Swagelok MS-TBE-2 series, MS-BTB-M series, MS-TBE-1 series, MS-BTB-2 series, MS-BTB-1 series User Manual

Page 1

Bench Top Tube Bender

User’s Manual

■

Electric and manual units

■

Bends fractional and metric tubing

■

CE compliant

Page 2

2 Bench Top Bender User’s Manual

Contents

Safety Instructions ........................... 2

Technical Data .............................. 2

Tubing Data ................................. 3

Bend Layout ................................ 4

Manual Bender

Product Information .......................... 6

Setup ...................................... 7

Calibration .................................. 8

Unloading the Bender ......................... 9

Operation .................................. 10

Electric Bender

Product Information .......................... 11

Setup ...................................... 12

Calibration .................................. 14

Unloading the Bender ......................... 14

Operation .................................. 15

Measuring the Bend Angle ....................... 16

Bend Data Tables

Fractional Tubing ............................ 17

Metric Tubing ................................24

Fractional Tubing with Metric Dimensions ......... 30

Minimum Length of Last Leg

Fractional Tubing .............................37

Metric Tubing ............................... 38

Fractional Tubing with Metric Dimensions ......... 39

Maintenance .................................. 40

Replacement Parts ............................. 41

Accessories .................................. 43

Troubleshooting ............................... 44

Warranty ..................................... 44

Safety Instructions

READ THIS MANUAL BEFORE USING THE BENCH TOP TUBE BENDER.

WARNING

Statements that identify conditions or practices that could result in death or serious injury.

CAUTION

Statements that identify conditions or practices that could result in minor or moderate injury or damage to property.

CAUTION - EYE PROTECTION

Eye protection must be worn while operating or working near equipment.

CAUTION - PINCH POINTS

Keep hands, loose clothing, and long hair away from moving parts. Injury can occur.

Technical Data

Bending Range

1 to 180°. Do not bend tube in excess of 180°.

Dimensions (tube bender in case)

Width—21 in. (53 cm)

Depth—11 in. (28 cm)

Height—14.5 in. (37 cm)

Weight (tube bender in case, excluding tooling)

Manual unit—75 lb (34 kg)

Electric unit—79 lb (36 kg)

Power Requirements (electric unit)

MS-BTB-1—110 V (ac) 50/60 Hz; maximum current: 10 A

MS-BTB-2—230 V (ac) 50/60 Hz; maximum current: 5 A

Page 3

Bench Top Bender User’s Manual 3

Tubing Data

■

The Swagelok bench top tube bender bends 1/4, 3/8, 1/2, 5/8, 9/16, 3/4, 7/8, 1 in., and 1 1/4 in. and 6, 10, 12, 14, 15, 16, 18,

20, 22, 25, 28, and 30 mm outside diameter tubing in a variety of wall thicknesses.

■

Tubing should be free of scratches and suitable for bending and flaring.

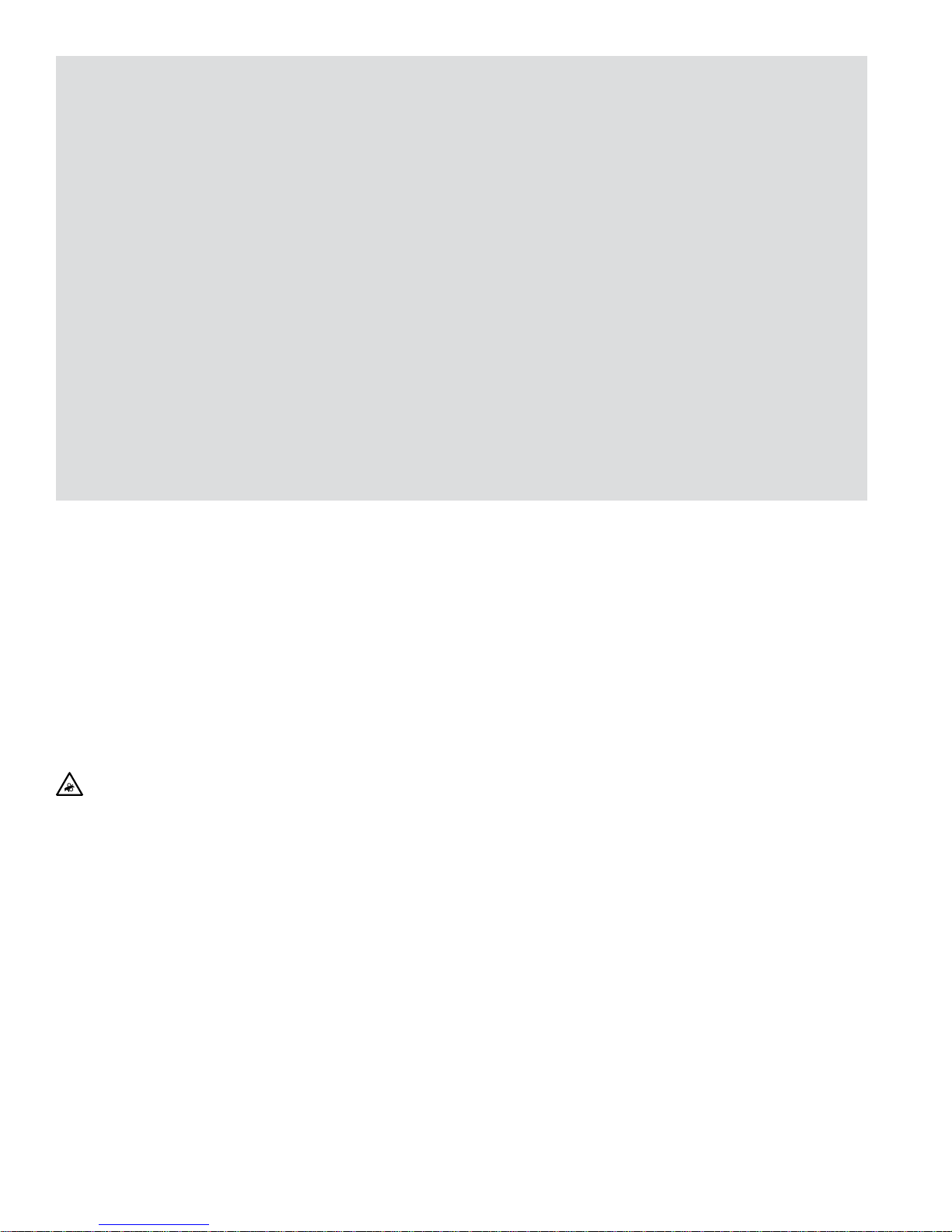

Fractional Tubing

Suggested Tubing

Ordering Information

Tub e

1 1/4 4.41 0.065/0.120 0.083/0.120

Approx

OD

1/4 1.42 0.028/0.065

3/8 1.42 0.035/0.065 0.035/0.083

3/8 2.20 0.035/0.065 0.035/0.083

1/2 1.42 0.035/0.083

1/2 2.20 0.035/0.065

5/8 1.81 0.035/0.095 0.049/0.095

3/4 2.20 0.049/0.109

7/8 2.64 0.049/0.109

Bend

Radius

1 3.23 0.049/0.120 0.065/0.120

Carbon Steel

Wall Thickness

Min/Max

Dimensions, in.

Stainless Steel

Wall Thickness

Min/Max

High-quality, soft-annealed, seamless

carbon steel hydraulic tubing ASTM

A179 or equivalent. Hardness 72 HRB

(130 HV) or less.

Fully annealed, high-quality (Type 304,

316, etc.) (seamless or welded and

drawn) stainless steel hydraulic tubing

ASTM A269 or A213, or equivalent.

Hardness 80 HRB (114 HV) or less.

Medium-Pressure Tubing IPT Series Tubing

Heav y-Wall

Nominal

Tub e

OD

1/4 1.42 0.065/0.095 0.028/0.065 0.071 0.084

3/8 1.42 0.083/0.134 0.035/0.083 — —

3/8 2.20 0.083/0.134 0.035/0.083 0.086 0.125

1/2 1.42 0.083/0.188 0.049/0.109 — —

9/16 3.23 — — 0.125 0.187

Approx

Bend

Radius

Annealed

Stainless Steel

Wall Thickness

Min/Max

Cold Drawn

1/8 Hard

Stainless Steel

Wall Thickness

Min/Max

Dimensions, in.

Medium-

Pressure

Stainless Steel

Wall Thickness

High-Pressure

Stainless Steel

Wall Thickness

Metric Tubing

Tub e

Approx

OD

Bend

Radius

6 36 0.8/1. 2

10 36 1.0/1.5

12 36 1.0/2.2 1.0/2.0

14 46 1.0/2. 2

15 46 1.0/2. 2

16 46 1.0/2.5 1.0/2.2

18 56 1.2/2.5

20 67 1.2/2.8

22 67 1.2/ 2. 8

25 82 1.2 / 3.0 1.8 /3.0

28 112 1.8 /3.0 1.8/3 .0

30 112 2.0/3.0

Carbon Steel

Wall Thickness

Min/Max

Dimensions, mm

Stainless Steel

Wall Thickness

Min/Max

Suggested Tubing Ordering Information

High-quality, soft-annealed, carbon steel hydraulic

tubing DIN-2391 or equivalent. Hardness 130 HV

(72 HRB) or less.

Fully annealed, high-quality (Type 304, 316, etc.)

stainless steel tubing EN ISO 1127 or equivalent.

Hardness 180 HV (80 HRB) or less.

Suggested Tubing

Ordering Information

Seamless, austenitic, cold-drawn tubing

ASTM A213 or equivalent. Hardness 95

HRB (210 HV) or higher.

Page 4

4 Bench Top Bender User’s Manual

Single Bend 90.eps

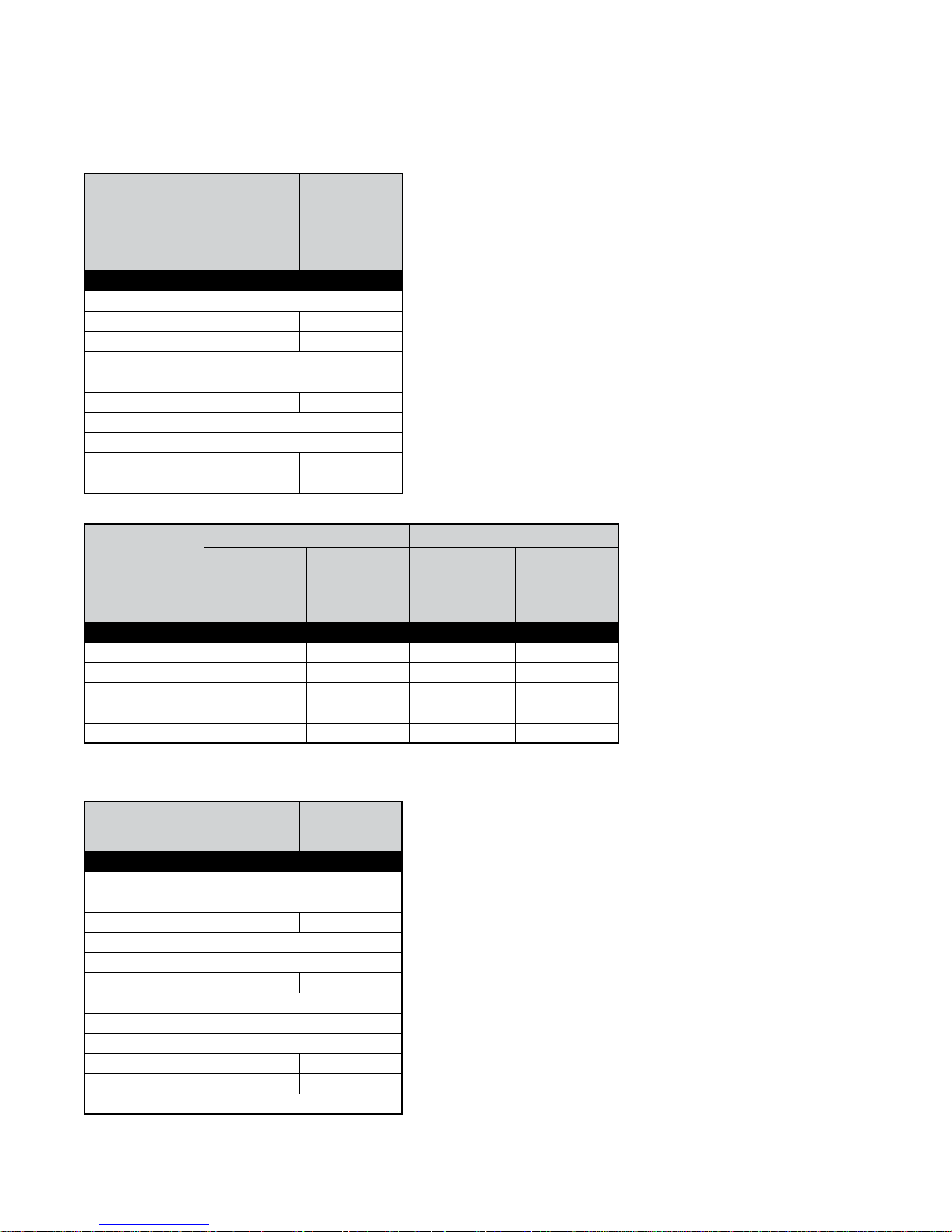

Bend Layout

This bender can be used to form single, offset, and other bends. This section contains information for measuring and marking

the tube prior to bending.

Note: Make all marks 360° around the tube.

Single Bend

1. Place a reference mark at the end of the tube from which you are beginning the measurements.

2. Measure from the reference mark and make a measurement mark on the tube at a distance equal to the length of first

leg. This mark is the vertex of the bend.

3. Measure the bend deduction distance for the angle being bent from the measurement mark (see Bend Data Tables

beginning on page 17) and make a bend mark on the tube.

■ If the bend deduction is positive, place the bend mark toward the reference mark.

■ If the bend deduction is negative, place the bend mark away from the reference mark.

4. Refer to the appropriate Operation section to bend the tube.

Length of First Leg

Reference

mark

Bend

mark

Single Bend

Multiple Bends

The Measure-Bend Method

1. Follow Single Bend steps 1 through 4.

2. Using the vertex of the previous bend as the reference

mark, repeat steps 2 through 4 for the next leg. (The

vertex is where the center lines of the two legs of the

angle intersect.)

Example:

Using 5/8 in. OD tube and an aluminum bend shoe, make a

90° bend 12 inches from the reference mark followed by a

45° bend with 12 inches between bends.

1. Place a reference mark at the end of the tube from

which you are beginning the measurements.

For the rst leg:

2. Measure 12 inches from the reference mark and make

a measurement mark to indicate the end of the first

leg.

3. The bend deduction in the Fractional Tubing Bend

Data table for a 90° bend using 5/8 in. tubing and an

aluminum bend shoe is 1 3/4 in.

4. Place the bend mark 1 3/4 in. from the measurement

mark going towards the reference mark.

5. Bend tube 90° according to the appropriate Operation

section.

For the second leg:

6. Measure 12 inches from the vertex of the 90° bend and

make a second measurement mark, away from the

reference mark.

7. The bend deduction distance in the Fractional Tubing

Bend Data table for a 45° bend using 5/8 in. tubing and

an aluminum bend shoe is 11/16 in.

8. Place a second bend mark 11/16 in. from the second

measurement mark going towards the first bend.

9. Bend tube according to the appropriate Operation

section.

Bend deduction

Length of first leg

Reference

mark

5/8 in. OD

tube

Bend

mark

Bend deduction

11/ 16 i n.

Ver tex

12 in.

Bend

mark

First Bend (90°)

45°

Second Bend (45°)

Measurement

mark

Bend deduction

1 3/4 in.

Center line

Ver tex

Length of

second leg

12 in.

Page 5

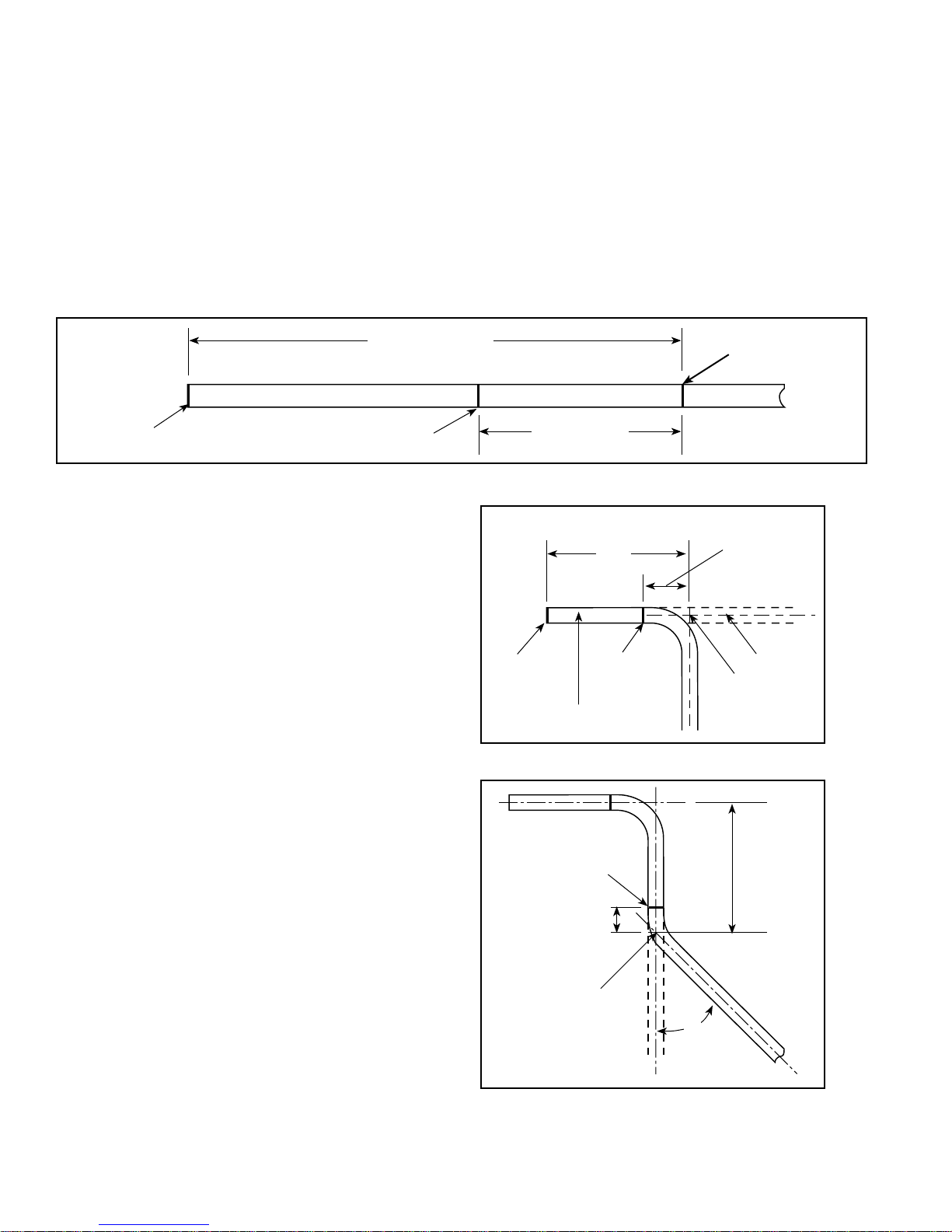

Reverse Bends

The Measure-Bend Method

Sometimes a multiple bend layout will require that a bend

be made in reverse. A reverse bend is made with the end of

the tube opposite the reference mark inserted into the bend

shoe rather than the end with the reference mark.

1. Measure from the vertex of the preceding bend and place

a second measurement mark farther down the tube at a

distance equal to the desired length of the leg.

2. Measuring from that measurement mark, place a bend

mark on the tube at the bend allowance for the angle

being bent. (See Bend Data tables beginning on page

17).

■ If the bend allowance is positive, place the bend

mark away from the preceding bend.

■ If the bend allowance is negative, place the bend

mark in the direction towards the preceding bend.

3. Bend tube according to the appropriate Operation

section.

Note: When loading the tube into the bender to make

a reverse bend, ensure that the end with the

reference mark is not inserted into the bend shoe.

Bench Top Bender User’s Manual 5

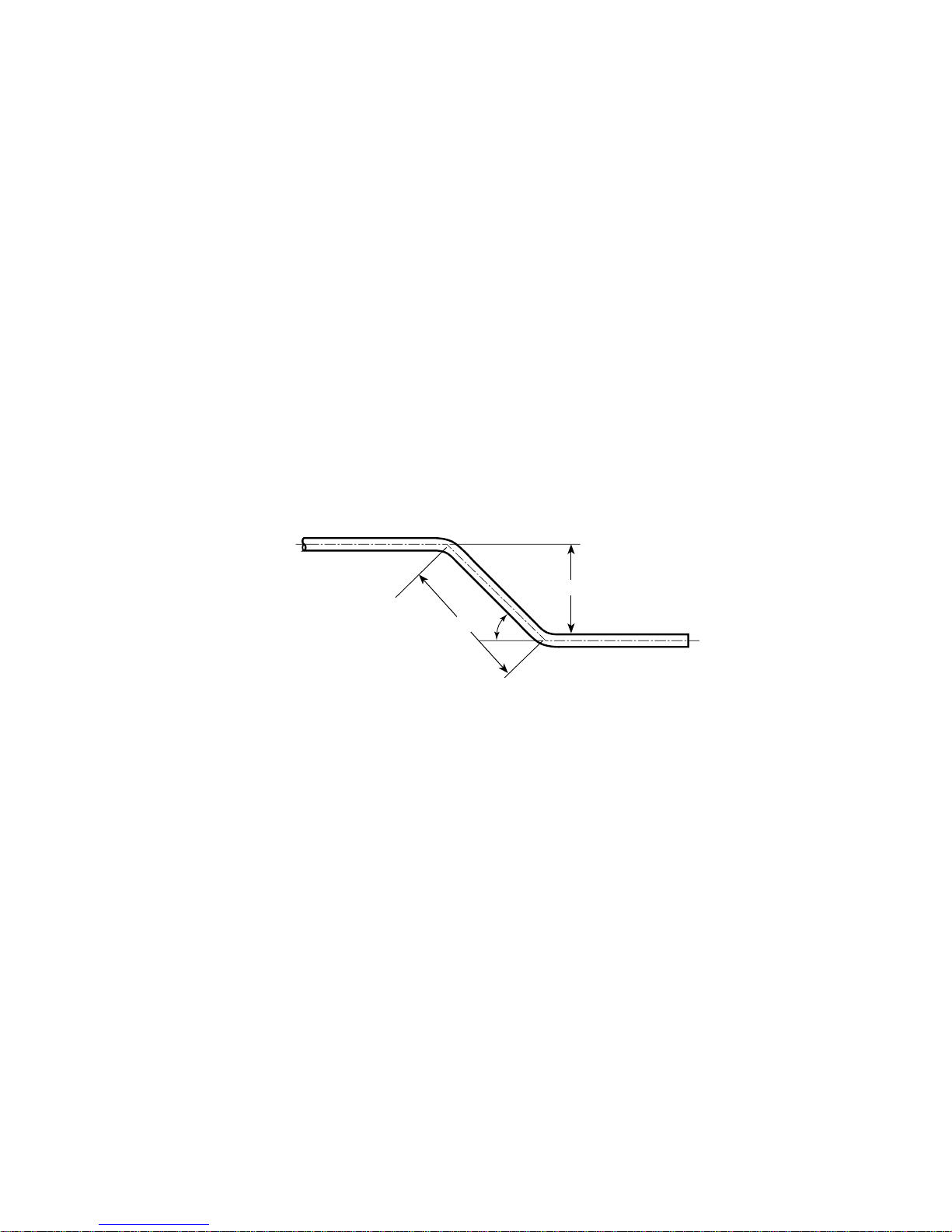

Offset Calculations

O

E

L

When offset exists, determine the length of offset (L) before calculating for the adjustment from the tube bend.

To determine the length of offset, select the offset angle (E). Then, multiply the offset dimension (O) by the offset bend

allowance.

Angle Offset Bend Offset (O) Length of Offset (L)

(E) Allowance

22.5° 2.613 × ________ = _______________

30° 2.000 × ________ = _______________

45° 1.414 × ________ = _______________

60° 1.154 × ________ = _______________

Page 6

6 Bench Top Bender User’s Manual

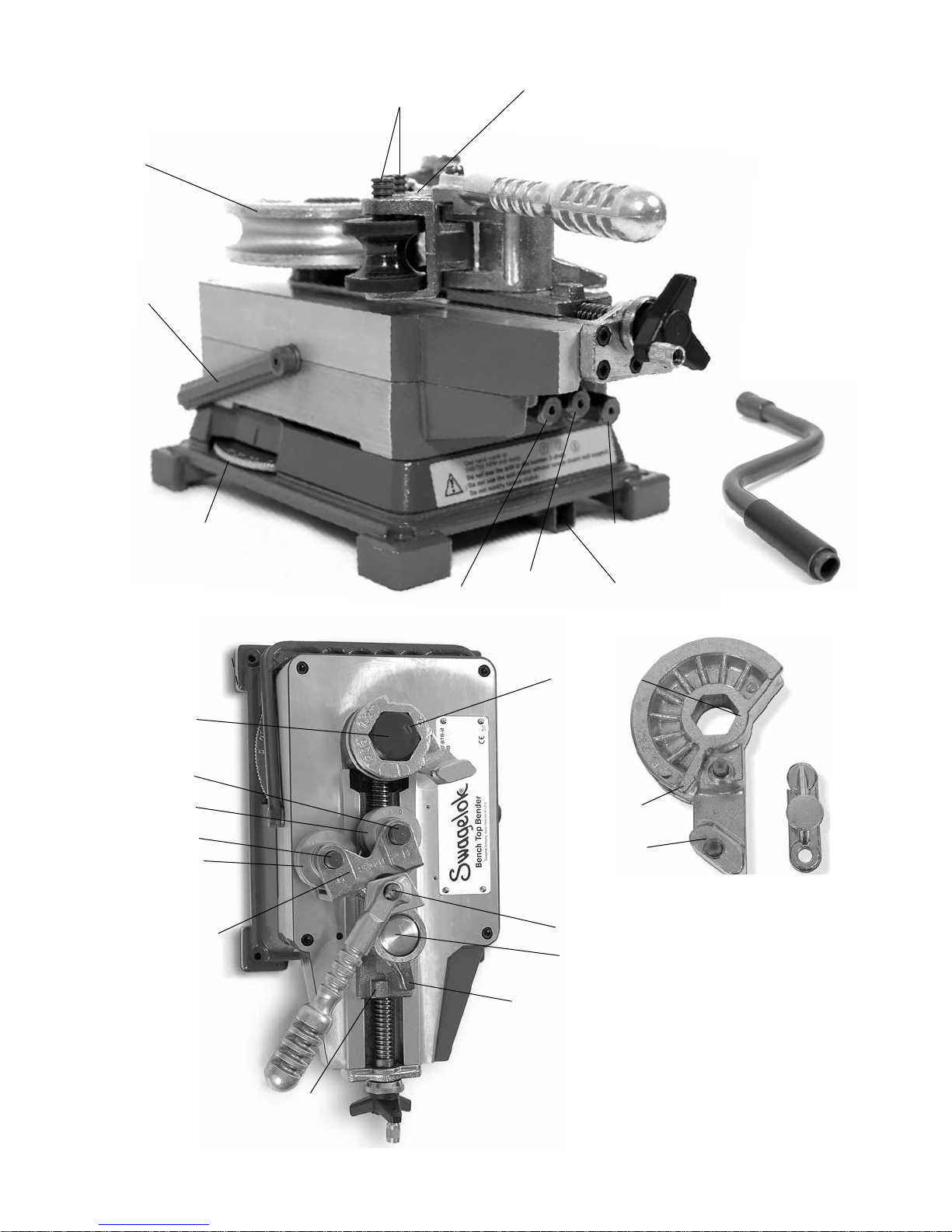

Manual Bender

Product Information

Bend shoe

Carrying

handle

Roller bracket

assembly

Roller pins

Roller bracket lever

Roller knob

Bend degree wheel

(2 1/2° increments)

Hex drive shaft

D pin

D roller

G pin

G roller

Roller bracket

assembly

Low bendspeed selector

Medium bendspeed selector

Zero reference

mark

Reference mark

Bracket pin

Bracket post

High bendspeed

selector

Drill yoke

support

Bend shoe

Clamp

arm

Hand crank

Support bracket

Aluminum only,

recommended when

using 1 in. or 25 mm

bend shoe.

Roller bracket lever

Bracket post stop

Bracket assembly stop

Roller knob

Page 7

Bench Top Bender User’s Manual 7

CAUTION

When lifting the bender, first place one hand under

the bender, then pick up the unit by grabbing the

carrying handle with your other hand.

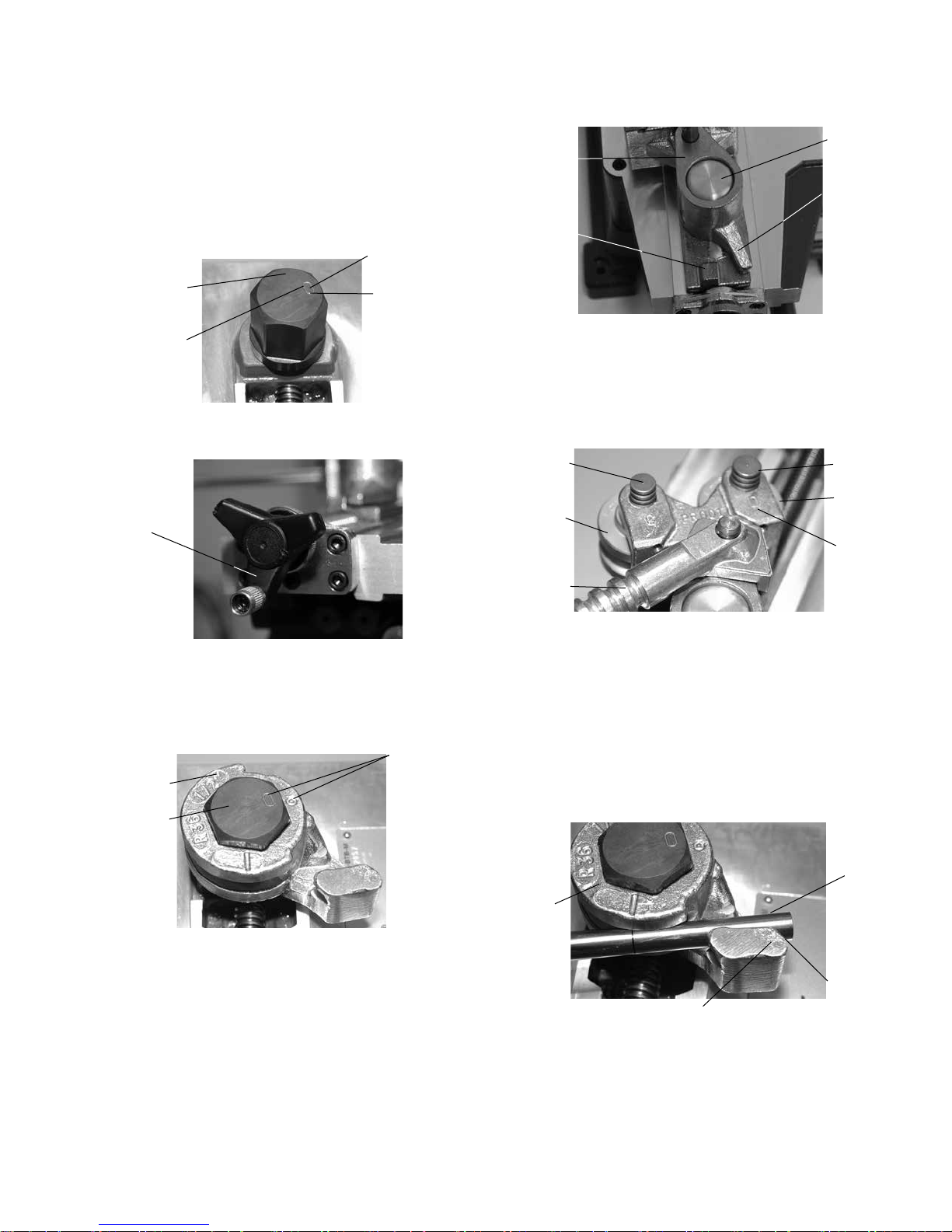

Setup

1. Place the hand crank on the high bend-speed selector.

2. Rotate the hand crank until the zero reference mark

on the hex drive shaft is between the 2 and 3 o’clock

position, when viewed from the operating position.

2 o’clock

Hex drive

shaft

Zero

reference

mark

3. Rotate the roller knob counterclockwise until it stops.

Roller

knob

3 o’clock

5. Install the roller bracket assembly on the bracket post.

Note: The roller bracket assembly stop must be to the

right of the bracket post stop.

Roller

bracket

assembly

Bracket

post stop

Bracket

post

Roller

bracket

assembly

stop

6. Place the roller bracket lever on the bracket pin.

Note: The lever must be fully bottomed on the pin.

7. Lift the roller pins, place the appropriate rollers in the

marked locations on the roller bracket, and replace the

roller pins.

G roller pin

G roller

Roller

bracket

lever

D roller pin

D roller

Roller

bracket

4. Place the appropriate bend shoe on the hex drive

shaft, aligning the zero reference marks on the shoe

and the shaft. The bend shoe must be fully bottomed on

the hex drive shaft.

Zero

reference

Bend shoe

Hex drive

shaft

marks

Note: The roller pins must be fully engaged with the

roller bracket assembly.

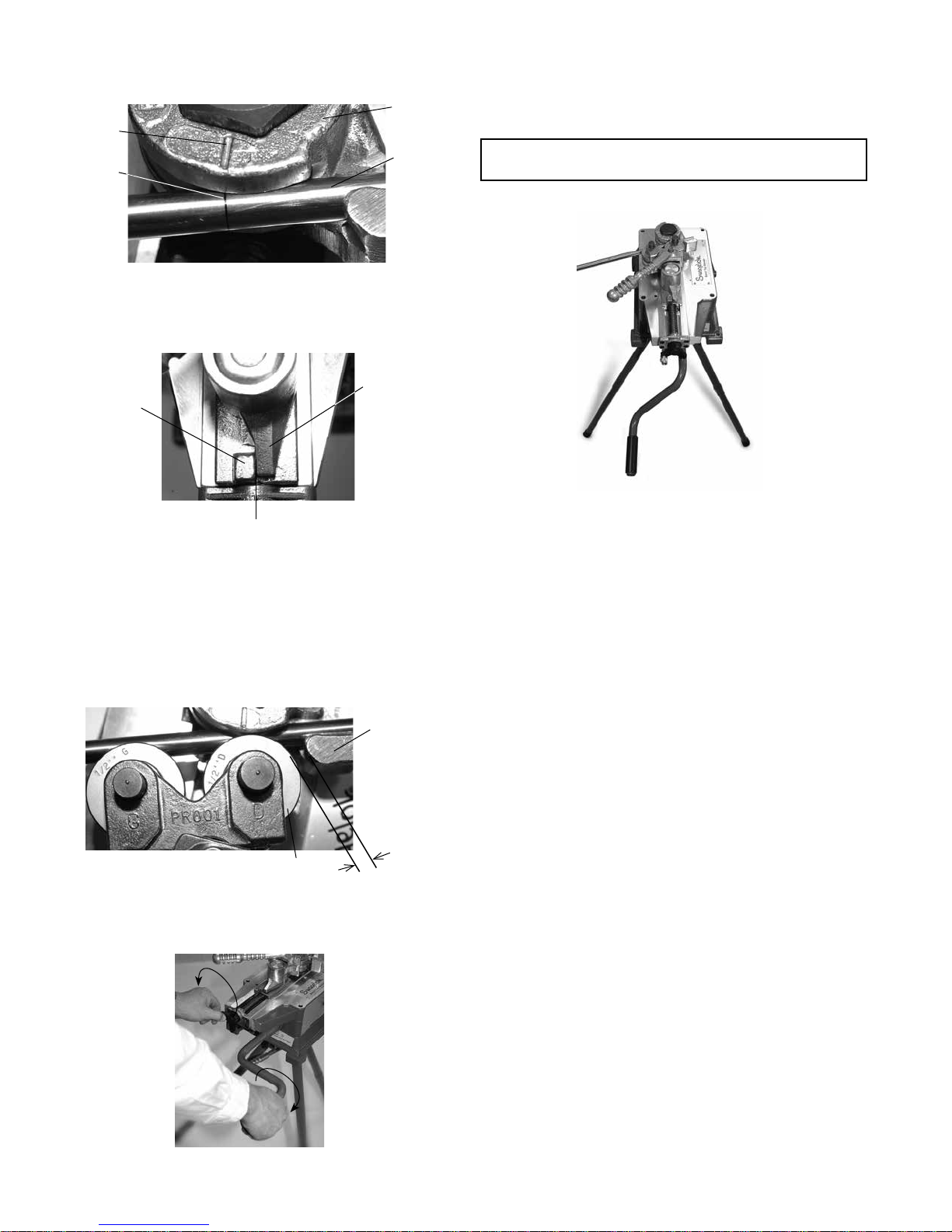

8. Mark tube according to Bend Layout.

9. Carefully insert the tube into the bend shoe, past the

clamp arm.

Caution

The end of the tube must extend past the right

edge of the clamp arm to prevent potential

damage to the tube during bending.

Tub e

Bend

shoe

Right

edge

Clamp arm

Page 8

8 Bench Top Bender User’s Manual

10. Align the bend mark on the tube with the reference

mark on the bend shoe.

Bend

Reference

mark

Bend

mark

shoe

Tub e

11. Turn the roller bracket lever clockwise until the roller

bracket assembly stop makes contact with the

bracket post stop.

Roller

Bracket

post stop

Contact

bracket

assembly

stop

12. Hold the tube and turn the roller knob clockwise until

the G and D rollers both make contact with the tube and

the roller knob is tight.

Note: The rollers may need to be guided onto smaller

diameter tubing.

13. Ensure there is approximately 3/8 in. or 10 mm

clearance between the D roller and the clamp arm of

the bend shoe.

Clamp arm

To decrease clearance:

Rotate the roller knob clockwise while slowly rotating the

hand crank counterclockwise.

Note: The roller knob must be tight.

Note: Do not turn the roller knob after this point or bend

consistency will be affected.

Roller bracket

lever

Hand crank

Calibration

Calibration is the process of positioning the bend degree

wheel to accurately display the angle being generated by the

be n d e r.

Calibration accounts for tube variables and mechanical play

in the bender, which is typically observed as springback.

Different materials, different lots of the same material, and

different wall thicknesses of the same material may exhibit

different bend characteristics.

Once the bender has been calibrated, recalibration is

recommended whenever:

■ OD or wall thickness of tube being bent is changed.

■ The roller knob has been turned after Calibration

completed.

■ The bend degree wheel does not accurately display

the bend angle.

D roller

To increase clearance:

Rotate the roller knob counterclockwise while slowly rotating

the hand crank clockwise and maintaining straight tube.

3/8 in.

1. Place the hand crank on the desired speed selector

for the tube being bent.

■ Low bend-speed selector (1) is suggested for large

diameter or heavy-wall tube.

■ Medium bend-speed selector (2) is suggested for

intermediate size and medium-wall tube.

■ High bend-speed selector (3) is suggested for small

diameter and thin-wall tube.

2. Slowly rotate the hand crank until the tube begins to

deect or bend (looking to the right of the rollers).

■ On low (1) and high (3) bend speeds, rotate the hand

crank clockwise.

■ On medium (2) bend speed, rotate the hand crank

counter-clockwise.

Page 9

Bench Top Bender User’s Manual 9

3. Keep the hand crank still and rotate the bend degree

wheel to zero.

Caution

Releasing the hand crank while tube is under

load may cause the hand crank to spin, possibly

leading to injury.

4. Rotate the hand crank until the bend wheel displays 5°

less than the desired bend angle. This will prevent setup

scrap due to overbending.

Example: For a desired bend angle of 90°, rotate the hand

crank until the bend degree wheel reads 85°.

5. Unload the bender (see Unloading the Bender) and

measure the bend angle of the tube (see Measuring

the Bend Angle). Make note of this measurement as it

is likely to be different than the angle displayed on the

bend wheel.

6. Reload the tube into the bender, lining up the bend mark

and the reference mark.

7. Rotate the hand crank until the bend degree wheel reads

the angle from step 4 (in example: 85°).

The bend angle indicated on the bend degree wheel will

now be very close to the bend angle produced. If further

adjustment is desired repeat steps 6 through 10.

Note: Tube springback is cumulative. Depending on the tube

variables, a smaller bend angle builds up less tube

springback during the bending process than a larger

bend angle. For example, if a 30° bend is attempted

using a bender that was calibrated to make a 90°

bend, the resulting bend may be larger than desired.

Conversely, if a 150° bend is attempted on the same

bender, the resulting bend may be smaller than

desired. It is advised to verify each bend angle.

Unloading the Bender

Note: Do not turn the roller knob to unload the bender.

Doing so will affect bend consistency.

Caution

Releasing the hand crank while the tube is under

load may cause the hand crank to spin, possibly

leading to injury.

1. Rotate the hand crank in the direction opposite that

used to bend the tube.

2. As the hand crank is rotated, gently push the roller

bracket lever counter-clockwise until the rollers swing

away from the tube and the tube can be removed from

the bender.

Note: Do not force the roller bracket lever.

8. Keep the hand crank still and rotate the bend degree

wheel to the measurement noted in step 5 (in example:

88°). This calibrates the bend degree wheel by setting it

to display the actual bend angle being produced.

9. Continue to rotate the hand crank until the bend degree

wheel reads the desired bend angle.

Hand crank

Roller bracket

lever

10. Unload the bender (see Unloading the Bender) and

measure the bend angle of the tube.

Page 10

10 Bench Top Bender User’s Manual

Operation

Before operating the bender mark the tube (see Bend

Layout) and follow the Setup and Calibration procedures.

CAUTION - PINCH POINTS

1. With the zero reference mark between the 2 and

3 o’clock position, place the hand crank on the desired

speed selector.

■ Low bend-speed selector (1) is suggested for large

diameter or heavy-wall tube.

■ Medium bend-speed selector (2) is suggested for

intermediate size and medium wall tube.

■ High bend-speed selector (3) is suggested for small

diameter and thin-wall tube.

2. Insert the tube carefully into the grooved section of the

bend shoe, past the clamp arm.

CAUTION

The end of the tube must extend past the right

edge of the clamp arm to prevent potential damage

to the tube during bending.

Tub e

Note: If the rollers touch the tube and prevent the stops from

making contact, gently turn the roller bracket lever

clockwise while rotating the hand crank.

Hand crank

Roller bracket

lever

5. Check the following before continuing:

■ The bend mark remains aligned with the reference

mark on the bend shoe.

■ The tube is positioned in the correct plane for bend.

■ The tube will not contact the bender housing during

the bend operation (for a multiple bend).

Bend

shoe

Right

edge

Clamp arm

3. Align the bend mark on the tube with the reference

mark on the bend shoe.

Reference

mark

Bend mark

4. Turn the roller bracket lever clockwise until the roller

bracket assembly stop and the bracket post stop

make contact.

Roller

Bracket

post stop

bracket

assembly

stop

Undesired

tube

contact

6. Rotate the hand crank until you reach the desired bend

angle on the bend degree wheel.

■ On low (1) and high (3) bend speeds, rotate the hand

crank clockwise to bend the tube.

■ On medium (2) bend speed, rotate the hand crank

counter-clockwise to bend the tube.

7. Unload the tube from the bender. See Unloading the

Bender.

8. Verify the bend angle (see Measuring the Bend Angle).

Make adjustments if necessary (see Calibration).

9. Use the hand crank on the high bend-speed selector (3)

to return the bend shoe to the starting position.

Contact

Note: Do not turn the roller knob or bend consistency will

be affected.

Page 11

Bench Top Bender User’s Manual 11

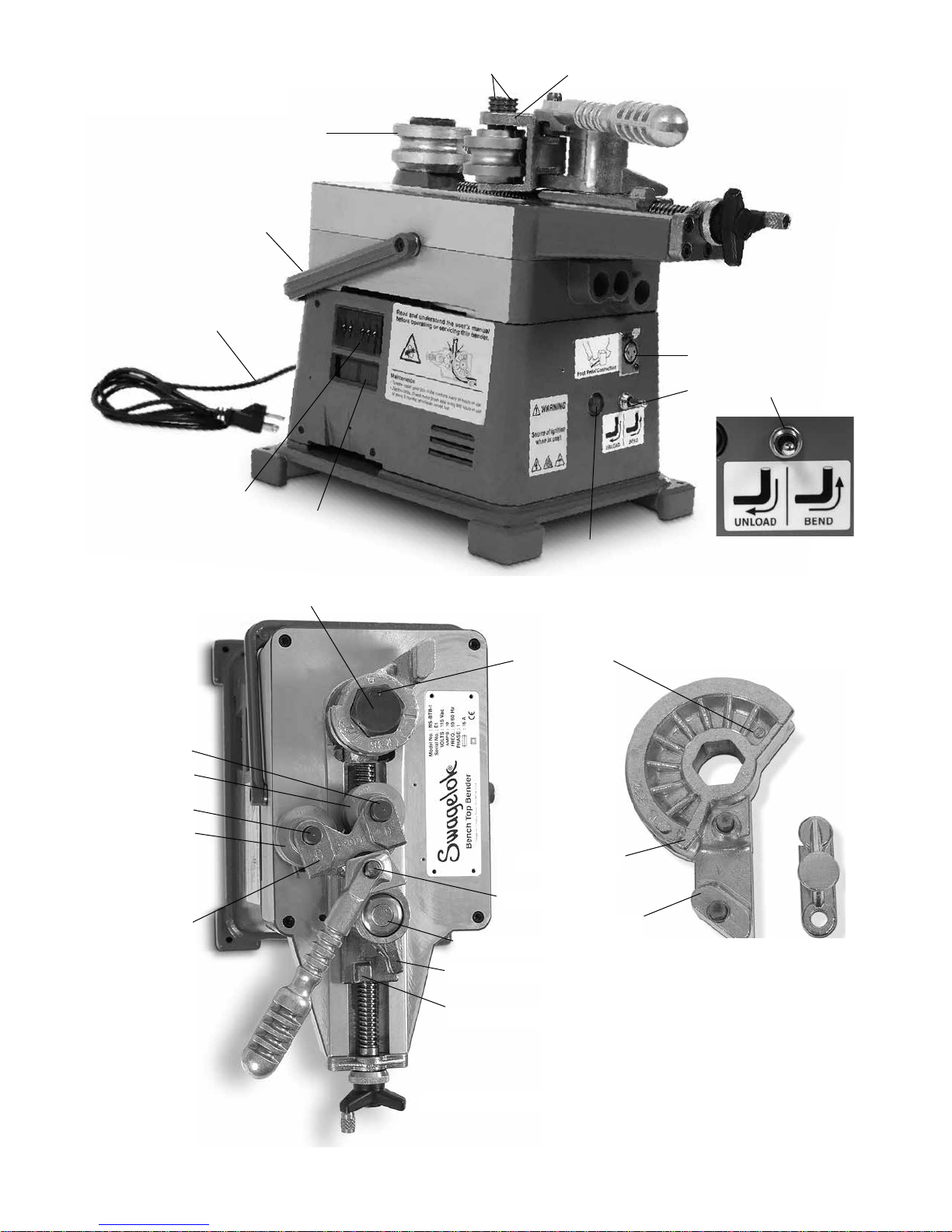

Electric Bender

Product Information

Carrying handle

Power cord

Bend angle

thumb wheels

Bend shoe

LED display

Roller pins

Rollerbracket

assembly

Roller bracket lever

Roller knob

Foot switch receptacle

Toggle switch

D pin

D roller

G pin

G roller

Roller bracket

Hex drive shaft

Overload indicator

Zero reference

mark

Bend shoe

Reference mark

Bracket pin

Bracket post

Bracket assembly stop

Bracket post stop

Clamp

arm

Support bracket

Aluminum only,

recommended when

using 1 in. or 25 mm

bend shoe.

Roller bracket lever

Roller knob

Page 12

12 Bench Top Bender User’s Manual

Electric bender must be operated in a safe environment to

avoid risk of re, explosion, or electric shock.

WARNING

Voltage greater than 30 V (ac) is present.

WARNING - KEEP DRY.

Do not expose the equipment to water or wet

locations.

WARNING - FIRE OR EXPLOSION.

Do not use equipment in a combustible or explosive

atmosphere. Flammable liquids or gases could

ignite.

Grounding and Extension Cord Information

WARNING

Electric bender must be grounded against electrical

shock. It is equipped with a three-wire conductor

and three-prong plug to fit a grounded receptacle.

Never connect the green or green/yellow wire to a

live terminal.

WARNING

For safe operation of the electric bender, the

extension cord wire size must meet the following

specifications:

For 0 to 25 ft (0 to 7.5 m), the recommended

minimum wire gauge is 14 AWG or 1.5 mm.

For 25 to 50 ft (7.5 to 15 m), the recommended

minimum wire gauge is 12 AWG or 2.5 mm.

CAUTION

When lifting the bender, first place one hand under

the bender, then pick up the unit by grabbing the

carrying handle with your other hand.

Setup

It is recommended that scrap tube be used during setup and

calibration of the Electric Bench Top Tube Bender.

3. Rotate the roller knob counterclockwise until it stops.

Roller knob

4. Place the appropriate bend shoe on the hex drive

shaft, aligning the zero reference marks on the shoe

and the shaft. The bend shoe must be fully bottomed on

the hex drive shaft.

Zero reference

marks

Bend shoe

Hex drive

shaft

5. Install the roller bracket assembly on the bracket post.

Note: The roller bracket assembly stop must be to the

right of the bracket post stop.

Bracket

post

Bracket

post stop

Roller

bracket

assembly

stop

1. Plug in the power cord.

2. Hold the toggle switch in the unload direction until

the motor stops. The zero reference mark on the hex

drive shaft should now be between the 2 and 3 o’clock

position.

Note: T he toggle switch is programmed to have a

safety time delay of approximately two seconds

between operations.

2 o’clock

Hex drive

shaft

Zero

reference

mark

3 o’clock

6. Place the roller bracket lever on the bracket pin.

Note: The lever must be fully bottomed on the pin.

7. Lift the roller pins, place the G and D rollers in the

marked locations on the roller bracket, and replace the

roller pins.

Note: The roller pins must be fully engaged into the

roller bracket assembly.

G roller pin

G roller

Roller

bracket

lever

D roller pin

D roller

Bracket

pin

Roller

bracket

assembly

Page 13

Bench Top Bender User’s Manual 13

8. Carefully insert the tube into the bend shoe, past the

clamp arm.

CAUTION

The end of the tube must extend past the right

edge of the clamp arm to prevent potential

damage to the tube during bending.

Tub e

Bend

shoe

Right

Clamp arm

9. Turn the roller bracket lever clockwise until the roller

bracket assembly stop makes contact with the bracket

post stop.

Bracket

post stop

edge

Roller

bracket

assembly

stop

If all three conditions are met, make note of the value

appearing on the three right bend angle thumb wheels

and proceed to Calibration.

If all three conditions are not met:

a. Turn the roller knob counter-clockwise until the tube

can be removed. Remove tube.

b. Advance the right-most bend angle thumb wheel

one digit.

Bend angle

thumb wheel

c. Hold the toggle switch in the bend direction until the

motor stops.

Contact

10. Hold the tube in the bend shoe and turn the roller knob

clockwise until both the G and D rollers make contact

with the tube.

Note: Smaller diameter tube may need to be guided into

the rollers.

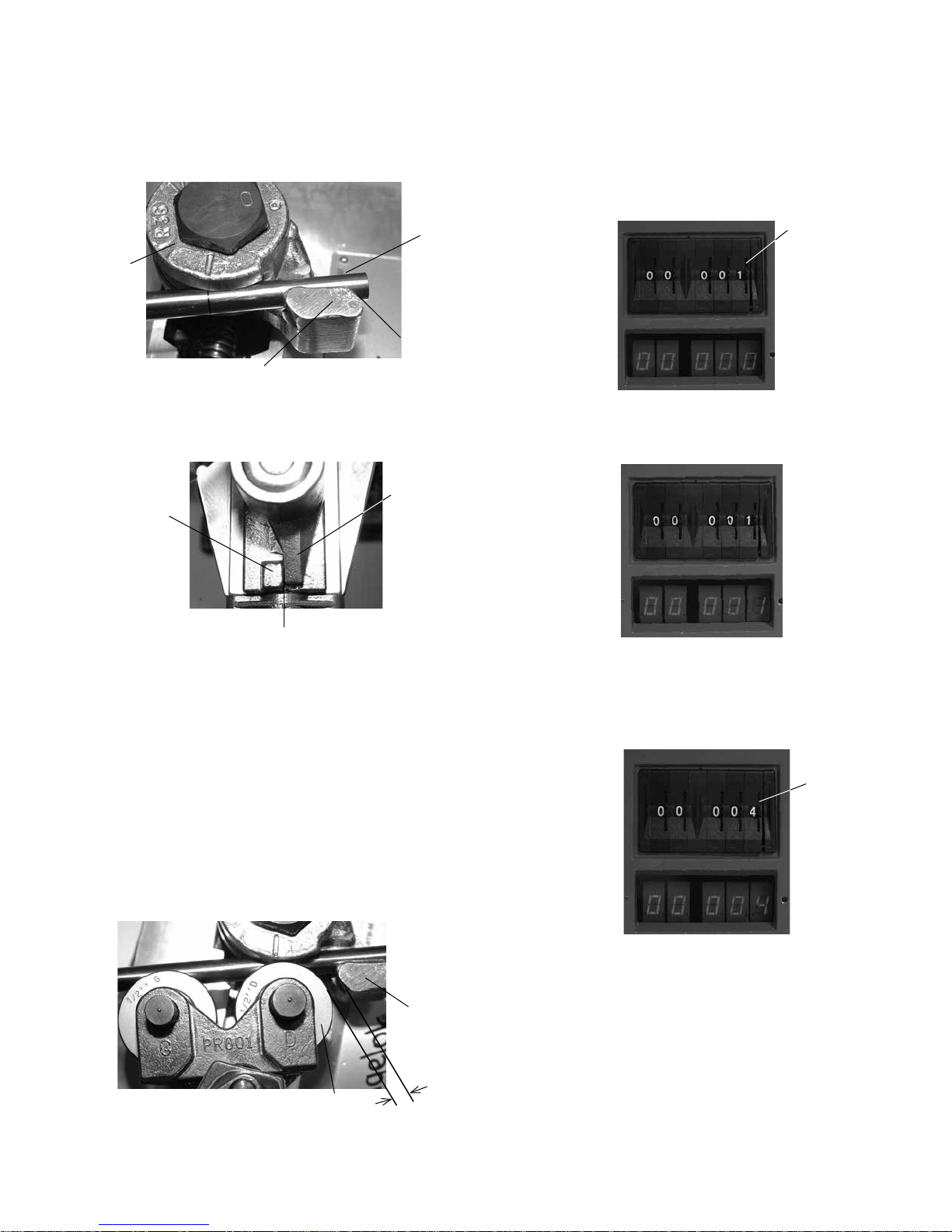

11. Once the roller knob is tight, the following conditions

must be met:

■ The roller bracket assembly stop and the bracket post

stop must maintain contact.

■ Both rollers must make contact with the tube.

■ There must be approximately 3/8 in. or 10 mm

clearance between the D roller and the clamp arm of

the bend shoe.

Clamp

arm

D roller

3/8 in.

d. Repeat steps 9 through 11 until all three conditions

are met.

12. Make note of the value on the right-most bend angle

thumb wheel.

Bend angle

thumb wheel

Example only

13. Turn the roller knob counter-clockwise until the tube can

be removed. Remove tube.

14. Advance the two right-most bend angle thumb wheels

until they display 010 or higher.

15. Hold the toggle switch in the bend direction until the

motor stops. Wait two seconds, then hold the toggle

switch in the unload direction until the motor stops.

16. Proceed to Calibration.

Page 14

14 Bench Top Bender User’s Manual

Calibration

Calibration is the process of accurately accounting for

tube variables and mechanical play in the bender, which

is typically observed as springback. Different materials,

different lots of the same material, and different wall

thicknesses of the same material may exhibit different bend

characteristics.

Once the bender has been calibrated, recalibration is

recommended whenever:

■ OD or wall thickness of tube being bent is changed.

■ The roller knob has been turned after Calibration has

been completed.

1. Set the right-most bend angle thumb wheel to the value

noted in step 12 of Setup. Hold the toggle switch in

the bend direction until the motor stops (do not jog the

switch).

2. Carefully insert the tube into the bend shoe, past the

clamp arm.

CAUTION

The end of the tube must extend past the right

edge of the clamp arm to prevent potential

damage to the tube during bending.

5. Set the bend angle thumb wheels to the desired bend

angle.

6. Hold the toggle switch in the bend direction until the

motor stops (do not jog the switch).

CAUTION - PINCH POINT

7. Unload the bender (see Unloading the Bender) and

measure the bend angle of the tube (see Measuring the

Bend Angle).

If the actual bend is smaller than the desired bend angle:

Subtract the actual bend angle from the desired bend

angle. The difference is the amount that must be added

to the desired bend angle when setting the bend angle

thumb wheels for all subsequent bends made with this

tube.

For example:

The desired bend angle entered is 90°.

The resulting calibration sample measures 86°.

90 – 86 = 4.

The bend angle thumb wheels must be set 4° more

than the desired bend angle for subsequent bends

with this size tube, i.e. for a 90° bend, the bend

angle thumb wheels must be set at 94°.

Bend angle

thumb wheels

Tub e

Bend

shoe

Right

Clamp arm

3. Turn the roller bracket lever clockwise until the roller

bracket assembly stop makes contact with the

bracket post stop.

Bracket

post stop

Contact

4. Hold the tube in the bend shoe and turn the roller knob

clockwise until the G and D rollers both make contact

with the tube.

Note: The rollers may need to be guided onto smaller

diameter tubing.

Note: The clearance between the D roller and the clamp

arm will now be approximately 1/4 in.

Note: Do not turn the roller knob after this point or bend

consistency will be affected.

edge

Roller

bracket

assembly

stop

If the actual bend is larger than the desired bend angle:

Subtract the desired bend angle from the actual

bend angle. The difference is the amount that must

be subtracted from the desired bend angle for all

subsequent bends made with this tube.

For example:

The desired bend angle entered is 90°.

The resulting calibration sample measures 92°.

92 – 90 = 2.

The bend angle thumb wheels must be set 2° less

than the desired bend angle for subsequent bends

with this size tube, i.e. for a 90° bend, the bend

angle thumb wheels must be set at 88°.

8. Make note of this amount.

Note: Tube springback is cumulative. Depending on the tube

variables, a smaller bend angle builds up less tube

springback during the bending process than a larger

bend angle. For example, if a 30° bend is attempted

using a bender that was calibrated to make a 90°

bend, the resulting bend may be larger than desired.

Conversely, if a 150° bend is attempted on the same

bender, the resulting bend may be smaller than

desired. It is advised to verify each bend angle.

Unloading the Bender

Note: Do not turn the roller knob to unload the bender.

Doing so will affect bend consistency.

1. Hold the toggle switch in the unload position until the

motor stops. While holding the toggle switch, gently

turn the roller bracket lever counter-clockwise until the

rollers swing away from the tube.

Page 15

Bench Top Bender User’s Manual 15

Note: Do not force the roller bracket lever.

Roller

bracket

lever

Tog g l e

switch

2. Hold the tube until the motor stops and the tube can be

removed from the bender.

Operation

Before operating the bender mark the tube (see Bend

Layout) and follow the Setup and Calibration procedures.

CAUTION - PINCH POINTS

1. Set the bend angle thumb wheels to the value noted in

step 12 of Setup.

Bend angle

thumb wheels

5. Align the bend mark on the tube with the reference

mark on the bend shoe (see Bend Layout for marking

tube).

Reference

mark

Bend mark

6. Rotate the roller bracket lever clockwise until the roller

bracket assembly stop and the bracket post stop make

contact.

Roller

Bracket

post stop

bracket

assembly

stop

Example only

2. Hold the toggle switch in the bend direction until the

motor stops (do not jog the switch).

3. Set the bend angle thumb wheels to the desired

bend angle plus or minus the amount noted in step 8 of

Calibration.

Bend angle

thumb wheels

Example only

4. Carefully insert the tube into the bend shoe, past the

clamp arm.

Caution

The end of the tube must extend past the right

edge of the tube clamp support area to prevent

potential damage to the tube during bending.

Tub e

Bend

shoe

Contact

Note: The clearance between the D roller and the clamp

arm will now be approximately 1/4 in.

7. Check the following before continuing:

■ The bend mark remains aligned with the reference

mark on the bend shoe.

■ The tube is positioned in the correct plane.

■ The tube will not contact the bender housing during

the bend operation (for a multiple bend).

Undesired

tube

contact

8. Hold the tube and push the toggle switch in the bend

direction until the motor stops (do not jog the switch).

9. Unload the tube. See Unloading the Bender.

10. Verify the bend angle (see Measuring the Bend Angle).

Clamp arm

Right

edge

Page 16

16 Bench Top Bender User’s Manual

Measuring the Bend Angle

This is one of many methods that may be used to measure

the bend angle.

A protractor will be needed for this method.

1. Place the bent tube on a piece of paper with the vertex

of the bend on the paper.

Tub e

Ver tex

2. Hold the tube against the paper, and mark the paper

along one edge of each leg of the bend with a pencil.

3. Align a ruler or other straight edge on one of the marks,

and extend it past the point where it will intersect with

the second mark when it is extended.

4. Repeat step 3 with the second mark. The intersection

point of the two marks represents the vertex of the

bend.

5. Place the origin of the protractor on the intersection

of the line. Rotate the protractor so the baseline of the

protractor is aligned with one of the marks and the

second mark intersects the scale on the protractor

(extend the marks with a pencil if necessary).

Origin

6. The second mark indicates the bend angle.

Note: The protractor will contain two scales. Read the

appropriate scale.

Page 17

Bench Top Bender User’s Manual 17

Bend Data Tables

The bend data provided reects results achieved using the Swagelok bench top tube bender.

Bend deduction – the distance from the vertex of the angle back to the point where the tube breaks tangent and the bend

actually begins. Sometimes referred to as ‘setback’, ‘take-up’ or ‘take-off’.

Bend length – the actual amount of tube consumed by the bend as measured along the centerline of the bend.

Adjustment (gain) – the difference between the actual length of tube used in a bend and the theoretical distance around a

sharp corner. The information provided in these tables accounts for adjustment (gain).

Bend allowance – the bend mark distance for reverse bends. The adjustment (gain) is pushed towards the reference mark or

previous bend during reverse bends.

Fractional Tubing

Dimensions are in inches.

1/4 in. OD, 36 mm (1.42 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing Medium–Pressure Tubing

Bend

Angle

Degrees

15 1/16 1/16 1/8 5/16 5/16 5/8 3/8 3/8 3/4

22 1/2 1/8 3/16 5/16 3/8 7/16 13/16 7/16 1/2 15/16

30 3/16 1/4 1/2 7/16 1/2 1 9/16 9/16 1 1/8

45 3/8 7/16 13/16 5/8 11/16 1 5/16 11/16 3/4 1 1/2

60 1/2 11/16 1 3/16 3/4 15/16 1 11/16 13/16 1 1 13/16

75 9/16 15/16 1 9/16 13/16 1 3/16 2 1/16 15/16 1 1/4 2 3/16

90 5/8 1 5/16 1 15/16 7/8 1 9/16 2 7/16 15/16 1 5/8 2 9/16

105 9/16 1 11/16 2 1/4 13/16 2 2 3/4 7/8 2 1/16 2 15/16

120 3/8 2 5/16 2 5/8 1/2 2 5/8 3 1/8 5/8 2 11/16 3 5/16

135 –1/4 3 1/4 3 –1/8 3 5/8 3 1/2 –1/16 3 11/16 3 11/16

150 –1 3/4 5 1/16 3 3/8 –1 5/8 5 1/2 3 7/8 –1 9/16 5 5/8 4 1/16

165 –6 13/16 10 9/16 3 3/4 –6 13/16 11 4 1/4 –6 3/4 11 1/8 4 7/16

180 2 13/16 1 5/16 4 1/16 3 1/16 1 9/16 4 9/16 3 3/16 1 5/8 4 3/4

Allowance

Aluminum Bend Shoe Steel Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

1/4 in. OD, IPT Series, 36 mm (1.42 in.) Radius Bend Shoe with Effective Bend Radius of 1.59 in.

Medium- and High-Pressure Tubing

Bend

Angle

Degrees

15 5/16 5/16 11/16

22 1/2 7/16 7/16 7/8

30 9/16 9/16 1 1/16

45 11/16 13/16 1 1/2

60 7/8 1 1/16 1 15/16

75 1 1 3/8 2 5/16

90 1 1/16 1 3/4 2 3/4

105 15/16 2 1/4 3 3/16

120 11/16 2 15/16 3 9/16

135 0 4 1/16 4

150 -1 3/4 6 3/16 4 7/16

165 -7 1/2 12 5/16 4 13/16

180 3 9/16 1 3/4 5 1/4

Bend

Allowance

IPT Series

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 18

18 Bench Top Bender User’s Manual

Fractional Tubing continued

Dimensions are in inches.

3/8 in. OD, 36 mm (1.42 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing Medium-Pressure Tubing

Bend

Angle

Degrees

15 –1/16 –1/16 –1/16 1/16 1/16 1/8 5/16 5/16 5/8

22 1/2 0 1/16 1/8 1/8 3/16 5/16 3/8 7/16 13/16

30 1/8 1/8 5/16 1/4 1/4 1/2 7/16 1/2 15/16

45 1/4 5/16 11/16 3/8 7/16 7/8 5/8 11/16 1 5/16

60 7/16 9/16 1 1/2 11/16 1 3/16 3/4 15/16 1 11/16

75 1/2 13/16 1 3/8 5/8 15/16 1 9/16 13/16 1 3/16 2

90 9/16 1 3/16 1 3/4 5/8 1 5/16 1 15/16 13/16 1 9/16 2 3/8

105 9/16 1 9/16 2 1/8 5/8 1 11/16 2 5/16 3/4 2 2 3/4

120 3/8 2 1/8 2 1/2 3/8 2 5/16 2 11/16 1/2 2 5/8 3 1/8

135 –3/16 3 1/16 2 7/8 –3/16 3 1/4 3 1/16 –3/16 3 5/8 3 7/16

150 –1 11/16 4 7/8 3 1/4 –1 11/16 5 1/16 3 7/16 –1 11/16 5 1/2 3 13/16

165 –6 3/4 10 5/16 3 5/8 –6 3/4 10 9/16 3 13/16 –6 7/8 11 4 3/16

180 2 13/16 1 3/16 3 15/16 2 7/8 1 5/16 4 1/8 3 1 9/16 4 1/2

Allowance

Aluminum Bend Shoe Steel Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

3/8 in. OD, 56 mm (2.20 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel

Bend

Angle

Degrees

15 5/16 5/16 11/16

22 1/2 7/16 1/2 15/16

30 5/8 5/8 1 1/4

45 7/8 1 1 7/8

60 1 1/16 1 3/8 2 7/16

75 1 1/4 1 13/16 3 1/16

90 1 5/16 2 3/8 3 5/8

105 1 3/16 3 1/16 4 1/4

120 3/4 4 1/16 4 13/16

135 -3/16 5 5/8 5 7/16

150 -2 11/16 8 11/16 6

165 -11 17 5/8 6 5/8

180 4 7/8 2 3/8 7 3/16

Bend

Allowance

Tubing

Steel Bend Shoe

Bend

Deduction

Bend

Length

3/8 in. OD, IPT Series, 56 mm (2.20 in.) Radius Bend

Shoe with Effective Bend Radius of 2.44 in.

Medium- and High-Pressure Tubing

Bend

Angle

Degrees

15 7/16 7/16 13/16

22 1/2 9/16 9/16 1 1/8

30 11/16 3/4 1 7/16

45 1 1 1/8 2 1/8

60 1 1/4 1 1/2 2 3/4

75 1 3/8 1 15/16 3 3/8

90 1 1/2 2 9/16 4

105 1 3/8 3 5/16 4 5/8

120 15/16 4 3/8 5 1/4

135 -1/8 6 5 15/16

150 -2 11/16 9 1/4 6 9/16

165 -11 1/2 18 11/16 7 3/16

180 5 5/16 2 9/16 7 13/16

Bend

Allowance

IPT Series

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 19

Bench Top Bender User’s Manual 19

Fractional Tubing continued

Dimensions are in inches.

1/2 in. OD, 36 mm (1.42 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing Medium-Pressure Tubing

Bend

Angle

Degrees

15 –1/16 –1/16 –1/8 1/8 1/8 1/4 1/16 1/16 3/16

22 1/2 0 1/16 1/16 3/16 1/4 7/16 3/16 3/16 3/8

30 1/16 1/8 3/16 1/4 5/16 9/16 1/4 5/16 9/16

45 1/4 5/16 9/16 7/16 1/2 15/16 3/8 1/2 7/8

60 3/8 9/16 15/16 9/16 3/4 1 5/16 9/16 3/4 1 1/4

75 7/16 13/16 1 1/4 5/8 1 1 5/8 5/8 1 1 5/8

90 7/16 1 3/16 1 5/8 5/8 1 3/8 2 5/8 1 5/16 2

105 7/16 1 9/16 2 9/16 1 3/4 2 3/8 5/8 1 3/4 2 5/16

120 1/4 2 1/8 2 3/8 3/8 2 3/8 2 3/4 3/8 2 5/16 2 11/16

135 –3/8 3 1/16 2 11/16 –1/4 3 5/16 3 1/16 –1/4 3 5/16 3 1/16

150 –1 13/16 4 7/8 3 1/16 –1 3/4 5 3/16 3 7/16 –1 11/16 5 1/8 3 7/16

165 –6 15/16 10 5/16 3 7/16 –6 7/8 10 11/16 3 13/16 –6 13/16 10 5/8 3 13/16

180 2 5/8 1 3/16 3 3/4 2 13/16 1 3/8 4 1/8 2 13/16 1 5/16 4 1/8

Allowance

Aluminum Bend Shoe Steel Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

1/2 in. OD, 56 mm (2.20 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 5/8 5/8 1 1/4

22 1/2 3/4 13/16 1 1/2

30 7/8 15/16 1 13/16

45 1 1/8 1 1/4 2 3/8

60 1 5/16 1 5/8 2 15/16

75 1 7/16 2 1/16 3 1/2

90 1 1/2 2 9/16 4 1/16

105 1 5/16 3 1/4 4 5/8

120 7/8 4 1/4 5 3/16

135 –1/8 5 13/16 5 3/4

150 –2 1/2 8 13/16 6 5/16

165 –10 1/2 17 5/16 6 7/8

180 4 7/8 2 9/16 7 7/16

Bend

Allowance

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 20

20 Bench Top Bender User’s Manual

Fractional Tubing continued

Dimensions are in inches.

9/16 in. OD, IPT Series, 82 mm (3.23 in.) Radius Bend Shoe with Effective Bend Radius of 3.47 in.

Medium- and High-Pressure Tubing

Bend

Angle

Degrees

15 7/16 7/16 7/8

22 1/2 11/16 11/16 1 3/8

30 7/8 15/16 1 13/16

45 1 1/4 1 7/16 2 11/16

60 1 5/8 2 3 5/8

75 1 7/8 2 11/16 4 1/2

90 1 15/16 3 1/2 5 7/16

105 1 13/16 4 1/2 6 5/16

120 1 3/16 6 7 1/4

135 -1/4 8 3/8 8 1/8

150 -3 15/16 12 15/16 9

165 -16 7/16 26 3/8 9 15/16

180 7 3/8 3 1/2 10 13/16

Bend

Allowance

IPT Series

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 21

Fractional Tubing continued

Dimensions are in inches.

5/8 in. OD, 46 mm (1.81 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 3/16 3/16 3/8 3/8 3/8 3/4

22 1/2 5/16 5/16 5/8 1/2 1/2 1

30 3/8 7/16 7/8 9/16 5/8 1 3/16

45 9/16 11/16 1 5/16 3/4 7/8 1 11/16

60 3/4 1 1 3/4 15/16 1 3/16 2 1/8

75 7/8 1 3/8 2 1/4 1 1/16 1 9/16 2 9/16

90 15/16 1 3/4 2 11/16 1 1/16 1 15/16 3

105 13/16 2 5/16 3 1/8 15/16 2 9/16 3 1/2

120 1/2 3 1/16 3 5/8 9/16 3 5/16 3 15/16

135 –1/4 4 5/16 4 1/16 –3/16 4 5/8 4 3/8

150 –2 3/16 6 11/16 4 1/2 –2 3/16 7 4 13/16

165 –8 11/16 13 11/16 5 –8 3/4 14 1/16 5 5/16

180 3 11/16 1 3/4 5 7/16 3 13/16 1 15/16 5 3/4

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bench Top Bender User’s Manual 21

Bend

Length

3/4 in. OD, 56 mm (2.20 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 3/8 3/8 3/4 1/2 9/16 1 1/16

22 1/2 1/2 9/16 1 5/8 11/16 1 5/16

30 5/8 11/16 1 5/16 3/4 13/16 1 5/8

45 7/8 1 1 7/8 1 1 3/16 2 3/16

60 1 1/16 1 3/8 2 7/16 1 1/4 1 1/2 2 3/4

75 1 3/16 1 13/16 2 15/16 1 3/8 1 15/16 3 5/16

90 1 1/4 2 5/16 3 1/2 1 7/16 2 7/16 3 7/8

105 1 1/8 3 4 1/16 1 1/4 3 3/16 4 7/16

120 11/16 3 15/16 4 5/8 13/16 4 1/8 5

135 –1/4 5 7/16 5 3/16 –1/8 5 11/16 5 9/16

150 –2 5/8 8 3/8 5 3/4 –2 1/2 8 5/8 6 1/8

165 –10 9/16 16 7/8 6 5/16 –10 1/2 17 3/16 6 11/16

180 4 9/16 2 5/16 6 7/8 4 3/4 2 7/16 7 1/4

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 22

22 Bench Top Bender User’s Manual

Fractional Tubing continued

Dimensions are in inches.

7/8 in. OD, 67 mm (2.64 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 1/4 1/4 1/2 0 0 0

22 1/2 3/8 7/16 13/16 1/8 3/16 5/16

30 9/16 5/8 1 3/16 5/16 3/8 11/16

45 7/8 1 1 7/8 9/16 3/4 1 5/16

60 1 1/8 1 7/16 2 9/16 13/16 1 3/16 2

75 1 5/16 1 15/16 3 3/16 1 1 11/16 2 11/16

90 1 3/8 2 9/16 3 7/8 1 1/16 2 5/16 3 3/8

105 1 1/4 3 5/16 4 9/16 1 3 1/16 4 1/16

120 13/16 4 7/16 5 1/4 5/8 4 1/8 4 11/16

135 –5/16 6 1/4 5 15/16 –7/16 5 7/8 5 3/8

150 –3 1/16 9 11/16 6 5/8 –3 3/16 9 1/4 6 1/16

165 –12 9/16 19 7/8 7 5/16 –12 11/16 19 7/16 6 3/4

180 5 7/16 2 9/16 8 5 1/8 2 5/16 7 7/16

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

1 in. OD, 82 mm (3.23 in.) Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 15/16 15/16 1 13/16 1/2 1/2 15/16

22 1/2 1 1/8 1 1/8 2 1/4 11/16 11/16 1 3/8

30 1 5/16 1 3/8 2 11/16 7/8 15/16 1 13/16

45 1 11/16 1 13/16 3 1/2 1 1/4 1 3/8 2 5/8

60 2 2 3/8 4 3/8 1 9/16 1 15/16 3 7/16

75 2 1/4 3 5 1/4 1 3/4 2 9/16 4 5/16

90 2 5/16 3 3/4 6 1/16 1 13/16 3 5/16 5 1/8

105 2 1/8 4 13/16 6 15/16 1 11/16 4 5/16 6

120 1 1/2 6 1/4 7 3/4 1 1/8 5 11/16 6 13/16

135 1/16 8 9/16 8 5/8 –1/4 7 7/8 7 5/8

150 –3 7/16 12 7/8 9 7/16 –3 11/16 12 3/16 8 1/2

165 –15 1/8 25 7/16 10 5/16 –15 5/16 24 5/8 9 5/16

180 7 7/16 3 3/4 11 1/8 6 7/8 3 5/16 10 1/8

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 23

Fractional Tubing continued

Dimensions are in inches.

1 1/4 in. OD, 112 mm (4.41 in.) Radius Bend Shoe

Standard Tubing

Bend

Angle

Degrees

15 13/16 7/8 1 11/16

22 1/2 1 1/16 1 3/16 2 3/16

30 1 5/16 1 7/16 2 3/4

45 1 3/4 2 1/8 3 7/8

60 2 1/8 2 13/16 5

75 2 7/16 3 11/16 6 1/16

90 2 1/2 4 11/16 7 3/16

105 2 3/16 6 1/16 8 1/4

120 1 3/8 8 9 3/8

135 –9/16 11 1/16 10 1/2

150 –5 5/16 16 15/16 11 9/16

165 –21 5/16 34 12 11/16

180 9 1/8 4 11/16 13 13/16

Carbon Steel and Stainless Steel Tubing

Bend

Allowance

Bend

Deduction

Bend

Length

Bench Top Bender User’s Manual 23

Page 24

24 Bench Top Bender User’s Manual

Metric Tubing

Dimensions are in millimeters.

6 mm OD, 36 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 –1 0 –1 8 9 17

22 1/2 1 2 4 10 11 22

30 4 5 8 13 14 26

45 7 10 17 16 19 35

60 11 16 26 20 25 44

75 13 23 35 22 32 53

90 14 31 45 23 40 63

105 13 41 54 20 52 72

120 7 56 63 13 68 81

135 –8 79 72 –3 93 90

150 –45 126 81 –42 141 99

165 –174 264 90 –173 281 108

180 68 31 99 77 40 117

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

10 mm OD, 36 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 –1 0 –1 4 5 9

22 1/2 1 2 4 6 7 13

30 4 5 8 8 10 18

45 7 10 17 11 15 26

60 11 16 26 14 21 35

75 13 23 35 16 28 44

90 14 31 45 17 36 53

105 13 41 54 14 47 61

120 7 56 63 8 62 70

135 –8 79 72 –8 87 79

150 –45 126 81 –47 134 88

165 –174 264 90 –177 273 96

180 68 31 99 69 36 105

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 25

Metric Tubing continued

Dimensions are in millimeters.

12 mm OD, 36 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 -3 -2 -5 1 2 3

22 1/2 -1 0 0 3 4 8

30 2 3 4 5 7 12

45 5 8 13 9 12 21

60 9 14 22 12 18 30

75 11 21 31 14 25 39

90 12 29 41 15 33 48

105 11 39 50 14 43 57

120 6 53 59 8 58 66

135 -9 76 68 -7 82 75

150 -46 123 77 -45 129 84

165 -175 261 86 -175 268 93

180 66 29 95 69 33 102

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bench Top Bender User’s Manual 25

Bend

Length

14 mm OD, 46 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 5 6 11 8 9 17

22 1/2 8 9 17 11 12 23

30 11 12 23 13 15 29

45 16 19 35 18 22 40

60 20 26 47 22 30 52

75 24 35 58 25 38 63

90 25 46 70 25 49 74

105 23 59 82 22 63 86

120 15 79 94 13 84 97

135 –4 110 106 –7 116 108

150 –53 171 118 –57 177 120

165 –219 348 130 –224 355 131

180 96 46 142 94 49 143

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 26

26 Bench Top Bender User’s Manual

Metric Tubing continued

Dimensions are in millimeters.

15 mm OD, 46 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 4 5 9 8 9 17

22 1/2 7 8 15 11 12 23

30 10 11 21 14 15 29

45 15 18 32 19 22 41

60 19 25 44 23 29 53

75 22 34 56 27 38 64

90 23 45 68 28 49 76

105 21 58 80 25 63 88

120 14 78 91 17 83 100

135 –6 109 103 –3 115 112

150 –54 169 115 –52 176 124

165 –220 347 127 –218 354 136

180 94 45 139 99 49 148

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

16 mm OD, 46 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 5 6 11 6 6 12

22 1/2 8 9 16 8 9 18

30 10 12 22 11 12 23

45 15 19 34 16 19 35

60 19 26 46 20 27 47

75 22 35 57 23 35 59

90 23 46 69 24 46 70

105 21 59 80 22 60 82

120 13 79 92 14 80 94

135 –7 110 104 –6 111 105

150 –56 171 115 –55 172 117

165 –222 348 127 –221 349 129

180 93 46 139 95 46 141

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 27

Metric Tubing continued

Dimensions are in millimeters.

18 mm OD, 56 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 8 8 16 14 14 28

22 1/2 11 12 23 17 18 35

30 14 16 30 20 22 42

45 20 24 44 27 30 57

60 25 33 58 32 39 71

75 28 44 72 35 50 85

90 29 57 86 36 63 99

105 26 74 101 33 81 114

120 16 98 115 22 106 128

135 –8 137 129 –3 146 142

150 –68 211 143 –64 221 156

165 –270 427 157 –268 438 171

180 114 57 171 122 63 185

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bench Top Bender User’s Manual 27

Bend

Length

20 mm OD, 67 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 3 4 7 1 2 3

22 1/2 7 8 15 5 6 12

30 11 13 24 9 11 20

45 18 23 41 17 21 38

60 24 34 57 23 32 55

75 28 46 74 28 44 72

90 29 62 91 29 60 89

105 27 81 108 27 79 106

120 16 109 125 17 107 124

135 –12 154 142 –10 151 141

150 –83 242 159 –80 238 158

165 –324 500 176 –321 496 175

180 130 62 192 132 60 192

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 28

28 Bench Top Bender User’s Manual

Metric Tubing continued

Dimensions are in millimeters.

22 mm OD, 67 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 9 10 19 7 7 14

22 1/2 13 14 27 11 12 23

30 17 19 36 15 16 31

45 24 29 53 22 26 49

60 30 40 69 29 37 66

75 34 52 86 33 50 83

90 35 68 103 35 66 100

105 32 88 120 32 86 117

120 20 117 137 21 114 135

135 –9 163 154 –8 160 152

150 –81 252 171 –78 248 169

165 –323 511 188 –320 506 186

180 136 68 204 138 66 203

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

25 mm OD, 82 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 24 25 49 12 13 24

22 1/2 29 30 60 16 18 35

30 34 36 70 21 24 45

45 43 48 91 29 36 65

60 51 61 113 37 49 86

75 57 77 134 41 65 106

90 59 96 155 43 84 127

105 53 123 176 38 109 147

120 36 161 197 23 145 168

135 –1 219 218 –13 201 188

150 –90 329 239 –101 309 209

165 –388 649 260 –397 627 229

180 186 96 282 166 84 250

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 29

Metric Tubing continued

Dimensions are in millimeters.

28 mm OD, 112 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 11 12 23

22 1/2 18 20 37

30 24 28 51

45 36 44 80

60 46 62 108

75 53 83 136

90 55 110 164

105 50 143 193

120 30 191 221

135 –17 267 249

150 –136 414 277

165 –541 846 306

180 224 110 334

Bend

Allowance

Steel Bend Shoe

Bend

Deduction

Bench Top Bender User’s Manual 29

Bend

Length

30 mm OD, 112 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 9 10 18

22 1/2 15 17 32

30 22 25 47

45 34 41 75

60 44 60 103

75 51 81 132

90 53 107 160

105 48 140 188

120 29 187 217

135 –18 263 245

150 –136 410 273

165 –540 842 302

180 223 107 330

Bend

Allowance

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 30

30 Bench Top Bender User’s Manual

Fractional Tubing with Metric Dimensions

Tube OD is in inches. Bend radius, bend shoe, and bend dimensions are in millimeters.

1/4 in. OD, 36 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing Medium-Pressure Tubing

Bend

Angle

Degrees

15 1 2 3 8 8 16 9 10 19

22 1/2 3 4 7 10 10 20 12 12 24

30 5 6 12 12 13 25 14 14 28

45 9 12 21 16 18 34 18 20 38

60 13 18 30 19 24 43 21 26 47

75 15 25 40 21 31 52 24 33 56

90 16 33 49 22 39 62 25 41 66

105 15 43 58 20 51 71 22 53 75

120 9 58 67 13 67 80 15 69 84

135 –6 82 76 –3 92 89 –1 94 93

150 –44 129 85 –42 140 98 –40 143 103

165 –174 268 95 –173 280 107 –171 283 112

180 71 33 104 77 39 117 81 41 121

Allowance

Aluminum Bend Shoe Steel Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

1/4 in. OD, IPT Series, 36 mm Radius Bend Shoe with Effective Bend Radius of 40 mm

Medium- and High-Pressure Tubing

Bend

Angle

Degrees

15 8 8 17

22 1/2 11 11 22

30 13 14 27

45 18 20 38

60 22 26 48

75 25 34 59

90 26 43 69

105 24 56 80

120 17 74 90

135 -1 101 101

150 -43 155 111

165 -188 310 122

180 89 43 132

Bend

Allowance

IPT Series

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 31

Bench Top Bender User’s Manual 31

Fractional Tubing with Metric Dimensions

Tube OD is in inches. Bend radius, bend shoe, and bend dimensions are in millimeters.

3/8 in. OD, 36 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing Medium-Pressure Tubing

Bend

Angle

Degrees

15 –1 –1 –2 1 2 3 7 8 15

22 1/2 1 2 3 4 4 8 10 10 20

30 3 4 7 6 6 12 12 13 25

45 7 9 17 10 12 22 15 18 34

60 11 15 26 13 18 31 19 24 43

75 13 22 35 16 25 40 21 31 52

90 14 31 45 17 33 50 21 39 61

105 14 41 54 16 43 59 19 51 70

120 8 55 63 10 58 68 12 67 79

135 –6 79 73 –5 82 77 –4 92 88

150 –43 125 82 –43 129 87 –43 140 97

165 –173 264 91 –172 268 96 –174 280 106

180 70 31 101 73 33 105 76 39 115

Allowance

Aluminum Bend Shoe Steel Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

3/8 in. OD, 56 mm Radius Bend Shoe

Carbon Steel and Stainless Steel

Bend

Angle

Degrees

15 8 9 17

22 1/2 12 13 24

30 15 17 32

45 22 25 47

60 27 35 62

75 31 46 77

90 33 60 93

105 30 78 108

120 20 103 123

135 -5 144 138

150 -68 222 153

165 -281 450 169

180 124 60 184

Bend

Allowance

Tubing

Steel Bend Shoe

Bend

Deduction

Bend

Length

3/8 in. OD, IPT Series, 56 mm Radius Bend Shoe with

Effective Bend Radius of 62 mm

Medium- and High-Pressure Tubing

Bend

Angle

Degrees

15 10 11 21

22 1/2 14 15 29

30 18 19 37

45 25 28 53

60 31 38 69

75 36 50 86

90 37 64 102

105 34 84 118

120 24 111 134

135 -3 153 150

150 -69 235 166

165 -293 475 183

180 134 64 199

Bend

Allowance

IPT Series

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 32

32 Bench Top Bender User’s Manual

Fractional Tubing with Metric Dimensions continued

Tube OD is in inches. Bend radius, bend shoe, and bend dimensions are in millimeters.

1/2 in. OD, 36 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing Medium-Pressure Tubing

Bend

Angle

Degrees

15 –2 –2 –4 3 3 6 2 2 4

22 1/2 0 1 1 5 6 10 4 5 9

30 2 3 5 7 8 15 6 7 14

45 6 9 14 11 13 24 10 13 23

60 9 14 23 14 19 33 13 18 32

75 11 21 32 16 26 42 16 25 41

90 12 30 42 17 35 51 17 34 50

105 11 40 51 15 45 60 15 44 59

120 6 54 60 9 60 69 9 59 69

135 –9 78 69 –6 85 78 –6 84 78

150 –46 124 78 –45 132 87 –44 131 87

165 –176 262 87 –175 271 96 –174 270 96

180 66 30 96 71 35 105 72 34 105

Allowance

Aluminum Bend Shoe Steel Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

1/2 in. OD, 56 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 16 16 32

22 1/2 19 20 39

30 22 24 46

45 28 32 60

60 33 41 74

75 37 52 89

90 38 65 103

105 34 83 117

120 23 109 131

135 –2 148 146

150 –63 223 160

165 –267 441 174

180 124 65 189

Allowance

Bend

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 33

Bench Top Bender User’s Manual 33

Fractional Tubing with Metric Dimensions continued

Tube OD is in inches. Bend radius, bend shoe, and bend dimensions are in millimeters.

9/16 in. OD, IPT Series, 82 mm. Radius Bend Shoe with Effective Bend Radius of 88 mm

Medium- and High-Pressure Tubing

Bend

Angle

Degrees

15 11 12 23

22 1/2 17 18 34

30 22 24 46

45 32 36 69

60 41 51 92

75 47 68 115

90 49 88 137

105 46 115 160

120 31 152 183

135 -6 212 206

150 -99 328 229

165 -416 668 252

180 187 88 275

Bend

Allowance

IPT Series

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 34

34 Bench Top Bender User’s Manual

Fractional Tubing with Metric Dimensions continued

Tube OD is in inches. Bend radius, bend shoe, and bend dimensions are in millimeters.

5/8 in. OD, 46 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 6 6 10 9 10 20

22 1/2 8 8 16 12 13 25

30 10 12 22 15 16 31

45 15 18 33 19 23 43

60 19 26 45 23 31 54

75 22 34 57 26 39 66

90 23 45 68 27 50 77

105 21 59 80 24 65 89

120 13 79 92 15 85 100

135 –7 110 103 –5 117 112

150 –56 170 115 –55 178 123

165 –221 348 126 –222 357 135

180 93 45 138 96 50 146

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

3/4 in. OD, 56 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 9 10 19 13 14 27

22 1/2 12 14 26 17 18 34

30 16 17 33 20 21 41

45 22 26 47 26 30 56

60 27 35 61 31 39 70

75 30 45 75 35 49 84

90 31 58 89 36 62 98

105 28 76 104 32 80 112

120 18 100 118 21 105 127

135 –7 139 132 –4 145 141

150 –67 213 146 –64 219 155

165 –269 429 160 –267 436 169

180 116 58 174 121 62 184

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 35

Fractional Tubing with Metric Dimensions continued

Tube OD is in inches. Bend radius, bend shoe, and bend dimensions are in millimeters.

7/8 in. OD, 67 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 6 6 12 0 0 0

22 1/2 10 11 21 4 5 8

30 14 16 30 8 9 17

45 22 25 47 15 19 34

60 28 36 64 21 30 51

75 33 49 82 26 43 68

90 34 65 99 27 58 86

105 32 85 116 25 77 103

120 21 113 134 15 105 120

135 –7 158 151 –12 149 137

150 –78 246 168 –82 236 154

165 –320 505 186 –322 494 171

180 138 65 203 130 58 189

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Bench Top Bender User’s Manual 35

1 in. OD, 82 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 23 23 47 12 12 24

22 1/2 28 29 57 17 18 35

30 34 35 68 22 24 46

45 43 47 90 31 36 67

60 51 60 111 39 49 88

75 57 76 133 45 65 109

90 59 95 154 47 84 130

105 54 122 175 43 109 152

120 38 159 197 29 144 173

135 2 217 218 –6 200 194

150 –87 327 240 –93 309 215

165 –385 646 261 –389 626 236

180 188 95 283 174 84 258

Allowance

Aluminum Bend Shoe Steel Bend Shoe

Bend

Bend

Deduction

Bend

Length

Bend

Allowance

Deduction

Bend

Bend

Length

Page 36

36 Bench Top Bender User’s Manual

Fractional Tubing with Metric Dimensions continued

Tube OD is in inches. Bend radius, bend shoe, and bend dimensions are in millimeters.

1 1/4 in. OD, 112 mm Radius Bend Shoe

Carbon Steel and Stainless Steel Tubing

Bend

Angle

Degrees

15 20 22 42

22 1/2 27 29 56

30 33 37 70

45 45 53 98

60 54 72 126

75 61 93 154

90 63 119 182

105 56 154 210

120 35 203 238

135 –15 281 266

150 –136 430 294

165 –154 864 322

180 231 119 350

Allowance

Bend

Steel Bend Shoe

Bend

Deduction

Bend

Length

Page 37

Minimum Length of Last Leg

During bending, both rollers must remain on the tube until

the desired bend angle is achieved. If the length of tube is

too short, the bend may not reach its desired angle or the

end of the tube may be damaged.

Specifying a nal leg length equal to or greater than the

minimum length of last leg length in the following tables will

ensure a sufcient amount of tube exists to allow the nal

bend to be made correctly.

Minimum Length of Last Leg Tables

Fractional Tubing

Dimensions are in inches.

Aluminum Bend Shoe

Tube OD 1/4 3/8 1/2 5/8 3/4 7/8 1

Bend Radius 1.42 1.42 1.42 1.81 2.20 2.64 3.23

2 9/16 2 1/2 2 11/16 3 1/2 4 1/4 3 11/16 4 11/16

2 11/16 2 5/8 2 13/16 3 5/8 4 7/16 3 7/8 4 7/8

2 3/4 2 3/4 2 7/8 3 3/4 4 9/16 4 1/16 5 1/8

2 15/16 2 15/16 3 1/16 4 4 7/8 4 7/16 5 9/16

3 3/16 3 3/16 3 5/16 4 5/16 5 1/4 4 7/8 6 1/8

3 7/16 3 7/16 3 9/16 4 11/16 5 11/16 5 3/8 6 3/4

3 13/16 3 3/4 3 15/16 5 1/16 6 3/16 6 7 1/2

4 3/16 4 3/16 4 5/16 5 5/8 6 7/8 6 3/4 8 9/16

4 13/16 4 3/4 4 7/8 6 3/8 7 13/16 7 7/8 10

5 3/4 5 11/16 5 13/16 7 5/8 9 5/16 9 11/16 12 5/16

7 9/16 7 1/2 7 5/8 10 12 1/4 13 1/8 16 5/8

13 1/16 12 15/16 13 1/16 17 20 3/4 23 5/16 29 3/16

3 13/16 3 3/4 3 15/16 5 1/16 6 3/16 6 7 1/2

Bend Angle, Degrees

15

22 1/2

30

45

60

75

90

105

120

135

150

165

180

Bench Top Bender User’s Manual 37

Steel Bend Shoe

1/4

Tube OD 1/4

Bend Radius 1.42 1.42 1.42 1.42 1.42 2.20 2.20 1.42 1.42 2.20

3 7/16 3 1/2 3 7/16 3 5/8 3 1/2 4 1/8 4 3 3/8 3 5/16 4 1/4

3 9/16 3 5/8 3 9/16 3 3/4 3 5/8 4 5/16 4 1/8 3 1/2 3 7/16 4 7/16

3 5/8 3 11/16 3 11/16 3 13/16 3 11/16 4 7/16 4 5/16 3 9/16 3 9/16 4 9/16

3 13/16 3 7/8 3 15/16 4 3 7/8 4 13/16 4 11/16 3 3/4 3 3/4 4 7/8

4 1/16 4 1/8 4 3/16 4 1/4 4 1/8 5 3/16 5 1/16 4 4 5 1/4

4 5/16 4 3/8 4 1/2 4 1/2 4 3/8 5 5/8 5 1/2 4 1/4 4 1/4 5 11/16

4 11/16 4 3/4 4 7/8 4 7/8 4 3/4 6 3/16 6 1/8 4 5/8 4 9/16 6 3/16

5 1/8 5 3/16 5 3/8 5 1/4 5 3/16 6 7/8 6 7/8 5 5 6 7/8

5 3/4 5 13/16 6 1/16 5 7/8 5 13/16 7 7/8 7 15/16 5 5/8 5 9/16 7 7/8

6 3/4 6 13/16 7 3/16 6 13/16 6 13/16 9 7/16 9 9/16 6 9/16 6 9/16 9 7/16

8 5/8 8 3/4 9 5/16 8 5/8 8 11/16 12 1/2 12 13/16 8 7/16 8 3/8 12 7/16

14 1/8 14 1/4 15 7/16 14 1/8 14 3/16 21 7/16 22 1/4 13 15/16 13 7/8 20 15/16

4 11/16 4 3/4 4 7/8 4 7/8 4 3/4 6 3/16 6 1/8 4 5/8 4 9/16 6 3/16

Bend Angle, Degrees

15

22 1/2

30

45

60

75

90

105

120

135

150

165

180

Medium

Pressure

1/4 IPT

Series 3/8

3/8

Medium

Pressure 3/8

3/8 IPT

Series 1/2

1/2

Medium

Pressure 1/2

Page 38

38 Bench Top Bender User’s Manual

Minimum Length of Last Leg Tables

Fractional Tubing

Dimensions are in inches.

Steel Bend Shoe

15

30

45

60

75

90

105

120

135

150

165

180

9/16 IPT

Series 5/8 3/4 7/8 1 1 1/4

5 3 11/16 4 5/16 4 7/16 5 1/4 5 3/4

5 1/4 3 13/16 4 7/16 4 5/8 5 7/16 6 1/16

5 7/16 3 15/16 4 9/16 4 13/16 5 11/16 6 5/16

5 15/16 4 3/16 4 15/16 5 3/16 6 1/8 7

6 9/16 4 1/2 5 1/4 5 5/8 6 11/16 7 11/16

7 3/16 4 7/8 5 11/16 6 1/8 7 5/16 8 9/16

8 5 1/4 6 3/16 6 3/4 8 1/16 9 9/16

9 1/16 5 7/8 6 15/16 7 1/2 9 1/16 10 15/16

10 9/16 6 5/8 7 7/8 8 9/16 10 7/16 12 7/8

12 7/8 7 15/16 9 7/16 10 5/16 12 5/8 15 15/16

17 1/2 10 5/16 12 3/8 13 11/16 16 15/16 21 13/16

30 7/8 17 3/8 20 15/16 23 7/8 29 3/8 38 7/8

8 5 1/4 6 3/16 6 3/4 8 1/16 9 9/16

Tube OD

Bend Radius 3.23 1.81 2.20 2.64 3.23 4.41

22 1/2

Bend Angle, Degrees

Metric Tubing

Dimensions are in millimeters.

Aluminum Bend Shoe

Tube OD 6 10 12 14 15 16 18 20 22 25

Bend Radius 36 36 36 46 46 46 56 67 67 82

63 65 69 88 87 89 102 89 96 122

65 67 71 91 90 92 106 93 100 128

68 70 74 94 93 95 110 98 105 133

73 75 79 101 100 102 118 108 115 145

79 81 85 108 108 109 127 119 126 159

86 88 92 117 116 118 138 131 138 174

94 96 100 128 127 129 151 147 154 194

104 106 110 141 141 142 168 166 174 221

119 121 124 161 160 162 192 194 203 258

142 144 147 192 191 193 231 239 249 316

189 191 194 253 252 254 305 327 338 427

327 329 332 430 429 431 521 585 597 746

94 96 100 128 127 129 151 147 154 194

Bend Angle, Degrees

15

22 1/2

30

45

60

75

90

105

120

135

150

165

180

Steel Bend Shoe

Tube OD 6 10 12 14 15 16 18 20 22 25 28 30

Bend Radius 36 36 36 46 46 46 56 67 67 82 112 112

15

22 1/2

30

45

60

75

90

105

120

Bend Angle, Degrees

135

150

165

180

87 80 83 91 91 89 108 112 118 130 141 140

89 82 85 94 94 92 112 116 123 136 149 147

92 85 88 97 97 95 116 121 127 141 157 155

97 90 93 104 104 102 124 131 137 153 173 171

103 96 99 112 112 110 133 142 148 167 191 190

110 103 106 120 120 118 144 154 161 182 212 211

118 111 114 131 131 129 157 170 177 202 239 237

130 122 124 145 145 143 175 189 197 227 272 270

146 137 139 166 166 163 200 217 225 262 320 317

171 162 163 198 197 194 240 261 271 318 396 393

219 209 210 259 258 255 315 348 359 427 543 540

359 348 349 437 436 432 532 606 617 744 975 972

118 111 114 131 131 129 157 170 177 202 239 237

Page 39

Bench Top Bender User’s Manual 39

Minimum Length of Last Leg Tables

Fractional Tubing with Metric Dimensions

Tube OD is in inches. Bend radius and length are in millimeters.

Aluminum Bend Shoe

Tube OD 1/4 3/8 1/2 5/8 3/4 7/8 1

Bend Radius 36 36 36 46 56 67 82

15

22 1/2

30

45

60

75

90

105

120

Bend Angle, Degrees

135

150

165

180

Steel Bend Shoe

Tube OD 1/4

Bend Radius 36 36 36 36 36 56 56 36 36 56

15

22 1/2

30

45

60

75

90

105

120

Bend Angle, Degrees

135

150

165

180

65 64 69 89 108 94 119

67 66 71 92 112 98 125

70 69 74 95 116 103 130

75 74 79 102 124 112 142

81 80 85 110 133 123 156

88 87 92 118 144 136 171

96 95 100 129 157 152 190

107 105 110 143 174 172 217

121 120 124 163 199 200 255

146 144 148 194 237 245 313

193 190 194 254 311 334 423

332 329 333 432 528 592 742

96 95 100 129 157 152 190

1/4

Medium

Pressure

87 89 88 92 89 105 101 85 85 108

90 91 90 95 91 109 105 88 87 112

92 94 93 97 94 113 110 90 90 116

97 99 99 103 99 122 119 96 95 124

103 105 105 108 105 132 129 102 101 133

110 112 113 115 112 143 141 108 108 144

119 120 122 124 120 157 155 117 116 157

130 132 135 134 132 175 174 128 127 175

146 148 153 149 148 200 201 143 142 201

171 174 181 173 173 240 244 167 166 241

219 222 234 220 221 318 326 214 213 316

359 362 389 359 361 546 566 354 352 534

119 120 122 124 120 157 155 117 116 157

1/4 IPT

Series 3/8

3/8

Medium

Pressure 3/8

3/8 IPT

Series 1/2

1/2

Medium

Pressure 1/2

Steel Bend Shoe

15

30

45

60

75

90

105

120

135

150

165

180

9/16 IPT

Series 5/8 3/4 7/8 1 1 1/4

127 94 109 113 133 146

133 97 113 118 139 153

139 100 117 122 144 161

152 107 125 132 156 177

166 115 134 143 170 196

183 123 145 156 185 217

203 134 158 172 204 243

230 149 176 190 229 278

268 169 201 218 265 327

328 201 240 262 321 405

444 262 315 349 429 554

784 441 532 607 746 988

203 134 158 172 204 243

Tube OD

Bend Radius 82 46 56 67 82 112

22 1/2

Bend Angle, Degrees

Page 40

40 Bench Top Bender User’s Manual

Maintenance

All Models

Using the supplied grease gun, grease the two points on the

upper gearbox of the bender after every 24 hours of operation.

Grease points

The grease must be a high-grade, multipurpose grease

meeting Castrol® Molub-Alloy-860/220-1 ES or Tribol

4020/220-1 specications.

Electric bender motor brush replacements are available for

use in the eld. Any other repairs to the electric or manual

tube bender are to be made by a Swagelok authorized

service center. Swagelok reserves the right not to make

repairs in situations where the bender has been altered.

Electric Models

Inspect components for wear or damage periodically.

Motor Brush Inspection, Removal, and Replacement

The motor brushes should be inspected for wear after every

800 hours of operation, or every six months, and replaced

when their length is 1/4 in. (6.4 mm) or less.

3. Using a at screwdriver or a similar tool, rotate the

spring away from the motor brush and remove the

motor brush from the housing.

Note: Complete replacement of one brush, then replace the

second brush.

Spring

Releasing

motor brush

Removing

motor brush

4. Inspect the brushes for wear. Replace when the length

is 1/4 in. (6.4 mm) or less.

1/4 in.

WARNING

Remove unit from power source.

CAUTION

The motor brushes are under spring tension.

CAUTION

Serious damage may occur to the motor if brushes

are not replaced when worn.

1. Turn the bender over. Remove the four socket-head

cap screws using a 5 mm hex key.

Socket-head

cap screws

2. Remove the bottom cover.

Socket-head

cap screws

Motor

brushes

Replace brush

New brush

5. Reverse steps 1 through 3 to install the new motor

brush. Ensure that the brush spring is secured properly

in the housing.

Proper brush

installation

Improper brush

installation

Page 41

Replacement Parts