Page 1

P

P----30

PP

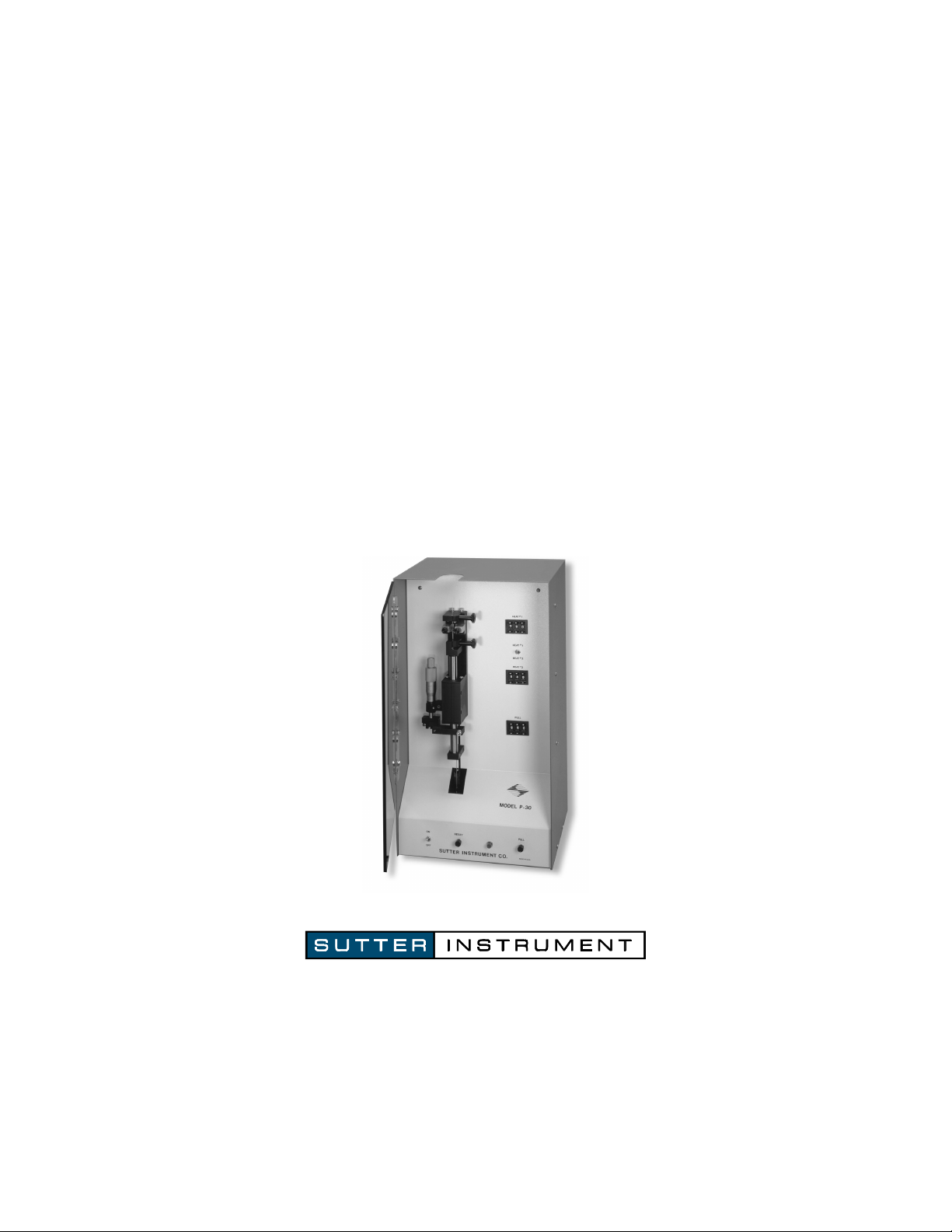

Micropipette Puller

Micropipette Puller

Micropipette PullerMicropipette Puller

Operation Manual

Rev. 3.10 ( 20100120)

30

3030

Sutter Instrument Company

One Digital Drive

Novato, CA 94949

Voice: 415-883-0128 Web: www.sutter.com

Fax: 415-883-0572 Email: info@sutter.com

Page 2

II

Copyright © 2007-2010 Sutter Instrument Company. All Rights Reserved.

No part of this manual may be reproduced, stored in a retrieval system, or transmitted, in

any form or by any means, electronic, mechanical, photocopying, microfilming, recording, or

otherwise, without written permission from Sutter Instrument Company.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 3

III

Mains Voltage

Mains Voltage Mains Voltage

Mains Voltage

DIS C LAIM ER

DIS C LAIM ER

DIS C LAIM ERDIS C LAIM ER

The pipette puller Model P-30 is designed for the specific use of creating micropipettes and

no other use is recommended.

This instrument creates items that should only be used in a laboratory environment for use

on animal tissues. It is not intended for use, nor should be used, in human experimentation,

or applied to humans in any way. This is not a medical device.

Do not open or attempt to repair the instrument without expressed and explicit instructions

from Sutter Instrument Company. Extreme heat and high voltages are present and could

cause injury.

Do not allow unauthorized and or untrained operatives to use this device.

Any misuse will be the sole responsibility of the user/owner and Sutter Instruments assumes

no implied or inferred liability for direct or consequential damages from this instrument if it

is operated or used in any way other than for which it is designed.

SAF E TY W ARNI N G

SAF E TY W ARNI N G

SAF E TY W ARNI N GSAF E TY W ARNI N G

Replace fuse only with the same type and rating as indicated in the following table.

Replace fuse only with the same type and rating as indicated in the following table.

Replace fuse only with the same type and rating as indicated in the following table. Replace fuse only with the same type and rating as indicated in the following table.

Fuse

Fuse

FuseFuse

(Type: T

Setting

Setting

SettingSetting

Rating

Rating Manufacturer Examples

RatingRating

“110”

(100 – 120

VAC)

“220”

(200 – 240

VAC)

A spare fuse is provided, which is located in the power input module. Please refer to the

A spare fuse is provided, which is located in the power input module. Please refer to the

A spare fuse is provided, which is located in the power input module. Please refer to the A spare fuse is provided, which is located in the power input module. Please refer to the

Fuse Replacement appendix located in the end portion of this manual.

Fuse Replacement appendix located in the end portion of this manual.

Fuse Replacement appendix located in the end portion of this manual.Fuse Replacement appendix located in the end portion of this manual.

To prevent fire or sho

To prevent fire or shock hazard do not expose the unit to rain or moisture.

To prevent fire or shoTo prevent fire or sho

To avoid electrical shock:

To avoid electrical shock:

To avoid electrical shock:To avoid electrical shock:

•

Do not disassemble the unit. Refer servicing to qualified personnel.

Do not disassemble the unit. Refer servicing to qualified personnel.

Do not disassemble the unit. Refer servicing to qualified personnel.Do not disassemble the unit. Refer servicing to qualified personnel.

•

Always use the grounded power supply cord set provided to connect the unit to a

Always use the grounded power supply cord set provided to connect the unit to a

Always use the grounded power supply cord set provided to connect the unit to a Always use the grounded power supply cord set provided to connect the unit to a

grounded outlet (3

grounded outlet (3----prong)

grounded outlet (3grounded outlet (3

that an electrical hazard develops.

that an electrical hazard develops.

that an electrical hazard develops.that an electrical hazard develops.

2A, 250V

(Time Delay)

T1.25A,

250V

ck hazard do not expose the unit to rain or moisture.

ck hazard do not expose the unit to rain or moisture.ck hazard do not expose the unit to rain or moisture.

prong). This is required to protect you from injury in the event

prong)prong)

(Type: Time Delay, 5mm x 20mm, glass tube)

(Type: T(Type: T

. This is required to protect you from injury in the event

. This is required to protect you from injury in the event . This is required to protect you from injury in the event

ime Delay, 5mm x 20mm, glass tube)

ime Delay, 5mm x 20mm, glass tube)ime Delay, 5mm x 20mm, glass tube)

Manufacturer Examples

Manufacturer ExamplesManufacturer Examples

Bussmann: GMC-2A, GMC-2-R (RoHS), GDC-2A, or

S506-2A (RoHS)

Littelfuse: 239 002 or 239.002.P (RoHS)

Bussmann: GDC-1.25A or S506-1.25R (RoHS)

Littelfuse: 218 1.25 or 218 1.25P (RoHS)

To avoid burns do not touch the heating filament, the brass clamps holding the filament

To avoid burns do not touch the heating filament, the brass clamps holding the filament

To avoid burns do not touch the heating filament, the brass clamps holding the filament To avoid burns do not touch the heating filament, the brass clamps holding the filament

or the heated ends of glass pipettes that have been pulled.

or the heated ends of glass pipettes that have been pulled.

or the heated ends of glass pipettes that have been pulled.or the heated ends of glass pipettes that have been pulled.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 4

IV

PRE C AUTI O N

PRE C AUTI O NSSSS

PRE C AUTI O NPRECA U TIO N

On Operation

On Operation

On OperationOn Operation

Failure to comply with any of the following precautions may damage this device.

Failure to comply with any of the following precautions may damage this device.

Failure to comply with any of the following precautions may damage this device. Failure to comply with any of the following precautions may damage this device.

Failure to comply with any of the following precautions may damage this device.

Failure to comply with any of the following precautions may damage this device.

Failure to comply with any of the following precautions may damage this device. Failure to comply with any of the following precautions may damage this device.

Operate the P

Operate the P----30 using 110V a.c. and 60Hz, or 220V

Operate the POperate the P

The P

The P----30 is designed for operation in a laboratory environment (pollution degree I).

The PThe P

The P

The P----30 is designed for connection to a standard laboratory power outlet (overvoltage category

The PThe P

II).

II).

II).II).

This unit was not designed for operation

This unit was not designed for operation at altitudes above 2000 meters nor was it tested for

This unit was not designed for operationThis unit was not designed for operation

safety above 2000 meters.

safety above 2000 meters.

safety above 2000 meters.safety above 2000 meters.

Only use Sutter Instrument Company replacement heating filaments.

Only use Sutter Instrument Company replacement heating filaments.

Only use Sutter Instrument Company replacement heating filaments.Only use Sutter Instrument Company replacement heating filaments.

On Handling Micropipettes

On Handling Micropipettes

On Handling MicropipettesOn Handling Micropipettes

Failure to comply with any of the following precautions

Failure to comply with any of the following precautions may result in injury to the users of

Failure to comply with any of the following precautionsFailure to comply with any of the following precautions

this device as well as those working in the general area near the device.

this device as well as those working in the general area near the device.

this device as well as those working in the general area near the device.this device as well as those working in the general area near the device.

30 is designed for operation in a laboratory environment (pollution degree I).

30 is designed for operation in a laboratory environment (pollution degree I).30 is designed for operation in a laboratory environment (pollution degree I).

30 is designed for connection to a standard laboratory power outlet (overvoltage category

30 is designed for connection to a standard laboratory power outlet (overvoltage category 30 is designed for connection to a standard laboratory power outlet (overvoltage category

30 using 110V a.c. and 60Hz, or 220V a.c. and 50Hz line voltage.

30 using 110V a.c. and 60Hz, or 220V30 using 110V a.c. and 60Hz, or 220V

at altitudes above 2000 meters nor was it tested for

at altitudes above 2000 meters nor was it tested for at altitudes above 2000 meters nor was it tested for

a.c. and 50Hz line voltage.

a.c. and 50Hz line voltage. a.c. and 50Hz line voltage.

may result in injury to the users of

may result in injury to the users of may result in injury to the users of

The micropipettes created using this instrument are very sharp and relatively fragile. Contact

The micropipettes created using this instrument are very sharp and relatively fragile. Contact

The micropipettes created using this instrument are very sharp and relatively fragile. Contact The micropipettes created using this instrument are very sharp and relatively fragile. Contact

with the pulled micropipette tips, therefore, sh

with the pulled micropipette tips, therefore, should be avoided to prevent accidentally impaling

with the pulled micropipette tips, therefore, shwith the pulled micropipette tips, therefore, sh

yourself.

yourself.

yourself. yourself.

Always dispose of micropipettes by placing them into a well

Always dispose of micropipettes by placing them into a well----marked, spill

Always dispose of micropipettes by placing them into a wellAlways dispose of micropipettes by placing them into a well

container.

container.

container.container.

Use only with glassware recommended by Sutter Instrument Company in the following section of

Use only with glassware recommended by Sutter Instrument Company in the following section of

Use only with glassware recommended by Sutter Instrument Company in the following section of Use only with glassware recommended by Sutter Instrument Company in the following section of

th

this manual.

is manual.

thth

is manual.is manual.

ould be avoided to prevent accidentally impaling

ould be avoided to prevent accidentally impaling ould be avoided to prevent accidentally impaling

marked, spill----proof “sharps”

marked, spillmarked, spill

proof “sharps”

proof “sharps” proof “sharps”

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 5

V

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

DISCLAIMER

DISCLAIMER ................................

DISCLAIMERDISCLAIMER

SAFETY WARNING

SAFETY WARNING ................................

SAFETY WARNINGSAFETY WARNING

PRECAUTION

PRECAUTIONSSSS ................................

PRECAUTIONPRECAUTION

On Operation..........................................................................................................................................iv

On Handling Micropipettes ..................................................................................................................iv

1.

1. Introduction

Introduction................................

1.1.

Introduction Introduction

1.1 Technical Support.............................................................................................................................1

1.2 Glass Capillary & Heating Filament Specifications......................................................................1

2.

2. Product Description

Product Description ................................

2.2.

Product Description Product Description

2.1 Packing List.......................................................................................................................................3

2.2 Front Panel........................................................................................................................................3

2.2.1 Lower Panel Display and Controls...........................................................................................3

2.2.2 Upper Panel Display and Controls...........................................................................................3

2.3 Mechanical Description (Puller Anatomy).....................................................................................4

2.3.1 Slide Assembly............................................................................................................................4

2.3.2 Pull Solenoid...............................................................................................................................5

2.3.3 Patch Block (Figure 4-1)............................................................................................................5

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...........................................................

................................................................

................................................................

................................................................

................................................................

................................................................

..........................................................

................................................................

......................................

................................................................

...........................iii

......................................................

..................................

................................................................

.......................................

................................................................

..........................3333

....................................................

......iii

iii

............

iiiiii

iii

iiiiii

..iv

iv

....

iviv

.......1111

..............

3.

3. Installation

Installation ................................

3.3.

Installation Installation

3.1 Line Power (Mains) ..........................................................................................................................7

4.

4. Operating Instructions

Operating Instructions ................................

4.4.

Operating Instructions Operating Instructions

4.1 First Time Use ..................................................................................................................................9

4.2 General Operation ............................................................................................................................9

4.3 Pulling a Micropipette......................................................................................................................9

4.4 Multicycle Pulling: Pulling a Patch-Type Micropipette .............................................................10

4.4.1 Heat Settings............................................................................................................................10

4.4.2 Pull Setting ...............................................................................................................................10

4.4.3 Trip Point Micrometer ............................................................................................................10

4.4.4 Patch Block (spacer) ................................................................................................................11

4.5 Patch Pipette Pull Sequence..........................................................................................................11

4.5.1 First cycle..................................................................................................................................11

4.5.2 Second cycle ..............................................................................................................................11

4.6 Controls Adjustment ......................................................................................................................12

5.

5. Maintenance

Maintenance................................

5.5.

Maintenance Maintenance

5.1 Filament Replacement ...................................................................................................................15

5.2 Lubrication ......................................................................................................................................15

5.3 Rubber Pads on Clamps.................................................................................................................16

5.4 Troubleshooting..............................................................................................................................16

APPENDIX A.

APPENDIX A. Limited Warranty

APPENDIX A.APPENDIX A.

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

Limited Warranty................................

Limited Warranty Limited Warranty

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.....................................................

................................................................

................................................................

................................................................

................................................................

................................................................

........................................

................................................................

.....................9999

..........................................

....................................

................................................................

......................................

................................................................

........7777

................

......19

............

....15

15

........

1515

19

1919

APPENDIX B.

APPENDIX B. Accessories

APPENDIX B.APPENDIX B.

Nichrome filament block assembly (P-30-NFL/M) ...........................................................................21

Accessories ................................

Accessories Accessories

................................................................

................................................................

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

................................................................

................................................................

.................................................

................................................................

.................21

..................................

21

2121

Page 6

VI

Platinum/iridium filament block assembly (P-30-PFL/M)...............................................................21

Pipette storage box 4 3/4 x 3 5/8 x 3/4 inches (BX10)........................................................................21

Pipette storage box - long 7 x 3 5/8 x 3/4 inches (BX20) ...................................................................21

BV-10 Microelectrode Beveler (BV-10)...............................................................................................21

Glass Capillary Tubing.........................................................................................................................21

Puller Filaments....................................................................................................................................21

APPENDIX C.

APPENDIX C. Fuse Replacement

APPENDIX C.APPENDIX C.

APPENDIX D.

APPENDIX D. Technical Specifications

APPENDIX D.APPENDIX D.

INDEX

INDEX................................

INDEXINDEX

TABLE OF FIGURES

TABLE OF FIGURES

TABLE OF FIGURESTABLE OF FIGURES

Figure 2-1. P-30 Mechanical Assembly....................................................................................................6

Figure 3-1. P-30 Cabinet (rear view)........................................................................................................7

Figure 4-1. Patch Block Placement. .......................................................................................................12

Figure 5-1. Top view of platinum filament glass...................................................................................15

Figure C-1. Fuse holder............................................................................................................................23

................................................................

................................................................

Fuse Replacement ................................

Fuse Replacement Fuse Replacement

Technical Specifications................................

Technical Specifications Technical Specifications

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.....................................

................................................................

............................................................

................................................................

.................................................

................................................................

............................25

........................................................

.................27

..................................

.....23

..........

23

2323

25

2525

27

2727

TABLE OF TABLES

TABLE OF TABLES

TABLE OF TABLESTABLE OF TABLES

Table C-1. Mains fuse type and ratings..................................................................................................23

Table D-1. Mains fuse type and ratings. ................................................................................................25

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 7

1

1.

1. IN TROD U CTI O N

INT R ODUC TION

1.1.

INT R ODUC TIONIN TROD UCTI O N

The P-30 Micropipette Puller is a derivative of a vertical puller design initially developed at

the National Institutes of Health in the late 1950’s. The P-30 is designed to be a basic,

economical and simple to operate puller for those investigations where tip diameters down to

0.3 micron and moderate taper lengths are satisfactory. Despite its low cost, the P-30 has

been designed with a number of quality and convenience features. The power supplies for

the filament and pull solenoid are constant current and are thermally protected. Dual heat

settings are provided for multi-step pipette fabrications such as are used in patch clamp

investigations. The front cover completely encloses the pulling mechanism to prevent erratic

results caused by drafts; and the front panel is sloped to prevent broken capillaries from

entering the solenoid area. In addition, CMOS logic is used throughout for its high noise

immunity and low power consumption.

This manual, though brief, describes all that you need to know to operate the P-30. The

following pages provide descriptions of the mechanical assembly, controls and displays along

with basic information on using the puller. The P-30 provides a consistent, reproducible

environment for the manufacture of micropipettes. Its successful use will depend on

providing the minimal maintenance detailed on the following pages, information on desirable

pulling conditions obtained from colleagues and the literature; and finally, from your own

experience and experimentation.

Throughout this manual reference will be made to the size of the glass tubing used to pull

micropipettes. The convention used here for describing the outside diameter (O.D.) and

inside diameter (I.D.) is as follows: O.D. x I.D. These dimensions will always be given in

millimeters (mm).

1.1

1.1 Technical Support

Technical Support

1.11.1

Technical SupportTechnical Support

Unlimited technical support is provided by Sutter Instrument Company at no charge to our

customers. Our technical support staff is available between the hours of 8:00 AM and 5:00

PM (Pacific Standard Time) at (415) 883

info@sutter.com

info@sutter.com.

info@sutter.cominfo@sutter.com

1.2

1.2 Glass Capillary & Heating Filament Specifications

Glass Capillary & Heating Filament Specifications

1.21.2

Glass Capillary & Heating Filament SpecificationsGlass Capillary & Heating Filament Specifications

The P-30 micropipette puller is designed for use with borosilicate, aluminosilicate or other

lower melting-point glass tubing or rod ranging from 1.0mm to 2.0mm in diameter. This

instrument does not pull fused silica or quartz glassware. The full selection of glassware

available from Sutter Instrument Co. is listed in the catalogue included with this instrument

or can be found on the Sutter Instrument Company’s World Wide Web site www.sutter.com

This instrument is designed to accommodate either a Nichrome wire filament or the Sutter

Trough-type platinum filaments that are shown in the Sutter Catalogue. The selection of

replacement filaments for the P-30 can also be viewed on Sutter Instrument Company’s

World Wide Web site at wwwwww.sutter.com

REPLACEMENT HEATING FILAMENTS IN THIS INSTRUMENT! Instructions for

replacing the Heating Filament can be found in the Maintenance section of this manual.

(415) 883----0128

(415) 883(415) 883

ww.sutter.com. ONLY USE SUTTER-SUPPLIED

ww.sutter.comww.sutter.com

0128. You may also E-mail your queries to

01280128

www.sutter.com.

www.sutter.comwww.sutter.com

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 8

2

(This page intentionally left blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 9

3

2.

2. PR ODU C T DE S CRI P TION

PROD UCT D ESC RIPTI ON

2.2.

PROD UCT D ESC RIPTI ONPRODU CT D ESCR I PTIO N

2.1

2.1 Packing List

Packing List

2.12.1

Packing ListPacking List

Make certain that you have received all of the following items in the P-30 shipping box:

PPPP----30 micropipette puller

30 micropipette puller

30 micropipette puller30 micropipette puller

Power cord

Power cord

Power cordPower cord

Box of sample glass

Box of sample glass

Box of sample glassBox of sample glass

3 Spare heating filaments

3 Spare heating filaments

3 Spare heating filaments3 Spare heating filaments

Patch Block attachment

Patch Block attachment

Patch Block attachmentPatch Block attachment

Warranty

Warranty registration

Warranty Warranty

Catalog

Catalog

CatalogCatalog

The Model P-30 is shipped to you in a prefabricated foam mold. Please take note of this

method of packaging. Should it ever be necessary to ship the puller to another location, the

same method of packaging should be employed. Additional packing material may be

purchased from Sutter Instrument Company.

registration

registrationregistration

IMPORTANT: Improper packaging is a form of abuse and, as such, can be responsible for

IMPORTANT: Improper packaging is a form of abuse and, as such, can be responsible for

IMPORTANT: Improper packaging is a form of abuse and, as such, can be responsible for IMPORTANT: Improper packaging is a form of abuse and, as such, can be responsible for

voiding the warranty where shipping damage is sustained because of such packing.

voiding the warranty where shipping damage is sustained because of such packing.

voiding the warranty where shipping damage is sustained because of such packing.voiding the warranty where shipping damage is sustained because of such packing.

2.2

2.2 Front Panel

Front Panel

2.22.2

Front PanelFront Panel

The front panel controls are used to apply power to the instrument, set heat and pull

strength values and to start and stop pulling sequences. Controls on the lower portion of the

front panel will be described first.

2.2.1

2.2.1 Lower Panel Display and

Lower Panel Display and Controls

2.2.12.2.1

Lower Panel Display and Lower Panel Display and

On/Off Switch

On/Off Switch On applies power to the instrument. Red lamp is illuminated when

On/Off SwitchOn/Off Switch

power is on.

Reset Switch

Reset Switch

Reset SwitchReset Switch

Pull Switch

Pull Switch

Pull SwitchPull Switch

2.2.2

2.2.2 Upper Panel Display and Controls.

Upper Panel Display and Controls.

2.2.22.2.2

Upper Panel Display and Controls.Upper Panel Display and Controls.

Used to reset circuitry to an initialized condition. It is typical use is

to turn off the heat during multi-step fabrications (patch type

pipettes).

Initiates the pulling process.

Controls

ControlsControls

Heat 1/Heat 2 switch

Heat 1/Heat 2 switch This switch determines which of the two heat values is active.

Heat 1/Heat 2 switchHeat 1/Heat 2 switch

HEAT 1 control

HEAT 1 control HEAT 1 is a three-digit pushbutton control used to set the level of

HEAT 1 controlHEAT 1 control

electrical current supplied to the filament. The HEAT required to

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 10

4

melt a piece of glass is a function of the filament installed and the

particular glass size and composition. Maximum current available is

22.5 amperes

HEAT 2 control

HEAT 2 control Same as Heat 1.

HEAT 2 controlHEAT 2 control

PULL Strength

PULL Strength

PULL Strength PULL Strength

control

control

controlcontrol

A three-digit pushbutton control used to set the level of electrical

current supplied to the pull solenoid.

This parameter controls the

force of the hard pull. In general, the higher the PULL, the smaller

the pipette’s tip diameter and the longer the taper.

Trip Point

Trip Point

Trip Point Trip Point

Micrometer (

Micrometer (Figure

Micrometer (Micrometer (

2-1H)

H)

H)H)

A micrometer with 0.001-inch divisions that is used to adjust the

distance to which the glass draws out before a hard pull is initiated.

2.3

2.3 Mechanical Description (Puller Anatomy)

Mechanical Description (Puller Anatomy)

2.32.3

Mechanical Description (Puller Anatomy)Mechanical Description (Puller Anatomy)

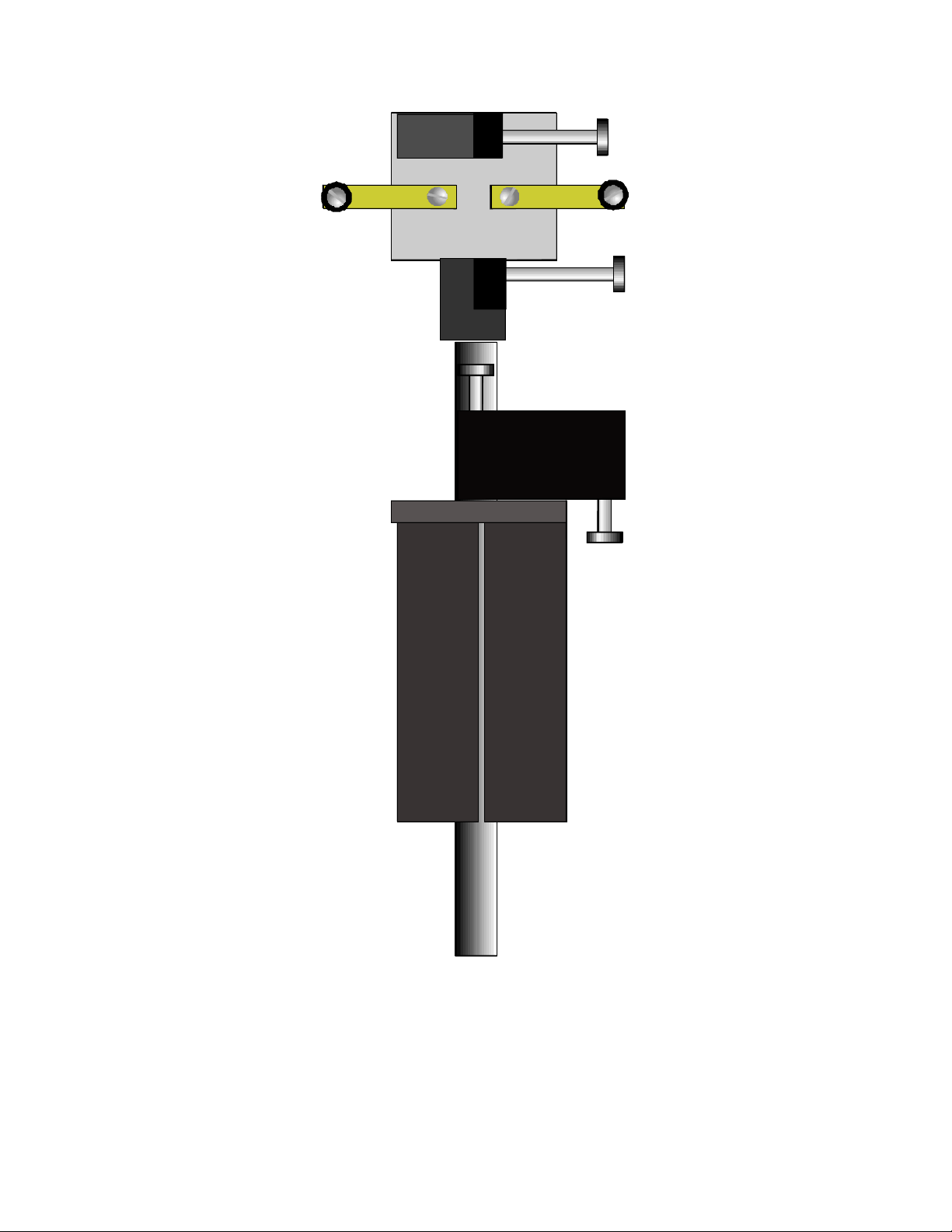

This section presents a basic mechanical description of the P-30, with particular emphasis on

terminology. Knowing the names of the various parts greatly facilitates communication

between the investigators and the manufacturer when discussing adjustments or service

problems.

2.3.1

2.3.1 Slide Assembly

Slide Assembly

2.3.12.3.1

Slide AssemblySlide Assembly

The Slide Assembly

Slide Assembly consists of all the mechanical parts that make up the glass pulling

Slide AssemblySlide Assembly

mechanism. Its elements are described below.

Upper (Stationary) Glass Clamp As

Upper (Stationary) Glass Clamp Assembly

Upper (Stationary) Glass Clamp AsUpper (Stationary) Glass Clamp As

sembly ((((Figure 2-1A):

sembly sembly

A): This assembly clamps one end of

A):A):

the capillary glass above the filament. This clamp is loosened for repositioning the glass

when doing multi-step pulling.

Filament Assembly

Filament Assembly (

Filament AssemblyFilament Assembly

(Figure 2-1B):

( (

B): Your P-30 was assembled with one of two heat filament

B):B):

configurations; platinum/iridium foil or nichrome coil. The platinum/iridium assembly

consists of two brass clamping blocks and two black nylon thumb screws which secure the

filament between spring loaded clamps. The nichrome assembly consists of a series of brass

bus bars and posts for conducting current to the filament. Brass thumb screws secure the

filament to the conducting posts.

Lower (Moving) Glass Clamp Assembly

Lower (Moving) Glass Clamp Assembly (

Lower (Moving) Glass Clamp AssemblyLower (Moving) Glass Clamp Assembly

(Figure 2-1C):

( (

C): This assembly clamps the lower end

C):C):

of the glass capillary, and is attached to the upper end of the slide bar.

Slide Bar

Slide Bar (

Slide BarSlide Bar

(Figure 2-1D):

( (

D): The slide bar is a hardened steel tube that guides the descent of the

D):D):

lower glass clamp during pipette pulling. The weight of this bar and its attachments are

resposible for the pulling force during the initial(gravity) phase of pulling.

Bushing Blocks and Guide Bushings

Bushing Blocks and Guide Bushings ((((Figure 2-1E):

Bushing Blocks and Guide Bushings Bushing Blocks and Guide Bushings

E): The bushing blocks contain the precision

E):E):

linear guide bearings that form the descent path for the slide bar.

Trip Flag Holder

Trip Flag Holder (

Trip Flag HolderTrip Flag Holder

(Figure 2-1F):

( (

F): The trip flag holder is located on the slide bar. It is held in

F):F):

place by a thumb screw, its position being dependent on the type of pipette being pulled. The

trip flag extends to the left of the slide mechanism so that it may interrupt the light path of

the optical switch, which is located on the end of the trip point micrometer. The flag

interrupts or “trips” the optical switch as it passes through the swith on its descent. The trip

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 11

5

point is adjusted by turning the trip point micrometer. Turning the micrometer clockwise

increases the length of the weak pull, indicated by a decrease in the reading on the

micrometer.

Guide Flag Holder

Guide Flag Holder (

Guide Flag HolderGuide Flag Holder

(Figure 2-1G):

( (

G): The guide flag holder is attached to the lower end of the

G):G):

slide bar. The attached flag extends back into a slot in the cabinet and serves to prevent

rotation of the slide bar and associated parts during pipette pulling. The guide flag holder is

also the point of attachement for the pull solenoid. The patch block provides two adjustable

spacers used in forming patch pipettes.

2.3.2

2.3.2 Pull Solenoid

Pull Solenoid

2.3.22.3.2

Pull SolenoidPull Solenoid

The pull solenoid (located just below the slide assembly in the angled portion of the cabinet)

is responsible for accelerating the slide bar during the second (solenoid) phase of pipette

formation. It is energized when the trip flag interrupts the optical switch as described above.

2.3.3

2.3.3 Patch Block (

Patch Block (Figure

2.3.32.3.3

Patch Block (Patch Block (

Figure 4444----1111))))

Figure Figure

The patch block is a metal block with screws on the top and bottom sides. The patch block

provides two adjustable spacers used in forming patch pipettes.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 12

6

Figure 2-1. P-30 Mechanical Assembly.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 13

7

3.

3. IN STAL LATI O N

INS T ALLA TION

3.3.

INS T ALLA TIONINSTA L LAT I ON

3.1

3.1 Line Power (Mains)

Line Power (Mains)

3.13.1

Line Power (Mains)Line Power (Mains)

The power cord provided with the P-30 connects to the power entry module located on the

back of the unit (see diagram below). This module also includes the line fuse.

Figure 3-1. P-30 Cabinet (rear view).

Confirm that the Voltage Selector Switch on the Power Entry Module is set to the proper

value (110V a.c. or 220V a.c.). If it is not, turn the selector switch until the appropriate value

is lined up with the indicator. Note that the Line fuse differs for the two different line

is lined up with the indicator. Note that the Line fuse differs for the two different line

is lined up with the indicator. Note that the Line fuse differs for the two different line is lined up with the indicator. Note that the Line fuse differs for the two different line

vvvvoltages (see the Technical Specifications). If you have to change the voltage selector you

oltages (see the Technical Specifications). If you have to change the voltage selector you

oltages (see the Technical Specifications). If you have to change the voltage selector you oltages (see the Technical Specifications). If you have to change the voltage selector you

may also have to replace the fuse, otherwise your protection from fire and electric shock may

may also have to replace the fuse, otherwise your protection from fire and electric shock may

may also have to replace the fuse, otherwise your protection from fire and electric shock may may also have to replace the fuse, otherwise your protection from fire and electric shock may

be compromised.

be compromised.

be compromised.be compromised.

If it is not, turn the selector switch until the appropriate value

If it is not, turn the selector switch until the appropriate value If it is not, turn the selector switch until the appropriate value

Make certain that the Power Switch located on the front panel of the P-30 cabinet is turned

OFF. Plug the power cord provided with the P-30 into the Line Input socket on the Power

Entry Module and then to a power source of the appropriate voltage and frequency.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 14

8

(This page intentionally left blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 15

9

4.

4. O P ERAT I NG I NSTR UCTI O

OPER A TIN G IN S TRU C TIO NS

4.4.

OPER A TIN G IN S TRU C TIOOPE R ATIN G IN STRU CTIO

4.1

4.1 First Time Use

First Time Use

4.14.1

First Time UseFirst Time Use

1. Load a piece of the supplied sample glass into puller as follows:

• Loosen the upper and lower clamping knobs.

• Place glass in V-groove in upper clamp; slide it downward until about 1 cm of glass

extends above the top clamp. Tighten upper clamp

• Pull lower clamp up until it no longer moves and tighten clamping knob.

2. Press the PULL button. The heating filament should turn on and the glass should

separate within 15 seconds.

4.2

4.2 General Operation

General Operation

4.24.2

General OperationGeneral Operation

The P-30 is quite simple to operate. However, common sense indicates that an instrument

that can melt glass must be used with some caution and a complete understanding of its

controls. Do not leave the puller powered on and unattended; particularly while a pullsequence is in progress. Pay extra attention when pulling pipettes after any control values

have been changed.

NS

NSN S

The following steps outline a basic pulling sequence. The pipette being pulled is hypothetical

(with respect to the settings mentioned) and is intended only as an example of the normal

pulling procedure. The pipette shapes and tip diameter obtained from a puller of this type

are dependent on the rate at which heat is added to the glass (rate of change of viscosity),

weight of the moving portion of the slide assembly, distance traveled during gravity pull

phase, and force of solenoid pull. When you have found settings that produce the desired

pipette, make note of the time it takes for the pull to take place and the distance being

traveled before the hard pull. The time for a pull is most important, particularly when

having to install a new filament. No two filaments are exactly alike with respect to their

resistance; thus, the heat setting may not be the same for two different filaments to supply

the same amount of heat. All other factors being unchanged (pull strength, glass size,

acceleration due to gravity, etc.), if the heat output of the new filament is adjusted to produce

a pull in the same amount of time as the previous filament the pipettes should be equivalent.

4.3

4.3 Pulling a Micropipette

Pulling a Micropipette

4.34.3

Pulling a MicropipettePulling a Micropipette

Turn instrument on, and make sure that the desired heat value has been selected. If one is

setting a heat value for the first time, then press PULL (no glass in puller) and increase the

HEAT control while watching the filament. If using a platinum filament, be sure the heat

value is initially set at a low value (e.g. 300 for a 1.5mm filament, 650 for a 3.0mm filament).

High heat values can destroy the platinum filaments. Because of the time constant of the

nichrome filament, allow a few moments to pass after making any changes to let the filament

stabilize at the new heat setting. When the filament glows at desired heat level, note the

selected value. Press RESET to turn off filament.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 16

10

Open upper glass clamp and insert glass capillary into jaws. Close down clamp on capillary

until glass is gripped lightly so glass can still slide. Slide capillary down through filament to

the point where the lower glass clamp can be raised up to grip lower end of capillary..

Tighten upper clamp and raise lower clamp over capillary. As glass capillaries may have a

slight curve to them, take care when inserting the capillary into the lower jaws. Tighten

lower glass clamp. The setting of the trip point is an important determinant of the size and

shape that will be obtained and will be covered below. Close front door and press PULL.

The following sequence takes place: 1) Filament turns on and glass is heated to softening

point. 2) As glass softens, lower glass clamp and slide bar descent under the influence of

gravity until the trip flag interrupts the optical switch. 3) The optical switch deactivates the

heat and activates the pull solenoid for approximately one second to complete pull.

Remove lower and upper pipettes.

4.4

4.4 Multicycle Pulling: Pulling a Patch

Multicycle Pulling: Pulling a Patch----Type Micropipette

4.44.4

Multicycle Pulling: Pulling a PatchMulticycle Pulling: Pulling a Patch

Type Micropipette

Type MicropipetteType Micropipette

Patch type pipettes are characteristically stubby with a large taper angle and relatively large

tips (> 1 micron). To construct this type of pipette, it is desirable to process the glass in

multiple heating cycles. The P-30 can be used for two-step pipette fabrication with the use of

the dual heat settings and the supplied Patch Block. The first of the two steps draws the

glass out without separating. The glass tube must then be manually repositioned so that the

drawn-out portion is again centered within the heating element. The second step then draws

the glass out until it separates to form a pipette.

4.4.1

4.4.1 Heat Settings

Heat Settings

4.4.14.4.1

Heat SettingsHeat Settings

HEAT 1 is used for the first step, and is generally set at a fairly high level (e.g. 750 for 3mm

platinum filament or 970 for nichrome filament). HEAT 2 is used for the second step, after

the glass has already been pulled once. HEAT 2 will normally be less than HEAT 1, and is

more critical than HEAT 1. The exact value for your particular application will have to be

determined on a trail and error basis.

4.4.2

4.4.2 Pull Settin

Pull Settingggg

4.4.24.4.2

Pull SettinPull Settin

Pull is normally set to zero for patch pipettes because the weight of the sliding components

provides the force that draws out the glass. If you desire, the solenoid plunger may be

disconnected from the slide assembly by loosening the set screw that attaches the cable to the

slide flag holder. This will decrease the weight by about 20%.

4.4.3

4.4.3 Trip Point

Trip Point Micrometer

4.4.34.4.3

Trip Point Trip Point

icrometer

icrometericrometer

The micrometer should be advanced so that the flag does not interrupt the optical switch

until the second step is complete. Because the solenoid is generally not used in forming

patch pipettes, the trip point system serves primarily as a means of turning off the heat.

While it is easy to reposition the trip point for each step, it is generally more convenient to

use the RESET button to turn the heat off after the first step. Thus, the optical switch will

normally be placed so that the flag passes through the switch in the second step. This will

cause the heat to turn off automatically at the end of the second step.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 17

11

4.4.4

4.4.4 Patch Block (spacer)

Patch Block (spacer)

4.4.44.4.4

Patch Block (spacer)Patch Block (spacer)

The two screws on the Patch Block are provided so that the block can act as two adjustable

spacers. The 10/32 cap head screws supplied accept a 5/32 hex key wrench; the thumbnuts

are used to lock the screws in position. The thumbnuts are different colors so you can

differentiate Spacer 1 versus Spacer 2. One spacer is needed to limit the draw of the first pull

cycle. The second spacer is needed to reposition the glass within the heating filament prior

to pulling the glass apart in the second step. The position of the two screws in the Patch

Block will need to be determined empirically.

4.5

4.5 Patch Pipette Pull Sequence

Patch Pipette Pull Sequence

4.54.5

Patch Pipette Pull SequencePatch Pipette Pull Sequence

4.5.1

4.5.1 First cycle

First cycle

4.5.14.5.1

First cycleFirst cycle

Set the HEAT switch to HEAT 1 and load capillary. Place the Patch Block so that is sits on

the top of the bearing block behind the slide bar as show in Figure 4-1. The head of the

screw will act to stop the slide mechanism by hitting the underside of the lower slide. The

length of the first pull will be determined by the space between the top of the Patch Block

screw and the bottom of the lower glass clamp assembly. Press PULL, wait until the slide

drops onto the screw and then press RESET. Remove Patch Block.

4.5.2

4.5.2 Second cycle

Second cycle

4.5.24.5.2

Second cycleSecond cycle

Since the heating filament is fixed in position and the glass is drawn in one direction, it

follows that the portion of the glass that has been reduced in size will not be centered in the

filament at the end of the first step. Reposition the glass by first loosening the upper glass

clamp, lifting the lower slide assembly until the glass is re-centered within the filament, and

then re-tightening the upper clamp. To consistently re-center the glass, insert the Patch

Block (second screw) between the top of the bearing block and the bottom of the lower glass

clamp. Tighten the upper glass clamp while the lower glass clamp rests on the head of the

screw. Remove the Patch Block. Set the HEAT switch to HEAT 2, and press PULL. The

pipette should separate during this cycle, and the heat will automatically turn off.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 18

12

Figure 4-1. Patch Block Placement.

4.6

4.6 Controls Adjustment

Controls Adjustment

4.64.6

Controls AdjustmentControls Adjustment

In order to make the pipettes you desire, you first must understand the effects of the controls

and the various parameters on the glass. The general rule-of-thumb is that both an increase

in the heat and an increase in the pull strength will produce smaller tips and longer tapers.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 19

13

Thus, to obtain the smallest possible tips, you would use a high heat setting (e.g. 980 for

nichrome filament and 750 for 3mm platinum filament) and a pull setting above 950.

The setting of the optical switch is more complicated. Your P-30 optical switch was set at 2.5

to produce fine micropipettes with 1mm O.D. x .5mm I.D. borosilicate glass when it was

shipped to you. As the optical switch is moved lower, the distance traveled in the weak pull

will increase. The longer the weak pull, the more the glass is attenuated in diameter. This

will influence the rate at which the glass can be drawn-out during the subsequent hard pull

as well as the rate of cooling during that pull. In addition, the length of the weak pull will

determine the position of the solenoid plunger in the solenoid coil, which in turn will alter

the force developed by the solenoid. It follows that some trial and error adjustment of the

optical switch may be required to obtain a particular result. If the weak pull is too short you

may find that the tips are quite large. If the weak pull is too long the pipettes may form long

wispy threads rather than tips.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 20

14

(This page intentionally left blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 21

15

.5-1mm

5.

5. MA INT E NANC E

MAIN TENA NCE

5.5.

MAIN TENA NCEMAIN TENAN CE

5.1

5.1 Filament Replacement

Filament Replacement

5.15.1

Filament ReplacementFilament Replacement

Platinum filament life will vary with several factors; operation temperature, frequency of

use, and the amount of care taken to avoid damage. Filament deterioration becomes more

rapid at higher operating temperatures, so it is good practice to keep the heating current as

low as possible, consistent with forming tips of the desired size and configuration.

Significant deterioration of the filament is indicated by the appearance of small holes. These

holes raise the resistance of the filament and necessitate higher HEAT setting to produce the

same heat output.

Platinum trough filaments for the P-30 are available in three widths: 1.5mm, 2.0m and

3.0mm. Heat delivery to the glass is partially a function of filament width. Thus, both the

length of an electrode and the tip diameter will be affected by the filament width. A 3.0mm

wide filament will tend to produce longer pipettes and be capable of producing smaller tip

diameters. The 1.5mm wide filament will produce shorter pipette, but cannot be used to pull

as fine a tip as the wider filament.

To replace the filament, first loosen the thumbscrews that clamp the filament in place.

Remove the old filament. The sides of the new filament should be relatively parallel or

slightly less than parallel as illustrated in Figure 5-1. Grasp the new filament with a pair of

forceps and place the filament wings between the clamping jaws. Center the filament

relative to a piece of glass loaded in the upper glass clamp. Tighten the thumbnuts.

The entire heater block assembly is spring loaded to allow you to adjust the

forward/backward position of the platinum filament relative to a piece of glass. The back of

the filament should be approximately 0.5 mm to 1 mm away from the glass tubing (Figure

5-1). To move the back of the filament towards you, loosen the two Allen head screws located

on the black nylon block just above and below the brass clamp assembly. The heater

assembly will slide forward on the guide pins until movement is restricted by the screws. To

move the filament away from you, simply turn the Allen head screws clockwise an equal

amount until you have attained the desired filament position.

Figure 5-1. Top view of platinum filament glass.

5.2

5.2 Lubrication

Lubrication

5.25.2

Lubrication Lubrication

The slide bar should occasionally be wiped down with a light oil to protect it from corrosion.

Note that materials such as 3-in-1 oil are not sutiable as they leave a residue which can

“gum-up” the slide bar and bushings.

No other P-30 components require lubrication.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 22

16

5.3

5.3 Rubber Pads on Clamps

Rubber Pads on Clamps

5.35.3

Rubber Pads on ClampsRubber Pads on Clamps

The rubber pads attached to the upper and lower glass clamps can wear down to the extent

that it becomes difficult to adequately clamp the glass in place. If this should occur, please

contact the technical support staff at Sutter and request some replacement pads. The pads

can be bonded to the clamps with cyanoacrylate (“super glue”) or a similar bonding material.

5.4

5.4 Troubleshooting

Troubleshooting

5.45.4

TroubleshootingTroubleshooting

We have provided this section as an aid for troubleshooting some of the common electronic

problems of the P-30. Discussions of circuit board level troubleshooting and circuit board

schematics have intentionally been left out. Any work done with the cabinet cover removed

requires very careful attention to the hazardous voltages that exist inside cabinet, and should

therefore be performed by qualified service personnel only. We ask that you please contact

Sutter for further information and advice prior to removing the cabinet. Instructions and

circuit schematics can be supplied upon request.

1. Pilot light not on, no pull or heat:

Pilot light not on, no pull or heat:

Pilot light not on, no pull or heat:Pilot light not on, no pull or heat:

Check and make sure that the power cord is connected to a working circuit and that the

power has been switched on. If the power is good, disconnect the power cord and check to

see if the fuse on the rear of the cabinet has blown. If the fuse is good, put it back in

place and reconnect the power. If the unit seemed to turn off during a prolonged pull, the

internal protective thermostat may have opened. The thermostat will automatically reset

if the instrument is turned off for about ½ hour. If the fuse has blown, suspect failed

power MOSFET transistor(s) in the constant current power supplies (see below). Contact

Sutter for MOSFET replacement instructions.

3. Pilot light on, no heat:

Pilot light on, no heat:

Pilot light on, no heat:Pilot light on, no heat:

If the pilot light is on, there is no need to check the fuse or power connections, although

you may wish to check for low line voltage. If the heat fails to turn on when the PULL

button is pressed, make sure that there is a reasonable heat value entered and that the

HEAT 1/HEAT2 switch is set to select the desired value. Check that the optical switch is

not interrupted by the flag. With no glass loaded, press PULL and carefully lift the slide

unit until the flag interrupts the optical switch. This should activate the pull, which will

forcefully draw the slide bar down. If the pull is not activated, refer to (3).

If pull is working, the basic logic circuits and the power supplies are functional. Check to

make sure the thumbnuts that hold the filament in place are tight. Inspect the filament

for a possible break. If you have a nichrome assembly, check the screws that hold the

binding posts to the copper straps and the screws that secure those straps to insure that

good contact is made throughout. Further checks require removal of the cover portion of

the cabinet. Please contact the technical support staff at Sutter if further

troubleshooting is required.

4. Pilot light on, no heat or pull:

Pilot light on, no heat or pull:

Pilot light on, no heat or pull:Pilot light on, no heat or pull:

These symptoms suggest one of three faults: 1) the 40-volt power supply has failed; 2) the

2.5-volt reference has failed; and, 3) the logic circuits fail to correctly enable the heat and

pull. To check any of these faults requires that the cabinet be removed from the puller.

Please contact Sutter prior to troubleshooting these faults. A circuit diagram and

instructions can be supplied if necessary.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 23

17

5. Pilot light on, heat works, no pull:

Pilot light on, heat works, no pull:

Pilot light on, heat works, no pull:Pilot light on, heat works, no pull:

If the heat does not turn off when the optical switch is interrupted, suspect the optical

switch. If the heat does turn off, but the pull never turns on, the logic and constant

current circuits need to be checked. Please contact Sutter if this is required.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 24

18

(This page intentionally left blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 25

19

APP E NDIX A.

APP E NDIX A. L IMIT E D WA RRAN TY

APP E NDIX A.A PPEN D IX A .

LIM I TED W ARRA NTY

LIM I TED W ARRA NTYLIM I TED W ARRA NTY

Sutter Instrument Company, a division of Sutter Instrument Corporation, limits the

warranty on this instrument to repair or replacement of defective components for one year

after the date of shipment, provided the instrument has been operated in accordance with

the instructions outlined in the instruction manual.

Abuse, misuse or unauthorized repairs will void this warranty.

Limited warranty work is performed only at the factory, and the cost of shipment both ways

is borne by the user.

This instrument is designed to pull glass pipettes for use on animal tissues. It is not

intended for use, and should not be used, in human experimentation or applied to humans in

any way.

The limited warranty is as stated above and no implied or inferred liability for direct or

consequential damages is intended.

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 26

20

(This page intentionally blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 27

21

APP E NDIX B.

APP E NDIX B. A C CES S ORIE S

APP E NDIX B.A PPE N DIX B.

The following accessories are available for the P-30 Micropipette Puller. See

http://www.sutter.com for more detail and availability P-30 accessories, and for part numbers

not expressed in the following list.

Nichrome filament block assembly (P

Nichrome filament block assembly (P----30

Nichrome filament block assembly (PNichrome filament block assembly (P

Platinum/iridium filament block assembly (P

Platinum/iridium filament block assembly (P----30

Platinum/iridium filament block assembly (PPlatinum/iridium filament block assembly (P

Pipette storage box 4 3/4 x 3 5/8 x 3/4 inches (BX10)

Pipette storage box 4 3/4 x 3 5/8 x 3/4 inches (BX10)

Pipette storage box 4 3/4 x 3 5/8 x 3/4 inches (BX10)Pipette storage box 4 3/4 x 3 5/8 x 3/4 inches (BX10)

Pipette storage box

Pipette storage box ---- long 7 x 3 5/8 x 3/4 inches (BX20)

Pipette storage box Pipette storage box

ACC E SSO R IES

ACC E SSO R IESAC C ESSO RIES

30----NFL/M)

NFL/M)

3030

NFL/M)NFL/M)

30----PFL/M)

3030

long 7 x 3 5/8 x 3/4 inches (BX20)

long 7 x 3 5/8 x 3/4 inches (BX20) long 7 x 3 5/8 x 3/4 inches (BX20)

PFL/M)

PFL/M)PFL/M)

BV

BV----10 Microelectrode Beveler (

10 Microelectrode Beveler (BV

BVBV

10 Microelectrode Beveler (10 Microelectrode Beveler (

Glass Capillary Tubing

Glass Capillary Tubing

Glass Capillary TubingGlass Capillary Tubing

Puller Filaments

Puller Filaments

Puller FilamentsPuller Filaments

BV----10)

10)

BVBV

10)10)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 28

22

(This page intentionally blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 29

23

APP E NDIX C.

APP E NDIX C. FU SE R EPLA C EME N T

APP E NDIX C.APPEND I X C .

FUS E REP L ACE MENT

FUS E REP L ACE MENTFUS E REP L ACE MENT

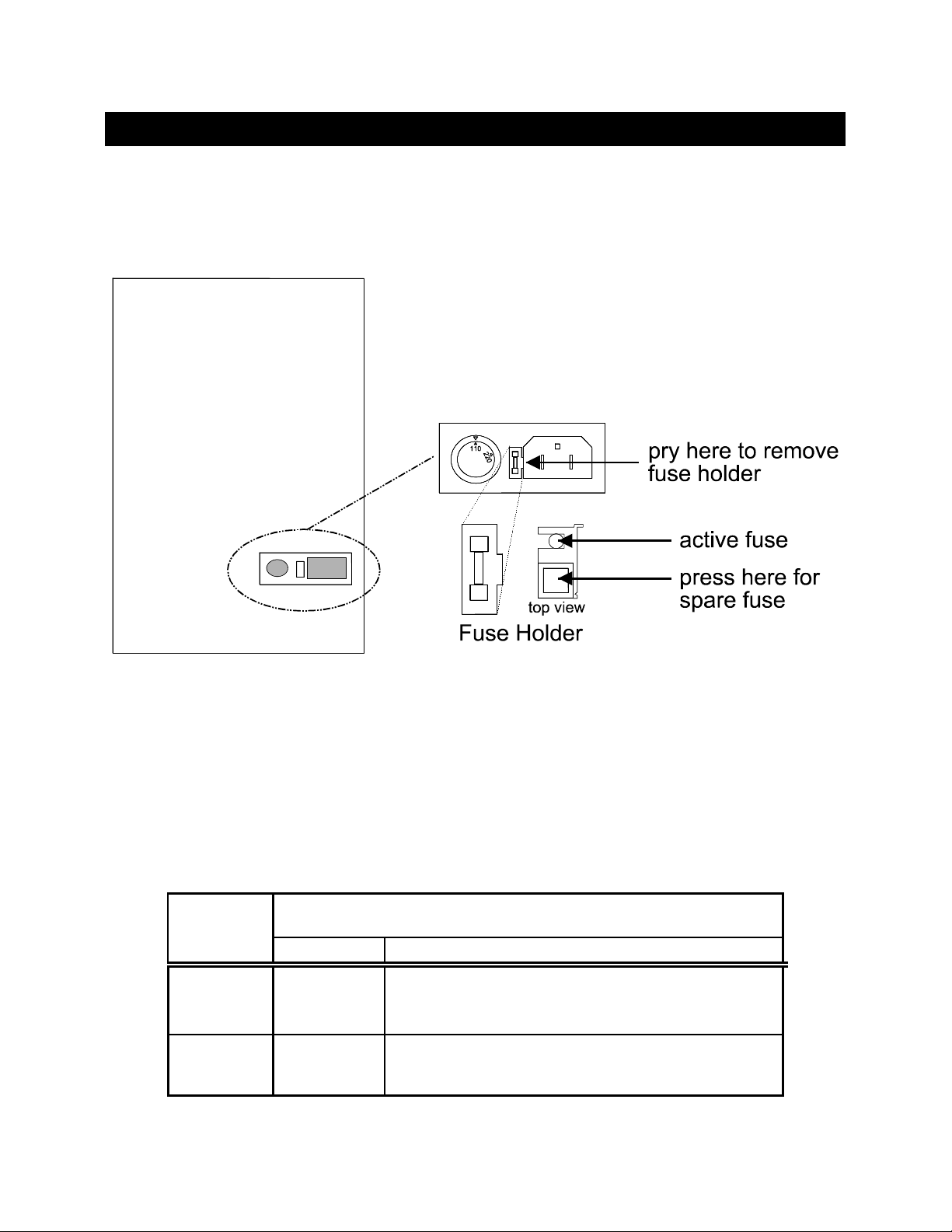

In the event that the puller fails to power up when the power switch is turned on, check the

line power fuse to see if it has blown. The fuse is located in the fuse holder on the power

entry module on the back of the P-30. To remove the fuse holder first unplug the power cord

from the power entry module. This will reveal a slot just under the edge of the fuse holder.

Use a screwdriver to pry the holder straight out of the power entry module.

Figure C-1. Fuse holder.

The fuse that is readily visible in the fuse holder when you take it out is the one that is

“active” when the holder is installed. A spare fuse is also stored within the fuse holder. It is

concealed in a compartment as shown in Figure C-1. To remove the spare fuse, press down

on the end of the compartment and push it out of the other end. The old fuse can serve as a

convenient tool for pushing the spare fuse compartment out. Replace the active fuse with the

spare and re-install the fuse holder and power cord. If the P-30 fails to power up with the

new fuse installed, call Sutter Instrument technical support personnel for assistance.

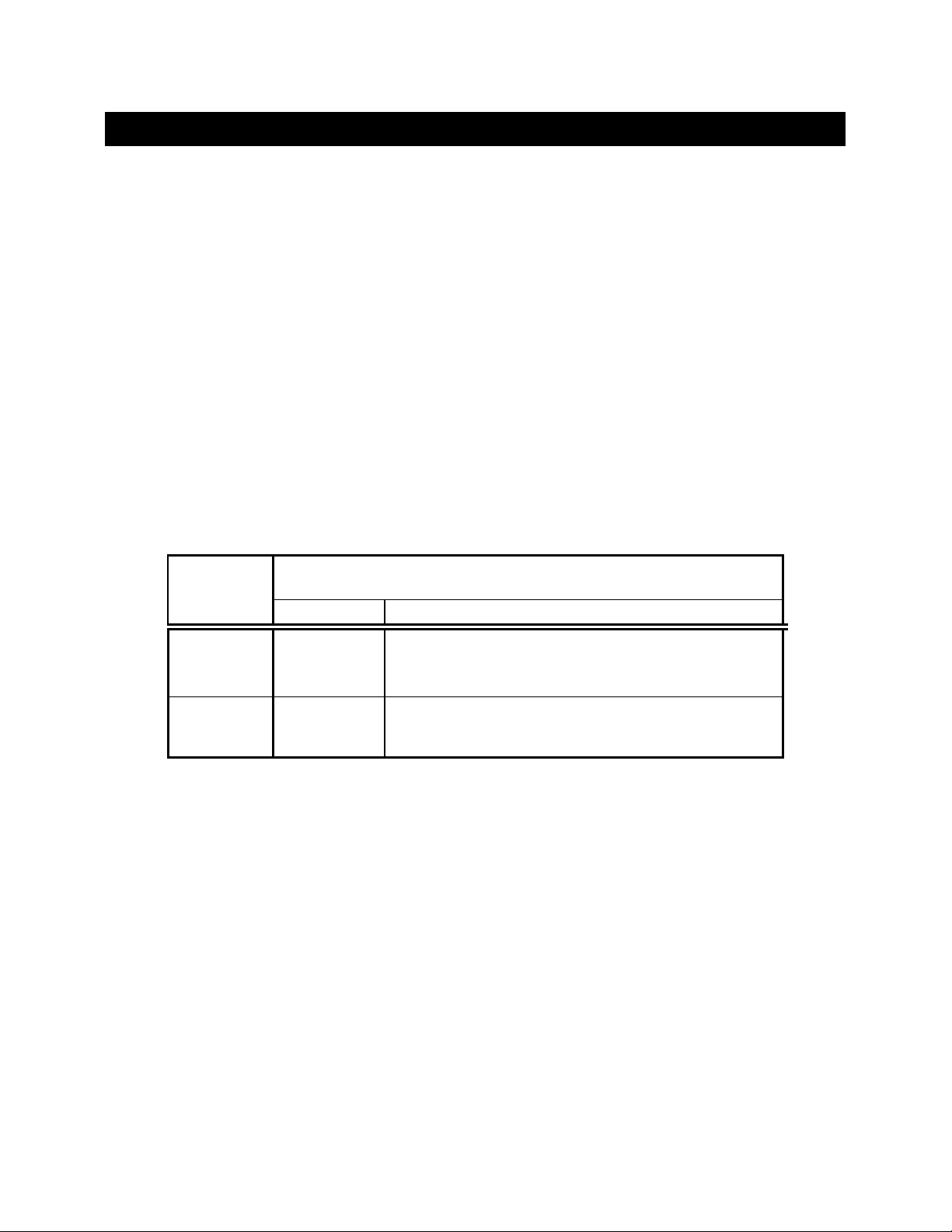

Table C-1. Mains fuse type and ratings.

Fuse

Mains Voltage

Mains Voltage

Mains VoltageMains Voltage

Setting

Setting

SettingSetting

“110”

(100 – 120

VAC)

“220”

(200 – 240

VAC)

(Type: Time Delay, 5mm x 20mm, glass tube)

(Type: Time Delay, 5mm x 20mm, glass tube)

(Type: Time Delay, 5mm x 20mm, glass tube)(Type: Time Delay, 5mm x 20mm, glass tube)

Rating

Rating Manufacturer Examples

RatingRating

2A, 250V

(Time Delay)

T1.25A,

250V

Bussmann: GMC-2A, GMC-2-R (RoHS), GDC-2A, or

S506-2A (RoHS)

Littelfuse: 239 002 or 239.002.P (RoHS)

Bussmann: GDC-1.25A or S506-1.25R (RoHS)

Littelfuse: 218 1.25 or 218 1.25P (RoHS)

Fuse

FuseFuse

Manufacturer Examples

Manufacturer ExamplesManufacturer Examples

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 30

24

(This page intentionally blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 31

25

APP E NDIX D.

Mains Voltage

Mains Voltage Mains Voltage

Mains Voltage

APP E NDIX D. T E CHN I CAL SPEC I FICA T

APP E NDIX D.APPEN DIX D.

TEC H NICA L SP E CIF I CAT IONS

TEC H NICA L SP E CIF I CATTE CHNI CAL SPEC I FICA T

ION S

ION SION S

Dimensions (H x W x D):

Dimensions (H x W x D): 18 x 10 x 9 in (46 x

Dimensions (H x W x D):Dimensions (H x W x D):

Weight:

Weight: 35 lb.

Weight:Weight:

Electrical:

Electrical:

Electrical:Electrical:

Mains voltage

Mains voltage 110

Mains voltageMains voltage

Maximum power consumption

Maximum power consumption 180 VA

Maximum power consumptionMaximum power consumption

Mains fuse (rear of cabinet)

Mains fuse (rear of cabinet)

Mains fuse (rear of cabinet) Mains fuse (rear of cabinet)

Table D-1. Mains fuse type and ratings.

(Type: Time Delay, 5mm x 20mm, glass tube)

Setting

Setting

SettingSetting

“110”

(100 – 120

VAC)

“220”

(200 – 240

VAC)

Rating

Rating Manufacture

RatingRating

2A, 250V

(Time Delay)

T1.25A,

250V

(Type: Time Delay, 5mm x 20mm, glass tube)

(Type: Time Delay, 5mm x 20mm, glass tube)(Type: Time Delay, 5mm x 20mm, glass tube)

Bussmann: GMC-2A, GMC-2-R (RoHS), GDC-2A, or

S506-2A (RoHS)

Littelfuse: 239 002 or 239.002.P (RoHS)

Bussmann: GDC-1.25A or S506-1.25R (RoHS)

Littelfuse: 218 1.25 or 218 1.25P (RoHS)

18 x 10 x 9 in (46 x 25 x 23 cm)

18 x 10 x 9 in (46 x18 x 10 x 9 in (46 x

35 lb. (16

35 lb. 35 lb.

110----120 V, 60 Hz

110110

220

220----240 V, 50 Hz

220220

180 VA

180 VA180 VA

(16 kg)

kg)

(16(16

kg) kg)

120 V, 60 Hz

120 V, 60 Hz120 V, 60 Hz

240 V, 50 Hz

240 V, 50 Hz240 V, 50 Hz

Fuse

Fuse

FuseFuse

Manufacturer Examples

ManufactureManufacture

Power cord

Power cord 10A, 250V, with safety ground plug

Power cordPower cord

10A, 250V, with safety ground plug

10A, 250V, with safety ground plug10A, 250V, with safety ground plug

25 x 23 cm)

25 x 23 cm) 25 x 23 cm)

r Examples

r Examplesr Examples

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 32

26

(This page intentionally left blank.)

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 33

27

IND E X

IND E X

IND E XIN DE X

AAAA

MMMM

accessories ..............................................................23

CCCC

controls

front panel, lower.................................................5

front panel, upper................................................5

controls adjustment...............................................14

DDDD

dimensions..............................................................29

of glass ..................................................................1

disclaimer ............................................................... iii

FFFF

first-time use..........................................................11

front panel................................................................5

fuse

holder..................................................................25

location ...............................................................25

spare....................................................................25

fuse replacement....................................................25

fuses, replacement

mains................................................................... iii

mains...................................................................29

GGGG

glass

dimensions............................................................1

glassware

loading ................................................................11

precautions..........................................................iv

specifications........................................................1

HHHH

heat

definition ..............................................................5

IIII

ID...............................................................................1

KKKK

keys

PULL....................................................................5

reset.......................................................................5

LLLL

line power (mains)...................................................9

mains.........................................................................9

fuses .................................................................... iii

fuses ....................................................................29

power consumption ...........................................29

power cord..........................................................29

voltage.................................................................29

maintenance...........................................................17

filament replacement ........................................17

lubrication ..........................................................17

rubber pads on clamps ......................................18

mechanical description

patch block ...........................................................7

pull solenoid .........................................................7

slide assembly

bushing blocks and guide bushings ...............7

filament assembly............................................6

guide flag holder ..............................................7

lower (moving) glass clamp assembly............6

side bar..............................................................6

trip flag holder .................................................7

upper (stationary) glass clamp assembly.......6

slide assembly.......................................................6

mechanical description (puller anatomy)..............6

NNNN

notes

user......................................................................33

OOOO

OD.............................................................................1

operation.................................................................11

heat settings.......................................................12

multicycle pulling (pulling a patch-type

micropipette)..................................................12

patch block (spacer)...........................................13

patch pipette pull sequence ..............................13

first cycle.........................................................13

second cycle....................................................13

precautions..........................................................iv

pull settings........................................................12

pulling a micropipette .......................................11

trip point micrometer........................................12

PPPP

power

consumption.......................................................29

power cord

mains...................................................................29

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 34

28

power entry module...............................................25

power switch ............................................................9

pull

definition ..............................................................6

puller anatomy.........................................................6

SSSS

safety warnings...................................................... iii

avoiding fire/shock hazard................................ iii

slide assembly ..........................................................6

TTTT

technical specifications..........................................29

technical support .....................................................1

troubleshooting......................................................18

UUUU

unpacking.................................................................5

VVVV

voltage

mains...................................................................29

voltage selector switch.............................................9

WWWW

warranty.................................................................21

weight .....................................................................29

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 35

29

NOTES

NOTES

NOTESNOTES

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Page 36

30

NOTES

NOTES

NOTESNOTES

P-30 MICROPIPETTE PULLER OPERATION MANUAL – REV. 3.10 (20100120)

Loading...

Loading...