AMI Soditrace

Version 6.10 and higher

s Manual

Operator’

A-96.250.551 / 100717

Customer Support

SWAN and its representatives maintain a fully trained staff of technical specialists

around the world. For any technical question, contact your nearest

SWAN representative, or the manufacturer:

SWAN ANALYTISCHE INSTRUMENTE AG

Studbachstrasse 13

8340 Hinwil

Switzerland

Internet: www.swan.ch

E-mail: support@swan.ch

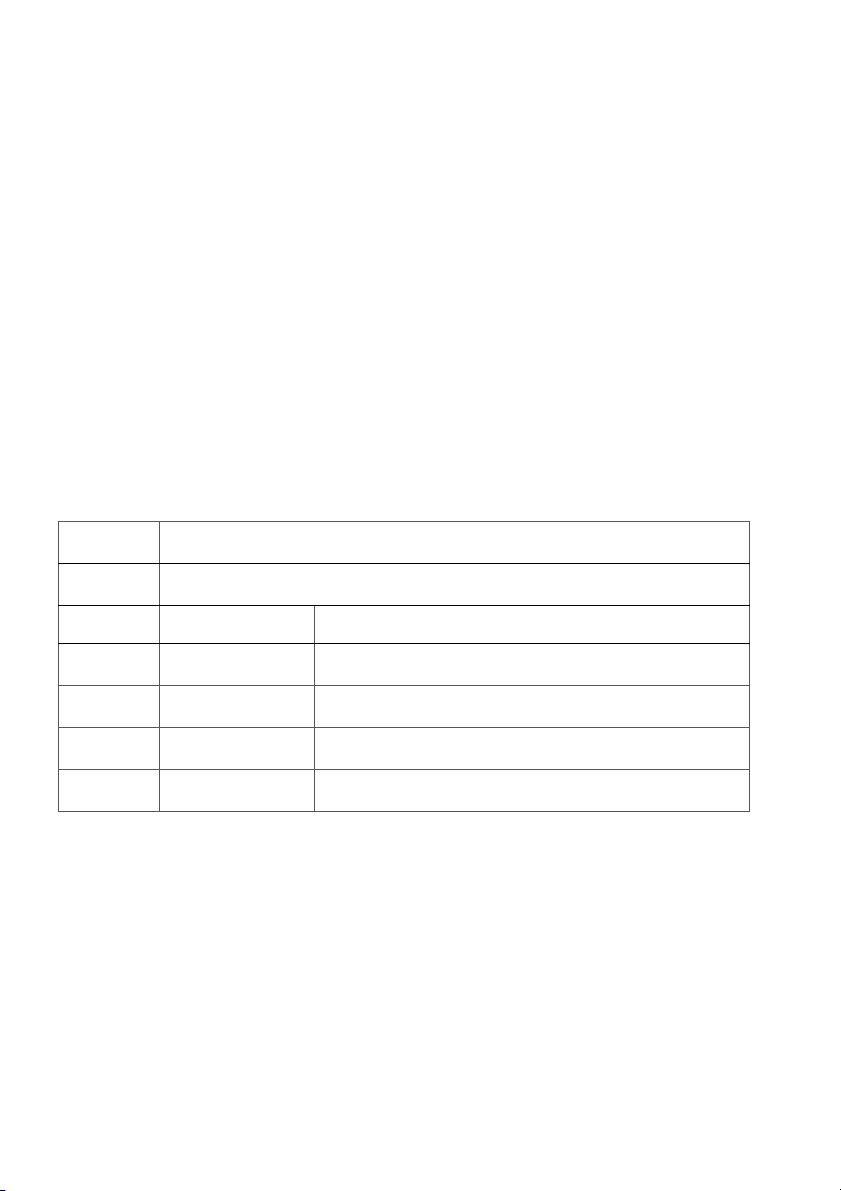

Document Status

Title:

ID:

AMI Soditrace Operator’s Manual

A-96.250.551

Revision Issue

00 Sept. 2009 Preliminary Edition

01 Nov. 2009

02 Oct. 2012 Update to Firmware version 5.30, USB interface

03 July 2017 New mainboard V2.5, Firmware version 6.10

© 2017, SWAN ANALYTISCHE INSTRUMENTE AG, Switzerland, all rights reserved

subject to change without notice

.

AMI Soditrace

Table of Contents

1. Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.1. Warning Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2. General Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.1. Description of the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2.2. Instrument Specification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.3. Instrument Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.1. Installation Checklist Monitors . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.2. Mounting of Instrument Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.3. Connecting Sample and Waste . . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.4. Installation of Electrodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

3.4.1 Install the Sodium Electrode . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

3.4.2 Install the Reference Electrode . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.4.3 Install the Temperature Sensor. . . . . . . . . . . . . . . . . . . . . . . . . 29

3.5. Install Standard and Regeneration Bottle . . . . . . . . . . . . . . . . . . . 30

3.6. Install Reagent Bottle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.7. Install Air Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.8. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

3.8.1 Connection Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

3.8.2 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.9. Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.9.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.9.2 Alarm Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.9.3 Relay Contacts 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.10. Signal Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.10.1 Signal Output 1 and 2 (current outputs) . . . . . . . . . . . . . . . . . . 41

3.11. Interface Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.11.1 Signal Output 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.11.2 Profibus, Modbus Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

3.11.3 USB Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

4. Instrument Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.1. Establish Sample Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2. Liquid System Function Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4.2.1 Hi Level Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

4.2.2 Fill Loop. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2.3 Mix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

A-96.250.551 / 100717 1

AMI Soditrace

4.2.4 Test Valve 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4.2.5 Test Valve 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

4.3. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

4.3.1 Calendar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.1. Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

5.2. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.3. Software Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.4. Changing Parameters and values. . . . . . . . . . . . . . . . . . . . . . . . . 54

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.1. Maintenance Schedule . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2. Maintenance of Sodium Electrode . . . . . . . . . . . . . . . . . . . . . . . . 56

6.3. Maintenance of Reference Electrode . . . . . . . . . . . . . . . . . . . . . . 57

6.4. Maintenance of Conductivity Sensor . . . . . . . . . . . . . . . . . . . . . . 58

6.5. Maintenance of Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.6. Maintenance of Flow Cell . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

6.7. Process Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

6.8. Regeneration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

6.9. Calibration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

6.10. Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

6.11. Tube Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.11.1 Tube Numbering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

6.11.2 Tube Connections Liquid Handling . . . . . . . . . . . . . . . . . . . . . . 70

6.11.3 Tube Connections Reagent and Regeneration Handling . . . . . 71

6.12. Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

6.13. Longer Stop of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

7. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.1. Tubing overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.2. Problems During Valve Block Test . . . . . . . . . . . . . . . . . . . . . . . . 75

7.3. Calibration Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

7.4. Other Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

7.5. Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

8. Program Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.1. Messages (Main Menu 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

8.2. Diagnostics (Main Menu 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

8.3. Maintenance (Main Menu 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

8.4. Operation (Main Menu 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

8.5. Installation (Main Menu 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

2 A-96.250.551 / 100717

AMI Soditrace

9. Program List and Explanations. . . . . . . . . . . . . . . . . . . . . . . . . 92

1 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

4 Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

10. Material Safety Data sheets . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

10.1. Reagents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

11. Default Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

12. Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

13. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

A-96.250.551 / 100717 3

AMI Soditrace

Safety Instructions

AMI Soditrace - Operator’s Manual

This document describes the main steps for instrument setup, operation and maintenance.

1. Safety Instructions

General The instructions included in this section explain the potential risks

Target

audience

OM Location The AMI Operator’s Manual shall be kept in proximity of the instru-

Qualification,

Training

associated with instrument operation and provide important safety

practices designed to minimize these risks.

If you carefully follow the information contained in this section, you

can protect yourself from hazards and create a safer work environment.

More safety instructions are given throughout this manual, at the

respective locations where observation is most important.

Strictly follow all safety instructions in this publication.

Operator: Qualified person who uses the equipment for its intended

purpose.

Instrument operation requires thorough knowledge of applications,

instrument functions and software program as well as all applicable

safety rules and regulations.

ment.

To be qualified for instrument installation and operation, you must:

read and understand the instructions in this manual as well as

the Material Safety Data Sheets.

know the relevant safety rules and regulations.

4 A-96.250.551 / 100717

AMI Soditrace

Safety Instructions

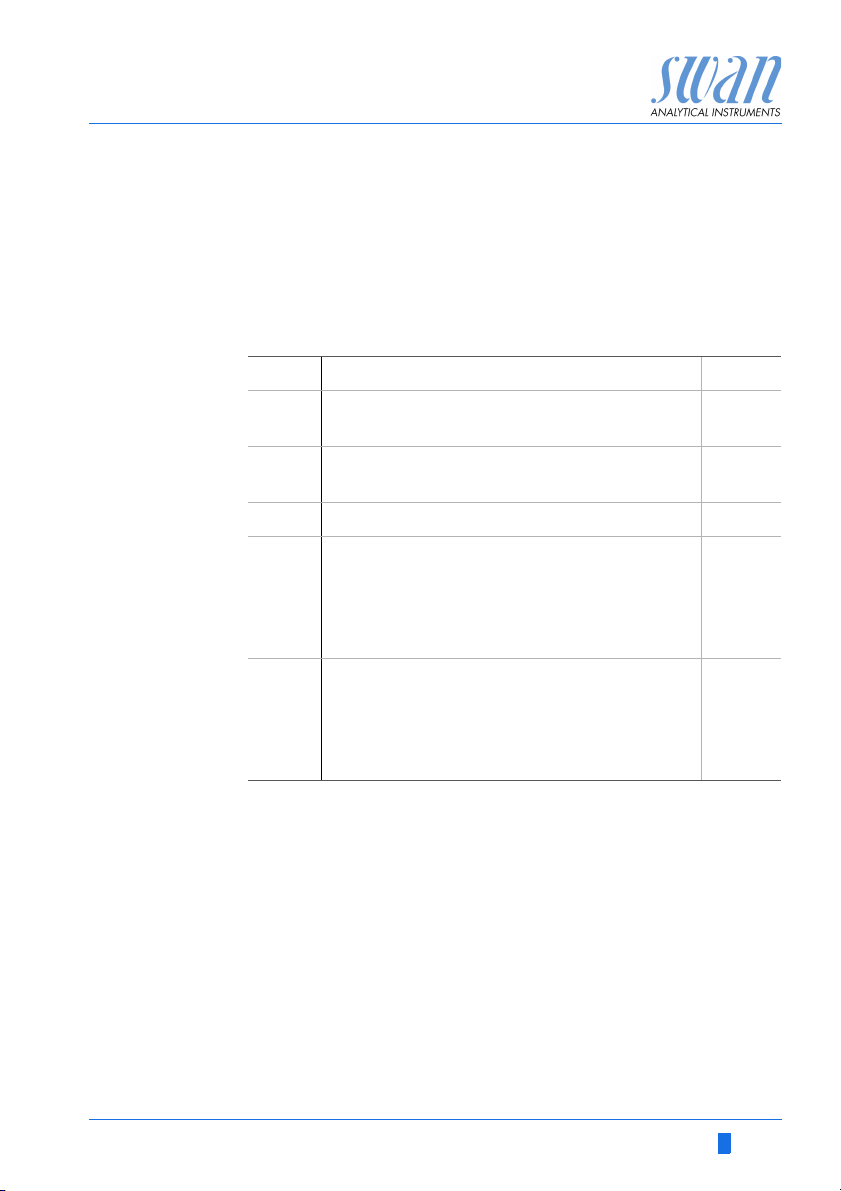

1.1. Warning Notices

The symbols used for safety-related notices have the following significance:

DANGER

Your life or physical wellbeing are in serious danger if such

warnings are ignored.

Follow the prevention instructions carefully.

WARNING

Severe injuries or damage to the equipment can occur if such

warnings are ignored.

Follow the prevention instructions carefully.

CAUTION

Damage to the equipment, minor injury, malfunctions or incorrect process can be the consequence if such warnings are ignored.

Follow the prevention instructions carefully.

Mandatory

Signs

A-96.250.551 / 100717 5

The importance of the mandatory signs in this manual.

Safety goggles

Safety gloves

AMI Soditrace

Safety Instructions

Warning Signs The importance of the warning signs in this manual.

Electrical shock hazard

Corrosive

Harmful to health

Flammable

Warning general

Attention general

1.2. General Safety Regulations

Legal

Requirements

Spare Parts

and

Disposables

The user is responsible for proper system operation.

All precautions must be followed to ensure safe operation of the instrument.

Use only official SWAN spare parts and disposables. If other parts

are used during the normal warranty period, the manufacturer’s

warranty is voided.

6 A-96.250.551 / 100717

AMI Soditrace

Safety Instructions

Modifications Modifications and instrument upgrades shall only be carried out by

an authorized Service Technician. SWAN will not accept responsibility for any claim resulting from unauthorized modification or alteration.

WARNING

Electrical Shock Hazard

If proper operation is no longer possible, the instrument must be

disconnected from all power lines, and measures must be taken

to prevent inadvertent operation.

To prevent from electrical shock, always make sure that the

ground wire is connected.

Service shall be performed by authorized personnel only.

Whenever electronic service is required, disconnect instru-

ment power and power of devices connected to.

– relay 1,

– relay 2,

– alarm relay

WARNING

For safe instrument installation and operation you must read

and understand the instructions in this manual.

WARNING

Only SWAN trained and authorized personnel shall perform the

tasks described in this document.

Download

MSDS

A-96.250.551 / 100717 7

The current Material Safety Data Sheets (MSDS) for the Reagents

listed below are available for downloading at www.swan.ch.

Regeneration Solution for SS Na

Catalogue No. A-85.810.200

Reference Filling Solution KCl

Catalogue No. A-87.892.400

Sodium Standard Solution 1000 ppm

Catalogue No. A-85.141.400

Diisopropylamine for synthesis

Catalogue No. 803646

AMI Soditrace

Product Description

2. Product Description

2.1. Description of the System

Application

Range

Signal

Outputs

Relays Two potential-free contacts programmable as limit switches for

Alarm Relay One potential free contact.

Input For potential-free contact to freeze the measuring value or to inter-

Communica-

tion interfaces

(optional)

Safety

Features

Sodium measurement is used for quality control in high purity water

applications and to monitor break through of ion exchangers.

Two signal outputs programmable for measured values (freely scalable, linear, bilinear, log) or as continuous control output (control

parameters programmable).

Current loop: 0/4–20 mA

Maximal burden: 510 Ω

Third signal output available as an option. The third signal output

can be operated as a current source or as a current sink (selectable

via switch).

measuring values, controllers or timer for system cleaning with automatic hold function.

Maximum load: 1 A / 250 VAC

Alternatively:

Open during normal operation, closed on error and loss of

power.

Closed during normal operation, open on error and loss of

power.

Summary alarm indication for programmable alarm values and instrument faults.

rupt control in automated installations (hold function or remote-off).

USB Interface for logger download

Third signal output (can be used in parallel to the USB interface)

RS485 with Fieldbus protocol Modbus or Profibus DP

No data loss after power failure. All data is saved in non-volatile

memory.

Over voltage protection of in- and outputs.

Galvanic separation of measuring inputs and signal outputs.

8 A-96.250.551 / 100717

AMI Soditrace

Product Description

Measuring

principle

The sodium measurement as used in this instrument is based on a

proven glass ion sensitive electrode. The logarithmic response can

be described as follows:

+ SINa * log {(CNa + CB) / C

E = E

O

ISO

}

With the abbreviations

E The measured potential of the electrode pair.

E

SI

O

The measured potential when the Sodium

concentration in the sample equals C

The temperature dependent slope of the

NA

iso

.

electrode response (R*T / n*F).

C

Na

C

B

The Sodium concentration in the sample.

The detection limit of the system. This term

[mV]

[mV]

[mV/

dec]

[ppb]

[ppb]

is used to define the curvature of the electrode response near the detection limit. It

depends on pH, other interferences like

potassium and other ions, and temperature.

C

ISO

The Sodium concentration in the sample

[ppb]

where the measured potential of the electrode pair is temperature-independent. It

equals the reference point for the temperature compensation.

Sodium measurements below 1 ppb require a special glass formulation for the sensing electrode response.

Ammonium and pH interferences from the unconditioned sample

are eliminated by a suitable reagent.

The measuring limit of 0.001 ppb sodium requires the conditioning

of the sample to a minimum of pH 12 while sample integrity has to

be maintained. The best results are obtained with Disopropylamine

(DIPA).

A-96.250.551 / 100717 9

AMI Soditrace

V1

V2

V5

V4

V3

AB C

G

G

L

G

H

HI

D

J

K

LMN

PO

Q

EF

Product Description

Fluidics

overview

Temperature sensor

A

Reference electrode

B

Sodium electrode

C

Standard solution

D

Regeneration solution

E

Air pump

F

Reference chamber

G

Overflow low level

G

L

G

Overflow high level

H

H

Measuring chamber

I

J

K

L

M

N

O

P

Q

Calibration chamber

Constant head

Conductivity sensor

Air lift pump

Calibration loop

Flow regulating valve

Overflow constant head

Sample inlet

Reagent bottle (DIPA)

10 A-96.250.551 / 100717

AMI Soditrace

Product Description

Solenoid

valves

The following illustration gives an overview about the solenoid

valve position on the valve block [C] and their switching state if they

are de-energized.

A

no

AB

V1

V2

V3

V4

V5

co

nc

C

V1

V2

V3 V5

Sample outlet valve

open during on-line measurement

closed during calibration.

Sample inlet valve

Doses the standard solution for the calibration by filling

the calibration loop [M]

Sample inlet valve

Doses the standard solution for the calibration by filling

the calibration loop [M]

Reagent valve

Valve V4 is controlled via the conductivity sensor [K]

Supplies the air lift pump either with air or DIPA vapor

Is used for reagent dosing (DIPA).

Regeneration valve

Supplies the air lift pump during on-line measurement

adds regeneration solution during regeneration cycle.

no

co

nc

V4

Solenoid valve de-energized

B

Solenoid valve energized

C

Valve block

no

normally open

nc

normally closed

co

common

A-96.250.551 / 100717 11

AMI Soditrace

Product Description

On-line

operation

Control of re-

agent addition

During on-line operation the AMI Soditrace works in the Mode

<Low Level>.

The sample enters the system at the sample inlet [P] and flows into

the constant head [J].

Adjust the flow regulating valve [N] so that always a small part of

the sample flows through the overflow tube [O] into the waste. This

adjustment ensures a sufficient sample flow through valve V2 and

V3 and then via airlift pump [L] into the measuring chamber [H]

where the Sodium electrode [C] is installed. This arrangement

guarantees a very constant sample stream of 20 ml per minute and

at the same time a sample conditioning to pH 12 (see Control of

Reagent Addition below).

To prevent any back-diffusion and thus contamination in the measuring chamber [H], the sample overflows into the calibration chamber [I] from there into the reference chamber [G] and through the

low level overflow [G

ture is measured in the reference chamber with the temperature

sensor [A]. It is used to compensate the Sodium reading following

the Nernst algorithm.

The reagent addition system is driven by the air pump [F]. The Air

flows through the energized valve V4 to the reagent bottle [Q],

where it is picking up reagent vapor. From there it flows to the air lift

pump where the sample is enriched with DIPA.

If valve V4 is not energized, the air flows direct to the airlift pump [L]

via valve V4 and V5.

The conductivity sensor [K] measures the amount of reagent added

to the sample, and a PID controller activates or deactivates valve 4

so that the conductivity reading remains constant. A conductivity of

450 µS/cm should be maintained for low Sodium readings. Upon

exhaustion of the reagent, the conductivity will fall below the setpoint and trigger an error message.

] and valve V1 into the waste. The tempera-

L

12 A-96.250.551 / 100717

AMI Soditrace

V2

V5

V4

V3

AB C

GHIDJ

K

LM N

PO

Q

EF

V1

G

L

G

H

Product Description

A

Temperature sensor

B

Reference electrode

C

Sodium electrode

D

Standard solution

E

Regeneration solution

F

Air pump

G

Reference chamber

G

Low level overflow

L

G

High level overflow

H

H

Measuring chamber

I

Calibration chamber

J

Constant head

K

Conductivity sensor

L

Air lift pump

M

Calibration loop

N

Flow regulating valve

O

Overflow constant head

P

Sample inlet

Q

Reagent bottle (DIPA)

Regeneration The system automatically regenerates the sodium electrode [C] ac-

cording to the programmed interval or 12 h before a calibration. By

opening valve V5 the regeneration solution [E] flows through the

airlift pump [L] and etches the sodium electrode [C].

A-96.250.551 / 100717 13

AMI Soditrace

V2

V5

V4

V3

AB C

GHIDJ

K

LM N

PO

Q

EF

V1

G

L

G

H

Product Description

A

Temperature sensor

B

Reference electrode

C

Sodium electrode

D

Standard solution

E

Regeneration solution

F

Air pump

G

Reference chamber

G

Overflow low level

L

G

Overflow high level

H

H

Measuring chamber

I

Calibration chamber

J

Constant head

K

Conductivity sensor

L

Air lift pump

M

Calibration loop

N

Flow regulating valve

O

Overflow constant head

P

Sample inlet

Q

Reagent bottle (DIPA)

Calibration Before the 3-point calibration starts, valve V1 closes and the mea-

suring cell is filled until the sample overflows via the overflow high

level [GH] into the waste. Then the sample flow is stopped by deenergizing valve V2, and the trapped volume of sample circulates

in a closed loop through valve 2 and valve 3 driven by the airlift

pump (L).This circulation is called Mix, see figure below.

14 A-96.250.551 / 100717

AMI Soditrace

V2

V5

V4

V3

AB C

GHIDJ

K

LM N

PO

Q

EF

V1

G

L

G

H

Product Description

A

Temperature sensor

B

Reference electrode

C

Sodium electrode

D

Standard solution

E

Regeneration solution

F

Air pump

G

Reference chamber

G

Overflow low level

L

G

Overflow high level

H

H

Measuring chamber

I

Calibration chamber

J

Constant head

K

Conductivity sensor

L

Air lift pump

M

Calibration loop

N

Flow regulating valve

O

Overflow constant head

P

Sample inlet

Q

Reagent bottle (DIPA)

To this volume, a 500 times smaller volume of standard is added.

The calibration loop (M) is filled with standard (D) by activating

valve V2 and V3 simultaneously.

A-96.250.551 / 100717 15

AMI Soditrace

V2

V5

V4

V3

AB C

GHIDJ

K

PO

Q

EF

V1

G

L

G

H

Product Description

When the valves are deactivated, the content of the calibration loop

is flushed into the measuring cell. For the first calibration point, the

calibration loop is filled once with standard and then flushed into the

measuring cell. The sample is then recirculated until a constant mV

reading is attained.

AB C

EF

G

GHIDJ

L

V1

G

H

16 A-96.250.551 / 100717

K

LM N

V2

V3

PO

V5

V4

Q

AMI Soditrace

Product Description

For the second calibration point, the calibration loop is filled and

flushed, twice. Again the sample is recirculated until a constant mV

reading is attained.

For the third calibration point, the calibration loop is filled and

flushed, seven times.

With three addition steps, an increase of one order of magnitude in

Sodium concentration is achieved.

Example Standard concentration: 5 ppm

Point No No of additions Final concentration [ppb]

1 110

2 230

3 7 100

The ability to produce 1 ppb Sodium concentration additions with

the factory calibrated injection loop, gives credibility to subsequent

measured values below 1 ppb.

A-96.250.551 / 100717 17

AMI Soditrace

Product Description

2.2. Instrument Specification

Power Supply Voltage:

Power consumption:

Electronics Aluminium with a protection degree of IP 66 / NEMA 4X

housing Ambient temperature:

Limit range of operation:

Storage and transport:

Humidity:

Display:

Sample

requirements

On-site The analyzer site must permit connections to:

requirements Sample inlet:

Flow rate:

Temperature:

Inlet pressure:

Outlet pressure:

pH value:

Ammonium concentration:

Acidity:

Dissolved solids:

no oil and no grease

Sample outlet:

100–240 VAC (± 10%)

50/ 60 Hz (± 5%)

or 24 VDC (± 10%)

max. 30 VA

-10 to +50 °C

-25 to +65 °C

-30 to +85 °C

10–90% rel., non condensing

backlit LCD, 75 x 45 mm

min. 100 ml/ min

5–45 °C (41–113 F)

0.3–3 bar (4– 43 PSI)

pressure free

>= pH7.0

< 10 ppm

< 50 ppm (CaCO3)

< 10 ppm

Serto PVDF 6 mm

G ½” adapter for flexible tube

20 x 15 mm

18 A-96.250.551 / 100717

AMI Soditrace

Product Description

Dimensions Panel:

Screws:

Weight:

850 (33.5”)

400x860x150 mm, stainless steel

8 mm diameter

13.0 kg /28.70 lbs

400 (15.7”)

374 (14.7”)13

13

824 (32.5”)

A-96.250.551 / 100717 19

AMI Soditrace

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

Product Description

2.3. Instrument Overview

A

Panel

B

Transmitter

20 A-96.250.551 / 100717

C

Reference electrolyte bottle

D

Standard solution

E

Regeneration solution

F

Air pump

G

Air filter

H

Reagent bottle (DIPA)

I

Conductivity sensor

J

Valve block

K

Waste

L

Sample inlet

M

Flow regulating valve

N

Flow cell

O

Sodium electrode

P

Reference electrode

Q

Temperature sensor (behind

reference electrode)

AMI Soditrace

Installation

3. Installation

3.1. Installation Checklist Monitors

Check Instrument’s specification must conform to the National Electrical

Code, all state and local codes, and all plant codes and standards

for electrical equipment.

On site requirements

Installation Mounting of Instrument Panel, p. 22.

Install the

electrodes

Electrical Wiring

Reagent and filter connections

Standard and

Regeneration

100– 240 VAC (± 10%), 50/60 Hz (± 5%) or 24 VDC, isolated

(±15%) power outlet with ground connection and 20 VA

Sample line with sufficient sample flow and pressure (see Instru-

ment Specification, p. 18.

Connecting Sample and Waste, p. 23.

Install the Sodium Electrode, p. 25):

Check if air bubbles are inside the electrode.

Install the sodium electrode.

Connect the cable S to the sodium electrode.

Etch the sodium electrode

Install the Reference Electrode, p. 26):

Connect the KCl bottle to the supply pipe of the reference

electrode

Puncture the KCl bottle.

Open and close the ground joint diaphragm of the reference

electrode.

Install KCl bottle.

Connect the cable R to the reference electrode.

NOTICE: Do not switch on the Instrument until all electrical

connections are made.

Connect all external devices like limit switches, current loops and

pumps (see Connection Diagram, p. 36.)

We recommend to use DIPA to operate the instrument. Use a

reagent bottle with either G45 thread (Schott) or a bottle from

Merck with a thread adapter.

Rinse the standard and regeneration bottle well with deionized

water.

Prepare the sodium standard according to your needs.

Install the standard bottle.

Install the regeneration bottle.

A-96.250.551 / 100717 21

AMI Soditrace

Installation

Power-up Open the flow regulating valve and adjust the sample flow.

Wait until the flow cell is completely filled.

Switch on power.

Instrument

set-up

Fill tubes Make sure that the:

Check solenoid

valves

Run-in period Let the instrument run continuously for 24 h.

3.2. Mounting of Instrument Panel

Mounting re-

quirements

Program all parameters for sensor and external devices

(interface, recorders, etc.).

Program all parameters for instrument operation (limits, alarms).

Make sure that the standard concentration is programmed

correctly.

tube 2

tube 4

tube13

are bubble-free. See Tube Replacement, p. 69

Check all solenoid valves for proper function according to , p. 72

The first part of this chapter describes the preparing and placing of

the system for use.

The instrument must only be installed by trained personnel.

Mount the instrument in vertical position.

For ease of operation mount it so that the display is at eye

level.

For the installation a kit containing the following installation

material is available:

– 4 Screws 8x60 mm

– 4 Dowels

– 4 Washers 8.4/24 mm

For dimensions see picture Dimensions, p. 19.

The instrument is only intended for indoor installation.

22 A-96.250.551 / 100717

AMI Soditrace

B

C

D

A

Installation

3.3. Connecting Sample and Waste

Sample inlet Use plastic tube (FEP, PA, or PE 4 x 6 mm) to connect the sample

inlet and outlet.

CAUTION

Damage of flow cell possible

Never use steel tubings or fittings directly on the acrylic glass.

A

Screw connection

B

Compression ferrule

C

Knurled nut

D

Flexible tube

Waste Connect the 1/2” tube to the waste nozzle and place it into the at-

mospheric drain.

A-96.250.551 / 100717 23

AMI Soditrace

A

B

C

D

E

I

H

G

F

A

B

C

D

Installation

3.4. Installation of Electrodes

Position of

electrodes in

the flow cell

The cables of the electrodes are already connected. The temperature sensor is fixed to the mounting panel with a tape. The conductivity sensor is factory-mounted.

The Picture below shows the measuring cell with the electrode’s

positions.

How to install the Sodium and reference electrode is shown on the

following pages. (See also Maintenance of Sodium Electrode, p. 56

and Maintenance of Reference Electrode, p. 57.)

A

Reference electrode

B

Conductivity sensor

C

Sample inlet

D

Reference chamber

overflow

E

Constant head overflow

F

Air lift pump

G

Regulation valve

H

Sodium electrode

I

Temperature sensor

Sensor

connections

on front-end

board

24 A-96.250.551 / 100717

A

Conductivity

B

Sodium

C

Reference

D

Temperature

AMI Soditrace

A

B

D

C

E

F

G

H

I

Installation

3.4.1 Install the Sodium Electrode

General Sodium electrodes are sensitive, electrochemical devices with a

very high internal impedance. To maintain correct operation make

sure that:

the sensing glass bulb stays clean.

no air bubbles are trapped in the glass bulb of the electrode.

the electrical connectors stay clean and dry.

Unpacking The electrode is supplied separately and is installed into the flow

cell after the installation of the monitor is finished. The electrode is

protected with a protective cap on the sensing glass bulb as well as

on the electrical connector.

Remove the connector cap from the connector only when the electrode is mounted in the measuring cell.

A

Sensor plug

B

Connector cap

C

Electrode shaft

D

Measuring chamber

E

Sensing glass bulb

F

Union screw

G

Washer

H

O-ring

I

Protective cap

Install the sodium electrode as follows:

A-96.250.551 / 100717 25

1 Remove the protective cap [I] from the electrode with a careful

turning and pulling movement.

2 Slip the union nut [F], and washer [G] on the electrode shaft [C].

3

Wet the O-ring [H] and slip it carefully over the electrode shaft [C].

4 Make sure no air bubbles are trapped in the sensing glass bulb

[E]. If so, shake the electrode like a clinical thermometer until

the bubble is vanished.

AMI Soditrace

A

B

C

Installation

5 Insert the electrode into the measuring chamber [C] and push

down completely.

6 Tighten the union screw [F] finger tight.

7 Remove the connector cap [B] from the electrode.

8 Screw the connector [A] onto the electrode.

3.4.2 Install the Reference Electrode

General Sodium electrodes are sensitive, electrochemical devices with a

very high internal impedance. The SWAN reference electrode is a

double junction Calomel / KCl type electrode. The outer liquid junction is a liquid glass sleeve, guaranteeing easy maintenance and

long life time.

To maintain correct operation make sure that:

the ground joint diaphragm stays clean and a KCl flow of

about 1ml/day is maintained.

no air bubbles are trapped in the electrode and in the tube to

the KCl reservoir.

the electrical connectors stay clean and dry.

Unpaking The electrode is supplied separately and is installed into the flow

Prepare the

KCl Bottle

cell after the installation of the monitor is finished. The electrode is

protected with a protective cap on the ground joint diaphragm as

well as on the electrical connector.

Remove the connector cap from the connector only when the electrode is mounted in the measuring cell.

A

Seal cap

B

Dosing tip

C

KCl bottle

1 Remove the seal cap [A] from the dosing tip [B].

2 Cut off the upper sealed part of the dosing tip.

26 A-96.250.551 / 100717

AMI Soditrace

Installation

Prepare the

reference elec-

trode

After longer storage of the reference electrode, the diaphragm may

be clogged wit salt deposits of KCl. Therefore it is recommended to

open an clean the diaphragm before installing the reference electrode.

CAUTION

Damage of flow cell possible

Electrolyte is corrosive.

Prevent electrolyte from dripping onto the measuring cell.

A

KCl bottle

B

A

B

C

D

E

F

G

H

I

To clean the reference electrode proceed as follows:

Trapped air bubble

C

Dosing tip

D

Stopper

E

KCl supply pipe

F

Ring-shaped sleeve

opened

G

Electrolyte outlet hole

H

Ring-shaped sleeve

closed

I

Protective cap

1 Remove the protective cap [I] from the ground joint diaphragm

with a careful turning and pulling movement.

2 Remove the stopper [D] from the KCl supply pipe [E].

3 Connect the KCl supply pipe to the dosing tip [C] of the KCl bot-

tle.

4 Fix the KCl bottle upside down in the holder on the panel.

5 Puncture the bottle bottom to allow pressure equilibration.

6 Hold the reference electrode with the ground joint diaphragm

pointing downwards.

7 Slightly lift the ring-shaped sleeve of the ground-joint diaphragm

and allow a little electrolyte to flow out into a tissue.

A-96.250.551 / 100717 27

AMI Soditrace

A

B

D

C

E

F

G

Installation

8 Push the ring-shaped sleeve carefully over the ground-joint dia-

9 Knock against the KCl bottle to remove trapped air bubbles [B]

Install the ref-

erence sensor

phragm.

NOTICE: Air bubbles trapped in the dosing tip of the KCl bottle

may stop the KCl flow to the reference electrode, which results

in wrong measuring values.

in the dosing tip.

A

Sensor plug

B

Connector cap

C

Sensor shaft

D

Reference chamber

Install the reference electrode as follows:

Slip the union screw [E], and washer [F] on the electrode shaft [C].

1

2

Wet the O-ring [G] and slip it carefully over the electrode shaft [C].

3 Insert the electrode into the reference chamber [C] and push it

down until he ground joint diaphragm is about 0.5 cm above the

bottom.

4 Tighten the union screw [E] finger tight.

28 A-96.250.551 / 100717

E

Union screw

F

Washer

G

O-ring

AMI Soditrace

A

ABBCC

Installation

5 Remove the connector cap [B] from the electrode.

6 Screw the connector [A] onto the electrode.

3.4.3 Install the Temperature Sensor

The temperature sensor is fixed to the panel with an adhesive tape

and already connected to the front end PCB in the AMI transmitter.

A

Temperature sensor

B

Reference sensor

C

Sodium sensor

A-96.250.551 / 100717 29

To install the temperature sensor proceed as follows:

1 Remove the temperature sensor [A] from the panel.

2 Put the temperature sensor in the designated hole marked

with [A].

3 Push it into the hole as far as it will go.

AMI Soditrace

Exit Enter

Standard

A

B

C

D

Installation

3.5. Install Standard and Regeneration Bottle

Mixing

standard

ABStandard bottle

Bottle holder

Prepare sodium standard using the 1’000 ppm stock solution. The

final concentration must correspond to the concentrations pro-

grammed in the instrument (default = 16 ppm).

1 Before preparing the standard, rinse bottle carefully with high

purity water.

2 Depending on measuring range use amount of stock solution

according table below.

3 Fill up standard bottle to 500 Millliter with high purity water.

4 Turn the bottle holder [B] downwards and screw the standard

bottle firmly on.

5 Turn the bottle holder upwards in vertical position.

CDRegeneration bottle

Pressure compensation

30 A-96.250.551 / 100717

AMI Soditrace

Installation

Meas. Range Amount of standard Result

< 1 ppb 2 ml 4’000 ppb (4 ppm)

< 5 ppb 5 ml 10’000 ppb

< 10 ppb 10 ml 20’000 ppb

NOTICE:

• Do not prepare standards below 1 ppm.

• If using a concentration other then default (16 ppm) change

setting in menu 4.1.3, p. 104

• Especially low concentration standards are preferably

prepared directly in the plastic standard bottle to prevent

contamination.

CAUTION

Upon first installation and after changing the standard concentration, flush the tube well with standard.

See Liquid System Function Test, p. 44

Regeneration

solution

A-96.250.551 / 100717 31

Use only original Swan Regeneration solution.

1 Turn the bottle holder downwards and screw the regeneration

bottle firmly on.

2 Turn the bottle upwards in vertical position

AMI Soditrace

A

B

C

E

F

D

H

G

Installation

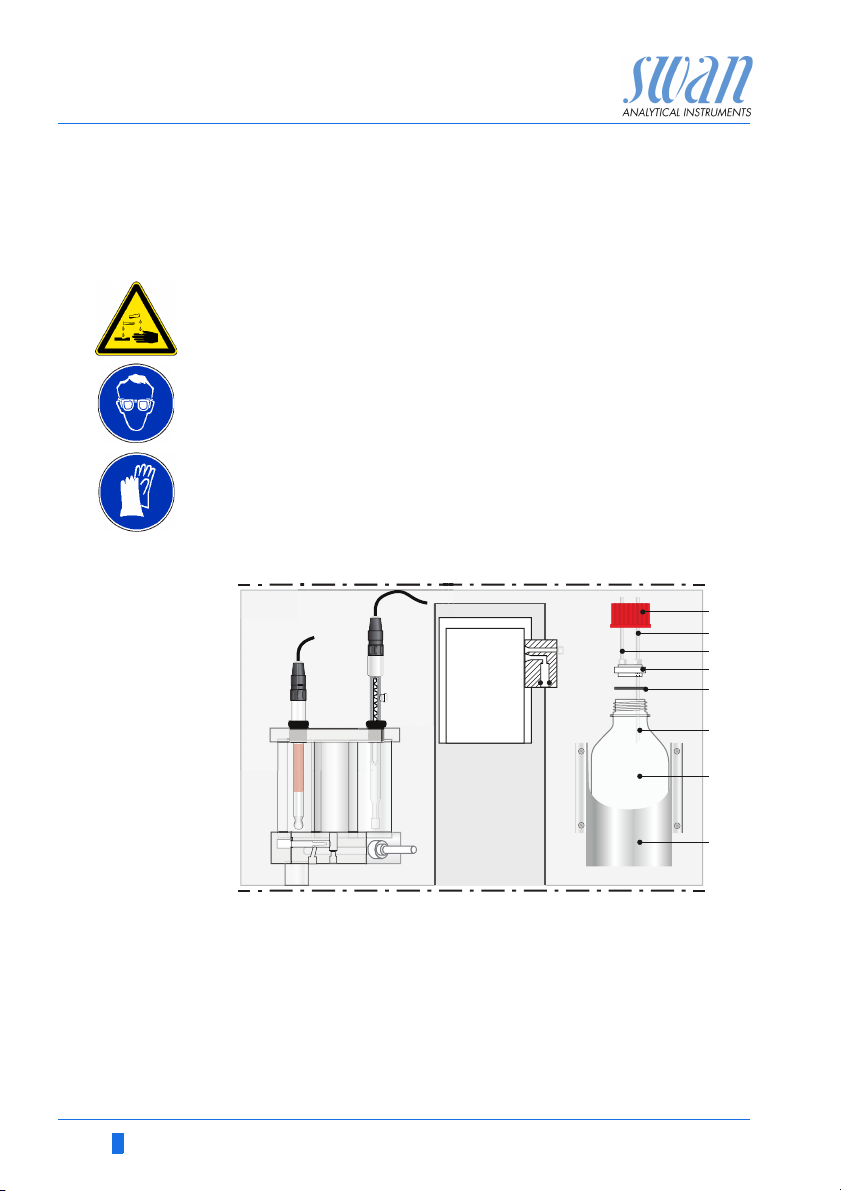

3.6. Install Reagent Bottle

WARNING

Diisopropylamine is corrosive.

Read the Safety Data Sheets (SDS) first.

Wear suitable protective clothing, gloves and eye/face protec-

tion.

Avoid inhalation of DIPA vapor. To prevent formation of re-

agent vapors:

– close the reagent bottle firmly

– check the EPDM seal regularly

– In case of contact with eyes, rinse immediately with plenty

of water eyelid wide open for at least 10 min, summon

medical advice. In case of accident or if you feel unwell,

summon medical advice immediately.

A

Screw cover G 45

B

Tube 11 from air lift pump

C

Tube 8 to valve 4

D

Tube holder

The Tubes are already installed into the tube holder [D] and the

EPDM seal [E] seats on the bottom of the tube holder. To install the

DIPA bottle proceed as follows:

32 A-96.250.551 / 100717

E

EPDM seal

F

Short tube

G

DIPA reagent bottle

H

Bottle holder

AMI Soditrace

Installation

1 Put the DIPA bottle [G] into the bottle holder [H]

2 Put the tube holder onto the DIPA bottle

3 Screw the screw cover onto the DIPA bottle and tighten it firmly.

3.7. Install Air Filter

A

B

c

D

ABAir pump

Outlet tube 7 to valve 4

To install the air filter proceed as follows:

1 Push the air filter [D] into the air inlet [C] of the air pump [A] as

far as it will go.

For commissioning of the instrument see chapter 4, Instrument Set-

up, p. 44

A-96.250.551 / 100717 33

CDAir inlet with O-ring seal

Air filter

AMI Soditrace

Installation

3.8. Electrical Connections

Cable

thicknesses

In order to comply with IP66, use the following cable thicknesses

WARNING

Risk of electrical shock.

Do not perform any work on electrical components if the transmitter is switched on. Failure to follow safety instructions could

result in serious injury or death.

Always turn off AC power before manipulating electric parts.

Grounding requirements: Only operate the instrument from

an power outlet which has a ground connection.

Make sure the power specification of the instrument corre-

sponds to the power on site.

ABC

PG 11 cable gland: cable Ø

A

B

PG 7 cable gland: cable Ø

C

PG 9 cable gland: cable Ø

NOTICE: Protect unused cable glands

Wire For Power and Relays: Use max. 1.5 mm

stranded wire with end sleeves.

For Signal Outputs and Input: Use 0.25 mm

stranded wire with end sleeves.

outer

3–6.5 mm

outer

4–8 mm

outer

5–10 mm

2

/ AWG 14

2

/ AWG 23

34 A-96.250.551 / 100717

AMI Soditrace

Installation

WARNING

External Voltage.

External supplied devices connected to relay 1 or 2 or to the

alarm relay can cause electrical shocks

Make sure that the devices connected to the following con-

tacts are disconnected from the power before resuming installation.

– relay 1

– relay 2

– alarm relay

WARNING

To prevent from electrical shock, do not connect the instrument

to the power unless the ground wire (PE) is connected.

Do not connect unless specifically instructed to do so.

WARNING

The mains of the AMI Transmitter must be secured by a main

switch and appropriate fuse or circuit breaker.

A-96.250.551 / 100717 35

AMI Soditrace

Installation

3.8.1 Connection Diagram

CAUTION

Use only the terminals shown in this diagram, and only for the

mentioned purpose. Use of any other terminals will cause short

circuits with possible corresponding consequences to material

and personnel.

36 A-96.250.551 / 100717

AMI Soditrace

A

B

C

D

Installation

3.8.2 Power Supply

WARNING

Risk of electrical shock

Do not perform any work on electrical components if the transmitter is switched on. Failure to follow safety instructions could

result in serious injury or death.

Always turn off AC power before manipulating electric parts.

Installation and maintenance of electrical parts must be per-

formed by professionals.

A

Power supply connector

B

Neutral conductor, Terminal 2

C

Phase conductor, Terminal 1

D

Protective earth PE

NOTICE: The protective earth wire (Ground) has to be

connected to the grounding terminal.

Installation

requirements

A-96.250.551 / 100717 37

The installation must meet the following requirements.

Mains fuse 1.6 AT

Mains cable to comply with standards IEC 60227 or IEC

60245; flammable rating FV1

Mains equipped with an external switch or circuit-breaker

– near the instrument

– easily accessible to the operator

– marked as interrupter for AMI Soditrace

AMI Soditrace

10

12

11

0V

1)

10

12

11

0V

Installation

3.9. Relay Contacts

Programming of the relay contacts see 5.3 Relay Contacts, p. 78

3.9.1 Input

If signal output is set to hold, measurement is interrupted if input is

active.

3.9.2 Alarm Relay

Alarm output for system errors.

Error codes see Troubleshooting, p. 74

NOTICE: Use only potential-free (dry) contacts. The total

resistance (sum of cable resistance and resistance of the relay

contact) must be less than 50 Ω.

• Terminals 30/31

NOTICE: Max. load 1 AT / 250 VAC

NOTICE: With certain alarms and certain settings of the AMI

transmitter the alarm relay does not switch. The error, however,

is shown on the display.

Ter min als Description Relay connection

1)

NC

Normally

Closed

10/11 Active (opened) during normal

operation.

Inactive (closed) on error and

loss of power.

NO

Normally

Open

12/11 Active (closed) during normal

operation.

Inactive (opened) on error and

loss of power.

1) usual use

38 A-96.250.551 / 100717

AMI Soditrace

6

0V

7

6

0V

7

A

B

Installation

3.9.3 Relay Contacts 1 and 2

Relay 1 and 2 can be configured as normally open or as normally

closed. Standard for both relays is normally open. To configure a

Relay as normally closed, set the jumper in the upper position.

NOTICE: Rated load 1 AT / 250 VAC

NOTICE: Some error codes and the instrument status may

influence the status of the relays described below.

Relay

config. Terminals

Normally

Open

Normally

Closed

6/7: Relay 1

8/9: Relay 2

6/7: Relay 1

8/9: Relay 2

Jumper

pos. Description Relay configuration

Inactive (opened) during

normal operation and

loss of power.

Active (closed) when a

programmed function is

executed.

Inactive (closed) during

normal operation and

loss of power.

Active (opened) when a

programmed function is

executed.

ABJumper set as normally open (standard setting)

Jumper set as normally closed

For programming see Menu Installation 5.3.2 and 5.3.3, p. 105

A-96.250.551 / 100717 39

AMI Soditrace

A

BC

DE

Installation

CAUTION

Risk of damage of the relays in the AMI Transmitter due to

heavy inductive load.

Heavy inductive or directly controlled loads (solenoid valves,

dosing pumps) may destroy the relay contacts.

To switch inductive loads > 0.1 A use an AMI relay box avail-

able as an option or suitable external power relays.

Inductive load Small inductive loads (max 0.1A) as for example the coil of a power

Resistive load Resistive loads (max. 1A) and control signals for PLC, impulse

Actuators Actuators, like motor valves, are using both relays: One relay con-

relay can be switched directly. To avoid noise voltage in the

AMI Transmitter it is mandatory to connect a snubber circuit in parallel to the load. A snubber is not necessary if an AMI relaybox is

used.

A

AC or DC power supply

B

AMI Transmitter

C

External power relay

D

Snubber

E

Power relay coil

pumps and so on can be connected without further measures

A

AB

C

tact is used for opening, the other for closing the valve, i.e. with the

2 relay contacts available, only one motor valve can be controlled.

Motors with loads bigger than 0.1A must be controlled via external

power relays or an AMI relay box.

A

BC

AMI Transmitter

B

PLC or controlled pulse pump

C

Logic

A

AC or DC power supply

B

AMI Transmitter

C

Actuator

M

40 A-96.250.551 / 100717

AMI Soditrace

A

B

C

D

Installation

3.10. Signal Outputs

3.10.1 Signal Output 1 and 2 (current outputs)

Signal output 1: Terminals 14 (+) and 13 (-)

Signal output 2: Terminals 15 (+) and 13 (-)

For programming see Program List and Explanations, p. 92, Menu

Installation

3.11. Interface Options

NOTICE: Max. burden 510 Ω.

If signals are sent to two different receivers, use signal isolator

(loop isolator).

A

AMI Transmitter

B

Slot for interfaces

C

Frontend PCB

D

Screw terminals

The slot for interfaces can be used to expand the functionality of

the AMI instrument with either:

Third signal output

a Profibus or Modbus connection

an USB Interface

A-96.250.551 / 100717 41

AMI Soditrace

Installation

3.11.1 Signal Output 3

Terminals 38 (+) and 37 (-).

Requires the additional board for the third signal output 0/4–20 mA.

The third signal output can be operated as a current source or as a

current sink (switchable via switch [A]). For detailed information see

the corresponding installation instruction.

Third signal output 0/4 - 20 mA PCB

A Operating mode selector switch

3.11.2 Profibus, Modbus Interface

Terminal 37 PB, Terminal 38 PA

To connect several instruments by means of a network or to config-

ure a PROFIBUS DP connection, consult the PROFIBUS manual.

Use appropriate network cable.

NOTICE: Max. burden 510 Ω.

A

NOTICE: The switch must be ON, if only one instrument is

installed, or on the last instrument in the bus.

OFF

ON

A

Profibus, Modbus Interface PCB (RS 485)

A On - OFF switch

42 A-96.250.551 / 100717

AMI Soditrace

A

B

Installation

3.11.3 USB Interface

The USB Interface is used to store Logger data and for Firmware

upload. For detailed information see the corresponding installation

instruction.

The optional third signal output 0/4 – 20 mA PCB [B] can be

plugged onto the USB interface and used in parallel.

USB Interface

A USB interface PCB

B Third signal output 0/4 - 20 mA PCB

A-96.250.551 / 100717 43

AMI Soditrace

3.2.1

Service

Test Valve Block

Man. Regeneration

Man. Calibration

Man. Verification

3.2.1.5

Test Valve Block

ModeMeasure

EMF 195.57 mV

Conductivity 450 uS

Timer 410 Sec

3.2.1.5

Test Valve Block

Mode Measure

EMF 195.57 mV

Conductivity 450 uS

Timer 410 Sec

Fill Loop

Mode

Measure

Hi Level

Mix

Instrument Setup

4. Instrument Setup

4.1. Establish Sample Flow

1 Open sample flow tap.

2 Wait until the flow cell is completely filled.

3 Switch on power.

4.2. Liquid System Function Test

The liquid system function test is of vital importance to make sure

that all tubes are filled and connected without leakage and that all

solenoid valves are working properly.

Possible sources of error are listed at the end of each test. Should

an error occur during a test see chapter

correction of errors.

Perform the liquid system function test exactly in the order as described below. Do not start the next test if the current test has failed.

Navigate to Menu <Maintenance>,

<Service>, <Test Valve Block>

Press [Enter]

Troubleshooting, p. 74

for

Mode Measure is already highlighted.

Press [Enter].

Start with the test “Hi Level”,

see chap. 4.2.1, 2 45

Select Mode “Hi Level”.

Press [Enter].

Then continue with the tests

“Fill Loop” see 4.2.2, 2 46

and

“Mix” see 4.2.3, 2 46

44 A-96.250.551 / 100717

AMI Soditrace

V2

V5 V4

V3

V1

Instrument Setup

4.2.1 Hi Level Test

With the test “Hi Level” the function of valve 1 is tested.

High level must be reached within 4 minutes.

Low level

V5 V4

V1

V2

V3

High level

If High Level is not reached within 4 minutes, see Problems During

Valve Block Test, p. 75

A-96.250.551 / 100717 45

AMI Soditrace

V2

V5 V4

V3

V1

Instrument Setup

4.2.2 Fill Loop

With the test “Fill Loop” the function of valve 2 and 3 activated is

tested.

Standard flow is ok if air bubbles are formed in the standard bottle.

If no air bubbles are formed in the standard bottle see Problems

During Valve Block Test, p. 75

4.2.3 Mix

With the test “Mix” the function of valve 2 and 3 is tested. Observe

the mV indication. The mV reading must go through a maximum

within 30 s and reach stable values after 5 min.

V5 V4

V2

V3

V1

If the values ar not stable after 5 min, see Problems During Valve

Block Test, p. 75.

46 A-96.250.551 / 100717

AMI Soditrace

V2

V5 V4

V3

V1

Instrument Setup

4.2.4 Test Valve 5

Navigate to Menu <Man. Regeneration> and start the function regeneration:

The instrument displays the actual state of the regeneration process in the following order: Mix –> Regenerate –> End.

If Regenerate is displayed, valve 5 is opened and regeneration

solution flows through tube 13, valve 5, and tube 10 into the flow

cell. If the flow of regeneration solution is ok if air bubbles are

formed in the regeneration solution bottle and conductivity reading

is > 2000 S.

If the conductivity value is not reached, the Error 22, “No Reg.

Agent” is triggered, see Other Errors, p. 81

A-96.250.551 / 100717 47

AMI Soditrace

Instrument Setup

4.2.5 Test Valve 4

Perform this test only after all other tests have been completed successfully.

With this test the control of valve 4 via conductivity sensor is tested.

WARNING

DIPA is

Flammable

Corrosive

Harmful

Carefully read the Safety Data Sheet before handling DIPA

V5 V4

V1

V2

V3

Return to normal operation, let the instrument run and check the

following parameters.

Menu Diagnostics/Sensors / Cond. Sensor:

Conductivity must fluctuate between 430 and 450 µS/cm

Menu Diagnostics/Sample:

check (Ctl) Actual and Ctl Average

(Ctl) Actual must be < 90 %, if it remains on 100 % the DIPA

bottle is not connected

If the specified values are not reached, see Problems During Valve

Block Test, p. 75

48 A-96.250.551 / 100717

AMI Soditrace

5.1.2.1

Maintenance Plan

Start time18:00:00

Calendar

Delay 300 Sec

Signal Outputs hold

Output/ Control hold

5.1.2.2.1

Calendar

Tuesday

Wednesday

Thursday

Friday

Monday

Instrument Setup

4.3. Programming

4.3.1 Calendar

The implemented calendar is based on the CRON format. It starts

with Sunday and ends with Saturday. Usually a month has three full

weeks and two weeks which are part thereof.

Therefore, if you program a task which has to be carried out weekly,

always program the task in the 2nd, 3rd or 4th week of a month.

Example:

In the table below it can be seen, that if a task is programmed on

Monday in the 1st week, it is not carried out because the week

starts only on Wednesday

Week Sun Mon Tues Wed Thurs Fri Sat

1st 1 2 3 4

2nd567891011

3rd12131415161718

4th19202122232425

Last2627282930

Programming Example how to program a regeneration on Monday in the 3rd

week of a month.

Navigate to Menu <Installation>,

<Sensors>, <Maintenance Plan>

Press <Enter>

Set the desired “Start time”.

Press <Enter>

A-96.250.551 / 100717 49

Navigate to Calendar.

Press <Enter>

Monday is already highlighted.

AMI Soditrace

5.1.2.2.1.1

Monday

1st weekoff

3rd week off

4th week off

Last week off

2nd week off

1st weekoff

3rd week off

4th week off

Last week off

2nd week off

5.1.2.2.1.1

Monday

reg. + ver.

3rd week

off

regenerate

reg. + cal.

5.1.2.2.1.1

Monday

1st weekoff

3rd week regenerate

4th week off

Last week off

2nd week off

Instrument Setup

To change the settings of Monday

Press <Enter>

1st week is already highlighted. Navi-

gate to 3rd week.

Press <Enter>.

Navigate to “regenerate”.

Press <Enter>.

The 3rd week is set to “regenerate”.

Press <Exit>.

Press <Enter> to save.

50 A-96.250.551 / 100717

AMI Soditrace

Exit Enter

BCDA

25.4°C

RUN

448 uS

14:10:45

R1

0.008 ppb

R2

1

Installation

Operation

Diagnostics

Messages

Maintenance

Main Menu

Enter

Exit

Operation

5. Operation

5.1. Keys

A to exit a menu or command (rejecting any changes)

B to move DOWN in a menu list and to decrease digits

C to move UP in a menu list and to increase digits

D to open a selected sub-menu

to move back to the previous menu level

to accept an entry

Program

Access, Exit

A-96.250.551 / 100717 51

AMI Soditrace

RUN

15:20:18

R1

R2

448 µS 24.8°C

ppb

0.008

AB E

F

G

H

I

DC

Operation

5.2. Display

A

B

C

D

E

F

G

H

I

RUN normal operation

HOLD input closed or cal delay: Instrument on hold (shows

status of signal outputs).

OFF input closed: control/limit is interrupted (shows status

ERROR Error

Indicates a verification error

Keys locked, transmitter control via Profibus

Time

Process values

Sample temperature

Conductivity

Relay status

of signal outputs).

Fatal Error

Relay status, symbols

upper/lower limit not yet reached

upper/lower limit reached

control upw./downw. no action

52 A-96.250.551 / 100717

control upw./downw. active, dark bar indicates control intensity

motor valve closed

motor valve: open, dark bar indicates approx. position

timer

timer: timing active (hand rotating)

AMI Soditrace

1

Messages

Operation

Maintenance

Diagnostics

Main Menu

Installation

1.1

Pending Errors

Messages

Maintenance List

Message List

2.1

Interface

I/O State

Sample

Identification

Sensors

Diagnostics

3.1

Process Cal.

Service

Maintenance

Set Time 23.09.06 16:30:00

Simulation

4.1

Logger

Relay Contacts

Sensors

Operation

5.1

Interface

Miscellaneous

Relay Contacts

Sensors

Signal Outputs

Installation

Operation

5.3. Software Structure

Menu Messages 1

Reveals pending errors as well as an event history

(time and state of events that have occurred at an

earlier point of time).

It contains user relevant data.

Menu Diagnostics 2

Provides user relevant instrument and sample data.

A-96.250.551 / 100717 53

Menu Maintenance 3

For instrument calibration, relay and signal output

simulation, and to set the instrument time.

It is used by the service personnel.

Menu Operation 4

User relevant parameters that might need to be

modified during daily routine. Normally password

protected and used by the process-operator.

Subset of menu 5 - Installation, but process-related.

Menu Installation 5

For initial instrument set up by SWAN authorized

person, to set all instrument parameters. Can be

protected by means of password.

AMI Soditrace

5.2.2.1

Signal Output 2

Scaling

Parameter Temperature

Current Loop 4 - 20 mA

Function linear

Scaling

Parameter Temperature

Current Loop 4 - 20 mA

Function linear

5.2.2.1

Signal Output 2

Parameter

Sodium

Temperature

Conductivity

5.2.2.1

Signal Output 2

Parameter Conductivity

Scaling

Current Loop 4 - 20 mA

Function linear

Parameter Conductivity

Scaling

Current Loop 4 - 20 mA

Function linear

5.2.2.1

Signal Output 2

No

Save ?

Yes

5.3.1.1.1

Alarm High 20.0 ppb

Alarm Sodium

Alarm Low 0.000 ppb

Hysteresis 10.0 ppb

Delay 5 Sec

5.3.1.1.1

Alarm Sodium

Alarm Low 0.000 ppb

Hysteresis 10.0 ppb

Delay 5 Sec

Alarm High 9.00 ppb

Operation

5.4. Changing Parameters and values

The following example shows how to change the Signal Output 2:

Changing

parameters

1 Select the parameter you want to

change.

2 Press <Enter>

3 Press < > or< > key to

highlight the required parameter.

4 Press <Enter> to confirm the se-

lection or <Exit> to keep the previous parameter).

The selected parameter is

highlighted (but not saved yet).

5 Press <Exit>.

Yes is highlighted.

6 Press <Enter> to save the new pa-

rameter.

The system reboots, the new

parameter is set.

Changing

values

1 Select the value you want to

change.

2 Press <Enter>.

3 Set required value with < >

or< > key.

4 Press <Enter> to confirm the new

value.

5 Press <Exit>.

Yes is highlighted.

54 A-96.250.551 / 100717

6 Press <Enter> to save the new val-

ue.

AMI Soditrace

Maintenance

6. Maintenance

6.1. Maintenance Schedule

WARNING

Stop operation before maintenance.

Remove DIPA bottle and wait until conductivity is approxi-

mately 0.

Stop sample flow.

Shut off power of the instrument.

Weekly or

every 2 weeks

Monthly Check sealing of reagent bottle, replace if necessary.

Half-yearly Replace sealing of reagent bottle (EPDM)

Yearly Replace valve 4

Reagent

consumption

The following specifications are only valid if the SWAN standard

calendar settings are used.

Check air lift pump for regular bubble formation.

Check level of reagent (DIPA) bottle.

Check level of KCl reservoir.

Check level of regeneration bottle.

Check level of standard bottle.

If necessary refill bottles.

Replace the sodium electrode.

Replace the reference electrode.

If necessary, remove deposited iron in the system by

washing in soft detergent and by using rust remover.

Replace the tubes, if heavily covered with iron.

One 100 ml bottle electrolyte lasts for one month.

500 ml standard solution containing 16 ppm Na lasts for

2months.

500 ml regeneration solution lasts for 4 months.

A-96.250.551 / 100717 55

AMI Soditrace

A

B

D

C

E

Maintenance

6.2. Maintenance of Sodium Electrode

Sodium electrodes are sensitive electrochemical devices with very

high internal impedance. To maintain correct operation, make sure

that.

the sensing glass bulb stays clean

no air bubbles are trapped between glass bulb and glass tube

the electrical connectors stay absolutely clean and dry.

A

Sensor plug

B

Connector cap

C

Union screw

D

Washer

E

O-ring

Remove the

sodium

electrode

Cleaning Remove adhered iron deposits by wiping the electrode gently with

Install See Install the Sodium Electrode, p. 25

1 Unscrew and remove the sensor plug [A].

Take care that the connector stays dry and clean as long as

no electrode is connected.

2 Screw the connector cap onto the sensor.

3 Completely unscrew the union screw [C] from the threaded

hole.

4 Remove the electrode together with the union screw, washer

and O-ring from the measuring cell.

5 Slip the O-ring carefully over the measuring bulb and remove

both nut and washer.

a paper tissue. Rinse the electrode with distilled water.

After installation etch the sodium electrode.

56 A-96.250.551 / 100717

AMI Soditrace

A

B

D

C

E

F

Maintenance

6.3. Maintenance of Reference Electrode

A

Sensor plug

B

Connector cap

C

Union screw

D

Washer

E

O-ring

F

Ring-shaped sleeve

Remove the

reference

electrode

Cleaning 1 Remove any iron deposits with a soft paper tissue.

Install the

reference

electrode

A-96.250.551 / 100717 57

1 Completely unscrew the union screw [C] from the threaded

hole.

2 Remove the KCl bottle from its holder.

Remember that the bottle was punctured - do not spill KCl.

3 Remove the reference electrode from the flow cell.

2 Slip the ring-shaped sleeve [F] upwards with a turning and

pushing movement.

3 Let flow out about 1 ml KCl.

4 Fix the ring-shaped sleeve finger tight with a gentle turning and

pulling movement.

5 Replace or refill KCl reservoir. Use only original SWAN KCl.

See Install the Reference Electrode, p. 26

AMI Soditrace

A

E

F

B

C

D

Maintenance

6.4. Maintenance of Conductivity Sensor

The conductivity sensor is used to maintain a constant conductivity

of 450 µS/cm. To get correct measuring values, it is of vital importance, that the conductivity sensor is installed and aligned correctly.

A

Base plate top view

B

Union screw

C

Conductivity sensor

Remove the

conductivity

sensor

Cleaning Remove any iron deposits with a soft paper tissue. Do not use or-

Install the

conductivity

sensor

1 Completely unscrew the union screw [B] from the threaded

hole.

2 Remove the conductivity sensor from the base plate.

ganic detergents!

1 Insert the conductivity sensor into the base plate.

2 Insert the conductivity sensor so that its sensing tip is aligned

with the outer edge of the sample inlet hole and its measuring

slot is aligned vertically (see dashed red lines).

3 Tighten the union screw.

58 A-96.250.551 / 100717

D

Base plate side view

E

Guiding sleeve

F

O-ring

AMI Soditrace

Maintenance

6.5. Maintenance of Solenoid Valve

NOTICE: Never use the membranes again after a valve has

been opened.

Dismount 1 Drain the measuring cell completely before dismounting a sole-

Disassembling 1 Unscrew solenoid support [C] and bottom nut [O].

noid valve.

2 Tilt the standard and the regeneration bottle down.

3 Remove the tubes from the defective valve.

4 Unscrew knurled nut [A].

5 Pull valve assembly out of coil body [B].

Take care not to loose the springs!

2 Remove the membrane holders.

Normally the membranes stick to the valve body.

3 Remove the membranes with pointed pliers.

Do not use the membranes again!

4 Clean the valve body [H] with soft detergent.

A-96.250.551 / 100717 59

AMI Soditrace

A

B

C

D

E

F

G

H

I

K

L

M

N

O

Maintenance

Drawing

Assembling 1 Put new membranes on the membrane holders.

60 A-96.250.551 / 100717

2 Place membrane 1 with holder in valve body.

3 Place washer 1 on membrane and push down carefully.

4 Place conical spring with smaller end on membrane holder.

5 Screw on the bottom screw finger tightly.

6 Turn valve body upside down and place Teflon distance bar in

Mounting 1 Push valve assembly in coil body.

centre hole of valve body.

7 Place membrane 2 with holder in valve body.

8 Place washer 2 on membrane and push down carefully.

9 Place long spring in solenoid.

10 Screw on the solenoid support finger tightly.

2 Mount all tubes.

3 Only then screw on the knurled nut finger tightly.

A

Knurled nut

B

Coil body

C

Solenoid support

D

Washer 2

E

Long spring

F

Solenoid with membrane holder

G

Membrane 2

H

Valve body

I

Teflon distance bar

K

Membrane 1

L

Membrane holder

M

Conical spring

N

Washer 1

O

Bottom nut

AMI Soditrace

Maintenance

6.6. Maintenance of Flow Cell

CAUTION

Possible damage of acrylic glass parts due to scrubbing

materials.

Never use organic solvents or scrubbing materials to clean

acrylic glass parts.

Use soft detergent and rinse well.

NOTICE: Never use silicone oil or grease to seal standard

bottle holder and o-rings.

Use teflon paste or spray to grease moving parts.

Dismount 1 Shut off the instrument and stop the sample flow.

2 Drain the measuring cell completely by pulling downwards the

two overflow tubes [M] and [N].

3 Tilt the standard and the regeneration bottle down

4 Remove all sensors.

5 Remove all tube connections.

6 Unscrew the M5x70 mm fixing screw of the cover plate [E].

7 Unscrew the two M5x 70 mm fixing screws [S] of the base plate.

8 Remove the measuring cell from the panel.

Disassembling 1 Remove the airlift pump [X].

2 Unscrew and remove the three M5x115 mm screws [D].

3 Remove the cover plate [E].

4 Remove the:

Calibration cell tube [H]

Constant head tube [I]

Reference cell tube [J]

Measuring cell tube [K]

Overflow tube low level [L]

Overflow tube high level [M]

Overflow tube constant head [N]

Conductivity sensor

and their O-rings from the base plate.

Cleaning Clean all parts with a soft detergent and rinse well afterwards.

Grease all O-rings with teflon spray or paste.

A-96.250.551 / 100717 61

AMI Soditrace

A

B

C

D

E

F

F

G

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

U

V

W

X

A

Maintenance

Exploded

drawing

A

Union screw M20

B

Washer

C

O-ring 11 x3.5

D

Screw M5x115

E

Cover plate

F

O-ring 54x3.5

G

O-ring 34x3.5

H

Calibration cell tube

I

Constant head tube

J

Reference cell tube

K

Measuring cell tube

L

Overflow tube low

level

M

Overflow tube high

level

N

Overflow tube

constant head

O

O-ring 21x3

P

O-ring 10x4

Q

Flow regulating valve

R

Base plate

S

Fixing screw M5x70

T

Serto tube adapter

U

O-ring 24x3.5

V

O-ring 11 x3.5

W

Guiding sleeve for

Conductivity sensor

X

Air lift pump

62 A-96.250.551 / 100717

AMI Soditrace

N

U

X

M

105

Maintenance

Assembling 1 Mount the o-rings on all tubes.

2 Insert the measuring cell tube [K] into the inner bore at the left

side of the base plate (see exploded drawing).

3 Insert the overflow tube low level [L] into the inner bore at the

right side of the base plate (see exploded drawing).

4 Insert the Calibration cell tube [H] and the Reference cell tube

[J] into the outer bores of the base plate (see exploded drawing).

5 Insert the constant head tube [I] into the bore of the base plate

(see exploded drawing).

6 Put the cover plate on the tubes and push down firmly until it

rests on the tubes.

7 Screw the flow cell assembly together with the three

M5x115 mm screws. Do not force!

Detail drawing

M

Overflow tube high level

N

Overflow tube constant head

U

O-ring 24x3.5

X

Air lift pump

8 Push the two overflow tubes [M] and [N] through the bores of

the base plate 105 mm into the flow cell, measured from the

lower edge of the base plate (see detail drawing).

9 Mount the airlift pump [X].

Install the flow

cell onto the

panel

A-96.250.551 / 100717 63

1 Screw the cell assembly onto the panel.

2 Mount all tubes according to chapter Tube Replacement, p. 69

3 Install all sensors according to chapter Installation of Elec-

trodes, p. 24.

4 Turn on sample flow and instrument.

NOTICE: Run the instrument in normal operation for at least

24 hours before performing a calibration.

AMI Soditrace

3.1

Service

Simulation

Maintenance

Set Time 05.10.12 16:30:00

Process Cal.

Process Cal.

Offset 25.27 mV

Save <Enter>

Process Value 0.012 ppb

3.1.4

Current Value 0.012 ppb