Swann AMU pH-Redox Operator's Manual

AMU pH-Redox

Version 6.20 and higher

s Manual

Operator’

A-96.250.441 / 060619

Customer Support

SWAN and its representatives maintain a fully trained staff of technical specialists

around the world. For any technical question, contact your nearest

SWAN representative, or the manufacturer:

SWAN ANALYTISCHE INSTRUMENTE AG

Studbachstrasse 13

8340 Hinwil

Switzerland

Internet: www.swan.ch

E-mail: support@swan.ch

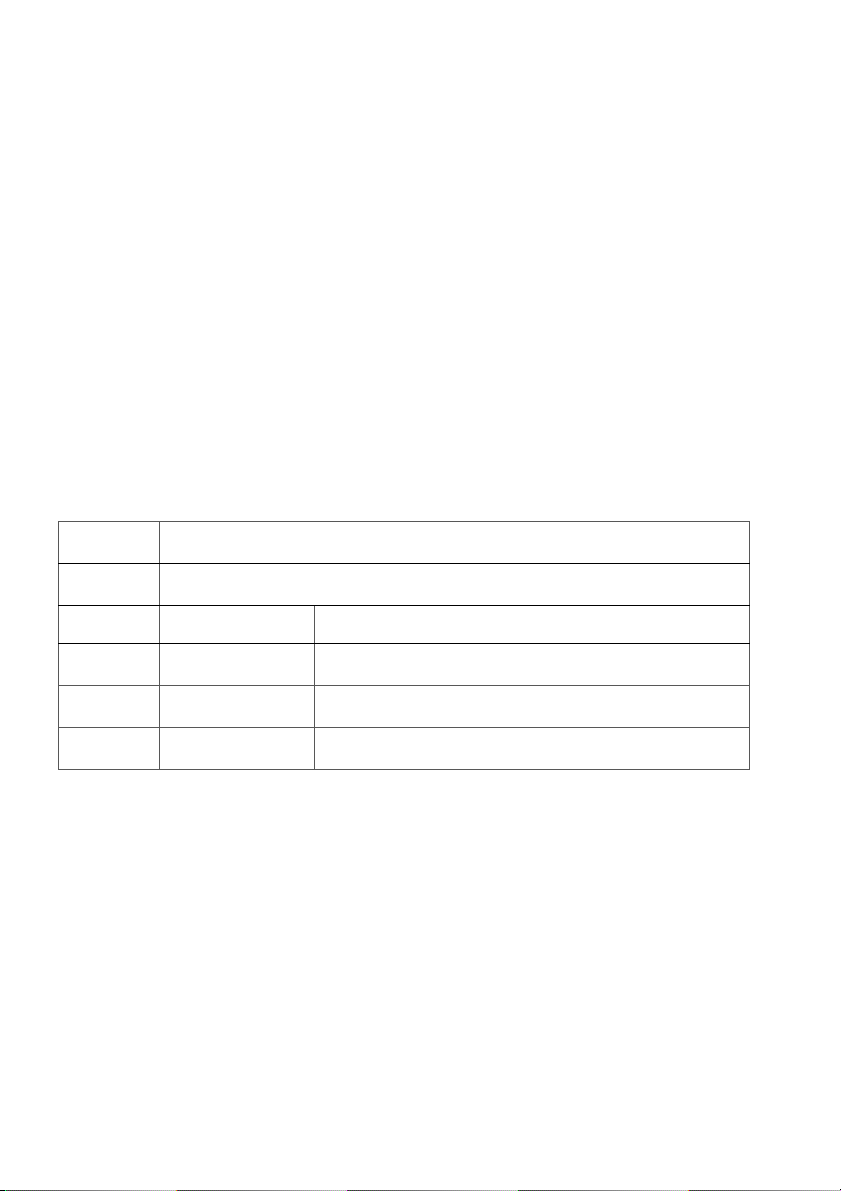

Document Status

Title:

ID:

AMU pH-Redox Operator’s Manual

A-96.250.441

Revision Issue

00 Sept. 2006 First Edition

01 June 2019 Update to firmware V6.20

© 2019, SWAN ANALYTISCHE INSTRUMENTE AG, Switzerland, all rights reserved

subject to change without notice.

AMU pH-Redox

Table of Contents

1. Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1. Warning Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2. General Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1. Description of the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2. Single Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.1 AMU pH-Redox Transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.2.2 Flow Cell M-Flow 10-3PG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2.2.3 Flow Cell QV-Flow SS316L pHRT . . . . . . . . . . . . . . . . . . . . . . 15

2.2.4 Flow Cell B-Flow IS1000. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.2.5 Swansensor pH and Redox Standard. . . . . . . . . . . . . . . . . . . . 17

2.2.6 Swansensor pH and Redox AY. . . . . . . . . . . . . . . . . . . . . . . . . 18

2.2.7 Swansensor pH and Redox SI . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.2.8 Swansensor pH and Redox FL . . . . . . . . . . . . . . . . . . . . . . . . . 20

2.2.9 Swansensor Reference FL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.2.10 Spray Nozzle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.1. Installation Checklist Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

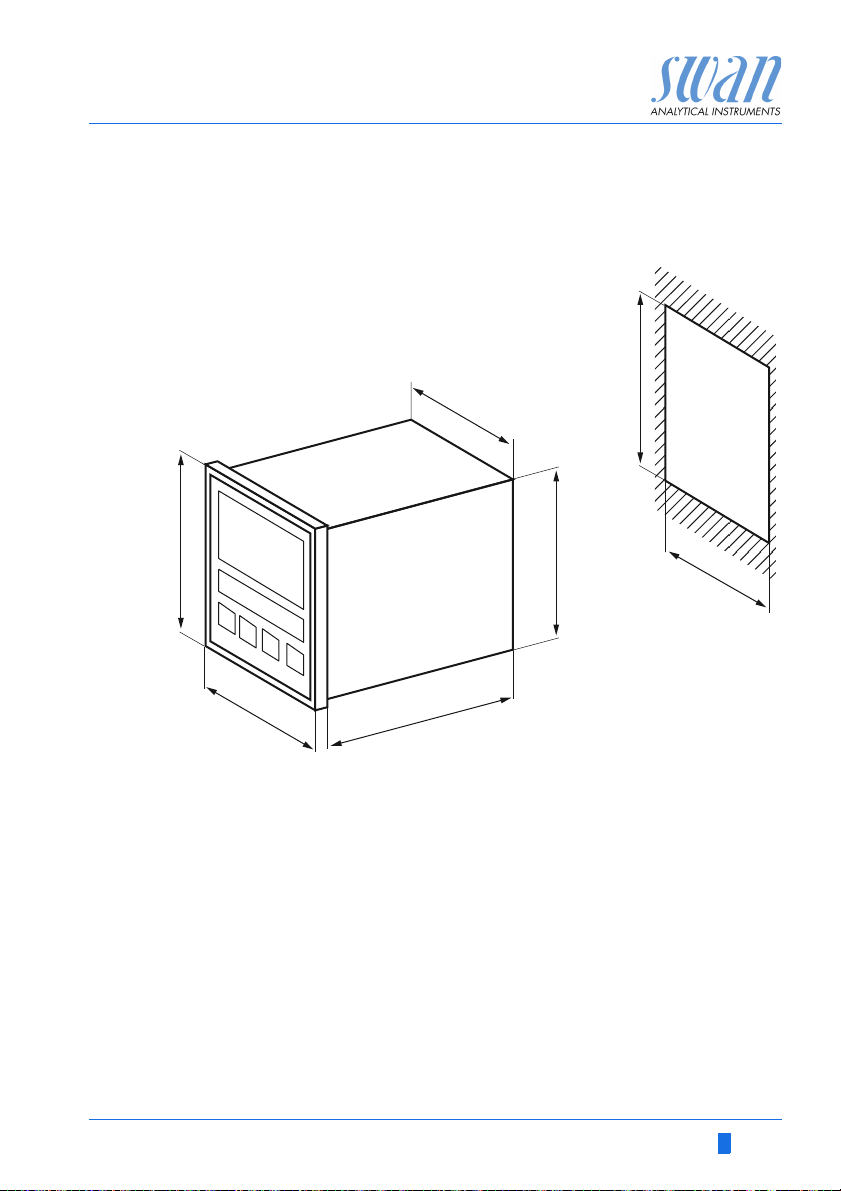

3.2. Dimensions of the AMU Transmitter. . . . . . . . . . . . . . . . . . . . . . . 23

3.3. Connecting Sample Inlet and Outlet. . . . . . . . . . . . . . . . . . . . . . . 24

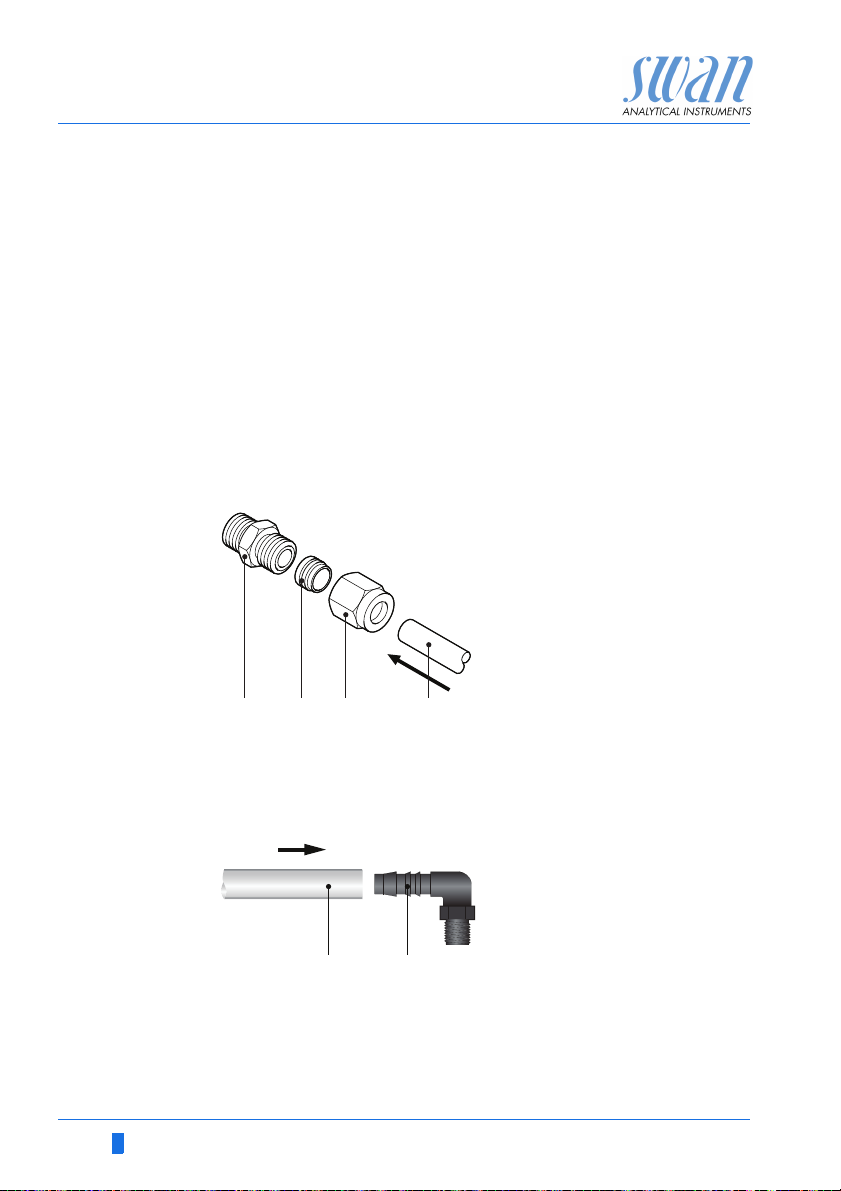

3.3.1 Serto Fitting Stainless Steel for QV-Flow Cell. . . . . . . . . . . . . . 24

3.3.2 Elbow Hose Nozzle for M-Flow Cell . . . . . . . . . . . . . . . . . . . . . 24

3.4. Flow Cell QV-Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.1 Install Swansensor pH or Redox SI . . . . . . . . . . . . . . . . . . . . . 25

3.4.2 Adapter Set . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3.5. Flow Cell M-Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.5.1 Install Swansensor pH/Redox Standard or AY . . . . . . . . . . . . . 28

3.6. Connect the Swansensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

3.7. Install Spray Nozzle (Option) into M-Flow Cell . . . . . . . . . . . . . . . 31

3.8. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.9. Power supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.10. Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.11. Flow Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.12. Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.13. Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.13.1 Alarm Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

A-96.250.441 / 060619 1

AMU pH-Redox

3.13.2 Relay 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

3.14. Signal Output 1 and 2 (current outputs) . . . . . . . . . . . . . . . . . . . . 35

3.15. Interfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.15.1 RS232 Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.15.2 Profibus (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.15.3 Modbus (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

4. Instrument Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.1. Establish Sample Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

4.2. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.1. Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.2. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

5.3. Software Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5.4. Changing Parameters and values. . . . . . . . . . . . . . . . . . . . . . . . . 43

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.1. Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6.2. Stop of Operation for Maintenance. . . . . . . . . . . . . . . . . . . . . . . . 45

6.3. Maintenance of Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.3.1 Clean pH/ ORP SI or FL Electrodes . . . . . . . . . . . . . . . . . . . . . 45

6.3.2 Clean pH/ORP Standard or AY Electrodes. . . . . . . . . . . . . . . . 47

6.4. Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.5. Longer Stop of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

7. Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8. Program Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.1. Messages (Main Menu 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.2. Diagnostics (Main Menu 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.3. Maintenance (Main Menu 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.4. Operation (Main Menu 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.5. Installation (Main Menu 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9. Program List and Explanations. . . . . . . . . . . . . . . . . . . . . . . . . 61

1 Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2 A-96.250.441 / 060619

AMU pH-Redox

10. Safety Data sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

11. Default Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

12. Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

A-96.250.441 / 060619 3

AMU pH-Redox

Safety Instructions

AMU pH-Redox - Operator’s Manual

This document describes the main steps for instrument setup, operation and maintenance.

1. Safety Instructions

General The instructions included in this section explain the potential risks

Targ et

audience

OM Location The AMI Operator’s Manual shall be kept in proximity of the instru-

Qualification,

Training

associated with instrument operation and provide important safety

practices designed to minimize these risks.

If you carefully follow the information contained in this section, you

can protect yourself from hazards and create a safer work environment.

More safety instructions are given throughout this manual, at the

respective locations where observation is most important.

Strictly follow all safety instructions in this publication.

Operator: Qualified person who uses the equipment

for its intended purpose.

Instrument operation requires thorough knowledge of applications,

instrument functions and software program as well as all applicable

safety rules and regulations.

ment.

To be qualified for instrument installation and operation, you must:

read and understand the instructions in this manual as well as

the Material Safety Data Sheets.

know the relevant safety rules and regulations.

4 A-96.250.441 / 060619

AMU pH-Redox

Safety Instructions

1.1. Warning Notices

The symbols used for safety-related notices have the following significance:

DANGER

Your life or physical wellbeing are in serious danger if such

warnings are ignored.

Follow the prevention instructions carefully.

WARNING

Severe injuries or damage to the equipment can occur if such

warnings are ignored.

Follow the prevention instructions carefully.

CAUTION

Damage to the equipment, minor injury, malfunctions or incorrect process can be the consequence if such warnings are ignored.

Follow the prevention instructions carefully.

Mandatory

Signs

A-96.250.441 / 060619 5

The importance of the mandatory signs in this manual.

Safety goggles

Safety gloves

AMU pH-Redox

Safety Instructions

Warning Signs The importance of the warning signs in this manual.

Electrical shock hazard

Corrosive

Harmful to health

Flammable

Warning general

Attention general

1.2. General Safety Regulations

Legal

Requirements

Spare Parts

and

Disposables

Modifications Modifications and instrument upgrades shall only be carried out by

The user is responsible for proper system operation. All precautions must be followed to ensure safe operation of the instrument.

Use only official SWAN spare parts and disposables. If other parts

are used during the normal warranty period, the manufacturer’s

warranty is voided.

an authorized Service Technician. SWAN will not accept responsibility for any claim resulting from unauthorized modification or alteration.

6 A-96.250.441 / 060619

AMU pH-Redox

Safety Instructions

WARNING

Risk of Electrical Shock

If proper operation is no longer possible, the instrument must be

disconnected from all power lines, and measures must be taken

to prevent inadvertent operation.

To prevent from electrical shock, always make sure that the

Service shall be performed by authorized personnel only.

Whenever electronic service is required, disconnect instru-

WARNING

For safe instrument installation and operation you must read

and understand the instructions in this manual.

ground wire is connected.

ment power and power of devices connected to.

– relay 1,

– relay 2,

– alarm relay

WARNING

Only SWAN trained and authorized personnel shall perform the

tasks described in this document.

Download

MSDS

A-96.250.441 / 060619 7

The current Safety Data Sheets (SDS) for the above listed Reagents are available for downloading at www.swan.ch.

AMU pH-Redox

Product Description

2. Product Description

2.1. Description of the System

Application pH and ORP are measured in many applications as for example

pH Measuring

Principle

(simplified)

ORP Measur-

ing Principle

(simplified)

Tem per atu re

compensation

potable water, high purity water or waste water. Each application

requires different fittings, flow cells, and sensors.

The pH measurement is based on a voltage measurement. A voltage can only be measured between two different potentials, therefore, the pH measuring chain contains a measuring electrode and a

reference electrode. The reference electrode maintains a constant

potential whereas the potential of the measuring electrode changes

with the pH value. The voltage which results from this potential difference is measured and displayed on the transmitter as pH value.

The measuring chain is designed so that the voltage is zero at

pH 7.

The ORP (redox) measurement is based on a voltage measurement. A voltage can only be measured between two different potentials, therefore, the ORP (redox) measuring chain contains a

measuring electrode and a reference electrode. The reference

electrode maintains a constant potential whereas the potential of

the measuring electrode changes with the ORP value. The voltage

which results from this potential difference is measured and displayed on the transmitter as ORP value in millivolt (mV). Both electrodes are integrated in one housing = combined electrode.

pH: The pH value depends on the sample temperature. To

compensate temperature fluctuations a temperature sensor is

installed in the flow cell.

ORP: Temperature compensation is not necessary.

Potable water, waste water: Compensation according to Nernst.

High purity water (Power plant, semiconductor): Nernst or non-lin-

ear solution temperature compensation, or linear compensation

with coefficient.

8 A-96.250.441 / 060619

AMU pH-Redox

Product Description

Signal

Outputs

Relays Two potential-free contacts programmable as limit switches for

Alarm Relay One potential free contact.

Input One input for potential-free contact to freeze the measuring value

Communica-

tion Interface

Safety

Features

pH Electrode For the AMU pH-Redox four types of pH electrodes are available.

Two signal outputs programmable for measured values (freely scalable, linear, bilinear, log) or as continuous control output (control

parameters programmable).

Current loop: 0/4–20 mA

Maximal burden: 510 Ω

measuring values, controllers or timer for system cleaning with automatic hold function.

Maximum load: 100 mA/ 50 V

Open (closed)* during normal operation, closed (open)* on error

and power loss (* as defined when ordering). Summary alarm indication for programmable alarm values and instrument faults.

Maximum load: 100 mA/ 50 V

or to interrupt control in automated installations (hold function or remote off).

RS232 interface for logger download with HyperTerminal

RS485 interface with Fieldbus protocol Modbus or Profibus DP

(optional)

No data loss after power failure. All data is saved in non-volatile

memory. Over voltage protection of in- and outputs. Galvanic separation of measuring inputs and signal outputs.

The Swansensor pH Standard is a combined gel electrode for

application in drinking water and swimming pools. Gel electrodes

can not be filled again and have a limited life time.

The Swansensor pH SI is a combined electrode with liquid

electrolyte (KCl) for the measurement of pH in power plants.

The Swansensor pH AY is a combined gel electrode for

application in waste water due to additional salt supplies

The Swansensor pH FL for the measurement of pH in high purity

water. This sensor can only be used in combination with

Swansensor Reference FL, A-87.860.100.

A-96.250.441 / 060619 9

AMU pH-Redox

Product Description

ORP Electrode For the AMU pH-Redox four types of redox (ORP) electrodes are

available.

The Swansensor redox (ORP) Standard is a combined gel

electrode for application in drinking water and swimming pools.

Gel electrodes can not be filled again and have a limited life time.

The Swansensor redox (ORP) SI is a combined electrode with

liquid electrolyte (KCl) for the measurement of redox (ORP) value

in power plants.

The Swansensor redox (ORP) AY is a combined gel electrode for

application in waste water due to additional salt supplies.

The Swansensor ORP FL for the measurement of the redox

potential in high purity water. This sensor can only be used in

combination with Swansensor Reference FL,

A-87.860.100.

Reference

electrode

Consumables One 200 ml bottle of 3.5 M KCl lasts for 1 month.

Fluidics

QV-Flow

Swansensor Reference FL, reference electrode for Swansensor pH

FL or Swansensor Redox FL

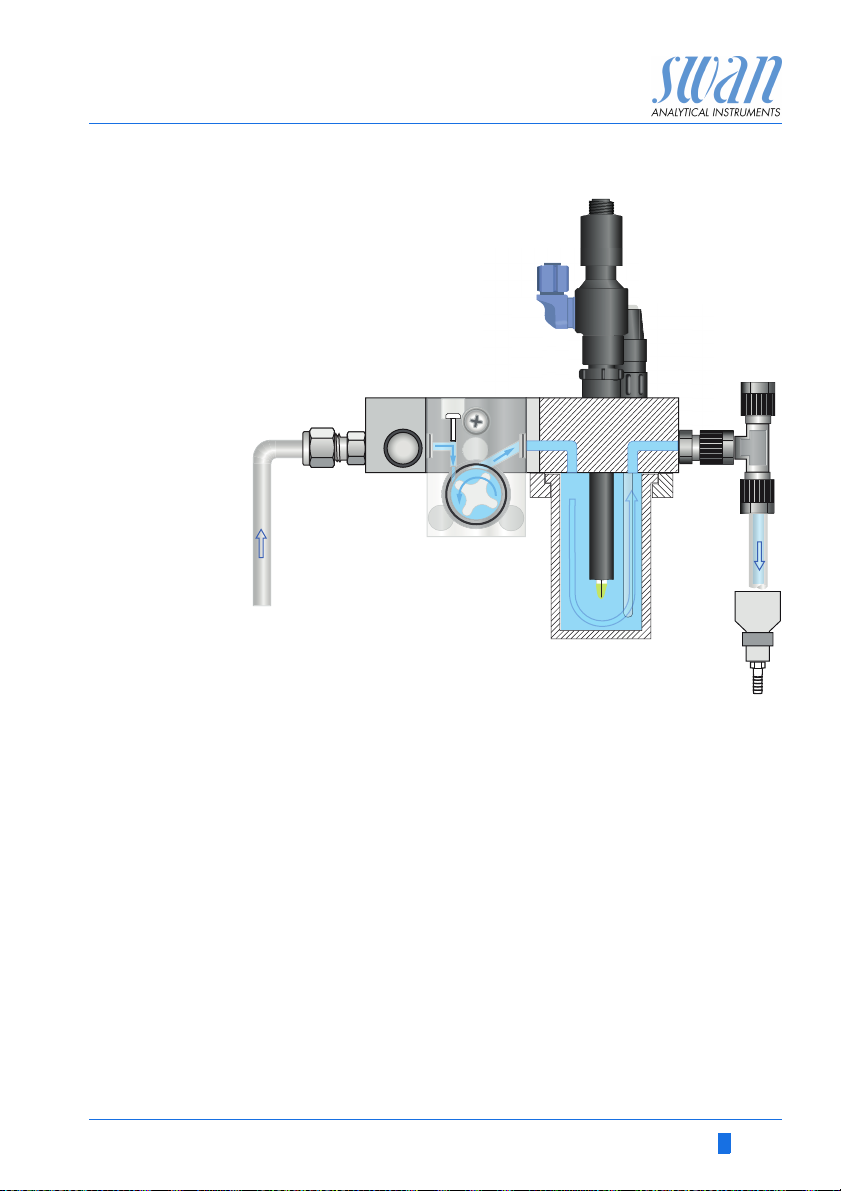

The flow cell QV-Flow consists of the flow regulating valve [D], the

flow sensor [F], the flow cell block [E], the vessel [G] and a built-in

temperature sensor [B].

The sample enters at the sample inlet [C]. It flows through the flow

regulating valve [D], where the flow rate can be adjusted. Then the

sample flows via the flow sensor [F] and the flow cell block [E] into

the vessel [G], were the pH of the sample is measured. The pH value depends on the sample temperature. The measuring value of

the temperature sensor [B] is used to recalculate the pH measuring

value to the standard sample temperature of 25 °C.

The sample leaves the vessel via flow cell block through the sample outlet [H] and flows into the pressure free drain [I].

10 A-96.250.441 / 060619

AMU pH-Redox

Product Description

CD E

A

B

FG

H

I

A

pH sensor

B

Temperature sensor

C

Sample inlet (stainless steel

tube)

D

Flow regulating valve

A-96.250.441 / 060619 11

E

Flow cell block

F

Flow sensor

G

Vessel (stainless steel)

H

Sample outlet

I

Drain

AMU pH-Redox

Product Description

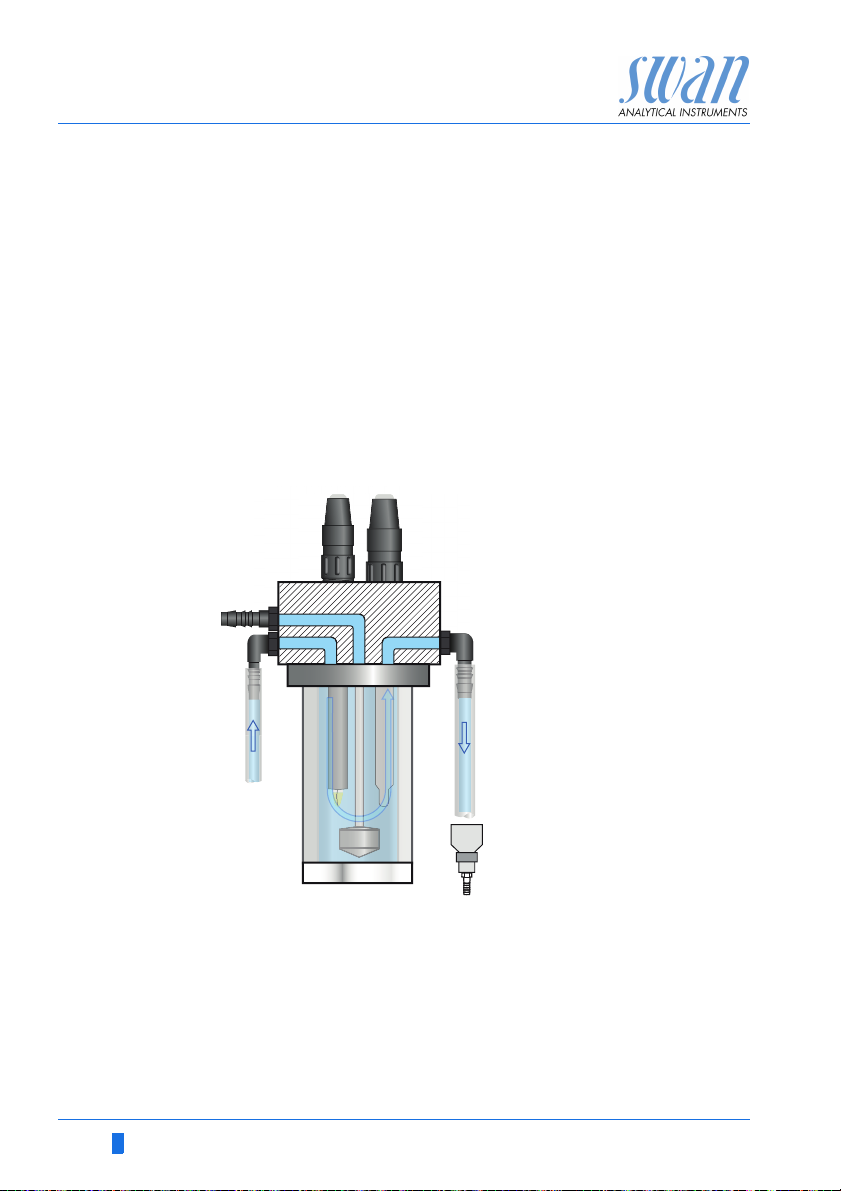

Fluidics

M-Flow

The flow cell M-Flow 10-3PG consists of the flow cell block [C] and

the calibration vessel [D]. The pH sensor [A] and the temperature

sensor [B] are screwed into the flow cell block [C].

Optionally a spray nozzle [F] can be installed. The spray nozzle allows the cleaning of the sensor tips without removing the sensors.

The sample enters at the sample inlet [H] and flows then through

the flow cell block into the calibration vessel [D], were pH and redox

are measured. The pH value depends on the sample temperature.

The measuring value of the temperature sensor [B] is used to recalculate the pH measuring value to a predefined average sample

temperature.

The sample leaves the calibration vessel via flow cell block through

the sample outlet [E] and flows into the pressure free drain [G].

AB

C

D

H

E

A

pH sensor

B

Temperature sensor

C

Flow cell block

D

Calibration vessel

F

G

E

F

G

H

Sample outlet

Spray nozzle

Drain

Sample inlet

12 A-96.250.441 / 060619

AMU pH-Redox

Product Description

2.2. Single Components

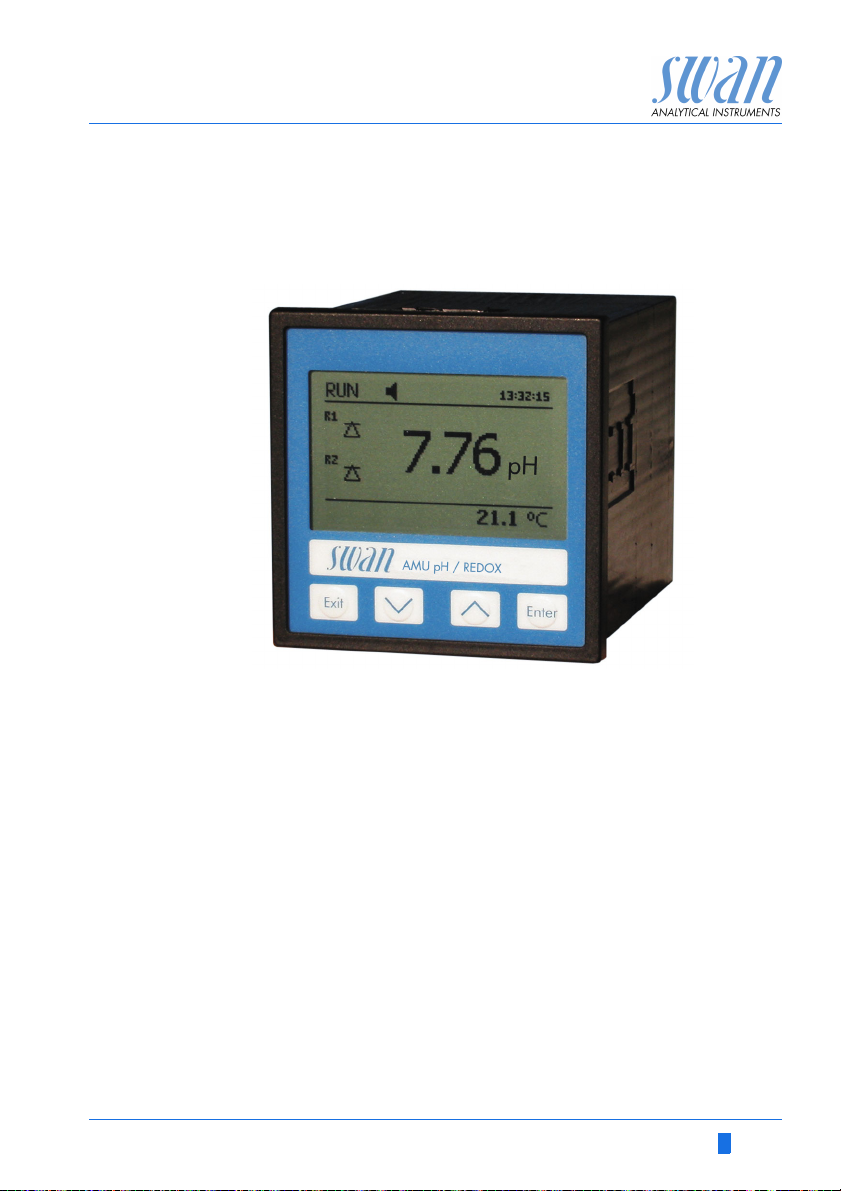

2.2.1 AMU pH-Redox Transmitter

General Electronics housing:

Protection degree:

Ambient temperature:

Humidity:

Display:

Dimensions:

Weight:

Power supply Voltage:

Power consumption:

pH

Measuring range:

measurement

ORP

measurement

A-96.250.441 / 060619 13

Resolution

Reference temperature:

Measuring range:

Resolution:

®

resin

Noryl

IP54 (front)

-10 to +50 °C

10–90% rel., non condensing

backlit LCD, 75 x 45 mm

96 x 96 x 120 mm (DIN 43700)

0.45 kg

100–240 VAC (±10%)

50/60 Hz (±5%)

or 24 VDC (±15%)

max. 8 VA

0.00 to 14.00

0.01

25 °C

-500 to +1500 mV

1 mV

AMU pH-Redox

Product Description

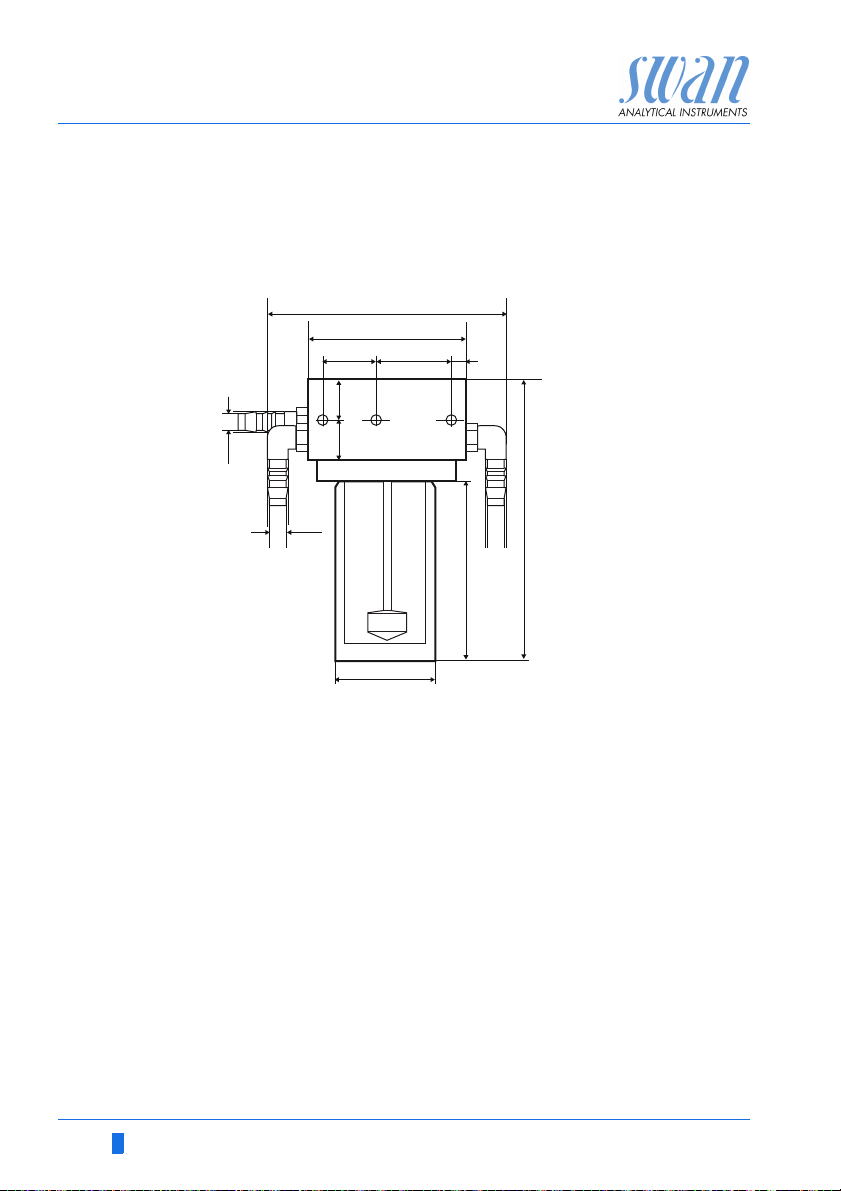

2.2.2 Flow Cell M-Flow 10-3PG

Flow cell for potable water applications for the installation of three

sensors, i.e. a pH or redox sensor, a reference sensor and a temperature sensor. Sensor cleaning available as an option.

142

90

33 38

9

10

23 23

10

60

Connections Sample:

Cleaning water:

Sensor:

Equipped with elbow hose nozzle for 10 mm tube.

Sample For the flow cell without electrodes!

conditions Flow rate:

Temperature:

Inlet pressure:

Outlet pressure:

Particle size:

No strong acids and bases.

No organic solvents.

Dimensions Width:

Front-to-back:

Height:

Mounting:

161

102

G 1/4” thread

G 1/4” thread

Screw connection: PG 13.5 mm

Installation depth:120 mm

4 to 15 l/h

up to 50 °C

up to 1 bar @ 25 °C

Pressure free

below 0.5 mm

90 to 142 mm

138 mm

161 mm

3 screws M5

14 A-96.250.441 / 060619

AMU pH-Redox

169

195

118

101

143

74

127

71

7.5

95

13

9

22.5

29

43

Product Description

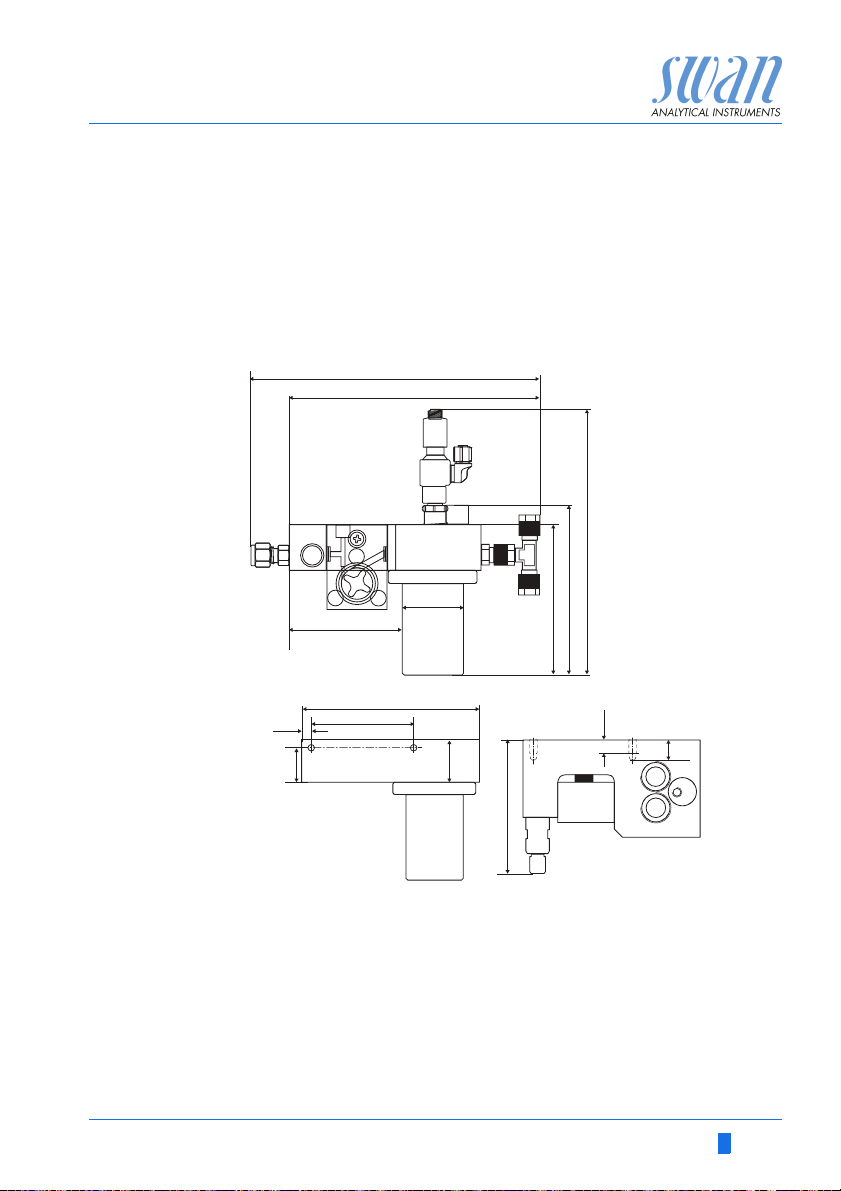

2.2.3 Flow Cell QV-Flow SS316L pHRT

Made of stainless steel SS316L with built-in Pt1000 temperature

sensor and a Swagelok connection for 1/4" tube. With flow measurement and needle valve.

For the installation of two sensors i.e. a pH or redox sensor and a

reference sensor. Recommended for the use with Swansensor pH/

Redox SI. Other sensors require an adapter set for installation.

Technical data Sample inlet:

Sample outlet:

Sample temperature:

Sample flow:

A-96.250.441 / 060619 15

Pressure:

Sensor:

Swagelok G 1/4” thread

Serto 90° angle for 8x6 mm tube

(tube 1.5 m included in delivery)

0–50 °C

5–10 l/h

max. 2 bar at 50 °C

Sample outlet pressure free

Screw connection: PG 13,5 mm

Installation depth: 75 mm

AMU pH-Redox

88

65

20

23

94

29

55

120

198

29

Product Description

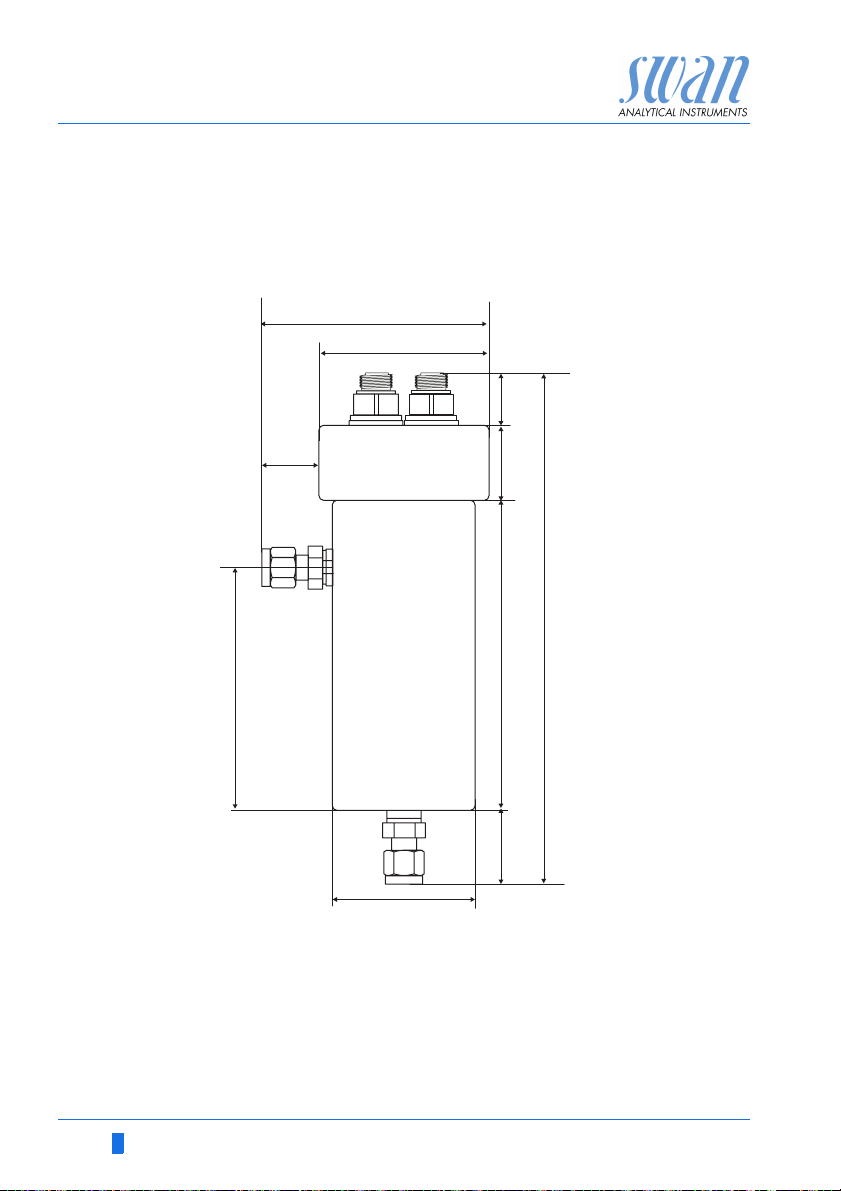

2.2.4 Flow Cell B-Flow IS1000

Stainless steel flow cell for 2 sensors with integrated Pt1000 temperature sensor. Suitable for all sensors with PG13.5 screw head

and a max. shaft length of 120 mm.

Technical data Sample inlet and outlet:

Operating temperature flow cell:

Operating temperature sensors:

Operating pressure low cell:

Operating pressure sensors:

2 x ¼" NPT female thread

up to 130 °C

up to 50 °C

max. 10 bar

max. 5 bar

16 A-96.250.441 / 060619

AMU pH-Redox

31

13

Ø 12

120 ±2

Product Description

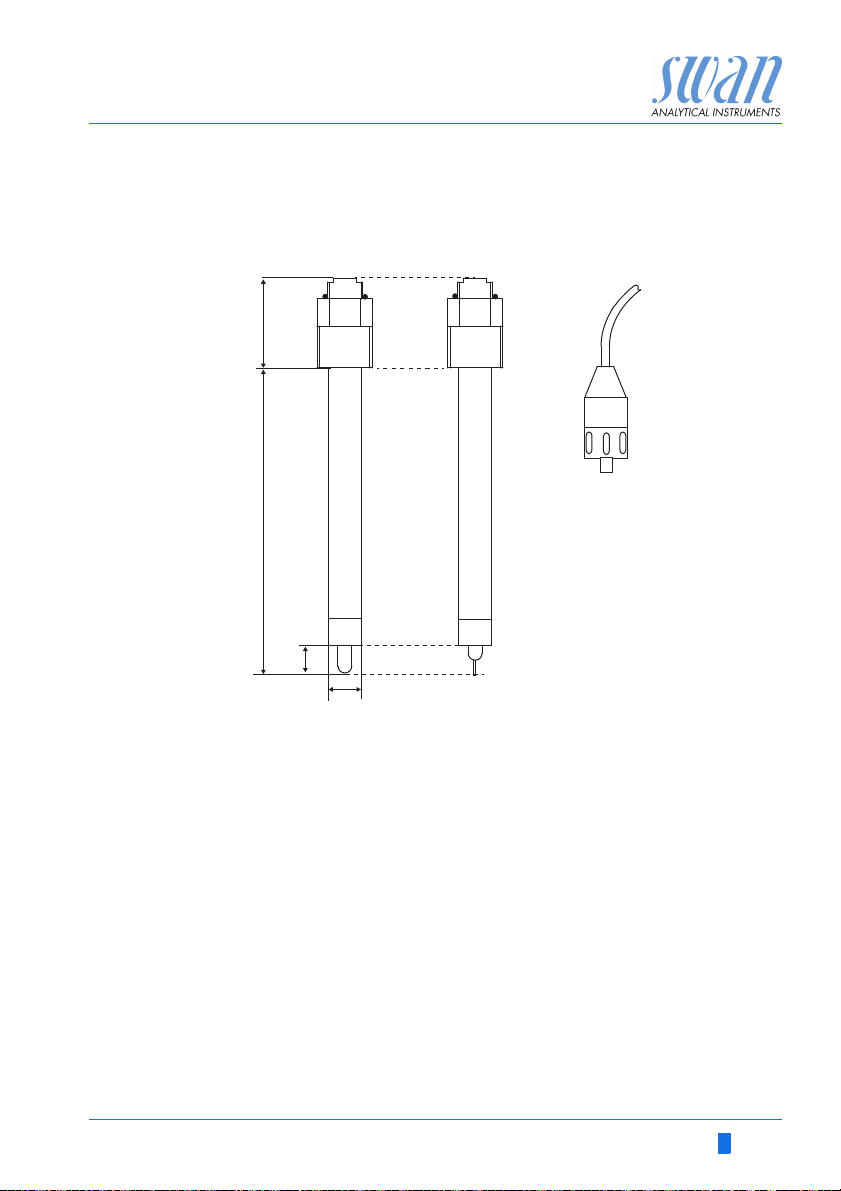

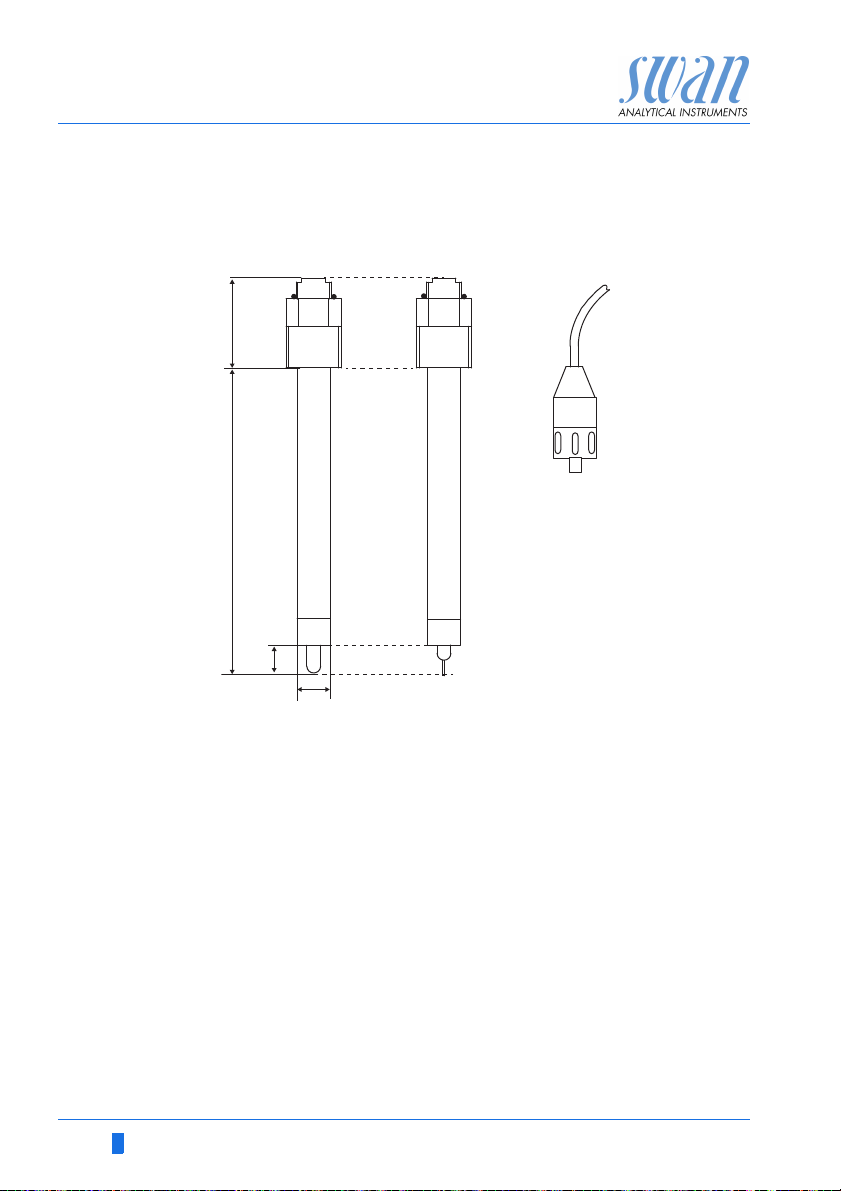

2.2.5 Swansensor pH and Redox Standard

Combined electrode with gel electrolyte for application in drinking

water and swimming pools.

pH-Sensor Redox Sensor Sensor cable with

plug

Specifications

pH Sensor

Specifications

ORP Sensor

A-96.250.441 / 060619 17

Operative and measuring range:

Operating temperature:

Pressure:

Conductivity measuring medium:

Connection:

Operative and measuring range:

Operating temperature:

Pressure:

Conductivity measuring medium:

Connection:

1 to 13 pH

0–50 °C

<2 bar

>150 µS/cm

plug PG 13.5

-400 to +1200 mV

0–50 °C

<2 bar

>150 µS/cm

plug PG 13.5

AMU pH-Redox

31

13

Ø 12

120 ±2

Product Description

2.2.6 Swansensor pH and Redox AY

Combined electrode with gel electrolyte for application in waste water due to additional salt supplies.

pH-Sensor Redox Sensor Sensor cable with

plug

Specifications

Specifications

pH-Sensor

ORP-Sensor

Operative and measuring range:

Operating temperature:

Pressure:

Conductivity measuring medium:

Connection:

Operative and measuring range:

Operating temperature:

Pressure:

Conductivity measuring medium:

Connection:

1 to 13 pH

0–50 °C

<2 bar

>100 µS/cm

plug PG 13.5

-400 to +1200 mV

0–50 °C

<2 bar

>100 µS/cm

plug PG 13.5

18 A-96.250.441 / 060619

AMU pH-Redox

Product Description

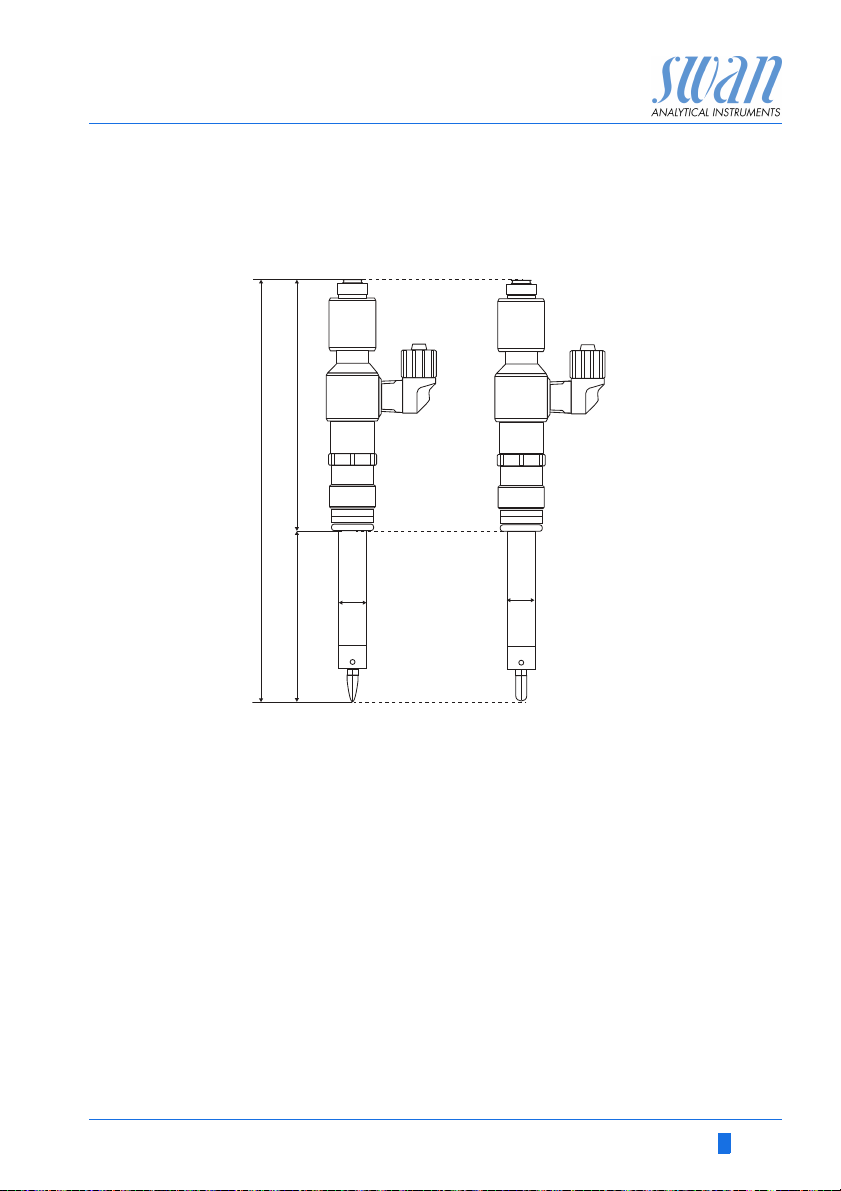

2.2.7 Swansensor pH and Redox SI

pH/Redox electrode with reference electrode for the measurement

of pH/Redox value in power plants.

184

110

75

12

12

pH Sensor Redox Sensor

Specifications

pH-Sensor

Specifications

Redox-Sensor

A-96.250.441 / 060619 19

Operative and measuring range:

Operating temperature:

Electrolyte:

Pressure:

min. Conductivity:

Connection:

Operative and measuring range:

Operating temperature:

Electrolyte:

Pressure:

min. Conductivity:

Connection:

1 to 12 pH

0–50 °C

KCl, 3.5 M

pressure free

0.055 µS/cm

plug PG 13.5

-500 to +1500 mV

0–50 °C

KCl 3.5 M

pressure free

3 µS/cm

plug PG 13.5

AMU pH-Redox

31

13

Ø 12

120 ±2

Product Description

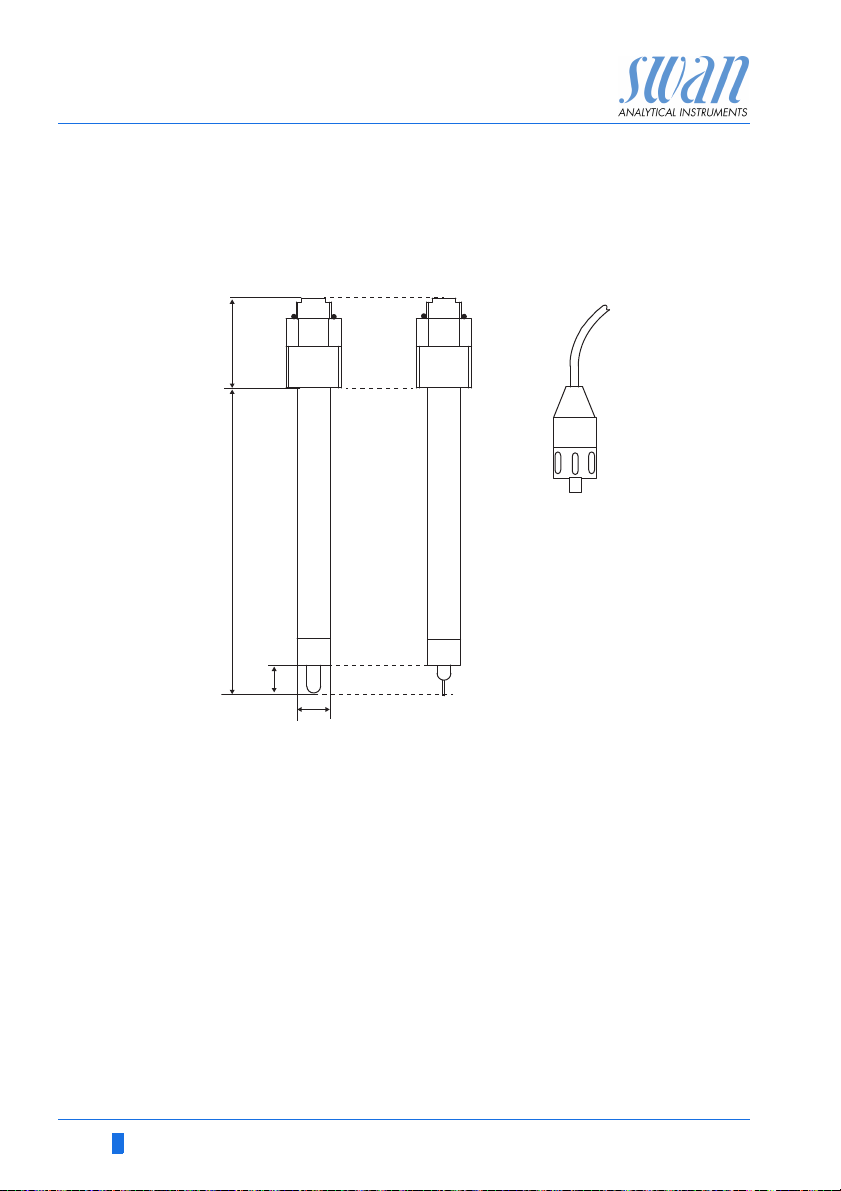

2.2.8 Swansensor pH and Redox FL

pH/Redox electrode for the measurement of pH value or redox potential in high purity water. Only in combination with Swansensor

Reference FL.

pH-Sensor ORP Sensor Sensor cable with plug

Specifications

pH-Sensor

Specifications

Redox-Sensor

Operative and measuring range:

Reference electrode:

Operating temperature:

Pressure:

Conductivity measuring medium:

Connection:

Operative and measuring range:

Reference electrode:

Operating temperature:

Pressure:

Conductivity measuring medium:

Connection:

1 to 12 pH

Reference FL

0–50 °C

pressure free

min. 0.055 µS/cm

plug PG 13.5

-500 to +1500 mV

Reference FL

0–50 °C

pressure free

min. 0.055 µS/cm

plug PG 13.5

20 A-96.250.441 / 060619

AMU pH-Redox

12

75

110

184

Product Description

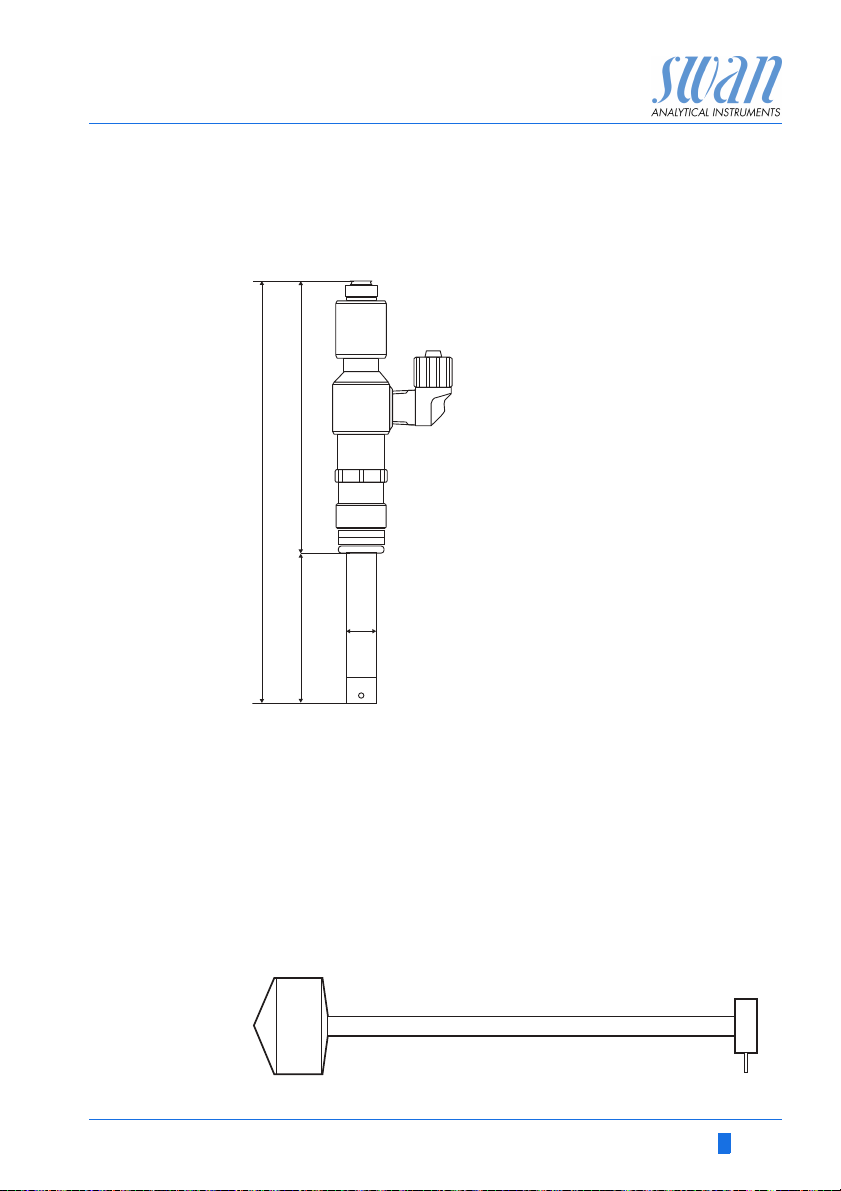

2.2.9 Swansensor Reference FL

Reference electrode for Swansensor pH FL or Swansensor Redox

FL.

Specifications Reference system:

Electrolyte:

Operating temperature:

Pressure:

Min. Conductivity:

Connection:

Ag/AgCl

KCl, 3.5 M

0–50 °C

pressure free

min. 0.055 µS/cm

plug PG 13.5

2.2.10 Spray Nozzle

For automatic cleaning of the sensor tips applicable with flow cell

M-Flow 10-3PG.

A-96.250.441 / 060619 21

AMU pH-Redox

Installation

3. Installation

3.1. Installation Checklist Monitors

Check Instrument’s specification must conform to your power ratings.

Do not switch on power until all external devices are connected.

Installation The transmitter is intended for panel mounting. The dimensions

are shown in Dimensions of the AMU Transmitter, p. 23.

Electrical Connections

pH/ORP

sensor

Power-up Turn on the sample flow and wait until the flow cell is completely

Instrument

set-up

Run-in period Let the instrument run continuously for 1 h.

pH sensor

calibration

ORP sensor

calibration

Connect all external devices, see Electrical Connections, p. 32.

Connect the power cord, but do not switch on power until all

external devices are connected.

Install the sensors, see Flow Cell QV-Flow, p. 25 or Flow Cell M-

Flow, p. 28.

Connect the sensor cables.

Store the protective caps for later use.

filled.

Switch on power.

First, the transmitter performs a self test, displays the firmware

version and then starts normal operation.

Adjust sample flow. Program all parameters for sensor and

external devices (interface, recorders, etc.). Program all parameters for instrument operation (limits, alarms).

Perform standard calibration or process calibration according to

Calibration, p. 48.

Perform standard calibration or process calibration according to

Calibration, p. 48.

22 A-96.250.441 / 060619

AMU pH-Redox

96 mm

89.8 mm

89.8 mm

112 m m

7 mm

96 mm

92 mm

92 mm

Installation

3.2. Dimensions of the AMU Transmitter

A-96.250.441 / 060619 23

AMU pH-Redox

ABC D

AB

Installation

3.3. Connecting Sample Inlet and Outlet

3.3.1 Serto Fitting Stainless Steel for QV-Flow Cell

Preparation Cut the tube to length and deburr it. The tube must be straight and

free from blemishes for approximately 1,5 x tube diameter from the

end.

Lubrication with lubricating oil, MoS2, Teflon etc. is recommended

for the assembly and reassembly of bigger sized unions (thread,

compression ferrule).

Installation 1 Screw on the union nut by hand until finger tight. At the same

time, push the tube against the body.

2 Tighten down the union nut 1¾ rotation using an open ended

spanner. Hold Body from turning with a second wrench.

A

Body

B

Compression ferrule

C

Union nut

D

Tube

3.3.2 Elbow Hose Nozzle for M-Flow Cell

Use plastic tube (FEP, PA, or PE 10 x 12 mm) to connect the sample inlet and outlet.

ABPlastic tube 10 x 12

Elbow hose nozzle

24 A-96.250.441 / 060619

AMU pH-Redox

A

B

C

Installation

3.4. Flow Cell QV-Flow

3.4.1 Install Swansensor pH or Redox SI

CAUTION

Fragile parts

The pH and ORP sensors are fragile.

Handle with care.

Do not spill KCl when removing the protective cap.

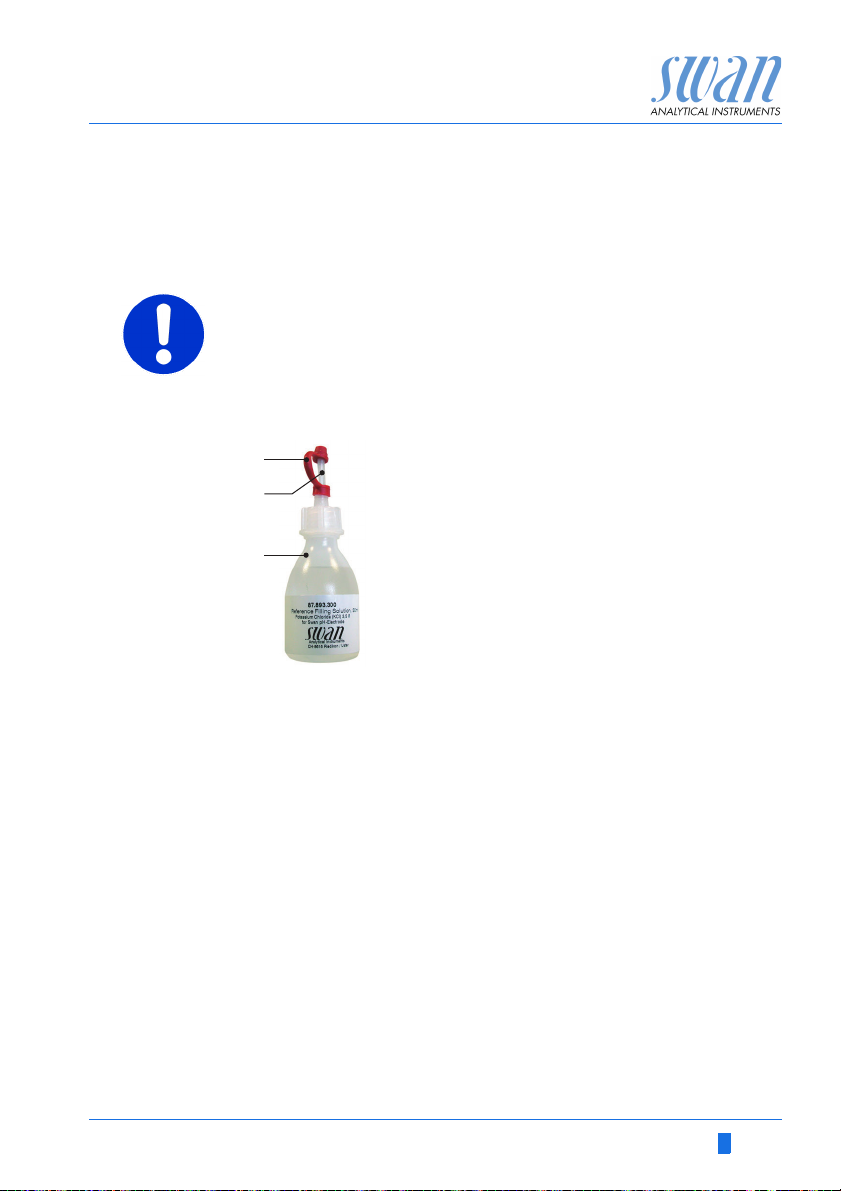

Prepare the

KCl Bottle

A

Seal cap

B

Dosing tip

C

KCl bottle

1 Remove the seal cap [A] from the dosing tip [B].

2 Cut off the upper sealed part of the dosing tip.

A-96.250.441 / 060619 25

Loading...

Loading...