Suzuki AN650/A Supplementary Service Manual

AN650

USE THIS MANUAL WITH:

AN650 SERVICE MANUAL (99500-36113-01E)

/

A

99501-36160-01E

AN650/AK7 (’07-MODEL) 1

AN650/AK7 (’07-MODEL)

This manual describes service data, service specifications, FI and servicing procedures which

differ from those of the AN650/AK6 (’06-model).

NOTE:

• Any differences between the AN650/AK6 (’06-model) and AN650/AK7 (’07-model) in

specifications and service data are indicated with an asterisk mark (*).

• Please refer to the AN650K6 (’06-model) service manual for details which are not given

in this manual.

CONTENTS

SPECIFICATIONS (AN650K7)........................................................................... 3

SPECIFICATIONS (AN650AK7) ........................................................................ 5

SDS CHECK ....................................................................................................... 7

FI SYSTEM WIRING DIAGRAM......................................................................... 11

ECM/PCM TERMINAL........................................................................................ 12

FAIL-SAFE FUNCTION............................................................................. 14

MALFUNCTION CODE AND DEFECTIVE CONDITION .......................... 15

“C40” (P0505 or P0506 and P0507) ISC VALVE CIRCUIT

MALFUNCTION......................................................................................... 16

“C41” (P2505) ECM/PCM POWER INPUT CIRCUIT

MALFUNCTION......................................................................................... 21

“C44” (P0130/P0135) HO2 SENSOR (HO2S) CIRCUIT

MALFUNCTION......................................................................................... 23

“C49” (P1656) PAIR CONTROL SOLENOID VALVE CIRCUIT

MALFUNCTION......................................................................................... 27

ISC VALVE REMOVAL ............................................................................. 29

ISC VALVE INSPECTION......................................................................... 29

ISC VALVE INSTALLATION..................................................................... 29

ISC VALVE PRE-SET ............................................................................... 30

THROTTLE VALVE SYNCHRONIZATION............................................... 31

WIRING HARNESS, CABLE AND HOSE ROUTING ........................................ 33

WIRING HARNESS ROUTING ................................................................. 33

THROTTLE BODY INSTALLATION AND HOSE ROUTING ................... 34

SPECIAL TOOLS ............................................................................................... 35

TIGHTENING TORQUE CHART............................................................... 35

SERVICE DATA (AN650K7) .............................................................................. 36

SERVICE DATA (AN650AK7)............................................................................ 45

WIRING DIAGRAM............................................................................................. 55

SAMPLE

© COPYRIGHT SUZUKI MOTOR CORPORATION 2007

2 AN650/AK7 (’07-MODEL)

AN650/AK7 (’07-MODEL)

COUNTRY AND AREA CODES

The following codes stand for the applicable country(-ies) and area(-s).

MODEL CODE COUNTRY or AREA EFFECTIVE FRAME NO.

U.K.

E.U.

Australia

Canada

U.K.

E.U.

Australia

Canada

Korea

AN650

AN650A

E-02

E-03

E-19

E-24

E-28

E-33

E-02

E-03

E-19

E-24

E-28

E-33

E-51

U.S.A. (Except for california)

California (U.S.A.)

U.S.A. (Except for california)

California (U.S.A.)

JS1BU111200100524 –

JS1BU111200 100001 –

JS1BU111100114140 –

JS1BU121300100404 –

JS1BU111200 100001 –

JS1BU111200 100001 –

JS1BU132200100227 –

JS1CP51B 72100001 –

JS1BU132100117025 –

JS1BU142300100012 –

JS1CP51B 72100001 –

JS1CP51B 72100001 –

JS1BU132470100001 –

SAMPLE

AN650/AK7 (’07-MODEL) 3

SPECIFICATIONS (AN650K7)

DIMENSIONS AND DRY MASS

Overall length ..................................................................................... 2 260 mm (89.0 in)

Overall width....................................................................................... 810 mm (31.9 in)

Overall height ..................................................................................... 1 435 mm (56.5 in)

Wheelbase ......................................................................................... 1 595 mm (62.8 in)

Ground clearance ............................................................................... 130 mm ( 5.1 in)

Seat height ......................................................................................... 750 mm (29.5 in)

Dry mass ............................................................................................ 235 kg (518 lbs)

ENGINE

Type.................................................................................................... 4-stroke, liquid-cooled, DOHC

Number of cylinders ........................................................................... 2

Bore.................................................................................................... 75.5 mm (2.972 in)

Stroke................................................................................................. 71.3 mm (2.807 in)

Displacement...................................................................................... 638 cm

Compression ratio .............................................................................. 11.2 : 1

Fuel system ........................................................................................ Fuel injection

Air cleaner.......................................................................................... Non-woven fabric element

Starter system.................................................................................... Electric

Lubrication system ............................................................................. Wet sump

Idle speed........................................................................................... 1 200 ± 100 r/min

DRIVE TRAIN

Clutch ................................................................................................. Wet multi-plate,automatic,centrifugal type

Primary reduction ratio ....................................................................... 1.333 (88/66)

Gearshift pattern................................................................................. Automatic & Manual shift

Automatic transmission ratio .............................................................. Variable change (1.800-0.465)

Secondary reduction ratio .................................................................. 3.934 (39/31 × 43/25 × 40/22)

Final reduction ratio ............................................................................ 1.580 (32/31 × 31/32 × 34/31 × 49/34)

Drive system....................................................................................... Gear drive

CHASSIS

Front suspension................................................................................ Telescopic, coil spring, oil damped

Rear suspension ................................................................................ Swingarm type, coil spring, oil damped

Front fork stroke.................................................................................. 110 mm (4.3 in)

Rear wheel travel................................................................................ 100 mm (3.9 in)

Caster................................................................................................. 26° 10’

Trail..................................................................................................... 106 mm (4.17 in)

Steering angle.................................................................................... 41° (right and left)

Turning radius..................................................................................... 2.7 m (8.9 ft)

Front brake ......................................................................................... Disc brake,twin

Rear brake.......................................................................................... Disc brake

Front tire size ...................................................................................... 120/70R15M/C 56H, tubeless

Rear tire size ...................................................................................... 160/60R14M/C 65H, tubeless

ELECTRICAL

Ignition type ........................................................................................ Electronic ignition (Transistorized)

Ignition timing ..................................................................................... 10° B.T.D.C. at 1 200 r/min

Spark plug .......................................................................................... NGK CR8E or DENSO U24ESR-N

Battery................................................................................................ 12 V 43.2 kC (12 Ah)/10 HR

Generator ........................................................................................... Three-phase A.C. generator

Main fuse............................................................................................ 40 A

CVT fuse ............................................................................................ 40 A

Fuse ................................................................................................... 15/15/15/15/10/10/10 A ..........................E-02, 19

Headlight ............................................................................................ 12 V 60 + 55/55 + 55 (H4 + H7)..............E-02, 19

12 V 60/55 × 2 (H4 × 2) ..........................E-03, 24, 28, 33

Position/Parking light.......................................................................... 12 V 5 W × 2..E-02, 19

Brake light/Taillight.............................................................................. 12 V 21/5 W × 2

License plate light............................................................................... 12 V 5 W

Trunk light ........................................................................................... 12 V 5 W

Turn signal light .................................................................................. 12 V 21 W

Instrument panel light ......................................................................... 12 V 1.4 W × 2

Coolant temperature warning light ..................................................... 12 V 1.4 W

Fuel injection warning light................................................................. 12 V 1.4 W

Oil pressure warning light................................................................... 12 V 1.4 W

Brake lock warning light...................................................................... 12 V 1.4 W

High beam indicator light.................................................................... 12 V 1.4 W

Turn signal indicator light.................................................................... 12 V 1.4 W × 2

Power mode indicator light ................................................................. 12 V 1.4 W

Drive indicator light ............................................................................. 12 V 1.4 W

Gear position indicator light................................................................ 12 V 1.4 W × 5

Immobilizer indicator light ................................................................... LED....... E-02, 19, 24

Over drive indicator light..................................................................... 12 V 1.4 W

SAMPLE

3

(38.9 cu. in)

15/15/15/15/15/10/10 A ..........................E-03, 24, 28, 33

4 AN650A/K7 (’07-MODEL)

CAPACITIES

Fuel tank, including reserve ............................................................... 15.0 L (4.0/3.3 US/Imp gal)

Engine oil, oil change......................................................................... 2 600 ml (2.7/2.3 US/Imp qt)

Transmission oil, oil change ................................................................ 360 ml (12.2/12.7US/Imp oz)

Final gear oil, oil change..................................................................... 300 ml (10.1/10.6US/Imp oz)

Coolant................................................................................................ 1.6 L (1.7/1.4 US/Imp qt)

with filter change .............................................................. 2 900 ml (3.1/2.6 US/Imp qt)

overhaul ............................................................................ 3 400 ml (3.6/3.0 US/Imp qt)

overhaul ................................................................... 400 ml (13.5/14.1US/Imp oz)

overhaul ....................................................................... 430 ml (14.5/15.1US/Imp oz)

SAMPLE

AN650/AK7 (’07-MODEL) 5

SPECIFICATIONS (AN650AK7)

DIMENSIONS AND DRY MASS

Overall length ..................................................................................... 2 260 mm (89.0 in)

Overall width....................................................................................... 810 mm (31.9 in)

Overall height ..................................................................................... 1 435 mm (56.5 in)

Wheelbase ......................................................................................... 1 595 mm (62.8 in)

Ground clearance ............................................................................... 130 mm ( 5.1 in)

Seat height ......................................................................................... 750 mm (29.5 in)

Dry mass ............................................................................................ 243 kg (535 lbs)

ENGINE

Type.................................................................................................... 4-stroke, liquid-cooled, DOHC

Number of cylinders ........................................................................... 2

Bore.................................................................................................... 75.5 mm (2.972 in)

Stroke................................................................................................. 71.3 mm (2.807 in)

Displacement...................................................................................... 638 cm

Compression ratio .............................................................................. 11.2 : 1

Fuel system ........................................................................................ Fuel injection

Air cleaner.......................................................................................... Non-woven fabric element

Starter system.................................................................................... Electric

Lubrication system ............................................................................. Wet sump

Idle speed........................................................................................... 1 200 ± 100 r/min

DRIVE TRAIN

Clutch ................................................................................................. Wet multi-plate,automatic,centrifugal type

Primary reduction ratio ....................................................................... 1.333 (88/66)

Gearshift pattern................................................................................. Automatic & Manual shift

Automatic transmission ratio .............................................................. Variable change (1.800-0.465)

Secondary reduction ratio .................................................................. 3.934 (39/31 × 43/25 × 40/22)

Final reduction ratio ............................................................................ 1.580 (32/31 × 31/32 × 34/31 × 49/34)

Drive system....................................................................................... Gear drive

CHASSIS

Front suspension................................................................................ Telescopic, coil spring, oil damped

Rear suspension ................................................................................ Swingarm type, coil spring, oil damped

Front fork stroke.................................................................................. 110 mm (4.3 in)

Rear wheel travel................................................................................ 100 mm (3.9 in)

Caster................................................................................................. 26° 10’

Trail..................................................................................................... 106 mm (4.17 in)

Steering angle.................................................................................... 41° (right and left)

Turning radius..................................................................................... 2.7 m (8.9 ft)

Front brake ......................................................................................... Disc brake,twin

Rear brake.......................................................................................... Disc brake

Front tire size ...................................................................................... 120/70R15M/C 56H, tubeless

Rear tire size ...................................................................................... 160/60R14M/C 65H, tubeless

ELECTRICAL

Ignition type ........................................................................................ Electronic ignition (Transistorized)

Ignition timing ..................................................................................... 10° B.T.D.C. at 1 200 r/min

Spark plug .......................................................................................... NGK CR8E or DENSO U24ESR-N

Battery................................................................................................ 12 V 43.2 kC (12 Ah)/10 HR

Generator ........................................................................................... Three-phase A.C. generator

Main fuse............................................................................................ 40 A

CVT fuse ............................................................................................ 40 A

Fuse ................................................................................................... 15/15/15/15/15/10/10/15/15 A

Headlight ............................................................................................ 12 V 60 + 55/55 + 55 (H4 + H7)..............E-02, 19, 51

12 V 60/55 × 2 (H4 × 2) ..........................E-03, 24, 28, 33

Position/Parking light.......................................................................... 12 V 5 W × 2..E-02, 19, 51

Brake light/Taillight.............................................................................. 12 V 21/5 W × 2

License plate light............................................................................... 12 V 5 W

Trunk light ........................................................................................... 12 V 5 W

Turn signal light .................................................................................. 12 V 21 W

Instrument panel light ......................................................................... 12 V 1.4 W × 2

Coolant temperature warning light ..................................................... 12 V 1.4 W

Fuel injection warning light................................................................. 12 V 1.4 W

Oil pressure warning light................................................................... 12 V 1.4 W

Brake lock warning light...................................................................... 12 V 1.4 W

High beam indicator light.................................................................... 12 V 1.4 W

Turn signal indicator light.................................................................... 12 V 1.4 W × 2

Power mode indicator light ................................................................. 12 V 1.4 W

Drive indicator light ............................................................................. 12 V 1.4 W

Gear position indicator light................................................................ 12 V 1.4 W × 5

ABS indicator light.............................................................................. 12 V 1.4 W

Immobilizer indicator light ................................................................... LED....... E-02, 19, 24, 51

Over drive indicator light..................................................................... 12 V 1.4 W

SAMPLE

3

(38.9 cu. in)

6 AN650A/K7 (’07-MODEL)

CAPACITIES

Fuel tank, including reserve ............................................................... 15.0 L (4.0/3.3 US/Imp gal)

Engine oil, oil change......................................................................... 2 600 ml (2.7/2.3 US/Imp qt)

Transmission oil, oil change ................................................................ 360 ml (12.2/12.7US/Imp oz)

Final gear oil, oil change..................................................................... 300 ml (10.1/10.6US/Imp oz)

Coolant................................................................................................ 1.6 L (1.7/1.4 US/Imp qt)

with filter change .............................................................. 2 900 ml (3.1/2.6 US/Imp qt)

overhaul ............................................................................ 3 400 ml (3.6/3.0 US/Imp qt)

overhaul ................................................................... 400 ml (13.5/14.1US/Imp oz)

overhaul ....................................................................... 430 ml (14.5/15.1US/Imp oz)

SAMPLE

AN650/AK7 (’07-MODEL) 7

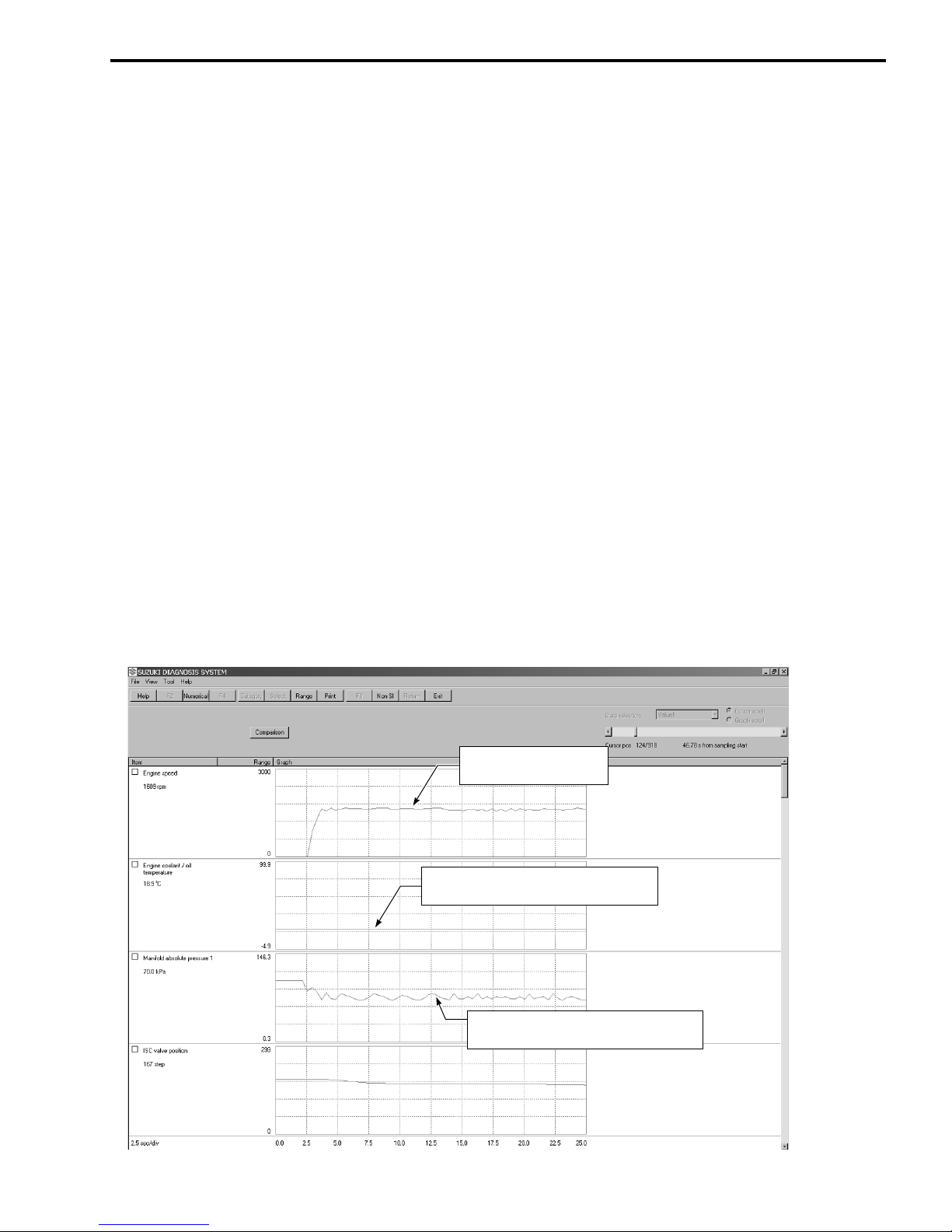

SDS CHECK

Using SDS, sample the data at the time of new and periodic vehicle inspections.

After saving the sampled data in the computer, file them by model and by user.

The periodically filed data help improve the accuracy of troubleshooting since they can indicate the condition

of vehicle functions that has changed with time.

For example, when a vehicle is brought in for service but the troubleshooting of a failure is not easy, comparing the current data value to the past filed data value at time of normal condition can allow the specific

engine failure to be determined.

Also, in the case of a customer vehicle which is not periodically brought in for service with no past data value

having been saved, if the data value of a good vehicle condition have been already saved as a master

(STD), comparison between the same models helps facilitate the troubleshooting.

• Set up the SDS tools. (Refer to the SDS operation manual for further details.)

! 09904-41010: SDS set tool

99565-01010-010: CD-ROM Ver.10

NOTE:

* Before taking the sample of data, check and clear the Past DTC. (Refer to the SDS operation manual for

further details.)

* A number of different data under a fixed condition as shown below should be saved or filed as sample.

SAMPLE:

Data sampled from cold starting through warm-up

SAMPLE

Check the engine r/min.

XXXX r/min

Check the engine coolant temperature.

XX ˚C

Check the manifold absolute pressure.

XX kPa

8 AN650A/K7 (’07-MODEL)

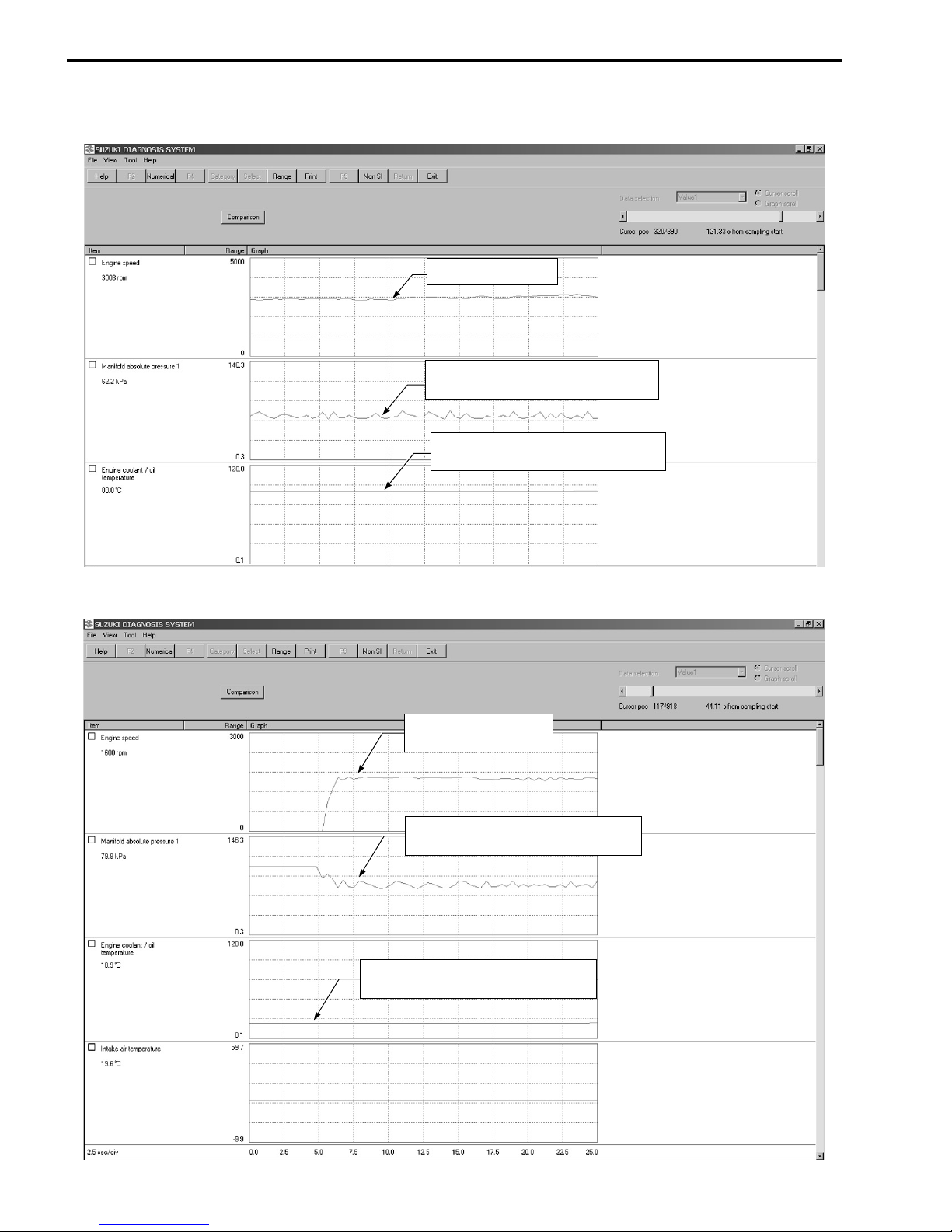

Data at 3 000 r/min under no load

Approx. 3 000 r/min

Check the manifold absolute pressure.

XX kPa

Check the engine coolant temperature.

XX ˚C

Data of manifold absolute pressure operation at the time of cold starting

Check the engine r/min.

SAMPLE

XXXX r/min

Check the manifold absolute pressure.

XX kPa

Check the engine coolant temperature.

XX ˚C

Data of intake negative pressure during idling (100 °C)

Check the manifold absolute pressure.

XX kPa

AN650/AK7 (’07-MODEL) 9

Check the engine coolant temperature.

Approx. 100 ˚C

Data of manifold absolute pressure operation at the time of hot starting

SAMPLE

Check the engine r/min.

XXXX r/min

Check the manifold absolute pressure.

XX kPa

Check the engine coolant temperature.

XX ˚C

10 AN650A/K7 (’07-MODEL)

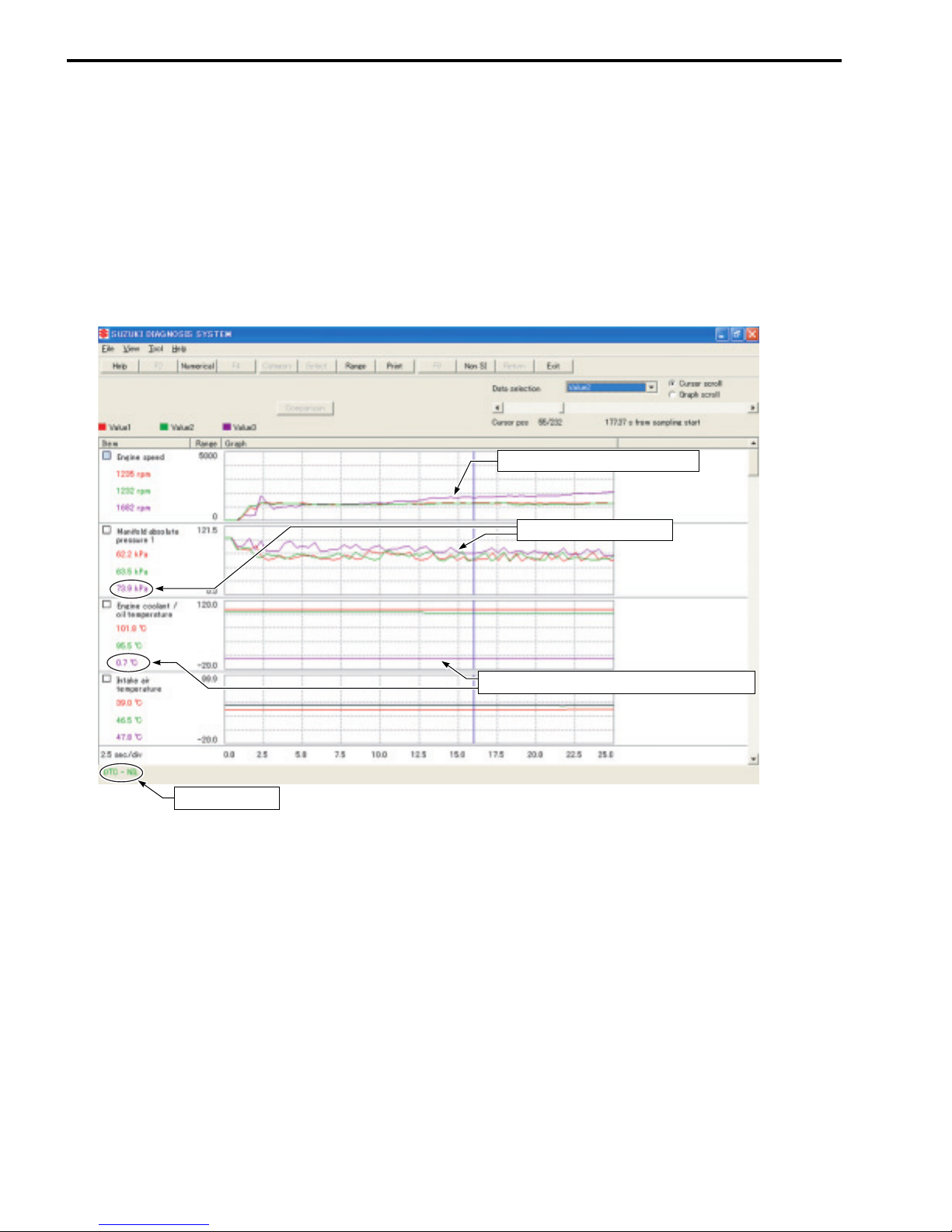

Example of trouble

Three data; value 1 (current data 1), value 2 (past data 2) and value 3 (past data 3); can be made in comparison by showing them in the graph. Read the change of value by comparing the current data to the past data

that have been saved under the same condition, then you may determine how changes have occurred with

the pass of time and identify what problem is currently occurring.

With DTC not output, if the value of engine coolant temperature is found to be lower than the data saved

previously, the possible cause may probably lie in a sensor circuit open or ground circuit opened or influence

of internal resistance value changes, etc.

Unstable idling speed (Too high)

No DTC output

Abnormal curve of graph

Abnormal value of engine coolant temperature

SAMPLE

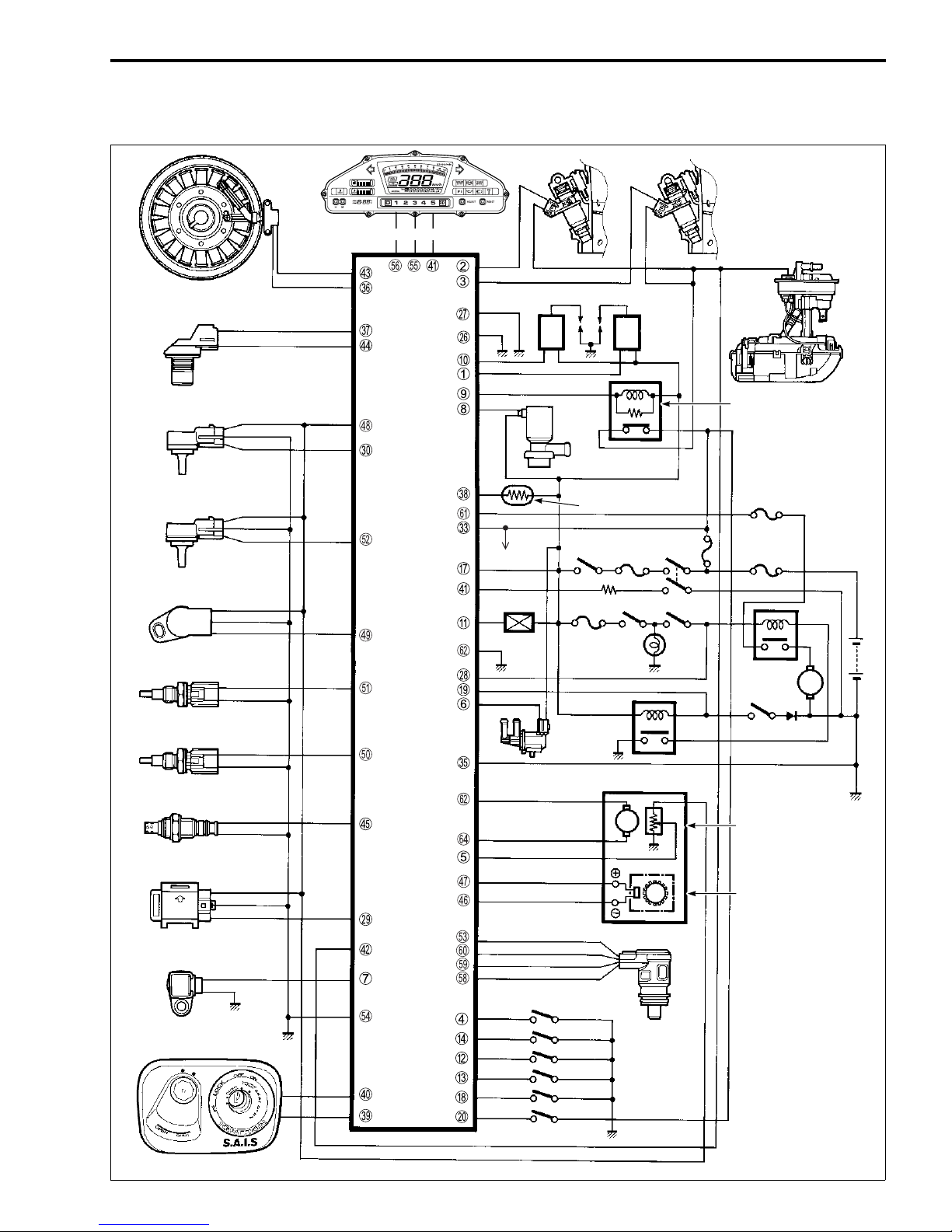

FI SYSTEM WIRING DIAGRAM

AN650/AK7 (’07-MODEL) 11

Fuel injector #1 Fuel injector #2

Crankshaft position sensor(CKPS)

Camshaft position sensor (CMPS)

B/Y

Br

Intake air pressure sensor (IAPS)

Ambient pressure sensor

(APS)

Throttle position sensor

(TPS)

Engine coolant temperature

sensor (ECTS)

Intake air temperature

sensor (IATS)

HO2 sensor (HO2S)

Tip-over sensor (TOS)

Speed sensor

Combination

meter

W

W/G

R

Lg/B

G/Y

P/B

B/Bl

Dg

SAMPLE

P/W O/BlBr/W

*1

ECM/PCM

Gr/W

Gr/B

Ignition coil #1

B/W

B/W

W/Bl

B/Y

Y/Bl

G/Bl

Y/W

R/B

R/Bl

To

Combination

meter

O/W

O/Y

*2

Gr/Y

Cooling

B

fan relay

Y/G

G

Dbr

*3

B/W

Ignition coil #2

PA IR

control

solenoid

valve

HO2 sensor heater

Engine

stop switch

EVAP system

purge control

solenoid

valve

15 A

10 A

Brake light

Ignition

switch

Starter

switch

switch

Brake

light

Side-stand relay

CVT unit

R/W

B/G

Br/R

Y/R

G/R

G/B

B/Lg

P/W

P

W/B

Br

Bl

G

CVT motor

M

Fuel pump

Fuel pump relay

40 A

30 A

Starter

relay

M

Side-stand switch

Pulley position sensor

Secondary pulley

revolution sensor

Immobilizer

B/Br

B/O

Y/Bl

Y

G/W

R/W

Lg/Y

*1

*1

Lg

W/B

Shift up

switch

Shift down

switch

Powe r

switch

Mode

switch

Center stand

switch

Brake light

switch

ISC valve

*1: For E-02, 19, 24

*2: For E-03, 28, 33

*3: For E-33 only

12 AN650A/K7 (’07-MODEL)

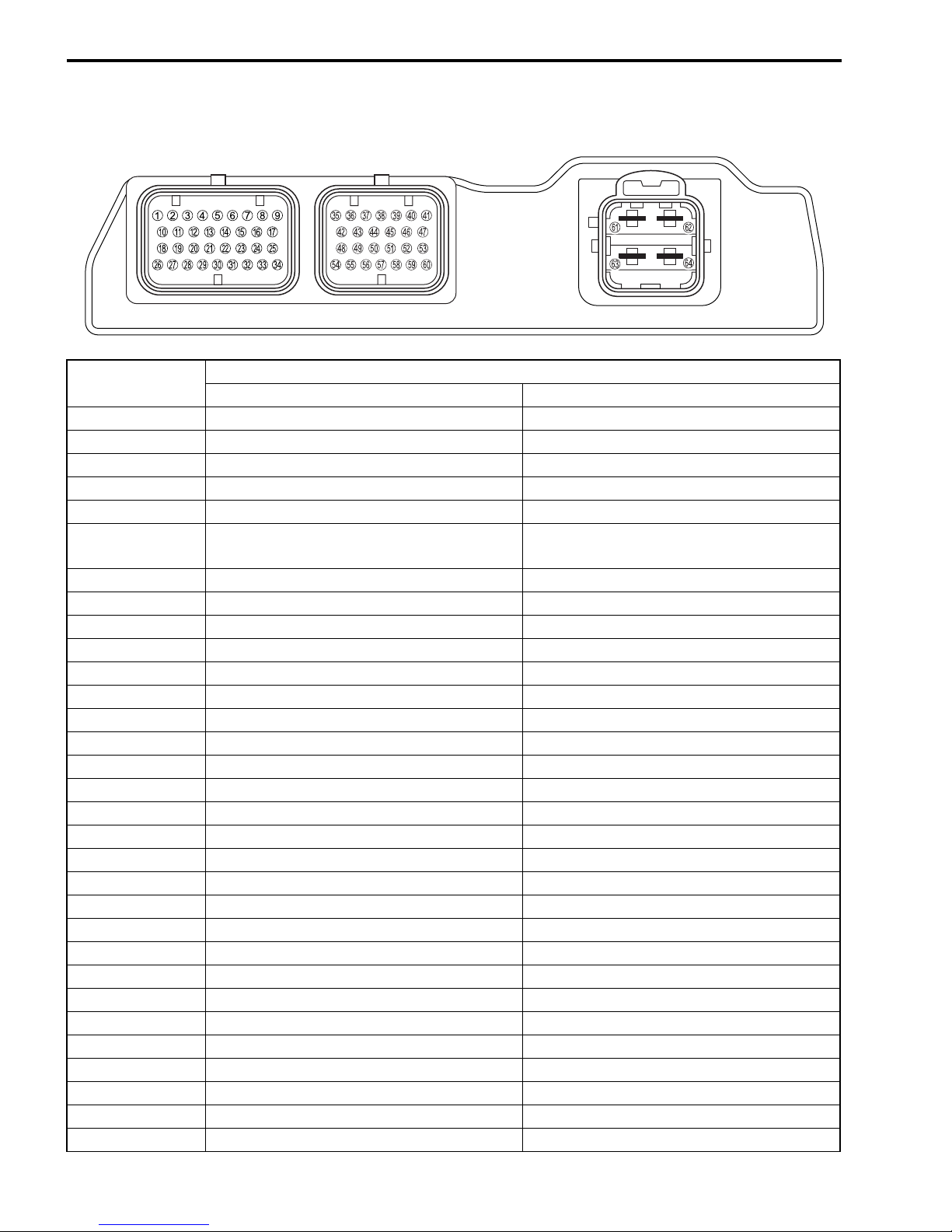

ECM/PCM TERMINAL

ECM TERMINAL

NO.

1 Ignition coil (IG2) ←

2 Fuel injector (#1) ←

3 Fuel injector (#2) ←

4 Shift up switch (UP) ←

5 Pulley position sensor (PPS) ←

6

7 Speed sensor (SPD) ←

8 PAIR control solenoid valve (PAIR) ←

9 Fuel pump relay (FP) ←

0 Ignition coil (IG1) ←

A Cooling fan relay (FRL) ←

B Power switch (POWER) ←

C Mode switch (MODE) ←

D Shift down switch (DOWN) ←

E ——

F ——

G Battery (+B) ←

H Center stand switch (CSTD) ←

I Side-stand switch (SS) ←

J Brake switch (BRK) ←

K ——

L ——

M ——

N ——

O ——

P Ground (E03) ←

Q Ground (E01) ←

R Starter relay (STA) ←

S — TO sensor (DON)

T — IAP sensor (PM)

U ——

CIRCUIT

K6 K7

PTVC heater (PTC) EVAP system purge control solenoid valve

(E-33 only)

SAMPLE

AN650/AK7 (’07-MODEL) 13

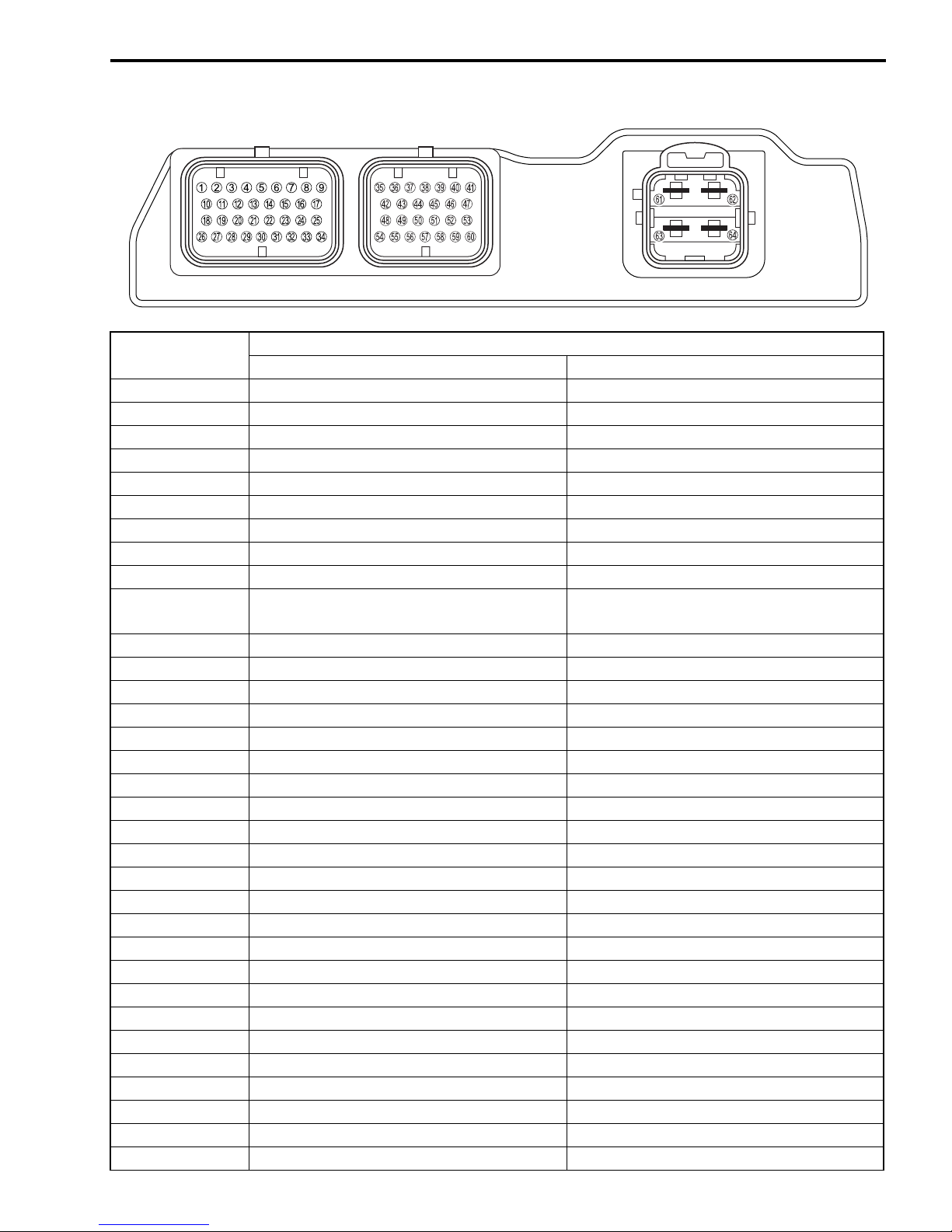

ECM TERMINAL

NO.

V ——

W Battery (BATT) ←

X ——

Y Ground (E1) ←

Z CKP sensor (N-) ←

[ CMP sensor (G+) ←

\ HO2 sensor heater (OXH) ←

] Immobilizer (TXCK) (For E-02, 19, 24) ←

^ Immobilizer (RXCK) (For E-02, 19, 24) ←

a

b Injector power voltage (VM) ←

c CKP sensor (N+) ←

d CMP sensor (G-) ←

e HO2 sensor (OX) ←

f

g

h Sensor power (Vcc) ←

i TP sensor (VTA) ←

j IAT sensor (THA) ←

k ECT sensor (THW) ←

l AP sensor (PA) ←

m — ISC valve 1A (IS1A)

n Ground (E2) ←

o Tachometer (TACO) ←

p Meter communication (ETCH) ←

q ——

r IAP sensor (PM) ISC valve 2B (IS2B)

s TO sensor (DON) ISC valve 2A (IS2A)

t IG switch (AT) ISC valve 1B (IS1B)

u Battery (VB) ←

v CVT motor (MO+) ←

w Ground ←

x CVT motor (MO-) ←

CIRCUIT

K6 K7

Immobilizer LED (Meter) (For E-02, 19, 24)

Anti-thief switch (AT) (For E-03, 28, 33)

Secondary pulley revolution sensor (SPR-)

Secondary pulley revolution sensor (SPR+)

SAMPLE

←

←

←

14 AN650A/K7 (’07-MODEL)

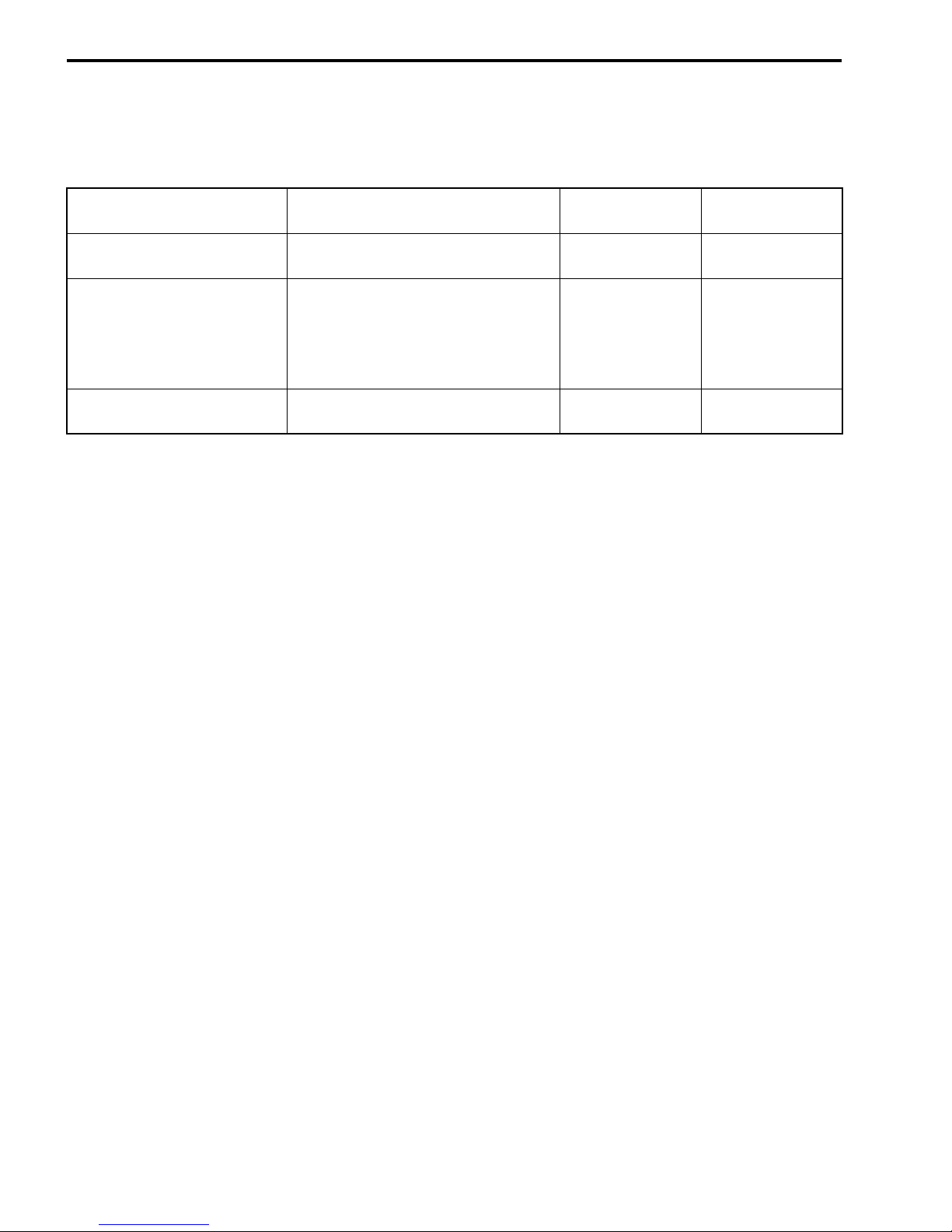

FAIL-SAFE FUNCTION

FI system is provided with fail-safe function to allow the engine to start and the motorcycle to run in a minimum performance necessary even under malfunction condition.

ITEM FAIL-SAFE MODE

HO2 sensor Feedback compensation is inhibited.

(Air/fuel ratio is fixed to normal.)

PAIR control solenoid valve ECM stops controlling PAIR control

solenoid valve.

HO2 sensor feedback compensation

is inhibited.

Power for HO2 sensor is shut off.

ISC valve When motor disconnection or lock

occurs, power from ECM is shut off.

The engine can start and can run even if the above signal is not received from each sensor. But, the engine

running condition is not complete, providing only emergency help (by fail-safe circuit). In this case, it is necessary to bring the motorcycle to the workshop for complete repair.

STARTING

ABILITY

“YES” “YES”

“YES” “YES”

“YES” “YES”

RUNNING

ABILITY

SAMPLE

MALFUNCTION CODE AND DEFECTIVE CONDITION

AN650/AK7 (’07-MODEL) 15

DTC No.

C00 NO FAULT

C40 (P0505)

C40 (P0506)

C40 (P0507)

C41 (P2505)

C44

P0130

C44

P0135

C49 PAIR control

P1656

DETECTED

ISC valve

ECM/PCM

power input

signal

HO2 sensor HO2 sensor output voltage is not input

solenoid

valve

ITEM

SAMPLE

DETECTED FAILURE CONDITION CHECK FOR

––––––––––– –––––––––––

Although current is flowing though the

ISC valve motor, the current detection

is not possible.

Idle speed is lower than the desired

idle speed.

Idle speed is higher than the desired

idle speed.

No voltage is applied to the ECM,

although the ignition switch is turned

ON.

to ECM during engine operation and

running condition.

(Sensor voltage < 1.0 V)

In other than the above value, C44

(P0130) is indicated.

The Heater can not operate so that

heater operation voltage is not supply

to the oxygen heater circuit, C44

(P0135) is indicated.

PAIR control solenoid valve voltage is

not input to ECM.

ISC valve circuit open or shorted

to ground

Air passage clogged

ISC valve is fixed

ISC valve pre-set position is

incorrect

ISC valve is fixed

ISC valve pre-set position is

incorrect

Lead wire/coupler connection of

ECM terminal to fuel fuse, fuel

fuse, battery voltage to ECM

(BATT) shorted to ground or

open

HO2 sensor circuit open

HO2 sensor lead wire/coupler

connection

Battery voltage supply to the

HO2 sensor

PAIR control solenoid valve, lead

wire/coupler

16 AN650A/K7 (’07-MODEL)

1

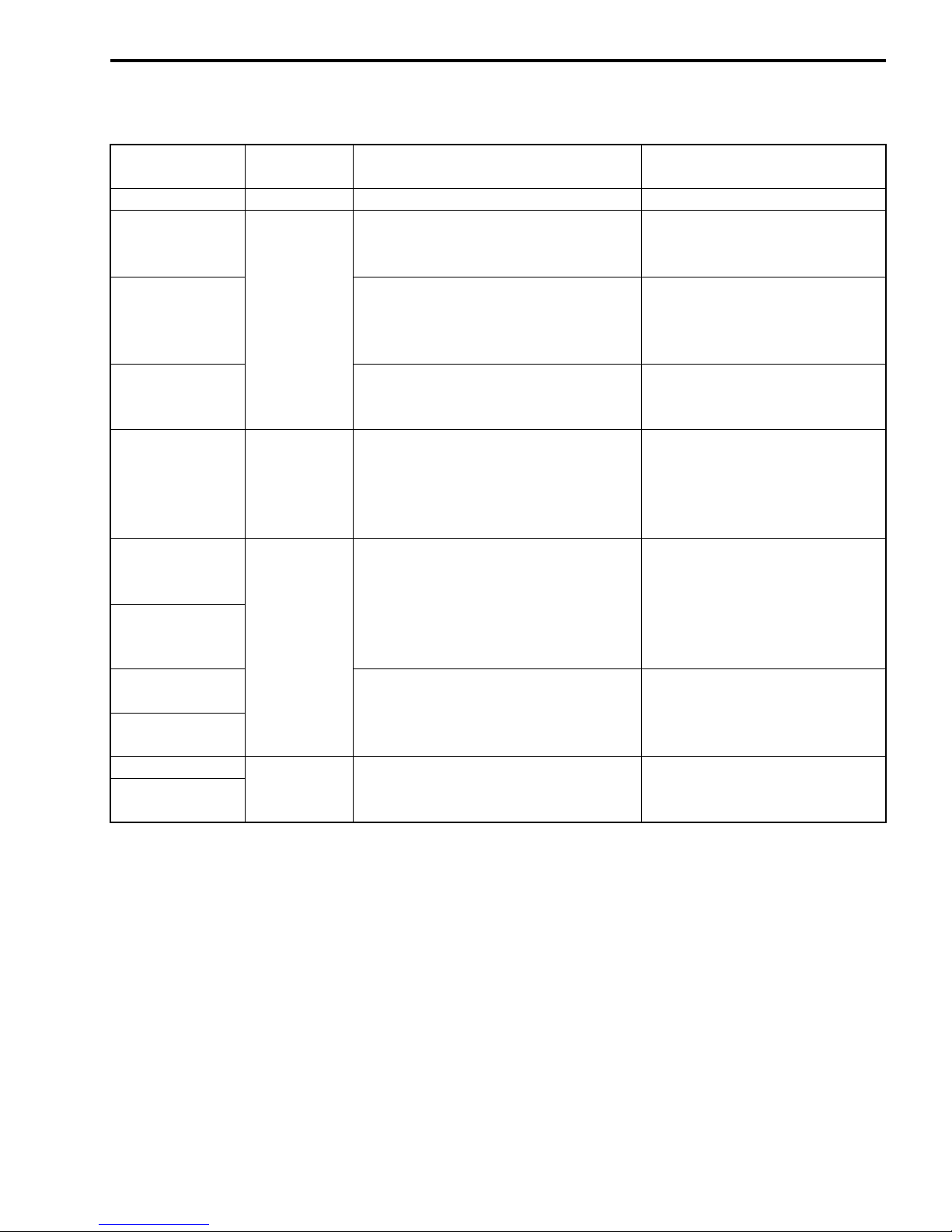

“C40” (P0505 or P0506 and P0507) ISC VALVE CIRCUIT MALFUNCTION

DETECTED CONDITION POSSIBLE CAUSE

C40

(P0505)

C40

(P0506)

C40

(P0507)

Although current is flowing though the

ISC valve motor, the current detection is

not possible.

Idle speed is lower than the desired idle

speed.

Idle speed is higher than the desired

idle speed.

• ISC valve circuit open or shorted to ground

• Power source circuit open

• Air passage clogged

• ISC valve is fixed

• ISC valve pre-set position is incorrect

• ISC valve is fixed

• ISC valve pre-set position is incorrect

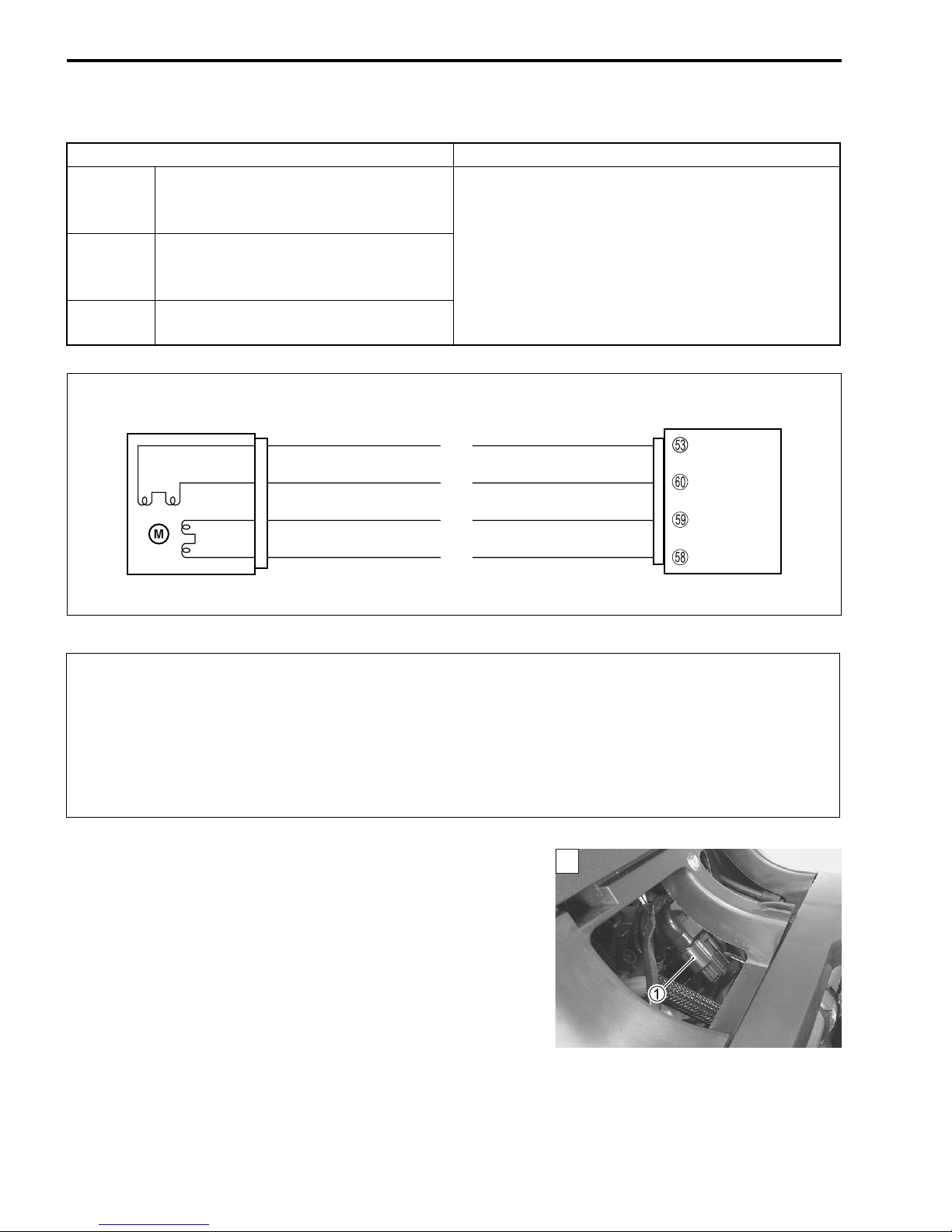

ISC valve

B/Lg

P/W

G

W/B

"

* Be careful not to disconnect the ISC valve coupler at least 5 seconds after ignition switch is

turned OFF.

If the ECM coupler or ISC valve coupler is disconnected within 5 seconds after ignition switch

is turned OFF, there is a possibility of an unusual valve position being written in ECM and

causing an error of ISC valve operation.

* When using the multi-circuit tester, do not strongly touch the terminal of the ECM coupler

with a needle pointed tester probe to prevent the terminal damage or terminal bend.

INSPECTION

Step 1

1) Turn the ignition switch OFF.

2) Remove the maintenance lid. (#AN650K3 9-13)

3) Check the ISC valve coupler

If OK, then check the ISC valve lead wire continuity.

SAMPLE

1 for loose or poor contacts.

ECM

ISC. 1A

ISC. 1B

ISC. 2A

ISC. 2B

4) Remove the front panel. (#AN650K3 9-8)

1

1

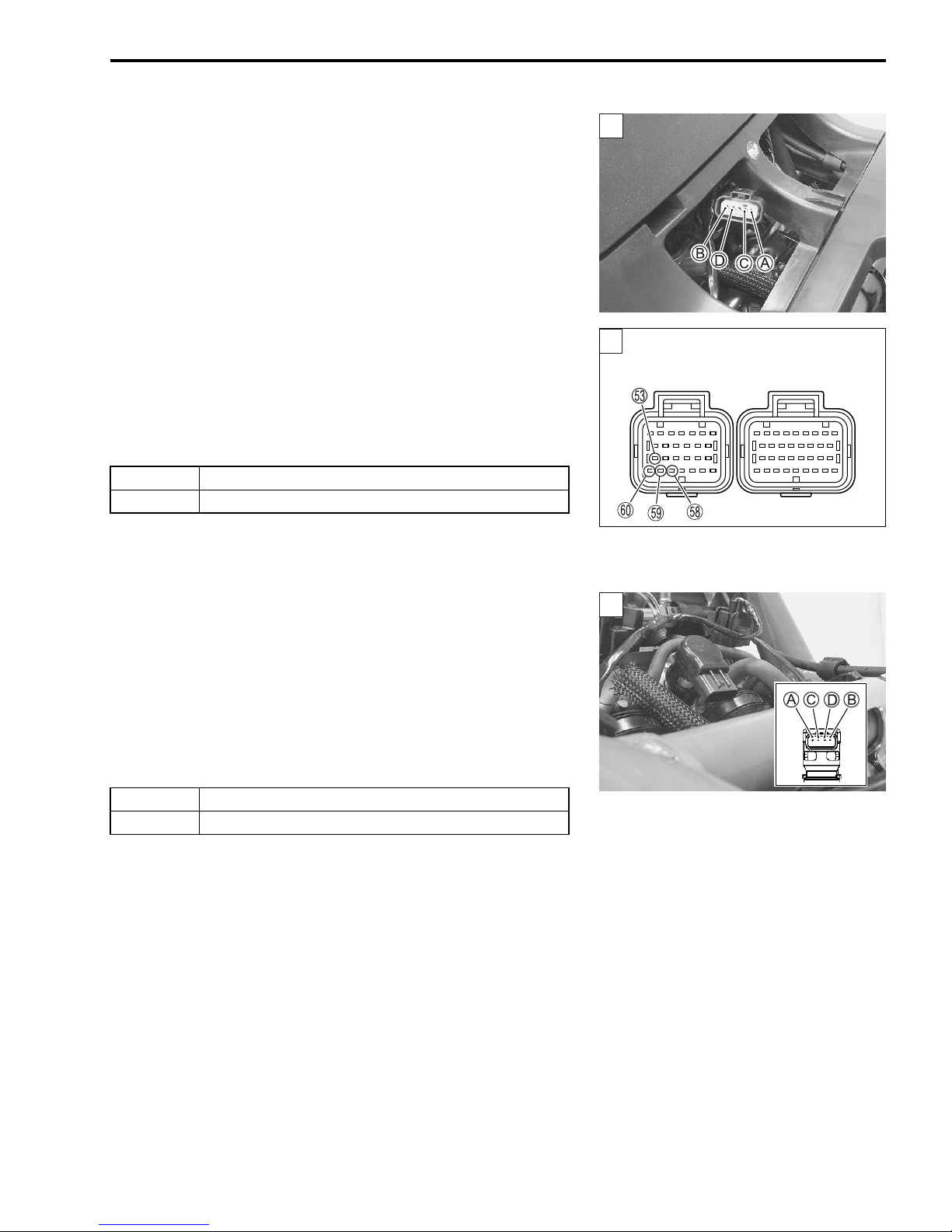

ECM coupler (Harness side)

2

5) Disconnect the ISC valve coupler and ECM couplers.

6) Check the continuity between terminals

minals

(W/B) and

$ ISC valve lead wire continuity: Continuity (%)

! 09900-25008: Multi-circuit tester set

& Tester knob indication: Continuity test (%)

Is the continuity OK?

B (P/W) and

r.

09900-25009: Needle pointed probe set

YES Go to Step 2.

NO Y, B/Lg, P/W, G or W/B wire open.

t, terminals

A (B/Lg) and

C (G) and

s, terminals

AN650/AK7 (’07-MODEL) 17

m, ter-

D

7) After repairing the trouble, clear the DTC using SDS tool.

(Refer to the SDS operation manual for further details.)

Step 2

1) Remove the front box. (#AN650K3 9-18)

2) Measure the resistance between terminals

nals

C and

$ ISC valve resistance: Approx. 80

D.

(Terminal

(Terminal

A – Terminal

C – Terminal

A and

Ω

at 25 °C (77 °F)

B, termi-

B)

D)

SAMPLE

Is the resistance OK?

YES If wire is OK, intermittent trouble or faulty ECM.

NO Replace the ISC valve with a new one.

3) After repairing the trouble, clear the DTC using SDS tool.

(Refer to the SDS operation manual for further details.)

18 AN650A/K7 (’07-MODEL)

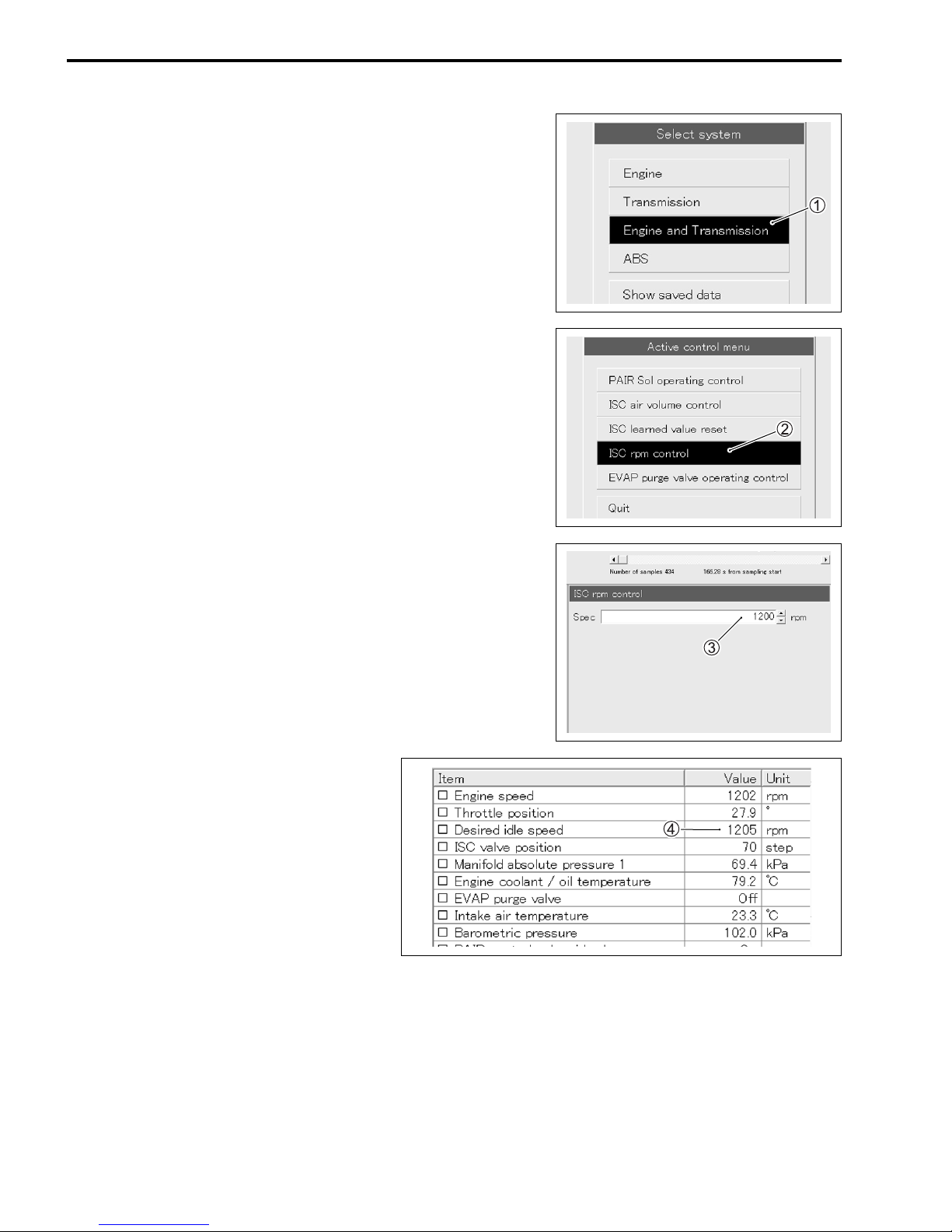

ACTIVE CONTROL INSPECTION (ISC RPM CONTROL)

Check 1

1) Place the motorcycle on the center stand.

2) Pull the parking brake lever and make sure that the rear

wheel is locked.

3) Set up the SDS tool. (Refer to the SDS operation manual for

further details.)

4) Check that the engine is running.

5) Click the “Engine and Transmission”

1.

6) Click the “ISC rpm control”

7) Check that the “Spec”

8) Check that the “Desired idle speed”

idle rpm.

2.

3 is idle speed 1 200 ± 100 rpm.

SAMPLE

4 is within the specified

Loading...

Loading...