Page 1

Power Supply

www.swagelok.com

This manual contains important information for the safe

and effective operation of the Swagelok® Welding System

M200 power supply. Users should read and understand its

contents before operating the M200 power supply.

User’s Manual

Page 2

2 M200 Power Supply User’s Manual

Page 3

Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Safety Summary . . . . . . . . . . . . . . . . . . . . . 5

Signal Words and Safety Alert Symbols

Used in this Manual . . . . . . . . . . . . . . . . . 5

M200 Power Supply Warning Label . . . . . . . . . . . 10

Referenced Documents . . . . . . . . . . . . . . . . . 11

Installation and Setup . . . . . . . . . . . . . . . . . . . 13

Description . . . . . . . . . . . . . . . . . . . . . . . . 14

Unpacking the M200 Power Supply . . . . . . . . . . . 16

Registration Information . . . . . . . . . . . . . . . . . 17

Tools and Accessories Required . . . . . . . . . . . 18

Electrical Requirements . . . . . . . . . . . . . . . 18

Setting up the M200 Power Supply . . . . . . . . . . . 19

Installing the Weld Head . . . . . . . . . . . . . . . . . 20

Setting Up the Gas Supply System . . . . . . . . . . . 21

Typical OD Shield / ID Purge Gas Supply System . . 21

Powering On the M200 Power Supply for the First Time 22

Powering Off the M200 Power Supply . . . . . . . . . . 22

Restarting the M200 Power Supply . . . . . . . . . . . 22

Using the Touch Screen . . . . . . . . . . . . . . . . . 23

User Interface . . . . . . . . . . . . . . . . . . . . 23

M200 Power Supply User’s Manual 3

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . 25

Weld Screens . . . . . . . . . . . . . . . . . . . . . . 28

Performing a Weld . . . . . . . . . . . . . . . . . . 34

File Screens . . . . . . . . . . . . . . . . . . . . . . . 35

Program Screens . . . . . . . . . . . . . . . . . . . . 38

Weld Log Screens . . . . . . . . . . . . . . . . . . . . 39

Setup Screens . . . . . . . . . . . . . . . . . . . . . . 42

Remote Pendant . . . . . . . . . . . . . . . . . . . . . 47

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . 48

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Changing Paper . . . . . . . . . . . . . . . . . . . 49

Clearing a Paper Jam . . . . . . . . . . . . . . . . 50

Installing and Replacing the Optional Fan Filter . . . . . 51

Weld Parameter Development . . . . . . . . . . . . . . 52

Weld Parameter Changes . . . . . . . . . . . . . . . . 53

Creating a Weld Procedure Guideline . . . . . . . . 53

Weld Procedure Guideline Worksheets . . . . . . . . . 54

Page 4

4 M200 Power Supply User’s Manual

Advanced Weld Procedure Techniques . . . . . . . . . . 64

Tacks . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Ramp Time . . . . . . . . . . . . . . . . . . . . . . . . 66

Ramping Up in Level 1 . . . . . . . . . . . . . . . . 67

Added Rotor Delay Time Before Welding . . . . . . 69

Step Programs for Multilevel Weld Procedures . . . . . 71

Weld Parameter Guideline

Worksheet Reference Data . . . . . . . . . . . . . . . 80

Single Level Mode Operation . . . . . . . . . . . . . . . 84

Single Level Current-Control Group . . . . . . . . . . . 84

Single Level Timing-Control Group . . . . . . . . . . . 85

Single Level Weld Process Buttons . . . . . . . . . . . 86

Single Level Status Indicator Lights . . . . . . . . . . . 87

Single Level Weld Status Conditions . . . . . . . . . . 87

Single Level Weld Procedure Guidelines . . . . . . . . 88

Evaluating Weld Quality . . . . . . . . . . . . . . . . . . 96

Identifying Proper Welds . . . . . . . . . . . . . . . . . 96

Identifying Typical Weld Discontinuities . . . . . . . . . 96

Improper Welds . . . . . . . . . . . . . . . . . . . . . 97

No ID Penetration . . . . . . . . . . . . . . . . . . 97

Increased ID Convexity and Weld Bead Width . . . . 98

Weld-Puddle Overlap . . . . . . . . . . . . . . . . . 98

Specifications . . . . . . . . . . . . . . . . . . . . . . . 100

M200 Power Supply Output and Duty Cycle . . . . . . 100

M200 Power Supply with 115 V Input . . . . . . . . 100

M200 Power Supply Cycle Times . . . . . . . . . . 101

M200 Power Supply Dimensions . . . . . . . . . . . . 101

Use of Extension Cords

with the M200 Power Supply . . . . . . . . . . . . . . 101

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . 102

Weld Status Conditions . . . . . . . . . . . . . . . . . 102

Disable . . . . . . . . . . . . . . . . . . . . . . . . 102

Operational . . . . . . . . . . . . . . . . . . . . . . 104

Weld Errors . . . . . . . . . . . . . . . . . . . . . . 106

Weld System Hardware and

Weld Process Problems . . . . . . . . . . . . . . . . . 108

Power Supply Repair . . . . . . . . . . . . . . . . . . 116

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Swagelok Embedded System

End User License Agreement . . . . . . . . . . . . . . . 122

The Swagelok Limited Lifetime Warranty . . . . . . . . 124

Page 5

Safety

Safety Summary

Arc welding can be hazardous.

Read the entire safety information section and

M200 Power Supply User’s Manual before using

this product. Failure to do so can result in serious

injury or death.

Signal Words and Safety Alert Symbols

Used in this Manual

WARNING Statements that indicate a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION Statements that indicate a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

NOTICE Statements that indicate a hazardous situation

which, if not avoided, could result in damage to

the equipment or other property.

M200 Power Supply User’s Manual 5

Safety alert symbol indicating a potential personal injury

hazard.

Safety alert symbol indicating a potential for personal

injury from electrical shock.

Safety alert symbol indicating a potential for personal

injury from exposure to fumes and gases.

Safety alert symbol indicating a potential for personal

injury from exposure to the weld arc.

Safety alert symbol indicating a potential for personal

injury resulting from a welding related re or explosion.

Safety alert symbol indicating a potential for personal

injury resulting from a welding related cylinder explosion.

Page 6

6 M200 Power Supply User’s Manual

WARNING

Orbital gas tungsten arc welding (GTAW) can be

hazardous. Only qualified persons should use this

equipment.

After welding, the work piece, weld head, electrode,

fixture block, and collets can be extremely hot and

may cause burns.

Keep children away.

Pacemaker wearers should consult with their

physician before operating this equipment.

Read and understand ANSI Standard Z49.1, “Safety

in Welding and Cutting,” from the American

Welding Society and OSHA Safety and Health

Standards, 29 CFR 1910 and 1926, from the U.S.

Government Printing Office.

The M200 power supply has no internal serviceable

parts and should not be disassembled. Return the

M200 power supply to an authorized Swagelok

sales and service representative for service.

ELECTRIC SHOCK can kill.

Touching live electrical parts and failure to operate

equipment properly can cause fatal electric shock

and severe burns. Incorrectly installed or improperly

grounded equipment is a hazard. To avoid injury:

■ Do not touch live electrical parts.

■ Keep all panels and covers securely in place. Do not

touch electrode connector, electrode, or rotor after

pressing start. The electrode is electrically charged

during the weld process.

■ Follow local electrical codes and the guidelines in

this manual when installing the M200 power supply.

Shock hazards can exist even when equipment is

properly installed, so it is important that the operator

be trained in the proper use of the equipment and

follow established safety practices.

■ Frequently inspect input power cord for damage or

bare wiring—replace immediately if damaged.

■ Properly unplug the power cord. Grasp the plug to

remove it from the receptacle.

Page 7

FUMES AND GASES can be hazardous.

Welding produces fumes and gases. Breathing these

fumes and gases may be hazardous to your health.

Build-up of gases can displace oxygen and cause injury

or death. To avoid injury:

■ Do not breathe fumes or gases.

■ Ventilate the area and/or use exhaust at the arc to

remove welding fumes and gases.

■ When welding materials that produce toxic fumes,

such as galvanized steel, lead, cadmium-plated

steel or other coated metals (unless the coating is

removed from the weld area), or any other welding

material, keep exposure below threshold limit

values (TLV), permissible exposure limits (PEL),

or other applicable health and safety limitation. If

necessary, wear a respirator. Read and understand

the Material Safety Data Sheets (MSDS) and

follow the manufacturer’s instructions for metals,

consumables, coatings, cleaners, degreasers, or

any other substance that may be present during the

weld process.

■ Do not work in a conned space unless it is well

ventilated or you are wearing an air-supplied

respirator. Always have a trained watch-person

nearby. Welding fumes and gases can displace air

and lower the oxygen level causing injury or death.

Be sure the breathing air is safe.

■ Do not weld in locations near degreasing, cleaning,

or spraying operations. The heat and rays of the

arc can react with vapors to form highly toxic and

irritating gases.

■ The ultraviolet light emitted by the welding arc

acts on the oxygen in the surrounding atmosphere

to produce ozone. Test results➀, based upon

present sampling methods, indicate the average

concentration of ozone generated in GTAW process

does not constitute a hazard under conditions of

good ventilation and welding practice.

■ Shut off gas supply when not in use.

M200 Power Supply User’s Manual 7

➀ Welding Handbook, Vol 2, 8th ed., American Welding Society.

Page 8

8 M200 Power Supply User’s Manual

ARC RAYS can burn eyes.

Arc rays from the welding process produce intense

visible and invisible (ultraviolet and infrared) rays that

can burn eyes. The M200 power supply is meant for

use only with enclosed Swagelok weld heads, which

minimize exposure to these harmful rays. To avoid

injury:

■ Do not look at welding arc.

■ Use protective screens or barriers to protect others

from ash and glare; warn others not to watch the

arc.

■ Wear personal protective equipment, including eye

protection.

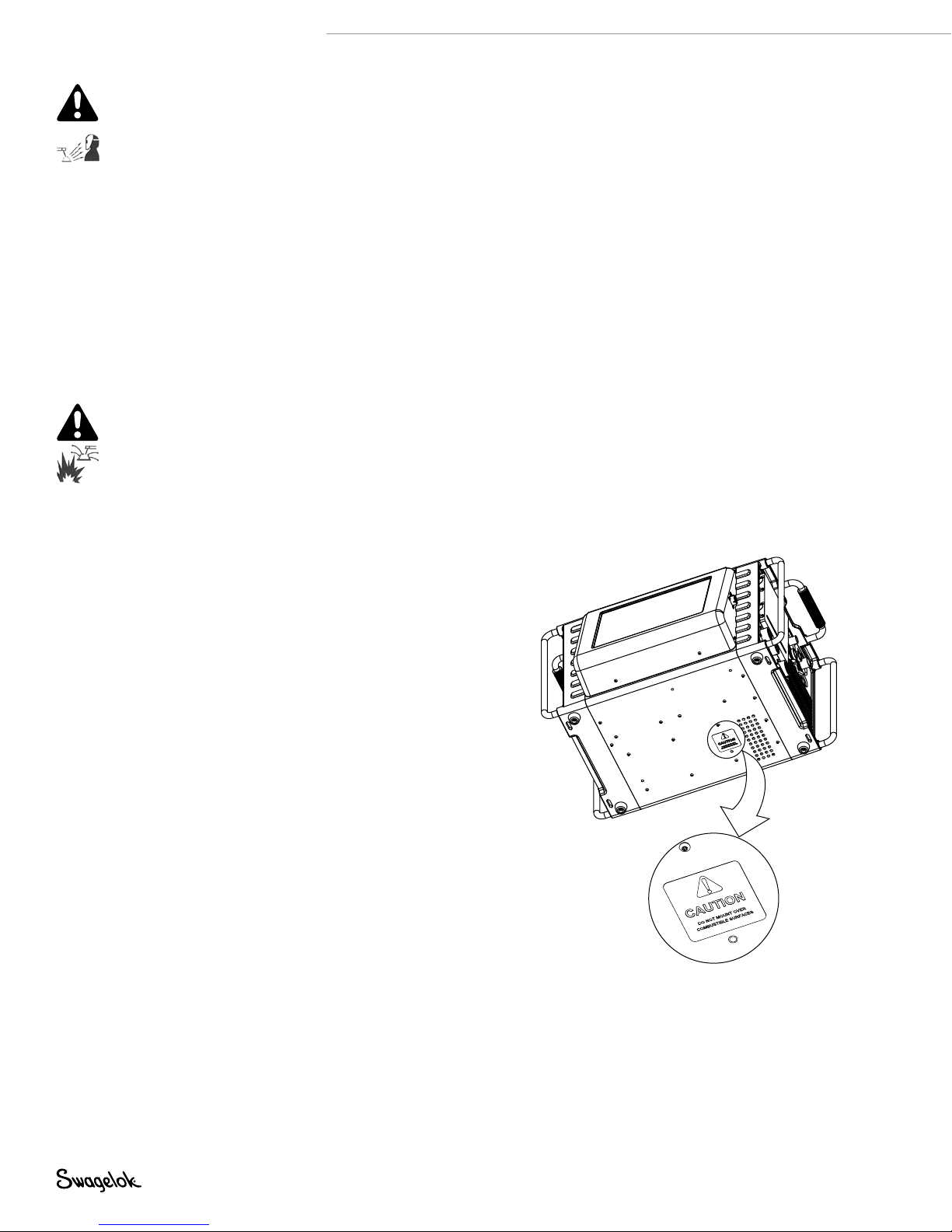

WELDING can cause fire or explosion.

Welding on closed containers, such as tanks, drums, or

pipes, can cause them to explode. The hot work piece

and hot equipment can cause res and burns. Ensure

the area is free of combustibles before welding. To

avoid injury:

■ Do not place the M200 power supply over a

combustible surface. See the label on the bottom of

the M200 power supply (Fig. 1).

■ Do not weld in a combustible environment.

■ Watch for re, and keep a re extinguisher nearby.

■ Do not weld on closed containers such as tanks,

drums, or pipes, unless they are properly prepared

in accordance with AWS F4.1.

■ Do not use the M200 power supply to thaw frozen

pipes.

■ Do not use extension cords that are in poor physical

condition or have insufcient current capacity.

Failure to do so can pose re and shock hazards.

■ Sparks and spatter are thrown from the weld arc.

The M200 power supply is meant for use with

enclosed weld heads, which minimizes exposure

to spatter. Wear proper protective equipment,

including eye protection.

Fig. 1— M200 Power Supply Mounting

Caution Label

Page 9

CYLINDERS may explode if damaged.

Gas cylinders used as part of the orbital GTAW process

contain gas under high pressure. If damaged, a cylinder

can explode. To avoid injury:

■ Protect compressed gas cylinders from excessive

heat, mechanical shocks, slag, open ames, sparks,

and arcs. Follow all site safety precautions and

protocol.

■ Install cylinders in an upright position by securing

to a stationary support or cylinder rack to prevent

falling or tipping.

■ Keep cylinders away from any welding or other

electrical circuits.

■ Never weld on a pressurized cylinder—explosion will

result.

■ Use only correct shielding gas cylinders, regulators,

hoses, and ttings designed for the specic

application; maintain them and associated parts in

good condition.

■ Keep head and face away from valve outlet when

opening cylinder valve.

■ Keep valve protective cap in place over valve except

when cylinder is in use or connected for use.

■ Read and follow instructions on compressed

gas cylinders, associated equipment, and CGA

publication P-1 listed in Referenced Documents,

page 11.

M200 Power Supply User’s Manual 9

Page 10

10 M200 Power Supply User’s Manual

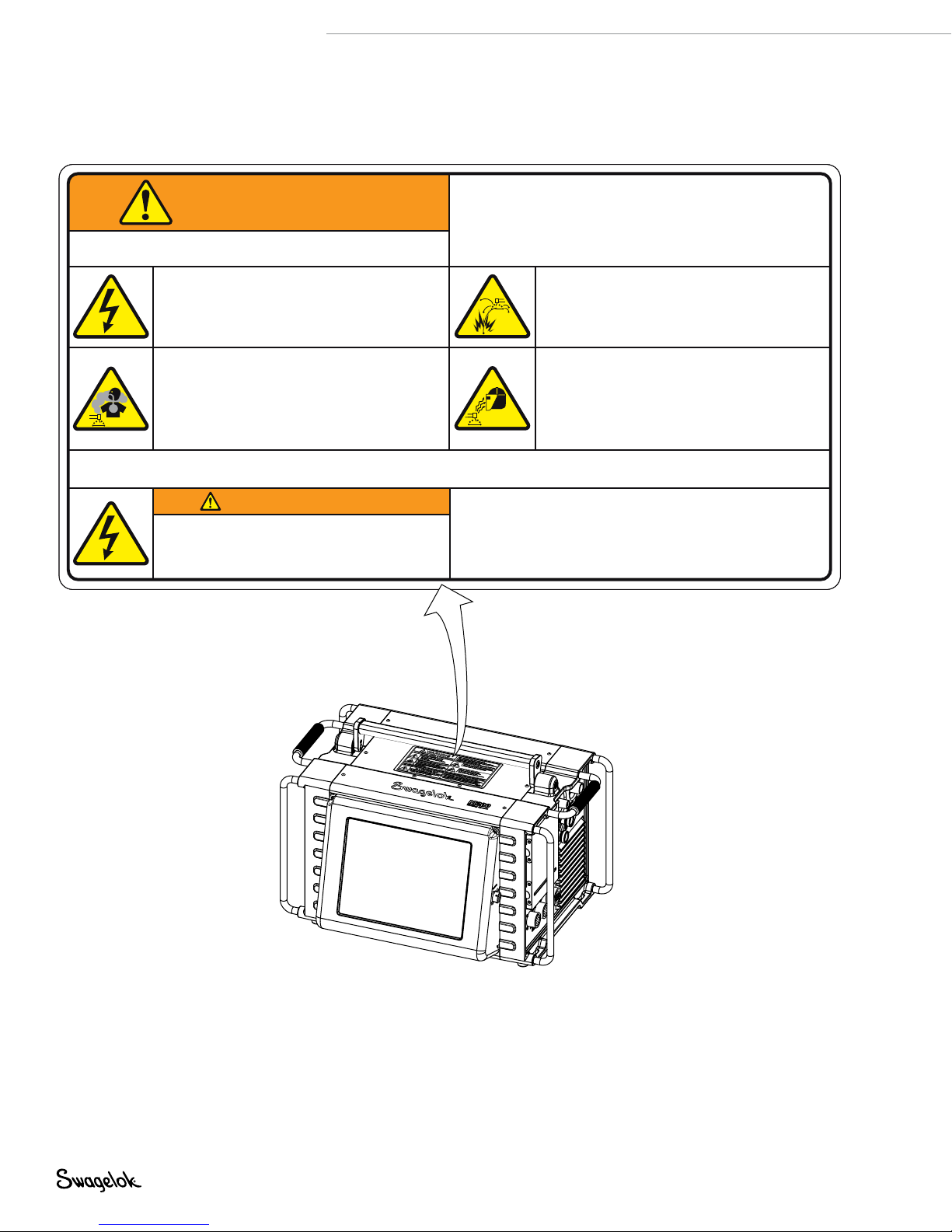

M200 Power Supply Warning Label

This warning label must remain afxed to the top of the power

supply (Fig. 2).

ARC WELDING can be hazardous.

• Read and follow this label and the User’s Manual.

WARNING

Do Not Remove, Destroy, or Cover This Label

For user information contact Swagelok Co. (www.Swagelok.com)

ELECTRIC SHOCK can kill.

• Do not touch live electrical parts.

• Electrode and rotor are live during

weld cycle.

• Keep all panels and covers securely in place.

FUMES AND GASES can be hazardous.

•

Do not breathe fumes or gases.

•

Use ventilation or exhaust to remove fumes

from breathing zone.

•

Read Material Safety Data Sheets (MSDS’s

and follow manufacturer’s instructions for

the material used.

Read American National Standard Z49.1, “Safety in Welding and Cutting,” from American Welding Society, 550 N.W. LeJeune Rd., Miami, FL 33126;

OSHA Safety and Health Standards, 29 CFR 1910 and 1926, from U.S. Government Printing Office, P.O. Box 371954, Pittsburgh, PA 15250

AVERTISSEMENT

UN CHOC ELECTRIQUE peut être mortel.

• Seules des personnes qualifiées peuvent

installer et utiliser cet appareil.

• Only qualified persons are to install and operate this unit.

• Keep children away.

• Pacemaker wearers keep away.

• Return to authorized sales and service center for service.

WELDING can cause fire or explosion.

• Do not weld on closed containers.

• Do not use in a combustible environment

or over a combustible surface.

ARC RAYS can burn eyes.

• Do not look at welding arc.

)

• Wear personal protective equipment

including eye and ear protection.

LE SOUDAGE A L’ARC peut être dangereux.

•

Lisez et respectez cette étiquette ainsi que le manuel utilisateur.

•

Ne pas utiliser dans un environment combustible ou au

dessus d'une surface combustible.

•

Ne touchez pas les parties électriques sous tension.

• L'électrode et le rotor sont sous tension pendant le soudage.

SWS-M200-LBL-WARN-E

Fig. 2—M200 Power Supply Warning Label

Page 11

Referenced Documents

1. AWS F4 .1, Recommended Safe Practices for the

Preparation for Welding and Cutting of Containers and

Piping.

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126 (www.aws.org).

2. ANSI Z49.1, Safety in Welding Cutting, and Allied

Processes.

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126 (www.aws.org).

3. CGA Publication P-1, Safe Handling of Compressed Gases

in Cylinders.

Compressed Gas Association, 4221 Walney Road, 5th Floor,

Chantilly VA 20151-2923, (www.cganet.com).

4. OSHA 29CFR 1910 Subpart Q, Welding Cutting, and

Brazing.

Acquire from U.S. Government Printing Ofce,

Superintendent of Documents, P.O. Box 371954, Pittsburgh,

PA 15250 (www.osha.gov).

5. OSHA 29CFR 1926 Subpart J, Welding and Cutting.

Acquire from U.S. Government Printing Ofce,

Superintendent of Documents, P.O. Box 371954, Pittsburgh,

PA 15250 (www.osha.gov).

M200 Power Supply User’s Manual 11

Page 12

12 M200 Power Supply User’s Manual

Page 13

M200 Power Supply User’s Manual 13

Installation and Setup

Page 14

14 M200 Power Supply User’s Manual

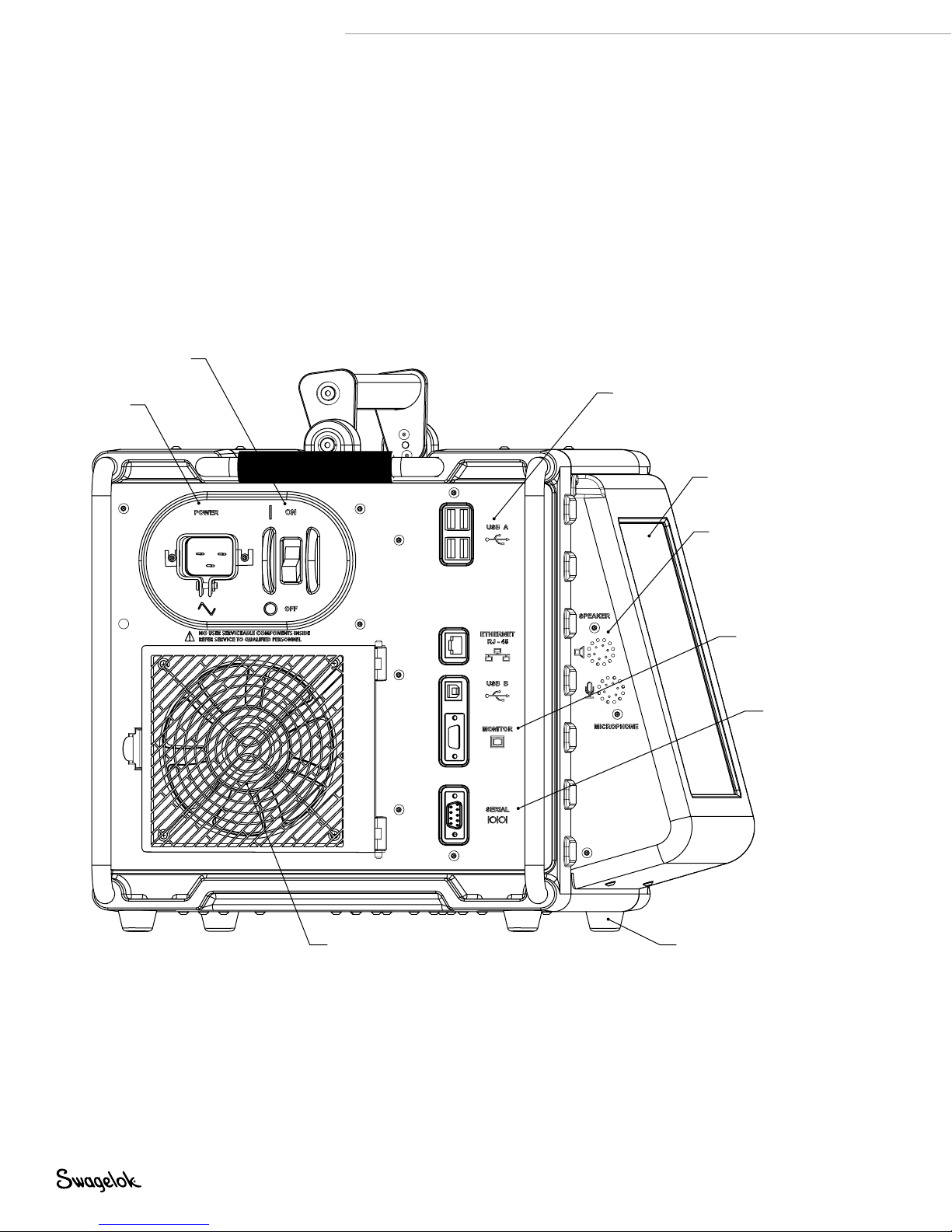

Description

The Swagelok Welding System M200 power supply

provides precise control of weld current, electrode

travel speed, and OD shield gas ow to produce

consistent and repeatable weld results.

The unit features a touch-screen display for easy

navigation and data input. To access menus and

input weld data, the operator presses the touch

screen over the selection. In the Single Level Mode,

users can enter data using simulated thumb wheels.

On/of f switch

Four USB A version 1.1 ports on the side of the M200

power supply accept compatible USB hardware,

such as a USB mouse or keyboard, with no additional

software required. A USB ash drive (not supplied)

provides portable memory and can be used to

transfer data to other M200 power supply units and/

or a PC. A 1 GB USB ash drive is recommended.

There are additional ports for video SVGA output and

a serial cable for direct PC connection.

Power cord

connection

4 USB A 1.1 ports

Touch screen

Speaker

Video (SVGA) out

connection

Serial output

connection

Fig. 3—M200 Power Supply Left Side

Fan housing

Nonslip feet

Page 15

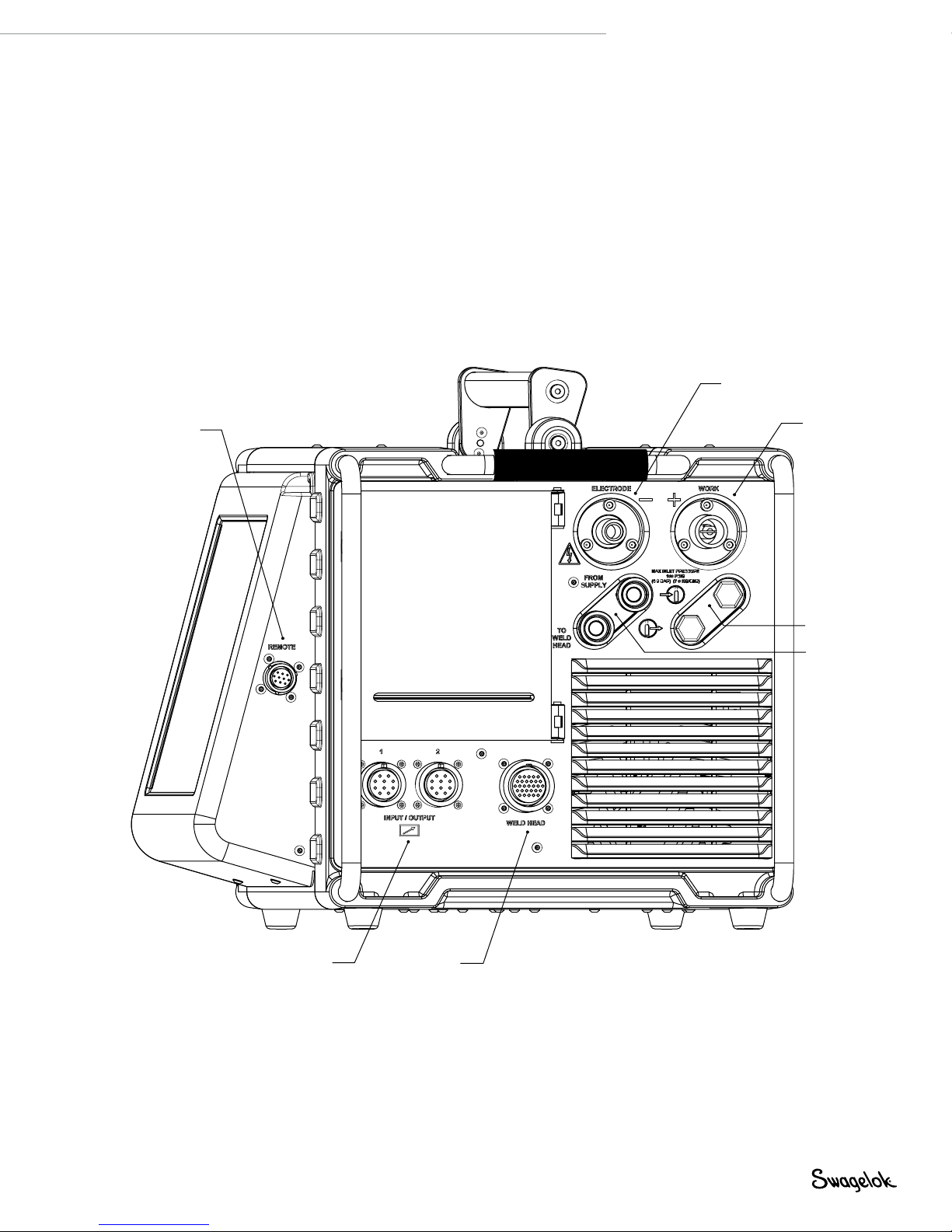

Remote

pendant

connection

M200 Power Supply User’s Manual 15

Electrode

connection (red)

Work

connection

(green)

Auxiliary output

connections

Printer housing

Weld head

connection

Fig. 4—M200 Power Supply Right Side

ID shield gas

connections

OD shield gas

connections

Page 16

16 M200 Power Supply User’s Manual

Unpacking the M200 Power Supply

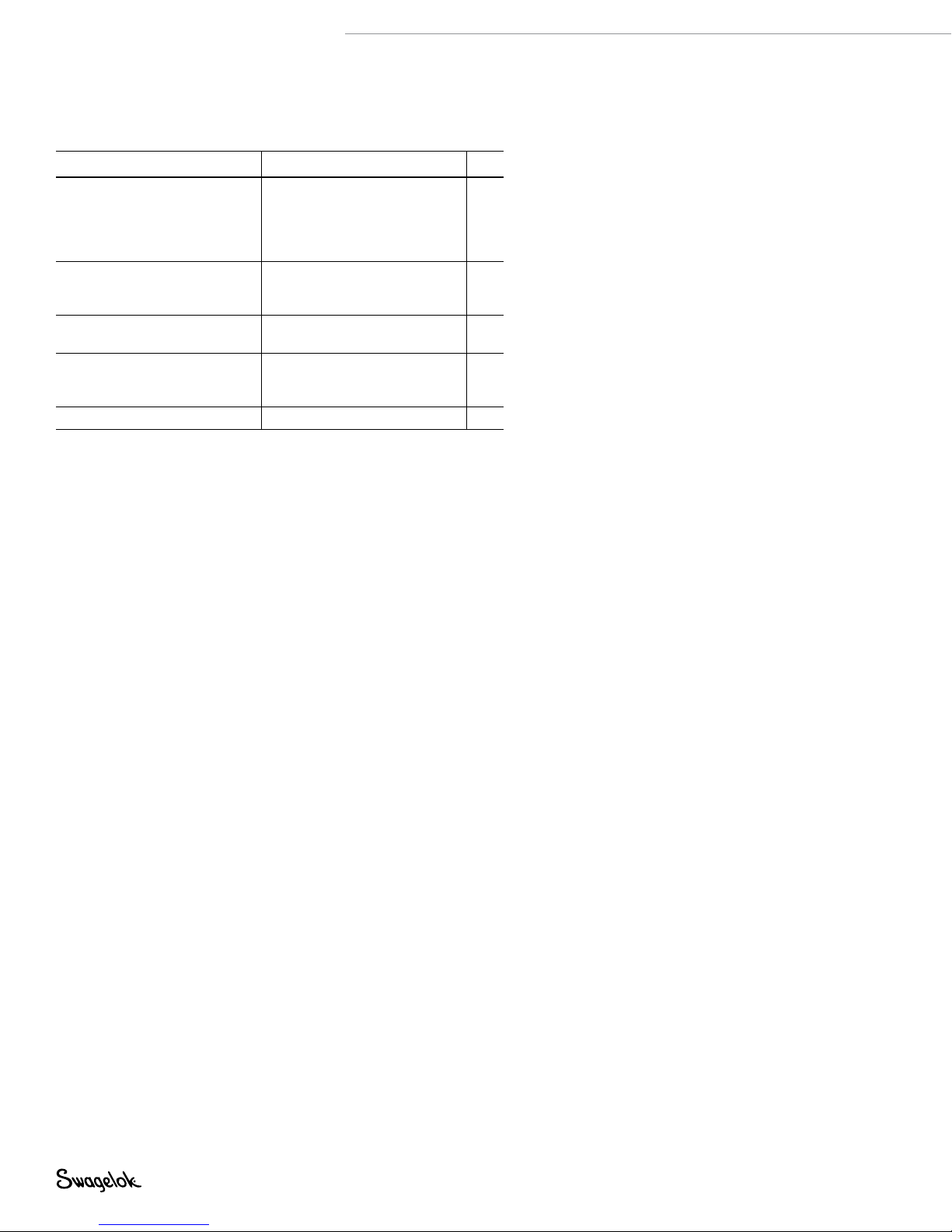

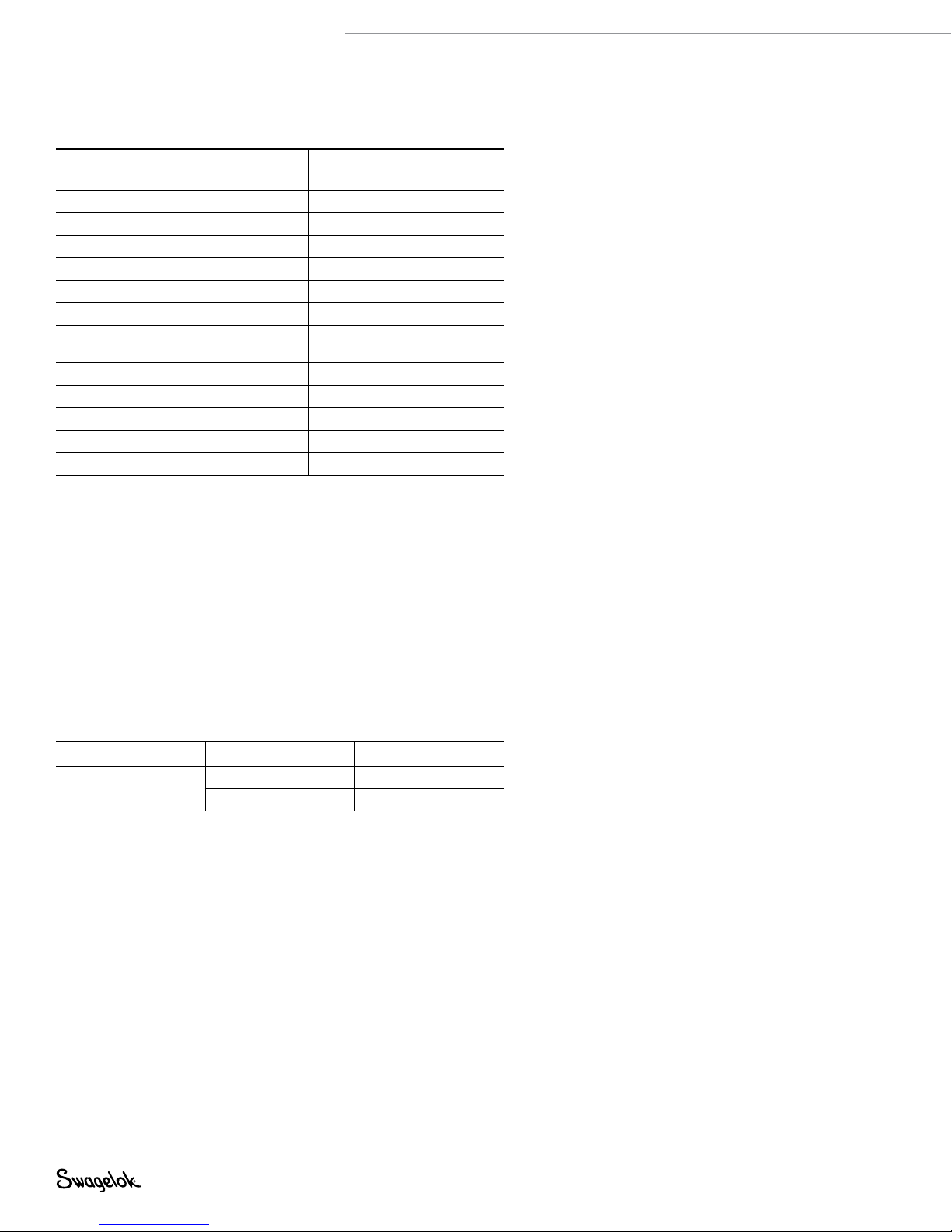

Table 1—Shipping Case Contents

Description Ordering Number Qty

M200 power supply SWS-M200-XX-Y

- XX denotes power cord

plug type

- Y denotes user’s manual

language

Power cord CWS-CORD-X

- X denotes power cord

plug type

1/4 in. male

Quick-Connect stem

M200 Power Supply

User’s Manual

Warranty Information Form — 1

SS-QC4-S-400 1

MS-13-212-Y

- Y denotes user’s manual

language other than English

Remove the contents of the shipping case (Table 1):

1. Use the handle on the top of the M200 power supply to lift it

out of the case. Place the M200 power supply upright on a

stable surface.

2. Check the M200 power supply and accessories for damage.

3. Record the model number and serial number from the rating

label on the back of the M200 power supply (Fig. 5), along

with the delivery date, on the M200 Power Supply Warranty

Information form and the Registration Information form,

page 17. Return the Warranty Information form to your

authorized Swagelok representative to activate the warranty.

1

1

1

Note: Contact your authorized Swagelok

representative if the unit is damaged.

Note: Do not store the M200 power

supply near corrosive materials.

Store indoors and cover when not

in use.

Page 17

Registration Information

Your authorized Swagelok representative provides support and

service for your M200 power supply and Swagelok weld heads.

Please take a moment to ll out the information listed below.

See the rating label on the back of the M200 power supply.

(Fig. 5) for the model and serial numbers.

Keep this information available in case you need to contact your

authorized Swagelok representative.

Date of Delivery: _________________________________________

Power Supply Model Number: ____________________________

Serial Number: ____________________________

Weld Head Model Number: ____________________________

Serial Number: ____________________________

Weld Head Model Number: ____________________________

Serial Number: ____________________________

M200 Power Supply User’s Manual 17

Weld Head Model Number: ____________________________

Serial Number: ____________________________

Weld Head Model Number: ____________________________

Serial Number: ____________________________

Company Name: _________________________________________

Swagelok Distributorship: _________________________________

Fig. 5—M200 Power Supply Rating Label

Page 18

18 M200 Power Supply User’s Manual

Tools and Accessories Required

Table 2—Tools and Accessories

Tool/Accessory Included-

Hex wrenches (1/2 to 5/32 in.) Yes Weld head

Electrode package Yes

Arc gap gauge Yes

Flat-blade screw driver Yes Weld head

Centering gauge Yes

Calipers or micrometer No —

Purge kit

(Ordering number: SWS-PURGE-KIT)

Low-moisture gas lines No —

Gas source No —

Pressure regulator No —

ID purge gas flow meter No —

Pressure gauge No —

➀ The Series 40 weld head does not include an electrode, arc gap gauge, or

centering gauge package.

➀

➀

➀

No —

Provided

With

Weld head

Weld head

Fixture block

Electrical Requirements

M200 Power Supply Installation

All user-supplied wiring and related components must be installed

in accordance with local electrical codes. A dedicated electrical

circuit may be required to maintain optimum current levels. If

input voltage is 100 V or less, output power capabilities may be

reduced.

WARNING

The M200 power supply must

be grounded or electrical shock

can result.

Table 3—Voltage and Current Requirements

Power Supply Model Voltage Requirement Service Current

M200

100 V (ac) 20 A

230 V (ac) 16 A

See Specifications, page 100, for detailed power input and

output information.

Using Extension Cords

Extension cords may be used with the M200 power supply.

Extension cords must meet the current capacity specications

in Table 43, page 101.

Page 19

M200 Power Supply User’s Manual 19

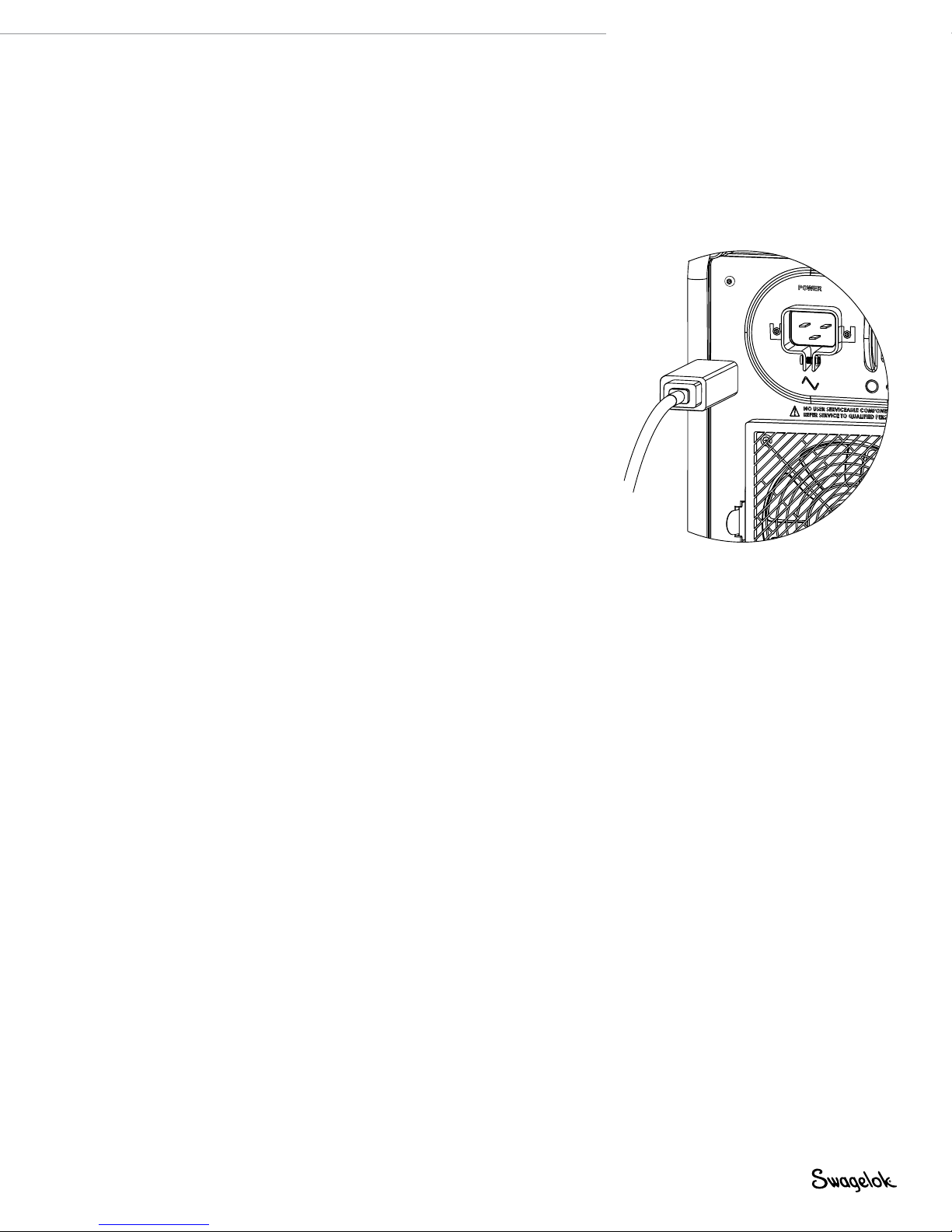

Setting up the M200 Power Supply

1. Position the M200 power supply so that both sides are

accessible.

2. Make sure the power switch on the left side of the M200

power supply is in the off ( O ) position.

3. Connect the power cord to the power connector on the

side of the unit (Fig. 6). Turn the connector a quarter-turn

clockwise to lock it in place.

4. Optional: Install the fan lter on the left side of the M200

power supply. See page 51.

Note: The M200 power supply should not

be operated when resting on either

the left or the right side (printer or

fan/filter side) or when tilted more

than 15° on its horizontal axis. The

MFC will not function properly in

these positions.

Fig. 6—Connecting the Power Cord

Page 20

20 M200 Power Supply User’s Manual

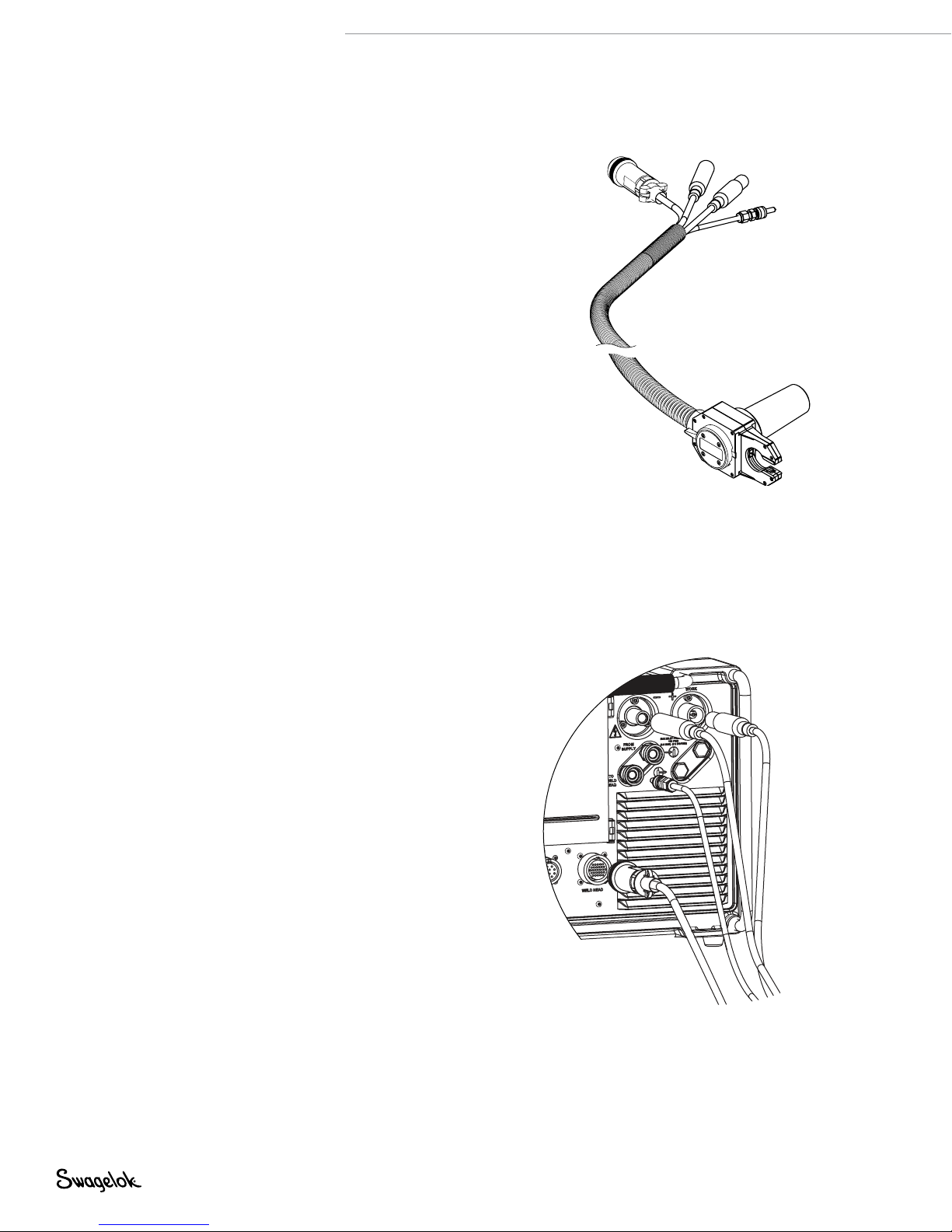

Installing the Weld Head

The weld head assembly attaches to the right side of the M200

power supply with four separate connectors (Fig. 7) :

■

Weld head quarter-turn connector

■

Electrode (red)

■

Work (green)

■

Weld head OD shield gas.

1. Align the notch on the weld head quarter-turn connector

with the small tab in the M200 power supply socket

labeled weld head (Fig. 8) and insert the connector. Turn

it clockwise to lock it in place. An audible click indicates

that the connection is locked. This connection provides the

control signals to drive the weld head.

Note: Use the weld head adapter cable, ordered separately,

if the weld head does not have a quarter-turn

connection. Attach the weld head adapter cable to

the end of the threaded multipin connector. Tighten

the weld head adapter cable until only two or three

threads are visible.

2. Insert the red connector arrow side up into the M200 power

supply red socket labeled electrode. Turn the connector

one-quarter turn clockwise to lock it in place. This

connection is the negative (–) terminal of the weld head.

3. Insert the green connector arrow side up into the M200

power supply green socket labeled work. Turn the

connector one-quarter turn clockwise to lock it in place.

This connection is the positive (+) terminal of the weld head.

4. Insert the weld head OD shield gas Swagelok quick-connect

stem into the M200 power supply tting labeled to weld

head. This connection provides shielding gas to the weld

head through the mass ow controller in the power supply.

Weld head

quarter-turn

connector

Fig. 7— Weld Head Assembly Connections

NOTICE

All connections must be fully seated

and locked in place to prevent damage

to connections or weld head.

Electrode (red)

Work (green)

Weld head

OD shield gas

Fig. 8— Connecting the Weld Head

Assembly to the Power Supply

WARNING

Do not remove the weld head

from the M200 power supply

while a weld is in process.

Electrical shock can result.

Page 21

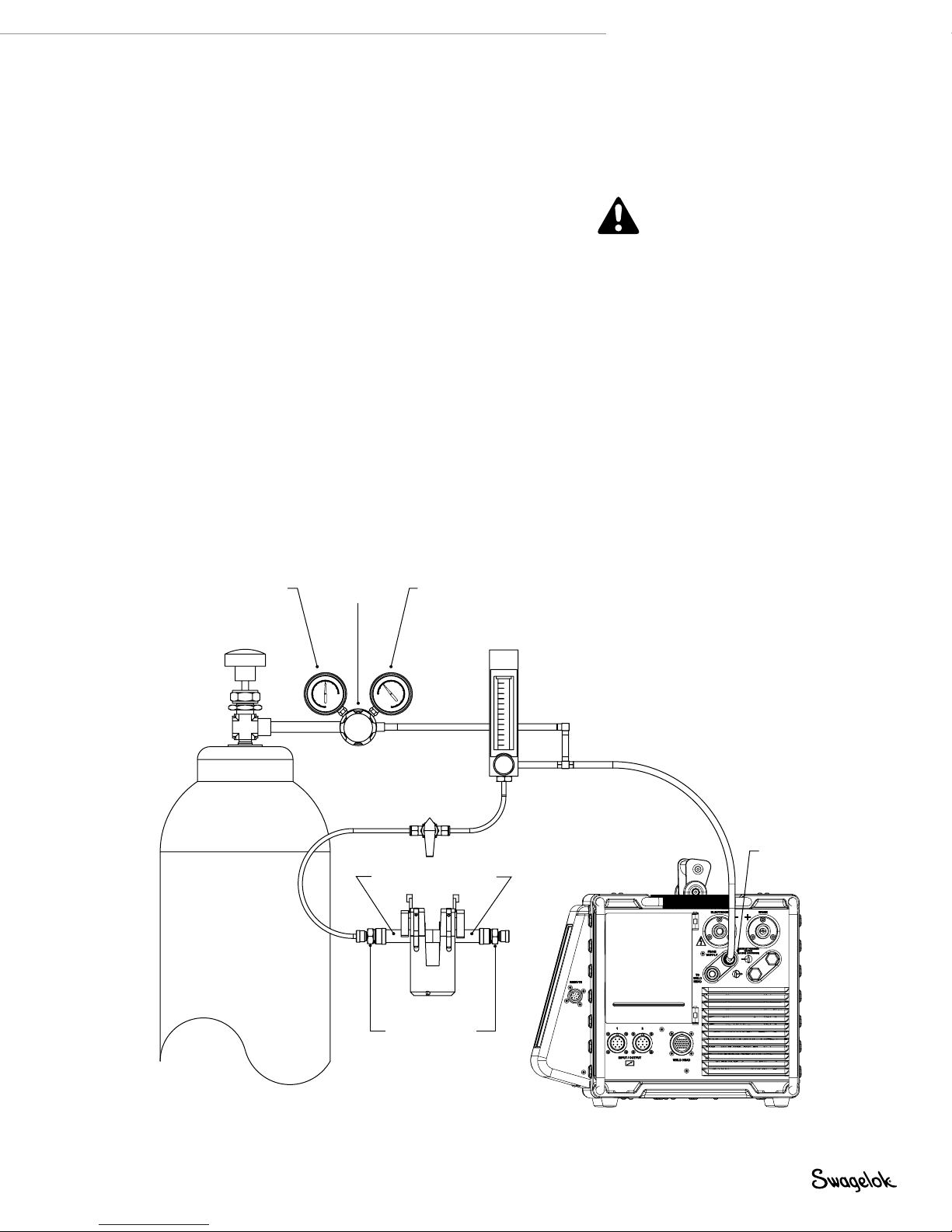

Setting Up the Gas Supply System

The M200 power supply has an integral mass ow controller

(MFC) to control and monitor the ow of the gas supply system

that provides OD shield gas to the weld head. OD shield gas

lls the weld chamber to protect the electrode and weld puddle

from contaminating elements in the surrounding air.

ID purge gas ows within a tube or at the back of a weld joint to

remove oxygen and prevent oxidation.

Typical OD Shield / ID Purge Gas Supply System

Figure 9 shows a typical gas supply system. Before setting up

the gas supply system, read and understand the Safety section

of this manual. See page 5.

1. Make sure the gas storage containers are upright and

secured before use.

2. Check all connections for leaks.

3. Use only Swagelok quick-connect stems (ordering number

SS-QC4-S-400) as gas connectors on the M200 power supply.

4. Regulate the OD shield gas pressure to obtain the desired

ow rate. The typical pressure range is 45 to 50 psig (3.1 to

3.4 bar). Flow rates greater than 70 std ft3/h (33 std L/min)

may require higher pressures.

M200 Power Supply User’s Manual 21

CAUTION

Do not mix or interchange

parts with those of other

manufacturers. Personal injury

or equipment damage can result.

NOTICE

Do not exceed an inlet pressure of

100 psig (6.8 bar) or MFC can be

damaged.

NOTICE

The MFC is not a shutoff device. There

may be gas flow of up to 1/2 std ft

(0.24 std L/min) when the shield gas is

off.

3

/h

High-pressure

gauge

(0 to 3000 psig

[206 bar])

Inert gas cylinder

Two-stage

regulator

Tubing to be welded

(Swagelok union or reducing

union with nylon ferrules or

ultra-torr fitting. See Table 2

for purge kit ordering

Low-pressure

gauge

(0 to 100 psig

[6.8 bar])

ID purge gas

shutoff valve

Fixture block

Purge fittings

nu mber.)

Flow meter for

ID purge gas

Supply manifold

M200

power supply

OD shield gas

supply inlet

Fig. 9—Typical Gas Supply System

Page 22

22 M200 Power Supply User’s Manual

Powering On the M200 Power Supply

for the First Time

1. Connect the power cord to a properly rated and grounded

electrical receptacle.

2. Power on the M200 power supply by toggling the on/off

switch on the left side of the unit to the on ( I ) position. The

Swagelok screen will appear.

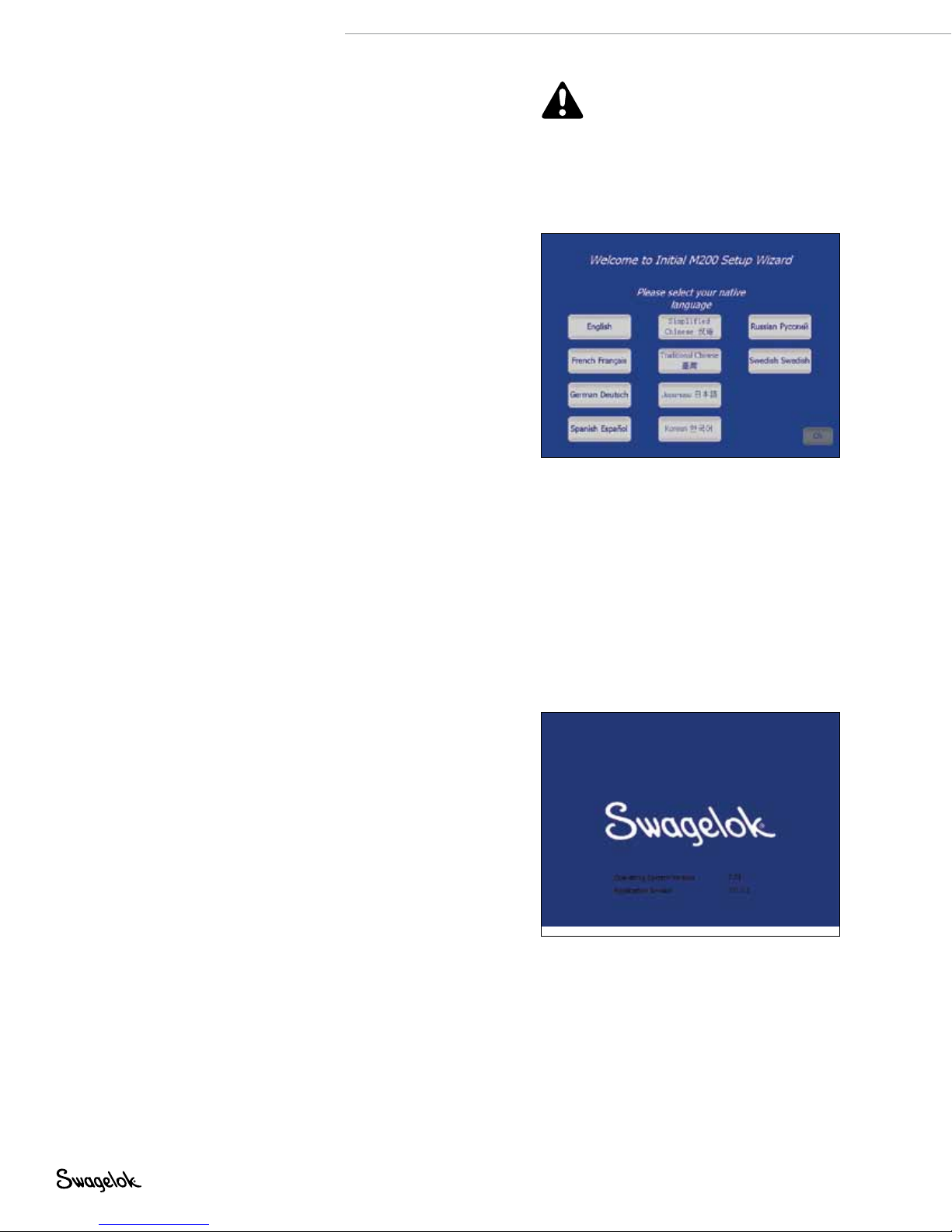

3. The Setup Wizard (Fig. 10) will prompt the user to select a

user language.

4. The Swagelok Embedded System End User License

Agreement (page 122) will appear. You must accept the

terms of this agreement to continue the Setup Wizard and

use the M200 power supply.

5. Set the owner password. If desired, set security or

programmer passwords. See Passwords, page 46, for

more information.

6. The Main Menu will appear.

Note: The fan will turn on automatically. Press the Fan

button to turn the fan off.

CAUTION

The rotor will move when the

M200 power supply is powered

on. The rotor is a potential

pinch point.

Fig. 10—Language Setup Wizard

Powering Off the M200 Power Supply

To power off the M200 power supply, toggle the on/off switch

on the left side of the power supply to the off ( O ) p osition.

Note: Do not power off the M200 power supply when

updating software.

Restarting the M200 Power Supply

1. Power on the M200 power supply by toggling the on/off

switch on the left side of the unit to the on ( I ) position.

2. The Swagelok screen (Fig. 11) will appear.

3. Enter the security or programmer password if one has been

set.

4. The Main Menu will appear.

Note: The owner password is the master

key to the M200 power supply. If

it is lost or forgotten, contact your

authorized Swagelok representative.

After ownership of the unit is

verified, you will receive a temporary

password to allow access to the unit.

Fig. 11—Swagelok Screen

Note: The MFC requires 5 minutes to

warm up to ensure accurate gas flow

control if the M200 power supply is

not at operating temperature.

Page 23

M200 Power Supply User’s Manual 23

Using the Touch Screen

The touch screen of the M200 power supply is the built-in

method for navigating functions and entering data.

The touch screen responds to ngertip operation and was

designed to accommodate gloves. The touch screen may be

difcult to use if it is dirty or has water droplets on its face.

Keep the touch screen clean and dry.

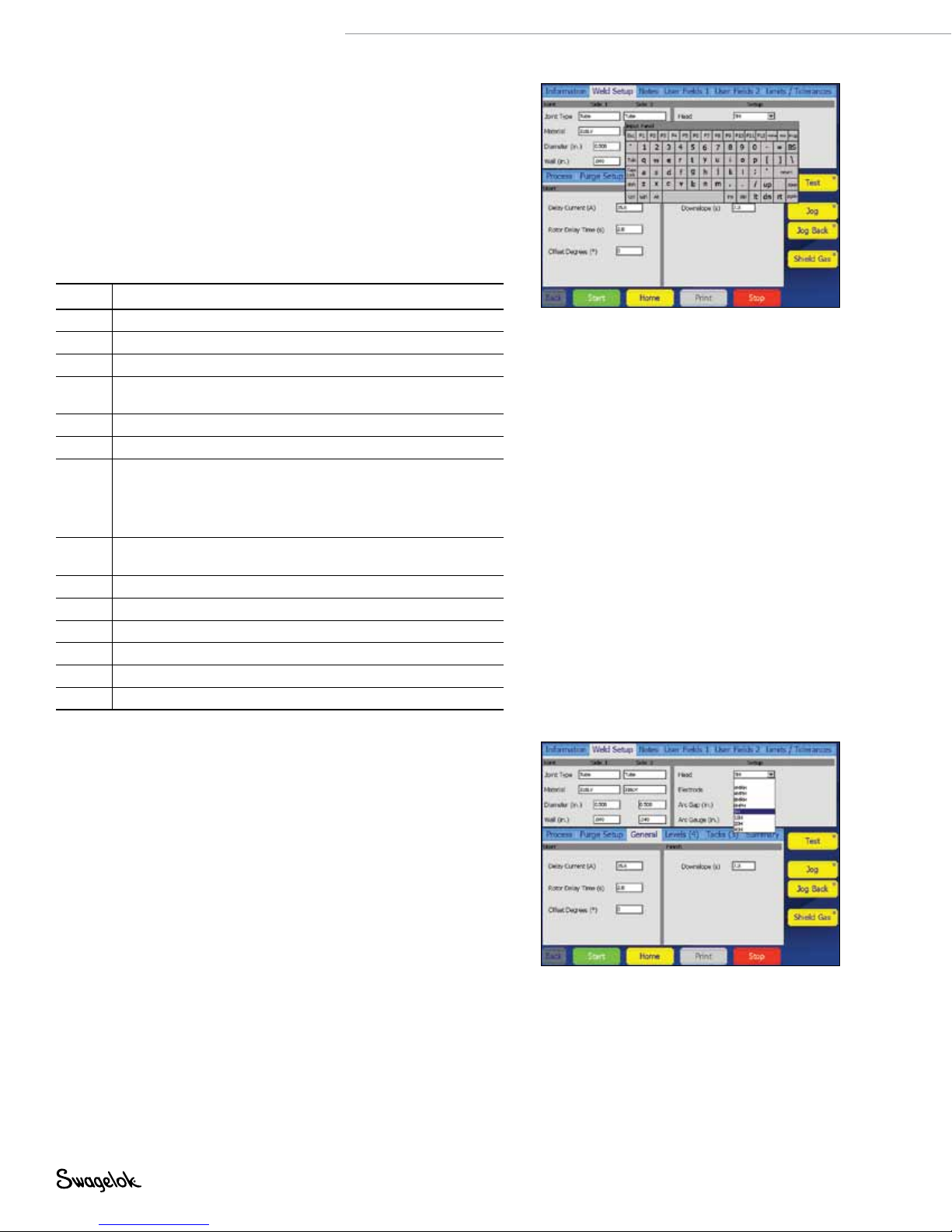

If the touch screen does not respond as expected, it may

need to be calibrated. From the Main Menu, select Setup >

Touchscreen > Calibrate Touchscreen (Fig. 12). A series of

cross hair targets will appear onscreen. While in the position

(seated or standing) you normally use the M200 power supply,

touch each target (Fig. 13) as it appears. When no more targets

appear, the M200 power supply is calibrated.

User Interface

The user interface of the M200 power supply was designed for

easy navigation.

The “path” at the top of each screen (except the Weld screens)

indicates your location:

Path Location

Main > Setup Setup mode

Main > Program > Auto Create Auto Create function

in the Program mode

Note: Do not expose the M200 power

supply to water or visible moisture.

The touch screen can be cleaned

with glass cleaner and a clean cloth.

To prevent accidental operation,

power off the M200 power supply

before cleaning.

Fig. 12—Calibrate Touchscreen Button

To select a function or mode, press the onscreen button or

tab with your nger. To enter information, press the eld to be

lled in. Depending on the information to be entered, a numeric

keypad, alphanumeric keyboard, or drop-down menu will appear.

A USB mouse and keyboard also can be connected to the M200

power supply for data entry.

Numeric Keypad

The valid range for the selected parameter will display at the

bottom of the keypad.

■

Press the number keys (Fig. 14) to enter information. Press

Done to save the settings and close the keypad.

■

Press <- Bksp to erase the last character entered. Press

Clear to erase the entire entry.

Fig. 13—Calibration Target Screen

Fig. 14— Numeric Keypad

Page 24

24 M200 Power Supply User’s Manual

Keyboard

■

Use the onscreen keyboard (Fig. 15) as you would a

computer keyboard.

■

To reposition the keyboard, press the gray bar at the top of

keyboard and drag it to the new position.

■

To close the keyboard, press return.

Note: The return key will not start a new line of text.

Table 4—Key Functions

Key Function

Home Moves cursor to the beginning of the line.

End Moves cursor to the end of the line.

Prop Moves cursor to the end of the line.

BS Backspace. Deletes character to the left of the cursor.

Tab Closes the keyboard.

return Closes the keyboard.

Ctrl Ctrl + z: Undo last step.

del Deletes character to right of cursor.

lt Moves cursor one space to the left.

rt Moves cursor one space to the right.

up Moves cursor to line above.

dn Moves cursor to line below.

pgup Moves to the preceding page.

pgdn Moves to the next page.

Also deletes selections that have been highlighted.

Ctrl + x: Cut and save selected/highlighted text.

Ctrl + c: Copy and save elected/highlighted text.

Ctrl + v: Paste saved text at cursor point.

Also deletes selections that have been highlighted.

Fig. 15— Onscreen Keyboard

Note: To select text, highlight it by pressing

and dragging your finger over the

selection.

Drop-Down Menus

Drop-down menus (Fig. 16) allow you to select entries from

a list. Drop-down menus are indicated by a down arrow (▼).

Press the eld or arrow to display the list of selections. Highlight

the selection to change the value.

Fig. 16—Drop-Down Menu

Page 25

Operation

This section describes the basic operation of the M200 power

supply.

Main Menu

The Main Menu (Fig. 17 ) provides access to the M200 power

supply’s functions. Select functions by pressing the onscreen

button or by using a USB mouse to click on the selection. The

Main Menu buttons are described in Table.

M200 Power Supply User’s Manual 25

Fig. 17—Main Menu

Page 26

26 M200 Power Supply User’s Manual

Table 5—Main Menu Selections and Functions

Weld

File

Program

Weld Log

Setup

Next Home

The Weld screens display detailed information

about the weld and are used to input parameters,

start the weld, and monitor the weld process.

The information displayed on the Weld screens is

saved with the weld procedure.

See page 28 for more information about the

Weld screens.

The File screens are used to print, preview, delete,

load, and save weld procedures. The File mode

applies only to weld procedures and does not affect

the M200 power supply Setup or Weld Log files.

See page 35 for more information about the File

screens.

The Program screens are used to create new weld

procedures using Auto Create or Manual Create.

See page 38 for more information about the

Program screens.

The Weld Log screens are similar to the File

screens but are exclusively for Weld Log records.

Weld Log records may be viewed, printed, copied,

or deleted using these screens. Weld Log records

may be saved to a USB flash drive for transfer to

a PC. Weld Log records may also be exported to a

PC using a serial cable.

See page 39 for more information about the

Weld Log screens.

The Setup screens are used to change options,

set dimensional units and passwords, and review

settings. Changes are saved in the M200 power

supply’s internal memory and are not part of a weld

procedure.

The Setup mode also contains utilities for updating

software, resetting weld counts, and monitoring

free memory.

See page 42 for more information about the

Setup screens.

When a Swagelok weld head is first connected

to the M200 power supply, the power supply

assumes the rotor is at true home. If it is not,

press Next Home to move the rotor to the next

of several “home” positions. The weld head

model determines the number of home positions.

Continue pressing Next Home until the rotor

reaches true home (Fig. 18.)

If the weld head cannot find true home, see

Troubleshooting, page 109.

Note: In any M200 power supply screen

or menu, press Back to return to

the previous screen. Press Refresh

to reload and update the current

screen.

CAUTION

The rotor will move when Next

Home is pressed. The rotor is a

potential pinch point.

True home

(fully open)

Not true home

Fig. 18—Rotor Home Position

Page 27

Table 5—Main Menu Selections and Functions

M200 Power Supply User’s Manual 27

Lock Out

(Fig. 19)

Paper Feed

Fan

Single Level

Mode

Language

(Fig. 20)

Help

About

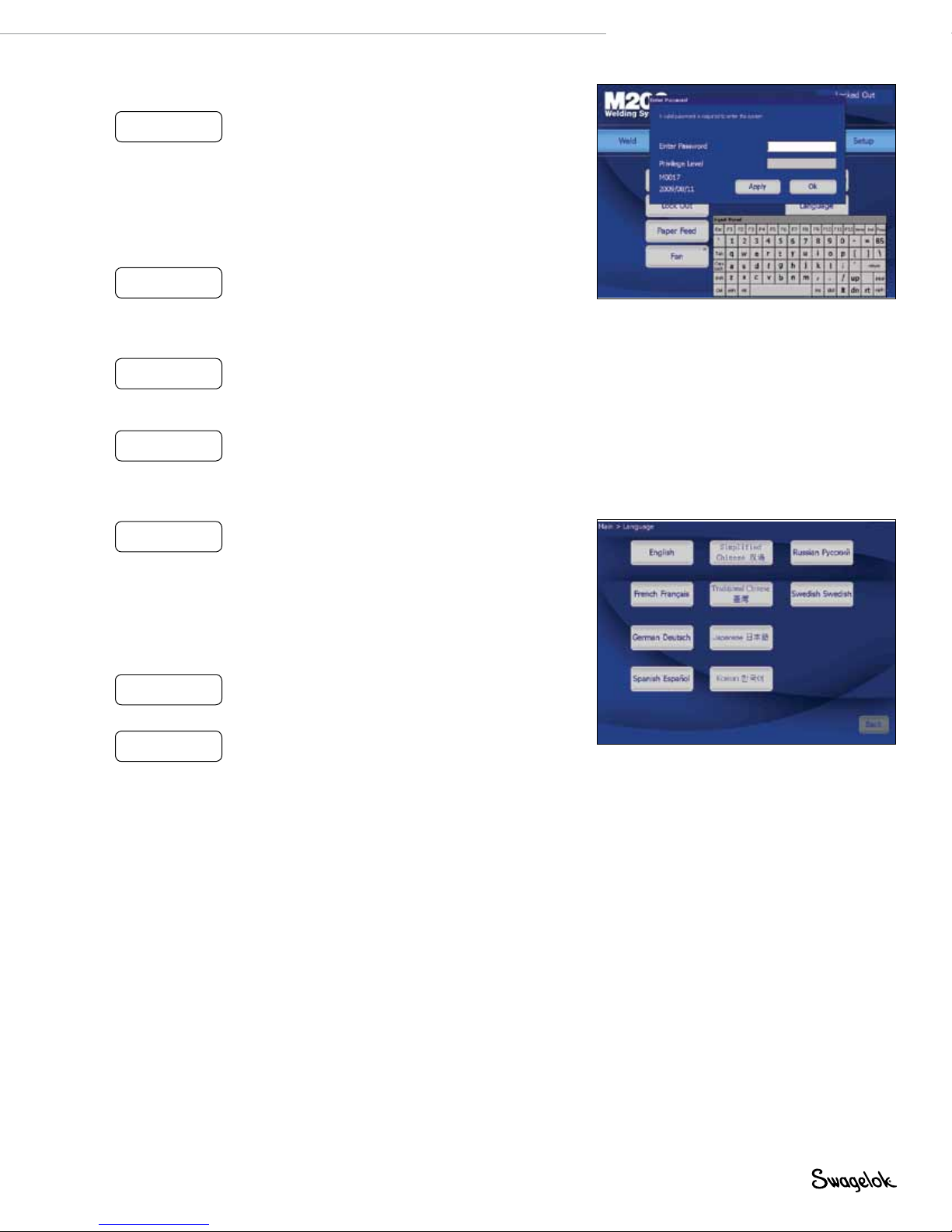

Pressing Lock Out will lock the M200 power

supply. Once the M200 power supply is locked

out, pressing any button on the screen will

cause a password prompt to appear. The owner,

programmer, or security password must be entered.

Note: This feature is not available unless a

programmer or security password has been

set in Setup.

See Passwords, page 46, for more information.

The printer is located on the right side of the M200

power supply, above the weld head connection.

Paper Feed advances the paper through the printer.

See page 45 for information on changing the

paper feed length.

The fan is normally in the Fan Power-On State and

will turn on as needed to cool the M200 power

supply. To turn the fan on manually, press Fan. The

fan will run continuously until Fan is pressed again.

Single Level Mode is for users who prefer

the Swagelok D75 and D100 power supply

programming format.

See Single Level Mode Operation, page 84, for

more information.

The Language screen allows you to change the

language shown on the M200 power supply’s

screens.

Press the Language button to select the new

language. As soon as the language is selected,

the Back button at the bottom of the screen will

display that language. Press the Back button to

return to the Main Menu, and the screen will be in

the selected language.

Displays the user’s manual. The user manual will

display in the language selected if available. The

English version will display if it is not available.

Displays copyright and patent information.

Fig. 19— Password Prompt Screen

Note: Changing the Fan Power-On State

to off on the Setup > Operation tab

will prevent the fan from turning on

automatically when the M200 power

supply is powered on.

Fig. 20—Language Screen

Page 28

28 M200 Power Supply User’s Manual

Weld Screens

The Weld screens (Fig. 21) are used to view and adjust (see

Note) the parameters of the active weld procedure. The screen

is divided into upper and lower sections.

The Upper Section Tabs contain information related to the weld

procedure and options: user elds, limits / tolerances, etc.

The Lower Section Tabs are elds that make up the basic

parameters of a weld: purge settings, levels, tacks, and general

settings.

Upper

section

tabs

Note: Changing the weld procedure

parameters will add “(modified)” to

the weld procedure name on the

screen and cause the name to turn

red in color. The weld procedure

must be saved to make the changes

a permanent part of the procedure.

See Table 9, page 35.

Weld

procedure

name

Lower

section

tabs

OD shield

gas visual

gauge

Status indicator

Time-

remaining

counter

Weld

procedure

parameters

Fig. 21—Weld Screens

Electrode position

Used to change

electrode

Test the active

procedure (no

current applied)

Jogs electrode

clockwise

Jogs electrode

counterclockwise

Turns on OD

shield gas

Weld head

installed

Weld count

Page 29

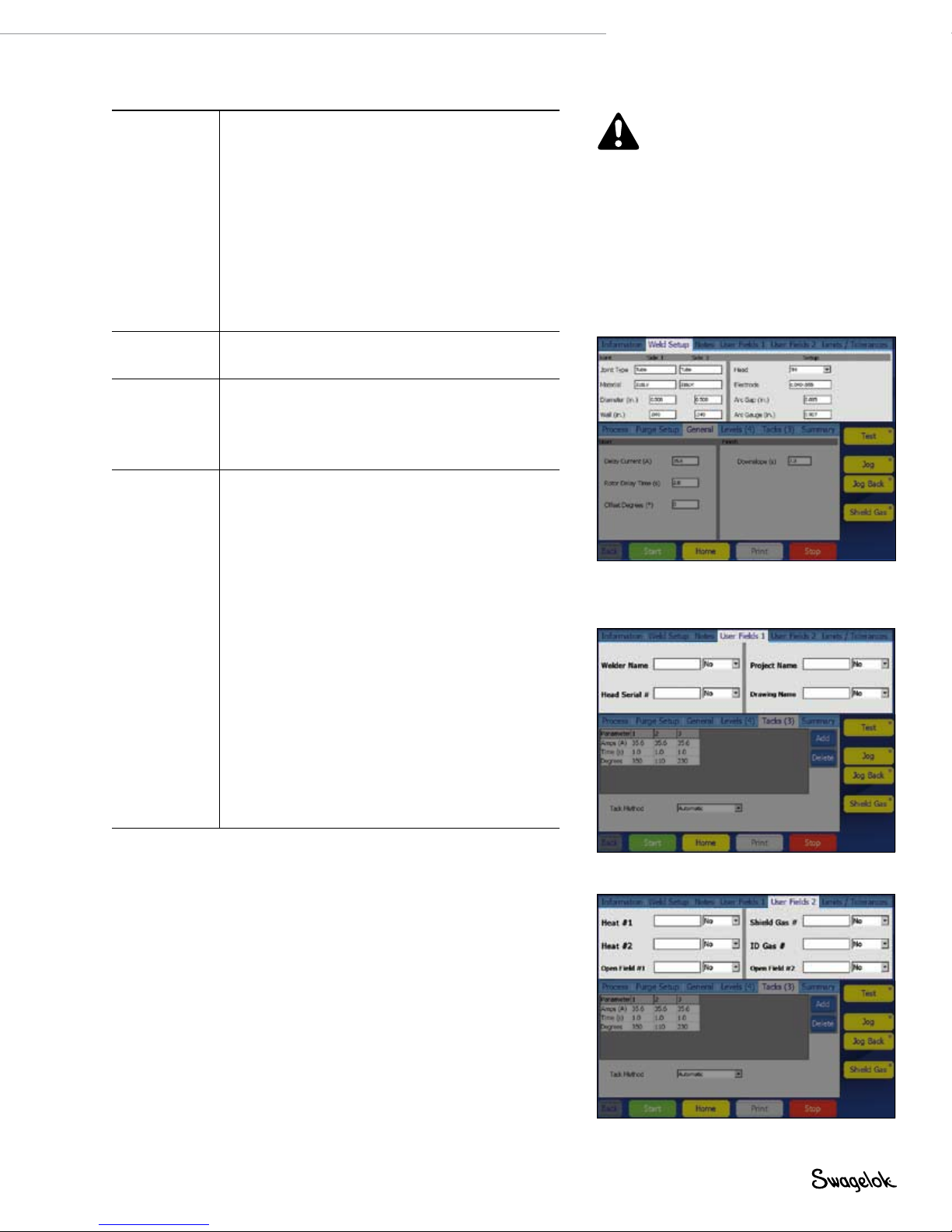

Table 6—Weld Upper Section Tabs

M200 Power Supply User’s Manual 29

Information

(Fig. 21)

Weld Setup

(Fig. 22)

Notes Displays an open field for entering comments and

User Fields 1

User Fields 2

(Fig. 23,

Fig. 24)

Displays a summary of weld setup parameters as

well as ID purge and OD shield gas types for the

active weld procedure. The eight most recent entries

for the Programmer field will display in a drop-down

box.

The Information tab also displays the Electrode

Change button, which positions the rotor for

electrode replacement and prevents the M200 power

supply from welding.

See the weld head user’s manual for instructions on

electrode replacement. After replacing the electrode,

press Electrode Change again. The rotor will move

back to the home position.

Displays the Joint and Setup fields and allows

adjustment of values.

observations. Press the white area once to display

the onscreen keyboard. Notes will be saved with

the weld procedure and shown in the Weld Log as

Procedure Notes.

Displays User Fields 1 and 2.

The software will remember the eight most

recent entries for each field and display them in a

drop-down box.

The owner or programmer can set data entry

requirements that must be completed before a weld

is performed. This information is part of the weld

procedure and is stored in the Weld Log.

Three options are available in drop-down boxes next

to each user field:

No An entry is not required for this field. It may

be entered at the discretion of the user.

Yes An entry is required for the field. The

entry will remain in that field until a new

weld procedure is loaded. Failure to enter

information into this field will cause a

disable code.

Change An entry is required in the field and must

be reentered with every weld. Failure to

enter information into this field will cause

a disable code.

CAUTION

The rotor will move when

Electrode Change is pressed.

The rotor is a potential pinch

point.

Note: Electrode Change disables most

other M200 power supply buttons.

Fig. 22—Weld Setup Tab

Fig. 23—User Fields 1 Tab

Fig. 24—User Fields 2 Tab

Page 30

30 M200 Power Supply User’s Manual

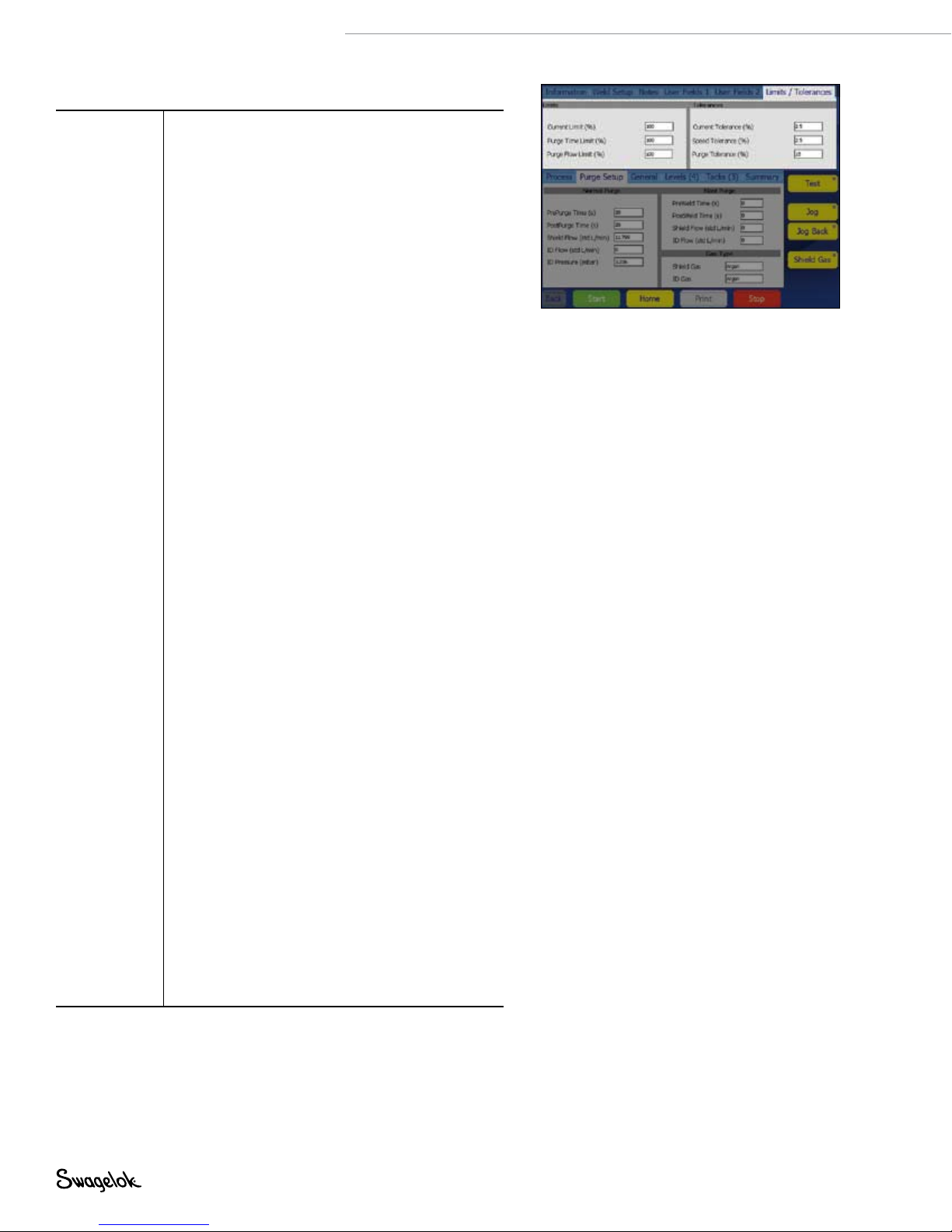

Table 6—Weld Upper Section Tabs

Limits /

Tolerances

(Fig. 25)

Limits

Limits are used to restrict the amount of adjustment

a user with a security password can make without

entering a programmer or owner password.

Limits from 0 to 100 % are set at the programmer

and owner levels. Current and Purge Limits are

represented as a percentage of the weld procedure

values.

Example: if the Average Amps for Level 1 is

100 A and the current limit is 50 %, the M200

power supply will not allow an adjustment of

Average Amps above 150 A or below 50 A. The

factory default for limits is 100 %.

Average Amps can be adjusted within the limits on

the lower section Levels tab using the up and down

buttons.

See Adjusting Average Amps, page 31, for more

information.

Purge parameters can be adjusted within the limits

on the Purge Setup tab.

Tolerances

The Weld Log records out-of-range values for

Average Amps, Average Speed, and OD Shield Flow

in the Weld Log, based on tolerances set. Tolerances

are adjustable at the programmer and owner levels,

as a percentage of the base value.

■

Current and speed tolerances are adjustable

up to 9.9 %. The factory default for new weld

procedures is 2.5 %.

■

Purge tolerance is adjustable up to 100 %. The

factory default is 15 %.

Example: if the Average Amps for Level 1 is

100 A and the current tolerance is 5 %, the M200

power supply will return a current tolerance error

at the end of the weld if the Average Amps is

below 95 A or exceeds 105 A.

Current tolerance. If the Average Amps tolerance is

exceeded during the weld, a current tolerance error

will be recorded.

Speed tolerance. If the average speed is outside of

the average speed tolerance at the end of the weld,

a speed tolerance error will be recorded.

Purge tolerance. Purge tolerance is represented

by the yellow band in the shield gas flow meter

displayed on the process tab. If the OD shield flow

is outside of the tolerance, the shield gas bar flow

meter display will turn red. If there is no OD shield

gas present during prepurge, the M200 power

supply will not proceed. If the OD shield gas flow

drops below 8 std ft

3

/h (3.8 std L/min) during a weld,

the M200 power supply will stop welding to prevent

possible damage to the weld head.

See page 106, Weld Errors.

Fig. 25— Limits / Tolerances Tab

Page 31

Table 7—Weld Lower Section Tabs

M200 Power Supply User’s Manual 31

Process

(Fig. 26)

Purge Setup

(Fig. 27)

General

(Fig. 28)

Levels (X)

(Fig. 29)

Displays the status and progress of the weld,

including tacks, error messages and electrode

position.

Displays the Normal Purge, Blast Purge, and Gas

Type fields.

Displays the Start and Finish fields.

A level is a section of the weld procedure defined by

the parameters shown in Fig. 29. Parameters can be

varied by level.

A weld procedure can have from 1 to 99 levels. The

number in parentheses indicates the number of

levels specified in that weld procedure.

Levels are shown in the process window in real time

during the weld. To add a level, press the top of a

column to highlight it, then press the Add button

on the right side of the window. A new column

containing a copy of the selected column’s data

will be added after the selected column. Repeat for

additional levels.

To delete one or more levels, press the top of the

column or columns to select them. Press the Delete

button on the right side of the window.

Adjusting Average Amps

Adjust Up / Down allows a user with a security

password to make Average Amps adjustments

within the limits and tolerances set by the owner or

programmer.

Select the level or levels to be adjusted and press

the up or down buttons to adjust Average Amps

(page 30) within the limits in a weld procedure

defined by the programmer. If no level is selected, all

levels are affected by Adjust Up / Down.

Average Amps is reduced with the down button or

increased with the up button.

■

The rst three presses of the up or down button

increase or decrease High Amps Width in

increments of 10 %, up to 30 %.

■

The next three presses of the up or down button

increase or decrease High Amps in increments

of 10 %, up to 30 %.

■

The nal three presses of the up or down button

increase or decrease Low Amps in increments of

10 %, up to 30 %.

To return to the original values for the weld

procedure you must reload the program from

memory.

See Limits / Tolerances, page 30, for more

information.

Fig. 26—Process Tab

Fig. 27—Purge Setup Tab

Fig. 28—General Setup Tab

Fig. 29—Levels Tab

Page 32

32 M200 Power Supply User’s Manual

Table 7—Weld Lower Section Tabs

Tacks (X)

(Fig. 30)

The M200 power supply supports weld procedures

with tacks—nonpenetrating spot welds used to hold

work pieces in place. The number in parentheses

indicates the number of tacks specified for the weld

procedure.

To set the tack method, choose from the options

available in the drop-down box next to the user field:

Automatic The entire selected weld procedure

will be completed when the Start

button is pressed on the Process

tab.

Tacks Only Only the tacks portion of the

selected weld procedure will be

completed. When the user returns

to the Process tab, a Start Tacks

button will appear under the Weld

Head Installed graphic. Press this

button to complete the tacks.

The Start button will change to

Start Levels. Press this button to

begin the remainder of the weld

procedure.

To add tacks, press the top of a column to highlight

it, then press the Add button on the right side of

the window. A new column containing a copy of

the selected column’s data will be added after the

selected column. Repeat for additional tacks.

To delete tacks, press the top of the column or

columns to select them, then press the Delete button

on the right side of the window.

Use the onscreen keypad to enter or change a

parameter.

See page 65 for more information about weld

procedures using tacks.

Fig. 30—Tacks Tab

Note: Tacks should be offset at least 10°

from the location of the arc start

of the levels to prevent arc wander

at arc start. The weld head returns

to the true home position after the

tacking section of a weld procedure.

Summary

(Fig. 31)

This tab provides information on the M200 power

supply’s Disable, Operational, and Error conditions

when a weld procedure is loaded.

The View button allows a look at the last completed

weld in the Weld Log.

The Clear Errors button remove all nonactive errors

from the Summary View (but not the Weld Log.)

Choose the Active Only check box to limit the

Summary View to the active weld.

Weld Log notes will print with the Weld Log.

Fig. 31—Summary Tab

Page 33

Table 8—Weld Screen Buttons

Test

Jog

Jog Back

Shield Gas

Start

Home

Print

Check or demonstrate a weld procedure with

this mode. Press to put the power supply in an

alternate operating mode that will not supply

current to the electrode. Press again to stop. The

current and voltage displays will not operate and

the weld counter will not advance. The light in

the corner of the button will blink while the power

supply is in Test mode.

Press to move rotor clockwise. Press again to stop.

The light in the corner of the button will blink while

the rotor is moving.

Press to move rotor counterclockwise. Press again

to stop. The light in the corner of the button will

blink while the rotor is moving.

Activates the mass flow controller and starts the

flow of OD shield gas to the weld head. Shield

gas will flow to the weld head until you press the

button again. Pressing the Shield Gas button does

not override Purge Setup settings in the weld

procedure, but gas will continue to flow after the

weld procedure is complete.

Starts the weld process.

See Performing a Weld, page 34.

Press to return the rotor to its true home position.

The rotor will move at maximum speed when

traveling to the home position, regardless of the

programmed rotor speed.

Prints last completed Weld Log record.

M200 Power Supply User’s Manual 33

Stop

Aborts the weld and halts the rotor if pressed

during the weld process. Stop also turns off OD

shield gas flow.

Page 34

34 M200 Power Supply User’s Manual

Performing a Weld

Read and understand all safety information contained in

this manual before starting the weld.

1. Complete all side panel connections as described in Setting

Up the M200 Power Supply, page 19, Installing the

Weld Head, page 20, and Setting Up the Gas Supply

System, page 21.

2. Install the electrode and set the arc gap using the arc gap

gauge in accordance with the weld head user’s manual.

3. Install the collets in the xture block.

4. Align and clamp the work pieces in the xture block.

5. Load an existing weld procedure as described in Load /

Save / Print / Delete Tab, page 35, or create a new weld

procedure as described in Program, page 38.

6. Connect the ID purge gas line to the work pieces to be

welded and set the ow meter.

7. Connect the weld head to the xture block.

8. Press the Start button.

WARNING

Do not touch the cable

connectors during the weld. If

the cables have been damaged,

the potential for an electrical

shock exists.

Display Indications During Welding

During welding, the status messages are displayed on the

Process tab, along with a time-remaining counter.

After the Weld is Complete

1. The M200 power supply will return to the “Ready” state.

2. Check the xture block to conrm that it has cooled before

handling. Increasing the postpurge or blast purge postweld

time will aid cooling.

3. Remove the weld head from the xture block. If it is difcult

to remove, release one of the side plate levers.

4. Remove the ID purge gas lines from the welded assembly.

5. Remove the welded assembly.

Weld Status Conditions

See Troubleshooting, page 102, for a list of disable,

operational, and weld error conditions.

CAUTION

Use gloves or other protective

devices if you must handle parts

immediately after welding. The

parts can be extremely hot and

may cause burns.

NOTICE

Do not immerse the hot fixture block in

water after welding. Allow the fixture

block to cool before performing the

next weld.

Note: Inspect the electrode after each

weld. Look for oxidation, wear, or

weld material on the tip.

Page 35

File Screens

The File screens are used to load, save, print, copy, delete, and

view weld procedures.

The Main > File screen has two tabs:

■

Load / Save / Print / Delete

■

File Copy

When the File screen opens, the M200 power supply searches

the internal memory and a connected USB ash drive. A large

number of folders can slow the search process. To reduce the

time required, delete unnecessary les or folders in the internal

memory and on the USB ash drive.

Load / Save / Print / Delete Tab

The File screen opens in the Load / Save / Print / Delete tab,

showing Folder and File Views in separate panes (Fig. 32):

■

The Folder View displays folders for the internal memory

and a connected USB ash drive.

■

The File View displays the weld procedures contained in an

open folder. The active weld procedure will have a green

icon.

In the Folder View, press the folder name or icon to open it.

The weld procedures will be displayed in the File View pane

in alphabetical order. The Folder View will also display any

subfolders contained in the original folder.

The buttons on the lower left (Print, View, Delete, and Load)

require you to select a le or folder before you press a button.

Press a weld procedure in the File View pane to highlight it. The

weld procedure name will appear in the File Name box below

the File View pane.

Enter a le name in the File Name box before pressing the Save,

Rename, or Create Folder buttons on the lower right of the

screen.

When a le name is entered and saved, a description that

includes the OD, wall thickness, tubing material, number of

levels, number of tacks, and weld head model will be added

automatically to the le name and displayed in the File View,

and whenever the weld procedure is loaded:

User’s manual example [0.500 - 0.049 316LV 04 03 5H A]

User’s manual example programmer-selected le name

0.500 OD of work piece

0.049 wall thickness of work piece

316LV tubing material

04 number of levels

03 number of tacks

5H weld head model needed for

weld procedure

A ATW weld procedure

P pipe schedule

S step program

The display will automatically change to the Weld/Process tab

after a Save has been performed.

M200 Power Supply User’s Manual 35

Selected file (with green icon)

Folder View pane File View pane

File Name boxStatus line

Fig. 32—Load / Save / Print / Delete Tab

Note: File names are limited to

alphanumeric characters. The M200

power supply software does not

support symbols such as:

, + , – , % , / , ” , ’ , , , or

similar characters.

Page 36

36 M200 Power Supply User’s Manual

Table 9—Load / Save / Print / Delete Tab Buttons

Print

Select the weld procedure in the File View pane

and press Print.

View

Delete

Load

Save

Rename

Create

Folder

Select the weld procedure from the File View

pane and press View. The file preview window

will appear showing the weld procedure name, a

description, the programmer’s name, and the date

the weld procedure was saved. Joint, Level, and

Tack parameters will also be displayed.

Press OK to return to the File screen.

Select the weld procedure or folder and press

Delete. A dialog box will open asking you to

confirm the delete. Press Yes to delete the weld

procedure or folder.

Select the weld procedure from the File View pane

and press Load. A message in the Status line will

confirm that the weld procedure was successfully

loaded.

Select the folder in which to save the weld

procedure. Press the File Name box. The keyboard

will appear. Enter the name of the new weld

procedure and press Save. The weld procedure will

be saved and displayed in the File View pane.

To rename a weld procedure, select the weld

procedure. The weld procedure name will be

shown in the File Name box. Press Rename and an

input box and a keyboard will be displayed. Enter a

new file name and press Rename in the input box.

Create Folder allows you to create an empty

subfolder in internal memory or on the USB flash

drive.

To create a new subfolder, highlight the folder you

want to put the new subfolder in and select the File

Name box. Enter the name of the new folder using

the keyboard and press Create Folder.

The new subfolder will appear in the Folder View

pane.

Note: Folders cannot be renamed using

Rename.

Page 37

M200 Power Supply User’s Manual 37

File Copy Tab

The File Copy tab (Fig. 33) allows the user to copy folders and

les between folders in internal memory or to and from a USB

ash drive.

When the File Copy tab opens, the internal memory and USB

Flash Drive (if attached) folders will be shown in both folder

panes. Press a folder twice to display its contents. Press twice

again to close it.

To copy a le, select the destination folder and the le to copy.

Press Copy >> or << Copy. If you select a folder, the entire

folder will be copied.

The Folder Move elds show the name of the folder or le

selected. The Status line at the bottom of the screen displays

status and error messages.

Table 10—File Copy Tab Buttons

Copy >>

<< Copy

Copies the selected folder or file from the left

Folder Move field to the selected destination in the

right Folder Move field.

Copies the selected folder or file from the right

Folder Move field to the selected destination in the

left Folder Move field.

Folder panes

Folder Move fields

Status line

Fig. 33—File Copy Tab

Page 38

38 M200 Power Supply User’s Manual

Program Screens

The Program screens (Fig. 34) are used to create new weld

procedures using Auto Create or Manual Create.

Table 11—Program Screen Buttons

Auto Create

(Fig. 35)

Manual

Create

(Fig. 36)

When you select Auto Create, a dialog box will

ask you to confirm overwriting the active weld

procedure. Press Yes to overwrite the active weld

procedure.

The active fields on the Auto Create screen are

shown in black. As these fields are completed, the

inactive fields (in gray) will activate in response to

the entries.

The eight most recent entries for the Programmer

field will display in a drop-down box.

To change the # Levels and # Tacks entries from

the default, press the field to display the keypad.

Enter your changes and press Done.

The Save Procedure drop-down box has two

options:

■

Active (No - Save) will take you directly to the

Main > Weld screen for immediate use. You

can run the weld procedure and make changes

before saving.

■

Save Procedure will take you to the Main > File

screen. On this screen you can enter a name

for the weld procedure and save it to internal

memory or the external USB ash drive.

Manual Create allows programmers to write their

own weld procedures using the Weld screens.

When you select Manual Create, a dialog box will

open, asking you to confirm overwriting the active

weld procedure. Press Yes to overwrite the active

weld procedure.

The Weld screen will open, with all data cleared,

so that you can enter parameters for a new weld

procedure.

See Weld Parameter Development, page 52,

for more information and worksheets for use in

developing a weld procedure.

The Manual Create screen may also be used to

clear the active weld procedure.

Fig. 34—Program Screen

Fig. 35—Auto Create Screen

Fig. 36—Manual Create Screen

Page 39

Weld Log Screens

A Weld Log record is saved to internal memory for every

completed weld. This feature cannot be disabled, but Weld Log

records can be deleted after they are saved to internal memory.

The Weld Log records the following data:

Description Weld procedure, with specific settings

Inputs Weld level information

Outputs Weld results

Performance

Confirmation

The Weld Log screen has two tabs:

■

View / Print / Serial

■

Export / Copy / Delete

The Weld Log screen manages Weld Log records, which are

saved to the Internal Memory\Weld Log folder. Subfolders

cannot be created in the internal memory\Weld Log folder.

Weld Log les can be copied to an external USB ash drive.

Subfolders can be created on the USB ash drive.

After every completed weld, a Weld Log le name is created

automatically in accordance with the following convention:

2007-09-27 10-56 00012 001251 123456.xml

2007-09-27 date

10-56 time (24 h clock)

00012 weld counter (resettable)

001251 arc start counter (nonresettable)

123456 M200 power supply serial number

.xml le format

Operational conditions, errors, notes

M200 Power Supply User’s Manual 39

View / Print / Serial Tab

The Weld Log screen opens in the View / Print / Serial tab,

displaying two panes (Fig. 37):

■

Folder View (left pane) displays folders in the Internal

Memory\Weld Log and the USB ash drive\Weld Log (if drive

is connected).

■

File View (right pane) displays the les contained in the

selected folder in the Folder View pane.

Fig. 37—View / Print / Serial Tab

Page 40

40 M200 Power Supply User’s Manual

Table 12—View / Print / Serial / Tab Buttons

View

Print

Select the Weld Log from the File View pane and

press View. The File Preview window will appear,

showing the weld procedure name, the weld

count, performance confirmation (including any

errors), and time created. Joint, Level, and Tack

parameters will also be displayed. Press OK to

return to the Weld Log screen.

Prints the selected Weld Log record.

Serial

Transfers files and folders directly to a PC using a

serial cable.

M200 power supply serial port settings:

Baud rate: 38 400

Data bits: 8

Parity: None

Stop bits: 1

Flow control: None

Page 41

Export / Copy / Delete Tab

The Export / Copy / Delete tab (Fig. 38) opens, showing two

panes:

■

Internal Memory / USB Flash Drive (left pane) displays the

folders in the Internal Memory \ Weld Log and USB Flash

Drive \ Weld Log (if drive is connected).

■

USB_Flash_Drive_ONLY (right pane) displays the folders for

USB Flash Drive \ Weld Log.

The selected folder and les will appear in the Name eld

below the pane.

M200 Power Supply User’s Manual 41

Table 13—Export / Copy / Delete Tab Buttons

Export

(Fig. 39)

Copy

Create

Folder

Delete

The Export button allows the Weld Log record to

be exported from the Internal Memory\Weld Log

into a text file.

Each Weld Log record is a separate line. Fields

are separated by commas within the Weld Log.

The exported file can be imported into Microsoft

®

Excel

or Access®.

Select the folder to be exported and press Export.

The Weld Log Export dialog box will open. The

From and To locations will be shown.

Enter a file name in the Weld Log Name field.

Check Append to File if the file name already exists

and you want to add the data to the file. If the file

name exists and Append to File is not selected, the

file will be overwritten.

Select a Date Range, Dimensional Units, Flow

Units, Pressure Units, and Date Format and press

Export.

Select a folder or file from the Internal Memory /

USB Flash Drive pane and press Copy. The folder

or file will be copied to the USB flash drive folder

on the right.

Allows you to create an empty folder in the USB

Flash Drive / Weld Log folders. Folders you create

must go into a previously existing folder.

To create an empty folder, highlight the USB Flash

Drive folder you want to put the new folder in.

Press the Weld Log Name field below the USB

Flash Drive pane. Type in the name of the new

folder and press Create Folder.

The new folder will appear in the USB Flash Drive /

Weld Log folders in both panes.

Folder contents can be deleted from internal

memory and the USB flash drive. To delete a folder

and its contents, highlight the folder and press

Delete. A dialog box will ask you to confirm the

delete. Press Yes to delete the folder.

Name field Weld Log Name field

Fig. 38— Export / Copy / Delete Tab

®

Fig. 39— Weld Log Export Dialog Box

Page 42

42 M200 Power Supply User’s Manual

Setup Screens

The Setup screen (Fig. 40) is divided into upper and lower

sections.

The Upper Section Tabs apply primarily to system parameters:

passwords, language, software, etc.

The Lower Section Tabs apply primarily to hardware

parameters: touch screen, printer, ow control, etc.

Fig. 40—Setup Screen

Page 43

Table 14—Setup Upper Section Tabs

M200 Power Supply User’s Manual 43

Weld Log

(Fig. 41)

Operation

(Fig. 42)

Specifies the frequency of the Weld Log printout.

When set to zero, the printer prints out a Weld Log

only when the Print button is pressed. Setting Auto

Print Count to any other number defines the interval

at which Weld Logs are printed: set to 1, the printer

prints after every weld; set to 10, the printer prints

after every 10th weld, etc.

Allows the user to set some of the M200 power

supply functions:

Jog Speed %: Enables the user to set the speed

of the weld head when jogging as a percentage of

the weld head full speed. See the weld head user’s

manual for the full speed ratings of individual weld

heads.

Electrode Touch Volts: This is the voltage setting

used to detect if the electrode touches the weld

puddle. The factory setting of 4 V should not be

adjusted without testing, but may have to be raised

when using longer weld head extension cables.

Raising the voltage makes the M200 power supply

more sensitive and can cause it to record an

electrode touch when there was none and generate

an error code. Lowering the voltage can allow an

electrode touch without generating an error code.

Fan Power-On State: The default setting for the fan

power-on state is

on. The first time the M200 power

supply is powered on, the fan button on the Main

screen will blink and the fan will be in the continuous

run state. Changing the Fan Power-On state to

off

will make the default for the fan button on the main

screen

off. The user can not disable the fan during

the weld cycle. The fan is always on during the weld

cycle.

Fig. 41—Weld Log Tab

Fig. 42— Operation Tab

Page 44

44 M200 Power Supply User’s Manual

Table 14—Setup Upper Section Tabs

Passwords

(Fig. 43 ,

Fig. 44,

Fig. 45)

Shows the current privilege level of the user screen

and allows passwords to be set or reset.

Setting Passwords

The owner password is set in the Setup Wizard the

first time the M200 power supply is powered on. To

set security or programmer passwords:

■

Press the Current Privilege Level button (Fig. 43,

set by default at the Programmer level). A dropdown menu (Fig. 44) will appear on the right side

of the screen that allows you to choose the level

of security for the M200 power supply.

■

Select Owner If you choose to set passwords.

You can now use the Change Security and

Change Programmer buttons to set these

passwords (Fig. 45).

Resetting Passwords

The Current Privilege Level button displays the level

of security in effect:

■

With owner privilege, you can reset any

password.

■

With programmer privilege, you can reset the

programmer or security password.

■

With security privilege, you can reset the

security password.

Press the Change Owner, Change Security, or

Change Programmer buttons to reset the passwords.

Removing Passwords

Programmer and security passwords can be

removed by pressing Enter on the prompt screen

before entering a new password. The owner

password can be reset but not removed.

See Passwords, page 46, for more information.

Language /

Regional /

Dimensional units, time and language are set from

this tab. These settings will affect most screens.

Time

(Fig. 46)

Software Displays the current software version and enables

software updates.

To update software:

■

Insert the USB ash drive containing the

software update into a USB A port on the M200

power supply and press Update Software. Enter

the owner password and carefully follow the

onscreen prompts.

■

Do not power off the M200 power supply during

the software update. The update will take

approximately 5 minutes.

■

Restart the M200 power supply after the

software update is complete for the updates to

take effect.

Counters /

Statistics

The read-only section keeps track of arc starts,

welds, and misfires. The User Counters section

allows setting the weld counter and gives the

option of counting the weld misfires in with the weld

counter.

Service Displays the serial number and the last calibration

date of the M200 power supply.

Fig. 43—Current Privilege Level Button

Fig. 44—Privilege Level Dropdown Menu

Fig. 45—Setting or Resetting Passwords

Fig. 46— Language / Regional / Time Tab

Page 45

Table 15—Setup Lower Section Tabs

M200 Power Supply User’s Manual 45

Touchscreen Press Calibrate Touchscreen to recalibrate the cursor

Printer

(Fig. 47)

Remote Displays Remote status (connected, type) and

Weld Head Displays weld head status (head connected, head

Flow Control Allows disabling of the MFC that controls the OD

Sound Turns the Alarm on or off. When this function is

Internal

Memory

USB Flash

Memory

position relative to your fingertip.

See page 23 for more information about

calibrating the touch screen.

Press Front Panel Key Click on or off to turn on or

off the audible click heard when a button is pressed.

Displays Printer status (paper out, head up) and

settings.

Use this screen to set the Paper Feed Length (short,

medium, long) and Paper Cut (manual, partial, full).

settings. Use this screen to turn the Remote Key

Click on or off.

type).

shield gas and turns off disable, operational, and

error codes associated with OD shield gas flow.

on and a weld error occurs, the audible alarm will

sound. The error displays on the Status line and is

recorded in the Weld Log.

Displays the status of the system memory (capacity,

used space, free space).

Displays the status of the USB flash drive memory

(capacity, used space, free space).

Fig. 47— Printer Tab

NOTICE

Disabling the shield gas flow control

allows a weld to be performed without

using the M200 power supply internal

shield gas flow control. Shield gas

is essential to cooling the weld head

and shielding the weld zone. Failure to

provide an alternative (external) means

of shielding can result in weld head

and fixture damage.

Page 46

46 M200 Power Supply User’s Manual

Passwords

The M200 power supply may be programmed with up to three

different password levels to restrict access to different features.

One password is available for each level of security. Privileges

will be granted based on the password entered at login.

Setting programmer and security passwords is optional. If neither

programmer nor security password is set, all users will have

programmer rights. All passwords can be set, reset, or removed

from their own level or higher.

When all three levels of passwords are set, the following levels of

security are enabled:

Security password. The security password gives access to all

features and functions of the M200 power supply except:

■

Weld parameters cannot be changed outside of the

predetermined limits of the weld procedure.

■

Software cannot be updated.

■

Access to weld procedures is limited to internal memory.

■

The programmer and owner passwords cannot be reset.

If a security password is set, but not a programmer password,

the security password will allow programmer privileges.

Programmer password. The programmer password gives

access to all features and functions of the M200 power supply,

except:

■

Software cannot be updated.

■

The owner password cannot be reset.

If a programmer password is set, but not a security password,

either the owner password or the programmer password may