AMI INSPECTOR

Hydrogen

Version 6.21 and higher

A-96.250.741 / 050218

Operator’

s Manual

© 2016, SWAN ANALYTISCHE INSTRUMENTE AG, Switzerland, all rights reserved

subject to change without notice.

Customer Support

SWAN and its representatives maintain a fully trained staff of technical specialists

around the world. For any technical question, contact your nearest

SWAN representative, or the manufacturer:

SWAN ANALYTISCHE INSTRUMENTE AG

Studbachstrasse 13

8340 Hinwil

Switzerland

Internet: www.swan.ch

E-mail: support@swan.ch

Document Status

Title:

Monitor AMI INSPECTOR Hydrogen Operator’s Manual

ID:

A-96.250.741

Revision Issue

00 May 2013 First Edition

01 Nov. 2013 New main board, integrated USB interface

02 Jan. 2016 AMI Inspector Version 2-A (with AMIAKKU main-

board) and Firmware version 6.00

AMI INSPECTOR Hydrogen

A-96.250.741 / 050218 1

Table of Contents

1. Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.1. Warning Notices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.2. General Safety Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.1. Description of the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.2. Instrument Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.3. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1. Installation Check List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2. Connecting Sample Inlet and Outlet. . . . . . . . . . . . . . . . . . . . . . . 14

3.2.1 Connect the Sample Inlet to the Quick-Lock Coupling . . . . . . . 14

3.2.2 Connect the Sample Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.3. Electrical Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

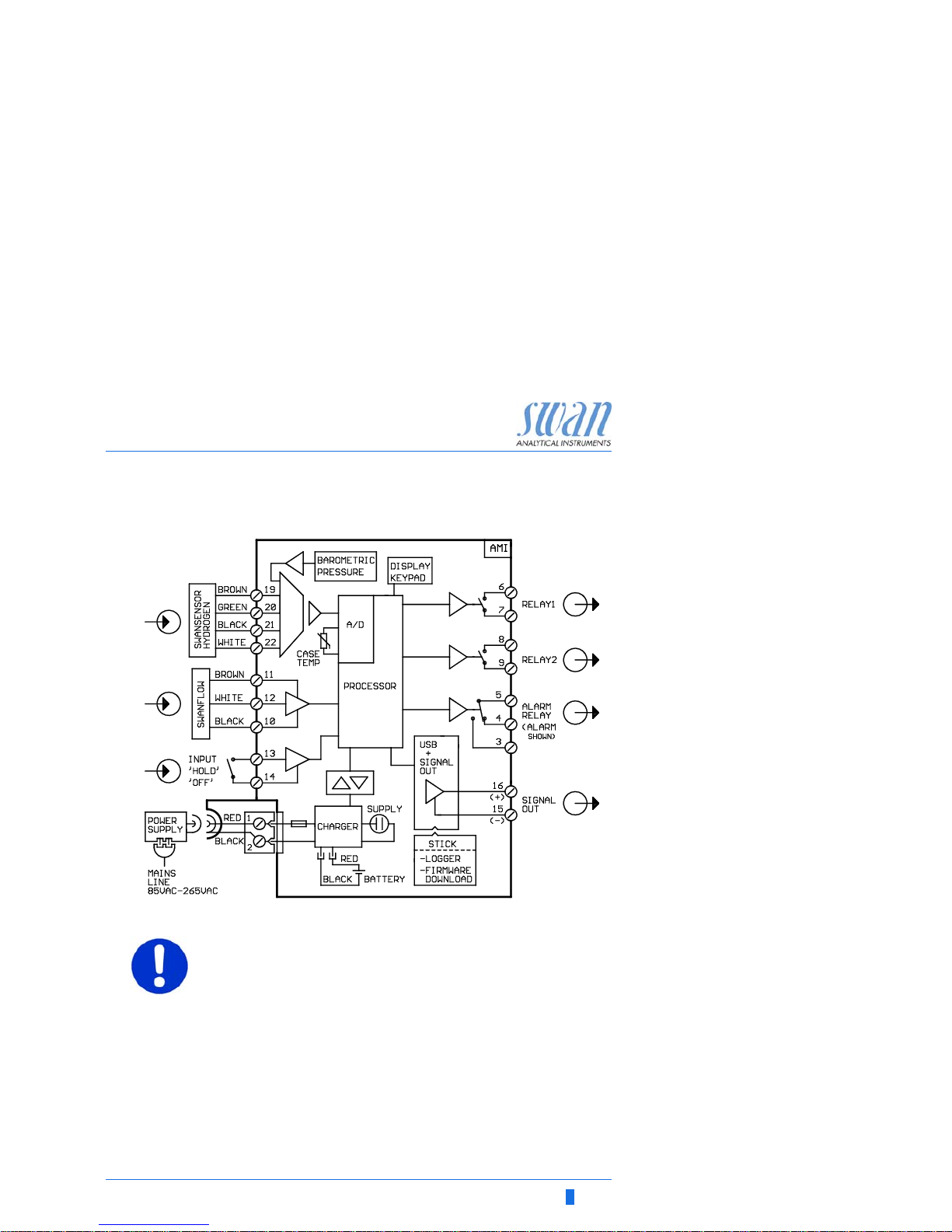

3.4. Connection Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

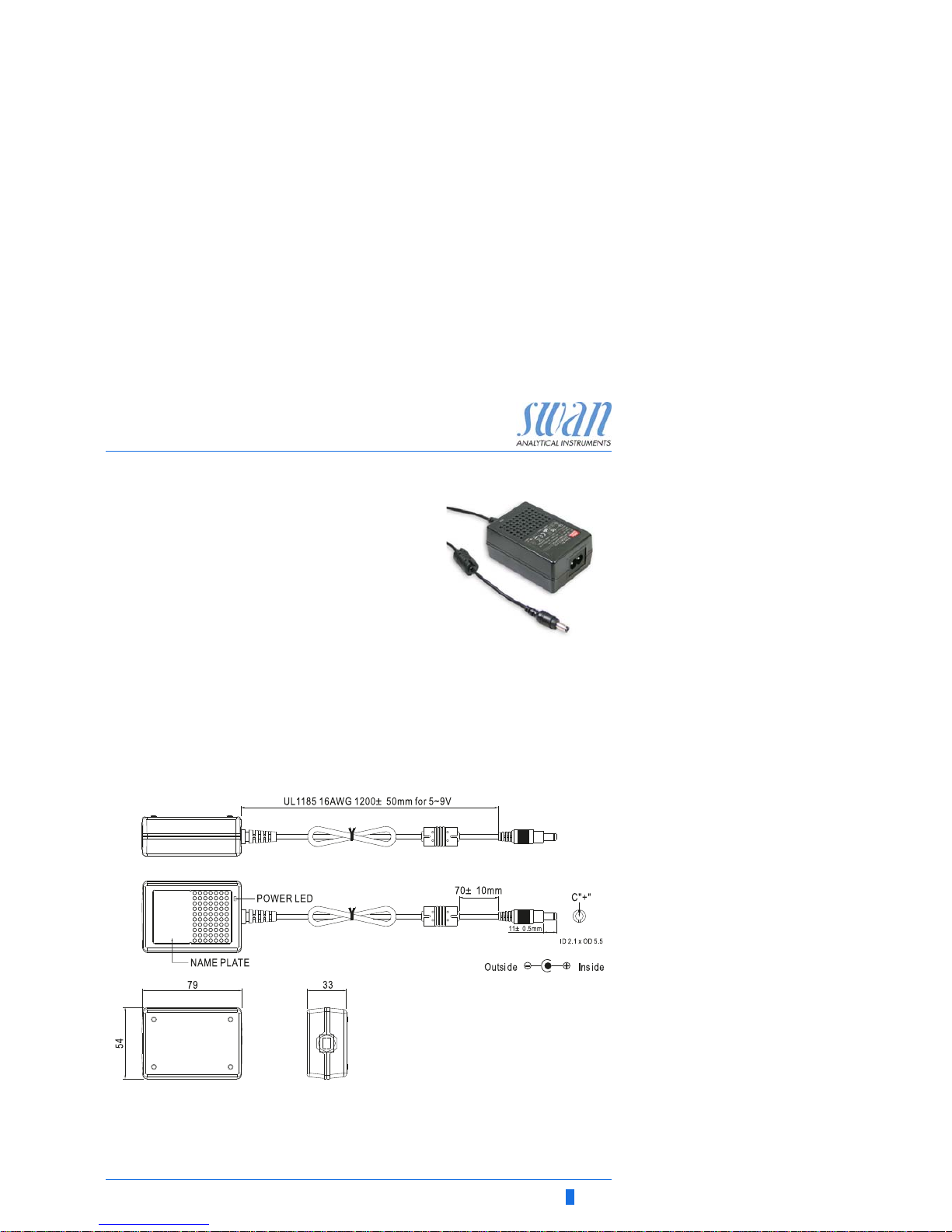

3.4.1 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

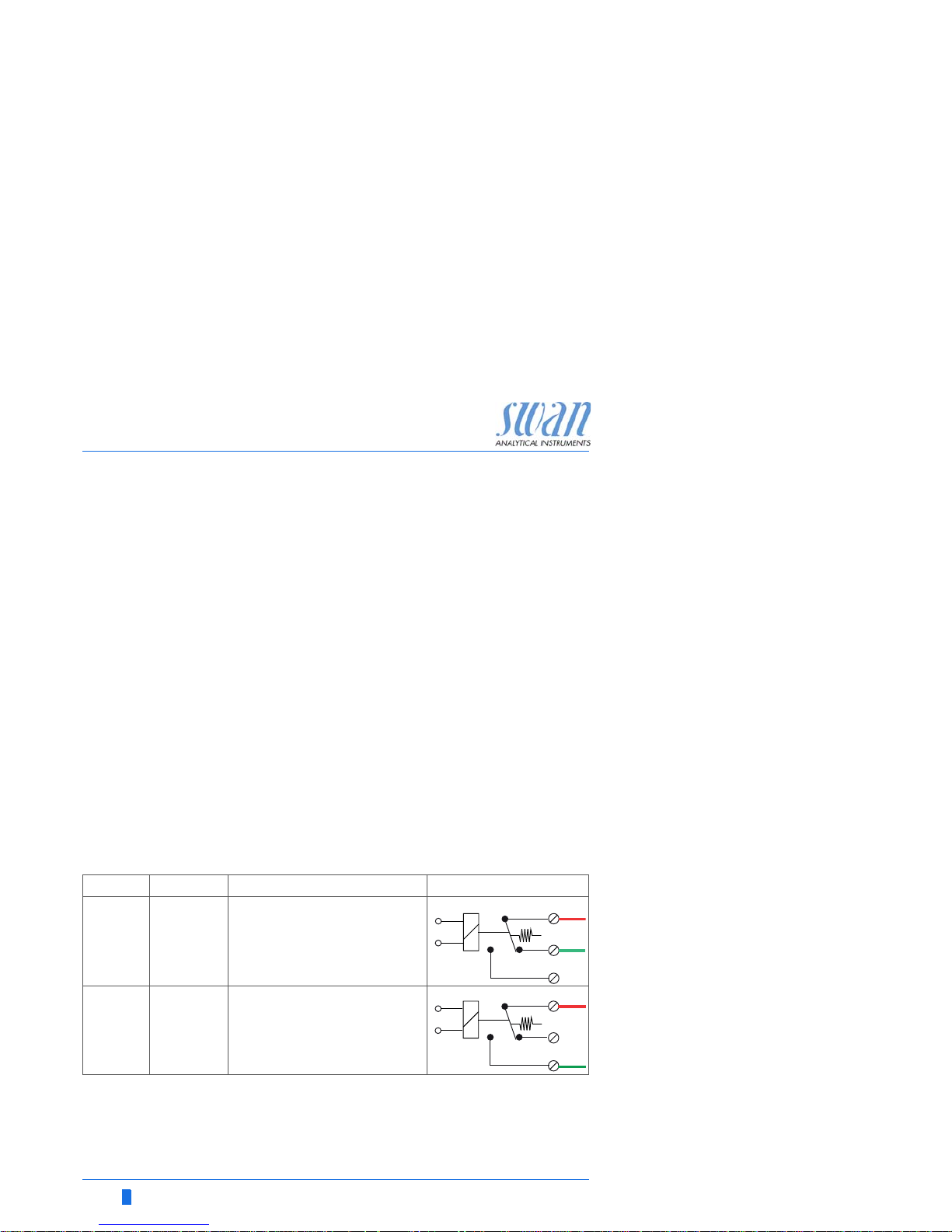

3.5. Relay Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.1 Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3.5.2 Alarm Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

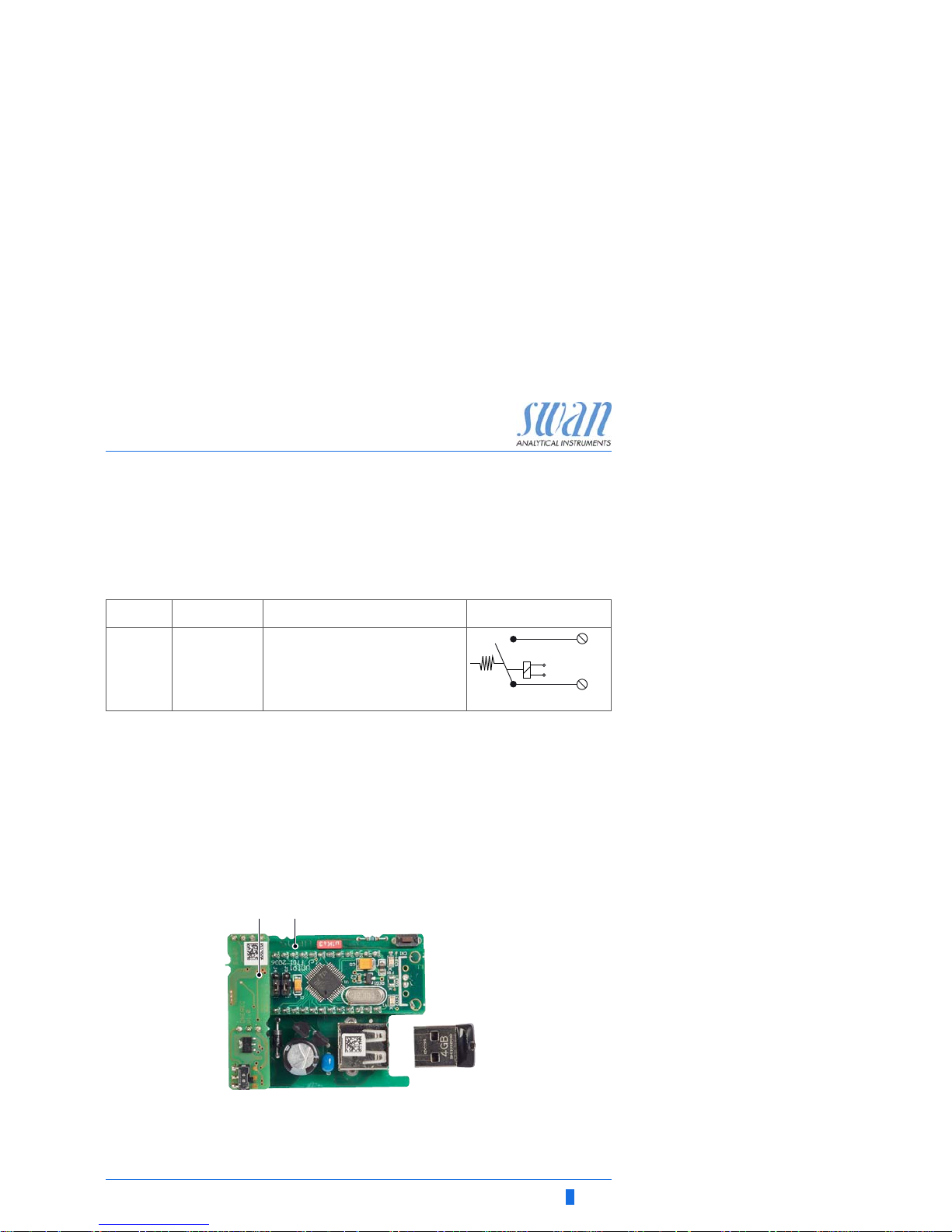

3.5.3 Relay Contacts 1 and 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.6. Signal Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Instrument Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.1. Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5. Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.1. Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.2. Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.3. Software Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.4. Changing Parameters and values . . . . . . . . . . . . . . . . . . . . . . . . 26

6. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.1. Maintenance Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2. Stop of Operation for Maintenance. . . . . . . . . . . . . . . . . . . . . . . . 27

6.3. Maintenance of the Hydrogen Sensor . . . . . . . . . . . . . . . . . . . . . 28

6.3.1 Hydrogen Sensor Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.3.2 Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.3.3 Replace Hydrogen Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.4. Quality Assurance of the Instrument . . . . . . . . . . . . . . . . . . . . . . 32

2 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

6.4.1 Activate SWAN Quality assurance procedure. . . . . . . . . . . . . . 33

6.4.2 Pre-test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.3 Connect the sample lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.4 Carry out comparison measurement . . . . . . . . . . . . . . . . . . . . . 36

6.4.5 Completion of the measurement . . . . . . . . . . . . . . . . . . . . . . . . 37

6.5. Replacing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.6. Replacing the Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.7. Longer Stop of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7. Error List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8. Program Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.1. Messages (Main Menu 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.2. Diagnostics (Main Menu 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

8.3. Maintenance (Main Menu 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

8.4. Operation (Main Menu 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

8.5. Installation (Main Menu 5). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9. Program List and Explanations . . . . . . . . . . . . . . . . . . . . . . . . . 49

1 Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

2 Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

10. Default Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

11. Index. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

12. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

AMI INSPECTOR Hydrogen

Safety Instructions

A-96.250.741 / 050218 3

AMI INSPECTOR Hydrogen Operator’s Manual

This document describes the main steps for instrument setup, operation and maintenance.

1. Safety Instructions

General The instructions included in this section explain the potential risks

associated with instrument operation and provide important safety

practices designed to minimize these risks.

If you carefully follow the information contained in this section, you

can protect yourself from hazards and create a safer work environment.

More safety instructions are given throughout this manual, at the

respective locations where observation is most important.

Strictly follow all safety instructions in this publication.

Tar get

audience

Operator: Qualified person who uses the equipment

for its intended purpose.

Instrument operation requires thorough knowledge of applications,

instrument functions and software program as well as all applicable

safety rules and regulations.

OM Location The AMI Operator’s Manual shall be kept in proximity of the instru-

ment.

Qualification,

Training

To be qualified for instrument installation and operation, you must:

read and understand the instructions in this manual as well as

the Material Safety Data Sheets.

know the relevant safety rules and regulations.

4 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Safety Instructions

1.1. Warning Notices

The symbols used for safety-related notices have the following significance:

DANGER

Your life or physical wellbeing are in serious danger if such

warnings are ignored.

Follow the prevention instructions carefully.

WARNING

Severe injuries or damage to the equipment can occur if such

warnings are ignored.

Follow the prevention instructions carefully.

CAUTION

Damage to the equipment, minor injury, malfunctions or incorrect process can be the consequence if such warnings are ignored.

Follow the prevention instructions carefully.

Mandatory

Signs

The importance of the mandatory signs in this manual.

Safety goggles

Safety gloves

AMI INSPECTOR Hydrogen

Safety Instructions

A-96.250.741 / 050218 5

Warning Signs The importance of the warning signs in this manual.

Electrical shock hazard

Corrosive

Harmful to health

Flammable

Warning general

Attention general

6 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Safety Instructions

1.2. General Safety Regulations

Legal

Requirements

The user is responsible for proper system operation.

All precautions must be followed to ensure safe operation

of the instrument.

Spare Parts

and

Disposables

Use only official SWAN spare parts and disposables. If other parts

are used during the normal warranty period, the manufacturer’s

warranty is voided.

Modifications Modifications and instrument upgrades shall only be carried out by

an authorized Service Technician. SWAN will not accept responsibility for any claim resulting from unauthorized modification or alteration.

WARNING

Risk of Electrical Shock

If proper operation is no longer possible, the instrument must be

disconnected from all power lines, and measures must be taken

to prevent inadvertent operation.

To prevent from electrical shock, always make sure that the

ground wire is connected.

Service shall be performed by authorized personnel only.

Whenever electronic service is required, disconnect instru-

ment power and power of devices connected to.

–relay 1,

–relay 2,

– alarm relay

WARNING

For safe instrument installation and operation you must read

and understand the instructions in this manual.

WARNING

Only SWAN trained and authorized personnel shall perform the

tasks described in this document.

AMI INSPECTOR Hydrogen

Product Description

A-96.250.741 / 050218 7

2. Product Description

This chapter contains technical data, requirements and performance data.

2.1. Description of the System

The portable AMI INSPECTOR instrument is a complete monitoring

system mounted on a small panel with supporting stand and a rechargeable battery for stand-alone operation (>24h), designed as

an inspection equipment for quality assurance of online process

monitors.

Features General Features of AMI INSPECTORs are:

Battery life after full charge:

– >24h at full load (

use of 3 relays, USB, signal output, logger

)

– >36h at minimum load (use of logger only)

Charging time: approx. 6 hours

Controlled shut-down if battery is empty.

Display of remaining battery life in hours.

For longer battery life the back light of the LC Display is dis-

abled.

Continuous operation using power adapter. The battery

should be discharged at least once a month (normal usage

until the monitor automatically shuts down).

Battery The Li-Ion battery is located in the housing of the AMI transmitter.

See chapter Power Supply, p. 18 regarding power supply and

charging of the battery.

Safety features No data loss after power failure, all data is saved in non-volatile

memory. Over voltage protection of in- and outputs.

Galvanic separation of measuring inputs and signal outputs.

USB interface Built-in USB interface for logger download. Use the USB stick sup-

plied by Swan only (other USB sticks can dramatically reduce battery life).

8 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Product Description

Signal Output One signal output programmable for measured values (freely

scaleable, linear or bilinear) or as continuous control output (control

parameters programmable).

Current loop: 0/4–20 mA

Maximal burden: 510

Relay Two potential-free contacts programmable as limit switches for

measuring values, controllers or timer for system cleaning with automatic hold function.

Maximum load: 100 mA/50 VAC

Alarm Relay One potential free contact.

Alternatively:

Open during normal operation, closed on error and loss of

power.

Closed during normal operation, open on error and loss of

power.

Summary alarm indication for programmable alarm values and instrument faults.

Input For potential-free contact to freeze the measuring value or to inter-

rupt control in automated installations (hold function or remote-off)

Measuring

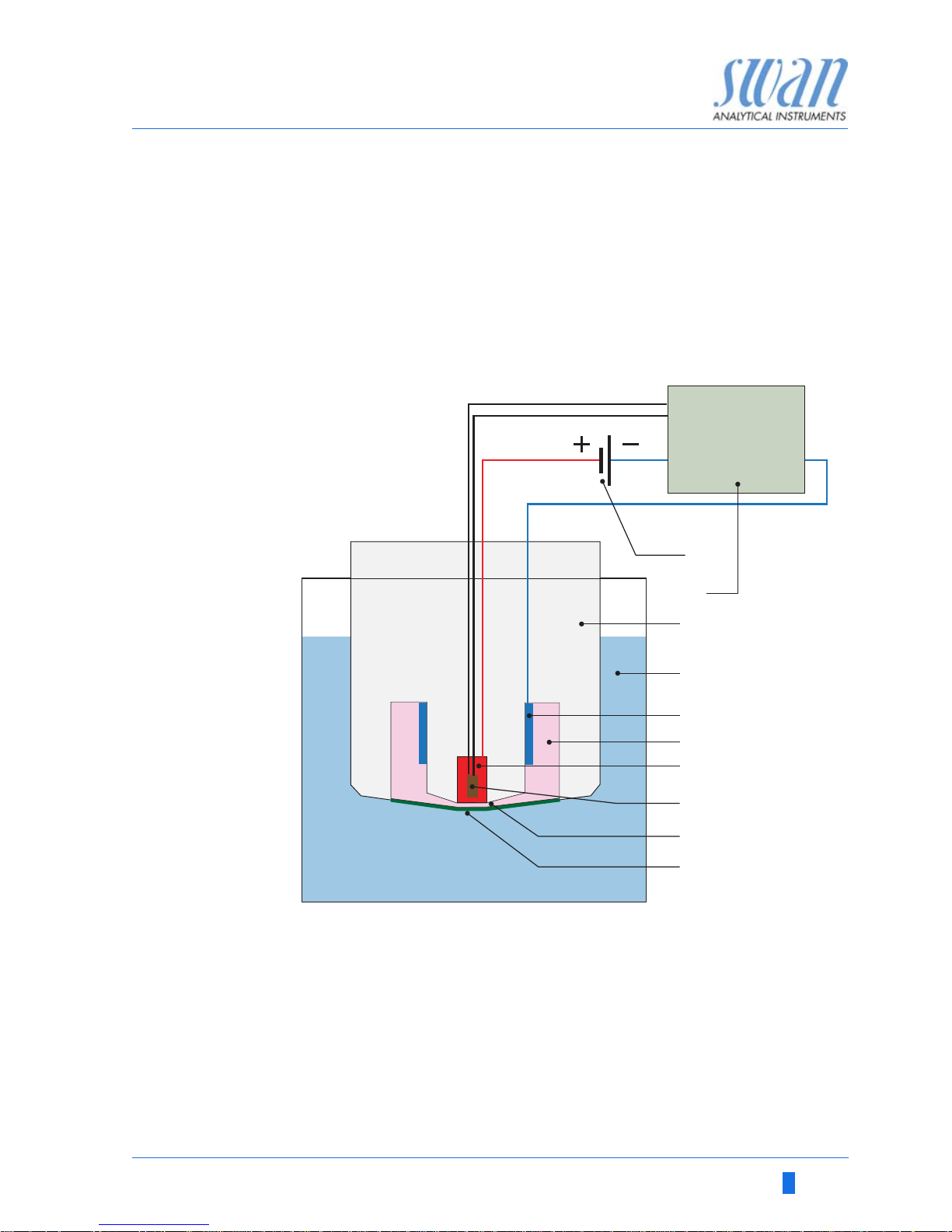

principle

Hydrogen is measured by an amperometric method. A small voltage, called polarization voltage, is applied between two electrodes.

If a hydrogen molecule hits the positively charged platinum electrode (anode) it will be oxidized. This means that two electrons are

removed under the influence of the positive voltage and the catalytic properties of the platinum. This leaves two (charged) protons and

two electrons behind.

(1) H2 ––> 2 H

+

+ 2 e

-

The two electrons are transported by the polarization voltage

source to the negatively charged silver-silver chloride electrode

(cathode), causing the following reaction:

(2) AgCl + 2 e

-

––> Ag + 2 Cl

-

Finally the two kinds of ions produced will combine into a small

amount of hydrochloric acid:

(3) 2 H+ + 2 Cl

-

––> 2 HCl

If the hydrogen concentration in the sample increases more hydrogen molecules will hit the platinum anode within a given time.

Therefore more electrons will be transported within a given time

which corresponds actually to an increased electrical current. This

current can be measured by the electronics. It is directly proportional to the concentration of hydrogen in the sample. Formula (2) indi-

AMI INSPECTOR Hydrogen

Product Description

A-96.250.741 / 050218 9

cates that in the course of the hydrogen measurement the silver

chloride is reduced to elemental silver. If all silver chloride has been

converted to silver the hydrogen sensor has to be refurbished in the

factory. However there is enough silver chloride provided to keep

the sensor operational during two years under normal conditions.

The actual SWAN hydrogen-sensor design is based on the wellknown Clark principle. Clark-type oxygen sensors have been successfully in use for many years.

Hydrogen sen-

sor schematic

view

A

B

C

D

E

Polarization voltage source

Display

Sensor Body

Sample

Silver cathode

F

G

H

I

J

Electrolyte

Platinum Anode

Temperature sensor

Thin layer of electrolyte

Hydrogen permeable

membrane

25.6 °C

1.24 ppb

A

B

C

D

E

F

G

H

J

I

10 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Product Description

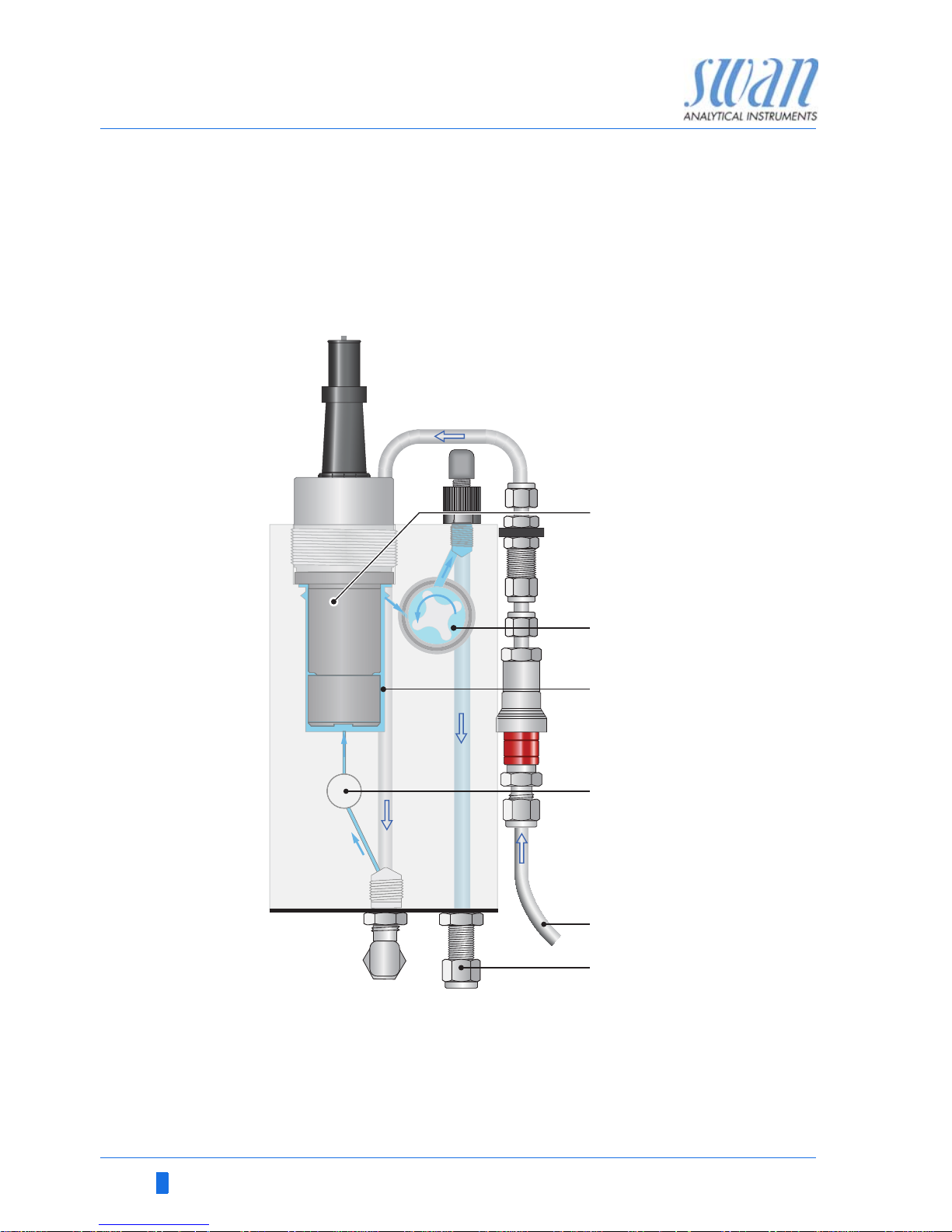

Fluidics The sample flows via sample inlet [E] through the flow regulating

valve [D], where the flow rate can be adjusted. Then the sample

flows into the measuring cell [C] were the hydrogen concentration

of the sample is measured.

The sample leaves the measuring cell via flow sensor [B] through

the sample outlet [F].

A

B

C

Hydrogen sensor

Flow sensor

Measuring cell

D

E

F

Flow regulating valve

Sample inlet

Sample outlet

A

B

C

D

E

F

AMI INSPECTOR Hydrogen

Product Description

A-96.250.741 / 050218 11

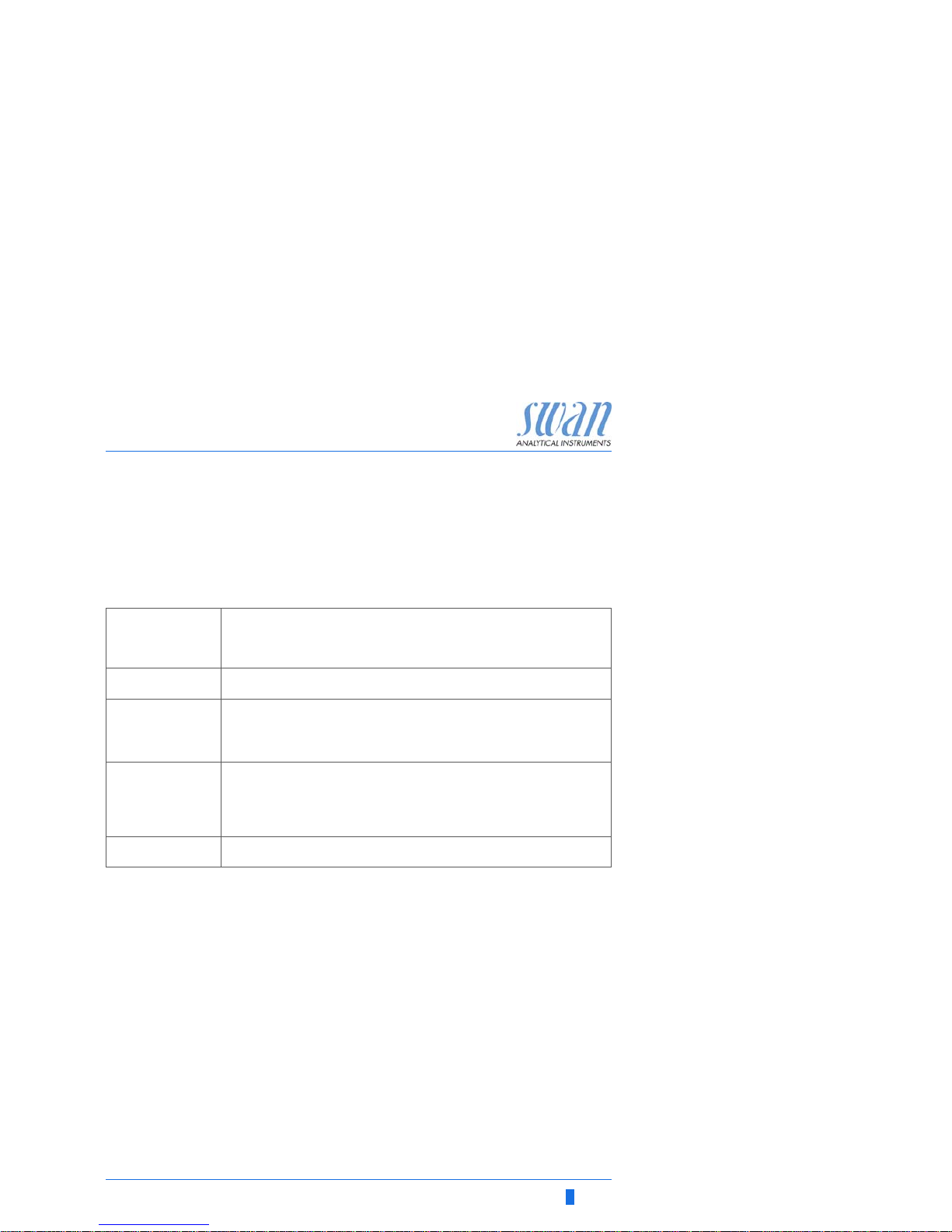

2.2. Instrument Overview

A

B

C

D

AMI Transmitter

Hydrogen sensor

Flow cell

Flow sensor

E

F

G

Flow regulating valve

Sample outlet

Sample inlet

A

B

D

C

F

G

E

12 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Product Description

2.3. Technical Data

Power Supply Battery

Use original, supplied power adapter only.

Voltage:

Power consumption:

Charging time:

Battery type:

85–265 VAC, 50/60 Hz

max. 20 VA

6h

Li-Ion

During charging protect from heat impact and keep splash-proof

(not IP66).

Operating time Stand-alone (Battery):

Connected adapter:

> 24h

continuous

Controlled shut-down when battery is empty, remaining time is displayed.

Electronics Aluminium with a protection degree of IP 66 / NEMA 4X

housing Ambient temperature:

Humidity:

Display:

-10 to +50 °C

10–90% rel., non condensing

backlit LCD, 75 x 45 mm

Sample

requirements

Flow rate:

Temperature:

Inlet pressure:

Outlet pressure:

6 to 20 l/h

up to 45 °C

0.2 to 1 bar

pressure free

Flow cell and

connection

Flow cell made of acrylic glass with built-in flow adjustment valve

and digital sample flow meter

Sample inlet:

Sample outlet:

1/4” Swagelok tube adapter

flexible tube 8x 6 mm

Measuring

Range

Range

0.1 to 199 ppb

200 to 800 ppb

0 – 50% saturation

Resolution

0.1 ppb

1 ppb

0.1% Saturation

Accuracy

Reprodu-

cibility

±3 % of measured value or ± 0.5 ppb

±1 % of measured value or ± 0.5 ppb

AMI INSPECTOR Hydrogen

Installation

A-96.250.741 / 050218 13

3. Installation

3.1. Installation Check List

Check

Instrument’s specification must conform to your AC power

ratings. See External power adapter, p. 19.

Check if the battery is fully charged.

Installation

Connect the sample and waste line.

Power-up

Open the flow regulating valve.

Switch on power

Adjust the sample flow to 6–20 l/h.

Instrument

Setup

Program all parameters for external devices (interface,

recorders, etc.)

Program all parameters for instrument operation (limits,

alarms).

Run-in period

Let the instrument run continuously for 1 h.

14 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Installation

3.2. Connecting Sample Inlet and Outlet

3.2.1 Connect the Sample Inlet to the Quick-Lock Coupling

The AMI INSPECTOR Hydrogen is delivered with a quick-lock coupling. To connect the sample line to the AMI INSPECTOR Hydrogen, simply push the nipple into the quick-lock coupling.

A

B

C

D

Flow cell block

Quick-lock coupling

Nipple

Sample outlet

A

B

C

D

AMI INSPECTOR Hydrogen

Installation

A-96.250.741 / 050218 15

3.2.2 Connect the Sample Outlet

Installation 1 Loosen the union nut [B] but do not remove it.

2 Push the FEP tube [A] through the union nut [B] as far as it

reaches the stop of the threaded tube [E].

3 Tighten the union nut 1¾ rotation using an open ended spanner.

Hold Body from turning with a second wrench.

4 Put the FEP Tube into a pressure free drain with sufficient ca-

pacity.

A

B

C

FEP tube 8x 6

Union nut

Compression ferrule

D

E

F

Compression cone

Threaded tube

Tightened connection

ABCD E

F

16 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Installation

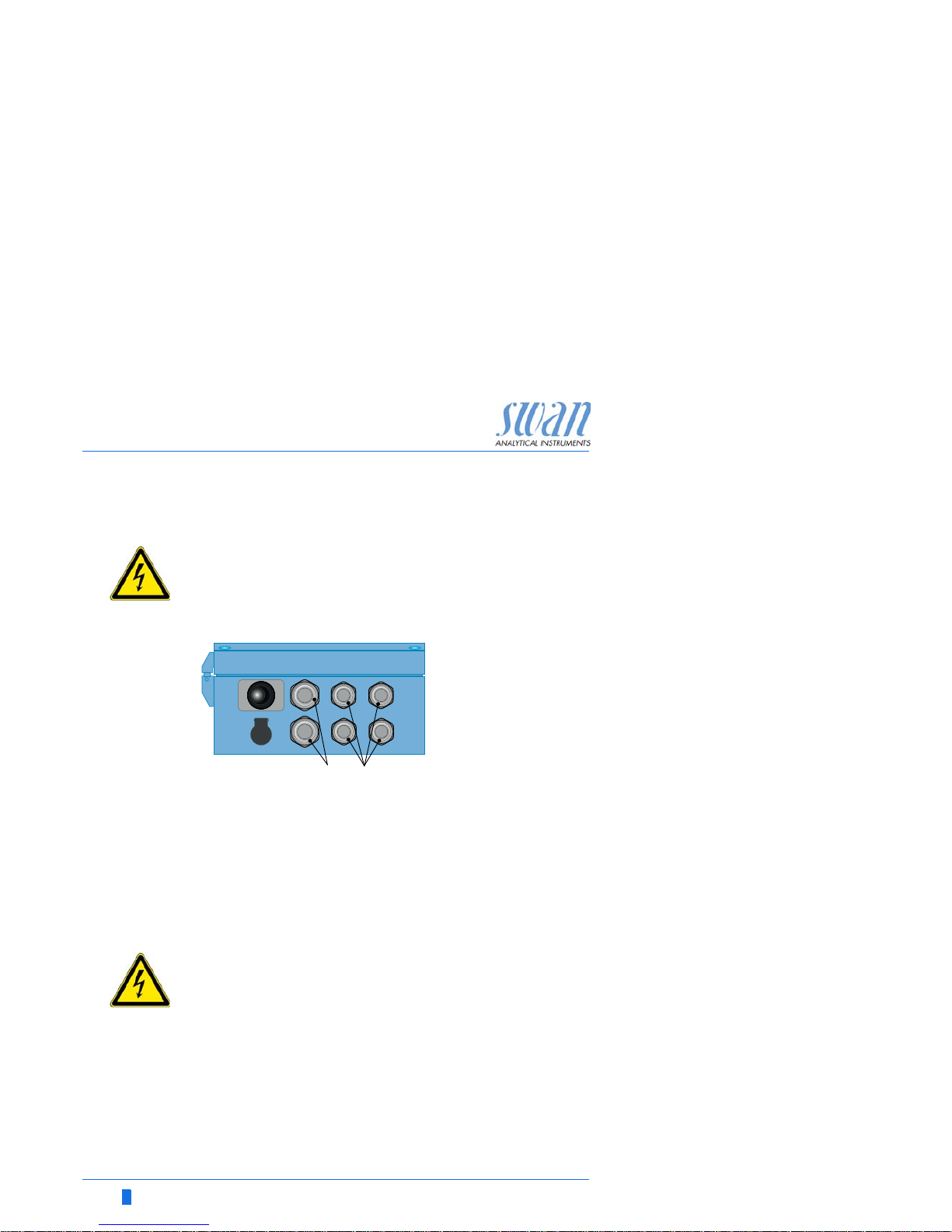

3.3. Electrical Connections

WARNING

Always turn off DC power before manipulating electric parts.

Make sure the power specification of the instrument corresponds to the power on site.

Cable

thicknesses

In order to comply with IP66, use the following cable thicknesses

NOTICE: Protect unused cable glands

Wire For Relays: Use max. 1.5 mm2 / AWG 14 stranded wire with

end sleeves.

For Signal Outputs and Input: Use 0.25 mm

2

/ AWG 23

stranded wire with end sleeves.

WARNING

External Voltage

External supplied devices connected to relay 1 or 2 or to the

alarm relay can cause electrical shocks.

Make sure that the devices connected to the following con-

tacts are disconnected from the power before continuing the

installation.

–relay 1

–relay 2

– alarm relay

A

B

PG 9 cable gland: cable Ø

outer

4–8 mm

PG 7 cable gland: cable Ø

outer

3–6.5 mm

ON

OFF

AB

AMI INSPECTOR Hydrogen

Installation

A-96.250.741 / 050218 17

3.4. Connection Diagram

CAUTION

Use only the terminals shown in this diagram, and only for the

mentioned purpose. Use of any other terminals will cause short

circuits with possible corresponding consequences to material

and personnel.

18 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Installation

3.4.1 Power Supply

Contrary to all other Swan online process monitors the AMI INSPECTOR transmitter is supplied with power by battery only. The

rechargeable battery (Li-Ion) enables a stand-alone operation for at

least 24 hours.

WARNING

Do not provide power directly to the transmitter as this will destroy the motherboard. All AMI INSPECTOR transmitters are

supplied with power by battery only.

Charging Use the original supplied power adapter to charge AMI INSPEC-

TOR only. Charging time: approx 6h.

Fully charged a stand-alone operating time of at least 24h is guar-

anteed:

>24h at full load (use of 3 relays, USB, signal outputs, logger)

>36h at minimal load (use of logger only)

In case that the battery is discharged completely the firmware will

automatically shut down.

Switch Power

ON - OFF

Switch the instrument ON or OFF using the toggle switch on the

transmitter.

Continuous

operation

For continuous operation use the power adapter as well.

CAUTION

If the AMI powers ON and then immediately shuts OFF, the

battery is empty. Do not hold the toggle switch in ON position,

as this can damage the battery.

CAUTION

During charging protect from heat impact and keep splash-

proof (plug of power adapter is not IP66).

Do not supply external devices, e.g. pumps, magnetic valves

or any other current consumers with AMI INSPECTOR

CAUTION

Use the original supplied power adapter to charge AMI IN-

SPECTOR only. Use of any other power adapter can damage

the battery or cause malfunction

AMI INSPECTOR Hydrogen

Installation

A-96.250.741 / 050218 19

External

power adapter

Universal input range

85 - 265 VAC

Continuous short circuit protection

Over voltage protection

LED indicator for power on

2-pin AC inlet (IEC 320-C8) for

detachable country-specific power

cord

Power cords Two different power cords are supplied:

Power cord with type C plug (Europlug)

Power cord with type A plug (NEMA-1)

If a different plug type is needed, please purchase a suitable power

cord from your local supplier.

NOTICE: Do not use any plug adapters.

Dimensions

Unit: mm

20 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Installation

3.5. Relay Contacts

Programming of the relay contacts see 5.3 Relay Contacts, p. 58

3.5.1 Input

NOTICE: Use only potential-free (dry) contacts.

Terminals 13/ 14

If signal output is set to hold, measurement is interrupted if input is

active.

For programming see menu 5.3.4, p. 64.

3.5.2 Alarm Relay

NOTICE: For resistive loads only; do not use with capacitive or

inductive loads. Max. load 1 A / 250 VAC

Alarm output for system errors.

Error codes see Error List, p. 40

Programming see menu 5.3.1, p. 58

NOTICE: With certain alarms and certain settings of the AMI

transmitter the alarm relay does not switch. The error, however,

is shown on the display.

1) usual use

Ter min als Description Relay connection

NC

1)

Normally

Closed

5/4 Active (opened) during normal

operation.

Inactive (closed) on error and

loss of power.

NO

Normally

Open

5/ 3 Active (closed) during normal

operation.

Inactive (opened) on error and

loss of power.

4

3

5

0V

1)

4

3

5

0V

AMI INSPECTOR Hydrogen

Installation

A-96.250.741 / 050218 21

3.5.3 Relay Contacts 1 and 2

NOTICE: For resistive loads only; do not use with capacitive or

inductive loads. Rated load 100 mA / 50 VAC

For programming see Menu Installation 5.3.2 and 5.3.3, p. 60

3.6. Signal Output

The signal output 0/4–20 mA PCB is plugged onto the USB interface PCB.

NOTICE: Max. burden 510 Ω.

Terminals 16 (+) and 15 (-).

For programming see menu 5.2 Signal Outputs, p. 54.

Terminals Description

Relay connection

NO

Normally

Open

6/ 7: Relay 1

8/ 9: Relay 2

Inactive (opened) during normal

operation and loss of power.

Active (closed) when a programmed function is executed.

A

B

Signal output 0/4–20 mA PCB

USB interface

A B

6/8

0V

7/9

22 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Instrument Setup

4. Instrument Setup

Establish

Sample Flow

1 Switch off the instruments.

2 Connect sample lines, see Connect the sample lines, p. 34.

3 Open the flow regulating valve.

4 Switch the instrument ON using the toggle switch of the battery.

5 Check if the battery is fully charged.

6 Adjust the flow to 6–20 l/h. The actual flow is shown on the

transmitter.

4.1. Programming

Sensor

parameters

Check the sensor parameters in menu <Installation>\

<Sensors>\<Sensor parameters>.

The sensor characteristics are printed on the label of each sensor.

The following parameters are required:

I

s

(saturation current)

p (air pressure)

Programming Program all parameters for external devices (interface, recorders,

etc.) Program all parameters for instrument operation (limits,

alarms). See Program Overview, p. 43 and for explanations, see

Program List and Explanations, p. 49.

SwanSensor Hydrogen

A-87.260.001 Is: 3.025 µA

xxxxxxx p: 953 hPa

AMI INSPECTOR Hydrogen

Operation

A-96.250.741 / 050218 23

5. Operation

5.1. Keys

Program

Access, Exit

Sensor

Maintenance

An automatic sensor regeneration is carried out at configurable intervals and takes 2 minutes. During this time the signal outputs are

set to hold.

A to exit a menu or command (rejecting any changes)

to move back to the previous menu level

B to move DOWN in a menu list and to decrease digits

C to move UP in a menu list and to increase digits

D to open a selected sub-menu

to accept an entry

Exit Enter

BCDA

25.4°C

RUN

9 l/h

14:10:45

R1

1.05 ppb

R2

1

Installation

Operation

Diagnostics

Messages

Maintenance

Main Menu

Enter

Exit

Sensor

Maintenance

HOLD

25.1 °C

0.0 l/h

15:20:18

01:45

R1

R2

24 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Operation

5.2. Display

Relay status, symbols

A RUN normal operation

HOLD input closed or cal delay: Instrument on hold (shows

status of signal outputs).

OFF input closed: control/limit is interrupted (shows status

of signal outputs).

B ERROR Error

Fatal Error

C Battery status (remaining operating time in h)

D Time

E Process values

F Sample temperature

G Sample flow

H Relay status

upper/lower limit not yet reached

upper/lower limit reached

control upw./downw. no action

control upw./downw. active, dark bar indicates control intensity

motor valve closed

motor valve: open, dark bar indicates approx. position

timer

timer: timing active (hand rotating)

RUN

25 °C

15:20:18

15

R1

R2

ppb

1.05

5.8 l/h

AB

F

E

DC

G

H

AMI INSPECTOR Hydrogen

Operation

A-96.250.741 / 050218 25

5.3. Software Structure

Menu Messages 1

Reveals pending errors as well as an event history

(time and state of events that have occurred at an

earlier point of time).

It contains user relevant data.

Menu Diagnostics 2

Provides user relevant instrument and sample data.

Menu Maintenance 3

For instrument calibration, relay and signal output

simulation, and to set the instrument time.

It is used by the service personnel.

Menu Operation 4

User relevant parameters that might need to be

modified during daily routine. Normally password

protected and used by the process-operator.

Subset of menu 5 - Installation, but process-related.

Menu Installation 5

For initial instrument set up by SWAN authorized

person, to set all instrument parameters. Can be

protected by means of password.

1

Messages

Operation

Maintenance

Diagnostics

Main Menu

Installation

1.1

Pending Errors

Messages

Maintenance List

Message List

2.1

Interface

I/O State

Sample

Identification

Sensors

Diagnostics

3.1

Calibration

Maintenance

Set Time 23.09.06 16:30:00

Simulation

Service

4.1

Logger

Relay Contacts

Sensors

Operation

5.1

Interface

Miscellaneous

Relay Contacts

Sensors

Signal Outputs

Installation

26 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Operation

5.4. Changing Parameters and values

Changing

parameters

The following example shows how to change the logger interval:

Changing

values

1 Select the parameter you want to

change.

2 Press [Enter]

3 Press [ ] or [ ] key to

highlight the required parameter.

4 Press [Enter] to confirm the selec-

tion or [Exit] to keep the previous

parameter).

The selected parameter is

highlighted (but not saved yet).

5 Press [Exit].

Yes is highlighted.

6 Press [Enter] to save the new pa-

rameter.

The system reboots, the new

parameter is set.

5.1.2

Sensors

Sensor type FOME

Temperature NT5K

Standards

Disinf. Free chlorine

4.4.1

Logger

Log interval 30 min

Clear logger no

4.1.3

Logger

Clear logger no

Log interval 30min

1 Hour

Interval.

5 min

30 min

10 min

4.1.3

Logger

Log interval 10 min

Clear logger no

4.1.3

Logger

Log interval

Clear logger no

No

Save ?

Yes

1 Select the value you want to

change.

2 Press [Enter].

3 Set required value with [ ] or

[] key.

4 Press [Enter] to confirm the new

value.

5 Press [Exit].

Yes is highlighted.

6 Press [Enter] to save the new val-

ue.

5.3.1.1.1

Alarm High 10.00 ppb

Alarm Hydrogen

Alarm Low 2.00 ppb

Hysteresis 0.10 ppb

Delay 5 Sec

5.3.1.1.1

Alarm Hydrogen

Alarm Low 2.00 ppb

Hysteresis 0.10 ppb

Delay 5 Sec

Alarm High 8.00 ppb

AMI INSPECTOR Hydrogen

Maintenance

A-96.250.741 / 050218 27

6. Maintenance

6.1. Maintenance Table

6.2. Stop of Operation for Maintenance

1 Shut off power of the instrument.

2 Stop sample flow by closing the flow regulating valve.

If required Perform a calibration.

Two years or if

required

Send the sensor to Swan for revision.

After installation of the revised sensor, program saturation

current and air pressure (5.1.3.1, p. 53 and 5.1.3.2, p. 53)

as indicated on the sensor label.

To avoid a longer interruption of the measuring operation, a

second hydrogen sensor can be purchased. The two sensors

can then be used alternately. If two sensors are available, the

following procedure is recommended:

Send the replacement sensor to Swan for revision shortly

before replacement.

After installing the revised sensor, store the unused sensor

in its original packaging in a cold, dry and dark place.

28 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Maintenance

6.3. Maintenance of the Hydrogen Sensor

6.3.1 Hydrogen Sensor Handling

Never attempt to open the hydrogen sensor.

Always store the sensor in water or in the wet flow cell.

Always keep the sensor connected to the AMI INSPECTOR

Hydrogen.

Always keep the sensor polarized. Without polarization the

sensor suffers a loss of sensitivity.

The AMI INSPECTOR Hydrogen has a buffered polarization

source which will keep the hydrogen-sensor polarized for

some days, even if the AMI INSPECTOR Hydrogen is

switched off.

However, it is a good idea to keep the AMI running all the

time. The AMI INSPECTOR Hydrogen should be connected

to the power supply and switched on even if it is not in use.

During calibration do not expose the sensor to 100 % Hydro-

gen longer than 6 minutes. Otherwise the extremely dry gas

might dry out the capillary layer of electrolyte between platinum anode and plastic membrane, which makes the sensor

response unstable.

The hydrogen molecule is very small and migrates into al-

most any material including electrolyte, plastics and even

metals and will remain there for some time. After a calibration

it may take a few hours until the residual current of the sensor

has dropped enough to measure very low levels of hydrogen

again.

The hydrogen-sensor shows usually a small positive offset,

which means there is a small positive value in air (without hydrogen, normally below one ppb). This value can be set to

zero: <Installation > Sensors > Miscellaneous > Offset. Use

with care!

AMI INSPECTOR Hydrogen

Maintenance

A-96.250.741 / 050218 29

6.3.2 Calibration

The hydrogen sensor of the AMI INSPECTOR Hydrogen is calibrated with pure hydrogen. To perform a calibration proceed as follows:

NOTICE: Do not expose the sensor to 100 % Hydrogen longer

than 6 minutes.

1 Stop the sample flow at the main tap.

2 Navigate to menu <Maintenance> /<Calibration>.

3 Press [Enter] to start the calibration and follow the dialog on the

display.

A

B

C

D

E

Threaded sleeve

Hydrogen sensor

Quick-lock coupling

Hydrogen tube

Sample tube

A

B

D

E

C

30 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Maintenance

If the calibration fails again, the hydrogen sensor has to replaced

by a new one.

4 Unscrew and remove the thread-

ed sleeve [A].

5 Remove the hydrogen sensor [B]

from the flow cell.

6 Dry the sensor membrane and the

flow cell with a soft paper tissue.

7 Remove the sample inlet [E] from

the quick-lock coupling [C].

8 Connect the hydrogen supply tube

[D] to the quick-lock coupling.

9 Flush the flow cell with hydrogen.

10 Stop hydrogen flow and dry the

flow cell.

11 Re-insert the hydrogen sensor into

the flow cell.

Make sure that the sensor

membrane is dry.

12 Start the hydrogen flow

13 Press [Enter] to start the calibra-

tion measurement.

The saturation should reach 100%,

the saturation current should be about

3.3 A to 3.5 A. If the measuring values are not stable during the measuring period, the calibration will be

discarded.

If this is the case, check and if necessary correct your measurement arrangement and try again.

If the calibration was successful press

[Enter] to save.

3.1.5

Calibration

Close regulating valve

to turn off sample flow.

<Enter> to continue

3.1.5

Calibration

Take sensor out of

flow cell and dry

membrane and sensor

<Enter> to continue

3.1.5

Calibration

Connect flow cell to a

source of hydrogen and

Dry flow cell inside.

flush with hydrogen.

<Enter> to continue

3.1.5

Calibration

Remount sensor and let

hydrogen stream through

value is accepted.

flow cell gently until

<Enter> to continue

3.1.1

Calibration

Saturation 98.7 %

Sat. Current 3.35

A

Progress

3.1.1

Calibration

Saturation 100 %

Sat. Current 3.45

A

<Enter> to save

AMI INSPECTOR Hydrogen

Maintenance

A-96.250.741 / 050218 31

6.3.3 Replace Hydrogen Sensor

To replace the hydrogen sensor proceed as follows:

Remove the

old sensor

1 Switch off the AMI Inspector Hydrogen.

2 Close the flow regulating valve [D].

3 Unscrew and remove the threaded sleeve [A] from the flow cell.

4 Remove the hydrogen sensor [C] from the flow cell.

5 Unscrew and remove the sensor connector [B] from the hydro-

gen sensor.

Install the new

sensor

1 Screw the connector onto the hydrogen sensor and tighten it.

2 Put the hydrogen sensor into the flow cell.

3 Screw the threaded sleeve into the thread of the flow cell to fix

the hydrogen sensor.

4 Open the flow regulating valve and adjust the sample flow to

6–20 l/h.

5 Switch on the AMI Inspector Hydrogen.

6 Let the new sensor run in for at least 1h.

A

B

C

D

Threaded sleeve

Sensor connector

Hydrogen sensor

Flow regulating valve

A

C

B

D

32 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Maintenance

6.4. Quality Assurance of the Instrument

Every SWAN on-line instrument is equipped with integrated, autonomous quality assurance functions to survey the plausibility of each

measurement.

For the AMI Hydrogen these are:

continuous monitoring of sample flow

continuous monitoring of the temperature inside the transmit-

ter case

periodic accuracy test with ultra high precision resistors

Further a manual, menu driven inspection procedure can be carried

out using a certified reference instrument. Running at the same

sampling point as an inspection equipment, the AMI INSPECTOR

Hydrogen verifies the measuring results. After enabling the quality

assurance procedure by defining the quality assurance level, the

instrument reminds the user periodically to run the procedure and

results are stored in a history for review.

Quality

assurance

level

Central feature of the quality assurance function is the assignment

of the monitored process to a Quality assurance level.

There are three predefined levels plus a user level. Hereby the inspection interval, the deviation limits of temperature and measuring

result between the inspection equipment and the monitoring instrument are defined.

Level 1: Trend; Measurement used as an additional informa-

tion to follow the process indicating trends.

Level 2: Standard; Monitoring of several parameters of a pro-

cess (e.g. hydrogen, saturation). In case of instrument failure,

other parameters can be used for process monitoring.

Level 3: Crucial; Monitoring of critical processes, value is

used for control of another part or subsystem (valve, dosing

unit, etc.).

Additional level:

Quality level 4: User; User defined inspection interval, maxi-

mal deviation of temperature and measuring result.

AMI INSPECTOR Hydrogen

Maintenance

A-96.250.741 / 050218 33

Procedure The standard workflow contains following procedures:

1 Activate SWAN Quality assurance procedure

2 Pre-test

3 Connect instruments

4 Carry out comparison measurement

5 Completion of the measurement

NOTICE: The procedure should only be carried out through

qualified personnel.

6.4.1 Activate SWAN Quality assurance procedure

Enable quality assurance procedure at each instrument by selecting the quality level in menu 5.1.2.

The corresponding submenus are then activated.

NOTICE: The activation is necessary the first time only.

Quality Level

max. deviation

temperature [°C]

a)

max. deviation

result [%]

min. inspection

interval

0: Off

Off Off

Off

1: Trend

0.5 °C 10 %

annual

2: Standard

0.4 °C 5 %

quarterly

3: Crucial

0.3 °C 5 %

monthly

4: User

0 - 2°C 0 - 20%

annual, quarterly,

monthly

a) sample temperature must have 25°C +/- 5°C.

34 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Maintenance

6.4.2 Pre-test

Reference instrument: AMI INSPECTOR Hydrogen:

– Check certificate; reference instrument certificate not older

than one year.

– Check battery; Battery of the AMI INSPECTOR Hydrogen

should be completely charged. Remaining operating time

on display minimum 20 hours.

– Sensor is in working condition

On-line instrument: Monitor AMI Hydrogen:

– Good order and condition; Flow cell free of particles,

Sensor surface free of deposits.

– Check message list; Review the message list in menu 1.3

and check for frequently alarms (as for example flow

alarms). If alarms occur frequently remove cause before

starting the procedure.

6.4.3 Connect the sample lines

See corresponding chapter in the manual of the process monitor

which shall be checked with a reference instrument.

The choice of sampling depends strongly on local conditions on

site. Possible sampling:

via sample point,

via T-fitting or

via piggyback/ downstream

NOTICE:

• avoid ingress of air, use screwed fitting,

• sample as near as possible to the process monitor,

• wait approx. 10 minutes, whilst measurement is running, until

measurement value and temperature are stabilized.

Example As an example following picture shows the connection of the refer-

ence instrument via T-fitting to the process monitor.

AMI INSPECTOR Hydrogen

Maintenance

A-96.250.741 / 050218 35

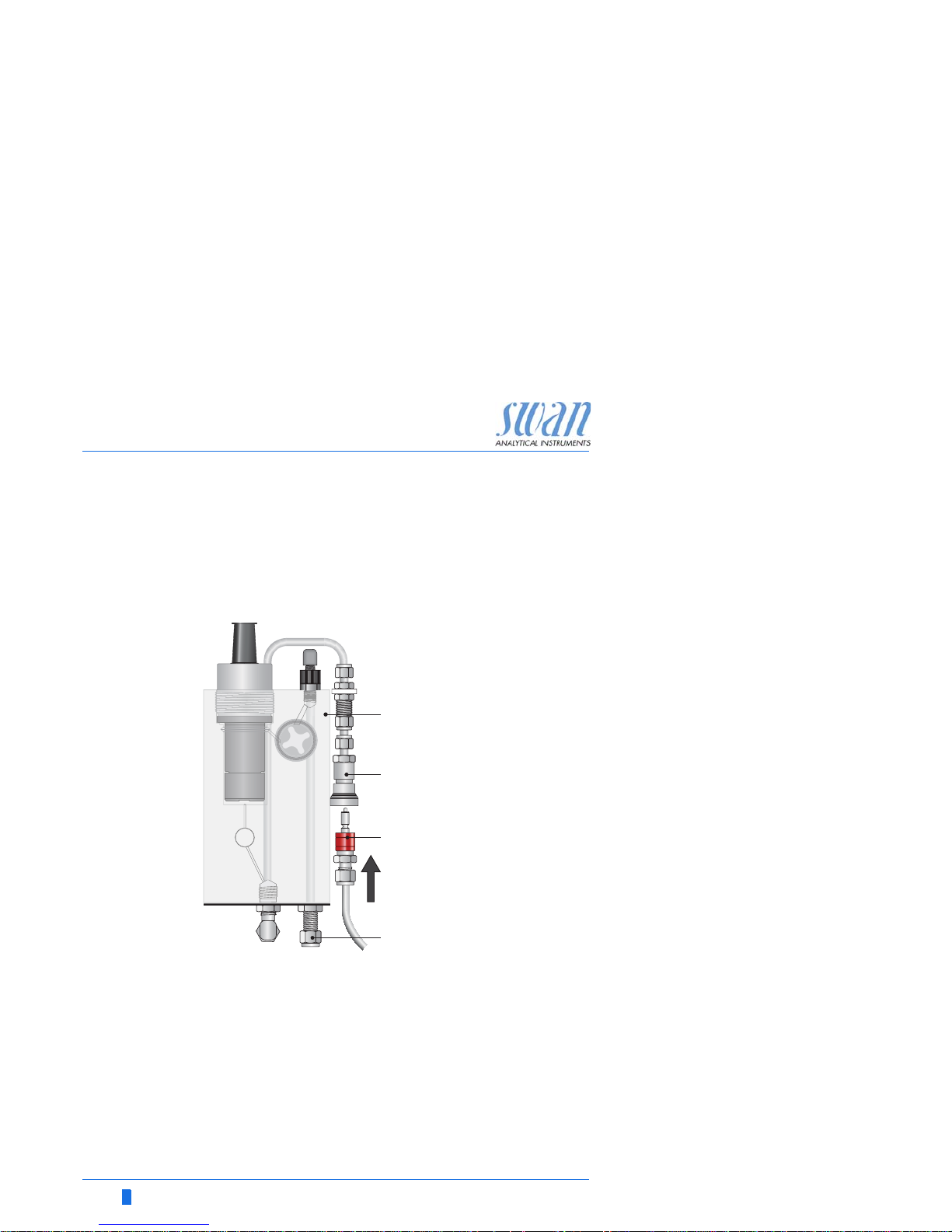

1 Stop sample flow to the monitor AMI Hydrogen by closing the

appropriate valve, e.g. back pressure regulator, sample preparation or flow regulating valve at flow cell.

2 Connect sample line of the monitor AMI Hydrogen [A] with the

sample inlet of the reference instrument AMI INSPECTOR Hydrogen [B]. Use the supplied tube.

3 Connect sample outlet of the reference instrument AMI IN-

SPECTOR Hydrogen to the sample outlet funnel of the monitor.

4 Switch on the AMI INSPECTOR Hydrogen. Open the flow regu-

lating valve and regulate the sample flow to 10 l/h. The actual

flow is shown on the transmitter.

A

B

C

D

Monitor AMI Hydrogen

AMI INSPECTOR Hydrogen

Reference flow cell

On-line flow cell

E

F

G

Sample outlet

Sample inlet

T-fitting

A

B

C

D

E

F

G

36 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Maintenance

6.4.4 Carry out comparison measurement

The comparison measurement is menu driven. To carry out the

comparison measurement, proceed as follows:

1 On the monitor AMI Hydrogen, navigate to the <Maintenance>/

<Quality Assurance> menu.

2 Press [Enter].

3 Follow the dialog on the Display.

4 Carry out pre test preparations

Connect instruments.

Regulate sample flow to 10 l/h using the appropriate valve.

5 Wait 10 minutes whilst measure-

ment is running.

Press [Enter] to continue.

6 Read the hydrogen value of the

reference instrument and enter under “Inspector.” by using the

[ ] or [ ] keys.

7 Press [Enter] to confirm.

8 Read temperature value of the ref-

erence instrument and enter under “Inspector Temp.” by using the

[ ] or [ ] keys.

9 Press [Enter] to confirm.

10 Press [Enter] to continue.

The results are saved in QAHistory regardless if successful

or not

3.5.5

Quality Assurance

- Carry out preparations

- Install Inspector

- Sample flow to 10 l/h

<Enter> to continue

3.5.5

Quality Assurance

Value H2 0.05 ppb

Value Temp. 25.00 C

Wait 10 Minutes

<Enter> to continue

3.5.3

Quality Assurance

Value H2 0.05 ppb

Value Temp. 25.00 C

<Enter> to continue

Inspector H2 0.06 ppb

Inspector Temp. 25.0 C

3.5.4

Quality Assurance

Value H2 0.05 ppb

Value Temp. 25.00 C

<Enter> to continue

Inspector 0.06 ppm

Inspector Temp. 25.0 C

3.5.5

Quality Assurance

Max. Dev. H2 0.5 %

Max. Dev. Temp. 0.4 °C

QA-Check succesful

Dev. H2 0.1 %

Dev. Temp. 0.4 °C

AMI INSPECTOR Hydrogen

Maintenance

A-96.250.741 / 050218 37

6.4.5 Completion of the measurement

1 Stop the sample flow to the AMI INSPECTOR Hydrogen by

closing the appropriate valve, e.g. back pressure regulator,

sample preparation or flow regulating valve at flow cell again.

2 Close flow regulating valve of the AMI Inspector.

3 Disconnect the AMI Inspector by removing the tubes and con-

nect the sample outlet of the Monitor AMI INSPECTOR Hydrogen to the sample outlet funnel again.

4 Start sample flow again and regulate sample flow.

5 Shutdown the AMI INSPECTOR Hydrogen.

If the instrument will not be used for a longer period of time, see

Longer Stop of Operation, p. 39.

38 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Maintenance

6.5. Replacing Fuses

WARNING

External Voltage.

External supplied devices connected to relay 1 or 2 or to the

alarm relay can cause electrical shocks.

Make sure that the devices connected to the following con-

tacts are disconnected from the power before continuing the

installation.

–relay 1

–relay 2

– alarm relay

Find and repair the cause for the short circuit before replacing the

fuse. Use tweezers or needle-nosed pliers to remove the defective

fuse.

Use original fuses provided by SWAN only.

A 1.25 AF/250V Instrument power supply

A

AMI INSPECTOR Hydrogen

Maintenance

A-96.250.741 / 050218 39

6.6. Replacing the Battery

1 Switch the AMI Inspector off.

2 If connected, disconnect the power adapter from the power

jack.

3 Open the transmitter housing.

4 Pull out the ribbon cable [C] from the mainboard.

5 Disconnect battery plug [B] and replace the battery.

6.7. Longer Stop of Operation

1 Stop sample flow.

2 Do not shut off power of the instrument.

NOTICE: The hydrogen sensor is polarized and a loss of

polarization will result in loss of sensitivity. If the AMI

INSPECTOR Hydrogen is switched off the polarization buffer

will be discharged within a few days.

3 Leave the sensor in the wet flow cell.

A

B

C

Battery

Battery plug

Ribbon cable

CBA

40 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Error List

7. Error List

Error

Non-fatal Error. Indicates an alarm if a programmed value is exceeded.

Such Errors are marked E0xx (bold and black).

Fatal Error (blinking symbol)

Control of dosing devices is interrupted.

The indicated measured values are possibly incorrect.

Fatal Errors are divided in the following two categories:

Errors which disappear if correct measuring conditions are re-

covered (i.e. Sample Flow low).

Such Errors are marked E0xx (bold and orange)

Errors which indicate a hardware failure of the instrument.

Such Errors are marked E0xx (bold and red)

Error or fatal Error

Error not yet acknowledged.

Check Pending Errors 1.1.5 * and

take corrective action.

Press [ENTER].

Navigate to menu Messages.

Press [ENTER].

Navigate to menu Pending Errors.

Press [ENTER].

Press [ENTER] to acknowledge the

Pending Errors. The Error is reset and

saved in the Message List.

* Menu numbers see

Program Overview, p. 43

25.4°C

HOLD

8 l/h

14:10:45

R1

7.04 ppm

R2

1

Installation

Operation

Diagnostics

Messages

Maintenance

Main Menu

1.1

Message List

Pending Errors

Maintenance List

Messages

1.1.5

Pending Errors

Error Code E002

Alarm low

<Enter> to Acknowledge

AMI INSPECTOR Hydrogen

Error List

A-96.250.741 / 050218 41

Error Description Corrective action

E001 Hydrogen Alarm high

– check process

– check programmed value,

see 5.3.1.1.1, p. 58

E002 Hydrogen Alarm low

– check process

– check programmed value,

see 5.3.1.1.22, p. 58

E003 Saturation Alarm high

– check process

– check programmed value,

see 5.3.1.4, p. 59

E004 Saturation Alarm low

– check process

– check programmed value,

see 5.3.1.4, p. 59

E007 Sample Temp. high

– check process

– check programmed value,

see 5.3.1.3.1, p. 59

E008 Sample Temp. low

– check process

– check programmed value,

see 5.3.1.3.22, p. 59

E009 Sample Flow high

– check sample flow

– check programmed value,

see 5.3.1.2.2, p. 59

E010 Sample Flow low

– establish sample flow

– clean instrument

– check programmed value,

see 5.3.1.2.32, p. 59

E011 Temp. shorted

– Check wiring of sensor

– Check sensor

E012 Temp. disconnected

– Check wiring of sensor

– Check sensor

42 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Error List

E013 Case Temp. high

– check case/environment temperature

– check programmed value,

see 5.3.1.5.1, p. 60

E014 Case Temp. low

– check case/environment temperature

– check programmed value,

see 5.3.1.5.2, p. 60

E017 Control Timeout

– check control device or programming in

Installation, Relay contact, Relay 1/2

see 5.3.2 and 5.3.3, p. 60

E024 Input active

– See If Fault Yes is programmed in Menu

see 5.3.4, p. 64

E026 IC LM75

– call service

E030 EEProm Frontend

– call service

E031 Calibration Recout

– call service

E032 Wrong Frontend

– call service

E033 Power-on

– none, normal status

E034 Power-down

– none, normal status

Error Description Corrective action

AMI INSPECTOR Hydrogen

Program Overview

A-96.250.741 / 050218 43

8. Program Overview

For explanations about each parameter of the menus see Program

List and Explanations, p. 49.

Menu 1 Messages informs about pending errors and mainte-

nance tasks and shows the error history. Password protection

possible. No settings can be modified.

Menu 2 Diagnostics is always accessible for everybody. No

password protection. No settings can be modified.

Menu 3 Maintenance is for service: Calibration, simulation of

outputs and set time/date. Please protect with password.

Menu 4 Operation is for the user, allowing to set limits, alarm

values, etc. The presetting is done in the menu Installation

(only for the System engineer). Please protect with password.

Menu 5 Installation: Defining assignment of all inputs and

outputs, measuring parameters, interface, passwords, etc.

Menu for the system engineer. Password strongly recommended.

8.1. Messages (Main Menu 1)

Pending Errors Pending Errors 1.1.5* * Menu numbers

1.1*

Maintenance List Maintenance List 1.2.5*

1.2*

Message List Number 1.3.1*

1.3* Date, Time

44 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program Overview

8.2. Diagnostics (Main Menu 2)

Identification Desig. AMI Hydrogen * Menu numbers

2.1* Version 6.21-10/17

Factory Test Instrument 2.1.3.1*

2.1.3* Motherboard

Front End

Operating Time Years / Days / Hours / Minutes / Seconds 2.1.4.1*

2.1.4*

Sensors Sensor Current Value

2.2* 2.2.1* (Raw value tc)

(Raw value)

Saturation

Cal. History Number 2.2.1.5.1*

2.2.1.5* Date, Time

Sat. Current

Air pressure

Miscellaneous Case Temp. 2.2.2.1*

2.2.2* Air pressure

Sample Sample ID 2.3.1*

2.3* Temperature °C

Nt5K Ohm

I/O State Alarm Relay 2.4.1*

2.4* Relay 1/2 2.4.2*

Input

Signal Output 3

Interface Protocol 2.5.1*

2.5* USB Stick

AMI INSPECTOR Hydrogen

Program Overview

A-96.250.741 / 050218 45

8.3. Maintenance (Main Menu 3)

Calibration Calibration 3.1.5 * Menu numbers

3.1*

Sevice Electrolyte Last filling

3.2* 3.2.1* Remaining amount

Remaining time

New Filling 3.2.1.5*

Simulation Alarm Relay 3.3.1*

3.3* Relay 1 3.3.2*

Relay 2 3.3.3*

Signal Output 3 3.3.6*

Set Time (Date), (Time)

3.4*

46 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program Overview

8.4. Operation (Main Menu 4)

Sensors Filter Time Const. 4.1.1*

4.1* Hold after Cal. 4.1.2*

Relay Contacts Alarm Relay Alarm Hydrogene Alarm High 4.2.1.1.1*

4.2* 4.2.1* 4.2.1.1* Alarm Low 4.2.1.1.22*

Hysteresis 4.2.1.1.32*

Delay 4.2.1.1.42*

Alarm Saturation Alarm High 4.2.1.2.1*

4.2.1.2* Alarm Low 4.2.1.2.22*

Hysteresis 4.2.1.2.32*

Delay 4.2.1.2.42*

Relay 1/2 Setpoint 4.2.x.100*

4.2.2* - 4.2.3* Hysteresis 4.2.x.200*

Delay 4.2.x.30*

Input Active 4.2.4.1*

4.2.4* Signal Outputs 4.2.4.2*

Output / Control 4.2.4.3*

Fault 4.2.4.4*

Delay 4.2.4.5*

Logger Log Interval 4.3.1*

4.3* Clear Logger 4.3.2* * Menu numbers

Eject USB Stick 4.3.3*

AMI INSPECTOR Hydrogen

Program Overview

A-96.250.741 / 050218 47

8.5. Installation (Main Menu 5)

Sensors Miscellaneous Flow 5.1.1.1* * Menu numbers

5.1* 5.1.1* Offset 5.1.1.2*

Maintenance Int. 5.1.1.3*

Sensor parameters Saturation current 5.1.3.1*

5.1.3* Air pressure 5.1.3.2*

Signal Outputs Signal Output 3 Parameter 5.2.1.1*

5.2* 5.2.1* Current Loop 5.2.1.2*

Function 5.2.1.3*

Scaling Range Low 5.2.x.40.10*

5.2.x.40 Range High 5.2.x.40.20*

Relay Contacts Alarm Relay Alarm Hydrogen Alarm High 5.3.1.1.1*

5.3* 5.3.1* 5.3.1.1* Alarm Low 5.3.1.1.22

Hysteresis 5.3.1.1.32

Delay 5.3.1.1.42

Sample Flow Flow Alarm 5.3.1.2.1

5.3.1.2* Alarm High 5.3.1.2.2*

Alarm Low 5.3.1.2.32*

Sample Temp. Alarm High 5.3.1.3.1*

5.3.1.3* Alarm Low 5.3.1.3.22*

Alarm Saturation Alarm High 5.3.1.4.1*

5.3.1.4* Alarm Low 5.3.1.4.22

Hysteresis 5.3.1.4.32

Delay 5.3.1.4.42

Case Temp. Case Temp. high 5.3.1.5.1*

5.3.1.5* Case Temp. low 5.3.1.5.2*

Relay 1/2 Function 5.3.2.1–5.3.3.1*

5.3.2* - 5.3.3* Parameter 5.3.2.20–5.3.3.20*

Setpoint 5.3.2.300–5.3.3.301*

Hysteresis 5.3.2.400–5.3.3.401*

Delay 5.3.2.50–5.3.3.50*

Input Active 5.3.4.1*

5.3.4* Signal Outputs 5.3.4.2*

Output/Control 5.3.4.3*

Fault 5.3.4.4*

Delay 5.3.4.5*

48 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program Overview

Miscellaneous Language 5.4.1*

5.4* Set defaults 5.4.2*

Load Firmware 5.4.3*

Password Messages 5.4.4.1*

5.4.4* Maintenance 5.4.4.2*

Operation 5.4.4.3*

Installation 5.4.4.4*

Sample ID 5.4.5*

Interface Protocol USB Stick

5.5* 5.5.1* * Menu numbers

AMI INSPECTOR Hydrogen

Program List and Explanations

A-96.250.741 / 050218 49

9. Program List and Explanations

1 Messages

1.1 Pending Errors

1.1.5 Provides the list of active errors with their status (active, acknowledged). If an active error is acknowledged, the alarm relay opens

again. Cleared errors are moved to the Message list.

1.2 Maintenance List

1.2.5 Provides the list of necessary maintenance. Cleared maintenance

messages are moved to the Message list.

1.3 Message List

1.3.1 Shows the error history: Error code, date / time of issue and status

(active, acknowledged, cleared). 65 errors are memorized. Then

the oldest error is cleared to save the newest error (circular buffer)..

2 Diagnostics

In diagnostics mode, the values can only be viewed, not modified.

2.1 Identification

Desig.: Designation of the instrument.

Version: Firmware of instrument (e.g. 6.21-10/17)

2.1.3 Factory Test: Test date of the Instrument and Motherboard.

2.1.4 Operating Time: Shows the operating time in Years, Days, Hours,

Minutes and Seconds.

2.2 Sensors

2.2.1 Sensor

Current value: Shows the actual measuring value in ppb.

Raw value tc: Shows the actual temperature compensated mea-

suring value in mA.

Raw value: Shows the actual uncompensated measuring value

in mA.

Saturation Shows the actual saturation in %

50 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program List and Explanations

2.2.1.5 Cal. History

Review the diagnostic values of the last calibration of the hydrogen

sensor. Max. 64 data records are memorized.

Number: Counter of calibrations.

Date, Time: Date and time of the calibration.

Sat. Current: Saturation current at the time of the calibration.

Air pressure: Air pressure at the time of the calibration.

2.2.2 Miscellaneous:

2.2.2.1 Case Temp: Shows the actual temperature in °C inside the

transmitter.

Air pressure: Shows the actual air pressure in hPa

2.3 Sample

2.3.301 Sample ID: Shows the assigned sample identification. This

identification is defined by the user to identify the location of the

sample

Temperature: Shows temperature in °C.

(Nt5K): Shows raw value of the temperature in

Sample Flow: Shows the sample flow in l/ h

(Raw value) Shows the sample flow in Hz

2.4 I/O State

Shows actual status of all in- and outputs.

2.4.1

2.5 Interface

2.5.1 Protocol USB Stick.

Alarm Relay: Active or inactive.

Relay 1 and 2: Active or inactive.

Input: Open or closed.

Signal Output 3: Actual current in mA

AMI INSPECTOR Hydrogen

Program List and Explanations

A-96.250.741 / 050218 51

3 Maintenance

3.1 Calibration

3.1.1 Start a calibration and follow the instructions on the screen. Displayed values are saturation in % and the saturation current in mA.

The indication bar shows the progress. Detailed explanation see

Calibration, p. 29.

3.2 Service

3.2.1 Electrolyte

Not applicable.

3.3 Simulation

In this menu the following relays and signal outputs can be tested:

Alarm relay

Relay 1and 2

Signal output 3

Select a relay or signal output with the [ ] or [ ] keys,

press the [Enter]> key to confirm. Then change the value with the

[ ] or [ ] keys. After confirming the setting with the [Enter]

key, the value is simulated by the relay/signal output.

At the absence of any key activities, the instrument will switch back

to normal mode after 20 min. If you quit the menu, all simulated

values will be reset.

3.4 Set Time

Adjust date and time.

Alarm Relay: Active or inactive.

Relay 1 and 2: Active or inactive.

Input: Open or closed.

Signal Output 3: Current in mA

52 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program List and Explanations

4 Operation

4.1 Sensors

4.1.1 Filter Time Constant: Used to damp noisy signals. The higher the

filter time constant, the slower the system reacts to changes of the

measured value.

Range: 5– 300 Sec

4.1.2 Hold after Cal: Delay permitting the instrument to stabilize again

after calibration. During calibration plus hold-time, the signal

outputs are frozen (held on last valid value), alarm values, limits are

not active.

Range: 0– 6‘000 Sec

4.2 Relay Contacts

See Relay Contacts, p. 20.

4.3 Logger

The instrument is equipped with an internal logger. The data can be

copied to the USB stick installed in the transmitter.

The logger can save approx. 1500 data records. The Records

consists of: Date, time, alarms, measuring values, raw values, case

temperature, flow.

4.3.1 Log Interval: Select a convenient log interval. Consult the table

below to estimate the max logging time. When the logging buffer is

full, the oldest data record is erased to make room for the newest

one (circular buffer).

Range: 1 Second to 1 hour

4.3.2 Clear Logger: If confirmed with yes, the complete logger data is

deleted. A new data series is started.

4.3.3 Eject USB Stick

Press [ENTER] to copy all logger data to the USB Stick.

Interval 1 s 5 s 1 min 5 min 10 min 30 min 1 h

Time 25 min 2 h 25 h 5 d 10 d 31 d 62 d

AMI INSPECTOR Hydrogen

Program List and Explanations

A-96.250.741 / 050218 53

5 Installation

5.1 Sensors

5.1.1 Miscellaneous

5.1.1.1 Flow: Select the installed flow meter:

none

Q-Flow

5.1.1.2 Offset: Manual, small correction of the offset. Range 0–3 ppb.

5.1.1.3 Maintenance Int.: Select the interval of the automatic sensor regen-

eration:

Off

3 hours

6 hours

12 hours

5.1.2 Quality Assurance

Not applicable.

5.1.3 Sensor parameters

5.1.3.1 Saturation current: Enter the saturation current printed on the

sensor label.

Range: 3000–4500 µA

5.1.3.2 Air pressure: Enter the air pressure printed on the sensor label.

Range: 900–1100 hPa

54 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program List and Explanations

5.2 Signal Outputs

5.2.1 Signal Output 3 (signal outputs 1 and 2 are deactivated)

5.2.1.1 Parameter: Assign one of the process values to the signal output.

Available values:

Hydrogen

Temperature

Sample Flow (if a flow sensor is selected)

Saturation

5.2.1.2 Current Loop: Select the current range of the signal output.

Make sure the connected device works with the same current

range.

Available ranges: 0–20 mA or 4–20 mA

5.2.1.3 Function: Define if the signal output is used to transmit a process

value or to drive a control unit. Available functions are:

Linear, bilinear or logarithmic for process values.

See As process values, p. 54

Control upwards or control downwards for controllers.

See As control output, p. 56

As process

values

The process value can be represented in 3 ways: linear, bilinear or

logarithmic. See graphs below.

ABlinear

bilinear

X Measured value

20

0.0 0.1 0.2 0.3 0.4 0.5

10 12

(0 - 20 [mA])

0 / 4

(4 - 20 [mA])

[mA]

X

AB

AMI INSPECTOR Hydrogen

Program List and Explanations

A-96.250.741 / 050218 55

5.2.1.40 Scaling: Enter beginning and end point (Range low & high) of the

linear or logarithmic scale. In addition, the midpoint for the bilinear

scale.

Parameter: Hydrogen.

Range low: 0.00 ppb – 20.00 ppm

Range high: 0.00 ppb –20.00 ppm

Parameter: Temperature

Range low: -30 to + 130 °C

Range high: 30 to + 130 °C

Parameter: Sample flow

Range low: 0– 50 l/h

Range high: 0– 50 l/h

Parameter: Saturation

Range low: 0– 200 %

Range high: 0– 200 %

X Measured value (logarithmic)

20

1

01234

10 100 1’000 10’000

10 12

(0 - 20 [mA])

0 / 4

426

(4 - 20 [mA])

[mA]

X

56 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program List and Explanations

As control

output

Signal outputs can be used for driving control units. We distinguish

different kinds of controls:

P-controller: The controller action is proportional to the devia-

tion from the setpoint. The controller is characterized by the

P-Band. In the steady-state, the setpoint will never be

reached. The deviation is called steady-state error.

Parameters: setpoint, P-Band

PI-controller: The combination of a P-controller with an

I-controller will minimize the steady-state error. If the reset

time is set to zero, the I-controller is switched off.

Parameters: setpoint, P-Band, reset time.

PD-controller: The combination of a P-controller with a

D-controller will minimize the response time to a fast change

of the process value. If the derivative time is set to zero, the

D-controller is switched off.

Parameters: setpoint, P-Band, derivative time.

PID-controller: The combination of a P-, an I - and a D-con-

troller allows a proper control of the process.

Parameters: setpoint, P-Band, reset time, derivative time.

Ziegler-Nichols method for the optimization of a PID controller:

Parameters: Setpoint, P-Band, Reset time, Derivative time

The point of intersection of the tangent with the respective axis will

result in the parameters a and L.

Consult the manual of the control unit for connecting and

programming details. Choose control upwards or downwards.

A

B

X

Response to maximum control output

Tangent on the inflection point

Time

Xp

Tn

Tv

= 1.2/a

= 2L

= L/2

X

Y

B

A

L

a

AMI INSPECTOR Hydrogen

Program List and Explanations

A-96.250.741 / 050218 57

Setpoint: User defined precess value for the selected parameter.

P-Band: Range below (upwards control) or above (downwards con-

trol) the set-point, within which the dosing intensity is reduced from

100% to 0% to reach the set-point without overshooting.

5.2.1.43 Control Parameters: if Parameter = Hydrogen

5.2.1.43.10 Setopint:

Range: 0.00 ppb – 20.00 ppm

5.2.1.43.20 P-Band:

Range: 0.00 ppb – 20.00 ppm

5.2.1.43 Control Parameters: if Parameter = Temperature

5.2.1.43.11 Setopint:

Range: -30 to + 130 °C

5.2.1.43.21 P-Band:

Range: 0 to + 100 °C

5.2.1.43 Control Parameters: if Parameter = Sample flow

5.2.1.43.12 Setopint:

Range: 0– 50 l/h

5.2.1.43.22 P-Band:

Range: 0– 50 l/h

5.2.1.43 Control Parameters: if Parameter = Saturation

5.2.1.43.13 Setopint:

Range: 0– 200%

5.2.1.43.23 P-Band:

Range: 0– 200%

5.2.1.43.3 Reset time: The reset time is the time till the step response of a

single I-controller will reach the same value as it will be suddenly

reached by a P-controller.

Range: 0– 9’000 sec

5.2.1.43.4 Derivative time: The derivative time is the time till the ramp

response of a single P-controller will reach the same value as it will

be suddenly reached by a D-controller.

Range: 0– 9’000 sec

5.2.1.43.5 Control timeout: If a controller action (dosing intensity) is constantly

over 90% during a defined period of time and the process value

does not come closer to the setpoint, the dosing process will be

stopped for safety reasons.

Range: 0– 720 min

58 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program List and Explanations

5.3 Relay Contacts

5.3.1 Alarm Relay: The alarm relay is used as cumulative error indicator.

Under normal operating conditions the contact is active.

The contact is inactive at:

Power loss

Detection of system faults like defective sensors or electronic

parts

High case temperature

Process values out of programmed ranges.

Program alarm levels for the following parameters:

Meas. Value

Temperature

Sample Flow (if a flow sensor is selected)

Case Temperature high

Case Temperature low

5.3.1.1 Alarm Hydrogen

5.3.1.1.1 Alarm High: If the measured value rises above the alarm high

value, the alarm relay is activated and E001, is displayed in the

message list.

Range: 0.00 ppb –20.00 ppm

5.3.1.1.22 Alarm Low: If the measured value falls below the alarm low value,

the alarm relay is activated and E002 is displayed in the message

list.

Range: 0.00 ppb –20.00 ppm

5.3.1.1.32 Hysteresis: Within the hyst. range, the relay does not switch. This

prevents damage of relays contacts when the measured value

fluctuates around the alarm value.

Range. 0.00 ppb –20.00 ppm

5.3.1.1.42 Delay: Duration, the activation of the alarm relay is retarded after

the measuring value has risen above/fallen below the programmed

alarm.

Range: 0– 28‘800 Sec

AMI INSPECTOR Hydrogen

Program List and Explanations

A-96.250.741 / 050218 59

5.3.1.2 Sample Flow: Define at which sample flow a flow alarm should be

issued.

5.3.1.2.1 Flow Alarm: Program if the alarm relay should be activated if there

is a flow alarm. Choose between yes or no. The flow alarm will

always be indicated in the display, pending error list, saved in the

message list and the logger.

Available values: Yes or no

NOTICE: Sufficient flow is essential for a correct measurement.

We recommend to program yes.

5.3.1.2.2 Alarm High: If the measuring values rises above the programmed

value E009 will be issued.

Range: 12– 20 l/h

5.3.1.2.32 Alarm Low: If the measuring values falls below the programmed

value E010 will be issued.

Range: 5– 20 l/h

5.3.1.3 Sample Temp.: Define at which sample temperature an alarm

should be issued.

5.3.1.3.1 Alarm High: If the measured value rises above the alarm high

value, the alarm relay is activated and E007 is issued.

Range: 30– 100 °C

5.3.1.3.22 Alarm Low: If the measured value rises above the alarm high value,

the alarm relay is activated and E008 is issued.

Range: -10 to +20 °C

5.3.1.4 Alarm Saturation

5.3.1.4.1 Alarm High: If the measured value rises above the alarm high

value, the alarm relay is activated and E001, is displayed in the

message list.

Range: 0.00 – 200 %

5.3.1.4.22 Alarm Low: If the measured value falls below the alarm low value,

the alarm relay is activated and E002 is displayed in the message

list.

Range: 0.00 – 200 %

5.3.1.4.32 Hysteresis: Within the hyst. range, the relay does not switch. This

prevents damage of relays contacts when the measured value

fluctuates around the alarm value.

Range. 0.00 – 200 %

5.3.1.4.42 Delay: Duration, the activation of the alarm relay is retarded after

the measuring value has risen above/fallen below the programmed

alarm.

Range: 0– 28‘800 Sec

60 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program List and Explanations

5.3.1.5 Case Temp.

5.3.1.5.1 Case Temp. high: Set the alarm high value for temperature of

electronics housing. If the value rises above the programmed value

E013 is issued.

Range: 30– 75 °C

5.3.1.5.2 Case Temp. low: Set the alarm low value for temperature of

electronics housing. If the value falls below the programmed value

E014 is issued.

Range: -10 to + 20 °C

5.3.2 and 5.3.3 Relay 1 and 2: The function of relay contacts 1 or 2 are defined by

the user

NOTICE: The navigation in the menu <Relay 1> and <Relay 2>

is equal. For reason of simplicity only the menu numbers of

Relay 1 are used in the following.

1 First select the functions as:

- Limit upper/ lower,

- Control upwards/ downwards,

- Timer

- Fieldbus,

2 Then enter the necessary data depending on the selected func-

tion. The same values may also be entered in menu 4.2 Relay

Contacts, p. 52

When the relays are used as upper or lower limit switches, program

the following:

5.3.2.20 Parameter: choose one of the following process values

Hydrogen

Temperature

Sample Flow

Saturation

5.3.2.300 Setpoint: If the measured value rises above respectively falls below

the set-point, the relay is activated.

Parameter Hydrogen: Range: 0.00 ppb –20.00 ppm

Parameter Temperature: Range: -30 to + 130 °C

Parameter Sample flow: Range: 0– 50 l/h

Parameter Saturation: Range: 0– 200 %

5.3.2.1 Function = Limit upper/lower:

AMI INSPECTOR Hydrogen

Program List and Explanations

A-96.250.741 / 050218 61

5.3.2.400 Hysteresis: within the hysteresis range, the relay does not switch.

This prevents damage of relay contacts when the measured value

fluctuates around the alarm value.

Parameter Hydrogen; Range: 0.00 ppb –20.00 ppm

Parameter Temperature; Range: 0–100 °C

Parameter Sample flow; Range: 0–50 l/h

Parameter Saturation; Range: 0 –200 %

5.3.2.50 Delay: Duration, the activation of the alarm relay is retarded after

the measuring value has risen above/fallen below the programmed

alarm.

Range. 0– 600 Sec

The relays may be used to drive control units such as solenoid

valves, membrane dosing pumps or motor valves. When driving a

motor valve both relays are needed, relay 1 to open and relay 2 to

close the valve.

5.3.2.22 Parameter: choose one of the following process values

Hydrogen

Temperature

Sample Flow

Saturation

5.3.2.32 Settings

Choose the respective actuator:

Time proportional

Frequency

Motor valve

Examples of metering devices that are driven time proportional are

solenoid valves, peristaltic pumps.

Dosing is controlled by the operating time.

5.3.2.32.20 Cycle time: duration of one control cycle (on/off change).

Range: 0– 600 sec.

5.3.2.32.30 Response time: Minimal time the metering device needs to react.

Range: 0– 240 sec.

5.3.2.32.4 Control Parameters:

Range for each Parameter same as 5.2.1.43, p. 57

5.3.2.1 Function = Control upwards/ downwards::

Actuator = Time proportional

62 A-96.250.741 / 050218

AMI INSPECTOR Hydrogen

Program List and Explanations

Examples of metering devices that are pulse frequency driven are

the classic membrane pumps with a potential free triggering input.

Dosing is controlled by the repetition speed of dosing shots.

5.3.2.32.21 Pulse frequency: Max. pulses per minute the device is able to re-

spond to. Range: 20– 300/min.

5.3.2.32.31 Control Parameters:

Range for each Parameter same as 5.2.1.43, p. 57

Dosing is controlled by the position of a motor driven mixing valve.

5.3.2.32.22 Run time: Time needed to open a completely closed valve

Range: 5– 300 Sec.