DR-100 Series COFDM

DIGITAL RECEIVER

Versions: DR-102 Diversity 2

DR-106 Diversity 6

USER’S MANUAL

Version 1.1

SVP

Broadcast

Microwave

2

Contents

Chapter 1: Introduction

The objective of this first part is to provide a general description of the DR100 receiver.

Chapter 2: Connections

This second part offers a detailed description of each of the connections on

the DR-100 receiver.

Chapter 3: Technical features

The objective of this chapter is to provide detailed technical features of the

DR-100 receiver: inputs, outputs, power supply, remote control, and

physical and environmental characteristics.

Chapter 4: Front panel controls on the demodulator unit.

This chapter offers a detailed description of every the control on the front

panel of the rack-mount demodulator unit.

Chapter 5: Local control of the equipment

This chapter provides a detailed description of the local control procedures

for the DR-100 receiver, using the display and the keypad on the rackmount demodulator unit. Each of the menus and sub-menus are described

in detail. Required steps to configure and monitor the unit’s parameters are

defined.

Chapter 6: NetC Software to control remotely a network of

SVP equipment

This chapter provides a detailed description of NetC software. This program

allows the control of several SVP systems at the same time, provided they

all are in the same local area network.

Chapter 7: Remote control via RS-232 connection

This chapter provides a detailed description of how to remotely control the

DR-100 series receivers via a RS-232 connection.

3

4

DEAR CUSTOMER:

We would like to thank you for selecting this equipment and welcome you to

the SVP’s growing family of products.

We are sure that the addition of this equipment to your existing installation

will cause you nothing but satisfaction.

Please read these instructions carefully, and keep them at hand in case you

have to refer to them.

5

IMPORTANT NOTES:

1. The DR-100 series digital COFDM receiver is completely compatible with

the DVB-T standard included in European Standard ETSI EN300744.

2. There are two different models available: the DR-102 diversity 2 receiver

and the DR-106 diversity 6 receiver. Two down-converters can be

connected to the DR-102 receiver and up to 6 down-converters can be

connected to diversity 6 receiver. Each down-converter is connected to

an independent receiver antenna in order to provide diversity.

3. The complete receiver system consist of two parts: first, the down-

converters installed outdoors next to the receiver antennas and second

the rack control unit DR-102 or DR-106 installed indoors which

demodulates and decodes received incoming signal from the downconverters.

4. DR-100 series receivers usually work with SVP DC-COFDM down-

converters, which are available in bands of 500MHz in the frequency

range from 1.3 to 10.5GHz

5. In the receiver’s site is important to determine if the channel in which

the transmission will be carried out is interfered. In addition, special care

must be taken in 2400 to 2500MHz band, due to the possible presence

of WiFi signals.

6. While installing the equipment, the power supply to the down-converters

should be disabled in the Setup configuration menu of the rack-mount

demodulator unit, to avoid the risk of short-circuits.

7. The receiver system must be well chilled. Some space must be left next

to the sides of the equipment for ventilation purposes. This is especially

important when it is installed in a rack case.

8. If you wish to install the rack-mount demodulator unit horizontally,

guides should be used, due to the weight of the equipment.

9. It is not advisable to use a power lead with a cross section smaller than

that of the lead supplied, sing this would cause a drop in the supply

voltage and deficient operation of the equipment.

10.The front panel of the DR-100 series receivers is automatically locked

when the user stops manipulating the equipment for 30 minutes.

11.Only authorized personnel should open the product and any repair or

warranty will be invalidated is the seals are open.

Contents

1 Description ......................................................................... 1

List of figures

Figure 1.1 Connection diagram of the DR-100 series equipments .............. 1

Figure 1.2 A flight case for the rack-mount demodulator .......................... 2

Chapter 1

Introduction

Chapter 1: Introduction

1

1 Description

The DR-100 series COFDM digital receivers receive the signal from the

down-converters which are installed outdoors next to the receiver antenna.

It demodulates and decodes incoming signal. Afterward the signal sent by

the transmitter is obtained at its outputs in video, SDI and ASI formats.

Figure 1.1 Connection diagram of the DR-100 series equipments

There are two different models available: the DR-102 diversity 2 receiver

and the DR-106 diversity 6 receiver. Two down-converters can be

connected to the DR-102 receiver and up to 6 down-converters can be

connected to diversity 6 receiver. Each down-converter is connected to an

independent receiver antenna in order to provide diversity. This allows

several different antennas to be installed, in order to take advantage of

their combined characteristics, or several antennas, of similar types or

different types can be installed oriented in different directions to offer wider

coverage. Using a diversity system makes the link more robust and offers

better performance than a non-diversity system.

The complete receiver system consist of two parts: first, the downconverters installed outdoors next to the receiver antennas and second the

rack control unit DR-102 or DR-106 installed indoors which demodulates

and decodes received incoming signal from the down-converters.

DR-100 series receivers usually work with SVP DC-COFDM down-converters,

which are available in bands of 500MHz in the frequency range from 1.3 to

10.5GHz

The diversity technique used in the DR-100series digital COFDM receivers is

known as "Maximum Ratio Combining” (MRC), in which the signal to be

demodulated is the result of combining the best sub-carriers in each signal

delivered by the down-converters; in other words, the unit does not simply

select the input signal from one of the down-converters, it combines these

signals in such a way that the signal used by the demodulator is always the

best signal available.

Chapter 1: Introduction

2

The IF signals delivered by the down-converters are fed into the rack-mount

demodulator, which demodulates them using the MRC diversity technique

and then decodes them to obtain two composite video signals, two SDI

digital signals, four analogue audio signals and four digital audio signals

embedded in the SDI signal. All models of the DR-100 series also have a

DVB-ASI transport stream output that can be extremely useful if several

decoders are to be chained or to implement an intermediate ASI feed

without having to decode it. They also have a Genlock reference input in

order to lock the SDI output signals.

This equipment is capable to receive GPS data or other data types

introduced, at different speeds, in the data channel in SVP transmitters.

The display and the keypad on the front panel of the demodulator

equipment can be used to monitor many parameters of interest, such as the

modulation, the Viterbi coding or the FEC, and the guard interval used

(obtained when the TPS, [Transmission Parameter Signalling] carriers are

demodulated), signal levels, link quality parameters such as the SNR, the

MER and the BER and the presence of alarms and/or warnings.

When steering the antennas, the main screen showing the signal levels and

the SNR of the IF inputs is very helpful. These measurements are displayed

as a bar graph and as numerical values. The numerical values do not

express signal levels or SNR in dB, they are merely indicative. The scale for

the signal levels is from 1 to 100, and the SNR values range from 1 to 10.

These measurements are really useful while orienting the antennas.

There is also a UDP/IP Ethernet link that allows these and many other

parameters to be controlled and monitored from a remote station.

The equipment can be AC mains powered or run off DC batteries. The

switchover from the mains to batteries is automatic. The down-converters

are powered from the demodulator unit via the IF coaxial cable that

connects them together.

The Down-Converters are waterproof and are installed next to the reception

antennas.

An optional flight case is available for the rack-mount demodulator. Its size

is 2 units rack; consequently, two equipments can be transported in it.

Figure 1.2 A flight case for the rack-mount demodulator

3

Contents

1 Introduction ........................................................................ 4

2 Power supply ...................................................................... 5

3 Video ................................................................................. 5

4 Audio ................................................................................. 6

5 DVB-ASI ............................................................................. 6

6 Genlock .............................................................................. 6

7 Data Out ............................................................................ 6

8 Remote control .................................................................... 7

9 Down-converter .................................................................. 7

10 Antenna ............................................................................. 7

List of figures

Figure 1.1 Back view of the rack-mount demodulator .............................. 4

Figure 1.2 The down-converter ............................................................. 4

Figure 9.1 Connection of the receiver antenna ........................................ 7

Chapter 2

Connections

Chapter 2: Connections

4

1 Introduction

All connectors of the rack-mount demodulator unit are on the rear panel, as

shown in the figure below:

Figure 1.1 Back view of the rack-mount demodulator

On the other hand, the connectors on the down-converter are on both the

top panel and the bottom panel, as shown below:

Figure 1.2 The DC down-converter

Chapter 3 offers detailed technical features of all of the connectors.

Chapter 2: Connections

5

2 Power supply

The equipment can be powered by an AC source between 90 and 240V, or a

DC source of 11 to 36 V. The down-converters are powered from the rackmount demodulator unit via the IF coaxial cable that connects them

together.

When the equipment is powered by an AC source, this is connected to a

switching power supply that gives a 12V output.

The power-supply board receives either the 12V supply from this power

supply or a DC voltage between 11 and 36V from the DC power input, and

converts the input to the supply voltages required by the equipment:

+3.3V, +5V, +12V and –12V.

The mains frequency should be between 50 and 60 Hz.

The AC mains input uses a Neutrik MLC connector. A cable with the required

connectors is supplied with the equipment.

The AC power connector used in this equipment is designed to prevent

accidental disconnection. To extract the connector, pull back the locking clip

and rotate the connector, as indicated on the connector itself.

It is not advisable to use a power lead with a cross-section less than that of

the lead supplied, since this would cause a drop in the supply voltage and

deficient operation of the equipment.

The DC power supply is connected via a Neutrik 4-pin male XLR connector

with a safety clip to prevent accidental disconnection.

The IF inputs of the demodulator supply +12V to power the downconverters.

3 Video

The DR-100 series receivers include two analogue composite video outputs

and two SDI digital video outputs.

Each of these signals is available on 75Ω insulated BNC connectors located

on the rear panel of the rack-mount demodulator unit.

The SDI digital video outputs are compatible with the SMPTE-259M

standard.

We recommend the use of RG-59 video cable. If this type is not used, we

recommend that the cable used that does not attenuate the high-frequency

components of the video signal. When the cable has been selected, it is

important to determine the length required. For cables longer than 50m, it

is advisable to check the cable and the losses that occur on them.

Chapter 2: Connections

6

It is important that 75Ω connectors be used. This is because the female

output connector of the demodulator unit may be damaged, and because an

impedance mismatch will occur.

4 Audio

The DR-100 series receivers deliver analogue audio signals and digital audio

signals embedded in the SDI signal.

The equipments have four analogue audio outputs, available on 3-pin male

XLR connectors on the rear panel of the rack-mount demodulator unit.

The pinout of the XLR-3 connectors is the following one:

PIN-1: Ground

PIN-2: Hot (+)

PIN-3: Cold (-)

For the output connections of the digital audio signals embedded in the SDI

signal they can be used the same 75Ω insulated BNC connectors that are

used to transport the digital video signals.

The SDI digital video outputs with the four digital audio signals embedded

in each of them are compatible with the SMPTE-272M standard.

5 DVB-ASI

The DR-100 series receivers have a DVB-ASI Transport Stream output,

compatible with the EN50083-9 standard, available on an insulated 75Ω

BNC connector on the rear panel of the rack-mount demodulator unit.

This output may be extremely useful if an intermediate ASI feed is required

without needing to decode the audio and video signals and then recode

them into MPEG-2 in the transmitter equipment.

6 Genlock

The DR-100 receivers have a Genlock external reference input in order to

lock the video and SDI digital outputs to it. The connection is available on a

75Ω insulated BNC connector located on the rear panel of the rack-mount

demodulator unit.

7 Data Out

The DR-100 receiver can get data introduced to the data channel of the SVP

transmitters. The information is available in a DB9 connector in the rear

panel of the rack equipment.

Chapter 2: Connections

7

The receiver can also be controlled remotely via an RS-232 connection.

From the set up menu the user will establish whether the DB9 port will be

used as a data out port or as a remote control port.

8 Remote control

The DR-100 series receivers can be controlled and monitored remotely over

an Ethernet link.

The link is connected via an 8-pin RJ-45 connector with a 10/100 Base-T

network interface. This connector is located on the rear panel of the rackmount demodulator.

9 Down-converter

The connection between the rack-mount demodulator unit and the downconverter uses coaxial cable, whose maximum length depends on the type

of coaxial cable used. If the Celflex ½” coaxial cable is used, the maximum

length is 150m but if the RG-214 coaxial cable is used, the maximum length

is reduced to 75m.

10 Antenna

The antenna is connected to the female N-type connector on the top panel

of the down-converter.

The down-converter can be mounted next to the receiver antenna on a

mast with a maximum diameter of 60mm. This provides a simple, easy

mounting method, as can be seen in the photograph below:

Figure 10.1 Connection of the receiver antenna

Chapter 2: Connections

8

The fittings to clamp the down-converter to the mast are supplied with the

down-converter.

Chapter 3: Technical features

9

Contents

1 Inputs .......................................................................... 10-10

1.1 RF Section ....................................................................... 10-10

1.2 IF Section ........................................................................ 10-10

1.3 Genlock .......................................................................... 10-11

2 Outputs ......................................................................... 2-11

2.1 SDI (Serial Digital Interface) ................................................ 2-11

2.2 Composite video ................................................................. 2-12

2.3 Analogue audio outputs ....................................................... 2-12

2.4 ASI OUT ............................................................................ 2-13

2.5 Data Out ........................................................................... 2-13

3 Power supplies ............................................................... 3-13

3.1 AC Power .......................................................................... 3-13

3.2 DC Power .......................................................................... 3-13

4 Remote control ............................................................... 4-14

5 Physical characteristics .................................................... 5-14

6 Environmental conditions ................................................. 6-14

List of tables

Table 1.1 RF input features ........................................................... 10-10

Table 1.2 IF (Intermediate Frequency) input features ....................... 10-10

Table 1.3 Genlock external reference input features ......................... 10-11

Table 2.1 SDI output features ......................................................... 2-11

Table 2.2 Composite video output features ........................................ 2-12

Table 2.3 Audio output features ....................................................... 2-12

Table 2.4 DVB-ASI Transport Stream output features ......................... 2-13

Table 2.5 Data Out output features .................................................. 2-13

Table 3.1 AC power supply features ................................................. 3-13

Table 3.2 DC power supply features ................................................. 3-13

Table 4.1 Remote control ................................................................ 4-14

Table 5.1 Physical characteristics of the rack-mount demodulator unit .. 5-14

Table 5.2 Physical characteristics of the down-converter ..................... 5-14

Table 6.1 Environmental features .................................................... 6-14

Chapter 3

Technical features

Chapter 3: Technical features

10

1 Inputs

1.1 RF Section

Table 1.1 RF input features

Item Feature

Connector designation RF INPUT

Type of connector Female “N” type

Impedance 50Ω

Input frequency ranges 1.3 to 10.5GHz

(in 500MHz bands)

Noise figure <2 dB

Minimum input signal level QPSK: 1/2: -95 dBm

2/3: -94 dBm

3/4: -93 dBm

5/6: -92 dBm

7/8: -91 dBm

16QAM: 1/2: -87 dBm

2/3: -86 dBm

3/4: -85 dBm

5/6: -84 dBm

7/8: -83 dBm

64QAM: 1/2: -80 dBm

2/3: -79 dBm

3/4: -78 dBm

5/6: -77 dBm

7/8: -76 dBm

IP3 of the internal LNA +33 dBm

Phase noise <-98 dBc/Hz@10KHz

Conversion gain >25dB

Number of poles of the input filter 5 (Interdigital)

Static protection Yes

1.2 IF Section

The DR-100 series receivers have one, two or six IF inputs, depending on the

model (DR-102 or DR-106). The features are shown in the table below:

Table 1.2 IF (Intermediate Frequency) input features

Item Feature

Connector designation Demodulator: IF1...IF6

Down-converter: I.F.

OUTPUT&DC

Type of connector Demodulator: N female

Down-converter: N female

Frequency ranges 48 to 860 MHz

Impedance 50Ω

Maximum length of IF cable RG-214: 75m

Celflex1/2”: 150m

Chapter 3: Technical features

11

Diversity Up to 6 using the MRC

technique (Maximum Ratio

Combining)

Bandwidth 5 MHz, 6 MHz, 7 MHz or 8 MHz

Constellation QPSK, 16-QAM or 64-QAM

Guard interval 1/4, 1/8, 1/16, 1/32

FEC 1/2, 2/3, 3/4, 5/6, 7/8

Mode 2K

1.3 Genlock

The DR-100 series receivers have a Genlock reference input to lock the SDI

digital video outputs to an external source.

Table 1.3 Genlock external reference input features

Item Feature

Connector designation Genlock

Type of connector Insulated BNC female

Impedance 75Ω

Signal level From 0.5 to 4 Vpp

2 Outputs

2.1 SDI (Serial Digital Interface)

The DR-100 series receivers have two SDI digital video outputs, whose features

are shown in the following table:

Table 2.1 SDI output features

Item Feature

Connector designation SDI

Type of connector Insulated BNC female

Impedance 75Ω

Output level 800mVpp nominal ±10%

Return losses > 15 dB, 5-270 MHz

Bitrate 270 Mbit/s

Standard SMPTE-259M

Video decoding standard MPEG-2 (ISO/IEC 13818-2):

- 422P@ML

- MP@ML

- Super low delay

Video format

- 525i

- 625i

Aspect ratio

- 4/3

- 16/9

Chapter 3: Technical features

12

2.2 Composite video

The DR-100 series receivers include two composite video outputs. Their features

are shown in the table below:

Table 2.2 Composite video output features

Item Feature

Connector designation VIDEO

Video connector Insulated BNC female

Impedance 75Ω

System PAL

Video decoding standard MPEG-2 (ISO/IEC 13818-2):

- 422P@ML

- MP@ML

- Super low delay

Video format

- PAL

- NTSC

Aspect ratio

- 4/3.

- 16/9.

2.3 Analogue audio outputs

The DR-100 series receiver includes four audio outputs. Their features are

shown in the table below:

Table 2.3 Audio output features

Item Feature

Number of audio channels 4

Connector designations AUDIO 1 LEFT

AUDIO 1 RIGHT

AUDIO 2 LEFT

AUDIO 2 RIGHT

Audio connectors XLR-3 male

Audio output level Line, +15dBm maximum

Impedance 30Ω

Sampling frequency 48 KHz

Audio decoding standard MPEG-1 L2

The pinout of the audio connectors is

Pin 1=> ground

Pins 2 and 3 => signals

Chapter 3: Technical features

13

2.4 ASI OUT

Table 2.4 DVB-ASI Transport Stream output features

Item Feature

Connector designation ASI OUT

Type of connector Insulated BNC female

Impedance 75Ω

Standard EN50083-9

Packet length 188/204 bytes

Maximum bitrate 31 Mbit/s

2.5 Data Out/RS-232 remote control

Table 2.5 Data Out output features

Item Feature

Connector designation Data out

Type of connector DB9

Standard RS-232

Output bitrate 2400 to 115.200bps

3 Power supplies

3.1 AC Power

Table 3.1 AC power supply features

Item Feature

Connector designation POWER A.C.

Connector Neutrik MLC

Supply voltage 90-240 V. (50/60Hz)

3.2 DC Power

Table 3.2 DC power supply features

Item Feature

Connector designation POWER D.C.

Connector XLR-4 male

Supply voltage 11-36 V.

Consumption Down-converter:450mA@12V

The pinout is:

Pins1 and 2 => ground

Pins 3 and 4 => +11V to +36V

Chapter 3: Technical features

14

4 Remote control

Table 4.1 Remote control

Item Feature

Connector designation ETHERNET

Connector RJ-45 8 pins 10/100 Base-T

The pinout is:

Pin 1 => TxD+ (out)

Pin 2 => TxD- (out)

Pin 3 => RxD+ (in)

Pin 6 => RxD- (in)

5 Physical characteristics

Table 5.1 Physical characteristics of the rack-mount demodulator unit

Item Feature

Dimensions 1U 19” rack

Depth 330mm

Table 5.2 Physical characteristics of the down-converter

Item Feature

Width 100mm

Height 200mm

Depth 60mm

Weight 1.8Kg

Maximum mast diameter 60mm

6 Environmental conditions

Table 6.1 Environmental features

Item Feature

Operating temperature range -10ºC to +55ºC

15

Contents

1 Turning on the equipment (POWER ON / OFF) ....................... 16

2 Locking the keypad (LOCK) ................................................. 16

3 Remote control (Remote) .................................................... 16

4 Alarms (Alarm).................................................................. 17

5 Menu ............................................................................... 17

6 Up, down, left, right, enter .................................................. 17

List of figures

Figure 1.1 The On/Off button ............................................................. 16

Figure 2.1 Lock button ...................................................................... 16

Figure 3.1 Remote control button ....................................................... 17

Figure 4.1 Alarm button .................................................................... 17

Figure 5.1 Menu button ..................................................................... 17

Figure 6.1 Navigation controls ............................................................ 18

Figure 2.1 Using equipment’s menus ................................................... 21

Chapter 4

Front panel controls on the

demodulator unit

Chapter 4:Front panel controls on the demodulator unit

16

1 Turning on the equipment (POWER ON / OFF)

To turn the equipment on or off, keep this button pressed for several

seconds. When the equipment is turned on, the display will show the startup message (model and version of the equipment) for a few seconds, and

then it will display one of the two main screens. Screen one: frequency,

constellation, Viterbi coding or FEC, guard interval and number of cuts, or

screen two: signal level and SNR of the different IF signals on the

demodulator’s inputs, shown as bar graphs and numbers. This on/off button

works regardless of whether DC or AC power is used.

If the power fails while the equipment is operating, it will restart

automatically when the power returns, without it being necessary to press

the on/off button again.

Figure 1.1 The On/Off button

The LED next to this button indicates when the equipment is turned on:

The LED lights up in green when the equipment is turned on.

The LED flashes red when there is power into the equipment but it is

turned off.

2 Locking the keypad (LOCK)

This button is used to lock and unlock the keypad. When the keypad is

locked, the LED next to this button lights up in green, and stays lit until this

button is pressed again to unlock the keypad. The lock state is memorised

when the equipment is turned off. This button must be pressed during

approximately 3 seconds to lock or unlock the keypad.

The purpose of this button is to prevent unwanted manipulation of the

equipment (unwanted changes to the configuration, etc).

Figure 2.1 Lock button

3 Remote control (Remote)

This button is used to activate the remote control mode. When the LED next

to this button is lit in green, the equipment is ready for being controlled

remotely control via the Ethernet link. To activate or defuse the remote

Chapter 4:Front panel controls on the demodulator unit

17

control, simply press this button. When the equipment establishes

communication with the remote equipment, the LED flashes in green. In this

state, the different parameters of the DR-100 series receiver that can be

configured and monitored, they can be controlled locally and remotely.

To monitor and configure the equipment by remote control, a program must

be installed in the remote station. The last version of this program is

available in our website, www.svpbm.com

.

Figure 3.1 Remote control button

4 Alarms (Alarm)

When the equipment detects the existence of one or more alarms, the

corresponding LED lights in red, and when one or more warnings are

detected, the LED lights in orange. When the ALARM button is pressed, the

equipment displays the alarms and/or warnings it has detected. To exit the

alarm menu and return to the main menu, simply press the ALARM button

again.

Figure 4.1 Alarm button

5 Menu

This button is used to enter and exit the equipment control menu and the

submenus, plus other specific functions within each submenu

Figure 5.1 Menu button

6 Up, down, left, right, enter

The arrow buttons and the ENT (Enter) button are used to navigate through

the menus.

Chapter 4:Front panel controls on the demodulator unit

18

Figure 6.1 Navigation controls

For more details regarding local control of the equipment, see chapter 5 of

this manual, Local control of the equipment.

19

Contents

1 Introduction ...................................................................... 21

2 Using the equipment’s menus .............................................. 21

3 The “Setup Configuration” Menu .......................................... 22

3.1 Reception frequency .............................................................. 23

3.2 Down-converter local oscillator frequency ................................. 23

3.3 Down-converter power supply ................................................. 24

3.4 Bandwidth ............................................................................ 24

3.5 PID capture mode .................................................................. 24

3.6 Format of the video outputs .................................................... 24

3.7 Audio DID ............................................................................ 24

3.8 IF cable ................................................................................ 25

3.9 Format of the DVB-ASI output signal packets ............................ 25

3.10 Data Options ...................................................................... 26

3.11 Ethernet communications parameters .................................... 26

3.12 Clock and date ................................................................... 27

3.13 Location labels ................................................................... 27

4 The “Monitor Status” Menu .................................................. 28

4.1 Reception frequency .............................................................. 29

4.2 Down-converter select ........................................................... 29

4.3 Down-converter local oscillator frequency ................................. 29

4.4 Power supply for the down-converters (Enabled or Disabled) ....... 29

4.5 Bandwidth ............................................................................ 29

4.6 Constellation, Viterbi coding and guard interval ......................... 29

4.7 Quality and signal strength ..................................................... 29

4.8 BER (Bit Error Rate) ............................................................... 30

4.9 Transport Stream parameters ................................................. 30

4.10 Profile and Level ................................................................. 30

4.11 Audio signals parameters. .................................................... 31

4.12 Genlock ............................................................................. 31

4.13 Output format of the DVB-ASI packets ................................... 31

4.14 The temperature of the rack-mount demodulator .................... 31

4.15 Power supply voltage of the demodulator unit ......................... 31

Chapter 5

Local control of the

equipment

20

4.16 Power source (AC or DC) ..................................................... 31

4.17 Ethernet communications parameters .................................... 32

4.18 Date and time .................................................................... 32

4.19 List of alarms and warnings .................................................. 32

4.20 Location of the equipment and Source and Destination nodes ... 32

5 Monitoring alarms and warnings .......................................... 32

5.1 Parameters that can cause alarms ........................................... 33

5.2 Parameters that can cause warnings ........................................ 34

List of figures

Figure 2.1 Using equipment’s menus ................................................... 21

List of tables

Table 3.1 The “SETUP CONFIGURATION” Menu ..................................... 23

Table 4.1 The “MONITOR STATUS” Menu ............................................. 28

Chapter 5: Local control of the equipment

21

1 Introduction

The DR-100 series receivers can be controlled and monitored either locally and

remotely (via an Ethernet LAN connection).

The equipment has two main display screens: one of them displays the receiver

frequency, the presence or absence of DVB-ASI MPEG-2 data, the constellation,

the Viterbi coding or FEC, the guard interval and the number of faults or cuts

produced in the link

1

; the other shows the signal level and SNR of the IF

signal(s) being received by the demodulator.

In the second screen, to monitor the signal levels of the different demodulators,

just press the UP and DOWN buttons. Alternatively, to monitor the signal levels

of all of the demodulators simultaneously, press the LEFT and RIGHT buttons

This second option is extremely useful when adjusting the orientation of the

antennas.

To change from one main screen to the other, press the ENT button. When the

equipment is turned off, the last main screen displayed is memorised. When the

equipment is turned back on, or when the power returns after a power cut, the

display will show the corresponding main screen.

When the user stops manipulating the equipment (when several 30 minutes have

passed since the last order), the equipment is locked and the display shows the

last main screen that was accessed and.

2 Using the equipment’s menus

To enter the menu, press the MENU button on the front panel. Once in the

menus, the user can navigate through them with the arrow buttons and the ENT

button. To exit the menu and return to the main screen, simply press the MENU

button again.

Figure 2.1 Using equipment’s menus

The function of each of the buttons in figure 5.2 is explained below in detail:

1

The DR-100 series receivers include a fault counter. Every time that the equipment detects

a fault in input signal, it increments the counter. To reset the counter to zero, press the LEFT

arrow button.

Chapter 5: Local control of the equipment

22

DOWN: moves to the next option in the current menu, and also has other

specific functions.

UP: moves to the previous option in the current menu, and also has other

specific functions.

RIGHT: used for specific functions.

LEFT: used for specific functions.

ENT: this button has several functions. It is used to enter submenus

2

, to select

an option when there are several choices and for other specific functions.

3 The “Setup Configuration” Menu

This section contains a detailed description of each of the parameters that can be

configured in the DR-100 series receivers via the SETUP CONFIGURATION menu.

To enter the SETUP CONFIGURATION menu, press the MENU button, use the UP

and DOWN buttons to select the SETUP CONFIGURATION menu, then press the

ENT button.

To navigate through the menu and configure the different parameters, use the

UP, DOWN, LEFT, RIGHT and ENT buttons.

2

The existence of a submenú is indicated on the display by the ENTER symbol.

Chapter 5: Local control of the equipment

23

The table below shows the different lines in the SETUP CONFIGURATION menu:

Table 3.1 The “SETUP CONFIGURATION” Menu

Line no. Function

1 Rx Frequency (MHz)

2 Down-Converter Local Oscillator (MHz).

3 Down-Converter Power Supply: Enable/disable

4 Bandwidth (5, 6, 7, 8 MHz).

5 PID mode (Auto / Manual).

6 Output Format (PAL or NTSC).

7 Audio DID (G1, G2, G3, G4)

8 IF cable. (Type and length)

9 ASI Packet Format (188/204).

10 Data options

11 Ethernet Parameters (Local IP, Remote IP, Gateway, Port)

12 Clock and Date

13 Location Labels (Place, From, To)

The steps required to configure each of the parameters listed in this table will

now be explained in detail.

3.1 Reception frequency

To configure the reception frequency, move to line 1 in the SETUP

CONFIGURATION menu using the UP and DOWN buttons, and then press the ENT

button. When this button is pressed, the cursor will be placed over the first digit,

which can be changed by pressing the UP and DOWN buttons. To change the

other digits, press the LEFT and RIGHT buttons until the cursor is over the digit

to be changed. When the desired frequency has been set, press the ENT button

and the equipment will be locked onto that frequency. If the frequency setting is

not valid, the equipment will display an alarm (Frequency out of Range).

3.2 Down-converter local oscillator frequency

To configure the local oscillator frequency in the down-converter, move to line 2

in the SETUP CONFIGURATION menu using the UP and DOWN buttons, then

press the ENT button. When this button is pressed, the cursor will be placed over

the first digit, which can be changed by pressing the UP and DOWN buttons. To

change the other digits, press the LEFT and RIGHT buttons until the cursor is

over the digit to be changed. When the desired local oscillator frequency has

been set, press the ENT button to configure the equipment to use this LO

frequency.

Chapter 5: Local control of the equipment

24

3.3 Down-converter power supply

To enable or disable the power supplies to the down-converters, move to line 3

in the SETUP CONFIGURATION menu using the UP and DOWN arrows, then press

the ENT button to enable or disable the power-supply feed to the downconverters through the IF coaxial cable.

3.4 Bandwidth

To configure the desired bandwidth for the received signal, move to line 4 in the

SETUP CONFIGURATION menu using the UP and DOWN arrows, then press the

LEFT and RIGHT buttons to select the desired bandwidth. The equipment can

receive signals with the following bandwidths: 5 MHz, 6 MHz, 7 MHz or 8 MHz

3.5 PID capture mode

The equipment can select the program to be decoded in two ways: manually or

automatically.

In manual mode, the user has to input the number of the program to be

decoded, the PID from the PMT table corresponding to the program, the PID of

the PCR, the PID of the video signal to be decoded and the PID of the audio 1

and audio 2 signals (the LEFT and RIGHT channels that constitute each audio

signal have the same PID). To do this, first move to line 5 in the SETUP

CONFIGURATION menu, then select manual mode using the LEFT or RIGHT

button, and then press the ENT button to enter a submenu where the parameters

indicated above can be set for the program to be decoded.

In automatic mode, the equipment automatically decodes the lowest program

number received in the transport stream after the input IF signal has been

decoded. In this case, the user does not have to enter any parameters. To select

this mode, move to line 5 in the SETUP CONFIGURATION menu and use the LEFT

and RIGHT buttons to select automatic mode.

3.6 Format of the video outputs

To configure the output format of the video signals (PAL or NTSC) move to line 6

in the SETUP CONFIGURATION menu using the UP and DOWN arrows, then press

the LEFT and RIGHT buttons to select the desired format.

3.7 Audio DID

To configure the identifier of the audio group (composed of four channels) in

which the audio signals are wanted to be embedded in the SDI outputs, move to

Chapter 5: Local control of the equipment

25

line 7 in the SETUP CONFIGURATION menu using the UP and DOWN arrows, then

press the LEFT and RIGHT buttons to select the desired audio DID.

According to SMPTE-272M standard, in a SDI digital video signal until 4 audio

groups can be embedded. Each of audio group is composed of 4 audio channels

and consequently until 16 audio channels can be embedded in a SDI signal. The

DR-100 series receivers can decode four audio channels only, that is, an audio

group; therefore it is necessary to specify the audio group (among the four audio

groups in which the audio signals can be embedded in the SDI signal) in which

the four audio channels (decoded by the receiver) are wanted to be embedded.

According to the SMPTE-272M standard, the audio DID of each of audio group is

the following one:

Group 1=> Audio DID: 767

Group 2=> Audio DID: 509

Group 3=> Audio DID: 507

Group 4=> Audio DID: 761

3.8 IF cable

In order to extend the dynamic range of the receiver, and that it is able to

receive strong input signals it is recommended to configure the type and the

length of the IF cable used.

The receiver modifies the attenuation of an internal attenuator depending on the

IF cable type used, the length of that cable and the frequency in IF of the

received signal and it is able to extend 20dB the dynamic range of the receiver.

To configure the information about the IF cable, move to line 8 in the SETUP

CONFIGURATION menu using the UP and DOWN arrows, then press right and left

arrows, two options are available: not used and configuration.

To configure this parameter press right arrow to enter configuration menu and

then press ENT button. Cable type blinks and can be selected using UP and

DOWN arrows among the 6 preset cable types. When the cable type has been

chosen press ENT button. Afterwards, the cursor will be placed over the first digit

of the cable length parameter, which can be changed by pressing the UP and

DOWN buttons. To change the other digits, press the LEFT and RIGHT buttons

until the cursor is over the digit to be changed. When the desired length has

been set, press the ENT button

Not used option has to be selected when that IF input is not used.

3.9 Format of the DVB-ASI output signal packets

To configure the format of the DVB-ASI output signal packets (188 or 204

bytes), move to line 9 in the SETUP CONFIGURATION menu using the UP and

Chapter 5: Local control of the equipment

26

DOWN arrows, then press the LEFT and RIGHT buttons to select the desired

format.

3.10 Data Options

To configure data channel the user has to move to line no10 and press enter,

data options submenu will appear. The following parameters can be configured in

this submenu:

Ethernet: Enables the data output over the Ethernet connection. This option is

not available yet.

RS-232: GPS/ Data Output/ HyperTerminal. It configures operation mode of

the RS-232 connection. When GPS option is selected the baud rate is set to

4800bps. With data output option, the data introduced in SVP transmitter is

obtained. Data flow speed must be configured by Baud parameter and should

be equal to the data input speed in the transmitter. HyperTerminal option

allows the user to remotely control the receiver via de RS-232 connection.

Baud rate has to be configured.

Baud: data flow speed configured by this parameter. Data flow speed is

selectable: 2.400, 4.800, 9.600, 19.200, 38.400, 57.600, 76.800,

115.200bps.

3.11 Ethernet communications parameters

To configure the communications port and the local and remote IP addresses,

move to line 11 in the SETUP CONFIGURATION menu using the UP and DOWN

buttons, then press the ENT button to enter the corresponding submenu.

The following parameters can be configured in this submenu:

Local IP address of the receiver.

The IP address of the gateway or router.

The subnet mask.

The public IP address of the remote station to which the receiver must

connect.

The communications port to be used for communications between the receiver

and the remote station.

The first three parameters (local IP address, router IP address and the subnet

mask) configure the local network of which the receiver is a part.

To configure each of these parameters, press the ENT button, and the cursor will

appear over the first digit. Use the UP and DOWN buttons to change the digit. To

change the other digits, press the LEFT and RIGHT buttons until the cursor is

over the digit to be changed.

When all of the Ethernet parameters have been set, press the MENU button to

confirm the settings, the press the MENU button again to exit the submenu.

Chapter 5: Local control of the equipment

27

3.12 Clock and date

To configure the date and time, move to line 12 in the SETUP CONFIGURATION

menu using the UP and DOWN buttons. Once on this line, simply press the ENT

button to place the cursor over the first digit of the time. Use the UP and DOWN

arrows to change the digit. To change the other digits in the time and the date,

select them using the LEFT and RIGHT arrows, then change them with the UP

and DOWN arrows. Once the date has been set, the equipment will

automatically display the first three letters of the day of the week in English.

In addition, the equipment automatically changes to summer time and winter

time and includes the 29

th

of February in leap years.

3.13 Location labels

To configure the location of the equipment and the source and destination nodes,

move to line 13 in the SETUP CONFIGURATION menu using the UP and DOWN

buttons, then press the ENT button to enter the corresponding submenu. In this

submenu, the following locations can be configured:

The location of the equipment: pressing the ENT button, the cursor will be

placed over the first letter. The UP and DOWN arrows will change the letter in

alphabetical order. To change the other letters, press the LEFT and RIGHT

buttons until the cursor is over the letter to be changed.

The location of the source and destination nodes of the link: to configure the

source and destination nodes of the link in question, press the ENT button

several times until the cursor is located over the first letter after the FROM or

TO labels. To set the locations, follow the same procedure as for the location

of the equipment.

When all of the parameters for the equipment location and the source and

destination nodes have been set, press the MENU button to confirm the settings,

the press the MENU button again to exit the submenu.

If the user does not press any buttons during several minutes, the DR-100 series

receiver will automatically exit the menu or submenu it was left in and display

the main screen that was used the last time.

To exit any submenu, press the MENU button.

Chapter 5: Local control of the equipment

28

4 The “Monitor Status” Menu

The MONITOR STATUS menu is used to monitor the status of different

parameters in the receiver. It cannot be used to configure these parameters.

This section contains detailed descriptions of all of the parameters that can be

monitored or displayed via the MONITOR STATUS menu of the DR-100 series

receivers.

To enter this menu, press the MENU button, use the UP and DOWN buttons to

select the MONITOR STATUS menu, and then press the ENT button.

The UP and DOWN buttons are used to navigate through the menu options.

The table below shows the different lines in the MONITOR STATUS menu:

Table 4.1 The “MONITOR STATUS” Menu

Line no. Function

1 Rx Frequency (MHz)

2 Down-Converter Select

3 Down-Converter Local Oscillator

4 Down-Converter(Enable/Disable)

5 Bandwidth (5, 6, 7, 8 MHz).

6

Constellation (QPSK, 16QAM, 64QAM), FEC (1/2, 2/3, 3/4, 5/6 or 7/8)

Guard interval (1/4, 1/8, 1/16 or 1/32).

7

Demodulator: 1,2,...,6

Input signals quality parameter measurement (signal level, MER, SNR).

8 BER (Bit Error Ratio)

9 PID info (Transport Stream parameters)

10 Profile and level (Video encoding format).

11 Video output format (PAL or NTSC).

12 Audio options (Bitrate per audio pair)

13 Genlock (present/no present).

14 Output ASI packet format (188/204 bytes).

15 Data options

16 Rack temperature

17 Power supply voltage.

18 Power source (Mains or DC).

19 Ethernet configuration (Ethernet communication configuration).

20 Clock and Date.

21 Alarms and warnings list

22 Logbook

23 Equipment model, serial number and firmware version.

24 Location labels

The steps required to monitor each of the parameters listed in this table will now

be explained in detail:

Chapter 5: Local control of the equipment

29

4.1 Reception frequency

To observe the reception frequency, move to line 1 in the MONITOR STATUS

menu using the UP and DOWN buttons. This parameter can also be seen in one

of the equipment’s main screens.

4.2 Down-converter select

In DR-100 series receivers, the down-converters used convert RF received signal

to UHF band.

4.3 Down-converter local oscillator frequency

To observe the frequency of the local oscillator used in the down-converter,

move to line 3 in the MONITOR STATUS menu using the UP and DOWN buttons.

4.4 Power supply for the down-converters (Enabled or Disabled)

To see if the power for the down-converters is enabled or disabled, i.e., to see if

they are being powered by the demodulator, move to line 4 of the MONITOR

STATUS menu using the UP and DOWN buttons. If the supply is enabled, the

display will show DW.Converter: ENABLE, and if it is disabled, it will show

DW.Converter: DISABLE.

4.5 Bandwidth

To observe the bandwidth in use 5, 6, 7 or 8MHz, move to line 5 in the MONITOR

STATUS menu using the UP and DOWN buttons.

4.6 Constellation, Viterbi coding and guard interval

To observe the constellation, the Viterbi coding and the guard interval in use,

move to line 6 in the MONITOR STATUS menu using the UP and DOWN buttons.

This data is obtained by the demodulator when it demodulates the TPS carriers

(Transmission Parameter Signalling).

4.7 Quality and signal strength

Via line 7 of the MONITOR STATUS menu, several quality and signal level

parameters can be observed for each received signal. To select the downconverter whose received signal is wanted to be displayed (1, 2, 3, 4, 5 or 6),

Chapter 5: Local control of the equipment

30

use the LEFT and RIGHT arrows. Once the signal to view has been selected,

simply press the ENT button to monitor the following parameters:

Signal Level: this measurement corresponds to the signal strength measured

in the demodulator, not in the down-converter, antenna. The signal level

measured in the demodulator depends on the cable length used to link the

demodulator and the down converter. Depending on the cable length cable loses

will vary. So, the signal strength measure in the demodulator is indicative, this

level is represented with a graphic bar and a number between o and 100.

C/N (Carrier to Noise Ratio): This is a very important parameter as it

represents the quality of the measured signal. Observing this parameter is

possible to determine if the received signal is interfered. This measure is

represented with a graphic bar and numerically. The value of this measure is

indicative as a 0-8 scale is used.

MER (Modulation Error Ratio): This parameter measures signal quality after is

has been demodulated. It has a direct relation with BER parameter.

Signal level and the C/N can also be observed in one of the two main screens.

4.8 BER (Bit Error Rate)

To observe the Bit Error Rate (BER), move to line 8 in the MONITOR STATUS

menu using the UP and DOWN buttons. This rate is measured after demodulating

the signal and applying Viterbi decoding.

4.9 Transport Stream parameters

To observe the information about the Transport Stream, move to line 9 in the

MONITOR STATUS menu using the UP and DOWN buttons and then press the

ENT button to enter a new submenu, whose content is the following one:

Video Pid: video packets identifier.

Audio 1 Pid: identifier of the packets about the first audio.

Audio 2 Pid: identifier of the packets about the second audio.

PMT Pid: identifier of the packets that transport the information about the PMT

(Program Map Table) table.

PCR Pid: identifier of the packets about the PCR (Program Clock Reference).

Prog.Number: program number.

4.10 Profile and Level

To observe the video encoding profile and level (422/420 and Standard/Super

low delay), move to line 10 in the MONITOR STATUS menu using the UP and

DOWN buttons.

Chapter 5: Local control of the equipment

31

4.11 Audio signals parameters.

To observe on the one hand, the bitrate used after the audio signals are

compressed and the other hand, the audio DID for the embedded audio in the

SDI output signals, move to line 11 in the MONITOR STATUS menu using the UP

and DOWN buttons.

4.12 Genlock

To observe if the Genlock input is enabled or disabled and the used offset move

to line 12 in the MONITOR STATUS menu using the UP and DOWN buttons and

then press the ENT button to enter a new submenu.

4.13 Output format of the DVB-ASI packets

To observe the format of the DVB-ASI output packets (188 ó 204 bytes) move to

line 13 in the MONITOR STATUS menu using the UP and DOWN buttons.

4.14 The temperature of the rack-mount demodulator

Line 14 of the MONITOR STATUS menu shows the actual temperature in the

demodulator unit. When the equipment senses a temperature of 45ºC, it

automatically turns on a fan inside the unit, which continues in operation until

the temperature falls to 42ºC. This increases the lifetime of the fan

4.15 Power supply voltage of the demodulator unit

To observe the power supply voltage of the demodulator unit, move to line 15 in

the MONITOR STATUS menu using the UP and DOWN buttons.

4.16 Power source (AC or DC)

The equipment always displays the power source it is using, AC Mains or DC

battery supply. To observe the power source, move to line 16 in the MONITOR

STATUS menu using the UP and DOWN buttons. If the AC power is cut off, the

unit automatically switches over to use the battery.

When the equipment is running off the battery, it displays a warning.

Chapter 5: Local control of the equipment

32

4.17 Ethernet communications parameters

To observe the Ethernet communications parameters, move to line 17 in the

MONITOR STATUS menu using the UP and DOWN buttons, then press the ENT

button to enter the corresponding submenu. In this submenu, the port and the

local and remote IP addresses can be viewed.

4.18 Date and time

To monitor the date and time settings, move to line 18 in the MONITOR STATUS

menu using the UP and DOWN buttons.

4.19 List of alarms and warnings

When the equipment indicates the existence of an alarm (the LED next to the

ALARM button lights in red) or/and a warning (the LED lights in orange), the user

can view the alarms/warnings by simply pressing the ALARM button or via the

MONITOR STATUS menu. To view the alarms/warnings via the MONITOR STATUS

menu, move to line 19 in the menu using the UP and DOWN buttons, then press

the ENT button to enter the “Alarms and Warnings List” submenu. If there are no

alarms or warnings, the LED next to the ALARM button will be out, and if the

user presses the ALARM button or accesses the “Alarms and Warnings list”

submenu, the unit displays “No alarms” and “No warnings”.

4.20 Location of the equipment and Source and Destination nodes

To view the information on the location, move to line 20 of the MONITOR

STATUS menu using the UP and DOWN buttons and press the ENT key to enter a

submenu that displays the location of the equipment and the location of the

source and destination nodes of the communications link.

If the user does not press any buttons during 30 minutes, the DR-100 series

receivers will automatically exit the menu or submenu it was left in and display

the main screen that was used the last time.

5 Monitoring alarms and warnings

The DR-100 series receivers constantly indicate the existence of alarms and/or

warnings via the LED next to the ALARM button:

If this LED is out, there are no active alarms or warnings.

If this LED lights in orange, the equipment has activated one or more

warnings, but no alarms.

Chapter 5: Local control of the equipment

33

If this LED lights in red, the equipment has activated one or more alarms,

although there may also be some warnings.

There are two methods to determine which alarms/warnings have been

activated:

The ALARM button: when this button is pressed, the equipment displays a list

of the active alarms and/or warnings. If there are no active alarms or

warnings, the unit displays “No alarms” and “No warnings”.

The “MONITOR STATUS” menu: the list of active alarms and warnings can also

be viewed via the MONITOR STATUS menu. To do this, move to line 18 in the

menu using the UP and DOWN buttons, then press the ENT button to enter the

“Alarms and Warnings List” submenu. As before, if there are no active alarms

or warnings, the unit displays “No alarms” and “No warnings”.

To exit the alarms menu, simply press the ALARM button.

The parameters that can cause alarms or warnings to be activated are listed

below:

5.1 Parameters that can cause alarms

Temperature: if the temperature inside the rack-mount unit reaches or

exceeds 70ºC, an alarm is triggered and the red LED next to the Alarm button

lights. In addition, the temperature displayed in line 16 of the MONITOR

STATUS menu blinks. When the temperature drops to 65ºC, the alarm is

cancelled.

Power supply voltage of the unit: if the power supply voltage to the

demodulator unit is below 11V or above 36V, an alarm is triggered and the red

LED next to the Alarm button lights. In addition, the voltage displayed in line

17 of the MONITOR STATUS menu blinks. The unit stops displaying the alarm

when the power supply voltage is 11V or greater, but no more than 36V.

Reception frequency out of range: if the user enters an invalid reception

frequency, an alarm is triggered and the red LED next to the Alarm button

lights. In addition, the frequency that has been entered will blink, both in the

main screen and in line 1 of the MONITOR STATUS menu. In this case, the

user must revise both the receiver frequency and the local oscillator frequency

configurations.

Internal equipment error: if this alarm appears, the user should contact SVP’s

technical department.

Chapter 5: Local control of the equipment

34

5.2 Parameters that can cause warnings

No RF signal: if the equipment detects no signal in neither of the IF inputs, it

displays a warning, and the LED next to the Alarm button lights in orange.

No MPEG-2 DVB-ASI data (No MPEG Data): if the equipment cannot

demodulate the IF input signal(s), and therefore cannot extract a valid ASI

signal, it displays a warning, and the LED next to the Alarm button lights in

orange.

35

Contents

1 Installation ....................................................................... 36

Chapter 6

Installation

Chapter 6:Installation

36

1 Installation

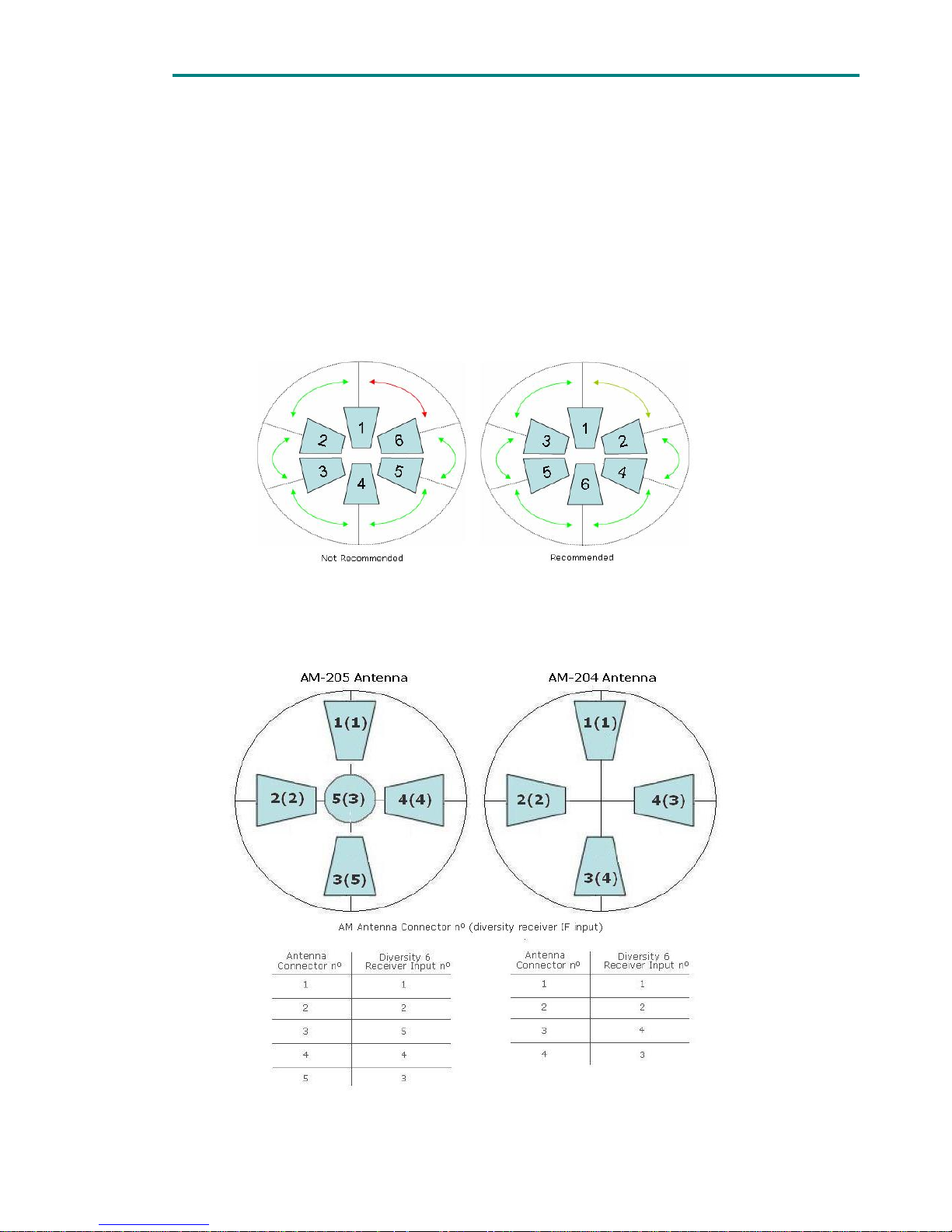

When several inputs are connected to the DR-106 receiver, due to input

signals processing delays, it is recommended not to have too high transition

between areas covered by the antennas connected to adjacent IF inputs of

the diversity 6 receivers.

The figure bellow shows the recommended and the less recommended

connection layout:

Figure 5.1 Not Recommended and Recommended connections

When AM-204 and AM-205 antennas are used in the receiver site,

connection should be performed as follow:

Figure 5.2 Figure 4 AM-205 and AM-204 connection to diversity 6 receivers

37

2

Contents

1 Introduction ...................................................................... 38

2 Installation ....................................................................... 38

3 Software Operation ............................................................ 39

3.1 Network Configuration ............................................................ 39

3.2 Equipment control ................................................................. 40

3.2.1 Monitor tab ..................................................................... 41

3.2.2 Data tab ......................................................................... 43

3.2.3 Logbook tab .................................................................... 44

List of figures

Figure 2.1 Front view of DR-70 ........................................................... 38

Figure 3.1 Main screen or the NetC program......................................... 39

Figure 3.2 Dialog box to add a new machine to the net .......................... 40

Figure 3.3 Monitor tab for DR-100 receiver .......................................... 41

Figure 3.4 Monitor tab for DT-70 transmitter ........................................ 42

Figure 3.5 Data tab ........................................................................... 43

Figure 3.6 Logbook Tab ..................................................................... 44

Chapter 7

NetC Software to control

remotely a network of SVP

e

q

uipment

Chapter 7: NetC Software to control remotely a network of SVP equipment

38

1 Introduction

NetC, Network Controller, is the new equipment control software developed by

SVP Broadcast Microwave. This new software lets the user control multiple SVP

machines simultaneously provided they are connected to the same local area

network.

Remote configuration and monitoring of DR-100/HDR-100 series, DR-70/HDR-70

and DT-70/HDT-70 equipment can be carried out with this new software.

Next, installation and operation of this software is described.

2 Installation

To be able to control remotely SVP machines is necessary to install the software

and then to configure the machines to make possible their communication with

the computer on which the software has been installed.

The control software application is delivered in a CD together with SVP

equipments. This software is also available on our web site:

http://www.svpbm.com/ing/support.htm

. On the web site there will always be

available the latest version of this software.

Installation of this software starts when setup file is selected. Then just follow

installation process.

To control the equipment remotely, the following steps are required:

1. The LED next to the REMOTE button must be lit in green. The REMOTE

button is used to select the remote control mode. When the LED next to

this button is lit in green, the equipment is set for remote control via the

Ethernet link, while if this LED is out, the equipment can only be controlled

locally. To activate o defuse the remote control, simply press this button.

Figure 2.1 Front view of DR-70

2. When the equipment is set for remote control (the REMOTE LED is lit in

green), the Ethernet communications parameters must be configured. Go

to Setup Configuration Menu, enter Ethernet Parameters submenu and set

the following parameters:

Chapter 7: NetC Software to control remotely a network of SVP equipment

39

a. Local IP address: this is the IP address of the SVP machine within

the LAN that it is connected to. This IP address does not have to be

fixed.

b. The IP address of the gateway or router: this is the IP address of

the router in the LAN to which the receiver is connected.

c. The subnet mask: depending on the configuration of this mask and

the remote IP address, packets transmitted by the receiver will

either be transmitted within the LAN or outside the LAN, via the

router.

d. The public IP address of the remote station to which the SVP

machine must connect. This is the IP address of the computer the

software is installed on. This IP address must be fixed.

e. The communications port to be used for communications between

the machine and the remote station. The router in the LAN to which

the remote station is connected must be configured so that packets

sent to this port are routed to the IP address configured in point d.

This completes the definition of the connection between the receiver

and the remote station. This last configuration is set in the router’s

NAT table (Network Address Translation).

3 Software Operation

Once the installation is done, we can proceed with the execution of the software.

The operation of the control software can be divided into two sections: network

configuration and equipment control.

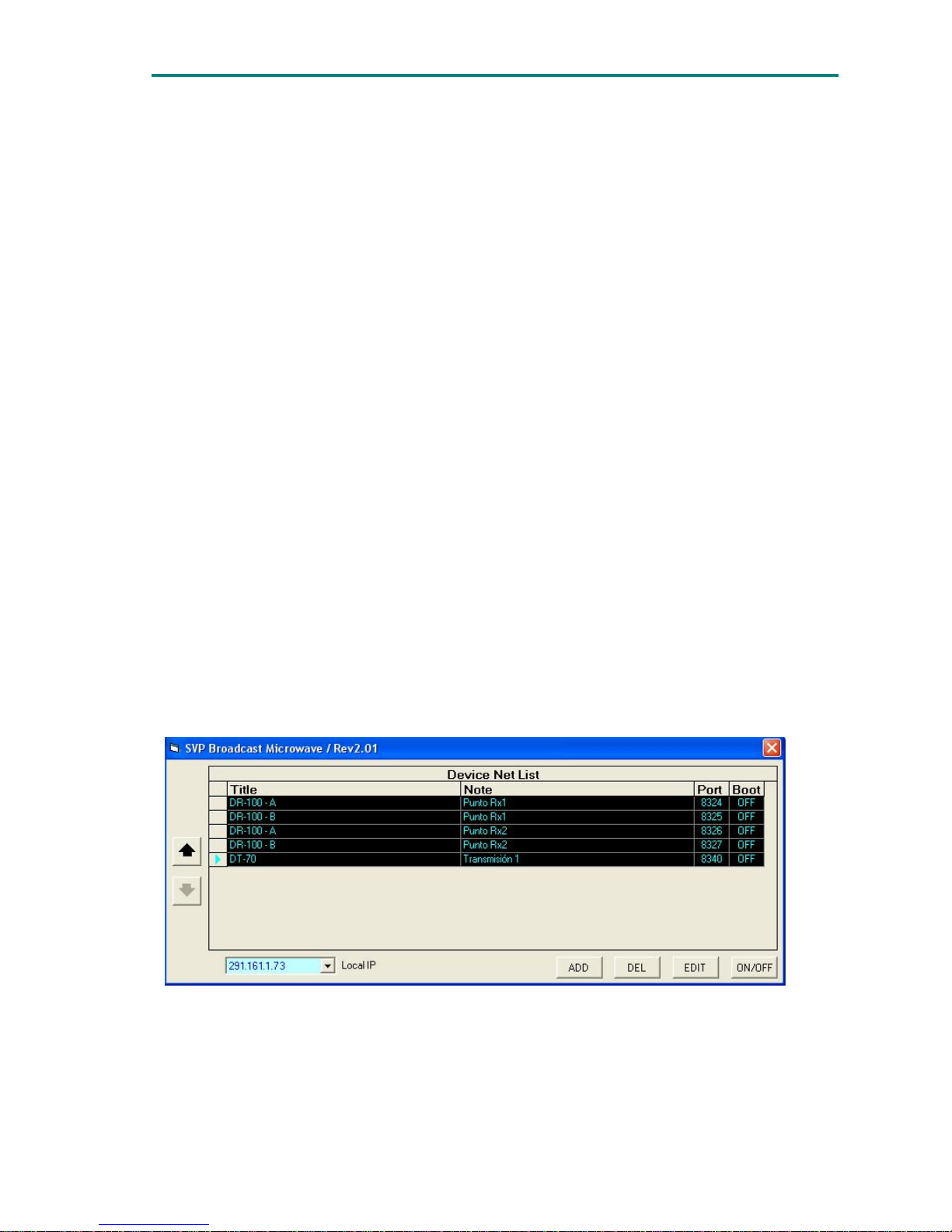

3.1 Network Configuration

When the program is run the main screen appears.

Figure 3.1 Main screen or the NetC program

Chapter 7: NetC Software to control remotely a network of SVP equipment

40

In this screen following parameters can be configured:

• Add/remove equipments to/from the network

• Edit on each equipment: name, port or notes section

• Open/close the control screen for each equipment

• Organize the list of equipments

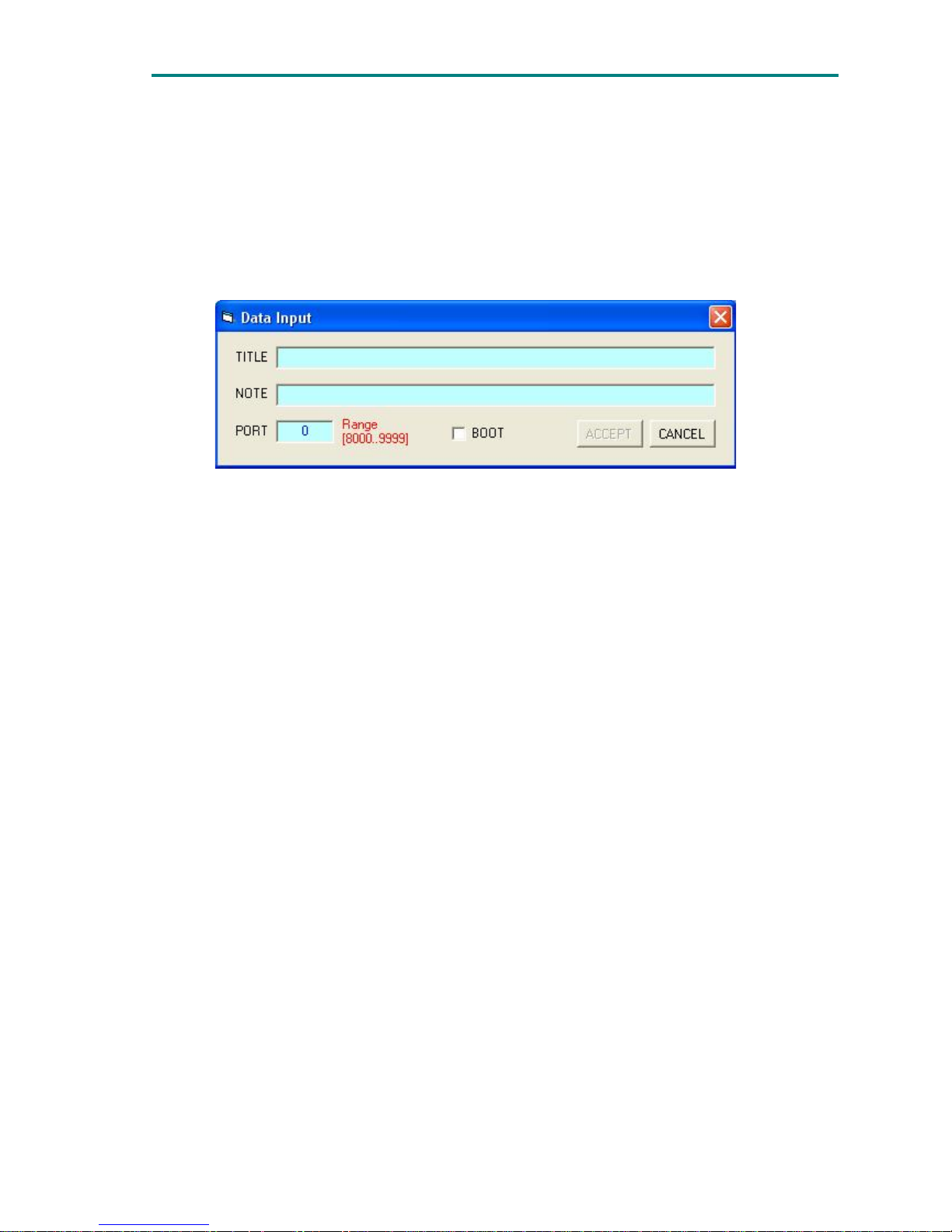

To add a new machine, ADD button must be clicked. Then following dialog box

will open:

Figure 3.2 Dialog box to add a new machine to the net

• Title: field to assign the name to the equipment that will be remotely

controlled.

• Note: paragraph to make any comment on the equipment.

• Port: communications port assigned to the machine that is to be included

in the network.

• Boot: If this field is active, the machine's control screen will open

automatically when the program is run.

To remove a machine from the network DEL button must be pressed.

Edit button opens the data input dialog box of the equipment that has been

previously selected on the main screen. Every field can be changed.

The ON/OFF button opens/closes the control window to manage equipments

remotely.

Arrows UP/DOWN are used to modify the position of the selected equipment on

the list.

3.2 Equipment control

To open the control interface of SVP equipment, first, the machine must be

selected on the main screen and then ON/OFF button must be pressed.

When the ON/OFF button is pressed a window is opened. This window has three

tabs: Monitor tab, Data tab and Logbook tab.

Chapter 7: NetC Software to control remotely a network of SVP equipment

41

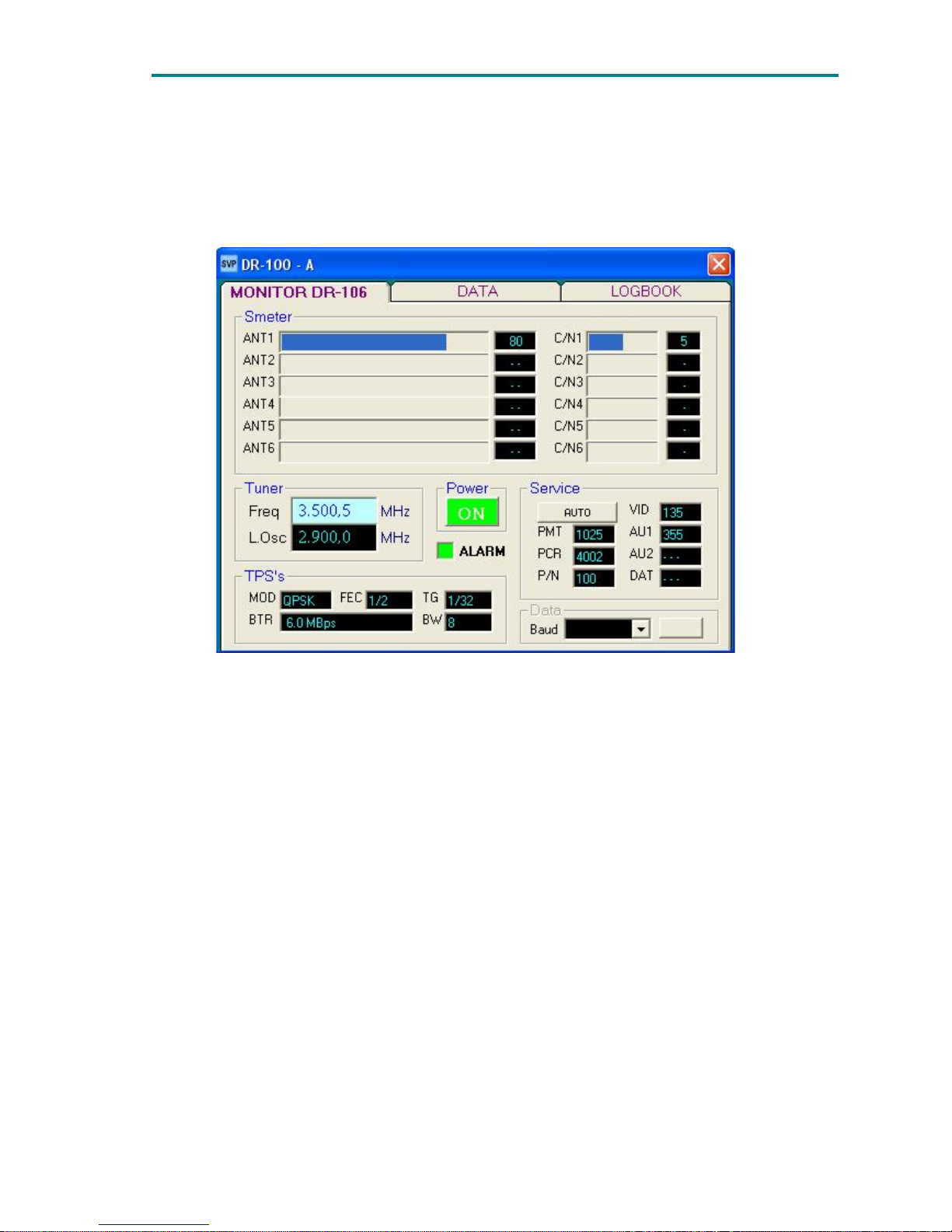

3.2.1 Monitor tab

The monitor tab allows the user to configure the most important parameters of

each machine. The content of the tab is different depending on the machine that

is connected.

Figure 3.3 Monitor tab for DR-100 receiver

For receivers the parameters displayed on the tab are the following:

• Signal Level: received signal level in each antenna. The value is

numerically and graphically displayed.

• C/N: signal to noise ratio of the signal present in each antenna. It is shown

not only numerically but also graphically.

• Reception frequency: user configurable parameter.

• Local oscillator frequency.

• Power button and shutdown.

• Information of TPS carriers (constellation, FEC code, Viterbi, and guard

interval).

• Bitrate total received in bps.

• Bandwidth in MHz

• Decoded information corresponding to the service (table PMT PID, PID for

the packets that carry the Program Clock Reference PCR, no agenda, Video

PID, Audio PID 1 PID 2 and PID audio data).

For transmitters the parameters displayed on the tab are the following:

Chapter 7: NetC Software to control remotely a network of SVP equipment

42

Figure 3.4 Monitor tab for DT-70 transmitter

The monitor tab for the transmitters, displays all data corresponding to the

transmitted COFDM signal; MPEG-2 codification, COFDM modulation,

transmission frequency and transmission power. The monitor tab is divided in the

following fields:

Input: In this field audio and video input types are configured and monitored

o Audio options: analogue or digital, embedded in SDI signal.

o Video options: composite analogue, PAL, digital SDI or DVB-ASI

Transport Stream.

When DVB-ASI input is selected the two fields on the right side are active,

one monitors the input bit rate of the ASI Transport Stream and the other

shows the packet format. There is also an overflow indicator.

Power: the On/Off button

RF field: the parameters of the up converter are monitored and some of them

can be configured. The parameters to configure the up-converter are:

o Transmission frequency

o Power supply, to feed the up-converter.

The parameters monitored are:

o Real transmitted power

o Reverse power

o Up-converter temperature

o Power supply voltage

o Up converter status (Enable/disable).

Service: In this field parameters related to video encoding, Transport Stream

and COFDM modulation are configured:

o Transport Stream: Video packets PID

Audio 1 (pair 1) PID

Chapter 7: NetC Software to control remotely a network of SVP equipment

43

Audio 2 (pair 2) PID

Program number

PMT table PID

PCR (Program Clock Reference) PID

o COFDM modulation: Constellation (QPSK, 16QAM or 64QAM)

FEC (1/2, 2/3, 3/4, 5/6 or 7/8)

Guard Interval (1/4, 1/8, 1/16 ó 1/32)

Channel bandwidth (5, 6, 7 or 8MHz)

o Video coding: MPEG-2 422 or 420

o Latency: Super low delay or Standard delay.

o Aspect ratio (4/3 ó 16/9).

o Each audio pair bitrate.

o Total transmitted bitrate.

Audio: in this field each audio pair can be enabled or disabled. Besides, each

audio level is monitored with a graphic bar and also with a numeric value. It

also points out the maximum peak value reached. This measurement is only

available when audio input signal is analogue.

3.2.2 Data tab

Provides general information about the machine connected to the local area

network: Local IP, Remote IP, port, device model, serial number, version,

temperature, etc.

Figure 3.5 Data tab

Chapter 7: NetC Software to control remotely a network of SVP equipment

44

3.2.3 Logbook tab

The logbook tab shows the last 32 warnings/alarms. However all the alarms

occurred during the day are stored in a file.

In the directory where NetC software has been installed there is a folder named

logbook. Inside logbook directory there are several folders one for each SVP

equipment on the net. The name of each folder is the text written in Title field

when the machine was added to the network. The file with the logbook

information, alarms and warnings, is stored in the corresponding folder.

Figure 3.6 Logbook Tab

Chapter 8: Remote Control via RS-232 Connection

45

Contents

1 Introduction ...................................................................... 46

2 Operation ......................................................................... 46

Chapter 8

Remote Control

via RS-232 connection

Chapter 8: Remote Control via RS-232 Connection

46

1 Introduction

The DR-100 series receivers can be controlled remotely through a RS-232

connection. A DB9 connector is located in the rear panel of the receiver.

The connection between the PC and the receiver has to be configured in order to

be able to remotely control the receiver.

2 Operation

To setup the connection, the user should configure the RS-232 connection

parameters in the Setup Configuration menu of the receiver. Steps to follow are

described below:

1.- Press ENT button to access to the main menu

2.- Using UP and DOWN arrows select Setup Configuration Menu and press ENT

button

3.- Move to line nº 10 Data options and press ENT button

In the submenu following parameters will appear:

1.- Ethernet: This option is currently locked

2.- RS-232: GPS/ Data out/ HyperTerminal

3.- Baud: 2400 – 115200bps. This parameter is locked to 4800bps when GPS

option is selected.

Once RS-232 parameter in the receiver is configured as HyperTerminal, the

receiver will allow the operator to control it remotely from a PC using the

HyperTerminal or a equivalent application. Baud rate should be the same in the

PC application and in the receiver.

The equipment is controlled remotely by a PC. RS-232 connection

Once the connection has been established between the receiver and the

computer in the HyperTerminal main window receiver’s status information will be

displayed.

-----------------------------------------“DR-120 Rev: 4.33 [ON]”

“SN: 485109902”

“Frequency: 2480,5MHz”

“BandW: 8MHz”

“TPS: 16QAM 3/4 1/16”

“PID: MANUAL”

“PMT PID: 1006”

“PCR PID: 1007”

Chapter 8: Remote Control via RS-232 Connection

47

“Vid PID: 2044”

“Au1 PID: 2048”

“Au2 PID: 2049”

------------------------------------------

There are several commands used to set or retrieve information from the

receiver. To each command the receiver will answer either with the required

information or with a message confirming that the parameter has been

configured properly.

All the commands that are sent to the receiver should end with the ‘ENTER’ key.

We will refer to it as ‘Enter’.

When the user types a single ‘Enter’ the receiver will respond:

-----------------------------------------“Command Error”

“Help + Enter for instructions”

------------------------------------------

There are several commands that must be typed before pressing ‘Enter’ key.

Each command indicates to the receiver to carry out a concrete action.

By typing ‘Help’ and pressing ‘Enter’ the receiver will display which commands

can be used and how does de operator have to type the instructions and

commands.

-----------------------------------------“Info + Enter”

“System=[on,off] + Enter”

“Frequency=xxxx,x + Enter”

“BandW=[5…8] + Enter”

“PID=[Auto, Manual] + Enter”

“[PMT, PCR, Vid, Au1,Au2]_PID=x +Enter”

------------------------------------------

These are standard commands; upon request more fields can be added.

a) INFO Command: The receiver will show the user main information

-----------------------------------------“SVP Broadcast Microwave”

“DR-120 Rev: 4.33 [ON]”

“SN: 485109902”

“Frequency: 2480,5MHz”

“BandW: 8MHz”

“TPS: 16QAM 3/4 1/16”

“PID: MANUAL”

“PMT PID: 1006”

“PCR PID: 1007”