaned after every use.

Never use a Tumble Dryer without

the filter in place.

1. Remove the filter from the

dryer.

2. Open and clean the filter.

WATER CONTAINER

Empty the water container after every cycle.

1. Remove the water container from the dryer.

2. Empty the water container intoa sink.

3. Replace the water container ensuring it is fully pushed home.

NOTE: -

Priming for water collection.

When the dryer is new, depending on the type of load dried. It may take one or two cycles for water to

be collected in the water container.

Once primed, water will be collected after every drying cycle.

2

Page 16

16 of 34

Service Manual UK

Indesit Company

English

CONDENSER UNIT - CONDENSER DRYERS

For normal domestic use, the condenser should be cleaned once a month.

1. Open the condenser cover by pulling on the handle.

2. Rotate the 3 clips and pull the condenser towards you to remove. Some water is normal.

3. Flush the condenser unit from the rear to remove fluff deposits.

4. Refit the condenser, with the arrows pointing upwards. Once pushed home, rotate the 3 clips to

lock into place.

Open this flap by pulling the handle

Release the latches to remove the condenser

Remove and Rinse the Condenser

Refit the condenser the correct way up

over a sink or bath

Page 17

17 of 34

Indesit Company

Service Manual UK English

DRYER OVERVIEW

Introduction of Simplified Electronics

These Models are fitted with a new Electronic Module, which is fixed to a plastic carrier, located behind

the Console.

This Module replaces the Control Module (previously located in the Base), the Display Module +

Control Interface (previously located behind the Dashboard) and the Module to Display interface

harness, fitted to 2013 Production Tumble Dryers.

It is NOT interchangeable with earlier products which use 2 modules.

The module is covered with a white plastic water shield which must always be fitted correctly and

retained with its fixing clip.

Programming Connector

The module is programmed using Memwriter and a Hardware

Key or with a SmartCard Reader and Card, connected using a

Low End Adaptor.

(See pages 27 & 28 - Contol Board Programming)

These models have an Auto Test Cycle. See pages 7 & 8.

Fault Codes

These Models do NOT display a fault code if the dryer is in a

Fault Condition. See page 6.

Plastic Wate

r

Shield

Control

Module

Low End

Adaptor

Connection

point

Drum

Fluff

Barrier

(if fitted)

Low End Adaptor connector

Page 18

18 of 34

Service Manual UK

Indesit Company

English

DRYER OVERVIEW - CONDENSER MODELS

These Condenser Auto Tumble Dryers are freestanding with a round door on the front that can be

opened to allow the drum to be loaded with clothes.

The door is NOT reversible.

The facia moulding across the top of the front panel houses the dryer user controls and water

container.

Within the cabinet is a drum, which is capable of accepting a maximum 7 or 8 Kg* (depending on

model) load of damp clothing.

The drum is supported at the front by 4 plastic bearing pads or 1 drum support wheel and 2 bearing

pads (depending on model) mounted on the front air duct and a single bearing at the rear located in

the rear panel. A shaft fixed to the rear of the drum runs in the rear bearing.

The drum is driven by a belt, which p asses around it s pe riph ery an d on to the sh af t o f a moto r secured

to the base of the dryer. The belt is elasticated and tensioned by a pulley mounted to the motor.

As well as driving the drum the motor also drives impellers (rotors), fixed to each end of its shaft.

The front impeller draws cold air into the dryer, while the rear impeller recirculates drying air. The

addition of heat to the recirculating air is provided by a heating unit attached to the rear panel, enabling

the air to hold moisture when in contact with the wet load, thus causing it to dry.

As the warm recirculating air passes through the drum it collects lint as well as moisture. To prevent

the lint from blocking the heat exchanger (condenser), the air is passed through a filter located in the

front air duct door. The filter unit is positioned so as to be easily removable for cleaning by the user.

After passing through the filter, the circulating air is dusted through passageways in a heat exchanger

(condenser) located in a housing on the base of the dryer. Cold air is drawn into the dryer and flows

across the heat exchanger passageways. This cold air is not mixed with the warm damp recirculating

air , but is drawn into the dryer. This has the effect of reducing the circulat ing air temperature , causing it

to give up its moisture. (Cold air holds less moisture than hot air.) The now warm cooling air is

exhausted through the rear of the dryer.

The moisture removed from the recirculating air is pumped to a removable container mounted in the

left-hand side of the console. The user can easily withdraw the container to dispose of the collected

condense.

There is no requirement for venting to atmosphere on this dryer.

Cooling Air Circuit (open to atmosphere)

Recirculating Air Circuit (sealed)

CONDENSER DRYER

AIR FLOW

Page 19

19 of 34

Indesit Company

Service Manual UK English

Controls Overview

The user controls consist of a programme selection knob, option buttons and a Start/Pause button.

The control system consists of a user interface and control module, a thermistor mounted at the top of

the front air duct and one mounted on the heater assembly and a conductivity sensor.

The conductivity sensor is mounted in the front air

duct.

A single wire connects the sensor to the control

module.

The thermistors and conductivity sensor send values

back to the control module. The control module then

determines the programme duration and required

dryness of the load in a set of values for a particular

programme held within the control module software.

The combined Control and Power Module is a single

unit located at the top front right hand side of the dryer directly behind the console panel.

This module does not have a standard service port, and requires the use of a Low End Adaptor to

connect the Hardware Key to permit module programming.

The control module must be programmed with the relevant eeprom file if the control module is

replaced, the eeprom file becomes corrupted or if an updated file becomes available.

Programme Duration:

Once the programme has started the mo dule will determin e programme length for the si ze and type of

load. This detection is made within 10 minutes of the start of the progra mme and is achieved by use of

the front thermistor, rear thermistor and conductivity sensor. The module will then adjust the

programme time accordingly.

If the clothes are not sensed as dry when the 10 minute Cool Tumble period is reached, the module

does not start the Cool Tumble but continues to dry the clothes until the value from the conductivity

sensor indicates that the clothes are dry. The programme then advances into Cool Tumble.

Maximum Programme Period:

If after the maximum permitted programme time of 300 minutes (Note: this is an internal default value.)

the clothes are still not sensed as dry, the programme advances to Cool Tumble and completes the

programme. No fault is indicated if this occurs.

Heater Control

The control module also controls the heater. This has an upper and lower element. The lower (static)

element is permanently energised (except in cool tumble) and the upper element (dynamic) is cycled

on and off by the control module during a programme to maintain the correct temperature within the

drum for the programme selected.

If the user turns off the power or disconnects the mains cable or there is a power cut, the dryer will

remember its last settings and resume the programme when the start button is pressed.

If the event of a controls or thermistor failure, a cycling thermostat and one-shot thermostat are fitted

as safety devices.

Bearing Pads

Conductivity

Sensing Strip

Drum Support Wheels

Page 20

20 of 34

Service Manual UK

Indesit Company

English

FUNCTIONS DESCRIPTION

The Drying Guide allows you to consult a user friendly table of fabric types and load capacities.

The PROGRAMME knob sets the programme: rotate it until the indicator is pointing to the programme

you want to select. This will also power the dryer to the ON state. This replaces the On/Off button

found on previous models.

When either ’OFF’ (Hotpoint models) or the knob marker ’()’ (Indesit models), is positioned in the 12

o'clock position, it turns the machine Off and Cancels the Programme.

The OPTION buttons/lights select available options for your selected programme. The lights indicate

that the option has been selected.

The START/PAUSE button/light starts a selected programme. When you press this button there

will be one beep and the progress light s will flas h to confirm the acti on. When a programme is runn ing,

holding this button in pauses the programme and stops the dryer.

The light is green when programme is running, flashing amber if the programme has been paused or

flashing green if on stand-by waiting to start a programme.

Stand-by Mode

30 minutes after a programme has finished, if th e dryer is sti ll 'On' and no bu ttons have been tou ched,

the dryer will go into Stand-By mode. The LEDs and display will switch off. To reactivate and to remove

the dryer from Stand-By mode, turn the Programme Selector to position "1".

It will take a few seconds to recover from "Standby".

Another programme can be started or the dryer swit ched off by turning the selector to the OFF position.

The Progress or Delay lights show you the status of the programme, or the delay time when they

flash. During a delayed start the light s flash to show the delay selected. When (not flashing) they show

each stage of the programme by the corresponding light turning on.

The Empty Water indicator light signals that the water container should be emptied. The light will take

a few seconds to go out after replacing the empty water cont ainer, the dryer must be running for this to

happen. Note: If the water bottle fills the indicator light flashes, the heat is turned off and your clothes

will not dry.

The Clean Filter light gives you a reminder before every programme that it is essential to clean the

filter every time the dryer is used.

The Clean Condenser light gives you a reminder that it is essential to cle an the co nden ser at re gula r

intervals.

Page 21

21 of 34

Indesit Company

Service Manual UK English

USING THE DRYER

1. Load the Dryer with Laundry

2. Turn the Power On to the Dryer

3. Turn the Selector Knob to the required Programme - this will turn the Dryer On and select the

programme in one action.

4. Set any required options - if available

5. Push the Start/Pause Button to begin the programme.

Note:

Turning the programme knob to another programme after the cycle has started will NOT change

the cycle to the new programme. You must cancel it first.

Cancelling a Programme

To cancel a programme turn the selector knob to the OFF position and wait until it ends.

Then you can select another programme.

Automatic pre-post Crease Care

This is an automatic function which provides an anti-crease treatment both before and after the

drying programme.

By periodically rotating the drum before the start of the drying cycle, when a delayed start is

selected, the formation of creases is prevented.

On certain programmes the drum also rotates periodically at the end of the drying cycle.

The phase is stopped when the door is opened or when the knob is set to OFF.

Page 22

22 of 34

Service Manual UK

Indesit Company

English

OPTION BUTTONS

Note: Some buttons are disabled by software when their selection is not appropriate.

Start/Pause

This button is used to start every programme or to continue a programme if the door has been opened

and then closed, or if there has been a power interruption.

Pressing and holding in this button when a programme is running cancels the programme.

Low Heat

This Option can be set on Timed Cycles and some automatic Cycles.

If the Option if not available, when the button is pushed the LED will flash and a beep is heard.

When the Low Heat Option is enabled, the Target Heating Temperature is Reduced - therefore the

clothes will take longer to dry.

Alarm

When this Option is set the Buzzer Sounds at the end of the Drying Cycle to Signal that the

programme has ended and the garments are ready to wear.

Page 23

23 of 34

Indesit Company

Service Manual UK English

PROGRESS, ADVICE & WARNING LAMPS

Clean Filter / Empty Water Container LED

LED On -

Reminder to empty the water container and clean

the filter. The filter must be cleaned after every

use.

LED flashing and buzzer sounds -

The water container must be emptied immediately

and the dryer restarted. The flashing LED

indicates the container is full and the dryer will turn

the heater off.

After restarting, the LE D will take a few seconds to

go out.

Clean Condenser LED

The LED comes on every 20 cycles to remind the user that the condenser must be regularly cleaned.

The cycling on of the clean condenser LED is only controlled by the control module and is displayed as

a reminder. This dryer does not sense the state of the condenser.

Progress Lamps

During Drying Cycle:

Drying Denotes the dryer is drying the clothes

Cool Tumble Denotes the dryer is on the Cool Down period

End Denotes the cycle has finished.

Page 24

24 of 34

Service Manual UK

Indesit Company

English

COMPONENTS

Door

The door is constructed of several components, the outer

shell being powder coated metal.

And an inner lining consists of a moulding that clips into

position on the outer door shell.

The hinges are reversible, the extra holes on the opposite

side of the front panel being filled with blanking plugs. The

blanks need removal before changing the hing e side that

can be completed by diagonally transposing the hinges.

Filter

Comprises of a plastic mesh moulded into its housing,

which slides into the front air duct.

Door Switch

Normally open single pole microswitch activated by the

door on closure. This is the first switch in the electrical

circuit and therefore its rating, corresponds to the full loading of the product.

Control Module

This is an Electronic Device that monitors and controls all devices within the tumble dryer.

A production module is pre programmed at the factory with the relevant programmed file.

Service Modules are supplied non programmed and it is ne ce ssa ry for the Modul e to be prog ra mme d

by the Service Engineer. See pages 27 - 28 for Module programming.

Drum

The drum comprises of a zinc coated front and rear body and two

removable plastic lifters. The rear of the drum is perforated to allow

the passage of air. Fixed to the rear pressing is a support shaft which

runs in a bearing located in the rear panel of the dryer.

A drive pin and collar on the drum shaft prevents forward thrust

during use. The front lock seam of the drum rotates on front drum

support wheels.

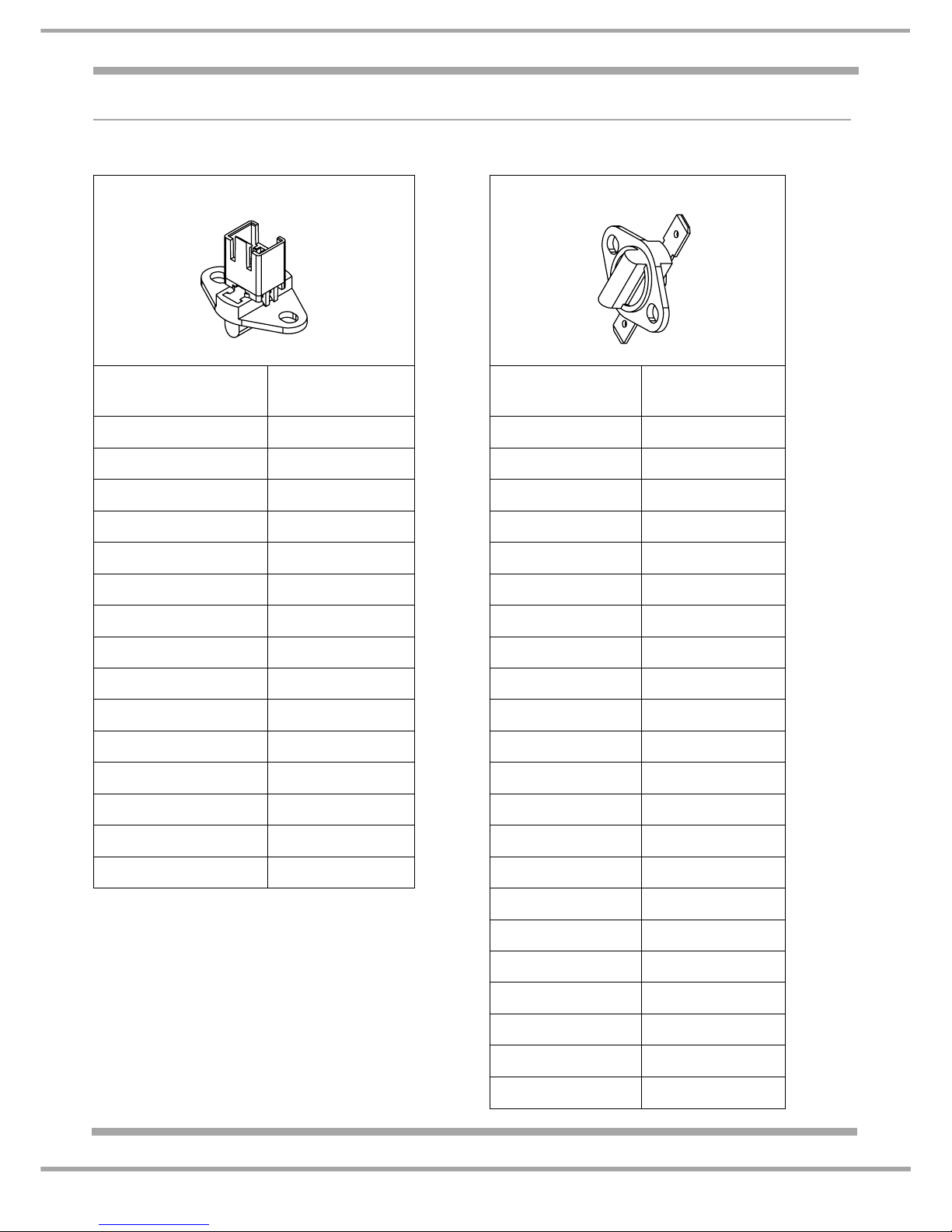

Rear Thermistor

Fitted to the heater assembly above the heater.

Used by the electronics for controlling the temperature into the rear of the dryer.

Front Thermistor

Fitted to the bottom of the front air duct moulding, used by the electronics for controlling the

temperature.

One-Shot (Safety) Thermostat (White Spot)

The drum has a patterned finish to allow

for better air circulation within the drum.

Curved Drum paddles give extra garment

care.

Water

container

Condenser

cover handle

(pull to open)

Filter

Air intake

grille

Model &

Serial

Numbers

Rating plate

Patterned drum from a model fitted

with a stainless steel drum

Page 25

25 of 34

Indesit Company

Service Manual UK English

This device is a disc type thermostat set to operate at 143°C.

It is used as a Safety Device.

It is positioned above the element. If this device fails it cannot

be reset.

Cycling Thermostat ( 120°C +/- 3°C )

The cycling thermostat is mounted adjacent to the one-shot (safety) and is designed to open at 120°C. It

limits the temperature of the heat entering the drum.

Heater Unit ( for Condenser models = 2.3 kW )

Consists of coils wound on 'mica' supports, which are supported by ‘mica’ end insulators.

These end insulators fit into a steel pressing that also locates the rear thermal controls. This is fixed by

screws to the rear cover. This pressing also forms air guides. The heater elements thermal controls,

thermistors and rear cover are supplied as an assembly and has a 5 - way and a 2 - Way connector

provided to interface with the electronic module.

The heater has upper and lower heater sections.

The lower (static) heater is permanently energised and the upper heater (dynamic) is cycled on and off

by the control module during a programme to maintain the correct temperature for the programme

selected. See page 12 for Heater Technical information.

Motor

A two pole P.S.C running at 2800 rpm with the impeller fitted to the rear end of the shaft and the drive

belt running directly in grooves in the front end of the shaft. It is protected from overload by a

self-resetting internal cut-out that interrupts the electrical supply to the windings.

It is used together with a capacitor that is mounted on the base of the dryer.

Pump & Float Switch

Mounted on the bottom right-hand side of the rear panel, condensate water from the condenser

chamber is pumped via an external hose to the water container situated behind the console.

Operation of the Float Switch (water container full)

When the water container becomes full, the excess water is diverted back into the pump reservoir, which

causes the float to rise and the operation of the micro switch signals the module, the container is full.

After 2 minutes the machine will stop with the Start/Pause LED Flashing and the Empty Water LED

illuminated.

Drum Rear Seal

This unit comprises of a ring of foam with a webbing bearing face. Lubrication is applied to the drum where

the webbing surface runs, to reduce noise and wear. The seal reduces air losses at the rear of the drum.

The joints in the foam are sealed with glue and the joints in the webbing are stitched to further reduce air

leakage.

Drum Earthing

Drum Earthing is obtained by the teardrop bearing fixing

screw.

NOTE: - It is important that the correct screw is always

used to secure the teardrop bearing.

Teardrop bearing

Earth Screw

Page 26

26 of 34

Service Manual UK

Indesit Company

English

PROGRAMMES

Programmes

Standard Cotton:

Dries your items to a dryness level that allows you to put your clothes away straight from the dryer.

Cotton Extra Dry:

Dries your items to the maximum possible dryness level. Even drier than Standard Cotton dry.

Synthetics

Recommended to delicately dry synthetic fabrics.

Delicates

This program can also used for delicates/acrylic fabrics (2 Kg).

Jeans

It can also be used on other garments made from the same material, such as jackets.

Loads dried using this programme are usually ready to wear, the edges or seams may be slightly

damp. If this is the case, try turning the jeans inside out and running the programme again for a short

period.

Note: We do not recommend that you use this programme if your jeans have elastic waist bands,

studs or embroidery.

Refresh

A short programme suitable for refreshing fibres and garments. It lasts about 20 minutes.

Note: As this is not a drying programme, it is not to be used for garments that are still wet.

Programme

Max. load

(kg)

Compatible options

Cycle

duration*

1 Standard Cotton

Max Alarm - Low Heat.

140'

2 Cotton Extra Dry

Max Alarm.

150'

3 Synthetics

4 Alarm.

100'

4 Delicates

2 Alarm.

130’

5 Jeans

3 Alarm.

90’

6 Refresh

- Alarm.

20’

Timed drying cycle

30’ 60’ 80’100’120’140’160’180’ 200’

- Alarm - Low Heat.

-

* note: The duration of these programs will depend on the size of the load, types of textiles, the spin speed used in your washer

and any extra options selected.

Page 27

27 of 34

Indesit Company

Service Manual UK English

CONTROL BOARD PROGRAMMING for Modules with fixed EEProm

NOTE: This board does NOT have a physically replaceable EEProm.

Programming a Main Board

There are a number of ways the board can be pr ogrammed - some of which are not applicable to certain

markets.

Types of programming:

1. Handheld Terminal (Not UK)

2. Emit / Memwriter (UK - Indesit / Hotpoint Service Engineers)

3. Smart Reader & Smart Card (certain areas of UK market) see photo below and following page.

PROGRAMMING (Using EMIT)

This dryer can be programmed via the Emit PC, using a USB le ad (Part No. C00289046), Hardware key

(Part No. C00289048) and the Memwriter software.

Smart

Smart Card

this card holds

the program file

and can ONLY

be used ONCE.

Card

After the module

has been programmed

the card is automatically

erased.

Reader

USB Hardware Key and USB Cable

Connector pins are NOT replaceable

A

A = USB connector

B = not used

A

B

Part No. C00289046

Part No. C00289048

Page 28

28 of 34

Service Manual UK

Indesit Company

English

Connection to the Module

The Smartcard Reader or Hardware Ke y (shown below) MUST only be co nnected to the mo dule using

a Low End Adaptor - See method below. The Low End Adaptor edge connector plug connects to CN1

on the Module. The plastic Water Shield must be secured correctly after programming.

PROGRAMMING (Using Smartcard Reader / Card)

If the Module has been replaced during a repair the board will require programming using the following

method. A module which is not programmed will not function.

1. Do NOT connect the dryer to electrical supply at this point.

2. Insert the pre-programmed card into the Card reader. Care must be taken at this point to ensure the

card is inserted correctly with the Chip on the card facing the PCB of the Reader.

3. Insert the Reader and Card into module connection port located at the front of the dryer - see photo.

4. Connect the dryer to the Electrical supply;

Observe the electronic component side of the SmartCard Reader.

The LEDs on the Smart Card Reader will light in this sequence:

a. Red ON: Good Communication between Smart Card Reader & Card. See also Note 1 below.

b. Red OFF; Green Blinking: Download taking place.

c. At end,

Green ON = Download OK, module programmed, Red ON = Download NOT OK -see Note 1.

below.

6. Disconnect the appliance from the electricity supply.

7. Remove the Smart Card Reader.

8. Connect the appliance to the Electrical supply.

Note 1.

a If the Red LED is flashing SLOWLY, a card is inserted but either the card is blank (previously

used), is incorrectly inserted or there is a poor connection between the card and card reader.

b If the Red LED is flashing RAPIDLY, a card is NOT inserted or not inserted fully.

Note 2. SmartCard Re-Use

The Smart Card cannot be used again. It is erased after a su ccessful download of the settings file onto

the module.

Connection CN1

Hardware Key

Low End Adaptor

and USB cable

Plastic Water Shield

or Smartcard

Reader

Page 29

29 of 34

Indesit Company

Service Manual UK English

DISMANTLING INSTRUCTIONS - CONDENSER MODELS

SAFETY NOTES

1. ENSURE THAT THE APPLIANCE IS UNPLUGGED BEFORE DISMANTLING.

2. BEWARE OF SHARP EDGES ON METAL PANELS AND PRESSED PARTS.

A. Top Cover

1. Remove the 2 screws securing the top cover to the back panel.

2. Slide the top cover back and lift clear of the retainers.

B. Side Panels

1. Remove the top cover.

2. Remove the 3 screws securing the side panel to the rear panel.

3. Pull the side panel backward to disengage from the lugs on the base panel.

NOTE:- Different length screws are used to secure the side panels.

Take note of the screw length and positions when removing the side panels.

C. Console Panel

1. Remove the water container.

2. Remove the top cover as in (A).

3. Remove left side panel as in (B).

7. Carefully remove the plastic securing rivet which retains the plastic water shield.

8. Release the lower console securing lugs.

9. Noting the harness connections, disconnect the module.

10. Pull the console clear of the front Panel.

11. When reassembling, the Plastic Water Shield MUST be refitted and secured with the plastic rivet.

4. Remove the 2 screws on the left hand side of

console securing the water container housing to

the console.

5. Remove the 1 screw fixing the Water Container to

the front panel from the rear of the console (see

Fig. A).

6. Remove the 2 round headed screws securing the

console to each side panel along its top edge.

Screw revealed

after removing

the side panel

Water Shield

Plastic Rivet

Page 30

30 of 34

Service Manual UK

Indesit Company

English

D. Interface and Control Module Assembly

1. Remove the top cover as in (A).

2. Remove the console as in (C).

3. Remove the screws securing the Module to

the Console

4. Remove the programme knob by

compressing the tabs - see photo.

E. Belt

1. Remove the side panels as in (B).

2. Remove the cooling impeller cover using a small blade screwdriver to lift the cover locking tabs.

3. Remove the cooling impeller.

4. Remove the rear bearing as in (J).

5. Remove the heater unit as in (L).

6. Remove the recirculating impeller.

7. Remove the 3 hex head screws behind the recirculating impeller securing the motor to rear of the

base moulding. This will release tension on the belt.

8. Rotate the motor towards the centre of the dryer to disengage the belt from the jockey pulley.

9. Remove the 2 screws securing the rear panel to the side strut.

10. Remove the 2 screws securing the water container housing to the rear panel.

11. Remove the hose spigot from the container housing by rotating 90°.

12. Pull the rear panel backward to disengage the drum shaft from the dr um rear panel and slide the

belt back to remove from the drum.

13. Replace in reverse order. When refitting the belt first position the belt over the jockey wheel, refit

as in (N).

F. Front Panel, Door Seal & Front Thermistor

1. Remove the top cover as in (A).

2. Remove the console as in (C).

3. Remove the plinth.

4. Remove the 2 screws securing the front panel to the side strut.

5. Remove the 6 screws securing the front panel to the air duct.

6. Remove the 3 screws located behind the plinth securing the front panel to the base.

7. The front panel can now removed leaving the air duct in position.

G. Air Duct

1. Remove the front panel as in F).

2. Remove the belt as in (E).

3. Lift the air duct upwards to remove from the base.

Compress programme knob retaining tabs

Page 31

31 of 34

Indesit Company

Service Manual UK English

H. Front Bearing Pads / Support Wheels

Note: Either may be fitted - depending on production variations.

Ha Bearing Support Pads

1. Remove the drum as in (O).

2. Unclip the bearing pads which are located

on the front air duct.

Hb Drum Support Wheels

1. Remove the Drum (O).

2. Unscrew the Bearing Support Wheel fixing bolt.

Note:

When first started, it is normal for the drum to make

a noise for approximately 2 minutes, while th e drum

support wheels centralise to the load conditions.

I. Door Switch

1. Remove the top cover as in (A).

2. Remove the console as in (C).

3. Depress the locking tab securing the switch to the front panel and remove the switch.

J. Rear Bearing (Tear Drop shaped)

1. Remove the rear bearing cover.

2. Remove the drive pin and collar.

3. Remove the tear drop bearing fixing screw.

4. Slide the bearing off the drum shaft.

Bearing Support Pads

Support

wheel

fixing bolt

Teardrop Bearing

fixing Screw

Page 32

32 of 34

Service Manual UK

Indesit Company

English

K. Pump & Float Switch

1. Depress the 2 pump cover locating tabs and pull the cover clear (Photos 1 and 2).

2. Access can now be gained

to the pump and float

switch.

3. To remove the pump float

switch assembly, release

the 2 clips either side of the

assembly and lift clear

(Photo 3).

L. Heating Assembly, Thermostats & Thermistor

1. Remove the right hand side panel.

2. Disconnect the wiring to the heater multi-pin connector.

3. Remove the 8 screws securing the heater unit to the rear panel.

4. Remove the 2 screws securing the heater to the rear cover.

NOTE 1: If replacing the thermostats both the cycling and one-shot

thermostat MUST

be replaced should either fail.

NOTE 2: A cable tie must be used to secure the 3 way plug into

the heater connector - refer to photo.

NOTE 3: When refitting the heater cover, ensure the heater wiring

is not trapped between the inner and outer rear panels.

NOTE 4: 2 different screws are used to fit the heater cover.

The longer screws are to secure the heater cover to the base assembly.

Photo 1 Photo 2

Released Clips

Photo 3

Shown with

cover

removed

Cable Tie

Page 33

33 of 34

Indesit Company

Service Manual UK English

M. Motor

1. Slacken the belt as in (E) 1 to 8.

2. Lift the motor clear from the base moulding.

3. Replace in reverse order first positioning the belt over the jockey wheel.

It will be necessary to use the motor special tool as a lever on the motor casing (as illustrated) to

enable it to be rotated under tension to line up the holes in rear moulding with the fixing holes on

the motor casing.

Refit the 3 hex head screws.

N. Drum Assembly

1. Remove the top cover as in (A).

2. Remove the side panels as in (B).

3. Remove the console as in (C).

4. Slacken the belt as in (E) 1 to 8.

5. Remove the rear bearing as in (J).

6. Remove the front panel as in (F) leaving the air duct attached to the front panel if required.

7. The drum can now be removed from the rear panel.

8. Replace in reverse order.

NOTE: When reassembling, a new drive pin must be fitted.

O. Rear Seal

1. Remove the drum as in (N).

2. Remove the rear seal and clean any remnants of the seal and adhesive from the inner face of rear

panel.

IMPORTANT NOTE

The correct size Drum Rear Seal must be always be fitted to the Dryer.

Refer to the parts system for correct part number.

Rotate motor with the motor special

tool using downward pressure to

tension the belt and line up motor

fixings in rear moulding

Note: It is recommended the motor

If Pipe Grips or a similar tool is used,

ensure the pliers do not cause damage

to the motor windings.

Special Tool is used to fit the motor/belt.

Page 34

34 of 34

Service Manual UK

Indesit Company

English

END

Indesit Company UK Ltd.

2015

Loading...

Loading...