Sutter Instrument Lambda 10-2, Lambda 10-232S, Lambda 10-250, Lambda 10-232, Lambda 10-2S Operation Manuals

Page 1

Lambda 10

Lambda 10----2

Lambda 10Lambda 10

Optical Filter Changer

Optical Filter Changer

Optical Filter Changer Optical Filter Changer

Control

Control System

Control Control

Operation Manual

Operation Manual

Operation ManualOperation Manual

Rev. 2.04 ( 20120224)

System

SystemSystem

2

22

One Digital Drive

Novato, CA 94949

Voice: 415-883-0128 Web: www.sutter.com

Fax: 415-883-0572 Email: info@sutter.com

Page 2

ii

Copyright © 2011 Sutter Instrument Company. All Rights Reserved.

LAMBDA 10® is a registered trademark of Sutter Instrument Company.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 3

DIS CLA IMER

DIS CLA IMER

DIS CLA IMERDIS CLA IMER

The LAMBDA 10

LAMBDA 10----2222 Optical Filter Changer system is designed for the specific use of

LAMBDA 10 LAMBDA 10

iii

changing filters into and out of an optical pathway and no other use is recommended.

This instrument is designed for use in a laboratory environment. It is not intended for use,

nor should it be used, in human experimentation or applied to humans in any way. This is

not a medical device.

Do not open or attempt to repair the instrument. Extreme heat and high voltages are

present and could cause injury.

Do not allow unauthorized and/or untrained operative to use this device.

Any misuse will be the sole responsibility of the user/owner and Sutter Instrument Company

assumes no implied or inferred liability for direct or consequential damages from this

instrument if it is operated or used in any way other than for which it is designed.

SAF ETY WA R NIN GS AND

SAF ETY WA R NIN GS AND P RECA UTI ON S

SAF ETY WA R NIN GS AND SAF ETY WA R NIN GS AND

Electrical

Electrical

ElectricalElectrical

PREC AUT ION S

PREC AUT ION SPREC AUT ION S

Operate the Lambda 10

Operate the Lambda 10----2 using 110

Operate the Lambda 10Operate the Lambda 10

voltage. This instrument is designe

voltage. This instrument is designed for connection to a standard laboratory power

voltage. This instrument is designevoltage. This instrument is designe

outlet (Overvoltage Category II), and because it is a microprocessor

outlet (Overvoltage Category II), and because it is a microprocessor--

outlet (Overvoltage Category II), and because it is a microprocessoroutlet (Overvoltage Category II), and because it is a microprocessor

it should be accorded the same system wiring precautions as any 'computer type'

it should be accorded the same system wiring precautions as any 'computer type'

it should be accorded the same system wiring precautions as any 'computer type' it should be accorded the same system wiring precautions as any 'computer type'

system. A surge protector and power reg

system. A surge protector and power regulator are recommended.

system. A surge protector and power regsystem. A surge protector and power reg

Avoiding Electrical Shock and Fire

Avoiding Electrical Shock and Fire----related Injury

Avoiding Electrical Shock and FireAvoiding Electrical Shock and Fire

Fuse Replacement: Replace only with the same type and rating:

Fuse Replacement: Replace only with the same type and rating:

Fuse Replacement: Replace only with the same type and rating: Fuse Replacement: Replace only with the same type and rating:

Voltage

Voltage Voltage

Setting

Setting

SettingSetting

110V

110V 1.5A, 250V

110V110V

220V

220V T0.63A, 250V

220V220V

A spare fuse is located in the power input module. Please refer to the fuse

A spare fuse is located in the power input module. Please refer to the fuse----replacement

A spare fuse is located in the power input module. Please refer to the fuseA spare fuse is located in the power input module. Please refer to the fuse

appendix for more details on fuse ratings and for i

appendix for more details on fuse ratings and for instructions on how to change the

appendix for more details on fuse ratings and for iappendix for more details on fuse ratings and for i

fuse.

fuse.

fuse. fuse.

Always use the grounded power supply cord set provided to connect the system to

Always use the grounded power supply cord set provided to connect the system to

Always use the grounded power supply cord set provided to connect the system to Always use the grounded power supply cord set provided to connect the system to

a grounded outlet (3

a grounded outlet (3----prong).

a grounded outlet (3a grounded outlet (3

that an electrical hazard occurs.

that an electrical hazard occurs.

that an electrical hazard occurs.that an electrical hazard occurs.

Do not disassemble the system. Refer servicing to qualified personnel.

Do not disassemble the system. Refer servicing to qualified personnel.

Do not disassemble the system. Refer servicing to qualified personnel.Do not disassemble the system. Refer servicing to qualified personnel.

Type and Rating

Type and Rating

Type and RatingType and Rating

1.5A, 250V Bussmann GMC

1.5A, 250V1.5A, 250V

T0.63A, 250V Bussmann GDC

T0.63A, 250VT0.63A, 250V

2 using 110----120 V AC, 60 Hz, or 220

2 using 1102 using 110

Fuse

Fuse:

FuseFuse

Bussmann GMC----1.5A or GMC

Bussmann GMCBussmann GMC

Bussmann GDC----630mA or S506

Bussmann GDCBussmann GDC

Littelfuse: 218.630 or 218.063P (RoHS)

Littelfuse: 218.630 or 218.063P (RoHS)

Littelfuse: 218.630 or 218.063P (RoHS)Littelfuse: 218.630 or 218.063P (RoHS)

prong). This is required to protect you from injury in the event

prong). prong).

This is required to protect you from injury in the event

This is required to protect you from injury in the event This is required to protect you from injury in the event

120 V AC, 60 Hz, or 220----240 V AC., 50 Hz line

120 V AC, 60 Hz, or 220120 V AC, 60 Hz, or 220

d for connection to a standard laboratory power

d for connection to a standard laboratory power d for connection to a standard laboratory power

ulator are recommended.

ulator are recommended.ulator are recommended.

: (Time Delay, 5mm x 20mm, glass tube)

(Time Delay, 5mm x 20mm, glass tube) Voltage

: :

(Time Delay, 5mm x 20mm, glass tube)(Time Delay, 5mm x 20mm, glass tube)

Manufacturer Examples

Manufacturer Examples

Manufacturer ExamplesManufacturer Examples

1.5A or GMC----1.5

1.5A or GMC1.5A or GMC

630mA or S506----630

630mA or S506630mA or S506

related Injury

related Injuryrelated Injury

1.5----R (RoHS)

1.51.5

nstructions on how to change the

nstructions on how to change the nstructions on how to change the

240 V AC., 50 Hz line

240 V AC., 50 Hz line 240 V AC., 50 Hz line

--controlled device,

controlled device,

----

controlled device, controlled device,

R (RoHS)

R (RoHS)R (RoHS)

630----R (RoHS); or

R (RoHS); or

630630

R (RoHS); orR (RoHS); or

replacement

replacement replacement

Optical Radiatio

Optical Radiationnnn

Optical RadiatioOptical Radiatio

This system is designed for use in conjunction with high

This system is designed for use in conjunction with high----intensity light sources. Failure to

This system is designed for use in conjunction with highThis system is designed for use in conjunction with high

comply with any of the following precautions may result in injury to the users o

comply with any of the following precautions may result in injury to the users of this

comply with any of the following precautions may result in injury to the users ocomply with any of the following precautions may result in injury to the users o

device as well as those working in the general area near the device.

device as well as those working in the general area near the device.

device as well as those working in the general area near the device.device as well as those working in the general area near the device.

To prevent fire or shock hazard do not expose the unit to rain or moisture.

To prevent fire or shock hazard do not expose the unit to rain or moisture.

To prevent fire or shock hazard do not expose the unit to rain or moisture.To prevent fire or shock hazard do not expose the unit to rain or moisture.

intensity light sources. Failure to

intensity light sources. Failure to intensity light sources. Failure to

f this

f this f this

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 4

iv

Electromagnetic Interference

Electromagnetic Interference

Electromagnetic InterferenceElectromagnetic Interference

To comply with FDA and CE electromagnetic immunity and interfer

To comply with FDA and CE electromagnetic immunity and interference standards; and to

To comply with FDA and CE electromagnetic immunity and interferTo comply with FDA and CE electromagnetic immunity and interfer

reduce the electromagnetic coupling between this and other equipment in your lab always

reduce the electromagnetic coupling between this and other equipment in your lab always

reduce the electromagnetic coupling between this and other equipment in your lab always reduce the electromagnetic coupling between this and other equipment in your lab always

use the type and length of interconnect cables provided with the unit for the

use the type and length of interconnect cables provided with the unit for the

use the type and length of interconnect cables provided with the unit for the use the type and length of interconnect cables provided with the unit for the

interconnection of

interconnection of one or more f

interconnection ofinterconnection of

232 or parallel interface

232 or parallel interface, or o

232 or parallel interface232 or parallel interface

SPECIFICATIONS appendix for more details)

SPECIFICATIONS appendix for more details)....

SPECIFICATIONS appendix for more details)SPECIFICATIONS appendix for more details)

Operational

Operational

OperationalOperational

Fai

Failure to comply with any of the following precautions may damage this device.

FaiFai

Never look into the optical pathway of the high intensity light sources typically

Never look into the optical pathway of the high intensity light sources typically

Never look into the optical pathway of the high intensity light sources typically Never look into the optical pathway of the high intensity light sources typically

used with this instrument. Doing so can cause permanent eye damage.

used with this instrument. Doing so can cause permanent eye damage.

used with this instrument. Doing so can cause permanent eye damage.used with this instrument. Doing so can cause permanent eye damage.

The high

The high----intensity light s

The high The high

significant amount of heat. Direct contact with the housing of those instruments can

significant amount of heat. Direct contact with the housing of those instruments can

significant amount of heat. Direct contact with the housing of those instruments can significant amount of heat. Direct contact with the housing of those instruments can

cause serious burns.

cause serious burns.

cause serious burns.cause serious burns.

lure to comply with any of the following precautions may damage this device.

lure to comply with any of the following precautions may damage this device. lure to comply with any of the following precautions may damage this device.

This instrument is designed for operation in a laboratory environment (Pollution

This instrument is designed for operation in a laboratory environment (Pollution

This instrument is designed for operation in a laboratory environment (Pollution This instrument is designed for operation in a laboratory environment (Pollution

Degree I).

Degree I).

Degree I).Degree I).

This unit is not designed for operation at altitudes above 2000 meters nor was it test

This unit is not designed for operation at altitudes above 2000 meters nor was it tested

This unit is not designed for operation at altitudes above 2000 meters nor was it testThis unit is not designed for operation at altitudes above 2000 meters nor was it test

for safety above 2000 meters.

for safety above 2000 meters.

for safety above 2000 meters.for safety above 2000 meters.

intensity light sources typically used with this instrument also produce a

intensity light sintensity light s

one or more filter wheels and/or shutters

one or more f one or more f

, or other equipment via TTL connections

, or o, or o

ources typically used with this instrument also produce a

ources typically used with this instrument also produce a ources typically used with this instrument also produce a

ence standards; and to

ence standards; and to ence standards; and to

ilter wheels and/or shutters, h

ilter wheels and/or shuttersilter wheels and/or shutters

ther equipment via TTL connections ((((ssssee the TECHNICAL

ther equipment via TTL connectionsther equipment via TTL connections

, host

ost computer via serial RS

, h, h

computer via serial RS----

ost ost

computer via serial RScomputer via serial RS

ee the TECHNICAL

ee the TECHNICAL ee the TECHNICAL

ed

ed ed

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN THE

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN THE

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN THE DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN THE

CONTROLLER AND THE MECHANICAL UNITS

CONTROLLER AND THE MECHANICAL UNITS (FILTER WHEELS AND/OR

CONTROLLER AND THE MECHANICAL UNITS CONTROLLER AND THE MECHANICAL UNITS

SHUTTERS)

SHUTTERS) WHILE POWER IS ON.

SHUTTERS) SHUTTERS)

Please allow at least 20 seconds after turning the unit off before disconnecting

Please allow at least 20 seconds after turning the unit off before disconnecting the

Please allow at least 20 seconds after turning the unit off before disconnectingPlease allow at least 20 seconds after turning the unit off before disconnecting

mechanical units. Failure to do this may result in damage to the electronics.

mechanical units. Failure to do this may result in damage to the electronics.

mechanical units. Failure to do this may result in damage to the electronics.mechanical units. Failure to do this may result in damage to the electronics.

Operate only in a location where there is a free flow of fresh air on all sides.

Operate only in a location where there is a free flow of fresh air on all sides.

Operate only in a location where there is a free flow of fresh air on all sides. Operate only in a location where there is a free flow of fresh air on all sides.

NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.

NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.

NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.NEVER ALLOW THE FREE FLOW OF AIR TO BE RESTRICTED.

WHILE POWER IS ON.

WHILE POWER IS ON. WHILE POWER IS ON.

(FILTER WHEELS AND/OR

(FILTER WHEELS AND/OR (FILTER WHEELS AND/OR

the

the the

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 5

v

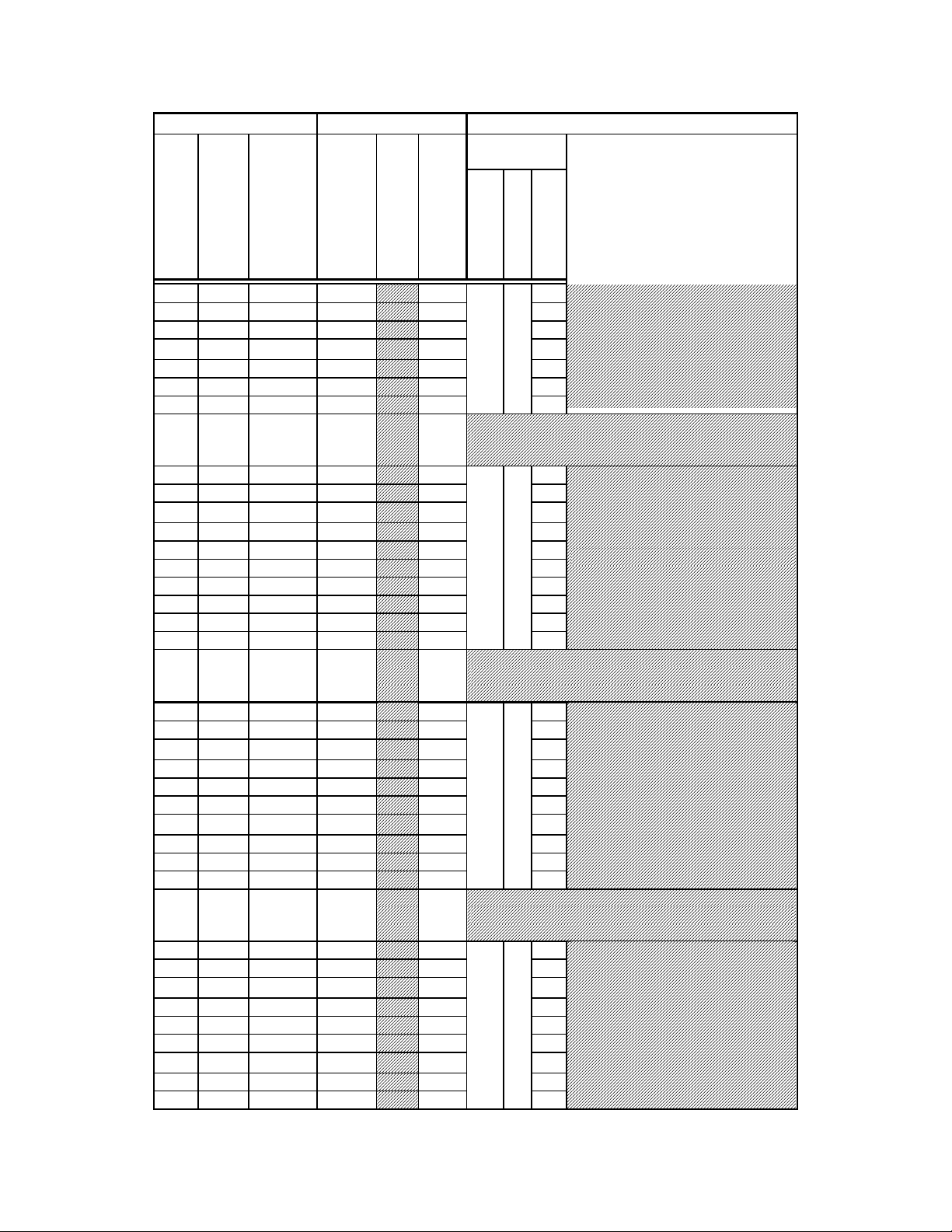

TABLE OF CONTENTS

DDDDISCLAIMER

ISCLAIMER................................

ISCLAIMERISCLAIMER

SAFETY WARNINGS AND PRECAUTIONS

SAFETY WARNINGS AND PRECAUTIONS................................

SAFETY WARNINGS AND PRECAUTIONSSAFETY WARNINGS AND PRECAUTIONS

Electrical .................................................................................................................................................iii

Avoiding Electrical Shock and Fire-related Injury ............................................................................iii

Optical Radiation ...................................................................................................................................iv

Electromagnetic Interference...............................................................................................................iv

Operational.............................................................................................................................................iv

1. GENERAL

1. GENERAL ................................

1. GENERAL1. GENERAL

1.1 Introduction.......................................................................................................................................1

1.1.1 How to Use this Manual............................................................................................................1

1.1.2 Technical Support......................................................................................................................1

1.2 General Description..........................................................................................................................1

1.2.1 Systems........................................................................................................................................2

1.2.2 Filter Wheels and Shutters.......................................................................................................2

1.2.3 Filters ..........................................................................................................................................4

1.2.4 Slide-In and Drop-In Filter Holders ........................................................................................4

1.2.5 Shutters.......................................................................................................................................5

1.2.6 Adapters......................................................................................................................................5

1.2.7 Other and Optional Accessories...............................................................................................5

1.2.7.1 Liquid Light Guide (LLG)..................................................................................................5

1.3 Functional Description.....................................................................................................................5

1.3.1 Stepping Motor Operation........................................................................................................5

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................

................................................................

................................................................

................................................................

.....................................

................................................................

................ iii

................................

........................................

................................................................

........1111

................

..... iii

iii

..........

iiiiii

iii

iiiiii

2. INSTALLATION

2. INSTALLATION ................................

2. INSTALLATION2. INSTALLATION

2.1 Unpacking..........................................................................................................................................7

2.2 Pre-installation Considerations ......................................................................................................7

2.2.1 Vibrations....................................................................................................................................7

2.3 Installing the Controller ..................................................................................................................8

2.3.1 Line Power (Mains) ...................................................................................................................8

2.4 Installing the Filter Wheel ............................................................................................................10

2.4.1 Filter Wheel Assembly Set Up................................................................................................11

2.5 First Time Use ................................................................................................................................12

2.5.1 Make It Go ................................................................................................................................12

2.6 Loading Filters................................................................................................................................13

2.6.1 Filter Orientation.....................................................................................................................13

2.6.2 Filter Cups and Filter Holders...............................................................................................13

2.6.3 Installation of Filters into Filter Holders .............................................................................15

2.6.4 Installation of Filters into Filter Cups ..................................................................................17

2.7 Filter Loading Tips.........................................................................................................................18

2.7.1 Selection of a Filter Position...................................................................................................18

2.7.2 Use of Blanking Discs..............................................................................................................18

2.7.3 Neutral Density Filters ...........................................................................................................19

3.

3. OPERATIONS

OPERATIONS ................................

3.3.

OPERATIONS OPERATIONS

3.1 First Time Use ................................................................................................................................21

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

.............................................................

................................................................

...............................................................

................................................................

.............................7777

..........................................................

...............................21

..............................................................

21

2121

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 6

vi

3.2 Principles of Operation..................................................................................................................21

3.3 Rear Panel Connectors...................................................................................................................21

3.4 Front Panel Controls......................................................................................................................23

3.4.1 Keypad.......................................................................................................................................23

3.4.2 RESET Button.........................................................................................................................23

3.4.3 Display.......................................................................................................................................23

3.5 Power-Up Sequence........................................................................................................................24

3.5.1 Selecting the Wheel .................................................................................................................25

3.5.2 Selecting the Filter Position ...................................................................................................25

3.5.3 Selecting the Filter Switching Speed.....................................................................................25

3.5.4 Selecting the Shutter Position (Open/Close)........................................................................26

3.5.5 Error Detection and Recovery................................................................................................27

3.5.6 Movement Errors: Causes and Solutions.............................................................................27

3.5.6.1 Filter Weight vs. Speed.....................................................................................................27

3.5.6.2 Oscillation when Stopping ...............................................................................................28

3.5.6.3 Oscillations when Moving ................................................................................................28

3.5.6.4 Movement Errors after Successive Moves......................................................................28

3.5.7 Helpful Tips about Movement Errors...................................................................................28

4.

4. EXTERNAL CONTROL OPERATIONS

EXTERNAL CONTROL OPERATIONS ................................

4.4.

EXTERNAL CONTROL OPERATIONS EXTERNAL CONTROL OPERATIONS

4.1 General.............................................................................................................................................31

4.2 Parallel Interface ............................................................................................................................31

4.2.1 Connecting to the Parallel Port Interface.............................................................................31

4.2.2 Input Command Structure .....................................................................................................32

4.2.2.1 Filter Commands...............................................................................................................33

4.2.2.2 Special Commands: ON LINE, BATCH, and SHUTTER Commands......................34

4.2.2.3 Output Command Structure: BUSY and ERROR lines..............................................36

4.2.3 Strategies for Controlling the Lambda 10-2 via the Parallel Port.....................................37

4.2.3.1 Using Input Lines Only....................................................................................................37

4.2.3.2 Using Fewer than Eight Input Lines..............................................................................37

4.2.3.3 Using the BUSY Line........................................................................................................37

4.2.3.4 Using the ERROR Line ....................................................................................................38

4.2.4 Using a Computer’s Parallel (Printer) Port .........................................................................38

4.2.4.1 Connecting to the PC Parallel (Printer) Port................................................................39

4.2.4.2 Input Command Structure...............................................................................................40

4.2.4.3 Output Command Structure: BUSY and ERROR Lines.............................................41

4.3 Dedicated TTL Line .......................................................................................................................42

4.4 Serial RS-232 Interface ..................................................................................................................43

4.4.1 Connecting to the Serial Port.................................................................................................43

4.4.2 Input Command Structure .....................................................................................................44

4.4.2.1 Filter Commands...............................................................................................................44

4.4.3 Special Commands: ON LINE, SHUTTER and BATCH commands...............................45

4.4.4 Output Command Structure: Command Echo and <CR>...............................................46

................................................................

................................................................

....................................................

................................................................

....................31

........................................

31

3131

5.

5. MAINTENANCE

MAINTENANCE ................................

5.5.

MAINTENANCE MAINTENANCE

APPENDIX A.

APPENDIX A. LIMITED WARRANTY

APPENDIX A.APPENDIX A.

APPENDIX B.

APPENDIX B. ACCESSORIES

APPENDIX B.APPENDIX B.

B.1. Filter Wheels..................................................................................................................................51

................................................................

................................................................

LIMITED WARRANTY ................................

LIMITED WARRANTY LIMITED WARRANTY

ACCESSORIES................................

ACCESSORIES ACCESSORIES

................................................................

................................................................

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...........................................................

................................................................

..........................................................

................................................................

........................................

................................................................

...........................47

......................................................

..........................49

....................................................

........51

................

47

4747

49

4949

51

5151

Page 7

vii

B.2. Shutter............................................................................................................................................51

B.3. Filter Holders and Liquid Light Guides.....................................................................................51

B.4. Cables .............................................................................................................................................52

APPENDIX C.

APPENDIX C. FUSE REPLACEMENT

APPENDIX C.APPENDIX C.

APPENDIX D.

APPENDIX D. TECHNICAL SPECIFICATIONS

APPENDIX D.APPENDIX D.

D.1. Controller (rack mount)...............................................................................................................55

D.2. Filter Wheel, 25 mm (1”) (with Shutter, without Stand)........................................................56

APPENDIX E.

APPENDIX E. EXTERNAL CONTROL COMMAND REFERENCE

APPENDIX E.APPENDIX E.

FUSE REPLACEMENT ................................

FUSE REPLACEMENT FUSE REPLACEMENT

TECHNICAL SPECIFICATIONS................................

TECHNICAL SPECIFICATIONS TECHNICAL SPECIFICATIONS

EXTERNAL CONTROL COMMAND REFERENCE ................................

EXTERNAL CONTROL COMMAND REFERENCE EXTERNAL CONTROL COMMAND REFERENCE

................................................................

................................................................

................................................................

................................................................

.........................................................

................................................................

.........................................

................................................................

.........................................

................................................................

.........................53

..................................................

53

5353

.........55

55

..................

5555

.........57

57

..................

5757

TABLE OF FIGURES

Figure 1-1. Lambda 10-2 Filter Wheel (without shutter)......................................................................3

Figure 1-2. Lambda 10-2 filter wheel housing (with shutter)...............................................................3

Figure 2-1. Lambda 10-2 Cabinet (rear view)......................................................................................... 9

Figure 2-2. Lambda 10-2 Cabinet (front view)........................................................................................9

Figure 2-3. Power connection..................................................................................................................10

Figure 2-4. Schematic diagram of two possible experimental configurations...................................10

Figure 2-5. Filter wheel mounting stand...............................................................................................11

Figure 2-6. Filter wheel connection........................................................................................................12

Figure 2-7. Initialization screen..............................................................................................................12

Figure 2-8. Initialization screen in local mode......................................................................................13

Figure 2-9. Filter holder components.....................................................................................................14

Figure 2-10. Removing the retaining ring.............................................................................................15

Figure 2-11. Installing a filter into a Slide-In Filter Holder................................................................16

Figure 2-12. Assembly order of filter holder parts ...............................................................................16

Figure 2-13. Filter ports (plug is removed from the loading port) .....................................................17

Figure 3-1. Electrical connections ..........................................................................................................22

Figure 3-2. Lambda 10-2 Controller Keypad.........................................................................................23

Figure 3-3. Status display screen............................................................................................................24

Figure 3-4. Status display defaults.........................................................................................................24

Figure 3-5. Display showing selected filter wheel.................................................................................25

Figure 3-6. Screen showing prompt for speed selection.......................................................................26

Figure 3-7. Entering the speed ...............................................................................................................26

Figure 3-8. Status display screen after pressing LOCAL. ...................................................................27

Figure 4-1. Parallel interface DB-25 connector on the Lambda 10-2.................................................31

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 8

viii

Figure 4-2. PC parallel (printer) port.....................................................................................................39

Figure 4-3. Serial port pin assignments.................................................................................................44

Figure 5-1. Power entry module .............................................................................................................53

Figure 5-2. Fuse holder............................................................................................................................54

TABLE OF TABLES

Table 2-1. Maximum allowable filter thickness....................................................................................15

Table 3-1. Filter switching times (in milliseconds)...............................................................................26

Table 4-1. Lambda 10-2 Parallel Interface Pin Assignments..............................................................32

Table 4-2. Filter command structure.....................................................................................................33

Table 4-3. Special command codes..........................................................................................................34

Table 4-4. PC and Lambda 10-2 parallel port pin assignments..........................................................40

Table 4-5. PC printer adapter addresses ...............................................................................................41

Table 4-6. Commands for the dedicated TTL line................................................................................43

Table 4-7. Creating a serial port filter command..................................................................................45

Table C-1. Fuse type and rating. ............................................................................................................54

Table D-1. Mains fuse type and rating...................................................................................................55

Table D-2. Cable specifications. ..............................................................................................................56

Table E-1. Complete Remote-control command reference..................................................................57

Table E-2. Filter command structure. ...................................................................................................62

TABLE OF LISTINGS

Listing 4-1. Batch transfer via PC parallel port program....................................................................36

Listing 4-2. Program to obtain the Lambda 10-2 status on the PC parallel port.............................41

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 9

1.

1. GEN ERA L

GEN ERA L

1.1.

GEN ERA LGE NER AL

1.1

1.1 Introduction

Introduction

1.11.1

IntroductionIntroduction

The Lambda 10-2 is an optical filter wheel system designed for rapid change of wavelength

and comprises two subsystems: A controller and one or two filter wheels, each with or

without a shutter, that are to be placed in the optical pathway of your existing experimental

setup. Next is a description on how this manual is organized and the manner in which its use

is intended, followed by a general and functional description of the system.

1.1.1

1.1.1 How to Use this Manual

How to Use this Manual

1.1.11.1.1

How to Use this ManualHow to Use this Manual

This manual is organized in a manner that is best suited for the typical manner in which the

reader would learn about the system, and then install, operate, and maintain it. Prior to the

table of contents of this manual is a disclaimer and a series of cautionary and warning notes

that should be read first. This first chapter provides an overall description of the system,

leaving more in-depth technical information towards the end of the chapter. The next

chapter describes how to install the system, followed by one or more chapters that provide

operation instructions, and ending with a chapter on maintenance. Following the final

chapter are several appendices that provide supplemental information. The installation

chapter covers everything related to installation, from unpacking the equipment as received,

through to ensuring that everything is correctly installed and is operating correctly. The

operation chapters cover the two basic types of user interaction with the system: Manual

(local) control and external computer control. Please take the time to read these instructions

to assure the safe and proper use of this instrument.

1

1.1.2

1.1.2 Technical Support

Technical Support

1.1.21.1.2

Technical SupportTechnical Support

Unlimited technical support is provided by Sutter Instrument Company at no charge to our

customers. Our technical support staff is available between the hours of 8:00 AM and 5:00

PM (Pacific Time) at (415) 883

1.2

1.2 General Description

General Description

1.21.2

General DescriptionGeneral Description

The LAMBDA

LAMBDA 10

LAMBDALAMBDA

for microscopy and other applications, which require rapid and accurate wavelength

switching. The LAMBDA

providing enhanced capability while retaining the same outstanding mechanical

performance. The Lambda 10-2 controller can control up to two filter wheels and two highspeed shutters, and provides for both manual (local) control as well as external computer

control (via either of the provided serial (RS-232) or parallel interfaces).

The controller system is designed around three embedded microcontrollers: one slave for

each wheel and a master for control and communication. The electronics for two wheels and

two shutters are already installed, even if you only ordered a single wheel system. If you add

a second wheel or shutter later, there will be no additional electronics to buy. The embedded

microcontrollers automatically determine the number of filter wheels that are installed, so

there are no jumpers or switches to set.

10----2222 is a microprocessor controlled, high-speed optical filter wheel designed

1010

LAMBDA 10

LAMBDALAMBDA

(415) 883----0128

(415) 883(415) 883

0128. You may also E-mail your queries to info@sutter.com.

01280128

10----2222 supersedes the previous Lambda 10 filter wheel controller

1010

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 10

2

The controller can run a single wheel and shutter under remote control through a parallel

input using the same simple protocol as the original Lambda 10 controller. New commands

have been added so that the 8-bit parallel input can efficiently control two wheels and two

shutters without using any additional lines. The serial input uses the same command set as

the parallel port, and provides full control of two wheels and two shutters. Either use the

DB-25 cable provided to connect to the parallel port or the DB-9 cable provided to connect to

the serial port.

The following instructions are meant to help you set up the Lambda 10-2 and become

familiar with the manual mode of filter selection. Further details on controller functionality,

filter installation, and remote communications can be found in other sections of this manual.

1.2.1

1.2.1 Systems

Systems

1.2.11.2.1

SystemsSystems

LB10

LB10----2222: Includes one 25mm filter wheel without shutter, support base with mounting rods,

LB10LB10

rack mount1 controller unit with wheel drive cable, parallel and serial interface cables for

connection to PC, two drop-in filter holders, spanner wrench, 10 blanking discs, power cord,

and manual.

LB10

LB10----2S

LB10LB10

2S: Same as above—with a Uniblitz®2 shutter assembly and two slide-in filter holders.

2S2S

LB10

LB10----232

LB10LB10

232: Same as LB10-2 except with 32mm, T-mount threaded filter wheel (no drop-in

232232

filters) and modified 10-2 controller.

LB10

LB10----232S

LB10LB10

232S: Same as LB10-232 except with a Uniblitz® shutter (no drop-in or slide-in filters)

232S232S

and modified 10-2 controller.

LB10

LB10----250

LB10LB10

250: Same as LB10-2 except with 50mm, 5 position wheel.

250250

1.2.2

1.2.2 Filter Wheels

Filter Wheels and Shutters

1.2.21.2.2

Filter WheelsFilter Wheels

and Shutters

and Shutters and Shutters

When a Lambda 10-2 Filter Wheel system is purchased, its configuration may include one to

two filter wheels, each one with or without a shutter. If the Lambda 10-2 system is

purchased with only one 10-position 25mm (1-inch) filter wheel, you may wish to add a

second filter wheel of the same type later, in which case the second filter wheel can be added

without modification. A 10-position 32mm and a 5-position 50mm filter wheel are also

available for use with the Lambda 10-2 controller. Each port of the controller to which a

32mm or 50mm filter wheel is to be connected, however, must be modified by Sutter

Instrument Co. before said filter wheel can be connected. Note that

wheels manufactured by Sutter Instrument.

wheels manufactured by Sutter Instrument.

wheels manufactured by Sutter Instrument. wheels manufactured by Sutter Instrument.

Note that you must

Note that Note that

you must only use filter

you mustyou must

only use filter

only use filter only use filter

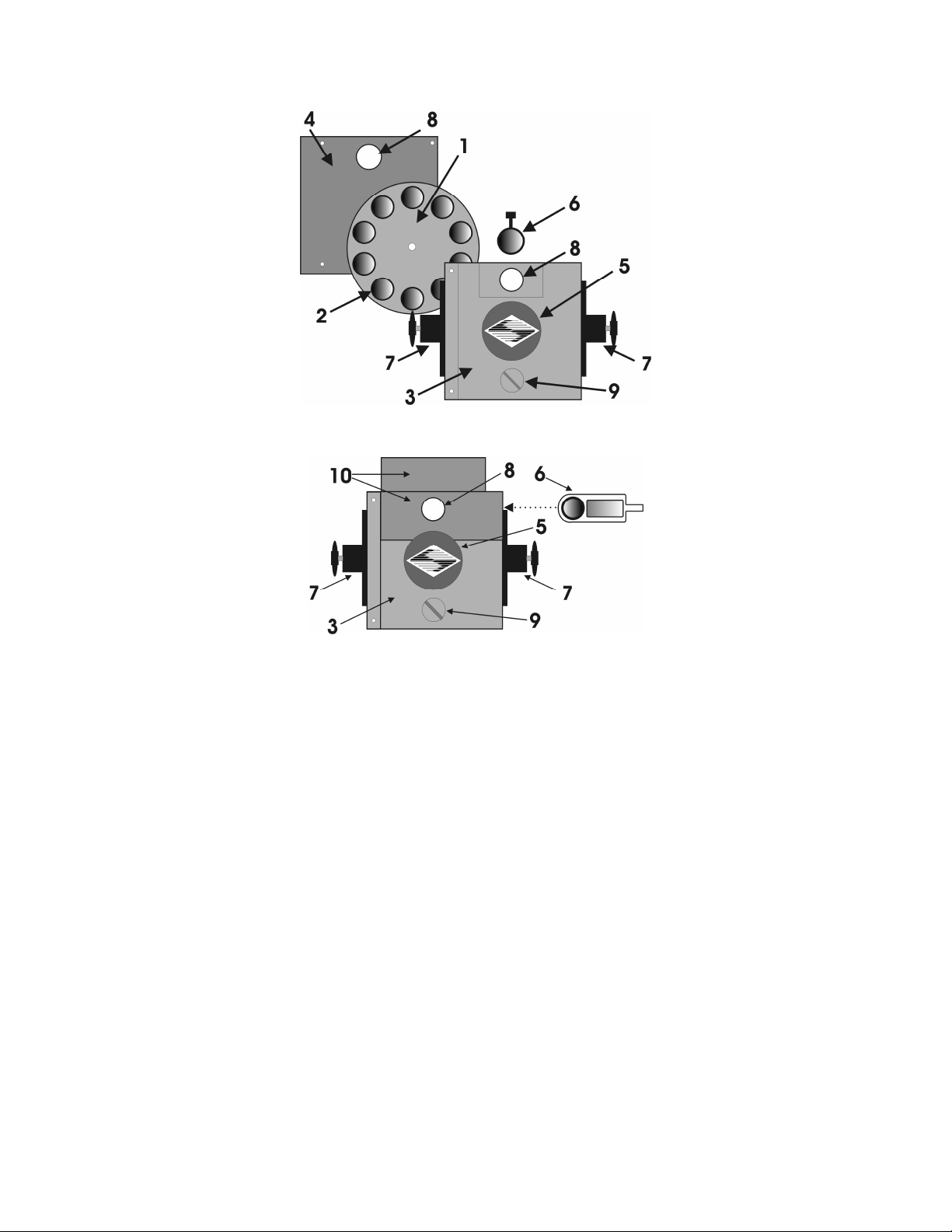

The basic components of the filter wheel mechanical assembly are shown below in Figure 1-1

and Figure 1-2. The only components that are to be removed by the user are the drop-in or

slide in filter holders and the plug in the loading port. At no time should the user remove the

cover plate from the wheel housing.

1

Tabletop controller box is available upon request.

2

Uniblitz® is a registered trademark of Vincent Associates.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 11

3

Figure 1-1. Lambda 10-2 Filter Wheel (without shutter)

Figure 1-2. Lambda 10-2 filter wheel housing (with shutter)

1. 10-position wheel (removed from motor hub

2. Installed filter cup

3. Wheel housing

4. Cover plate (removed from wheel housing

5. Stepper motor

6. Drop-in filter holder (Figure 1-1) or slide-in filter holder (Figure 1-2)

7. Mounting ears

8. Optical port

9. Loading port (plug installed)

10. Shutter housing

All filter wheel options are listed in the Sutter Instrument catalogue and in the following

list.

10

10----position, 25mm filter wheels:

position, 25mm filter wheels:

1010

position, 25mm filter wheels:position, 25mm filter wheels:

LB10

LB10----NW

LB10LB10

NW (without shutter)

NWNW

LB10

LB10----NWS

LB10LB10

NWS (with shutter)

NWSNWS

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 12

4

LB10

LB10----NWE

LB10LB10

LB10

LB10----WD

LB10LB10

LB10

LB10----WDS

LB10LB10

NWE (without shutter and set up for emission)

NWENWE

WD (two wheels mounted back to back, without shutter)

WDWD

WDS (two wheels mounted back to back, with one shutter and one slide-in filter

WDSWDS

holder)

10

10----position 32mm filter wheels:

position 32mm filter wheels:

1010

position 32mm filter wheels:position 32mm filter wheels:

LB10

LB10----W32

LB10LB10

LB10

LB10----W32S

LB10LB10

5555----position 50mm filter wheel:

LB10

LB10----W50

LB10LB10

W32 (without shutter)

W32W32

W32S (with shutter)

W32SW32S

position 50mm filter wheel:

position 50mm filter wheel:position 50mm filter wheel:

W50 (without shutter).

W50W50

NOTE: All shutters mentioned in this manual for use with the Lambda 10

NOTE: All shutters mentioned in this manual for use with the Lambda 10----2 are

NOTE: All shutters mentioned in this manual for use with the Lambda 10NOTE: All shutters mentioned in this manual for use with the Lambda 10

shutters.

shutters.

shutters.shutters.

1.2.3

1.2.3 Filters

Filters

1.2.31.2.3

FiltersFilters

2 are Uniblitz

2 are 2 are

®®®®3333

The Lambda 10-2 filter changer is designed for use with any 1-inch or 25-mm filter with a

thickness that does not exceed the following dimensions:

4.5 mm (0.18 in.) for Slide

4.5 mm (0.18 in.) for Slide----in filter holders

4.5 mm (0.18 in.) for Slide4.5 mm (0.18 in.) for Slide

5.38 mm (0.21 in.) for Drop

5.38 mm (0.21 in.) for Drop----in filter holders

5.38 mm (0.21 in.) for Drop5.38 mm (0.21 in.) for Drop

9 mm (0.35 in.) for filter cups

9 mm (0.35 in.) for filter cups

9 mm (0.35 in.) for filter cups9 mm (0.35 in.) for filter cups

in filter holders

in filter holdersin filter holders

in filter holders

in filter holdersin filter holders

Filter wheels designed for use with 32 mm filters will accept filters with a thickness that

does not exceed the following dimensions:

9 mm (0.35 in.) for filter cups

9 mm (0.35 in.) for filter cups

9 mm (0.35 in.) for filter cups9 mm (0.35 in.) for filter cups

Instructions for installing filters into the filter wheel can be found in the FILTER WHEEL

chapter of this manual. Filters are not supplied by Sutter Instru

conforming to the above specifications can be purchased from any filter manufacturer.

conforming to the above specifications can be purchased from any filter manufacturer.

conforming to the above specifications can be purchased from any filter manufacturer.conforming to the above specifications can be purchased from any filter manufacturer.

1.2.4

1.2.4 Slide

Slide----In and Drop

1.2.41.2.4

In and Drop----In Filter Holders

SlideSlide

In and DropIn and Drop

Filters are not supplied by Sutter Instrument. However, filters

Filters are not supplied by Sutter InstruFilters are not supplied by Sutter Instru

In Filter Holders

In Filter HoldersIn Filter Holders

ment. However, filters

ment. However, filters ment. However, filters

Many users like to have extra Slide-in or Drop-in filter holders for more convenient

replacement of these “fixed” filters. Only use filter holders made by Sutter Instrument

Company in the Lambda 10

Company in the Lambda 10----2 Filter Wheel.

Company in the Lambda 10Company in the Lambda 10

2 Filter Wheel. Extra filter holders are readily available from

2 Filter Wheel. 2 Filter Wheel.

Only use filter holders made by Sutter Instrument

Only use filter holders made by Sutter Instrument Only use filter holders made by Sutter Instrument

Sutter Instrument Company or their distributors and are listed as “SLIDE-IN” and “DROPIN” in the Sutter catalogue. At this point, there are no slide-in filter holders for 32 mm

systems, although a 32-mm Drop-in filter holder is available. In addition, there is a fixed

filter position for a heat-blocking filter in most 32-mm microscope adapters offered by Sutter

Instrument Company. Slide-in and drop-in filter holders are not available for the 50 mm

filter wheels.

1.2.5

1.2.5 Shutters

Shutters

1.2.51.2.5

ShuttersShutters

If you purchase a Lambda 10-2 Filter Wheel system without a shutter and later decide to add

one to the system, the Filter Wheel must be returned to the factory for the upgrade. The

Lambda 10-2 Filter Wheel controller can support a retrofit shutter without modification.

3

Uniblitz® is a registered trademark of Vincent Associates.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 13

5

However, you must

you must only use shutters installed by Sutter Instrume

you mustyou must

only use shutters installed by Sutter Instrument.

only use shutters installed by Sutter Instrumeonly use shutters installed by Sutter Instrume

nt. This upgrade is

nt. nt.

available only at Sutter Instrument’s factory (or through their distributors) and is listed as

“SHUTTER” in the Sutter catalogue (or “WHEEL” in older catalogues).

1.2.6

1.2.6 Adapters

Adapters

1.2.61.2.6

AdaptersAdapters

Most microscopes, cameras, light sources and other optical instruments to which the Lambda

10-2 may be interfaced will require some sort of adapter to link the devices. Adapters for

interfacing the filter wheel to most instruments are available from Sutter Instrument or can

be custom built by Sutter Instrument. Suitable adapters are available from other sources,

as well, but Sutter Instrument assumes no responsibility for the performance, suitability

as well, but Sutter Instrument assumes no responsibility for the performance, suitability

as well, but Sutter Instrument assumes no responsibility for the performance, suitability as well, but Sutter Instrument assumes no responsibility for the performance, suitability

and safety of adapters built by the user or other manufacturers.

and safety of adapters built by the user or other manufacturers.

and safety of adapters built by the user or other manufacturers.and safety of adapters built by the user or other manufacturers.

1.2.7

1.2.7 Other and Optional Acce

Other and Optional Accessories

1.2.71.2.7

Other and Optional AcceOther and Optional Acce

ssories

ssoriesssories

Suitable adapters are available from other sources,

Suitable adapters are available from other sources, Suitable adapters are available from other sources,

1.2.7.1 Liquid Light Guide (LLG)

A 2-meter, 3mm diameter liquid light guide is optionally available from Sutter Instrument

(P/N: LLG). The LLG includes a C-mount, lens, and lens tube.

1.3

1.3 Functional Description

Functional Description

1.31.3

Functional DescriptionFunctional Description

1.3.1

1.3.1 Stepping Motor Operation

Stepping Motor Operation

1.3.11.3.1

Stepping Motor OperationStepping Motor Operation

Stepping motors are not as familiar to most people as the common DC motor, but there are

some similarities. The DC motor consists of an armature, an electromagnet mounted on a

rotating shaft, which is located inside a permanent magnet. Current is supplied to the

electromagnet through brushes that rub on contacts on the armature. When the

electromagnet is energized, the armature rotates to align the poles of the electromagnet with

the opposite poles of the permanent magnet. Of course, before this can occur, the rotation of

the armature changes the contact plates rubbing on the brushes so that the current is

reversed. This causes the poles of the electromagnet to reverse, establishing a force for

continued rotation. This switching action is called commutation.

In stepping motors, the rotating element, called a rotor, is generally a permanent magnet

while the fixed element, the stator, is the electromagnet. The key difference between

stepping motors and DC motors, however, is the method of commutation. The DC motor

commutates automatically as it rotates. Thus, the timing of the commutation is determined

by the speed of rotation, which may vary with the load or applied power. The commutation of

the stepping motor is set by external electronics, forcing the motor to rotate at a

predetermined rate. If the load is such that the motor does not have the force to produce the

correct rate of rotation, the rotation will become erratic and may even reverse.

The force exerted between two magnet poles is proportional to the square of the distance

between the poles. A motor with a single electromagnet and only two poles would exhibit

considerable loss of power when the distance between the poles of the permanent magnet

and the electromagnet was greatest. It is understandable that, in most practical DC motors,

the armature has more than two poles. This allows the commutation to occur over a smaller

angle of rotation, so that the active poles can always be relatively close to the poles of the

permanent magnet.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 14

6

Stepping motors are also made with multiple poles on both the rotor and stator the exact

arrangement determines the number of steps per revolution. The motor used in the Lambda

10-2 has 200 steps per revolution (1.8 degrees per step). There are usually two windings in

the stator, and a single step of rotation is produced by reversing the current on one of the

windings. Reversing the current on the second winding will then produce another step. If the

first winding is then reversed again, returning to its original value, a third step will result.

Finally, reversing the second winding, so that both windings are back to their original state,

will produce a fourth step. This pattern may then be repeated to continue rotation in the

same direction. Reversing the sequence produces steps of rotation in the opposite direction.

The rate and distance of rotation is determined by the rate and number of commutation

steps. As long as the current is held constant in both windings, the rotor will not rotate. This

makes the stepping motor ideal for producing fast start and stop movements. Some

limitations should be considered. Given that there are only 4 states of the control electronics

(2 polarities for each of the 2 windings) but 200 steps per revolution, it follows that, for each

of these four states, there are 50 possible rotary positions. In order to establish the absolute

position an external sensor must be added. Absolute position only needs to be determined

once so long as the subsequent moves occur without errors.

Correct operation of stepping motors, which is outlined above, is not always obtained. If the

motor lacks the torque to accelerate and decelerate the load at the rate indicated by the

control electronics, the resulting move may differ from that commanded by the control

electronics. For instance, if enough external force is applied, the motor shaft may be rotated

even though the command signal has not changed. For small rotations (less than 3.6

degrees), the motor shaft will return to the correct position if the force is removed. For

larger rotations, the shaft will stop at the nearest of the 50 correct positions for that

command signal when the external force is removed.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 15

2.

2. IN S TAL LAT ION

INS TAL LAT ION

2.2.

INS TAL LAT IONIN STA LLA TIO N

2.1

2.1 Unpacking

Unpacking

2.12.1

UnpackingUnpacking

The Lambda 10-2 and associated hardware comes packed in a single carton. The following is

a list of the components found there. If two wheels were ordered, two of everything should

have been received (except those items marked with an asterisk (*)). If you believe that any

of these components are missing or show obvious signs of damage from shipping, please

contact the factory.

1 or 2 Filter Wheels, each a 10 position 25 or 32 mm, or 5

1 or 2 Filter Wheels, each a 10 position 25 or 32 mm, or 5----position 50 mm, and each

1 or 2 Filter Wheels, each a 10 position 25 or 32 mm, or 51 or 2 Filter Wheels, each a 10 position 25 or 32 mm, or 5

with or without a shutter (25 or 35 mm

with or without a shutter (25 or 35 mm

with or without a shutter (25 or 35 mmwith or without a shutter (25 or 35 mm

Lambda 10

Lambda 10----2 Controller*

Lambda 10Lambda 10

Support Base per filter wheel

Support Base per filter wheel

Support Base per filter wheelSupport Base per filter wheel

2 Support Rods p

2 Support Rods per filter wheel

2 Support Rods p2 Support Rods p

2 Base Clamps per filter wheel

2 Base Clamps per filter wheel

2 Base Clamps per filter wheel2 Base Clamps per filter wheel

Filter Wheel to Controller Connecting Cable (1 per filter wheel)

Filter Wheel to Controller Connecting Cable (1 per filter wheel)

Filter Wheel to Controller Connecting Cable (1 per filter wheel)Filter Wheel to Controller Connecting Cable (1 per filter wheel)

Parallel Interface Cable*

Parallel Interface Cable*

Parallel Interface Cable*Parallel Interface Cable*

Serial Interface Cable*

Serial Interface Cable*

Serial Interface Cable*Serial Interface Cable*

Power Cord*

Power Cord*

Power Cord*Power Cord*

2 Individual Filter Holders (per filter wheel)

2 Individual Filter Holders (per filter wheel)

2 Individual Filter Holders (per filter wheel)2 Individual Filter Holders (per filter wheel)

Retaining Ring Driver*

Retaining Ring Driver*

Retaining Ring Driver*Retaining Ring Driver*

Manual*

Manual*

Manual*Manual*

Micr

Microscope Adapters (if ordered)

oscope Adapters (if ordered)

MicrMicr

oscope Adapters (if ordered)oscope Adapters (if ordered)

2 Controller*

2 Controller*2 Controller*

er filter wheel

er filter wheeler filter wheel

position 50 mm, and each

position 50 mm, and each position 50 mm, and each

Each 10-position filter wheel is shipped with nine positions of the wheel containing retaining

rings, spacer rings and blanking discs. One of the individual filter holders contains the same

three components. The second individual filter holder and one position of the wheel (position

#1) contain only retainers and spacers.

7

The Lambda 10-2 is shipped to you in a prefabricated foam mold. Please take note of this

method of packaging. Should it ever be necessary to ship the puller to another location, the

same method of packaging should be employed. Additional packing material may be

purchased from Sutter Instruments.

IMPORTANT: Improper packaging is a form of abuse and, as such, can be responsible for

voiding the warranty where shipping damage is sustained because of such packing.

2.2

2.2 Pre

Pre----installation Considerations

2.22.2

2.2.1

2.2.1 Vibrations

2.2.12.2.1

installation Considerations

PrePre

installation Considerationsinstallation Considerations

Vibrations

VibrationsVibrations

The Lambda 10-2 filter wheel system was designed to produce fast filter changes with a

minimum of vibration. The microprocessor controls the trajectory of each move using

microsteps with programmed acceleration and deceleration profiles. The result is a system so

smooth that customers using the Lambda 10 for the first time have called to report that

their wheel isn’t turning simply because they could not hear or feel anything.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 16

8

Although the Lambda 10-2 is smooth and quiet, even the slightest vibration can produce

problems for the electrophysiologist. Vibration can come from several sources. The most

pronounced effects normally come from the high-speed shutter, if that option has been

included. The shutter produces a very sharp impulse which is best avoided by finding

another way of turning the light on and off such as turning to a blanked filter position.

When the motor accelerates and decelerates the filter wheel rapidly, the torque applied tends

to turn the motor and the Lambda housing in the opposite direction. If the housing is not

firmly attached, this may appear as vibration that increases with the selected speed and the

weight of filters loaded. This is not usually a problem if the wheel is firmly mounted to a

good solid surface.

Stepping motor-based systems can produce considerable vibration and noise if the rate at

which steps are taken excites a system resonance. This problem is greatly reduced by

reducing the step size with microstepping, as in the Lambda 10-2. Even when microstepping

is used, it is possible to produce vibration by selecting a speed that is not optimal or by

starting a new move within a few milliseconds of the end of the previous move. For example,

with only two typical filters loaded speed 1 should give a very smooth move that stops with

little vibration. Speed 2, 3, and 7 may all produce more vibration at the end of a move with

this load even though they are slower speeds.

At a minimum, we recommend that the Lambda 10-2 should be firmly mounted to a solid

surface by the support stand, which is included with each unit. Do not depend on the optical

coupling between the microscope and the Lambda 10 to support and stabilize the Lambda

10. This configuration will be adequate in many cases. If there is still too much vibration, the

wheel may be mounted using the support stand, but with an air gap between the Lambda 10

and the microscope.

The best cure for vibration is isolation. One simple approach is to mount the filter wheel to a

wall or a separate table. If the microscope is on an air table, be aware that the microscope

might drift relative to a filter wheel mounted on a separate, stable surface. In such cases, it

may be better to couple the Lambda 10 to the microscope with a flexible light guide. Contact

Sutter Instrument for detail of our light-guide adapter system.

2.3

2.3 Installing the Controller

Installing the Controller

2.32.3

Installing the ControllerInstalling the Controller

2.3.1

2.3.1 Line Po

Line Power (Mains)

2.3.12.3.1

Line PoLine Po

wer (Mains)

wer (Mains)wer (Mains)

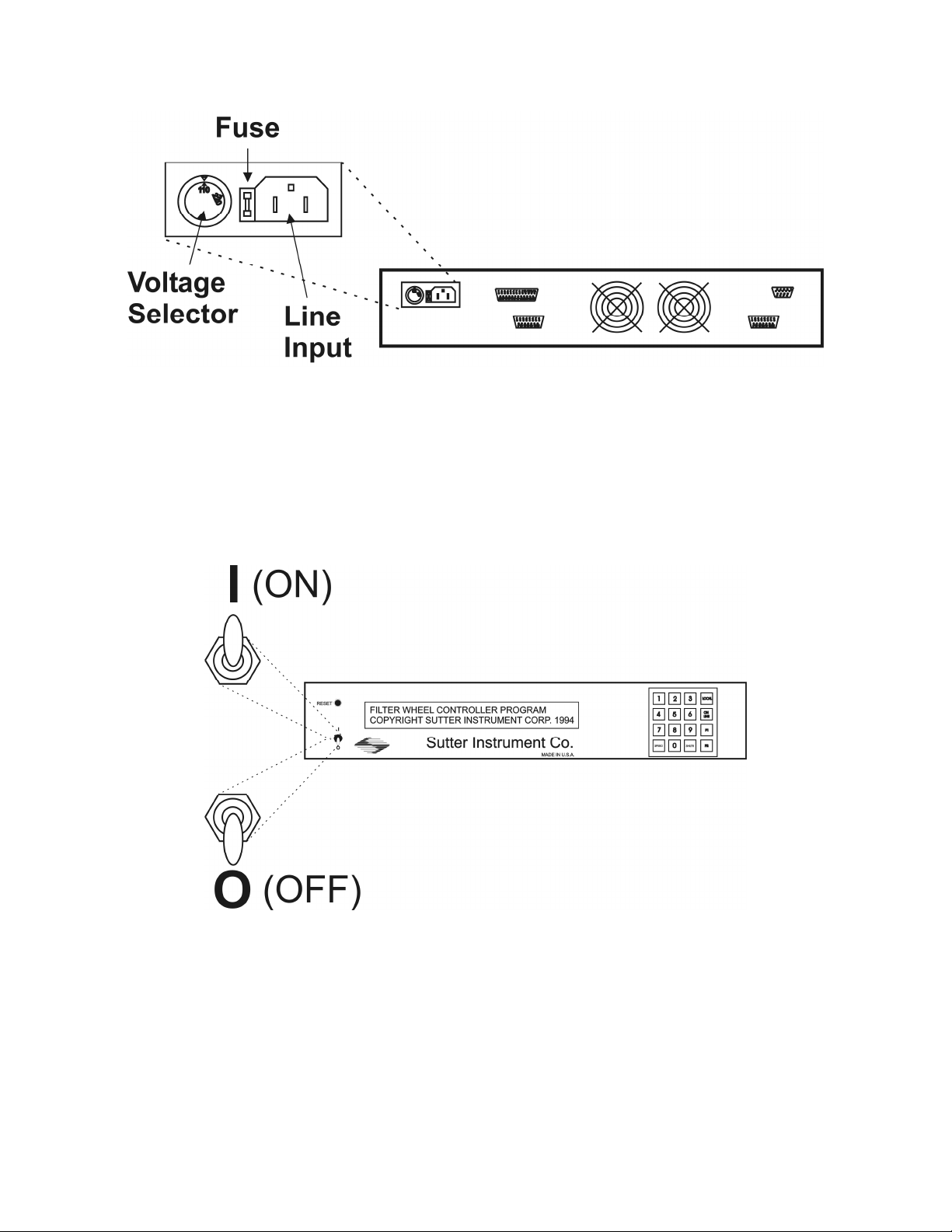

The power cord provided with the Lambda 10-2 connects to the Power Entry Module located

on the back of the unit (see Figure 2-1). This Module also includes the Line Fuse and Voltage

Selector Switch.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 17

Figure 2-1. Lambda 10-2 Cabinet (rear view).

Confirm that the Voltage Selector Switch on the Power Entry Module is set to the proper

value (110V a.c. or 220V a.c.). If it is not, turn the selector switch until the appropriate value

is lined up with the indicator. You must also replace the fuse with the appropriate value (see

the Technical Specifications), otherwise your protection from fire and electric shock may be

compromised.

9

Make certain that the ON/OFF Switch located on the front panel of the Lambda 10-2 cabinet

is turned OFF.

Figure 2-2. Lambda 10-2 Cabinet (front view)

Plug the power cord provided with the Lambda 10-2 into the Line Input socket on the Power

Entry Module and then to a power source of the appropriate voltage and frequency.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 18

10

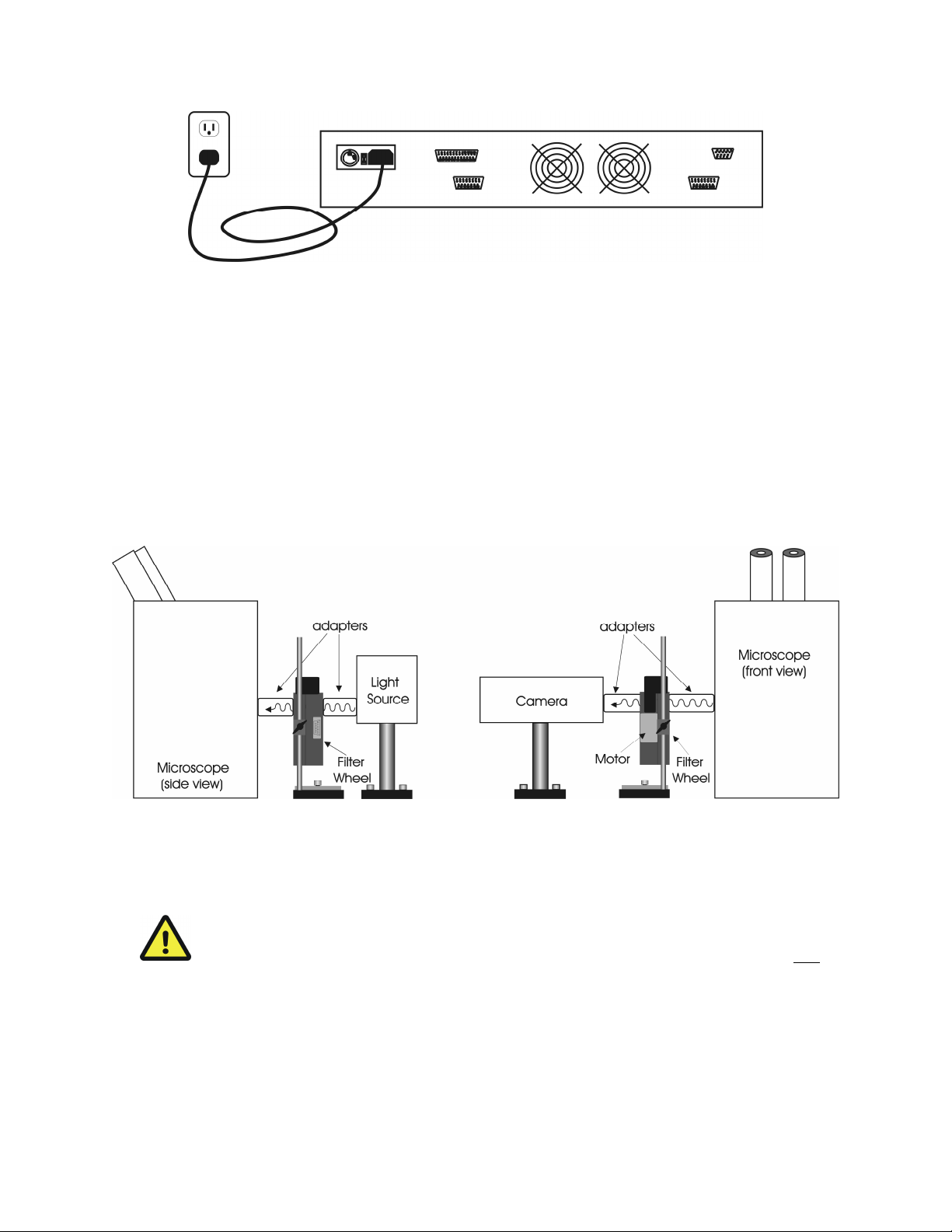

Figure 2-3. Power connection

2.4

2.4 Installing the Filter Wheel

Installing the Filter Wheel

2.42.4

Installing the Filter WheelInstalling the Filter Wheel

If you have not yet mounted the filter wheel on the support hardware, please refer to the

FIRST TIME USE chapter of this manual for instructions. Now move the mounted filter

wheel to the approximate final location and adjust the filter wheel to the desired height. The

filter wheel can be mounted on the posts in either orientation (optical port up or down), as

required. The filter wheel can now be interfaced with other instruments (e.g. a microscope

and a light source) using an appropriate adapter (Figure 2-4). If you need to purchase an

adapter or require a custom adapter for your experimental setup, please contact the

Technical Support staff at Sutter Instrument Company by phone (415 883-0128) or by Email (info@sutter.com).

Figure 2-4. Schematic diagram of two possible experimental configurations

The optical ports in the filter wheel housing and cover plate are threaded 1-32 (standard Cmount) allowing direct connection of like-threaded devices (camera adapters, microscope

adapters, etc.)

project more than 0.180 inches into the port. Allow

project more than 0.180 inches into the port. Allowing threaded devices to penetrate

project more than 0.180 inches into the port. Allowproject more than 0.180 inches into the port. Allow

further could result in damage to the filter wheel or filter cups.

further could result in damage to the filter wheel or filter cups.

further could result in damage to the filter wheel or filter cups. further could result in damage to the filter wheel or filter cups.

CAUTION

CAUTION: Care should be taken that any devices threaded into the ports

CAUTION CAUTION

: Care should be taken that any devices threaded into the ports not

: Care should be taken that any devices threaded into the ports : Care should be taken that any devices threaded into the ports

ing threaded devices to penetrate

ing threaded devices to penetrate ing threaded devices to penetrate

not

notnot

Once the filter wheel has been attached to the other instrument(s), tighten the wing screws

to lock the filter wheel at its final height. It is intended that the filter wheel be supported on

the two posts included with your system. These posts can be screwed into the base provided

or into any surface with ¼”-20 holes drilled on 6” centers at an appropriate position on the

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 19

11

tabletop or optical bench. When using the support rod base always secure it to the tabletop

using the toe clamps provided with the system.

If a heavy light source is to be used (such as a vapor lamp with integral igniter) it should

have its own separate support system.

If your filter wheel has a shutter, the side of the filter wheel on which the shutter is installed

(the “motor side” as shown in Figure 2-4) would typically be mounted toward the light

source. Placing the shutter between the lamp and filters limits the amount of heat and light

to which the filters are exposed and increases the filters’ useful lifetime.

2.4.1

2.4.1 Filter Wheel Assembly Set Up

Filter Wheel Assembly Set Up

2.4.12.4.1

Filter Wheel Assembly Set UpFilter Wheel Assembly Set Up

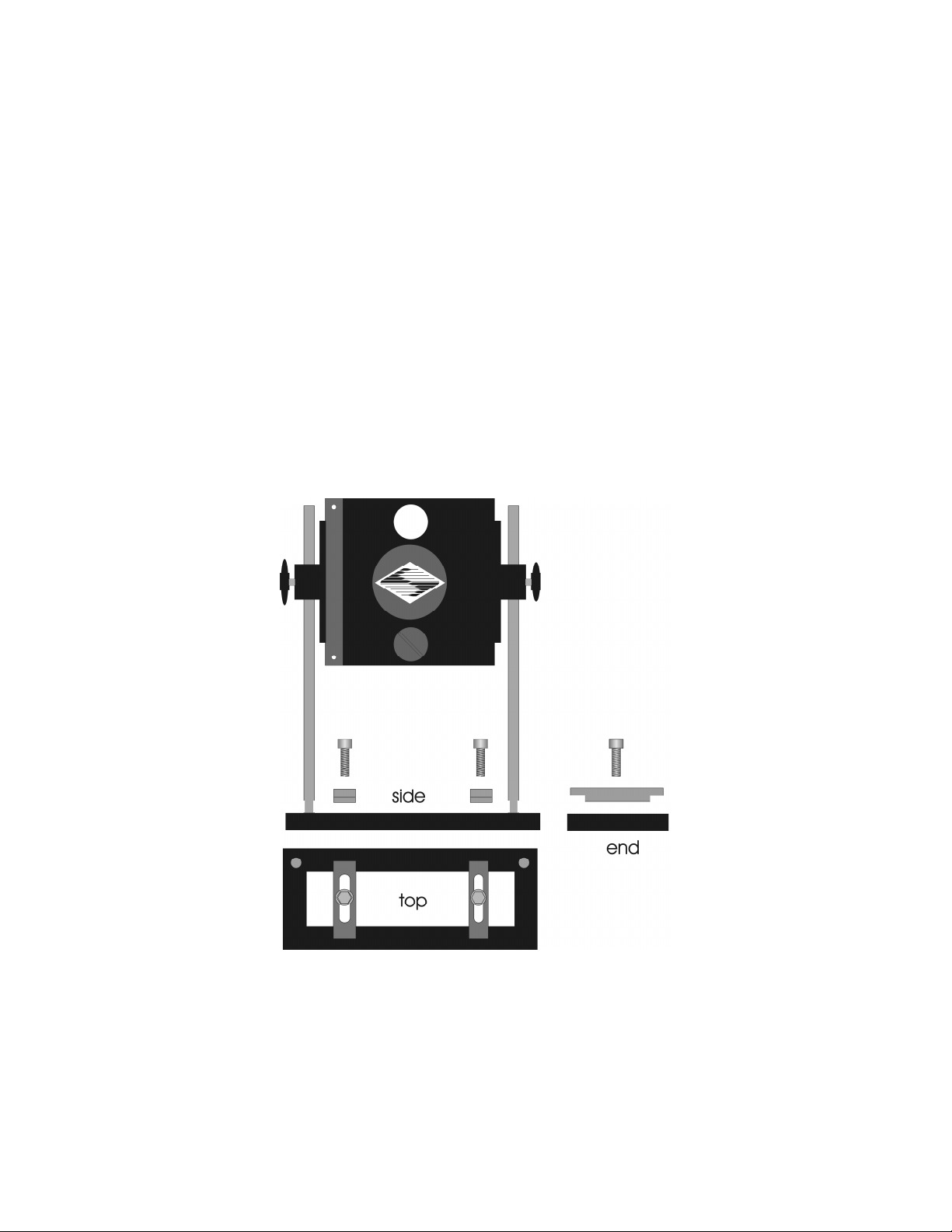

1. Assemble the two Support Rods to the Support Base. Flats have been machined near the

threaded end of these rods to facilitate tightening with a wrench. The pair of support

base clamps should be used to anchor the base to some convenient location for testing.

These clamps are designed to allow anchoring to any of the popular hole-patterns found

in optical benches.

2. Slide the filter wheel down onto the support rods and lock it at a convenient height using

the wing screws on the mounting ears of the filter wheel.

Figure 2-5. Filter wheel mounting stand

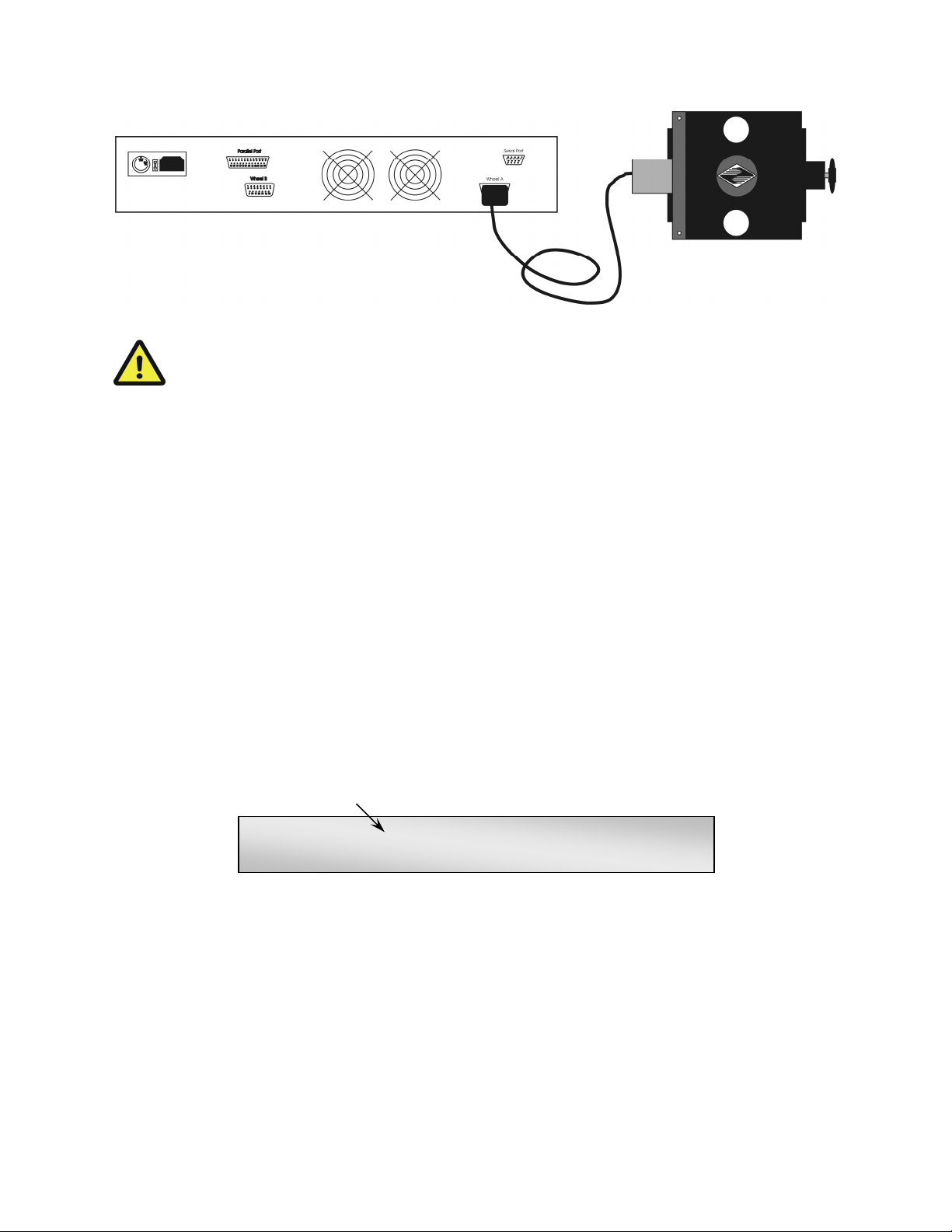

3. Connect the controller and filter wheel(s) with the appropriate cable(s) provided. It is

important that the screws anchoring the cable ends be tight to ensure a good connection

for the motor power leads and positioning signals.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 20

12

Figure 2-6. Filter wheel connection

CAUTION:

CAUTION: DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN

CAUTION: CAUTION:

THE CONTROLLER AND THE MECHANICAL UNITS (FILTER WHEELS AND/OR

THE CONTROLLER AND THE MECHANICAL UNITS (FILTER WHEELS AND/OR

THE CONTROLLER AND THE MECHANICAL UNITS (FILTER WHEELS AND/OR THE CONTROLLER AND THE MECHANICAL UNITS (FILTER WHEELS AND/OR

SHUTTER

SHUTTERS) WHILE POWER IS ON.

SHUTTERSHUTTER

S) WHILE POWER IS ON.

S) WHILE POWER IS ON. S) WHILE POWER IS ON.

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN

DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN DO NOT CONNECT OR DISCONNECT THE CABLES BETWEEN

Please allow at least 20 seconds after turning the unit off before disconnecting the

Please allow at least 20 seconds after turning the unit off before disconnecting the

Please allow at least 20 seconds after turning the unit off before disconnecting the Please allow at least 20 seconds after turning the unit off before disconnecting the

mechanical units. Failure to do this may result in damage to the electronics.

mechanical units. Failure to do this may result in damage to the electronics.

mechanical units. Failure to do this may result in damage to the electronics.mechanical units. Failure to do this may result in damage to the electronics.

2.5

2.5 First Time Use

First Time Use

2.52.5

First Time UseFirst Time Use

Make certain that the Lambda 10-2 controller is properly connected to the mains power

(refer to Section 2.3.1 and to Figure 2-1 and Figure 2-2).

2.5.1

2.5.1 Make It Go

Make It Go

2.5.12.5.1

Make It GoMake It Go

1. Turn on the power using the ON/OFF switch on the front panel of the Lambda 10-2

controller cabinet (see Figure 2-2). The controller will briefly display an initialization

screen and the filter wheel will automatically go to the “Home” (0) filter position. The

current filter position will appear on the controller front panel display.

Filter position currently

selected on Filter Wheel A

FILTER-A # 0 SP. 2 B NOT CONNECTED

PARALLEL SHUTTER A-OFF B-OFF

Figure 2-7. Initialization screen.

2. The Lambda 10-2 will initially be set to respond to the parallel port as its input source.

To manually select a filter you must first press the LOCAL key on the keypad. The

display will now indicate that the MANUAL (keypad) input source is active.

LAMBDA 10-2 OPERATION MANUAL – REV. 2.04 (20120224)

Page 21

13

FILTER-A # 0 SP. 2 B NOT CONNECTED

MANUAL-A SHUTTER A-OFF B-OFF

Input source currently

selected (MANUAL=keypad)

Figure 2-8. Initialization screen in local mode.

3. Press any numeric key on the keypad to manually select the corresponding filter position.

4. To select the filter wheel speed press the SPEED key on the keypad. The display will

prompt you through the SPEED change routine. The smaller the number you enter (0 to

7), the faster the filter wheel will move. The default SPEED setting upon startup is 2.

5. If a shutter is installed, press the SHUTR key on the keypad to toggle the shutter open

and closed. See the MANUAL CONTROL chapter for a more detailed description of

shutter operation.

Now that you have completed this FIRST TIME USE section of this manual, you should be