Page 1

Lambda 10

Lambda 10----3

Lambda 10Lambda 10

Optical Filter Changer and

Optical Filter Changer and

Optical Filter Changer and Optical Filter Changer and

SmartShutter

SmartShutter™ Control System

SmartShutterSmartShutter

Operation Manual

Operation Manual

Operation ManualOperation Manual

Rev. 3.03 ( 20110829)

™ Control System

™ Control System™ Control System

3

33

One Digital Drive

Novato, CA 94949

Voice: 415-883-0128 Web: www.sutter.com

Fax: 415-883-0572 Email: info@sutter.com

Page 2

ii

Copyright © 2011 Sutter Instrument Company. All Rights Reserved.

LAMBDA 10 ® is a registered trademark, and SmartShutter™ is a trademark, both of

Sutter Instrument Company.

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 3

iii

DIS C LAIM ER

DIS C LAIM ER

DIS C LAIM ERDIS C LAIM ER

The Lambda 10

Lambda 10----3333 is an optical filter switcher and shutter controller designed for the specific

Lambda 10Lambda 10

use of changing filters into and out of an optical pathway and no other use is recommended.

This instrument is designed for use in a laboratory environment. It is not intended, nor

should it be used in human experimentation or applied to humans in any way. This is not a

medical device.

Do not open or attempt to repair the instrument. Extreme heat and high voltages are present

and could cause injury.

Do not allow unauthorized and/or untrained operative to use this device.

Any misuse will be the sole responsibility of the user/owner and Sutter Instrument Company

assumes no implied or inferred liability for direct or consequential damages from this

instrument if it is operated or used in any way other than for which it is designed.

SAFE TY W ARNI N GS A ND

SAFE TY W ARNI N GS A ND PREC AUTI ONS

SAFE TY W ARNI N GS A ND SAFE TY W ARNI N GS A ND

Electrical

Electrical

ElectricalElectrical

PRECA UTIO NS

PRECA UTIO NSPRECA UTIO NS

Operate the Lambda 10

Operate the Lambda 10----3 using 110

Operate the Lambda 10Operate the Lambda 10

voltage.

voltage. This instrument is designed for connection to a standard laboratory power outle

voltage. voltage.

(Overvoltage Category II), and because it is a microprocessor

(Overvoltage Category II), and because it is a microprocessor--

(Overvoltage Category II), and because it is a microprocessor(Overvoltage Category II), and because it is a microprocessor

be accorded the same system wiring precautions as any 'computer type' system. A surge

be accorded the same system wiring precautions as any 'computer type' system. A surge

be accorded the same system wiring precautions as any 'computer type' system. A surge be accorded the same system wiring precautions as any 'computer type' system. A surge

protector and power regulator are recommended.

protector and power regulator are recommended.

protector and power regulator are recommended.protector and power regulator are recommended.

Fuse Replacement:

A spare fuse is located in the power input module. Please refer to the fuse

A spare fuse is located in the power input module. Please refer to the fuse----replacement

A spare fuse is located in the power input module. Please refer to the fuseA spare fuse is located in the power input module. Please refer to the fuse

appendix for more details on fuse ratings and for instructions on how to change the fuse.

appendix for more details on fuse ratings and for instructions on how to change the fuse.

appendix for more details on fuse ratings and for instructions on how to change the fuse. appendix for more details on fuse ratings and for instructions on how to change the fuse.

Avoiding Electrical Shock and Fire

Avoiding Electrical Shock and Fire----related Injury

Avoiding Electrical Shock and FireAvoiding Electrical Shock and Fire

grounded outlet (3

grounded outlet (3----prong). This is required to protect you from injury in the event th

grounded outlet (3grounded outlet (3

an electrical hazard occurs.

an electrical hazard occurs.

an electrical hazard occurs.an electrical hazard occurs.

Do not disassemble the system. Refer servicing to qualified personnel.

Do not disassemble the system. Refer servicing to qualified personnel.

Do not disassemble the system. Refer servicing to qualified personnel.Do not disassemble the system. Refer servicing to qualified personnel.

This instrument is designed for connection to a standard laboratory power outlet

This instrument is designed for connection to a standard laboratory power outleThis instrument is designed for connection to a standard laboratory power outle

Fuse Replacement: Replace

Fuse Replacement: Fuse Replacement:

T3.15A, 250V,

T3.15A, 250V, 5 x 20mm, Time Delay fuse

T3.15A, 250V, T3.15A, 250V,

(Examples: Bussmann GDC

(Examples: Bussmann GDC----3.15A or S506

(Examples: Bussmann GDC(Examples: Bussmann GDC

Always use the grounded power supply cord set provided to connect the system to a

Always use the grounded power supply cord set provided to connect the system to a

Always use the grounded power supply cord set provided to connect the system to a Always use the grounded power supply cord set provided to connect the system to a

To prevent fire or shock hazard do not expose the unit to rain or moisture.

To prevent fire or shock hazard do not expose the unit to rain or moisture.

To prevent fire or shock hazard do not expose the unit to rain or moisture. To prevent fire or shock hazard do not expose the unit to rain or moisture.

3 using 110----120 V AC, 60 Hz, or 220

3 using 1103 using 110

Replace only with the same type and rating:

Replace Replace

5 x 20mm, Time Delay fuse (IEC 60127

5 x 20mm, Time Delay fuse 5 x 20mm, Time Delay fuse

Littelfuse 218 3.15 or 218 3.15P (RoHS))

Littelfuse 218 3.15 or 218 3.15P (RoHS))

Littelfuse 218 3.15 or 218 3.15P (RoHS)) Littelfuse 218 3.15 or 218 3.15P (RoHS))

prong). This is required to protect you from injury in the event that

prong). This is required to protect you from injury in the event thprong). This is required to protect you from injury in the event th

120 V AC, 60 Hz, or 220----240 V AC., 50 Hz line

120 V AC, 60 Hz, or 220120 V AC, 60 Hz, or 220

only with the same type and rating:

only with the same type and rating: only with the same type and rating:

(IEC 60127----2, Sheet III)

(IEC 60127(IEC 60127

3.15A or S506----3333.15R (RoHS); or

3.15A or S5063.15A or S506

related Injury

related Injuryrelated Injury

240 V AC., 50 Hz line

240 V AC., 50 Hz line 240 V AC., 50 Hz line

--controlled device, it should

controlled device, it should

----

controlled device, it should controlled device, it should

2, Sheet III)

2, Sheet III)2, Sheet III)

.15R (RoHS); or

.15R (RoHS); or.15R (RoHS); or

replacement

replacement replacement

at

at at

t

t t

Optical Radiation

Optical Radiation

Optical RadiationOptical Radiation

This system is designed for use in conjunction with high

This system is designed for use in conjunction with high----intensity light sources. Failure to

This system is designed for use in conjunction with highThis system is designed for use in conjunction with high

comply with any of the following precautions may result in injury to the users of this device

comply with any of the following precautions may result in injury to the users of this device

comply with any of the following precautions may result in injury to the users of this device comply with any of the following precautions may result in injury to the users of this device

as well as those working in the general area

as well as those working in the general area near the device.

as well as those working in the general area as well as those working in the general area

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

near the device.

near the device.near the device.

intensity light sources. Failure to

intensity light sources. Failure to intensity light sources. Failure to

Page 4

iv

Electromagnetic Interference

Electromagnetic Interference

Electromagnetic InterferenceElectromagnetic Interference

To comply with FDA and CE electromagnetic immunity and interference standards; and to

To comply with FDA and CE electromagnetic immunity and interference standards; and to

To comply with FDA and CE electromagnetic immunity and interference standards; and to To comply with FDA and CE electromagnetic immunity and interference standards; and to

reduce the electromagnetic couplin

reduce the electromagnetic coupling between this and other equipment in your lab always

reduce the electromagnetic couplinreduce the electromagnetic couplin

use the type and length of interconnect cables provided with the unit for the interconnection

use the type and length of interconnect cables provided with the unit for the interconnection

use the type and length of interconnect cables provided with the unit for the interconnection use the type and length of interconnect cables provided with the unit for the interconnection

of one or more filter wheels and/or shutters, h

of one or more filter wheels and/or shutters, host computer via serial RS

of one or more filter wheels and/or shutters, hof one or more filter wheels and/or shutters, h

interface, or othe

interface, or other equipment via TTL connections

interface, or otheinterface, or othe

appendix for more details).

appendix for more details).

appendix for more details).appendix for more details).

Never look into the optical pathway of the high intensity light sources typically used

Never look into the optical pathway of the high intensity light sources typically used

Never look into the optical pathway of the high intensity light sources typically used Never look into the optical pathway of the high intensity light sources typically used

with this instrument. Doing so can cause permanent eye damage.

with this instrument. Doing so can cause permanent eye damage.

with this instrument. Doing so can cause permanent eye damage.with this instrument. Doing so can cause permanent eye damage.

The high

The high----intensity light sources typically used with this instrument also produce a

The highThe high

ssssignificant amount of heat. Direct contact with the housing of those instruments can

ignificant amount of heat. Direct contact with the housing of those instruments can

ignificant amount of heat. Direct contact with the housing of those instruments can ignificant amount of heat. Direct contact with the housing of those instruments can

cause serious burns.

cause serious burns.

cause serious burns.cause serious burns.

The SmartShutter is Not a Safety Shutter:

The SmartShutter is Not a Safety Shutter: Sutter Instrument Co.’s SmartShutter is

The SmartShutter is Not a Safety Shutter: The SmartShutter is Not a Safety Shutter:

not i

not intended to be a ‘safety shutter.’ A safety shutter usually closes automatically in the

ntended to be a ‘safety shutter.’ A safety shutter usually closes automatically in the

not inot i

ntended to be a ‘safety shutter.’ A safety shutter usually closes automatically in the ntended to be a ‘safety shutter.’ A safety shutter usually closes automatically in the

event of a power failure and is designed with the primary goal of ensuring that it will not

event of a power failure and is designed with the primary goal of ensuring that it will not

event of a power failure and is designed with the primary goal of ensuring that it will not event of a power failure and is designed with the primary goal of ensuring that it will not

allow any unintended exposure. For laser safety applications, a shutter is no

allow any unintended exposure. For laser safety applications, a shutter is normally

allow any unintended exposure. For laser safety applications, a shutter is noallow any unintended exposure. For laser safety applications, a shutter is no

designed so that no single component failure allows an unintended exposure to the laser

designed so that no single component failure allows an unintended exposure to the laser

designed so that no single component failure allows an unintended exposure to the laser designed so that no single component failure allows an unintended exposure to the laser

beam. The SmartShutter is intended for use in the controlling of light in scientific and

beam. The SmartShutter is intended for use in the controlling of light in scientific and

beam. The SmartShutter is intended for use in the controlling of light in scientific and beam. The SmartShutter is intended for use in the controlling of light in scientific and

industrial applications. The SmartShutter was designed for high performa

industrial applications. The SmartShutter was designed for high performance and

industrial applications. The SmartShutter was designed for high performaindustrial applications. The SmartShutter was designed for high performa

durability, but without certain features that would be desirable in a safety shutter

durability, but without certain features that would be desirable in a safety shutter

durability, but without certain features that would be desirable in a safety shutter durability, but without certain features that would be desirable in a safety shutter

application.

application.

application. application.

intensity light sources typically used with this instrument also produce a

intensity light sources typically used with this instrument also produce a intensity light sources typically used with this instrument also produce a

Sutter Instrument Co.’s SmartShutter is

Sutter Instrument Co.’s SmartShutter is Sutter Instrument Co.’s SmartShutter is

rmally

rmally rmally

nce and

nce and nce and

g between this and other equipment in your lab always

g between this and other equipment in your lab always g between this and other equipment in your lab always

ost computer via serial RS----232 or parallel

ost computer via serial RSost computer via serial RS

r equipment via TTL connections (see the TECHNICAL SPECIFICATIONS

r equipment via TTL connectionsr equipment via TTL connections

(see the TECHNICAL SPECIFICATIONS

(see the TECHNICAL SPECIFICATIONS (see the TECHNICAL SPECIFICATIONS

232 or parallel

232 or parallel 232 or parallel

Operational

Operational

OperationalOperational

Failure to comply with any of the following precautions may

Failure to comply with any of the following precautions may damage this device.

Failure to comply with any of the following precautions may Failure to comply with any of the following precautions may

This instrument is designed for operation in a laboratory environment (Pollution Degree

This instrument is designed for operation in a laboratory environment (Pollution Degree

This instrument is designed for operation in a laboratory environment (Pollution Degree This instrument is designed for operation in a laboratory environment (Pollution Degree

I).

I).

I).I).

This unit is not designed for operation at altitudes above 2000 meters nor was it tested

This unit is not designed for operation at altitudes above 2000 meters nor was it tested

This unit is not designed for operation at altitudes above 2000 meters nor was it tested This unit is not designed for operation at altitudes above 2000 meters nor was it tested

for safety above 2000 meters.

for safety above 2000 meters.

for safety above 2000 meters.for safety above 2000 meters.

DO NOT CONNECT OR DISC

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN THE

DO NOT CONNECT OR DISCDO NOT CONNECT OR DISC

CONTROLLER AND THE MECHANICAL UNITS WHILE POWER IS ON.

CONTROLLER AND THE MECHANICAL UNITS WHILE POWER IS ON.

CONTROLLER AND THE MECHANICAL UNITS WHILE POWER IS ON. CONTROLLER AND THE MECHANICAL UNITS WHILE POWER IS ON.

ONNECT THE CABLES BETWEEN THE

ONNECT THE CABLES BETWEEN THE ONNECT THE CABLES BETWEEN THE

damage this device.

damage this device. damage this device.

Please allow at least 20 seconds after turning the unit off before disconnecting the

Please allow at least 20 seconds after turning the unit off before disconnecting the

Please allow at least 20 seconds after turning the unit off before disconnecting the Please allow at least 20 seconds after turning the unit off before disconnecting the

mechanical units. Failure to do this may result in damage to the electronics.

mechanical units. Failure to do this may result in damage to the electronics.

mechanical units. Failure to do this may result in damage to the electronics.mechanical units. Failure to do this may result in damage to the electronics.

Oper

Operate only in a location where there is a free flow of fresh air on all sides.

ate only in a location where there is a free flow of fresh air on all sides.

OperOper

ate only in a location where there is a free flow of fresh air on all sides. ate only in a location where there is a free flow of fresh air on all sides.

NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.

NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.

NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 5

v

TABLE OF CONTENTS

DISCLAIMER

DISCLAIMER ................................

DISCLAIMERDISCLAIMER

SAFETY WARNINGS AND PRECAUTIO

SAFETY WARNINGS AND PRECAUTIONS

SAFETY WARNINGS AND PRECAUTIOSAFETY WARNINGS AND PRECAUTIO

Electrical .................................................................................................................................................iii

Avoiding Electrical Shock and Fire-related Injury.............................................................................iii

Optical Radiation ...................................................................................................................................iii

Electromagnetic Interference...............................................................................................................iv

Operational .............................................................................................................................................iv

1. GENERAL INFORMATION

1. GENERAL INFORMATION ................................

1. GENERAL INFORMATION1. GENERAL INFORMATION

1.1 Introduction.......................................................................................................................................1

1.1.1 How to use this Manual.............................................................................................................1

1.1.2 Technical Support......................................................................................................................1

1.2 General Description..........................................................................................................................1

1.3 Filter Wheel.......................................................................................................................................2

1.3.1 Mechanical Description .............................................................................................................2

1.3.2 Filter Wheels...............................................................................................................................3

1.3.2.1 Mechanical Description.......................................................................................................4

1.3.3 Filters...........................................................................................................................................4

1.3.4 Slide-in or Drop-in Filter Holders............................................................................................5

1.3.5 Shutters.......................................................................................................................................5

1.3.6 SmartShutter Mounts ...............................................................................................................6

1.3.7 Cables ..........................................................................................................................................6

1.3.8 Devices for TTL-Control of Shutters .......................................................................................6

Adapters................................................................................................................................................6

1.4 SmartShutter ....................................................................................................................................7

1.4.1 Step Motor Based Shutter Advantages....................................................................................7

1.4.2 Modes...........................................................................................................................................9

1.4.3 Special Considerations.............................................................................................................10

1.4.3.1 Mounting............................................................................................................................10

1.4.3.2 Opening and Closing Times .............................................................................................10

1.4.3.3 Repetition Rates and Duty Cycle.....................................................................................11

1.5 Controller.........................................................................................................................................12

1.5.1 Principles of Operation............................................................................................................12

1.5.2 Rear Panel Connectors ............................................................................................................12

1.5.3 Front Panel Controls...............................................................................................................15

1.5.3.1 Power Switch.....................................................................................................................15

1.5.3.2 Keypad................................................................................................................................15

1.5.3.3 Display ................................................................................................................................16

1.6 Options and Accessories.................................................................................................................16

1.6.1 Supported Filter Wheel and Shutter Configurations...........................................................16

1.7 Functional Description...................................................................................................................17

1.7.1 Stepping Motor Operation ......................................................................................................17

................................................................

................................................................

................................................................

................................................................

NS................................

................................................................

NSNS

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...................................................

................................................................

......................................

................................................................

...................iii

......................................

...........................................

................................................................

...........1111

......................

......iii

iii

............

iiiiii

iii

iiiiii

2.

2. INSTALLATION

INSTALLATION ................................

2.2.

INSTALLATION INSTALLATION

2.1 Unpacking........................................................................................................................................19

................................................................

................................................................

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

................................................................

................................................................

............................................................

................................................................

............................19

........................................................

19

1919

Page 6

vi

2.2 Pre-Installation Considerations ....................................................................................................20

2.2.1 Vibrations..................................................................................................................................20

2.3 Installing the Filter Wheel.............................................................................................................21

2.4 Filter Wheel Assembly....................................................................................................................22

2.5 Loading Filters................................................................................................................................23

2.5.1 Filter Orientation.....................................................................................................................23

2.5.2 Filter Cups and Filter Holders................................................................................................23

2.5.3 Installation of Filters into Filter Holders..............................................................................25

2.5.4 Installation of Filters into Filter Cups...................................................................................27

2.6 Filter Loading Tips.........................................................................................................................29

2.6.1 Selection of a Filter Position...................................................................................................29

2.6.2 Use of Blanking Discs ..............................................................................................................29

2.6.3 Neutral Density Filters............................................................................................................29

2.7 Shutter Options...............................................................................................................................29

2.8 Mounting a SmartShutter in a Lambda LS.................................................................................30

3.

3. OPERATIONS

OPERATIONS ................................

3.3.

OPERATIONS OPERATIONS

3.1 First Time Use ................................................................................................................................31

3.1.1 Line Power (Mains)..................................................................................................................31

3.2 Basic Operation...............................................................................................................................32

3.2.1 Initialization .............................................................................................................................32

3.3 Make It Go.......................................................................................................................................32

4.

4. OPERATIONS: MANUAL CONTROL

OPERATIONS: MANUAL CONTROL................................

4.4.

OPERATIONS: MANUAL CONTROL OPERATIONS: MANUAL CONTROL

4.1 Power -Up Sequence.......................................................................................................................35

4.2 Setting the Position of the Active Filter Wheel...........................................................................36

4.3 Toggling Shutter States (S1 and S2) ............................................................................................36

4.4 Displaying the Main Menu.............................................................................................................36

4.5 Selecting Various Modes and Configurations with the MODE Key .........................................36

4.6 Selecting the Active Filter Wheel for Manual Control (MODE 1) ............................................37

4.7 Selecting the Speed for the Active Filter Wheel (MODE 2).......................................................37

4.8 Selecting Shutter TTL Control (MODE 3) ..................................................................................38

4.8.1 Enabling Shutter TTL Control (MODE 3 1 or MODE 3 3)................................................38

4.8.2 Determining the Shutter TTL Control Mode (MODE 3 1 1|2|3 or MODE 3 3 1|2|3)...38

4.9 Selecting a Test Mode (MODE 4)..................................................................................................39

4.10 Selecting SmartShutter Modes (MODE 5) ................................................................................39

4.10.1 Setting a SmartShutter to Neutral Density Mode.............................................................39

4.11 Saving and Restoring SmartShutter Mode Configurations (MODE 6)..................................40

4.12 New Menus as of Lambda 10-3 Firmware Rev. 1.21 ................................................................40

4.12.1 Setting Power-up Defaults (MODE 7).................................................................................40

4.12.1.1 Setting the Speed Defaults for Wheels A, B, & C (MODE 7 1 1|2|3 [0 – 7])............40

4.12.1.2 Setting the Position (Filter) Defaults for Wheels A, B, & C (MODE 7 1 5|6|7 [0 –

7]).....................................................................................................................................................41

4.12.1.3 Setting the Default Communications Port (MODE 7 1 4).........................................41

4.12.1.4 Setting the Current SmartShutter Mode as the Default (MODE 7 1 8 1|2)............41

4.12.1.5 Resetting All to Factory Defaults (MODE 7 2)............................................................41

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.........................................................

................................................................

................................31

................................................................

.........................35

..................................................

31

3131

35

3535

5.

5. EXTERNAL COMMAND CONTROL

EXTERNAL COMMAND CONTROL OPERATIONS OVERVIEW

5.5.

EXTERNAL COMMAND CONTROL EXTERNAL COMMAND CONTROL

5.1 Input Command Structure............................................................................................................43

5.1.1 Command Descriptions ...........................................................................................................43

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

OPERATIONS OVERVIEW ................................

OPERATIONS OVERVIEWOPERATIONS OVERVIEW

..........................................

................................................................

..........43

....................

43

4343

Page 7

vii

5.2 Filter Wheel Commands ................................................................................................................47

5.2.1 Filter Wheel Command Byte Encoding.................................................................................49

5.3 Shutter Commands.........................................................................................................................49

5.3.1 Open Shutter A ........................................................................................................................51

5.3.2 Open Shutter A Conditionally ................................................................................................51

5.3.3 Close Shutter A.........................................................................................................................51

5.3.4 Open Shutter B ........................................................................................................................51

5.3.5 Open Shutter B Conditionally ................................................................................................51

5.3.6 Close Shutter B.........................................................................................................................51

5.3.7 Open Shutter C.........................................................................................................................51

5.3.8 Open Shutter C Conditionally ................................................................................................51

5.3.9 Close Shutter C.........................................................................................................................51

5.3.10 Fast-Mode Shutter.................................................................................................................51

5.3.11 Soft-Mode Shutter..................................................................................................................51

5.3.12 Neutral Density Mode Shutter.............................................................................................51

5.4 Special Commands..........................................................................................................................52

5.4.1 Batch Start and Batch End.....................................................................................................53

5.4.2 Status.........................................................................................................................................53

5.4.3 All Motors Power On ...............................................................................................................55

5.4.4 All Motors Power Off...............................................................................................................56

5.4.5 Batch Transfer..........................................................................................................................56

5.4.6 Transfer to On Line.................................................................................................................56

5.4.7 Transfer to Local......................................................................................................................56

5.4.8 Reset ..........................................................................................................................................56

5.4.9 Get Controller Type and Configuration ................................................................................56

5.5 Shutter Control without Remote Commands via Dedicated TTL Line ...................................57

5.6 Remote Control Command Programming...................................................................................58

5.6.1 Preparing the Command Byte................................................................................................58

5.6.1.1 Encoding Filter Commands Into a Single Byte..............................................................58

5.6.1.2 Shutter or Special Commands .........................................................................................59

5.6.2 Command Transmission Protocol..........................................................................................59

5.6.2.1 Confirmation Command Echo.........................................................................................59

5.6.2.2 Command Completion Indicator .....................................................................................59

6.

6. EXTERNAL SERIAL RS

EXTERNAL SERIAL RS----232 INTERFACE CONTROL

6.6.

EXTERNAL SERIAL RS EXTERNAL SERIAL RS

6.1 Connecting to the Serial Port........................................................................................................61

6.2 Input Command Set and Protocol ................................................................................................62

7.

7. EXTERNAL USB INTERFACE CONTROL

EXTERNAL USB INTERFACE CONTROL ................................

7.7.

EXTERNAL USB INTERFACE CONTROL EXTERNAL USB INTERFACE CONTROL

7.1 Installing the Lambda 10-3 as a USB Device on a Windows System using the Standard

Device Driver.........................................................................................................................................63

7.1.1 Installation Steps .....................................................................................................................64

7.1.2 Interactive USB Device Driver Installation..........................................................................65

7.2 Installing the Lambda 10-3 as a USB Device on a Windows System using CDM (Combined

Driver Model) Device Driver................................................................................................................67

7.3 Installing the USB interface for non-Windows systems.............................................................68

7.4 Verifying USB Communication between Remote Computer and Lambda 10-3 .....................68

7.5 Uninstalling the USB Driver for the Lambda 10-3.....................................................................70

7.6 Remote Commands and the USB Interface.................................................................................71

232 INTERFACE CONTROL................................

232 INTERFACE CONTROL232 INTERFACE CONTROL

................................................................

................................................................

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

.............................................................

................................................................

................................................

................................................................

.............................61

..........................................................

................63

................................

61

6161

63

6363

Page 8

viii

8.

8. EXTERNAL PARALLEL I

EXTERNAL PARALLEL INTERFACE CONTROL

8.8.

EXTERNAL PARALLEL I EXTERNAL PARALLEL I

8.1 Connecting to the Parallel Port Interface....................................................................................73

8.2 Input Command Structure............................................................................................................74

8.2.1 Filter Commands......................................................................................................................75

8.2.2 Special Commands: ON LINE, BATCH, and SHUTTER Commands .............................76

8.3 Output Command Structure: BUSY and ERROR lines............................................................76

8.4 Strategies for Controlling the Lambda 10-3 via the Parallel Port ............................................77

8.4.1 Using Input Lines Only...........................................................................................................77

8.4.2 Using Fewer than Eight Input Lines.....................................................................................77

8.4.3 Using the BUSY Line ..............................................................................................................78

8.4.4 Using the ERROR Line...........................................................................................................78

8.5 Using a Computer’s Parallel (Printer) Port.................................................................................78

8.5.1 Connecting to the PC Parallel (Printer) Port.......................................................................79

8.5.2 Input Command Structure .....................................................................................................80

8.5.3 Output Command Structure: BUSY and ERROR Lines....................................................81

8.6 Dedicated TTL Line........................................................................................................................82

9.

9. OPERATING INSTRUCTIONS: EXTERNAL LOGIC LEVEL (TTL) SHUTTER CONTROL

OPERATING INSTRUCTIONS: EXTERNAL LOGIC LEVEL (TTL) SHUTTER CONTROL

9.9.

OPERATING INSTRUCTIONS: EXTERNAL LOGIC LEVEL (TTL) SHUTTER CONTROL OPERATING INSTRUCTIONS: EXTERNAL LOGIC LEVEL (TTL) SHUTTER CONTROL

................................

................................................................

................................................................

9.1 Using the Computer’s Parallel Port for Control.........................................................................85

9.2 Enabling/Disabling and Setting the Type of TTL IN Control...................................................87

................................................................

................................................................

NTERFACE CONTROL................................

NTERFACE CONTROLNTERFACE CONTROL

................................................................

................................................................

................................................................

................................................................

..............................................................

................................................................

....................................

................................................................

..............................85

............................................................

....73

........

73

7373

85

8585

10. MAINTENANCE

10. MAINTENANCE................................

10. MAINTENANCE10. MAINTENANCE

11. TROUBLESHOOTING

11. TROUBLESHOOTING................................

11. TROUBLESHOOTING11. TROUBLESHOOTING

11.1 Filter Wheel Error Detection and Recovery ..............................................................................91

11.2 Filter Wheel Movement Errors: Causes and Solutions...........................................................91

11.2.1 Filter Weight vs. Speed..........................................................................................................91

11.2.2 Oscillation when Stopping ....................................................................................................91

11.2.3 Oscillations when Moving .....................................................................................................91

11.2.4 Movement Errors after Successive Moves ..........................................................................92

11.3 Helpful Tips about Filter Wheel Movement Errors..................................................................92

11.4 SmartShutter Movement Errors: Causes and Solutions ........................................................92

11.4.1 SmartShutter Movement Errors after Successive Moves .................................................92

APPENDIX A. LIMITED WARRANTY

APPENDIX A. LIMITED WARRANTY................................

APPENDIX A. LIMITED WARRANTYAPPENDIX A. LIMITED WARRANTY

APPENDIX B.

APPENDIX B. ACCESSORIES

APPENDIX B.APPENDIX B.

B.1. Filter Wheels..................................................................................................................................97

B.2. SmartShutter.................................................................................................................................98

APPENDIX C. FUSE REPLACEMENT

APPENDIX C. FUSE REPLACEMENT................................

APPENDIX C. FUSE REPLACEMENTAPPENDIX C. FUSE REPLACEMENT

APPENDIX D. TECHNICAL SPECIF

APPENDIX D. TECHNICAL SPECIFICATIONS

APPENDIX D. TECHNICAL SPECIFAPPENDIX D. TECHNICAL SPECIF

D.1. Controller.....................................................................................................................................101

D.2. Filter Wheel, 25 mm (1”): ..........................................................................................................105

D.3. Filter Wheel, 32 mm (1.27”):.....................................................................................................105

D.4. SmartShutter, 25 mm (1 in) (standalone):...............................................................................105

D.5. SmartShutter, 35 mm (1.38 in) (standalone):..........................................................................106

ACCESSORIES ................................

ACCESSORIES ACCESSORIES

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

ICATIONS................................

ICATIONSICATIONS

................................................................

................................................................

..........................................................

................................................................

................................................

................................................................

............................................................

................................................................

.........................................

................................................................

...........................................................

................................................................

.........................................

................................................................

..........................89

....................................................

................91

................................

............................95

........................................................

.........97

..................

...........................99

......................................................

.........101

..................

89

8989

91

9191

95

9595

97

9797

99

9999

101

101101

APPENDIX F. EXTERNAL CONTROL COMMAND REFERENCE

APPENDIX F. EXTERNAL CONTROL COMMAND REFERENCE ................................

APPENDIX F. EXTERNAL CONTROL COMMAND REFERENCEAPPENDIX F. EXTERNAL CONTROL COMMAND REFERENCE

INDEX

INDEX................................

INDEXINDEX

................................................................

................................................................

................................................................

................................................................

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

................................................................

................................................................

..........................................

................................................................

...............................................

................................................................

...............117

..............................

..........107

107

....................

107107

117

117117

Page 9

ix

TABLE OF FIGURES

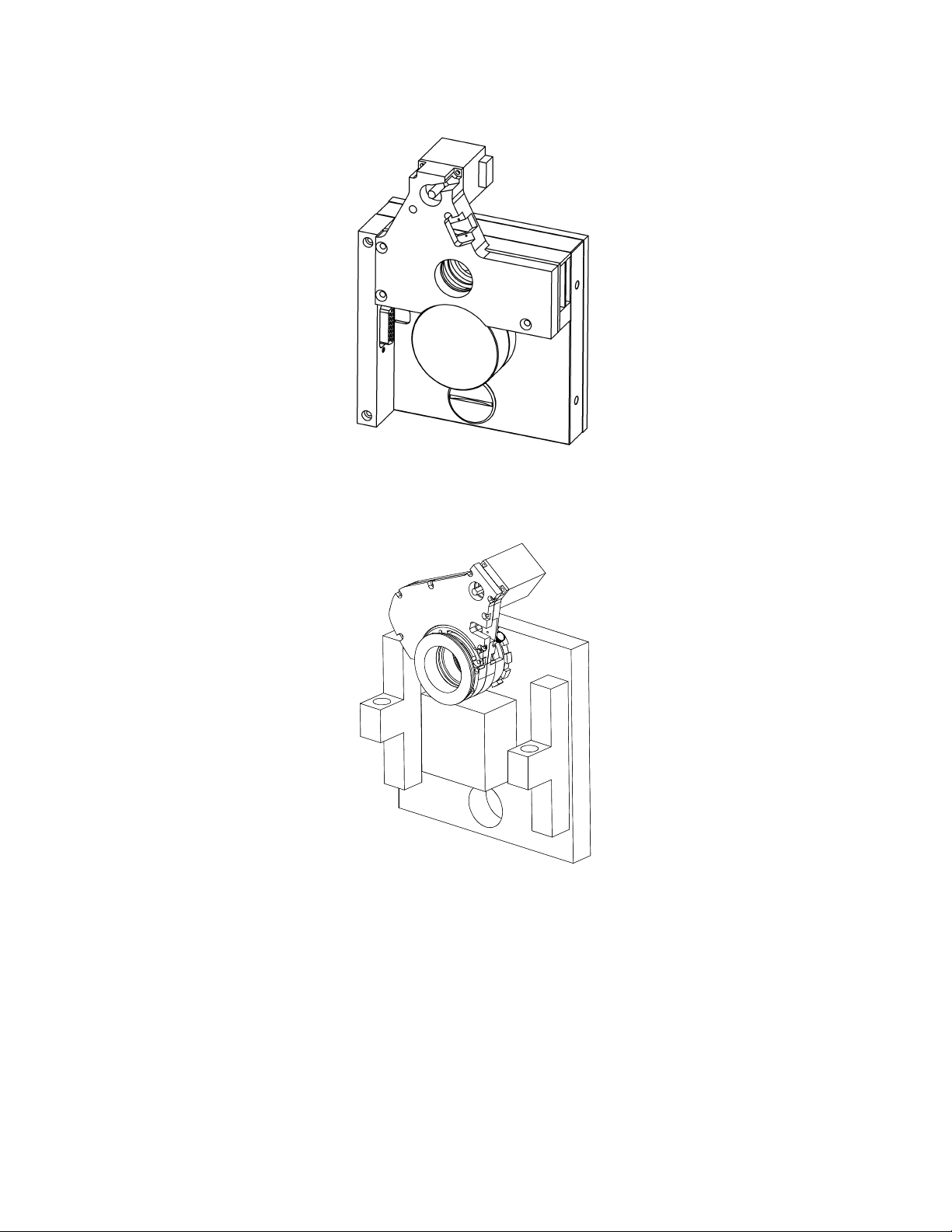

Figure 1-1. Lambda 10-3 filter wheel (without shutter). .......................................................................3

Figure 1-2. Lambda 10-3 filter wheel housing (with shutter). ..............................................................3

Figure 1-3. Lambda 10-3 filter wheel housing with SmartShutter.......................................................3

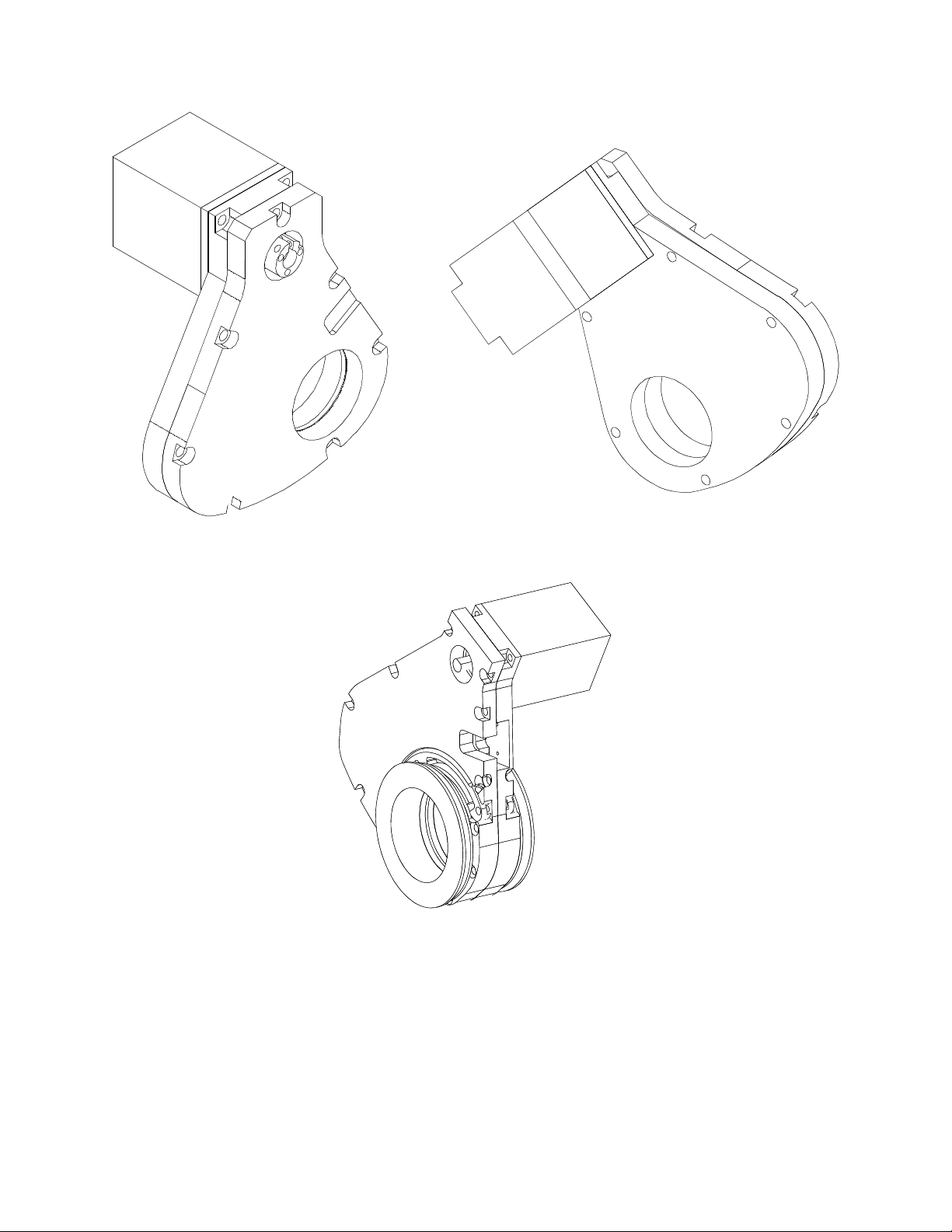

Figure 1-4. 25mm SmartShutter (standalone)........................................................................................8

Figure 1-5. 35mm SmartShutter (standalone)........................................................................................8

Figure 1-6. 25mm SmartShutter mounted on the housing of a 25mm Filter Wheel. ........................9

Figure 1-7. 35mm SmartShutter mounted on 32mm Filter Wheel Assembly. ...................................9

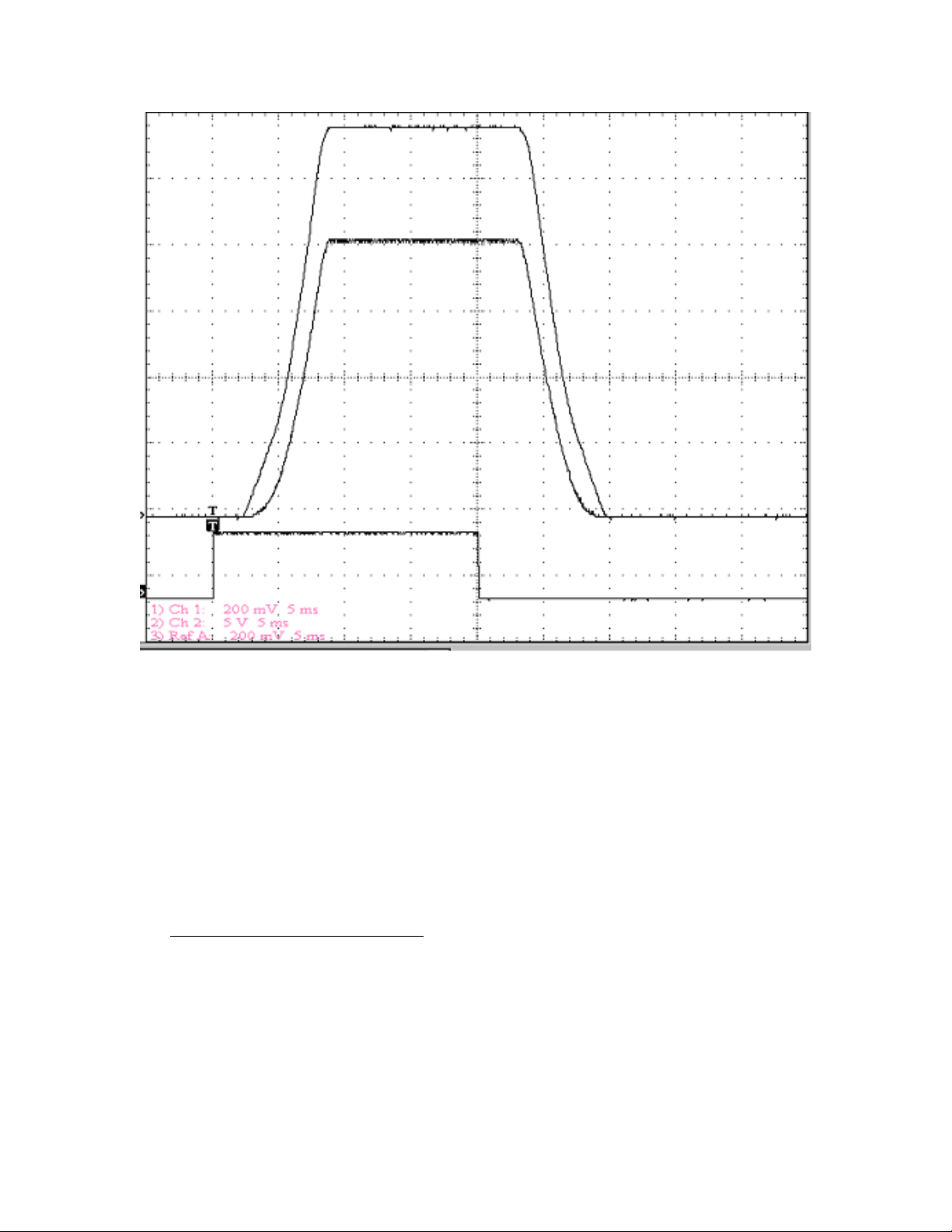

Figure 1-8. SmartShutter timing............................................................................................................11

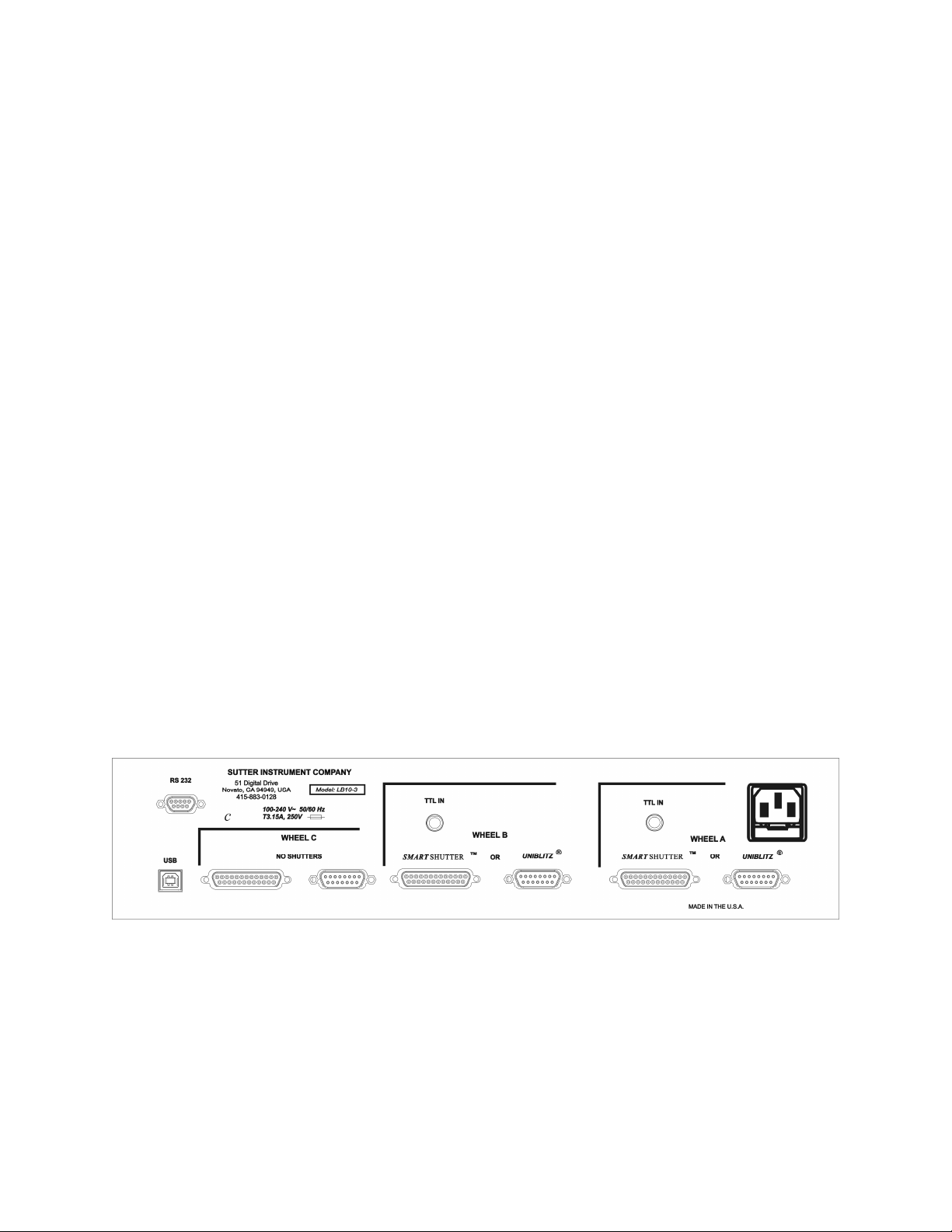

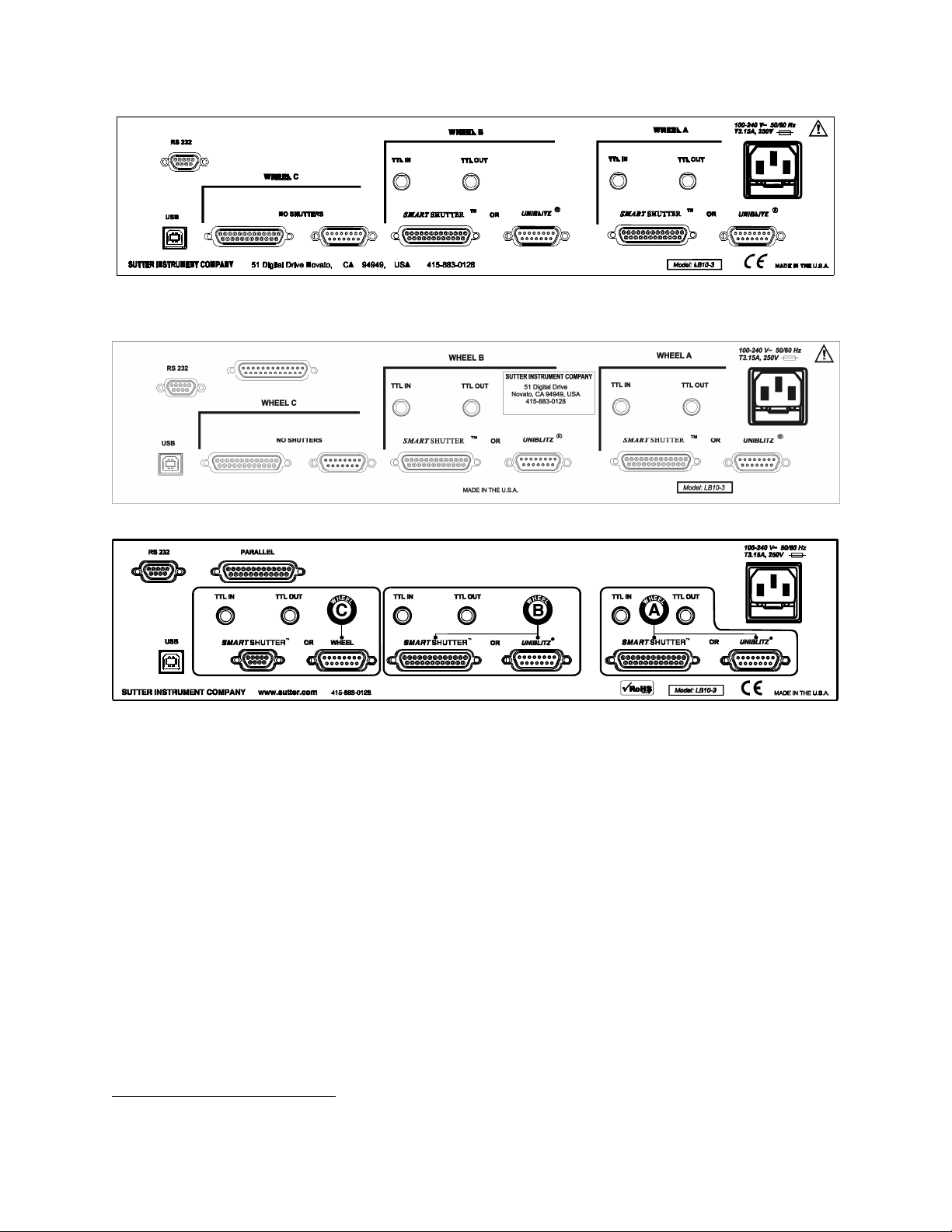

Figure 1-9. Generation 1 rear panel electrical connections. ................................................................12

Figure 1-10. Generation 2 rear panel electrical connections...............................................................13

Figure 1-11. Generation 3 rear panel electrical connections)..............................................................13

Figure 1-12. Generation 4 rear panel electrical connections...............................................................13

Figure 1-13. Lambda 10-3 front panel controls.....................................................................................15

Figure 2-1. Schematic diagram of two possible experimental configurations. ..................................21

Figure 2-2. Filter wheel-mounting stand...............................................................................................22

Figure 2-3. Filter wheel connection.......................................................................................................23

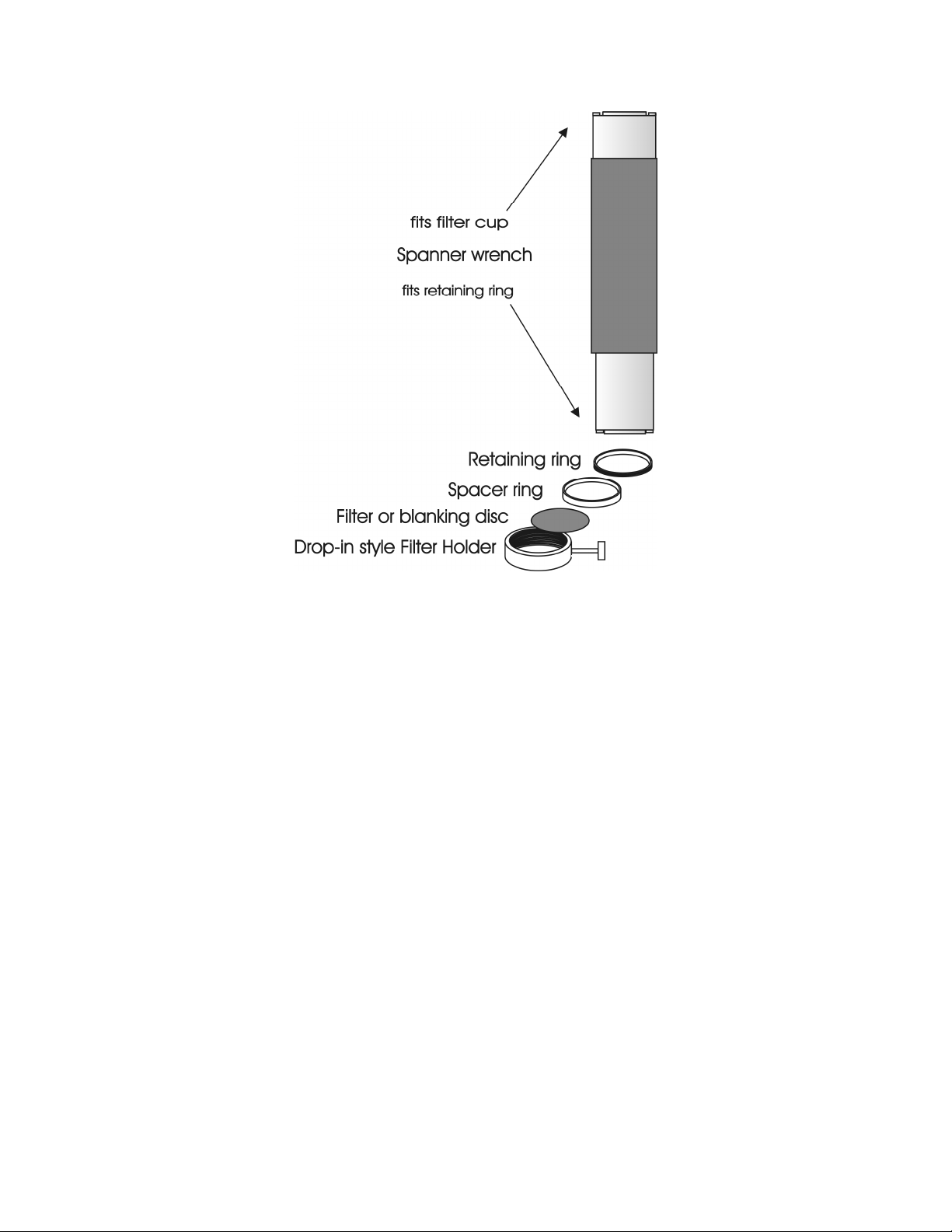

Figure 2-4. Filter holder components.....................................................................................................24

Figure 2-5. Changing filters in the Slide-In Filter Holder. ..................................................................25

Figure 2-6. Removing the retaining ring................................................................................................26

Figure 2-7. Assembly order of filter holder parts.................................................................................26

Figure 2-8. Filter ports (plug is removed from the loading port). .......................................................28

Figure 3-1. Lambda 10-3 cabinet (rear view) showing power connection and fuse. .........................31

Figure 3-2. Power switch (front panel). .................................................................................................31

Figure 3-3. Power connection..................................................................................................................32

Figure 6-1. Serial port pin assignments.................................................................................................61

Figure 7-1. The USB cable device connector.........................................................................................64

Figure 7-2. The Lambda 10-3 USB receptacle. .....................................................................................64

Figure 7-3. Host connector end of USB cable........................................................................................65

Figure 7-4 -- USB host receptacle on remote computer.......................................................................65

Figure 7-5 New USB device detected message box...............................................................................65

Figure 7-6 -- Digital Signature dialog box..............................................................................................66

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 10

x

Figure 7-7 -- Specifying location of driver files......................................................................................66

Figure 7-8 Browsing for the driver file needed......................................................................................67

Figure 7-9 USBTest main screen..........................................................................................................69

Figure 8-1. Location of parallel port on rear of Lambda 10-3 controller cabinet..............................73

Figure 8-2. Parallel interface DB-25 connector on the Lambda 10-3.................................................73

Figure 8-3. PC parallel (printer) port.....................................................................................................79

Figure 9-1. Location of TTL IN jumpers on the Lambda 10-3 controller board. ..............................86

Figure 9-2. TTL IN jumpers detail.........................................................................................................87

Figure 11-1. Rear view of the Lambda 10-3 showing the power entry module and fuse location...99

TABLE OF TABLES

Table 2-1. Maximum allowable filter thickness. ...................................................................................25

Table 4-1. Filter switching times (in milliseconds)...............................................................................38

Table 4-2. Factory defaults for filter wheels, SmartShutters, and communications ports..............42

Table 5-1. Remote control command categories. ..................................................................................43

Table 5-2. Remote Control Commands..................................................................................................44

Table 5-3. Command Code Ranges.........................................................................................................47

Table 5-4. Filter Command Structure....................................................................................................48

Table 5-5. Shutter commands. ................................................................................................................49

Table 5-6. Special command codes..........................................................................................................52

Table 5-7. Status command return codes and data. .............................................................................53

Table 5-8. “Get Controller Type and Configuration” command return codes and data. .................57

Table 8-1. Lambda 10-3 Parallel Interface Pin Assignments..............................................................74

Table 8-2. Filter command structure. ....................................................................................................75

Table 8-3. PC and Lambda 10-3 parallel port pin assignments ..........................................................80

Table 8-4. PC printer adapter addresses................................................................................................81

Table 8-5. Computer parallel port commands for TTL control of shutters. ......................................83

Table 9-1. Commands for PC parallel port control of dedicated TTL line.........................................85

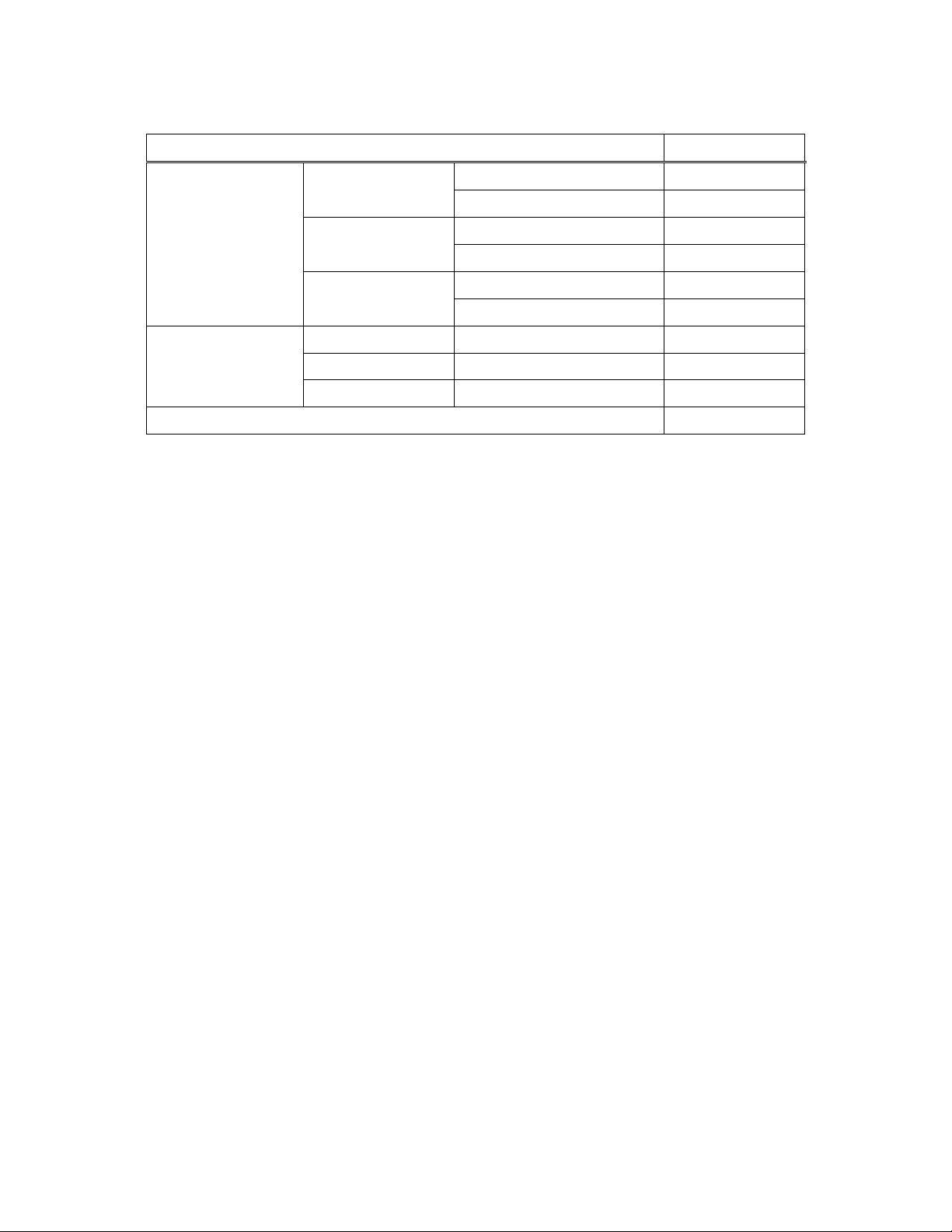

Table D-1. Lambda 10-3 pre-2010 version controller cables..............................................................101

Table D-2. Lambda 10-3 2010 version controller cables. ...................................................................103

Table F-3. Complete Command Reference. .........................................................................................107

Table F-4. Filter command structure...................................................................................................112

Table F-5. Status command return codes and data............................................................................113

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 11

xi

Table F-6. Get Controller Type and Configuration command return data. ....................................115

TABLE OF LISTINGS

Listing 8-1. Batch transfer via PC parallel port program....................................................................76

Listing 8-2. Program to obtain the Lambda 10-3 status on the PC parallel port..............................81

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 12

xii

(This page intentionally blank.)

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 13

1

1.

1. G ENER AL I NFOR M ATIO N

GEN E RAL INFO RMATI ON

1.1.

GEN E RAL INFO RMATI ONG ENERA L IN FORM ATION

1.1

1.1 Introduction

Introduction

1.11.1

IntroductionIntroduction

The Lambda 10-3 is a filter wheel and shutter control system designed for the rapid change

and aperture control of wavelength, and is comprised of two subsystems: 1) a controller, and

2) a combination of filter wheels and shutters that are placed in the optical pathway(s) of

your existing experimental setup. The controller is microprocessor-controlled with capability

of delivering power and control signals to one to two filter wheels, and optionally to one to

two integrated shutters. Each integrated shutter may be a SmartShutter or a conventional

shutter. Each of the two filter wheel/shutter combinations may also consist of a standalone

filter wheel and a standalone SmartShutter. A third standalone filter wheel (without

integrated shutter) is also supported. In the latest revision of the Lambda 10-3, the third

standalone filter wheel may be replaced with a standalone SmartShutter.

1.1.1

1.1.1 How to use this Manual

How to use this Manual

1.1.11.1.1

How to use this ManualHow to use this Manual

Installation of the filter wheel and filters is discussed in the FILTER WHEEL section,

SmartShutter installation is discussed in the SMARTSHUTTER section, and installation and

manual operation of the controller are discussed in the CONTROLLER section. This unit

supports a SmartShutter

three filter wheels are also supported, two of which may be equipped with shutters. Finally,

the remote operation of the Lambda 10-3 through its serial and USB ports is discussed in the

REMOTE CONTROL sections.

SmartShutter or a traditional shutter. Up to two shutters are supported. Up to

SmartShutterSmartShutter

1.1.2

1.1.2 Technical Support

Technical Support

1.1.21.1.2

Technical SupportTechnical Support

Unlimited technical support is provided by Sutter Instrument Company at no charge to our

customers. Our technical support staff is available between the hours of 8:00 AM and 5:00

PM (Pacific Time) at (415) 883

1.2

1.2 General Description

General Description

1.21.2

General DescriptionGeneral Description

The Lambda 10-3 is a microprocessor controlled, high-speed filter wheel system designed for

microscopy and other applications that require rapid and accurate wavelength switching. The

Lambda 10-3 controller can control two filter wheels each with a high-speed shutter and a

third filter wheel without a shutter, and features both USB and serial RS-232 input for

remote control.

The controller is designed around an embedded microcontroller, which automatically

determines the equipment installed. The electronics for controlling a shutter are already

installed, even if you did not order that option. If you add a shutter later, there are no

additional electronics to buy, although you may need to configure the circuit board for the

size of shutter if you wish to install a UNIBLITZ shutter.

The controller can run up to three filter wheels, up to two of which can be equipped with a

shutter, or different combinations of filter wheels and standalone smart shutters, all under

remote control through a USB or serial input using the same simple protocol as the previous

Lambda 10- 2 controller with only minor differences. The USB and the serial RS-232

interfaces use the exact same remote control command set. Some important considerations

(415) 883----0128

(415) 883(415) 883

0128. You may also E-mail your queries to info@sutter.com

01280128

info@sutter.com.

info@sutter.cominfo@sutter.com

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 14

2

about using a combination of input sources (e.g., the keypad and the Serial port) are

discussed in the Remote Control section of this manual.

The following instructions are meant to help you set up the Lambda 10-3 and become

familiar with the manual mode of filter selection. Other sections of this manual contain

detailed discussions on the functionality of the controller, how filters are installed, and

setting up remote control communications.

The LAMBDA SmartShutter

LAMBDA SmartShutter is a microprocessor controlled, high-speed shutter designed for

LAMBDA SmartShutter LAMBDA SmartShutter

microscopy and other applications that require a shutter function. The Lambda 10-3

controller can control two SmartShutters. Shutters are commonly used to turn off a light

source in order to prevent photo bleaching or other photo damage. In addition, they may be

used to select between multiple light sources or light paths, such as transmitted light versus

fluorescence excitation. SmartShutters, in particular, have the ability to be placed into one of

several modes. These modes determine the way the actual shutter action works: Fast Mode,

Soft Mode, and Neutral Density Mode. Fast Mode provides for the fastest open/close action of

the shutter. Soft Mode, is slightly slower than Fast Mode, and provides for a somewhat

gradual open/close action, as well as being quieter. Neutral Density Mode allows for the

control of the aperture of the open state of the shutter – between 1 and 144 microsteps may

be selected for the Neutral Density Mode. Neutral Density Mode also provides for the control

of light intensity without affecting the wavelength.

The primary use of the shutter is as an accessory to the Lambda 10 series of filter wheels, but

it is also used as a stand-alone piece for the transmitted light arm of inverted microscopes.

The electro-mechanical shutters actuated by solenoids have been used by most optical

manufacturers for decades, and have some outstanding features. They act quickly, they can

be driven by simple electronics, and the package is quite thin. However, these units are prone

to frequent failures and usually cannot be repaired. There is effectively no warranty from the

manufacturer for the end user. Although they can produce short bursts of operation at 30

Hertz, they will overheat and fail quickly if this rate of opening is maintained. These shutters

also produce a good deal of vibration and audible noise.

1.3

1.3 Filter Wheel

Filter Wheel

1.31.3

Filter WheelFilter Wheel

1.3.1

1.3.1 Mechanical Description

Mechanical Description

1.3.11.3.1

Mechanical DescriptionMechanical Description

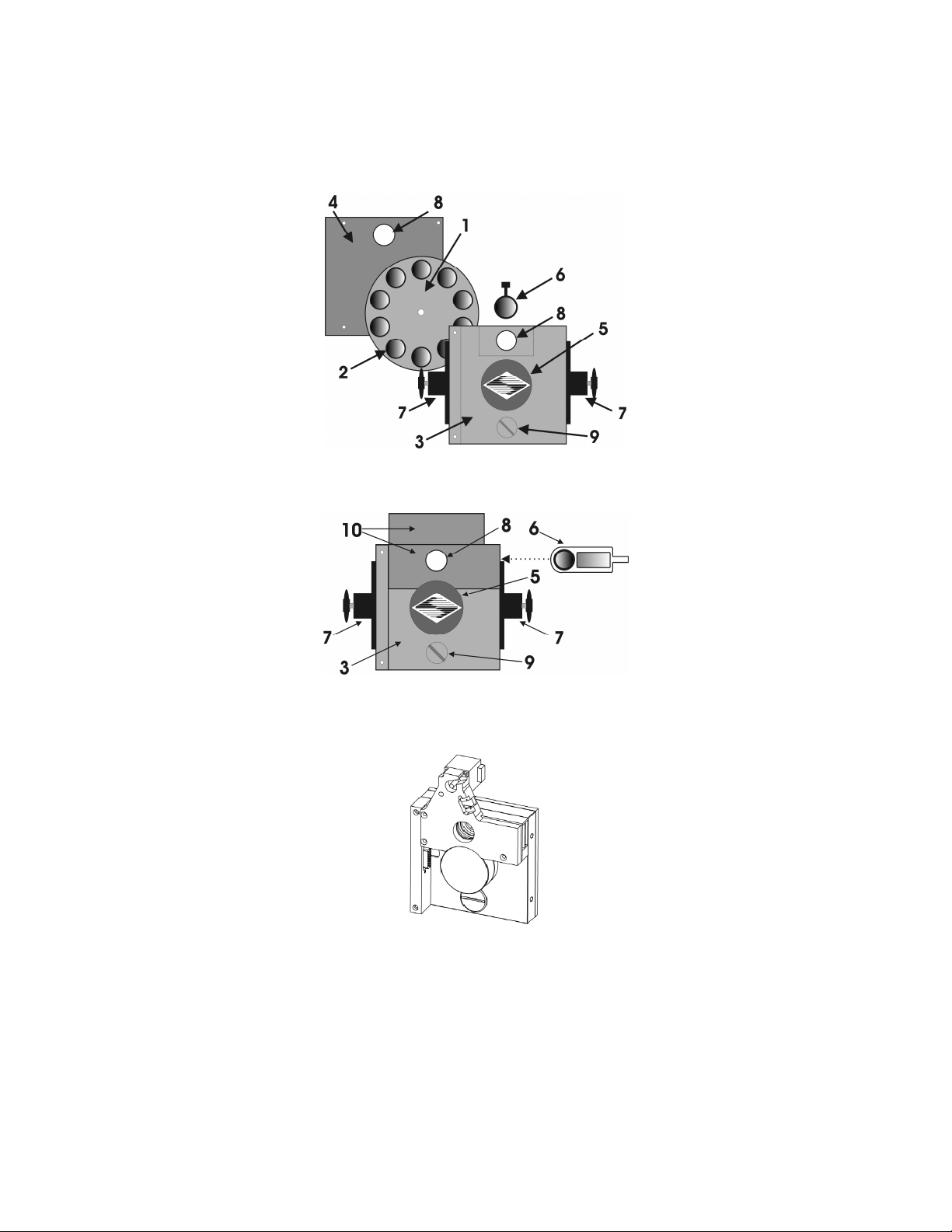

The basic components of the filter wheel mechanical assembly are shown in following figures.

The only components that are to be removed by the user are the drop-in or slide-in filter

holders and the plug in the loading port. At no time should the user remove the cover plate

from the wheel housing.

1. 10-position wheel (removed from motor hub)

2. Installed filter cup

3. Wheel housing

4. Cover plate (removed from wheel housing

5. Stepper motor

6. Drop-in filter holder (Figure 1-1) or slide-in filter holder (Figure 1-2)

7. Mounting ears

8. Optical port

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 15

3

9. Loading port (plug installed)

10. Shutter housing

Figure 1-1. Lambda 10-3 filter wheel (without shutter).

Figure 1-2. Lambda 10-3 filter wheel housing (with shutter).

Figure 1-3. Lambda 10-3 filter wheel housing with SmartShutter.

1.3.2

1.3.2 Filter Wheels

Filter Wheels

1.3.21.3.2

Filter WheelsFilter Wheels

When a Lambda 10-3 Filter Wheel system is purchased, its configuration may include one

filter wheel, with or without a shutter. If the Lambda 10-3 system is purchased with a 10position 25mm (1-inch) filter wheel, you may wish to exchange the filter wheel with a 10position 32mm or a 5-position 50mm filter wheel. If the filter wheel being replaced is a 10position 32mm filter wheel equipped with a 35mm shutter (UNIBLITZ® or SmartShutter),

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 16

4

then Lambda 10-3 controller must be modified by Sutter Instrument Co. before said filter

wheel with shutter is connected. If the 32mm filter wheel is not equipped with a shutter, or if

installing a 50mm filter wheel, then no modification to the Lambda 10-3 controller is needed.

Note that

Note that you must

Note that Note that

you must only

you mustyou must

only use filter wheels manufactured by Sutter Instrument Company.

onlyonly

use filter wheels manufactured by Sutter Instrument Company. All

use filter wheels manufactured by Sutter Instrument Company. use filter wheels manufactured by Sutter Instrument Company.

filter wheel options are listed in Sutter Instrument’s catalogue and web site

(http://www.sutter.com), and in the following list.

LB10

10

10----position, 25mm fil

position, 25mm filter wheels

1010

position, 25mm filposition, 25mm fil

4444----position, 25mm filter wheels:

position, 25mm filter wheels:

position, 25mm filter wheels:position, 25mm filter wheels:

10

10----position 32mm filter wheels:

position 32mm filter wheels:

1010

position 32mm filter wheels:position 32mm filter wheels:

5555----position 50mm filter wheel

position 50mm filter wheel::::

position 50mm filter wheelposition 50mm filter wheel

ter wheels::::

ter wheelster wheels

LB10----NW (without shutter)

LB10LB10

LB10

LB10----NWIQ (with 25mm SmartShutter (IQ25

LB10LB10

LB10

LB10----NWS (with UNIBLITZ® shutter)

LB10LB10

LB10

LB10----NWE (without shutter and set up for emission)

LB10LB10

LB10

LB10----WHS4 (without shutter)

LB10LB10

LB10

LB10----WHS4IQ (with SmartShut

LB10LB10

LB10

LB10----WHS4E (without shutter and set up for

LB10LB10

emission)

emission)

emission)emission)

LB10

LB10----W32 (without shutter)

LB10LB10

LB10

LB10----NW32IQ (with 35mm SmartShutter (IQ35

LB10LB10

LB10

LB10----W32S (with 35mm UNIBLITZ® shutter)

LB10LB10

LB10

LB10----W50 (without shu

LB10LB10

NW (without shutter)

NW (without shutter)NW (without shutter)

NWIQ (with 25mm SmartShutter (IQ25----W2))

NWIQ (with 25mm SmartShutter (IQ25NWIQ (with 25mm SmartShutter (IQ25

NWS (with UNIBLITZ® shutter)

NWS (with UNIBLITZ® shutter)NWS (with UNIBLITZ® shutter)

NWE (without shutter and set up for emission)

NWE (without shutter and set up for emission)NWE (without shutter and set up for emission)

WHS4 (without shutter)

WHS4 (without shutter)WHS4 (without shutter)

WHS4IQ (with SmartShutter)

WHS4IQ (with SmartShutWHS4IQ (with SmartShut

WHS4E (without shutter and set up for

WHS4E (without shutter and set up for WHS4E (without shutter and set up for

W32 (without shutter)

W32 (without shutter)W32 (without shutter)

NW32IQ (with 35mm SmartShutter (IQ35----W))

NW32IQ (with 35mm SmartShutter (IQ35NW32IQ (with 35mm SmartShutter (IQ35

W32S (with 35mm UNIBLITZ® shutter)

W32S (with 35mm UNIBLITZ® shutter)W32S (with 35mm UNIBLITZ® shutter)

W50 (without shutter).

W50 (without shuW50 (without shu

tter).

tter).tter).

ter)

ter)ter)

W2))

W2))W2))

W))

W))W))

1.3.2.1 Mechanical Description

The basic components of the filter wheel mechanical assembly are shown in following figures.

The only components that are to be removed by the user are the drop-in or slide-in filter

holders and the plug in the loading port. At no time should the user remove the cover plate

from the wheel housing.

1. 10-position wheel (removed from motor hub)

2. Installed filter cup

3. Wheel housing

4. Cover plate (removed from wheel housing

5. Stepper motor

6. Drop-in filter holder (Figure 1-1) or slide-in filter holder (Figure 1-2)

7. Mounting ears

8. Optical port

9. Loading port (plug installed)

10. Shutter housing

1.3.3

1.3.3 Filters

Filters

1.3.31.3.3

FiltersFilters

The Lambda 10-3 Controller can be used with a range of filter wheels. Most of these wheels

accept both 25 mm and 1-inch diameter filters. When larger filters are required, wheels are

available that accept 32 mm and 50 mm diameter filters.

LAMBDA 10-3 OPERATION MANUAL – REV. 3.03 (20110829)

Page 17

5

Filter wheels designed for use with 1 inch or 25 mm filters will accept filters with a thickness

that does not exceed the following dimensions:

4.5 mm (0.18 in.) for Slide

4.5 mm (0.18 in.) for Slide----in filter holders

4.5 mm (0.18 in.) for Slide4.5 mm (0.18 in.) for Slide

5.38 mm (0.21 in.) for Drop

5.38 mm (0.21 in.) for Drop----in filter holders

5.38 mm (0.21 in.) for Drop5.38 mm (0.21 in.) for Drop

9 mm (0.35 in.) for Filter cups

9 mm (0.35 in.) for Filter cups

9 mm (0.35 in.) for Filter cups9 mm (0.35 in.) for Filter cups

in filter holders

in filter holdersin filter holders

in filter holders

in filter holdersin filter holders

Filter wheels designed for use with 32 mm filters will accept filters with a thickness that does

not exceed the following dimensions:

9 mm (0.35 in.) for Filter cups

9 mm (0.35 in.) for Filter cups

9 mm (0.35 in.) for Filter cups9 mm (0.35 in.) for Filter cups

Instructions for installing filters into the filter wheel can be found in the FILTER WHEEL

chapter of this manual. Filters are not supplied by Sutter Instrument Company but filters

conforming to the above

conforming to the above specifications can be purchased from any filter manufacturer.

conforming to the above conforming to the above

1.3.4

1.3.4 Slide

Slide----in or Drop

1.3.41.3.4

in or Drop----in Filter Holders

SlideSlide

in or Dropin or Drop

Filters are not supplied by Sutter Instrument Company but filters

Filters are not supplied by Sutter Instrument Company but filters Filters are not supplied by Sutter Instrument Company but filters

specifications can be purchased from any filter manufacturer.

specifications can be purchased from any filter manufacturer.specifications can be purchased from any filter manufacturer.

in Filter Holders

in Filter Holdersin Filter Holders

Many users prefer having extra Slide-in or Drop-in filter holders for more convenient

replacement of these “fixed” filters. Only use filter holders made by Sutter Instrument

Company in the Lambda 10

Company in the Lambda 10----3 Filter Wheel.

Company in the Lambda 10Company in the Lambda 10

3 Filter Wheel. Extra filter holders for one-inch wheels are

3 Filter Wheel. 3 Filter Wheel.

Only use filter holders made by Sutter Instrument

Only use filter holders made by Sutter Instrument Only use filter holders made by Sutter Instrument

readily available from Sutter Instrument Company or their distributors and are listed as

“SLIDE-IN” and “DROP-IN” in the Sutter catalogue. At this point, there are no slide-in

filter holders for 32 mm systems, although a 32-mm Drop-in filter holder is available. In

addition, there is a fixed filter position for a heat-blocking filter in most 32-mm microscope

adapters offered by Sutter Instrument Company. Slide-in and drop-in filter holders are not

available for the 50 mm filter wheels.

1.3.5

1.3.5 Shutters

Shutters

1.3.51.3.5

ShuttersShutters

If you purchase a Lambda 10-3 Filter Wheel system without a shutter and later decide to add

one to the system, the Filter Wheel must be returned to the factory for the upgrade. The

current version of the Lambda 10-3 Filter Wheel controller can support a retrofit with a

SmartShutter or traditional shutter, without modification. The installation of a traditional

shutter may require the setting of a jumper to configure the driver circuit for the size of

shutter installed. You must

contact Sutter Instrument Company or your distributor for details

contact Sutter Instrument Company or your distributor for details.

contact Sutter Instrument Company or your distributor for detailscontact Sutter Instrument Company or your distributor for details

You must only use shutters installed by Sutter Instrument Company

You must You must

only use shutters installed by Sutter Instrument Company --

only use shutters installed by Sutter Instrument Company only use shutters installed by Sutter Instrument Company

--

----

In addition to the shutters that are integrated with filter wheels listed previously under

“Filter Wheels”, the following SmartShutters are supported by the Lambda 10-3:

IQ12

IQ12----SA

SA 12.5mm SmartShutter™ with stand-alone housing

IQ12IQ12

SASA

IQ25

IQ25----SA1