Suzuki AN400, AN400ZA, AN400A, 2009 AN400, 2009 AN400ZA Supplementary Service Manual

...

AN400/A/ZA

SUPPLEMENTARY SERVICE MANUAL

USE THIS MANUAL WITH:

AN400 SERVICE MANUAL (99500-34101-01E)

9 9 5 0 1 - 3 4 1 7 0 - 0 1 E

FOREWORD

This SUPPLEMENTARY SERVICE MANUAL is a supplement to SUZUKI AN400 SERVICE MANUAL.

It has been prepared exclusively for the following applicable model.

Applicable model:

AN400/A/ZAK9

This supplementary service manual describes only service information which differ from that of the main manual. Therefore, whenever servicing the above applicable model, consult this supplement first. And for any section, item or description not found in this supplement, refer to the main manual below.

Main Manual:

Manual Name Manual No.

AN400 SERVICE MANUAL 99500-34101-01E

Other information considered as generally known is not included.

Read the GENERAL INFORMATION section to familiarize yourself with the motorcycle and its maintenance.

Use this section as well as other sections to use as a guide for proper inspection and service.

This manual will help you know the motorcycle better so that you can assure your customers of fast and reliable

service.

* This manual has been prepared on the basis of the latest specifications at the time of publication. If modifi-

cations have been made since then, differences may exist between the content of this manual and the

actual motorcycle.

* Illustrations in this manual are used to show the basic principles of operation and work procedures. They

may not represent the actual motorcycle exactly in detail.

* This manual is written for persons who have enough knowledge, skills and tools, including special tools, for

servicing SUZUKI motorcycles. If you do not have the proper knowledge and tools, ask your authorized

SUZUKI motorcycle dealer to help you.

!

WARNING

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the motorcycle unsafe for the

rider and passenger.

© COPYRIGHT SUZUKI MOTOR CORPORATION 2009

TABLE OF CONTENTS

NOTE

For the screen toned sections with asterisk (*) in the “TABLE OF CONTENTS” below, refer to the same

sections of the service manual mentioned in the “FOREWORD” of this manual.

Precautions............................................................... 00-i

Precautions ............................................................ 00-1

General Information ................................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubrication ..................................0B-*

Service Data...........................................................0C-1

Engine ......................................................................... 1-i

Precautions ............................................................... 1-*

Engine General Information and Diagnosis ............1A-*

Emission Control Devices .......................................1B-*

Engine Electrical Devices....................................... 1C-*

Engine Mechanical.................................................1D-1

Engine Lubrication System .....................................1E-*

Engine Cooling System...........................................1F-*

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-*

Starting System........................................................ 1I-*

Charging System..................................................... 1J-*

Exhaust System ......................................................1K-*

Suspension................................................................. 2-i

Precautions ............................................................... 2-*

Suspension General Diagnosis...............................2A-*

Front Suspension ....................................................2B-*

Rear Suspension....................................................2C-1

Wheels and Tires ...................................................2D-1

00

0

1

2

3

4

5

6

Driveline / Axle ........................................................... 3-*

Precautions ............................................................... 3-*

Drive Chain / Drive Train / Drive Shaft ....................3A-*

Brake ........................................................................... 4-i

Precautions ............................................................... 4-*

Brake Control System and Diagnosis ....................4A-1

Front Brakes............................................................4B-*

Rear Brakes ........................................................... 4C-*

Parking Brake......................................................... 4D-*

ABS ........................................................................ 4E-1

Transmission / Transaxle .......................................... 5-i

Precautions ............................................................... 5-*

Automatic Transmission......................................... 5A-1

Steering....................................................................... 6-i

Precautions ............................................................... 6-*

Steering General Diagnosis ....................................6A-*

Steering / Handlebar ..............................................6B-1

Body and Accessories............................................... 9-i

Precautions ............................................................... 9-*

Wiring Systems ...................................................... 9A-1

Lighting Systems.....................................................9B-*

Combination Meter / Fuel Meter / Horn..................9C-1

Exterior Parts ......................................................... 9D-1

Body Structure ....................................................... 9E-1

9

Table of Contents 00- i

Section 00

Precautions

CONTENTS

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

00

Precautions ...............................................00-1

Precautions........................................................... 00-1

Warning / Caution / Note...................................... 00-*

General Precautions ............................................ 00-*

Precautions for Electrical Circuit Service ............. 00-*

Precautions for ABS (AN400A/ZAK9) ................. 00-1

00-1 Precautions:

Precautions

Precautions

Precautions

Precautions for ABS (AN400A/ZAK9)

B905H10000004

ABS Wiring

• The ABS parts are connected to various lead wires.

The coupler and lead wire connections, as well as the

lead wire and wire harness routings must be done

correctly. Make sure that the proper clamps are used

and positioned correctly.

NOTE

If all of the connections are not properly

connected, the ABS may not operate

correctly. For connector and coupler

precautions. Refer to “Precautions for

Electrical Circuit Service” in related manual.

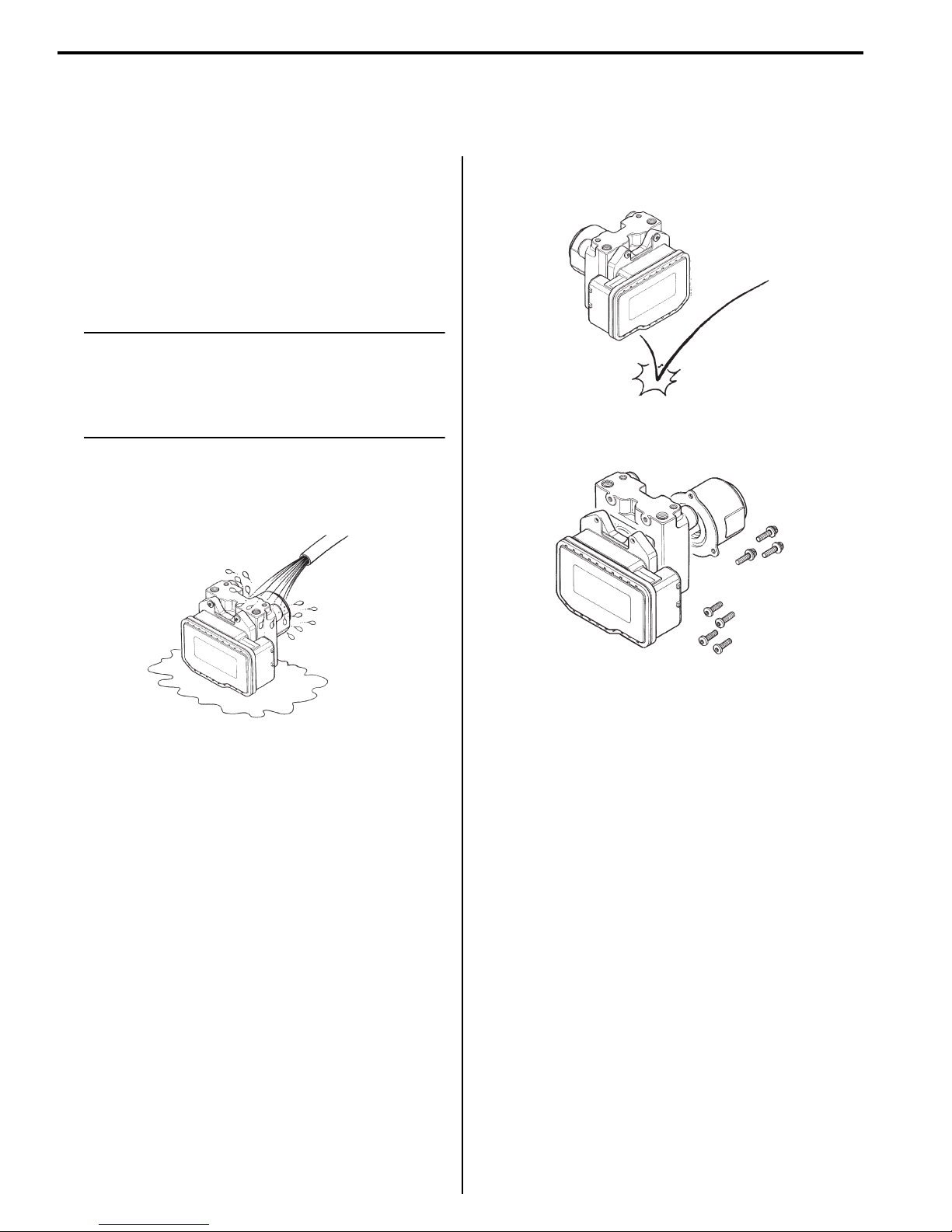

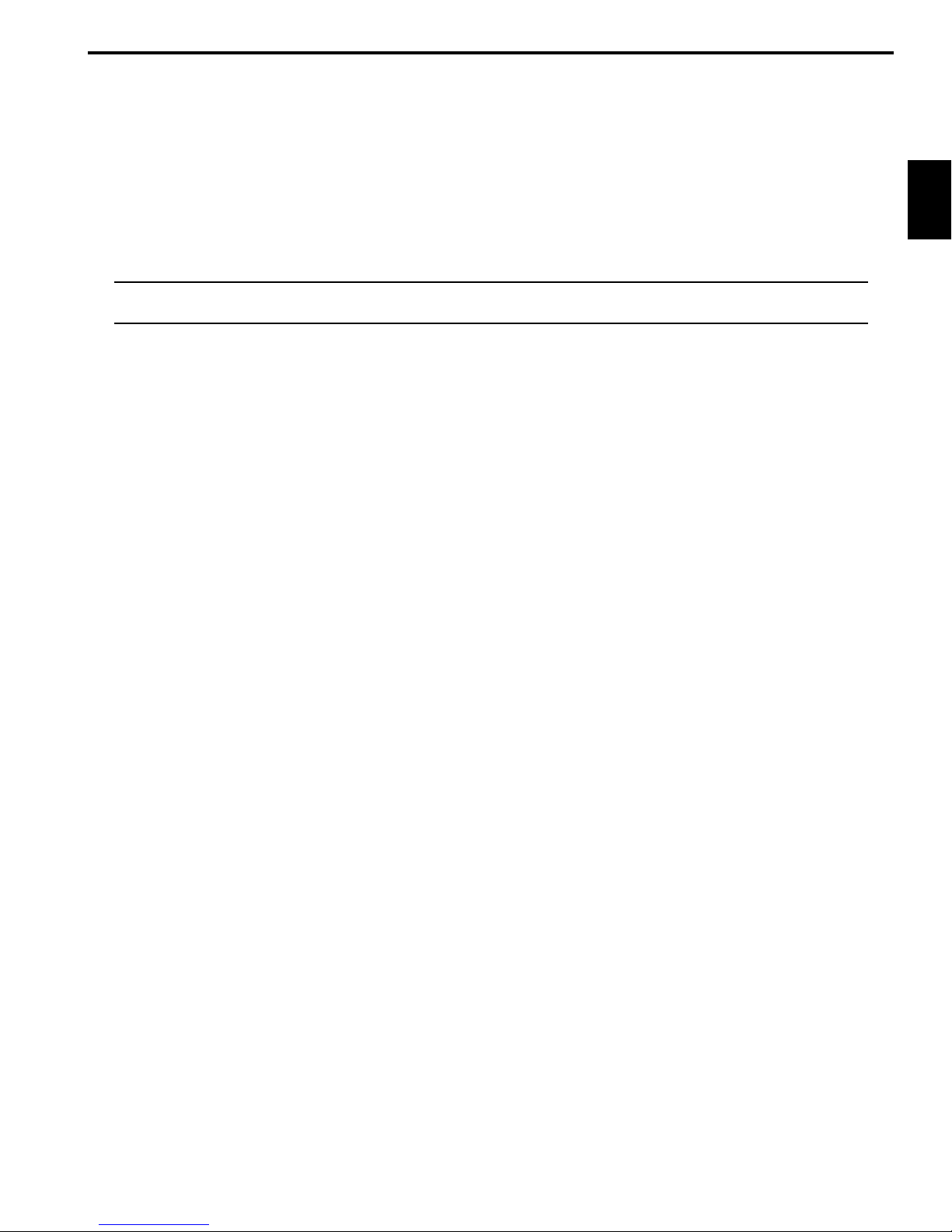

ABS Control Unit/HU

• Never allow dust or water to contact the ABS control

unit/HU.

• Never subject the ABS control unit/HU to strong

impacts or allow them to be dropped.

I649G1000003-02

• The ABS control unit/HU cannot be disassembled.

Replace the whole unit with a new one.

I649G1000004-02

I649G1000005-02

Table of Contents 0- i

Section 0

General Information

CONTENTS

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

0

General Information ................................ 0A-1

General Description ............................................. 0A-1

Symbols ...............................................................0A-*

Abbreviations .......................................................0A-*

Vehicle Side View (AN400K7) .............................0A-*

Vehicle Side View (AN400ZK7) ...........................0A-*

Vehicle Identification Number ..............................0A-*

Fuel / Oil / Engine Coolant Recommendation......0A-*

Engine Coolant Recommendation .......................0A-*

BREAK-IN Procedures.........................................0A-*

Country and Area Codes .....................................0A-*

Wire Color Symbols .............................................0A-*

Warning, Caution and Information Labels

Location .............................................................0A-*

Abbreviations (AN400A/ZAK9) ........................... 0A-1

Vehicle Side View (AN400/A/ZAK9).................... 0A-1

Country and Area Codes (AN400/A/ZAK9)......... 0A-2

Component Location ........................................... 0A-*

Electrical Components Location ..........................0A-*

Specifications.......................................................0A-3

Specifications (AN400K7) ....................................0A-*

Specifications (AN400ZK7) ..................................0A-*

Specifications (AN400K8) ....................................0A-*

Specifications (AN400ZK8) ..................................0A-*

Specifications (AN400K9) ................................... 0A-3

Specifications (AN400AK9)................................. 0A-3

Specifications (AN400ZAK9) .............................. 0A-4

Special Tools and Equipment ............................. 0A-5

Special Tool ........................................................ 0A-5

Maintenance and Lubrication..................0B-*

Precautions........................................................... 0B-*

Precautions for Maintenance ...............................0B-*

General Description ............................................. 0B-*

Recommended Fluids and Lubricants..................0B-*

Scheduled Maintenance ...................................... 0B-*

Periodic Maintenance Schedule Chart.................0B-*

Lubrication Points ................................................0B-*

Repair Instructions .............................................. 0B-*

Air Cleaner Element Removal and Installation .....0B-*

Air Cleaner Element Inspection ...........................0B-*

Spark Plug Removal and Installation ...................0B-*

Spark Plug Inspection and Cleaning ....................0B-*

Valve Clearance Inspection and Adjustment .......0B-*

Fuel Line Inspection ............................................ 0B-*

Evaporative Emission Control System (E-33

Only).................................................................. 0B-*

Engine Oil and Filter Change .............................. 0B-*

Final Reduction Gear Oil Replacement............... 0B-*

Cooling Fan Filter Removal and Installation ....... 0B-*

Cooling Fan Filter Inspection and Cleaning ........ 0B-*

Drive V-belt Removal and Installation ................. 0B-*

Drive V-belt Inspection ........................................ 0B-*

Throttle Cable Play Inspection and

Adjustment ........................................................ 0B-*

Cooling System Inspection.................................. 0B-*

Air Bleeding From the Cooling Circuit ................. 0B-*

Radiator Hose Inspection.................................... 0B-*

Brake System Inspection .................................... 0B-*

Brake Hose Replacement ................................... 0B-*

Air Bleeding from Brake Fluid Circuit .................. 0B-*

Brake Fluid Replacement.................................... 0B-*

Tire Inspection..................................................... 0B-*

Steering System Inspection ................................ 0B-*

Front Fork Inspection .......................................... 0B-*

Rear Suspension Inspection ............................... 0B-*

Exhaust Pipe and Muffler Mounting

Inspection.......................................................... 0B-*

Chassis Bolt and Nut Inspection ......................... 0B-*

Compression Pressure Check ............................ 0B-*

Oil Pressure Check ............................................. 0B-*

SDS Check.......................................................... 0B-*

Automatic Clutch Inspection................................ 0B-*

Parking Brake (Brake-lock) Inspection................ 0B-*

Parking Brake (Brake-lock) Adjustment .............. 0B-*

Specifications....................................................... 0B-*

Tightening Torque Specifications........................ 0B-*

Special Tools and Equipment ............................. 0B-*

Recommended Service Material ......................... 0B-*

Special Tool ........................................................ 0B-*

Service Data ............................................. 0C-1

Specifications.......................................................0C-1

Service Data (AN400/ZK7).................................. 0C-*

Service Data (AN400/ZK8).................................. 0C-*

Tightening Torque List ........................................ 0C-*

Service Data (AN400K9).....................................0C-1

Service Data (AN400A/ZAK9).............................0C-2

Tightening Torque List (AN400AK9) ...................0C-3

0A-1 General Information:

General Information

General Information

General Description

Abbreviations (AN400A/ZAK9)

NOTE

Please refer to the AN400K8 service manual for other abbreviations which are not given in this manual.

A:

ABS: Anti-lock Brake System

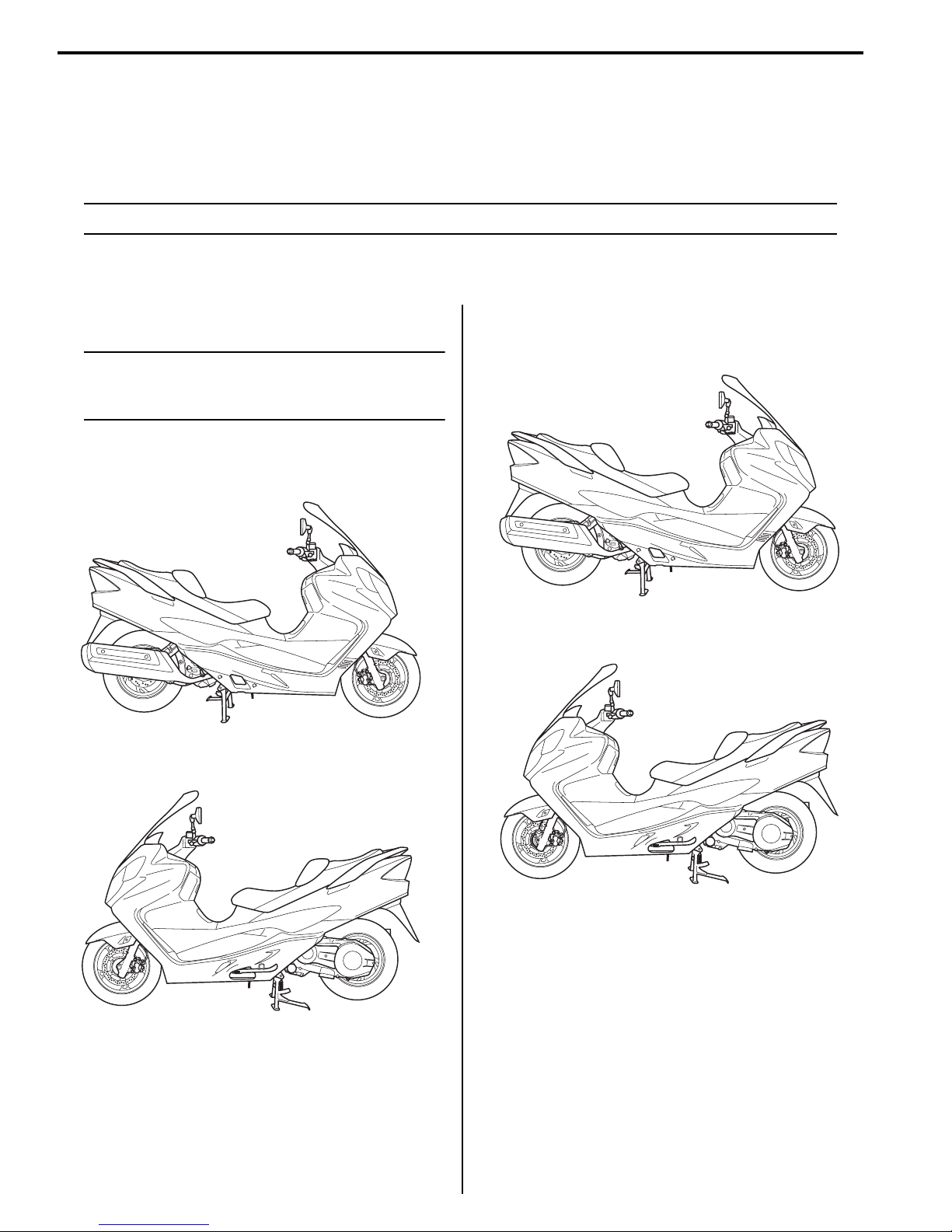

Vehicle Side View (AN400/A/ZAK9)

B905H10101013

NOTE

Difference between illustration and actual

motorcycles may exist depending on the

markets.

SUZUKI AN400 (2009-model)

Right Side

SUZUKI AN400A (2009-model)

Right Side

B905H10101012

I905H1010003-01

Left Side

Left Side

I905H1010001-01

I905H1010004-02

I905H1010002-02

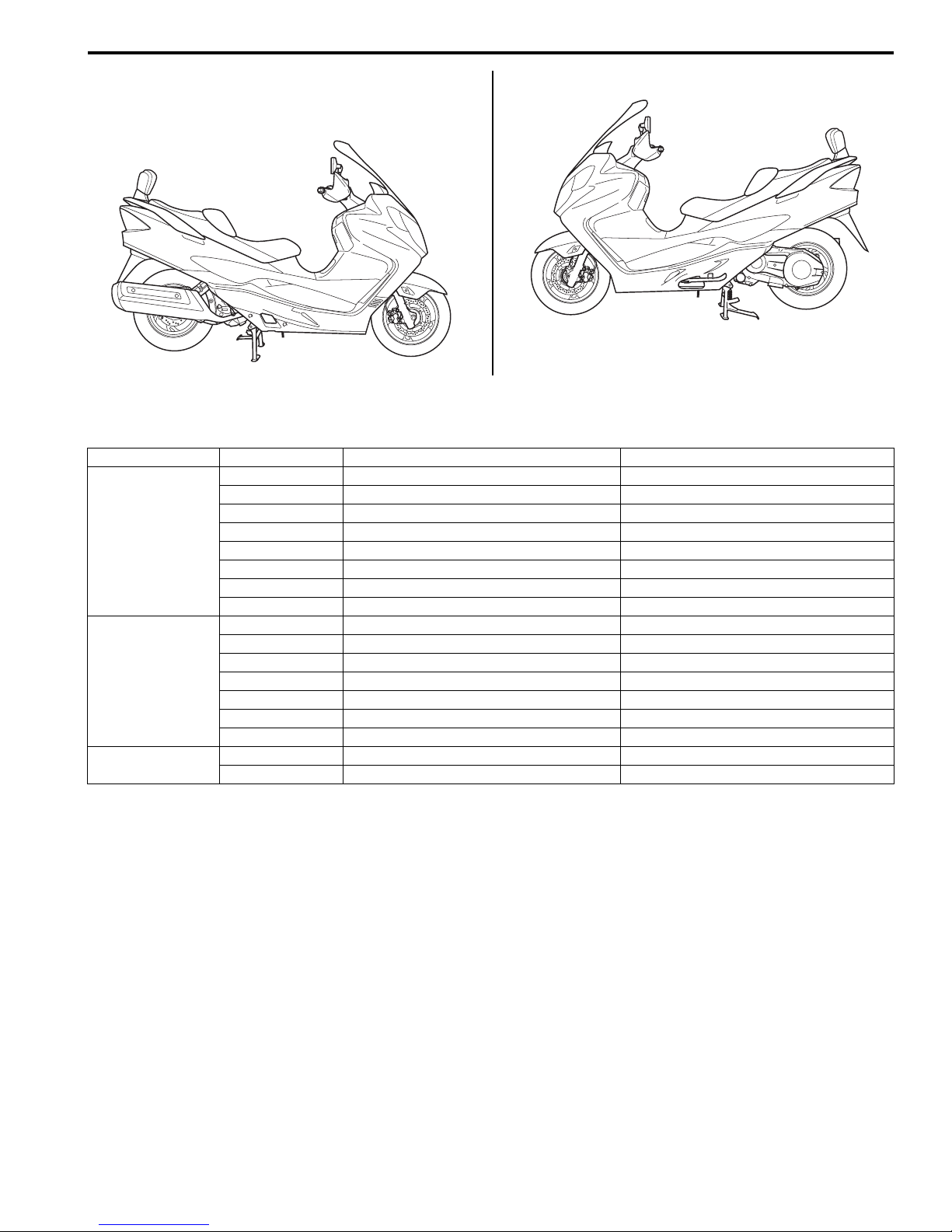

General Information: 0A-2

SUZUKI AN400ZA (2009-model)

Left Side

Right Side

I905H1010005-01

Country and Area Codes (AN400/A/ZAK9)

The following codes stand for the applicable country(-ies) and area(-s).

Model Code Country or Area Effective Frame No.

E-02 U.K. JS1CG111200100924 –

E-03 U.S.A. (Except for California) JS1CK44A 92100001 –

E-19 E.U. JS1CG111100135961 –

AN400 K9

AN400A K9

AN400ZA K9

E-24 Australia JS1CG111300100360 –

E-28 Canada JS1CK44A 92100001 –

E-33 California JS1CK44A 92100001 –

E-51 Korea JS1CG111590100001 –

E-54 Israel JS1CG111490100001 –

E-02 U.K. JS1CG113200100001 –

E-03 U.S.A. (Except for California) JS1CK44B 92100001 –

E-19 E.U. JS1CG113100100001 –

E-24 Australia JS1CG113300100001 –

E-28 Canada JS1CK44B 92100001 –

E-33 California JS1CK44B 92100001 –

E-54 Israel JS1CG113490100001 –

E-02 U.K. JS1CG114200100001 –

E-19 E.U. JS1CG114100100001 –

I905H1010006-02

B905H10101014

0A-3 General Information:

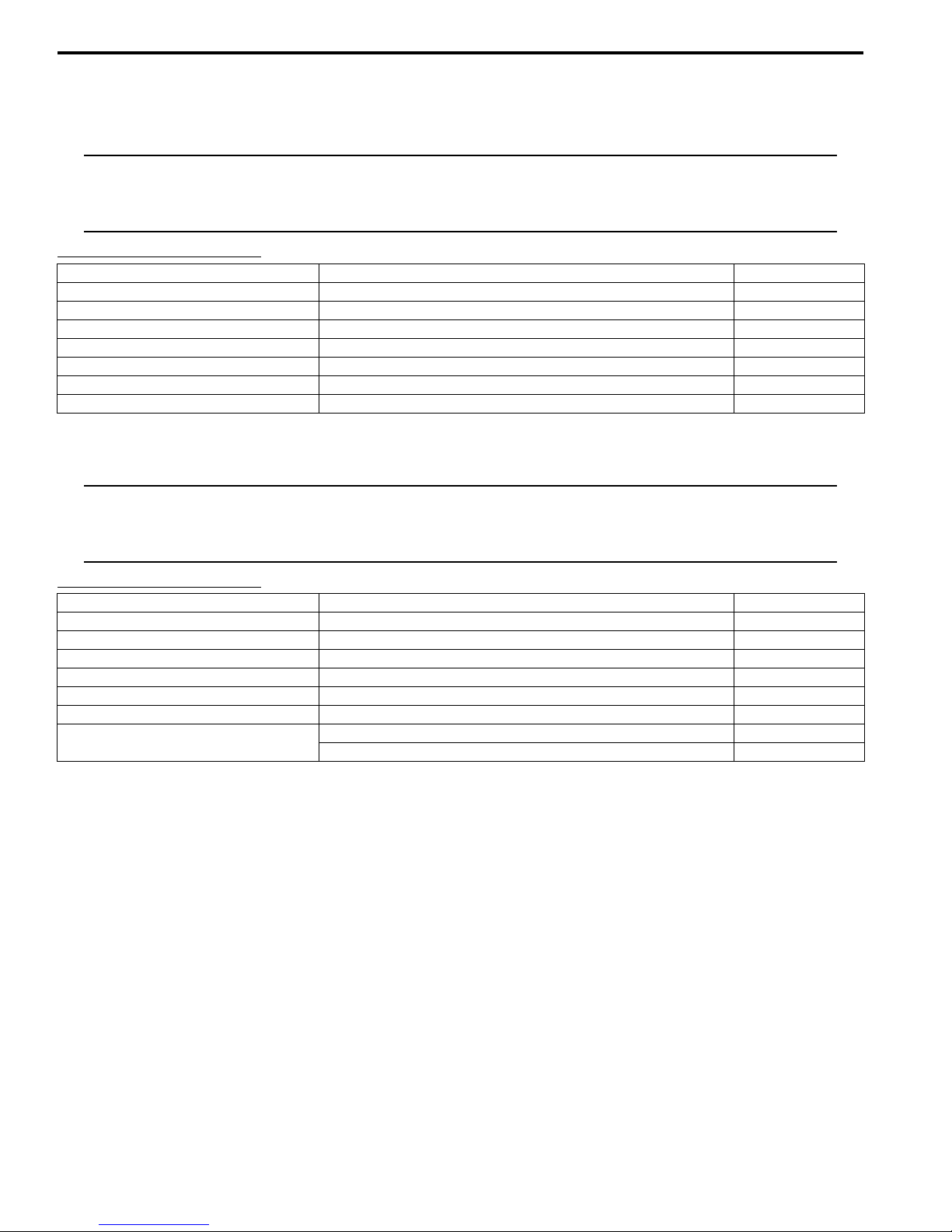

Specifications

Specifications (AN400K9)

NOTE

• These specifications are subject to change without notice.

• Any differences between the AN400K8 (’08-model) and AN400K9 (’09-model) in specifications are

indicated an asterisk mark (*).

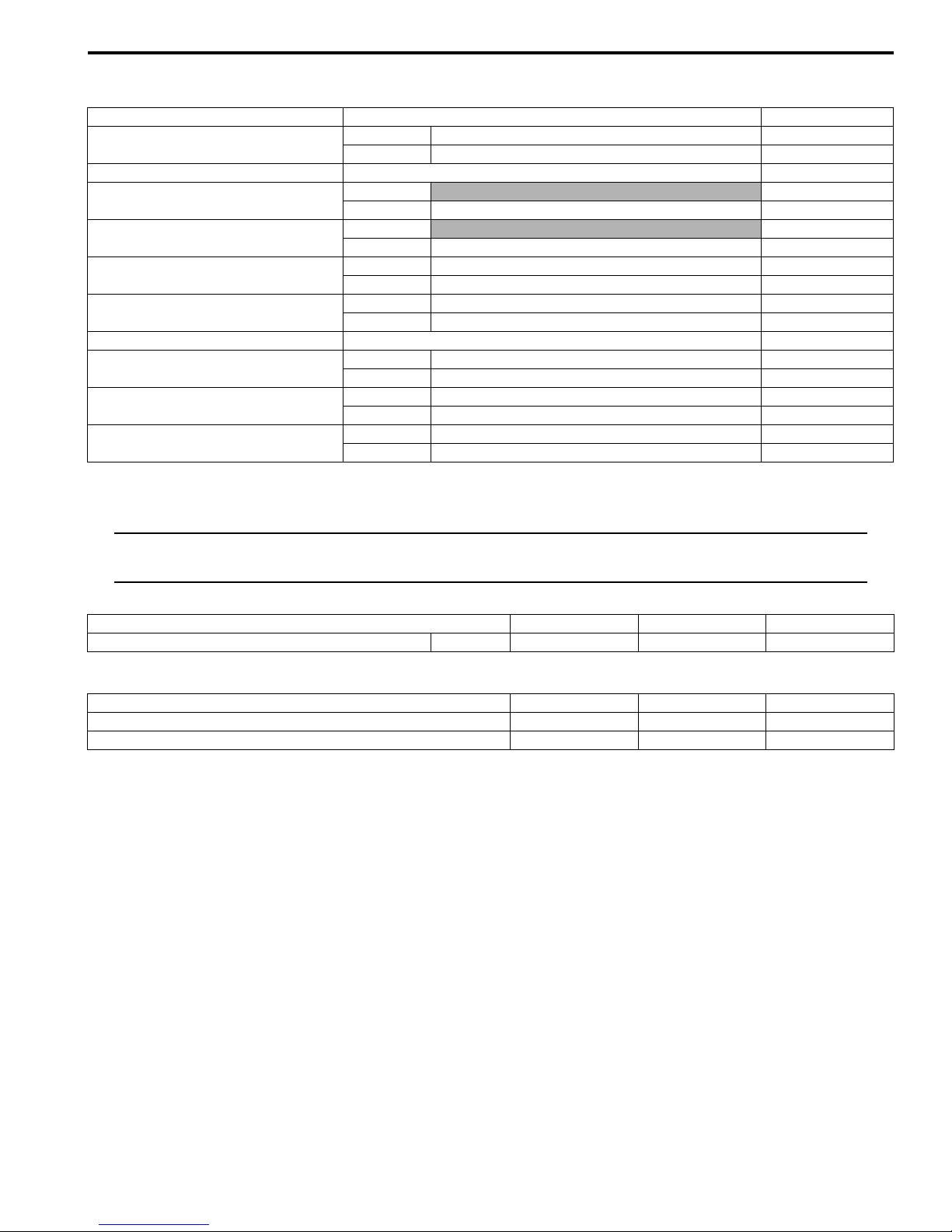

Dimensions and Curb Mass

Item Specification Remark

Overall length 2 270 mm (89.4 in)

Overall width 760 mm (29.9 in)

Overall height 1 385 mm (54.5 in)

Wheelbase 1 585 mm (62.4 in)

Ground clearance 125 mm (4.9 in)

Seat height 710 mm (28.0 in)

* Curb mass 216 kg (476 lbs)

Specifications (AN400AK9)

NOTE

• These specifications are subject to change without notice.

• Any differences between the AN400K9 (’09-model) and AN400AK9 (’09-model) in specifications are

indicated with an asterisk mark (*).

Dimensions and Curb Mass

Item Specification Remark

Overall length 2 270 mm (89.4 in)

Overall width 760 mm (29.9 in)

Overall height 1 385 mm (54.5 in)

Wheelbase 1 585 mm (62.4 in)

Ground clearance 125 mm (4.9 in)

Seat height 710 mm (28.0 in)

Curb mass

* 223 kg (491 lbs) E-33

* 222 kg (489 lbs) Others

B905H10107005

B905H10107006

General Information: 0A-4

Electrical

Item Specification Remark

lgnition type Electronic ignition (Transistorized)

lgnition timing 7° B. T. D. C at 1 450 r/min

Spark plug NGK: CR7E or DENSO: U22ESR-N

Battery 12 V 32.4 kC (9 Ah)/10 HR

Generator Three-phase A.C. generator

Main fuse 30 A

Fuse

10/10/15/10/15/10 A E-02, 19, 24, 54

15/15/15/10/15/10 A E-03, 28, 33

* ABS fuse 15/20 A

Headlight

12 V 60/55 W (H4) + 55 W (H7) E-02, 19, 24, 54

12 V 60/55 W (H4) x 2 E-03, 28, 33

Position/Parking light 12 V 5 W x 2 E-02, 19, 24, 54

Position light 12 V 5 W x 2 E-03, 28, 33

Brake light/Taillight 12 V 21/5 W x 2

License plate light 12 V 5 W

Helmet box light 12 V 5 W

Front turn signal light

12 V 27/8 W E-03, 28, 33

12 V 21 W Others

Rear turn signal light 12 V 21 W

Speedometer/Tachometer light LED

Coolant temperature meter light LED

Fuel level meter light LED

Turn signal indicator light LED x 2

High beam indicator light LED

Brake-lock indicator light LED

Oil change indicator LCD

Fuel injection warning light LED

Immobilizer indicator light LED E-02, 19, 24, 54

* ABS indicator light LED

Specifications (AN400ZAK9)

NOTE

• These specifications are subject to change without notice.

• Any differences between the AN400AK9 (’09-model) and AN400ZAK9 (’09-model) in specifications

are indicated with an asterisk mark (*).

Dimensions and Curb Mass

Item Specification Remark

Overall length 2 270 mm (89.4 in)

Overall width * 825 mm (32.5 in)

Overall height 1 385 mm (54.5 in)

Wheelbase 1 585 mm (62.4 in)

Ground clearance 125 mm (4.9 in)

Seat height 710 mm (28.0 in)

Curb mass * 225 kg (496 lbs)

B905H10107007

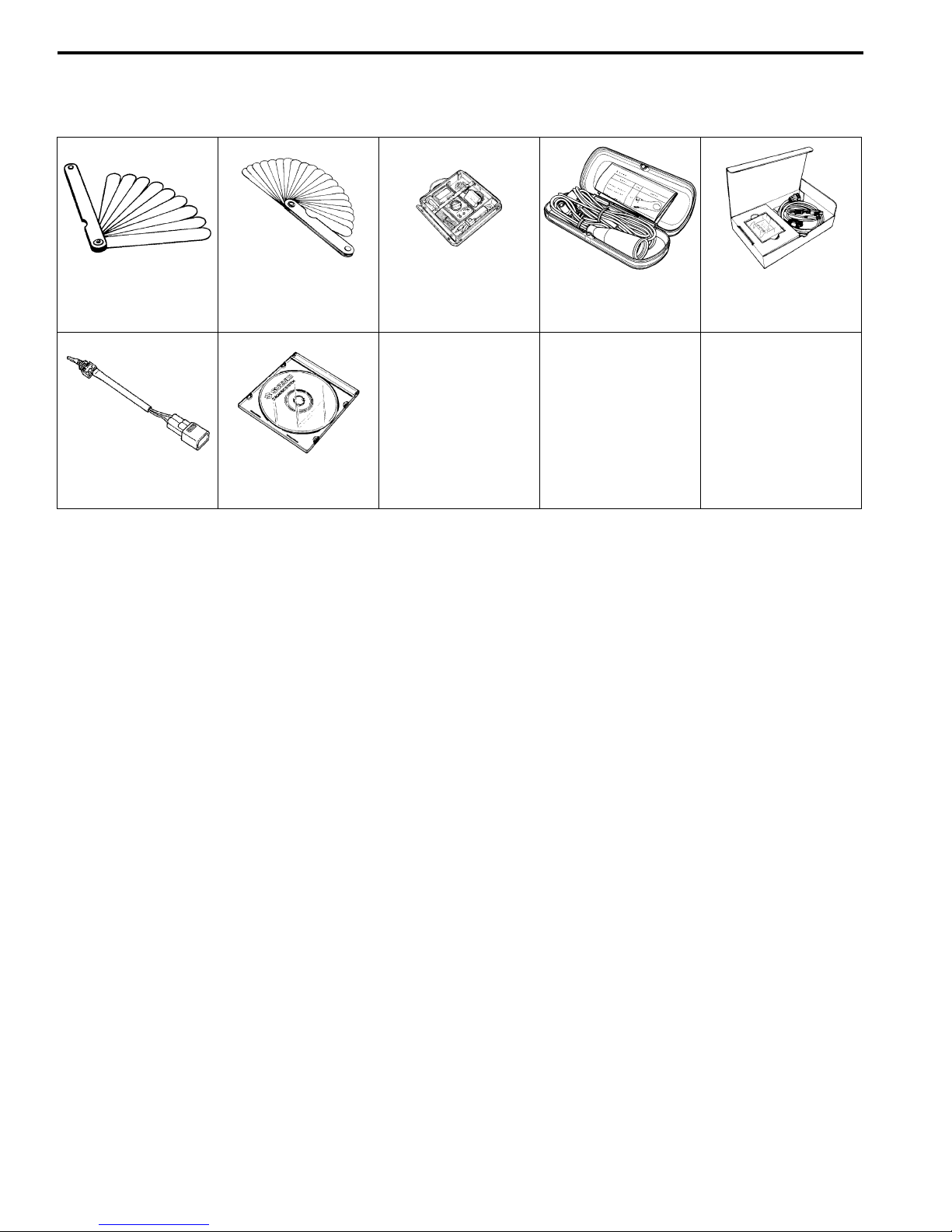

0A-5 General Information:

Special Tools and Equipment

Special Tool

09900–20803

Thickness gauge

09930–82710

Mode select switch

09900–20806

Thickness gauge

99565–01010–020

CD-ROM Ver.20

09900–25008

Multi circuit tester set

09900–25009

Needle-point probe

set

B905H10108002

09904–41010

SUZUKI Diagnostic

system set

General Information

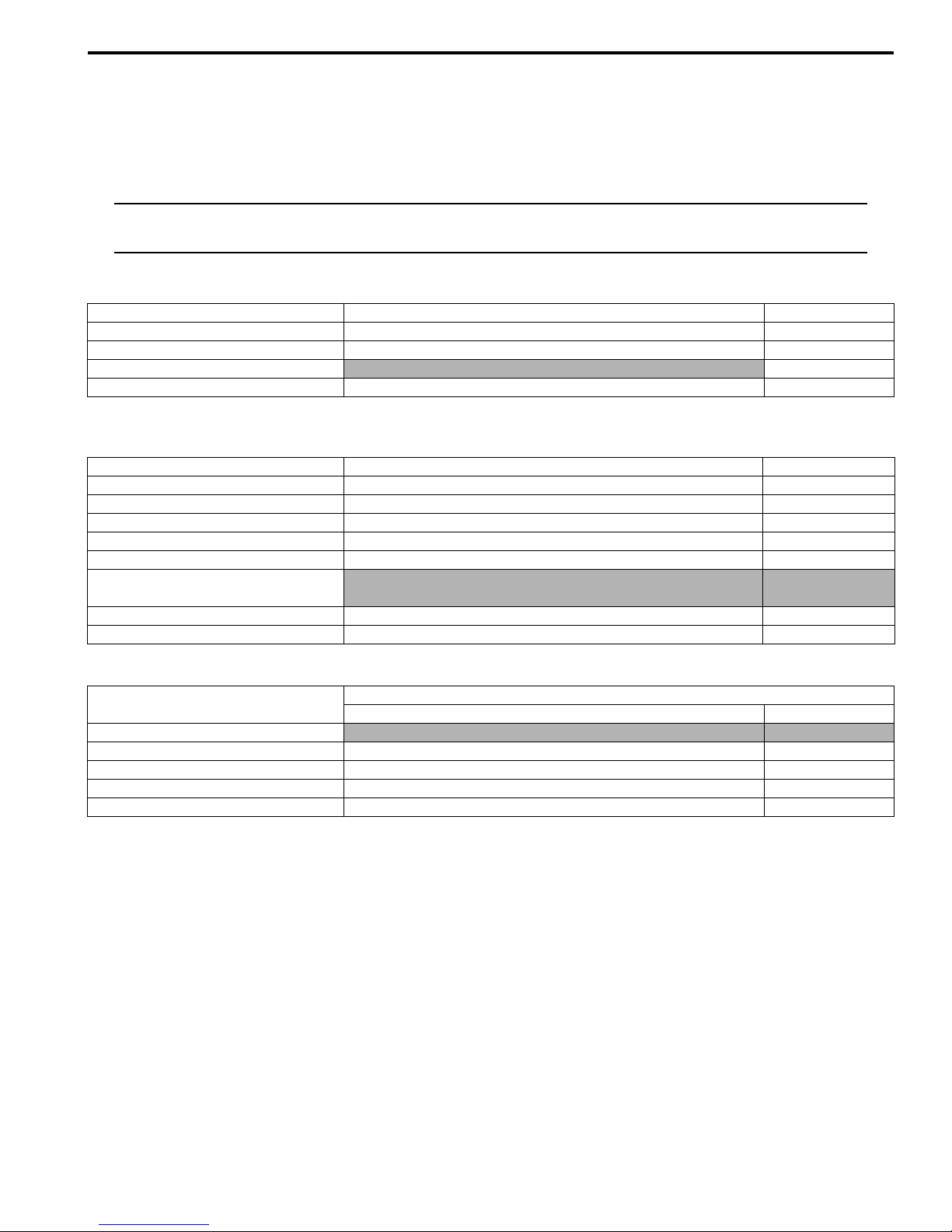

Service Data

Service Data: 0C-1

Specifications

Service Data (AN400K9)

B905H10307004

NOTE

Any differences between the AN400K8 (’08-model) and AN400K9 (’09-model) is service data are

indicated an asterisk mark (*).

Clutch

Unit: mm (in)

Item Specification Limit

Clutch wheel I.D. 160 – 160.2 (6.30 – 6.31) 160.5 (6.32)

Clutch shoe thickness 5.0 (2.0) 2.0 (0.08)

Engage r/min

Lock-up r/min 4 000 – 5 000 r/min —

Transmission

Unit: mm (in) Except ratio

Item Specification Note

Primary reduction ratio 1.000 —

Reduction ratio 2.200 – 0.839

Secondary reduction ratio 2.214 —

Final reduction ratio 2.666 —

Drive V-belt width 25.1 (0.99) 24.1 (0.95)

Movable driven face spring free

length

Movable drive face roller O.D. 26.00 – 26.16 (1.024 – 1.030) —

Drive/driven face ware — 0.4 (0.02)

* 2 600 – 3 200 r/min —

* 145.0 (5.7) * 137.8 (5.43)

Throttle Body

Specification

* 05H2 * 05H3

I.D. No.

Item

E-02, 03, 19, 24, 28, 51, 54 E-33

Bore size 38 mm (1.5 in) ←

Fast idle r/min 1 500 – 2 000 r/min ←

Idle r/min 1 450 ± 100 r/min ←

Throttle cable play 2.0 – 4.0 mm (0.08 – 0.16 in) ←

0C-2 Service Data:

Service Data (AN400A/ZAK9)

NOTE

Any differences between the AN400K9 (’09-model) and AN400A/ZAK9 (’09-model) in service data are

indicated an asterisk mark (*).

Electrical

Unit: mm (in)

Item Standard / Specification Note

HI

Headlight

LO

Meter

Fuse size

Ignition

Signal 15 A

Power source 10 A

Main 30 A

* ABS motor 20 A

* ABS valve 15 A

Wattage

Unit: W

Item

E-02, 19, 24, 54 E-03, 28, 33

Standard / Specification

Speedometer/tachometer light LED ←

Engine coolant temp. gauge light LED ←

Fuel level gauge light LED ←

Immobilizer indicator light LED ←

Oil change indicator LCD ←

FI indicator light LED ←

Brake-lock indicator light LED ←

High beam indicator light LED ←

Turn signal indicator light LED x 2 ←

* ABS indicator light LED ←

10 A E-02, 19, 24, 54

15 A E-03, 28, 33

10 A E-02, 19, 24, 54

15 A E-03, 28, 33

* 10 A

* 15 A

B905H10307005

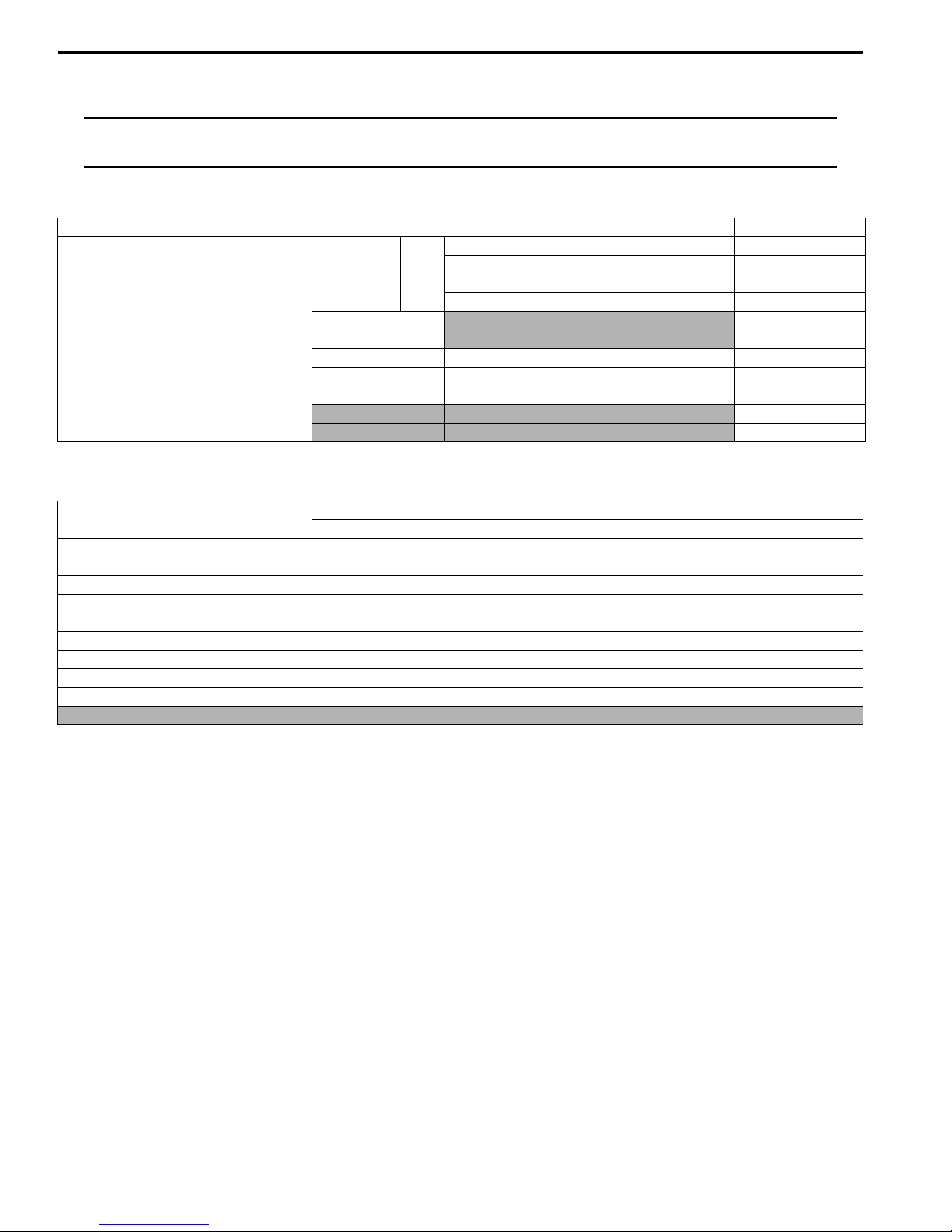

Service Data: 0C-3

Brake + Wheel

Unit: mm (in)

Item Standard Limit

Brake disc thickness

Front 4.5 ± 0.2 (0.18 ± 0.008) 4.0 (0.16)

Rear 5.0 ± 0.2 (0.20 ± 0.008) 4.5 (0.18)

Brake disc runout — 0.30 (0.01)

Master cylinder bore

Master cylinder piston diameter

Brake caliper cylinder bore

Brake caliper piston diameter

Front

Rear 12.700 – 12.743 (0.500 – 0.502) —

Front

Rear 12.657 – 12.684 (0.498 – 0.499) —

Front 25.400 – 25.450 (1.000 – 1.002) —

Rear 27.00 – 27.05 (1.063 – 1.065) —

Front 25.318 – 25.368 (0.997 – 0.999) —

Rear 26.918 – 26.968 (1.060 – 1.062) —

* 14.000 – 14.043 (0.551 – 0.553) —

* 13.957 – 13.984 (0.549 – 0.551) —

Brake fluid type DOT 4 —

Wheel rim runout

Wheel axle runout

Wheel rim size

Axial — 2.0 (0.08)

Radial — 2.0 (0.08)

Front — 0.25 (0.01)

Rear — 0.25 (0.01)

Front 14 M/C x MT3.00 —

Rear 13 M/C x MT4.00 —

Tightening Torque List (AN400AK9)

B905H10307006

NOTE

Please refer to the AN400K8 service manual for other tightening torque which are not given in this

manual.

Engine

Item N⋅m kgf-m lbf-ft

Main gallery plug M10 18 1.8 13.0

Chassis

Item N⋅m kgf-m lbf-ft

Brake pipe flare nut 16 1.6 11.5

Wheel speed sensor rotor bolt (Front & Rear) 6 0.6 4.5

0C-4 Service Data:

Section 1

Engine

CONTENTS

Table of Contents 1- i

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

Precautions ................................................. 1-*

Precautions.............................................................. 1-*

Precautions for Engine........................................... 1-*

Engine General Information and

Diagnosis ..................................................1A-*

General Description ............................................. 1A-*

Injection Timing Description .................................1A-*

Self-Diagnosis Function .......................................1A-*

Schematic and Routing Diagram........................ 1A-*

FI System Wiring Diagram ...................................1A-*

Terminal Alignment of ECM Coupler (Harness

Side)...................................................................1A-*

Component Location ........................................... 1A-*

FI System Parts Location.....................................1A-*

Diagnostic Information and Procedures............ 1A-*

Engine Symptom Diagnosis .................................1A-*

DTC Table............................................................1A-*

Fail-Safe Function Table......................................1A-*

FI System Troubleshooting ..................................1A-*

Self-Diagnostic Procedures .................................1A-*

Self-Diagnosis Reset Procedures ........................1A-*

Use of SDS Diagnostic Procedures .....................1A-*

Use of SDS Diagnosis Reset Procedures............1A-*

Show Data When Trouble (Displaying Data at

the Time of DTC) ...............................................1A-*

SDS Check ..........................................................1A-*

Malfunction Code and Defective Condition

Table ..................................................................1A-*

DTC “C12” (P0335): CKP Sensor Circuit

Malfunction.........................................................1A-*

DTC “C13” (P0105-H/L): IAP Sensor Circuit

Malfunction.........................................................1A-*

DTC “C14” (P0120/H/L): TP Sensor Circuit

Malfunction.........................................................1A-*

DTC “C15” (P0115-H/L): ECT Sensor Circuit

Malfunction.........................................................1A-*

DTC “C16” (P0500): Speed Sensor .....................1A-*

DTC “C21” (P0110-H/L): IAT Sensor Circuit

Malfunction.........................................................1A-*

DTC “C23” (P1651-H/L): TO Sensor Circuit

Malfunction.........................................................1A-*

DTC “C24” (P0351): Ignition System

Malfunction.........................................................1A-*

DTC “C28” (P1655): Secondary Throttle

Valve Actuator (STVA) Malfunction................... 1A-*

DTC “C29” (P1654-H/L): Secondary Throttle

Position Sensor (STPS) .................................... 1A-*

DTC “C32” (P0201): Fuel Injector Circuit

Malfunction........................................................ 1A-*

DTC “C40” (P0505, P0506 or P0507): ISC

Valve Circuit Malfunction................................... 1A-*

DTC “C41” (P0230-H/L): FP Relay Circuit

Malfunction........................................................ 1A-*

DTC “42” (P1650): IG Switch Circuit

Malfunction........................................................ 1A-*

DTC “C44” (P0130, P0135): HO2 Sensor

(HO2S) Circuit Malfunction ............................... 1A-*

Specifications....................................................... 1A-*

Service Data........................................................ 1A-*

Special Tools and Equipment ............................. 1A-*

Special Tool ........................................................ 1A-*

Emission Control Devices .......................1B-*

Precautions........................................................... 1B-*

Precautions for Emission Control Devices .......... 1B-*

General Description ............................................. 1B-*

Fuel Injection System Description....................... 1B-*

Crankcase Emission Control System

Description ........................................................ 1B-*

Exhaust Emission Control System

Description ........................................................ 1B-*

Noise Emission Control System Description ....... 1B-*

Repair Instructions .............................................. 1B-*

Heated Oxygen Sensor (HO2S) Removal and

Installation ......................................................... 1B-*

Heated Oxygen Sensor (HO2S) Inspection ........ 1B-*

PCV Hose Inspection .......................................... 1B-*

PCV Hose Removal and Installation ................... 1B-*

Specifications....................................................... 1B-*

Service Data........................................................ 1B-*

Tightening Torque Specifications........................ 1B-*

Special Tools and Equipment ............................. 1B-*

Special Tool ........................................................ 1B-*

Engine Electrical Devices ........................1C-*

Precautions........................................................... 1C-*

Precautions for Engine Electrical Device ............ 1C-*

1

1-ii Table of Contents

Repair Instructions .............................................. 1C-*

ECM Removal and Installation............................ 1C-*

CKP Sensor Inspection ....................................... 1C-*

CKP Sensor Removal and Installation ................ 1C-*

IAP Sensor Inspection......................................... 1C-*

IAP Sensor Removal and Installation.................. 1C-*

TP Sensor Inspection.......................................... 1C-*

TP Sensor Adjustment ........................................ 1C-*

TP Sensor Removal and Installation................... 1C-*

ECT Sensor Inspection ....................................... 1C-*

ECT Sensor Removal and Installation ................ 1C-*

Speed Sensor Inspection .................................... 1C-*

Speed Sensor Removal and Installation ............. 1C-*

IAT Sensor Inspection......................................... 1C-*

IAT Sensor Removal and Installation.................. 1C-*

TO Sensor Inspection ......................................... 1C-*

TO Sensor Removal and Installation .................. 1C-*

STP Sensor Inspection ....................................... 1C-*

STP Sensor Adjustment...................................... 1C-*

STP Sensor Removal and Installation ................ 1C-*

ISC Valve Inspection........................................... 1C-*

ISC Valve Removal and Installation.................... 1C-*

ISC Valve Pre-set (AN400/ZK7).......................... 1C-*

ISC Valve Preset and Opening Initialization

(AN400/ZK8) ..................................................... 1C-*

HO2 Sensor Inspection ....................................... 1C-*

HO2 Sensor Removal and Installation ................ 1C-*

Specifications....................................................... 1C-*

Service Data........................................................ 1C-*

Tightening Torque Specifications........................ 1C-*

Special Tools and Equipment ............................. 1C-*

Special Tool ........................................................ 1C-*

Engine Mechanical .................................. 1D-1

Precautions........................................................... 1D-*

Precautions for Engine Mechanical..................... 1D-*

Schematic and Routing Diagram........................1D-1

Camshaft and Sprocket Assembly Diagram ....... 1D-*

Throttle Cable Routing Diagram.......................... 1D-*

Throttle Cable Routing Diagram (AN400/A/

ZAK9)................................................................1D-1

Diagnostic Information and Procedures............ 1D-*

Compression Pressure Check ............................ 1D-*

Repair Instructions ..............................................1D-2

Engine Components Removable with the

Engine in Place ................................................. 1D-*

Engine Assembly Removal and Installation ........ 1D-*

Crankcase bracket Removal and Installation...... 1D-*

Crankcase bracket Inspection............................. 1D-*

Air Cleaner Box Removal and Installation........... 1D-*

Air Cleaner Element Inspection........................... 1D-*

Air Cleaner Drain Plug Inspection ....................... 1D-*

Throttle Cable Removal and Installation ............. 1D-*

Throttle Cable Adjustment................................... 1D-*

Throttle Body Components ................................. 1D-*

Throttle Body Construction.................................. 1D-*

Throttle Body Removal and Installation .............. 1D-*

Throttle Body Disassembly and Assembly.......... 1D-*

Throttle Body Inspection and Cleaning ............... 1D-*

Engine Top Side Disassembly ............................ 1D-*

Engine Top Side Assembly ................................. 1D-*

Camshaft Inspection ........................................... 1D-*

Cam Chain Tension Adjuster Inspection............. 1D-*

Cam Chain Guide Inspection .............................. 1D-*

Cylinder Head Disassembly and Reassembly .... 1D-*

Cylinder Head and Related Parts Inspection ...... 1D-*

Valve Guide Replacement .................................. 1D-*

Valve Seat Repair ............................................... 1D-*

Cylinder Disassembly and Assembly .................. 1D-*

Cylinder Inspection.............................................. 1D-*

Piston Ring Removal and Installation ................. 1D-*

Piston and Related Parts Inspection ................... 1D-*

Engine Bottom Side Disassembly ....................... 1D-*

Engine Bottom Side Assembly ............................ 1D-*

Cam Chain Tensioner Inspection........................ 1D-*

Conrod and Crankshaft Inspection...................... 1D-*

Width Between Crankshaft Webs ....................... 1D-*

Bearing Inspection .............................................. 1D-*

Bearing Removal and Installation ....................... 1D-*

Rear Suspension Mounting Bushing Removal

and Installation .................................................. 1D-*

Engine Bottom Side Assembly (AN400/A/

ZAK9) ................................................................1D-2

Specifications.......................................................1D-3

Service Data........................................................ 1D-*

Tightening Torque Specifications........................1D-3

Special Tools and Equipment .............................1D-3

Recommended Service Material .........................1D-3

Engine Lubrication System ..................... 1E-*

Precautions........................................................... 1E-*

Precautions for Engine Oil .................................. 1E-*

Schematic and Routing Diagram ........................ 1E-*

Engine Lubrication System Chart Diagram ......... 1E-*

Engine Lubrication Circuit Diagram..................... 1E-*

Diagnostic Information and Procedures............ 1E-*

Engine Lubrication Symptom Diagnosis ............. 1E-*

Oil Pressure Check ............................................. 1E-*

Repair Instructions .............................................. 1E-*

Engine Oil and Filter Replacement ..................... 1E-*

Oil Sump Filter Removal and Installation ............ 1E-*

Oil Sump Filter Cleaning ..................................... 1E-*

Oil Pump Removal and Installation ..................... 1E-*

Oil Pump Inspection ............................................ 1E-*

Piston Cooling Nozzle Removal and

Installation ......................................................... 1E-*

Piston Cooling Nozzle Inspection........................ 1E-*

Specifications....................................................... 1E-*

Service Data........................................................ 1E-*

Tightening Torque Specifications........................ 1E-*

Special Tools and Equipment ............................. 1E-*

Special Tool ........................................................ 1E-*

Engine Cooling System ........................... 1F-*

Precautions............................................................1F-*

Engine Cooling System Warning .........................1F-*

General Description ..............................................1F-*

Cooling System Description .................................1F-*

Table of Contents 1-iii

Engine Coolant Description ................................. 1F-*

Cooling Fan Thermo-Switch Description..............1F-*

Engine Coolant Temperature Sensor

Description .........................................................1F-*

Schematic and Routing Diagram.........................1F-*

Cooling Circuit Diagram ....................................... 1F-*

Radiator Hose Routing Diagram ..........................1F-*

Component Location ............................................1F-*

Engine Cooling System Components

Location .............................................................1F-*

Diagnostic Information and Procedures.............1F-*

Engine Cooling Symptom Diagnosis....................1F-*

Repair Instructions ...............................................1F-*

Cooling Circuit Inspection ....................................1F-*

Radiator Cap Inspection ...................................... 1F-*

Radiator Removal and Installation .......................1F-*

Radiator Cleaning ................................................1F-*

Radiator Hose Inspection.....................................1F-*

Radiator Hose Removal and Installation..............1F-*

Radiator Reservoir Tank Removal and

Installation..........................................................1F-*

Cooling Fan Inspection ........................................1F-*

Cooling Fan Removal and Installation .................1F-*

Cooling Fan Thermo-Switch Removal and

Installation..........................................................1F-*

Cooling Fan Thermo-Switch Inspection ...............1F-*

ECT Sensor Removal and Installation .................1F-*

ECT Sensor Inspection ........................................1F-*

Thermostat Removal and Installation...................1F-*

Thermostat Inspection .........................................1F-*

Water Pump Components....................................1F-*

Water Pump Construction ....................................1F-*

Water Pump Removal and Installation.................1F-*

Water Pump Disassembly and Assembly ............1F-*

Water Pump Related Parts Inspection .................1F-*

Specifications........................................................1F-*

Service Data ........................................................1F-*

Tightening Torque Specifications.........................1F-*

Special Tools and Equipment ..............................1F-*

Recommended Service Material ..........................1F-*

Special Tool .........................................................1F-*

Fuel System .............................................1G-1

Precautions........................................................... 1G-*

Precautions for Fuel System ............................... 1G-*

Schematic and Routing Diagram........................ 1G-*

Fuel Tank Hose Construction ............................. 1G-*

Diagnostic Information and Procedures............ 1G-*

Fuel System Diagnosis ....................................... 1G-*

Repair Instructions ..............................................1G-1

Fuel System Components................................... 1G-*

Fuel Tank Heat Shield Construction ................... 1G-*

Fuel Cut Valve Removal and Installation ............ 1G-*

Fuel Tank Removal and Installation.................... 1G-*

Fuel Pump Assembly Removal and

Installation......................................................... 1G-*

Fuel Drain Tray and FTPC Valve Removal

and Installation.................................................. 1G-*

Fuel Cut Valve Inspection ................................... 1G-*

FTPC Valve Inspection ....................................... 1G-*

Fuel Pump Disassembly and Assembly .............. 1G-*

Fuel Pressure Inspection .................................... 1G-*

Fuel Pump Relay Inspection ............................... 1G-*

Fuel Mesh Filter Inspection ................................. 1G-*

Fuel Level Gauge Inspection .............................. 1G-*

Fuel Pump Inspection ......................................... 1G-*

Fuel Injector Inspection ....................................... 1G-*

Fuel Injector Removal and Installation ................ 1G-*

Fuel Pump Components (AN400/A/ZAK9)......... 1G-1

Fuel Pump Disassembly and Assembly

(AN400/A/ZAK9) .............................................. 1G-2

Specifications...................................................... 1G-2

Service Data........................................................ 1G-*

Tightening Torque Specifications....................... 1G-2

Special Tools and Equipment ............................ 1G-2

Special Tool ........................................................ 1G-*

Recommended Service Material ........................ 1G-2

Ignition System.........................................1H-*

General Description ............................................. 1H-*

Immobilizer Description (For E-02, 19, 24, 54) .... 1H-*

Schematic and Routing Diagram........................ 1H-*

Ignition System Diagram ..................................... 1H-*

Diagnostic Information and Procedures............ 1H-*

Ignition System Symptom Diagnosis................... 1H-*

No Spark or Poor Spark ...................................... 1H-*

Repair Instructions .............................................. 1H-*

Spark Plug Removal and Installation .................. 1H-*

Spark Plug Inspection and Cleaning ................... 1H-*

Ignition Coil Inspection ........................................ 1H-*

Ignition Coil Assembly Removal and

Installation ......................................................... 1H-*

Spark Plug Removal and Installation .................. 1H-*

Spark Plug Inspection ......................................... 1H-*

CKP Sensor Inspection ....................................... 1H-*

CKP Sensor Removal and Installation ................ 1H-*

Engine Stop Switch Inspection............................ 1H-*

Ignition Switch Inspection.................................... 1H-*

Ignition Switch Removal and Installation............. 1H-*

Specifications....................................................... 1H-*

Service Data........................................................ 1H-*

Special Tools and Equipment ............................. 1H-*

Special Tool ........................................................ 1H-*

Starting System ......................................... 1I-*

Schematic and Routing Diagram..........................1I-*

Starting System Diagram ......................................1I-*

Component Location .............................................1I-*

Starting System Components Location................. 1I-*

Diagnostic Information and Procedures.............. 1I-*

Starter Motor will not Run......................................1I-*

Repair Instructions ................................................1I-*

Starter Motor Components.................................... 1I-*

Starter Motor Removal and Installation................. 1I-*

Starter Motor Disassembly and Assembly ............1I-*

Starter Motor Inspection........................................ 1I-*

Starter Relay Removal and Installation................. 1I-*

Starter Relay Inspection........................................1I-*

1-iv Table of Contents

Turn Signal / Side-stand Relay Removal and

Installation........................................................... 1I-*

Side-stand / Ignition Interlock System Parts

Inspection............................................................1I-*

Starter Clutch Component..................................... 1I-*

Starter Clutch Removal and Installation................ 1I-*

Starter Clutch Inspection....................................... 1I-*

Starter Clutch Disassembly and Assembly ........... 1I-*

Starter Button Inspection....................................... 1I-*

Specifications......................................................... 1I-*

Service Data.......................................................... 1I-*

Tightening Torque Specifications.......................... 1I-*

Special Tools and Equipment ...............................1I-*

Recommended Service Material ........................... 1I-*

Special Tool .......................................................... 1I-*

Charging System.......................................1J-*

Schematic and Routing Diagram.........................1J-*

Charging System Diagram ................................... 1J-*

Component Location ............................................1J-*

Charging System Components Location.............. 1J-*

Diagnostic Information and Procedures............. 1J-*

Charging System Symptom Diagnosis................. 1J-*

Battery Runs Down Quickly ................................. 1J-*

Repair Instructions ............................................... 1J-*

Battery Current Leakage Inspection..................... 1J-*

Regulated Voltage Inspection .............................. 1J-*

Generator Coil Resistance Inspection.................. 1J-*

Generator No-load Performance Inspection ........ 1J-*

Regulator/Rectifier Inspection (Except

AN400K8 E-03, 28, 33) ...................................... 1J-*

Regulator/Rectifier Inspection (AN400K8 E-

03, 28, 33 only) .................................................. 1J-*

Generator Removal and Installation..................... 1J-*

Battery Components ............................................ 1J-*

Battery Initial Charging......................................... 1J-*

Battery Visual Inspection...................................... 1J-*

Battery Recharging .............................................. 1J-*

Battery Removal and Installation ......................... 1J-*

Specifications........................................................ 1J-*

Service Data......................................................... 1J-*

Tightening Torque Specifications......................... 1J-*

Special Tools and Equipment ..............................1J-*

Special Tool ......................................................... 1J-*

Exhaust System........................................1K-*

Precautions........................................................... 1K-*

Precautions for Exhaust System ......................... 1K-*

Repair Instructions .............................................. 1K-*

Exhaust System Construction (AN400/ZK7)....... 1K-*

Exhaust System Construction (AN400/ZK8)....... 1K-*

Exhaust Pipe / Muffler Removal and

Installation ......................................................... 1K-*

Exhaust System Inspection................................. 1K-*

HO2 Sensor Inspection ....................................... 1K-*

Specifications....................................................... 1K-*

Tightening Torque Specifications........................ 1K-*

Special Tools and Equipment ............................. 1K-*

Recommended Service Material ......................... 1K-*

Engine

Engine Mechanical

Schematic and Routing Diagram

Engine Mechanical: 1D-1

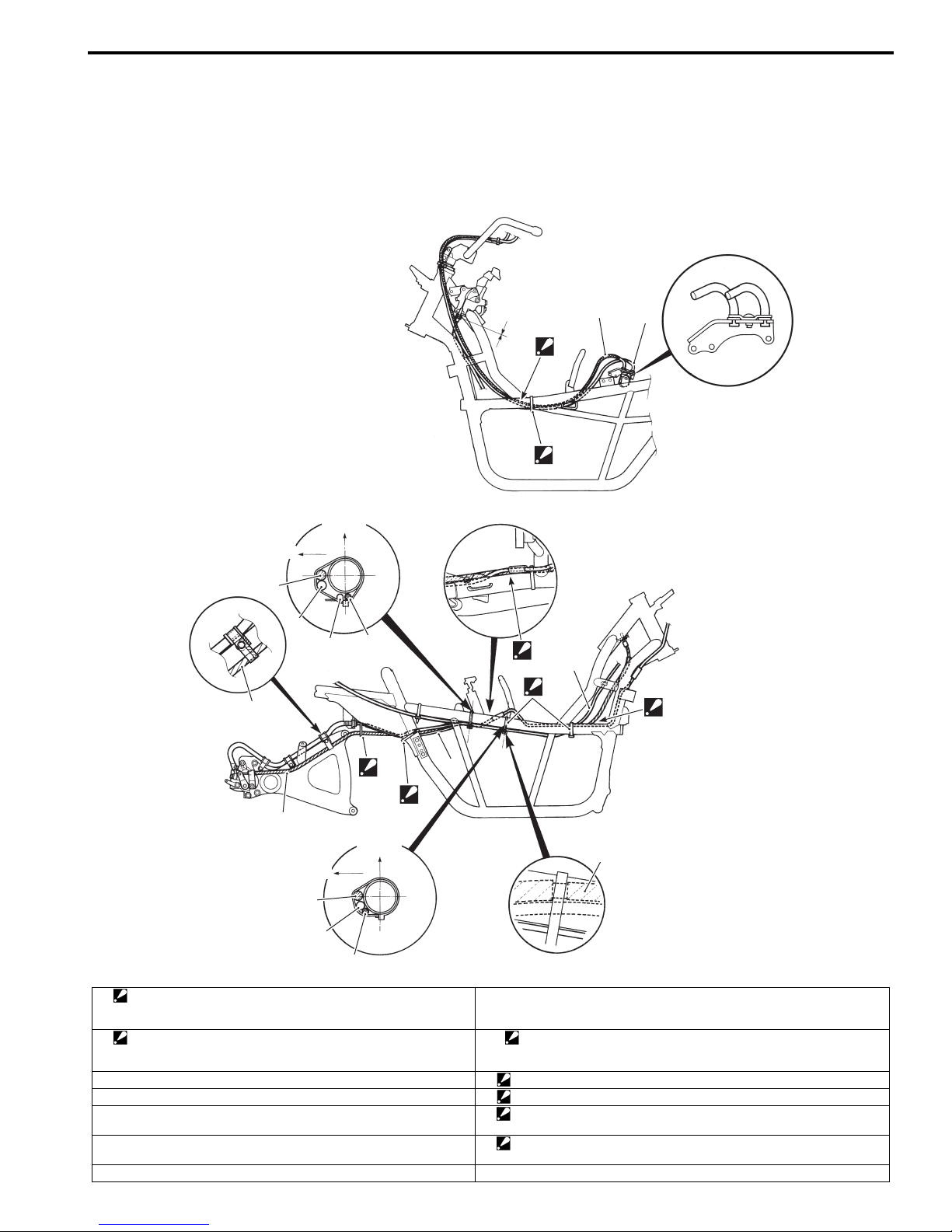

Throttle Cable Routing Diagram (AN400/A/ZAK9)

Upside

Inside

4

“a”

“D”

9

B905H11402003

8

7

5

3

6

“C”

3

1

4

“A”

5

“B”

2

4

Upside

4

Inside

4

5

3

I905H1140001-02

1. Clamp

: Bind the parking brake cable, starter motor lead wire and seatlock cable with the clamp.

2. Clamp

: Bind the parking brake cable and starter motor lead wire with the

clamp.

3. Seat-lock cable “A”: Pass the parking brake cable into the guide.

4. Parking brake cable “B”: Pass the parking brake cable inside of the brake hose.

5. Starter motor lead wire “C”: Pass the parking brake cable under the brake pipe. Do not slacken the

6. Brake pipe “D”: Pass the throttle cable No. 2 over the throttle cable No. 1. Pass the

7. Throttle cable No. 1 “a”: 0 mm (0 in)

8. Throttle cable No. 2

9. Clamp

: Clamp the throttle cable at white taping point.

parking brake cable.

throttle cables inside of the wiring harness.

1D-2 Engine Mechanical:

Repair Instructions

Engine Bottom Side Assembly (AN400/A/ZAK9)

B905H11406036

For engine bottom side assembly other than the

following, refer to “Engine Bottom Side Assembly” in

related manual.

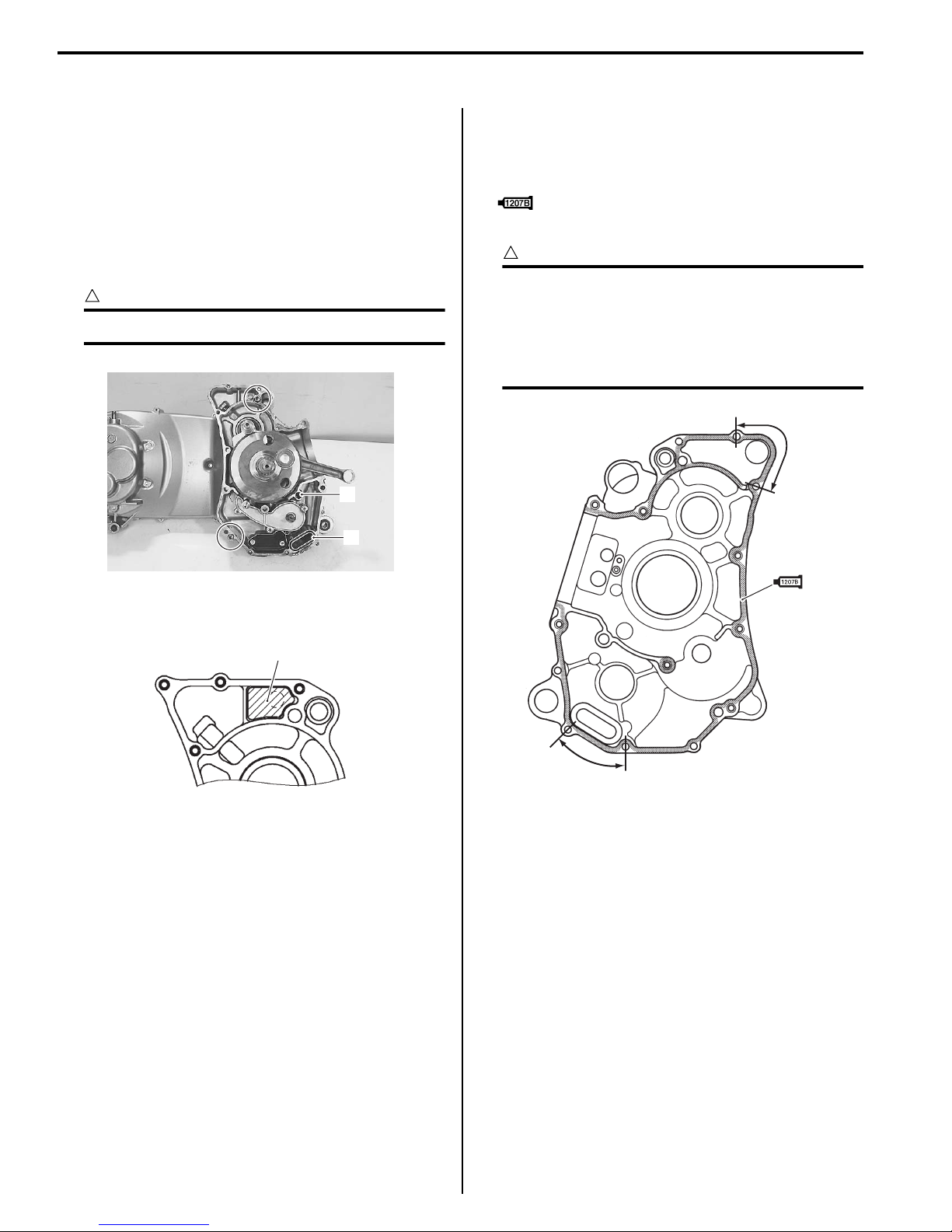

Crankcase

• Install the O-rings (1) and (2).

• Install the dowel pins.

!

CAUTION

Replace the O-rings with the new ones.

1

2

• Clean and degrees the crankcase mating surfaces

(both surfaces) with a cleaning solvent.

• Apply bond to the right crankcase and part “a” of the

left crankcase.

: Sealant 99000–31140 (SUZUKI BOND

No.1207B or equivalent)

!

CAUTION

• Coat the sealant evenly without break.

• Application of sealant must be performed

within a short period of time.

• Take extreme care not to let sealant enter

into the oil passages or bearings.

“a”

I705H1140118-04

• Install the oil breather separator (3) to the left

crankcase.

3

I905H1140003-01

“a”

I905H1140002-01

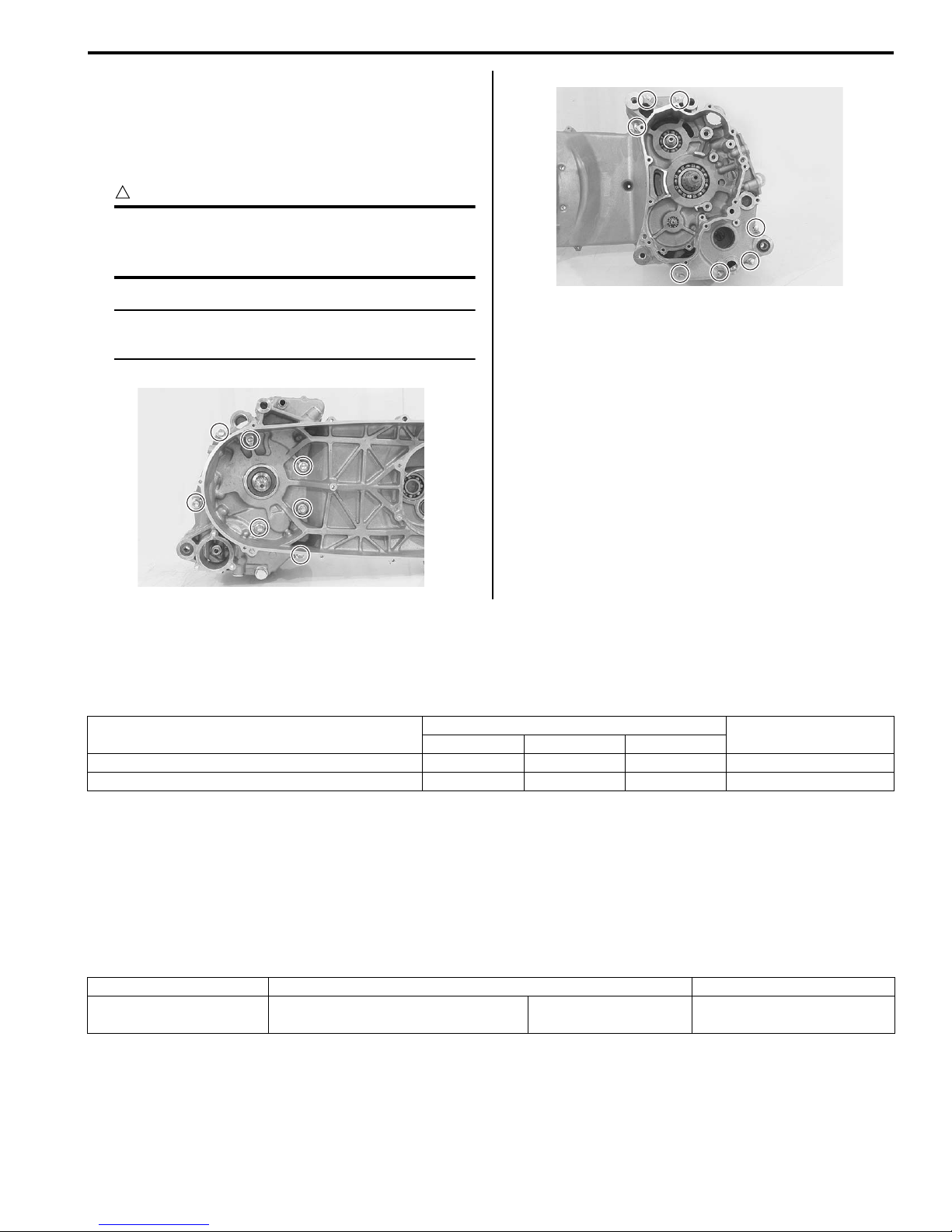

• Tighten the crankcase bolts to the specified torque.

Tightening torque

Crankcase bolt (M6): 11 N·m (1.1 kgf-m, 8.0 lbf-ft)

Crankcase bolt (M8): 22 N·m (2.2 kgf-m, 16.0 lbfft)

!

CAUTION

Tighten the larger diameter crankcase bolts

first and then smaller ones diagonally and

evenly.

NOTE

After crankcase bolts have been tightened,

check it crankshaft rotate smoothly.

Engine Mechanical: 1D-3

I705H1140101-01

I705H1140102-01

Specifications

Tightening Torque Specifications

Fastening part

N⋅m kgf-m lbf-ft

Crankcase bolt (M6) 11 1.1 8.0 )(Page 1D-3)

Crankcase bolt (M8) 22 2.2 16.0 )(Page 1D-3)

Reference:

For the tightening torque of fastener not specified in this section, refer to “Tightening Torque List” in Section 0C in

related manual.

Tightening torque

B905H11407002

Note

Special Tools and Equipment

Recommended Service Material

Material SUZUKI recommended product or Specification Note

Sealant SUZUKI BOND No.1207B or

equivalent

P/No.: 99000–31140 )(Page 1D-2)

B905H11408001

1G-1 Fuel System:

Engine

Fuel System

Repair Instructions

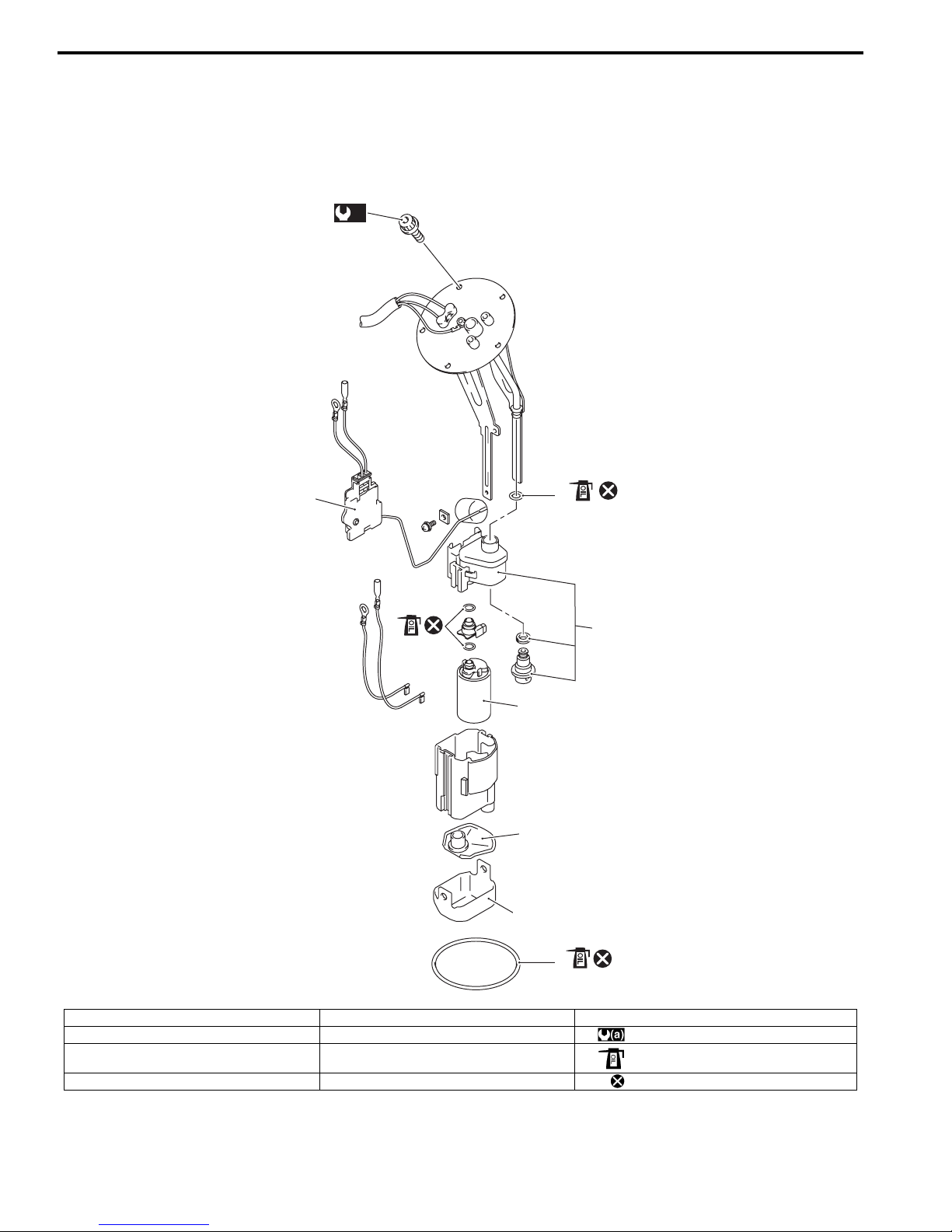

Fuel Pump Components (AN400/A/ZAK9)

(a)

9

1

B905H11706017

2

4

5

6

7

1. Fuel level gauge 5. Fuel pump 9. Fuel pump mounting bolt

2. O-ring 6. Fuel mesh filter : 10 N⋅m (1.0 kgf-m, 7.0 lbf-ft)

3. Fuel pressure regulator assembly 7. Dust cover : Apply engine oil.

3

8

I905H1170003-01

4. O-ring 8. O-ring : Do not reuse.

Fuel System: 1G-2

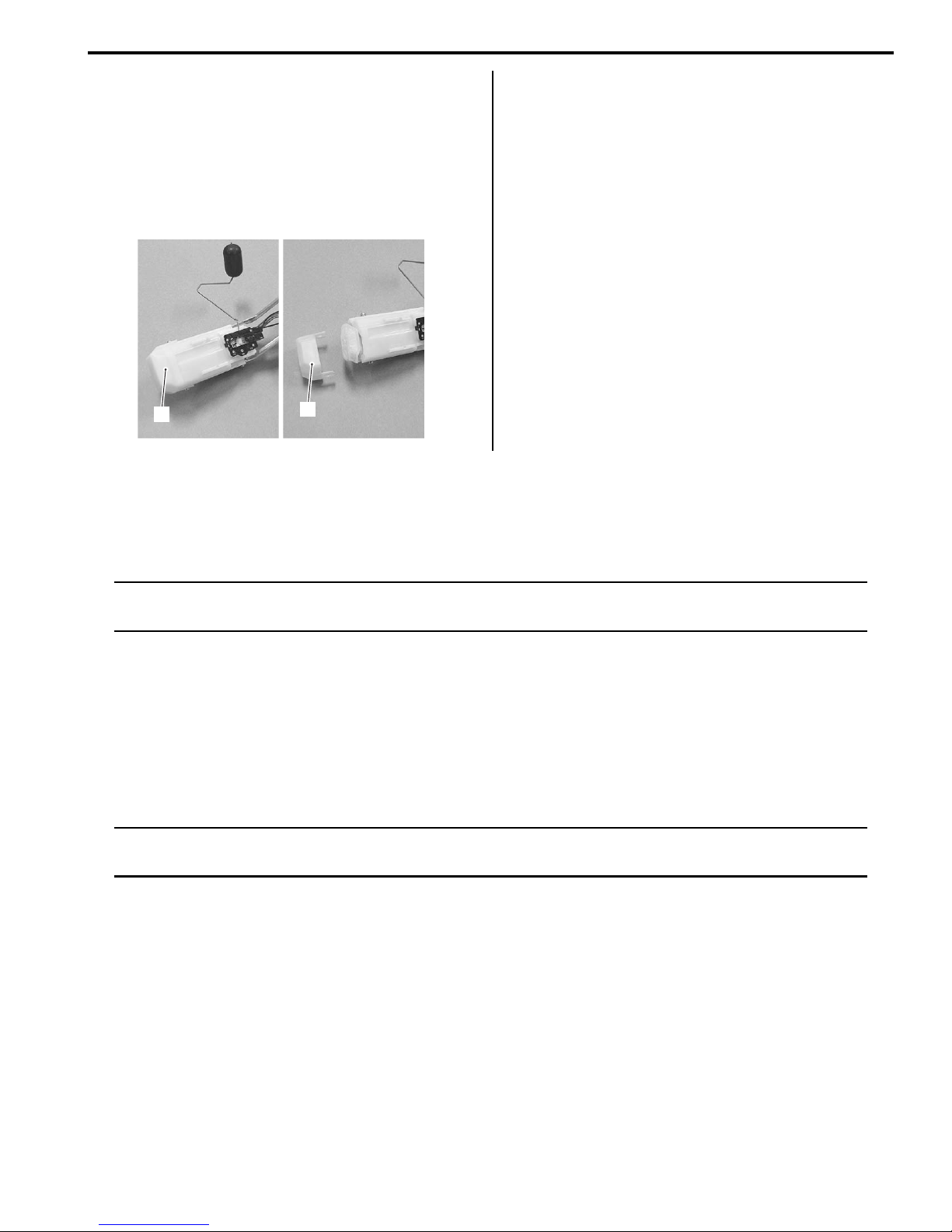

Fuel Pump Disassembly and Assembly (AN400/

A/ZAK9)

B905H11706018

Disassembly

1) Remove the fuel pump assembly.

Refer to “Fuel Pump Assembly Removal and

Installation” in related manual.

2) Remove the dust cover (1).

1

1

I905H1170002-01

Specifications

3) For the other procedure, refer to “Fuel Pump

Disassembly and Assembly” in related manual.

Assembly

Assemble the fuel pump assembly in the reverse order

of the disassembly.

Refer to “Fuel Pump Disassembly and Assembly” in

related manual.

Tightening Torque Specifications

B905H11707002

NOTE

The specified tightening torque is described in the following.

“Fuel Pump Components (AN400/A/ZAK9)” (Page 1G-1)

Reference:

For the tightening torque of fastener not specified in this section, refer to “Tightening Torque List” in Section 0C in

related manual.

Special Tools and Equipment

Recommended Service Material

NOTE

Required service material is also described in the following.

“Fuel Pump Components (AN400/A/ZAK9)” (Page 1G-1)

B905H11708003

1G-3 Fuel System:

Table of Contents 2- i

Section 2

Suspension

CONTENTS

NOTE

For the items with asterisk (*) in the “CONTENTS” below, refer to the same section of the service manual

mentioned in the “FOREWORD” of this manual.

Precautions ................................................. 2-*

Precautions.............................................................. 2-*

Precautions for Suspension ................................... 2-*

Suspension General Diagnosis...............2A-*

Diagnostic Information and Procedures............ 2A-*

Suspension and Wheel Symptom Diagnosis .......2A-*

Front Suspension .....................................2B-*

Repair Instructions .............................................. 2B-*

Front Fork Components .......................................2B-*

Front Fork Removal and Installation ....................2B-*

Front Fork Disassembly and Assembly................2B-*

Front Fork Inspection ...........................................2B-*

Front Fork Parts Inspection..................................2B-*

Specifications....................................................... 2B-*

Service Data ........................................................2B-*

Tightening Torque Specifications.........................2B-*

Special Tools and Equipment ............................. 2B-*

Recommended Service Material ..........................2B-*

Special Tool .........................................................2B-*

Rear Suspension ..................................... 2C-1

Repair Instructions ..............................................2C-1

Rear Suspension Components ........................... 2C-*

Rear Suspension Assembly Construction........... 2C-*

Rear Swingarm Components.............................. 2C-*

Rear Shock Absorber and Rear Shock

Absorber Assembly Removal and

Installation......................................................... 2C-*

Rear Suspension Inspection ............................... 2C-*

Rear Shock Absorber Inspection ........................ 2C-*

Rear Shock Absorber Gas Pressure Release..... 2C-*

Rear Suspension Adjustment ............................. 2C-*

Rear Swingarm Removal and Installation ........... 2C-*

Rear Swingarm Related Parts Inspection ........... 2C-*

Rear Swingarm Dust Seal / Bearing Removal

and Installation.................................................. 2C-*

Cushion Lever and Cushion Rod Inspection....... 2C-*

Cushion Lever Bearing Removal and

Installation......................................................... 2C-*

Crankcase Bracket Construction......................... 2C-*

Crankcase Bracket Removal and Installation ..... 2C-*

Crankcase Bracket Related Parts Inspection...... 2C-*

Crankcase Bracket Bearing Removal and

Installation ......................................................... 2C-*

Rear Swingarm Construction (AN400/A/

ZAK9) ................................................................2C-1

Specifications....................................................... 2C-*

Service Data........................................................ 2C-*

Tightening Torque Specifications........................ 2C-*

Special Tools and Equipment ............................. 2C-*

Recommended Service Material ......................... 2C-*

Special Tool ........................................................ 2C-*

Wheels and Tires ..................................... 2D-1

Precautions........................................................... 2D-*

Precautions for Wheel and Tire........................... 2D-*

Repair Instructions ..............................................2D-1

Front Wheel Components ................................... 2D-*

Front Wheel Assembly Construction................... 2D-*

Front Wheel Assembly Removal and

Installation ......................................................... 2D-*

Front Wheel Related Parts Inspection ................ 2D-*

Front Wheel Dust Seal / Bearing Removal

and Installation .................................................. 2D-*

Rear Wheel Components.................................... 2D-*

Rear Wheel Assembly Removal and

Installation ......................................................... 2D-*

Rear Wheel Related Parts Inspection ................. 2D-*

Tire Removal and Installation.............................. 2D-*

Wheel/Tire/Air Valve Inspection and Cleaning .... 2D-*

Air Valve Removal and Installation ..................... 2D-*

Wheel Balance Check and Adjustment............... 2D-*

Front Wheel Components (AN400A/ZAK9) ........2D-1

Front Wheel Assembly Construction

(AN400A/ZAK9) ................................................2D-2

Front Wheel Assembly Removal and

Installation (AN400A/ZAK9) ..............................2D-3

Rear Wheel Components (AN400A/ZAK9) .........2D-4

Rear Wheel Assembly Construction

(AN400A/ZAK9) ................................................2D-5

Rear Wheel Assembly Removal and

Installation (AN400A/ZAK9) ..............................2D-6

2

2-ii Table of Contents

Specifications.......................................................2D-7

Service Data........................................................ 2D-*

Tightening Torque Specifications........................2D-7

Special Tools and Equipment .............................2D-7

Recommended Service Material .........................2D-7

Special Tool ........................................................2D-7

Suspension

Rear Suspension

Rear Suspension: 2C-1

Repair Instructions

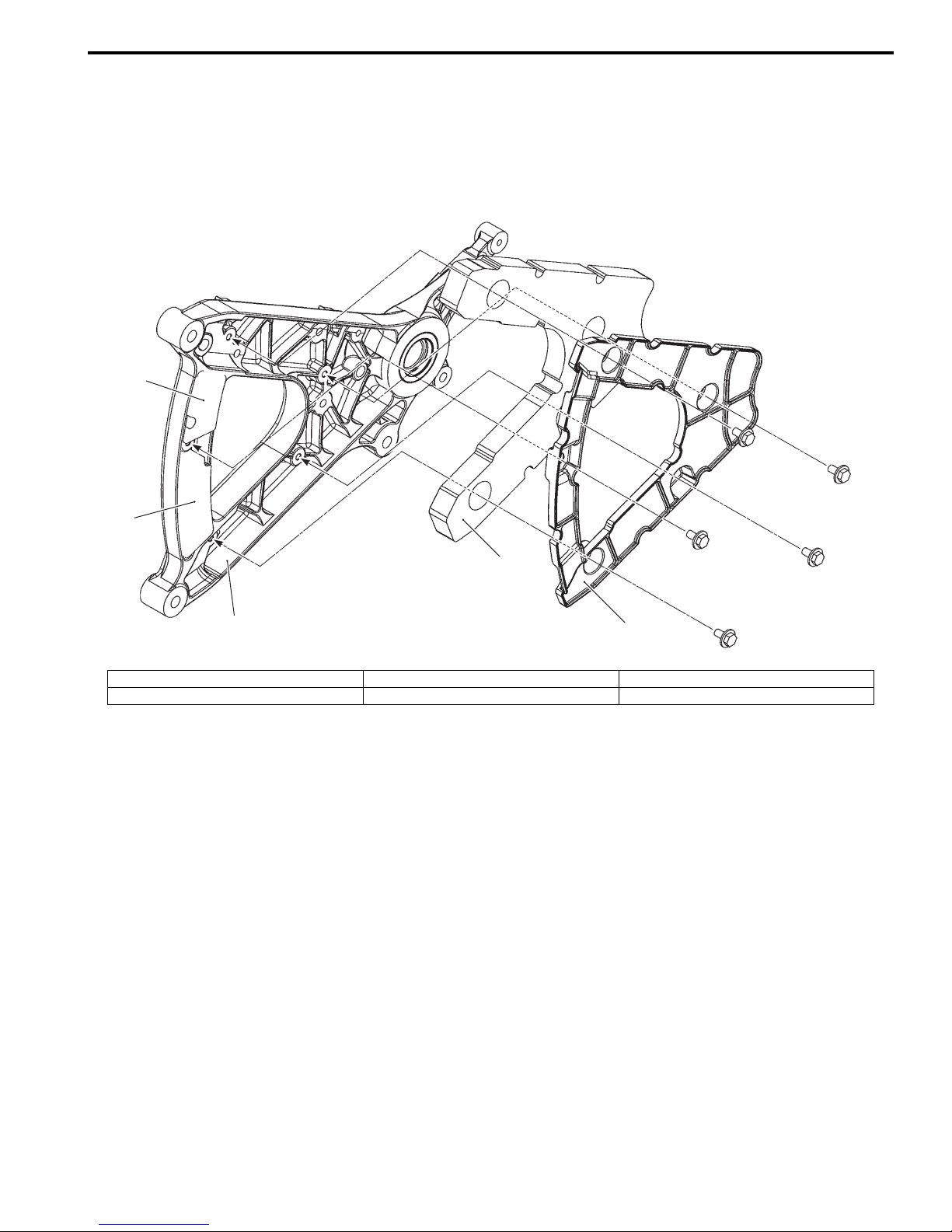

Rear Swingarm Construction (AN400/A/ZAK9)

3

2

B905H12306018

4

1

1. Rear swingarm 3. Swingarm cushion No. 2 5. Swingarm cushion cover

2. Swingarm cushion No. 3 4. Swingarm cushion No. 1

5

I905H1230001-01

2D-1 Wheels and Tires:

FWD

Suspension

Wheels and Tires

Repair Instructions

Front Wheel Components (AN400A/ZAK9)

(a)

5

8

B905H12406013

7

4

3

(b)

9

11

1

3

7

(b)

8

(c)

2

FWD

13

10

12

6

4

I905H1240001-02

1. Front wheel 6. Collar 11. Wheel balancer : 6 N⋅m (0.6 kgf-m, 4.5 lbf-ft)

2. Spacer 7. Brake disk 12. Wheel speed sensor rotor : Apply grease.

3. Bearing 8. Brake disk bolt 13. Wheel speed sensor rotor bolt : Apply thread lock to thread part.

4. Dust seal 9. Tire : 65 N⋅m (6.5 kgf-m, 47.0 lbf-ft) : Do not reuse.

5. Front axle 10. Air valve : 23 N⋅m (2.3 kgf-m, 16.5 lbf-ft)

Loading...

Loading...