Page 1

MP-285

Micromanipulator System

ROE

Basic Operations

Rev. 3.08 ( 20140809)

One Digital Drive

Novato, CA 94949

Voice: 415-883-0128 Web: www.sutter.com

Fax: 415-883-0572 Email: info@sutter.com

Page 2

ii

Copyright © 2014 Sutter Instrument Company. All Rights Reserved.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 3

iii

Mains Voltage

DIS CLAI M ER

The

MP-285

-system consists of one controller (MP-285), a user control device (ROE or

Joystick), and one electromechanical micromanipulator device (MP-285/M). The purpose of

the system is for the manipulation at the micro level of micropipettes and probes used in

conjunction with a microscope. No other use is recommended.

This instrument is designed for use in a laboratory environment. It is not intended, nor

should it be used in human experimentation or applied to humans in any way. This is not a

medical device.

Do not open or attempt to repair the instrument. High voltages are present and inadvertent

movement of the micromanipulator electromechanical could cause injury.

Do not allow unauthorized and/or untrained operative to use this device.

Any misuse will be the sole responsibility of the user/owner and Sutter Instrument Company

assumes no implied or inferred liability for direct or consequential damages from this

instrument if it is operated or used in any way other than for which it is designed.

SAF E TY W ARN ING S AND PRE CAU T ION S

Electrical

Operate the MP-285 using 110-- 240 V AC., 50-60 Hz line voltage. This instrument is

designed for use in a laboratory environment that has low electrical noise and mechanical

vibration. Surge suppression is recommended at all times.

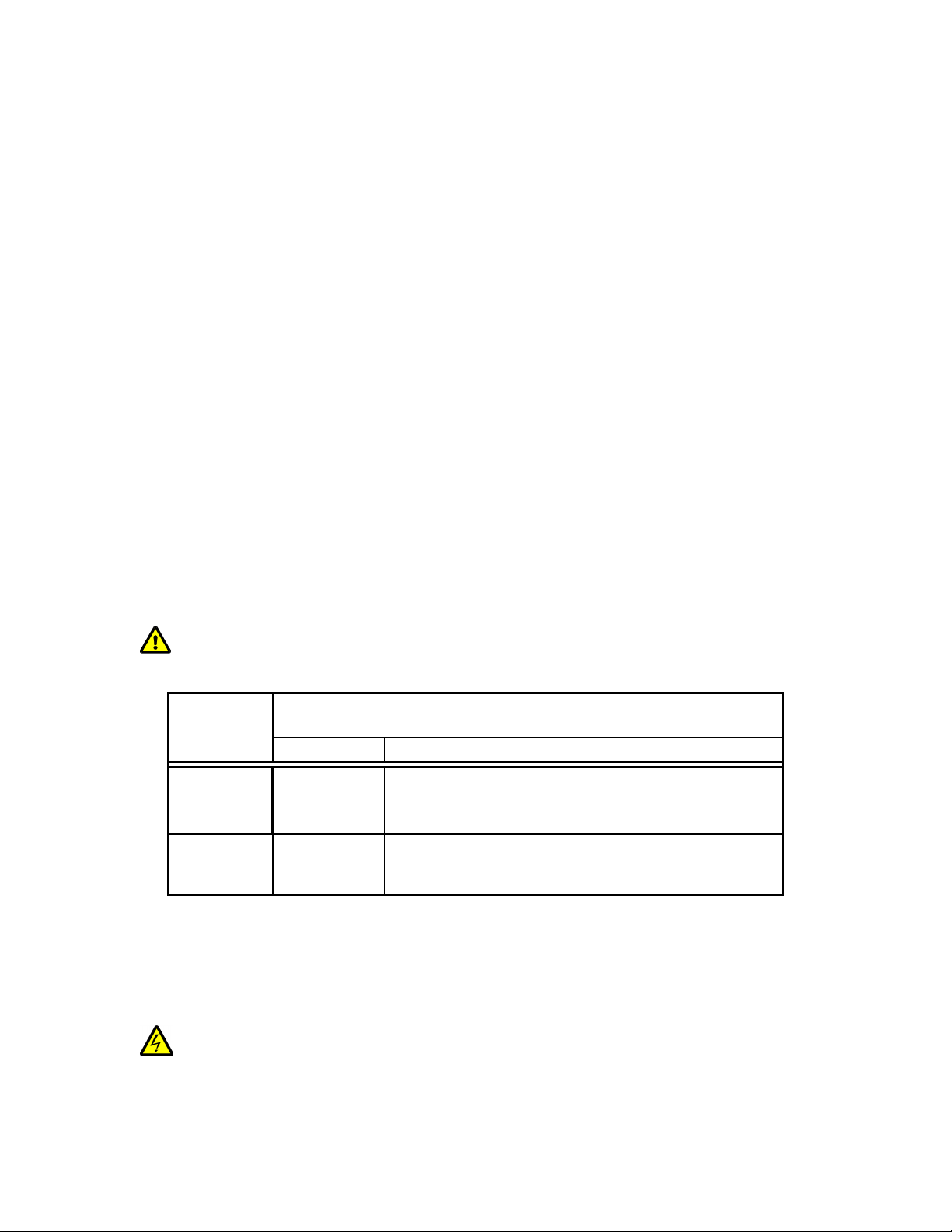

Fuse Replacement: Replace only with the same type and rating:

Mains fuse type and rating.

Fuse

Setting

“110”

(100 – 120

VAC)

“220”

(200 – 240

VAC)

Rating Manufacturer Examples

2A, 250V

(Time Delay)

T1.0A, 250V Bussmann: GDC-1A or S506-1A (RoHS)

(Type: Time Delay, 5mm x 20mm, glass tube)

Bussmann: GMC-2A, GMC-2-R (RoHS), GDC-2A, or

S506-2A (RoHS)

Littelfuse: 239 002 or 239.002.P (RoHS)

Littelfuse: 218 001 or 218 001.P (RoHS)

A spare fuse is located in the power input module. Please refer to the fuse-replacement

appendix for more details on fuse ratings and for instructions on how to change the fuse.

Avoiding Electrical Shock and Fire-related Injury

Always use the grounded power supply cord set provided to connect the system to a

grounded outlet (3-prong). This is required to protect you from injury in the event that

an electrical hazard occurs.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 4

iv

Do not disassemble the system. Refer servicing to qualified personnel.

To prevent fire or shock hazard do not expose the unit to rain or moisture.

Electromagnetic Interference

To comply with FDA and CE electromagnetic immunity and interference standards; and to

reduce the electromagnetic coupling between this and other equipment in your lab always

use the type and length of interconnect cables provided with the unit for the interconnection

of the ROE, MP-285/M electromechanical device, and host computer via serial RS-232

interface, (see the Technical Specifications appendix for more details).

Operational

Failure to comply with any of the following precautions may damage this device.

This instrument is designed for operation in a laboratory environment (Pollution Degree

I) that is free from mechanical vibrations, electrical noise and transients.

This unit is not designed for operation at altitudes above 2000 meters nor was it tested

for safety above 2000 meters.

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN THE

CONTROLLER AND THE MECHANICAL UNITS WHILE POWER IS ON.

Please allow at least 20 seconds after turning the unit off before disconnecting the

mechanical units. Failure to do this may result in damage to the electronics.

Operate this instrument only according to the instructions included in this manual.

Do not operate if there is any obvious damage to any part of the instrument.

Operate only in a location where there is a free flow of fresh air on all sides.

NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.

Do not operate this instrument near flammable materials. The use of any hazardous

materials with this instrument is not recommended and if undertaken is done so at the

users’ own risk.

Do not attempt to operate the instrument with the manipulator shipping screws in

place - severe motor damage may result.

Do not operate if there is any obvious damage to any part of the instrument. Do not

attempt to operate the instrument with the manipulator shipping screws in place - severe

motor damage may result. When transporting the mechanical manipulator, be sure to

install the shipping screws supplied in their correct locations. Failure to do this may

result in damage to the motors.

Never touch any part of the micromanipulator electromechanical device while it is in

operation and moving. Doing so can result in physical injury (e.g., fingers can be caught

and pinched between the moving parts of the micromanipulator).

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 5

v

As with all microinjection devices, sharp micropipettes can fly out of their holder

unexpectedly. Always take precautions to prevent this from happening. Never loosen the

micropipette holder chuck when the tubing is pressurized, and never point micropipette

holders at yourself or others. Always wear safety glasses when using sharp glass

micropipettes with pressure microinjectors.

Do not handle the manipulator mechanical while the power is on, and take care to

ensure no cables pass close to the mechanical manipulator.

Other

Use this instrument only for microinjection purposes in conjunction with the procedures

and guidelines in this manual.

Retain the original packaging for future transport of the instrument.

Some applications, such as piezo-impact microinjection call for the use of mercury in the

micropipette tip. The use of any hazardous materials with any Sutter Instrument’s

instrument is not recommended and if undertaken is done so at the users’ own risk.

When transporting the mechanical manipulator, be sure to install the shipping screws

supplied in their correct locations. Failure to do this may result in damage to the motors.

This instrument contains no user-serviceable components — do not open the instrument

casing. This instrument should be serviced and repaired only by Sutter Instrument or an

authorized Sutter Instrument servicing agent.

Sutter Instrument reserves the right to change specifications without prior notice.

This device is intended only for research purposes.

Handling Micropipettes

Failure to comply with any of the following precautions may result in injury to the users

of this device as well as those working in the general area near the device.

The micropipettes used with this instrument are very sharp and relatively fragile.

Contact with the pulled micropipette tips, therefore, should be avoided to prevent

accidentally impaling yourself.

Always dispose of micropipettes by placing them into a well-marked, spill-proof “sharps”

container.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 6

vi

(This page intentionally left blank.)

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 7

vii

TABLE OF CONTENTS

DISCLAIMER ......................................................................................................................................iii

SAFETY WARNINGS AND PRECAUTIONS...................................................................................iii

Electrical .................................................................................................................................................iii

Avoiding Electrical Shock and Fire-related Injury.............................................................................iii

Electromagnetic Interference...............................................................................................................iv

Operational.............................................................................................................................................iv

Other.........................................................................................................................................................v

Handling Micropipettes..........................................................................................................................v

1. GENERAL INFORMATION...........................................................................................................1

1.1 Structure of the MP-285 Documentation Package ...............................................................................1

1.2 Technical Support.............................................................................................................................1

2. SETUP...............................................................................................................................................3

2.1 Unpacking..........................................................................................................................................3

2.2 Initial Setup and Gross Movement.................................................................................................4

2.3 Installation of the MP-285 Micromanipulator on your Microscope............................................6

2.3.1 General Considerations.............................................................................................................6

2.3.2 Specifics.......................................................................................................................................6

2.4 Mounting Headstages.......................................................................................................................7

2.5 Adjusting the Rotating Dovetail Base.............................................................................................8

2.6 Minimizing Electrical Noise ............................................................................................................9

3. MICROSCOPIC MANIPULATION ..............................................................................................11

3.1 Some Basic Information.................................................................................................................11

3.2 SETUP Selection ............................................................................................................................11

3.3 Changing Minimal Resolution.......................................................................................................12

4. PULSE MOVEMENT.....................................................................................................................15

5. HOME FUNCTION........................................................................................................................17

5.1 How to Define a New Home ..........................................................................................................17

5.2 Moving to the New Home:.............................................................................................................17

5.3 Practical Use of the Home Function.............................................................................................17

6. GENERALIZED ROBOTIC MOVEMENTS.................................................................................19

6.1 Setting Absolute Zero.....................................................................................................................19

6.2 Redefining Home ............................................................................................................................19

6.3 Clearing Program Location #1 for Recording a New Robotic Series .......................................19

6.4 Teaching the MP-285 Controller a New Robotic Series.............................................................20

6.5 Executing the Newly Entered Program!......................................................................................21

6.6 Loading a Saved Program..............................................................................................................22

7. DIAGONAL OR 4TH AXIS MOVEMENTS .................................................................................23

8. ROE RESPONSE CHARACTERISTICS ......................................................................................25

8.1 Controlling ROE Knob to Manipulator Stepper Motor Axis Assignment................................25

8.2 Controlling Movement Amount per ROE Turn..........................................................................25

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 8

viii

APPENDIX A. LIMITED WARRANTY............................................................................................27

INDEX.................................................................................................................................................29

TABLE OF FIGURES

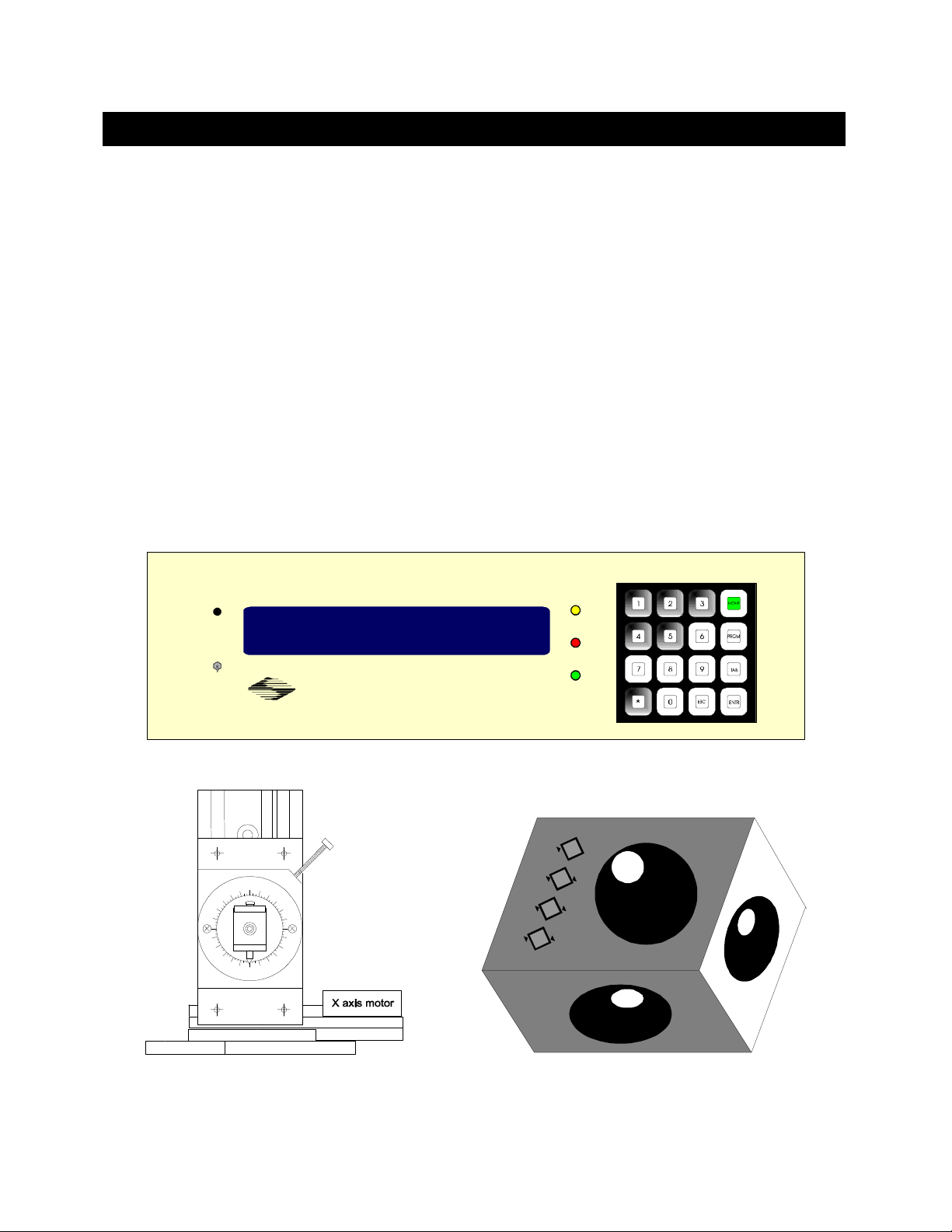

Figure 2-1. MP-285 Controller (front panel)...........................................................................................3

Figure 2-2. Manipulator. Figure 2-3. Rotary Optical Encoder (ROE)...............................................3

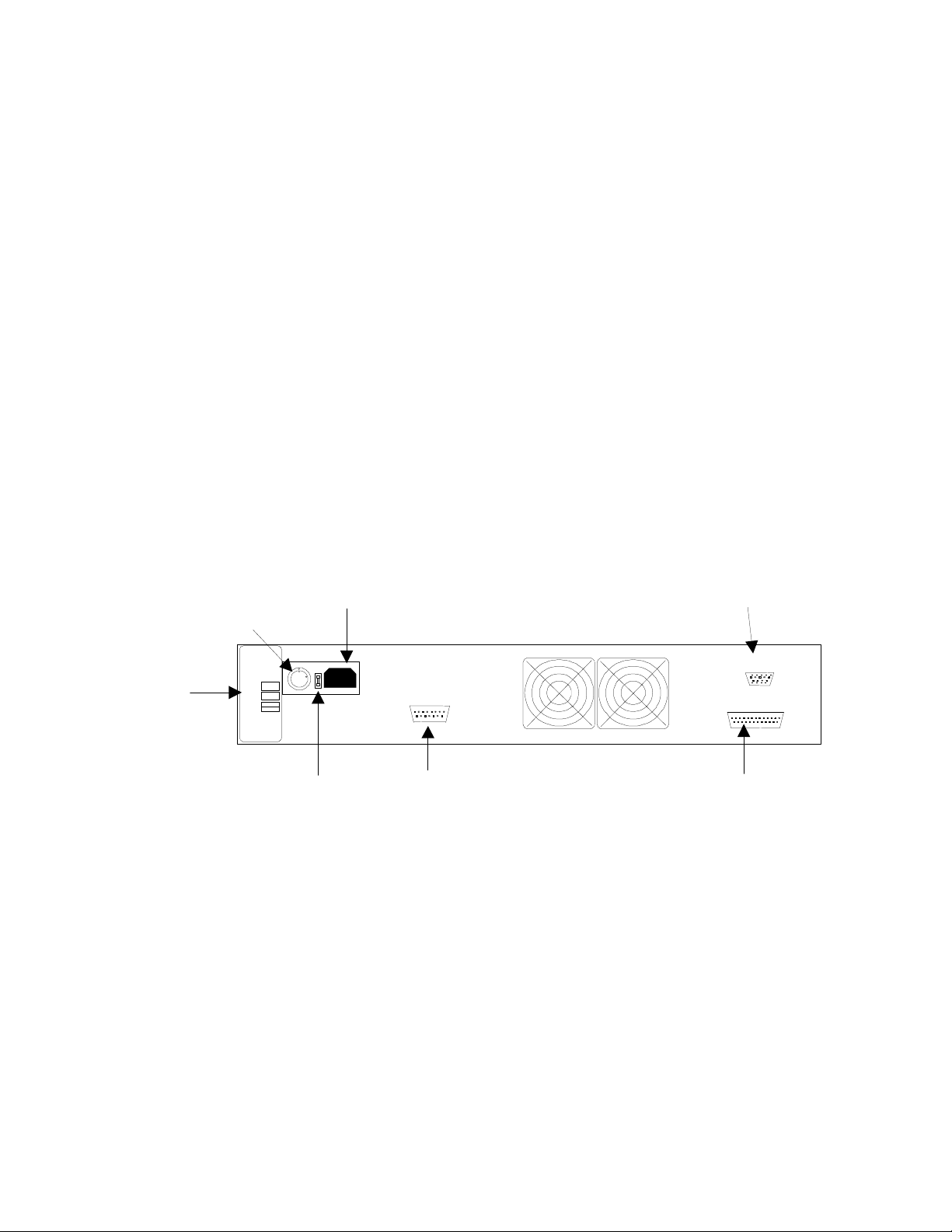

Figure 2-4. MP-285 controller rear connections. ....................................................................................4

Figure 2-5. Manipulator base dimensions................................................................................................6

Figure 2-6. Headstage mounting plate.....................................................................................................7

Figure 2-7. Mounting the headstage on the manipulator's Z-axis.........................................................8

Figure 2-8. Adjusting the headstage angle...............................................................................................8

TABLE OF TABLES

Table 3-1. Microsteps per ROE turn settings........................................................................................12

Table 3-2. Microns per ROE turn settings.............................................................................................13

Table 4-1. Microsteps and microns per Pulse settings. ........................................................................16

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 9

1

1. GEN E RAL INFO RMA TION

1.1 Structure of the MP-285 Documentation Package

The MP-285 is a highly versatile stepper motor driven micromanipulator. Because of this

versatility, the documentation necessary to cover various functions has rapidly grown to a

size best described as unwieldy and thus has generally not been useful to most operators.

In order to produce a more useful set of instructions, we have split the manual into two

parts. The first part, “Basic Operations”, has been kept short and covers major functions

with the aim of quickly guiding the first time user through the setup and use of the MP-285

for micromanipulation with emphasis on using the ROE (Rotary Optical Encoder) for user

control. These steps are, in many ways, identical to the steps performed any time one sets up

an MP-285 for use at a microscope. Many users will find that no other manual is necessary.

The second part, “Reference Manual”, provides in-depth coverage of the MP-285. It

documents the precise keystrokes (menu navigation) necessary to access each MP-285

function. The Reference Manual also describes, in detail, how to alter MP-285 performance

via add-on accessories, perform microcontroller robotic programming, and how to use the

serial computer interface.

1.2 Technical Support

Unlimited technical support is provided by Sutter Instrument Company at no charge to our

customers. Our technical support staff is available between the hours of 8:00 AM and 5:00

PM (Pacific Time) at

(415) 883-0128

. You may also E-mail your queries to

info@sutter.com

.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 10

2

(This page intentionally left blank.)

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 11

3

HOM

NOR

COAR

CON

DIA

FIN

PULS

2. SETU P

2.1 Unpacking

Carefully remove all components from the shipping container. One of each of the following

should be included:

MP-285 controller

MP-285 micromanipulator and D25 cable for connection to controller

Rotary Optical Encoder (ROE) and D15 cable for connection to controller

Controller power cord

Serial port cable (DB9 connectors)

Metal dovetail headstage mounting plate with plastic isolation plate

Metal dovetail rod clamp

2.5mm hex wrench for removing the shipping screws

7/64 hex wrench for adjusting the rotating dovetail base

MP-285 documentation

RESET

POWER

MP-285

SUTTER INSTRUMENT CO.

Figure 2-1. MP-285 Controller (front panel).

MADE IN U.S.A.

Figure 2-2. Manipulator. Figure 2-3. Rotary Optical Encoder (ROE).

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 12

4

1 2 3 4 5 6 7 8 9 10 11 12 13

14 15 16 17 18 19 20 21 22 23 24 25

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

110

220

FUSE

L

SUTTER

INSTRUMENT

51 Digital Drive

NOVATO, CA 94949 USA

(415) 883 - 0128

DISCONNECT POWER

BEFORE OPENING

UNIT!

MODEL

Hz

FUSE

VOLTS

DANGER

SERIAL PORT

MANIPULATOR

COMMAND INP

UT

You may have also received one or more accessories for mounting your MP-285 and/or

modifying the headstage mount to the manipulator (i.e., rotating base, microscope stage

mount, gantry stand, dovetail extension). Setup of these accessories is covered either in

documentation accompanying the accessory or in the

MP-285 Reference Manual

.

Remove all six shipping screws from the MP-285. Save the screws, warning tags, and hex

wrench in the event you need to transport your manipulator in the future. Once these screws

have been removed, handle the micromanipulator with care. The drive cables can be

damaged

2.2 Initial Setup and Gross Movement

Initially, you may want to simply connect your manipulator, controller, and ROE together and

try some gross movements in order to get a feel for the controls and how to make simple

movements. It is perfectly acceptable to set the manipulator in the middle of a bench top,

make all electrical connections and then observe the unit’s movement by eye. Even if you

wish to directly install your manipulator in your rig, it is useful to follow the initial setup

procedure in order to learn how to move the unit and allow easy access to the mounting

screws if subjected to unnecessary strain.

1. Connect the power cord to the MP-285 controller. Make certain that the voltage selector

next to the power cord socket on the back of the MP-285 controller has been set to the

appropriate voltage (110 or 220).

ABEL

VOLTAGE

SELECTOR

HIGH VOLTAGE

LINE POWER

FUSE

Figure 2-4. MP-285 controller rear connections.

INPUT DEVICE

CABLE (15 pin)

SERIAL PORT

CABLE (9 pin)

MANIPULATOR

CABLE (25 pin)

2. With the power OFF (front panel switch in the down position), use the D15 cable and

connect the ROE to the connection labeled “COMMAND INPUT” on the back of the MP285 controller.

CAUTION: Never connect or disconnect the ROE while the power is on!

3. With the power OFF, use the D25 cable and connect the MP-285 micromanipulator to the

DB 25 connector labeled “MANIPULATOR” on the back of the controller.

CAUTION: Never connect or disconnect the micromanipulator while the power is on!

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 13

5

CAUTION: Important! Check to make sure that you have removed all six shipping screws.

The unit can be severely damaged if you try to move one of the axes with the shipping screws

in place.

To observe movement of the manipulator do the following:

1. Turn the power ON (front panel switch up). Observe the startup screen:

S1 * * * M P - 2 8 5 C o n t r o l l e r * * * P1

P r e s s M O V E , P R G M o r s e l e c t m a g . w i t h *

2. Press the <MOVE> key on the MP-285 controller keypad. Observe the movement screen:

- 1 0 7 8 9 . 2 0 u m X - 1 0 7 7 8 . 2 4 u m Y

- 1 0 7 5 0 . 4 0 u m Z 0 . 2 0 u m R e s .

Assuming this was the initial power on from the unit after unpacking, you should have

coordinates similar to those above (-10,000µm to -12,000µm). These coordinates correspond

to the locations of the shipping screws.

Turn a knob on the ROE. You should see one of the axes on the manipulator move and the

coordinates on the screen of the controller change. The coordinates indicate how far you have

moved in micrometers along each of the three axes.

Before the unit was shipped from Sutter, its absolute origin (location 0,0,0) was set at the

center of travel of each axis. This same location was also defined as “Home”. This means that

you can make the manipulator move to the center of travel by a simple move to “Home”, as

follows:

1. Make sure you are still in the movement screen (coordinates displayed).

2. Press the button on the ROE marked <HOME>.

Observe the “rapid” movement of the manipulator to the center of travel of each axis. The

controller display will read, “Going home” during the move, and will display coordinates

close to 0,0,0 after the move is complete.

The MP-285 controller front panel is configured with three colored LEDs. When lit, these

LEDs indicate that a signal is being received from the input device. Each LED (yellow, red,

and green) indicates input originating from one of the three knobs on the ROE (top, left, and

right, respectively).

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 14

6

2.75”

2.75”

2.5”

2.5”

2.25”

2.3 Installation of the MP-285 Micromanipulator on your Microscope

2.3.1 General Considerations

In most applications, it is best to try to mount the MP-285 in a location that allows for the

widest range of movement. Usually, this means mounting so that the device is in the center

of travel when it is in its normal operating position. To facilitate this procedure, move the

manipulator to its center of travel before determining where it should be mounted.

The base of the MP 285 manipulator is also the mounting surface for the bearing ways of the

X-axis. When the base plate is pressed firmly against most mounting surfaces, torsional

stress can be transmitted to the base and thus misaligns the bearing ways. A supply of four

precision-thickness washers is included with your MP-285 manipulator. To limit

misalignment, you should use one on each of the four mounting screws between the MP-285

manipulator base and your mounting surface.

When mounting the MP-285 there should be no physical impediments to the full excursion of

the three axes. Pay particular attention to the screws or clamps used to secure the base of the

micromanipulator to make certain that the X-axis slide can move to the end of its travel

without obstruction.

Additional mounting considerations, as well as instructions pertaining to specific mounting

accessories can be found in the Reference Manual.

2.3.2 Specifics

The base of the MP-285 manipulator has four mounting holes on 2.5” centers. A template,

drawn to scale and based on the footprint shown below, can be used to drill holes in a suitable

mounting surface.

3.8125”

Figure 2-5. Manipulator base dimensions.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 15

7

dovetail mounting plate:

EPC: 1

-

1/16" x 2

-

7/32"

A

B

C

C

C

D D

This four-hole pattern is also compatible with the MP-285 rotary base, part #285RBI and the

mounting adapter plate, # 285210 (see the Reference Manual for further instructions).

While it is possible to insert and tighten all four mounting screws with the MP-285 in one

position, you may find it convenient to connect and power up the manipulator and position

the X-axis for the best access to the screw holes.

2.4 Mounting Headstages

The most stable way to mount a headstage is to fasten it directly to the Z-axis slide. The

mounting hardware included with the MP-285 is designed to eliminate the need for custom

machining of headstage and pipette holders. For example, Axon Instruments’ new 203B

headstage mounts directly to the rotating dovetail on the MP-285 Z-axis. Other headstages

require use of the dovetail mounting plate:

2 middle (D) holes

(2 holes, A & B)

CV-4: 1-1/8" x 1-15/16"

(4 holes, B & C)

Figure 2-6. Headstage mounting plate.

The plastic portion of the plate provides electrical isolation while allowing for a direct mount

of Axon Instruments’ CV-4 headstage or Heka Electronics’ EPC-7, 8, or 9 headstages. The

user can drill additional holes to allow the plate-mount installation of other headstages.

Headstage mounting instructions can be found in the Reference Manual.

Whether using the Axon 203B Headstage or another headstage mounted on the dovetail

mounting plate, the respective male dovetail is inserted into the female dovetail on the MP285 Z-axis. Slide the dovetail mounting plate/headstage assembly into the rotating-dovetail

base and secure it by tightening the dovetail clamp set screw with a Phillips-head

screwdriver.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 16

8

Rotating dovetail

Headstag

Dovetail mounting

Dovetail clamp set

Plastic isolation

0 15

15

0

45

30

30

15

45

15

30

30 15

45

15

30

30

15

45

15

30

30

Loosen then

retighten

Rotate

Figure 2-7. Mounting the headstage on the manipulator's Z-axis.

2.5 Adjusting the Rotating Dovetail Base

The rotating dovetail base allows the pipette holder or headstage to be rotated and firmly

fixed at any angle desired by the experimenter as required for access to a particular

microscope.

Headstage

Figure 2-8. Adjusting the headstage angle.

To adjust the rotary dovetail to your desired angle:

1. Loosen the brake set screw to rotate the headstage or pipette holder. Failure to loosen the

screw may lead to rapid deterioration of the brake and rotating disk thereby reducing the

ability to firmly secure the rotating dovetail.

2. Once you have determined the proper angle, firmly tighten the brake set screw to assure

stable positioning of the rotating dovetail.

It is not recommended that you use this rotational joint as a means of pipette replacement.

Repeated repositioning of the rotary disk and brake will lead to rapid deterioration of the

joint which may then not tighten properly to allow stable positioning of a pipette.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 17

9

2.6 Minimizing Electrical Noise

We are aware of two potential noise sources for users coupling their MP-285 with high-gain,

high input impedance, electrophysiological recording amplifiers. The first is associated with

the manipulator and its connecting cable from the controller. Under certain circumstances

these may act as an antenna concentrating electric field noise that originates from nearby

electrical equipment (computer monitors and fluorescent lights are the most notorious

offenders) and bringing it into close proximity with recording apparatus. Grounding the

manipulator will largely eliminate this noise source. Ground tabs are located on each motor

housing for this purpose. It should be noted that the manipulator produces negligible

electrical noise when it is not moving because it is powered by a linear power supply with no

AC current present.

The second potential source of noise is associated with the magnetic field radiated from the

power supply transformer in the controller. Certain electrophysiological amplifiers are more

susceptible to generating noise when exposed to this magnetic field. This noise can be

minimized or eliminated by allowing a maximal distance between your MP-285 controller and

your amplifier. It may be possible to decrease this noise source further by placing a soft steel

plate or a piece of high permeability metal between the controller and the amplifier.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 18

10

(This page intentionally left blank.)

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 19

11

3. MIC R OSCO PIC MAN I PU L ATIO N

3.1 Some Basic Information

Assuming you have already tried gross movement of the MP-285 as outlined above (Initial

Setup and Gross Movement) then you have an understanding of most of the features

necessary for microscopic manipulation using your MP-285. The controller makes two

changes to implement fine movement:

The number of microsteps commanded per revolution of the ROE is reduced.

The size of the microsteps produced by the stepping motor (minimal resolution) is

reduced from 0.2mm to 0.04mm.

These two changes give you a wide range of control over the amount of movement

commanded by a single turn of an ROE knob. In the gross movement mode, you are

commanding slightly over 700mm/turn. In the precise movement mode, you can command as

few as 20mm/turn.

As with the other portions of this User’s Manual, it is hoped that enough information has

been provided to get the average user “micromanipulating” with a minimum of time spent

covering unnecessary detail. If you find yourself needing additional detail on any of the items

covered, please consult the appropriate topic in the Reference Manual.

3.2 SETUP Selection

In order for the MP-285 to make precise movements and have a greater amount of control

over the movement, you instruct the controller to produce fewer microsteps (the minimal

increment of manipulator movement) per rotation of the ROE knobs. Using simple

commands, you choose one of four different “Setups” that vary the number of microsteps per

turn of the ROE knob over a range of 512 to 5120 per turn.

The following steps outline how to use your MP-285 to manipulate a pipette into position in

the field of view of your microscope. In doing so, you will learn how to switch from one setup

to another. The same procedure can also be used as the final steps of manipulator setup and

installation assuming the MP-285 is mounted on or near your microscope.

1. Turn on the manipulator power; while still in the main menu press <1>. This selects

Setup 1 and allows for rapid positioning of the pipette in your microscopic field of view.

The upper left-hand corner of the display should now read “S⇒1”.

2. Press <MOVE> to allow movement; remember that you cannot make movements unless

you see the movement screen displayed

3. Focus the microscope to a height slightly above your preparation.

4. Using the X and Y-axes, move the pipette tip to a position above the middle of your field

of view. In most cases, the first indication that the pipette is in the correct approximate

location is an out-of-focus shadow. You may need to work at a lower microscopic power to

visualize the tip.

5. Once you can see the shadow of the tip above your preparation, use the Z-axis control (top

ROE knob) to move the pipette down into focus. If you focused above your preparation,

you should not crash the pipette into your dish and/or preparation.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 20

12

If these operations are part of your initial installation, your manipulator may not be mounted

in a position to allow you to center the pipette tip in the microscope field of view. If this is

true, you will have to stop and adjust the mounting location of the manipulator and/or the

angle of approach of the pipette and/or the mounting of the headstage in the rotary dovetail.

After repositioning, you will be able to bring the pipette to the correct working location. See

the MP-285 Reference Manual for additional information on pipette positioning and Sutter

accessories to aid in pipette access to different microscopes.

NOTE: Once you can see the pipette in your field of view, you are ready for

micromanipulation.

1. Press <ESC> to get to the main menu

2. Press <4> to select Setup 4; the upper left hand corner of the display should now read

S⇒4.

3. Press <MOVE> to return to the movement screen.

4. Rotate the knobs on the ROE and observe the precise control you have over the

movement of the pipette. If you wish to have even better control, press the

<COARSE/FINE> button on the ROE (see below)

Four factory-installed Setups are selected from the main menu by pressing the corresponding

number (1 through 4) from the MP-285 keypad. Assuming you are in the movement screen

and you want to change the current Setup, the key sequence is as follows:

1. From the movement screen press <ESC> to access the main menu

2. Press the number key <1> through <4> corresponding to the Setup you wish to use.

The actual values for number of microsteps per ROE turn are as follows:

Table 3-1. Microsteps per ROE turn settings.

Setup

Number

Microsteps per

ROE turn

1 3694

2 5120

3 2560

4 512

3. Press <MOVE> to return to the movement screen and begin moving at the precision

specified by the selected Setup.

The selected setup is maintained when the MP-285 controller is turned off; you only need to

select a different setup when you wish to change precision of movement.

3.3 Changing Minimal Resolution

In addition to controlling the number of microsteps per ROE turn, you can also set the

microstep size to one of two values (coarse=0.2µm or fine=0.04µm). You then have two

different amounts of movement (ultimately two different precisions for each selected Setup).

To change resolution from one value to the other, simply press the <COARSE/FINE> button

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 21

13

on the top of the ROE (coarse is up, fine is down). The movement screen also displays the

resolution in the lower right corner “0.2 (or 0.04) µm Res”. Given a resolution in microns, we

can now re-specify the amount of movement per ROE turn in microns for Setups 1 through

4:

Table 3-2. Microns per ROE turn settings.

Setup

Number

1

2

3

4

Microns per ROE turn at

0.2µm 0.04µm

716.8 143.36

1024 204.8

512 102.4

102.4 20.48

Thus, you have a relatively wide range of precision of movement. In practice, many users end

up only using a very non-precise, fast moving setup (#1 or 2, coarse) for quickly positioning

the pipette and then a precise setup (#4, fine) for micromanipulation under the microscope.

You may find that none of these SETUPS delivers the type of responsiveness that you desire

from the MP-285. The MP-285 Reference Manual provides complete instructions for defining

and saving your own Setup.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 22

14

(This page intentionally left blank.)

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 23

15

4. PUL S E M O VEM ENT

So far, all the movements you have made, whether gross movement that can be easily seen by

eye or precise micro moves which can only be observed with the aid of a microscope, have

been in Continuous movement mode. The MP-285 controller is also capable of commanding

the micromanipulator to move in pulses, where both the length and speed of the individual

pulse is controlled. You might wish to use pulse movement mode in order to move a pipette

towards a target in quantized steps. Pulse mode has also been used as a means of final

approach to a cell membrane during “giga-seal” formation. Intracellular electrophysiologists

may find that a pulse approach at maximal speed (about 2.9mm/sec) may provide sufficient

impulse to impale some types of cells.

To change from continuous to pulse movement mode when using an ROE is quite simple.

Just locate and press the <CONT/PULSE> button on the ROE. The controller is in Pulse

mode when the button is depressed. The movement screen will also indicate Pulse mode

movement by display of the word “Pulses” in the upper right corner. If no word is displayed,

the unit is in continuous mode.

Pulse movement can be most easily observed under a microscope. If you have already

configured your microscope for micromanipulation as detailed in section “Microscopic

Manipulation” then simply follow these steps:

1. From the main menu press <3> to access a Setup with medium size pulses. Note that

each Setup defines a Pulse size. The size of the pulses is given in the table below.

2. Press <MOVE> to enter the movement screen

3. Depress the < CONT/PULSE > button on the ROE so that it is in the down position

4. Make sure the controller is set for coarse resolution microsteps (0.2 mm, ROE

<COARSE/FINE> button up)

5. Now turn the ROE knob while observing pipette movement under the microscope.

You should see movement in pulses of 10mm. The ROE produces eight pulses per turn when

in pulse mode. Thus, each full turn will produce a total movement of 80mm in eight 10mm

pulses. The speed of the movement is 1mm/second.

While only four factory installed Setups were described above, there are actually six: five and

six are identical to four with respect to the number of microsteps per ROE turn in

continuous mode movement (described above). They do differ in the size of pulses used in

Pulse movement mode. The following table lists the sizes of pulses for the six factoryinstalled setups in microsteps and micrometers as calculated for the two different microstep

resolutions:

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 24

16

Table 4-1. Microsteps and microns per Pulse settings.

Setup

Number

1

2

3

4

5

6

Microsteps

per Pulse

20 4 0.8

10 2 0.4

5 1 0.2

2 0.4 0.08

1 0.2 0.04

25 5 1

Microns per Pulse at

0.2µm 0.04µm

The speed of pulse movement is 5000 microsteps/second for all Setups. As there are two

different resolutions, this translates to the same two different speeds for each setup: 1

mm/second at coarse resolution and 200 mm/second at fine resolution.

You may find that no SETUP delivers the size and or speed pulses that you desire. The

reference manual gives complete instructions for defining pulse size and speed and saving

defined values to a new setup.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 25

17

5. HOME FU N CTI O N

“Go home” is the simplest of the programmable robotic functions available on the MP-285.

Using the home function, you can establish a point in space to which you can command the

micromanipulator to return. You may have used the home function to quickly move the

manipulator to the center of travel during the “Initial Setup” procedure. At the factory, the

center of travel for all three axes is established as both the absolute zero and the location of

“Home” but any location can be designated as “Home”. Once a new location is defined as

“Home”, the MP-285 controller will automatically move back to that location by a simple

press of the <HOME> button on the ROE.

5.1 How to Define a New Home

1. Press <MOVE> to access the movement screen

2. Move the manipulator to the desired home location

3. Press <*>. The Robotics Menu will appear:

H o m e ▓ N e w H o m e E x e c u t e L e a r n

S h o w h o m e S e l e c t P r o g r a m

4. Press <TAB> to move the cursor (indicated by the arrow) to “New Home”. Press

<ENTR>, the New Home menu will appear:

▓ A c c e p t n e w h o m e s p d = 2 0 0 0 u m / s

( T A B t o e d i t ) r e s = . 2 0 u m / S t e p

5. Press <ENTR> to accept the default speed and resolution. You will be back in the

movement screen.

5.2 Moving to the New Home:

The location you just selected is now the new home.

1. Use the ROE knobs to move away from the new home

2. Press the <HOME> button on the ROE

3. The controller will move back to the new home.

5.3 Practical Use of the Home Function

Many users find the ability to move to a specified location useful for bringing a pipette back

into the general area of the microscope’s field of view after installing a new pipette. Note that

the accuracy of repositioning is very dependent on exactness of pipette length and

installation into a holder. If you use the home function to reposition after pipette exchange,

you may want to follow these guidelines:

Define your home position as a location above the plane of focus of your preparation.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 26

18

Mark your pipette puller in such a way as to make pipettes of approximately the same

length.

Try to fabricate concentric pipettes.

Try to install your pipettes in the holder such that they always extend the same amount.

If you use a rotating device to position the manipulator, try to install it such that rotation

is up against a hard stop when the manipulator is in the operating location.

Note that you accepted the factory set speed and resolution for the move back to home. If you

wish, you can define both; for example, you can make the move to home even faster. Details

on how to specify speed and resolution are given in the MP-285 Reference Manual.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 27

19

6. GEN E RAL I ZED ROB OTIC MOV EMEN TS

In addition to a simple movement like “Go Home”, the MP-285 is also capable of learning and

remembering a complex series of Robotic movements. A series of recorded movements can be

executed once or many times in a loop. The series of moves can also be executed in the

reverse order in which they were recorded.

The following section teaches you how to record and execute a series of robotic movements by

demonstration. You will find it easy to use robotic movements to remove your pipette from

the field of view to a location where you can easily switch in a new pipette. Such a function

provides a complement to “Go Home”, used in the proceeding section, to robotically move a

pipette from a distant location to the field of view.

It is assumed that you have installed your micromanipulator at your microscope and are

capable of bringing your pipette into focus in your field of view. If you have not yet done so,

you may wish to proceed through the previous sections of this manual.

6.1 Setting Absolute Zero

With your pipette centered at a location in the middle of the field of view of your microscope,

you may find it advantageous to define this location as the absolute zero (0,0,0) for the MP285 controller. Once this is done, it is straightforward to know where you are when you are

looking at the coordinate display on the controller. It is probably a good idea to define the

zero as a location slightly above the surface of your preparation and/or specimen dish. This

way you will be less likely to smash pipettes into your work. To set the absolute zero, do the

following (from the movement screen):

1. <ESC> to main menu and press <PRGM>

2. <TAB> 2X to “SETUP” and press <ENTR>

3. <ENTR> to access “AXES” menu

4. <ENTR> to access “New Origin”

5. <ENTR> 2X more to complete the reset

6. <ESC> 3X back to main menu and press <MOVE>

You should be back in the movement screen and the coordinates on the display should read

0.00mm.

6.2 Redefining Home

If you also wish to set this location as your home location, you must redefine it as such:

1. Press <*> then <TAB> to “New Home”

2. Press <ENTR> to access “New Home”

3. Press <ENTR> to accept the default speed and resolution.

4. You will be back in the movement screen.

6.3 Clearing Program Location #1 for Recording a New Robotic Series

Robotic movements are initially stored in program location #1. If there is another series

already stored in this location that you wish to retain you must move it to another location

first. When shipped, program location #1 is occupied by a test routine. While you probably

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 28

20

have no reason to save this routine, you may wish to save it to another location simply to

learn the procedure for later reference. To move program #1 to a new location and free up

location #1, follow these steps (from the movement screen):

1. Press <*> to enter the Robotics menu

2. <TAB> 5X to “Select program” and press <ENTR>

3. Press <ENTR> to accept “Save/Clear”

4. <TAB> to a free location (for e.g. #7) and press <ENTR>

5. <ESC> back to the movement screen

Note that the original copy of program #1 is still in location 1 and will be overwritten when

new robotic moves are entered.

6.4 Teaching the MP-285 Controller a New Robotic Series

You are ready to teach the controller a series of movements to robotically move the

manipulator to a location where pipette exchange is possible:

1. Press <ESC> to reach the main menu and press <1> to put the manipulator in Setup

#1 for coarse movement, press <MOVE> to return to the movement screen

2. Press <*> to enter the Robotics menu. <TAB> 3X to “Learn” and press <ENTR> to

gain access to Learn functions. You will be issued the following warning:

W A R N I N G : P r o g r a m 1 c o n t a i n s v e c t o r s .

P r e s s E S C t o q u i t o r a n o t h e r t o c o n t i n u e .

3. If you have already saved Program 1, or if you do not need to, then press any key other

than <ESC> to continue to the following screen:

P r o g r a m 1 : A d d v e c t o r s a f t e r 6 - o r - .

S t a r t n e w p r o g r a m 1 w i t h v e c t o r n o . 1

4. <TAB> to “Start new …” and press <ENTR> to access the main Learn mode menu:

▓ A d d v e c t o r a f t e r 0 E n d p r o g r a m

I n s e r t p a u s e G o h o m e D e l e t e

5. Press <ENTR> to add the first vector (actually the end point of the first move). You will

enter a screen that <**>asks for the desired speed for the move.

▓ A c c e p t n e w h o m e s p d = 2 0 0 0 u m / s

( T A B t o e d i t ) r e s = . 2 0 u m / S t e p

6. <TAB> to “spd”, press <ENTR>, and press <6550> to put in a speed of 6550mm/sec.

This will make the manipulator move as fast as possible during robotic movement.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 29

21

Now you should see a screen similar to the movement screen but with one exception, the

<L> in the lower right corner indicates that you are in “Learn mode”. You cannot leave this

mode properly without formally ending your learned series of movements.

1. Now, move your manipulator to a location where you can most easily exchange your

pipette. This will most likely, but not necessarily, involve moving the Z-axis to its maximal

upward extension and the X-axis to its maximal rightward extension (for a right-side

mount manipulator). You may also want to move the y-axis.

2. Press <*>, then press <ENTR> to add new vector

3. Press <*>, then <TAB> 1X to “End program” and press <ENTR>

You may have a dish that requires a circuitous route for entry and exit. If this is true, you can

easily define a multiple step route out of the dish by multiple cycles of steps one and two

above to make a move and then record it by entering the new vector and then finally using

step three to end the program.

To store your newly entered routine in a location other than program location #1, follow the

steps detailed in the section “Clear Program Location #1 for recording a new Robotic

Series”.

6.5 Executing the Newly Entered Program!

Presumably, you have just entered the Robotic Series described above. It can now be used to

move your pipette effortlessly from your working location to a position where you can

exchange for a new pipette. Note that if you have not just entered the new series in program

location #1, you must first load the program location that contains the series. To do this,

follow the instructions below under “Loading a Saved Program”.

In order to observe the robotic movement, you must first bring the pipette back into the

working location by the following command from the move screen:

Press the <HOME> button on the ROE

The controller screen will display the words “Going home” and the manipulator will

methodically move the pipette back to your field of view. If you did not change the pipette

while you recorded the robotic series, then the pipette tip should come back exactly to the

location you defined as “Home” earlier.

To use the Robotic series to move the pipette out for exchange follow these steps:

1. From the move screen, press <*> to enter the Robotics menu

2. <TAB> 2X to “Execute” and press <ENTR> to access the Execute menu:

▓ D o o n c e L o o p Reverse

A b s / R e l N o w : A b s o l u t e , P r o g r a m 1

3. Press <ENTR> again to accept “Do once”

The screen will display the words “Executing. To stop: press key & hold until end of move”.

As the robotic moves were entered at the fastest possible speed (6550mm/sec) setting the

move should appear significantly faster than the move to home above. If you wish, you can

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 30

22

change your move to home to the speed of 6550mm/sec from the default value of 2000mm/sec

(home speed can be changed whenever you enter a new home).

If you programmed a multiple step withdrawal pattern to move your pipette out through a

circuitous route, you may want to use a similar pattern to move your pipette into the

working area. This can be accomplished simply by executing the above robotic movement in

reverse:

1. From the move screen, press <*> to enter the Robotics menu

2. <TAB> 2X to “Execute” and press <ENTR>

3. <TAB> 2X to “Reverse” and press <ENTR> to accept.

The manipulator will position the pipette in the center of your field of view in the reverse

order of the steps you used to move it out when you taught the controller this routine above.

6.6 Loading a Saved Program

If the program you wish to run has been saved but is not currently loaded, perform the

following steps:

1. Press <*> to enter the Robotics menu

2. <TAB> 5X to “Select program” and press <ENTR>

3. <TAB> to “Load” and press <ENTR> to accept

4. <TAB> to a desired program and press <ENTR>

5. <ESC> back to the movement screen

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 31

23

7. DIAG ONA L OR 4TH AXI S MO VEM E NTS

By simultaneous movement of two axes, the MP-285 is able to produce movement in a

synthetic fourth axis or diagonal. This feature allows for axial micropipette movement along

an axis at an angle with respect to the coordinate system defined by the three axes (x, y, and

z) of the manipulator.

To make diagonal movements while in the movement screen:

1. Press the remote NORM/DIAG button on the encoder (down and lit = diagonal mode).

2. The movement screen should now indicate that the controller is in diagonal mode as

evidenced by the word “Diagonal” in the lower middle of the screen.

3. Diagonal movement is accomplished by turning the Z-axis knob on the ROE.

The controller is factory programmed to produce fourth axis movement in the X-Z plane at a

45-degree angle. Establishment of fourth axis movement at other angles or in other planes is

covered in detail in the

MP-285 Reference Manual

.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 32

24

(This page intentionally left blank.)

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 33

25

8. ROE RES P ONS E CH A RA C TERI STIC S

The response characteristics of the ROE are fully adjustable. For purposes of simplicity, this

manual indicates limited adjustment to the values preprogrammed in factory installed

Setups. It is possible to further tailor ROE response to your usage. The following list outlines

the part of the controller menu and the corresponding part of the MP-285 Reference Manual

which deals with each adjustment.

8.1 Controlling ROE Knob to Manipulator Stepper Motor Axis Assignment

The MP-285 software allows full control over which ROE knob is connected to each of the

three physical axes of the manipulator. Furthermore, one can control the direction of

movement commanded by a given input. Axes assignment is covered in the manual under

Controller Configuration and is adjusted using the menu command [PRGM\Setup\Axes].

8.2 Controlling Movement Amount per ROE Turn

How much and how fast the MP-285 manipulator moves in response to a single turn of the

ROE knob is controlled by a single parameter for continuous movement and two parameters

for pulse movement. These parameters are described in detail in the MP-285 Reference

Manual under Controller Configuration and are adjusted using the menu command

[PRGM\Continuous] for continuous movement and the command [PRGM\Pulse Mode] for

pulse movement. A subset of these parameters can also be adjusted during movement using

the menu command [MOVE\1,2,4 or 5] as described in the Movement Screen section of the

MP-285 Reference Manual

.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 34

26

(This page intentionally left blank.)

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 35

27

APP E NDI X A. LIM I TED WAR R ANT Y

Sutter Instrument Company, a division of Sutter Instrument Corporation, limits the

warranty on this instrument to repair and replacement of defective components for two

years from date of shipment, provided the instrument has been operated in accordance

with the instructions outlined in this manual.

Abuse, misuse, or unauthorized repairs will void this warranty.

Warranty work will be performed only at the factory.

The cost of shipment both ways is paid for by Sutter Instrument during the first three

months this warranty is in effect, after which the cost is the responsibility of the

customer.

The limited warranty is as stated above and no implied or inferred liability for direct or

consequential damages is intended.

Consumables are exempt from this warranty.

An extended warranty for up to three additional years can be purchased at the time of

ordering, or until the original warranty expires. For pricing and other information, please

contact Sutter Instrument.

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 36

28

(This page intentionally blank.)

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 37

29

IND E X

D

diagonal or 4th axis movements...........................23

disclaimer ............................................................... iii

F

fuses, replacement

mains................................................................... iii

G

general information.................................................1

generalized robotic movements............................19

glassware

precautions...........................................................v

H

home function ........................................................17

M

mains

fuses .................................................................... iii

microscopic manipulation.....................................11

movement

amount per ROE turn.......................................25

control of.............................................................25

N

notes

user............................................................... 29, 30

P

precautions............................................................. iii

electrical.............................................................. iii

pulse movement.....................................................15

R

ROE response characteristics...............................25

S

safety warnings...................................................... iii

electrical.............................................................. iii

mains fuse........................................................... iii

safety warnings & precautions

operational...........................................................iv

safety warnings & precautions........................ iii, iv

setup..........................................................................3

T

technical support .....................................................1

W

warranty.................................................................27

NOTES

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Page 38

30

NOTES

MP-285 SYSTEM ROE BASIC OPERATIONS – REV. 3.08 (20140809)

Loading...

Loading...