Page 1

OPERATION MANUAL

Rev. 1.11 ( 20071128)

MPC

MPC----325

MPCMPC

Micromanipulator

Micromanipulator

MicromanipulatorMicromanipulator

System

System

SystemSystem

325----2

325325

2

22

Page 2

Page 3

MP

MP----325

MPMP

325----2222

325325

Micromanipulator System

Operation Manual

(Rev. 1.11 (20071128))

Sutter Instrument Company

One Digital Drive

Novato, CA 94949

voice: 415-883-0128 web: www.sutter.com

fax: 415-883-0572 email: info@sutter.com

Page 4

II

Copyright © 2007 Sutter Instrument Company. All Rights Reserved.

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 5

III

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

1. INTRODUCTION .................................................................................................................................................................... 1

1.1 S

TRUCTURE OF THE

1.2 C

OMPONENTS OF THE

2. MPC-200 MULTI-MANIPULATOR CONTROLLER AND ROE-200 INPUT DEVICE OPERATIONS ............ 3

2.1 E

LECTRICAL CONNECTIONS AND INITIAL OPERATING INSTRUCTIONS

2.2 I

NITIAL OPERATING INSTRUCTIONS

2.3 M

AIN CONTROLS ON THE

2.3.1 White Buttons: ...............................................................................................................................................................5

2.3.2 Black Selector Switches: ...............................................................................................................................................6

2.3.3 Other Controls on the ROE-200................................................................................................................................... 7

2.4 C

ONTROLS ON THE

3. MP-225/M MANIPULATOR MECHANICAL MOUNTING INSTRUCTIONS......................................................13

3.1 M

OUNTING

3.2 S

ETTING HEADSTAGE/PIPETTE ANGLE AND PIPETTE EXCHANGE

3.3 H

EADSTAGE MOUNTING

3.4 M

ODULAR CONSTRUCTION

3.5 M

INIMIZING ELECTRICAL NOISE

3.6 I

NSTRUCTIONS FOR CHANGING HANDEDNESS

3.7 I

NSTRUCTIONS USED IN SPECIAL INSTALLATIONS ONLY

INDEX ..........................................................................................................................................................................................19

MP-225/M

MPC-325 D

MPC-325...........................................................................................................................................1

MPC-200...............................................................................................................................................9

TO A STAND OR PLATFORM

OCUMENTATION PACKAGE

......................................................................................................................................3

ROE-200.....................................................................................................................................5

..........................................................................................................13

.....................................................................................................................................................15

.................................................................................................................................................16

........................................................................................................................................16

...................................................................................................................16

..............................................................................................1

...............................................................................3

.....................................................................................14

..................................................................................................17

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 6

Page 7

1

1.

1. IN TRO DUC TI ON

INT RODU CTI ON

1.1.

INT RODU CTI ONINT RODU CTI ON

1.1

1.1 Structure of the MPC

Structure of the MPC----325 Documentatio

1.11.1

Structure of the MPCStructure of the MPC

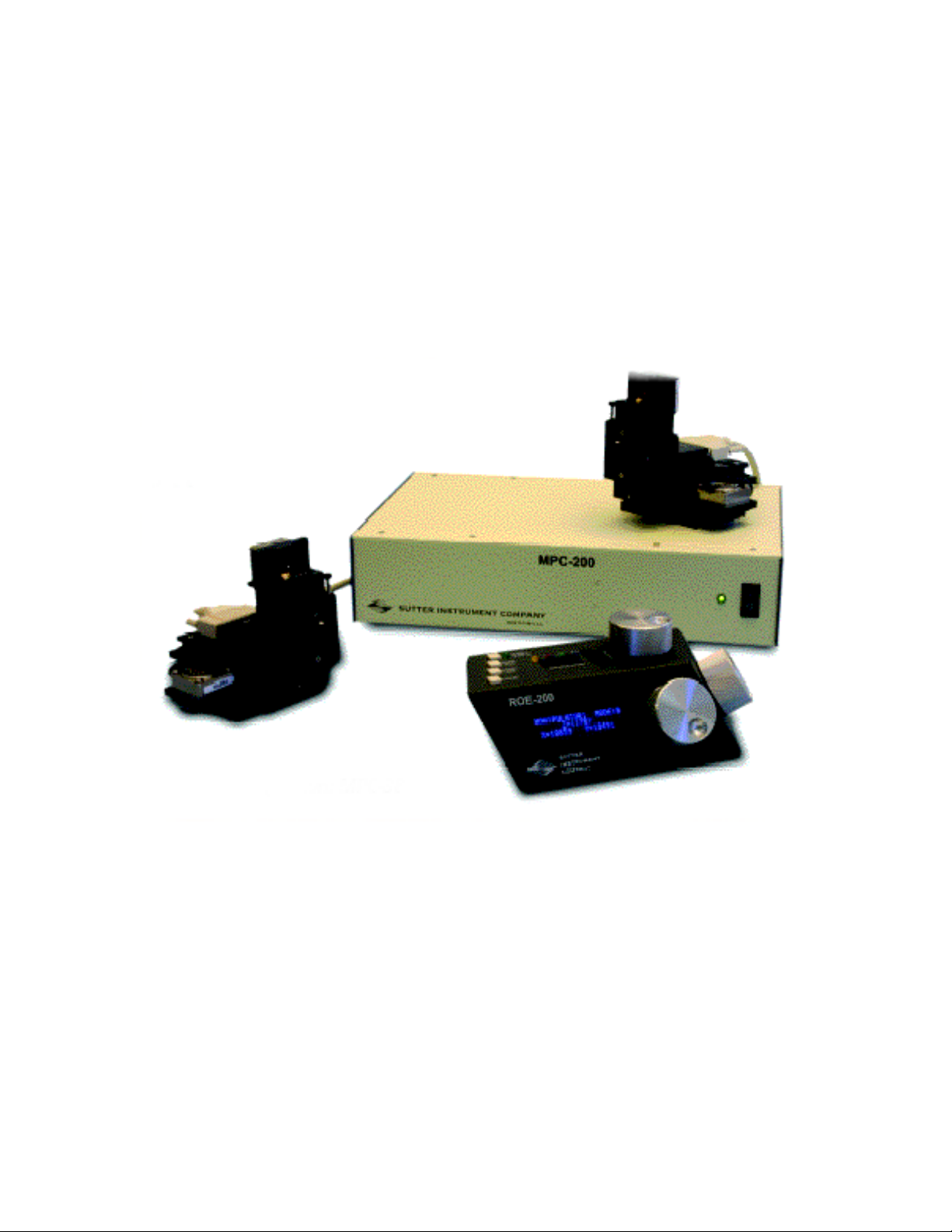

The MPC-325-2 is a manipulator system comprised of the MPC-200 controller, the ROE-200

input device and two MP-225/M stepper motor manipulators. The manual consists of two

parts, “Operations” that describes the functions of the MPC-200 controller and ROE input

device and “Setup” that describes how to install the MP-225/M mechanicals.

1.2

1.2 Components of the MPC

Components of the MPC----325

1.21.2

Components of the MPCComponents of the MPC

Carefully remove all components from the shipping container. In addition to this manual,

the following should be included:

• MPC-200 controller

• ROE-200 Rotary Optical Encoder input device

• Two MP-225/M manipulator mechanicals

• Two MP-225 Adapter boxes (adapts 3 wire MP-225/M mechanical to DB-25 cable)

• Two DB-25 cables (connect adapter boxes to the controller).

• RJ-45 cable (8 conductor) connects the ROE to the controller

• RJ-12 cable (6 conductor) daisy-chains two MPC-200 controllers

• USB cable for computer control of the MPC-325-2 system

• Power cable appropriate for your location

• Two X285210 mounting adapter plates and hardware to attach mechanicals to their

mounting surfaces

• Two X285204 four inch dovetail extensions for mounting headstages

• Two dovetail rod clamps

• 2.5mm hex wrench(s) for removing the shipping screws

• 1.5mm hex wrench(s) for adjusting pipette angle

325 Documentation Package

325 Documentatio325 Documentatio

325

325 325

n Package

n Package n Package

IMPORTA

IMPORTANT

IMPORTAIMPORTA

Once you have unpacked your MPC

Once you have unpacked your MPC----325

Once you have unpacked your MPCOnce you have unpacked your MPC

warning tags, from each MP

warning tags, from each MP----225/M. You must remove these screws before operating the

warning tags, from each MPwarning tags, from each MP

manipulators. Save the screws, warning tags, and hex wrench in the event you nee

manipulators. Save the screws, warning tags, and hex wrench in the event you need to

manipulators. Save the screws, warning tags, and hex wrench in the event you neemanipulators. Save the screws, warning tags, and hex wrench in the event you nee

transport either manipulator in the future. Once these screws have been removed, handle

transport either manipulator in the future. Once these screws have been removed, handle

transport either manipulator in the future. Once these screws have been removed, handle transport either manipulator in the future. Once these screws have been removed, handle

the micromanipulators with care. The mechanisms can be damaged if the axes are moved

the micromanipulators with care. The mechanisms can be damaged if the axes are moved

the micromanipulators with care. The mechanisms can be damaged if the axes are moved the micromanipulators with care. The mechanisms can be damaged if the axes are moved

without the screws in place.

without the screws in place.

without the screws in place.without the screws in place.

NT

NT NT

325----2, remove 6 shipping screws, indicated by the red

2, remove 6 shipping screws, indicated by the red

325325

2, remove 6 shipping screws, indicated by the red 2, remove 6 shipping screws, indicated by the red

225/M. You must remove these screws before operating the

225/M. You must remove these screws before operating the 225/M. You must remove these screws before operating the

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

d to

d to d to

Page 8

Page 9

3

MANIPULATORS

CONTROLLER

FUSE HOLDER

2.

2. M PC

MPC ----2 00 M ULTI

2.2.

MPCMPC

2.1

2.1 Electrical Connections and Initial Operating Instructions

Electrical Connections and Initial Operating Instructions

2.12.1

Electrical Connections and Initial Operating InstructionsElectrical Connections and Initial Operating Instructions

Initially, you may want to simply connect the two manipulators, the controller, and the ROE

together and try some gross movements in order to get a feel for the controls and how to

make simple movements. It is perfectly acceptable to set the manipulators in the middle of a

bench top, make all electrical connections and then observe each unit’s movement by eye.

Even if you wish to directly install the manipulators in your rig, it is useful to follow the

initial setup procedure to learn how to move the units to allow easy access to the mounting

screws.

1. Connect the power cord to the power entry module on the back of the MPC-200

controller.

200 MUL TI----M ANIP U

200 MUL TI200 MUL TI

INP UT D EVI CE O PERA TI

INP UT D EVI CE O PERA TIO NS

INP UT D EVI CE O PERA TIINP UT D EVI CE O PERA TI

POWER CORD

MAN IPU LAT OR C ONTR OLLE R A ND

MAN IPUMAN IPU

LAT OR C ONT RO LLE R AN D R OE

LAT OR C ONT RO LLE R AN DLAT OR C ONT RO LLE R AN D

ONS

ONSONS

RO E----2 00

RO E RO E

200

200 200

CONNECT

DAISY CHAIN SECOND

1. With the power OFF (front panel switch in the “0” position), connect the ROE-200 input

box to the MPC-200 controller using the RJ-45 8-conductor cable. *

CONTROLLER output on the back of the ROE and the COMMAND INPUT on the back

of the controller.

2. With the power OFF, run a DB-25 cable from each of the two MP-285/M mechanicals to

the DB-25 connectors marked “MANIPULATOR A” and “MANIPULATOR B” on the

back of the controller.****

• NOTE: Never connect or disconnect the ROE or the MP

NOTE: Never connect or disconnect the ROE or the MP----285/M while the power is on!

NOTE: Never connect or disconnect the ROE or the MPNOTE: Never connect or disconnect the ROE or the MP

2.2

2.2 Initial Operating Instructions

Initial Operating Instructions

2.22.2

Initial Operating Instructions Initial Operating Instructions

After all connections are made, power up the MPC-325-2 using the 0/I switch on the front of

the controller. As it initializes, you will see a start up screen on the ROE-200 that briefly

displays the name of the device and the version of the installed firmware. As the power

switch is the only control you will need to access on the MPC-200, the controller can

ultimately be placed in an out of the way location (e.g. under your bench).

CONNECT ROE-200

Figure 2-1. Rear of MPC-200 controller cabinet..

285/M while the power is on!

285/M while the power is on!285/M while the power is on!

* Use the

* *

Once the start-up sequence has finished, you will see a display that gives the coordinates of

the manipulator. The LED marked 1 will light and the left hand corner of the display shows

“Drive A” to indicate that the ROE is ready to operate the MP-225/M connected at the

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 10

4

MANIPULATOR A output. Confirm that you get a coordinate display and that you have

removed the shipping screws from both manipulators. If you do not get a coordinate display,

go to the trouble shooting section at the back of the manual. If you have not yet removed the

shipping screws, turn the power off again and remove all shipping screws from both

manipulators.

All functions necessary during normal operation are provided by 4 push buttons and two

rocker switches on the top of the ROE-200. Other setup functions are done via buttons and

DIP switches located on the back of the ROE-200 and DIP switches on the back of the MPC200 controller.

The MPC-200 controller and ROE-200 have a built in Centering function. This is activated

by pressing the white “CENTER” button on the back of the ROE. If both MP-225/M

manipulators are sitting in a wide-open area, and the shipping screws are removed, press the

CENTER button. The ROE-200 display will display the message “PLEASE WAIT MOVE IN

PROGRESS” and the first manipulator will center. After the CENTER operation is

complete, the manipulator axes will each be at the center of travel and the display will read

12500 for X, Y and Z.

From this location, you can move 12500 microns in each direction on each axis. The unit will

stop automatically at each end of travel (00000 or 25000 microns). These ends are

determined by firmware. Each axis also has magnetic end of travel switches that are not

activated in normal operation. If the magnetic switches are activated, you will see the

message EOT (for End Of Travel) on one of the displayed axes.

If you wish, you can easily switch to the second manipulator (connected to the

MANIPULATOR B output on the back of the controller). This is done by pressing the

Manipulator toggle once. The LED marked 2 will light and the left hand corner of the

display will change to “Drive B”. While you are controlling the second manipulator, press

CENTER to make sure that this manipulator’s coordinate system is initialized. After

centering, you can demonstrate that the manual knobs are now moving this manipulator.

When the MPC-200 controller is first turned on, the speed of movement is at its fastest,

coarsest Mode. Movement mode can be finer and slower by changing the black “Mode”

toggle switch. As MODE increases from 0, smaller movements are commanded by the same

turn of the ROE knob. MODE 5 or 6 is probably what you will use for the final approach to a

cell. MODE 0, or “Accelerated Mode” is used for fast movements to move the pipette large

distances. In MODE 0, when you turn the ROE knobs slowly, you get relatively slow

movement that is useful for final moves to place a pipette near a cell. Conversely, when you

make prolonged, rapid turns of the ROE knob, the controller/ROE automatically accelerates

to maximum speed to allow for prolonged, long distance movements. This would be most

useful for manual pipette exchange.

If you toggle from Drive A to Drive B and back again you will see that the display coordinates

and Mode settings are maintained for Drive A while you are using Drive B and vice versa.

The remaining functions of the ROE are explained in the next section.

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 11

5

2.3

2.3 Main Controls on the ROE

Main Controls on the ROE----200

2.32.3

Main Controls on the ROEMain Controls on the ROE

2.3.1

2.3.1 White Buttons:

White Buttons:

2.3.12.3.1

White Buttons: White Buttons:

DIAG/NORM:

DIAG/NORM: Pressing the DIAG/NORM button will cause the green LED near the button to

DIAG/NORM: DIAG/NORM:

200

200200

light, indicating the MPC-200/ROE-200 is in Diagonal mode. In this mode, rotation of the Zaxis knob produces diagonal movement. A second press will put the manipulator back into

Normal mode. When in diagonal mode, the X and Y knobs remain active, allowing you to

readjust the X and Y positioning of the pipette as you approach a cell in diagonal mode. Angle

of diagonal mode movement is set via DIP switches on the back of the MPC-200 controller.

(See Controller DIP switch setting instructions on Pages 9-10). When using MODE 9 (MODE

toggle set to 9), Diagonal mode produces short, quick, impulse-like movement that may be

useful in sharp pipette impalements.

When you switch to Diagonal mode, the ROE-200 display is changed from absolute to relative

coordinates and the current location is set to 0,0,0. This allows users to invoke relative

measurements using the display as a measuring device. A fourth coordinate that gives

movement along the diagonal is also added for users who wish to measure the movement of

along the axis coaxial with a pipette. When you return to Normal mode, the absolute

coordinate system is recovered. The relative coordinate feature can be disabled via DIP

switch 2 on back of the ROE-200.

Figure 2-2. Top view of ROE-200..

HOME:

HOME: When pressed, the manipulator will make a move along a stereotypic path to the

HOME: HOME:

location 0,0,0 or "home”. Home is the location where you would most likely exchange your

pipette and is maximal up on the Z-axis, maximal right on the X-axis (maximal left on a lefthanded manipulator) and maximal front on the Y-axis. The stereotypic path of the movement

is first along the currently set diagonal until either the X-axis or Z-axis reaches its origin (0).

Which one of these occurs first is a function of the diagonal angle and the location at the time

HOME is pressed. Once the first limit is reached, the unit will move the two remaining axes

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 12

6

simultaneously to their origins (0). The only allowed change in this stereotyped move is that

the Y-axis move can be eliminated. This is done via DIP switch 8 on the back of the MPC-200

controller. (See Controller DIP switch setting instructions on Page 11).

WORK POS.

WORK POS.: This button has three functions:

WORK POS.WORK POS.

1. With the STOP/SET button is held down, a momentary press of WORK POS. makes the

current location the "Work Position". A beeper will sound to indicate that the operation is

complete and the location has been saved. Typically, this is a location where the pipette

tip is under the microscope objective and near the cells or tissue of interest.

2. Once you have defined a Work Position, a momentary press of WORK POS. will cause the

manipulator to move to the defined Work Position, providing the manipulator last move

was to Home. The move will occur along the predefined path that the manipulator moved

to get to Home (described above) but in the opposite direction. This is the reason why

Work Position moves must

must follow Home moves; the move to Home defines the return

mustmust

trip. In either case, the movement along the diagonal as you come in and out of the

preparation/dish/bath should assure that the pipette tip will not hit anything on the way

in or out.

3. When WORK POS. is held down for longer than 2 seconds, the current manipulator is

locked so that none of the buttons or the ROE knobs will cause it to move. The lock is

released by holding WORK POS. down again. A beep will indicate that the lock is enabled

or disabled and the display will indicate the locked state.

STOP/SET:

STOP/SET: This button has two functions:

STOP/SET: STOP/SET:

1. When held down, STOP/SET" performs a "Set" function in combination with the "WORK

POS." key. Think of it as a shift key when held down.

2. A momentary press of STOP/SET during a robotic move (see HOME, WORK POS. and

CENTER) will immediately "Stop" the movement. Think of this as your panic button

when you see your pipette headed somewhere that you don't want it to go!

when you see your pipette headed somewhere that you don't want it to go!

when you see your pipette headed somewhere that you don't want it to go!when you see your pipette headed somewhere that you don't want it to go!

2.3.2

2.3.2 Black Selector Switches:

Black Selector Switches:

2.3.22.3.2

Black Selector Switches: Black Selector Switches:

MODE:

MODE: The MODE Selector controls the speed and the relative fineness of movement of the

MODE: MODE:

Think of this as your panic button

Think of this as your panic button Think of this as your panic button

manipulator produced by rotating the ROE knobs. As MODE increases from 0 to 9,

movement gets finer and slower. As explained in "INITIAL OPERATING INSTRUCTIONS",

MODE 0 is Accelerated Mode. In MODE 0, slow turns of the ROE knob produce medium

course moves for moving a pipette under a microscope in the vicinity of a cell. Prolonged, fast

turns of the ROE knobs cause the controller to accelerate to top speed for long, imprecise

movements for rapid manual positioning of the pipette. The remaining MODES (1-9) produce

moves of increasing sensitivity and decreasing speed. In practice, most users will find that

MODE 5 or 6 will provide the necessary dexterity of movement for the final approach to a

cell. The current MODE setting is displayed in the upper right of the ROE-200 display.

MANIPULATOR:

MANIPULATOR: The MANIPULATOR Selector toggles the active manipulator. In the

MANIPULATOR:MANIPULATOR:

MPC-325, there is only one active manipulator; therefore, the MANIPULATOR Selector has

no function. You can toggle the switch, but no change will occur. With only one manipulator

attached, the words "ROE-200" are displayed. If the manipulator is connected to the

"MANIPULATOR A" output on the back of the MPC-200 controller LED 1 will be lit. If the

manipulator is connected to the "MANIPULATOR B" output on the back of the MPC-200

controller LED 2 will be lit. If you connect an additional MP-225/M or MP-285/M

manipulator in the future, the controller will automatically detect the second manipulator,

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 13

7

the MANIPULATOR toggle will become active and the display will indicate which

manipulator is active with the words "Drive A" or "Drive B".

Figure 2-3. Side view of ROE-200..

2.3.3

2.3.3 Other Controls on the ROE

Other Controls on the ROE----200

2.3.32.3.3

Other Controls on the ROEOther Controls on the ROE

CENTER (round push button on the back of ROE

CENTER (round push button on the back of ROE----200)

CENTER (round push button on the back of ROECENTER (round push button on the back of ROE

200

200 200

200): CENTER is an initialization

200)200)

function that is used when the unit is first set up and occasionally during normal operation.

CENTER should only be done in the absence of a pipette as the manipulator makes large

CENTER should only be done in the absence of a pipette as the manipulator makes large

CENTER should only be done in the absence of a pipette as the manipulator makes large CENTER should only be done in the absence of a pipette as the manipulator makes large

robotic movements to its extreme ranges of motion

robotic movements to its extreme ranges of motion.

robotic movements to its extreme ranges of motionrobotic movements to its extreme ranges of motion

. To CENTER, press and release the white

. .

button on the back of the ROE-200. This will cause a prolonged movement in each axis to the

end of travel (EOT) sensors beyond the origin (0,0,0). Once the sensors are found, a short

move in the opposite direction is made and this location is defined as (0,0,0). Finally, the unit

moves to the location (12500, 12500, 12500), the center of travel of each axis. If the unit is

turned off, or STOP/SET is pressed during the running of CENTER, the unit will not be

correctly initialized. In this case, it is necessary to cycle the power off and on and run

CENTER again to its completion.

DIP Switches (on back of ROE

DIP Switches (on back of ROE----200):

DIP Switches (on back of ROEDIP Switches (on back of ROE

200): There are four DIP switches on the back of the ROE-

200): 200):

200 which govern global and/or ROE settings.

Switch 1:

Switch 1: When ON disables all MODES on the MODE Selector except for MODE 0 and 5.

Switch 1:Switch 1:

Some users may find that they only need Accelerated MODE and a single fine MODE. This

will allow them to more easily switch between the two. Factory default is OFF, enabling all

MODES.

Switch 2:

Switch 2: When OFF, disables relative coordinates during Diagonal Mode. Factory default is

Switch 2: Switch 2:

ON, relative display enabled during Diagonal Mode.

Switch 3:

Switch 3: When OFF, the MANIPULATOR Selector functions in a cyclical fashion. After

Switch 3: Switch 3:

reaching the highest number manipulator, a further push of MANIPULATOR cycles the user

back to the lowest number manipulator. When DIP switch 3 is set to ON, the selector does

not cycle back to the first manipulator. Factory default is OFF, allowing cycling back.

Switch 4:

Switch 4: Reserved for future use. Must be kept ON for proper functioning!

Switch 4:Switch 4:

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Must be kept ON for proper functioning!

Must be kept ON for proper functioning!Must be kept ON for proper functioning!

Page 14

8

NOTES

NOTES

NOTESNOTES

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 15

9

2.4

2.4 Controls on the MPC

Controls on the MPC----200

2.42.4

Controls on the MPCControls on the MPC

Power

Power Switch:

PowerPower

Switch: The power switch for the MPC-200 is located on the front panel of the

Switch: Switch:

200

200 200

controller. At power up, the microprocessor in the ROE-200 scans the attached equipment

and configures the system accordingly. Among the checks/configurations that are made:

1. Determines the number and type of manipulators that are attached. The MPC-200/ROE-

200 system is able determine how many and what type of manipulators (MP-285/M or

MP-225/M) are connected and to what outputs they are connected. It then sets the

current for each output to the correct value for the mechanicals found. If no

manipulators are found, the controller will return the message “NO MANIPULATOR

DETECTED, PLEASE TURN OFF CONTROLLER AND ATTACH MANIPULATOR”

2. The ROE-200 is capable of connecting to more than one MPC-200 controller. On power

up the ROE makes a determination of how many controllers are attached and configures

properly. If the power is off on the second controller, the ROE-200 displays a message

“PLEASE TURN ON ALL CONTROLLERS, THEN PRESS SET TO START”.

DIP Switches:

DIP Switches: Two banks of 8 DIP switches are located on the back of the MPC-200

DIP Switches:DIP Switches:

controller. Each bank is assigned to, and configures, one of the two manipulator outputs on

the back of the controller (MANIPULATOR A or B). Users familiar with the Sutter

Instrument MP-225 controller will find that they have the same function as the

configuration DIP switches on the MP-225 ROE. The switches are numbered 1 through 8.

In all cases, the 0 or OFF position is opposite the direction of the switch number and the 1 or

ON position is in the direction of the switch number and is also indicated by an arrow and

the word “ON” next to Switch 1. In order for any new switch settings to take effect, the

controller must be powered off and on.

The figure below shows the two banks of switches on the back of the MPC-200 controller.

Figure 2-4. Configuration switches on rear of MPC-200 controller cabinet.

Switches 1,2,3 and 4

Switches 1,2,3 and 4 set the angle of the Diagonal mode movement.

Switches 1,2,3 and 4Switches 1,2,3 and 4

The following table provides the angles that can be used and the DIP switch settings of

switches 1,2,3 and 4. As indicated in the inset to the left of the table, the angles fall into two

different quadrants according to whether the angles are more or less steep than 45 degrees.

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 16

10

steep

45º

Table 2-1. Configuration switch settings for different angles of steepness.

DIP switch number

Angle

1 2 3 4

7 1 1 1 1

11 0 1 1 1

14 1 0 1 1

21 0 0 1 1

27 1 1 0 1

29 * 0 1 0 1

35 1 0 0 1

39 0 0 0 1

Less

steep

than 45º

45 1 1 1 0

DIP switch number

Angle

1 2 3 4

39 0 1 1 0

35 1 0 1 0

29 0 0 1 0

27 1 1 0 0

More

21 0 1 0 0

14 1 0 0 0

than

11 0 0 0 0

*Factory default near 30

degrees

Switches 5, 6 and 7

Switches 5, 6 and 7 set the direction of the movement produced by a clockwise turn

Switches 5, 6 and 7Switches 5, 6 and 7

(advancing right hand screw) of the ROE knob for each axis.

With the switch set to 0, a clockwise turn of the knob produces a decrement in the display;

when the switch is set to 1, a clockwise turn of the knob produces an increment in the

display. An increment in the display coincides with movement downward in the Z axis,

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 17

11

movement toward the rear of your setup in the Y axis and movement producing pipette

advancement in the X axis.

The factory default is 1,1,1 for switches 5,6 and 7.

Switch number

Corresponding axis

Switch 8

Switch 8 determines whether or not the Y-axis is included in HOME and WORK POS. robotic

Switch 8Switch 8

5 6 7

X

Y Z

moves. If switch 8 is set to 0, the Y axis is moved to a location where the pipette is towards

the user in HOME move and is moved back to whatever Y coordinate was recorded during

SET-WORK POS. in the WORK POS. move. If switch 8 is set to 1, the Y axis is not moved (Y

position ignored) during the HOME or WORK POS. moves. The factory default for switch 8

is 0; the Y axis will move during HOME and WORK POS. moves.

Remember that the settings on the A switches apply to the MANIPULATOR A output and

the settings on the B switches apply to the MANIPULATOR B output. Thus, you can have,

for example, different angles of approach on your two manipulators or a different direction of

turning to advance the pipette on a left versus a right-handed manipulator.

Figure 2-5. Configuration switches (rear of MPC-200 controller).

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 18

Page 19

13

TAPERED PEG (TYP)

MOUNTING ADAPTER PLATE

3.

3. M P

MP ----2 25/M MAN IPU LATO R

3.3.

The following sections describe how to mount your MP-225/M to a stand using the mounting

adapter plate, how to adjust pipette angle and change pipettes, how to mount different

headstages and finally, the modular nature of the mechanical. It is assumed that if you are

setting up an MPC-325-2, that you will repeat the setup instructions for two mechanicals.

The figure below shows a right-handed MP-225/M. You may have a left-handed unit,

especially if you have a two-manipulator system, but the setup is identical.

3.1

3.1

3.13.1

The MP-225/M mounts to the mounting adapter plate (X285210) using four tapered pegs

with locking screws. The figure below shows the location of the front locking setscrews:

225 /M M ANI PULA TOR MEC HANICAL MOU NTIN G

MPMP

225 /M M ANI PULA TOR225 /M M ANI PULA TOR

INS TRU CTIO NS

INS TRU CTIO NS

INS TRU CTIO NSINS TRU CTIO NS

Mo

Mounting MP

unting MP----225/M to a Stand or Platform

MoMo

unting MPunting MP

225/M to a Stand or Platform

225/M to a Stand or Platform225/M to a Stand or Platform

ME CHAN ICAL MOU NTI NG

ME CHAN ICAL MOU NTI NG ME CHAN ICAL MOU NTI NG

THUMB SCREW

Z

PHILLIPS HEAD

SCREW (TYP)

SWING GATE

LOCKING SCREWS

Figure 3-1. Angled side view of MP-225/M showing swing gate and mounting adapter plate.

The rear pair of screws is in a similar location in the back of the manipulator. The

manipulator is shipped

manipulator is shipped with the adapter plate in place; it must be removed to mount the

manipulator is shippedmanipulator is shipped

manipulator!

manipulator!

manipulator!manipulator!

with the adapter plate in place; it must be removed to mount the

with the adapter plate in place; it must be removed to mount the with the adapter plate in place; it must be removed to mount the

X

Y

The

The The

To remove the plate, first loosen the locking screws and then pull the mounting plate

straight down. The figure above shows the plate removed from the X axis. Once removed,

the mounting adapter plate can be secured to any flat surface carrying ¼-20 or 10-32 holes

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 20

14

on one-inch centers (such as a Sutter MT-stand or MD series platform) using the supplied

hardware. After mounting the adapter plate on your stand or platform, align the pegs on top

of the plate with the holes in the manipulator, push the X-axis firmly onto the plate, and

retighten the locking hex set screws.

3.2

3.2

Setting Headstage/Pipette Angle and Pipette Exchange

Setting Headstage/Pipette Angle and Pipette Exchange

3.23.2

Setting Headstage/Pipette Angle and Pipette ExchangeSetting Headstage/Pipette Angle and Pipette Exchange

Mounted on the front of the Z-axis of the manipulator is the “swing-out gate”. The swingout gate is the mounting surface for the rotary dovetail that holds various

electrophysiological headstages and/or micro tools at defined angles. The swing-out gate is

also provides for easy exchange of pipettes during an experiment.

The angle of the rotary dovetail is adjusted by loosening the hex set screw located on the

hinge side of the swing-out gate (see figure below). You can set a particular angle using the

knife-edge on the dovetail and the scale on the faceplate. After choosing an angle, press the

rotary dovetail firmly into the pocket in the swing gate and retighten the screw to fix the

angle.

THUMB SCREW:

LOOSEN TO OPEN

SWING GATE

HEX SET SCREW:

LOOSEN TO CHANGE

PIPETTE ANGLE

Figure 3-2. Locations of screws used to open swing gate and changing pipette angle.

To change pipettes, loosen the thumbscrew on the swing-out gate (above left). The gate will

open allowing the headstage and holder to rotate almost 90 degrees. After replacing your

pipette, make sure to close the gate tightly and tighten the thumbscrew securely while

holding the gate closed. The thumbscrew is designed to pull the gate closed with tightening.

Tightening with thumb and finger is sufficient.

The height of the swing-out gate on the front of the Z-axis is adjustable. To change the

position, open the gate and loosen the 4 Phillips-head screws that mount the swing gate (see

figure, Page 13). As shipped from the factory, the gate is positioned to allow access to the Z-

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 21

15

Heka EPC

-

10 or

Axon 203B

Phillips

-

head

Head stage

Connection to 4 inch dovetail:

EPC7,8 & 9: 1-1/16" x 2-7/32"

axis shipping screw holes. You may find it beneficial to move the gate up before you start

using your MP-225/M.

3.3

3.3 Headstage Mounting

Headstage Mounting

3.33.3

Headstage MountingHeadstage Mounting

Axon headstages 203B or CV-7 and the Heka EPC-10 headstage have an integral dovetail

that slides directly into the rotary dovetail on the MP-225/M. The figure below shows an

example of this type of headstage mounted in a left-handed manipulator and in profile (on

the right), the location of the Phillips-head screw that secures the headstage dovetail in its

mate on the manipulator.

Figure 3-3. Headstage mounting.

screw

Older Axon and Heka headstages mount using the 4-inch dovetail (X285204) and a plastic

plate. A typical headstage of this type is shown mounted in a right-handed MP-225/M (right

panel). The plastic plate used with the 4-inch dovetail is shown in the left panel of the figure

and the holes are indicated to mount common headstages. Additional holes could be easily

added to accommodate less common headstage footprints.

C

A

D

D D

C

(2 holes, A & B)

CV-4: 1-1/8" x 1-15/16"

(4 holes, B & C)

( 3 holes, D)

C

B

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 22

16

Figure 3-4. Using a dovetail for headstage mounting.

Rod mounted headstages and micro tools are accommodated by use of a rod clamp that fits

into the dovetail (not shown). All the headstage adapters and mounting hardware are

included with the manipulator and are shipped in a zip lock plastic bag.

3.4

3.4 Modular Construction

Modular Construction

3.43.4

Modular ConstructionModular Construction

The three axes of the MP-225/M are identical. They are connected to each other with

tapered pegs and hex locking screws, four between each axis. The peg and locking screw

attachment is identical to the attachment of the mounting adapter plate to the bottom of the

manipulator. The manipulators are shipped pre-assembled in either the right or the lefthanded configuration. Because of the modular construction, handedness can be easily

switched. If you wish to change one of your mechanicals from right handed to left handed or

vice versa see “Instructions for Changing Handedness” included later in this section.

The modular construction of the MP-225/M mechanical allows for some flexibility in the

connections between axes. In the standard configuration, the axes are stacked X, Y, and Z

from bottom to top (see figure on Page 13). However, the 3 axes can be used separately or

assembled in non-standard configurations. If you assemble the manipulator in other

configurations, make sur

configurations, make sure that the axes do not interfere with one another!

configurations, make surconfigurations, make sur

the Z-axis is mounted in a lower location on the right angle that connects it to the Y-axis, it

may interfere with the full travel of the Y-axis.

e that the axes do not interfere with one another! For example, if

e that the axes do not interfere with one another!e that the axes do not interfere with one another!

If you assemble the manipulator in other

If you assemble the manipulator in other If you assemble the manipulator in other

You may have also received one or more accessories for mounting your MP-225/M and/or

modifying the headstage mount to the manipulator (i.e. rotating base, microscope stage

mount, gantry stand, dovetail extension). Setup of these accessories is normally covered in

documentation accompanying the accessory.

If you intend to use the right angle adapter (285300) with your MP-225/M in order to rotate

the manipulator 90 degrees, please see “Instructions used in Special Installations Only” near

the end of this manual.

3.5

3.5 Minimizing Electrical Noise

Minimizing Electrical Noise

3.53.5

Minimizing Electrical NoiseMinimizing Electrical Noise

We are aware of one potential noise source that users coupling their MP-325 with high-gain,

high-input impedance, electrophysiological recording amplifiers may experience. Under

certain circumstances, the manipulator and/or the drive cable coming from the controller

may act as an antenna picking up electric field noise from nearby electrical equipment and

bringing it into your setup. Grounding the manipulator will largely eliminate this noise

source. Try to attach to one of the silver Phillips-head screws on the side of one or more of

the axes. It should be noted that the manipulator produces negligible electrical noise when it

is not moving because it is powered by a linear power supply with no AC current present.

3.6

3.6 Instructi

Instructions for Changing Handedness

3.63.6

InstructiInstructi

ons for Changing Handedness

ons for Changing Handednessons for Changing Handedness

To switch from Right-handed to Left-handed:

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 23

17

RIGHT HAND

LEFT HAND

X-AXIS ROTATING

LOCKING SCREWS FOR

CHANGING HANDEDNESS

LOCKING SCREWS FOR

CHANGING HANDEDNESS

SWING GATE ROTATED

AND TUMB SCREW MOVED

1. Loosen four hex set screws, two on each side of the Y axis, that lock four tapered pins on

the top of the X-axis in the holes in the bottom of the Y-axis (the four screws are

indicated in the left and right panels below).

2. Pull the X-axis straight down (left panel).

3. Rotate the X-axis 180 degrees in the X-Y plane so that the motor and wire of the X axis

are on the left side of the manipulator (middle panel).

4. Reinsert the pins into the holes in the bottom of the Y axis (right panel).

5. Retighten the hex set screws in the sides of the Y-axis.

6. Open the swing gate and remove the four screws that attach it to the Z-axis (swing gate

shown open on Page 13).

7. Rotate the swing gate 180 degrees in the Z-X plane and reattach to the front of the Z-axis.

8. Remove the thumbscrew from the bottom of the swing gate and install in the similar hole

in the top of the swing gate (rotated swing gate shown in right panel).

To switch from left to right, simply reverse these directions.

3.7

3.7 Instructions Used in Special In

Instructions Used in Special Installations Only

3.73.7

Instructions Used in Special InInstructions Used in Special In

TO INSTALL AND USE THE RIGHT ANGLE ADAPTER (285300)

Open the swing-out gate and remove it from the front of the MP-225/M by removing the four

Phillips-head screws. Next, install the right angle adapter on the front of the MP-225/M

using the supplied M3-0.5 hex head screws. Finally, install the swing out gate on the right

angle adapter using the four Phillips-head screws. With the right angle in place, the

Figure 3-5. Rotating the MP-225/M for right and left handedness.

stallations Only

stallations Onlystallations Only

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 24

18

manipulator (right handed) can be turned 90 degrees clockwise so that its bulk faces to the

right instead of the back of your microscope.

Having made the 90-degree rotation, if you wish to use the automated features and diagonal

movement mode of the MP-225/M, two other minor changes must be made:

First, as the X and Y-axes have interchanged with the 90-degree rotation, the wires

controlling these two axes must be switched at the connector box.

Second, in order to have the Y axis movement be in the forward direction during the home

move, you need to rotate the Y axis 180 degrees with respect to the rest of the manipulator.

To reverse the Y (bottom axis in the rotated configuration), locate and loosen the 4 set screws

that attach the Y to the X. These are on the sides of the X or middle axis in the stack. When

the set screws are loose, you can move the Y off the X, rotate it 180 degrees and reinsert its

mounting posts into the correct holes in the X (the holes with set screws). Finally, press the

two axes firmly together and retighten the setscrews. Now the Y-axis will move forward

during the home move and back during the work position move.

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 25

19

IND EX

IND EX

IND EXIN DEX

C

Changing Handedness.................................................... 17

Components.......................................................................1

Controls....................................................................... 5, 10

MPC-200.................................................................... 10

DIP Switches ......................................................... 10

Power switch.......................................................... 10

ROE-200........................................................................5

black selector switches ........................................ 6, 7

other

DIP switches.........................................................7

other...........................................................................7

CENTER ..............................................................7

white buttons.............................................................5

DIAG/NORM ......................................................5

HOME..................................................................5

STOP/SET............................................................6

WORK POS.........................................................6

E

Electrical Connections......................................................3

I

Initial Operating Instructions............................................3

Installing and using right angle adapter .........................18

M

Minimizing Electrical Noise ..........................................17

Mounting

headstage.....................................................................15

MP-225/M Manipulator Mechanical.........................13

MP-225/M to a Stand or Platform.............................13

P

Pipette Exchange.............................................................14

S

Setting Headstage/Pipette Angle....................................14

Special installations.........................................................18

MPC-325-2 OPERATION MANUAL – REV. 1.11 (20071128)

Page 26

Page 27

Addendum

Addendum

AddendumAddendum

To

To

ToTo

All Operation Manuals of

All Operation Manuals of

All Operation Manuals ofAll Operation Manuals of

MPC

MPC----200/ROE

MPCMPC

200/ROE----200

200/ROE200/ROE

MPC

MPC----Series Systems

MPCMPC

Series Systems

Series SystemsSeries Systems

200----Equipped

200200

Equipped

EquippedEquipped

Rev. 1.00 – November 28, 2007

As of Version 3.11 (November 12, 2007) of the firmware for the MPC

As of Version 3.11 (November 12, 2007) of the firmware for the MPC----200 micromanipulator

As of Version 3.11 (November 12, 2007) of the firmware for the MPCAs of Version 3.11 (November 12, 2007) of the firmware for the MPC

controller and ROE

controller and ROE----200 input device, the CENTER routine associated with the white button on the

controller and ROEcontroller and ROE

rear of the ROE

rear of the ROE----200 has been replaced with a C

rear of the ROErear of the ROE

pipette. Thus, it can be used in the middle of an experiment when you see the message EOT (end of

pipette. Thus, it can be used in the middle of an experiment when you see the message EOT (end of

pipette. Thus, it can be used in the middle of an experiment when you see the message EOT (end of pipette. Thus, it can be used in the middle of an experiment when you see the message EOT (end of

travel) displayed on the ROE

travel) displayed on the ROE----200. Please note that all references to CENTER in the current

travel) displayed on the ROEtravel) displayed on the ROE

manual should be

manual should be replaced with CALIBRATE. Furthermore, the detailed instructions regarding the

manual should bemanual should be

centering routine in section 2.3.3 should be replaced with the CALIBRATE instructions below.

centering routine in section 2.3.3 should be replaced with the CALIBRATE instructions below.

centering routine in section 2.3.3 should be replaced with the CALIBRATE instructions below.centering routine in section 2.3.3 should be replaced with the CALIBRATE instructions below.

200 input device, the CENTER routine associated with the white button on the

200 input device, the CENTER routine associated with the white button on the 200 input device, the CENTER routine associated with the white button on the

200 has been replaced with a CALIBRATE routine that is less likely to break a

200 has been replaced with a C200 has been replaced with a C

200. Please note that all references to CENTER in the current

200. Please note that all references to CENTER in the current 200. Please note that all references to CENTER in the current

replaced with CALIBRATE. Furthermore, the detailed instructions regarding the

replaced with CALIBRATE. Furthermore, the detailed instructions regarding the replaced with CALIBRATE. Furthermore, the detailed instructions regarding the

ALIBRATE routine that is less likely to break a

ALIBRATE routine that is less likely to break a ALIBRATE routine that is less likely to break a

200 micromanipulator

200 micromanipulator 200 micromanipulator

Figure 1. Location of the CALIBRATE button on the ROE-200.

CALIBRATE is used in t

CALIBRATE is used in two ways. When the unit is first set up, CALIBRATE is used to establish

CALIBRATE is used in tCALIBRATE is used in t

the zero location. Then, occasionally, during normal operation, CALIBRATE is used to reestablish

the zero location. Then, occasionally, during normal operation, CALIBRATE is used to reestablish

the zero location. Then, occasionally, during normal operation, CALIBRATE is used to reestablish the zero location. Then, occasionally, during normal operation, CALIBRATE is used to reestablish

the zero location. CALIBRATE follows a more conservative path than CENTER, and can gen

the zero location. CALIBRATE follows a more conservative path than CENTER, and can generally

the zero location. CALIBRATE follows a more conservative path than CENTER, and can genthe zero location. CALIBRATE follows a more conservative path than CENTER, and can gen

be used in the presence of a pipette.

be used in the presence of a pipette.

be used in the presence of a pipette.be used in the presence of a pipette.

To CALIBRATE, press and release the white button on the back of the ROE

To CALIBRATE, press and release the white button on the back of the ROE----200. The manipulator

To CALIBRATE, press and release the white button on the back of the ROETo CALIBRATE, press and release the white button on the back of the ROE

will back away from the current location along the established diagonal (like a HOME move), and

will back away from the current location along the established diagonal (like a HOME move), and

will back away from the current location along the established diagonal (like a HOME move), and will back away from the current location along the established diagonal (like a HOME move), and

ultimately move to th

ultimately move to the end of travel (EOT) sensors, beyond the origin (0,0,0). Once the sensors are

ultimately move to thultimately move to th

found, a short move in the opposite direction is made and this location is defined as (0,0,0). The

found, a short move in the opposite direction is made and this location is defined as (0,0,0). The

found, a short move in the opposite direction is made and this location is defined as (0,0,0). The found, a short move in the opposite direction is made and this location is defined as (0,0,0). The

purpose of CALIBRATE is to allow 0,0,0 or HOME to be safely reestablished du

purpose of CALIBRATE is to allow 0,0,0 or HOME to be safely reestablished during the course of an

purpose of CALIBRATE is to allow 0,0,0 or HOME to be safely reestablished dupurpose of CALIBRATE is to allow 0,0,0 or HOME to be safely reestablished du

experiment without risking damage to the pipette.

experiment without risking damage to the pipette.

experiment without risking damage to the pipette.experiment without risking damage to the pipette.

If the unit is turned off, or STOP/SET is pressed during the running of CALIBRATE, the unit will

If the unit is turned off, or STOP/SET is pressed during the running of CALIBRATE, the unit will

If the unit is turned off, or STOP/SET is pressed during the running of CALIBRATE, the unit will If the unit is turned off, or STOP/SET is pressed during the running of CALIBRATE, the unit will

not be correctly initialized. In this case, it is necessary to cycle the power off and

not be correctly initialized. In this case, it is necessary to cycle the power off and on, and then run

not be correctly initialized. In this case, it is necessary to cycle the power off andnot be correctly initialized. In this case, it is necessary to cycle the power off and

CALIBRATE again to its completion.

CALIBRATE again to its completion.

CALIBRATE again to its completion.CALIBRATE again to its completion.

ADDENDUM TO ALL OPERATION MANUALS OF MPC-200/ROE-200-EQUIPPED MPC-SERIES SYSTEMS – REV. 1.00

wo ways. When the unit is first set up, CALIBRATE is used to establish

wo ways. When the unit is first set up, CALIBRATE is used to establish wo ways. When the unit is first set up, CALIBRATE is used to establish

erally

erally erally

200. The manipulator

200. The manipulator 200. The manipulator

e end of travel (EOT) sensors, beyond the origin (0,0,0). Once the sensors are

e end of travel (EOT) sensors, beyond the origin (0,0,0). Once the sensors are e end of travel (EOT) sensors, beyond the origin (0,0,0). Once the sensors are

ring the course of an

ring the course of an ring the course of an

on, and then run

on, and then run on, and then run

Loading...

Loading...