Page 1

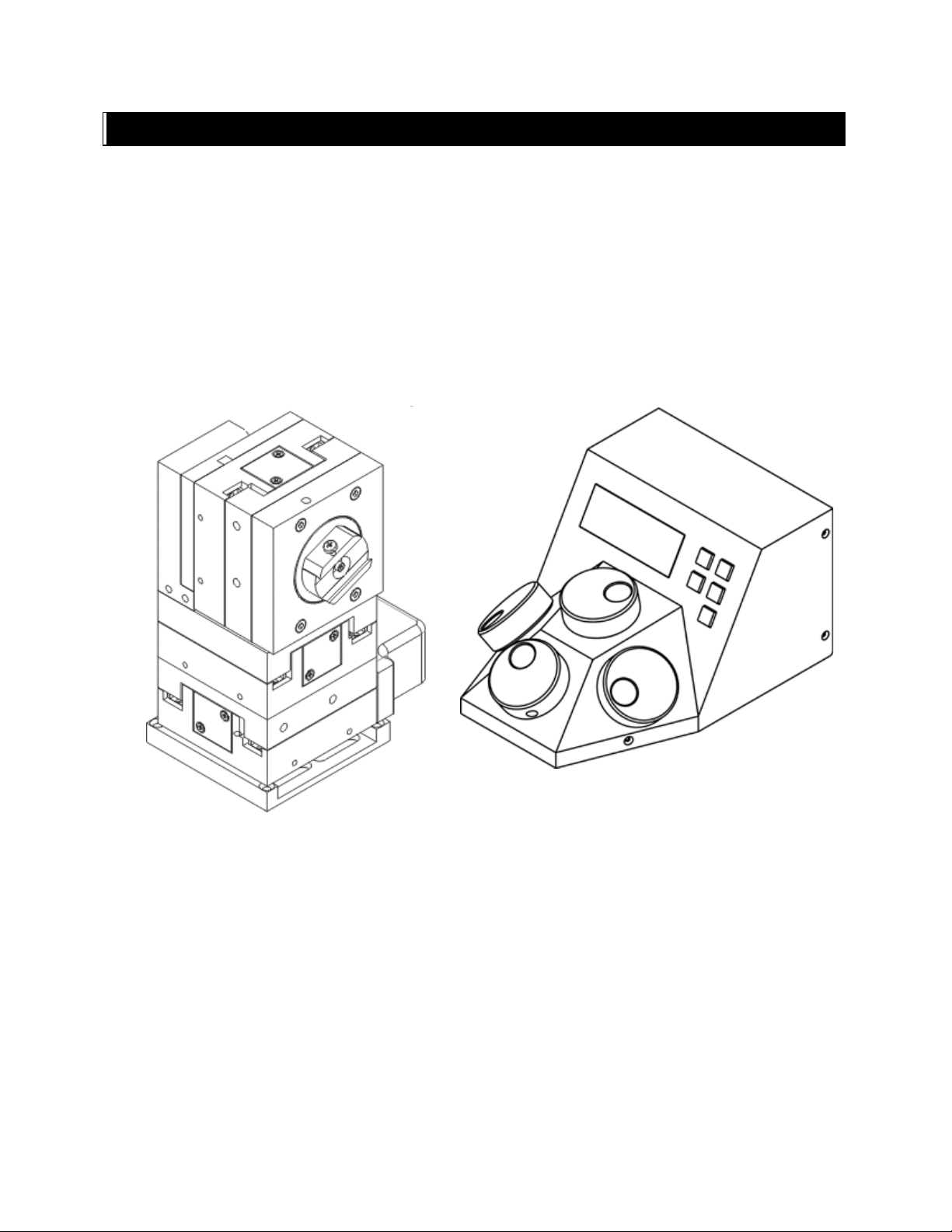

TRIO™ MP-245A

Three-Axis Motorized

Micromanipulator System

Operation Manual

With Synthetic Fourth “D” Axis and

USB Interface for External Control

Rev. 3.12b (20191001)

One Digital Drive

Voice: 415-883-0128 Web: www.sutter.com

Fax: 415-883-0572 Email: info@sutter.com

Novato, CA 94949

Page 2

2

(The picture on the cover page shows a TRIO MP-245A ROE/controller and a TRIO MP-245/M

micromanipulator. The Sutter Instrument IPA Headstage shown mounted on the micromanipulator is not

included in the TRIO MP-245A Series system.)

Copyright © 2019 Sutter Instrument Company. All Rights Reserved.

TRIO™ is a trademark of Sutter Instrument Company.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 3

Page 4

Page 5

3

DISCLAIMER

The TRIO MP-245A consists of one electromechanical micromanipulator device and one ROE

(Rotary Optical Encoder) with integrated controller. The purpose of the system is for the

manipulation at the micro level of micropipettes and probes used in conjunction with a

microscope. No other use is recommended.

This instrument is designed for use in a laboratory environment. It is not intended nor

should it be used in human experimentation or applied to humans in any way. This is not a

medical device.

Unless otherwise indicated in this manual or by Sutter Instrument Technical Support for

reconfiguration, do not open or attempt to repair the instrument.

Do not allow an unauthorized and/or untrained operative to use this device.

Any misuse will be the sole responsibility of the user/owner and Sutter Instrument Company

assumes no implied or inferred liability for direct or consequential damages from this

instrument if it is operated or used in any way other than for which it is designed.

SAFETY WARNINGS AND PRECAUTIONS

Electrical

Operate the TRIO MP-245A using 110 – 240 VAC., 50-60 Hz line voltage. This instrument

is designed for use in a laboratory environment that has low electrical noise and

mechanical vibration. Surge suppression is always recommended

NOTE: There are no user-replaceable fuses in the TRIO MP-245A system.

The TRIO MP-245A system’s power supply consists of an external AC to DC

switching power adapter. If the external power adapter is damaged due to a mains over or

under voltage, it must be replaced.

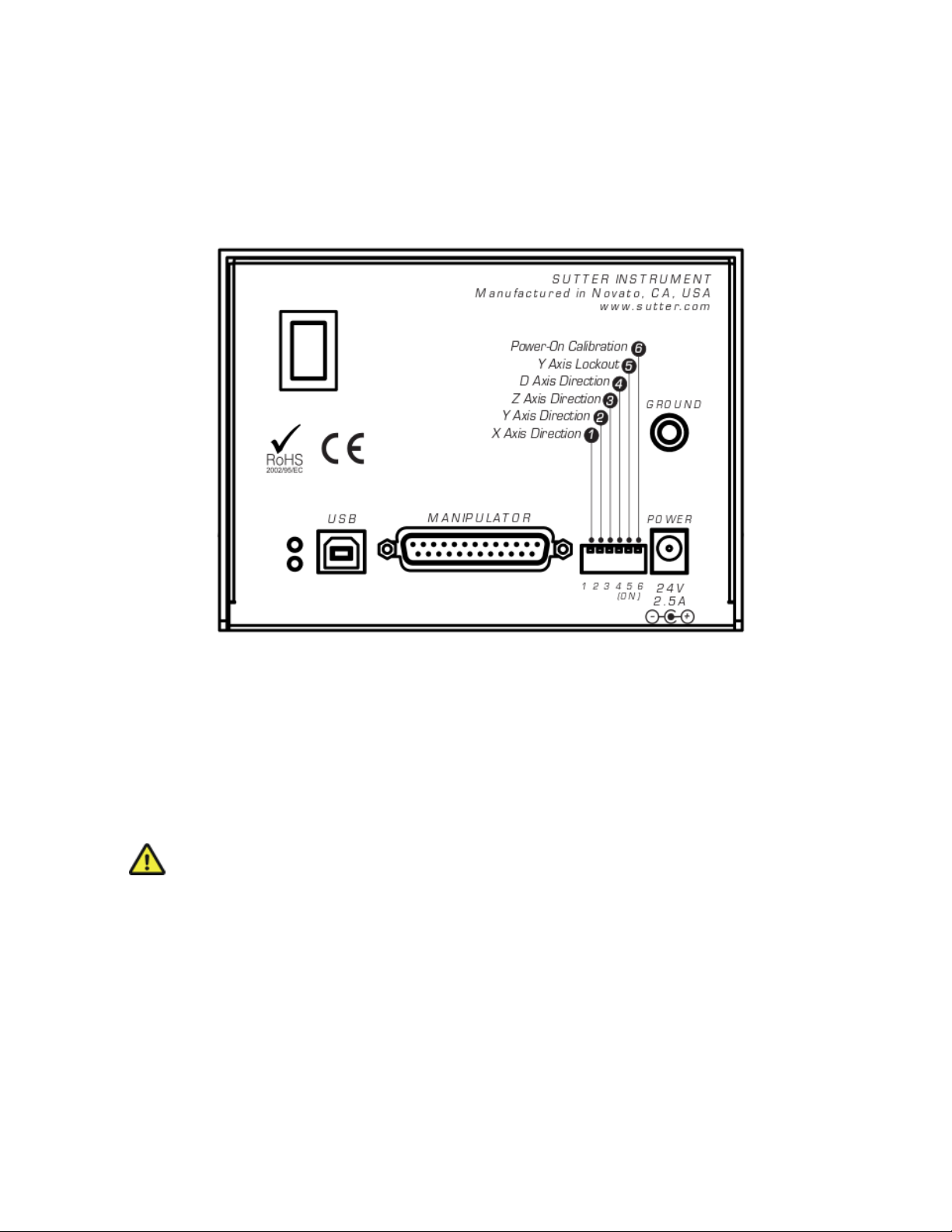

GROUNDING/EARTHING: Proper grounding protects the ROE/controller

electronics, reduces/eliminates electromagnetic interference, and improves the safety of the

system operator. The ROE/controller provides a socket (labeled GROUND) that accepts a

banana plug attached to a suitably gauged insulated wire, the other end of which (alligator

clip) connects to a solid, proper ground.

Avoiding Electrical Shock and Fire-related Injury

Always use the grounded power cord provided to connect the system’s power adapter to a

grounded/earthed mains outlet (3-prong). This is required to protect you from injury in the

event that an electrical hazard occurs.

Do not disassemble the system. Refer servicing to qualified personnel.

To prevent fire or shock hazard do not expose the unit to rain or moisture.

Electromagnetic Interference

To comply with FDA and CE/EU electromagnetic immunity and interference standards; and

to reduce the electromagnetic coupling between this and other equipment in your lab always

use the type and length of interconnect cables provided for interconnecting the electromechanical devices and ROE/controller (refer to Technical Specifications for more details).

Operational

Failure to comply with any of the following precautions may damage this device.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 6

4

This instrument is designed for operation in a laboratory environment (Pollution Degree I)

that is free from mechanical vibrations, electrical noise and transients.

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN THE

CONTROLLER AND THE MECHANICAL UNITS WHILE POWER IS ON.

Please allow at least 20 seconds after turning the unit off before disconnecting the

mechanical units. Failure to do so may result in damage to the electronics.

Operate this instrument only according to the instructions included in this manual.

Do not operate if there is any obvious damage to any part of the instrument.

Do not operate this instrument near flammable materials. The use of any hazardous

materials with this instrument is not recommended and, if undertaken, is done so at the

users’ own risk.

Do not operate if there is any obvious damage to any part of the instrument. Do not

attempt to operate the instrument with the TRIO MP-245/M electromechanical

manipulator shipping tape in place or severe motor damage may result. When transporting

the mechanical manipulator, be sure to reinstall the shipping tape (using masking tape or

equivalent only) to the original locations. Failure to do this may result in damage to the

motors.

Never touch any part of the micromanipulator electromechanical device while it is in

operation and moving. Doing so can result in physical injury (e.g., fingers can be caught

and pinched between the moving parts of the micromanipulator).

If the TRIO MP-245A system is used in a microinjection environment, please observe

the following. As with most micromanipulation devices, sharp micropipettes can fly out of

their holder unexpectedly. Always take precautions to prevent this from happening. Never

loosen the micropipette holder chuck when the tubing is pressurized, and never point

micropipette holders at yourself or others. Always wear safety glasses when using sharp

glass micropipettes with pressure tubing.

Take care to ensure no cables pass close to the TRIO MP-245/M electromechanical

micromanipulator within the spherical movement limits of all its axes combined.

Other

Retain the original packaging for future transport of the instrument.

Sutter Instrument reserves the right to change specifications without prior notice.

Use of this instrument is for research purposes only.

Handling Micropipettes

Failure to comply with any of the following precautions may result in injury to the users

of this device as well as those working in the general area near the device.

The micropipettes used with this instrument are very sharp and relatively fragile. Avoid

contact with micropipette tips to prevent accidentally impaling oneself.

Always dispose of micropipettes by placing them into a well-marked, spill-proof “sharps”

container.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 7

5

TABLE OF CONTENTS

DISCLAIMER ....................................................................................................................................... 3

SAFETY WARNINGS AND PRECAUTIONS .................................................................................... 3

Electrical .................................................................................................................................................. 3

Avoiding Electrical Shock and Fire-related Injury .............................................................................. 3

Electromagnetic Interference ............................................................................................................ 3

Operational .............................................................................................................................................. 3

Other......................................................................................................................................................... 4

Handling Micropipettes .......................................................................................................................... 4

1. INTRODUCTION ............................................................................................................................. 9

1.1 Structure of the TRIO MP-245A Documentation Package ......................................................... 9

1.2 Components of the TRIO MP-245A System .................................................................................. 9

1.3 Overview .......................................................................................................................................... 10

1.3.1 Features ..................................................................................................................................... 10

1.3.2 Description ................................................................................................................................ 10

2. INSTALLATION ............................................................................................................................ 13

2.1 Mounting Instructions ................................................................................................................... 13

2.1.1 Mounting the TRIO MP-245/M to the Stand or Platform .................................................. 13

2.2 Headstage Mounting ...................................................................................................................... 14

2.3 Other Accessories ............................................................................................................................ 14

2.4 Electrical Connections and Initial Operating Instructions ........................................................ 14

2.5 ROE/Controller Rear Panel Controls and Configuration........................................................... 15

2.5.1 Power Switch ............................................................................................................................ 15

2.5.2 Rear-Panel Configuration Switches ....................................................................................... 16

2.5.2.1 Rear-Panel Switches 1, 2, 3 and 4: Knob Rotation Directionality for Forward (+)

Movement ....................................................................................................................................... 16

2.5.2.2 Rear-Panel Switch 5: Y-Axis Lockout during Homing .................................................. 16

2.5.2.3 Rear-Panel Switch 6: Calibration Homing on Power On ............................................. 16

2.5.1 Internal Configuration Switches ............................................................................................ 17

2.5.1.1 Internal Switch 1 Reserved .............................................................................................. 17

2.5.1.2 Internal Switch 2: Electromechanical Device Compatibility. ....................................... 17

2.5.1.3 Internal Switch 3 Reserved .............................................................................................. 17

2.5.1.4 Internal Switch 4 Linear/Nonlinear Manual Operation ............................................... 17

3. OPERATIONS ................................................................................................................................ 19

3.1 Main Controls and Indicators on the ROE/Controller ............................................................... 19

3.2 Display .............................................................................................................................................. 19

3.2.1 Initial Startup ........................................................................................................................... 19

3.3 Control Operations ......................................................................................................................... 20

3.3.1 Maximum Positive Position Values: ...................................................................................... 20

3.3.2 Setting Position for HOME or WORK ................................................................................... 20

3.3.3 Setting the Angle of the Pipette/Headstage Holder ............................................................. 20

3.3.4 Operating the Virtual D Axis .................................................................................................. 20

3.3.5 Moving to the Home Position ................................................................................................. 21

3.3.6 Moving to the Work Position .................................................................................................. 21

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 8

6

3.3.7 Setting Absolute/Relative Coordinates Mode ........................................................................ 22

3.3.8 Mode Indications ...................................................................................................................... 22

3.3.9 Speed Control and ROE Knob Movements (SPEED) .......................................................... 23

3.3.10 Movement Knobs Disabling and Lock Mode ([SPEED]/LOCK) ...................................... 23

3.3.11 Pausing Home Movements (HOME (while moving to Home)) ........................................ 23

3.3.12 Pausing Work Movements (WORK (while moving to Work)) .......................................... 23

3.3.13 Pulse Mode and Virtual D-Axis Movement (PULSE) ........................................................ 23

3.4 Micropipette/Headstage Exchange ............................................................................................... 23

4. EXTERNAL CONTROL ................................................................................................................ 25

4.1 General ............................................................................................................................................. 25

4.2 Virtual COM Port (VCP) Serial Port Settings ............................................................................. 25

4.3 Protocol and Handshaking ............................................................................................................ 25

4.4 Command Sequence Formatting .................................................................................................. 26

4.5 Axis Position Command Parameters ............................................................................................ 26

4.6 Microsteps and Microns (Micrometers) ........................................................................................ 27

4.7 Commands ....................................................................................................................................... 27

4.7.1 Get Current Position and Angle (‘c’ or ‘C’) Command ........................................................ 27

4.7.2 Move to Controller-Defined HOME Position (‘h’) Command ............................................. 28

4.7.3 Move to Controller-Defined WORK Position (‘w’) Command ............................................ 28

4.7.4 Move to Specified “Home” Position (‘H’) Command ........................................................... 28

4.7.5 Move to Specified “Work” Position (‘W’) Command............................................................ 29

4.7.6 Move in Straight Line to Specified Position at Specified Speed (‘S’) Command .............. 29

4.7.7 Interrupt Straight-Line Move (‘^C’) Command ................................................................. 30

4.7.8 Move to Specified X-Axis Position (‘x’ or ‘X’) Command ..................................................... 30

4.7.9 Move to Specified Y-Axis Position (‘y’ or ‘Y’) Command ..................................................... 31

4.7.10 Move to Specified Z-Axis Position (‘z’ or ‘Z’) Command ................................................... 31

4.7.11 Setting the Angle (‘A’) Command ........................................................................................ 31

4.7.12 Recalibrate (‘R’) Command ................................................................................................... 32

4.7.13 Notes ........................................................................................................................................ 32

5. MAINTENANCE ............................................................................................................................ 35

6. RECONFIGURATION ................................................................................................................... 35

6.1 Changing the Rotary Knob Functions on the ROE/Controller ................................................. 35

APPENDIX A. LIMITED WARRANTY ............................................................................................ 37

APPENDIX B. ACCESSORIES ......................................................................................................... 38

APPENDIX C. TECHNICAL SPECIFICATIONS ........................................................................... 39

APPENDIX D. QUICK REFERENCE .............................................................................................. 41

D.1. Manual Operation ......................................................................................................................... 41

D.2. Configuration................................................................................................................................. 41

Rear-Panel DIP Switches ............................................................................................................... 41

Internal DIP Switches .................................................................................................................... 41

D.3. External Control ........................................................................................................................... 42

INDEX ................................................................................................................................................. 47

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 9

7

TABLE OF FIGURES

Figure 1-1. The TRIO MP-245A system .................................................................................................. 9

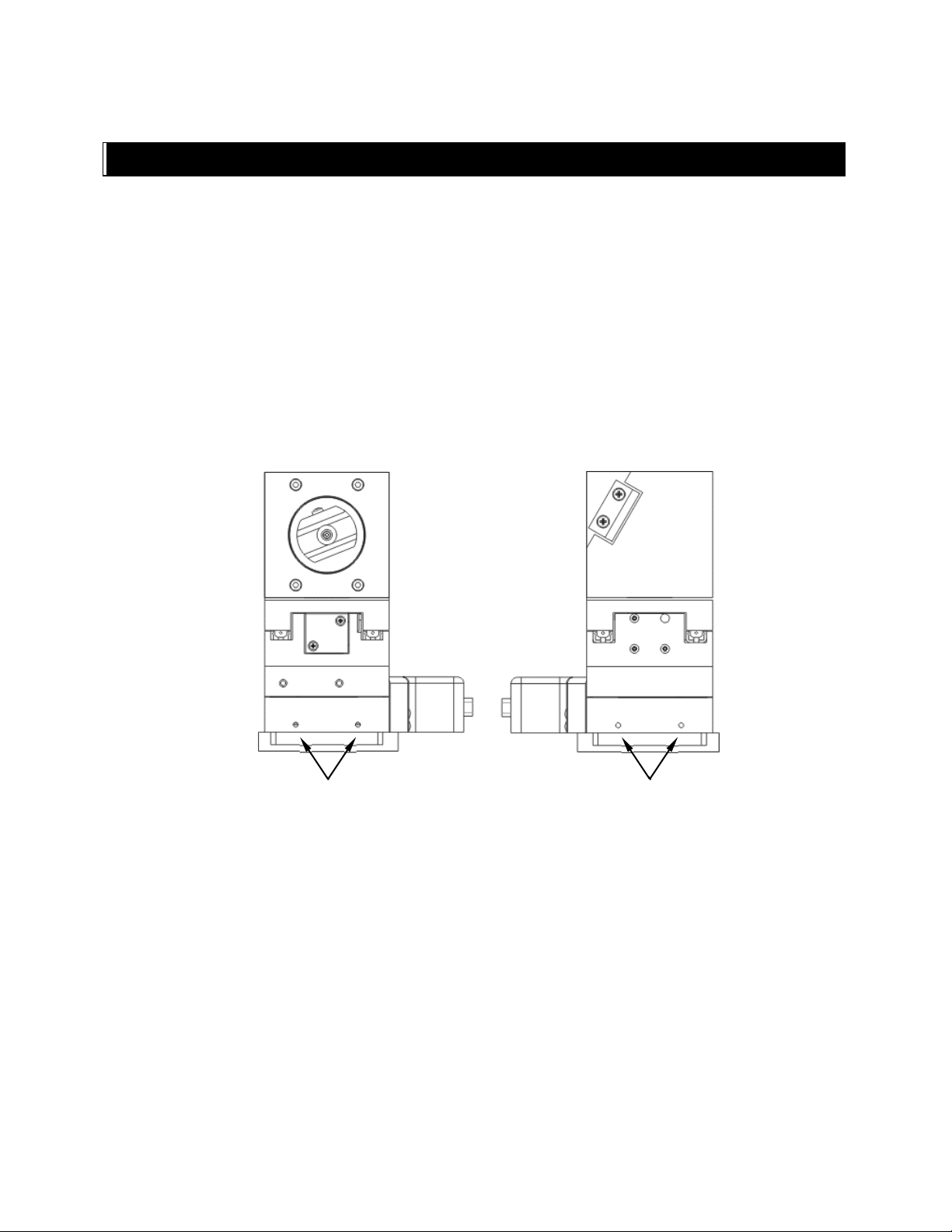

Figure 2-1. Side view of TRIO MP-245/M showing mounting adapter plate and lock screws. ........ 13

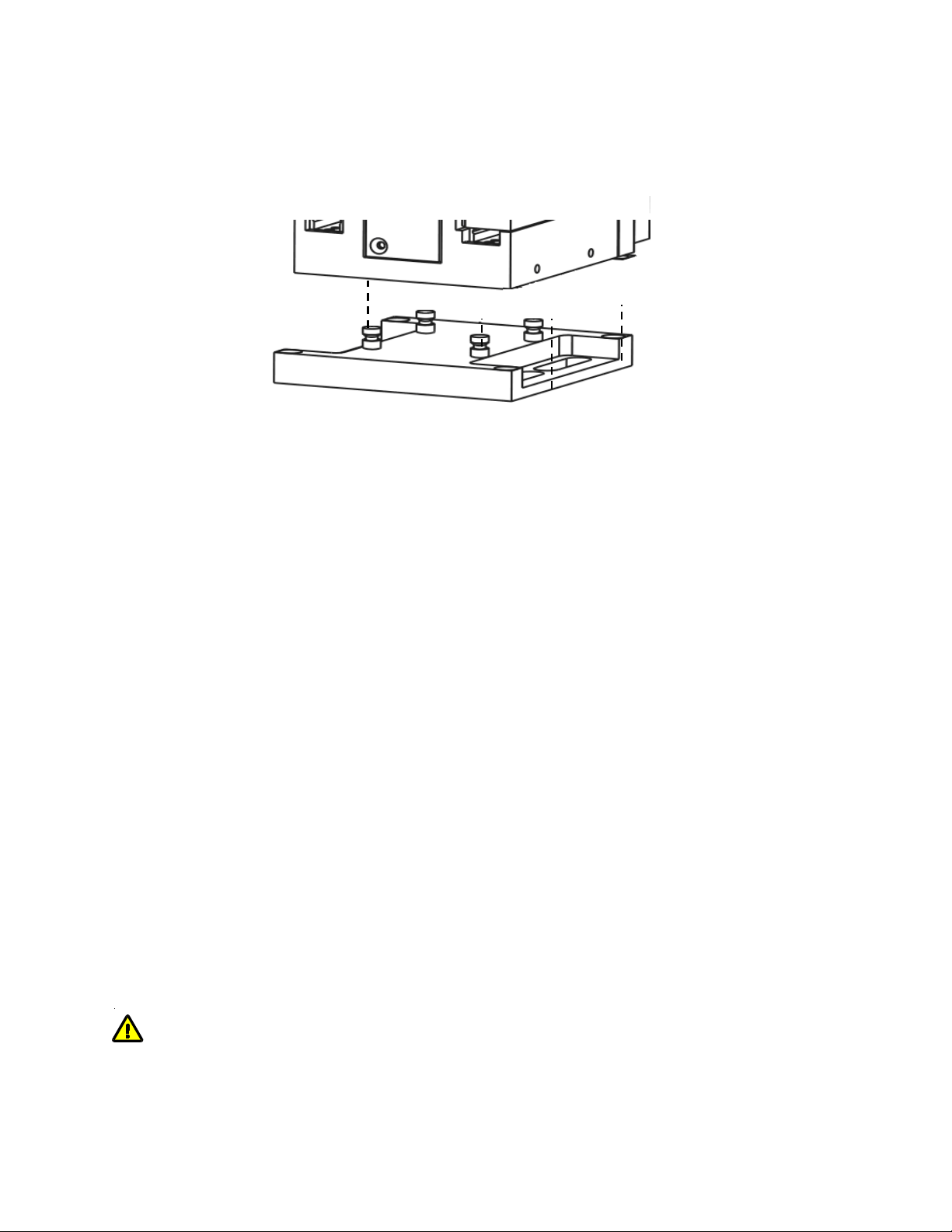

Figure 2-2. Mounting the TRIO MP-245/M on the Adapter Plate ...................................................... 14

Figure 2-3. Rear of TRIO MP-245A ROE/Controller cabinet .............................................................. 15

Figure 2-4. Configuration switches on rear-panel (switch positions shown are factory defaults). .. 16

Figure 2-5. Internal configuration switches (switch positions shown are factory defaults). ........... 17

Figure 3-1. LCD Display showing startup screen. ................................................................................ 19

Figure 3-2. Startup screen ....................................................................................................................... 19

Figure 3-3. Factory default startup (Home) position ............................................................................ 20

Figure 3-4. Maximum positive values..................................................................................................... 20

Figure 3-5. Moving to Home position (screen is amber while moving) .............................................. 21

Figure 3-6. Factory default Home position ............................................................................................ 21

Figure 3-7. Example Home position defined and saved ....................................................................... 21

Figure 3-8. Example Work position ........................................................................................................ 21

Figure 3-9. Relative mode ........................................................................................................................ 22

Figure 3-10. Relative mode ...................................................................................................................... 22

Figure 3-11. Absolute mode ..................................................................................................................... 22

Figure 3-12. Angled side view of TRIO MP-245/M to change headstage mount ............................... 24

Figure 6-1. Locations of the axis connectors inside the ROE/Controller ........................................... 35

TABLE OF TABLES

Table 2-1. Rear-Panel Configuration Switches 1 - 4: Configuring the direction of each axis. ......... 16

Table 2-2. Rear-Panel Configuration Switch 5: Y-Axis Homing Movement Lock Out.................... 16

Table 2-3. Rear-Panel Configuration Switch 6: Configuring power-on positional memory or

calibration. ............................................................................................................................... 16

Table 2-4. Internal Configuration Switch 2: Electromechanical device compatibility. .................... 17

Table 3-1. Maximum positive position value of each axis .................................................................... 20

Table 3-2. Screen colors and modes ........................................................................................................ 23

Table 4-1. USB-VCP interface serial port settings. .............................................................................. 25

Table 4-2. Microns/microsteps conversion. ............................................................................................ 27

Table 4-3. Ranges and bounds ................................................................................................................. 27

Table 4-4. Get Current Position and Angle (‘c’ or ‘C’) command. ...................................................... 28

Table 4-5. Move to controller-defined HOME position (‘h’) command. ............................................. 28

Table 4-6. Move to controller -defined WORK position (‘w’) command. ............................................ 28

Table 4-7. Move to specified “Home” position (‘H’) command. .......................................................... 29

Table 4-8. Move to specified “Work” position (‘W’) command. ........................................................... 29

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 10

8

Table 4-9. Straight-line move to specified position (‘S’) command. .................................................... 29

Table 4-10. Straight-Line Move ‘S’ Command Speeds. ........................................................................ 30

Table 4-11. Interrupt a straight-line move in progress (‘^C’) command. ......................................... 30

Table 4-12. Move to specified X-axis position (‘x’ or ‘X’) command. ................................................... 31

Table 4-13. Move to specified Y-axis position (‘y’ or ‘Y’) command. ................................................... 31

Table 4-14. Move to specified Z-axis position (‘z’ or ‘Z’) command. .................................................... 31

Table 4-15. Set the angle (‘A’) command. .............................................................................................. 32

Table 4-16. Recalibrate (‘R’) command. ................................................................................................. 32

Table 4-16. Straight-Line Move ‘S’ Command Speeds. ........................................................................ 34

Table C-1. TRIO MP-245A cables and receptacles/connectors. ........................................................... 39

Table D-1. Configuration Switches (External) 1 – 6. ............................................................................ 41

Table D-2. Configuration Switches (Internal) 1 - 4 .............................................................................. 41

Table D-3. USB-VCP interface serial port settings............................................................................... 42

Table D-4. Microns/microsteps conversion. ........................................................................................... 43

Table D-5. Ranges and bounds. ............................................................................................................... 43

Table D-6. TRIO MP-245A external control commands. ..................................................................... 43

Table D-7. Straight-Line Move ‘S’ Command Speeds. ......................................................................... 46

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 11

9

TRIO MP-245/M

TRIO MP-245/E

1. INTRODUCTION

1.1 Structure of the TRIO MP-245A Documentation Package

The TRIO MP-245A 3-Axis Micromanipulator System is comprised of a ROE/controller, a

power adapter, and a TRIO MP-245/M stepper-motor-based electromechanical

micromanipulator. This manual consists of four parts: This chapter, Introduction, which

provides an overview and general description of the TRIO MP-245A system; Chapter 2,

Installation, which describes how to install, set up, and configure all components of the

system; Chapter 3, Operations, which describes how to operate the TRIO MP-245A; Chapter

4, Maintenance, describes how to perform routine and other maintenance; and Chapter 5,

Reconfiguration, describes the reconfiguration possibilities of the TRIO MP-245A system.

ELECTROMECHANICAL

MICROMANIPULATOR

ROE/CONTROLLER

Figure 1-1. The TRIO MP-245A system

1.2 Components of the TRIO MP-245A System

Carefully remove all components from the shipping container. In addition to this manual, the

following should be included:

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 12

10

TRIO MP-245A ROE Rotary Optical Encoder input device with built-in controller and

external power adapter.

TRIO MP-245/M electromechanical micromanipulator

26-pin HD DSUB cable (connects the ROE/controller to the TRIO MP-245/M

electromechanical micromanipulator).

Power adapter

Power adapter AC mains cable appropriate for your location

Ground/Earth cable

USB Cable

IMPORTANT

Once the TRIO MP-245A system has been unpacked, remove the shipping tape from the

various locations on the TRIO MP-245/M electromechanical micromanipulator. The shipping

tape must be removed before operating the TRIO MP-245A system. If you need to transport

the TRIO MP-245/M in the future, reapply 2 to 3-inch pieces of masking tape to the same

locations. Once the tape has been removed, handle the TRIO MP-245/M with care. The

mechanisms can be damaged if any of the axes are inadvertently moved without the tape in

place.

1.3 Overview

1.3.1 Features

Three independent axes (X, Y, and Z) each with 25mm travel with a virtual fourth axis

(D) for coaxial pipette movement utilizing a tangent function factoring the holder’s angle

and the X and Z axes.

Sub-micron 100nm resolution

Digital display indicates coordinates in relative or absolute

User-friendly, fanless compact controller with ROE preserves bench space

Push button control of multiple functions – work, home, Lock, pulse and relative

Robotic home- and work-position moves for easy automated pipette exchange

1.3.2 Description

The TRIO MP-245A, the newest Sutter Instrument motorized manipulator, is easy to use and

has three independent axes. The X, Y, and Z axes provide 25mm range of motion. D-axis

movement is accomplished virtually using a tangent function of the chosen angle of the

holder and simultaneously moving X and Z. The ROE controller has a digital display and

keys for Home, Work, Pulse, Lock, and Relative. The compact, intuitive controller takes up

minimal bench space, is fan-free, and easy to use.

While the axes provide X and Y orthogonal motion typical of most motorized manipulators,

Sutter has introduced a diagonal axis with the

coaxially at the exact desired angle of approach.

TRIO MP-245A so one can move the electrode

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 13

11

The TRIO MP-245A’s ROE provides fine control of electrode position and the rate of rotation

of ROE dials for each axis determines the speed of travel. The finest step size is less than

100nm. Five conveniently located buttons on the ROE provide control of all the basic

functions you will need in normal operation (Work, Home, Lock, Relative, and Pulse).

Press and hold WORK (for 3 seconds) to quickly store a work position, tap HOME to move all

axes to an initial location that is useful for changing electrodes, or press and hold the HOME

button (for 3 seconds) to memorize a new HOME position.

When ready to record data, the motor drive electronics can be suppressed by pressing the

LOCK button. In the LOCK mode, the display turns red and ROE input is locked out to avoid

any accidental motion.

Pressing and holding the RELATIVE button for three seconds at any location causes the

display coordinates to all zeroes. When activating relative mode, the display turns blue.

To return to viewing the absolute coordinates, tap the RELATIVE button to toggle back.

Finall y, tapping the PULSE button causes a 3μm advance in the diagonal. This rapid burst of

forward motion can assist in sharp electrode cell penetration.

All the electronics, except for a small power supply, are housed within the TRIO MP-245A

ROE and no separate controller or computer is required.

External computer control of the TRIO MP-245A is possible via the USB connector mounted

on the controller/ROE’s rear panel. The controller’s internal software is programmed with a

defined set of commands allowing for a wide range of micromanipulator/stage movements as

programmed in software residing in an external computer connected via USB.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 14

12

(This page intentionally left blank.)

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 15

13

Locking Screws

Locking Screws

2. INSTALLATION

When installing the TRIO MP-245A system for the first time, it is recommended that the

components of the system be installed in the following order: TRIO MP-245/M

electromechanical micromanipulator first, followed by the TRIO MP-245A/E ROE/Controller.

2.1 Mounting Instructions

The following sections describe how to mount the TRIO MP-245/M manipulator to a stand

using the mounting adapter plate, how to adjust the pipette angle and how to mount

different headstages.

2.1.1 Mounting the TRIO MP-245/M to the Stand or Platform

The TRIO MP-245/M attaches to the mounting adapter plate using four M3.5x6 hex head

locking screws.

Figure 2-1. Side view of TRIO MP-245/M showing mounting adapter plate and lock screws.

The TRIO MP-245/M is shipped with the adapter plate in place. It is attached using four

tapered pegs, along with four locking screws.

To remove it, first loosen the four hex screws that secure the manipulator to the pegs in the

adapter plate. The rear pair is in a similar location in the back of the manipulator. Once the

locking screws are sufficiently loosened, lift the TRIO MP-245/M upwards from the adapter

plate.

Before attaching the adapter plate to the TRIO MP-245/M, you need to decide where to

position the manipulator on your stand/platform. The stand can be any flat surface carrying

¼-20, 10-32, or M6 holes on one-inch centers (such as a Sutter Instrument MT-series stand

or MD series platform).

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 16

14

Examine the space of the platform onto which installation is to take place. Attach the control

cable to TRIO MP-245/M and move the entire unit around on the platform until the precise

desired position is determined. A small bag containing the necessary hardware to attach the

TRIO MP-245/M to the stand is included.

Figure 2-2. Mounting the TRIO MP-245/M on the Adapter Plate

Once the plate is mounted, align the pegs on top of the plate with the holes in the

manipulator, push the X-axis firmly onto the plate, and re-tighten the locking hex set

screws.

2.2 Headstage Mounting

Sutter IPA headstage, Axon headstages 203B or CV-7, and the Heka EPC-10 headstage have

an integral dovetail that fits directly into the rotary dovetail slide bracket on the TRIO MP245/M. The dovetail slide bracket on the TRIO MP-245/M also supports older Axon and Heka

headstages when using the 4’’ dovetail extension.

Rod-mounted headstages and micro tools are accommodated using a rod clamp that fits into

the dovetail (not shown). All the headstage adapters and mounting hardware are included

with the manipulator and are shipped in a zip lock plastic bag.

2.3 Other Accessories

One or more accessories may have been ordered and received for mounting the TRIO MP245/M and/or modifying the headstage mount to the manipulator (i.e., rotating base,

microscope stage mount, gantry, dovetail extension, etc.). Setup of these accessories is

normally covered in documentation accompanying the accessory.

2.4 Electrical Connections and Initial Operating Instructions

Initially, you may want to simply connect the TRIO MP-245/M micromanipulator and the

ROE/Controller together and try some gross movements in order to get a feel for the controls

and how to make simple movements. It is perfectly acceptable to set the manipulators in the

middle of a bench top, make all electrical connections and then observe each unit’s

movement by eye.

CAUTION: Unless the TRIO MP-245/M micromanipulator electromechanical baseplate

is firmly bolted down to a breadboard or solidly to a firm surface, the TRIO MP-245/M is

likely to tip over when fully extending all of its axes, especially if it is loaded with a headstage

that extends beyond the TRIO MP-245/M’s current center of gravity.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 17

15

Upon deciding to directly install the TRIO MP-245A system in your rig, it is useful to follow

the initial setup procedure to learn how to move the units to allow easy access to the

mounting screws.

1. With the power switch on the back of the ROE in the OFF (0) position, connect the power

adapter’s 24VDC cable to the POWER receptacle.

Figure 2-3. Rear of TRIO MP-245A ROE/Controller cabinet

2. With the power OFF (rear panel switch in the “0” position), connect a well-

grounded/earthed wire to the GROUND banana plug receptacle.

3. With the power OFF, connect the male end of the DB-25 cable to the MANIPULATOR

connector on the ROE, the other end of which is connected to the TRIO MP-245/M

micromanipulator electromechanical.

(See cautionary note below.)

4. Verify that the six switches on the rear of the ROE are set as desired.

5. Power up the system by moving the power switch on the rear of the ROE to the “1”

position.

* CAUTION: NEVER CONNECT OR DISCONNECT THE ROE/CONTROLLER

FROM THE TRIO MP-245/M WHILE THE POWER IS ON!

2.5 ROE/Controller Rear Panel Controls and Configuration

2.5.1 Power Switch

The power switch for the TRIO MP-245A system is located on the rear panel of the

ROE/controller. At power up, the microprocessor in the ROE/controller scans the attached

equipment and configures the system accordingly.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 18

16

Rear-Panel

Switch #

Y-Axis Homing Movement Lock Out

Enabled

Disabled

5

ON (Down)*

Rear-Panel

Switch #

Definition

State

Setting

Position

6

Calibration

Homing on Power

On

Enabled: Calibrates to 1,000 µm for all axes on

power on. Power-off position is forgotten.

ON*

DOWN*

Rear-Panel

Switch #

Axis

Knob Rotation Directionality for Forward (+) Movement

Clockwise

Counterclockwise

1

X

OFF (Up)*

2

Y

OFF (Up)*

3

Z

OFF (Up)*

4

D

OFF (Up)*

1 2 3 4 5 6

2.5.2 Rear-Panel Configuration Switches

Figure 2-4. Configuration switches on rear-panel (switch positions shown are factory defaults).

2.5.2.1 Rear-Panel Switches 1, 2, 3 and 4: Knob Rotation Directionality for Forward (+) Movement

These switches set the directionality for each of the four axes.

Table 2-1. Rear-Panel Configuration Switches 1 - 4: Configuring the direction of each axis.

ON (Down)**

ON (Down)**

ON (Down)

ON (Down)

* Factory default (typical setting for right-hand-mounted manipulator).

** Possible setting for a right-handed manipulator used on the left.

2.5.2.2 Rear-Panel Switch 5: Y-Axis Lockout during Homing

Configures whether the Y axis is locked out while homing.

Table 2-2. Rear-Panel Configuration Switch 5: Y-Axis Homing Movement Lock Out.

OFF (Up)

* Factory default (recommended normal operation setting).

2.5.2.3 Rear-Panel Switch 6: Calibration Homing on Power On

Table 2-3. Rear-Panel Configuration Switch 6: Configuring power-on positional memory or calibration.

* Factory default (recommended normal operation setting)

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Disabled: No calibration occurs on power on.

Power-off position is retained on power on

OFF UP

Page 19

17

Internal

Switch #

Definition

State

Setting

Position

2

Eletromechanical

device

compatibility

OFF*

UP*

78

1 2 3 4

2.5.1 Internal Configuration Switches

Figure 2-5. Internal configuration switches (switch positions shown are factory defaults).

2.5.1.1 Internal Switch 1 Reserved

Internal Switch 1 is unused and reserved for future use.

2.5.1.2 Internal Switch 2: Electromechanical Device Compatibility.

Table 2-4. Internal Configuration Switch 2: Electromechanical device compatibility.

MP-845/M, MP-845S/M, & MP-245/M series

MP-285/M series micromanipulator; 3DMS or MT-

stage; MOM & SOM objective mover)

ON DOWN

* Factory default (recommended normal operation setting)

2.5.1.3 Internal Switch 3 Reserved

Internal Switch 3 is unused and reserved for future use.

2.5.1.4 Internal Switch 4 Linear/Nonlinear Manual Operation

Internal Switch 4 switches between linear and nonlinear manual operation. Contact Sutter

Instrument technical support for more information.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 20

18

(This page intentionally left blank.)

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 21

19

DISPLAY

Z-AXIS

CONTROL

Y-AXIS

CONTROL

D-AXIS

CONTROL

(SYN

X-AXIS

CONTROL

RELATIVE

MODE

PULSE &

ANGLE

MODES

WORK

POSITION

HOME

POSITION

SPEED &

LOCK

MODES

TRIO / MP-245A

SUTTER

INSTRUMENT CORP.

(Text in

Green)

TRIO / MP-245A

REV 2.4

(Text in

Green)

3. OPERATIONS

3.1 Main Controls and Indicators on the ROE/Controller

-SET

THETIC)

Figure 3-1. Front view of the TRIO MP-245A ROE/Controller

3.2 Display

3.2.1 Initial Startup

Figure 3-1. LCD Display showing startup screen.

When starting the TRIO MP-245A system for the first time or if the HOME position has not

yet been defined (saved), the values of all four axes will be 1,000 micrometers (microns).

Figure 3-2. Startup screen

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 22

20

Axis

Maximum Position

Value (in microns)

X

25,000

Y

25,000

Z

25,000

(Text in

Green)

(Text in

Green)

X= 1000 Y= 1000

Z= 1000 >=

X=25000 Y=25000

Z=25000 >=

Figure 3-3. Factory default startup (Home) position

3.3 Control Operations

3.3.1 Maximum Positive Position Values:

Move the dial of an axis clockwise until its position value stops incrementing. The following

table lists the maximum position value (in microns) for each axis.

Table 3-1. Maximum positive position value of each axis

Figure 3-4. Maximum positive values

3.3.2 Setting Position for HOME or WORK

To set position, hold down HOME or WORK button for 3 seconds until beep sounds.

3.3.3 Setting the Angle of the Pipette/Headstage Holder

To change the angle of the holder, first loosen the set screw at the top of the rotary dovetail

bracket, rotate the holder to the desired angle, and then retighten the set sc r e w.

Measure the angle of the holder. (Tip: Many smart phones have an app with a level that can

assist the u s e r. )

3.3.4 Operating the Virtual D Axis

The TRIO MP-245A consists of three physical axes, X, Y and Z. A tangent function utilizing X

and Z axes and the angle of the holder has been implemented to create a virtual D axis. Use

between 10° and 90° for best results.

Zero (0°) is set with the diagonal being parallel to the table and 90° is set with the diagonal

being perpendicular to the table.

To set the angle measured above, on the ROE hold LOCK down for several seconds. The

screen will be red until the display indicates in green: “Select the angle in use (0-90)”.

Use the D dial on the ROE to set the value of the angle. Once this value is dialed in, do not

touch the ROE knob for 8-10 sec. The virtual D angle will now be set.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 23

21

X= 0 Y= 1524

Z= 0 >= 0

(Text in

Red)

(Text in

Green)

(Text in

Green)

X= 1000 Y= 1000

Z= 1000 >=

(Text in

Green)

X=1868 Y=1524

Z=1686 >=25

X=2868 Y=2524

Z=1686 >=25

3.3.5 Moving to the Home Position

Figure 3-5. Moving to Home position (screen is amber while moving)

If the Home position has not yet been defined and saved, the Home position values for all

axes will default to 1,000 microns, as shown in the following figure.

Figure 3-6. Factory default Home position

If the Home position has been previously defined (saved), pressing HOME will make a move

to the defined home position (see example in the following figure).

Figure 3-7. Example Home position defined and saved

To move to the Home position, press HOME. If the current position before pressing HOME is

greater than the Home position, the movement will be as follows:

NOTE: Movement to the Home position works only if X coordinates of the HOME position

are less than the WORK position. HOME and WORK positions cannot be the same.

1. Movement begins by retracting the Z axis (at the angle currently set) away from the

sample.

2. Movement then continues along the X axis toward the Home position.

3. The final movement is along the Y-axis towards the operator and away from the

microscope.

NOTE: Step 3 occurs only if “Y-Lockout” is disabled. Otherwise, no movement along the Yaxis occurs.

3.3.6 Moving to the Work Position

Figure 3-8. Example Work position

To move to the Work position, press the WORK button. If the current position before

pressing WORK is less than the Work position, the movement will be as follows:

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 24

22

X=- 893 Y= 1524

Z= 1686 >= 30

(Text in

Green)

X=- 893 Y= 1524

Z= 1686 >= 30

(Text in

Blue)

X=- 0 Y= 0

Z= 0 >= 0

(Text in

Blue)

1. Movement travels along the Y-axis away from the operator and towards the microscope.

2. Movement is then made along the X axis toward the sample. Travel then continues along

the diagonal until reaching its end-of-travel point.

NOTE: Step 1 occurs only if “Y-Lockout” is disabled. Otherwise, movement begins with

Step 2.

3.3.7 Setting Absolute/Relative Coordinates Mode

The RELATIVE button toggles between Relative and Absolute coordinate systems. The

default coordinate system on power up is Absolute, with the coordinates on the screen shown

in green. To switch to relative coordinates, press the RELATIVE button once. To reset the

current position to all zeroes, depress the RELATIVE for 3 seconds or until a beep is heard,

and then release the button. This resets the current position to all zeroes.

Press RELATIVE once (briefly for < 2 sec.)

Figure 3-9. Relative mode

Depress RELATIVE for 3 sec. or until beep sounds

Figure 3-10. Relative mode

Pressing RELATIVE briefly while in Relative mode, returns displayed coordinates back to

Absolute mode

Figure 3-11. Absolute mode

3.3.8 Mode Indications

The TRIO MP-245A system has three modes of operation: Absolute coordinates, Relative

coordinates, and Lock mode. The display turns color for each specific mode, as shown in the

following table.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 25

23

Screen Color

Mode

Example

Green

Absolute Coordinates

Blue

Relative Coordinates

Red

Knobs disabled during move to

X=- 0 Y= 0

Z= 0 >= 0

X= 1868 Y= 1524

Z= 1686 >= 2706

X= 0 Y= 1524

Z= 0 >= 0

Table 3-2. Screen colors and modes

Home or Work position, while in

Lock mode.

3.3.9 Speed Control and ROE Knob Movements (SPEED) The rate at which the ROE axis knobs move the electromechanical can be adjusted with the

SPEED button. Each press of the button cycles through four speeds: 0 (normal) through 3

(fastest).

3.3.10 Movement Knobs Disabling and Lock Mode ([SPEED]/LOCK) Axis-movement knobs are disabled during movements to Home, Work, or while in Lock Mode

(display is in red).

3.3.11 Pausing Home Movements (HOME (while moving to Home)) After Move to Home has been initiated, and while the move is in progress, pressing HOME a

second time pauses the manipulator. Pressing HOME again resumes movement.

3.3.12 Pausing Work Movements (WORK (while moving to Work)) After Move to Work has been initiated, and while the move is in progress, pressing WORK a

second time pauses the manipulator. Pressing WORK again resumes movement.

3.3.13 Pulse Mode and Virtual D-Axis Movement (PULSE)

Pulse mode advances the D axis in 2.85 µm steps. Each press of the PULSE button

increments the Diagonal axis by one 2.85-µm step beyond the current position. This feature

can be used to penetrate tough or resistant tissue.

3.4 Micropipette/Headstage Exchange

Mounted on the front of the Z-axis of the manipulator is the angle-control plate for the

headstage mount.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 26

24

Rotary dovetail holder

Rotary dovetail

Rotary dovetail angle

lock set screw

clamp screw

for rod/micropipette

holder or headstage

Figure 3-12. Angled side view of TRIO MP-245/M to change headstage mount

To change the headstage, loosen the screw in the center of the holding bracket. Slide the

headstage upward out of the dovetail groove. Make any adjustments needed of the headstage,

and then tighten down (but do not over tighten) the lock screw in the center of the holding

bracket.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 27

25

Property

Setting

4. EXTERNAL CONTROL

4.1 General

Controlling the TRIO MP-245A externally via computer is accomplished by sending

commands over the USB interface between the computer and the USB connector on the rear

panel of the TRIO MP-245A controller/ROE. The USB device driver for Windows is

downloadable from Sutter Instrument’s web site (www.sutter.com

requires Sutter Instrument’s USB CDM (Combined Driver Model) Version 2.10.00 or higher.

The CDM device driver consists of two device drivers: 1) USB device driver, and 2) VCP

(Virtual COM Port) device driver. Install the USB device driver first, followed by the VCP

device driver. The VCP device driver provides a serial RS-232 I/O interface between a

Windows application and the TRIO MP-245A. Although the VCP device driver is optional, its

installation is recommended even if it is not going to be used. Once installed, the VCP can be

enabled or disabled.

The CDM device driver package provides two I/O methodologies over which communications

with the controller over USB can be conducted: 1) USB Direct (D2XX mode), or 2) Serial RS232 asynchronous via the VCP device driver (VCP mode). The first method requires that the

VCP device driver not be installed, or if installed, that it be disabled. The second method

requires that the VCP be installed and enabled.

). The TRIO MP-245A

4.2 Virtual COM Port (VCP) Serial Port Settings

The following table lists the required RS-232 serial settings for the COM port (COM3,

COM5, etc.) generated by the installation or enabling of the VCP device driver.

Table 4-1. USB-VCP interface serial port settings.

Data (“Baud”) Rate (bits per second (bps)) 57600

Data Bits 8

Stop Bits 1

Parity None

Flow Control None

The settings shown in the above table can be set in the device driver’s properties (via the

Device Manager if in Windows) and/or programmatically in your application.

4.3 Protocol and Handshaking

Command sequences do not have terminators. All commands return an ASCII CR (Carriage

Return; 13 decimal, 0D hexadecimal) to indicate that the task associated with the command

has completed. When the controller completes the task associated with a command, it sends

ASCII CR back to the host computer indicating that it is ready to receive a new command. If

a command returns data, the last byte returned is the task-completed indicator.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 28

26

4.4 Command Sequence Formatting

Each command sequence consists of at least one byte, the first of which is the “command

byte”. Those commands that have parameters or arguments require a sequence of bytes that

follow the command byte. No delimiters are used between command sequence arguments,

and command sequence terminators are not used. Although most command bytes can be

expressed as ASCII displayable/printable characters, the rest of a command sequence must

generally be expressed as a sequence of unsigned byte values (0-255 decimal; 00 – FF

hexadecimal, or 00000000 – 11111111 binary). Each byte in a command sequence

transmitted to the controller must contain an unsigned binary value. Attempting to code

command sequences as “strings” is not advisable. Any command data returned by the

controller should be initially treated as a sequence of unsigned byte values upon reception.

Groups of contiguous bytes can later be combined to form larger values, as appropriate (e.g.,

2 bytes into 16-bit “word”, or 4 bytes into a 32-bit “long” or “double word”). For the TRIO

MP-245A, all axis position values (number of microsteps) are stored as “unsigned long” 32-bit

positive-only values, and each transmitted and received to and from the controller as four

contiguous bytes.

4.5 Axis Position Command Parameters

All axis positional information is exchanged between the controller and the host computer in

terms of microsteps. Conversion between microsteps and microns (micrometers) is the

responsibility of the software running on the host computer (see Microns/microsteps

conversion table for conversion factors).

Microsteps are stored as positive 32-bit values (“long” (or optionally, “signed long”), or

“unsigned long” for C/C++; “I32” or “U32” for LabVIEW). “Unsigned” means the value is

always positive; negative values are not allowed. The positive-only values can also be stored

in signed type variables, in which case care must be taken to ensure that only positive values

are exchanged with the controller.

The 32-bit value consists of four contiguous bytes, with a byte/bit-ordering format of Little

Endian (“Intel”) (most significant byte (MSB) in the first byte and least significant (LSB) in

the last byte). If the platform on which your application is running is Little Endian, then no

byte order reversal of axis position values is necessary. Examples of platforms using Little

Endian formatting include any system using an Intel/AMD processor (including Microsoft

Windows and Apple Mac OS X).

If the platform on which your application is running is Big Endian (e.g., Motorola PowerPC

CPU), then these 32-bit position values must have their bytes reverse-ordered after receiving

from, or before sending to, the controller. Examples of Big-Endian platforms include many

non-Intel-based systems, LabVIEW (regardless of operating system & CPU), and Java

(programming language/environment). MATLAB and Python (script programming language)

are examples of environments that adapt to the system on which each is running, so LittleEndian enforcement may be needed if running on a Big-Endian system. Some processors

(e.g., ARM) can be configured for specific endianess.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 29

27

Controller with Device

From/To Units

Conversion Factor

(multiplier)

MP-845/M, MP-845S/M,

MP-245/M*

micromanip

µm µsteps

10.66666666667

MP-285/M

3DMS

MT-78

stag

MOM

SOM

µm µsteps

8

Device

Axis

Millimeters

Microns

Microsteps

MP-845/M, MP-845S/M, or

MP-245/M* micromanipulator

MP-285/M micro-manipulator;

3DMS

MT-78

MOM

SOM objective mover

4.6 Microsteps and Microns (Micrometers)

All coordinates sent to and received from the controller are in microsteps. To convert

between microsteps and microns (micrometers), use the following conversion factors

(multipliers):

Table 4-2. Microns/microsteps conversion.

or

µsteps µm 0.09375

ulator

micromanipulator;

e;

* DB25 to DB26HD adapter required for MP-245/M.

or

objective mover

or

µsteps µm 0.125

For accuracy in your application, type these conversion factors as “double” (avoid using the

“float” type as it lacks precision with large values). When converting to microsteps, type the

result as a 32-bit “long”, “signed long”, or “I32” integer. When converting to microns, type

the result as “double” (64-bit double-precision floating-point values).

Table 4-3. Ranges and bounds

X, Y, & Z 0 – 25 0 – 25,000 0 – 266,667

or

* DB25 to DB26HD adapter required for MP-245/M.

NOTE: Origin is a physical position of travel that defines the center of the absolute position coordinate system (i.e., absolute

position 0).

Physical Positions: BOT (Beginning Of Travel), COT (Center Of Travel), & EOT (End Of Travel).

In the TRIO MP-245A, the Origin is fixed at BOT.

NOTE: Travel length of each axis is automatically determined by end-of-travel sensor.

stage;

or

X, Y, & Z 0 – 25 0 – 25,000 0 – 200,000

4.7 Commands

4.7.1 Get Current Position and Angle (‘c’ or ‘C’) Command

This command is used to obtain the current position (X, Y, & Z coordinates) of the

manipulator or stage and the current angle setting. The command sequence consists of one

byte as shown in the following table. The data received consists of fourteen bytes containing

X, Y, & Z position (32-bit) values in microsteps (4 bytes each), the angle in degrees (1 byte),

and the completion indicator (1 byte).

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 30

28

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All

1 0 99

67

63

43

0110 0011

0100 0011

0099

0043

‘c’

‘C’

Command

Rx.

All

0 (4)

X pos. in µsteps

4 (4)

Y pos. in µsteps

8 (4)

Z pos. in µsteps

12

0

90

00

5A

0000 0000

0101 1010

<NUL>

‘z’

Angle in degrees

13

13

0D

0000 1101

^M

<CR>

Completion indicator

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All

1 0 104

68

0110 1000

0104

‘h’

Command

Rx

All

1 0 13

0D

0000 1101

<CR>

Completion indicator

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

1 0 119

77

0111 0111

0119

‘w’

Command

Rx

1 0 13

0D

0000 1101

<CR>

Completion indicator

Table 4-4. Get Current Position and Angle (‘c’ or ‘C’) command.

or

-

or

-

or

-

or

or

-

4.7.2 Move to Controller-Defined HOME Position (‘h’) Command

moves to the position saved by the controller’s HOME button. X & Z move first (angle

determines order and simultaneity), and Y last.Table 4-5. Move to controller-defined HOME position

(‘h’) command.

4.7.3 Move to Controller-Defined WORK Position (‘w’) Command

moves to the position saved by the controller’s WORK button. Y moves first, and X & Z last

(angle determines order/simultaneity)Table 4-6. Move to controller -defined WORK position (‘w’)

command.

4.7.4 Move to Specified “Home” Position (‘H’) Command

This command instructs the controller to move all 3 axes to specified position, moving X & Z

(angle determines order/simultaneity), and

Y last (see

Ranges

table).

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 31

29

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All

13 0 72

48

0100 1000

0072

‘H’

Command

1 (4)

X µsteps

5 (4)

Y µsteps

9 (4)

Z µsteps

Rx

All

1 0 13

0D

0000 1101

^M

<CR>

Completion indicator

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All

13 0 87

57

0101 0111

0087

‘W’

Command

1 (4)

X µsteps

5 (4)

Y µsteps

9 (4)

Z µsteps

Rx

All

1 0 13

0D

0000 1101

^M

<CR>

Completion indicator

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All

14 0 83

53

1001 0111

0083

‘S’

Command

1 15

0

0F

00

0000 1111

0000 0000

0015

0000

^O

^@

Speed (15 – 0 (fastest

2 (4)

X µsteps

6 (4)

Y µsteps

10(4)

Z µsteps

Rx

All

1 0 13

0D

0000 1101

^M

<CR>

Completion indicator

Table 4-7. Move to specified “Home” position (‘H’) command.

4.7.5 Move to Specified “Work” Position (‘W’) Command

This command instructs the controller to move all 3 axes to specified position, moving Y first,

and X & Z last (angle determines order/simultaneity) (see

Table 4-8. Move to specified “Work” position (‘W’) command.

Ranges

table).

4.7.6 Move in Straight Line to Specified Position at Specified Speed (‘S’) Command

This command instructs the controller to move all three axes simultaneously in a straight

line to specified position (see

Ranges

table). The command sequence consists of seventeen

bytes.

Table 4-9. Straight-line move to specified position (‘S’) command.

-

-

-

-

-

through slowest))

While all move commands cause movement to occur at a rate of 5,000 microns/second, the

“Straight-Line Move ‘S’ command is specified with one of sixteen speeds. Actual speed for the

can be determined with the following formula: (5000 / 16) * (sp +1), where 5,000 is the

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 32

30

Speed Setting

(2nd Argument of ‘S’

Command Seq.)

mm/sec

or

µm/ms

µm/sec

or

nm/ms

nm/sec

in/sec

or

mil/ms

Percentage

of

Maximum

15

5.0000

5000.0

5000000

0.196850394

100.00%

14

4.6875

4687.5

4687500

0.184547244

93.75%

13

4.3750

4375.0

4375000

0.172244094

87.50%

12

4.0625

4062.5

4062500

0.159940945

81.25%

11

3.7500

3750.0

3750000

0.147637795

75.00%

10

3.4375

3437.5

3437500

0.135334646

68.75%

9

3.1250

3125.0

3125000

0.123031496

62.50%

8

2.8125

2812.5

2812500

0.110728346

56.25%

7

2.5000

2500.0

2500000

0.098425197

50.00%

6

2.1875

2187.5

2187500

0.086122047

43.75%

5

1.8750

1875.0

1875000

0.073818898

37.50%

4

1.5625

1562.5

1562500

0.061515748

31.25%

3

1.2500

1250.0

1250000

0.049212598

25.00%

2

0.9375

0937.5

937500

0.036909449

18.75%

1

0.6250

0625.0

625000

0.024606299

12.50%

0

0.3125

0312.5

312500

0.012303150

6.25%

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All 1 0 3 03

0000 0011

0003

^C

<ETX>

Command

Rx

1 0

13

0D

0000 1101

<CR>

Completion indicator

maximum speed in microns/second and “sp” is the speed level 0 (slowest) through 15

(fastest). For mm/second or microns/millisecond, multiply result by 0.001.

Table 4-10. Straight-Line Move ‘S’ Command Speeds.

4.7.7 Interrupt Straight-Line Move (‘^C’) Command

This command interrupts a move in progress (only for moves initiated by the “Straight-line”

move (‘S’) command). The command sequence consists of one byte.

Table 4-11. Interrupt a straight-line move in progress (‘^C’) command.

4.7.8 Move to Specified X-Axis Position (‘x’ or ‘X’) Command

This command moves to a specified position for only the X-axis.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 33

31

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All 5 0

120

90

78

5A

0111 1000

0101 1010

0120

0090

‘x’

‘X’

Command

1 (4)

X µsteps

Rx

1 0

13

0D

0000 1101

<CR>

Completion indicator

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All 5 0

121

91

79

5B

0111 1001

0101 1011

0121

0091

‘y’

‘Y’

Command

1 (4)

Y µsteps

Rx

1 0

13

0D

0000 1101

<CR>

Completion indicator

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All 5 0

122

92

7A

5C

0111 1010

0101 1100

0122

0092

‘z’

‘Z’

Command

1 (4)

Z µsteps

Rx

1 0

13

0D

0000 1101

<CR>

Completion indicator

Table 4-12. Move to specified X-axis position (‘x’ or ‘X’) command.

or

or

or

or

or

4.7.9 Move to Specified Y-Axis Position (‘y’ or ‘Y’) Command

This command moves to a specified position for only the Y-axis.

Table 4-13. Move to specified Y-axis position (‘y’ or ‘Y’) command.

or

or

or

or

or

4.7.10 Move to Specified Z-Axis Position (‘z’ or ‘Z’) Command

This command moves to a specified position for only the Z-axis.

Table 4-14. Move to specified Z-axis position (‘z’ or ‘Z’) command.

or

or

or

or

or

4.7.11 Setting the Angle (‘A’) Command

Sets the angle value, in degrees, to match the angle position of the rotary dovetail

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 34

32

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All 2 0

65

41

1010 1001

0065

‘A’

Command

1

0

90

00

5A

0000 0000

0101 1010

0000

0090

<NUL>

‘z’

Angle in degrees between 0 and

Movement

Rx

1 0

13

0D

0000 1101

<CR>

Completion indicator

Tx/-

Delay/-

Rx

Ver.

Total

Bytes

Byte

Offset

(Len.)

Value

Alt-

key-

pad #

Ctrl-

char

ASCII

def./char.

Description

Dec.

Hex.

Binary

Tx

All 1 0

82

62

1000 0010

0082

‘R’

Command

Rx

1 0

13

0D

0000 1101

<CR>

Completion indicator

Table 4-15. Set the angle (‘A’) command.

-

-

-

-

-

90. See

Angle Setting &

note

4.7.12 Recalibrate (‘R’) Command

Recalibrates the connected micromanipulator/stage to 1,000 microns in each axis.

Table 4-16. Recalibrate (‘R’) command.

4.7.13 Notes

1. Task-Complete Indicator: All commands will send back to the computer the “TaskComplete Indicator” to signal the command and its associated function in controller is

complete. The indicator consists of one (1) byte containing a value of 13 decimal (0D

hexadecimal), and which represents an ASCII CR (Carriage Return).

2. Intercommand Delay: A short delay (usually around 2 ms) is recommended between

commands (after sending a command sequence and before sending the next command).

3. Clearing Send/Receive Buffers: Clearing (purging) the transmit and receive buffers of the

I/O port immediately before sending any command is recommended.

4. Positions in Microsteps: All positions sent to and received from the controller are in

microsteps (µsteps). See

Microns/-microsteps conversion

table) for conversion between

µsteps and microns (micrometers (µm)).

5. Ranges and Bounds: See

Ranges and Bounds

table for exact minimum and maximum

values for each axis of each compatible device that can be connected. All move commands

must include positive values only for positions – negative positions must never be

specified. All positions are absolute as measured from the physical beginning of travel of

a device’s axis. In application programming, it is important that positional values be

checked (>= 0 and <= max.) to ensure that a negative absolute position is never sent to

the controller and that end of travel is not exceeded. All computational relative

positioning must always resolve to accurate absolute positions.

6. Absolute Positioning System Origin: The Origin is set to a physical position of travel to

define absolute position 0. The physical Origin position is fixed at beginning of travel

(BOT). This means that all higher positions (towards end of travel (EOT)) are positive

values; there are no lower positions and therefore no negative values are allowed.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 35

33

7. Absolute vs. Relative Positioning: Current position (‘c’) and move commands always use

absolute positions. All positions can be considered “relative” to the Origin (Position 0),

but all are in fact absolute positions. Any position that’s considered to be “relative” to the

current position, whatever that might be, can be handled synthetically by external

programming. However, care should be taken to ensure that all relative positions are

accurately translated to correct absolute positions before initiating a move command.

8. Position Value Typing: All positions sent and received to and from the controller are in

microsteps and consist of 32-bit integer values (four contiguous bytes). Position values

can be either positive or negative, so type must be “signed”. Although each positional

value is transmitted to, or received from, the controller as a sequence of four (4)

contiguous bytes, for computer application computational and storage purposes each

should be typed as a signed integer (“long” or “signed long” in C/C++; “I32” in

LabVIEW, etc.). Note that in Python, incorporating the optional NumPy package brings

robust data typing like that used in C/C++ to your program, simplifying coding and

adding positioning accuracy to the application.

9. Position Value Bit Ordering: All 32-bit position values transmitted to, and received from,

the controller must be bit/byte-ordered in “Little Endian” format. This means that the

least significant bit/byte is last (last to send and last to receive). Byte-order reversal may

be required on some platforms. Microsoft Windows, Intel-based Apple Macintosh systems

running Mac OS X, and most Intel/AMD processor-based Linux distributions handle byte

storage in Little-Endian byte order so byte reordering is not necessary before converting

to/from 32-bit “long” values. LabVIEW always handles “byte strings” in “Big Endian”

byte order irrespective of operating system and CPU, requiring that the four bytes

containing a microsteps value be reverse ordered before/after conversion to/from a

multibyte type value (I32, U32, etc.). MATLAB automatically adjusts the endianess of

multibyte storage entities to that of the system on which it is running, so explicit byte

reordering is generally unnecessary unless the underlying platform is Big Endian. If your

development platform does not have built-in Little/Big Endian conversion functions, bit

reordering can be accomplished by first swapping positions of the two bytes in each 16-bit

half of the 32-bit value, and then swap positions of the two halves. This method

efficiently and quickly changes the bit ordering of any multibyte value between the two

Endian formats (if Big Endian, it becomes Little Endian, and if Little Endian, it becomes

then Big Endian).

10. Travel Lengths and Durations: “Move” commands might have short to long distances of

travel. If not polling for return data, an appropriate delay should be inserted between the

sending of the command sequence and reception of return data so that the next command

is sent only after the move is complete. This delay can be auto calculated by determining

the distance of travel (difference between current and target positions) and rate of travel.

This delay is not needed if polling for return data. In either case, however, an appropriate

timeout must be set for the reception of data so that the I/O does not time out before the

move is made and/or the delay expires.

11. Movement Speeds: All move commands cause movement to occur at a rate of 5,000

microns/second, except for the “Straight-Line Move ‘S’ command which can be specified

with one of sixteen speeds. Actual speed for the “Straight-Line Move ‘S’ command can be

determined with the following formula: (5000 / 16) * (sp +1), where 5,000 is the

maximum speed in microns/second and “sp” is the speed level 0 (slowest) through 15

(fastest). For mm/second or microns/millisecond, multiply result by 0.001.

TRIO MP-245A FOUR-AXIS MICROMANIPULATOR SYSTEM OPERATION MANUAL – REV. 3.12B (20191001)

Page 36

34

Speed

Setting

mm/sec

or

µm/ms

µm/sec

or

nm/ms

nm/sec

in/sec

or

mil/ms

% of

Max.

15

5.0000

5000.0

5000000

0.196850394

100.00%

14

4.6875

4687.5

4687500

0.184547244

93.75%

13

4.3750

4375.0

4375000

0.172244094

87.50%

12

4.0625

4062.5

4062500

0.159940945

81.25%

11

3.7500

3750.0

3750000

0.147637795

75.00%

10

3.4375

3437.5

3437500

0.135334646

68.75%

9

3.1250

3125.0

3125000

0.123031496

62.50%

8

2.8125

2812.5

2812500

0.110728346

56.25%

7

2.5000

2500.0

2500000

0.098425197

50.00%

6

2.1875

2187.5

2187500

0.086122047

43.75%

5

1.8750

1875.0

1875000

0.073818898

37.50%