Suunny SP228 User Manual

CONTENT

Part 1: Operation instruction

Ⅰ General information .……………………………………… 1

Ⅱ Product description

..……………………………………… 2

Ⅲ System description…………………………………………4

Ⅳ Function description………………………………………10

Ⅴ Fault message …………………………………………… 15

Part 2: Installation instruction

Ⅰ General information ………………………………………17

Ⅱ Mounting……………………………………………………18

Ⅲ Electrical wiring……………………………………………19

Ⅳ Commissioning.……………………………………………20

Ⅴ Replacing pump……………………………………………21

Ⅵ Packing list…………………………………………………23

Work station series for solar water heating control system

1

Part 1: Operation instruction

Ⅰ. General information

1. About this manual

This manual describes the installation, function and operation of an integrated solar work station,

which is suitable for split pressurized solar heating system. Before installing and operating the device,

please read the following information carefully.

2. Safety regulations

♦ Installation, commissioning and maintenance of the device may only be performed by professional

personal.

♦ All operations that require opening the device are only to be conducted cleared from the power

supply. All safety regulations for working on the power supply are valid.

♦ The device must not be installed in rooms where easily inflammable material (e.g. gas or oil)

mixtures are present or may occur.

♦ Before connecting the work station, make sure that the energy supply matches the specifications of

the device. Protect the solar station against overloading and short-circuiting.

♦ All devices connected to the work station must conform to the technical specifications of the device.

♦ As soon as it becomes evident that safe operation is no longer possible, please immediately take

the device out of operation.

♦ Without lightning rod, please don’t use this device during a thunderstorm.

3. Liability waiver

♦ Improper installation or operation can cause damages to material and persons. The manufacturer

cannot monitor the compliance with these instructions or the circumstances and methods used for

installation, operation, utilization and maintenance of this device. Damage by mishandling or

improper installation on costumer site is immediately leading to warranty exclusion.

♦ As faults can never be excluded, we don’t offer a guarantee for the completeness of the drawings

and texts of this manual, they only represent some examples. They can only be used on own risk.

No liability is assumed for incorrect, incomplete or false information and the resulting damages.

♦ The manufacturer preserves the right to put changes to product, technical date or installation and

operation instructions without prior notice.

4. Symbols used

Danger: Failure to observe these instructions can lead to injury of persons or safety risks.

Attention: Failure to observe these instructions can result in damage to the product or

environment.

Note: Useful information and instructions.

ì

Operation steps: Indication of operation steps.

Work station series for solar water heating control system

2

Ⅱ. Product information

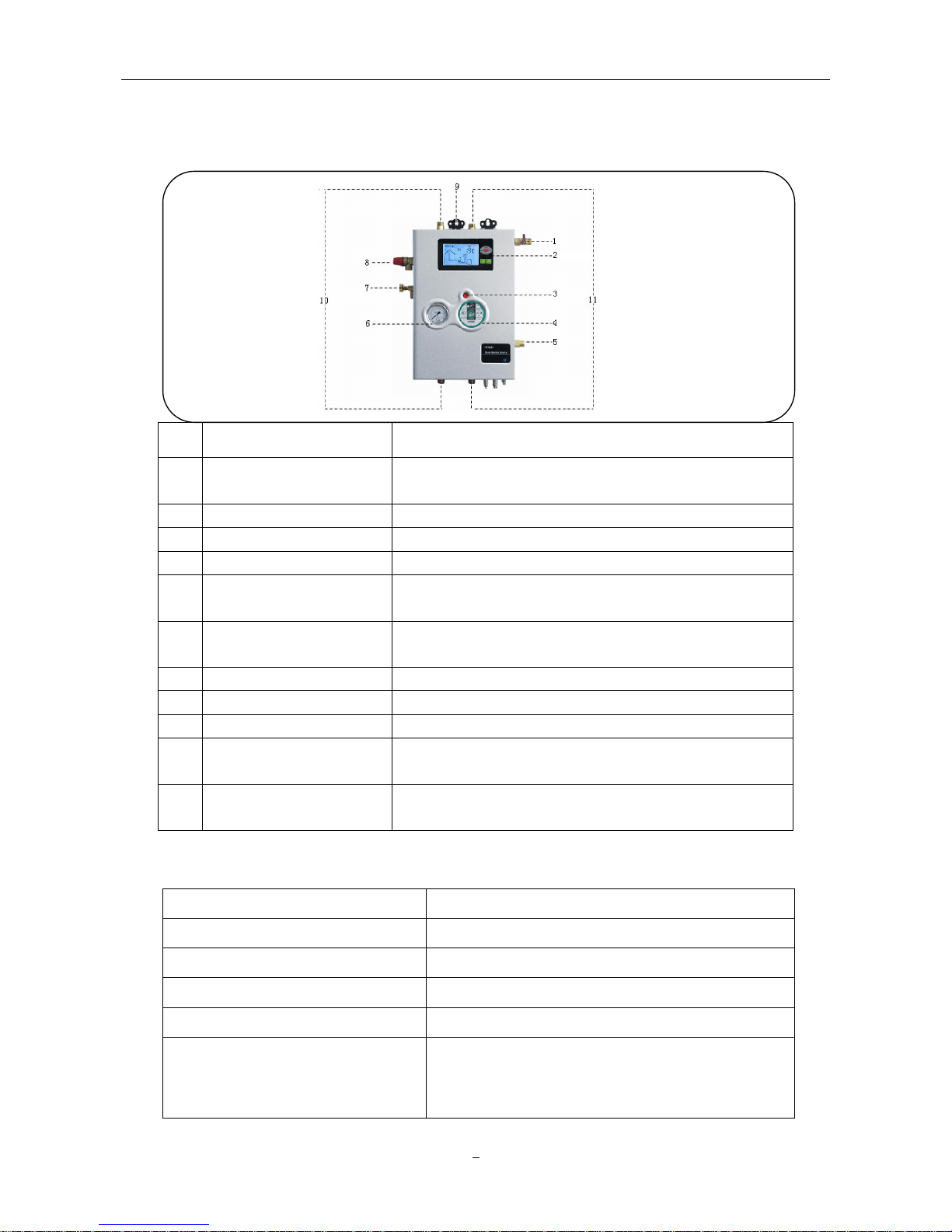

1. Components

No

Components Function description

1

Filling and flushing

connector

Through this connector medium can be pumped into

solar system

2 Operating screen (LCD) Display operating menu.

3 Pump speed regulation Three speed levels available, offers different flow rate.

4 Circulation pump WILO Star RS 15/6 (110V or 220V)

5

Expansion vessel

connector

Connect expansion vessel. Expansion vessel balances

the system pressure.

6 Manometer

Display system pressure (Max. 10 bar, normal working

pressure is approx. 2 bar)

7 Air vent valve Empty the air in the solar system

8 Security valve Protect the system against over-pressure.

9 Mounting point For fixing the solar pump station

10 Forward flow

Copper material, left side, Max. working temperature 150

℃, screw thread 1/2’ (DN15) as standard

11 Return flow

Copper material, right side. Max. working temperature

150 ℃, screw thread 1/2’ (DN15) as standard

2. Technical data

Dimension 450×310×150mm

Input voltage 200V~240V AC or 100V~120V AC

Power ≤3W

Accuracy of temperature measuring ±1℃

Range of temperature measuring

PT1000 : 0~199℃ NTC10K: 0~99℃

Input signals

2 x PT1000 sensor temperature probe ≤500℃,

silicon cable ≤280℃;

4 x NTC10K sensor temperature probe≤135℃,

PVC cable ≤105℃

Work station series for solar water heating control system

3

Output signals

1 x Auxiliary heating output (Max. load current: 15A)

4 x Relay output (Max. load current: 3A)

System design pressure 10 bar

Safety valve response pressure 6 bar

WILO pump SR15/6

Ambient temperature -10~50℃

Water protection grade

IP40

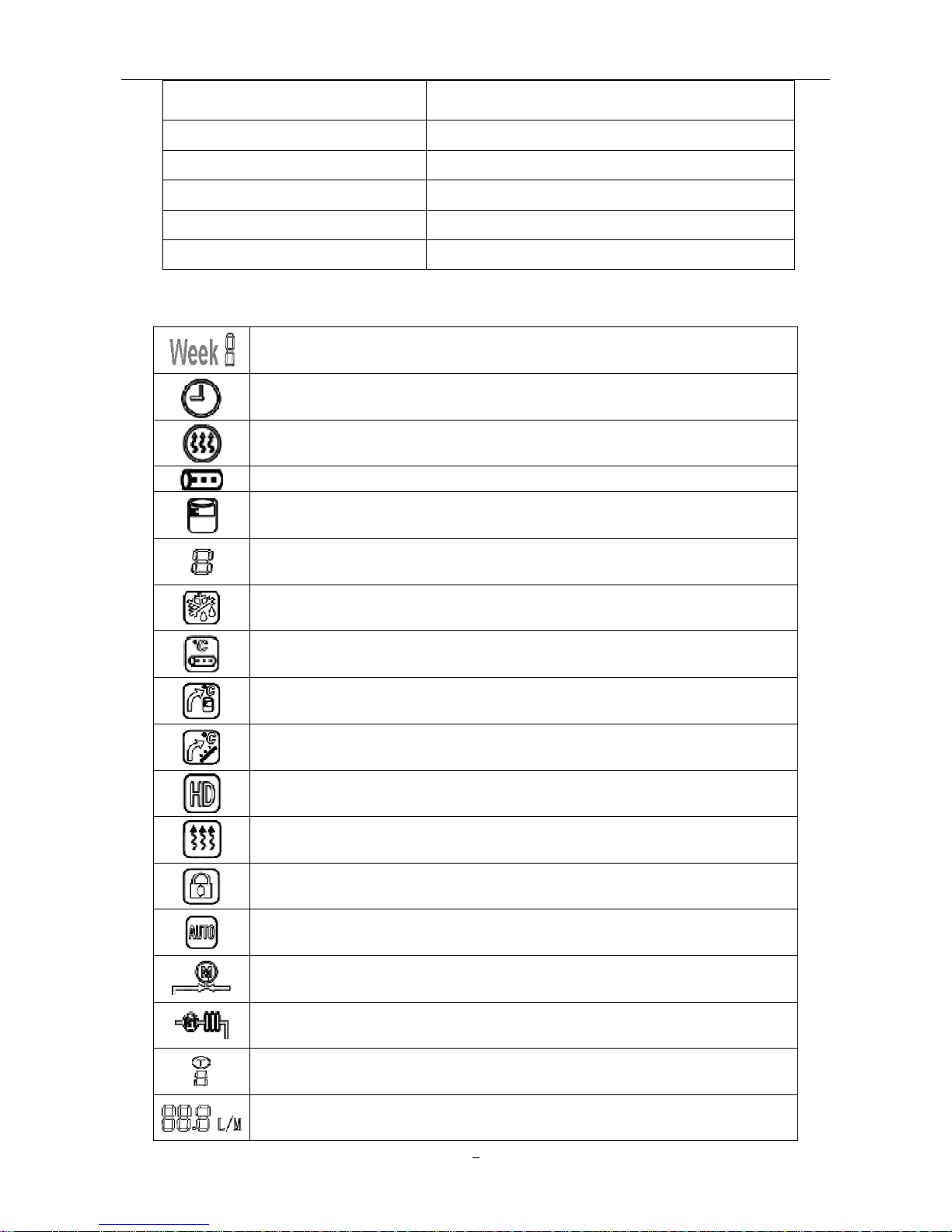

3. Display signals

Weekday: 7days of week can be set (e.g. Week 1 means “Monday”).

Time: Setting hours and minutes.

Time-controlled auxiliary heating: Setting three heating time periods.

Time-controlled hot water circulation: Setting three time periods.

Storage temperature: As turning-on/off temperature value for auxiliary heating.

Solar system indication. 8 systems are available.

Frost protection.

Temperature-controlled circulation function

Overheating protection for storage.

High temperature protection for solar collector.

Holiday function.

Switch on/off auxiliary heating manually.

Forbid/permit using auxiliary heating.

Reset.

Extended temperature-difference circulation function

Recooling the system through by-pass

Temperature display.

Flow rate display.

Work station series for solar water heating control system

4

Ⅲ System description (8 systems available)

Danger: If there is only one temperature sensor in water storage (usually in bottom part T2),

it is possible, and that the auxiliary heating function will not be activated or deactivated at a

right time, because the water temperature in top part of the storage (T3) cannot be measured.

In this case, if you still want to use auxiliary heating function, control program will automatically

take the signal from bottom temperature sensor (T2) instead of T3. However, water in top part

of storage might often be overheated. It may cause damages to material and persons. So it is

highly recommended not to use auxiliary heating in such a case.

Note: To lock this function, please press “Choose Function” button until the signal” ”

appears

on

the screen (see details in 8 Forbid/Permit auxiliary heating).

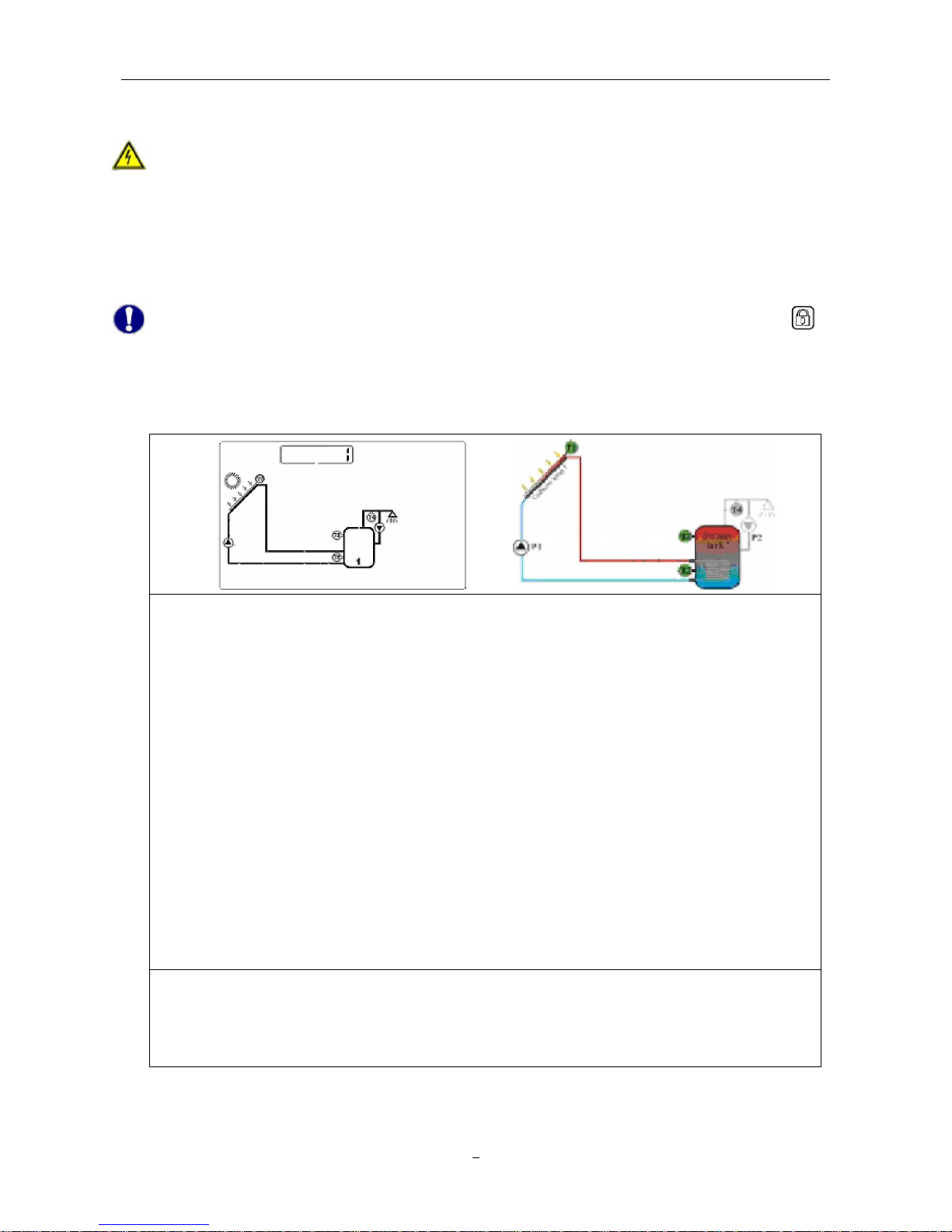

1. System 1: 1 collector array – 1 storage – 1 pump

Description:

The solar collector pump (P1) is activated as soon as the temperature difference

between the collector array (T1) and the storage (T2) is reached. When the temperature

difference between T1 and T2 drops below the switch-off temperature difference, or the

storage (T3) reaches its maximum storage temperature, the solar pump (P1) will be

switched off.

T3 is used to measure the temperature of the top part of storage. If the turning-on

condition for auxiliary heating is filled, the auxiliary heating will be activated

T1:

Temperature sensor for collector 1

T2: Temperature sensor in the bottom part of storage 1

T3: Temperature sensor in the top part of storage 1

T4: Temperature sensor for hot water pipe

P1: Solar collector pump

P2: Solar circulation pump

Note:

1. T3, T4, P2 are suitable for system 1-8.

2. T3 is alternative, when no sensor (T3) is installed in the top part of tank, control system

will use the signal of sensor T2 automatically to control the auxiliary heating.

Work station series for solar water heating control system

5

2. System 2: 1 collector array – 2 storage – 2 pumps

Description:

When switch–on temperature difference between collector array (T1) and one of the

storage (T2 or T5) is reached, the solar circuit pump (P1) or (P0) will switched on.

According to the priority switching, two storages (T2, T5) will be loaded one by one. Until

either of switch-off temperature difference between collector array (T1) and storage (T2,

T5) is reached, or the maximum storage temperature is reached, pump stops working.

T1:

Temperature sensor for collector 1

T2: Temperature sensor in the bottom part of storage 1

T3: Temperature sensor in the top part of storage 1

T4: Temperature sensor for hot water pipe

T5: Temperature sensor in storage 2

P0: Solar collector pump

P1: Solar collector pump

Note:

The default priority storage is storage1.

3. System 3: 1 collector array – 2 storages– 1 pump – 1 valve

Description:

When switch–on temperature difference between collector array (T1) and one of the

storage (T2 or T5) is reached, then the solar pump (P1) is switched on and valve (R1) is

set to the correct position depending on the storage to be loaded. According to the priority

switching, both storages (T2, T5) will be loaded one by one, until the relevant switch-off

temperature difference between the collector array (T1) and storage are reached.

(T2, T5) is reached or the maximum storage temperature of T2 or T5 is reached, pump

and valve stop working.

Work station series for solar water heating control system

6

T1: Temperature sensor for collector 1

T2: Temperature sensor in the bottom part of storage 1

T5: Temperature sensor in the bottom part of storage 2

P1: Solar collector pump

R1: Electromagnetic 3-way valve

Note:

1.

When there is no power in the system, the electromagnetic valve (R1) must be set to

storage (T2).

2. The default priority storage is storage 1.

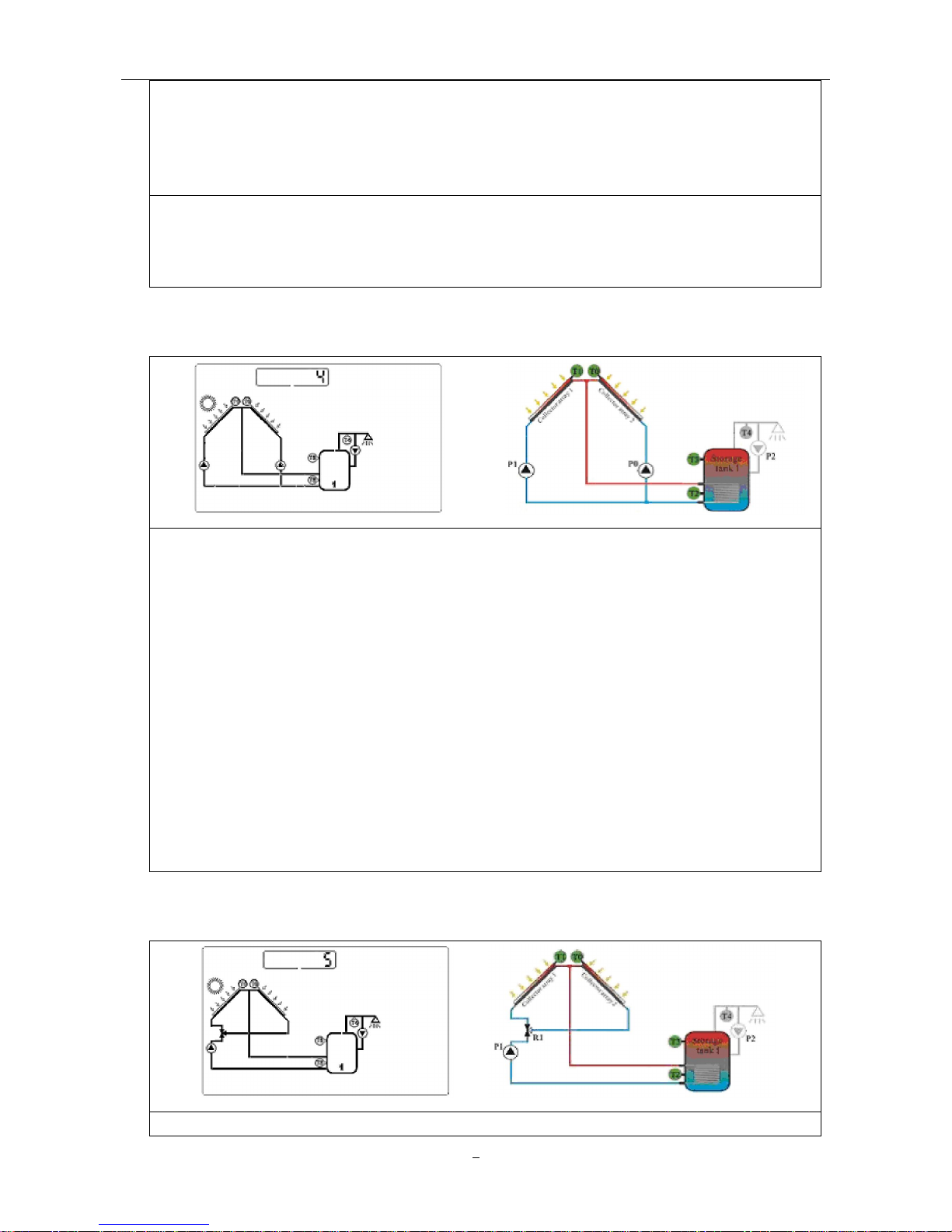

4. System 4: 2 collector arrays – 1 storage tank – 2 pumps

Description:

When switch–on temperature difference between storage (T2) and collector array (T1,

T0) is reached, then solar pump (P1) for collector array 1 (T1) or solar circuit pump (P0) for

collector array 2 (T0) is switched on, depending on where the temperature difference

occurs firstly. If the switch-on temperature difference is reached for both collector arrays

(T1, T0), then both pumps (P1, P0) are switched on. The pumps switch-off independently

for each other. When either of relevant switch-off temperature difference between one or

both collector arrays (T1, T0) and the storage (T2) falls below the threshold or the maximum

storage temperature is reached, then the corresponding circuit pump is switched off.

T0: Temperature sensor for collector 2

T1: Temperature sensor for collector 1

T2: Temperature sensor in the bottom part of storage1

P0: Solar collector pump

P1: Solar collector pump

5. System 5: 2 collector arrays – 1 storage – 1 pump – 1 valve

Description:

Loading...

Loading...