Page 1

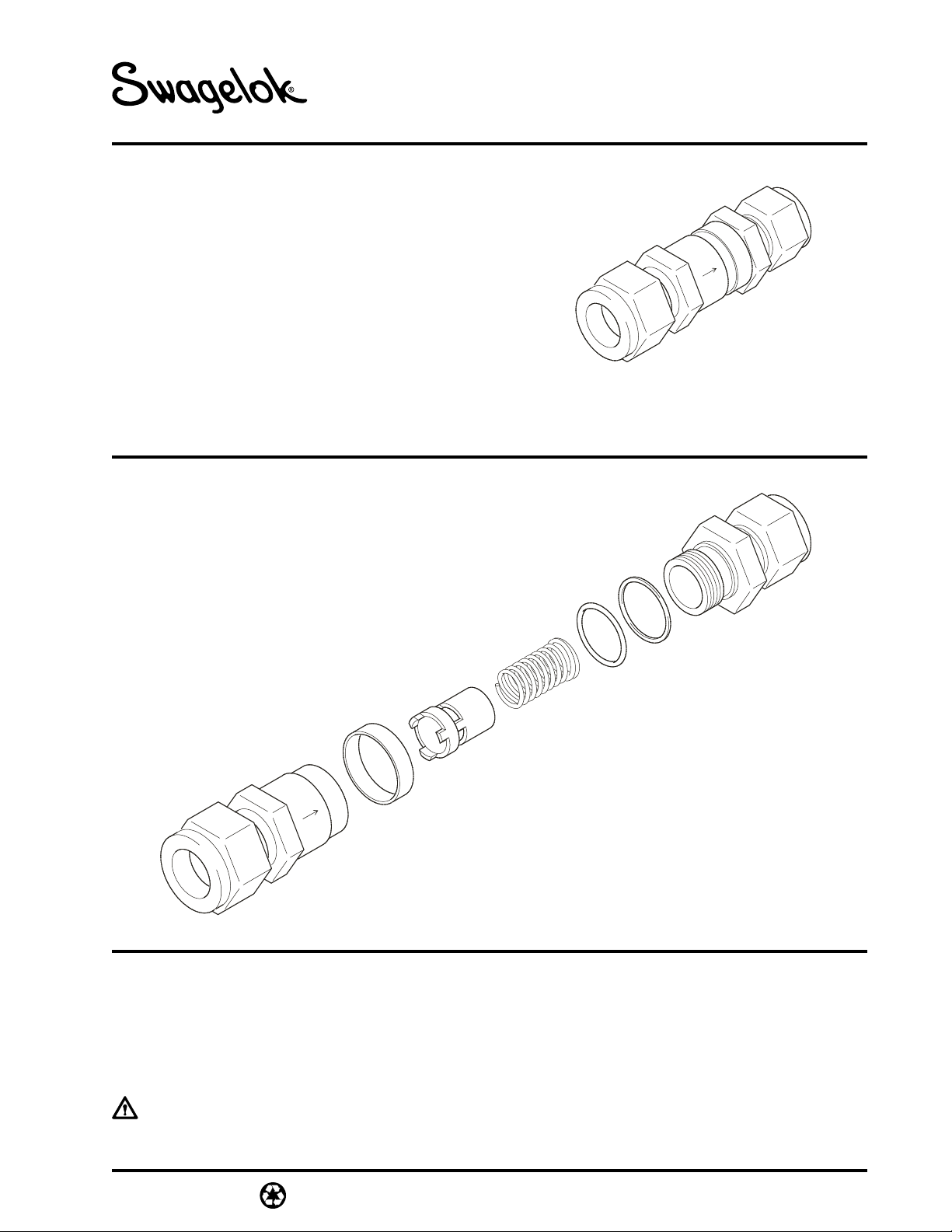

O-ring

Outlet Body

Backup Ring

Spring

Identification Ring

Poppet

Inlet Body

End Connection

End Connection

Body Hex

Body Hex

MS-CRD-0064

Revision 1 6-00-CP

XS Series Excess Flow Valve

Service Instructions

Contents

• Component Identification . . . . . . . . . . . . . . . 1

• Tool Requirements . . . . . . . . . . . . . . . . . . . . 2

• Installation . . . . . . . . . . . . . . . . . . . . . . . . . . 2

• Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

• Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . 3

• Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 3

• Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 6

Valve is shown with Swagelok®tube fitting end connections. These instructions also apply to XS series

valves with pipe ends and with VCR®and VCO®face-seal fitting end connections.

Component Identification

Definitions

Statements and symbols are used in this document

to identify safety concerns. Read the definitions

below before performing the service instructions.

This symbol indicates cautionary

information.

Caution: Indicates a potentially hazardous

situation. It may also be used to

alert against unsafe practices.

Notice: Indicates a statement of company

policy directly or indirectly related to

the safety of personnel or protection

of property.

Page 2

For Body

Hex

Qty. (1)

2

MS-CRD-0064

Revision 1 6-00-CP

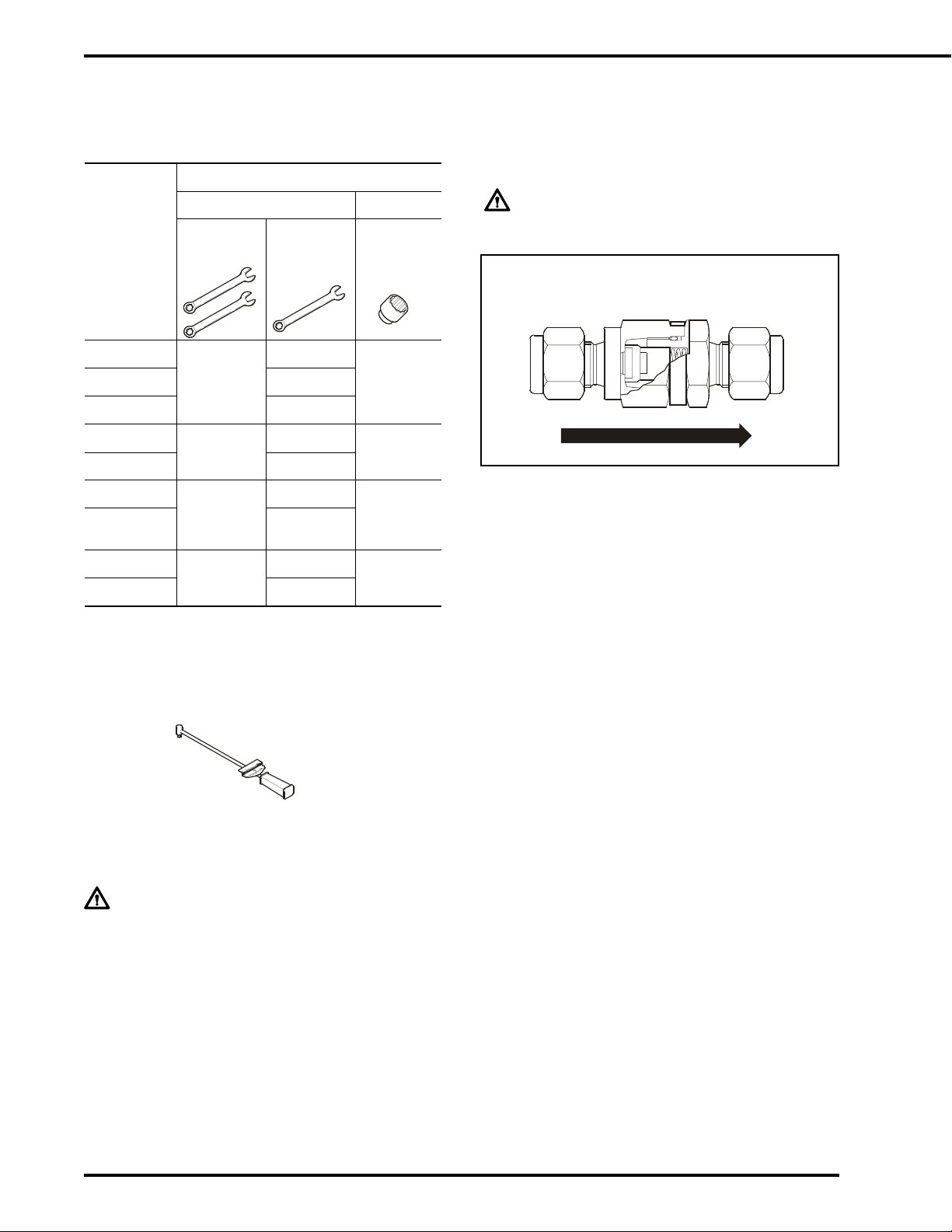

Tool Requirements

Tool size depends on the nominal end connection

size and style. See the table below.

Other Tools

Torque wrench rated to 200 in·lb (22.6 N·m).

Installation

1. Refer to the flow direction arrow on the excess

flow valve and install the valve in the

correct orientation.

IMPORTANT:

Verify proper flow direction when installing.

Inlet

Outlet

2. For valves with Swagelok tube fittings or VCO

®

or VCR®fittings, following the specific fitting

assembly instructions.

3. For valves with pipe fittings or straight thread

fittings, follow standard industry practices.

The flow direction verification card included

with the valve shows the proper flow direction.

Testing

1. Operate at normal flow rate. Create maximum

flow surges. Valve must remain open in both

instances.

2. Vent system line to simulate a break. Valve

must trip (close).

• If valve trips closed, proceed to step 3.

• If valve does not trip closed, replace the

spring with one of the lower-flow springs.

Repeat the Testing procedure.

3. Perform reset test by venting system to trip

valve. Close upstream or downstream valve to

allow the valve to reset. Valve must open and

allow normal flow.

4. Test the valve to ensure there is no leakage to

the atmosphere.

Nominal

End

Connection

Size

Tool Size and Quantity

Wrenches Socket

For Body

Hex Qty. (2)

For End

Connection

Qty. (1)

1/8 in.

11/16 in.

7/16 in.

11/16 in.

1/4 in. 9/16 in.

6 mm 14 mm

3/8 in.

1 in.

11/16 in.

1 in.

1/2 in. 7/8 in.

1/2 in. FNPT

11⁄16 in.

11⁄16 in.

11⁄16 in.

1/2 in.

BSP/ISO

11⁄16

in.

8 mm

1 in.

16 mm

1 in.

12 mm 22 mm

Caution:

Before servicing any installed valve you

must:

• depressurize the system

• purge the valve.

Flow Direction Verification Card

Page 3

3

MS-CRD-0064

Revision 1 6-00-CP

Spring Kit Contents

Standard-Flow

Spring

Medium-Flow

Spring

Low-Flow

Spring

XX GPM

XX GPM

XX GPM

Backup Ring

O-ring

One Set of Three Labels

GPM = gallons per minute (U.S. gal/min).

Body Hex Wrenches

Maintenance

Disassembly

1. Remove the excess flow valve from the

system.

2. Separate the inlet body from the outlet body.

4. Remove the spring.

Inlet Body

7. Remove the identification ring.

5. Remove the O-ring.

6. Remove the backup ring.

Outlet Body

3. Remove the poppet.

Page 4

4

MS-CRD-0064

Revision 1 6-00-CP

Reassembly

Outlet Body

1. Place the backup ring on the outlet body.

2. Lubricate the O-ring with a compatible

lubricant.

3. Slide the O-ring over the threads against the

backup ring.

4. Select the preferred replacement spring from

the table below.

5. Insert the spring, large end first, into the body.

6. Insert the poppet over the spring.

Body

threads

7. Lubricate the body threads with a systemcompatible lubricant

Nominal

End

Connection

Size

Spring

Nominal Flow, U.S. gal/min (L/min)

Standard

Flow

Medium

Flow

Low

Flow

1/8 in.

1/4 in.

6mm

XS4 XS4-3 XS4-1

5 (18.9) 3 (11.3) 1 (3.7)

3/8 in.

8 mm

XS6 XS6-6 XS6-3

9 (34.0) 6 ((22.7) 3 (11.3)

1/2 in.

12 mm

XS8 XS8-6 XS8-3

13

(44.2)

6

(22.7)

3

(11.3)

Page 5

5

MS-CRD-0064

Revision 1 6-00-CP

Inlet Body

8. Place the identification ring on the body.

9. Select the trip point label that matches the

replacement spring. Place the label on the

identification ring.

11. Tighten the valve bodies.

10. Thread the outlet and inlet bodies together.

Notice:

Do not pinch the O-ring and backup ring

between the outlet and the inlet bodies

during assembly.

The O-ring must fit tightly into the inlet body.

Tighten the

body halves to

approximately

200 in.·lb

(22.6 N

·m)

Body Hex Wrench

Body Hex

Socket

12. See Installation and Testing sections.

Page 6

6

MS-CRD-0064

Revision 1 6-00-CP

VCR, VCO, Swagelok — TM Swagelok Co.

© 2000 Swagelok Company

Safe Product Selection

When selecting products, the total system design

must be considered to ensure safe, trouble-free

performance. Function, material compatibility,

adequate ratings, proper installation, operation, and

maintenance are the responsibilities of the system

designer and user.

Caution: Do not mix or interchange parts with those

of other manufacturers

Symptom Possible Causes Corrective Action

Valve trips during

normal operation

Flow surges higher than expected. Evaluate a smaller valve.

Evaluate a lower trip range spring option.

Valve trips at

normal flow after

being in service for

some time.

Poppet openings are plugged. Clean or replace poppet.

Flush or blow down regularly.

Clean on a regular preventive maintenance

schedule.

Valve does not trip

at high flow

Valve is too large. Evaluate a smaller valve.

Evaluate a lower trip range spring option.

Low system pressure. System pressure must be greater than

trip pressure.

Evaluate a lower trip range spring option.

Poppet is stuck. The parts are contaminated. Clean

the parts thoroughly. Replace the damaged

parts.

Service regularly.

The parts are corroded. Replace corroded

parts. Select a compatible material.

Valve does not

reset itself

Bleed passage on

poppet is plugged.

The parts are contaminated. Clean

the parts thoroughly. Replace the

damaged parts.

Service regularly.

The parts are corroded. Replace corroded

parts. Select a compatible material.

Troubleshooting

Bleed

passage

Loading...

Loading...