Page 1

OPERATION MANUAL

Rev. 2.14 ( 20081107)

Lambda DG

Lambda DG----4

Lambda DGLambda DG

Lambda DG

Lambda DG----5

Lambda DGLambda DG

Ultra

Ultra----High

UltraUltra

Wavelength Switching

Wavelength Switching

Wavelength SwitchingWavelength Switching

Systems

Systems

SystemsSystems

and

and

andand

High----Speed

HighHigh

Speed

SpeedSpeed

4

44

5

55

Page 2

Page 3

Lambda DG

Lambda DG----4 and Lambda DG

Lambda DGLambda DG

4 and Lambda DG----5555

4 and Lambda DG4 and Lambda DG

Ultra-High-Speed Wavelength Switching

Systems

Operation Manual

(Rev. 2.14 (20081107))

Sutter Instrument Company

One Digital Drive

Novato, CA 94949

Voice: 415-883-0128 Web: www.sutter.com

Fax: 415-883-0572 Email: info@sutter.com

Page 4

II

Copyright © 2008 Sutter Instrument Company. All Rights Reserved.

LAMBDA 10 ® is a registered trademark, and

Sutter Instrument Company.

Smart

Shutter™ is a trademark, both of

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 5

TABLE OF CONTENTS

TABLE OF CONTENTS

TABLE OF CONTENTSTABLE OF CONTENTS

1. GENERAL INFORMATI

1. GENERAL INFORMATION

1. GENERAL INFORMATI1. GENERAL INFORMATI

1.1 A

BOUT THIS MANUAL

1.2 L

AMBDA

1.3 U

NPACKING

2. SAFETY WARNINGS

2. SAFETY WARNINGS ................................

2. SAFETY WARNINGS2. SAFETY WARNINGS

DG-4

AND LAMBDA

...................................................................................................................................... 1

ON ................................

................................................................

ONON

................................................................

......................................................................................................................1

DG-5.................................................................................................1

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

...................................................

................................................................

........................................

................................................................

........ 1111

................

................... 3333

......................................

III

2.1 TO F

3. MAKE IT GLOW

3. MAKE IT GLOW................................

3. MAKE IT GLOW3. MAKE IT GLOW

3.1 S

3.2 G

4. OPTICAL PATHWAY

4. OPTICAL PATHWAY ................................

4. OPTICAL PATHWAY4. OPTICAL PATHWAY

4.1 L

URTHER AVOID ELECTRICAL SHOCK

................................................................

................................................................

OME BASIC INFORMATION

ETTING STARTED

IGHT GUIDE

..........................................................................................................................6

................................................................

................................................................

& O

PTICAL HOLDER INSTALLATION

.............................................................................................................5

: ....................................................................................3

................................................................

................................................................

................................................................

................................................................

............................................................

................................................................

...................................................

................................................................

......................................................................9

............................ 5555

........................................................

................... 9999

......................................

4.1.1 Liquid Light Guide...................................................................................................................9

4.1.2 Liquid Light Guide Installation .............................................................................................9

4.1.3 Optical Holder........................................................................................................................10

4.2 L

OADING FILTERS

..........................................................................................................................10

4.2.1 Filter Orientation...................................................................................................................10

4.2.2 Loading Filters .......................................................................................................................11

4.2.3 Selection of a Filter Position.................................................................................................12

4.2.4 Blanking Discs........................................................................................................................12

4.2.5 Neutral Density Filters .........................................................................................................12

4.2.6 Filter Holder Installation......................................................................................................13

5. CONTROLLER

5. CONTROLLER ................................

5. CONTROLLER5. CONTROLLER

5.1 C

ONTROL ELECTRONICS

5.2 P

OWER-UP SEQUENCE

5.3 T

OP PANEL CONTROLS

................................................................

................................................................

...............................................................................................................15

...................................................................................................................15

.................................................................................................................16

................................................................

................................................................

............................................................

................................................................

............................ 15

........................................................

5.3.1 Keypad.....................................................................................................................................16

5.4 E

LECTRICAL CONNECTIONS

.........................................................................................................16

5.4.1 Parallel Port............................................................................................................................17

5.4.2 Serial Port...............................................................................................................................17

5.4.3 Filter Value Out.....................................................................................................................17

5.4.4 Sync..........................................................................................................................................18

5.4.5 DAC..........................................................................................................................................18

5.4.6 Strobe ......................................................................................................................................18

5.4.7 Line Power..............................................................................................................................18

5.5 F

USE

...............................................................................................................................................18

5.6 M

ODES OF OPERATION

(LOCAL).................................................................................................19

5.6.1 General Information..............................................................................................................19

5.6.2 Selecting an Operational Mode: The MODE Key..............................................................20

5.6.3 Move on Command Mode......................................................................................................21

5.6.4 Move on Sync Pulse Mode.....................................................................................................23

15

1515

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 6

IV

5.6.5 Move on Strobe Pulse Mode..................................................................................................24

5.6.6 Move on Sync, Inhibited by the Strobe Line Mode............................................................25

5.6.7 Edit a Filter Definition Mode ...............................................................................................27

5.6.7.1 General Information .................................................................................................................................................27

5.6.7.2 Filter Numbers...........................................................................................................................................................28

5.6.7.3 Attenuation.................................................................................................................................................................28

5.6.7.4 Programming a Filter Number (“Logical Filter”)\..............................................................................................29

5.6.7.5 Manual Adjustment of Attenuation .......................................................................................................................30

5.6.8 Setup Ring Buffer Mode........................................................................................................33

5.6.8.1 General Information .................................................................................................................................................33

5.6.8.2 Storing the FILTER NUMBER Sequence ............................................................................................................33

5.6.8.3 Viewing an Existing FILTER NUMBER Sequence ............................................................................................34

5.6.8.4 Running the RING BUFFER Sequence................................................................................................................35

5.6.9 Turbo-Blanking Mode ...........................................................................................................37

5.6.10 Display the First Four Filter Values Mode.......................................................................38

6. REMOTE INTERFACE

6. REMOTE INTERFACE ................................

6. REMOTE INTERFACE6. REMOTE INTERFACE

6.1 P

ARALLEL INTERFACE

................................................................

................................................................

...................................................................................................................39

................................................................

................................................................

..............................................

................................................................

.............. 39

............................

6.1.1 Connecting to the Lambda DG-4 parallel port...................................................................39

6.1.2 Input Lines..............................................................................................................................40

6.1.3 Command Codes.....................................................................................................................40

6.1.4 Busy Line ................................................................................................................................43

6.1.5 Interface Modes......................................................................................................................43

6.1.6 Controlling the Lambda DG-4 from a Computer’s Parallel (Printer) Port....................44

6.1.7 Reading the Status of the Lambda DG-4 ............................................................................46

6.1.8 Shutter Control ......................................................................................................................47

6.2 S

ERIAL INTERFACE

........................................................................................................................48

6.2.1 Connecting to the Lambda DG-4 Serial Input ...................................................................48

6.2.2 Controlling the Lambda DG-4 from a Computer’s Serial Port........................................49

6.2.3 Serial Port Command Echo ..................................................................................................50

6.2.4 Serial Port Command Completion Indicator......................................................................50

6.2.5 Reading the Status of the Lambda DG-4 ............................................................................50

39

3939

AAAAPPENDIX A. FUSE REPL

PPENDIX A. FUSE REPLACEMENT

PPENDIX A. FUSE REPLPPENDIX A. FUSE REPL

APPENDIX B. LIMITED

APPENDIX B. LIMITED WARRANTY

APPENDIX B. LIMITED APPENDIX B. LIMITED

APPENDIX C. DISCLAIM

APPENDIX C. DISCLAIMER

APPENDIX C. DISCLAIMAPPENDIX C. DISCLAIM

APPENDIX D. TECHNICA

APPENDIX D. TECHNICAL SPECIFICATIONS

APPENDIX D. TECHNICAAPPENDIX D. TECHNICA

APPENDI

APPENDIX E. REMOTE

APPENDIAPPENDI

TABLE OF FIGURES

TABLE OF FIGURES

TABLE OF FIGURESTABLE OF FIGURES

Figure 3-1. Lambda DG-4 optical pathway. ...........................................................................................5

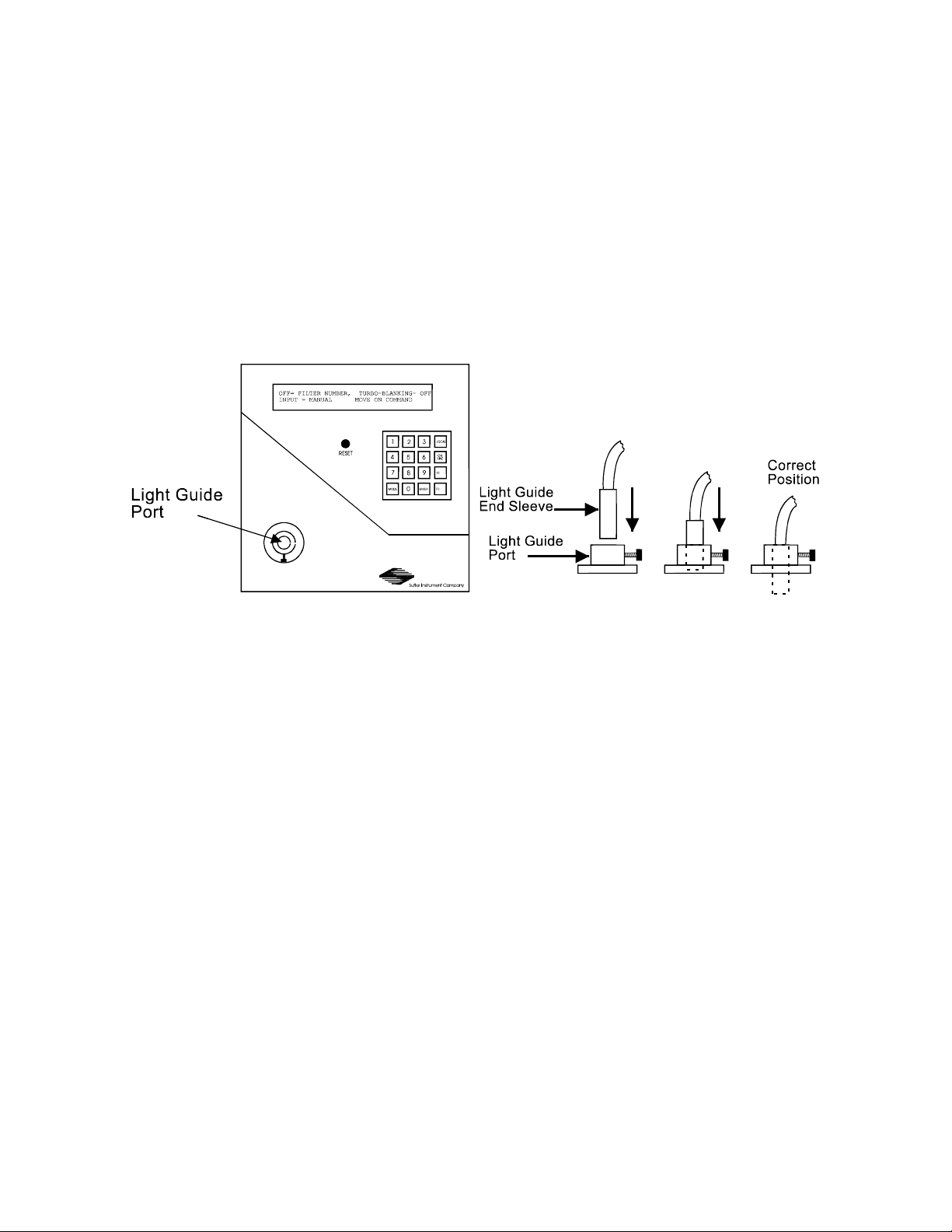

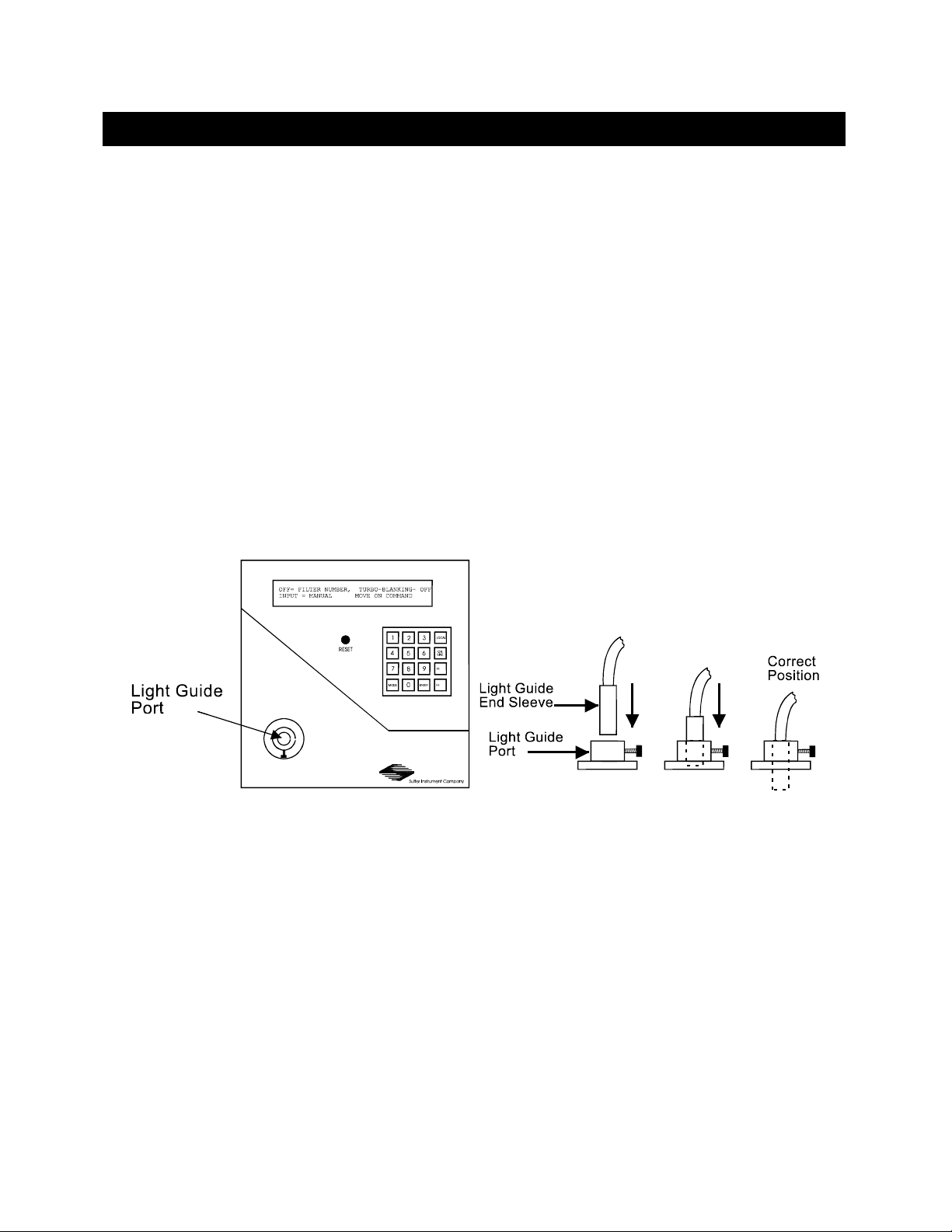

Figure 3-2. Light guide installation..........................................................................................................6

X E. REMOTE----CONTROL

X E. REMOTEX E. REMOTE

ACEMENT ................................

ACEMENTACEMENT

WARRANTY ................................

WARRANTYWARRANTY

ER ................................

................................................................

ERER

................................................................

L SPECIFICATIONS................................

L SPECIFICATIONSL SPECIFICATIONS

CONTROL COMMAND REFERENCE

CONTROL CONTROL

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

................................................................

COMMAND REFERENCE................................

COMMAND REFERENCECOMMAND REFERENCE

.......................................................

................................................................

........................................................

................................................................

........................................

................................................................

.......................................

................................................................

............................................

................................................................

.......................53

..............................................

........................55

................................................

............61

........................

53

5353

55

5555

........ 57

57

................

5757

....... 59

59

..............

5959

61

6161

Page 7

V

Figure 3-3. Lambda DG-4 left side. .........................................................................................................7

Figure 4-1. Liquid light guide installation..............................................................................................9

Figure 4-2. Light guide optical holder...................................................................................................10

Figure 4-3. Filter holder assembly.........................................................................................................11

Figure 4-4. Filter holder assembly with blanking disc........................................................................11

Figure 4-5. Lambda DG-4 left side. .......................................................................................................13

Figure 5-1. Keypad (top panel). .............................................................................................................16

Figure 5-2. Electrical connections (rear panel)....................................................................................17

Figure 5-3. Filter value out connector...................................................................................................18

Figure 5-4. Optical pathway based on filter position. .........................................................................27

Figure 5-5. DG-4 output attenuation....................................................................................................28

Figure 5-6. Log of attenuation vs. change in output galvanometer value. .......................................29

Figure 6-1. Parallel port DB25 connector (male).................................................................................39

Figure 6-2. DB25 Parallel connector.....................................................................................................45

Figure 6-3. Serial control connections (viewed from rear of cabinet). ..............................................48

Figure A-1. Fuse replacement................................................................................................................53

TABLE OF TABLES

TABLE OF TABLES

TABLE OF TABLESTABLE OF TABLES

Table 5-1. Input and output galvanometer values based on filter position......................................27

Table 6-1. Parallel port pin assignments..............................................................................................39

Table 6-2. Command code types. ...........................................................................................................40

Table 6-3. Controller commands............................................................................................................41

Table 6-4. Parallel port pin connections and definitions....................................................................45

Table 6-5. Parallel port numbering and addressing............................................................................46

Table 6-6. Shutter open and close commands......................................................................................48

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 8

VI

TableA-1. Mains fuse requirements according to lamp power ratings and line voltage.................54

Table D-1. Cable specifications...............................................................................................................60

Table E-1. Remote-control filter selection command reference..........................................................61

Table E-2. Filter selection command structure. ...................................................................................62

Table E-3. Remote-control special commands reference.....................................................................62

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 9

1.

1. G ENER AL INFO RMA TION

GEN ERAL IN FOR M ATI ON

1.1.

GEN ERAL IN FOR M ATI ONGEN ERAL IN FOR M ATI ON

1.1

1.1 About this Manual

About this Manual

1.11.1

About this ManualAbout this Manual

The Lambda DG-4 is an illumination system designed for rapid change of wavelength and

comprises three subsystems: controller, optical path and 175-Watt Xenon arc lamp with

power supply. All three subsystems are conveniently housed in one cabinet. For the most

part this manual is organized around those subsystems to provide you with ready access to

information, as you need it. Separate documentation for the lamp and its power supply

(provided by PerkinElmer Optoelectronics) accompanies this manual.

In the next few pages you will find information on the safe use of this device, unpacking

instructions and quick-start (“Make it Glow”) directions to help you get acquainted with the

operation of the Lambda DG-4 (using the manual mode). Please take the time to read these

instructions to assure the safe and proper use of this instrument.

This manual is currently under construction. If there are any areas that you feel should be

covered in greater detail we would like to hear from you. Please contact our Technical

Support staff with your suggestions (415-883-0128 or info@sutter.com).

1

1.2

1.2 Lambda DG

Lambda DG----4 and Lambda DG

1.21.2

Lambda DGLambda DG

4 and Lambda DG----5555

4 and Lambda DG4 and Lambda DG

Throughout this manual, unless otherwise noted, all references and descriptions pertaining

to “Lambda DG-4” (or just “DG-4”) apply equally to the Lambda DG-5. The only difference

between the Lambda DG-4 and Lambda DG-5 is the set of light interference filters, as

follows:

• The Lambda DG-4 filter set consists of four 25mm (1-inch) diameter filters.

• The Lambda DG-5 filter set consists of three 18mm and two 25mm (1-inch) diameter

filters.

Both models of the Lambda DG series are calibrated at the factory according to each one’s

filter set arrangement.

1.3

1.3 Unpacking

Unpacking

1.31.3

UnpackingUnpacking

The Lambda DG-4 and associated hardware comes packed in a single carton. The following

is a list of the components found there. If you believe that any of these components are

missing or show obvious signs of damage from shipping, please contact the factory.

Parallel Interface Cable

Serial Interface Cable

Power Cord

4 Individual Filter holders with retaining rings, spacer rings and blanking discs

Neutral Density holder retaining ring, spacer ring and blanking disc

Spanner Wrench

Liquid Light Guide

Manual

Microscope adapters (if ordered)

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 10

2

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 11

3

2.

2. S A FET Y W A RNI NGS

SAF ETY WAR NIN GS

2.2.

SAF ETY WAR NIN GSS AFET Y W ARN I NGS

Replace fuse only with the same type

Replace fuse only with the same type::::

Replace fuse only with the same type Replace fuse only with the same type

5 x 20 mm glass tube

5 x 20 mm glass tube

5 x 20 mm glass tube5 x 20 mm glass tube

TTTTime delay

ime delay (medium)

ime delayime delay

RRRRating:

ating:

ating:ating:

If this instrument is equipped with

If this instrument is equipped with a

If this instrument is equipped with If this instrument is equipped with

삟 100

삟 220

If this instrument is equipped with a

If this instrument is equipped with a 300

If this instrument is equipped with a If this instrument is equipped with a

삟 100

삟 220

A spare fuse is provided, being located in the power input module. Please refer to

A spare fuse is provided, being located in the power input module. Please refer to

A spare fuse is provided, being located in the power input module. Please refer to A spare fuse is provided, being located in the power input module. Please refer to

Appendix A

Appendix A:

Appendix AAppendix A

instructions on ho

instructions on how to change the fuse.

instructions on hoinstructions on ho

(medium),

(medium) (medium)

100 –––– 120 VAC Operation: 4.0A, 125V fuse; or

120 VAC Operation: 4.0A, 125V fuse; or

100 100

120 VAC Operation: 4.0A, 125V fuse; or 120 VAC Operation: 4.0A, 125V fuse; or

220 –––– 240 VAC Operation: T3.15A, 250V fuse.

240 VAC Operation: T3.15A, 250V fuse.

220 220

240 VAC Operation: T3.15A, 250V fuse. 240 VAC Operation: T3.15A, 250V fuse.

100 –––– 120 VAC Operation: 5.0A, 125V fuse, or

120 VAC Operation: 5.0A, 125V fuse, or

100 100

120 VAC Operation: 5.0A, 125V fuse, or 120 VAC Operation: 5.0A, 125V fuse, or

220 –––– 240 VAC Operation: T

240 VAC Operation: T3.15A, 250V fuse.

220 220

240 VAC Operation: T 240 VAC Operation: T

: FUSE

FUSE REPLACEMENT

: :

FUSEFUSE

w to change the fuse.

w to change the fuse.w to change the fuse.

, time lag

time lag,,,, or

, ,

time lagtime lag

REPLACEMENT for more details on fuse ratings and for

REPLACEMENTREPLACEMENT

or ““““slow blow

slow blow””””))))

or or

slow blowslow blow

a 175

175----Watt lamp

a a

3.15A, 250V fuse.

3.15A, 250V fuse.3.15A, 250V fuse.

for more details on fuse ratings and for

for more details on fuse ratings and for for more details on fuse ratings and for

Watt lamp, replace with

175175

Watt lampWatt lamp

300----Watt lamp

Watt lamp, replace with

300300

Watt lampWatt lamp

, replace with

, replace with, replace with

, replace with

, replace with, replace with

Infrared Radiation: The infrared radiation (and ultraviolet radiation) generated by

Infrared Radiation: The infrared radiation (and ultraviolet radiation) generated by

Infrared Radiation: The infrared radiation (and ultraviolet radiation) generated by Infrared Radiation: The infrared radiation (and ultraviolet radiation) generated by

this lamp can cause significant skin burns and eye damage.

this lamp can cause significant skin burns and eye damage.

this lamp can cause significant skin burns and eye damage.this lamp can cause significant skin burns and eye damage.

Explosion: High internal pressure

Explosion: High internal pressure exists in any xenon arc lamp.

Explosion: High internal pressureExplosion: High internal pressure

High Voltage: High ignition voltages, which exist inside the cabinet, can be lethal.

High Voltage: High ignition voltages, which exist inside the cabinet, can be lethal.

High Voltage: High ignition voltages, which exist inside the cabinet, can be lethal.High Voltage: High ignition voltages, which exist inside the cabinet, can be lethal.

Ozone: Because the UV

Ozone: Because the UV----enhanced version of the lamp generates significant ozone, it

Ozone: Because the UVOzone: Because the UV

must be used in a well

must be used in a well----ventilated environment. For mos

must be used in a wellmust be used in a well

requirement to ventilate the ozone

requirement to ventilate the ozone----free lamp.

requirement to ventilate the ozonerequirement to ventilate the ozone

2.1

2.1 To Further Avoid Electrical Shock

To Further Avoid Electrical Shock and Fire

2.12.1

To Further Avoid Electrical ShockTo Further Avoid Electrical Shock

Always use the grounded power supply cord set provided to connect the unit to a

Always use the grounded power supply cord set provided to connect the unit to a

Always use the grounded power supply cord set provided to connect the unit to a Always use the grounded power supply cord set provided to connect the unit to a

grounded outlet (3

grounded outlet (3----prong). This is required to protect you from injury i

grounded outlet (3grounded outlet (3

an electrical hazard occurs.

an electrical hazard occurs.

an electrical hazard occurs.an electrical hazard occurs.

Do not disassemble the unit. The only user serviceable parts are the line fuse, the

Do not disassemble the unit. The only user serviceable parts are the line fuse, the

Do not disassemble the unit. The only user serviceable parts are the line fuse, the Do not disassemble the unit. The only user serviceable parts are the line fuse, the

xenon bulb, and filters. The line fuse is accessible from the outside of the unit. The

xenon bulb, and filters. The line fuse is accessible from the outside of the unit. The

xenon bulb, and filters. The line fuse is accessible from the outside of the unit. The xenon bulb, and filters. The line fuse is accessible from the outside of the unit. The

bulb and the filters are accessible v

bulb and the filters are accessible via separate panels on the side of the unit. Bulb

bulb and the filters are accessible vbulb and the filters are accessible v

replacement and filter installation/removal are covered in separate sections of the

replacement and filter installation/removal are covered in separate sections of the

replacement and filter installation/removal are covered in separate sections of the replacement and filter installation/removal are covered in separate sections of the

manual and should only be attempted with the power cord disconnected.

manual and should only be attempted with the power cord disconnected.

manual and should only be attempted with the power cord disconnected.manual and should only be attempted with the power cord disconnected.

To prevent fire or shock hazard do not expose the un

To prevent fire or shock hazard do not expose the unit to rain or moisture.

To prevent fire or shock hazard do not expose the unTo prevent fire or shock hazard do not expose the un

enhanced version of the lamp generates significant ozone, it

enhanced version of the lamp generates significant ozone, it enhanced version of the lamp generates significant ozone, it

ventilated environment. For most users, there is no

ventilated environment. For mosventilated environment. For mos

prong). This is required to protect you from injury in the event that

prong). This is required to protect you from injury iprong). This is required to protect you from injury i

exists in any xenon arc lamp.

exists in any xenon arc lamp. exists in any xenon arc lamp.

t users, there is no

t users, there is no t users, there is no

free lamp.

free lamp.free lamp.

and Fire----related

and Fire and Fire

ia separate panels on the side of the unit. Bulb

ia separate panels on the side of the unit. Bulb ia separate panels on the side of the unit. Bulb

related Injury

relatedrelated

Injury

Injury Injury

it to rain or moisture.

it to rain or moisture.it to rain or moisture.

n the event that

n the event that n the event that

Finally, the original manufacturer of the xenon lamp and power supply used in the

Finally, the original manufacturer of the xenon lamp and power supply used in the

Finally, the original manufacturer of the xenon lamp and power supply used in the Finally, the original manufacturer of the xenon lamp and power supply used in the

Lambda DG

Lambda DG----4 provides the additional safety information on the following page. It is

Lambda DGLambda DG

intended to amplify the information given above.

intended to amplify the information given above.

intended to amplify the information given above.intended to amplify the information given above.

4 provides the additional safety information on the following page. It is

4 provides the additional safety information on the following page. It is 4 provides the additional safety information on the following page. It is

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 12

4

PerkinElmer Optoelectronics

44370 Christy Street

Fremont CA 94538

Phone: 510-979-6500

FAX: 510-687-1152

SHORT ARC XENON LAMPS AND SYSTEMS

Proper use and safe operating practices are the responsibility

of equipment manufacturers who incorporate the lamp into

equipment and users of such lamps and equipment. The

supplier of this lamp provides information on its products and

associated hazards, but it assumes no responsibility for aftersale operating and safety practices. All lamps are under

pressure and must be handled with care. Take appropriate

action through baffles, light shields, interlock switches or

other safeguards to protect personnel from harm due to

operation and/or failure of the lamp.

SAFE OPERATING INSTRUCTIONS

Do not operate this lamp except in accordance with proper

operating instructions and within recommended operating

specifications. Direct questions regarding lamp operation or

safety to your lamp supplier.

OPERATING HAZARDS

Read the following instructions and take all necessary precautions

I. EXPLOSION - The lamps are filled with xenon gas at very

high pressure. Lamps must be handled with the same care and

caution given any vessel containing these levels of pressure. A

hazard exists if the window or ceramic fractures and may

cause explosive mechanical failure. Face shields or proper

safety glasses are recommended during all handling

operations.

II. HIGH VOLTAGE - Ignition voltage of some lamp models

is very high and can be deadly. If portions of the circuit are

exposed, caution must be used in setup and operation of the

system. The input power must be disconnected from the power

source before attempting any service to the lamp.

III. INFRARED AND ULTRAVIOLET RADIATION - Do

not look directly at operating lamps orb reflected light.

Infrared and ultra violet radiation generated by the lamp can

cause skin burns and permanent eye damage.

CERMAX® Lamps

LAMP DISPOSAL

CERMAX lamps do not have reclaimable parts. Before

disposal, it is recommended to relieve a lamp’s gas pressure by

squeezing the tip-off with pliers until the gas escapes. If gas

pressure is not relieved, care should be taken to discard the

lamp in a landfill and not an incinerator.

SAFETY HAZARDS

The operation of lamps involves one or more of the following

hazards. In the absence of safe operating practices and

precautions, any one of these hazards could result in injury.

IV. OZONE - Some UV type lamps generate ozone, a toxic

gas, by virtue of the ultraviolet radiation. A lamp which gives

off ozone must be operated in a well ventilated area..

V. HOT SURFACES - Portions of the lamp can reach

temperatures of several hundred degrees centigrade and cause

serious burns if touched even after the lamp is turned off.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 13

5

3.

3. MA KE IT G LOW

MAK E IT GLO W

3.3.

MAK E IT GLO WMA K E I T GL OW

3.1

3.1 Some Basic Information

Some Basic Information

3.13.1

Some Basic InformationSome Basic Information

The optical path subsystem in the Lambda DG-4 is arranged so that 2 mirrors, each mounted

on a fast closed-loop servoed galvanometer, can route the collimated output of the lamp

through one of 4 optical paths (e.g., filter position 1 in the diagram below). Slide-in filter

holders allow 25 mm (or 1 inch) diameter filters to be introduced in each of the four optical

paths. An additional slide-in filter holder, intended for neutral density filters, is located in a

portion of the optical system common to all light paths. After passing through the filter

positions, the lamp output is focused on a 2-meter long UV (ultraviolet) transmitting light

guide, which acts as a conduit for the output to the microscope. At the output of the light

guide, an optical adapter collects the output and delivers it to the microscope.

Figure 3-1. Lambda DG-4 optical pathway.

The following instructions are meant to help you set up the Lambda DG-4 and verify that

the Lambda DG-4’s subsystems are operational using the manual mode of filter selection.

More detailed discussions of controller function, filter installation, the light source,

assignment of filter numbers and remote communications can be found in other sections of

this manual.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 14

6

3.2

3.2 Getting Started

Getting Started

3.23.2

Getting StartedGetting Started

1. Connect the power cord to the socket on the back panel of the Lambda DG-4. Make

certain that the voltage selector next to the power cord socket has been properly preset to

the appropriate voltage (110 or 220). Do not turn on the power, yet.

2. Insert either end of the light guide into the port on the top panel of the Lambda DG-4

cabinet (see below) and tighten the thumbscrew to hold it in place. The top of the light

guide end sleeve should be flush with the top surface of the port fitting (see below). This

should result in maximal or near-maximal light output from the light guide. Minor

adjustments up from this position may improve output, and can be easily made once the

system is fully installed.

Figure 3-2. Light guide installation.

3. The other end of the light guide should be installed in the microscope using the

appropriate adapters (see the installation sheet provided with the specific adapter that

has been ordered) or directed away from anyone’s eyes and toward a non-reflective

surface. DO NOT LOOK DIRECTLY INTO THE LIGHT GUIDE!

4. A hose should be connected to the 4” fitting on the back of the Lambda DG-4 cabinet to

ventilate the ozone from the xenon lamp to the environment or to an ozone removal

device.

5. Identify the small access door used to install the neutral density FILTER HOLDER.

This access door is located near the top edge of the left side panel on the Lambda DG-4

cabinet (see below). Loosen the black knob on the access door and slide it up to install

the empty Neutral Density FILTER HOLDER (the neutral density FILTER HOLDER

is the one whose bottom surface is flat rather than grooved). Make certain that the end

nearest the filter cup goes in first. If you would like to install a neutral density filter at

this time please refer to the “Loading Filters” section of this manual.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 15

7

Figure 3-3. Lambda DG-4 left side.

6. Identify the large access door used to install the interference FILTER HOLDERS. This

access door is located in the middle of the left side panel on the Lambda DG-4 cabinet

(see above). Loosen the black knob on the access door and slide it up to install the

remaining four FILTER HOLDERS (the ones that have a groove on their bottom

surface). Install the two FILTER HOLDERS that contain blanking disks in FILTER

POSITIONS 3 and 4. If you would like to install interference filters at this time, please

refer to the “Loading Filters” section of this manual.

7. Make certain that the free end of the light guide is installed into the microscope or is

directed toward a non-reflective surface and away from anyone’s eyes. DO NOT LOOK

DIRECTLY INTO THE LIGHT GUIDE.

8. Turn on the power to the lamp subsystem using the switch labeled LAMP on the back

panel of the Lambda DG-4 cabinet. Due to the current draw during lamp ignition, it is

important to power up the LAMP first (before the MAIN switch is turned on) to avoid

damage to the circuitry of the other Lambda DG-4 subsystems. This same precaution

applies to the order in which you power up other electronic and computer equipment that

might be powered from or grounded to the same circuit as the one used for the Lambda

DG-4. GO DIRECTLY TO THE NEXT STEP! DO NOT OPERATE THE LAMP FOR

MORE THAN A FEW SECONDS WITHOUT TURNING ON THE MAIN POWER

SWITCH!

9. Within a few seconds of turning on the LAMP switch turn on the power to the optical

path and controller subsystems using the switch labeled MAIN on the back panel of the

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 16

8

Lambda DG-4 cabinet. The Lambda DG-4 will boot up and briefly display the

initialization screen followed by the MAIN MENU (shown on top of next page).

OFF= FILTER NUMBER, TURBO-BLANKING- OFF

OFF= FILTER NUMBER, TURBO-BLANKING- OFF

OFF= FILTER NUMBER, TURBO-BLANKING- OFFOFF= FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND INPUT = MANUAL MOVE ON COMMAND

10. The Lambda DG-4 is under LOCAL (keypad) control upon start-up, as indicated by the

words “INPUT - MANUAL” on the MAIN MENU (see above). MOVE ON COMMAND is

the active operational mode at start-up, which means that filters are selected by pressing

the numeric keys corresponding to the desired FILTER NUMBER (see EDIT A FILTER

NUMBER definition of this value). The default FILTER NUMBER upon start-up is “0”.

This setting will disrupt the optical pathway within the Lambda DG-4 and prevent any

light output at the light guide port. The “0” FILTER NUMBER serves, then, as a

“shutter” whenever it is selected.

11. Press the “1” key followed by ENTER. This FILTER NUMBER is pre-programmed at

the factory to cause the light to be directed through the FILTER HOLDER that is loaded

into position 1 and then onto the light guide with maximal light output (i.e., minimal

attenuation).

12. Now experiment by selecting FILTER NUMBERS 0 through 4. Anytime you select a

single digit FILTER NUMBER you must complete the entry by pressing the ENTER key

or you must precede the single digit with a “0”. FILTER NUMBERS 0,1,2,3 and 4 are

pre-programmed to correspond with the closed “shutter” and the four FILTER

POSITIONS (with minimal attenuation), respectively.

Now that you have completed the “Make it Glow” section of the manual, you should be

familiar with the basic components and operation of the Lambda DG-4. To get set up for an

experimental application you will need to:

Install the LIGHT GUIDE into the OPTICAL HOLDER (if not already in place).

Install the OPTICAL HOLDER into the microscope using the appropriate adapter (if not

already in place).

Install the desired filters into the FILTER HOLDERS (if not already in place).

Program the desired FILTER NUMBERS.

Establish the desired interface between the Lambda DG-4 and your computer.

Each of these steps is discussed in the following sections of the manual.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 17

9

4.

4. O PTIC AL P ATH W AY

OPT ICAL PA T HWA Y

4.4.

OPT ICAL PA T HWA YOPT ICAL PA THWA Y

4.1

4.1 Light Guide & Optical Holder Installation

Light Guide & Optical Holder Installation

4.14.1

Light Guide & Optical Holder InstallationLight Guide & Optical Holder Installation

4.1.1

4.1.1 Liquid Light Guide

Liquid Light Guide

4.1.14.1.1

Liquid Light GuideLiquid Light Guide

The light output of the Lambda 10 DG4 is focused onto one end of a liquid light guide. The

output of the liquid light guide can then easily be coupled to your microscope or optical

system using correct mechanical adapter for your microscope. Please note that the light

guide has a minimum-bending radius of 40 mm (about 1.6 inches).

4.1.2

4.1.2 Liquid Light Guide Installation

Liquid Light Guide Installation

4.1.24.1.2

Liquid Light Guide InstallationLiquid Light Guide Installation

The liquid light guide should have black sleeves over the ferrules on both ends. These

ferrules, or “end sleeves”, are designed to slide into the mounting flange on the lambda DG-4

cabinet and the output adapter. Insert the end of the light guide into the light guide port

until the top of the black end sleeve is even with the top of the light guide port. Tighten the

locking screw on light guide port to secure the end of the light guide in position. This should

result in maximal or near-maximal light output from the light guide. Minor adjustments up

from this position may improve output; the adjustments can be easily made once the system

is fully installed.

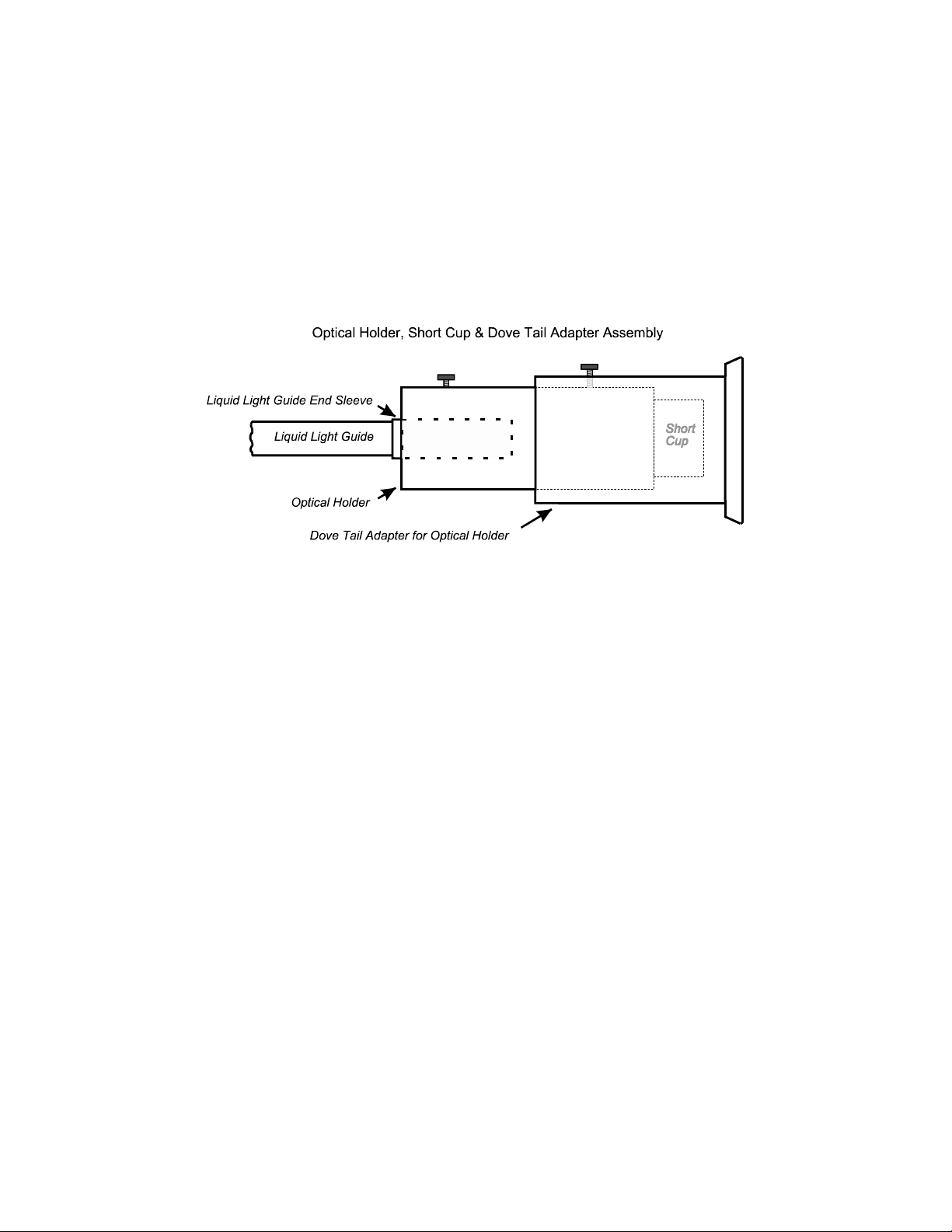

Figure 4-1. Liquid light guide installation.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 18

10

4.1.3

4.1.3 Optical Holder

Optical Holder

4.1.34.1.3

Optical Holder Optical Holder

The free end of the light guide slides into one end of the optical holder tube (shown below).

The other end of the optical holder tube has a UV grade fused silica lens system (in the

“short cup”). By sliding the light guide toward or away from these lenses, the light guide

output can be collimated or brought to a focus. The optical holder, in turn, slides into the

dovetail adapter, which has a “dovetail” collar on one end. This collar is used to fasten the

entire assembly to the microscope system using an adapter (not shown) that is specific to the

microscope make and model. Refer to the documentation included with each microscope

adapter for further installation instructions.

Figure 4-2. Light guide optical holder.

4.2

4.2 Loading Filters

Loading Filters

4.24.2

Loading FiltersLoading Filters

4.2.1

4.2.1 Filter Orientation

Filter Orientation

4.2.14.2.1

Filter OrientationFilter Orientation

The two sides of a filter are usually not identical due to differences in their surface coatings.

Some form of labeling will be present to differentiate the two sides. It is important to refer

to the filter manufacturer’s documentation to interpret the labeling and determine the

proper orientation relative to the light source. Remember, the light path inside the Lambda

DG-4 travels from BOTTOM TO TOP. Therefore, the filters should be oriented with their

“Lamp Side” down.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 19

4.2.2

4.2.2 Loading Filters

Loading Filters

4.2.24.2.2

Loading FiltersLoading Filters

11

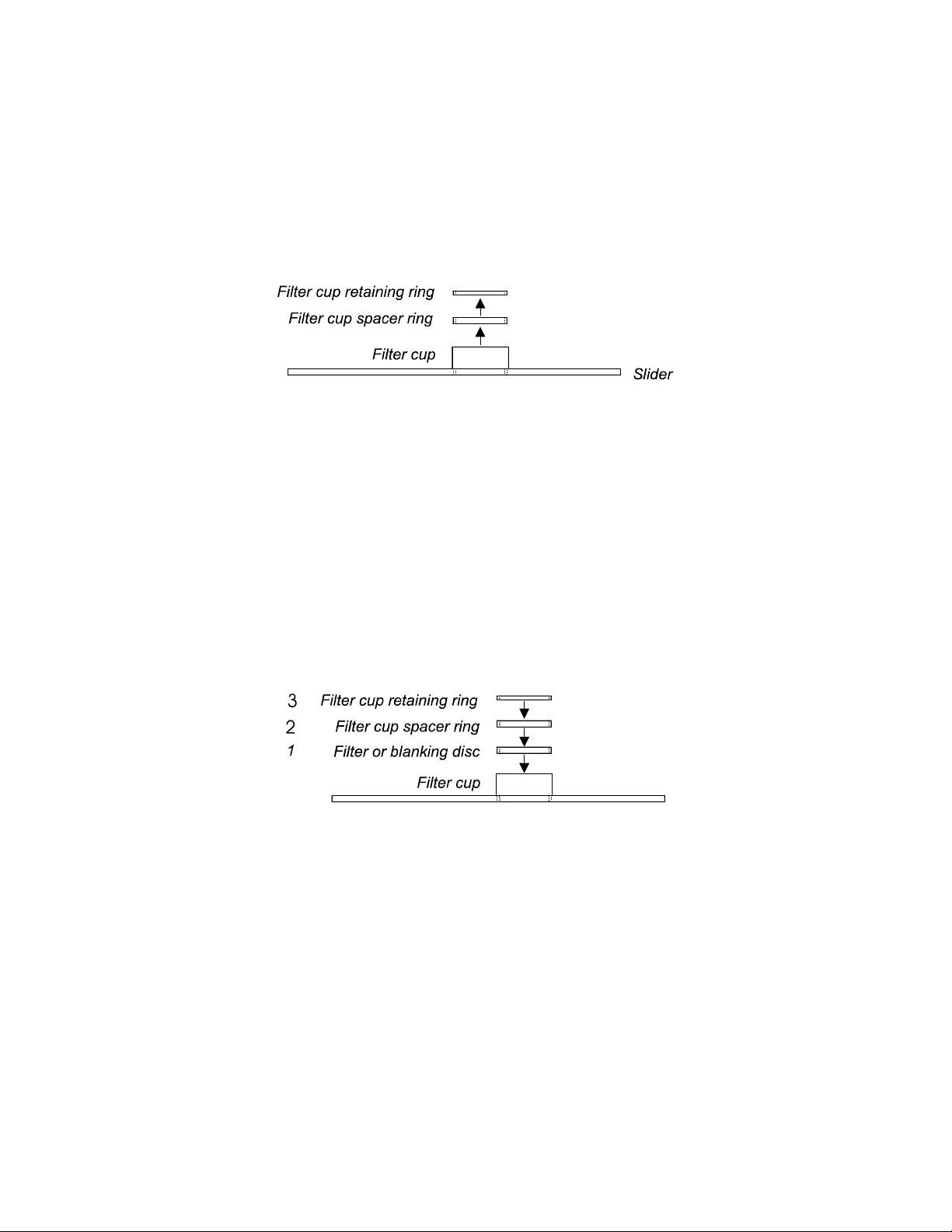

At the end of each filter holder is a filter cup assembly (shown below). There are at least two

items installed into the filter cup at the factory: a threaded retaining ring and a spacer ring

(to carry the force of the retaining ring to the unthreaded portion at the bottom of the cup).

In two of the filter cups, there will also be a blanking disc. Installation of filters into the

filter holders requires care and patience to avoid damaging the threads of the filter cups and

retaining rings as well as the filters.

Figure 4-3. Filter holder assembly.

The threaded retaining ring has two notches cut into it, 180 degrees apart. Place the

notched end of the brass spanner wrench into the notches on the retaining ring and carefully

unscrew it. If a retaining ring has been previously over-tightened, it is possible that the filter

cup will begin to unscrew from the slider. If this occurs, STOP. Turn the spanner wrench

around and, using the other end, insert it into the slots at the top of the cup. Then screw the

cup back into the slider. DO NOT push on the cup. Just screw it in until it seats firmly. It

should then be possible to remove the retaining ring.

Once the retaining ring is removed, the spacer (and blank, if present) should fall out. You

should become familiar with the assembly of this retaining system. In particular, you should

develop a feel for tightening the retaining ring without pushing on the wrench. This is

important because if you forcefully push on the filter holder while you are trying to load a

filter, you run the risk of scratching the filter.

Figure 4-4. Filter holder assembly with blanking disc.

Place the desired filter into the filter cup, first. With some 1” filters extra care must be

taken to avoid getting the filters jammed at an angle inside the filter cup.

Next, install the spacer ring into the filter cup. Unless the filter thickness precludes the use

of the spacer ring, always install the spacer to provide maximum separation between the

filter surface and end of the brass spanner wrench that is used to turn the retaining ring.

Finally, install the threaded retaining ring.

CAUTION: DO NOT OVER TIGHTEN THE RETAINING RING!

CAUTION: DO NOT OVER TIGHTEN THE RETAINING RING!

CAUTION: DO NOT OVER TIGHTEN THE RETAINING RING!CAUTION: DO NOT OVER TIGHTEN THE RETAINING RING!

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 20

12

4.2.3

4.2.3 Selection of a Filter Position

Selection of a Filter Position

4.2.34.2.3

Selection of a Filter PositionSelection of a Filter Position

In most cases, any given filter could be installed at any of the four FILTER POSITIONS.

However, some minor considerations may improve performance of the system. Adjacent

FILTER POSITIONS will require slightly less switching time. Therefore, if an experiment

will require rapid switching between two filters they should be located next to one another.

If separated by one or more filters, there will be brief transitions through the intervening

filter(s) unless the TURBO-BLANKING feature is enabled (see “Modes of Operation”).

While this feature eliminates the transmission of light at unwanted wavelengths, it does

further increase the time required for switching.

4.2.4

4.2.4 Blanking Discs

Blanking Discs

4.2.44.2.4

Blanking DiscsBlanking Discs

The blanking discs should only be removed from those positions that will contain a filter.

The discs are intended as a safety device for the occasion where you may be looking into the

microscope. We strongly urge that the discs be used. Please be careful and avoid the

possibility of direct visualization of high intensity light.

4.2.5

4.2.5 Neutral Density Filters

Neutral Density Filters

4.2.54.2.5

Neutral Density FiltersNeutral Density Filters

. Filter installation is the same for this filter holder as described above. The slide portion of

the neutral density filter holder, however, is mechanically different from those used for the

interference filters. As a result, the two types of holders may not be interchanged.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 21

13

4.2.6

4.2.6 Filter Holder Installation

Filter Holder Installation

4.2.64.2.6

Filter Holder InstallationFilter Holder Installation

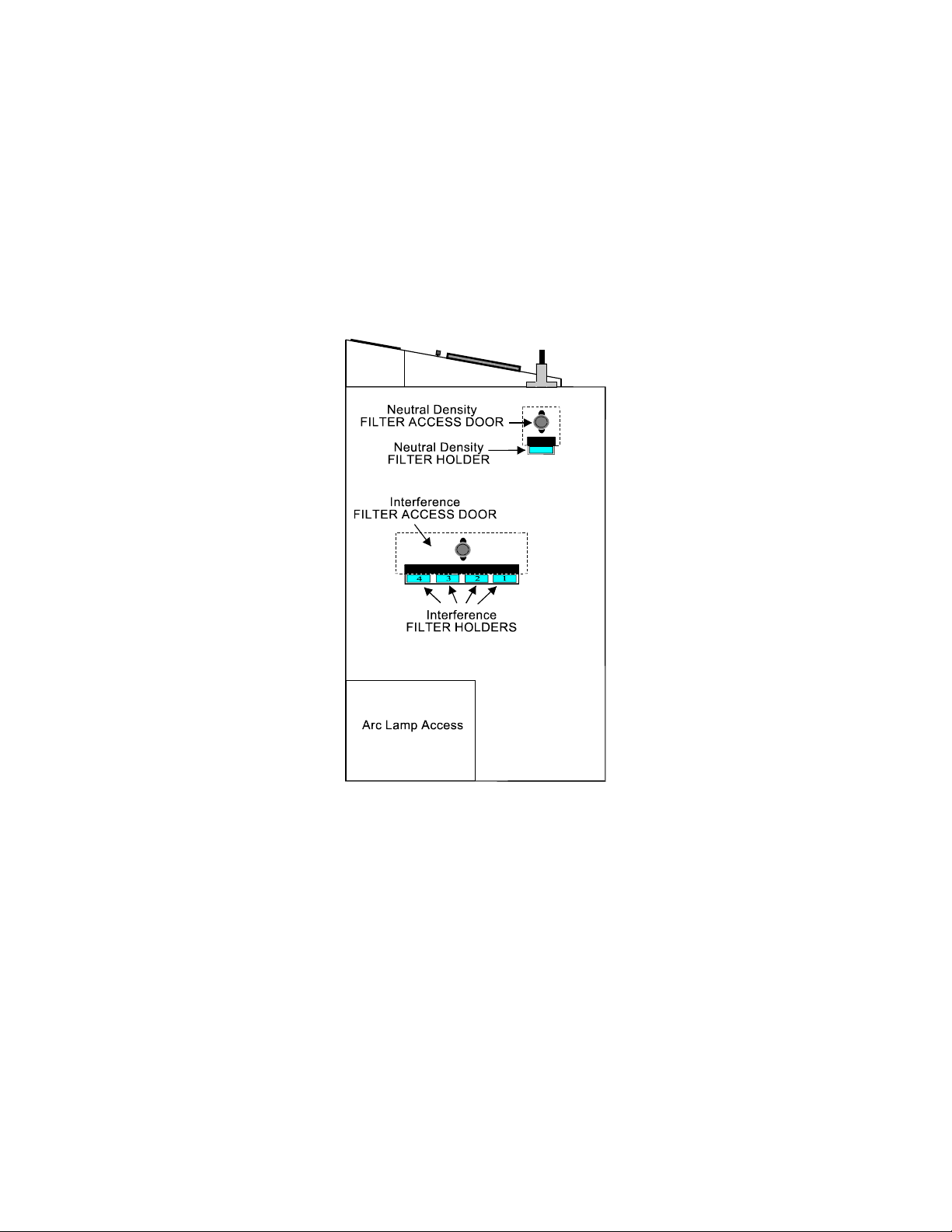

Identify the access doors used to install the neutral density FILTER HOLDER and the four

interference FILTER HOLDERS. The small access door located near the top edge of the left

side panel on the Lambda DG-4 cabinet (see below) is for the neutral-density FILTER

HOLDER. The larger door in the middle of the left side panel is fro the interference

FILTER HOLDER. Loosen the black knob on these access doors to slide them up and install

the appropriate FILTER HOLDER into the slot. The bottom of the neutral density FILTER

HOLDER is flat while the bottoms of the interference FILTER HOLDERS are grooved. For

this reason, these two types of FILTER HOLDERS are not interchangeable. Make certain

that the end nearest the filter cup goes in first.

Figure 4-5. Lambda DG-4 left side.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 22

Page 23

15

5.

5. C O NTR OLL E R

CON TROL LER

5.5.

CON TROL LERCON TROL LER

Although the Lambda DG-4 is simple to use, proper operation depends on the user

understanding the design and characteristics of this instrument. This section provides the

detailed information needed to begin operation and to control the unit from its keypad.

5.1

5.1 Control Electronics

Control Electronics

5.15.1

Control ElectronicsControl Electronics

The control electronics for the filter changer are activated by the “MAIN” power switch on

the rear of the unit. You may operate the control electronics without the lamp on, but it is

best to turn the control electronics off before the lamp is started. Once the lamp has been

started, the control electronics may be turned on again.

5.2

5.2 Power

Power----up Sequence

5.25.2

PowerPower

There are two switches on the back of the Lambda DG-4 labeled LAMP and MAIN. The

LAMP switch will ignite and power the xenon lamp. The MAIN switch applies power to the

controller and the fan that cools all of the electronics (including the xenon lamp power

supply). The MAIN switch should be turned on immediately after the LAMP switch is

turned on. If you are only configuring the Lambda DG-4 controller or a computer interface,

you do not need to switch on the LAMP before turning on the MAIN switch. The following

message will be briefly displayed on the front panel when the MAIN switch is turned on:

After a few seconds the MAIN MENU will be displayed:

At this point, the Controller subsystem is ready for operation.

up Sequence

up Sequenceup Sequence

SUTTER FAST FILTER CONTROLLER PROGRAM

SUTTER FAST FILTER CONTROLLER PROGRAM

SUTTER FAST FILTER CONTROLLER PROGRAM SUTTER FAST FILTER CONTROLLER PROGRAM

COPYRIGHT SUTTER INSTRUMENT CORP. 2006

COPYRIGHT SUTTER INSTRUMENT CORP. 2006

COPYRIGHT SUTTER INSTRUMENT CORP. 2006 COPYRIGHT SUTTER INSTRUMENT CORP. 2006

OFF= FILTER NUMBER, TURBO-BLANKING- OFF

OFF= FILTER NUMBER, TURBO-BLANKING- OFF

OFF= FILTER NUMBER, TURBO-BLANKING- OFFOFF= FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND INPUT = MANUAL MOVE ON COMMAND

When the unit is first turned on, the FILTER NUMBER

indicates that the filter selecting mirrors have been positioned to prevent lamp output from

the device. The status of the TURBO

OFF is the default setting for that feature when the controller is first powered up.

The second line of the display indicates if the unit is under local control and that the unit

will execute all commands as they are received.

The unit selects the PARALLEL MODE as the default remote interface at power on. If the

unit is under remote control at power on, the appropriate remote interface mode will be

automatically set and the display may change immediately to reflect any waiting computer

commands.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

TURBO----BLANKING

TURBOTURBO

FILTER NUMBER display will read “OFF”. This

FILTER NUMBERFILTER NUMBER

BLANKING feature (discussed below) is also shown;

BLANKINGBLANKING

Page 24

16

5.3

5.3 Top Panel Controls

Top Panel Controls

5.35.3

Top Panel ControlsTop Panel Controls

5.3.1

5.3.1 Keypad

Keypad

5.3.15.3.1

KeypadKeypad

Figure 5-1. Keypad (top panel).

There are 16 keys on the Lambda DG-4 keypad. The numerical keys 0 to 9 and six function

keys. Keys are read while depressed but the appropriate action will occur only when the key

is released. If a key is pressed while a move is in progress but released after the move is

over, the key will read normally. Keys pressed and released while a move is in progress are

ignored. In the REMOTE MODE only the LOCAL key is active. Holding any other key

down while in the REMOTE MODE may cause an interruption in the reading of new

commands from the remote computer. The functions of the keys are as follows:

0000----9999 These keys are used to select modes and make numerical entries while in the various

modes of operation. In the MOVE ON COMMAND mode, for example, a FILTER NUMBER

may be selected with these keys.

F1, F2

F1, F2 These key are presently used to manually increase or decrease the Output

F1, F2 F1, F2

Galvanometer Value (see EDIT A FILTER VALUE DEFINITION).

LOCAL

LOCAL Pressing this key puts the unit under LOCAL control. This is the only key that has

LOCALLOCAL

an effect when the Lambda DG-4 is ON LINE (i.e., under the remote control of an interfaced

external source, such as a computer.

ON LINE

ON LINE This key transfers control of the Lambda DG-4 to an interfaced external source,

ON LINE ON LINE

such as a computer. This transfer can also be done by sending the correct signal from the

external source as outlined under the interfacing section. The default input port is the

PARALLEL PORT, so the display will indicate PARALLEL MODE after the ON LINE key

has been pressed (unless the SERIAL PORT is active).

ENTER

ENTER This key is used in conjunction with the numeric keys for selecting FILTER

ENTERENTER

NUMBERS and entering other numeric data. It is also used to exit certain set-up modes

when data entry has been completed.

MODE

MODE This key is used to locally to set the mode of operation and to access setup modes.

MODEMODE

This key does not directly relate to the mode of input. Pressing the MODE key will initiate a

mode selection routine, which will present a series of linked menus (see the section on

“Selecting an Operational Mode”).

RESET

RESET Pressing the RESET button at any time causes the control unit to start the power-

RESETRESET

up sequence outlined above. The sequence starts with a delay after the end of the buttonpress. The display will be cleared until the initialization screen is written.

5.4

5.4 Electrical Connections

Electrical Connections

5.45.4

Electrical ConnectionsElectrical Connections

All Electrical connections are made on the rear panel of the Lambda DG-4.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 25

17

Figure 5-2. Electrical connections (rear panel).

5.4.1

5.4.1 Parallel Port

Parallel Port

5.4.15.4.1

Parallel PortParallel Port

This 25-pin DSUB connector is used for establishing a parallel interface between the

Lambda DG-4 and a remote device (computer) using the cable provided. This cable should

not be used simultaneously with the serial port cable.

5.4.2

5.4.2 Serial Port

Serial Port

5.4.25.4.2

Serial PortSerial Port

This 9-pin DSUB connector is used for establishing a serial interface between the Lambda

DG-4 and a remote device (computer) using the cable provided. This cable should not be

used simultaneously with the parallel port cable.

5.4.3

5.4.3 Filter Value Out

Filter Value Out

5.4.35.4.3

Filter Value OutFilter Value Out

This 8-pin, Modular connector provides a digital indicator of the value of the FILTER

NUMBER in use. Pin numbers 1 through 4 correspond to the bit number of the 4-bit binary

equivalent of the decimal FILTER NUMBER value. Pin 5 carries the BUSY line signal and

pins 6 through 8 are tied to ground.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 26

18

Figure 5-3. Filter value out connector.

5.4.4

5.4.4 Sync

Sync

5.4.45.4.4

SyncSync

This BNC connector is the video synchronization input. NOTE: THIS INPUT IS NOT

INTERNALLY GROUNDED. If the ground in the camera being used is floating, the

camera’s synchronization signal to the Lambda DG-4 SYNC input will cause the

galvanometers to oscillate at a high, irregular rate.

5.4.5

5.4.5 DAC

DAC

5.4.55.4.5

DACDAC

This BNC connector provides an analog indicator of the current FILTER NUMBER:

DAC Output = FILTER NUMBER x 400 mV

DAC Output = FILTER NUMBER x 400 mV

DAC Output = FILTER NUMBER x 400 mVDAC Output = FILTER NUMBER x 400 mV

5.4.6

5.4.6 Strobe

Strobe

5.4.65.4.6

StrobeStrobe

This BNC connector is the “trigger” input for the MOVE ON TRIGGER mode of operation.

5.4.7

5.4.7 Line Power

Line Power

5.4.75.4.7

Line PowerLine Power

This socket is used to connect the power cord provided with the Lambda DG-4.

5.5

5.5 Fuse

Fuse

5.55.5

FuseFuse

The fuse used in this instrument depends on the power rating of the installed lamp and

mains voltage. See Appendix A: FUSE REPLACEMENT for fuse-type details and fuse

installation.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 27

19

5.6

5.6 Modes of Operation (LOCAL)

Modes of Operation (LOCAL)

5.65.6

Modes of Operation (LOCAL)Modes of Operation (LOCAL)

5.6.1

5.6.1 General Information

General Information

5.6.15.6.1

General InformationGeneral Information

Filter switch timing can be controlled using one of four different operational modes.

• MOVE ON COMMAND (default mode)

• MOVE ON STROBE PULSE

• MOVE ON SYNC PULSE

• MOVE ON SYNC PULSE, INHIBITED BY THE STROBE LINE

The default mode (“MOVE ON COMMAND”) allows you to directly command filter changes

(e.g., using the numeric keys on the keypad when the Lambda DG-4 is under LOCAL

(“Manual”) control). Filter changes can also be controlled using an external trigger (“MOVE

ON STROBE PULSE”), video synchronization pulse (“MOVE ON SYNC PULSE”) or a

combination of these two external sources (“MOVE ON SYNC PULSE, INHIBITED BY

THE STROBE LINE”). By default, the Lambda DG-4 will be in the MOVE ON COMMAND

mode when it starts up, and at any time after a “triggered” mode has been inactivated. The

active operational mode (of these four) will be indicated on the right side of the bottom line

in the MAIN MENU.

In addition to the above operational modes that control the timing of the filter changes,

there are four others available which alter the Lambda DG-4’s function:

• EDIT A FILTER DEFINITION

• SETUP THE RING BUFFER

• TURBO-BLANKING

• DISPLAY THE FIRST 4 FILTER VALUES

All of the eight operational modes listed above may be accessed from any one of the three

sources of control input, LOCAL (keypad), SERIAL PORT or PARALLEL PORT. Although

the details of how an operational mode is selected may vary somewhat from one source of

input to another, its function remains the same. In this section, the operational modes will

be described in terms of LOCAL control. Separate sections discussing interfacing the

Lambda DG-4 with remote devices (computers) will cover access to these same modes of

operation using SERIAL and. PARALLEL inputs.

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 28

20

5.6.2

5.6.2 Selecting an Operational

Selecting an Operational Mode: The MODE Key

5.6.25.6.2

Selecting an OperationalSelecting an Operational

[MODE/1]

[MODE/1]

[MODE/1][MODE/1]

When the MAIN MENU is displayed, the MODE

Mode: The MODE Key

Mode: The MODE Key Mode: The MODE Key

MODE button on the keypad is used to start a

MODEMODE

mode selection routine. This routine will present options using a series of linked menus

(shown below). Each of the menus will give you the following choices:

• EXIT the mode selection routine and return to the MAIN MENU (press 0000)

• Go to the NEXT PAGE (press 1111)

• Select an OPERATIONAL MODE from the one or more options presented on the menu

(press the numeric key corresponding to the desired mode)

The series of menus in this routine and their options are as follows:

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING 0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

3 = DISPLAY THE FIRST 4 FILTER VALU

3 = DISPLAY THE FIRST 4 FILTER VALUES

3 = DISPLAY THE FIRST 4 FILTER VALU3 = DISPLAY THE FIRST 4 FILTER VALU

ES

ES ES

Pressing the 0000 key will return to the MAIN MENU. Repeatedly pressing 1111 for the NEXT

PAGE produces the following succession of menus:

0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC.

0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC.

0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC. 0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC.

PULSE, 5 FOR MOVE ON STROBE PULSE

PULSE, 5 FOR MOVE ON STROBE PULSE

PULSE, 5 FOR MOVE ON STROBE PULSE PULSE, 5 FOR MOVE ON STROBE PULSE

0=EXIT, 1=NEXT PAGE. PRESS 6 FOR MOVE ON

0=EXIT, 1=NEXT PAGE. PRESS 6 FOR MOVE ON

0=EXIT, 1=NEXT PAGE. PRESS 6 FOR MOVE ON0=EXIT, 1=NEXT PAGE. PRESS 6 FOR MOVE ON

SYNC, INHIBITED BY THE STROBE LINE

SYNC, INHIBITED BY THE STROBE LINE

SYNC, INHIBITED BY THE STROBE LINE SYNC, INHIBITED BY THE STROBE LINE

0=EXIT, 1=NEXT PAGE. 7 = EDIT A FILTER

0=EXIT, 1=NEXT PAGE. 7 = EDIT A FILTER

0=EXIT, 1=NEXT PAGE. 7 = EDIT A FILTER 0=EXIT, 1=NEXT PAGE. 7 = EDIT A FILTER

DEFINITION, 8 = SETUP THE RING BUFFER

DEFINITION, 8 = SETUP THE RING BUFFER

DEFINITION, 8 = SETUP THE RING BUFFER DEFINITION, 8 = SETUP THE RING BUFFER

Pressing 1111 again at this point will not produce further screens.

The above menus are of informational value, only. Once the MODE button has been pressed

any one of the seven operational modes presented (# 2 through 8) can be selected by pressing

the corresponding numeric key. For example, to set the MOVE ON SYNC PULSE mode,

simply press the MODE

MODE key, followed by the 4444 key to directly access that mode’s menu.

MODEMODE

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 29

5.6.3

5.6.3 Move on Command Mode

Move on Command Mode

5.6.35.6.3

Move on Command ModeMove on Command Mode

[1 through 15]

[1 through 15]

[1 through 15] [1 through 15]

Selecting a new filter: The numeric keys.

Selecting a new filter: The numeric keys.

Selecting a new filter: The numeric keys.Selecting a new filter: The numeric keys.

MOVE ON COMMAND mode, and under LOCAL control (“manual mode”) when it starts

up, unless remote commands are waiting on an interfaced device connected to an input port.

The default FILTER NUMBER will be 0, yielding no light output. Selection of a new

FILTER NUMBER is made using the keypad, and will immediately yield light through the

FILTER POSITION and at the ATTENUATION level previously programmed for that

FILTER NUMBER value (see the section on SETUP modes). Under LOCAL control, the

filter is selected by entering a value in the range of 0 to 15. If a single digit value is desired,

the user may either press 0000 and then the correct numeric key or just the single correct

numeric key followed by ENTER. If the value is a 2-digit number, press the correct 2 keys (1111

and then the second key) but do not press ENTER

a numeric key will select 0

a numeric key will select 0. Consequently, if you press a 2-digit number correctly and then

a numeric key will select 0a numeric key will select 0

press ENTER

ENTER you will briefly select the filter you desired and then filter 0 (closing the

ENTERENTER

“shutter”). The following examples demonstrate the two methods of entering a single digit

FILTER NUMBER (8 in this case).

By default, the Lambda DG-4 will be in the

ENTER. Pressing ENTER without first pressing

ENTERENTER

Pressing ENTER without first pressing

Pressing ENTER without first pressing Pressing ENTER without first pressing

21

Method 1: The main menu would look like this if the initial FILTER NUMBER = 10

10 = FILTER NUMBER, TURBO-BLANKING- OFF

10 = FILTER NUMBER, TURBO-BLANKING- OFF

The numeric key 8888 is then pressed to call for FILTER NUMBER = 8.

When the ENTER

Method 2: The main menu will look like this if the initial FILTER NUMBER = 10

The numeric key 0000 is pressed first.

ENTER key is then pressed, FILTER NUMBER 8 is then displayed correctly.

ENTERENTER

10 = FILTER NUMBER, TURBO-BLANKING- OFF10 = FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL MOVE ON

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON INPUT = MANUAL MOVE ON

80 = FILTER NUMBER, TURBO-BLANKING- OFF

80 = FILTER NUMBER, TURBO-BLANKING- OFF

80 = FILTER NUMBER, TURBO-BLANKING- OFF80 = FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND INPUT = MANUAL MOVE ON COMMAND

8 = FILTER NUMBER, TURBO-BLANKING- OFF

8 = FILTER NUMBER, TURBO-BLANKING- OFF

8 = FILTER NUMBER, TURBO-BLANKING- OFF 8 = FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND INPUT = MANUAL MOVE ON COMMAND

10 = FILTER NUMBER, TURBO-BLANKING- OFF

10 = FILTER NUMBER, TURBO-BLANKING- OFF

10 = FILTER NUMBER, TURBO-BLANKING- OFF10 = FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL M

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MINPUT = MANUAL M

OVE ON COMMAND

OVE ON COMMAND OVE ON COMMAND

COMMAND

COMMAND COMMAND

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 30

22

00 = FILTER NUMBER, TURBO-BLANKING- OFF

00 = FILTER NUMBER, TURBO-BLANKING- OFF

00 = FILTER NUMBER, TURBO-BLANKING- OFF00 = FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND INPUT = MANUAL MOVE ON COMMAND

The numeric key 8888 is pressed next with no further action required. FILTER NUMBER 8 is

then displayed correctly.

8 = FILTER NUMBER, TURBO-BLANKING- OFF

8 = FILTER NUMBER, TURBO-BLANKING- OFF

8 = FILTER NUMBER, TURBO-BLANKING- OFF 8 = FILTER NUMBER, TURBO-BLANKING- OFF

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND

INPUT = MANUAL MOVE ON COMMAND INPUT = MANUAL MOVE ON COMMAND

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 31

23

5.6.4

5.6.4 Move on Sync Pulse Mode

Move on Sync Pulse Mode

5.6.45.6.4

Move on Sync Pulse Mode Move on Sync Pulse Mode

[MODE/4]

[MODE/4]

[MODE/4] [MODE/4]

If the Move on Sync Pulse Mode is active, the controller will advance to the next filter in a

previously programmed FILTER NUMBER sequence (Ring Buffer) when an internal video

synchronization (sync) circuit detects the vertical sync pulse of a composite video signal

applied to the SYNC input on the rear of the Lambda DG-4. In this way, filter changes can

be coordinated to occur with the capture of video “frames”. The FILTER NUMBER

sequence can be programmed at your convenience and then executed later with precise

timing (see SET UP THE RING BUFFER). The FILTER NUMBERS can also be sent

individually via the serial or parallel port before the trigger event. This operational mode is

selected by pressing the MODE key followed by the 4444 key to get to the MOVE ON SYNC

PULSE menu. Alternatively, you can “page” through the mode selection menus by pressing

MODE followed by the 1 key. The following menu will be displayed:

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

Press 1111 for the NEXT PAGE to see the desired option or press the 0000 key to abort the routine

and return to the MAIN MENU.

Press 4444 to view the MOVE ON SYNC PULSE menu.

Press 1111 to activate MOVE ON SYNC PULSE and return to the MAIN MENU or press 0000 to

abort the mode selection routine and retain the current mode setting. The status of the

operational mode will be indicated in the lower line of the MAIN MENU display.

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING 0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

3 = DISPLAY TH

3 = DISPLAY THE FIRST 4 FILTER VALUES

3 = DISPLAY TH3 = DISPLAY TH

0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC.

0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC.

0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC. 0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC.

PULSE, 5 FOR MOVE ON STROBE PULSE

PULSE, 5 FOR MOVE ON STROBE PULSE

PULSE, 5 FOR MOVE ON STROBE PULSE PULSE, 5 FOR MOVE ON STROBE PULSE

ADVANCE TO NEXT FILTER ON SYNC IS OFF

ADVANCE TO NEXT FILTER ON SYNC IS OFF

ADVANCE TO NEXT FILTER ON SYNC IS OFF ADVANCE TO NEXT FILTER ON SYNC IS OFF

PRESS 1 TO TURN ON, 0 TO KEEP IT OFF

PRESS 1 TO TURN ON, 0 TO KEEP IT OFF

PRESS 1 TO TURN ON, 0 TO KEEP IT OFF PRESS 1 TO TURN ON, 0 TO KEEP IT OFF

10 = FILTER NUMBER, TURBO-BLANKING- OFF

10 = FILTER NUMBER, TURBO-BLANKING- OFF

10 = FILTER NUMBER, TURBO-BLANKING- OFF10 = FILTER NUMBER, TURBO-BLANKING- OFF

INPUT =

INPUT = MANUAL MOVE ON SYNC PULSE

INPUT =INPUT =

MANUAL MOVE ON SYNC PULSE

MANUAL MOVE ON SYNC PULSE MANUAL MOVE ON SYNC PULSE

E FIRST 4 FILTER VALUES

E FIRST 4 FILTER VALUES E FIRST 4 FILTER VALUES

LAMBDA DG-4 & DG-5 OPERATION MANUAL – REV. 2.14 (20081107)

Page 32

24

5.6.5

5.6.5 Move on Strobe Pulse Mode

Move on Strobe Pulse Mode

5.6.55.6.5

Move on Strobe Pulse Mode Move on Strobe Pulse Mode

[MODE/5]

[MODE/5]

[MODE/5] [MODE/5]

When this mode is active the controller will advance to the next filter in a previously

programmed FILTER NUMBER sequence (Ring Buffer) when a logic signal applied to the

STROBE input goes from low to high. The FILTER NUMBER sequence can be programmed

at your convenience and then executed later with precise timing (see SETUP THE RING

BUFFER). The FILTER NUMBERS can also be sent individually via the serial or parallel

port before the trigger event. This operational mode is selected by pressing the MODE key

followed by the 5555 key to get to the MOVE ON STROBE PULSE menu. Alternatively, you

can “page” through the mode selection menus by pressing MODE followed by the 1 key. The

following menu will be displayed:

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING0=EXIT, 1=NEXT PAGE, 2 = TURBO BLANKING

3 = DISPLAY THE FIRST 4 FILTER VALUES

3 = DISPLAY THE FIRST 4 FILTER VALUES

3 = DISPLAY THE FIRST 4 FILTER VALUES3 = DISPLAY THE FIRST 4 FILTER VALUES

Press 1111 for the NEXT PAGE to see the desired option or press the 0000 key to abort the routine

and return to the MAIN MENU.

0=EXIT, 1=NEXT PAGE. 4=

0=EXIT, 1=NEXT PAGE. 4= MOVE ON SYNC.

0=EXIT, 1=NEXT PAGE. 4=0=EXIT, 1=NEXT PAGE. 4=

PULSE, 5 FOR MOVE ON STROBE PULSE

PULSE, 5 FOR MOVE ON STROBE PULSE

PULSE, 5 FOR MOVE ON STROBE PULSEPULSE, 5 FOR MOVE ON STROBE PULSE