www.swagelok.com

WELDING SYSTEM

USER’S MANUAL

CWS-D100-1B

CWS-D100-2B

The Swagelok Limited

Lifetime Warranty

Swagelok hereby warrants to the purchaser of this Product that the

non-electrical components of the Product shall be free from defects in

material and workmanship for the life of the Product. All electrical

components installed in or on the Product are warranted to be free

from defects in material and workmanship for twelve months from the

date of purchase.

The purchaser’s remedies shall be limited to replacement and installation

of any parts that fail through a defect in material or workmanship.

MANUFACTURER SPECIFICALLY DISAVOWS ANY OTHER

REPRESENTATION, EXPRESS OR IMPLIED, WARRANTY, OR

LIABILITY RELATING TO THE CONDITION OF USE OF THE

PRODUCT, AND IN NO EVENT SHALL SWAGELOK BE LIABLE TO

PURCHASER, OR ANY THIRD PARTY, FOR ANY DIRECT OR

INDIRECT CONSEQUENTIAL OR INCIDENTAL DAMAGES.

Table of Contents

Foreword

Registration Information i. . . . . . . . . . . . . . . . . . . . . . . .

Safety Summary iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Statements iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Symbols iii. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Practices and Safety Precautions vii. . . . . . . .

User Precautions ix. . . . . . . . . . . . . . . . . . . . . . . . . .

Power Supply Warning Label x . . . . . . . . . . . . . . . .

Referenced Specifications xi. . . . . . . . . . . . . . . . . . .

Section 1 Introduction SWS D100

Gas Tungsten Arc Welding 1-2. . . . . . . . . . . . . . . . . . . . . .

Principles of the GTAW Process 1-2. . . . . . . . . . . . .

GTAW Process Advantages 1-2. . . . . . . . . . . . . . . . .

Process Variables 1-3. . . . . . . . . . . . . . . . . . . . . . . . . .

System Components 1-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

The SWS D100 Power Supply 1-4. . . . . . . . . . . . . . .

The Weld Head 1-5. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixture Blocks 1-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of SWS Operation 1-7. . . . . . . . . . . . . . . . . . . .

Specifications 1-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 2 Installation

Introduction 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Accessory Requirements 2-2. . . . . . . . . . . . . .

Electrical Requirements 2-3. . . . . . . . . . . . . . . . . . . . . . . .

Input Voltage 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using an Extension Cord 2-3. . . . . . . . . . . . . . . . . . . .

Unpacking and Inspecting System Components 2-4. . .

Unpacking the Power Supply 2-4. . . . . . . . . . . . . . . .

Unpacking the Weld Head Cable Assembly

and Related Components 2-5. . . . . . . . . . . . . . . . . . .

2005 Swagelok Company, all rights reserved

September 2005

TOC−1

Table of Contents

CWS−D100−B Welding System

Installing the SWS 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Power Supply 2-6. . . . . . . . . . . . . . . . . .

Installing the Weld Head 2-7. . . . . . . . . . . . . . . . . . . .

Installing the Gas Delivery System 2-9. . . . . . . . . . . . . . .

Introduction 2-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Typical Shielding/Purge Gas

Delivery System 2-10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Optional Gas Delivery System 2-12. . .

Preliminary Check 2-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 3 Operation

Introduction 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Front Panel Controls 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Current Control Switches 3-3. . . . . . . . . . . . . . . . . . . .

Timing Control Switches 3-4. . . . . . . . . . . . . . . . . . . .

Pushbuttons 3-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Indicator Lights 3-8. . . . . . . . . . . . . . . . . . . . . .

Digital Displays 3-9. . . . . . . . . . . . . . . . . . . . . . . . . . . .

SWS Modes of Operation 3-9. . . . . . . . . . . . . . . . . . . . . . .

Operational Mode 3-12. . . . . . . . . . . . . . . . . . . . . . . . . .

Program Mode 3-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Test Mode 3-22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Electrode in the Series 5/10/20

Weld Head 3-26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Proper Electrode 3-26. . . . . . . . . . . . . . .

Inserting the Electrode into a Rotor 3-26. . . . . . . . . . .

Setting the Arc Gap 3-27. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Arc Gap Gage 3-27. . . . . . . . . . . . . . . . . . .

Setting the Arc Gap 3-27. . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Work 3-28. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixturing the Work 3-29. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting the Fixture Block and Collets 3-29. . . . . . . .

Installing the Collets in a Tube Fixture Block 3-29. . .

Aligning the Work Pieces in the Tube

Fixture Block 3-30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Purge Gas Line 3-32. . . . . . . . . . . . . .

Connecting the Weld Head to the Fixture Block 3-33. . . .

Safety Interlock 3-33. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mating the Weld Head to the Fixture Block 3-34. . . .

TOC−2

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Entering the Weld Parameters 3-35. . . . . . . . . . . . . . . . . . .

Using a Weld Procedure Guideline 3-35. . . . . . . . . . .

Effects of Weld Parameters 3-36. . . . . . . . . . . . . . . . .

Setting the Shield Gas Flow 3-37. . . . . . . . . . . . . . . . . . . . .

Starting and Completing the Weld 3-37. . . . . . . . . . . . . . .

Display Indications During Welding 3-38. . . . . . . . . . .

After the Weld is Complete 3-39. . . . . . . . . . . . . . . . . .

Operation Summary 3-40. . . . . . . . . . . . . . . . . . . . . . . . . . .

Section 4 Micro Weld Heads CWS-4MRH-A,

CWS-4MFH-A, CWS-8MRH

Introduction 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Micro Fixture Tool 4-3. . . . . . . . . . . . . . . . . . . . .

Installing the Motor Module 4-3. . . . . . . . . . . . . . . . . . . . .

Installing the Micro Weld Head 4-4. . . . . . . . . . . . . . . . . .

Installing/Replacing the Electrode 4-6. . . . . . . . . . . . . . . .

Setting the Arc Gap 4-8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fixturing the Work 4-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting the Micro Weld Head to the Fixture 4-11. . . .

Considerations During Welding 4-13. . . . . . . . . . . . . . . . . .

Using the Optional Bench Mounting Bracket 4-14. . . . . . .

Series 4 Bench Mount Bracket 4-14. . . . . . . . . . . . . . .

Series 8 Bench Mount Bracket 4-15. . . . . . . . . . . . . . .

Table of Contents

Section 5 Weld Parameter Adjustment

Introduction 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Developing a Weld Procedure Guideline 5-1. . . . . . . . . .

Determining the Work Specifications 5-2. . . . . . . . . .

Setting the Front Panel Switches 5-3. . . . . . . . . . . . .

Example Weld Procedure Guideline Worksheet 5-9

Weld Procedure Guideline Worksheet 5-10. . . . . . . .

Evaluating the Weld 5-16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identifying Typical Weld Discontinuities 5-16. . . . . . .

Identifying Proper Welds 5-17. . . . . . . . . . . . . . . . . . . .

Adjusting Controls for Weld Quality 5-22. . . . . . . . . . . . . .

Section 6 Maintenance

Introduction 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series 5/10/20 Fixture Blocks 6-2. . . . . . . . . . . . . . . . . . .

Daily Maintenance 6-2. . . . . . . . . . . . . . . . . . . . . . . . .

Forty-Hour Maintenance 6-2. . . . . . . . . . . . . . . . . . . .

Micro Weld Head Fixture Blocks 6-3. . . . . . . . . . . . . . . . .

Daily Maintenance 6-3. . . . . . . . . . . . . . . . . . . . . . . . .

2005 Swagelok Company, all rights reserved

September 2005

TOC−3

Table of Contents

CWS−D100−B Welding System

Series 5/10/20 Weld Head 6-4. . . . . . . . . . . . . . . . . . . . . .

Daily Maintenance 6-4. . . . . . . . . . . . . . . . . . . . . . . . .

Forty-Hour Maintenance 6-4. . . . . . . . . . . . . . . . . . . .

Series 5/10/20 Weld Head Disassembly

and Cleaning 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Series 5/10/20 Weld Head Assembly 6-9. . . . . . . . .

Micro Weld Heads 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Daily Maintenance 6-10. . . . . . . . . . . . . . . . . . . . . . . . .

Eight-Hour Maintenance 6-11. . . . . . . . . . . . . . . . . . . .

Micro Weld Head Assembly 6-15. . . . . . . . . . . . . . . . .

Power Supply 6-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse Inspection and Replacement 6-15. . . . . . . . . . .

Section 7 Troubleshooting

Introduction 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Swagelok Welding System (SWS) Repair Procedure 7-1

Repair/Replacement Instructions 7-2. . . . . . . . . . . . .

Appendix A Glossary

Appendix B Optional Equipment

SWS Remote Pendant B-2. . . . . . . . . . . . . . . . . . . . . . . . .

Weld Head Extension Cables B-3. . . . . . . . . . . . . . . . . . .

Data Logging/Monitoring B-4. . . . . . . . . . . . . . . . . . . . . . . .

Data Recording Printer B-6. . . . . . . . . . . . . . . . . . . . . . . . .

Introduction B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unpacking and Inspection B-6. . . . . . . . . . . . . . . . . . .

Installation B-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating the Printer B-9. . . . . . . . . . . . . . . . . . . . . . .

Maintenance B-15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using a Standard RS-232 Printer B-16. . . . . . . . . . . . .

Appendix C Electrode Selection Tables

and Geometry

CWS-4MRH-A, CWS-4MFH-A

Micro Weld Heads C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CWS-8MRH Micro Weld Head C-1. . . . . . . . . . . . . . . . . . .

CWS-5H-B Weld Head C-2. . . . . . . . . . . . . . . . . . . . . . . . .

CWS-10H-A Weld Head C-2. . . . . . . . . . . . . . . . . . . . . . . .

CWS-20H-A/B Weld Head C-3. . . . . . . . . . . . . . . . . . . . . .

Electrode Geometry C-3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

TOC−4

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Appendix D Weld Head Information

MICRO WELD HEAD − TUBE WELDING D-2 . . . . . . . . .

SERIES 5 WELD HEAD − TUBE WELDING D-2 . . . . . . .

SERIES 10 WELD HEAD − TUBE WELDING D-3 . . . . .

SERIES 20 WELD HEAD − TUBE WELDING D-3 . . . . .

SERIES 20 WELD HEAD − PIPE WELDING D-4 . . . . . .

MICRO WELD HEAD − TUBE WELDING D-4 . . . . . . . . .

SERIES 5 WELD HEAD − TUBE WELDING D-5 . . . . . . .

SERIES 10 WELD HEAD − TUBE WELDING D-5. . . . .

SERIES 20 WELD HEAD − TUBE WELDING D-6. . . . .

Appendix E Arc Gap Gage Setting Tables

Wall Thickness and Arc Gap E-1. . . . . . . . . . . . . . . . . . . .

Weld Head Arc Gap Gage Setting Tables E-2. . . . . . . . .

Arc Gap Gage Setting Tables

for Swagelok ATW Fittings E-11. . . . . . . . . . . . . . . . . . . . . .

Arc Gap Gage Setting Formula E-12. . . . . . . . . . . . . . . . . .

Table of Contents

Appendix F Parts Drawings

Appendix G Gas Flow Rate Tables

Purge Rate and Pressure Tables G-1. . . . . . . . . . . . . . . .

Purge Rate and Pressure Tables Continued G-2. . . . . . .

General Suggested Shielding

Gas Flow Rates (Argon) G-2. . . . . . . . . . . . . . . . . . . . . . . .

Appendix H Fixture Block Alignment

Series 5 Fixture Block H-1. . . . . . . . . . . . . . . . . . . . . .

Series 20H-B Fixture Block H-5. . . . . . . . . . . . . . . . . .

Series 8 Micro Weld Head Fixture H-6. . . . . . . . . . . .

Appendix I Weld Procedure Guidelines

Index

2005 Swagelok Company, all rights reserved

September 2005

TOC−5

Table of Contents

CWS−D100−B Welding System

TOC−6

2005 Swagelok Company, all rights reserved

September 2005

Foreword

Registration Information

Your Swagelok representative can provide support and

service of your Swagelok Welding System (SWS) as well

as local stock of precision fittings and valves.

Please take a moment to fill out the warranty information

form as well as the information listed below. Keep this

information available in case you need to contact your

Swagelok representative.

Power Supply:

Model Number*:

Serial Number*:

Delivery Date:

* See rating label on the rear of the unit, shown in Figure 1.

Weld Head(s):

Weld Head:

Model Number:

Serial Number:

Delivery Date:

Model Number:

Serial Number:

Delivery Date:

Model Number:

Figure 1 Rating Label

Serial Number:

Delivery Date:

2005 Swagelok Company, all rights reserved

September 2005

i

Foreword

CWS−D100−B Welding System

ii

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Safety Summary

The safety information presented here pertains to both

R

the Swagelok

Gas Tungsten Arc Welding (GTAW).

Read Operating Instructions

Read all of the instructions in this manual prior to operating

the SWS.

Statements

Welding System (SWS) and the process of

Foreword

Caution!

Statements identify conditions or

practices that could result in damage to

the equipment or other property.

WARNING!

Statements identify conditions or

practices that could result in personal

injuries or loss of life.

Symbols

The following symbols are used in this manual and on

the equipment to visually identify where warning or

caution information is found. Consult symbols and

related instructions below for necessary actions to avoid

the hazards.

WARNING or Caution

This symbol identifies the location of all other

types of warning or caution information which

don’t have specific symbols. Accompanying

text will identify the specific nature of the

condition and if the condition is a warning

or caution.

2005 Swagelok Company, all rights reserved

September 2005

iii

Foreword

CWS−D100−B Welding System

ELECTRIC SHOCK can kill.

Touching live electrical parts can cause fatal

shocks and severe burns. Incorrectly installed or

improperly grounded equipment is a hazard.

D Do not touch live electrical parts

D No user serviceable parts in the power supply other

than a fuse. Refer all other power supply servicing

to your Authorized Swagelok representative.

D Keep all panels and covers securely in place. Do

not touch electrode connector, electrode, or rotor

after pressing start. The electrode is live during the

weld cycle.

D Verify that the power supply is properly grounded

before use. Make sure the power cord is plugged

into a properly wired and grounded receptacle.

D Follow local electrical codes and the guidelines in

the manual when installing the SWS. Failure to do

so may create an electrical shock hazard. Shock

hazards can exist even when equipment is properly

installed, so it is important that the operator be

trained in the proper use of the equipment and

follow established safety practices.

D Frequently inspect input power cord for damage or

bare wiring – replace immediately if damaged.

D Properly unplug the power cord. Grasp the plug to

remove it from the receptacle.

D Do not use extension cords that are in poor physical

condition or have insufficient current capacity.

Failure to do so can pose fire and shock hazards.

iv

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

FUMES AND GASES can be hazardous.

Welding produces fumes and gases. Breathing

these fumes and gases can be hazardous to your

health. Build−up of gases can displace oxygen

and cause injury or death.

D Do not breathe fumes or gases.

D If inside, ventilate the area and/or use exhaust at the

arc to remove welding fumes and gases.

D If ventilation is poor, use an approved air-supplied

respirator.

D Read the Material Safety Data Sheets (MSDSs) and

the manufacturer’s instructions for metals,

consumables, coatings, cleaners, and degreasers.

D Work in a confined space only if it is well

ventilated or while wearing an air−supplied

respirator. Always have a trained watch−person

nearby. Welding fumes and gases can displace air

and lower the oxygen level causing injury or death.

Be sure the breathing air is safe.

Foreword

D Do not weld in locations near degreasing, cleaning,

or spraying operations. The heat and rays of the arc

can react with vapors to form highly toxic and

irritating gases.

D Do not weld on coated metals, such as galvanized,

lead, or cadmium plated steel, unless the coating is

removed from the weld area, the area is well

ventilated, and if necessary, while wearing an

air−supplied respirator. The coatings and any

metals containing these elements can give off toxic

fumes if welded.

D The ultraviolet light emitted by the welding arc acts

on the oxygen in the surrounding atmosphere to

produce ozone. Test results1 , based upon present

sampling methods, indicate the average

concentration of ozone generated in GTAW process

does not constitute a hazard under conditions of

good ventilation and welding practice.

1 WELDING HANDBOOK, VOLUME 2, 8TH EDITION,

AMERICAN WELDING SOCIETY.

D Shut off shielding gas supply when not in use.

2005 Swagelok Company, all rights reserved

September 2005

v

Foreword

CWS−D100−B Welding System

ARC RAYS can burn eyes.

NOISE can damage hearing.

Arc rays from the welding process produce

intense visible and invisible (ultraviolet and

infrared) rays that can burn eyes. The SWS is

meant for use only with enclosed weld heads

which minimize exposure to these harmful rays.

D Do not look at welding arc.

D Use protective screens or barriers to protect

others from flash and glare; warn others not to

watch the arc.

D Wear approved ear protection if noise level

is high.

WELDING can cause fire or explosion.

Welding on closed containers, such as tanks,

drums, or pipes, can cause them to blow up.

The hot work piece and hot equipment can

cause fires and burns. Check and be sure the

area is safe before doing any welding.

D Protect yourself and others from the

hot work piece.

D Watch for fire, and keep a fire

extinguisher nearby.

D Do not weld on closed containers such as tanks,

drums, or pipes, unless they are

properly prepared according to AWS F4.1.

D Do not use welder to thaw frozen pipes.

D Do not use extension cords that are in poor physical

condition or have insufficient current capacity.

Failure to do so can pose fire and shock hazards.

vi

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Safe Practices and Safety Precautions

READ ANSI Z49.1

Safety and safe practices in welding, cutting and

allied processes are covered in ANSI Z49.1,

SAFETY IN WELDING AND CUTTING. When

using the SWS, follow all basic safety practices.

CYLINDERS can explode if damaged.

Shielding gas cylinders contain gas under high

pressure. If damaged, a cylinder can explode. Since

gas cylinders are normally part of the welding

process, be sure to treat them carefully.

D Protect compressed gas cylinders from excessive

heat, mechanical shocks, slag, open flames, sparks,

and arcs.

Foreword

WARNING!

SHIELDING GAS CYLINDERS

CAN EXPLODE IF DAMAGED

OR IMPROPERLY TREATED.

D Install cylinders in an upright position by securing

to a stationary support or cylinder rack to prevent

falling or tipping.

D Keep cylinders away from any welding or other

electrical circuits.

D Never weld on a pressurized cylinder − explosion

will result.

D Use only correct shielding gas cylinders, regulators,

hoses, and fittings designed for the specific

application; maintain them and associated parts in

good condition.

D Turn face away from valve outlet when opening

cylinder valve.

D Keep protective cap in place over valve except

when cylinder is in use or connected for use.

D Read and follow instructions on compressed gas

cylinders, associated equipment, and CGA

publication P−1 listed in Safety Standards.

2005 Swagelok Company, all rights reserved

September 2005

vii

Foreword

CWS−D100−B Welding System

WARNING!

SHIELDING GAS CYLINDERS

CAN EXPLODE IF DAMAGED

OR IMPROPERLY TREATED.

WARNING!

PACEMAKER WEARERS

KEEP AWAY.

HOT PARTS can cause severe burns.

After welding, the work piece, weld head,

and electrode can be extremely hot and may

cause burns.

MAGNETIC FIELDS can affect pacemakers.

D Pacemaker wearers keep away.

D Wearers should consult their doctor before going

near welding operations.

viii

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

User Precautions

Foreword

D Power Supply Grounding

The power supply is grounded through the ground

connector of the power cord. Avoid electrical shock

by making sure the power cord is plugged into a

properly wired and grounded receptacle before

turning the unit on.

D Water and Moisture

System components are not waterproof. Do not

expose the SWS equipment to water.

D Proper Use and Storage

Do not store or use near hazardous materials. Store

indoors and cover the system when not in use.

D Weld Heads

Disconnect the weld head completely from the

power supply prior to servicing.

WARNING!

VERIFY THAT THE SYSTEM

IS PROPERLY GROUNDED

BEFORE USE.

User service, including cleaning or component

replacement, is limited to those operations

identified in this manual.

D Fixture Blocks

Disconnect the fixture block from the weld head

prior to servicing. User service, including cleaning

or component replacement, is limited to those

operations identified in this manual.

D Power Supply Service

There are no user serviceable parts in the power

supply other than a fuse. Refer all other servicing

to your Authorized Swagelok sales and

service representative.

WARNING!

USERS SHOULD NOT

SERVICE THE

POWER SUPPLY.

2005 Swagelok Company, all rights reserved

September 2005

ix

Foreword

CWS−D100−B Welding System

Power Supply Warning Label

This warning label is affixed to the power supply.

x

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Referenced Specifications

1. AWS F4.1, Recommended Safe Practices for the Preparation

for Welding and Cutting of Containers and Piping.

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126 (www.aws.org

2. ANSI Z49.1, Safety in Welding Cutting, and Allied Processes.

American Welding Society, 550 N.W. LeJeune Rd, Miami, FL

33126 (www.aws.org

3. CGA Publication P−1, Safe Handling of Compressed Gases

in Cylinders.

Compressed Gas Association, 4221 Walney Road, 5th Floor,

Chantilly VA 20151−2923, ( www.cganet.com

).

).

).

Foreword

4. OSHA 29CFR 1910 Subpart Q, Welding Cutting, and Brazing.

Acquire from U.S. Government Printing Office, Superintendent

of Documents, P.O. Box 371954, Pittsburgh, PA 15250

(www.osha.gov

).

5. OSHA 29CFR 1926 Subpart J, Welding and Cutting.

Acquire from U.S. Government Printing Office,

Superintendent of Documents, P.O. Box 371954,

Pittsburgh, PA 15250 (www.osha.gov

).

2005 Swagelok Company, all rights reserved

September 2005

xi

Foreword

CWS−D100−B Welding System

xii

2005 Swagelok Company, all rights reserved

September 2005

Section 1

Introduction

SWS D100

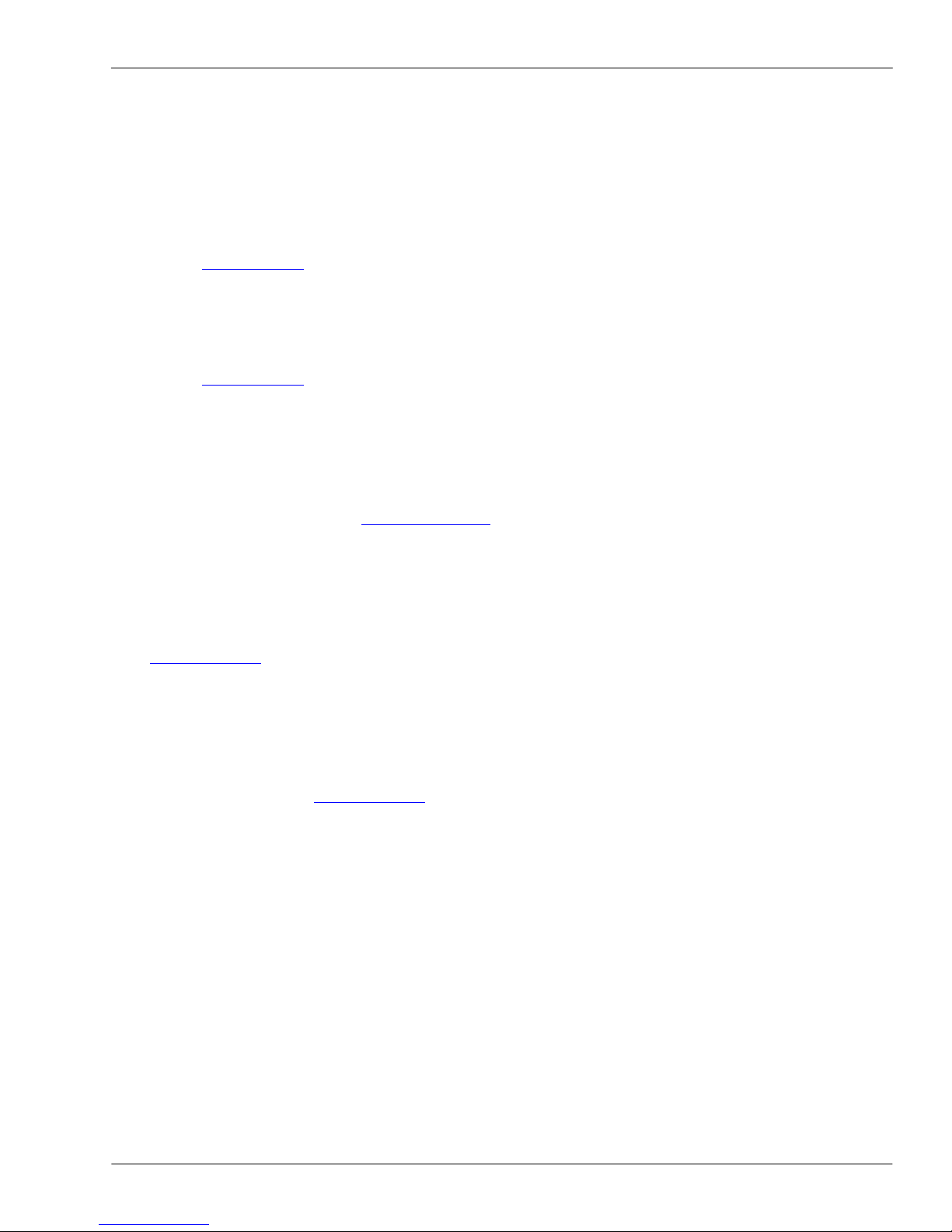

The Swagelok Welding System (SWS) is a versatile, portable and easy to use

orbital welding system. This section includes

D gas tungsten arc welding

D system components

D overview of SWS operation

D specifications.

2005 Swagelok Company, all rights reserved

September 2005

Figure 1-1 Swagelok Welding System

1-1

Introduction

CWS−D100−B Welding System

The purpose of this manual is to familiarize you with the SWS and to provide the

reference information needed to produce high-quality, repeatable welds.

While reading, you may encounter unfamiliar terminology. Some terms are common to

the welding industry and others particular to the SWS. Refer to Appendix A, Glossary,

if necessary.

Gas Tungsten Arc Welding

Principles of the GTAW Process

Gas Tungsten Arc Welding (GTAW) is a welding process that creates an arc between a

nonconsumable tungsten (or tungsten alloy) electrode and the work. The electrode is held

in a torch, rotor, or other device. GTAW uses a shielding gas, most commonly Argon, that

is delivered to the weld area. The shielding gas envelops the weld joint and electrode,

protecting both from contamination by the atmosphere.

The electric arc which creates the weld is produced by the passage of current through the

conductive ionized shielding gas. The arc is established between the tip of the electrode

and the work. Heat generated by the arc melts the base metal. Once the arc and weld

puddle are established, the electrode moves along the joint and the arc progressively melts

the joint surface. Filler wire, if used, is added to the leading edge of the weld puddle to

fill the joint.

GTAW provides precise control of heat input to the weld joint. For this reason, it is

preferred for joining thin gage metals and for making welds close to heat sensitive

components. The process offers advantages to many industries, ranging from the high

purity required in the semiconductor industry to autogenous manual welds of the

process industry.

The process can be used to weld almost all metals. GTAW can be used to weld all types of

joint geometries in tubing, pipe, or other structural shapes. It is particularly appropriate for

welding wall sections less than 3/8 in. (9,5 mm) thick.

GTAW Process Advantages

The GTAW process has the following advantages:

D produces superior quality welds

D allows excellent control of weld penetration

D welds almost all metals

D produces autogenous welds at high speeds

D allows precise control of the welding variables

D welds with or without filler metal

D eliminates spatter

1-2

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Process Variables

The major process variables in GTAW are arc current, arc voltage, and travel speed.

D Arc Current − The current measured between the tungsten electrode and the work.

Generally stated, arc current controls the weld penetration.

Direct Current Electrode Negative (DCEN) is common for GTAW. It offers the

advantages of deep penetration and fast welding speeds because most of the heat

generated in the welding process is transferred to the work.

D Arc Voltage − The voltage measured between the tungsten electrode and the work.

Arc voltage is affected by the following:

D arc current

D shape of the tungsten electrode tip

D type and purity of shielding gas

Introduction

D arc length (distance between the electrode and the work)

Arc length is important with this process because it affects the width of the weld

puddle; puddle width is proportional to arc length. The desired arc length is as short

as possible.

D Travel Speed − The speed that the electrode moves over the work while welding.

Travel speed affects both the width and weld penetration of GTAW. Its effect on

width is more pronounced than on penetration. Increasing travel speed decreases the

width of the weld.

Travel speed generally is fixed in mechanized welding. Other variables such as

current or voltage are varied to maintain control of the weld.

2005 Swagelok Company, all rights reserved

September 2005

1-3

Introduction

CWS−D100−B Welding System

System Components

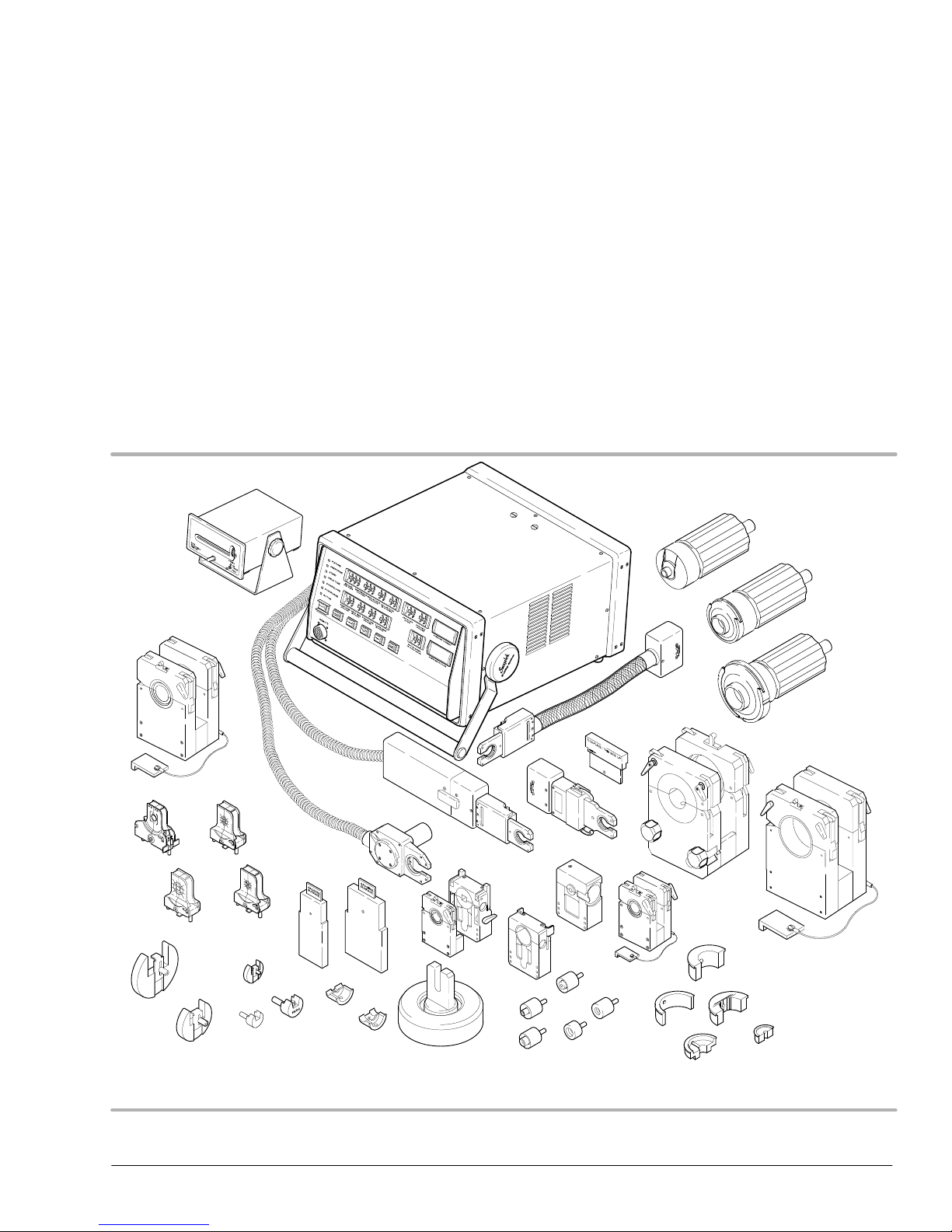

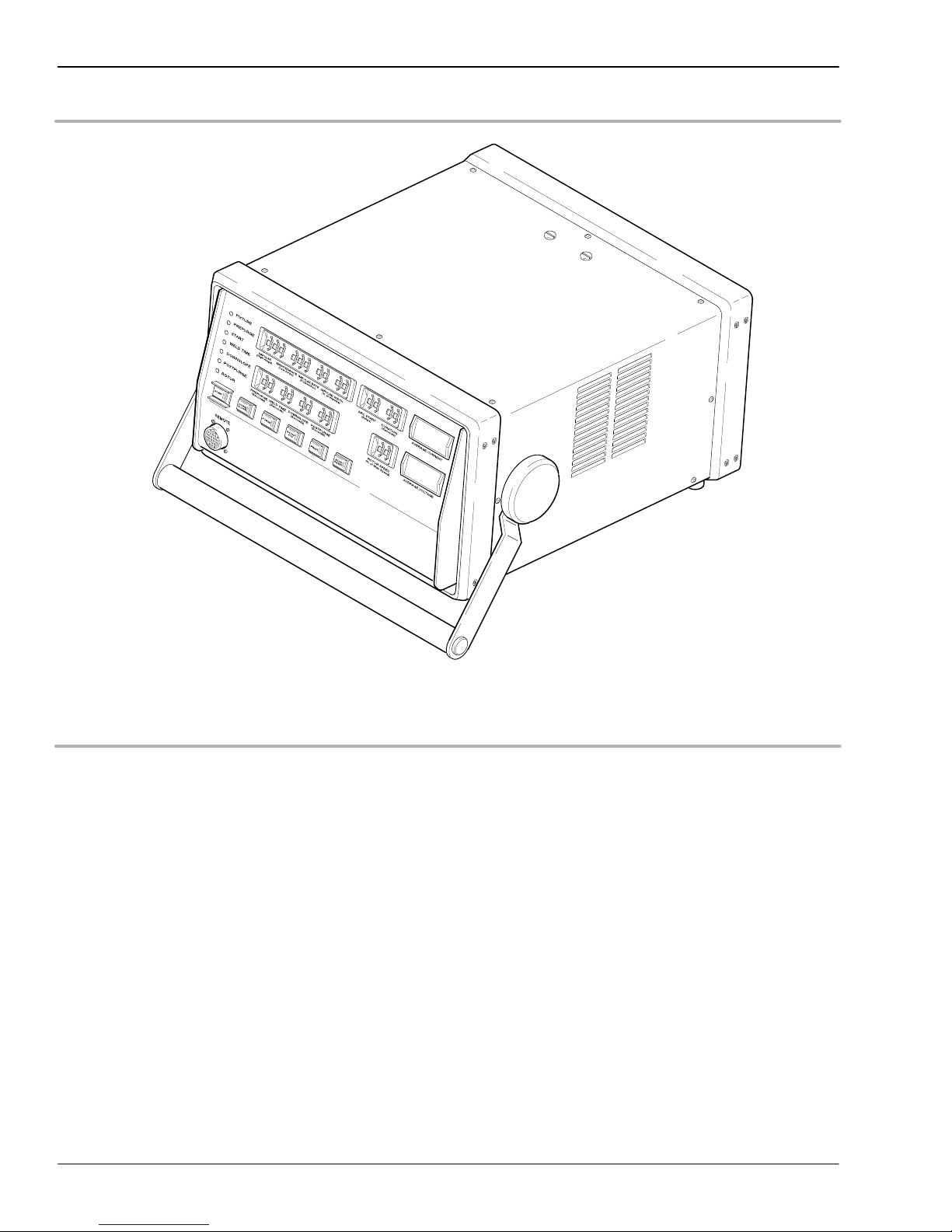

The SWS D100 Power Supply

The power supply features microcontroller electronics and closed-loop circuitry to

precisely control output current. Simplified controls and displays provide efficient

programming and monitoring of the welding process.

See Table 1-1 on page 1-9 for the power supply specifications.

Figure 1-2 SWS D100 Power Supply

1-4

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

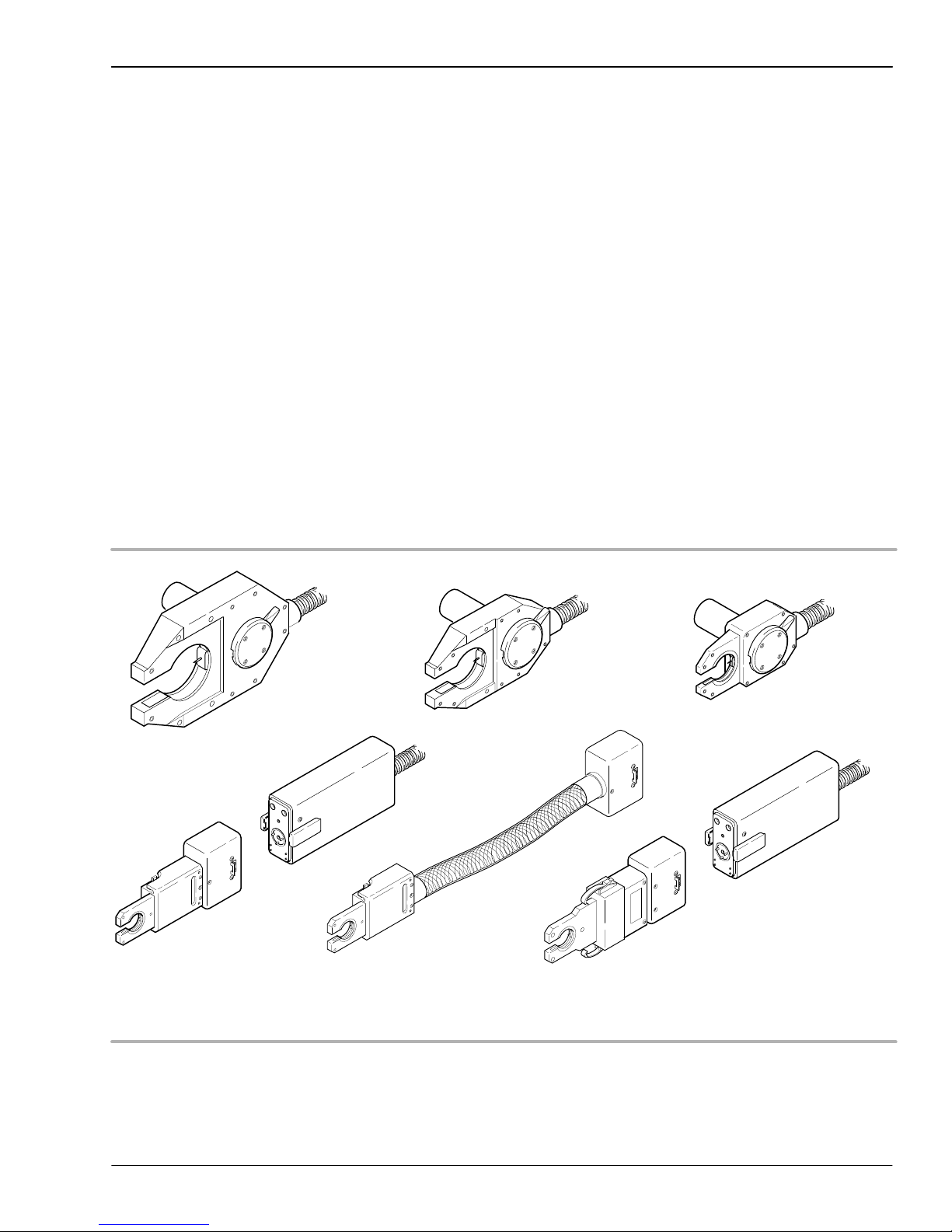

The Weld Head

The SWS weld heads deliver consistent, precise welds for outside diameters from 1/16 in.

to 2 in. (3 mm to 52 mm). There are six weld heads to choose from, depending on the size

of the work pieces. See Figure 1-3.

A dc motor in the weld head drives a rotor which carries the tungsten electrode around the

weld joint. Optical circuitry in the weld head sends precise feedback to the power supply

to control the speed of the rotor.

All moving parts in the weld head mount in low-friction devices to provide smooth,

consistent operation.

A spring-loaded, floating brush continuously contacts approximately one-third of the

circumference of the rotor at all times. This configuration ensures consistent, uniform

electrical conductance to the rotor and electrode.

Introduction

See Table 1-5 on page 1-10 for the weld head specifications.

Series Micro

Motor Module

Series 4 Micro

(Rigid)

Series 4 Micro

(Flexible)

Series 5Series 20 Series 10

Series Micro

Motor Module

Series 8 Micro

2005 Swagelok Company, all rights reserved

September 2005

Figure 1-3 Weld Heads

1-5

Introduction

CWS−D100−B Welding System

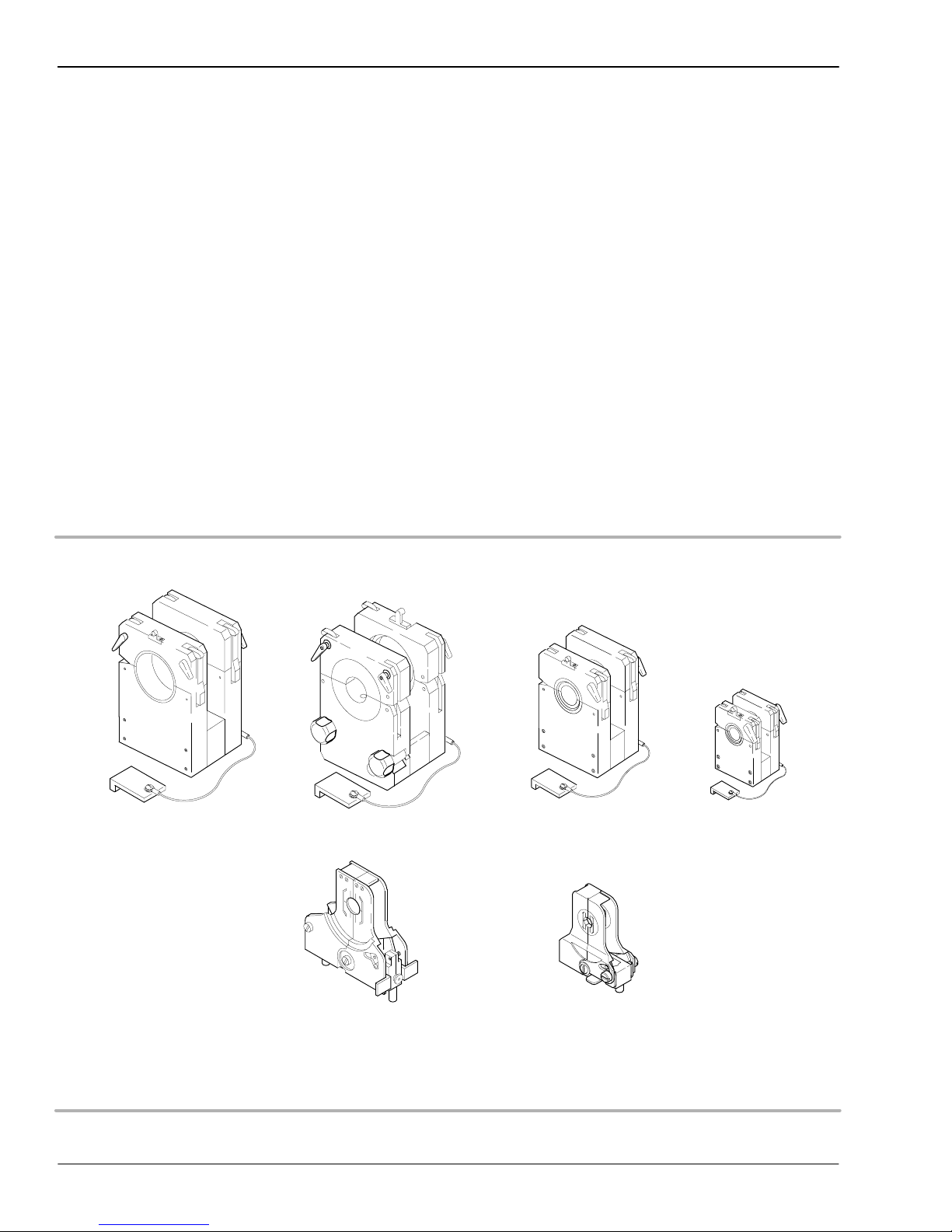

Fixture Blocks

The SWS fixture blocks accurately align and hold tubing, fittings, and valve bodies. The

modular design allows you to select different side plates and create the configuration

needed for the job.

The fixture block is separate from the weld head, allowing work pieces to be easily

aligned and fixtured before welding. The use of multiple fixture blocks offers

increased productivity.

Each fixture block is designed to accommodate a range of work piece sizes. A unique and

patented Universal Collet Insert (UCI) fits into the fixture block to match the diameter of

the work piece. The collet design firmly holds tubing and fittings that vary ± 0.005 in.

(0,13 mm) from nominal outside diameter. Collets are also available for thin wall pipe.

The collets exchange quickly, making the fixture block very adaptable to changing

work requirements. Tables 1-6, 1-7, and 1-8 list the available fixtures and collets.

Series 20-A Series 10

Series 20-B

Series 8

Series 4

Series 5

1-6

Figure 1-4 Standard Fixtures

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Overview of SWS Operation

GTAW Orbital welding is a proven method for welding cylindrical shapes such as

tubes, fittings, and pipe. The SWS design makes the orbital welding process efficient

and effective.

The SWS provides an advanced method of autogenous GTAW. The system uses a fixture

block and associated weld head to provide precise fixturing of the work pieces. The

welding parameters are controlled by the SWS power supply and are programmed by

the operator.

Operating the SWS is uncomplicated. The work piece sizes define the fixture block

configuration, collets, and weld head to be used.

The fixture block quickly clamps onto the work pieces. The weld joint is centered in the

fixture block using a centering gage. Since the fixture block is not part of the weld head,

multiple fixture blocks can be used to maximize weld setup efficiency.

Introduction

The weld head cable assembly attaches quickly to the power supply. Setup of the weld

head is limited to the selection of an electrode and setting the arc gap. The arc gap setting

depends on the characteristics of the work pieces. A gage is provided with the weld head

to assist in setting the arc gap. After the arc gap is set, the weld head attaches to the fixture

block and is secured with a locking ring.

The power supply uses rotary switches for weld parameter control. See Figure 1-5. The

appropriate switch settings are generally defined by the work pieces to be welded and are

refined using test welds. The correct settings used for a specific job are developed into a

weld procedure guideline. The guideline is used to maintain repeatability and quality

control for subsequent jobs of the same type.

2005 Swagelok Company, all rights reserved

September 2005

1-7

Introduction

CWS−D100−B Welding System

Figure 1-5 SWS D100 Front Panel Controls

1-8

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Specifications

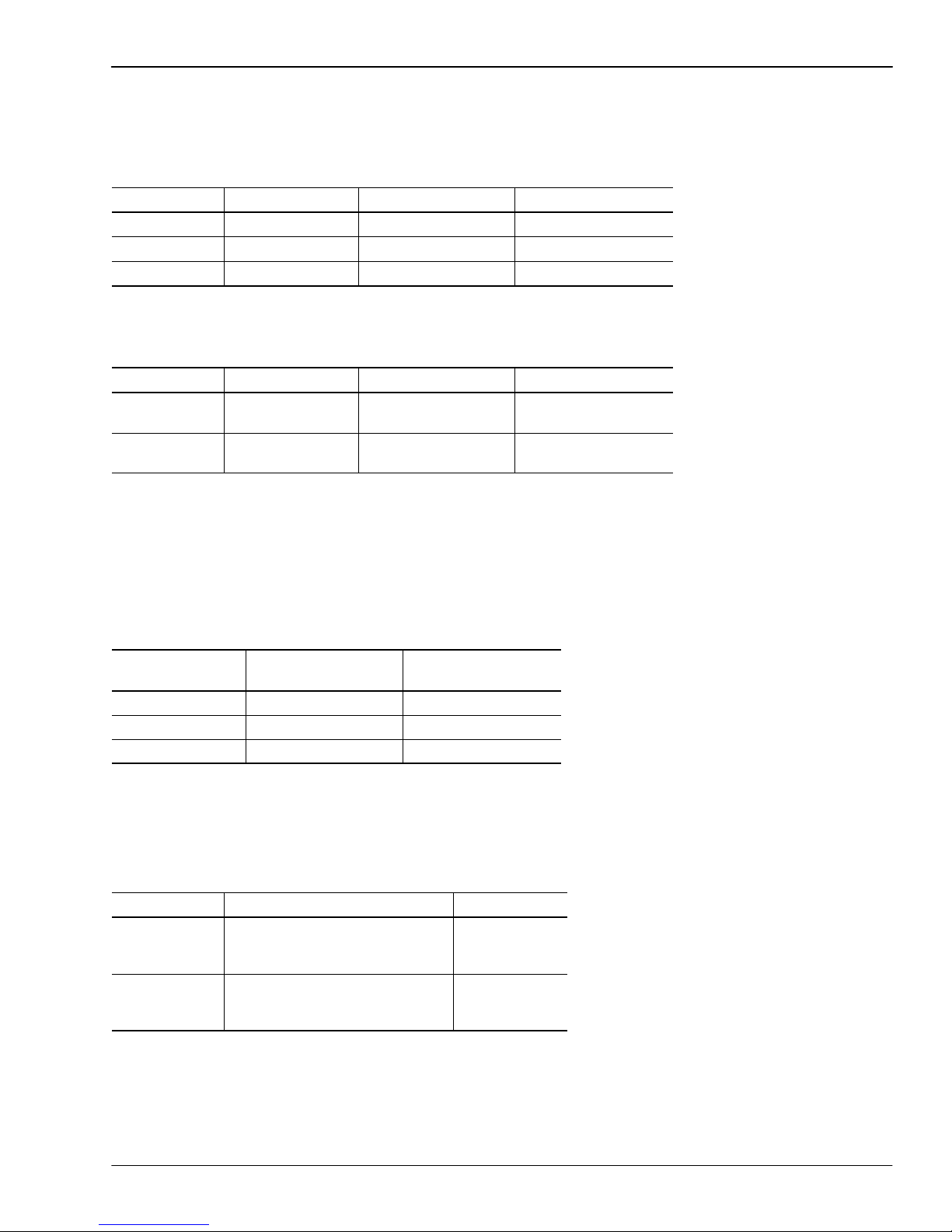

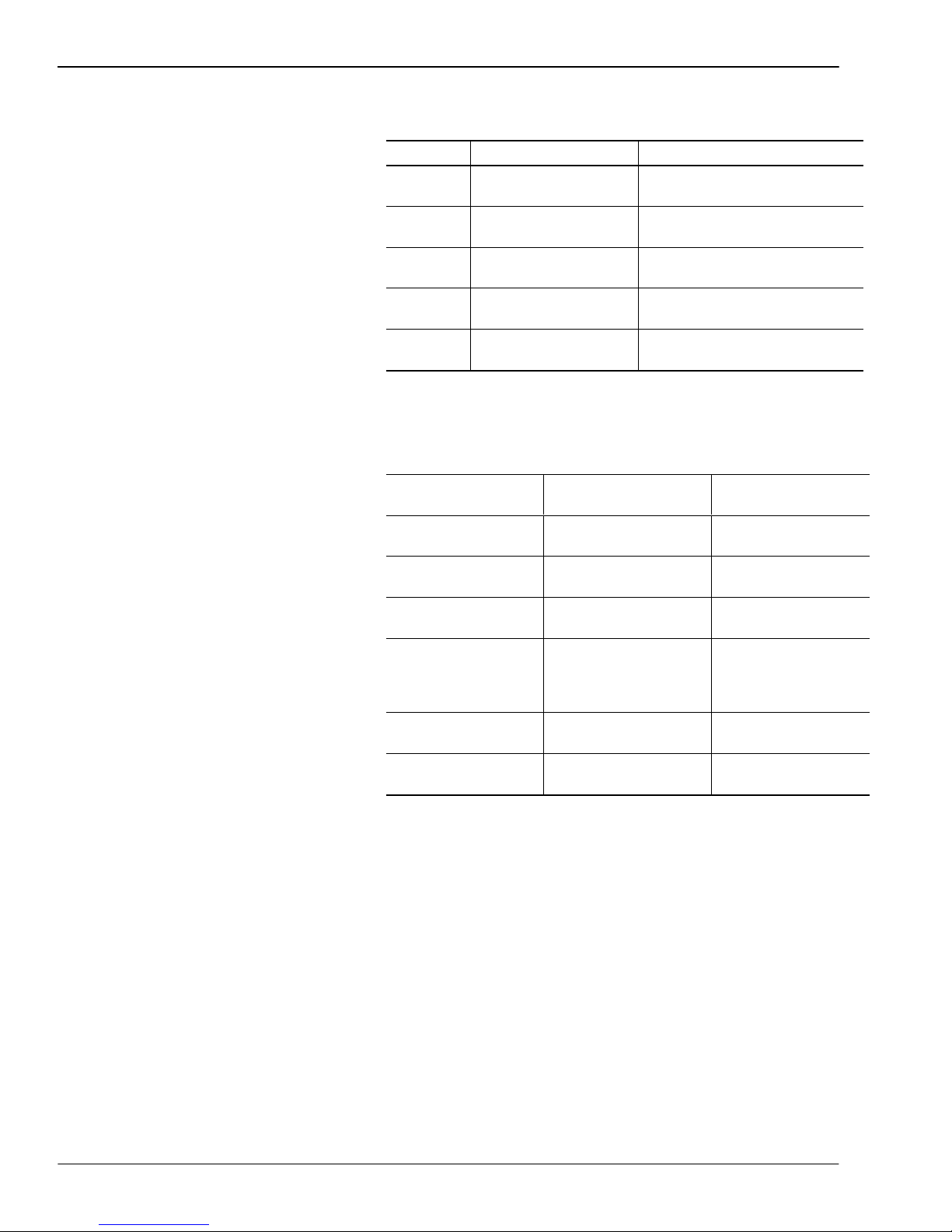

Table 1-1 Power Supply

Model Supply Voltage* Service Amps Output Current (dc)

CWS-D100-1B 115 V (ac) 20 A 2 to 100 A

CWS-D100-1B 115 V (ac) 15 A 2 to 70 A

CWS-D100-2B 230 V (ac) 15 A 2 to 100 A

* 10% input voltage tolerance, frequency range 50 Hz to 60 Hz

Table 1-2 Duty Cycle

Model 6.25 % 60 % 100 %

CWS-D100-1B 100 Amps

14 Volts

CWS-D100-2B 100 Amps

14 Volts

32.3 Amps

11.3 Volts

32.3 Amps

11.3 Volts

25 Amps

11 Volts

25 Amps

11 Volts

Introduction

Duty cycle is the ratio of time the power supply can weld to the time the power supply

must remain idle to cool. The 10 minute cycle is a recognized welding industry standard.

It represents the maximum weld time allowed, with the balance of the 10 minute cycle

required for cooling.

Table 1-3 10 Minute Cycle Times

Maximum Weld TIme

Duty Cycle Rating

30 % 3 7

60 % 6 4

100 % 10 0

(Minutes)

Required Idle Time

(Minutes)

Continually exceeding the duty cycle may activate an internal thermal protector that will

disable the power supply and display message code 50. Refer to pages 3-13 and 3-15.

Table 1-4 Power Supply Dimensions and Weight

Model Dimensions (overall) Weight

CWS-D100-1B 15 1/2 in. (39 cm) wide

20 in. (51 cm) deep

9 in. (23 cm) high (without handle)

CWS-D100-2B 15 1/2 in. (39 cm) wide

20 in. (51 cm) deep

9 in. (23 cm) high (without handle)

42 lbs (19 kg)

45 lbs (20.4 kg)

2005 Swagelok Company, all rights reserved

September 2005

1-9

Introduction

CWS−D100−B Welding System

Table 1-5 Weld Heads

Series Model OD Capacity

4 Micro* CWS-4MRH-A

CWS-4MFH-A

8 Micro* CWS-8MRH 1/4 to 1/2 in.

5 CWS-5H-B 1/8 to 5/8 in.

10 CWS-10H-A 1/4 to 1 in.

20 SWS-20H-B** 1/2 to 2 in.

* Requires CWS-M-MTR-A motor module

** Requires SWS-20TFB-A

1/16 to 1/4 in.

(3 to 6 mm)

(6 to 12 mm)

(3 to 16 mm)

(6 to 25 mm)

(12 to 52 mm)

Table 1-6 Standard Fixture Blocks

Minimum Weld

Model OD Capacity

CWS-4MFA-** 1/16 to 1/4 in.

(3 to 6 mm)

SWS-8MFA-** 1/4 to 1/2 in.

(6 to 12 mm)

CWS-5TFB 1/8 to 5/8 in.

(3 to 16 mm)

CWS-10TFB 1/4 to 1 in.

(6 to 25 mm)

CWS-20TFB 1/2 to 2 in.

(12 to 52 mm)

SWS-20TFB-A 1/2 to 2 in.

(12 to 52 mm)

** Designates size in 1/16ths or mm; 4MFA- includes sizes 01, 02, 04, 3

mm, and 6 mm. 8MF- includes sizes 04, 06, 08, 6 mm, 8 mm, 10 mm,

and 12 mm

Extension Length

1/4 in. (6 mm)

1/4 in. (6 mm)

3/4 in. (19 mm)

3/4 in. (19 mm)

(recessed)

15/16 in. (24 mm)

(no recess)

1 3/8 in. (35 mm)

1.45 in. (37 mm)

1-10

2005 Swagelok Company, all rights reserved

September 2005

CWS−D100−B Welding System

Table 1-7 Special Purpose Fixture Side Plates

Model Used for Comments

CWS-5FSP1

CWS-5FSP2

CWS-5HBDA-BW4

CWS-5HBDA-BW6

CWS-5HBDA-BW6MM

SWS-20FSP1L tubular weld fittings

SWS-20FSP1R tubular weld fittings

* DA − manual actuator only

VCR

, S Type

, VCO

,

VCR

B Type VCO fittings,

and tubing

Micro-Fit fittings

and tubing

BN, DL, DS,

HD, HB, DA* style

valve bodies

and tubing

and tubing

Introduction

weld extension length must be

less than 0.75 in. (19 mm)

requires adapter inserts

requires Micro-Fit fitting collets

1/4 in., 3/8 in., or 6 mm

tubular weld fittings and tubing butt

weld ends

0.80 in. (20 mm) weld

extension length

requires SWS-20UCI-XXTN collets

0.80 in. (20 mm) weld

extension length

requires SWS-20UCI-XXTN collets

Table 1-8 Collets

Model OD Capacity Comments

CWS-5UCI-** 1/8 in. to 5/8 in.

(3 mm to 16 mm)

CWS-5UFCI-.95 n/a fixture collets to hold adapter inserts for

CWS-5UFCI-** 1/8 in. to 5/8 in.

(3 mm to 16 mm)

CWS-5MWCI-04 1/8 in., 1/4 in., 6 mm for Micro-Fit fittings

CWS-5MWCI-06 3/8 in., 8 mm, 10 mm for Micro-Fit fittings

CWS-5MWCI-08 1/2 in., 12 mm for Micro-Fit fittings

CWS-10UCI-** 1/4 in. to 1 in.

(6 mm to 25 mm)

CWS-20UCI-** 1/2 in. to 2 in.

(12 mm to 52 mm)

CWS-20UCI-**P 1/4 in. to 1 1/2 in.

(10.2 mm to 48.3 mm)

SWS-20UCI-**TN 1/2 in. to 2 in.

(12 mm to 52 mm)

SWS-20UCI-MC n/a collet to hold ferrule mandrels for

** − Identifies the collet size in 1/16ths or metric (MM suffix)

tubing

add “mm” suffix for metric sizes.

CWS-5FSP1 side plate

tube collet for special purpose side plates

tubing

tubing

pipe

add J suffix for JIS pipe (-**PJ)

add MMP suffix for metric pipe (-**MMP)

tubular weld fitting collet for

SWS-20FSP1L and SWS-20FSP1R

add MM (MMTN) suffix for metric sizes

SWS-20TFB-A fixture block

2005 Swagelok Company, all rights reserved

September 2005

1-11

Introduction

CWS−D100−B Welding System

Table 1-9 Adapter Inserts for CWS-5FSP1

Model Used for Comments

CWS-5MBVCO-04 316L-4-BVCO-1

316L-4-VCO-1-4TB2

1/4 in. VCR

weld glands

CWS-5FVCR-04 1/4 in. VCR

weld glands

CWS-5FBVCO-04 316L-4-BVCO-3

1/4 in. VCR

weld glands

CWS-5MSVCR-04 6LV-4-SVCR-3 with captured male

CWS-5FSVCR-04 6LV-4-SVCR-3S

6LV-4-SVCR-3

glands must have

overall length of

1.12 in. (28 mm)

or less with

captured male

nut SS-4-SVCR-4

glands must have

overall length of

0.72 in. (18 mm)

or less with

captured female

nut SS-4-VCR-1

glands must have

overall length of

0.77 in. (20 mm)

or less with

captured female

nut SS-4-VCR-1

nut SS-4-SVCR-4

with captured female

nut SS-4-SVCR-1

WARNING!

DO NOT USE EXTENSION

CORDS THAT ARE IN POOR

PHYSICAL CONDITION OR

HAVE INSUFFICIENT

CURRENT CAPACITY.

FAILURE TO DO SO

CAN POSE FIRE AND

SHOCK HAZARDS.

Table 1-10 Extension Cords

Wire gauge

0 ft to 50 ft

Model Supply Voltage

CWS-D100-1B 115 V (ac) #12 AWG

CWS-D100-2B 230 V (ac) #12 AWG

Some power loss will occur, depending on the length of the extension

cord. See Table 1-10 to determine the minimum wire size to use.

(0 m to 15 m)

(2,5 mm)

(2,5 mm)

Wire gauge

50 ft to 100 ft

(15 m to 30 m)

#10 AWG

(4,0 mm)

#10 AWG

(4,0 mm)

1-12

2005 Swagelok Company, all rights reserved

September 2005

Section 2

Installation

Introduction

This section describes the procedures necessary for

installing the Swagelok Welding System (SWS). This

section includes:

D tools and accessory requirements

D electrical requirements

D unpacking and inspecting system components

D installing the SWS

D installing the gas delivery system

D preliminary check.

2005 Swagelok Company, All rights reserved

September 2005

2-1

Installation

CWS−D100−B Welding System

Tools and Accessory

Requirements

You need the following tools and accessories to install and

operate your SWS.

Tool/Accessory Included? Provided With

Hex Wrenches (0.050 in. to 5/32 in.) Yes Weld Head

Electrode Package Yes Weld Head

Arc Gap Gage Yes Weld Head

Flat Blade Screw Driver Yes Weld Head

Centering Gage Yes Fixture Block

Quick−Connect Stem Yes Power Supply

Secondary Solenoid Bypass Plug Yes Power Supply

Dial/Digital Calipers or Micrometer No −

Purge Connector(s) No −

(3)

(1)

(2)

No −

No −

No −

Shielding/Purge gas lines

Shielding/Purge Gas Source

Pressure Regulator

Internal Purge Gas Flow Meter No −

Shielding Gas Flow Meter No −

(1)

All lines used for shielding/purge gas should be the low moisture

absorption type.

(2)

A compressed gas bottle or liquid Dewar source can be used.

Argon is the gas most frequently used.

(3)

A two-stage gas regulator is suggested. The regulator should

reduce the source pressure to 25 psig to 50 psig (1.9 bar to

3.5 bar) for the arc shielding and internal (backing) purge

flow meters.

2-2

2005 Swagelok Company, All right reserved

September 2005

CWS−D100−B Welding System

Electrical Requirements

Input Voltage

Table 2-1 lists the electrical requirements for the

power supply.

Table 2-1 Power Supply Electrical Requirements

Installation

Power Supply

Model

CWS-D100-1B 115 V* (ac) 20 A

CWS-D100-2B 230 V (ac) 15 A

* If the input voltage is 100 V or less, the output power

capabilities may be reduced.

Voltage

Requirement

Service Current

Ensure that the following guidelines are adhered to

when considering the electrical requirements for the

power supply:

D All wiring and related components must

be installed according to local and

National Electrical Codes.

D The power supply must be grounded.

D A dedicated electrical circuit must be used.

Using an Extension Cord

WARNING!

THE POWER SUPPLY MUST

BE GROUNDED. IF IT IS NOT

GROUNDED, ELECTRIC

SHOCK CAN OCCUR.

If it is necessary to use an extension cord, follow

these guidelines:

D The wire size must meet the specifications

indicated in Table 1-10, located in

Section 1, Introduction.

D If the length of the cord is greater than 100 ft,

call your Swagelok representative for

recommended guidelines.

2005 Swagelok Company, All rights reserved

September 2005

Note: The voltage drop in an

extension cord 100 ft long may

affect the output performance of

the SWS.

2-3

Installation

CWS−D100−B Welding System

Unpacking and Inspecting

System Components

Unpacking the Power Supply

The SWS power supply is packaged in a wooden shipping

container. See Figure 2-1. The power supply part number

and serial number are located on a label on the outside of

the container.

Note: Keep the shipping container

and the foam inserts for storing

and/or shipping.

Table 2-2 lists the contents of the shipping container.

Table 2-2 Shipping Container Contents

Part Description Part No. Qty.

Welder Power Supply CWS-D100-*B 1

Power Cord CWS-CORD-* 1

1/4 in. Male QC SS-QC4-S-400 1

Secondary Solenoid Bypass Plug − 1

Swagelok Welding System

User’s Manual

* Denotes Model ** Denotes Language

CWS-MANUAL-D100B-** 1

Remove the contents of the shipping container by

performing the following steps:

1. Remove the following items:

D Swagelok Welding System User’s Manual

D Swagelok Quick-Connect stem

D secondary solenoid bypass plug

D power cord

Figure 2-1 Shipping Container

2-4

2. Remove the power supply by lifting it by the handle.

Remove the side foam inserts. Place the power supply

on a stable cart, platform, or table.

3. Check the power supply and accessories for damage.

4. Check that the serial number on the rear panel of the

power supply matches the serial number on the

shipping container label.

5. Record the model and serial numbers, and the

delivery dates on page i of the Forward section of

this user’s manual.

2005 Swagelok Company, All right reserved

September 2005

CWS−D100−B Welding System

Unpacking the Weld Head Cable

Assembly and Related Components

The following weld head components are packaged in a

foam-lined shipping container:

D weld head assembly

D arc gap gage

D electrode package

D tool package

1. Inspect the container for damage.

2. Remove the components from the container.

Installation

3. Check the items for any damage.

4. Verify that the weld head serial number matches the

serial number on the shipping container.

5. Record the model and serial numbers, and the

delivery dates on page i of the Forward section of

this user’s manual.

2005 Swagelok Company, All rights reserved

September 2005

2-5

Installation

CWS−D100−B Welding System

Installing the SWS

To get the maximum performance and reliability from your

SWS, it must be set up and installed properly.

Figure 2-2 Power Cord Receptacle

This section describes how to

D install the power supply

D install the weld head.

Installing the Power Supply

To install the power supply, follow these steps:

1. Place the power supply in a position such that the front

and rear panel controls are easily accessible.

2. Locate the power cord. Insert the cord into the polarized

receptacle on the rear of the power supply. See

Figure 2-2.

3. Tighten the connector lock at the base of the receptacle

to secure the cord in the receptacle.

Figure 2-3 Power Supply Circuit

Breaker in the OFF Position

4. Ensure that the power cord reaches an electrical outlet.

Do not connect the power cord to the outlet at this time.

5. Turn off the circuit breaker. Refer to Figure 2-3.

2-6

2005 Swagelok Company, All right reserved

September 2005

CWS−D100−B Welding System

Installation

Installing the Weld Head

The weld head assembly has four connectors that plug into

the power supply. See Figure 2-4.

The four connectors on the cable are

D fixture

D electrode (red)

D work (green)

D weld head shielding gas.

Connect the four connectors to the rear panel of the power

supply by performing the following steps (see Figure 2-5):

1. Locate the weld head assembly.

Fixture

Electrode

Work

Weld Head

Shielding Gas

Figure 2-4 Weld Head Assembly

2005 Swagelok Company, All rights reserved

September 2005

Figure 2-5 Weld Head Connectors

2-7

Installation

CWS−D100−B Welding System

Caution!

Ensure that the fixture

connector is fully seated in

the mating socket and the

threaded sleeve is tight.

Note: The weld head shielding

gas connector must be a

single-end shut-off (SESO)

Swagelok Quick-Connect

stem (SS-QC4-S-400).

2. Align the notch on the multi-pin connector with the

small tab in the mating socket on the rear panel labelled

FIXTURE. Insert the connector in the socket. Turn the

connector sleeve clockwise by hand until it is tight.

This connection provides the control signals to drive

the weld head.

3. Insert and fully seat the red connector into the socket

on the rear panel labelled

ELECTRODE. Twist the

connector 1/4-turn clockwise to lock it into place. This

connection is the negative (−) output terminal of the

weld head.

4. Insert the green connector into the socket on the rear

panel labelled

WORK. Twist the connector 1/4-turn

clockwise to lock it into place. This connection is the

positive (+) output terminal of the weld head.

5. Insert the weld head shielding gas connector

into the Swagelok Quick-Connect stem labelled

TO WELD HEAD. Ensure that the connector is firmly

attached. This connection provides shielding gas to the

weld head through a solenoid valve in the power supply.

2-8

2005 Swagelok Company, All right reserved

September 2005

CWS−D100−B Welding System

Installing the Gas

Delivery System

Introduction

The Gas Delivery System reduces oxidation or

contamination to the weld puddle, tungsten electrode,

and Heat Affected Zone (HAZ).

There are two types of gas delivery systems

commonly used:

D typical Gas Delivery System

Refer to the installation procedure beginning on

page 2-10.

Installation

D gas delivery system using a secondary shielding

gas solenoid valve

Refer to the installation procedure beginning on

page 2-12.

2005 Swagelok Company, All rights reserved

September 2005

2-9

Installation

CWS−D100−B Welding System

Installing the Typical Shielding/Purge

Gas Delivery System

Install the Shielding/Purge Gas Delivery System. Figure 2-6

shows a typical system. Be sure to adhere to the

following precautions:

D Ensure that the gas storage container(s) are secured

before using them.

D Ensure all connections are tight and do not leak.

D Use only a Swagelok single-ended shut-off

Quick-Connect stem on the shield/purge line

for the shielding gas connector.

D Adjust the low-pressure regulator gage to reduce

the gas storage container source pressure to 25 psig

to 50 psig.

When complete, continue to the Preliminary Check

procedure beginning on page 2-14.

2-10

2005 Swagelok Company, All right reserved

September 2005

CWS−D100−B Welding System

Installation

High Pressure Gage

(0 psig to 3000 psig)

Inert

Gas Cylinder

Purge Fitting

(Swagelok Union or

Reducing Union with Nylon

Ferrules or Ultra-Torr

2-stage Regulator

Tubing to be Welded

Low Pressure Gage

(0 psig to 150 psig)

Internal Purge

Gas Shut-Off Valve

)

SWS Fixture Block

Flow Meter for Internal

Purge Gas (Range

3

0 std ft

/h to 30 std ft3/h)

Supply

Manifold

Purge Fitting

(Swagelok Union or Reducing Union

with Nylon Ferrules or Ultra-Torr

for Purge Gas Restriction)

Flow Meter for Shielding Gas

(Range 0 std ft

3

/h to 50 std ft3/h)

Shielding Gas

Supply Inlet

SWS Power Supply

Figure 2-6 Typical Gas Delivery System

2005 Swagelok Company, All rights reserved

September 2005

2-11

Installation

CWS−D100−B Welding System

Installing the Optional Gas

Delivery System

The optional gas delivery system is generally used in

Ultra High Purity (UHP) gas systems where quick connects

are not permitted. This type of system uses an external

12 V (dc) secondary solenoid valve instead of using the

solenoid valve located inside the power supply. If necessary,

the secondary solenoid valve may be the high purity type.

Caution!

Do not insert the secondary

solenoid bypass plug into

the connector unless you are

using a secondary solenoid.

Inserting the plug disables

the power supply solenoid.

A secondary solenoid bypass plug is inserted in the

EXT GAS CONTROL connector on the rear panel to disable

the solenoid inside the power supply and provide +12 V to

control the secondary solenoid.

For the gas delivery system using a secondary shielding gas

solenoid valve, locate the:

D secondary solenoid bypass plug

D secondary shielding gas solenoid valve

D 1/4-turn internal purge gas shut-off valve.

Refer to Figure 2-7. Install the optional gas delivery system.

Be sure to adhere to the following precautions:

D Ensure that the gas storage container(s) are secured

before using them.

D Ensure all connections are tight and do not leak.

2-12

D Observe correct polarity on the secondary solenoid

bypass plug.

D Adjust the low pressure regulator gage to reduce

the gas storage container source pressure to

25 psig to 50 psig.

2005 Swagelok Company, All right reserved

September 2005

CWS−D100−B Welding System

Installation

SWS Fixture Block

SWS Power

Supply

Weld Head

Internal Purge Gas

Shut-Off Valve

Shielding Gas

Flow Meter

Secondary

Solenoid

Valve

Secondary Solenoid

Bypass Plug

2-stage Regulator

Supply

Manifold

Inert Gas

Cylinder

Internal

Purge Gas

Flow Meter

Figure 2-7 Optional Gas Delivery System

Secondary Solenoid

Bypass Plug

2005 Swagelok Company, All rights reserved

September 2005

2-13

Installation

CWS−D100−B Welding System

Preliminary Check

Before placing the SWS into operation, you should check

that the power supply is operating correctly.

To check the system, follow these steps:

1. Connect the power supply power cord to an

electrical outlet.

2. Turn on the power supply circuit breaker. After a

2 second to 4 second delay, the following is displayed:

D Blinking decimal point followed by a zero in

the Average Current and Average Voltage

displays on the power supply front panel.

See Figure 2-8.

Figure 2-8 Average Current and

Voltage Displays

D The amber-colored Fixture indicator light is

on indicating that the fixture block is not

attached to the weld head. See Figure 2-9.

If the power supply does not come on, refer to Section 7,

Troubleshooting, for a list of possible causes and

corrective actions.

Figure 2-9 Weld Status

Indicator Lights

2-14

2005 Swagelok Company, All right reserved

September 2005

CWS−D100−B Welding System

3. Position the weld head such that the rotor can be easily

seen. See Figure 2-10.

Installation

4. Press

STOP/RESET on the front panel.

D For series 5, 10, and 20 Weld Heads, the

rotor should make one-half of a rotation

(180° position) in the head. See Figure 2-11.

D For the micro head, the rotor should make one

complete rotation in the head.

5. Press

STOP/RESET on the front panel to return the rotor

to its home position.

6. Turn off the power supply.

If problems occur, refer to Section 7, Troubleshooting, for a

list of possible causes and corrective actions.

Rotor

Figure 2-10 Positioning the Weld

Head to View the Rotor Rotation

Note: The rotor must be returned to

its home position before welding.

2005 Swagelok Company, All rights reserved

September 2005

Figure 2-11 Checking the

Rotor Rotation

2-15

Installation

CWS−D100−B Welding System

2-16

2005 Swagelok Company, All right reserved

September 2005

Section 3

Operation

Introduction

This section describes the basic operation of the Swagelok

Welding System (SWS). This section includes

D front panel controls

D SWS modes of operation

D installing the electrode in the

Series 5/10/20 Weld Head

D setting the arc gap

D preparing the work

D fixturing the work

D connecting the weld head

to the fixture block

D entering the weld parameters

D setting the shield gas flow

D starting and completing the weld.

The description of the welding process in this section

uses a weld procedure guideline based on tubing with a

1/2 in. OD and 0.049 in. wall thickness. Remember that a

weld procedure guideline is a list of weld parameter settings

that have been determined for a particular job. Keep in mind

that the weld parameters listed in this section may not

produce an optimum weld since the purpose of this section

is to demonstrate the operation of the SWS. Section 5,

Weld Parameter Adjustment, describes how to optimize

welding parameters.

2005 Swagelok Company, all rights reserved

September 2005

3-1

Operation

CWS−D100−B Welding System

Front Panel Controls

20

7

8

21

1. Impulse rotary switch

2. Maintenance rotary switch

3. Impulse Rate rotary switch

4. Impulse Width rotary switch

5. Arc Start rotary switch

6. Duration rotary switch

7. Prepurge rotary switch

1 2 3 4 5 6

16 17 18 1914

15

8. Weld Time rotary switch

9. Downslope rotary switch

10. Postpurge rotary switch

11. Rotor Speed rotary switch

12. Average Current display

13. Average Voltage display

14. Start pushbutton

12

13

10

9

11

15. Downslope pushbutton

16. Purge pushbutton

17. Rotor Jog pushbutton

18. Print pushbutton

19. Stop/Reset pushbutton

20. Status indicator lights

21. Remote Pendant connector

3-2

Figure 3-1 Front Panel Controls

You operate the SWS by using pushbuttons and rotary

switches on the front panel of the power supply. The values

you program into the rotary switches are determined by the

weld procedure guidelines.

The front panel digital displays monitor the welding process

and show message code information. Message codes are

numbers that indicate weld parameter setup errors, power

supply status, etc.

The status indicator lights on the front panel show the

welding process sequence or flash a warning if the power

supply detects that a weld parameter is set incorrectly.

2005 Swagelok Company, All rights reserved

September 2005

CWS−D100−B Welding System

Current Control Switches

The current control switch group determines the

characteristics of the current output of the power supply

during a weld cycle. See Figure 3-2. The controls

function as follows:

D IMPULSE (High Amps) sets the maximum current output

used during the weld cycle. The impulse setting affects

the depth of penetration of the weld profile.

D MAINTENANCE (Low Amps) sets the minimum current

output used during the weld cycle. This is the current

level required to

D maintain the arc

D provide enough background heat to maintain the

weld puddle.

Operation

D IMPULSE RATE (Pulses/Sec) sets the number of changes

per second between the Impulse and Maintenance

current levels during the weld cycle.

D IMPULSE WIDTH (% of Impulse) sets the percentage of

time the current is at the Impulse current level for each

Impulse/Maintenance cycle.

D ARC START (Amps) sets the output current during the

duration period. This current level

D helps stabilize the initiated arc

D develops the weld puddle.

Figure 3-2 Current Controls

2005 Swagelok Company, all rights reserved

September 2005

3-3

Operation

CWS−D100−B Welding System

Timing Control Switches

The timing control switch group determines the weld cycle

timing. See Figure 3-3. The controls function as follows:

D PREPURGE (Seconds) is the time in which shielding gas

flows through the weld head and around the weld joint

before the arc is initiated.

D DURATION (Seconds) is the length of time between

the arc start period and the beginning of the weld

time cycle.

D The current specified on the arc start rotary switch

is maintained during this time.

D The rotor does not move during this time.

D WELD TIME (Seconds) is the actual welding time at the

average current. During the weld time, the output

current cycles between the impulse and maintenance

levels at the impulse rate and impulse width entered.

Figure 3-3 Timing Controls

D During this time, the rotor moves at the speed

specified by the rotor speed rotary switch.

D The weld time cycle forms the main body of

the weld.

D DOWNSLOPE (Seconds) is the time during which the

average weld current uniformly decreases until the arc

is extinguished.

D During this time, the rotor continues to move at the

speed specified by the rotor speed rotary switch.

D The downslope cycle reduces the chance of

weld cracking.

3-4

2005 Swagelok Company, All rights reserved

September 2005

CWS−D100−B Welding System

D POSTPURGE (Seconds) is the amount of time the

shielding gas continues to flow through the weld head

and around the weld joint after the arc is extinguished.

This gas flow prevents oxidation and contamination of

the weld bead and electrode while the work is cooling.

D ROTOR SPEED (% of Max Speed) is expressed as a

percentage of the maximum RPM that the rotor can

attain. A rotor speed setting of 99 gives the maximum

RPM for the weld head. See Table 3-1.

Table 3-1 Maximum Rotor Speed by

Weld Head Model

Maximum

Rotor Speed

Weld Head Model

Micro Weld Head 24 2.5

Series 5/10 Weld Head 12 5

Series 20 Weld Head 6 10

(RPM)

Seconds/

Revolution

Operation

Note: A minimum of 10 seconds

PREPURGE is recommended for all

SWS Weld Head models. If Weld

Head extension cables are used,

add one second for each foot of

cable added.

2005 Swagelok Company, all rights reserved

September 2005

3-5

Operation

CWS−D100−B Welding System

Pushbuttons

The front panel pushbuttons control the welding operation

and provide some manual control functions for the weld

head. See Figure 3-4. The pushbutton functions are

as follows:

D START initiates the welding sequence.

D DOWNSLOPE initiates the downslope cycle when pressed

during the weld time cycle. The downslope cycle

reduces the output current levels from the weld time

levels to zero during the time specified.

D STOP/RESET aborts the weld and halts the rotor if

pressed during the weld cycle. Push

to return the rotor to its home position as shown in

Figure 3-5 on page 3-7. The rotor will move at

maximum speed when traveling to the home position,

regardless of the programmed rotor speed. When not

welding, pushing

STOP/RESET causes the rotor to rotate

as shown in Table 3-2.

STOP/RESET again

Figure 3-4 Pushbuttons

Note: The external gas solenoid

referenced here may be used in

place of the internal solenoid

at the user’s option.

See Section 2, Installation, for

installation information.

Table 3-2 Stop/Reset Rotor Travel

Weld Head Model Rotor Travel

Micro Weld Head 1 Revolution

Series 5, 10, 20 1/2 Revolution

(no Fixture Block connected)

1 Revolution

(with Fixture Block connected)

D PURGE activates the internal solenoid valve or the

optional external gas solenoid valve and starts the flow

of shielding gas to the weld head. See Note. When

PURGE is depressed, shielding gas flows to the weld

head until you press the pushbutton again. The

pushbutton overrides the prepurge and postpurge timers

and allows shielding gas to continuously flow through

the weld head.

3-6

2005 Swagelok Company, All rights reserved

September 2005

CWS−D100−B Welding System

D ROTOR JOG advances the rotor manually. Press

and hold the pushbutton to move the rotor. Release

the pushbutton to stop the rotor.

ROTOR JOG can be

used to position the rotor for electrode replacement or

adjustment. The rotor will move at the speed defined

by the

D PRINT causes the power supply controller to transmit

ROTOR SPEED rotary switches.

weld data to the printer port on the rear of the unit. The

optional CWS-DRP printer accepts the data and prints

the record.

Operation

Figure 3-5 Rotor Home Position

2005 Swagelok Company, all rights reserved

September 2005

3-7

Operation

Figure 3-6 Status Indicator Lights

CWS−D100−B Welding System

Status Indicator Lights

The status indicator lights monitor certain elements of the

power supply operation. See Figure 3-6.

The conditions monitored by some of the indicators are

independent of the welding process. Most of the indicators

light during the welding process to show the control

sequence executed by the power supply. The control

sequence is affected by the values entered into the timing

control switches.

The lights also notify you if any weld parameter settings

exceed pre-defined limits. See Figure 3-8 for an example.

D Fixture indicates whether or not the weld head is

properly attached to the fixture block. If it is not

connected, the indicator light is on. The power supply

will not start a weld cycle when this indicator light

is on.

Caution!

DO NOT try to remove the

fixture block from the weld

head until all status indicator

lights are off.

D Prepurge indicates the prepurge cycle is active. The

Prepurge cycle occurs prior to arc start. This light

indicates that the shielding gas solenoid valve in the

power supply is energized, allowing the shielding gas to

flow to the weld head prior to starting the

welding cycle.

D Start indicates the power supply is in the arc start

portion of the weld cycle.

D Weld time indicates the weld cycle is in progress.

D Downslope indicates the downslope cycle is

in progress.

D Postpurge indicates the postpurge cycle is in progress.

The shielding gas continues to flow to the weld head,

and the rotor moves to the home position.

D Rotor indicates the rotor is in motion.

3-8

2005 Swagelok Company, All rights reserved

September 2005

CWS−D100−B Welding System

Digital Displays

The digital displays monitor system operation during

welding and provide message code information. See

Figure 3-7. The display functions are as follows:

D Average Current indicates the average arc current

measured during the weld sequence.

D Average Voltage indicates the average arc voltage

measured during the weld sequence.

The average voltage displayed during a weld cycle

varies with the arc gap, type of shielding gas, current

output, etc., but typically is in the 5 V to 15 V range.

The Average Current and Average Voltage displays are

also used for programming and displaying message codes.

See SWS Modes of Operation.

Operation

SWS Modes of Operation

The front panel controls serve two purposes. In addition to

controlling the weld parameters and weld sequences, the

controls are used to access the modes of the power supply.

The power supply has three modes of operation:

D operational

D program

D test

Each mode uses message codes to perform a variety of

functions. Generally, the message codes are grouped by

mode. Operational mode uses codes 1 to 11, 41, 42, 50,

and 51. Program mode uses 20 to 23, 30 to 35, 60 to 63,

and 99. Test mode uses 97 and 98.

The message codes are explained in detail later in

this section.

Figure 3-7 Digital Displays

Table 3-3 shows all the message codes used by the power

supply. Note that certain code ranges are marked Factory

Use. These codes, except for 64 to 96, are normally not

used, which is noted in the table.

2005 Swagelok Company, all rights reserved

September 2005

3-9

Operation

CWS−D100−B Welding System

Table 3-3 SWS Message Codes

Code No. Name

Normal

Operating

Range

Mode or

Setting to

Activate

Code Type

01 Impulse 2 A to 99.9 A < 2 Disable*

02 Maintenance 2 A to 99.9 A < 2 Disable*

03 Impulse Rate 1 Hz to 99 Hz < 1 Caution

04 Impulse Width 5 % to 95 % < 5 or > 95 Disable*

05 Arc Start 2 A to 99 A < 2 Disable*

06 Duration 0.0 to 5.0 > 5.0 Disable*

07 Prepurge 1 s to 99 s < 1 Caution

08 Weld Time 1 s to 99 s < 1 Disable*

09 Downslope 1 s to 99 s < 1 Disable*

10 Postpurge 1 s to 99 s < 1 Caution

11 Rotor Speed 5 % to 99 %

≥ 1 or < 5

Caution

< 1 Disable*

12 to 19 Factory use Not used

20 Resettable weld

counter

21 Automatic print

counter

0 to 9999 Program

mode

0 to 99 Program

mode

Programmable

Programmable

22 Enable signal

polarity

23 Arc Start power 0=low

0=low

1=high

1=normal

Program

mode

Program

mode

Programmable

Programmable

24 to 29 Factory use Not used

30 Time - hours 0 to 24 Program

Programmable

mode

31 Time - minutes 0 to 59 Program

Programmable

mode

32 Date - month 1 to 12 Program

Programmable

mode

33 Date - day 1 to 31 Program

Programmable

mode

34 Date - year 2 digit

00=2000

35 Date printing

format

0=mm/dd/yy

1=dd/mm/yy

Program

mode

Program

mode

Programmable

Programmable

36 to 40 Factory use Not used

41 Paper out No paper

Caution

installed with

printer

power on

3-10

2005 Swagelok Company, All rights reserved

September 2005

CWS−D100−B Welding System

Operation

Normal

Operating

Code No. Name

Range

42 Printing Data is

Mode or

Setting to

Activate

Code Type

Information only

transferred

to printer

port

43 to 49 Factory use Not used

50 Hi-temp Excessive

Disable*

internal

power

supply

temperature

51 Old head type No weld

Disable*

head or

non-safety

interlocked

weld head

connected

52 Rotor jam Rotor motion

impeded

Disable*

See Note (A)

53 to 59 Factory use Not used

60 Non-resettable

weld counter

61 Arc start

attempts

62 System serial

number

63 System

software

Program

mode

Program

mode

Program

mode

Program

mode

Information only

Information only

Information only

Information only

version

64 to 96 Factory use See Note (B)

97 Test switches/

Test mode

pushbuttons

98 Test indicator

Test mode

lights/displays

99 Print user

parameters

Program

mode

* The Prepurge, Start, Weld Time, Downslope, and Postpurge status

indicator lights are flashing.

Note (A): Press

again unless

STOP/RESET to clear the error. Rotor will not move

STOP/RESET is pressed a second time.

Note (B): Service may be necessary. Call your

Swagelok representative.

2005 Swagelok Company, all rights reserved

September 2005

3-11

Operation

CWS−D100−B Welding System

Operational Mode

When the power supply is turned on it enters the operational

mode. The Average Current and Average Voltage displays

show a blinking decimal point and a zero. If the weld head

is not attached to a fixture block, Fixture is on. The power

supply is ready to be used.

Weld Parameter Limits (Message codes 1 to 11)

Each front panel rotary switch controls a part of the welding

process. The power supply operates normally as long as

each switch setting is within certain limits. If the limits are

exceeded, the power supply reacts to the condition and

shows a message code on the front panel displays. If the

code display is accompanied by flashing status indicator

lights, a “disable” condition exists. If not, the code display

indicates a “caution” condition.

Message codes 1 to 11 refer to the front panel rotary

switches by number. See Table 3-4. See Figure 3-1 to

cross reference the switch position numbers.

Table 3-4 Weld Parameter Limit Message Codes

Normal

Operating

Code No. Name

01 Impulse 2 A to 99.9 A < 2 Disable*

02 Maintenance 2 A to 99.9 A < 2 Disable*

03 Impulse Rate 1 Hz to 99 Hz < 1 Caution

04 Impulse Width 5 % to 95 % < 5 or > 95 Disable*

05 Arc Start 2 A to 99 A < 2 Disable*

06 Duration 0.0 to 5.0 > 5 Disable*

07 Prepurge 1 s to 99 s < 1 Caution

08 Weld Time 1 s to 99 s < 1 Disable*

09 Downslope 1 s to 99 s < 1 Disable*

10 Postpurge 1 s to 99 s < 1 Caution

11 Rotor Speed 5 % to 99 %

Range

Mode or

Setting to

Activate

≥ 1 or < 5

< 1 Disable*

Code Type

Caution

3-12

* The Prepurge, Start, Weld Time, Downslope, and Postpurge status

indicator lights are flashing.

2005 Swagelok Company, All rights reserved

September 2005

CWS−D100−B Welding System

Disable Condition

The power supply enters a “disable” condition when a

serious fault exists or a front panel control is set to a value

that could damage the system. The power supply will not

start in a “disable” condition. The rotor can still be moved

while the “disable” condition exists, using

ROTOR JOG. The power supply shows the “disable”

STOP/RESET or

condition by flashing the status indicator lights shown in

Figure 3-8 and flashing a message code on the Average

Current and Average Voltage displays. The code shows

you what rotary switch is misprogrammed.

Caution Condition

A “caution” condition indicates that a front panel parameter