Swann AMI INSPECTOR Oxygen Operator's Manual

AMI INSPECTOR

Oxygen

Version 6.00 and higher

A-96.250.701 / 140716

Operat

or’s Manual

© 2016, SWAN ANALYTISCHE INSTRUMENTE AG, Switzerland, all rights reserved

subject to change without notice.

Customer Support

SWAN and its representatives maintain a fully trained staff of technical specialists

around the world. For any technical question, contact your nearest

SWAN representative, or the manufacturer:

SWAN ANALYTISCHE INSTRUMENTE AG

Studbachstrasse 13

8340 Hinwil

Switzerland

Internet: www.swan.ch

E-mail: support@swan.ch

Document Status

Title:

Monitor AMI INSPECTOR Oxygen Operator’s Manual

ID:

A-96.250.701

Revision Issue

00 Sep. 2011 First Edition

01 Nov. 2013 New main board, integrated USB interface

02 Jan. 2016 AMI Inspector Version 2-A (with AMIAKKU main-

board) and Firmware version 6.00

AMI INSPECTOR Oxygen

A-96.250.701 / 140716 1

Table of Contents

1. Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1. Warning Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2. General Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1. Description of the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2. Instrument Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.3. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1. Installation Check List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2. Connecting Sample Inlet and Outlet. . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 Connect the Sample Inlet to the Quick-Lock Coupling . . . . . . . 14

3.2.2 Connect the Sample Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3 Install the Swansensor Oxytrace G . . . . . . . . . . . . . . . . . . . . . . . 16

3.4. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

3.5. Connection Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6. Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6.2 Alarm Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6.3 Relay Contacts 1 and 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.7. Signal Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4. Instrument Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.1. Establish sample flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.2. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.1. Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.2. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.3. Software Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.4. Changing Parameters and values . . . . . . . . . . . . . . . . . . . . . . . . 27

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.1. Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.2. Stop of Operation for Maintenance. . . . . . . . . . . . . . . . . . . . . . . . 28

6.3. Maintenance of the Oxygen Sensor . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.1 Electrolyte exchange. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

2 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

6.3.2 Clean Swansensor Oxytrace and G Flow Cell . . . . . . . . . . . . . 31

6.4. Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.5 Zero-Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.6. Quality Assurance of the Instrument. . . . . . . . . . . . . . . . . . . . . . . 34

6.6.1 Activate SWAN Quality assurance procedure. . . . . . . . . . . . . . 36

6.6.2 Pre-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6.3 Connect the sample lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.6.4 Carry out comparison measurement . . . . . . . . . . . . . . . . . . . . . 38

6.6.5 Completion of the measurement . . . . . . . . . . . . . . . . . . . . . . . . 39

6.7. Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.8. Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

6.9. Longer Stop of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

7. Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8. Program Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.1. Messages (Main Menu 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.2. Diagnostics (Main Menu 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.3. Maintenance (Main Menu 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.4. Operation (Main Menu 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

8.5. Installation (Main Menu 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9. Program List and Explanations. . . . . . . . . . . . . . . . . . . . . . . . . 50

1 Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

10. Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

11. Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

12. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

AMI INSPECTOR Oxygen

Safety Instructions

A-96.250.701 / 140716 3

AMI INSPECTOR Oxygen Operator’s Manual

This document describes the main steps for instrument setup, operation and maintenance.

1. Safety Instructions

General The instructions included in this section explain the potential risks

associated with instrument operation and provide important safety

practices designed to minimize these risks.

If you carefully follow the information contained in this section, you

can protect yourself from hazards and create a safer work environment.

More safety instructions are given throughout this manual, at the

respective locations where observation is most important.

Strictly follow all safety instructions in this publication.

Tar get

audience

Operator: Qualified person who uses the equipment

for its intended purpose.

Instrument operation requires thorough knowledge of applications,

instrument functions and software program as well as all applicable

safety rules and regulations.

OM Location The AMI Operator’s Manual shall be kept in proximity of the instru-

ment.

Qualification,

Training

To be qualified for instrument installation and operation, you must:

read and understand the instructions in this manual as well as

the Material Safety Data Sheets.

know the relevant safety rules and regulations.

4 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Safety Instructions

1.1. Warning Notices

The symbols used for safety-related notices have the following significance:

DANGER

Your life or physical wellbeing are in serious danger if such

warnings are ignored.

Follow the prevention instructions carefully.

WARNING

Severe injuries or damage to the equipment can occur if such

warnings are ignored.

Follow the prevention instructions carefully.

CAUTION

Damage to the equipment, minor injury, malfunctions or incorrect process can be the consequence if such warnings are ignored.

Follow the prevention instructions carefully.

Mandatory

Signs

The importance of the mandatory signs in this manual.

Safety goggles

Safety gloves

AMI INSPECTOR Oxygen

Safety Instructions

A-96.250.701 / 140716 5

Warning Signs The importance of the warning signs in this manual.

Electrical shock hazard

Corrosive

Harmful to health

Flammable

Warning general

Attention general

6 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Safety Instructions

1.2. General Safety Regulations

Legal

Requirements

The user is responsible for proper system operation.

All precautions must be followed to ensure safe operation

of the instrument.

Spare Parts

and

Disposables

Use only official SWAN spare parts and disposables. If other parts

are used during the normal warranty period, the manufacturer’s

warranty is voided.

Modifications Modifications and instrument upgrades shall only be carried out by

an authorized Service Technician. SWAN will not accept responsibility for any claim resulting from unauthorized modification or alteration.

WARNING

Risk of Electrical Shock

If proper operation is no longer possible, the instrument must be

disconnected from all power lines, and measures must be taken

to prevent inadvertent operation.

To prevent from electrical shock, always make sure that the

ground wire is connected.

Service shall be performed by authorized personnel only.

Whenever electronic service is required, disconnect instru-

ment power and power of devices connected to.

– relay 1,

– relay 2,

– alarm relay

WARNING

For safe instrument installation and operation you must read

and understand the instructions in this manual.

WARNING

Only SWAN trained and authorized personnel shall perform the

tasks described in this document.

AMI INSPECTOR Oxygen

Product Description

A-96.250.701 / 140716 7

2. Product Description

This chapter contains technical data, requirements and performance data.

2.1. Description of the System

The portable AMI INSPECTOR instrument is a complete monitoring

system mounted on a small panel with supporting stand and a rechargeable battery for stand-alone operation (>24h), designed as

an inspection equipment for quality assurance of online process

monitors.

Features General Features of AMI INSPECTORs are:

Battery life after full charge:

– >24h at full load (use of 3 relays, USB, signal output, logger)

– >36h at minimum load (use of logger only)

Charging time: approx. 6 hours

Controlled shut-down if battery is empty.

Display of remaining battery life in hours.

For longer battery life the back light of the LC Display is dis-

abled.

Continuous operation using power adapter. The battery

should be discharged at least once a month (normal usage

until the monitor automatically shuts down).

Battery The Li-Ion battery is located in the housing of the AMI transmitter.

See chapter Power Supply, p. 19 regarding power supply and

charging of the battery.

Safety features No data loss after power failure, all data is saved in non-volatile

memory. Over voltage protection of in- and outputs.

Galvanic separation of measuring inputs and signal outputs.

USB interface Built in USB interface for logger download. Use the USB stick sup-

plied by Swan only (other USB sticks can dramatically reduce battery life).

Signal Output

(optional)

One signal output programmable for measured values (freely

scaleable, linear or bilinear) or as continuous control output (control

parameters programmable).

Current loop: 0/4–20 mA

Maximal burden: 510

8 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Product Description

Relay Two potential-free contacts programmable as limit switches for

measuring values, controllers or timer for system cleaning with automatic hold function.

Maximum load: 100 mA/ 50 VAC

Alarm Relay One potential free contact.

Alternatively:

Open during normal operation, closed on error and loss of

power.

Closed during normal operation, open on error and loss of

power.

Summary alarm indication for programmable alarm values and instrument faults.

Input For potential-free contact to freeze the measuring value or to inter-

rupt control in automated installations (hold function or remote-off)

Measuring

principle

Clark principle:

The sensor consists of one noble metal electrode (e.g. platinum or

gold), a reference electrode (mostly Ag/AgCl) and optionally a metal guard electrode.

The Clark-type electrode is the most widely used oxygen sensor for

measuring oxygen dissolved in a liquid. The basic principle is that

there is a cathode and an anode submersed in an electrolyte and a

voltage is applied between the two parts. Oxygen enters the sensor

through a permeable membrane by diffusion, and is reduced at the

cathode according to

O

2

+ 4e- + 2 H2O --> 4 OH

-

This reaction creates a measurable current. There is a linear correlation between the oxygen concentration and the electrical current.

The guard electrode is on the same voltage level as the cathode

but there is no current measurement. Oxygen which diffuses from

the electrolyte to the cathode is consumed by the guard electrode.

As a consequence, residual oxygen in the electrolyte will no more

disturb the measurement signal and the response time to low oxygen levels will be shorter.

Temperature

compensation

The measuring signal depends on temperature, but is automatically

compensated to 25 °C. The sample temperature is determined continuously by a temperature sensor inside the oxygen electrode.

AMI INSPECTOR Oxygen

Product Description

A-96.250.701 / 140716 9

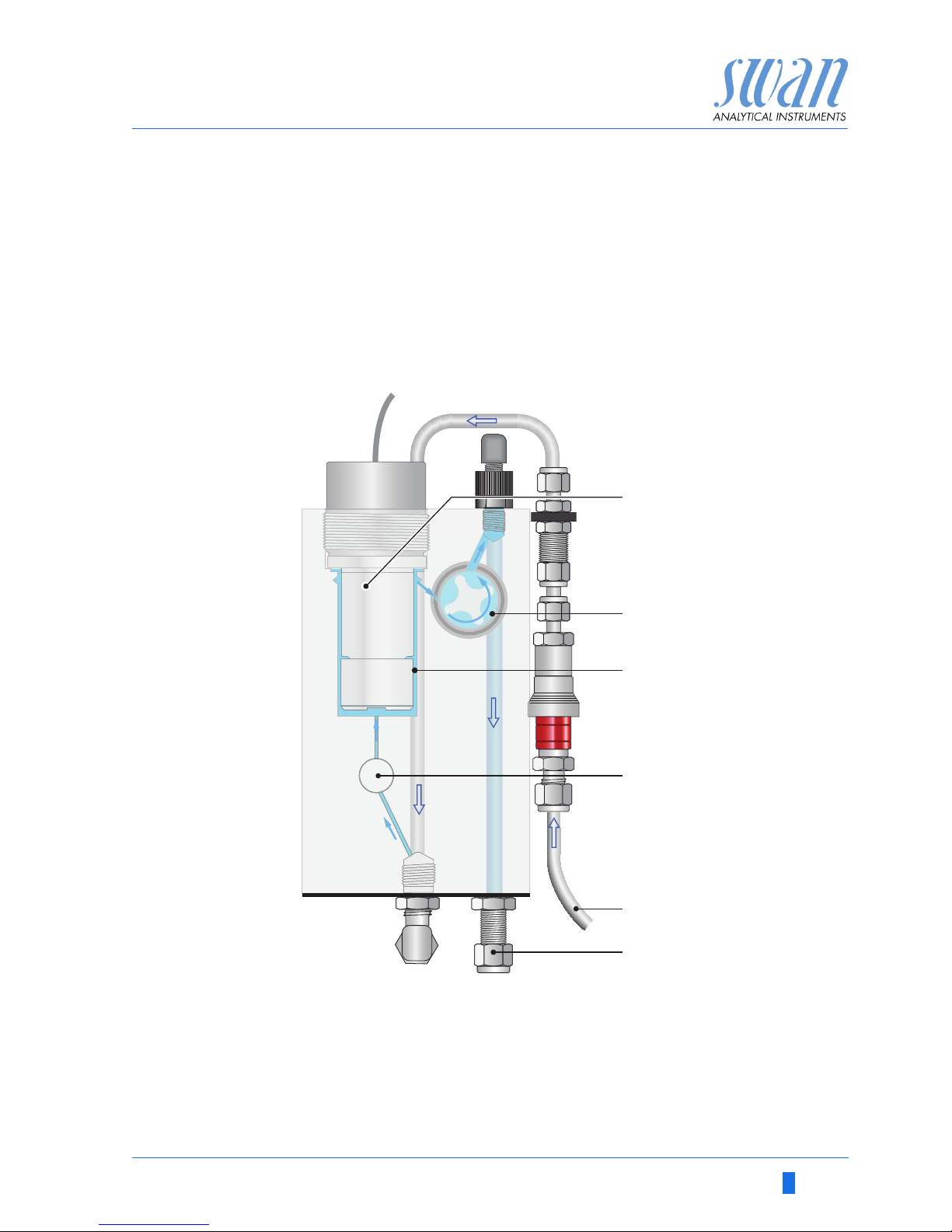

Fluidics Swansensor oxygen combined with QV-flow PMMA OTG flow cell.

The sample flows via sample inlet [E] through the flow regulating

valve [D], where the flow rate can be adjusted. Then the sample

flows into the measuring cell [C] were the Oxygen concentration

and temperature of the sample is measured.

The sample leaves the measuring cell via flow sensor [B] through

the sample outlet [F].

A

B

C

Oxygen sensor

Flow sensor

Flow cell

D

E

F

Flow regulating valve

Sample inlet

Sample outlet

A

B

C

D

E

F

10 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Product Description

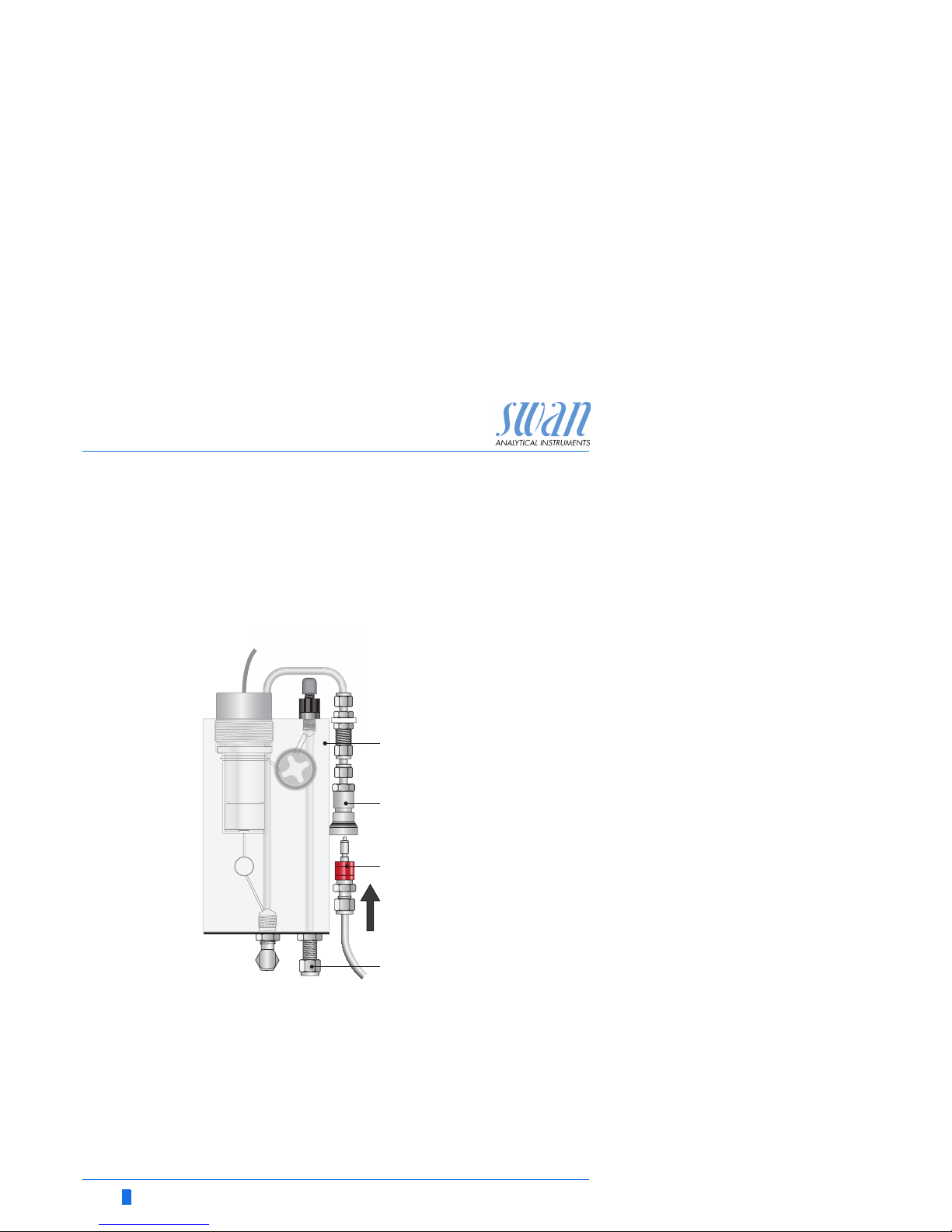

2.2. Instrument Overview

A

B

C

D

E

AMI Transmitter

Oxygen sensor

Flow cell

Flow sensor

Flow regulating valve

FGSample inlet

Sample outlet

A

B

D

C

F

G

E

AMI INSPECTOR Oxygen

Product Description

A-96.250.701 / 140716 11

2.3. Technical Data

Power Supply Battery

Use original, supplied power adapter only.

Voltage:

Power consumption:

Charging time:

Battery type:

85–265 VAC, 50/ 60 Hz

max. 20 VA

6h

Li-Ion

During charging protect from heat impact and keep splash-proof

(not IP66).

Operating time Stand-alone (Battery):

Connected adapter:

> 24h

continuous

Controlled shut-down when battery is empty, remaining time is displayed.

Electronics Aluminium with a protection degree of IP 66 / NEMA 4X

housing Ambient temperature:

Humidity:

Display:

-10 to +50 °C

10–90% rel., non condensing

backlit LCD, 75 x 45 mm

Sample

requirements

Flow rate:

Temperature:

Inlet pressure:

pH:

Suspended solids:

Outlet pressure:

8 to 25 l/h

up to 45 °C

0.2 to 1 bar

not lower than pH 4

less than 10 ppm

pressure free

Flow cell and

connection

Flow cell made of acrylic glass with built-in flow adjustment valve

and digital sample flow meter

Sample inlet:

Sample outlet:

1/4” Swagelok tube adapter

flexible tube 8x6 mm

Accuracy

Reproducibility

±1.5 % of measured value or ±0.2 ppb

±1 % of measured value or ±0.15 ppb

12 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Product Description

Sensor

Oxytrace G

Sensor for the measurement of dissolved oxygen in ultra pure

water. Precise oxygen measuring cell with integrated temperature

sensor and guard electrode for faster initial response time after

maintenance.

Technical data: Clark oxygen electrode

Cathode gold, anode silver, guard silver

Zero current-free electrode system

Robust 25 µm fluoropolymer diaphragm

Measuring

range:

0–20 ppm O

2

(25 °C)

Automatic range switching

Range

0.1 to 9.99 ppb

10 to 199.9 ppb

200 to 1999 ppb

2 to 20 ppm

0 – 200% saturation

Resolution

0.01 ppb

0.1 ppb

1.0 ppb

0.01 ppm

Accuracy: 0,3 % if calibration temperature = measuring temp. 1,5% at ± 10

°C deviation to cal. temperature

Precision:

Response time:

Minimal flow:

Operating tem-

perature:

± 1% of reading or ±0.15 ppb

t90 < 30 seconds (rising concentration)

50 cm/s Pressure resistance: 3 bar

max. 50 °C

Material:

Protection:

Weight:

polyacetal copolymer

IP 68

150 g

AMI INSPECTOR Oxygen

Installation

A-96.250.701 / 140716 13

3. Installation

3.1. Installation Check List

Check

Instrument’s specification must conform to your AC power

ratings. See External power adapter, p. 20.

Check if the battery is fully charged.

Installation

Connect the sample inlet and outlet, see Connecting Sample

Inlet and Outlet, p. 14.

Install the Swansensor Oxytrace G into the flow cell, see Install

the Swansensor Oxytrace G, p. 16.

Power-up

Open the flow regulating valve and adjust the sample flow to

8–25 l / h.

Switch on power.

Instrument

Setup

Program all parameters, see chapter 4.

Run-in period

Let the instrument run continuously for 1 h.

14 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Installation

3.2. Connecting Sample Inlet and Outlet

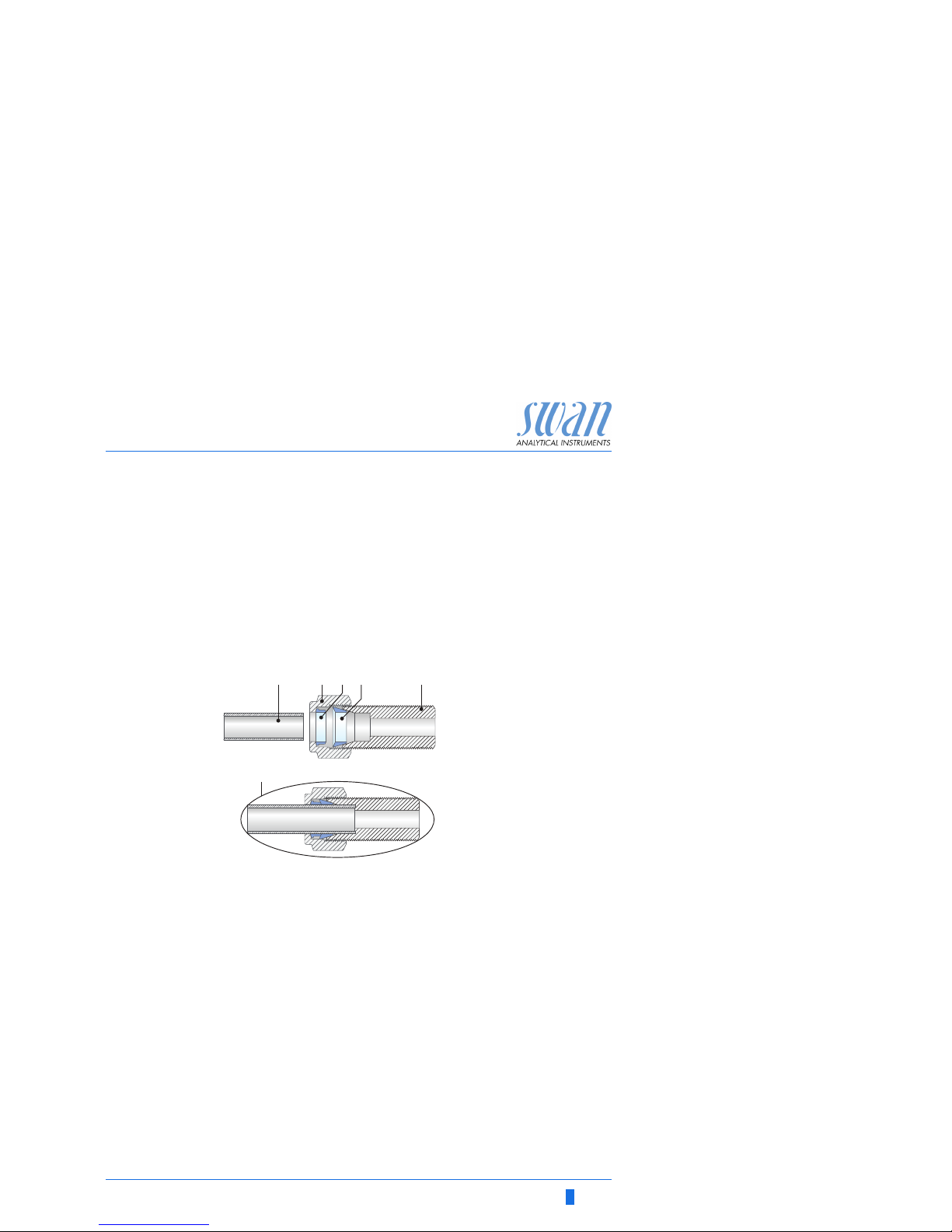

3.2.1 Connect the Sample Inlet to the Quick-Lock Coupling

The AMI INSPECTOR Oxygen is delivered with a quick-lock coupling. To connect the sample line to the AMI INSPECTOR Oxygen,

simply push the nipple into the quick-lock coupling.

A

B

C

D

Flow cell block

Quick-lock coupling

Nipple

Sample outlet

A

B

C

D

AMI INSPECTOR Oxygen

Installation

A-96.250.701 / 140716 15

3.2.2 Connect the Sample Outlet

Installation 1 Loosen the union nut [B] but do not remove it.

2 Push the FEP tube [A] through the union nut [B] as far as it

reaches the stop of the threaded tube [E].

3 Tighten the union nut 1¾ rotation using an open ended spanner.

Hold Body from turning with a second wrench.

4 Put the FEP Tube into a pressure free drain with sufficient ca-

pacity.

A

B

C

FEP tube 8x 6

Union nut

Compression ferrule

D

E

F

Compression cone

Threaded tube

Tightened connection

ABCD E

F

16 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Installation

3.3 Install the Swansensor Oxytrace G

The Swansensor Oxytrace G is delivered with prefilled electrolyte

chamber [E]. A transport protection cap [B] filled with water [D]

keeps the sensor wet during transport and storage. To install the

sensor proceed as follows:

1 Unscrew the fixing sleeve [A].

2 Remove the transport protection cap [B].

3 Clean the Swansensor Oxytrace G [C] with water.

4 Install the Swansensor Oxytrace G into the flow cell

Connect the sensor cable to the transmitter, see Connection Dia-

gram, p. 18.

A

B

C

D

E

Fixing sleeve

Transport protection cap

Swansensor Oxytrace G

Water

Sensor cap filled with electrolyte

A

B

C

D

E

AMI INSPECTOR Oxygen

Installation

A-96.250.701 / 140716 17

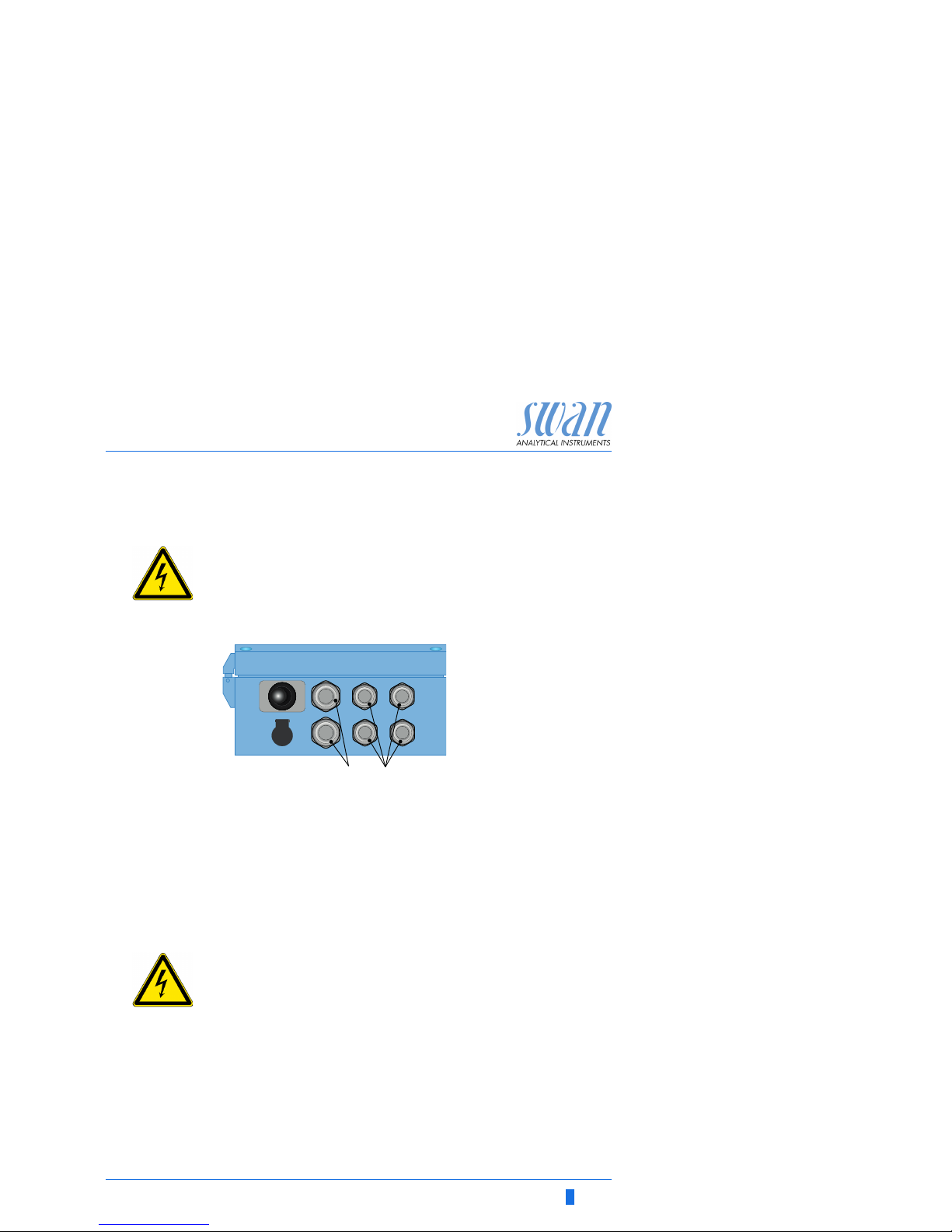

3.4. Electrical Connections

WARNING

Always turn off DC power before manipulating electric parts.

Make sure the power specification of the instrument corresponds to the power on site.

Cable

thicknesses

In order to comply with IP66, use the following cable thicknesses

NOTICE: Protect unused cable glands

Wire For Relays: Use max. 1.5 mm2 / AWG 14 stranded wire with

end sleeves.

For Signal Outputs and Input: Use 0.25 mm

2

/ AWG 23

stranded wire with end sleeves.

WARNING

External Voltage.

External supplied devices connected to relay 1 or 2 or to the

alarm relay can cause electrical shocks.

Make sure that the devices connected to the following con-

tacts are disconnected from the power before continuing the

installation.

– relay 1

– relay 2

– alarm relay

ABPG 9 cable gland: cable Ø

outer

4–8 mm

PG 7 cable gland: cable Ø

outer

3–6.5 mm

ON

OFF

AB

18 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Installation

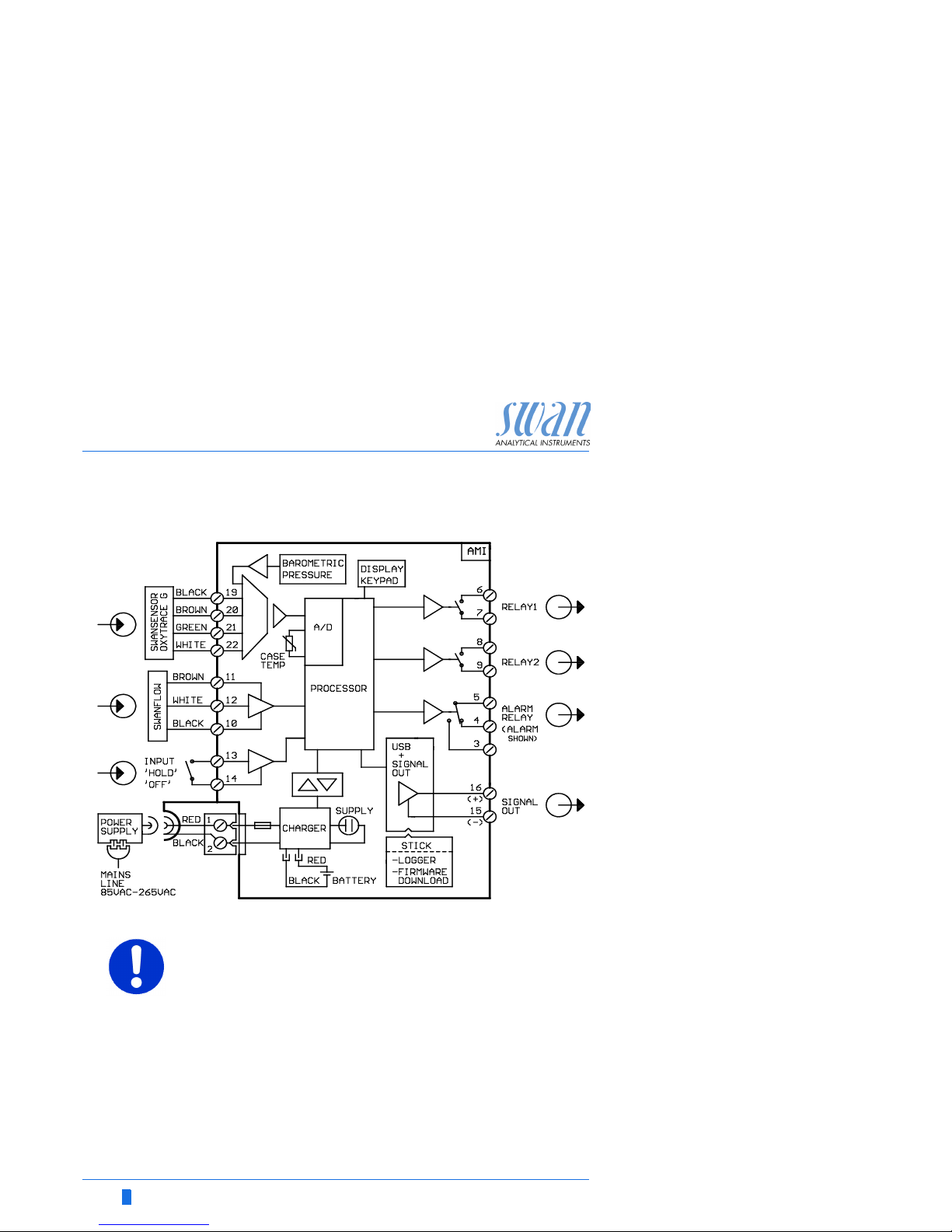

3.5. Connection Diagram

CAUTION

Use only the terminals shown in this diagram, and only for the

mentioned purpose. Use of any other terminals will cause short

circuits with possible corresponding consequences to material

and personnel.

AMI INSPECTOR Oxygen

Installation

A-96.250.701 / 140716 19

3.5.1 Power Supply

Contrary to all other Swan online process monitors the

AMI INSPECTOR transmitter is supplied with power by battery only. The rechargeable battery (Li-Ion) enables a stand-alone operation for at least 24 hours.

WARNING

Do not provide power directly to the transmitter as this will destroy the motherboard. All AMI INSPECTOR transmitters are

supplied with power by battery only.

Charging Use the original supplied power adapter to charge AMI INSPEC-

TOR only. Charging time: approx 6h.

Fully charged a stand-alone operating time of at least 24h is guar-

anteed:

>24h at full load (use of 3 relays, USB, signal output, logger)

>36h at minimal load (use of logger only)

In case that the battery is discharged completely the firmware will

automatically shut down.

Switch Power

ON - OFF

Switch the instrument ON or OFF using the toggle switch on the

transmitter.

Continuous

operation

For continuous operation use the power adapter as well.

CAUTION

If the AMI powers ON and then immediately shuts OFF, the

battery is empty. Do not hold the toggle switch in ON position,

as this can damage the battery.

CAUTION

During charging protect from heat impact and keep splash-

proof (plug of power adapter is not IP66).

Do not supply external devices, e.g. pumps, magnetic valves

or any other current consumers with AMI INSPECTOR

CAUTION

Use the original supplied power adapter to charge AMI IN-

SPECTOR only. Use of any other power adapter can damage

the battery or cause malfunction.

20 A-96.250.701 / 140716

AMI INSPECTOR Oxygen

Installation

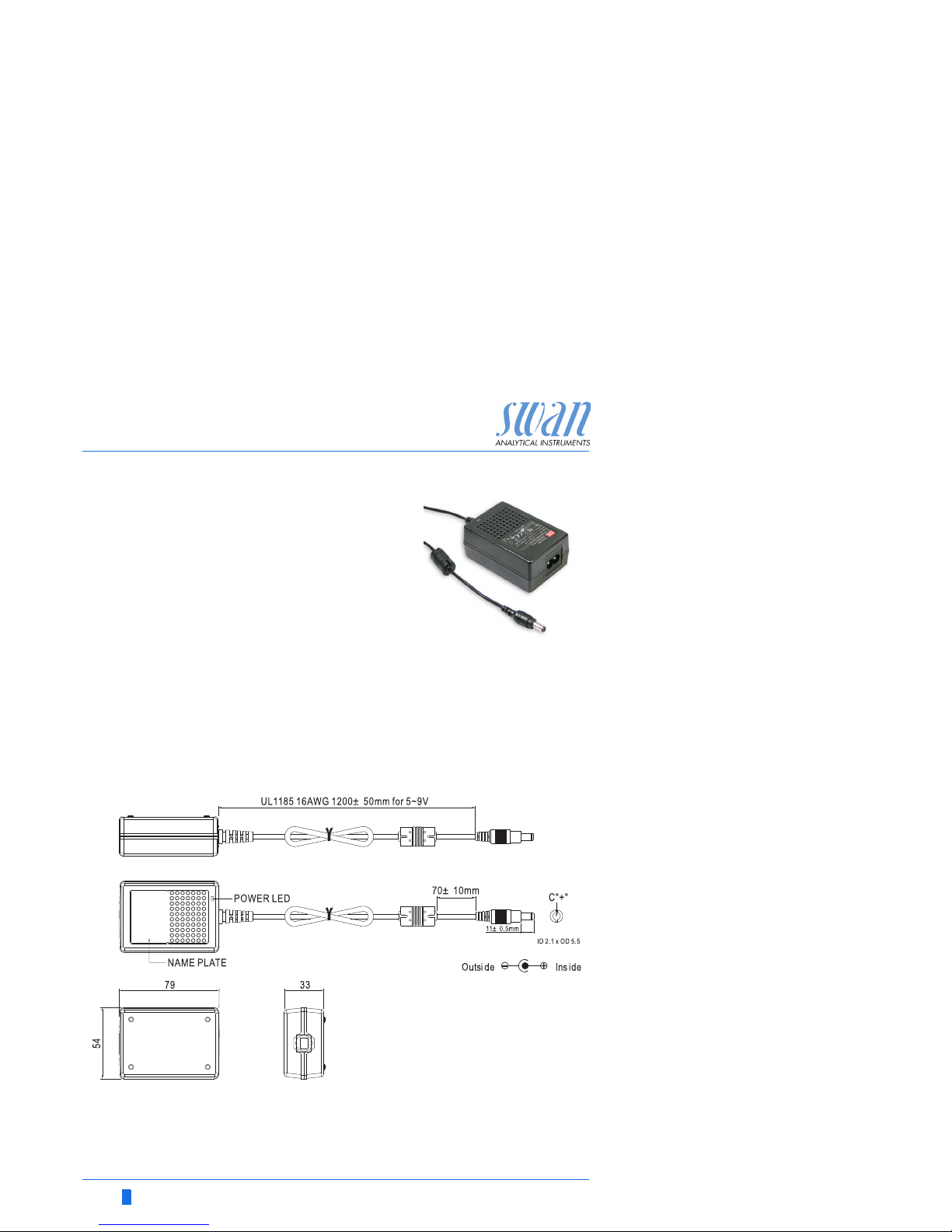

External

power adapter

Universal input range

85 - 265 VAC

Continuous short circuit protection

Over voltage protection

LED indicator for power on

2-pin AC inlet (IEC 320-C8) for

detachable country-specific power

cord

Power cords Two different power cords are supplied:

Power cord with type C plug (Europlug)

Power cord with type A plug (NEMA-1)

If a different plug type is needed, please purchase a suitable power

cord from your local supplier.

NOTICE: Do not use any plug adapters.

Dimensions

Unit: mm

AMI INSPECTOR Oxygen

Installation

A-96.250.701 / 140716 21

3.6. Relay Contacts

Programming of the relay contacts see 5.3 Relay Contacts, p. 59

3.6.1 Input

NOTICE: Use only potential-free (dry) contacts.

Terminals 13/14

If signal output is set to hold, measurement is interrupted if input is

active.

For programming see menu 5.3.4, p. 65

3.6.2 Alarm Relay

NOTICE: For resistive loads only; do not use with capacitive or

inductive loads. Max. load 1 A / 250 VAC.

Alarm output for system errors.

Error codes see Error List, p. 42

Programming see menu 5.3.1, p. 59

NOTICE: With certain alarms and certain settings of the AMI

transmitter the alarm relay does not switch. The error, however,

is shown on the display.

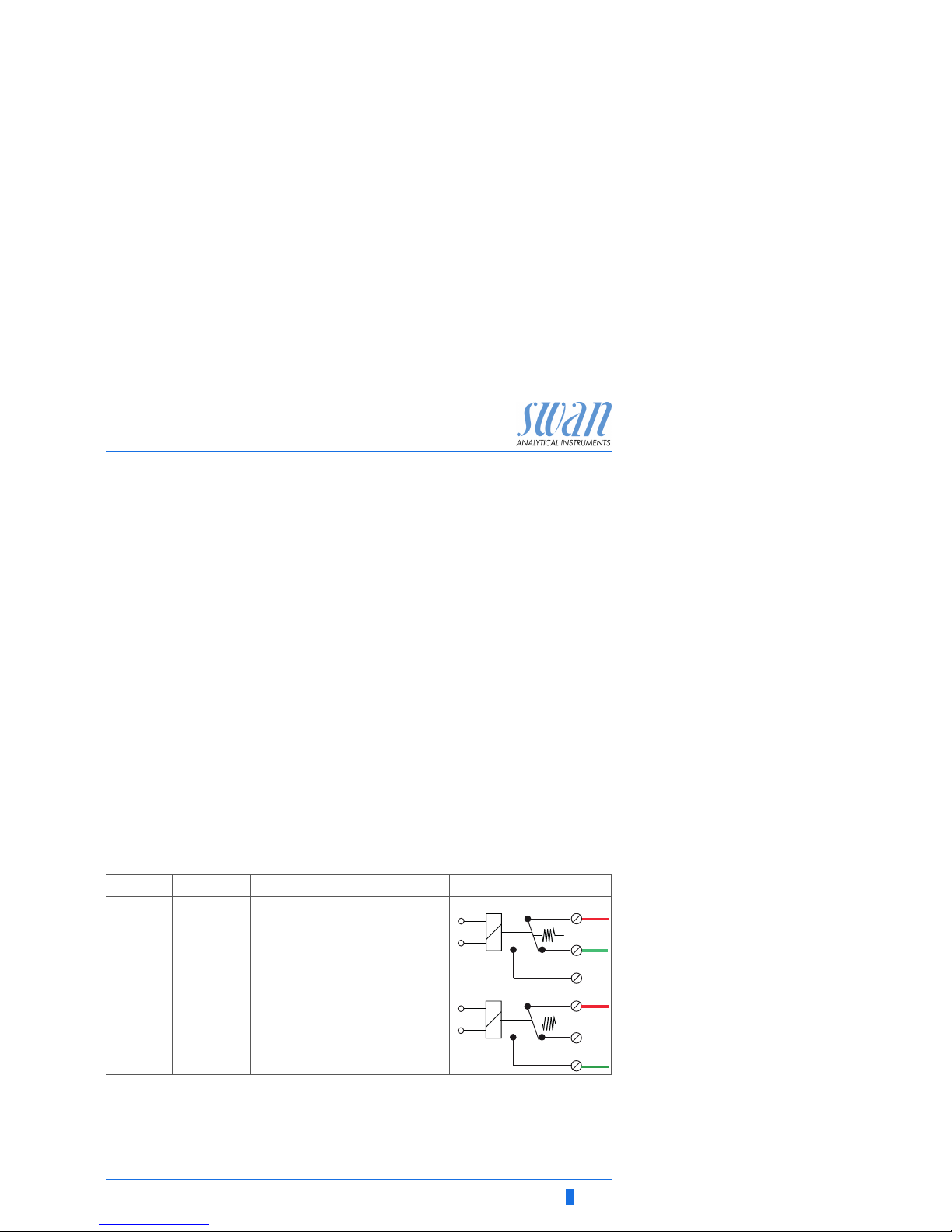

1) usual use

Terminals Description Relay connection

NC

1)

Normally

Closed

5/4 Active (opened) during normal

operation.

Inactive (closed) on error and

loss of power.

NO

Normally

Open

5/3 Active (closed) during normal

operation.

Inactive (opened) on error and

loss of power.

4

3

5

0V

1)

4

3

5

0V

Loading...

Loading...