Page 1

USER MANUAL

SV 200

NOISE MONITORING STATION

Warsaw, July 2017

Copyright © 2017 SVANTEK. All rights reserved.

Page 2

SV 200 USER MANUAL 2

CONTENTS

1 Introduction ...............................................................................................................................6

1.1 Sound Level Meter & Analyser features ...............................................................................6

1.2 General features of SV 200 ..................................................................................................7

1.3 Accessories included ...........................................................................................................7

1.4 Optional accessories available .............................................................................................7

2 Assembling the instrument.......................................................................................................8

2.1 Recommended order of assembly........................................................................................8

2.2 Delivered kit.........................................................................................................................8

2.3 Pre-assembling of the SV 200............................................................................................ 12

2.4 Pre-assembling of the meteorological beam (optional) ....................................................... 17

2.5 Power supply installation ................................ ................................................................... 19

2.6 Assembling of the meteorological beam (optional) on the mast .......................................... 19

2.7 Mounting the SV 200 ......................................................................................................... 20

2.8 Finishing ............................................................................................................................ 23

2.9 Important information ......................................................................................................... 23

2.10 Preparing for calibration ................................ ..................................................................... 23

2.11 Replacement of the foam windscreen ................................................................................ 27

3 Manual control of the instrument ........................................................................................... 28

3.1 LED indicators and Power button ....................................................................................... 29

3.2 SIM card slot (3G version only) .......................................................................................... 31

3.3 DC IN socket ..................................................................................................................... 31

3.4 External Communication Interface socket .......................................................................... 32

3.5 Antenna socket .................................................................................................................. 32

3.6 Calibration ......................................................................................................................... 32

3.7 Electrostatic actuator ......................................................................................................... 35

4 Basic operations ..................................................................................................................... 36

4.1 PC Software installation and activation .............................................................................. 36

4.2 Initial setup of the instrument ................................................................ ............................. 36

4.2.1 Basic configuration of wireless connection ..................................................................... 37

4.2.2 Starting measurement .................................................................................................... 43

4.3 Changing the working directory .......................................................................................... 45

4.4 Firmware upgrade ............................................................................................................. 46

4.4.1 User program upgrade ................................................................................................... 46

4.4.2 Web interface upgrade ................................................................................................... 48

4.4.3 Bootstrap program upgrade ................................ ........................................................... 49

5 Remote configuration ............................................................................................................. 50

Page 3

SV 200 USER MANUAL 3

5.1 Remote control principles .................................................................................................. 50

5.1.1 H24 Telit 3G Modem ................................ ...................................................................... 50

5.1.2 Web server .................................................................................................................... 52

5.1.3 SMS / E-mail alarming ................................................................ ................................... 53

5.1.4 SMS command exchange .............................................................................................. 53

5.1.5 Lantronix WiPort Modem ................................................................ ................................ 54

6 Instrument settings ................................................................................................................. 56

6.1 Connecting to the station ................................................................................................... 56

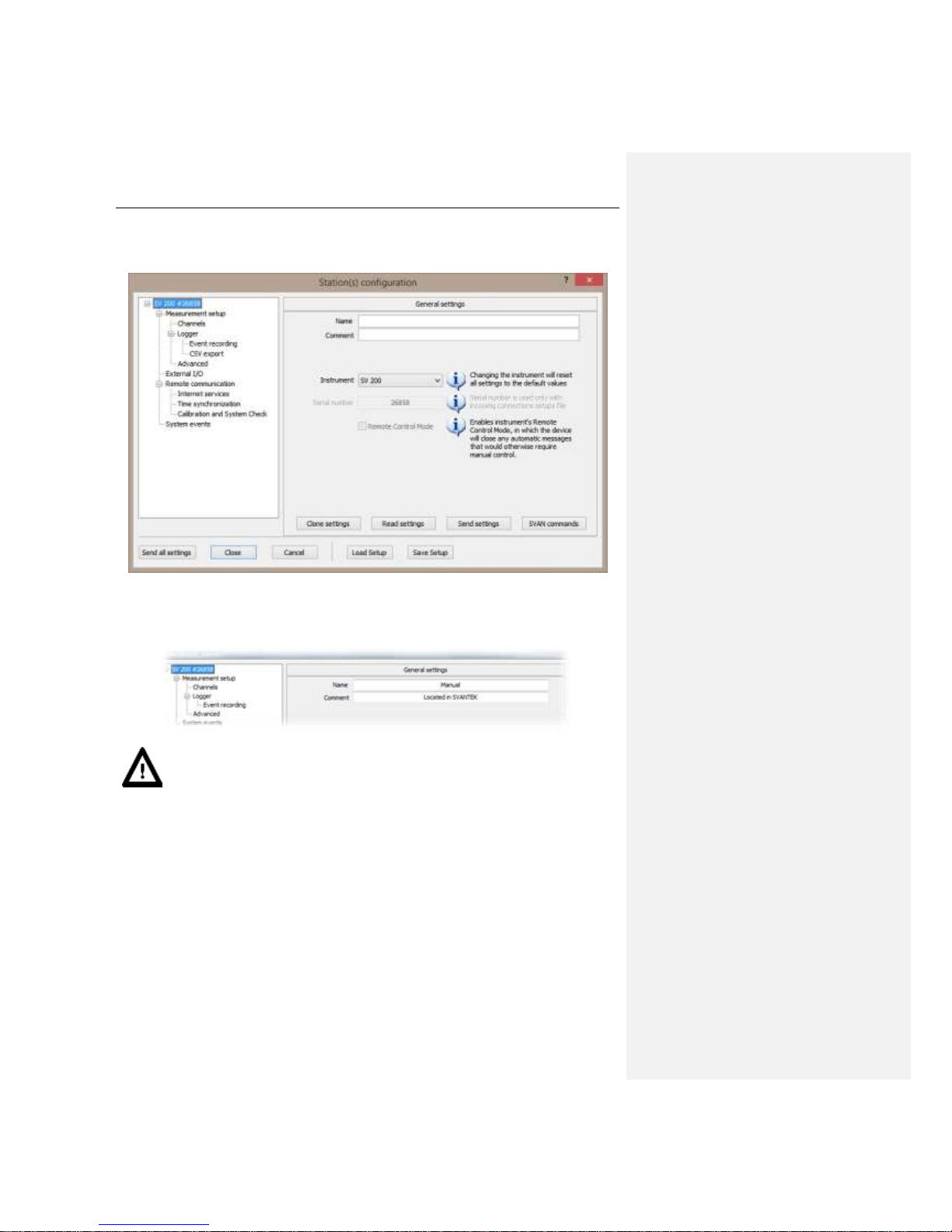

6.2 General settings ................................................................ ................................................ 57

6.3 Measurement setup ........................................................................................................... 58

6.3.1 Measurement function ................................................................................................... 58

6.3.2 Start delay ................................................................................................ ..................... 58

6.3.3 Integration period ........................................................................................................... 59

6.3.4 RMS Integration ............................................................................................................. 59

6.3.5 Repetition cycles ............................................................................................................ 59

6.3.6 Outdoor filter .................................................................................................................. 59

6.4 Channels ........................................................................................................................... 60

6.4.1 Weighting filter selection ................................................................................................ 60

6.4.2 RMS detector selection .................................................................................................. 60

6.5 Logger settings .................................................................................................................. 61

6.5.1 Logger on ...................................................................................................................... 61

6.5.2 Logger step.................................................................................................................... 61

6.5.3 Logger meteo ................................................................................................................ 62

6.5.4 Splitting mode ................................................................................................................ 62

6.5.5 Logger results ................................................................................................................ 62

6.6 Event recording ................................................................................................................. 63

6.6.1 Recording type .............................................................................................................. 63

6.6.2 Recording settings ......................................................................................................... 63

6.6.3 Trigger type ................................................................................................................... 64

6.7 CSV export ........................................................................................................................ 65

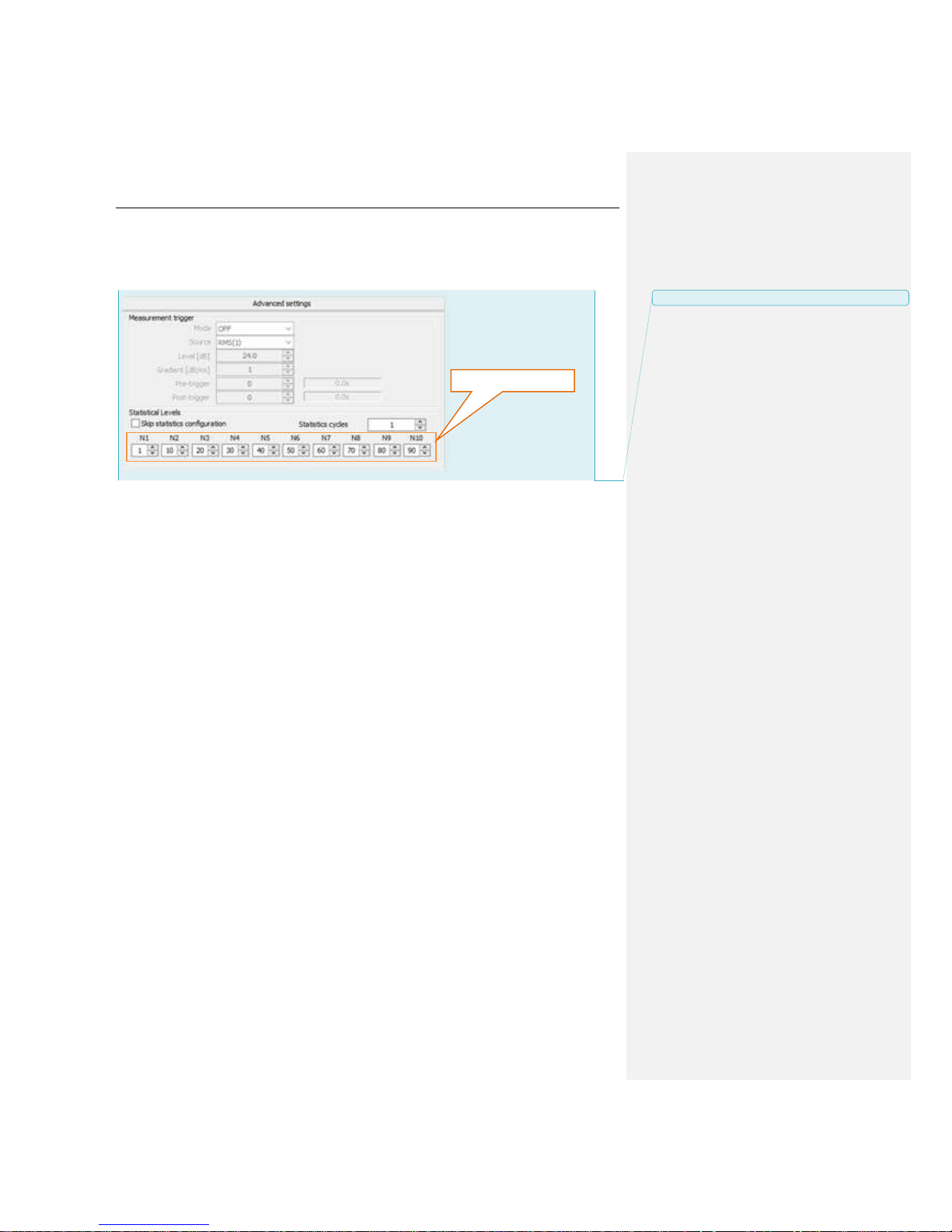

6.8 Advanced .......................................................................................................................... 66

6.9 External I/O ....................................................................................................................... 67

6.9.1 External device .............................................................................................................. 67

6.9.2 Device settings .............................................................................................................. 67

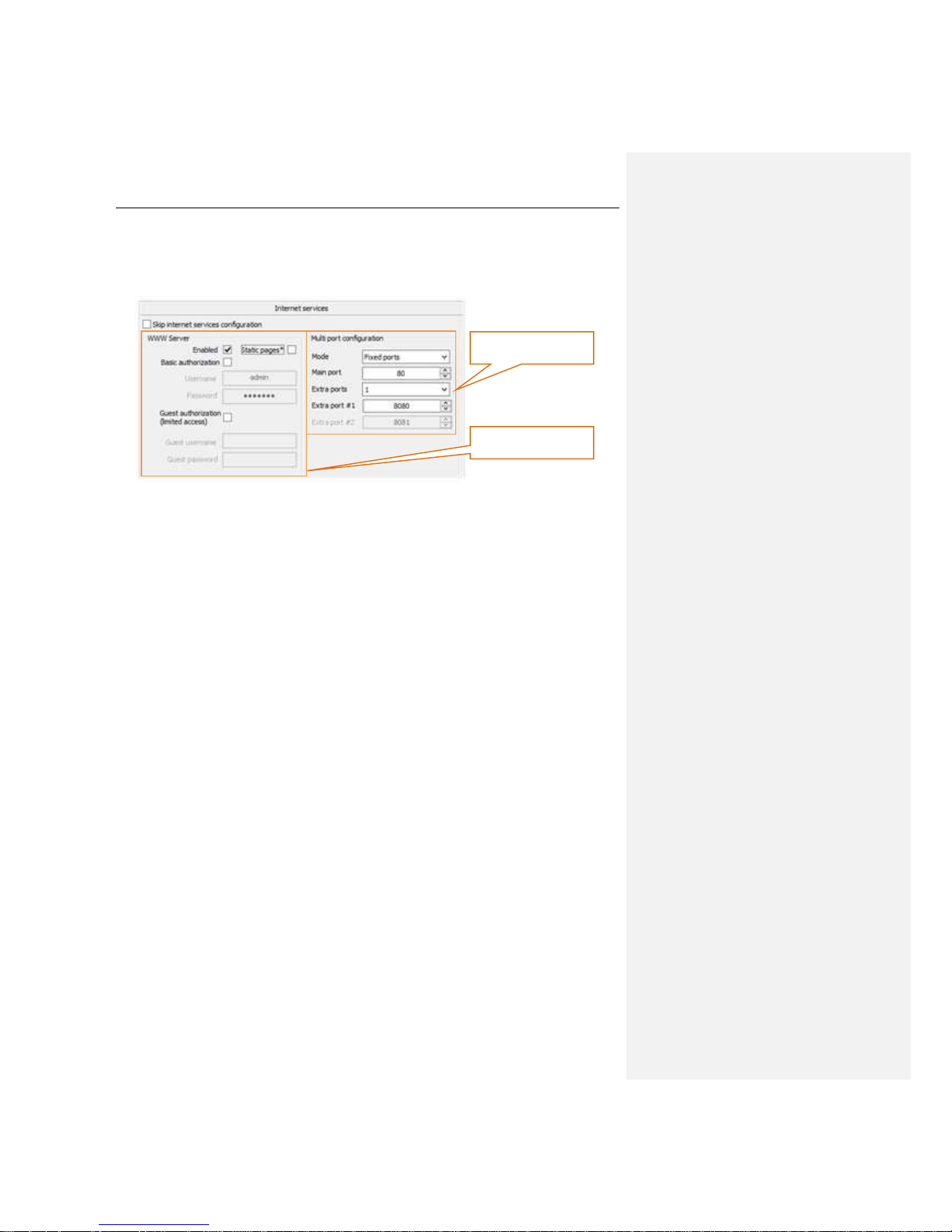

6.10 Internet services ................................................................................................................ 68

6.10.1 WWW Server ................................................................................................ ............. 68

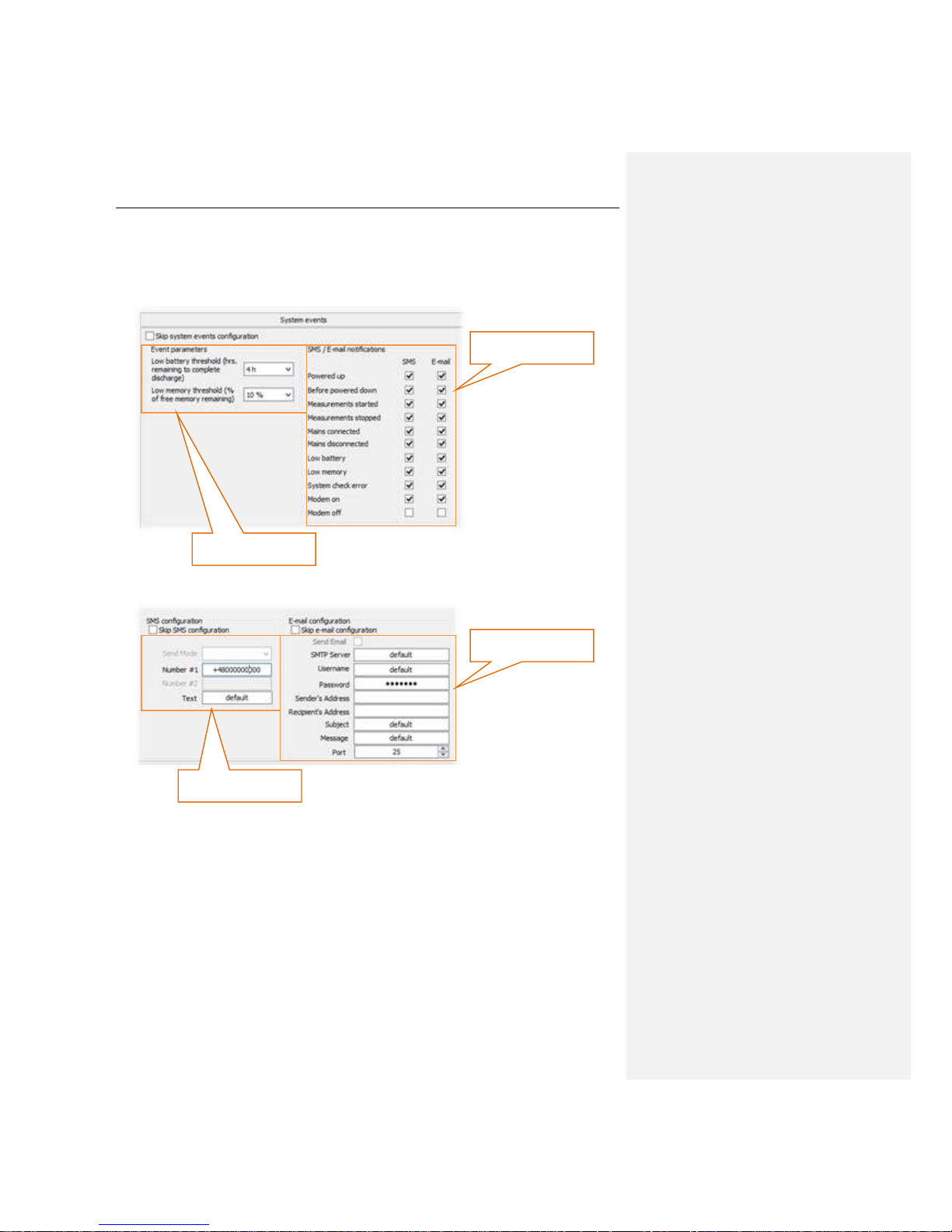

6.11 System events ................................ ................................................................................... 69

6.12 Time synchronization ......................................................................................................... 70

Page 4

SV 200 USER MANUAL 4

6.13 Calibration & System Check .............................................................................................. 71

6.13.1 Automatic calibration .................................................................................................. 71

6.13.2 Automatic system check ............................................................................................. 71

6.13.3 Logging ................................................................................................ ...................... 72

6.14 FTP data transfer ............................................................................................................... 72

7 WEB interface .......................................................................................................................... 73

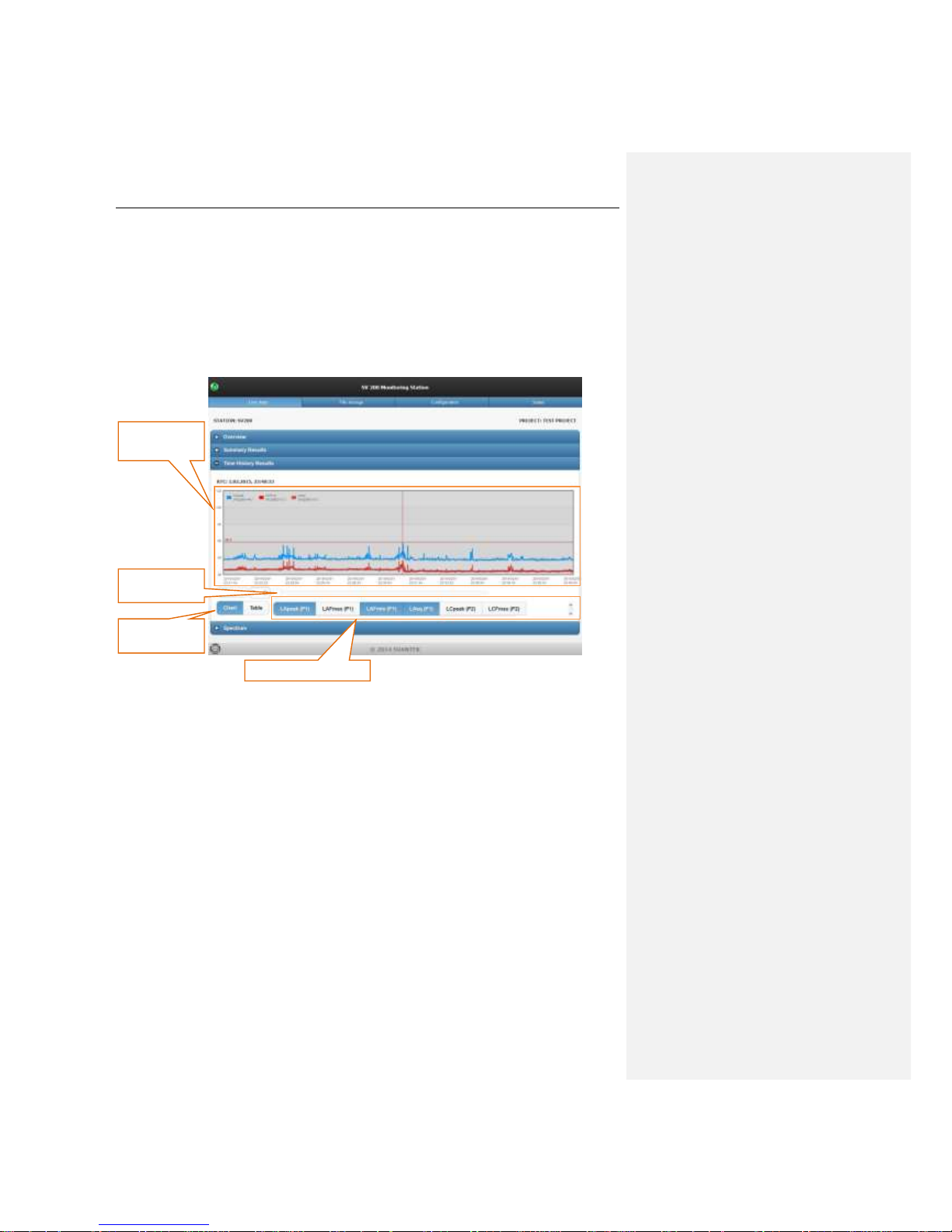

7.1 Live data page ................................ ................................................................................... 73

7.1.1 Overview section ........................................................................................................... 73

7.1.2 Summary Results section .............................................................................................. 74

7.1.3 Time History Results section .......................................................................................... 75

7.1.4 Spectrum section ........................................................................................................... 76

7.2 File storage page ............................................................................................................... 77

7.3 Configuration page ............................................................................................................ 78

7.3.1 Filters & detectors section .............................................................................................. 79

7.3.2 Storage section ................................................................ .............................................. 80

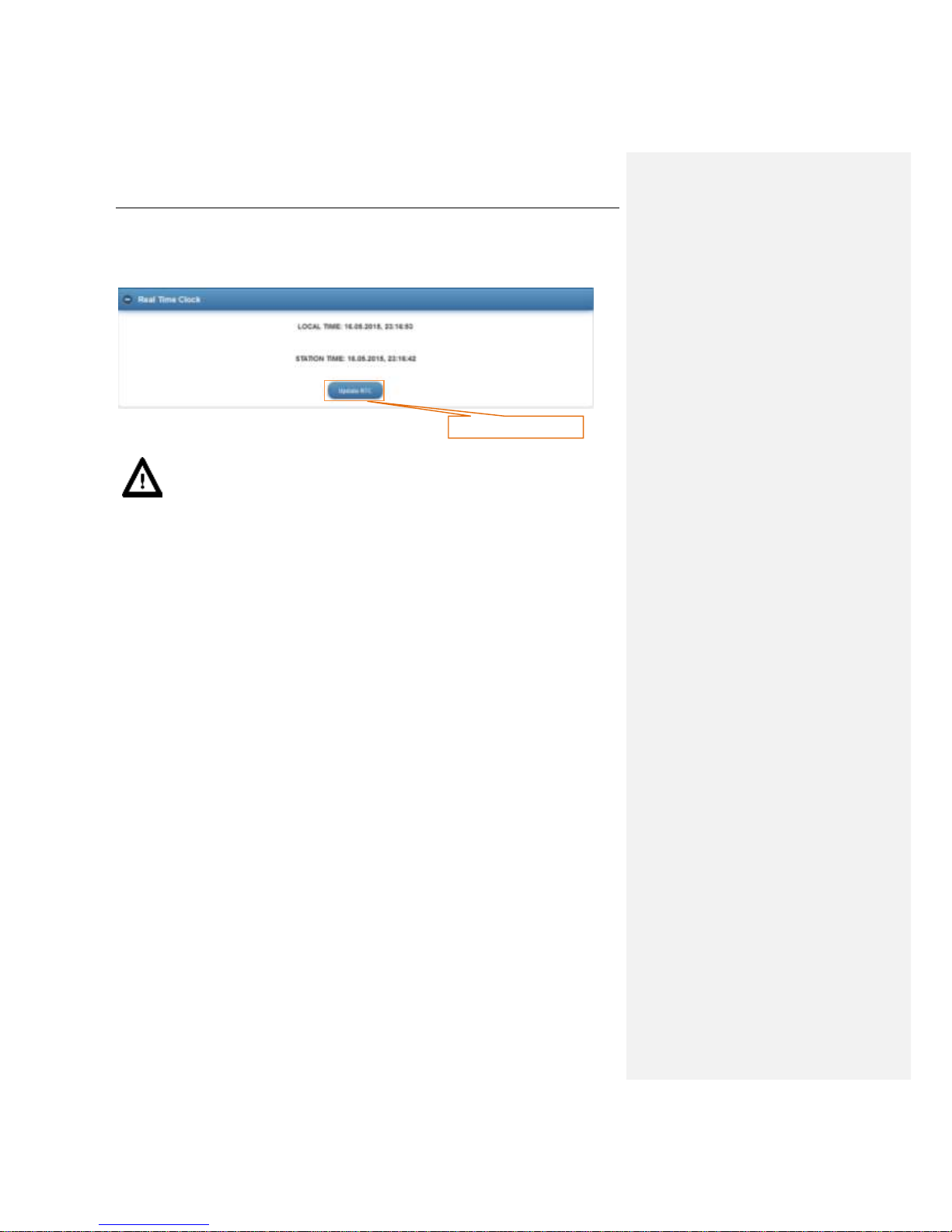

7.3.3 Real Time Clock ............................................................................................................ 82

7.3.4 Calibration and System Check ....................................................................................... 83

7.3.5 FTP Data Transfer ......................................................................................................... 85

7.3.6 Auxiliary settings ............................................................................................................ 86

7.3.7 Firmware update ............................................................................................................ 86

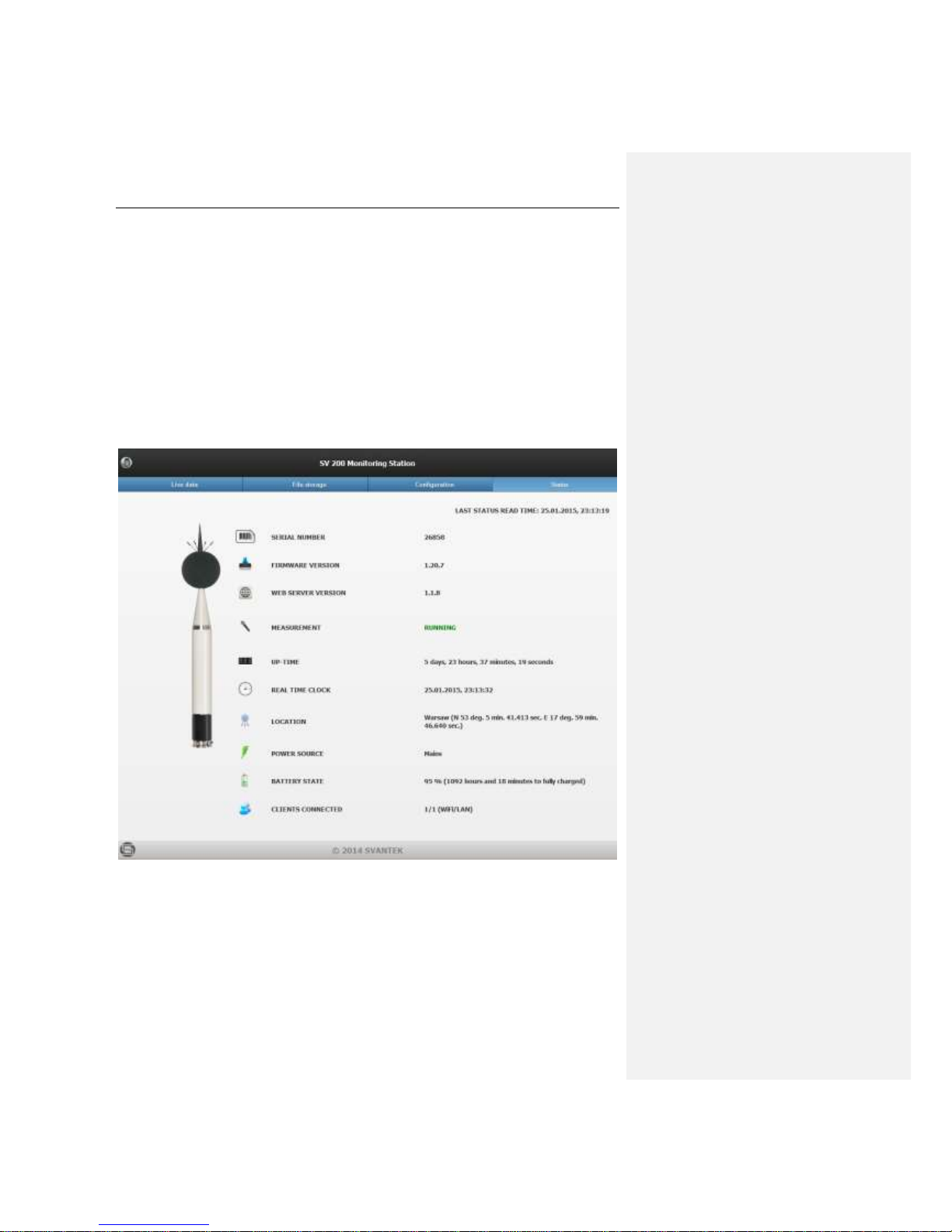

7.4 Status page ....................................................................................................................... 87

8 Data collecting ......................................................................................................................... 88

8.1 SVAN PC++ (RC) .............................................................................................................. 88

8.1.1 Beginning work with Remote Communication Center ..................................................... 88

8.1.2 Remote Communication Service .................................................................................... 90

8.1.4 SVAN Files .................................................................................................................... 91

8.1.5 Automatic Files Download .............................................................................................. 94

8.1.6 Continuous Logger Download ........................................................................................ 97

8.1.7 Live Results ................................................................................................................. 100

8.1.8 Alarms ................................................................................................ ......................... 102

8.2 FTP Client ....................................................................................................................... 103

8.2.1 FTP Push ................................................................ .................................................... 103

8.2.2 FTP Pull................................................................ ....................................................... 103

8.3 WEB Interface ................................................................................................ ................. 103

9 SV 200CU User CONTROL UNIT ........................................................................................... 104

9.1 Input and output sockets of the control unit ...................................................................... 104

9.2 Powering of the control unit .............................................................................................. 104

9.3 Manual control of SV200 .................................................................................................. 105

Page 5

SV 200 USER MANUAL 5

9.3.1 Control push-buttons on the front panel ........................................................................ 105

9.4 Swithing the control unit on and starting measurement ..................................................... 107

9.5 Description of icons ................................................................ ......................................... 107

9.6 Setting SV200 ................................................................................................................. 108

9.6.1 Basis of SV200 control ................................................................................................. 108

9.6.2 Setting the SV200 function ........................................................................................... 110

9.6.3 SV200 calibration ......................................................................................................... 110

9.7 Setting the measurement parameters – Measurement ..................................................... 112

9.7.1 Selection of measurement parameters - General Settings ............................................ 113

9.7.2 Selection of the microphone compensation filters – Compensation Filter ...................... 114

9.7.3 Setting a profile parameters – Profiles .......................................................................... 114

9.7.4 Setting the data logging functionality – Logging ............................................................ 114

9.7.5 Selection of the 1/1 Octave and 1/3 Octave spectrum parameters – Spectrum ............. 116

9.7.6 Setting ten statistical levels - Statistical Levels ............................................................. 116

9.8 Setting the display parameters – Display ................................................................ ......... 116

9.8.1 Modes of measurement results presentation ................................................................ 116

9.8.2 Spectrum scale and grid setting - Display Scale ........................................................... 118

9.8.3 Setting the parameters of the spectrum presentation - Spectrum View ......................... 119

9.8.4 Setting the display brightness and power saver- Screen Setup ..................................... 119

9.9 Managing the instrument files – File ................................................................................. 120

9.9.1 Scrolling the file list - File List ....................................................................................... 120

9.9.2 Checking the available memory – Free Memory ........................................................... 120

9.9.3 Erasing all files in a memory – Delete All ...................................................................... 120

9.10 Setting of the instrument parameters – Instrument ........................................................... 121

9.10.1 Checking the powering of the instrument – Battery ................................................... 121

9.10.2 Programming the instrument’s internal Real Time Clock – RTC ................................ 121

9.10.3 Setting the parameters of the serial interface - Serial Port ........................................ 122

9.10.4 Checking specification of the instrument - Unit Label ................................ ................ 122

9.15 Auxiliary settings – Auxiliary Setup ................................................................................... 122

9.15.1 Setting the language of the user interface – Language ............................................. 123

9.15.2 Return to the factory settings – Factory Settings ....................................................... 123

Page 6

SV 200 USER MANUAL 6

1 INTRODUCTION

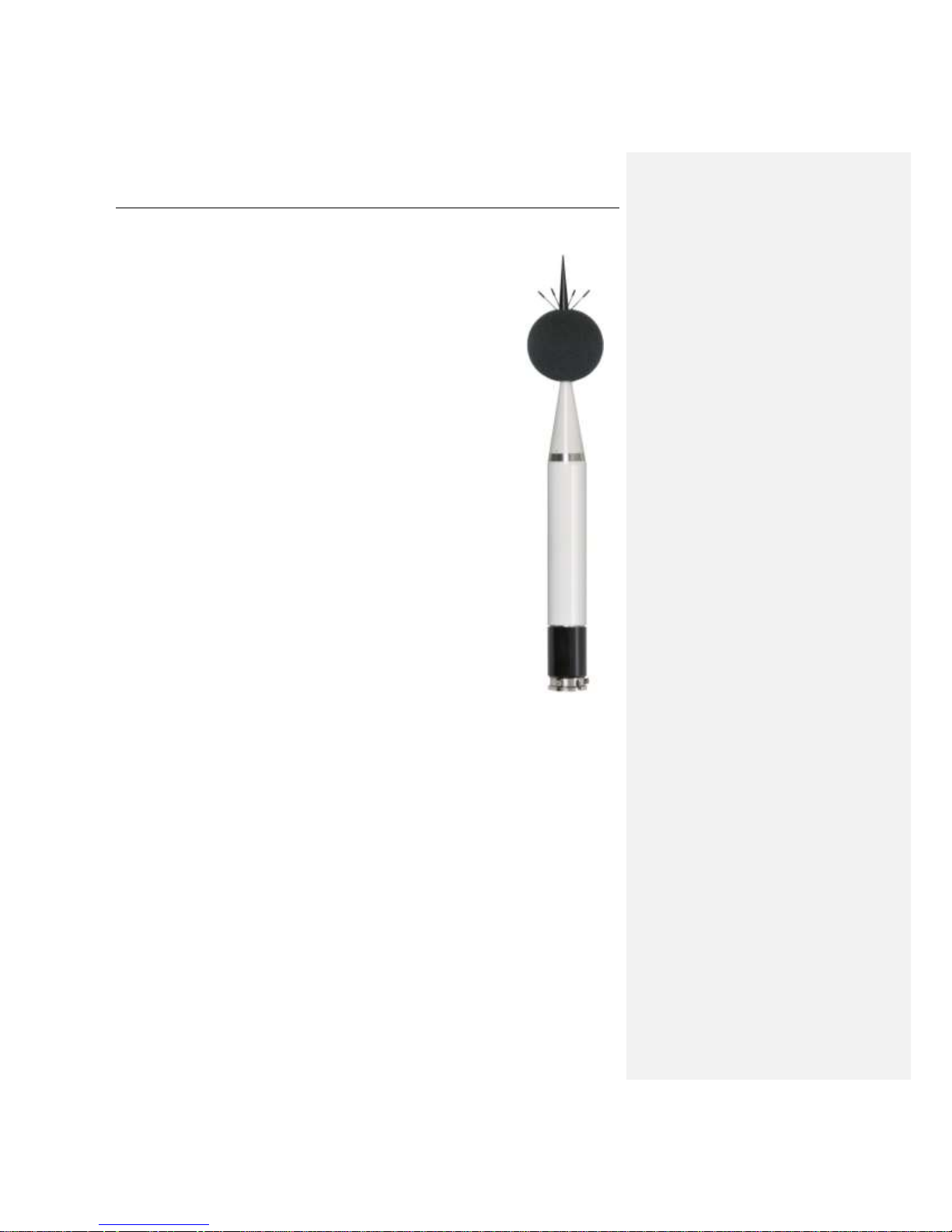

The SV 200 is a unique Noise Monitoring Terminal (NMT) which includes in single

portable housing: outdoor microphone, sound level meter and 1/1 & 1/3 octave

analyzer, advanced logger integrating controller and communication systems.

Using the most recent and State of the Art technological achievements, the

design of high integration outdoor system became available. In practice this

means that system can be easily transported and installed by one person in field.

The instrument is an ideal choice for unattended permanent and short period

environmental noise measurements together with weather conditions monitoring.

Instrument can be used for community and airport noise monitoring in the same

time.

The architecture of the system allow easy communication, data download and

configuration of the system using PC or any mobile device which has network

(internet) access to SV 200 and web browser.

The SV 200 meets Class 1 requirements of IEC 61672:2013 standard. NMT

provides broad band results with all required weighting filters, 1/1 octave & 1/3

octave spectra with complete statistical analysis.

Instrument can be easily calibrated in field using acoustic calibrator. Built-in

electrostatic actuator can be activated remotely or periodically in automated

mode for self-testing.

The SV 200 enables great logging capability which includes time history of broad

band results and spectra with two selectable logging steps down to 2 milliseconds

like also audio records on trigger. Data are stored on microSD card and can be

transferred over the internet on demand or in automatic mode to FTP server or

any PC.

SvanPC++ and SvanPC++_RC software provides advanced modes of

communication, files download, data visualization and measurement results

exporting. SvanPC++_EM environmental monitoring software is dedicated for

measurement data management, advanced data processing, analysis,

visualization and reporting.

Thanks to robust casing, protection against overheating & humidity condensation,

built-in rechargeable battery, this instrument is excellent for permanent

installation in all environmental conditions.

1.1 Sound Level Meter & Analyser features

• noise measurements: SPL, Leq, SEL, L

DEN

, L

tm3

, L

tm5

, L

peak

, L

max

, L

min

• statistics: Ln (L1 – L99), complete histogram in meter mode and 1/1 & 1/3 octave analysis

• Type 1 accuracy in the frequency range 3.5 Hz – 20 kHz and with 48 kHz sampling rate

• total linearity measurement range: 25 dBA LEQ ÷ 133 dB PEAK

• dynamic range: 115 dB

• parallel Impulse, Fast and Slow detectors for the measurement with A, C or Z weighting filters

• software selectable community and airport direction characteristics

• digital True RMS detector with peak detection, resolution 0.1 dB

• 1/1 octave real-time analysis meeting Class 1 requirements of IEC 61260, frequencies from

3.15 Hz to 20 kHz

• 1/3 octave real-time analysis meeting Class 1 requirements of IEC 61260, frequencies from

3.15 Hz to 20 kHz

• audio events recording: time domain records to wav file format on demand with selectable

sampling frequency and recording period

Page 7

SV 200 USER MANUAL 7

1.2 General features of SV 200

• Noise monitoring terminal fitted in one portable instrument dedicated for unattended permanent

and short period noise monitoring

• Noise measurements meeting IEC 61672-1, type 1 standard

• 1/1 & 1/3 octave real-time analysis

• Audio events recording

• Statistical analysis with up to 10 percentile values

• Community and airport direction characteristics, software selectable

• Remote, automated calibration check

• High efficiency windscreen

• Designed for outdoor use in all weather conditions

• Communication over 3G or Wi-Fi modems

• Weather monitoring module

• Easy remote access over PC or Smartphone by means of any Web browser

• Precise time synchronization and GPS position of the measurements

• Up to 45 hours autonomy (internal battery operating time with modem switched off)

• Advanced software for data processing and reporting SvanPC++_EM

• Direct connection of solar panel or DC power supply

• Robust design

• Ingress Protection Rating IP 65

• Easy and fast installation in field

1.3 Accessories included

• Microtech Gefell MK 255, 50 mV/Pa, prepolarised ½” condenser microphone

• integrated, non-removable microphone preamplifier

• Li-Ion rechargeable battery (non-removable)

• water proof external DC power supply

• built-in acoustic actuator, triggered manually or in automated mode,

• 16 GB micro SD card (non-removable)

• 3G modem (included in version SV 200_3G)

• Wi-Fi module (included in version SV 200_WiFi)

• SC256 USB cable

• standard mounting kit

1.4 Optional accessories available

• solar panel

• user control unit (on cable)

• SV 205B meteo module

• SV 58 GPS module

• alarm lamp

• SvanPC++_EM Environmental monitoring module for SvanPC++ application (hardware key,

single license)

• side mounting kit

Page 8

SV 200 USER MANUAL 8

2 ASSEMBLING THE INSTRUMENT

2.1 Recommended order of assembly

After unpacking, check the completeness of the set according to section 2.2.

Notice: It is advised to read sections 2.3 to 2.8 of the User Manual carefully before the

assembly.

Recommended order of installation:

1. pre-assembling of the SV 200 (see 2.3),

2. pre-assembling of the meteorological beam (see 2.4),

3. power supply installation (see 2.5),

4. assembling of the meteorological beam on the mast (see 2.6),

5. assembling of and start-up of the SV 200 device (see 2.7),

6. arrangement of the cabling (see 2.8).

2.2 Delivered kit

The kit delivered to the client consists of the following elements:

1. the SV 200 instrument containing sub-assemblies unavailable to clients:

• integrated, non-removable microphone preamplifier

• built-in electrostatic actuator, triggered manually or in automated mode

• Li-Ion rechargeable battery

• 16 GB micro SD card

• 3G modem (included in version SV 200_3G)

• Wi-Fi module (included in version SV 200_WiFi)

Page 9

SV 200 USER MANUAL 9

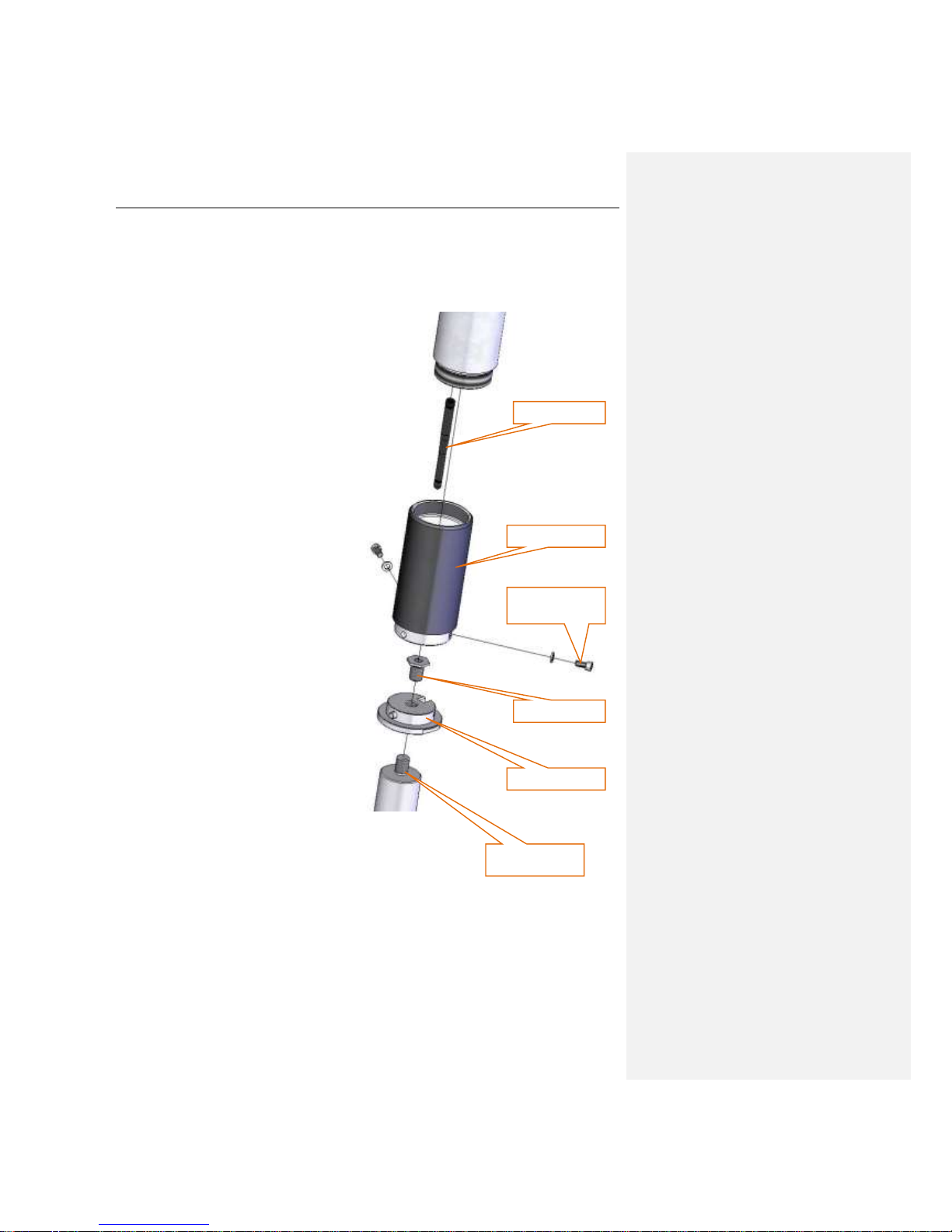

2. removable elements of the SV 200:

• Microtech Gefell MK 255, 50 mV/Pa, prepolarised ½” condenser microphone

• top cone with anti-bird spikes

• extension sleeve

• microphone protective sleeve

• SA209 5” foam windscreen

• 3G antenna (for version 1)

• Wi-Fi antenna (for version 2)

3. DC power supply kit consisting of:

• weatherproof DC power unit of the type SA213

• set of 4 dowels Φ 10 mm (with screws) for mounting the power unit into a wall

• 2 band clips for mast mounting of the power supply

4. SC256 cable to communicate with SV 200 using USB interface

top cone with

anti-bird spikes

SA209 foam

windscreen

extending sleeve

microphone

protective sleeve

microphone

Page 10

SV 200 USER MANUAL 10

5. Standard mounting kit consisting of:

• mounting sleeve

• base of the sleeve

• two bolts M6x12 with washers

• M14/

3/8

” adapter

base of the sleeve

M14/

3/8

” adapter

two bolts M6x12

with washers

mounting sleeve

wireless antenna

Example of pole

mounting

Page 11

SV 200 USER MANUAL 11

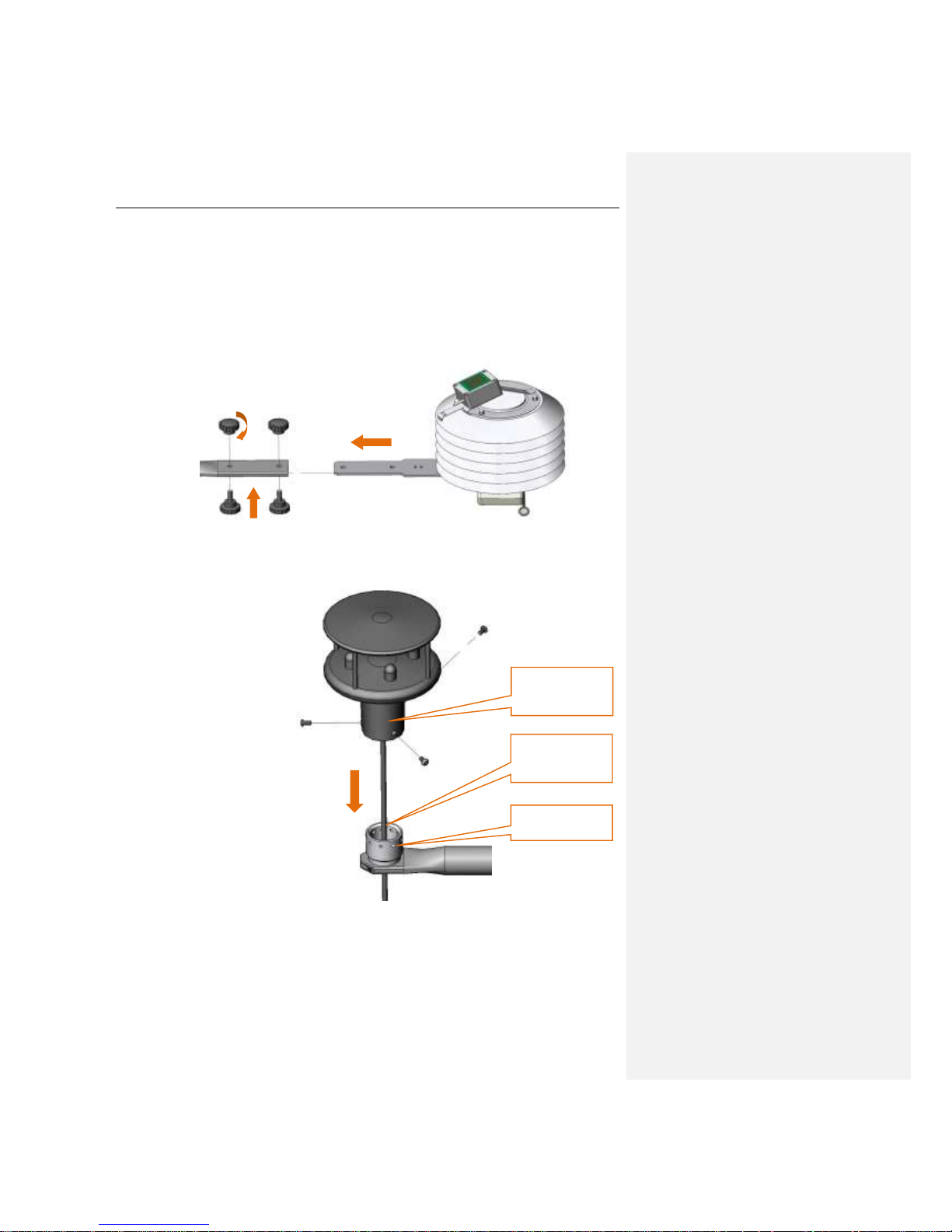

6. set of the elements of the meteorological beam (option), consisting of:

• SV205B hygro-baro-thermometer module (optionally with rain detector mounted on it)

• dedicated SC258 cable to connect the SV205B module to the SV 200

• ultrasonic wind-meter adapted to be connected to the SV205B device

• meteorological beam (fastening clamp inner diameter 45 mm)

• 4 knobs with nuts M8

• 2 knobs with bolts M8x25

• three cable holders 28/40 mm

• three bolts M5x10

• two tuning bolts

wind-meter

3 bolts M5x10

SV205B hygro-baro-thermometer

rain detector (optional)

2 knobs with nuts M8

beam fastening

clamp

2 knobs with nuts M8

2 knobs with

bolts M8x25

3 cable holders

meteorological beam

tuning bolts

Page 12

SV 200 USER MANUAL 12

7. set of tools, consisting of:

• special ring spanner 22mm

• special open spanner 65 mm

• Allen key 3mm

• Allen key 5mm

2.3 Pre-assembling of the SV 200

Install the microphone and the foam windscreen in the following order:

1. Check, if the SV 200 is switched off – LED indicators on the bottom panel of the instrument are

not lighting. If the device is on, turn it off (see Chapter 3.1)

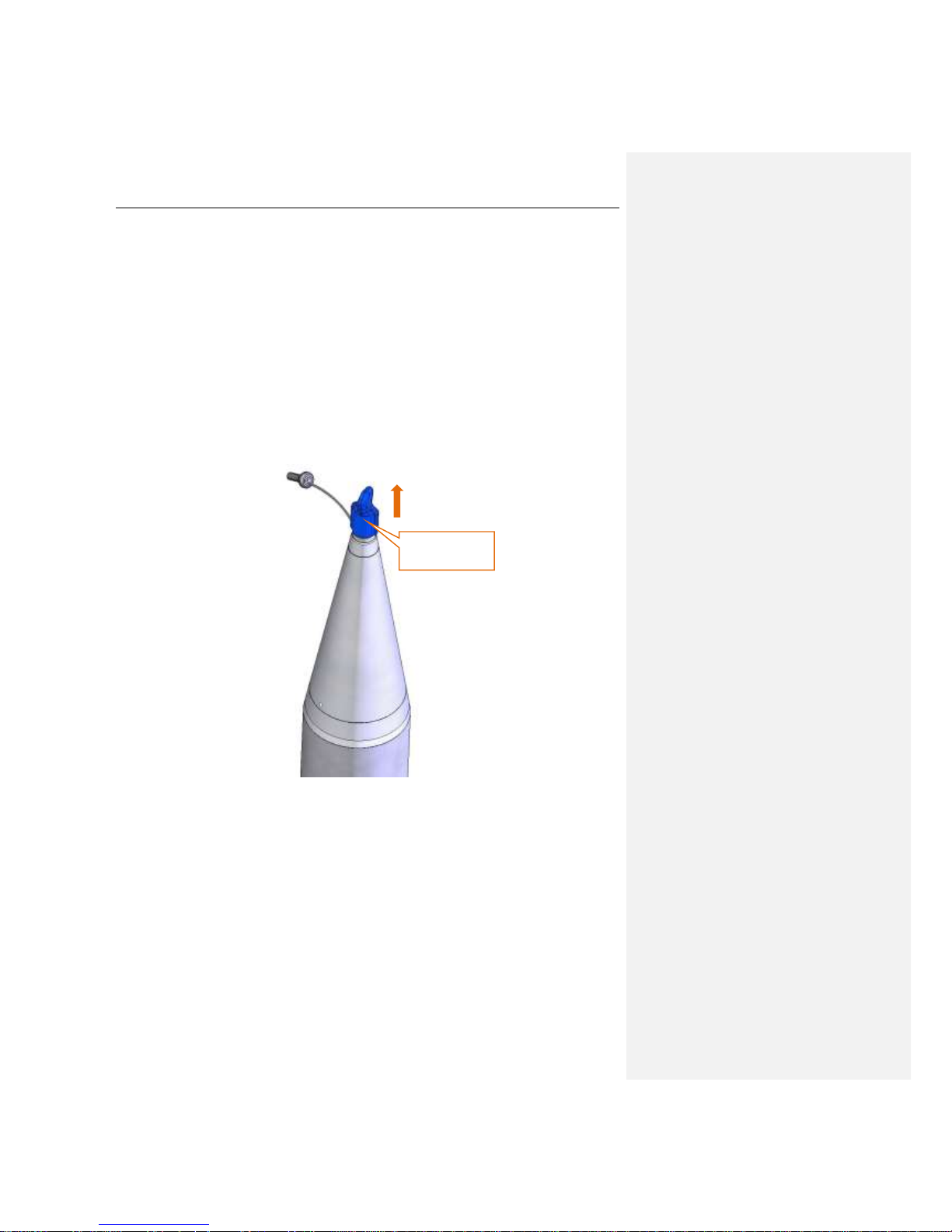

2. Place the SV200 upright (outer cone facing up) on a hard horizontal flat surface. The device

should not rock or overturn after this step.

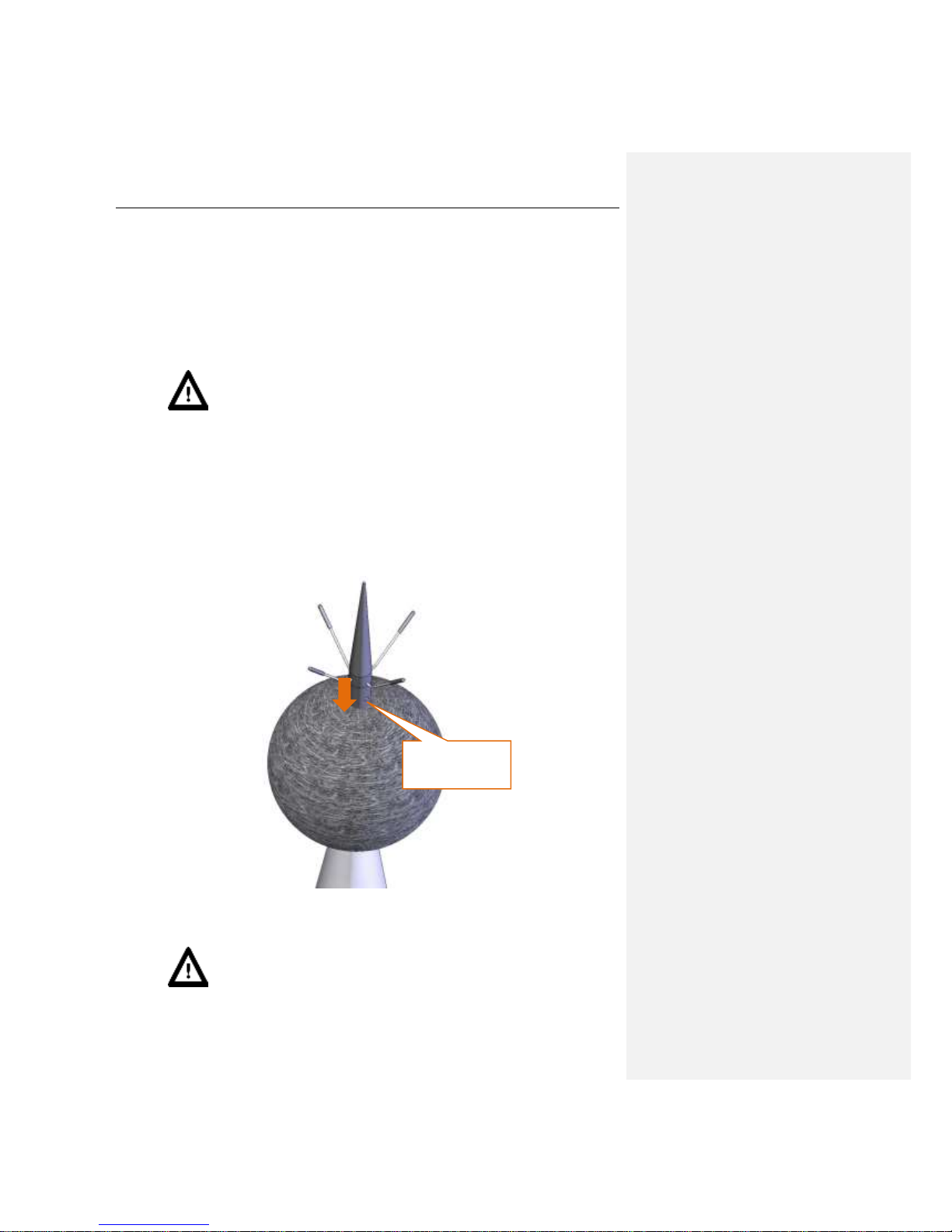

3. Take off the protective cap from the microphone socket.

take off the blue

protective cap

Page 13

SV 200 USER MANUAL 13

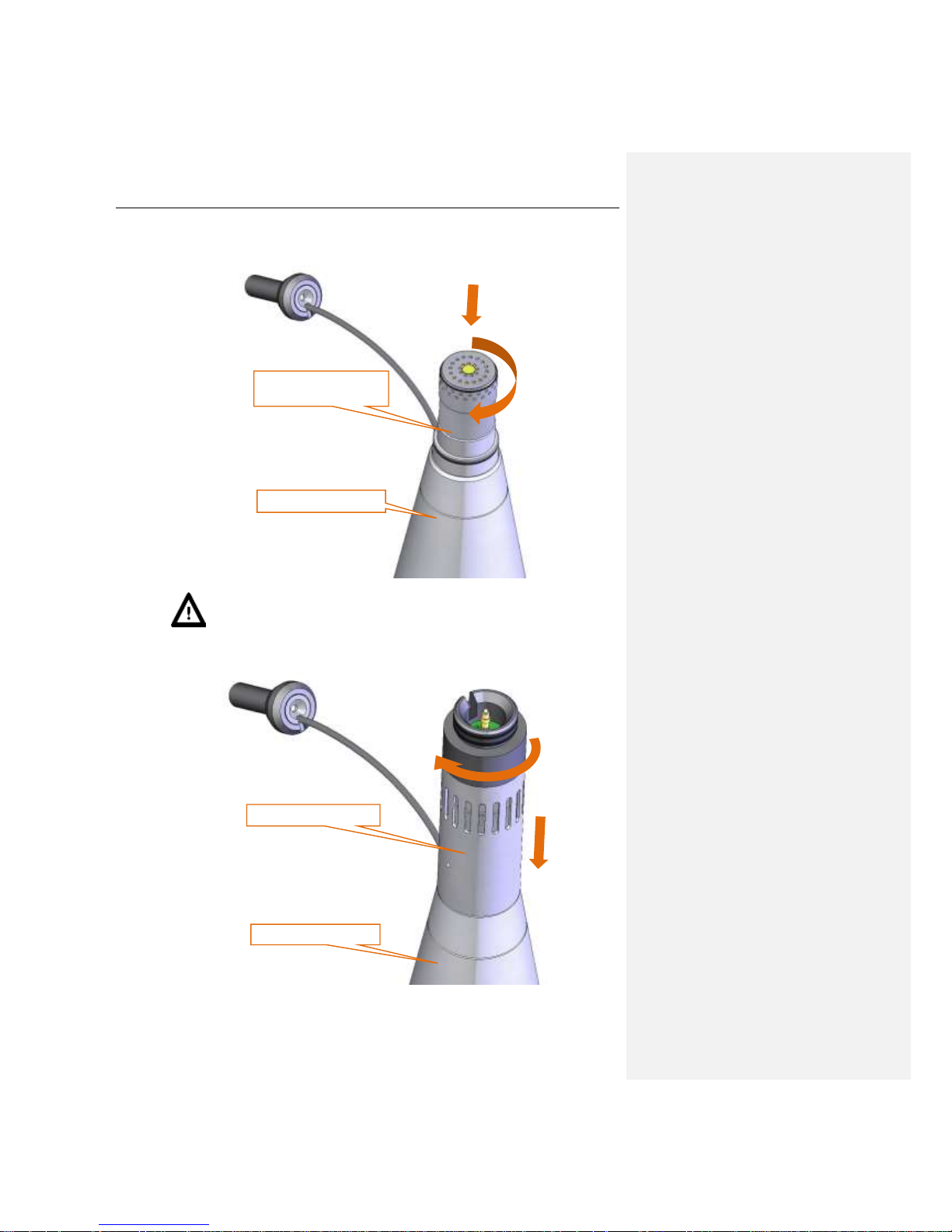

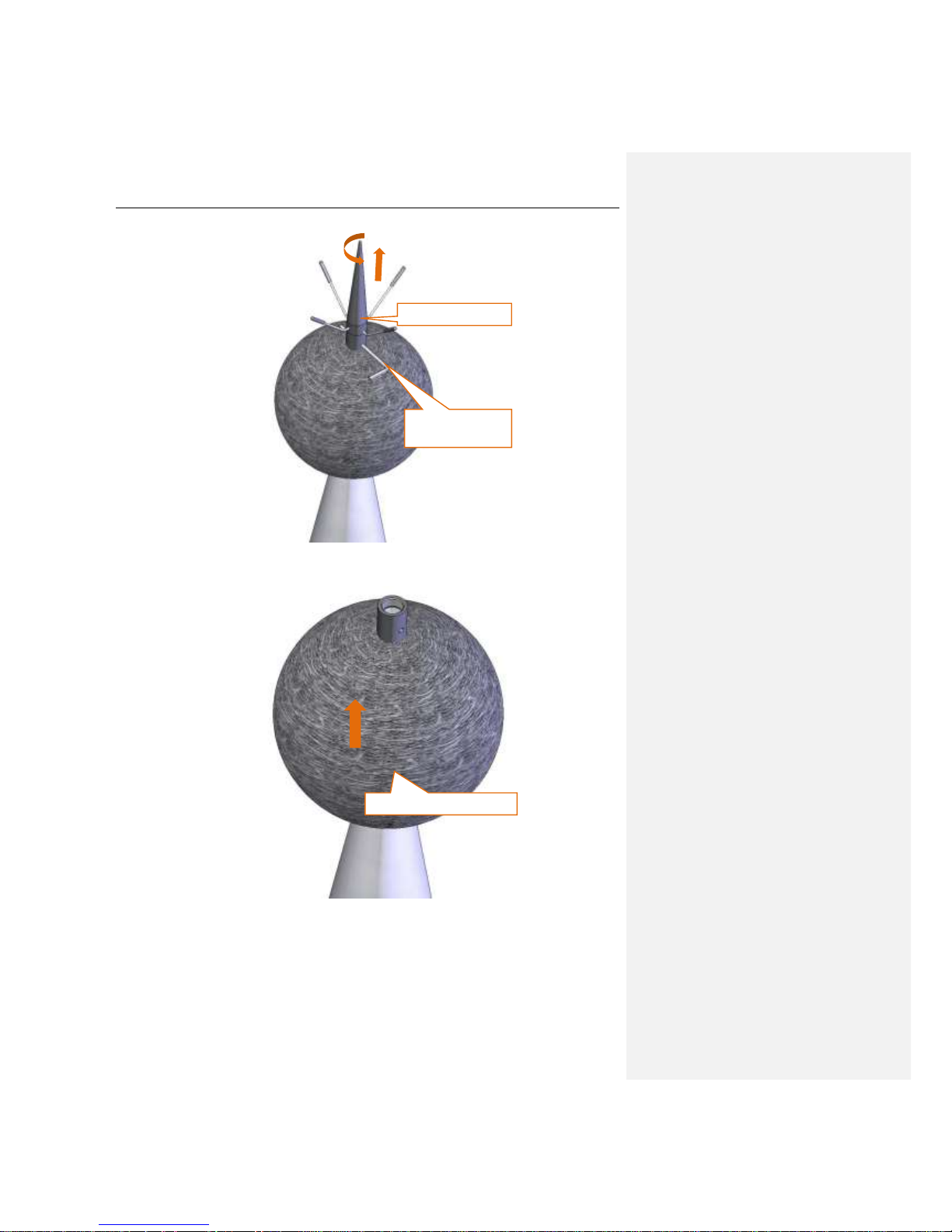

4. Holding outer cone in one hand, use the other hand to screw the microphone on the matching

thread extending from the outer cone (rotating the microphone clockwise)

Notice: It is advised to calibrate the SV 200 at this point. For more information see

Chapter 3.7.

5. Hold the outer cone with one hand, use the other hand to screw on the sleeve rotating it

clockwise.

hold firmly with one hand

screw the microphone on

the microphone socket

2

hold firmly with one hand

screw the sleeve on

1

2

Page 14

SV 200 USER MANUAL 14

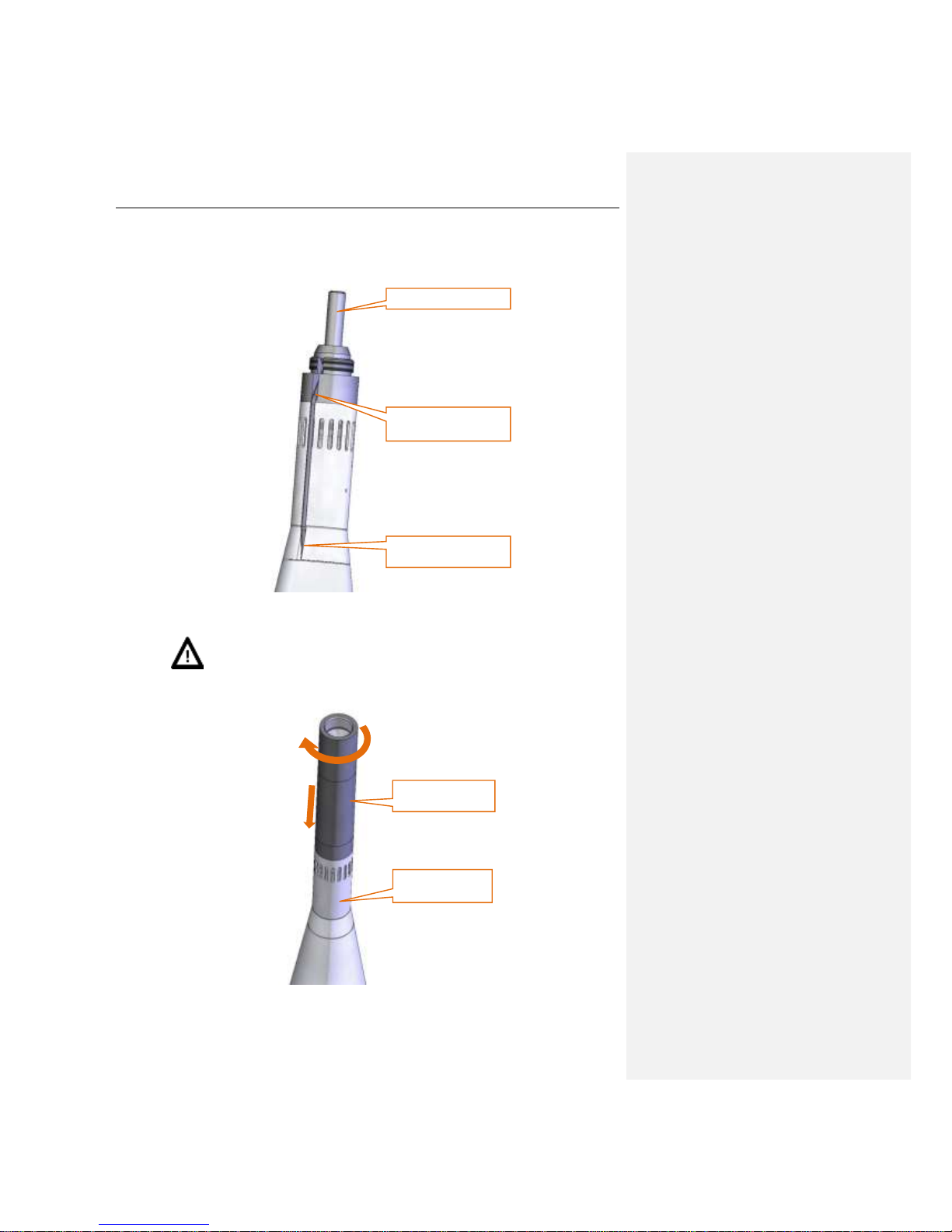

6. Align moving ring with the slot of the microphone protective sleeve so that the cable is not bent

in any direction. Gently place the actuator located at the end of the cable in the dedicated socket.

Put the actuator's cable into the slot of the sleeve.

7. Hold the microphone protective sleeve and the top cone with one hand, use the other hand to

screw on the extension sleeve, rotating it clockwise

Notice: It is important to keep the microphone protective sleeve still, to protect

actuator’s cable from damage.

insert into the socket

place the actuator cable

in the slot of the sleeve

align with the slot of the

sleeve

hold firmly with

one hand

screw the

1

2

Page 15

SV 200 USER MANUAL 15

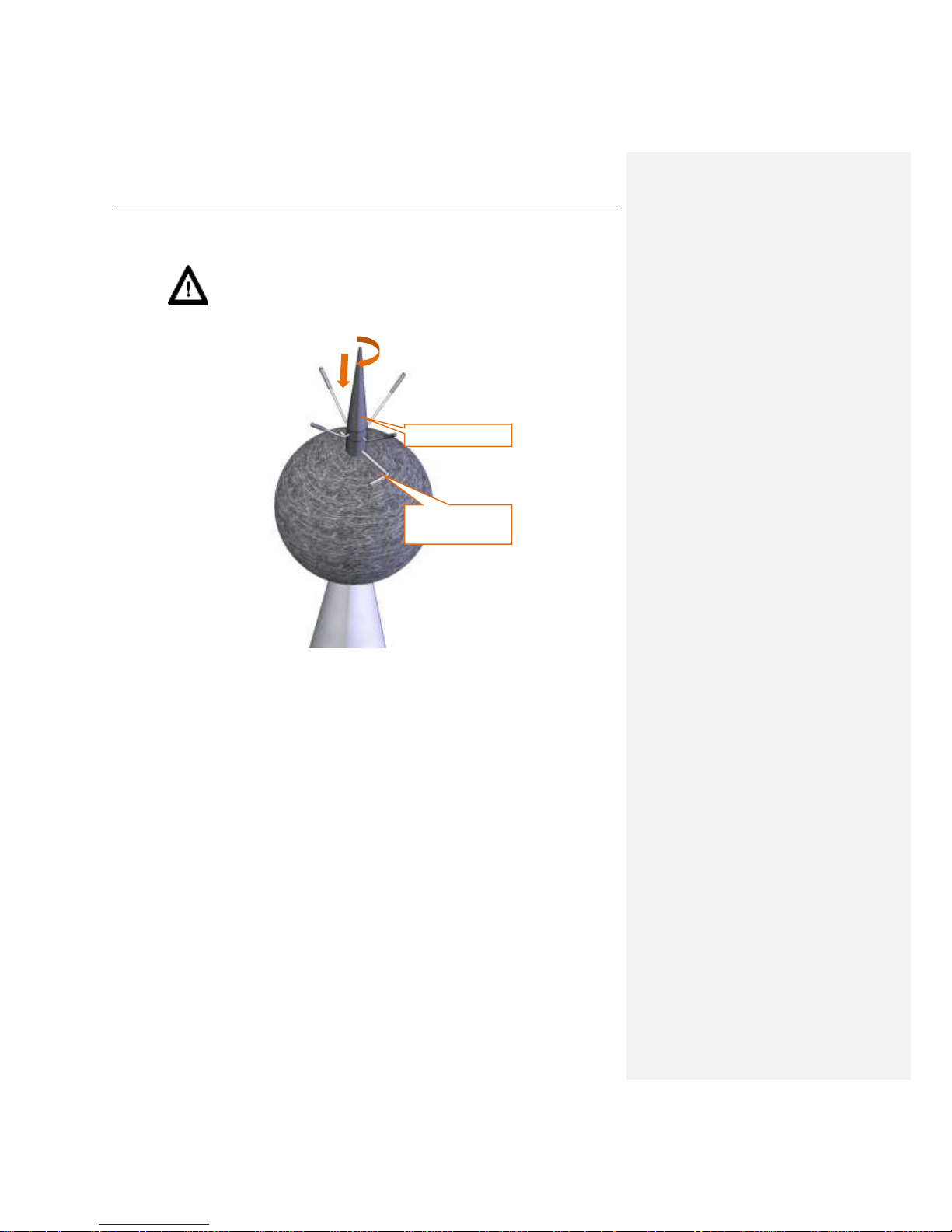

8. Slide the foam windscreen onto the extension sleeve and push the foam until you see the lateral

hole.

9. Insert the 3 mm Allen key into the hole.

push the foam windscreen

until you see the lateral hole

Page 16

SV 200 USER MANUAL 16

10. Holding the Allen key and the extension sleeve in one hand to keep them still, use the other

hand to screw on the top cone with the anti-bird spikes, rotating it clockwise.

Notice: It is important to keep the extension sleeve still, to protect actuator cable

from damage.

11. Take the Allen key out from the extension sleeve.

12. Move the foam windscreen to the place right under the spikes of the anti-bird device, make sure

it covers the microphone protective sleeve.

hold the Allen key

firmly in one hand

screw the top cone

Page 17

SV 200 USER MANUAL 17

13. Put the device horizontally to gain an easy access to the control panel.

14. Screw the wireless antenna.

In version 1 of the device, insert the SIM card into the SIM card socket (according to Chapter 3.2).

The device prepared in this way is ready for the electronic configuration (according to Chapter 3).

2.4 Pre-assembling of the meteorological beam (optional)

The meteorological beam may be pre-assembled during the installing preparations. The recommended

sequence of operations:

cover the sleeve

cover the hole

hold and screw on

insert the SIM card

Page 18

SV 200 USER MANUAL 18

1. Unscrew two sets of knobs (each containing of a nut and a screw) from the flattened end of the

beam.

2. Put the beam on a flat surface so that the mounting socket of the wind-meter on the other side

of the beam faces up

3. Put the SV205B device with the label facing down.

4. Slide the flat band extending from the SV205B into the slot at the flattened end of the beam

5. Screw the SV205B unit to the beam using the knobs (see point 1), place the knobs with the

nuts on the top of the beam.

6. Unscrew three M5 screws from the fastening socket of the wind-meter using an Allen key 3 mm.

7. Thread the cable of the wind-meter through fastening socket on the beam.

8. Place the wind-meter on the fastening socket.

9. Screw the wind-meter to the socket with the three screws unscrewed before (see point 6).

10. Put the cable connected to the wind-meter along the meteorological beam at the side opposite

to the fastening clamp

11. Plug the cable connector into the socket in the cable box in the bottom part of the SV205B unit

(the socked signed „Wind Speed Meter” is protected with a cap, which must be removed)

1

2

3

fastening socket of

the wind-meter

thread the cable

through the

fastening socket

place the wind-

meter on the

fastening socket

Page 19

SV 200 USER MANUAL 19

12. Push the cable into the cable holders located on the meteorological beam

13. Plug the SC258 cable connector into the socket in the cable box on the bottom of the SV205B

unit (the socket signed „External Interface” is protected with a cap, which must be removed).

2.5 Power supply installation

The power supply may be installed in the following two ways:

1. On a wall, for example, using 4 anchors.

2. On a mast, using 2 band clips.

The outdoor installation requires the power supply to be installed vertically, with the protective plate

facing up. The power supply must be installed on below the SV 200 device. The distance should be as

great as possible.

Notice: Choosing the assembling place one should take into account that the cable

connecting the power supply to the device is 2,5 meters long and must not be extended.

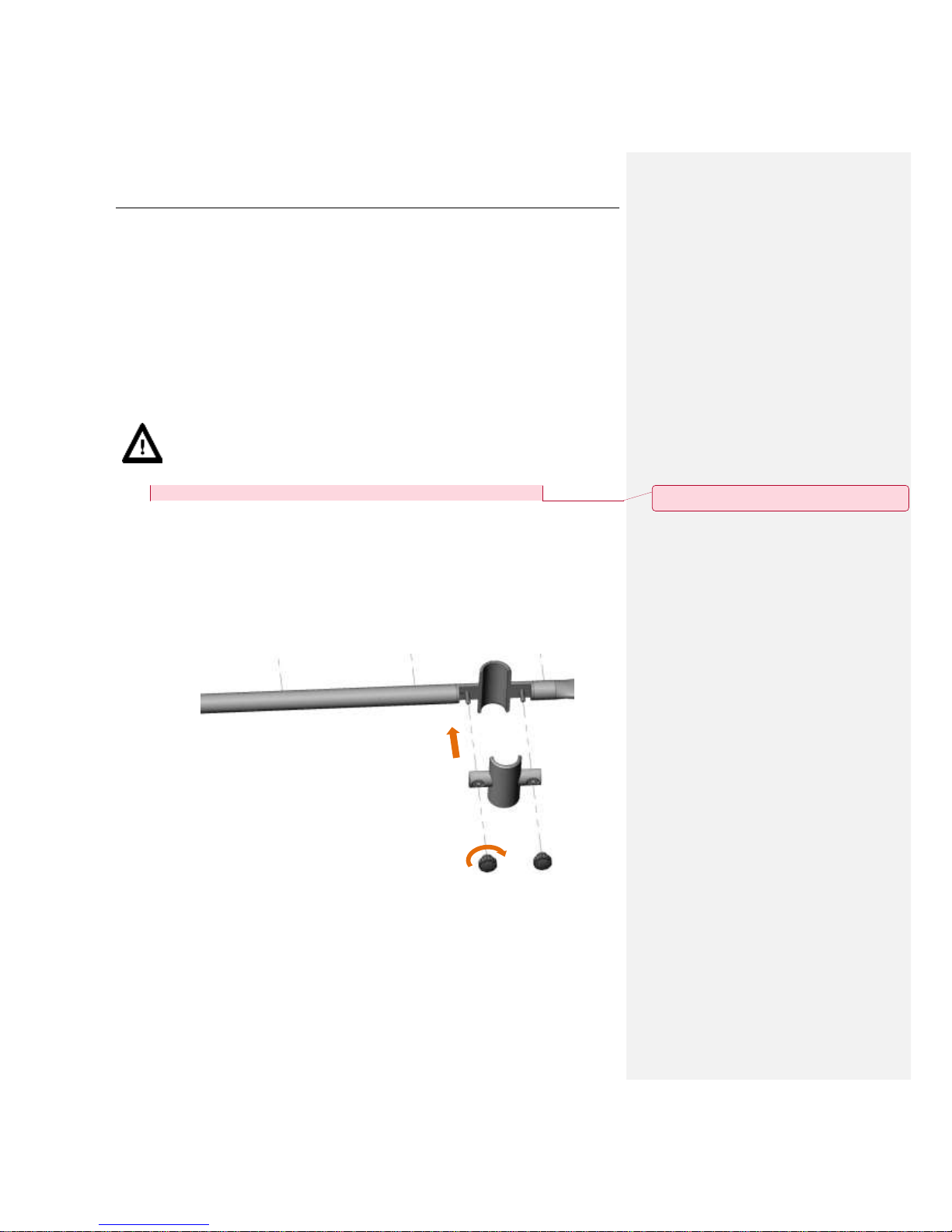

2.6 Assembling of the meteorological beam (optional) on the mast

The meteorological beam should be installed on the mast, at least 2 m above the ground. The distance

from the beam to the SV 200 device should be as great as possible, but it is limited to the length of the

SC258 cable. There must not be any cables or wires between the clamping ring of the meteorological

beam and the mast.

After fixing the fastening place:

1. Unscrew two knobs which hold the beam fastening clamp of the meteorological beam.

2. Place the beam at the fixed place.

3. Install the beam to the mast using beam fastening clamp and two knobs.

Z komentarzem [J1]: Kilka miesięcy temu WB zlecił WK

oprcowanie nowej belki co się z tym wydarzyło

Page 20

SV 200 USER MANUAL 20

4. To align the wind-meter loosen two tuning bolts with the Allen key 1,5 mm and rotate the

wind-meter until the red north pointer indicates the north.

Notice: You can determine the north direction using either mobile app or real-life

compass.

5. Fasten the tuning bolts again.

6. Alternatively, loosen meteo beam fastening clamp and rotate the beam until the triangleshaped mark indicates north. Remember to tighten the knobs afterwards!

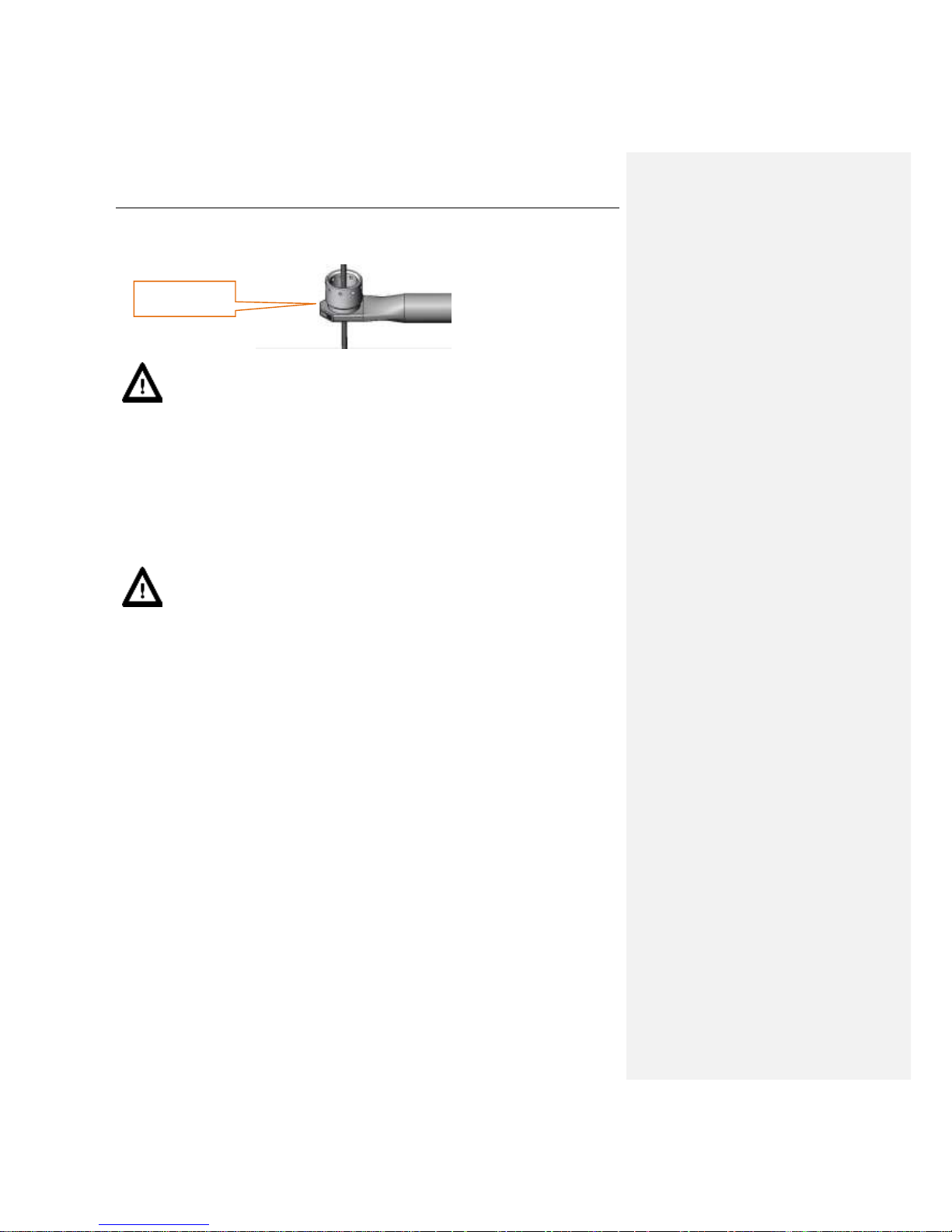

2.7 Mounting the SV 200

Coaxial mounting of the device on the mast Φ 45 mm ended with a bolt M14 is recommended.

Notice: The M14/

3/8

” adapter is intended for presentation mounting on photographic and

light tripods. It should not be used for unattended environmental monitoring.

Mounting on M14 thread

1. Unscrew two screws attaching the cup to the bottom of the cup with the Allen key 5mm.

2. Push the pin in the third hole in the bottom using a longer arm of the Allen key and take the

bottom off the cup.

3. Unscrew the M14/

3/8

” adapter from the bottom of the mounting sleeve using the special

spanners 22 and 65 mm.

loosen to align

properly

Page 21

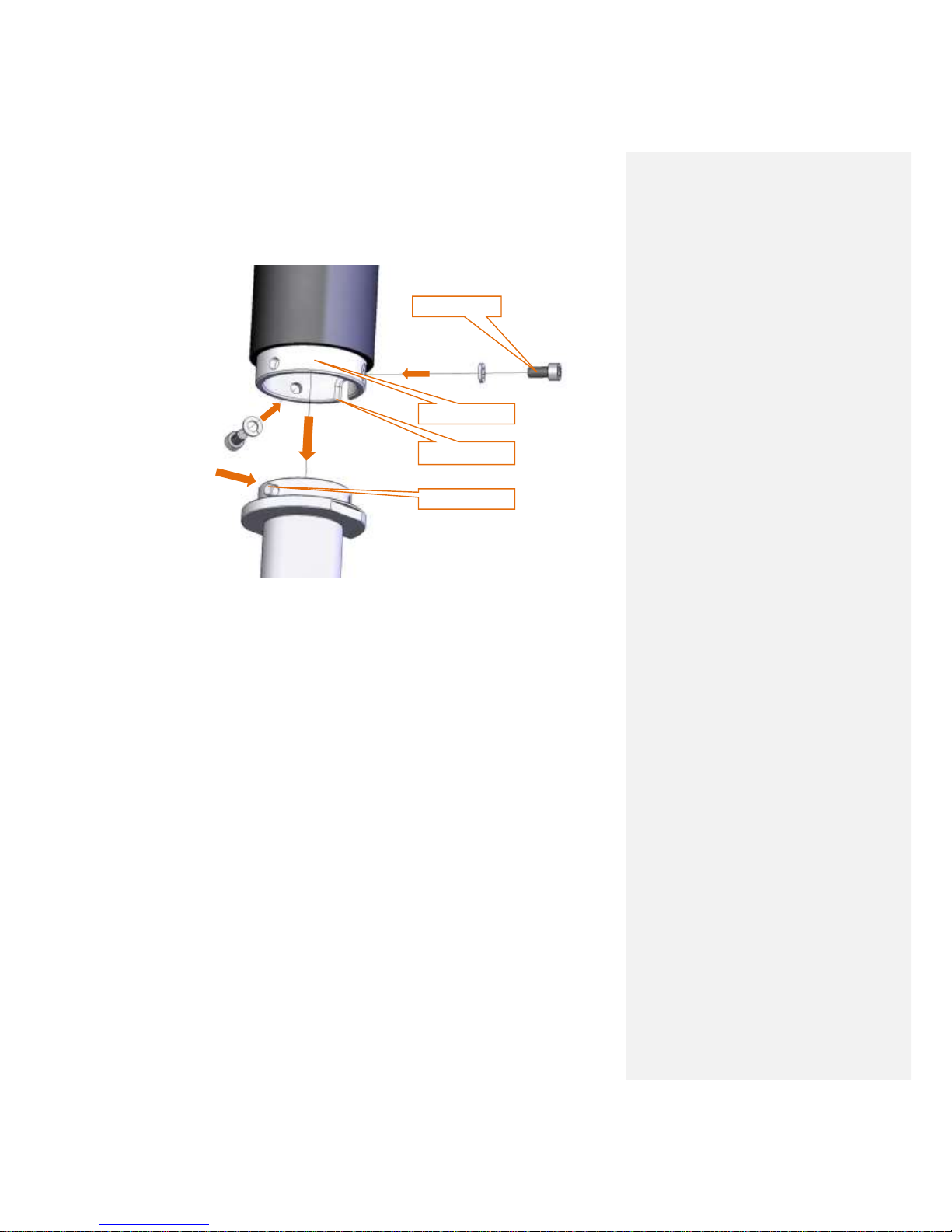

SV 200 USER MANUAL 21

4. Screw the base of the mounting sleeve on the M14 thread of the mast (with wider side facing

down).

5. Tighten the bottom of the mounting sleeve up with the special open spanner 65 mm.

6. Make sure the SV 200 is switched off and has a wireless antenna installed.

7. Hold the mounting sleeve with one hand (with the chamfered edge of the cup facing up).

8. Thread the SC258 cable (connected to the meteorological station) and the SA213 power supply

cable through the cup from the bottom to the top.

9. Plug the power supply cable connector in to the DC IN socket on the control panel.

10. Plug the SC258 cable connector in to the Ext. I/O socket on the panel of the SV 200.

11. Press the <Power> button on the control panel to switch the device on.

12. Screw the mounting sleeve on the thread of the SV 200.

13. Push the dowel protruding from the bottom of the cup with Allen key 5 mm.

slot for cables

screw on the base

Page 22

SV 200 USER MANUAL 22

14. Put the mounting sleeve on the bottom of the cup so that the cable slot in the bottom of the cup

covers the cable slot in the cup.

15. When the dowel is in the side hole of the cup, screw both threads fastening the cup to the

bottom of the cup using the Allen key 5 mm.

Mount in g on 3/8” thr ea d

1. Unscrew two screws attaching the cup to the bottom of the cup with the Allen key 5mm.

2. Push the pin into the third hole in the bottom using a longer arm of the Allen key and take the

bottom off the cup.

3. Screw the bottom of the cup on the 3/8” thread (with wider side facing down).

4. Tighten the bottom of the cup up with the special ring spanner 22 mm.

5. Then follow steps 6 to 15 from Mounting on M14 thread (above).

1

press the pin

2

3

3

slide the sleeve

slot for cables

screw on

Page 23

SV 200 USER MANUAL 23

2.8 Finishing

Attach the cables to the mast and the meteorological beam. Use some band clips at intervals not greater

than 50 cm (20”) on the mast and the cable holders delivered with the kit on the meteorological beam.

Lay the cables so that they are loose at the ends. The loose cable should hang a bit lower than the

connector to avoid accumulation of rainwater.

2.9 Important information

The SA209 foam protects microphone from wind and rain.

Notice: If SV 200 is used continuously for a long period of time it is recommended

to replace SA209 foam at least once a year.

During continuous usage the SA209 foam is exposed to different weather conditions with possibility of

causing mechanical damage to the foam’s structure. Therefore it is recommended, at least once a

quarter (3 months), to check the condition of the foam by examining the surface for cracks by squeezing

the foam. If cracks or holes are observed, the SA209 foam must be replaced.

SA209 foam must be replaced whenever squeezing it causes severing of small pieces of its surface.

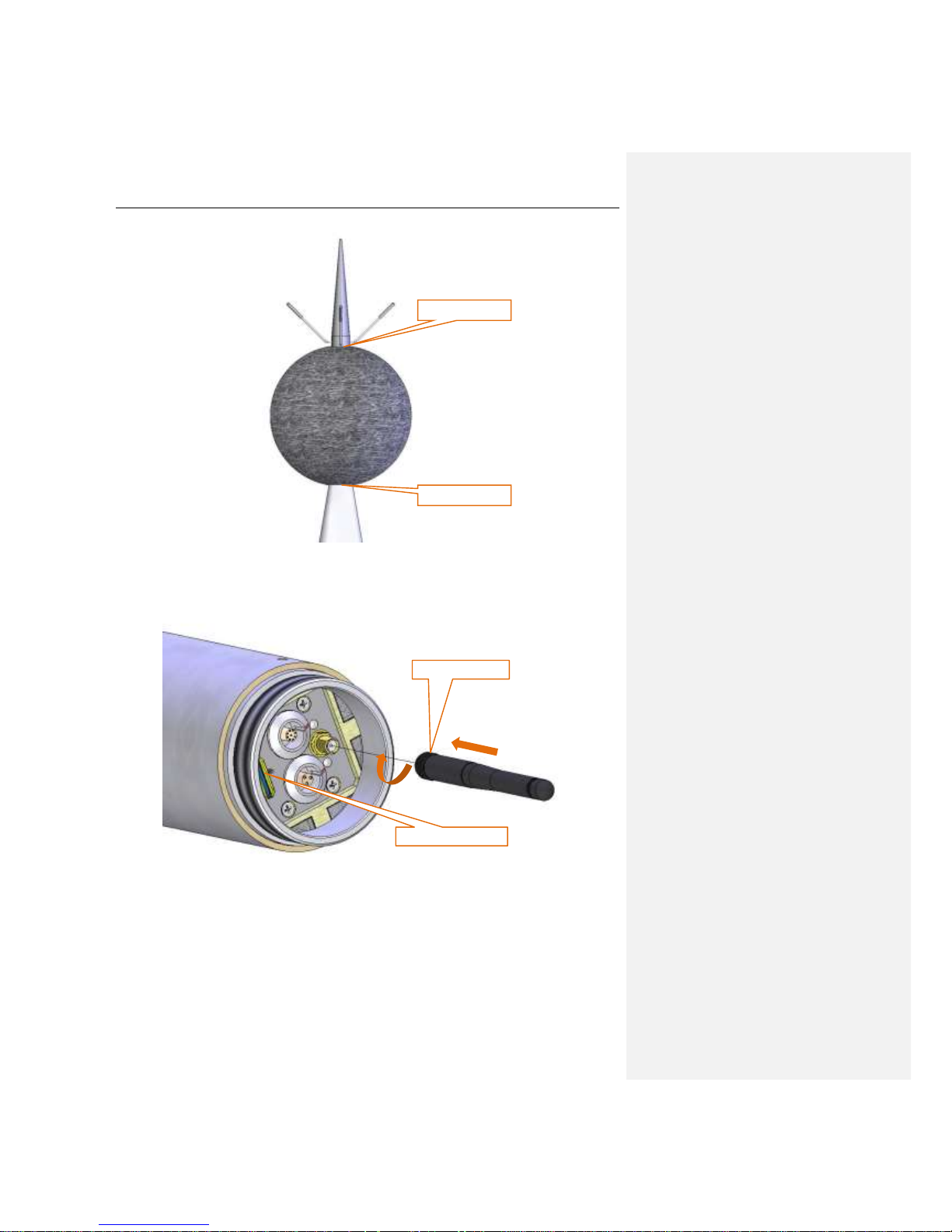

2.10 Preparing for calibration

If the SV 200 instrument is assembled and needs calibration, do what follows:

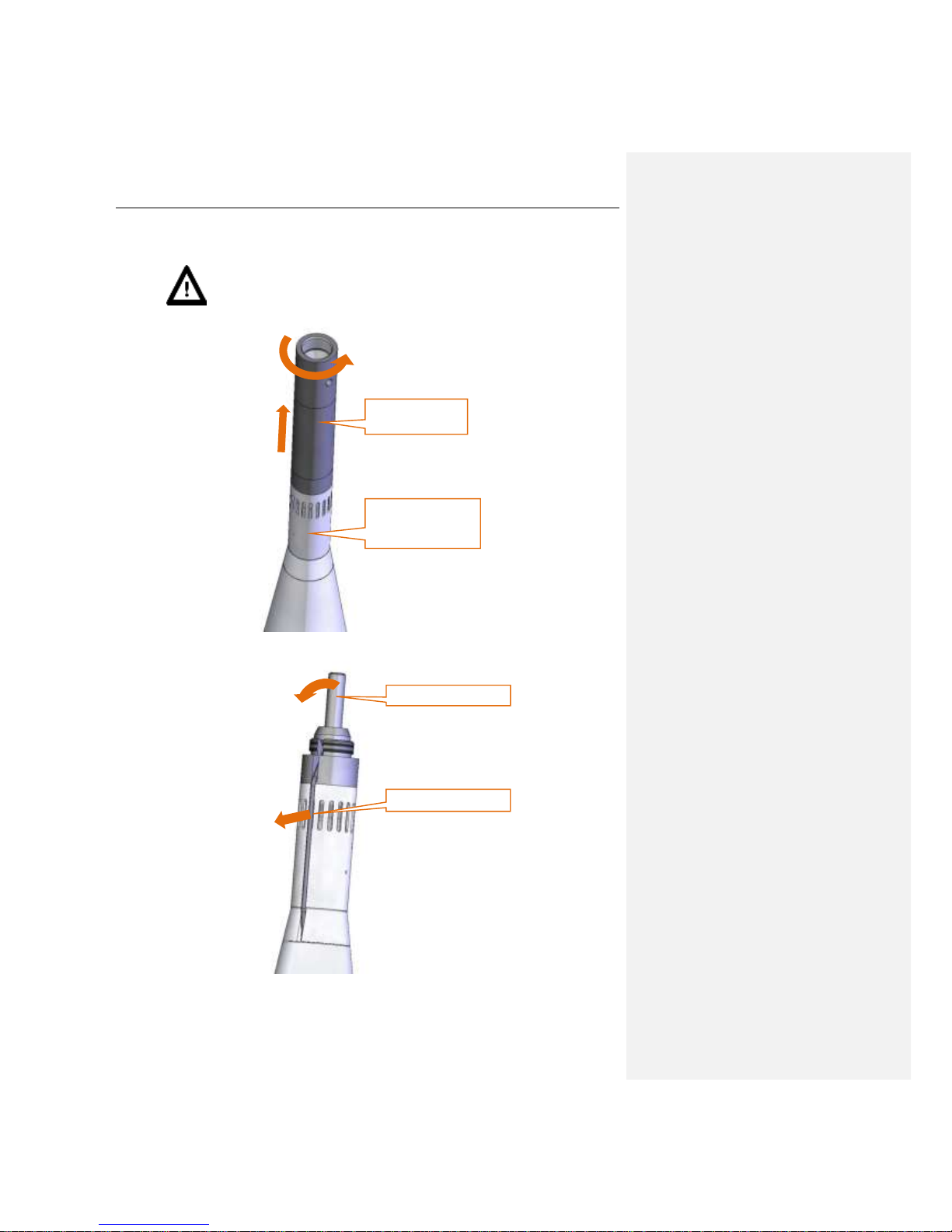

1. Push the foam windscreen until you see the lateral hole.

2. Insert the 3 mm Allen key into the hole.

3. Holding the Allen key and the extension sleeve in one hand to keep them still, use the other

hand to unscrew the top cone with the anti-bird spikes, rotating it counter-clockwise.

Notice: It is important to keep the extension sleeve still, to protect actuator cable

from damage.

push the foam

windscreen until you

see the lateral hole

Page 24

SV 200 USER MANUAL 24

4. Take the Allen key out from the extension sleeve.

5. Take the foam windscreen off the extension sleeve.

hold the Allen key

firmly in one hand

unscrew the top cone

take the foam windscreen off

Page 25

SV 200 USER MANUAL 25

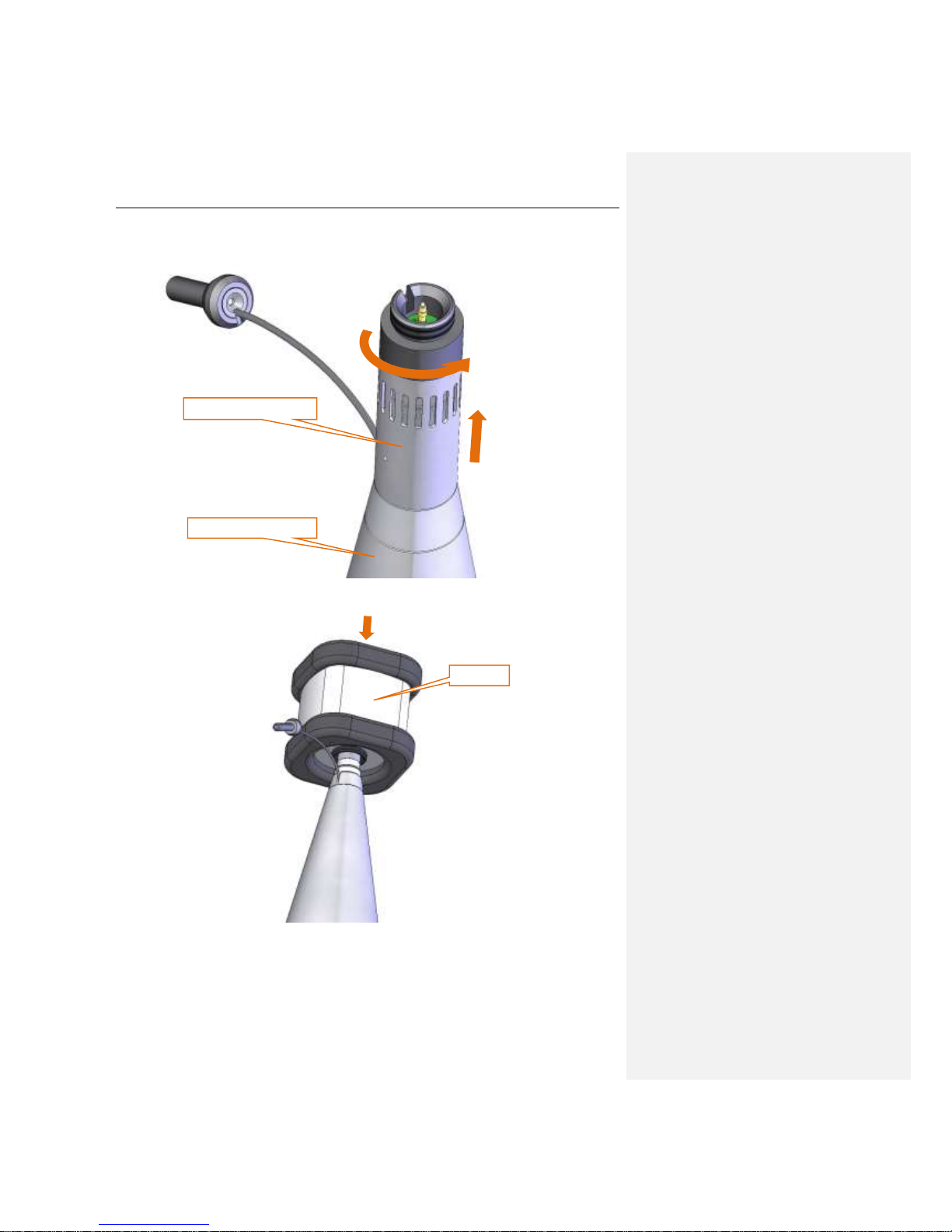

6. Hold the microphone protective sleeve and the outer cone with one hand, use the other hand to

unscrew the extension sleeve, rotating it counter-clockwise.

Notice: It is important to keep the microphone protective sleeve still, to protect

actuator cable from damage.

7. Gently remove the actuator form the socket. Let the cable hang loose.

hold the microphone

protective sleeve

firmly with one hand

unscrew the

extension sleeve

1

2

remove from the socket

let the cable hang loose

Page 26

SV 200 USER MANUAL 26

8. Take the outer cone with one hand, use the other hand to unscrew the microphone protective

sleeve rotating it counter-clockwise.

9. Put the calibrator on the microphone

10. Calibrate according to Chapter 3.7.

11. Take the calibrator off after the calibration.

12. Then follow steps 6 to 12 from Chapter 2.3.

hold firmly with one hand

unscrew the sleeve

1

2

calibrator

Page 27

SV 200 USER MANUAL 27

2.11 Replacement of the foam windscreen

1. Take the windscreen off according to steps 1 to 5 of Chapter 2.9.

2. Install new windscreen according to steps 8 to 12 of Chapter 2.3.

Page 28

SV 200 USER MANUAL 28

3 MANUAL CONTROL OF THE INSTRUMENT

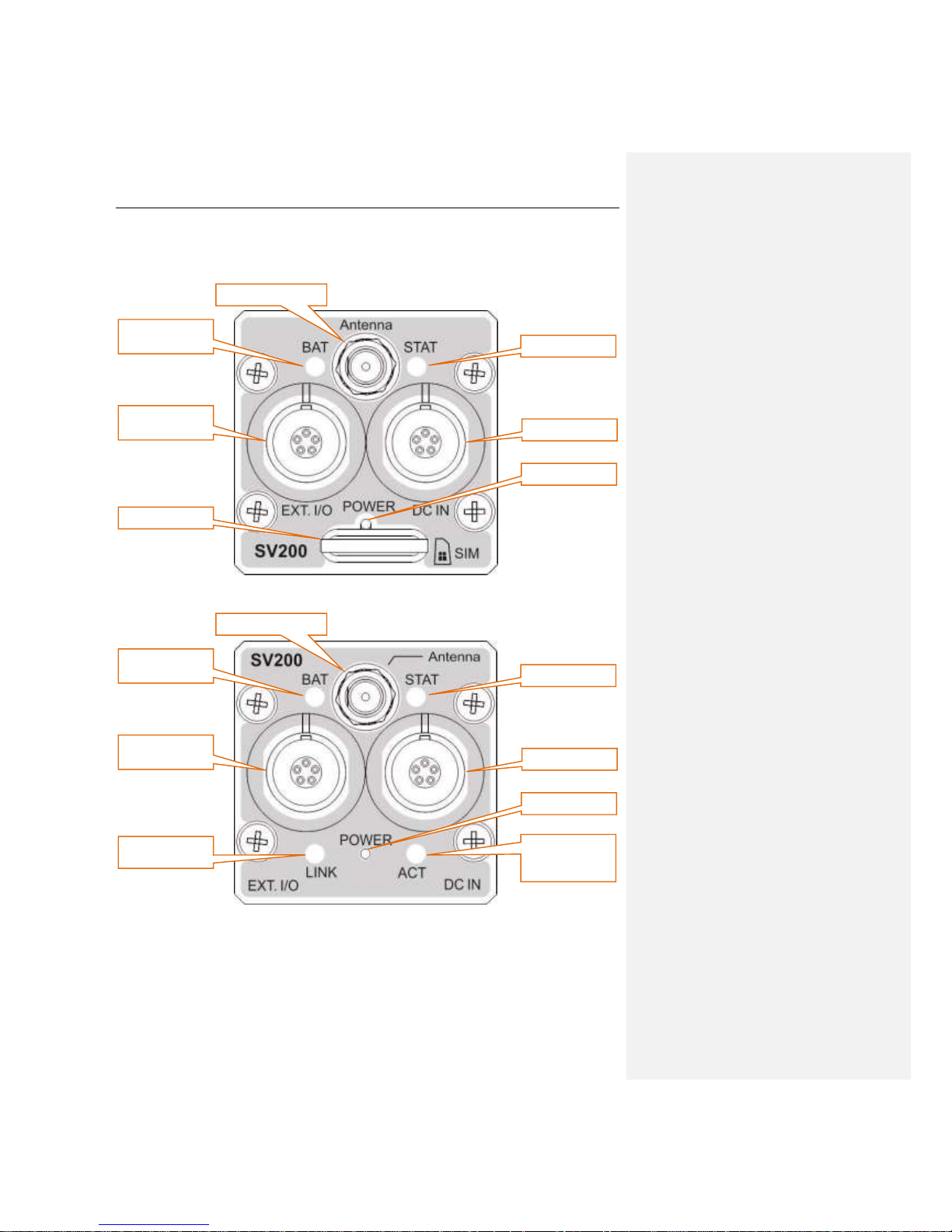

3G modem version

LAN/WiFi version

battery

indicator

Antenna socket

external

interface socket

DC IN socket

POWER button

SIM card slot

status indicator

battery

indicator

Antenna socket

external

interface socket

DC IN socket

POWER button

cable link

status indicator

LAN/WiFi

activity

indicator

Page 29

SV 200 USER MANUAL 29

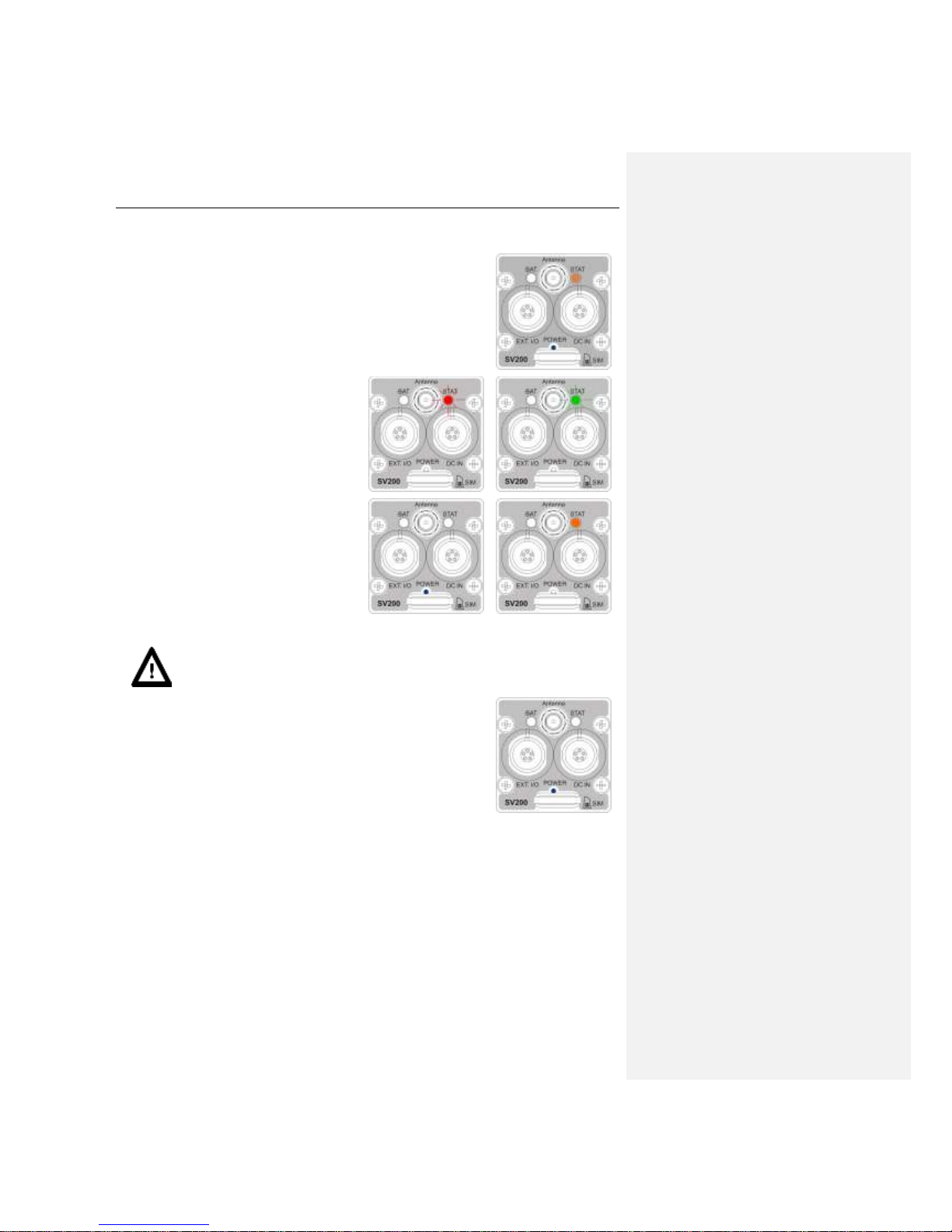

3.1 LED indicators and Power button

Switching the instrument on

The <Power> push-button is the only button on the control panel of the

instrument. It is used for switching the instrument on and off and also

starting/stopping the measurement manually.

When the SV 200 is turned off a short press of the <Power> button turns

it on. During the start-up process the STAT indicator turns orange.

Starting measurement

When the station is switched on the STAT LED

flashes in red (when the measurement is

stopped) or in green (when the measurement is

running). The short press of the <Power>

button, enables the user to start/stop the

measurement.

Switching the instrument off

To turn the SV 200 off press and hold the

<Power> button until the STAT indicator turns

orange. After a few seconds the instrument is

switched off.

Notice: Pressing the <Power> button for longer than 3 seconds during start-up, boots

the SV 200 in BOOTSTRAP mode, used for firmware update (Chapter 3.5). When the

instrument has entered the BOOTSTRAP mode, the STAT LED is solid green.

Resetting the instrument

To hardware reset the SV 200 press and hold the <Power> button for at

least 10 seconds.

Page 30

SV 200 USER MANUAL 30

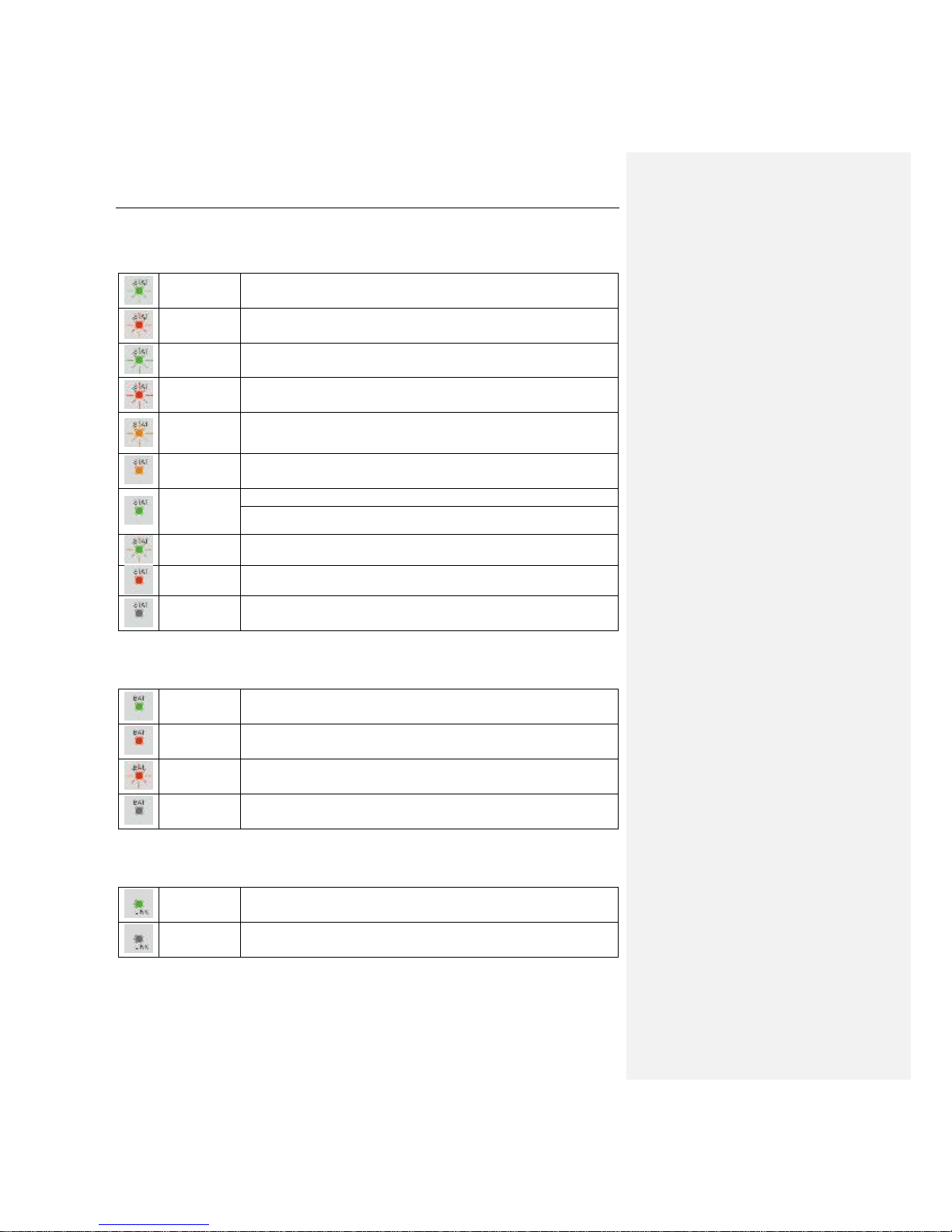

STAT indicator

Meaning of the STAT LED states is described in the below table.

green flashing

Measurement in progress

red flashing

Measurement stopped

green double

flashing

Measurement in progress, 3G connection established (3G version only)

red double

flashing

Measurement stopped, 3G connection established (3G version only)

orange

double

flashing

Measurement in progress, data transmission in progress (3G version only)

orange solid

Turning the instrument on/off

green solid

Bootstrap mode

Calibrator installed and Auto Calibration feature on: Auto Calibration procedure

completed

green and red

flashing

Calibrator installed and Auto Calibration feature on: Auto Calibration in progress

red solid

Calibrator installed and Auto Calibration feature on: Auto Calibration procedure failed

no light

Instrument turned off

BAT indicator

Meaning of the BAT LED states is described in the below table.

green solid

Battery charged

red solid

Charging battery

red flashing

Battery pack damaged or disconnected. Contact local SVANTEK

dealership

no light

When instrument connected to the power supply – battery deeply

discharged. Charging battery with low current

LINK indicator (LAN/WiFi version only)

Meaning of the LINK LED states is described in the below table.

green solid

LAN cable connected properly

no light

LAN cable disconnected

Page 31

SV 200 USER MANUAL 31

ACT indicator (LAN/WiFi version only)

Meaning of the ACT LED states is described in the below table.

green solid

LAN/WiFi connection estabilished

green rapidly

flashing

LAN/WiFi activity

3.2 SIM card slot (3G version only)

Notice: The SIM card slot is present only in devices equipped with 3G modem.

The SIM card should be inserted into the slot to ensure 3G connection. Push the card in until a click can

be heard. Make sure the contact area of the card is facing down.

To remove SIM card from the slot push it until the click is heard and pull the card out.

Further information on configuration of the 3G connection can be found in Chapter 6.

3.3 DC IN socket

The DC IN socket is used to connect external power source, i.e. provided power supply, optional solar

panel or external battery pack.

The SV 200 can be powered using one of the following power sources:

• Li-Ion batteries, fitted internally. Operating using the internal Li-Ion batteries depends on the

power consumption:

➢ up to 45 hours – modem off,

➢ up to 30 hours – 3G modem on,

➢ up to 20 hours – WiFi modem on.

• Provided AC power supply. Input 110-240 VAC, output +24 VDC 2.5A, IP66 housing.

• Optional solar panel. MPPT voltage 17 V-20 V, connected directly to the SV200, without using

power conditioner.

• External DC source. Voltage range 10.5 V – 24 V, e.g. 12 V or 24 V battery.

The internal battery is charged in a fully automatic cycle, when the instrument is connected to any

external power source. The SV200 charges itself irrespectively of it being turned on or off. The weather

conditions (i.e. temperature) are taken into account while charging to prevent any damage of the battery

caused by charging in too high or too low temperature.

Notice: The SV 200 is equipped with the mechanism which protects the internal Li-Ion

batteries from damage caused by critical discharge. When the battery is running flat, the

instrument is automatically switched off.

Page 32

SV 200 USER MANUAL 32

3.4 External Communication Interface socket

The EXT. I/O socket enables the user to connect the instrument to one of the following devices:

• PC (via USB)

• LAN

• SV 200CU user control unit

• SV 205B meteo module

• SV 58 GPS module

• Other RS232 device

• alarm lamp

• external trigger

3.5 Antenna socket

The Antenna socket is used to connect 3G or Wi-Fi antenna (depending on the version of the

instrument). Antenna is equipped with the matching plug with a locking screw, securing it to the body of

the instrument.

After plugging the antenna into the socket, the screw should be tightened to light resistance only. Do

not over tighten this connector.

3.6 Calibration

The instrument is factory calibrated with the supplied microphone for the standard environmental

conditions. Because the microphone sensitivity is a function of the temperature, ambient pressure and

humidity, when the absolute sound pressure level value is important, the absolute calibration of the

measurement channel should be performed.

Preparing for calibration

1. In order to access the microphone it is necessary to disassemble following parts of the SV 200

according to Chapter 2.10:

• con nozzle,

• SA 209 foam windscreen,

• extension sleeve,

• microphone protective sleeve,

2. After disassembling attach the acoustic calibrator, SV30A (or equivalent 114 dB / 1000 Hz)

carefully over the microphone of the instrument.

calibrator

Page 33

SV 200 USER MANUAL 33

Notice: It is also possible to use an electro-mechanical pistonphone, which generates the

signal (ca 124 dB) or different type of acoustic calibrator dedicated for ½” microphones.

In any case, before starting the calibration measurement, the user has to set the level of

the signal generated by the given calibrator, which is stated in the calibration certificate

of the unit.

3. Switch on the calibrator and wait ca 30 seconds for the tone to stabilise before starting the

calibration measurement.

Using Automatic Calibration feature of SV200

Notice: Automatic Calibration feature is switched off by default. To switch this feature on

see Chapter 6.13.

Automatic calibration feature was implemented to make calibration as easy as possible and to allow

technical personnel to perform a calibration of the SV200 with minimum knowledge and without any

additional devices like PC or SV200CU.

1. Switching the calibrator on begins the Automatic Calibration procedure.

2. Wait for the calibration to finish while STAT LED is flashing alternately red and green.

3. If Automatic Calibration is successful the STAT LED turns green. If otherwise the STAT

becomes solid red.

4. After detaching the calibrator from the SV200 the unit returns to its previous state.

Detailed description of the Automatic Calibration feature

The feature is based on 1 second integrated RMS(C) values which are calculated independently to

logger and summary results. These results are always available even if measurements are stopped,

which allows for the procedure to start any time.

The sound pressure level generated by the calibrator should be equal to previously configured level (see

Chapter 6.13) and stable within ±0,1dB margin

If previous conditions are met, measurements are stopped (if were running) and outdoor filter is turned

off. Automatic calibration is in progress, which is signalized by STAT LED alternate red and green

flashes. If level is stable (next three results are within ±0,1dB margin), calibration factor is calculated.

Automatic calibration success if calibration factor is within ±3dB.

To finish the automatic calibration procedure, just remove the calibrator. STAT LED of the SV200 returns

to its normal mode reflecting state of the SV200: start, stop, internet connection etc.

Page 34

SV 200 USER MANUAL 34

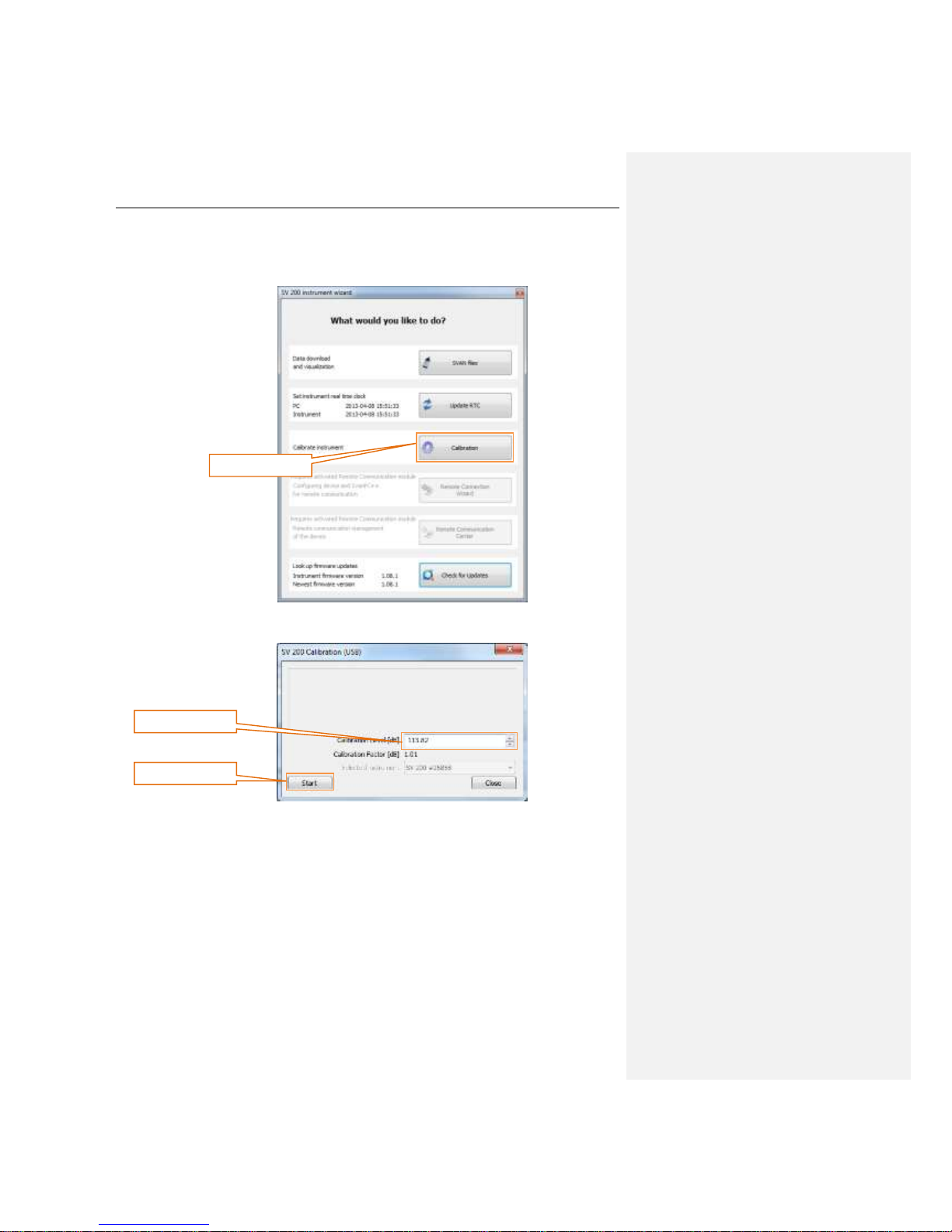

Using SvanPC++ with USB connection

1. Connect the SV 200 with PC using SC 256 cable and start SvanPC++.

2. When SV 200 instrument wizard appears on the screen, click Calibration.

3. Set desired calibration parameters in the SV 200 Calibration window.

Calibration button

Start button

Calibration level

Page 35

SV 200 USER MANUAL 35

4. Start the calibration measurement by pressing the Start. Performing the calibration (with Start

button) will result in calculating the Calibration Factor. Calibration measurement can be

terminated by pressing Terminate button.

Notice: During the calibration measurement, the level of external disturbances (acoustic

noise or vibrations) should not exceed a value of 20 dB below the level of signal generated

by the calibrator (94 dB when using a calibrator that generates a level of 114 dB).

5. Confirm obtained calibration factor by clicking Yes button.

6. Assemble the SV 200 according to Chapter 2.3 of the manual.

Using SV200CU User Control unit

See Chapter 9.6.3.

3.7 Electrostatic actuator

The Electrostatic actuator is used for remote calibration and system check of the instrument. It

generates a 94 dB (re. 20 μPa), 1 kHz tone.

The actuator can be turned on and off manually by the user with Web Interface or remotely using

suitable options in Automatic Files Download or Continuous Logger Download windows of SVAN

PC++ Remote Control.

Auto System Check feature enables the user to configure and schedule automatic checks of the

instrument. It can be set up using SvanPC++ (see Chapter 6.13) or in the Web Interface (see Chapter

7.3.4).

Notice: Actuator can be also controlled using #7,AC; remote function. For further

information see Appendix A.

Terminate button

Calibration factor

Page 36

SV 200 USER MANUAL 36

4 BASIC OPERATIONS

In order to configure the SV 200 the user has to assemble the instrument according to the instructions

in Chapter 2.3, connect the powers source and switch the power on by pressing the Power button.

4.1 PC Software installation and activation

To configure the SV 200 instrument for the first time the user needs to use PC running SVAN PC++

software. It allows you to easily control each function of the instrument and manage whole noise

monitoring station systems consisting of more than one SV 200 device.

1. Choose suitable PC. Make sure that it has active Internet connection if you wish to use SV 200

via the Internet. PC should be running Windows XP/Vista/7/8 operating system. Minimum

system requirements: 1GHz CPU, 1 GB RAM (2GB RAM for x64 system), 20 GB HDD,

1024x768 display.

2. Download and install SVAN PC++ software and Svantek USB Drivers from

http://svantek.com/lang-en/support/software.html website.

3. Prepare the activation key, that has been provided with the device.

4. On the Help menu click Enter Activation Keys… option and enter the key to activate Remote

Communication module.

5. Your SVAN PC++ software is ready to use with SV 200.

Notice: Remote Communication module is activated for each individual SVAN device.

Remember to enter activation key for any new device you wish to manage with RC

module.

4.2 Initial setup of the instrument

SV 200 can be easily configured with SVAN PC++ computer software. After connecting the instrument

to the computer running SVAN PC++ with SC 256 USB cable the SV 200 instrument wizard window

appears on the screen. It enables the user to:

• Manage the instruments’ file structure (SVAN files button)

• Set the instruments’ real time clock to be equal with computer clock (Update RTC button)

• Calibrate the instrument (Calibration button)

• Easily configure remote communication with the instrument (Remote Connection Wizard

button)

• Manage already configured devices (Remote Communication Center button)

• Look up for firmware updates (Check for Updates button)

Page 37

SV 200 USER MANUAL 37

4.2.1 Basic configuration of wireless connection

In order to access SV 200 remotely to download measurement files, manage configuration, receive

alarm emails etc. the instrument must be properly configured. SV 200 is equipped with either internal

3G modem or LAN/WiFi module. Before proceeding with configuration make sure, which version of the

instrument is going to be configured.

Notice: SVANTEK does not provide SIM card for the instrument. If you own SV 200 with

3G modem option it is necessary to purchase SIM card with data plan with deactivated

PIN code. For some features, like Web Interface, public IP address may be required. If

the instrument is intended for constant monitoring choose service provider that ensures

good reception at the measurement point.

Notice: SVANTEK does not provide SIM card for the instrument. If you own SV 200 with

3G modem option it is necessary to purchase SIM card with data plan. For some features,

like Web Interface, public IP address may be required. If the instrument is intended for

constant monitoring choose service provider that ensures good reception at the

measurement point.

Notice: for SIM cards with a static IP address it is not possible to use Remote

Connection Wizard feature described below. To set up wireless connection manually see

Chapter Błąd! Nie można odnaleźć źródła odwołania..

1. Connect the instrument to the PC configured according to Chapter 4.1 with the provided SC256

USB cable.

2. In SVAN PC++ SV200 instrument wizard window click Remote

Connection Wizard button. Remote Connection Wizard window

enables the user to create and manage connection systems

consisting of one or more SVATEK instruments capable of remote

connection (i.e. SV 200).

3. If there is no active connection system and the Add station button is inactive the user needs to

create one before configuration of a new monitoring station by clicking New connection system

button or load previously saved system from the *.svs file by clicking Load from file button.

4. To add new station to an existing connection system click Add station button.

Notice: For more details on wireless connections see Chapter 5.

New connection

system button

Add station button

Load from file

button

Page 38

SV 200 USER MANUAL 38

3G version

1. After clicking the Add station button the Select

system type… window will appear. Make sure the

SIM card is properly inserted into the SIM card slot

of the device. Click Internet button to continue

configuration.

2. Add new station window enables the user to configure all crucial parameters of 3G connection

in simple and user friendly way. The user can enter station name and description, to easily

identify the instrument after the wizard is finished. APN is mandatory field required to set up

the connection. APN value is specific for each mobile operator, who should deliver such

information.

3. DNS Server and Authorization mode should be left unchanged unless SIM card requires

otherwise. In such case suitable information should be delivered by the mobile service operator.

4. User is allowed to choose between two Registration modes: AS or DynDns. AS registration

mode is provided by SVANTEK and requires no additional information. To use this mode contact

your local SVANTEK distributor. DynDns mode requires the user to have active account on

www.dyn.com. In such case Hostname, Username and Password fields should be filled,

where Hostname is address assigned to the instrument and Username and Password are

dyn.com account login credentials.

APN field

Authorization mode

Registration mode

Page 39

SV 200 USER MANUAL 39

Notice: If the user wishes to use SV200’s web interface (Chapter 0), either DynDns

registration mode should be chosen or SIM card with static IP address should be used

for AS registration mode.

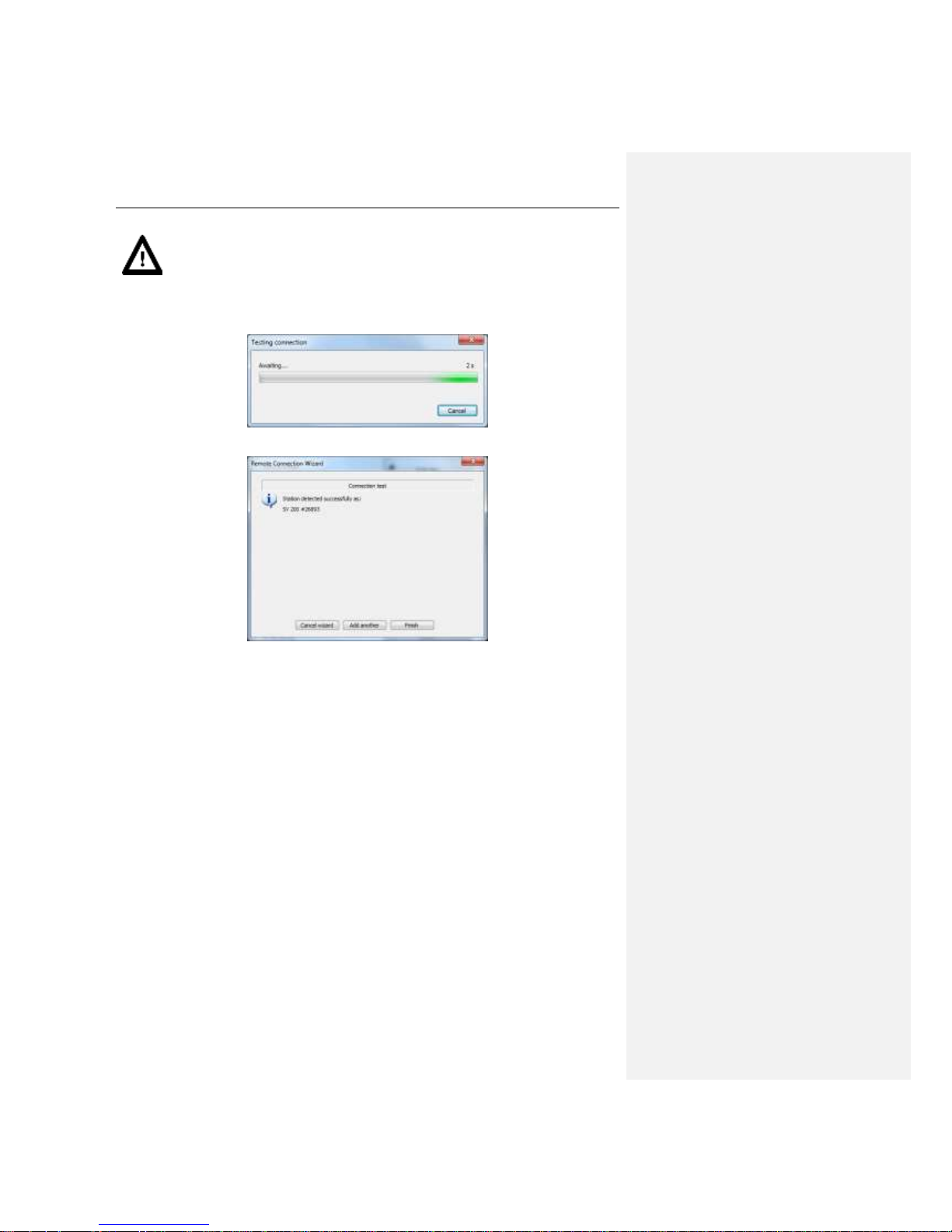

5. After entering all the required information SVAN PC++ will check connection settings. Wait until

process is finished. It may take a few minutes.

6. After finishing configuration the user can finish the wizard or add another instrument.

Page 40

SV 200 USER MANUAL 40

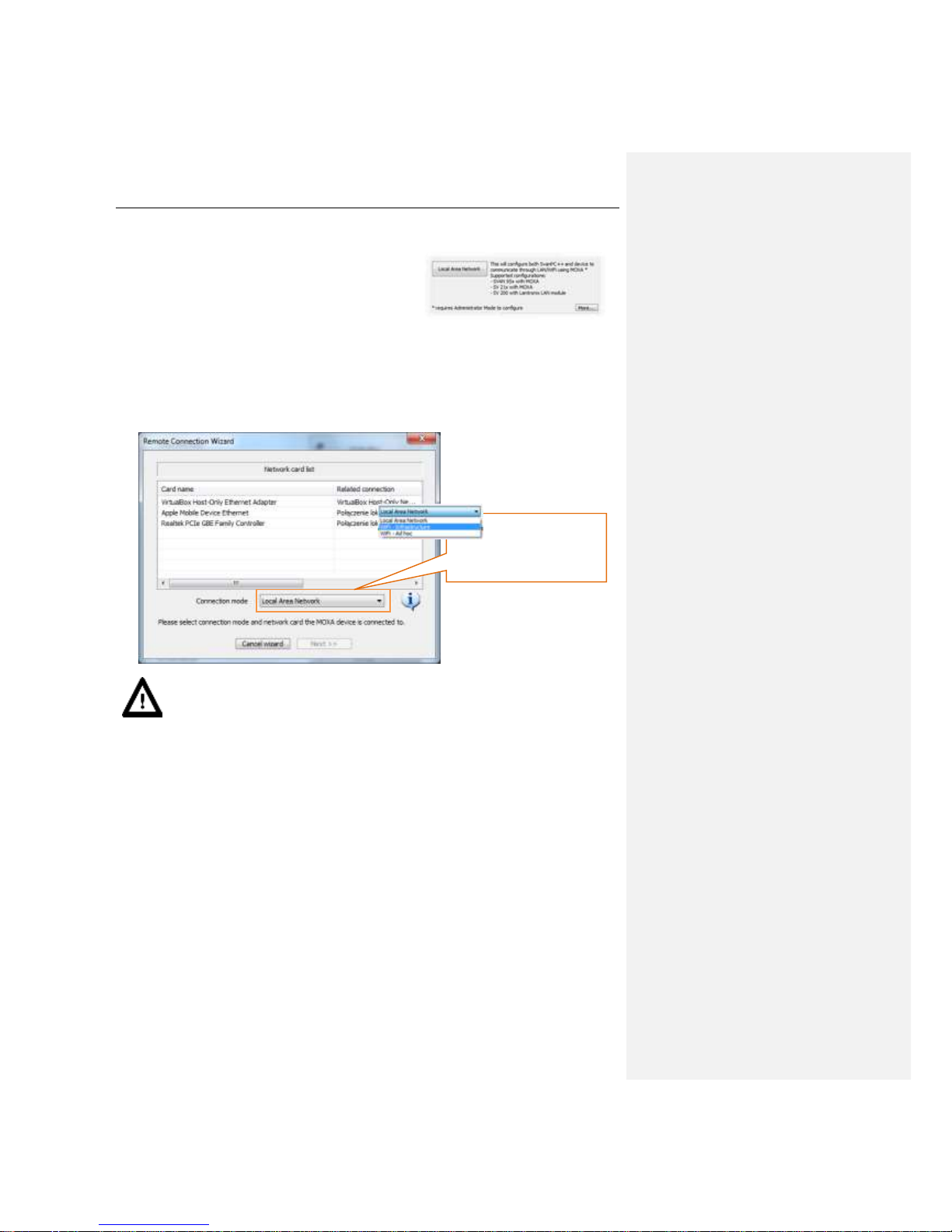

LAN/WiFi version

1. After clicking the Add station button the Select

system type… window will appear. Click Local

Area Network button to continue configuration.

2. Choose suitable Connection mode. If the user plans to connect the instrument via wired

connection Local Area Network connection mode should be chosen as well as the PC network

interface that will be used for connection. If the user intends to use wireless connection in an

existing WiFi network WiFi – Infrastructure option should be chosen. If the instrument is

supposed to create its’ own wireless network the user should chose WiFi – Ad hoc connection

mode.

Notice: Should WiFi – Ad hoc connection mode be chosen, PC wireless network

interface settings will be modified by the Wizard. If Windows Vista/7/8 is being used such

operation requires administrator rights.

Connection mode

Page 41

SV 200 USER MANUAL 41

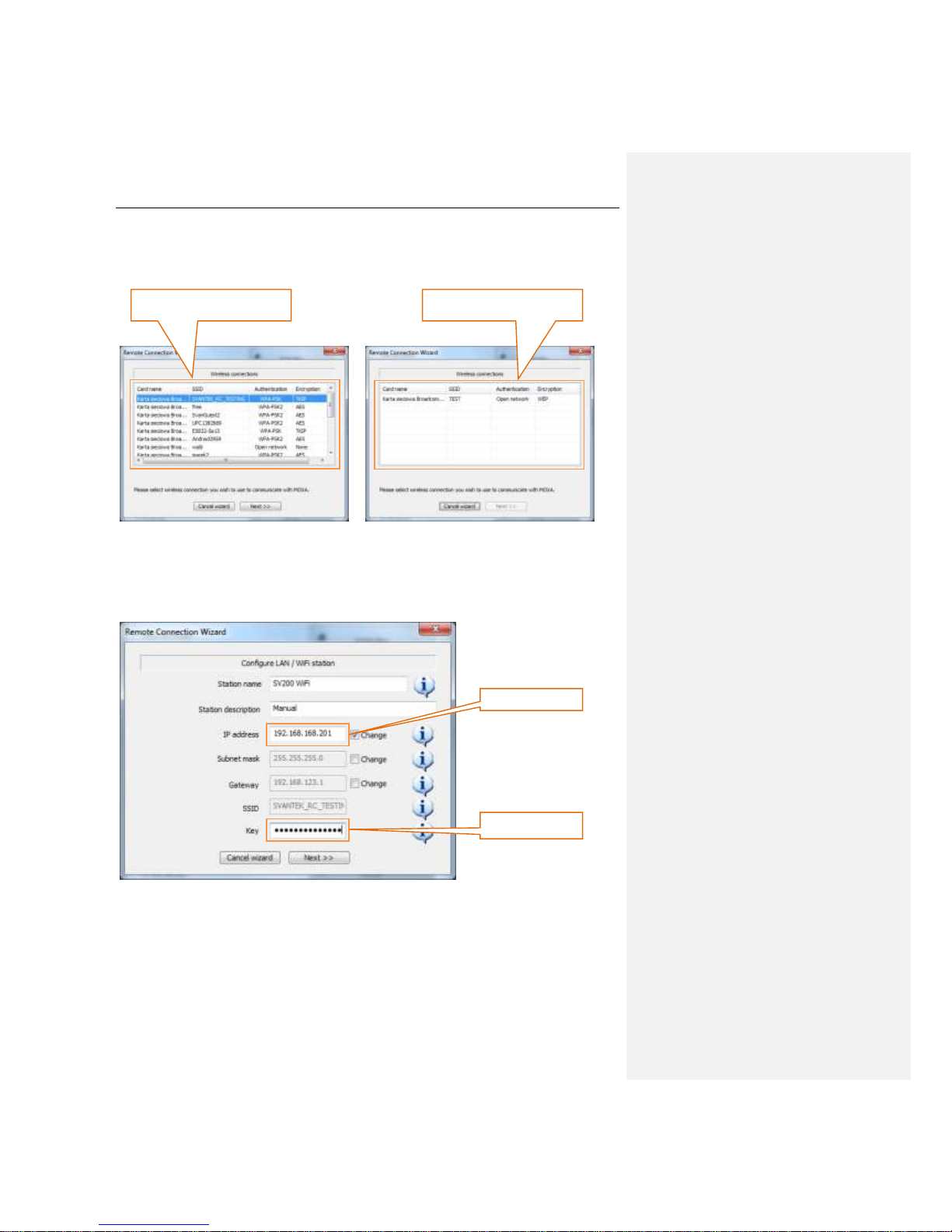

3. Depending on the connection mode the user needs to choose wireless network to connect to

(in case WiFi – Infrastructure mode was chosen previously), choose network interface to

reconfigure (in case WiFi – Ad hoc mode was chosen previously) or go straight to step 4.

4. Configure LAN / WiFi station window enables the user to configure all crucial parameters of

LAN/WiFi module in simple and user friendly way. The user can enter station name and

description, to easily identify the instrument after the wizard is finished. Network settings such

as IP Address, Subnet Mask and Gateway can be modified.

5. In case of wireless connection Network key should be entered.

Wireless network list

(WiFi – Infrastructure)

Wireless network interfaces

(WiFi – Ad hoc)

IP Address

Network Key

Page 42

SV 200 USER MANUAL 42

6. After entering all the required information SVAN PC++ will check connection settings. Ensure

that the PC is connected to the same network as the instrument for the connection test to

succeed. Wait until process is finished. It may take a few minutes.

7. After finishing configuration the user can finish the wizard or add another instrument.

Page 43

SV 200 USER MANUAL 43

4.2.2 Starting measurement

SV 200 is able to monitor and log noise by enabling up to three different parameter configuration

settings, also referred to as “ACOUSTIC PROFILE, each one with different filter (A, C and Z) and

detector (SLOW, FAST and IMPULSE) settings.

Notice: The SV 200 provides AutoStart feature. If the instrument is idle for 60 s the

measurement is automatically started.

Using POWER button

1. Make sure that the instrument is turned on.

2. Press <Power> push-button shortly.

3. Starting of the measurements will be signalized by green flashing STAT LED on the instrument’s

user panel.

Using SvanPC++

1. Make sure that the instrument is turned on.

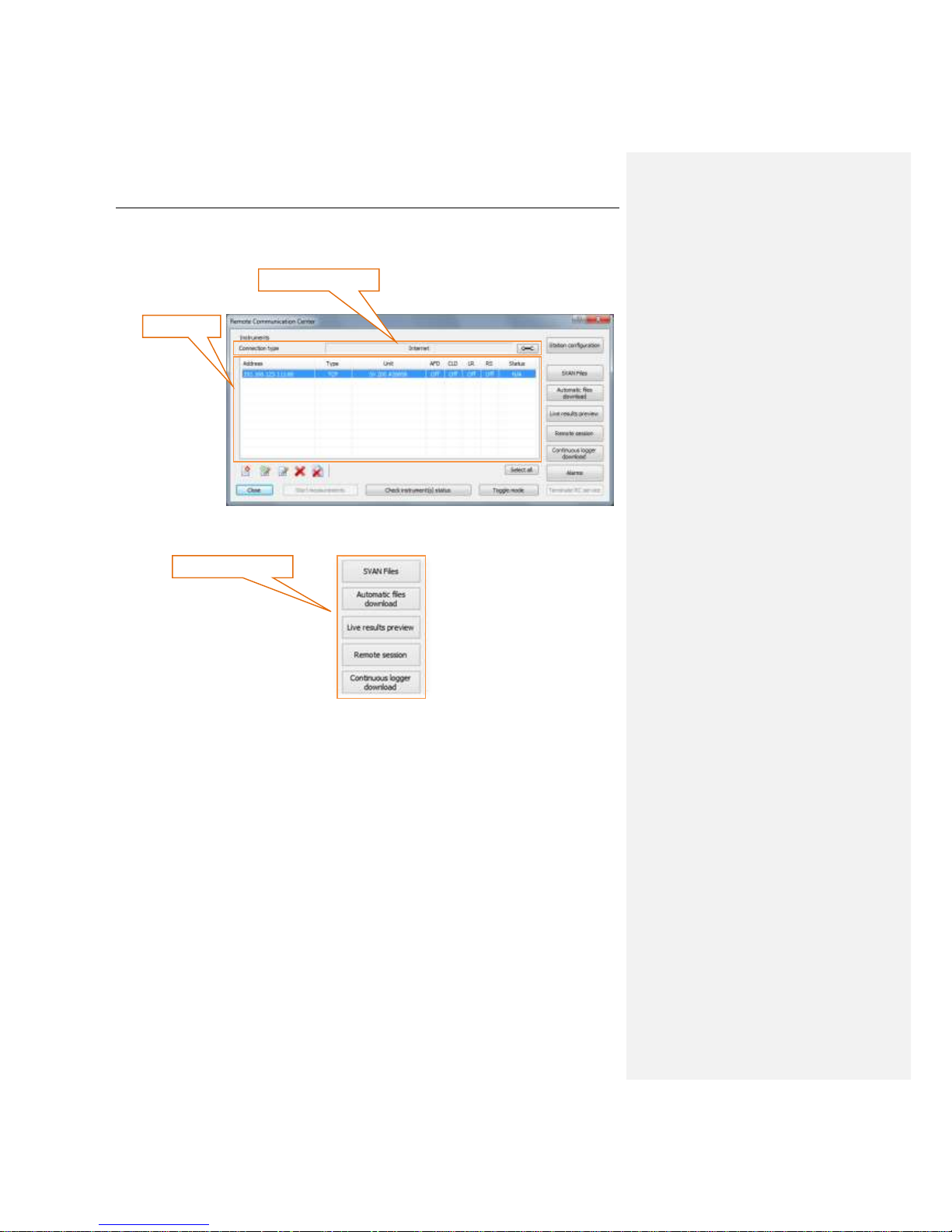

2. Open Remote Communication Center.

3. Make sure appropriate Connection type is selected. If you wish to communicate with the

instrument via 3G, LAN or WiFi connection select Internet. If you wish to communicate with the

instrument via USB cable select USB.

4. Select the station in Station list box.

5. Check the state of the instrument by clicking Check instrument(s) status. When the instrument

status is known, Start measurement button becomes enabled.

6. Click Start measurement button.

Connection type box

Station list

Check instrument

status button

Start

measurement

button

Page 44

SV 200 USER MANUAL 44

Using Web Interface

1. Open to the instruments’ Web Interface by entering IP address or domain name into your web

browser address bar.

2. Once Web Interface is loaded navigate to Configuration tab.

3. In Configuration tab click Start measurements button.

4. Starting of the measurements will be signalized by green flashing LED icon in the top left corner

of the Web Interface site.

Using SV 200CU User Control unit

See Chapter 9.4. on swithing the control unit on and starting measurement.

Configuration tab

Start measurements

button

Page 45

SV 200 USER MANUAL 45

4.3 Changing the working directory

Working directory is a folder on the SD card in which all the measurement data is stored.

Changing the working directory can be conducted with SVAN PC++ software either locally via USB

cable or remotely using RC module with SVAN Files feature.

1. Make sure measurement is not in progress.

2. After opening SVAN Files navigate to the desired directory using the left pane. The left pane

displays contents of the instrument SD card or internal memory. Create new directory if

necessary.

3. Click Set as working folder button.

4. Working directory of the SV200 is now set. All the result files are going to be stored in the

selected folder.

SVAN Files button

SVAN Files button

Navigation pane

Create new folder

Go to parent directory

Go to working folder

Set as working folder button

Page 46

SV 200 USER MANUAL 46

4.4 Firmware upgrade

The firmware which controls the SV 200 is possible for the user to upgrade. There are three separate

programs loaded into the instrument’s memory:

1. User Program,

2. BOOTSTRAP,

3. HARDBOOT.

The User Program controls all of the instrument’s functions i.e. measurements, communication, web

server etc. SVANTEK constantly improves functionalities included so it is recommended to install all

available firmware upgrades.

The BOOTSTRAP program is designed to conduct the upgrade process of the User Program.

SVANTEK releases updates of the BOOTSTRAP program when necessary because of major changes

in the User Program.

The HARDBOOT is unereasable program designed to conduct the upgrade or repair process of the

BOOTSTRAP only.

4.4.1 User program upgrade

To upgrade the instrument using USB cable

1. Switch the instrument off if it is switched on.

2. Connect the SV 200 to the PC using provided SC 256 cable.

3. Press and hold the <Power> push-button until the STAT indicator turns solid green. That boots

the instrument into BOOTSTRAP mode.

4. Run batch file included in the upgrade package.

Notice: Solid red STAT LED indicates error in booting process. Turn the SV 200 off and

start the upgrade process from the beginning.

Page 47

SV 200 USER MANUAL 47

To upgrade the instrument via Web interface

1. Open to the instruments’ Web Interface by entering IP address or domain name into your web

browser address bar.

2. Once Web Interface is loaded navigate to Configuration tab.

3. Make sure the measurement is stopped.

4. Expand Firmware upgrade section.

5. In order to load firmware click Browse button and locate firmware *.bin file on the PC.

6. Upload the selected file by clicking Upload button.

7. After the upload is finished select new firmware package in Firmware selector.

8. Click Load Firmware button.

9. Click Restart instrument button to finalize the process and wait 60 seconds for the connection

to renew. The measurements will start automatically.

Browse button

Upload button

Load firmware button

Restart instrument button

Stored firmware selector

Page 48

SV 200 USER MANUAL 48

4.4.2 Web interface upgrade

Some major firmware version upgrades may require the user to upgrade Web Interface as well. This

upgrade can be with SVAN PC++ software either locally via USB cable or remotely using RC module.

Notice: Remember to upgrade the Web Interface after firmware upgrade (Chapter 4.4.1).

1. Open SVAN Files by clicking the button on the Instrument Wizard (when connecting locally)

or Remote Communication Center (in case of remote connection).

2. After opening SVAN Files go to root directory by clicking Go to parent directory… button.

3. Make sure measurement is not in progress. Click Set as working folder button.

4. On the instrument panel select all files present in the root directory and click Delete.

SVAN Files button

SVAN Files button

Go to parent directory button

Set as working folder button

Delete button

Page 49

SV 200 USER MANUAL 49

5. On the local directory panel navigate to folder containing Web Server files. Select all files and

upload them into the root directory of the instrument by clicking Upload button.

6. After the upload process is finished do to DATA directory.

7. Click Set as working folder button.

4.4.3 Bootstrap program upgrade

Upgrade of the BOOTSTRAP program is conducted through the HARDBOOT service program. It is

possible only via USB cable.

1. Switch the instrument off if it is switched on.

2. Connect the SV 200 to the PC using provided SC 256 cable.

3. Press and hold the <Power> push-button until the STAT indicator turns solid green. Then press

the <Power> push-button shortly. If the STAT LED turned solid orange, the instrument entered

into HARDBOOT mode.

4. Run batch file included in the upgrade package.

Notice: Solid red STAT LED indicates error in booting process. Turn the SV 200 off and

start the upgrade process from the beginning.

Upload button

Page 50

SV 200 USER MANUAL 50

5 REMOTE CONFIGURATION

5.1 Remote control principles

Depending on the remote communication module chosen, the SV 200 comes equipped with either H24

Telit 3G Modem or with Lantronix WiPort LAN/WLAN. Both options offer means of communication using

industry standard protocols, allowing access for applications such as SvanPC++ via Internet.

5.1.1 H24 Telit 3G Modem

The H24 Telit 3G Modem module enables the user a wide array of interfacing capabilities through the

use of GSM based internet access. The SV 200 equipped with such a module has a SIM card slot to

which a proper card with an internet access plan needs to be inserted. The SIM card’s PIN code must

be deactivated beore use. The user is usually expected to have means of acquiring such a card on their

own as GSM services are country based.

Internet access, as provided by GSM operators, comes with a set parameters that define the visibility of

the address the SIM card is assigned each time it connects to the network. This address can be public

or private (meaning whether the address is accessible from the outside or not) and can be static or

dynamic (meaning whether the address is different each time the card connects to the Internet or stays

the same). The parameters define the range of available functionalities of the instrument when it comes

to how can it be accessed remotely.

The functionalities that H24 Telity 3G Modem module offers are:

• Main communication channel

• Web server

• SMS / E-mail alarms

• SMS command exchange

Main communication channel is a TCP connection (a lossless data exchange protocol) that can be

used to exchange commands as specified by Appendix A. This connection is primary means of

managing data and instrument by applications such as SvanPC++ and as such provides the most

accurate and real-live method of performing such tasks as data download, performance validation and

measurement start/stop. For more information about what can be achieved through the use of remote

commands see Appendix A. Remote Control.

Main communication channel of the SV 200 can be established by one of two available methods: TCP

Server or TCP Client.

TCP Server is a mode of main communication channel in which the H24 Telit 3G Modem is configured

to act as a server for incoming connections. For the use in SV 200, the modem is awaiting for the first

connection to be established on a designated port (called Data Port; default 8001). Such connection

can come from any application designed to act as an initiator of the TCP connection (such as SvanPC++)

called remote peer. This mode is recommended to be used as it places the initiative completely on the

controlling application's side. This mode requires the SIM card's plan to feature a public address (also

called public IP).

The TCP Server mode features a functionality called Registration. This functionality is a method of

translation of a dynamic address to a form of a static credentials. It is essential for effective use with

SIM card plans that feature a dynamic IP. The dynamic IP means that internet address changes each

time the modem equipped with a dynamic IP SIM card establishes connection to the Internet. As such,

it is impossible to determine what is the SV 200's internet address in a given moment. The Registration

feature allows the instrument to provide its current internet address for an external application to acquire

to later connect to it.

Page 51

SV 200 USER MANUAL 51

There are three Registration methods supported by SV 200:

1. SvanNET

2. DynDns

3. Address Server

The DynDns is a service that allows a static name to be translated to an internet address. The controlling

application uses the name to identify the SV 200 in the internet network as an address to connect to.

The properly configured instrument provides means to validate its internet address to be recognized in

internet network. The name provided by DynDns service is translated by the DNS protocol to a given

internet address to which an application can connect to.

Notice: This feature requires a paid DynDns account and its credentials (host name, login

name and password) need to be inputted into the SV 200 configuration. For more details

regarding DynDns service consult http://www.dyndns.org.

The Address Server is Svantek’s own means of providing the instrument's current internet address. In

this mode, the SV 200 provides its current internet address to Svantek server. SvanPC++ is then later

able to fetch said address to be able to connect to it. This mode requires no paid account and no

credentials of any sort as it comes preconfigured to the user, but it requires access to

www.svantek.com domain from the GSM operator network.

Notice: To use this mode contact your local SVANTEK distributor.

TCP Client is a mode of main communication channel in which the H24 Telit 3G Modem is configured

to initiate connection to a designated address (called remote host). Each time a reconnection period

(configurable; default 30 seconds) has elapsed, the SV 200 in such mode attempts to establish a TCP

connection to a designated address on a designated port (Data Port). Should the connection be

established successfully, the SV 200 is ready to exchange commands similar as in TCP Server mode.

Should the connection attempt fail or be broken by the remote host, the SV 200 will attempt to connect

again after another reconnection period has elapsed.

To prevent the connections from going idle (a state in which the connection seems active, but no data

can be transferred – it may happen due to GSM operator terminating the link, but the TCP protocol not

being able to detect it), any connection (be it Main communication channel or Web server connection),

will be terminated after a reconnection period during which no data is transferred.

Page 52

SV 200 USER MANUAL 52

5.1.2 Web server

Web Server enables access to most basic functionalities of data download and instrument control via a

Web Browser. The SV 200 features a web page that can be displayed by a web browser. This feature

can be accessed by entering either the instrument's internet address in the browser window. The Web

Server functions over the Main Communication Channel, excluding the exchange of regular commands

while browsing the instrument’s WWW pages. If Registration functionality is enabled with DynDns

mode configured, the user can input the instrument’s DynDns name in the web browser, rather than the

internet address.

Each SV 200 comes with its own set of default WWW files, ready to be used in such fashion, but the

instrument allows the user's files to be used in its stead. The WWW files are stored in the root folder of

the instrument’s SD card and can be updated using SvanPC++’s file upload function.

The default Web page of the instrument is a robust design, allowing display of various information. The

built-in command parser allows the browser to exchange dynamic data via the use of JavaScript, thus

enabling the possibility to view live data results, spectrum graphs, read and send current configuration

settings. Due to limited capabilities of the instrument as compared to dedicated web servers, the

functionality does not support parallel data transfer that is featured by modern browsers and as such

the web pages are designed in such a way to improve performance by delegating the browser to

download static resources (such as libraries, images and style sheets) from www.svantek.com domain.

However, should this site be unreachable from the instrument’s side, the page will attempt to fetch

resources from the SV 200 enabling its full functionality, although at reduced download rate. The Web

server is fit with a caching support, allowing the browsers to store static content on the computer’s disk

drive and use it the next time it connects to the SV 200 rather than force them to download the page

again.

Notice: The Web Server functionality of SV 200 requires a SIM card with a public

internet IP address.

Page 53

SV 200 USER MANUAL 53

5.1.3 SMS / E-mail alarming

SMS / E-mail alarming functionality allows the SV 200 equipped with a SIM card to acknowledge the

user with an information of a measurement value crossing a defined threshold with an SMS and/or Email notification. Whenever a defined condition is met, the SV 200 can send an SMS to a defined number

and/or an E-mail to a defined address to provide information, including the current value of the monitored

result, the profile it is measured in and the value of the threshold it's being measured against.