Page 1

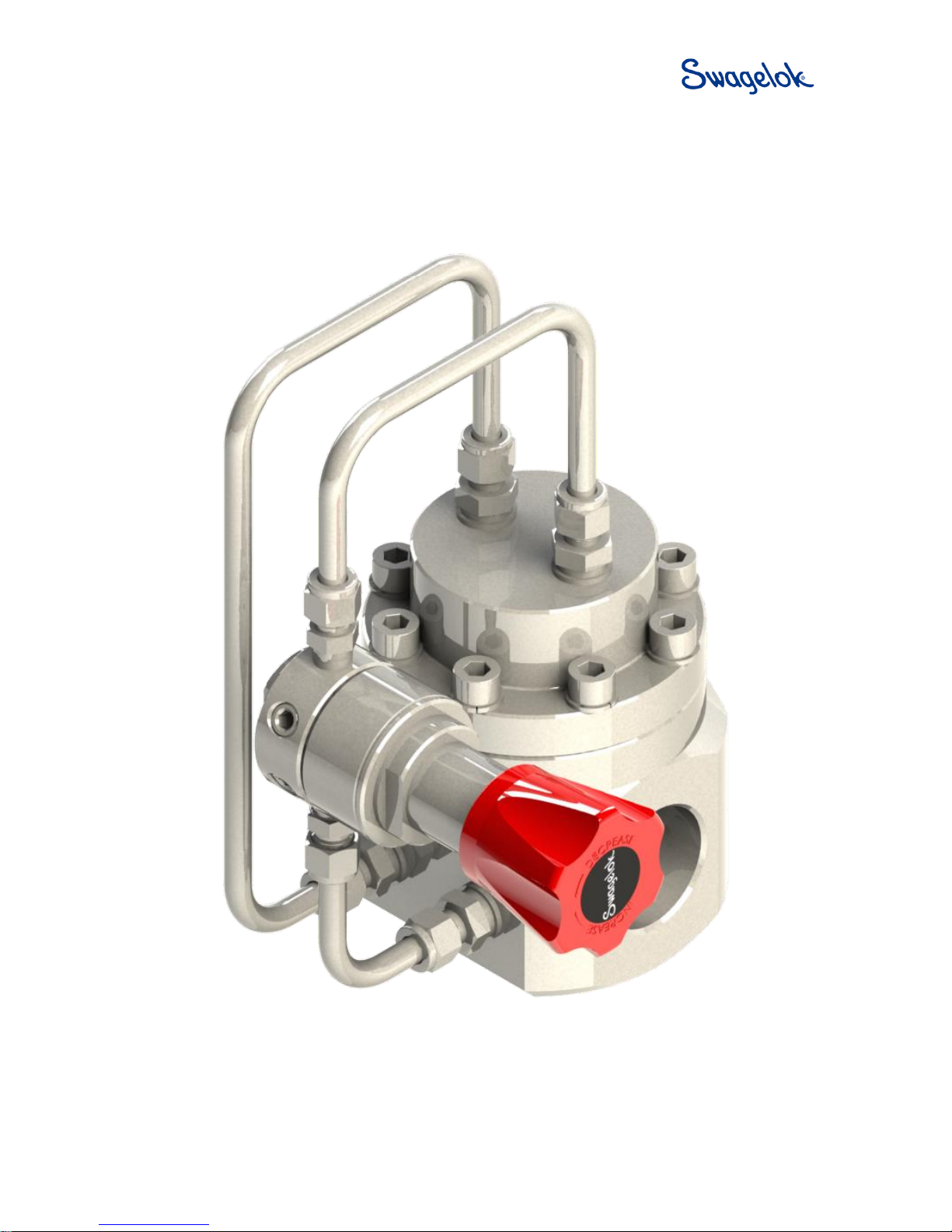

RD(H)10/15 Pressure-Reducing Regulator

User Manual

Read the complete manual before installing and using the regulator.

Page 2

2

Safe Product Selection

When selecting a product, the total system design must be considered to ensure safe, trouble-free

performance. Function, material compatibility, adequate ratings, proper installation, operation, and

maintenance are the responsibilities of the system designer and user.

WARNING

• Users must be trained and equipped for the handling, use and servicing of pressure

products and systems.

• Users must contact their gas or liquid supplier for specific safety precautions and

instructions.

• Gaseous media should be free of excessive moisture to prevent icing at high flow.

• Always wear the appropriate protective clothing, including safety glasses, gloves, etc. if

required.

• Follow the applicable safety and maintenance procedures.

• Obey specific local regulations.

• Do not exceed the maximum inlet and outlet pressure rating of the product or its

accessories.

• Operate within the temperature limits and any other conditions specified for the product.

• Do not drop or damage the product in any other way. This may negatively affect the

performance of the product which can cause the product to malfunction.

• Venting fluids and gases can be dangerous. Vent to a safe environment away from people.

Ensure adequate ventilation.

Page 3

3

Contents

Introduction ........................................................................................................................................................ 4

Overview.......................................................................................................................................................... 4

Standard Features ........................................................................................................................................... 4

Additional Options ........................................................................................................................................... 4

Oxygen Service ............................................................................................................................................... 4

Installation .......................................................................................................................................................... 5

Points of Attention Before Installation ............................................................................................................. 5

Installation ....................................................................................................................................................... 5

Dome Pressure Control ................................................................................................................................... 6

External Feedback .......................................................................................................................................... 9

Operation .......................................................................................................................................................... 10

Required Tools for Operation ........................................................................................................................ 10

Points of Attention Before Operation ............................................................................................................. 10

Adjusting the Set Pressure ............................................................................................................................ 10

Maintenance ..................................................................................................................................................... 11

Required Tools for Maintenance ................................................................................................................... 11

Points of Attention Before Removal from the System ................................................................................... 12

Removal from the System ............................................................................................................................. 12

Assembly Reference Data............................................................................................................................. 13

Disassembly .................................................................................................................................................. 18

Points of Attention Before Reassembly ......................................................................................................... 18

Reassembly ................................................................................................................................................... 19

RD(H)10 Series: Standard ............................................................................................................................ 19

RD(H)15 Series: Standard ............................................................................................................................ 19

External Feedback Option ............................................................................................................................. 19

Testing .............................................................................................................................................................. 20

Seat Leak Test .............................................................................................................................................. 20

Shell Leak Test .............................................................................................................................................. 20

Troubleshooting .............................................................................................................................................. 21

Page 4

4

Introduction

Overview

- The RD(H)10 and RD(H)15 series are dome loaded pressure reducing regulators designed for the

regulation of high pressure, high flow gases and liquids.

- For pressure and temperature rating information refer to the Pressure Regulators, RHPS Series catalog,

MS-02-430. Note that seat seal material selection can limit the regulator operational pressure at elevated

temperatures.

WARNING

Check that system pressures and temperatures do not exceed those stated on the regulator as

this could result in product failure.

Standard Features

- Bolted construction

- Stainless steel as standard

- Fully serviceable

- Diaphragm sensing

- Balanced poppet

- Pilot regulator

- Dynamic regulation

Additional Options

The regulator is available with the following options:

- External feedback to main regulator

- External feedback to pilot regulator

- Anti-tamper pilot regulator

Oxygen Service

- For more information about hazards and risks of oxygen enriched systems see the Swagelok Oxygen

System Safety technical report (MS-06-13).

- Cleaning and packaging to ensure compliance with product cleanliness requirements stated in ASTM G93

Level C is available. Refer to the Pressure Regulators, RHPS Series catalog, MS-02-430, for additional

information.

Page 5

5

Installation

CAUTION

Do not use the regulator as a shutoff device. A level of leakage across the regulator seat can

occur during normal operation.

Points of Attention Before Installation

This regulator can be equipped with a variety of different options. Before installing the regulator you should

fully understand the functions of the supplied options and the suitability of your particular regulator for the

intended application.

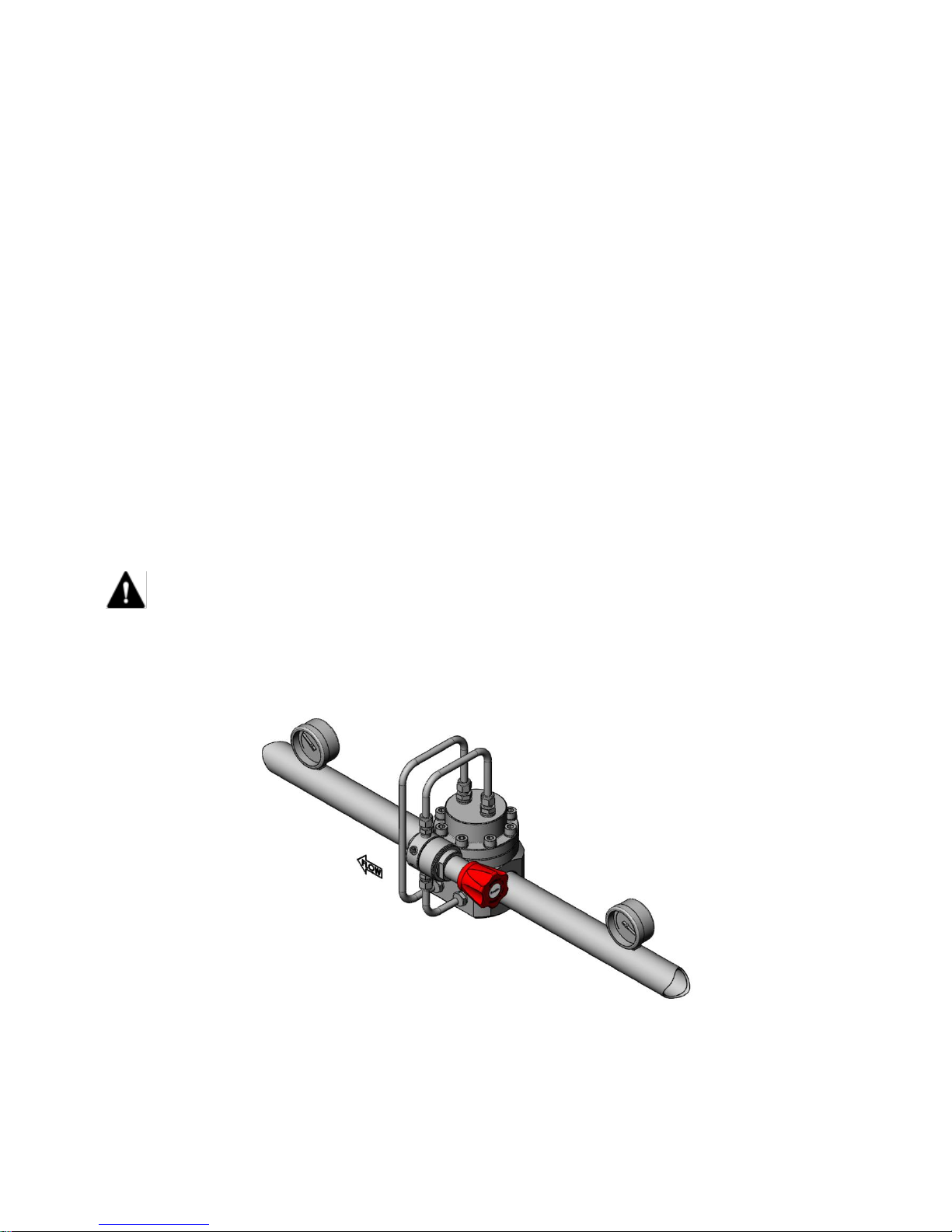

- The preferred mounting position of the regulator is horizontal with the dome facing upwards per Fig 1.

Alternative mounting positions may increase the risk of component wear.

- It may be necessary to remove the regulator from the system during maintenance or service. Ensure that

this is possible.

- The regulator is suitable for gases and liquids dependent on the options selected. For liquid applications

an integral pilot regulator should not be used. Ensure compatibility between the regulator’s materials of

construction and the system media.

- Swagelok recommends the use of a non-venting pilot regulator when the process media is hazardous or

toxic.

Installation

- Verify that the regulator, the connections and its accessories are undamaged.

- Verify that the regulator and its accessories are suitable for the system operating pressure and

temperature and have suitable connections.

- At the time of delivery any gauge ports may be plugged with blind fittings. Remove these and connect

gauges if desired.

- If inlet/outlet fittings are being used, assemble them to the regulator, per the manufacturer’s instructions,

prior to installing the regulator in the system.

CAUTION

Ensure all upstream tubing/pipework is clean and free from debris. Any swarf, lint, wire, etc. may

damage the regulator, resulting in a seat leak.

- Verify the flow direction of the system and mount the regulator accordingly.

- Securely make the appropriate connections to the regulator in accordance with the procedures

recommended by the connection manufacturer.

- Ensure that the tubing/pipework and the regulator are adequately supported and that there is no stress on

the connections.

- Upstream and downstream shutoff valves should be installed in the system to facilitate servicing,

maintenance and troubleshooting of the regulator.

WARNING

When using an RDH10 or RDH15 with an inlet pressure higher than 3625 psig (250 bar), a safety

valve must be installed in the outlet line to ensure the outlet pressure does not exceed 3625

psig (250 bar), which could result in product failure.

Page 6

6

Dome Pressure Control

The dome pressure of the regulator controls the outlet pressure. There are several methods available for

supplying and controlling the dome pressure.

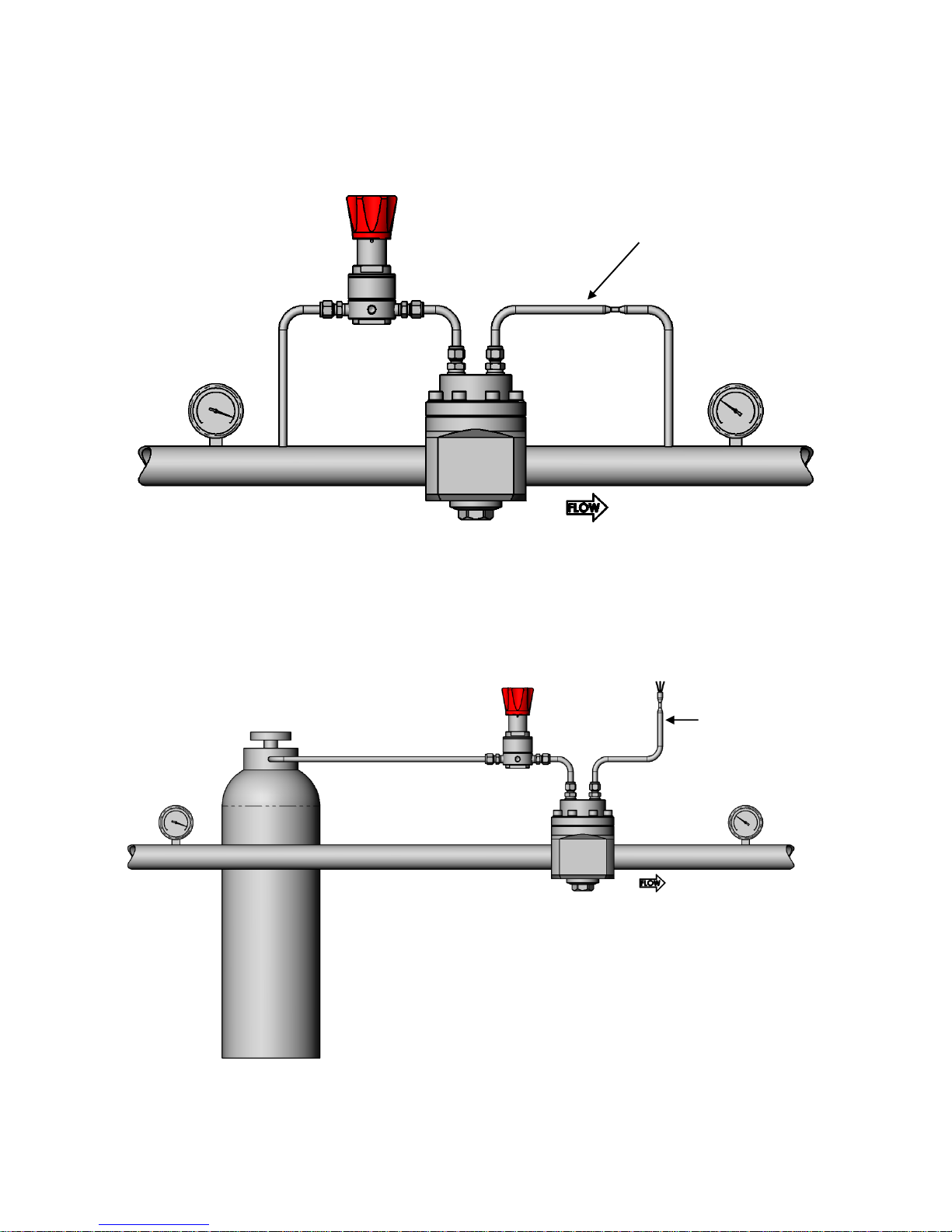

- Integral pilot control. In this setup the dome loaded regulator comes supplied with a pilot regulator as

part of the assembly (Fig 1). The pilot regulator, fed from the system pressure, is manually operated to

control the dome pressure (Fig 2). This setup is not suitable for liquid applications.

- External dome control. In this setup the dome pressure is supplied from an independent source, such as

a cylinder or mains supply (Fig 3). This setup is suitable for liquid applications.

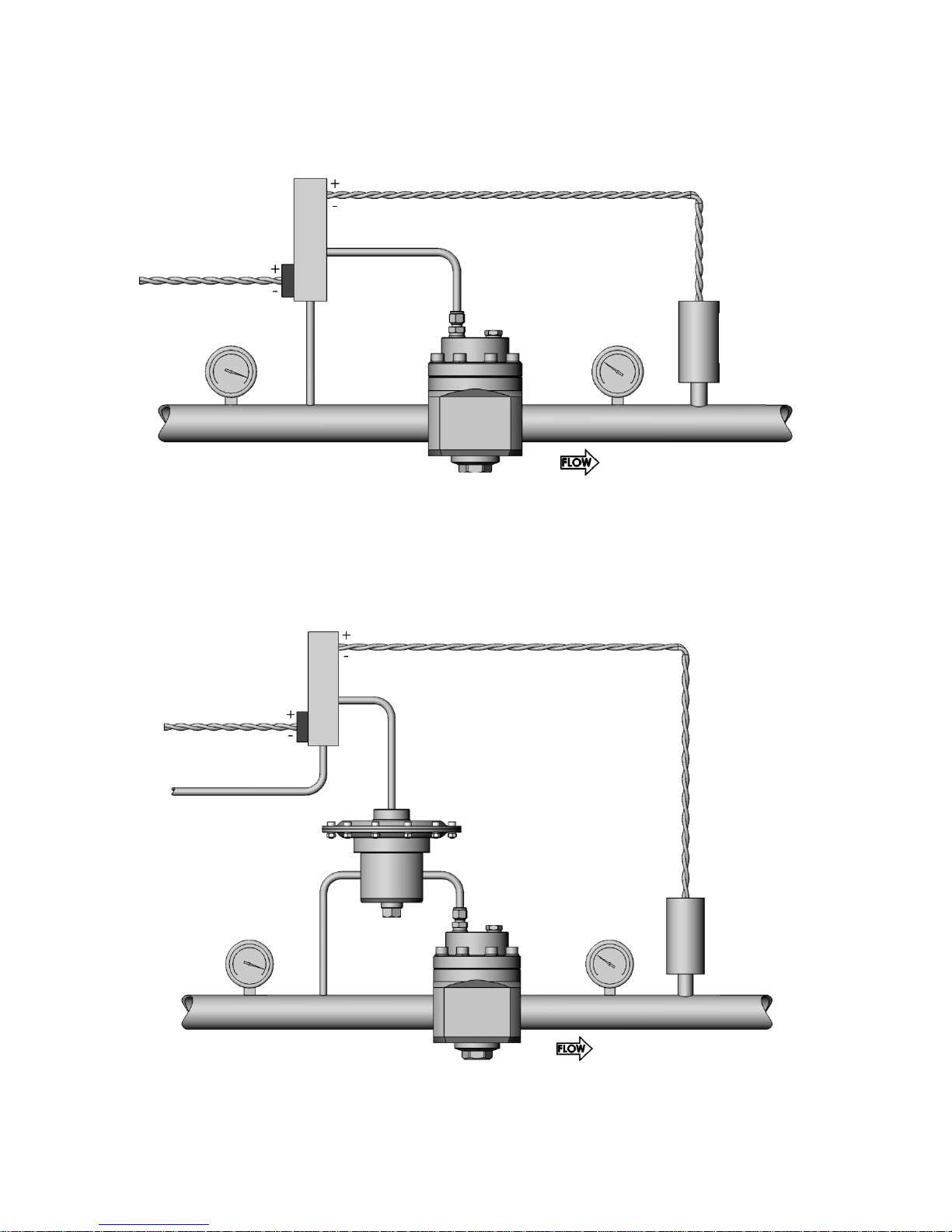

- Electronic control. In this setup an electronic pilot regulator, fed from the system pressure, is used in

conjunction with a pressure transducer to directly control the dome pressure (Fig 4). The outlet pressure

of the main regulator will be limited by the outlet pressure of the electronic regulator. This setup is not

suitable for liquid applications.

- Ratio control. In this setup a ratio pilot regulator, fed from the system pressure, is used to control the

dome pressure. The ratio pilot can be controlled by an electronic regulator and pressure transducer

combination (Fig 5) or by an external dome feed. The ratio pilot outlet pressure is proportionally larger

than its sensing pressure. This enables the main regulator to achieve full outlet pressure while being

controlled from a low pressure supply. This setup is not suitable for liquid applications.

The best performance will be achieved by allowing a small flow to continuously pass through the pilot

regulator. This flow can either be vented through an orifice (Fig 3) or, in gas systems, fed back through an

orifice into the downstream piping (Fig 2). This is usually referred to as “dynamic regulation”.

NOTICE

It is not recommended to place a gauge on the dome to set or check the outlet pressure.

Because of forces in the regulator, the dome pressure will differ slightly from the outlet

pressure. Place a gauge in the outlet line to set or check the outlet pressure.

Integral Pilot Assembly

Fig 1

Page 7

7

Integral Pilot Control Schematic

Fig 2

External Dome Control Schematic

Fig 3

Pilot regulator

“Dynamic Regulation”

venting to the outlet line

Dome regulator

Pilot regulator

“Dynamic Regulation”

venting to atmosphere

Dome regulator

Cylinder or

mains supply

Page 8

8

Electronic Control Schematic

Fig 4

Ratio Control Schematic

Fig 5

Electronic

pilot regulator

4-20mA/0-10V

4-20mA/0-10V

Dome regulator

Pressure

transducer

Ratio regulator

Electronic

pilot regulator

4-20mA/0-10V

4-20mA/0-10V

Dome regulator

Pressure

transducer

Page 9

9

External Feedback

The purpose of external feedback is to provide a more accurate and stable regulation of the outlet pressure.

This is achieved by sensing the outlet pressure downstream of the regulator and feeding it back to the

regulator’s sensing element.

- The external feedback line is to be connected in a turbulence-free zone in the downstream piping, at a

maximum distance of 5x the outside diameter of the downstream tubing/piping (Fig 6).

- The tube size of the external feedback should be 3/8 in. or 1/2 in. or the metric equivalent.

CAUTION

When using a regulator with external feedback, ensure that the outlet line is connected to the

external feedback port before applying pressure to the regulator. Failing to do so may lead to

damage and non-functioning of the regulator and no pressure regulation will occur.

CAUTION

Never connect the external feedback line downstream of a shut-off valve. Doing so may lead to

damage and non-functioning of the regulator and no pressure regulation will occur.

External Feedback Schematic

Fig 6

Shutoff valve

Shutoff valve

Inlet

pressure

Dome

pressure

Outlet

pressure

Max. 5X O.D.

O.D

External feedback line

Page 10

10

Operation

Required Tools for Operation

No tools are required for changing the set pressure on a standard regulator.

Points of Attention Before Operation

CAUTION

The product can be hot or cold, depending on the environmental temperature and the process

media temperature. Take the necessary precautions before operating or touching the product.

- Stopping flow through the regulator by closing a downstream shutoff valve may result in a rise in outlet

pressure above the set pressure. This is usually referred to as “lock-up”. This phenomenon does not

indicate a problem with the regulator.

- A decrease of the flow rate may result in a rise of the outlet pressure. An increase of the flow rate may

result in a fall of the outlet pressure. This is usually referred to as “droop”. This phenomenon does not

indicate a problem with the regulator.

- A decrease of the inlet pressure may result in a rise of the outlet pressure. An increase of the inlet

pressure may result in a fall of the outlet pressure. This is usually referred to as “inlet dependency” or

“Supply Pressure Effect (SPE)”. This phenomenon does not indicate a problem with the regulator.

Adjusting the Set Pressure

- The set pressure is the desired outlet pressure of the regulator.

- To set the regulator, ensure that the supply pressure is greater than the required set pressure but does

not exceed the maximum rating of the regulator.

- The regulator must be able to flow in order for it to reduce the outlet pressure.

1. Partially open any downstream valve. This will allow minimal flow through the regulator when adjusting the

set pressure, reducing media consumption during this process.

2. Ensure there is zero pressure in the dome.

3. Steadily open the supply valve to allow inlet pressure to the regulator.

4. To operate the regulator, turn the pilot adjustment knob clockwise to increase the set pressure. Turn the

knob counterclockwise to reduce the set pressure.

5. To obtain the most accurate set pressure, final adjustment must be made while increasing the set

pressure. If the desired outlet pressure is exceeded, reduce the pressure below this value then increase

up to it.

6. Fully open the downstream valve to allow full flow during operation.

7. Once under flow conditions make any final set pressure adjustments per steps 3 and 4 if required.

NOTICE

The pilot regulator knob assembly is retained by a C-ring. When backing off the knob do not

attempt to continue to unwind the knob once it has stopped. Doing so may damage the C-ring.

Page 11

11

Maintenance

WARNING

Incorrect or improper repair or servicing of this product can cause serious personal injury and

property damage.

- All repairs, servicing and testing of this product must be performed by competent personnel.

- Following any maintenance of the regulator, it is recommended that the product be tested for operation

and leakage.

- The product should be checked periodically for proper and safe operation. It is the user’s sole

responsibility to determine the frequency of maintenance based on the application.

- To reduce maintenance related system downtime to a minimum, either during commissioning or normal

operation, Swagelok recommends having maintenance kits readily available on site. The need for

maintenance kits is particularly important during the commissioning phase of a system installation due to

residual assembly debris remaining in the system. Such debris can cause a seat leak in the regulator,

resulting in components needing to be replaced.

Required Tools for Maintenance

Smooth-jawed vise

Calibrated torque wrench up to

37 lbf·ft (50 N·m)

36 mm socket

Seat mounting tool:

RHPS-10-SEAT-TOOL

RHPS-15-SEAT-TOOL

Appropriate wrenches

for disassembling tube

fittings

Lubricant (included in kit):

WL-8①

Krytox® 240 AC②

8 mm hex drive

Liquid leak detector

C-ring pliers

① Standard cleaned assemblies

② ASTM G93 or SC11 cleaned assemblies

Table 1

Page 12

12

Points of Attention Before Removal from the System

- Swagelok recommends removing the regulator from the system for servicing and maintenance.

- Follow all local system safety and maintenance procedures when removing the regulator.

WARNING

Before removing a regulator from the system, to avoid personal injury, you must:

• Depressurize the system and dome.

• Purge the system to remove any residual system media left in the regulator.

• Always vent to a safe environment away from people and ensure there is adequate

ventilation.

CAUTION

Check if the process media is hazardous or toxic. If required, take the necessary safety

precautions to ensure a safe workspace and your personal safety.

CAUTION

The product can be hot or cold, depending on the environmental temperature and the process

media temperature. Take the necessary precautions before operating or touching the product.

Removal from the System

1. Isolate the regulator from all pressure sources by closing all appropriate upstream valves in the system.

2. With the pilot regulator set, open all appropriate downstream valves to allow pressure to vent from the

regulator.

WARNING

Ensure all pressure on the inlet, outlet and dome has been fully vented. The accidental release

of residual trapped pressure can cause serious personal injury.

3. Ensure appropriate lifting equipment is available to enable the regulator to be supported and handled

once disconnected from the system.

4. Ensure that any external dome feed and/or external feedback connection is disconnected.

5. Disconnect and remove the regulator from the system.

Page 13

13

Assembly Reference Data

Item

Component Name

Kit Type(s)

Torque

lbf·ft (N·m)

Recommended Lubrication

(included in kit per table 1)

1

Body plug

C1, C2

37 (50)

Lubricate threads

2

Body plug O-ring

B1, B2, C1, C2

3

Poppet spring

C1, C5

4

Poppet backup ring

A1①, A2①, B1, B2,

C1

5

Poppet O-ring

A1①, A2①, B1, B2,

C1, C2②

Lubricate

6

Poppet

A1, A2, B1, C1

7

Seat

A1, B1, C1

RD(H)10 - 7 (10)

Lubricate threads

RD(H)15 - 11 (15)

8

Seat O-ring

A1, B1, B2, C1

9

Body

N/A

10

Body plate

C1

11

Body plate outer O-ring

B1, B2, C1

12

Body plate inner O-ring

B1, B2, C1

Lubricate

13

Retaining ring

C1

14

Diaphragm plate

C1

15

Diaphragm

B1, B2, C1, C3

16

Dome plate

N/A

17

Dome

N/A

18

BSP blind plug O-ring

B1, B2, C1

19

Blind plug

N/A

NPT: 15 (20)

Wrap threads in 2 layers of

PTFE tape. Lubricate tape.

BSP: 26 (35)

Lubricate threads

20

Washer

E1

21

Cap screw

E1

22 (30)

Lubricate threads

22

Parallel gasket

B1, B2, C1

23

Bleed fitting (reduced

orifice)

N/A

Per manufacturer instructions

24

Tube fitting

N/A

Per manufacturer instructions

25

Bleed tube

N/A

26

Feed tube

N/A

27

Pilot regulator

N/A

28

Dome tube

N/A

① RD(H)10 series only

② RD(H)15 series only

Table 2

For more information on RHPS series maintenance kits, refer to the Pressure Regulators, RHPS Series

catalog, MS-02-430.

Page 14

14

RD(H)10 and RD(H)15 Series, Exploded View

Fig 7

Page 15

15

Integral Pilot Regulator Assembly, Exploded View

Fig 8

Page 16

16

RDH10 Series, Standard, Section View

`

Fig 9

Page 17

17

RD15 Series, External Feedback Option, Section View

Fig 10

Page 18

18

Disassembly

- The following instructions describe how to fully disassemble the regulator for the purposes of

maintenance and repair.

- Note that not all components listed appear in all regulator configurations.

- Only disassemble the regulator as far as is required to replace the components supplied in the

maintenance kit.

- Discard all components being replaced.

1. If present remove the feed tube (26), dome tube (28), bleed tube (25), and pilot regulator (27).

2. Remove the body plug (1), poppet spring (3), and poppet (6) from the body (9).

3. Remove the body plug O-ring (2), poppet O-ring (5) and, if present, poppet backup ring (4) from the body

plug (1) and poppet (6).

4. Using the seat insertion tool, remove the seat (7) and seat O-ring (8).

5. Remove the cap screws (21) to remove the dome (17), dome plate (16), diaphragm (15), and diaphragm

plate (14).

6. Remove the retaining ring (13) to remove the body plate (10). For external feedback regulators remove

the inner (12) and outer (11) body plate O-rings.

Points of Attention Before Reassembly

- Visually inspect all components for abnormal wear or damage. Replace components in case of doubt.

- All parts must remain clean and undamaged before starting assembly.

- Maintenance kit components will be supplied preassembled where practicable to aid reassembly.

- Swagelok recommends replacing all O-rings removed during disassembly.

- Swagelok recommends that dynamic O-rings should be lightly lubricated per Table 2.

NOTICE

All threaded components must be lightly lubricated per Table 2 before reassembly to avoid

galling of threads.

Page 19

19

Reassembly

RD(H)10 Series: Standard

1. Fit the body plate (10) into the body (9) and retain with the retaining ring (13).

2. Fit the seat O-ring (8) into the body (9) and ensure that it is seated all the way round.

3. Lightly lubricate the seat threads (7) then insert the seat (7) into the body (9) using the seat insertion tool.

4. Torque the seat (7) to 7 lbf·ft (10 N·m). Take care not to pinch the seat O-ring (8) or damage the seat (7)

with the tool.

5. Fit the poppet O-ring (5) and, if present, backup ring (4) onto the poppet. Ensure they are oriented

correctly per Fig 9.

6. Lightly lubricate the poppet O-ring (5) then insert the poppet (6) through the seat (7) and body plate (10).

Take care not to damage either the seat (7) or poppet (6).

7. Place the poppet spring (3) onto the poppet (6).

8. Fit the body plug O-ring (2) onto the body plug (1) and lightly lubricate the body plug threads.

9. Insert the body plug (1) into the body (9) over the poppet spring (3). Torque to 37 lbf·ft (50 N·m).

10. Place the diaphragm plate (14) onto the poppet (6).

11. Place the diaphragm (15) onto the diaphragm plate (14) and locate it in the body (9).

12. Place the dome plate (16) centrally onto the diaphragm (15) then cover with the dome (17). Orient the

dome ports per Fig 8.

13. Lightly lubricate the cap screw threads (21) then use them and the washers (20) to secure the dome (17)

to the body (9). Torque to 22 lbf·ft (30 N·m).

14. If present, install the feed tube (26), dome tube (28), and pilot regulator (27) into the ports on the inlet side

of the body (9) per Fig 8.

15. If present, install the bleed tube (25) into the ports on the outlet side of the body (9) per Fig 8. Note that

the bleed fitting (23) can be identified by its reduced internal orifice.

16. If present, make up all tube fittings (23, 24) per the manufacturers recommendations.

RD(H)15 Series: Standard

1. Follow steps 1 through 3 of the RD(H)10 series standard reassembly procedure.

2. Torque the seat (7) to 11 lbf·ft (15 N·m). Take care not to pinch the seat O-ring (8) or damage the seat (7)

with the tool.

3. Fit the poppet O-ring (5) into the body plug (1).

4. Follow steps 6 through 16 of the RD(H)10 series standard reassembly procedure.

External Feedback Option

1. Fit the inner (12) and outer (11) body plate O-rings onto the body plate (10). Lightly lubricate the inner

body plate O-ring (12).

2. For size 10 regulators follow the RD(H)10 series standard reassembly procedure.

3. For size 15 regulators follow the RD(H)15 series standard reassembly procedure.

Page 20

20

Testing

Swagelok recommends that the regulator be tested for seat and shell leakage to atmosphere. A well

performing regulator will not show any indication of leaking. If any evidence of a leak is identified this must be

rectified. Any damaged components must be replaced.

Seat Leak Test

1. Ensure there is sufficient supply pressure to the regulator to be able to perform the tests.

2. Ensure that there is zero pressure in the dome.

3. Maintain an inlet pressure of approximately 14.5 psig (1 bar) on the regulator and close the downstream

shutoff valve.

4. Monitor the outlet pressure. An increase in pressure over time indicates a seat leak.

5. Repeat the procedure with the highest inlet pressure applicable for the regulator and system.

Shell Leak Test

1. Maintain an inlet pressure of approximately 29 psig (2 bar) on the regulator and close the downstream

shutoff valve.

2. Increase the outlet pressure to approximately 14.5 psig (1 bar).

3. Using liquid leak detector, check for bubbles at the dome to body interface and the body plug to body

interface.

4. Repeat the procedure with the highest inlet and outlet pressure applicable for the regulator and system.

Page 21

21

Troubleshooting

Symptom

Cause

Remedy

The outlet pressure creeps up,

without adjusting dome pressure.

A damaged poppet or seat.

Replace the poppet and/or seat.

Leakage around the body plug.

A damaged O-ring.

Replace the O-ring.

Leakage between the body and

the dome.

A damaged diaphragm.

Replace the diaphragm.

Insufficient torque on the cap

screws.

Tighten the cap screws per Table 2.

Controlled pressure drops off

sharply even when the flow is

within regulator capabilities.

The system filter element is

clogged.

Replace the system filter.

The required outlet pressure

cannot be reached.

The inlet pressure to the

regulator is not high enough.

Ensure that the inlet pressure to the

regulator is equal to or greater than the

desired set pressure.

The outlet pressure rises too

much when going from a dynamic

to a static situation.

There is too much flow in the

dynamic situation.

A larger regulator or parallel regulator is

required.

Review application flow capacity and

contact your local Swagelok distributor.

The outlet pressure does not drop

when the pressure in the dome is

lowered.

The regulator is non-venting.

A shutoff valve in the outlet line must be

opened to reduce the outlet pressure.

The outlet pressure has changed

without adjusting the dome

pressure.

Changes to the inlet pressure

may result in changes to the

outlet pressure.

Maintain a constant inlet pressure to the

regulator. See “Points of Attention

Before Operation” about dependency.

Changes to the flow may

result in changes to the outlet

pressure.

Maintain a constant flow through the

regulator. See “Points of Attention

Before Operation” about droop.

No pressure regulation occurs

with an external feedback

regulator

The outlet line has not been

connected to the external

feedback port.

Connect the outlet line to the external

feedback port. See External Feedback

for installation details.

Table 3

Page 22

22

Page 23

23

Page 24

Warranty Information

Swagelok products are backed by The Swagelok Limited Lifetime Warranty.

For a copy, visit swagelok.com or contact your authorized Swagelok representative.

Swagelok, Snoop - TM Swagelok Company

Krytox – TM The Chemours Company

© 2018 Swagelok Company

July 2018, RevC

MS-CRD-0180

Loading...

Loading...