Page 1

USER MANUAL

SVAN 977W

SOUND &

VIBRATION ANALYSER

Warsaw, February 2017

Copyright © 2017 SVANTEK. All rights reserved.

Page 2

2

SVANTEK 977W User Manual

Note: On account of continuous product improvement SVANTEK reserves the right to make

changes to product specifications without notice. To download the most up to date user's manual please visit

our web site at www.svantek.com.

This user’s manual presents the firmware revision named 1.26 and bootstrap revision named 1.06 (see the

Unit Label review to check version details).

The succeeding software revisions (marked with the higher numbers) can change the view of some displays

presented in the text of the manual.

WEEE Notice: Do not throw the device away with the unsorted municipal waste at the end of its life.

Instead, hand it in at an official collection point for recycling. By doing this you will help to preserve

the environment.

The software described in this manual is furnished under a license agreement and may be used only in

accordance with the terms of that agreement.

Copyright Notice

Copyright © 2016 Svantek Sp. z o.o.

All rights reserved.

Reproduction without permission is prohibited.

Trademarks

Trademarks or registered marks in this manual belong to their respective manufacturers.

Microsoft and Windows are registered trademarks of Microsoft Corporation.

The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc.

Disclaimer

Information in this document is subject to change without notice and does not represent a commitment on the

part of Svantek.

Svantek provides this document “as is,” without warranty of any kind, either expressed or implied, including,

but not limited to, its particular purpose. Svantek reserves the right to make improvements and/or changes to

this manual, or to the products and/or the programs described in this manual, at any time.

Information provided in this manual is intended to be accurate and reliable. However, Svantek assumes no

responsibility for its use, or for any infringements on the rights of third parties that may result from its use.

This product might include unintentional technical or typographical errors. Changes are periodically made to

the information herein to correct such errors, and these changes are incorporated into new editions of the

publication.

Technical Support Contact Information:

web: www.svantek.com

e-mail: office@svantek.com.pl

Page 3

3

SVANTEK 977W User Manual

CONTENTS

1. INTRODUCTION 7

1.1. SVAN 977W as Sound Level Meter & Analyser 8

1.2. SVAN 977W as Vibration Level Meter & Analyser 8

1.3. General features of SVAN 977W 8

1.4. Accessories included 8

1.5. Accessories available 9

1.6. Software options available 9

2. MANUAL CONTROL OF THE INSTRUMENT 10

2.1 Control push-buttons on the front panel 10

2.2 Input and output sockets of the instrument 13

3. INSTRUMENT SETTING 14

3.1. Basis of the instrument’s control 14

3.2. Powering of the instrument 16

3.3. Turning the instrument on 17

3.4. Description of icons 19

3.5. Data storage 20

3.1. Files downloading and uploading 24

4. FUNCTIONS OF THE INSTRUMENT – Function 25

4.1. Selection of the instrument mode – Mode 25

4.2. Measurement functions of the instrument - Measurement Function 25

4.3. Instrument’s calibration – Calibration 26

4.3.1. System Check 27

4.3.2. Calibration by Sensitivity in case of Acoustic signal 27

4.3.3. Calibration by Sensitivity in case of Vibration signal 28

4.3.4. Calibration By Measurement in case of Acoustic signal 29

4.3.5. Calibration By Measurement in case of Vibration signal 30

4.3.6. History of calibrations – Calibration History 31

4.3.7. Clear calibration records - Clear Calibr. History 31

4.3.8. Post measurement calibration – Post Calibration 32

5. MEASUREMENT PARAMETERS SETTING – Measurement 33

5.1 Setting the measurement parameters - General Settings 34

5.2 Setting the measurement trigger – Measurement Trigger 36

5.3 Setting parameters for profiles – Profiles 37

5.4 Setting of the data logging – Logging 38

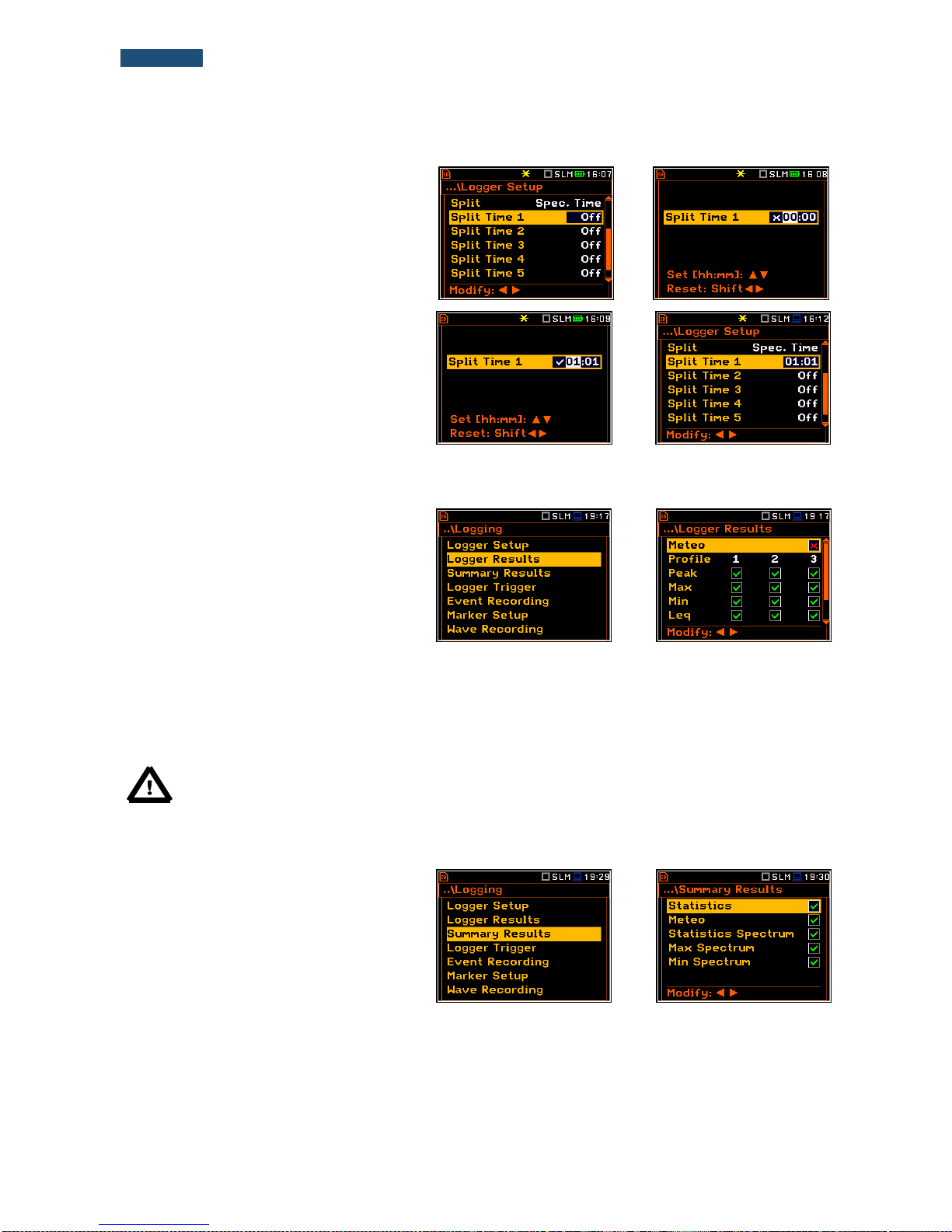

5.4.1 Setting the logger general parameters – Logger Setup 39

5.4.2 Selection of results for logging – Logger Results 41

5.4.3 Selection of summary results to be saved in the file – Summary Results 41

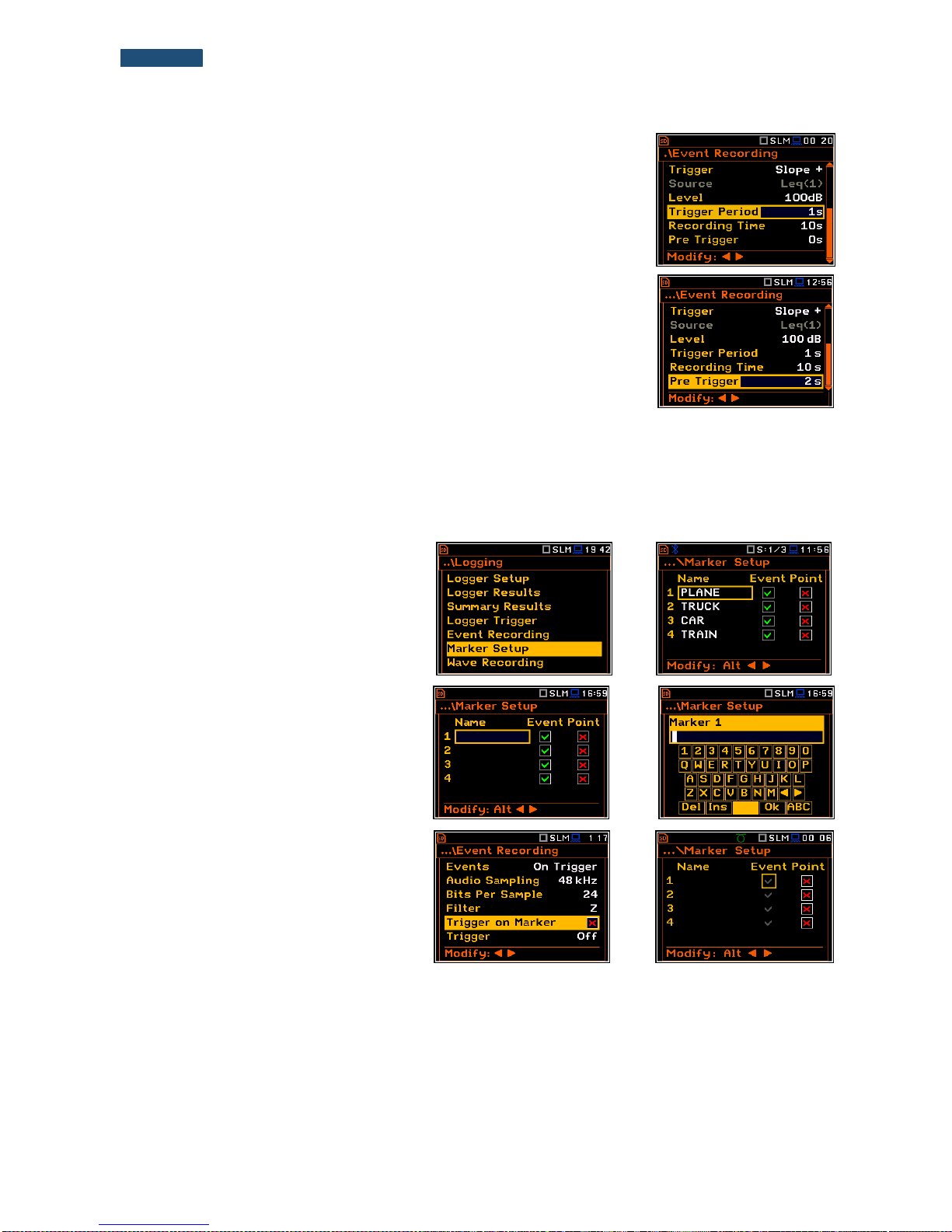

5.4.4 Setting the logger trigger parameters – Logger Trigger 42

Page 4

4

SVANTEK 977W User Manual

5.4.5 Setting the event recording – Event Recording 43

5.4.6 Setting the markers – Marker Setup 45

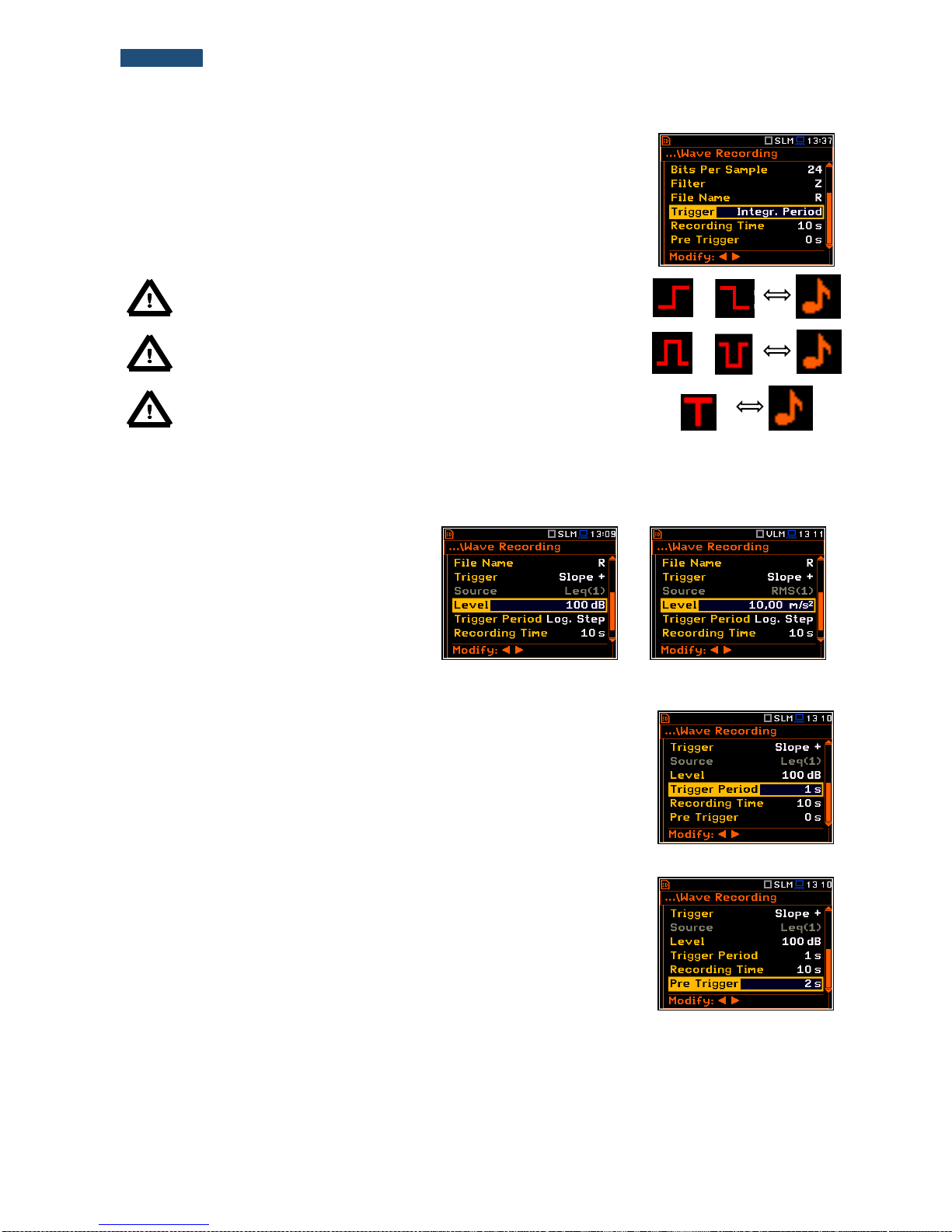

5.4.7 Setting the wave recording – Wave Recording 46

5.5 Setting the 1/1 Octave and 1/3 Octave spectra – Spectrum 48

5.6 Selection of the microphone compensation filters – Compensation Filter 48

5.7 Setting the measurement range – Range 48

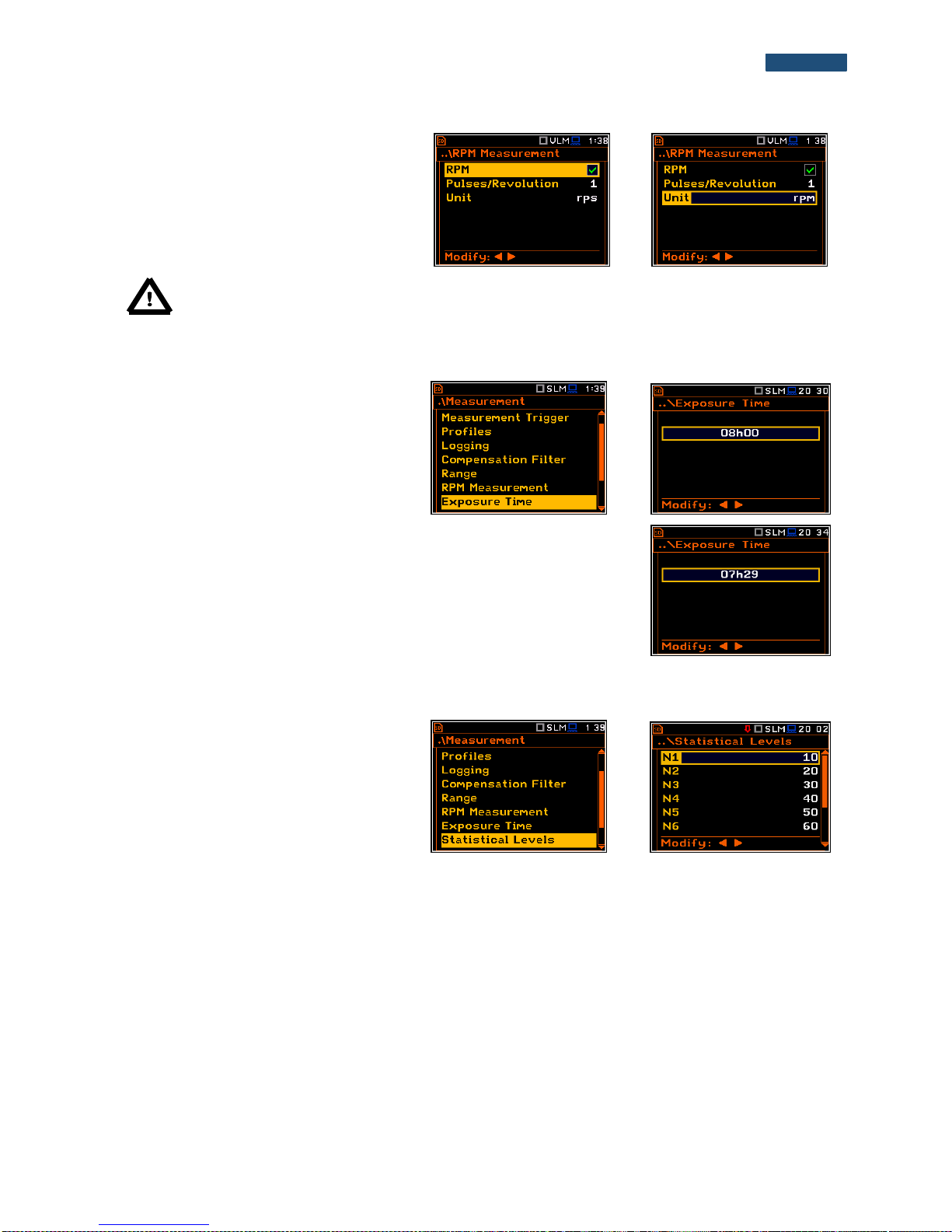

5.8 Setting the RPM measurements – RPM 49

5.9 Setting the exposure time - Exposure Time 50

5.10 Setting ten statistical levels - Statistical Levels 50

5.11 Programming the instrument’s internal timer – Timer 51

5.11.1 Example timer execution 52

5.12 Advanced alarm function - Alarms 52

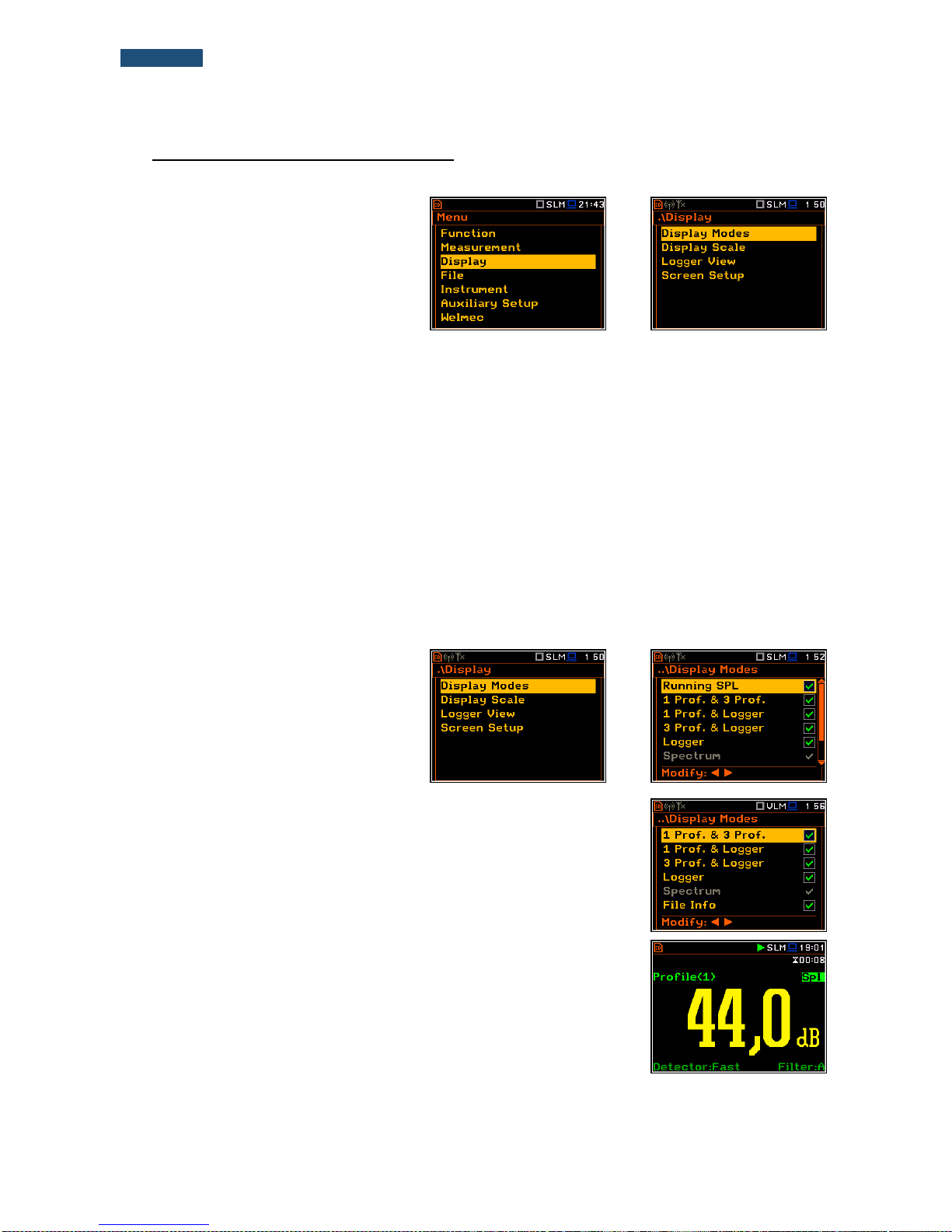

6. SETTING THE DATA VIEW – Display 53

6.1 Selection of the view modes - Display Modes 53

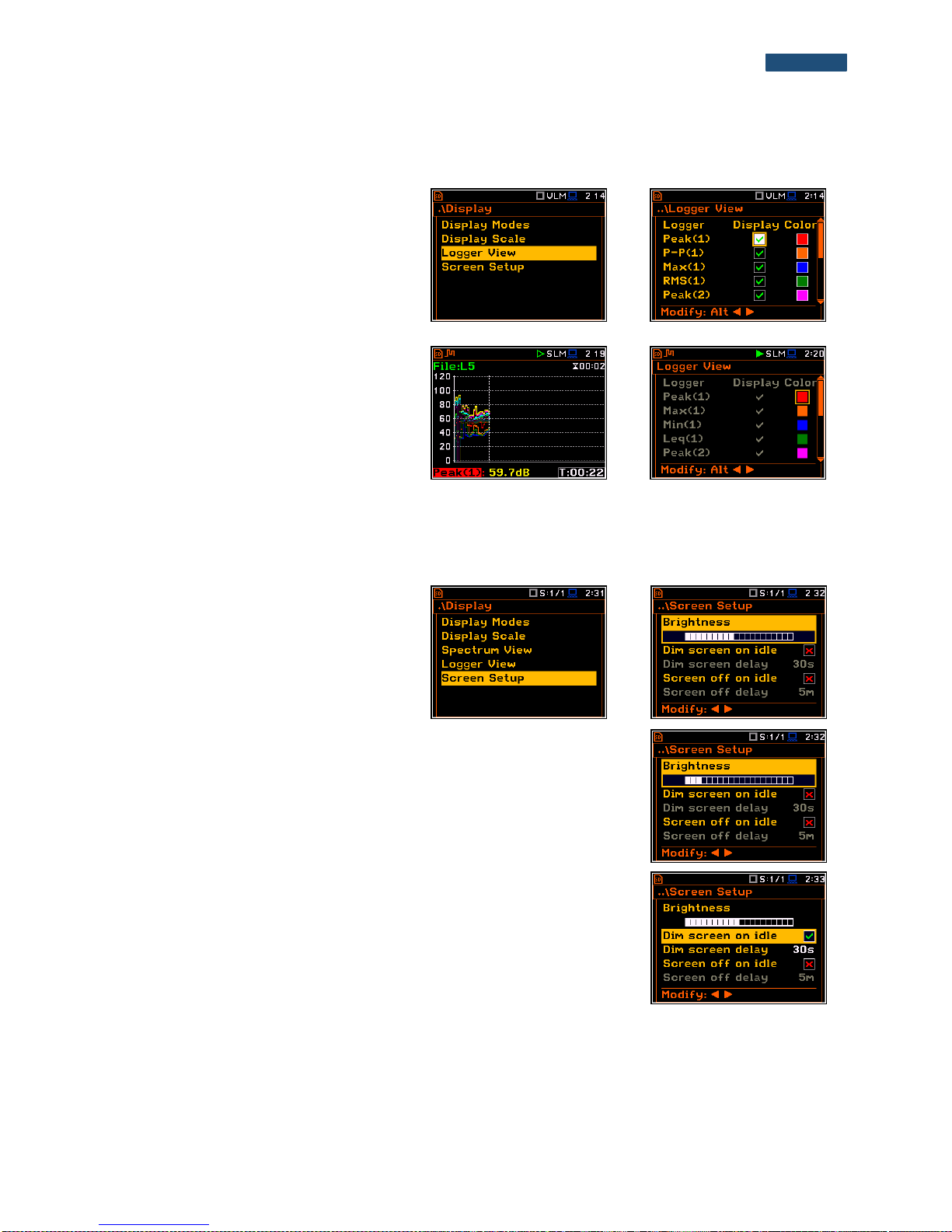

6.2 Setting the units and scale of result presentation - Display Scale 58

6.3 Setting view of the logger plot - Logger View 60

6.4 Setting the display brightness and power saver - Screen Setup 60

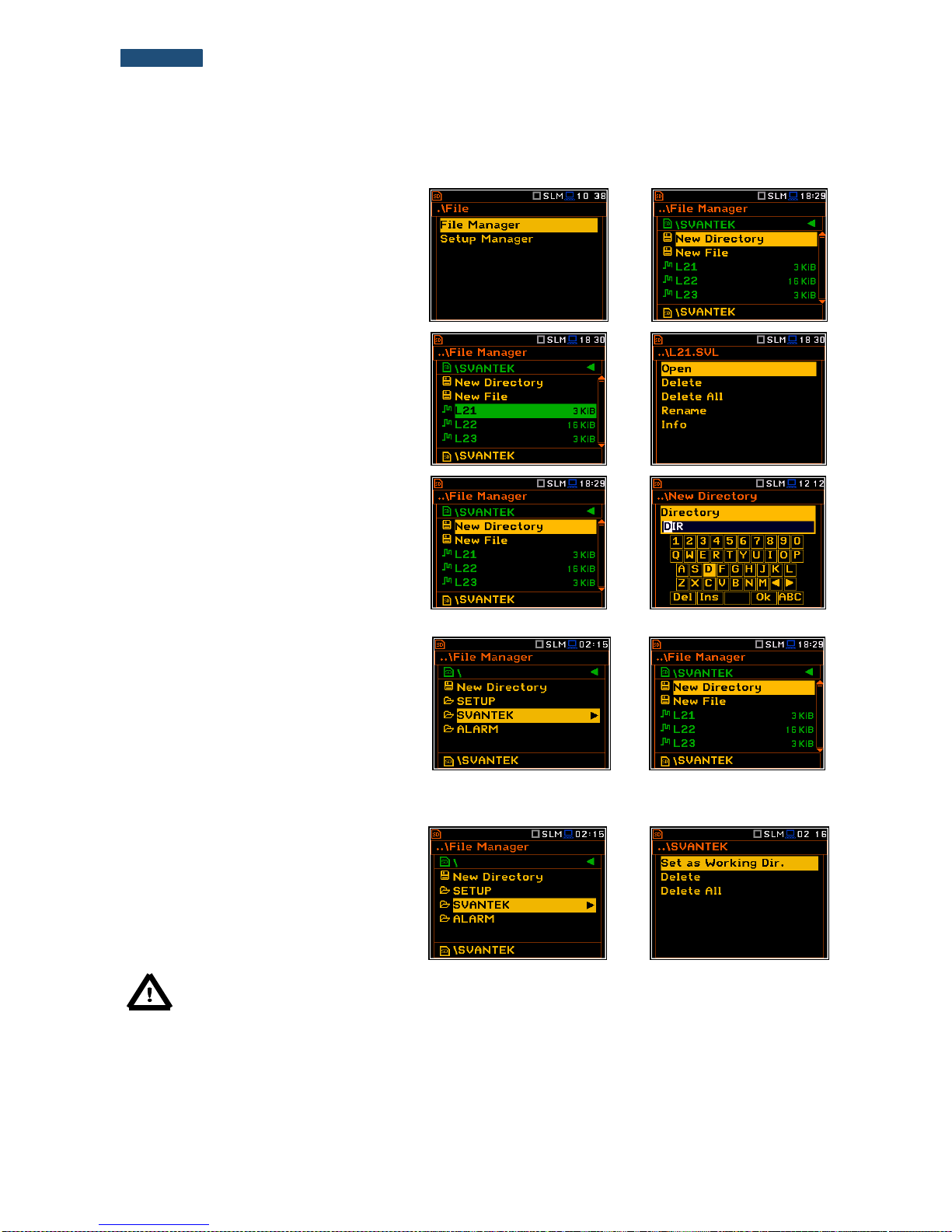

7. MANAGING THE FILES – File 62

7.1 Managing files saved in the external memory – File Manager 63

7.1.1 Assigning the directory for saved files – Set as Working Dir. 63

7.1.2 Opening file – Open 64

7.1.3 Deleting file/directory – Delete 64

7.1.4 Erasing all files in a directory – Delete All 64

7.1.5 Renaming files – Rename 65

7.1.6 Viewing information about files – Info 65

7.2 Managing the setup files – Setup Manager 65

8. SETTING THE HARDWARE PARAMETERS – Instrument 67

8.1. Measurement auto start - Auto Start 67

8.2. Checking the instrument powering – Battery 67

8.3. Setting the interface parameters - Communication Ports 68

8.4. Setting the external power parameters - External Power 69

8.5. Selection of the IEPE current supply - IEPE Current 69

8.6. Programming the keyboard – Keyboard Settings 69

8.7. Setting parameters of the I/O port - Multifunction I/O 70

8.8. Setting the instrument’s internal Real Time Clock – RTC 72

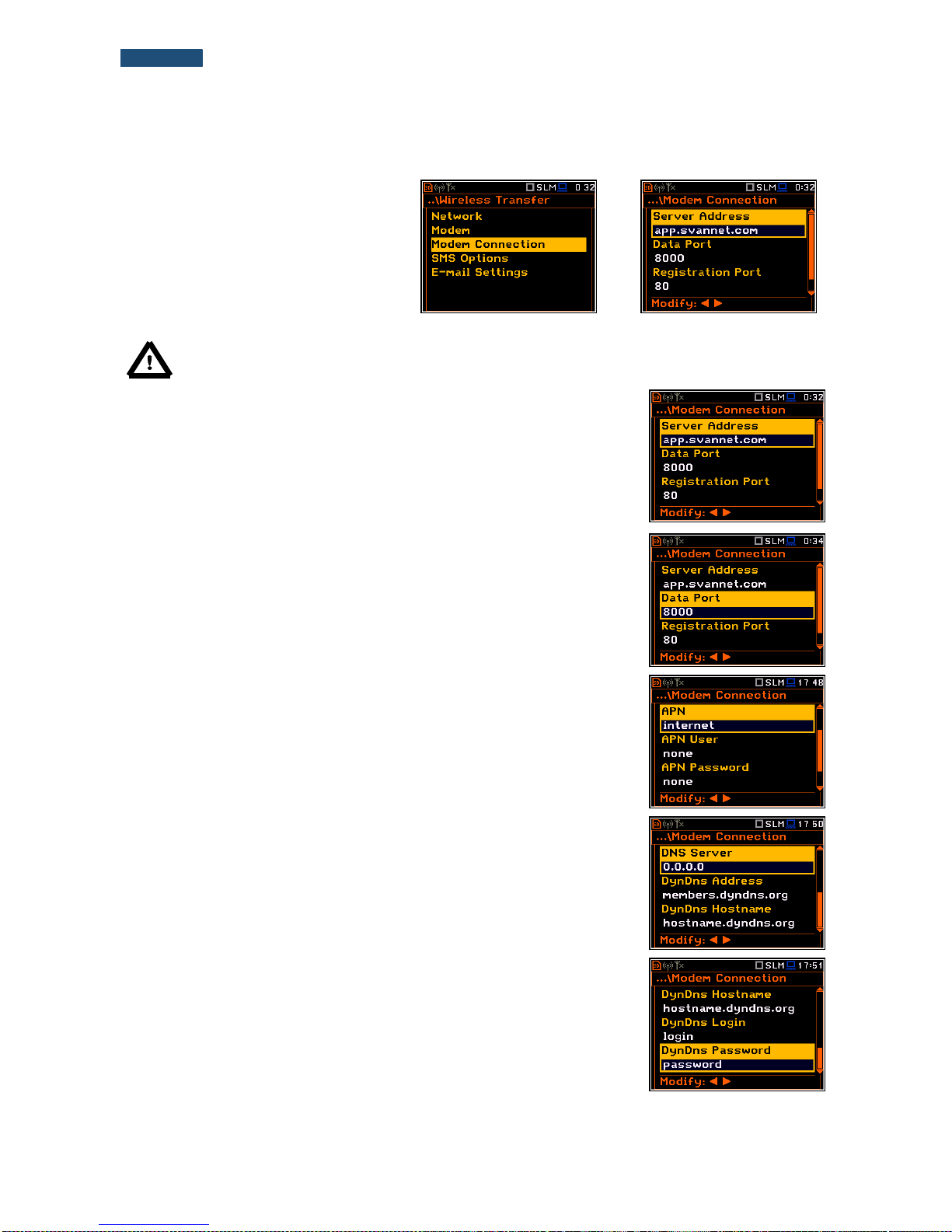

8.9. Setting the remote communication - Wireless Transfer 73

8.9.1. Selection of the network type – Network 73

8.9.2. Configuration of modem basic settings – Modem 73

8.9.3. Setting of support modem options - Modem Connection 75

Page 5

5

SVANTEK 977W User Manual

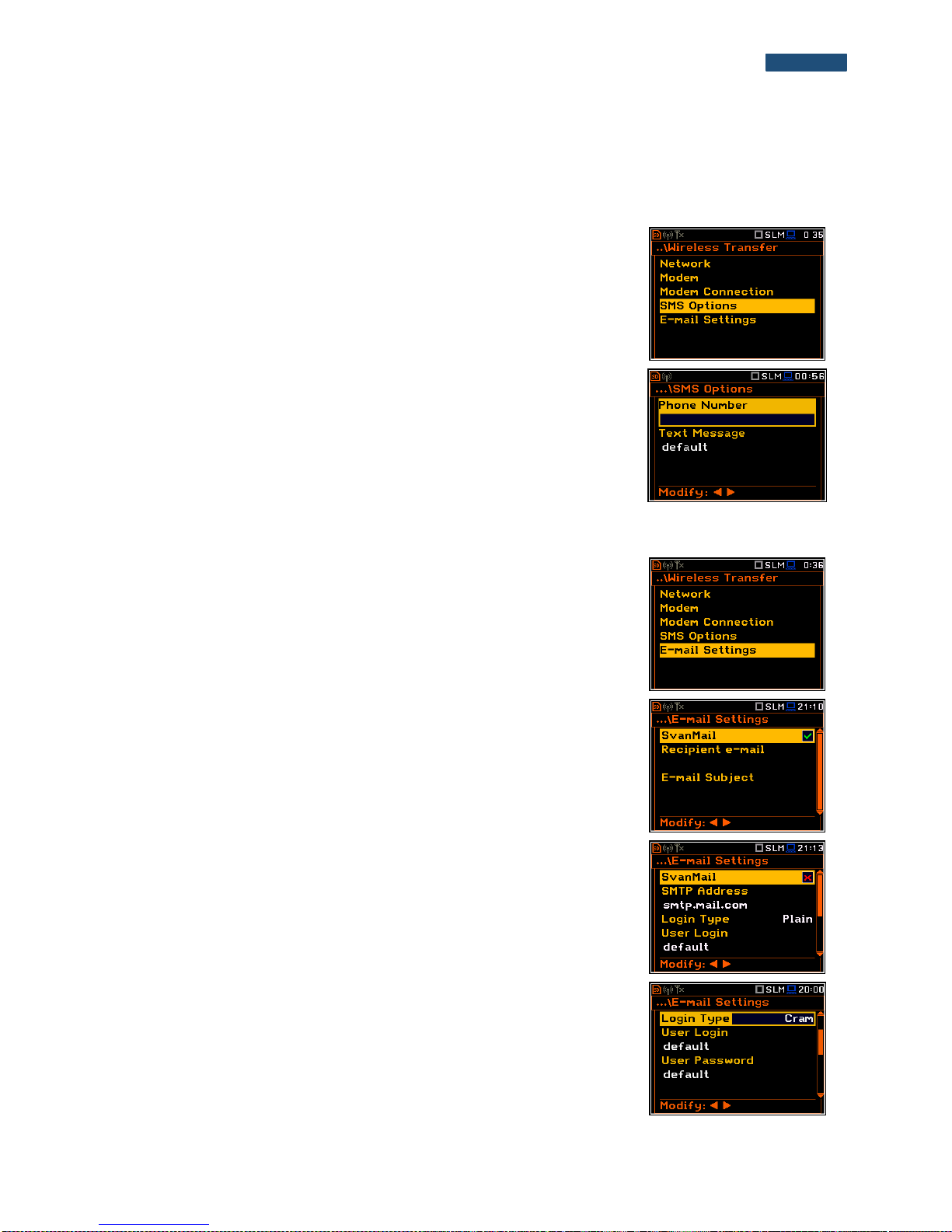

8.9.4. Configuration of SMS service - SMS Option 76

8.9.5. Configuration of e-mail service - E-mail Settings 76

8.10. Checking of the instrument specification - Unit Label 77

9. SETTING THE AUXILIARY PARAMETRS – Auxiliary Setup 78

9.1. Setting language of the user interface – Language 78

9.2. Restoring the factory settings – Factory Settings 78

9.3. Setting the reference levels - Reference Levels 79

9.4. Selection of the units for vibration results - Vibration Units 79

9.5. Warnings setup – Warnings 79

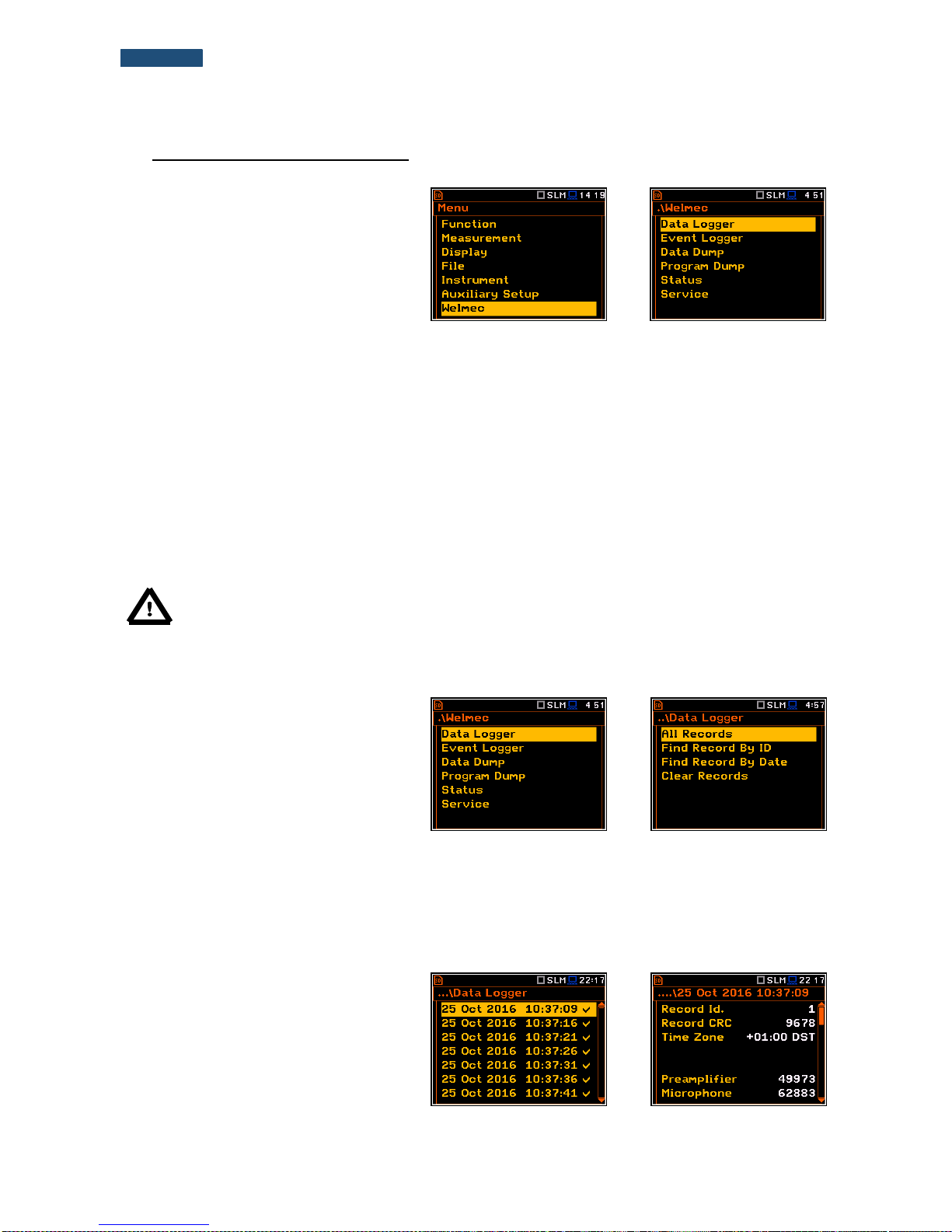

10. WELMEC SETTINGS – Welmec 81

10.1. Viewing data records – Data Logger 81

10.1.1. Viewing all data records – All Records 81

10.1.2. Selecting data records by ID – Find Records by ID 82

10.1.3. Selecting data records by date – Find Records by Date 82

10.1.4. Clearing all data records older than 2 years – Clear Records 83

10.2. Viewing event records – Event Logger 83

10.2.1. Viewing all event records – All Records 83

10.2.2. Filtering event records – Filter Records 85

10.2.3. Selecting event records by ID – Find Records by ID 85

10.2.4. Selecting event records by date – Find Records by Date 86

10.3. Data Logger dumping – Data Dump 86

10.4. Firmware memory dumping – Program Dump 86

10.5. Status of “welmec memory” – Status 87

10.6. Modification of Welmec related parameters – Service 87

10.6.1. Setting the real-time clock – RTC 87

10.6.2. Instrument calibration – Calibration 88

10.6.3. Setting the preamplifier serial number – Preamplifier 90

10.6.4. Setting the microphone serial number – Microphone 90

10.6.5. Repair registration – Register Repair 90

11. 1/1 AND 1/3 OCTAVE ANALYSER 91

11.1. Selection of the 1/1 Octave or 1/3 Octave functions 91

11.2. Setting the 1/1 Octave or 1/3 Octave analyser 92

11.2.1. Setting the measurement range for 1/1 Octave and 1/3 Octave - Range 92

11.2.2. Setting the parameters of 1/1 Octave and 1/3 Octave analysis - Spectrum 93

11.3. Saving the 1/1 or 1/3 Octave spectra as a time history – Logger Results 95

11.4. Setting the 1/1 Octave and 1/3 Octave spectra view 95

11.3.1. Presentation of 1/1 Octave and 1/3 Octave spectra 95

11.3.2. Setting scale of the spectrum plot - Scale 96

11.3.3. Selection of the spectra to be viewed - Spectrum View 97

Page 6

6

SVANTEK 977W User Manual

11.3.4. Selection of the spectrum type in Vibration mode - Spectrum Type 98

12. FFT ANALYSER 99

12.1. Selection of the FFT function 99

12.2. Setting the FFT analyser 99

12.2.1. Setting the measurement range for FFT - Range 100

12.2.2. Setting the parameters of FFT analysis - FFT 100

12.3. Saving the FFT spectra as a time history - Logger Results 101

12.4. Setting the FFT spectra view 101

12.2.3. Presentation of FFT spectra 102

12.2.4. Setting scale of spectrum plot - Scale 103

12.2.5. Selecting the spectrum types to be viewed - Spectrum View 104

12.2.6. Selection of the spectrum type in Vibration mode - Spectrum Type 104

13. REVERBERATION TIME MEASUREMENT - RT60 105

13.1. Selection of RT 60 function 105

13.2. Setting the RT60 analysis 105

13.3. Setting the RT60 view 108

13.4. Start RT60 measurements 108

13.5. Viewing of the RT60 results 110

14. MAINTENANCE 113

14.1. Powering the instrument 113

14.2. Memory card extraction and insertion 113

14.3. Transducers 114

14.4. Resetting the instrument 115

14.5. Firmware upgrade 115

14.6. Storing the instrument 116

14.7. Transportation and carrying 116

14.8. Cleaning 116

14.9. Troubleshooting 116

APPENDIXES

A. REMOTE CONTROL

B. DATA FILE STRUCTURES

C. TECHNICAL SPECIFICATIONS

D. DEFINITIONS AND FORMULAE OF MEASURED VALUES

H. REVERBERATION TIME

L. ADVANCED ALARMS

Page 7

7

SVANTEK 977W User Manual

1. INTRODUCTION

The SVAN 977W is an all-digital, Class 1 Sound & Vibration level meter (SLM

and VLM) as well as a real time 1/1 or 1/3 octave analyser. The instrument is

designed for general acoustic and vibration measurements, environmental

monitoring, occupational health and safety monitoring.

Three acoustic or vibration user configurable profiles allow parallel

measurements with independently defined frequency filters and RMS detector

time constants. Each profile provides significant number of results (like Spl, Leq,

Sel, Lden, LEPd, Ltm3, Ltm5, LN%, LR15, LR60, Ovl, Peak, Max and Min in

case of sound measurements or RMS, Ovl, Peak, P-P in case of vibration

measurements). Advanced time history logging for each profile provides

complete information about the measured signal using the external SD-card

fitted in the bottom of the meter and can be easy downloaded to any PC using

the USB interface and SvanPC++ software.

All required weighting filters: A, B, C, Z for sound measurements and HP1, HP3,

HP10, Vel1, Vel3, Vel10, VelMF, Dil1, Dil3, Dil10 and Wh for general vibration

measurements (like acceleration, velocity and displacement); are available with

this instrument.

Using the computational power of its digital signal processor the SVAN 977W

instrument can, simultaneously to the meter mode, perform the real time

1/1 Octave or 1/3 Octave analysis including calculations of statistical levels.

The instrument conforms the WELMEC requirements for built-for-purpose

measuring instrument (type P) for acoustic measurements.

Time domain waveform signal recording on the external SD-card is available as

an option and advanced trigger and alarm functions are available in the standard

version of this instrument.

A fast USB 1.1 interface (12 MHz) creates a real-time link for the PC "front-end" application of the SVAN 977W

instrument. With the use of optional interfaces (RS 232) the instrument can be remotely controlled from the PC

with the use of SvanPC++ software.

SVAN 977W is equipped with Bluetooth®1 v.2.0+EDR module and can be remotely control by the SvanMOBILE

Android platform smartphone application.

Working as a part of SV 277PRO monitoring station, equipped with 3G modem, SVAN 977W can transfer

measured data via Internet to the PC with the use of SvanPC++_RC option or via SvanNET Web service. The

instrument can be fully remotely controlled via these interfaces. The instrument has extended alarms features,

enables the user notification about exceeded threshold levels by SMS or mails.

The instrument is powered from four AA standard alkaline or rechargeable batteries (i.e. NiMH – a separate

charger is required). Powering the instrument from the External DC power source or the USB interface is also

possible.

Robust and lightweight design enhances the exceptional features of this new generation sound and vibration

instrument.

1

“The Bluetooth® word mark and logos are registered trademarks owned by Bluetooth SIG, Inc. and any use of such marks by

SVANTEK is under license. Other trademarks and trade names are those of their respective owners.

Page 8

8

SVANTEK 977W User Manual

1.1. SVAN 977W as Sound Level Meter & Analyser

noise measurements (Spl, Lmax, Lmin, Lpeak, Leq, Sel, Lden, LEPd, Ltm3, Ltm5 and 10 x LN%

statistics) in accordance with Type 1 IEC 61672-1:2013 accuracy in the frequency range 20 Hz to 20 kHz

with the SV 7052 microphone (3.15 Hz ÷ 20 kHz with GRAS 40AE microphone)

parallel Impulse, Fast and Slow detectors for the measurements with A, B, C and Z frequency filters

two measurement ranges 25 dB RMS(A) ÷ 123 dB Peak (Low) and 35 dB RMS(A) ÷ 140 dB Peak (High)

1/1 Octave and 1/3 Octave real time analysis - 10 filters with centre frequencies 31,5 Hz ÷ 16 kHz, and

31 filters with centre frequencies 20 Hz ÷ 20 kHz, in accordance with Type 1 IEC 61260-1: 2014.

1.2. SVAN 977W as Vibration Level Meter & Analyser

General Vibration measurements (acceleration, velocity and displacement) and optionally HVM meeting

ISO 8041:2005 and ISO 10816-1: 1995 standards in the frequency range depending on the parameters of

the attached accelerometer, i.e. with SV 80 general purpose transducer is equal to 0.5 Hz ÷ 14 kHz.

Parallel RMS, MTVV or Max, Peak, Peak–Peak measurements.

HP, HP1, HP3, HP10, Vel1, Vel3, Vel10, VelMF, Dil1, Dil3, Dil10 and Wh weighting filters.

1/1 Octave and 1/3 Octave real time analysis - 15 filters with centre frequencies 1 Hz ÷16 kHz, and 45

filters with centre frequencies 0.8 Hz ÷ 20 kHz, Type 1 IEC 61260-1: 2014.

1.3. General features of SVAN 977W

Conforms the WELMEC requirements for type P instrument for acoustic measurements

Advanced Data Logger function

1/1 octave band analyser on board

Time domain waveform signal recording (option)

Advanced trigger and alarm functions

USB 1.1 Client interface (real time PC "front end" application supported)

RS 232 interface

Bluetooth® v.2.0+EDR module

Integration time programmable up to 24 h

Power supply by four AA rechargeable or standard batteries

Hand held, light weight and robust case

Easy to use with menu driven user interface

1.4. Accessories included

SV 7052 prepolarised ½” microphone with nominal sensitivity 35 mV/Pa

SV 12L microphone preamplifier with IEPE power supply

SA 22 foam windscreen

SC 16 USB 1.1 cable

four AA alkaline batteries

SvanPC++ download and viewing software.

SC 77 output cable for I/O connector, Stereo Jack to 2 x BNC

Page 9

9

SVANTEK 977W User Manual

1.5. Accessories available

SA 277 outdoor protection Unit

SA 17A external battery pack using 6 x AA batteries

SA 143 carrying case for SVAN 95x and accessories (lightweight)

SA 79 carrying case for SVAN 9xx and accessories (waterproof)

SA 47 carrying bag for SVAN 95x and accessories (fabric material)

SV 55 RS 232 option for the SVAN 955

SV 80 general purpose vibration accelerometer 100 mV/g (10 mV/ms-2)

SC 27 coiled cable for accelerometer 2 m

SA 27/10-32 mounting magnetic base for accelerometer

SA 15 power supply

SA 31 external charger for four AA rechargeable batteries.

1.6. Software options available

SV 977_2 1/3 octave analysis for the SVAN 977W

SV 977_4 FFT analysis option for the SVAN 977W

SV 977_5 RT60 option for the SVAN 977W

SV 977_8 RPM Rotation measurement option (excluding Laser Tachometer) for the SVAN 977W

SV 977_15 Time domain waveform signal recording (to the micro SD card: *.srt or *.wav format) for

the SVAN 977W

Note: The software options for the instrument can be purchased at any time as only the introduction

of a special unlock code is required for their activation in a specific instrument. Contact your local

Svantek distributor for further information and costs for these options.

Page 10

10

SVANTEK 977W User Manual

2. MANUAL CONTROL OF THE INSTRUMENT

Control of the instrument has been developed in a fully interactive manner. The user can operate the instrument

by selecting the appropriate position from the selected Menu list. Thanks to that, the number of push-buttons for

control of the instrument has been reduced to nine for ease of use and convenience.

2.1 Control push-buttons on the front panel

The following control push-buttons are located on the front panel of the

instrument:

<ENTER>, <Menu>, <Save>,

<ESC>, <Cal.>, <S/P>,

<Shift>, [Markers]

<Alt>, [Markers]

▲,

◄,

►,

▼,

<Start/Stop>.

The name given in (...) brackets denotes the second push-button function which

is available after pressing it in conjunction (or in sequence) with the <Shift> push-

button. For the first two push-buttons the name given in square brackets […]

denotes also the third push-button function which is available after pressing it in

conjunction (or in sequence) with the <Alt> push-button.

<Shift>

The second function of a push-button (written in red colour on a push-button) can be

used when the <Shift> push-button is pressed. This push-button can be used in two

different ways:

as Shift like with a computer keyboard (e.g. while typing the filename); both

<Shift> and the second push-button must be pressed together (two finger

operation);

as 2nd Fun; this push-button can be pressed and released before pressing the

second one or pressed in parallel (while operating in “2nd Fun” mode, see the

following notice) with the second push-button (one finger operation).

The <Shift> push-button pressed in conjunction with <Alt> enables the user to activate

the Markers on the plots during the measurement.

<Alt>

This push-button enables the user to choose the third push-button function in case of

[<Save>] and [<Pause>] push-buttons. In order to select the third function the user must

press the <Alt> and the second push-button simultaneously.

Note: Simultaneously pressing the <Alt> and <Start/Stop> push-buttons switches the instrument on

or off.

<Start/Stop>

This push-button enables the user to start the measurement process when the

instrument is not measuring or to stop it when the instrument is in course of the

measurement. It is also possible to set the mode of this push-button such that in order

to start or stop the measurements the user has to press it simultaneously with the

<Shift> push-button. This can prevent accidentally starting or stopping a measurement

at the wrong time by just brushing against the Start/Stop button on its own.

Page 11

11

SVANTEK 977W User Manual

Note: Changing the <Start/Stop> push-button mode is performed in the Keyboard Settings window

of the Instrument list (see description of the Instrument list).

<ENTER>

This push-button enables the user to enter the selected position shown on the screen

Menu list or to confirm selected settings. Some additional functions of this push-button

will be described in the following chapters of this manual.

<Menu>

This push-button (<ENTER> pressed together with <Shift>) enables the user to enter

the main list containing seven sub-lists: Function, Measurement, Display, File,

Instrument, Auxiliary Setup and Welmec. Each of the above-mentioned menu lists

consists of sub-lists, elements and data windows. These main sub-lists will be described

in detail in the following chapters of the manual. Double pressing the <Menu> pushbutton enters a list containing the last eight opened sub-lists. It often speeds up the

control of the instrument as the user has faster access to the most frequently used sublists for easy navigation.

<Save>

This push-button (<ENTER> pressed together with <Alt>) enables the user to save the

measurement results (see description in chapter 3.5).

<ESC>

This push-button closes the control lists, sub-lists or windows. It acts in an opposite way

to the <ENTER> push-button. When the window is closed after pressing the <ESC>

push-button, any changes made in it are ignored in almost all cases.

<Cal.>

This push-button (<ESC> pressed together with <Shift>) opens the Calibration sublist.

<S/P>

This push-button (<ESC> pressed together with <Alt>) enables the user to pause or

break the measurement process temporarily during the measurement or to save the

setup file if the instrument is not running the measurement.

◄, ►

These push-buttons enable the user specifically to:

select the column in a multi column parameter list;

select the parameters value in an active position (e.g. filter Z, A, B or C, Start Delay

period: 1s, 2s, 3s, … etc.);

control the cursor in Spectrum, Logger and Statistics modes of result presentation;

select the position of the character in the text editing screen;

activate markers 2 and 3

speed up changing the numerical values of the parameters when pressed and held.

(◄, ►)

The ◄ or ► push-buttons pressed together with <Shift> enable the user specifically to:

change the parameters value with double step (e.g. Start Delay period: form 1s to

11s, 21s, … etc.);

to shift cursor from the first to the last position and back on the graphical view mode.

[◄, ►]

The ◄ or ► push-buttons pressed together with <Alt> enable the user specifically to:

select the parameters value in an active position in the matrix parameter list;

select the parameters value in an active position (e.g. filter Z, A, B or C, Start Delay

period: 1s, 2s, 3s … etc.);

insert or delete a character in the text edition screen.

▲, ▼

These push-buttons enable the user specifically to:

select line in the list;

select the active field on the result view screen;

select the correct character from the list in the text edition screen;

activate markers 1 and 4.

(▲,▼)

The ▲ or ▼ push-buttons pressed together with <Shift> enable the user specifically to:

shift the cursor from the first to the last position and back on the menu list;

Page 12

12

SVANTEK 977W User Manual

change the relationship between the Y-axis and X-axis of all plots presented on the

screen.

[▲,▼]

The ▲ or ▼ push-buttons pressed together with <Alt> enable the user specifically to:

change the mode of result presentation;

programme the Real-Time Clock (RTC) and Timer.

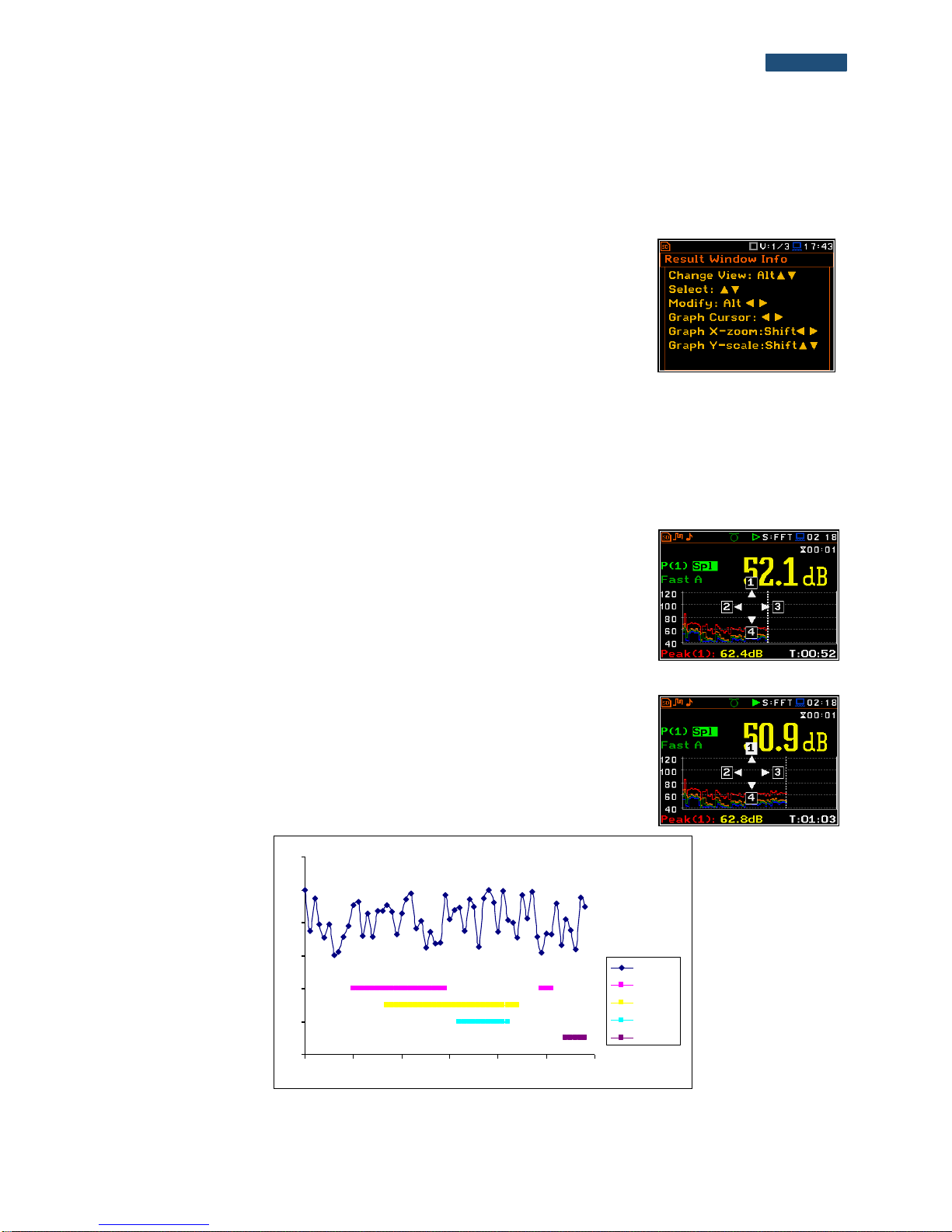

[Info]

The <Info> push-button (simultaneous pressing the ◄

and ► push-buttons) opens the window with the help

information in the measurement display modes. Press

<ESC> or <ENTER> to exit the Info screen.

<Markers>

The <Markers> push-button (<Alt> pressed together with <Shift>) enables the user to

mark special events, which occurred during the performed measurements (i.e. the

airplane flight, the dog barking, the train’s drive etc.). To activate the markers, the logger

should be switched on (path: <Menu> / Measurement / Logging / Logger Setup) and one

or more logger results (Peak, Max, Min, Leq for sound measurements or Peak, P–P,

Max, RMS for Vibration measurements) in profiles have to be activated (path: <Menu>

/ Measurement / Logging / Logger Results).

To enter the marker mode, the user must press <Shift> and <Alt> push-buttons

simultaneously during the measurement. Then four available markers appear on

the screen. To switch on marker number 1 the user must press ▲ push button

(number 2 - ◄, number 3 - ► and number 4 - ▼). Active marker number will be

highlighted. To switch off the marker the user should press the appropriate arrowbutton second time.

The markers disappear from the screen after pressing <Shift> and <Alt>, but

the status of markers doesn’t change. To continue working with the markers, the

user should press <Shift> and <Alt> again.

The current state of the markers is indicated in the logger file (cf. App. B for

details) and can be used to show them with the help of the dedicated presentation

software.

An example presentation of the markers on the time history plot is shown below

(to view a plot with markers the user should transfer data to the appropriate

software such as SvanPC++).

<Shift> / <Alt>

▲

20

30

40

50

60

70

80

13:30:00 13:30:09 13:30:17 13:30:26 13:30:35 13:30:43 13:30:52

Leq

Marker 1

Marker 2

Marker 3

Marker 4

Page 13

13

SVANTEK 977W User Manual

2.2 Input and output sockets of the instrument

Top cover of the instrument

The measurement input is placed in the centre of the instrument’s top cover. It is

the TNC compatible socket. The SV 12L microphone preamplifier has a specially

designed matching TNC plug and a locking screw to secure the preamplifier to

the meter body. The accelerometers must be connected to the instrument also

using the TNC connector. After connecting the preamplifier or the accelerometer

cable to the measurement input, the screw should be tightened to light resistance

only. Do not over tighten this connector. It is not necessary to remove this

preamplifier from the top of the instrument unless the meter is in a calibration

laboratory as it is always used close coupled to the meter body. The full

description of the signals connected to the socket is given in Appendix C.

Bottom cover of the instrument

In the bottom cover, there are four sockets, placed from the right to the left as

follows: 7-16V, Serial, USB and I/O.

There is a memory micro SD-card socket under the bottom cover of the

instrument and spaces for the 4 x AA batteries.

The USB socket is the USB Device 1.1 interface – a serial interface working with

12 MHz clock. Thanks to its speed, it is widely used in all PCs. In the instrument,

the standard 4-pin socket is used.

The Serial socket is Serial Port provides data transfer using RS232 data format

but in TTL logic standard by means of the SV 55 interface. It conforms to the EIA

Standard RS 232C and enables the user to programme remotely all instrument

functions and the transmissions to and from the instrument with speed from 300

bit/s to 115200 bit/s.

The additional multi-purpose input / output socket, called I/O, is a 3.5 mm jack

socket. On this socket, in case when the Analogue Output functionality is

selected, the signal from the input of the analogue / digital converter (before any

frequency correction) is available. This signal can be recorded using a magnetic

recorder or observed on an oscilloscope. The Digital Input as another

functionality that serves as the external trigger to the instrument, while the Digital

Output is used to generate the trigger pulse or alarm pulse from the instrument.

The user can connect an external DC power 7-16V adapter to the 7-16V socket

located on the bottom cover of the instrument. The current consumption depends

on the voltage of the power supplier.

There is a memory micro SD-card slot under the bottom cover of the instrument

and spaces for the 4 x AA batteries.

All sockets are described in detail in the Attachment C for this manual.

Note: Switch the power off before connecting the instrument to any other device (e.g. a Personal

Computer).

Page 14

14

SVANTEK 977W User Manual

3. INSTRUMENT SETTING

To perform measurements using the instrument the user only should connect the preamplifier with the

microphone already screwed on or the proper vibration transducer and to switch the power on by pressing the

<Alt> and <Start/Stop> push-buttons at the same time. Hold both buttons down for 1 or 2 seconds and release

to switch on.

3.1. Basis of the instrument’s control

The instrument is controlled by means of nine push-buttons on the keyboard. Using these push-buttons the user

can access all available functions and change the value of all available parameters. The functions are placed in

a system of lists and sub-lists.

The instrument's menu consists of different type of windows, which include: main menu list, sub-menu list, option

list, parameter list, text editor window, information window and file manager window with file command list.

Main menu

The main list contains the headers of six lists, which also contain sub-lists or

positions (elements). The main list is opened after pressing the <Menu> pushbutton. This list contains the following sub-lists: Function, Measurement,

Display, File, Instrument, Auxiliary Setup and Welmec (for Sound Meter

mode only).

Recent Items list

Double pressing the <Menu> push-button opens the list of recently accessed

menu items. This enables the user to access the most frequently used lists

quickly, without the necessity of passing through the whole menu path.

Position selection

The desired position in menu list is selecting

using the ▲ or ▼ push-buttons.

▼

Entering position

After selection of the desired position in the

menu list, the user should press the

<ENTER> push-button to enter it. After this

operation, a new sub-menu, option list,

parameter list or information window appears

on the display.

<ENT>

List of parameters

The parameter list contains parameters for which the user may select the value

from the available range. Pressing the <ENTER> push-button enables the user

to access the above mentioned sub-list.

The desired position in a list is accessed after pressing the ▲ or ▼ push-

button.

Page 15

15

SVANTEK 977W User Manual

Changing of the value in a selected position is performed by the ◄ or ►

push-buttons (or pressed together with <Shift>).

Option list

The option list consists of different choices, from which only one may be

selected. The selection of the option is performed as follows. The user should

highlight the desired option by means of the ▲ or ▼ push-buttons and then press

<ENTER>. This option becomes active and the list is closed. When the user reenters this list again, the last selected option will be marked.

If the parameter has a numerical value, the user may keep pressing the ◄ or ► push-buttons longer than 1

second to speed up the selection. In this case the parameter starts to change automatically until the user releases

the pressed buttons.

The user may change the numerical parameter value with a larger step (usually 10) by means of the ◄ or ►

push-buttons pressed together with <Shift>.

Matrix of parameters

When the list of parameters consists of more than one column the user may

change:

column by means of ◄ or ►

line in the same column by means of ▲ or ▼

value in a selected position by means of ◄ or ► with <Alt>

all values in the same column by means of ▲ or ▼ with <Shift>

all values in the same line by means of ◄ or ► with <Shift>.

Complex parameters

Some parameters like Start Hour, Start Day etc. are

complex (consisting of more than one value field).

The selection of values for such parameters is

performed in a special window, which is opened with

the ◄ or ► push-buttons. In the special window the

value is selected with the ◄ or ► or ▲ or ▼ pushbuttons and then confirmed by pressing <ENTER>.

In all cases the <ENTER> push-button is used for confirmation of the selection in a position and for closing the

opened sub-list. The sub-list is closed ignoring any changes made in the list by pressing the <ESC> push-button

and the user returns to the previous menu.

Information window

Some windows inform the user about the state of the instrument, available

memory, none existing files or loggers, standards fulfilled by the unit, etc. In order

to scroll through the list, the user has to use the ▲ or ▼ push-buttons. In order

to close such a window, the user has to press <ESC>.

Text editor window

In the text editor windows the user may edit text lines (file names, directory name

etc.) Such window contains the virtual keyboard to edit the text. The character

which is displayed inversely may be edited.

The user can select the position of the character in the virtual keyboard using

the ◄ or ► or ▲ or ▼ push-buttons.

►

Page 16

16

SVANTEK 977W User Manual

To change the uppercase to lowercase letters or symbols the user has to

select ABC button and press <ENTER>.

The user can insert, delete or change the position in the edited text using the

buttons of the keyboard: Ins, Del, ◄ and ►.

To confirm the editted name the user has to select Ok button and press

<ENTER>.

Help information

In most windows the last line or several lines at the bottom of the screen contain help information. It informs the

user how to select or modify the parameter’s value, change the character in the text line etc.

Inactive parameters

If some functions or parameters are not available, the positions in the menu or

parameter lists linked with this function or parameter became inactive (their

colour becomes grey). For example, if Logger (path: <Menu> / Measurement /

Logging / Logger Setup) is switched off, the Logger view mode is not active!

3.2. Powering of the instrument

The SVAN 977W can be powered by one of the following sources:

Four AA standard size internal batteries. In case of alkaline type, a new fully charged set can operate more

than 12 h (6.0 V / 1.6 Ah). Instead of the ordinary alkaline cells, four AA rechargeable batteries can be

used (a separate external charger is required for charging them). In this case, using the best NiMH type,

the operation time can be increased up to 16 h (4.8 V / 2.6 Ah)

External DC power source – 7 V DC÷16 V DC (1.5 W)

SA 17A external battery pack – operation time > 24 h (option)

USB interface – 500 mA HUB

For each of possible power source there is a different view presented in the Battery window of the Instrument

list.

When the instrument is powered from its internal batteries, the “Battery” icon is presented on the top line of the

display. When the voltage of the batteries is too low for reliable measurements, the icon is red or during attempt

to switch the instrument on the Low Battery! message occurs on the display for 2 seconds and the instrument

switches off by itself. A fully charged set of 4 batteries ensures more than 12 hours of continuous operation of

the instrument (with display Dim switched on). The battery condition can be checked by means of the Battery

function. It is also presented continuously on the top line of the display by means of the “Battery” icon.

When there is a connection to the USB interface (USB Device socket is

connected by means of the cable to a PC), the “computer” icon is presented

on the top of the display and in the Battery window there is the USB Power:

Voltage: x.xxV message.

When there is a connection to the 7–16V socket the “plug” icon is presented on

the top of the display and in the Battery window there is the External Power:

Voltage: yy.yyV message.

Page 17

17

SVANTEK 977W User Manual

When the instrument is powered from the

internal batteries the “battery” icon is

presented on the top of the display and the

Battery window presents the battery status

scale and battery voltage: Voltage: x.xxV. The

colour of the battery and the scale reflects the

battery capacity: green (>75%), yellow (>25%),

red (<25%).

►

To have right indication of the battery status the user should select the battery type in the Type position: Alkaline

or Rechargeable.

Note: In case when “Battery” icon is red it is strongly recommended to use an external power

adapter or USB interface as soon as possible to ensure reliable operation. If no suitable external

power source is provided the instrument will be switched off automatically after a short time!

Prolonging the internal source of the instrument’s power can be achieved by reducing the brightness of the

screen when possible. The settings of Brightness and power saver function may be done in the Screen Setup

window (path: <Menu> / Display / Screen Setup).

3.3. Turning the instrument on

Switching the instrument on

To switch the power on the user should press

the <Alt> and <Start/Stop> push-buttons at

the same time.

The instrument goes through the self-test

routine after switching on, displaying during

this time: manufacturer logo, name of the

instrument, program and bootstrap versions,

their CRC as well as preamplifier and

microphone serial numbers; and then it

enters:

the last used just before the unit switch

off view mode in case of Vibration

measurements or

the Running SPL view mode in case of

Sound measurements.

Starting measurement

To start the measurements the user should

press the <Start/Stop> push-button. The

measurement will be performed with the

current instrument settings, which are

preserved in the internal memory of the

instrument.

<Start>

Page 18

18

SVANTEK 977W User Manual

Setting the measurement parameters

The instrument as sold has default settings which the user may change, but

always return to them with the use of Factory Settings option in the

Auxiliary Setup menu.

Next chapters of the manual will describe in details what each parameter means

and how to change the instrument settings.

Main default settings

With default settings, the instrument will measure sound pressure level by virtual

meters, so called profiles (Measurement Mode: Sound;

Measurement Function: Level Meter) with 1 second delay from the <Start>

push-button pressure (Start Delay: 1 s), 1 minute integration time

(Integration Period: 00:01:00), infinitive repetition till press <Stop> push-button

(Repetition Cycle: Inf), linear integration (RMS Integration: Lin), free field

compensation (Compensation Filter: Free Field), active logging of the selected

results with 1 second step (Logger: On; Logger Step: 1 s; Logger Results:

Peak, Max, Min and Leq for all profiles) and summary results saving including

Statistics. Other functions are switched off like:

- measurement trigger (Measurement Trigger: Off),

- logger trigger (Logger Trigger: Off),

- event recording (Events: Off)

- wave recording (Wave Rec.: Off),

- timer (Timer Mode: Off).

The logger and summary results will be automatically saved in the file with the

name defined by the instrument and presented in the Logger Setup sub-list

(Logger Name: Lxxxx).

Default profile settings for Sound measurements:

Profile 1 - A weighting filter (Filter(1)=A), Fast RMS detector

(Detector(1)=Fast);

Profile 2 - C weighting filter (Filter(2)=C), Fast RMS detector

(Detector(2)=Fast);

Profile 3 - Z weighting filter (Filter(3)=Z), Fast RMS detector

(Detector(3)=Fast).

Default profiles settings for Vibration measurements:

Profile 1 - HP1 weighting filter (Filter(1)=HP1); 1.0s RMS detector

(Detector(1)=1.0s);

Profile 2 - HP3 weighting filter (Filter(2)=HP3), 1.0s RMS detector

(Detector(2)=1.0s);

Profile 3 - HP10 weighting filter (Filter(3)=HP10), 1.0s RMS detector

(Detector(3)=1.0s).

Page 19

19

SVANTEK 977W User Manual

3.4. Description of icons

Description of the instrument state

Additional information about the instrument’s state is given by

means of the row of icons visible in the top of the display.

The type of measurement function and the measurement mode

(SLM, VLM, S:1/1 etc.) as well as real time clock (RTC) is also

displayed in the same line together with icons.

The meanings of the icons are as follows:

“play” icon is displayed when the

measurement is running.

“memory warning” icon is displayed

when there is no external SD memory card

inserted.

“stop” icon is displayed when the

measurement is stopped.

“SD Card” icon is displayed when the

external micro SD card memory is

inserted.

“pause” icon is displayed when the

measurement is paused.

“RS232” icon is displayed when the

RS232 port is activated.

“computer” icon is displayed when there is

a successful USB connection with the PC.

“curve” icon is presented when the

current measurement results are logged

into the instrument’s logger file.

“note” icon is displayed when the wave

recording is active (wave files with extension

WAV are saved automatically)

“Trigger Level +” icon is displayed when

the “Level+” trigger is waiting for fulfilment

condition. The icon appears alternately

with the “play”, “curve” or “note” icons.

“arrow up” icon is displayed when overload

appears.

“Trigger Level –“ icon is displayed when

the trigger condition is set up to “Level-”

trigger is waiting for fulfilment condition.

The icon appears alternately with the

“play”, “curve” or “note” icons.

“arrow down” icon is displayed when under

range appears.

“Trigger Slope +” icon is displayed when

the “Slope+” trigger is waiting for fulfilment

condition. The icon appears alternately

with the “play”, “curve” or “note” icons.

“Alt” icon is displayed when the <Alt> push-

button is pressed.

“Trigger Slope –“ icon is displayed when

the “Slope-” trigger is waiting for fulfilment

condition. The icon appears alternately

with the “play”, “curve” or “note” icons.

“Shift” icon is displayed when the <Shift>

push-button is pressed.

“trigger” icon is displayed when other

than Level or Slope trigger is waiting for

fulfilment condition.

“lightning” icon is displayed when

polarisation voltage is 200V.

“bell’ icon is displayed when any alarm

appears

Page 20

20

SVANTEK 977W User Manual

“clock” icon is displayed when the timer is

On. It is active when the instrument is waiting

for the measurement start up to occur. When

the measurement start up is close, the icon

changes its colour to green and starts to blink.

“battery” icon is displayed when the

instrument is powered from the internal

batteries. Icon corresponds to the status of

the batteries (three, two, one or none

vertical bars inside the icon). When

voltage of batteries is too low, the icon

becomes red.

“satellite” icon is displayed when GPS is

active. Colours of the icon define the state of

the GPS: green – active, blue – searching,

grey – disconnected.

“Bluetooth” icon is displayed when the

Bluetooth® is switched on. Colours of the

icon define the state of the Bluetooth®:

blue – connected, grey – disconnected.

“plug” icon is displayed during external

power is connected to the 7-16V socket

icon is displayed if the current firmware is

different from the original one (which was

installed when the instrument has been

purchased)

Icons connected with modem functionality:

or

Icon is displayed when the GPRS function is

swithed on and there is no cable connection

with the modem

or

Icon is displayed when the GPRS function

is swithed on and there is no cable

connection with the modem

or

icon is displayed when the wireless

transmission (GPRS modem) is active, but

there is no connection with Host or SvanNET

or

icon is displayed if there is no GPRS

connection

or

icon is displayed if there is connection with

Host

icon is displayed if there is GPRS

connection and shows the level of the

GPRS signal. In additional GPRS

connection yellow and red arrows appear

icon is displayed if there is connection with

SvanNET.

3.5. Data storage

Memory type

All available measurement results and settings can be stored in the external memory (micro SD Card) as files in

the predefined or assigned directories. The setup files are stored in the predefined directory SETUP. The

predefined directories can be changed by the user or renamed.

The SD Card external memory is activated automatically after insertion of the card.

The “SD Card” icon is displayed when the external micro SD card memory is inserted in the memory

slot.

If the SD card is removed from the memory slot the “memory warning” icon appears instead of

“SD Card” icon.

The SD Card memory is organised as standard memory with directories and sub-directories (FAT32 file system).

It is possible to create and delete the directories.

The content of each memory file type can be checked with the help of the File Manager or Setup Manager

function of the File menu.

In the File Manager or Setup Manager

windows data files are described by their file

name with an extension (SVL, SVT or WAV)

as well as additional icon and size (2KB etc.).

Directory

Logger file .SVL

Page 21

21

SVANTEK 977W User Manual

New file or directory

Wave file .WAV

Setup file .SVT

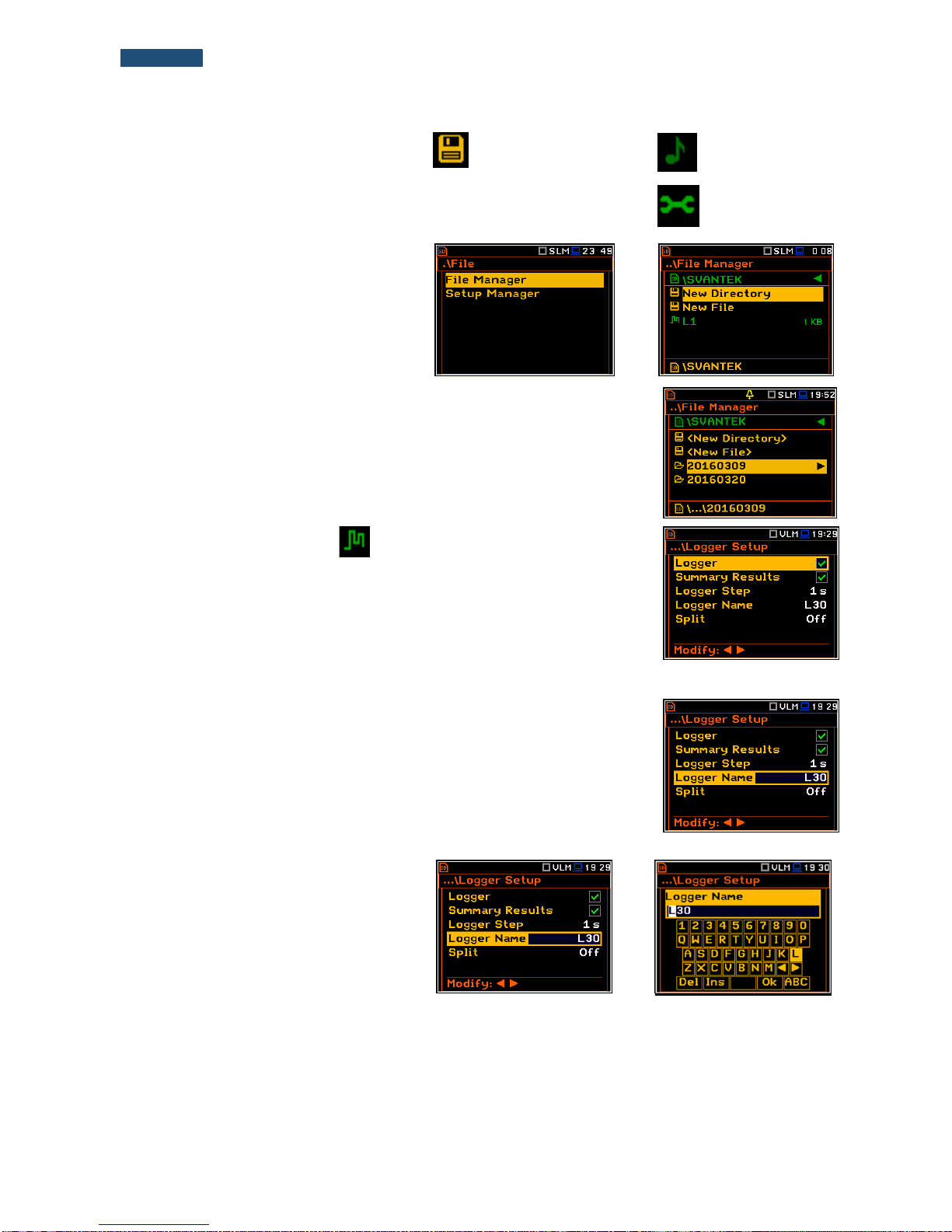

Managing directories and files

The user can manage the files saved on SD

card with the help of the File Manager or

Setup Manager function of the File menu.

<ENT>

The files are saved in the directory, which was set up as a working directory. The

working directory is displayed in the bottom line of the File Manager window

together with the memory icon.

Directories are created manually with the use of <New Directory> position.

In more details, File menu is described in chapter 7.

Automatic logger files saving

Files which contain the logger data are saved automatically in the SD Card

memory with an extension .SVL. To enable automatic saving several conditions

should be fulfilled:

1. SD card should be inserted and there should be enough space on it.

2. The Logger (path: <Menu> / Measurement / Logging / Logger Setup)

should be switched on.

The logger file name is defined automatically using a pattern LLdd, where LL is

the string of letters (so called prefix) and dd is a string of digits that forms a

number (path: <Menu> / Measurement / Logging / Logger Setup / Logger Name).

Up to 8 characters can be used to name a file.

The default prefix for the logger files is L.

The individual counter is assigned to every prefix of files the user has created

and saved in the working directory and is equal to the maximum number of these

files. So, the next saved file will always have a number higher than the counter.

The user can change the automatically

generated file name in the special screen,

which is opened after pressing the ◄ or ►

push-buttons.

If the user changes number of the name, the

instrument will accept only that names which

number is higher than the counter, assigned

to the file prefix.

After changing file name number and

pressing <Enter> the counter will be adjusted

to the new number.

►

The user can change the prefix. In such case the instrument assigns the new counter to the new prefix.

The file number automatically increases after every saving operation.

Page 22

22

SVANTEK 977W User Manual

The screens below show the automatic file saving during two subsequent measurements. Before and during first

measurement the file name L30 is displayed. This file is saved automatically in the SD card memory after the

measurement stop. After start of second measurement the instrument automatically changes the file name to

L31 and this file is saved after stop of the second measurement and so on.

<Start> <Stop> <Start>

Note: During the measurement run with data logging to the logger file the “curve” icon is displayed.

The user can quickly jump to the directory

where files were saved. To do this the user

should make the field with file name active by

means of ▲ or ▼ push-buttons and press

<Enter>.

<ENT>

If the user presses <Save> (<Alt>+<ENTER>) after the measurement the instrument opens the Logger Setup

window (path: <Menu> / Measurement / Logging / Logger Setup) with the selected Logger Name position and

the file name with the increased number. Pressing <Enter> will return the instrument to the measurement screen

with no results of the previous measurement and new file name in the file field.

<Save> <ENT>

Manual saving of Summary Results

If Logger or the Summary Results option is

switched off in the Logger Setup list (path:

<Menu> / Measurement / Logging /

Logger Setup) the automatic saving of result

data (so called Summary Results) is

switched off too. In such a case

Summary Results can be saved only

manually.

or

Note: If Logger is Off, the field with file name is empty!

There are two options for saving manually Summary Results data. One option is to press <Save> push-button

(<Alt>+<ENTER>) right after the measurement finishes. Another option is to create <New File> in the

File Manager.

Page 23

23

SVANTEK 977W User Manual

After pressing <Save> the New File window

appears with the predefined name which has

number increased by one to the latest saved.

In the New File window the user can enter a

new name for the file.

After edition of the automatically proposed

name, the user should select the Ok button

and press <ENTER>.

<Save>

File with the proposed or created by the user

name will be saved in the working directory

on the SD card.

<ENT>

Another option is to open the File Manager

window (path: <Menu> / File / File Manger),

select New File and press <ENTER>.

<ENT>

There is exception from this rule. If Logger

and Summary Results are switched on in

the Logger Setup list (path: <Menu> /

Measurement / Logging / Logger Setup) the

manual saving of Summary Results is

possible only through File Manager.

If the user press <Save> push-button after

the measurement the instrument opens the

Logger Setup window.

<Save>

Note: Saving is not possible when the instrument is measuring the signal. The message

“Measurement in progress!” is displayed for about 3 seconds.

Note: When no measurements were performed and there are no results to be saved all save

functions are disabled.

Automatic Wave files saving

Wave files contain signal recording data and are also saved automatically in the

SD Card memory with an extension .WAV. To enable automatic saving several

conditions should be fulfilled:

1. SD card should be inserted and there should be enough space on it.

2. The wave recording should be switched on (path: <Menu> / Measurement

/ Logging / Wave Recording / Wave Rec.: Continuous or On Trigger).

Page 24

24

SVANTEK 977W User Manual

The wave file name is defined automatically using the same rules as for the

logger files. The default prefix for the wave files is R.

Note: During the measurement run with wave recording to the wave file the “note” icon is displayed.

Note: The wave files usually are big and may use enormous memory space. Since the wave name

is not displayed on the result view screen, the user should remember that wave recording function is

active and switch it off always when wave recording is not required.

Saving the setup files

The measurement configuration setup files

can be stored in the SD Card memory with

an extension .SVT either by means of <S/P>

push-button or by creating the <New File> in

the Setup Manager list.

<S/P>

There is no automatic option for the setup

files saving, but the instrument always

generates new setup name automatically

with default prefix SET.

<ENT>

3.1. Files downloading and uploading

Downloading files

All files stored in the external memory (micro SD Card) can be downloaded to the PC. There are two ways to

download files.

First way is to extract the micro SD Card and use it directly in the PC.

Second way is to use SvanPV++ software, which enables the user download and upload functions as well as

data view and data processing options. In this case the instrument should be connected to the PC via SC 56

USB cable.

Note: Description of SvanPC++ is given in the “SvanPC++ User Manual”.

Uploading files

Same approach is used for uploading files (usually setup files).

Files can be upload via micro SD Card or via SvanPC++ software.

Page 25

25

SVANTEK 977W User Manual

4. FUNCTIONS OF THE INSTRUMENT – Function

To select the Function list, the user should

press the <Menu> push-button, select the

Function text and press <ENTER>. The

Function list contains three elements: Mode,

Measurement Function and Calibration.

<ENT>

4.1. Selection of the instrument mode – Mode

The device can work in two modes:

Sound Meter and Vibration Meter.

<ENT>

Note: In the manual text the Sound mode (or Sound measurements) refers to the Sound Meter

modes and the appropriate functions dedicated for the measurement and analysis of the acoustic

signal: Level Meter, 1/1 Octave, 1/3 Octave, FFT; the Vibration mode (or Vibration measurements)

refers to the Vibration Meter modes and the appropriate functions dedicated for the measurement

and analysis of the vibration signal: Level Meter, 1/1 Octave, 1/3 Octave, FFT.

4.2. Measurement functions of the instrument - Measurement Function

The main function of the instrument is the measurement of Sound pressure or Vibration broad band level

(Level Meter). The Sound Level Meter (SLM) function provides the user with functions meeting the standard

IEC 61672:2013 for Type 1 accuracy and the Vibration Level Meter (VLM) meeting the standard ISO 8041:2005.

The instrument can also be used for medium to the long-term acoustic monitoring using the huge capacity data

logger in which all the measurement results are stored.

The user may also use 1/1 and 1/3 real time octave band frequency analysis functions. These functions extend

the main Level Meter functionality of the instrument, because the selected 1/1 and 1/3 octave analysis is

performed together with all calculations of Level Meter.

To select the required function, the user

should enter the Measurement Function

list. After entering the

Measurement Function list, the set of the

available functions appears on the display:

Level Meter, 1/1 Octave, 1/3 Octave and

FFT (in case of Sound modes). The currently

active function is marked.

<ENT>

Note: The type of measurement function and the measurement mode is displayed in the upper line

of the screen.

- SLM Sound Level Meter,

- S:1/1 Sound 1/1 Octave,

- S:1/3 Sound 1/3 Octave,

- S:FFT Sound FFT,

- S:RT60 Sound RT60.

- VLM Vibration Level Meter,

- V:1/1 Vibration 1/1 Octave,

- V:1/3 Vibration 1/3 Octave,

- V:FFT Vibration FFT.

Page 26

26

SVANTEK 977W User Manual

Optional measurement functions that broaden the application of the instrument can be easily installed. These

options can be initially supplied by the manufacturer or purchased later and added by the user.

Note: It is not possible to change the measurement function during a measurement run. In this case

the instrument displays for about 3 seconds the message: “Measurement in Progress”. To change

the mode of the instrument the current measurement in progress must be finished!

4.3. Instrument’s calibration – Calibration

The instrument is factory calibrated with the supplied microphone for the standard environmental conditions.

Because the microphone sensitivity is a function of the temperature, ambient pressure and humidity, when the

absolute sound pressure level value is important, the absolute calibration of the measurement channel should

be performed. To select the calibration function, the user should enter the Calibration sub-list.

The Calibration sub-list consists of positions

which are used to perform the in-situ checks

and calibration (System Check,

Calibr. by Sensitivity,

Calibr. by Measurement), check the

calibration records (Calibration History) as

well as perform additional calibration after the

measurement session and add the results to

the file (Post Calibration).

<ENT>

To have access to the instrument’s

calibration (positions Calibr. by Sensitivity

or Calibr. by Measurement) in the

Sound Meter mode the user should have a

special right and know the Code to unlock

these positions.

<ENT>

Note: The new calibration factor for Sound Meter mode can be saved if it differs less than ±1.1 dB

from the factory one, or the last one defined by the authorised user and recorded in the Calibration

position (path: <Menu> / Welmec / Service / Calibration).

In the Vibration Meter mode, all calibration positions don’t require special

unlocking code. In addition to the Sound Meter mode there is one additional

position enabled the user to clear calibration records (Clear Calibr. History).

Note: The calibration factor is always added to the results and measurement range limits in the

Level Meter, 1/1 Octave, 1/3 Octave modes.

Note: It is advised to perform the system check of the instrument each time before the measurements

begin. If system check shows negative result, then it is necessary to perform calibration.

Note: The calibration level and the calibration result are expressed in different units depending on

the settings of the instrument. The metric or non-metric Vibration units are set in the Vibration Units

window (path: <Menu> / Auxiliary Setup / Vibration Units). Additionally, the linear or logarithmic units

are set in the Display Scale window (path: <Menu> / Display / Display Scale).

Note: It is not possible to check and calibrate the instrument during the execution of live

measurements. It is possible to open different lists and sub-lists but the positions in these lists are

displayed greyed out inversely and so - not accessible. The flashing “►” icon on the top line indicates

Page 27

27

SVANTEK 977W User Manual

that the instrument is in the measurement process. To change the sensitivity, the current

measurement in progress must be finished!

4.3.1. System Check

ISO 8041 standard advises users to perform in-situ checks of measurement

instrumentation. Checking should be carried out immediately before and after

measurements are made.

1. Select System Check in the Calibration sub-list and press the <ENTER>

push-button.

2. Select the calibrator signal level.

3. Attach the vibration calibrator to the instrument’s accelerometer.

4. Switch on the calibrator and wait approximately 30 seconds before starting

the system check measurement.

5. Start the calibration measurement by pressing the <Start/Stop> push-button.

The measurement starts after 5 second delay. The system check measurement

time is also predefined to 5 seconds. During the calibration period the <ESC>

and <Pause> push-buttons do not operate but it is possible to stop the

measurement using the <Start/Stop> push-button. Waiting for the calibration

measurement to begin, a Delay is counted down.

Measurement results in relationship with calibrator level will be compared against

current calibration factor and the instrument will assess whether the system

check was successful or failed, displaying relevant message together with

current calibration factor and measured calibration.

System check is considered successful in case its result is not more than 2 dB

different than the current calibration factor.

Press <ENTER> to exit System Check.

If system check measurement shows bigger difference than 2 dB the user should

manually stop the measurement with the <Start/Stop> push-button.

4.3.2. Calibration by Sensitivity in case of Acoustic signal

Calibration by using the microphone’s

published sensitivity information can be

performed in the following way:

1. Select the Calibr. by Sensitivity position

in the Calibration sub-list and press the

<ENTER> push-button.

<ENT>

Page 28

28

SVANTEK 977W User Manual

2. Set the sensitivity of the microphone taken

from its calibration certificate using the

<Shift> with ◄ or ► push-buttons and

then press <ENTER>.

After pressing the <ENTER> push-button and

confirmation by selecting Yes in the screen

with answer “Are you sure?” the calibration

factor is calculated, in relation to the nominal

value of 35.0 mV / Pa.

<ENT>

To avoid the calculation, the user should select No in the screen with answer “Are you sure?”.

For a microphone with sensitivity higher than 35.0 mV / Pa the calibration factor

will always be negative.

For a microphone with sensitivity lower than 35.0 mV / Pa the calibration factor

will always be positive.

The lowest available value of the sensitivity that can be introduced is equal to

35.0 µV / Pa (it conforms to the calibration factor equal to 60.0 dB) and the

highest value is equal to 35.0 V / Pa (calibration factor is equal to -60.0 dB).

If the new calibration factor differs more than

±1.1 dB from the factory one, or the last

changed by the authorised service, the

instrument will not save it.

A special warning will appear on the screen.

<ENT>

To return to the Calibration sub-list, the user should press the <ESC> push-button.

4.3.3. Calibration by Sensitivity in case of Vibration signal

The calibration by using the accelerometer’s published sensitivity information

can be performed in the following way:

1. Select the Calibr. by Sensitivity position in the Calibration sub-list and

press the <ENTER> push-button.

2. Set the sensitivity of the accelerometer taken from its calibration certificate

using the <Shift> with ◄ or ► push-buttons and then press <ENTER>.

After pressing the <ENTER> push-button and confirmation by selecting Yes in

the screen with answer “Are you sure?” the calibration factor is calculated in

relation to the nominal value of 10.0 mV / ms-2.

To avoid the calculation, the user should select No in the screen with answer

“Are you sure?”.

Page 29

29

SVANTEK 977W User Manual

For an accelerometer with sensitivity higher than 10.0 mV / ms-2 the calibration

factor will always be negative.

For an accelerometer with sensitivity lower than 10.0 mV / ms-2 the calibration

factor will always be positive.

The lowest available value of the sensitivity that can be introduced is equal to

10.0 µV / ms-2 (it conforms to the calibration factor equal to 60.0 dB) and the

highest value is equal to 10.0 V / ms-2 (calibration factor is equal to -60.0 dB).

4.3.4. Calibration By Measurement in case of Acoustic signal

Calibration by measurement for the sound measurements can be done in the

following way:

1. Select the calibration by measurement (highlight the

Calibr. by Measurement text) from the Calibration sub-list and press the

<ENTER> push-button.

2. Set the calibration level appropriate to the used calibrator.

3. Attach the acoustic calibrator SV 30A (or equivalent 114 dB / 1000 Hz)

carefully over the microphone of the instrument.

Note: It is also possible to use an electro-mechanical pistonphone, which generates a signal (ca

124 dB) or different type of acoustic calibrator dedicated for ½” microphones. In any case, before

starting the calibration measurement, the user has to set the level of the signal generated by the given

calibrator (Cal. Level position of Calibr. by Measurement sub-list), which is stated in the calibration

certificate of the unit (the value of the Cal. Level set by the manufacturer of SVAN 977W is equal to

114 dB). It is also necessary to switch the instrument Range to the High level setting.

4. Switch on the calibrator and wait approximately 30 seconds for the tone to

stabilise before starting the calibration measurement.

5. Start the calibration measurement by pressing the <Start/Stop> push-button.

The calibration delay time is set to 3 seconds

Waiting for the start of the measurement the

Delay is counted down on the display. After

the end of the measurement, the result is

displayed in the bottom line. The

measurement is running until the user

presses the <Start/Stop> push-button.

….

6. Press the <ENTER> push-button to

accept the calibration measurement

result, or <Esc> to exit without saving.

The calibration factor is calculated, stored

and displayed (cf. next Figure) after pressing

the <ENTER> push-button and confirmation

(Are you sure? Yes).

<ENT>

Page 30

30

SVANTEK 977W User Manual

It is recommended to repeat the calibration measurement a few times to ensure the integrity of the calibration.

The obtained results should be almost identical (with ±0.1 dB difference). Some possible reasons for unstable

results are as follows:

the calibrator is not properly attached to the instrument,

there are external acoustic disturbances such as high noise levels close by,

the calibrator or the measurement channel (the microphone, the preamplifier or the instrument itself)

are damaged.

Note: During the calibration measurement, any external disturbances (acoustic noise or vibrations)

should not exceed a value of 100 dB (when using a calibrator that generates a level of 114 dB).

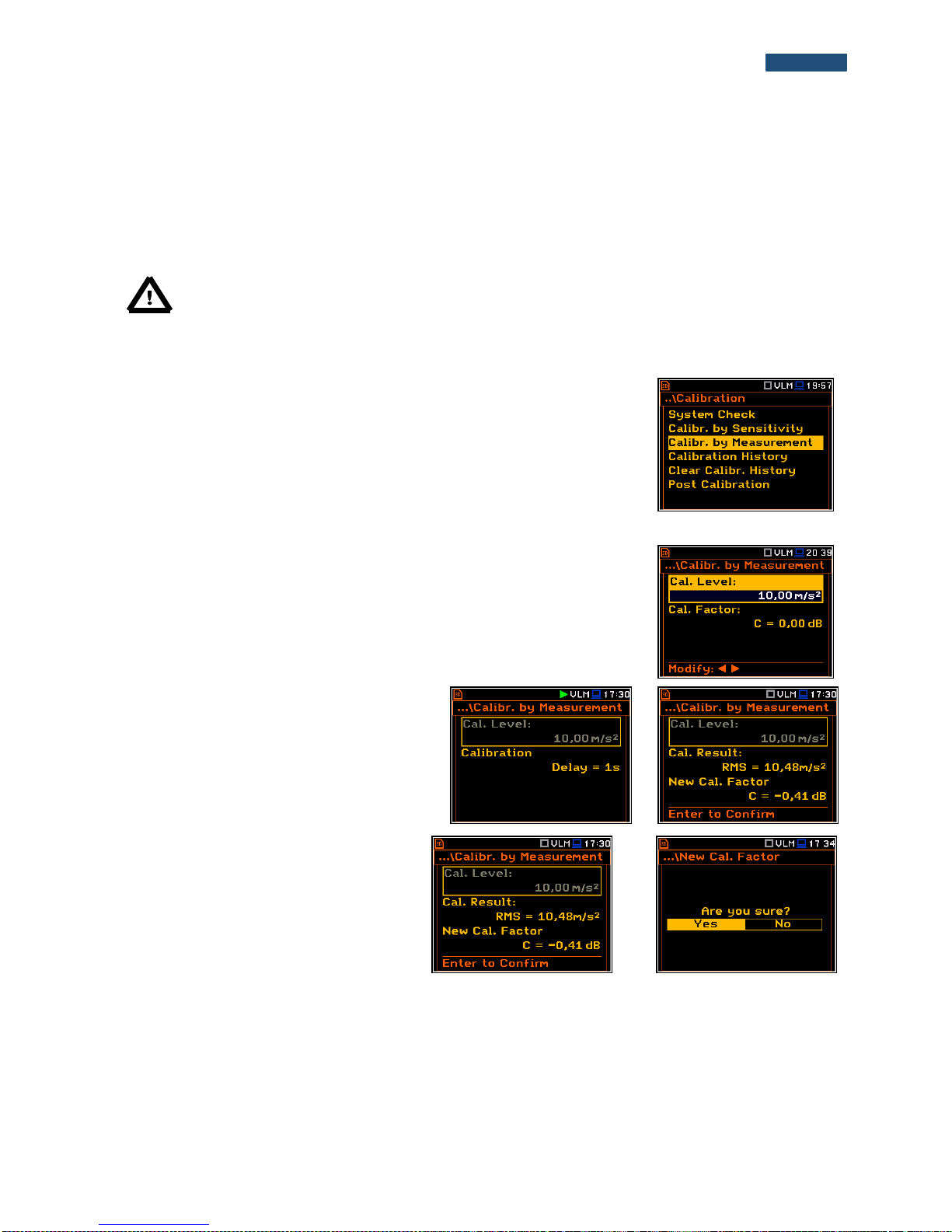

4.3.5. Calibration By Measurement in case of Vibration signal

Calibration by measurement for the vibration measurements can be done in the

following way:

1. Select the calibration by measurement (highlight the

Calibr. by Measurement text) from the Calibration sub-list and press the

<ENTER> push-button.

2. Set the calibration level appropriate to the used calibrator. The default level

for calibration in the vibration mode is 10 m/s2 at 159.2 Hz. Remember to

change this level if using an alternative vibration calibration signal source.

3. Attach the instrument’s accelerometer to the vibration calibrator using an

appropriate or recommended fixing method.

4. Switch on the calibrator and wait approximately 30 seconds before starting

the calibration measurement.

5. Start the calibration measurement by pressing the <Start/Stop> push-

button.

The calibration measurement starts after

3 second delay. Waiting for the calibration

measurement the Delay is counted down on the

display. The measurement lasts 5 second. After

the end of the measurement, its result is

displayed in the bottom line.

….

6. Press <ENTER> to accept the

measurement result, or <Esc> to exit

without saving.

The calibration factor is calculated, stored

and displayed after pressing the <ENTER>

push-button and confirmation (Are you

sure? Yes).

<ENT>

It is recommended to repeat the calibration measurement a few times to ensure the integrity of the calibration.

The obtained results should be almost identical (with ±0.1 dB difference). Some possible reasons for unstable

results are as follows:

the accelerometer is not properly attached to the calibrator,

there are external disturbances,

the calibrator or the measurement channel (the accelerometer or the instrument itself) are damaged.

Page 31

31

SVANTEK 977W User Manual

Note: During the calibration measurement, the external disturbances (vibrations or acoustic noise)

should not exceed a value of 1/10 of the level of the calibration level signal being used.

4.3.6. History of calibrations – Calibration History

The Calibration History window displays

records of performed calibrations. To review

the calibration records, the user should select

the required line in the Calibration History

window and press <ENTER>.

<ENT>

The window contains the required information

regarding the performed calibration.

Calibration records are a part of the event

records in the Welmec menu (path: <Menu>

/ Welmec / Event Logger / All Records) and

are a part of the Parameter Change group of

records.

▼

In case of Vibration Mode, the

Calibration History window has different

content, because no WELMEC requirements

is applied to the Vibration Meter mode.

<ENT>

4.3.7. Clear calibration records - Clear Calibr. History

The user can clear all stored vibration calibration records. In order to do this the

user has to choose the position Clear Calibr. History in the Calibration sub-list

and press <ENTER> to perform this operation.

The instrument requests the confirmation of the operation. The next pressing of

the <ENTER> push-button, when the No option is selected, closes the window

and returns the instrument to the Calibration sub-list.

After this operation, the Calibration History window will not contain any

previous calibration records. The content of this window is also cleared after the

Factory Settings operation.

Note: The acoustic calibration history can be cleared only by authorised person, which possess the

special rights and unlocking code to enter the Service menu (path: <Menu> / Welmec / Service).

Page 32

32

SVANTEK 977W User Manual

4.3.8. Post measurement calibration – Post Calibration

Sometimes it is required to perform so called

post-calibration of the instrument. Position

Post Calibration enables the user to perform

additional calibration after a measurement

session and add the results to the file saved

in the memory. The Post Calibration list

includes three options for saving postcalibration results: not to save (Off), save in

the last file (Last file) or save in the files

which will be created after the last calibration

(Files after last calibr).

<ENT>

Page 33

33

SVANTEK 977W User Manual

5. MEASUREMENT PARAMETERS SETTING – Measurement

The Measurement list contains the elements

that enable the user to set the measurement

parameters. To open the Measurement list,

the user should press the <Menu> pushbutton, select the Measurement text and

press <ENTER>.

<ENT>

The Measurement list contains the following items:

General Settings enables the user to set various general measurement parameters;

Measurement Trigger enables the user to set up the measurement trigger;

Profiles enables the user to program the profile parameters;

Logging enables the user to program the logging function;

Spectrum enables the user to set spectrum parameters;

Compensation Filter enables the user to switch on required microphone compensation filter;

Range enables the user to set the correct measurement range;

RPM Measurement enables the user to set the RPM measurements parameters;

Exposure Time enables the user to set the daily exposure time for dose results;

Statistical Levels enables the user to define 10 statistical levels;

Timer enables the user to program the internal timer;

Alarms enables the user to check the enable ability of alarm function.

The content of the Measurement list is different for

different Mode and Measurement Function and

other settings. Some examples for different modes

and measurement functions are presented.

Any parameter in the Measurement list can be changed only when the

instrument is not currently executing a measurement. The parameters are

displayed with grey colour. The blinking “►” icon on the top row indicates that

the instrument is performing a measurement.

Page 34

34

SVANTEK 977W User Manual

5.1 Setting the measurement parameters - General Settings

The General Settings list consists of the following

parameters: the delay of the start of measurements

(Start Delay), the maximum delay period for the

synchronization with RTC (Start Sync.), the

integration period / measurement run time

(Integration Period), the repetition of the

measurement cycles (Repetition Cycles), the

RMS detector type (RMS Integration) and the

intervals for day time period (Day Time Limits) in

case of Sound modes.

Time delay before the measurement start

The Start Delay position defines the delay period from the moment the

<Start/Stop> push-button is pressed to the start of the actual measurements

(the digital filters of the instrument constantly analyse the input signal even when

the measurement is stopped). This delay period can be set from 0 second to

60 seconds (with 1 second step by means of the ◄ or ► push-buttons and with

10 second step by means of the ◄ or ► push-buttons pressed together with

<Shift>).

Note: The minimum delay period is equal to 0 second. In the Calibration mode, the delay period is

always equal to 3 seconds.

Synchronisation of the measurement start

The Start Sync. position defines maximum delay period from pressing the

<Start/Stop> push-button to the start of the measurements to allow

synchronisation with the instrument’s RTC. The Start Sync. parameter can be

set as: Off, 1m, 15m, 30m and 1h. For example, if 1h was selected, then each

measurement starts from the first second of next real time hour after pressing

<Start/Stop> push-button, and then each hour after Integr. Period, if

Rep. Cycles is greater than one. The default value is set to Off.

Switching on/off the measurement period settings

The integration period can be set as infinite or can be defined together with the

Repetition Cycles number. The Integr. Period Inf position defines if the period

during which the signal is being measured is infinite or not. If the