Page 1

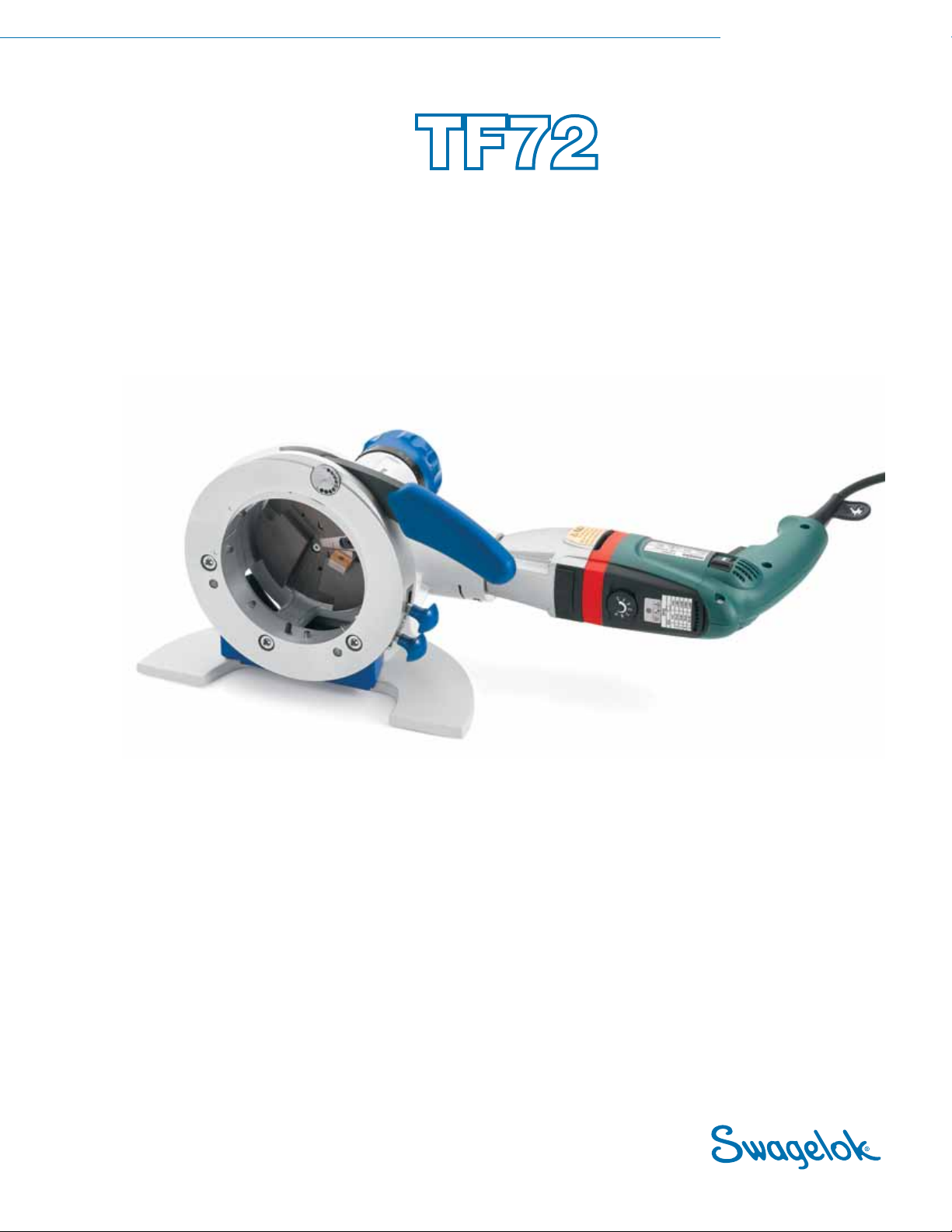

Tube Facing Tool

www.swagelok.com

This manual contains important information for the safe and

effective operation of the Swagelok® TF72 series tube facing

tool. Users should read and understand its contents before

operating the tube facing tool.

Page 2

2 Tube Facing Tool User’s Manual

Page 3

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Summary . . . . . . . . . . . . . . . . . . . . . . .5

Environmental Protection/Disposal . . . . . . . . . . . . . 7

Product Information . . . . . . . . . . . . . . . . . . . . . . 8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 9

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 10

Application range. . . . . . . . . . . . . . . . . . . . . . 10

Tube materials . . . . . . . . . . . . . . . . . . . . . . . 10

Technical data . . . . . . . . . . . . . . . . . . . . . . . 10

Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Description . . . . . . . . . . . . . . . . . . . . . . . . . 11

Unpacking the Tube Facing Tool . . . . . . . . . . . . . . 12

Installation of the Cutting Insert and the Tool Holder . . . 12

Installing the Collet Set. . . . . . . . . . . . . . . . . . . 13

Removing the Collet Set . . . . . . . . . . . . . . . . . . 13

Tube Facing Tool User’s Manual 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Adjusting for Tube Size. . . . . . . . . . . . . . . . . . . 14

Clamping the tube . . . . . . . . . . . . . . . . . . . . . 15

Removing the Tube. . . . . . . . . . . . . . . . . . . . . 15

Tool Speed Range . . . . . . . . . . . . . . . . . . . . . 15

Facing the Tube . . . . . . . . . . . . . . . . . . . . . . 16

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 18

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 19

Page 4

4 Tube Facing Tool User’s Manual

Page 5

Safety

Safety Summary

Read the entire safety information section and Tube

Facing Tool User’s Manual before using this product.

Failure to do so can result in serious injury or death.

Signal Words and Safety Alert Symbols

Used in this Manual

WARNING Statements that indicate a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION Statements that indicate a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

NOTICE Statements that indicate a hazardous situation

which, if not avoided, could result in damage to

the equipment or other property.

Tube Facing Tool User’s Manual 5

Safety alert symbol indicating a potential personal injury

hazard.

Safety alert symbol indicating a potential for personal

injury from electrical shock.

Safety Information

WARNING

Danger of death by electric shock

■ If the power cord is damaged, electrically live parts may

cause death if touched directly.

■ Do not allow the tool to run unattended.

■ The tool should be connected to a ground fault circuit

interrupt (GFCI) protected outlet.

■ Work on electrical equipment must be done by a

qualied electrician.

■ Switch off the tool, allow it to run until it stops rotating

and remove the plug from the power outlet before

changing tooling, maintaining, or transporting the tool.

Page 6

6 Tube Facing Tool User’s Manual

WARNING

Danger of eyes being injured by hot and sharp-edged

metal chips.

Eye protection must be worn while operating or working

near the equipment.

WARNING

Keep dry. Equipment and components are not

waterproof.

Do not use electric tools in a damp or wet environment.

WARNING

Fire or Explosion

Do not use in close proximity to ammable liquids or

gases.

WARNING

Danger of being injured by sharp cutting edges

■ Do not touch the cutting insert while the tool is

operating.

■ Wear safety gloves.

■ Do not remove chips or tubing from the work area

when the tube facing tool is still running and the

tool is not yet at rest.

■ Wear safety gloved to remove chips. Remove long

and bent chips with needle-nose pliers.

WARNING

Danger of being injured by rotating parts.

Keep hands, loose clothing, and long hair away from

rotating and moving parts.

Page 7

WARNING

Observe the following safety measures in order to

protect against risk of injury.

■ Inspect the tube facing tool daily for visible signs

of damage or defects. Have any damage or

defects repaired immediately.

■ Always ensure that the machine is in good working

order and comply with these notes on safety.

■ Only use the tube ODs, wall thickness, and

materials specied in these instructions. Other

materials should be used only after consulting

your authorized Swagelok representative.

■ Check that the work piece is correctly clamped.

■ Do not carry the tube facing tool by the power

cord and do not use the cord to pull out the plug.

Protect the cable from heat, oil and sharp edges

(chips).

■ Before and during the facing of tubing, ensure that

the viewing window is closed.

■ Always work with sharp cutting tools to reduce

vibrations.

■ Turn the tool off and wait until it stops rotating

when work is complete.

Tube Facing Tool User’s Manual 7

Environmental Protection/Disposal

■

Dispose of chips and used gear lubricant oil according to

local regulations.

Electric tools and accessories contain a large share of valuable

raw and synthetic materials, which can be recycled. Therefore:

■

Electrical (electronic) devices that are marked with the

symbol in Fig. 1, may not be disposed of with household

waste in accordance with European Union (EU) regulations.

■

By using local return and collection systems, you contribute

to the reuse, recycling and utilization of electrical (electronic)

devices.

■

Electrical (electronic) used devices contain parts, which

must be handled selectively according to EU regulations.

Separate collection and selective treatment is the basis for

environment-friendly disposal and the protection of human

health.

Fig. 1 RL 2002/96/EC Symbol

Page 8

8 Tube Facing Tool User’s Manual

Product Information

1

2

3

9

6

5

10

4

13

12

14

11

7

8

15

Fig 2 TF72 Series

1 Feed handle with scale divisions 9 Tube clamp adjustment dial

2 Housing 10 Tool holder and cutting insert

3 Viewing window 11 Bench mount bracket

4 ON/OFF switch 12 Collet locks

5 Collet guide 13 Tube clamps

6 Collet housing 14 Speed adjustment dial

7 Chip container 15 Motor

8 Tool mounting plate

Page 9

Accessories

TF Series Cutting Insert

The cutting insert is supplied and can be used with all TF series

tool holders.

Cutting Tool Holder for Beveling and Squaring

An adjustable tool holder is included with a Torx screw.

Additional tool holders with different bevel angels are available.

Stainless Steel Collet Set

These are used for deformation-free clamping of tubing. They

ensure precise mounting of tubing or Micro-Fit® ttings and a

quick change of collet sets without tools. For use on all tubing

materials with an OD from 1.00 to 4.50 in. (25.4 mm to 114 mm).

Tube Facing Tool User’s Manual 9

Fig 3 Cutting Insert

See Tube Facing Tools, MS-02-426, for additional information on the

optional accessories.

Fig 4 Cutting Tool Holder

Fig 5 Stainless Steel Collet Set

Page 10

10 Tube Facing Tool User’s Manua l

Specifications

Application range

Series TF72

Tube OD min. to max.

range

Wall thickness max 0.118 in. / 3.0 mm

Tube materials

■

Stainless steel

■

Nickel alloys - ex. Alloy 600, Alloy 625, Alloy 825

■

Aluminum

Contact your authorized Swagelok representative for information on additional materials.

Technical data

1/2 to 4 1/2 in. /

12to 114.3 mm)

Series TF72

Dimensions,

in. (mm)

Weight Without Accessories,

lb (kg)

Input voltage Single-phase alternating

Power, W 1100

Speed, r/min 0 to 52

Sound level (EN 23741), dB Approx. 83

Vibration level (EN 50144), m/s² 2.5

Service Current Requirement, A 10 minimum

20.7 W, 10.1 H, 8.9 D

(525 W, 256 H, 226 D)

22.5 (10.2)

current, protection class II

110 V 50/60 Hz

230 V 50/60 Hz

Page 11

Setup

Description

The tube facing tool is designed for facing and preparing tube

ends for welding in conformance with industry standards. It has

the following properties:

■

A cutting tool with multiple cutting edges. Only one cutting

tool is necessary for different tube wall thicknesses (up to

0.118 in./3 mm) and different tube materials (exclusively

ferrous materials).

■

A speed-controlled electric motor with speed stabilization

■

Restart protection to prevent the machine from starting in

an uncontrolled way after it has been reconnected to the

electrical power or after a power failure

■

A quick change system for collet sets

■

A feed dial with scale divisions:

Total travel: 0.591 in. (15 mm)

■

Travel per rotation: 0.118 in. (3 mm)

■

■

A viewing window that provides protection.

Tube Facing Tool User’s Manual 11

Page 12

12 Tube Facing Tool User’s Manual

Unpacking the Tube Facing Tool

Shipping Case Contents

■

1 Tube facing tool

■

1 Bench mount bracket

■

1 Tool holder with 1 cutting insert

■

1 Tool set (4 mm T-handle hex key, 3 mm hex key, T15Torx

driver)

■

1 User manual

Report any missing or damaged parts to your authorized

Swagelok representative immediately.

Installation of the Cutting Insert and the

Tool Holder

CAUTION

Do not touch the sharp cutting edges while mounting

the multifunctional tool. Wear protective gloves.

Cutting Insert

Attach the cutting insert to the tool holder with the curved side

of the insert away from the tool holder. Use the included T15

Torx driver to tighten the screw.

Tool Holder

CAUTION

Allow the tool to run until it stops rotating and

unplug the tool before changing tooling, performing

maintenance, or transporting the tool.

1. Install the tool holder into the guiding groove of the tube

facing tool housing.

2. Press the tool holder against the housing and tighten the set

screw using the 4 mm T-handle hex key.

Note: The tool holder must be ush with the housing.

The tool mounting plate offers different tool holder mounting

options, according to the size of the tube.

Fig 6 Installing the Cutting Insert

Fig 7 Installing the Tool Holder

1 in.

(25.4 mm)

2 in.

(50.8 mm)

3 in.

(76.2 mm)

Fig 8 Tool Mounting Plate

4 in.

(101 m m)

Page 13

Tube Facing Tool User’s Manual 13

Installing the Collet Set

1. Select the correct collet set according to the tube OD.

2. Move the tube clamp to the open position.

3. Place the lower collet in the housing at the collet guide. Slide

the lower collet clockwise until the collet locks lock into

place.

4. Place the upper collet in the housing at the collet guide.

Slide the upper collet counter clockwise until the collet locks

lock into place.

Removing the Collet Set

To remove a collet set, pull the collet locks until the collet set

can be removed.

Collet guide

Tube clamp

Collet locks

Fig 9 Install the Lower Collet

Collet guide

Fig 10 Install the Lower Collet, close-up

Fig 11 Install the Upper Collet

Page 14

14 Tube Facing Tool User’s Manual

Operation

The tool should only be operated using a ground fault circuit

interrupt (GFCI) protected outlet.

Adjusting for Tube Size

The TF72 series can be adjusted using the tube clamp

adjustment dial to compensate for variations in tube tolerances.

The adjustment dial has three marks: • (the factory setting), +,

and -.

The adjustment options are as follows:

Position of tube

clamp

Adjustment

required

towards:

Tube size is

nominal.

Position of the

tube clamp is

correct.

• - +

Tube size is

smaller than

nominal.

The tube clamp

rests on the

tool frame and

will not clamp

tube.

Tube size is

larger than

nominal.

The tube

clamp cannot

be lowered.

1. Lift the tube clamp and remove the tube, if necessary.

2. Loosen the socket screw on the tube clamp adjustment dial

using the provided 4 mm T-handle hex key.

3. Turn the tube clamp adjustment dial in the needed direction.

Allow the pin the engage into the adjustment dial.

4. Tighten the socket screw on the tube clamp adjustment dial

using the provided 4 mm T-handle hex key.

Fig 12 Tube Clamp Adjustment Dial

Fig 13 Loosening the Socket Screw

Page 15

Clamping the tube

CAUTION

Support long pieces of tubing with suitable fixtures.

Injury from tilting tool and/or tilting tubing could

result.

CAUTION

Verify that the tube facing tool is not rotating before

clamping the tube.

NOTICE

The cutting tool can be damaged by incorrect set

up. Before clamping the tube, verify there is space

between the cutting insert and the tube.

1. Open the collets by lifting the tube clamp counterclockwise

until it stops to open the collets.

2. Insert the tube in the collet set of the tube facing tool.

3. Secure the tube by lowering the tube clamp clockwise until

it stops.

Note: Clamp the tube squarely, ensuring that the tube and the

face of the collet set are perpendicular to each other. The

tube end will not have a right angle cut when this is not

true.

Tube Facing Tool User’s Manual 15

Tube clamp

Fig 14 Clamping the Tube

Removing the Tube

To remove the tube from the facing tool, lift the tube clamp until

it stops.

Tool Speed Range

Adjusting the Speed

Set the speed by turning the speed dial.

TF72

Level Tube OD,

in. (mm)

D 1.0 (25.4)

C 1.5 (38.1)

C 2.0 (50.8)

B 2.5 (63.5)

B 3.0 (76.2)

A 3.5 (88.9)

A 4.0 (102)

A 4.5 (114)

Fig 15 Speed Dial

Page 16

16 Tube Facing Tool User’s Manua l

Facing the Tube

WARNING

Allow the machine to run until it stops rotating after

cutting tube to avoid injury.

WARNING

Do not touch the tool holder or cutting insert while

the tool is in operation.

WARNING

Only operate the tool with a clamped tube and a

closed viewing window.

WARNING

Eye protection must be worn while operating or

working near the equipment.

WARNING

Keep hands, loose clothing, and long hair away from

rotating and moving parts.

WARNING

Wear safety gloves to remove chips. Remove long

and bent chips with needle-nose pliers or a similar

tool.

NOTICE

Excessive feed of the cutting insert into the tube

can damage the cutting tool or cause the tool to

overheat.

NOTICE

Verify there is space between the cutting tool

and the tube before clamping the tube to prevent

damage to the cutting tool. The cutting tool can be

damaged by a tube not cut at a right angle.

NOTICE

If speed is reduced too quickly, the tool may “dig”

into the tube, causing damage to the tube face and

the tool, and may cause the tool to stop. Reduce the

feed rate of the cutting insert and the tool speed

gradually.

Page 17

NOTICE

Verify the motor is in drill mode if the motor is

equipped with a hammer mode. Operating the tool in

hammer mode will cause damage to the tool and the

tube.

Turning “On” the TF72 Series

1. Check that the viewing window is closed, close if necessary.

2. Set the desired speed via the speed adjustment dial.

3. Activate the ON/OFF switch.

Note: If the tool vibrates after starting, the cutting speed is

too high. Reduce the speed according to Adjusting the

Speed.

Facing the Tube

■

Each division on the feed dial with scale adjustments equals

an advancement of 0.002 in. (0.05 mm).

■

It is recommended not to exceed a chip thickness of 0.002

in. (0.05 mm) while facing the tube. Excessive feed levels will

reduce the speed or stop the machine.

1. Slowly advance the cutting insert until it is in contact with

the tube.

2. Continue advancing the cutting insert until the desired result

is achieved.

Note: To achieve the optimum squareness and nish, the

tool should be allowed to rotate for 2 to 3 revolutions

without further advancement of the cutting insert.

3. Release the ON/OFF switch.

4. Remove the tube by turning the tube clamp

counterclockwise until it stops.

Tube Facing Tool User’s Manual 17

Page 18

18 Tube Facing Tool User’s Manua l

Maintenance

CAUTION

Allow the tool to run until it stops rotating and

unplug the tool before changing tooling, maintaining,

or transporting the tool.

When cleaning the tube facing tool, clear the collet set and tool

body of debris and dirt.

When changing the cutting insert, clean the tool holder and

inspect it for damage.

Breakaway Nut Replacement

Note: The ordering number for a replacement breakaway nut is

MS-TF-ADAPTER-2.

1. Verify the tool is unplugged.

2. Loosen the M5 × 16 set screw using the provided 4 mm hex

key.

3. Remove the collet housing half of the tool.

4. Remove the breakaway nut using a 19 mm deep-socket

rachet wrench.

5. Install the new breakaway nut. Securely tighten the

breakaway nut to the motor shaft.

6. Replace the collet housing half and tighten the M5 × 16 set

screw.

Fig 16 Loosening the Set Screw

Fig 17 Removing the Collet Housing

Half of Tool

Fig 18 Removing the Breakaway Nut

Fig 19 Breakaway Nut Removed from

Tool

Page 19

Troubleshooting

Problem Cause Remedy

The cutting insert has been

Cutting insert is causing a

“step” during facing.

The tube clamp does not

clamp correctly or has too

much play.

The motor is not running but

signal light is on.

Tool has excessive vibration.

The finished tube face is not

smooth or has a large burr.

fed too far into the tube.

Cutting insert or tool holder

is loose.

The tube dimensions

deviate from what the tool

has been set for.

Quick flashing light -

The restart inhibitor has

activated.

Slow flashing light - The

carbon brushes are worn

out.

Constant light - The motor

has overheated.

Speed is too high. Reduce the speed.

Axial or radial play in the

components.

Cutting insert is loose. Tighten the cutting insert.

Cutting insert is worn. Replace the cutting insert.

Tube Facing Tool User’s Manual 19

Take tube out of the tool and

disassemble the tool holder.

Remove chips using pliers. File down

the step.

Slowly advance the cutting insert

towards the tube during new cutting.

Tighten the cutting insert or the tool

holder.

Adjust the tool according to Adjust the

Tube Clamp.

Switch the tool off and back on. For

safety reasons, the tool will not restart

automatically after a power failure.

Have the carbon brushes replaced by

your authorized Swagelok sales and

service representative.

Unplug the tool and allow it to cool.

Check that the collet set is properly

secured.

Page 20

Warranty Information

Swagelok products are backed by The Swagelok Limited

Lifetime Warranty. For a copy, visit swagelok.com or

contact your authorized Swagelok Representative.

Swagelok, Micro-Fit—TM Swagelok Company

© 2011 Swagelok Company

Printed in U.S.A ., OM

April 2011, R0

MS -13-215

Loading...

Loading...