English

Instruction and operation manual

S 600

Portable compressed air purity analyzer

Dear Customer,

Thank you for choosing our product.

Please read the operating instructions in full and carefully observe them

before starting up the device. The manufacturer cannot be held liable

for any damage which occurs as a result of non-observance or noncompliance with this manual.

Should the device be tampered with in any manner other than a

procedure which is described and specified in the manual, the warranty

is cancelled and the manufacturer is exempt from liability.

The device is designed exclusively for the described application.

SUTO offers no guarantee for the suitability for any other purpose.

SUTO is also not liable for consequential damage resulting from the

delivery, capability or use of this device.

2 S 600

Table of contents

1. Safety instructions.......................................................................4

2. Application.................................................................................8

3. Features.....................................................................................8

4. Technical data.............................................................................9

4.1 General data..........................................................................9

4.2 Electrical data .....................................................................10

4.3 Accuracy..............................................................................10

5. Dimensions...............................................................................11

6. Installation on site.....................................................................14

6.1 Installation requirements.......................................................14

6.2 Connection with the optional isokinetic sampling device.............17

6.3 Connection without the isokinetic sampling device....................18

6.4 Electrical connections............................................................19

6.5 Compressed air connections (inlet and outlet)..........................20

7. Setup and configuration.............................................................22

8. Operation.................................................................................22

8.1 Value view...........................................................................23

8.2 Graphic view........................................................................24

8.3 Main menu...........................................................................24

8.3.1 Files..............................................................................25

8.3.2 Service Info ...................................................................25

8.3.3 System Setting...............................................................26

8.4 Icons in the status bar...........................................................27

9. Guided measurement.................................................................27

9.1 Steps for guided measurement...............................................29

9.2 Reports for guided measurements...........................................33

10. Optional accessories.................................................................34

11. Maintenance............................................................................34

12. Disposal or waste.....................................................................34

13. Warranty................................................................................34

S 600 3

1. Safety instructions

1. Safety instructions

Please check if this instruction manual accords to the

product type.

Please observe all notes and instructions indicated in this

manual. It contains essential information which must be

observed before and during installation, operation and

maintenance. Therefore this instruction manual must be read carefully

by the technician as well as by the responsible user / qualified

personnel.

This instruction manual must be available at the operation site of the

flow sensor at any time. In case of any obscurities or questions,

regarding this manual or the product, please contact the manufacturer.

WARNING!

Compressed air!

Any contact with quickly escaping air or bursting

parts of the compressed air system can lead to

serious injuries or even death!

• Do not exceed the maximum permitted pressure range (see

sensors label).

• Only use pressure tight installation material.

• Avoid that persons get hit by escaping air or bursting parts of the

instrument.

• The system must be pressure less during maintenance work.

• WARNING!

• Voltage used for supply!

• Any contact with energized parts of the

product, may lead to a electrical shock which

can lead to serious injuries or even death!

• Consider all regulations for electrical installations.

• The system must be disconnected from any power supply during

maintenance work.

4 S 600

1. Safety instructions

WARNING!

Permitted operating parameters!

Observe the permitted operating parameters, any

operation exceeding this parameters can lead to

malfunctions and may lead to damage on the

instrument or the system.

• Do not exceed the permitted operating parameters.

• Make sure the product is operated in its permitted limitations.

• Do not exceed or undercut the permitted storage and operation

temperature and pressure.

The product should be maintained and calibrated frequently, at least

annually.

General safety instructions

• It is not allowed to use the product in explosive areas.

• Please observe the national regulations before/during installation

and operation.

Remarks

• It is not allowed to disassemble the product.

• Always check the compressed air connectors in terms of stability

and tightness.

ATTENTION!

Measurement values can be affected by malfunction!

The product must be installed properly and

frequently maintained, otherwise it may lead to

wrong measurement values, which can lead to

wrong results.

• Always observe the direction of the flow when installing the

sensor. The direction is indicated on the housing.

• Do not exceed the maximum operation temperature at the sensors

tip.

• Avoid condensation on the sensor element as this will affect the

accuracy enormously.

S 600 5

1. Safety instructions

Storage and transportation

• Make sure that the transportation temperature is between

-10 °C ... 70 °C.

• For transportation it is recommended to use the packaging which

comes with the sensor.

• Please make sure that the storage temperature of the sensor is

between -10 °C ... 50 °C.

• Avoid direct UV and solar radiation during storage.

• For the storage the humidity must be < 90%, no condensation.

ATTENTION!

Equipment may get damaged!

Please make sure, that your measuring point is free

of excessive contamination/dirt. This should

maintained before every measurement.

• Observe the measuring point always before measurement if it is

free of contamination like water drops, oil drops or other rough

contaminations.

• Should water hit the inner electronics, the senors could be

seriously damaged.

• Check your measurement point with the enclosed test kit.

6 S 600

1. Safety instructions

ATTENTION!

Overpressure!

Remove always all protection caps before connecting

the compressed air to the inlet.

S 600 7

2. Application

2. Application

The portable compressed air purity analyzer S 600 can measure, record

and verify the quality parameters including particle quantity, dew point,

temperature, pressure, oil vapor content for a compressed air system.

The S 600 is mainly used in industrial environments, and is not

developed to be used in explosive areas. For the use in explosive areas,

please contact the manufacturer.

3. Features

• High-resolution 5” color touchscreen display and interface.

• USB port for transferring the data to a memory stick.

• Ethernet (Modbus / TCP and SUTO-Bus) interface for transferring

the data to SCADA systems.

• Data logger with the capacity of 100 million values.

• Integrated report generator for compressed air audits, used to

generate PDF files and copy them to a USB memory stick.

• All-in-one portable hand carried measurement device.

• TÜV approved measurement technology and quality assurance.

• Multi-dew-point measurement system for a wide range of

measurement and a very high accuracy.

• Latest PID sensor technology for oil vapor measurement.

• All-in-One device measuring five parameters in a single device:

Particle counter, dew point/humidity, oil vapor, temperature and

pressure (flow measurement as option).

• Isokinetic sampling tube for particle measurement as option.

8 S 600

4. Technical data

4. Technical data

4.1 General data

Data logger Internal, 100-million values

Parameter

Measuring

parameter

Range Reference

Particle 0.3 ... 0.5 µm

0.5 ... 1.0 µm

1.0 ... 5.0 µm

> 5.0 µm

Annex 1 /

DIN 14644

(with isokinetic

sampling device

DIN 8573)

Dew point -100 °C ... +20 °C DIN 8573

Oil vapor 0.003 ... 10 mg/m3ZLG/

AIM 07120604

Pressure 3 ... 15 barg DIN 1301

Temperature 0 ... 50 °C DIN 60751

Reference settings ISO 1217, 20 °C 1000 mbar

DIN 1343, 0 °C 1013 mbar

Measurement

principle

Parameter Principle

Particle

quantity

Laser optical detection

Dew point Ceramic humidity sensor,

oscillating crystal

Oil vapor PID

Volume flow Thermal mass flow (Anemometer)

Medium Compressed air, non corrosive components

Humidity of the

medium

< 40%, non condensation

Temp. of the

medium

0 °C ... 50 °C

S 600 9

4. Technical data

Operation pressure 3 ... 15 barg

Oil vapor sensor

durability

6,000 operating hours

Housing material PC + ABS, Aluminum

Protection class IP 65 (cover closed)

Dimension Please observe the drawings on the next page

Display 5” color graphic display, 800 x 4800 Pixels with

touchscreen interface

Weight 6.80 kg

4.2 Electrical data

Power supply Mains supply adapter (AC/DC)

Input: 100 ... 240 VAC, 50/60 Hz, 1.4 A

Output: 24 VDC, 2.5 A, 60 W max.

4.3 Accuracy

Accuracy

Parameter Accuracy

Particle

quantity

50% @ 0.3 ... 0.4 µm (per JIS)

100% @ 0.4 ... 5.0 µm (per JIS)

Dew point ± 2° C

Oil vapor 5% of value ± 0.003 mg/m

3

Volume flow ± 2 % of value ± 0.3 % of range

Temperature ± 0.1 K

Pressure ± 0.08 bar

10 S 600

5. Dimensions

5. Dimensions

Dimensions S 600 in mm (cover closed):

S 600 11

5. Dimensions

Dimensions isokinetic sampling device (option) in mm:

12 S 600

5. Dimensions

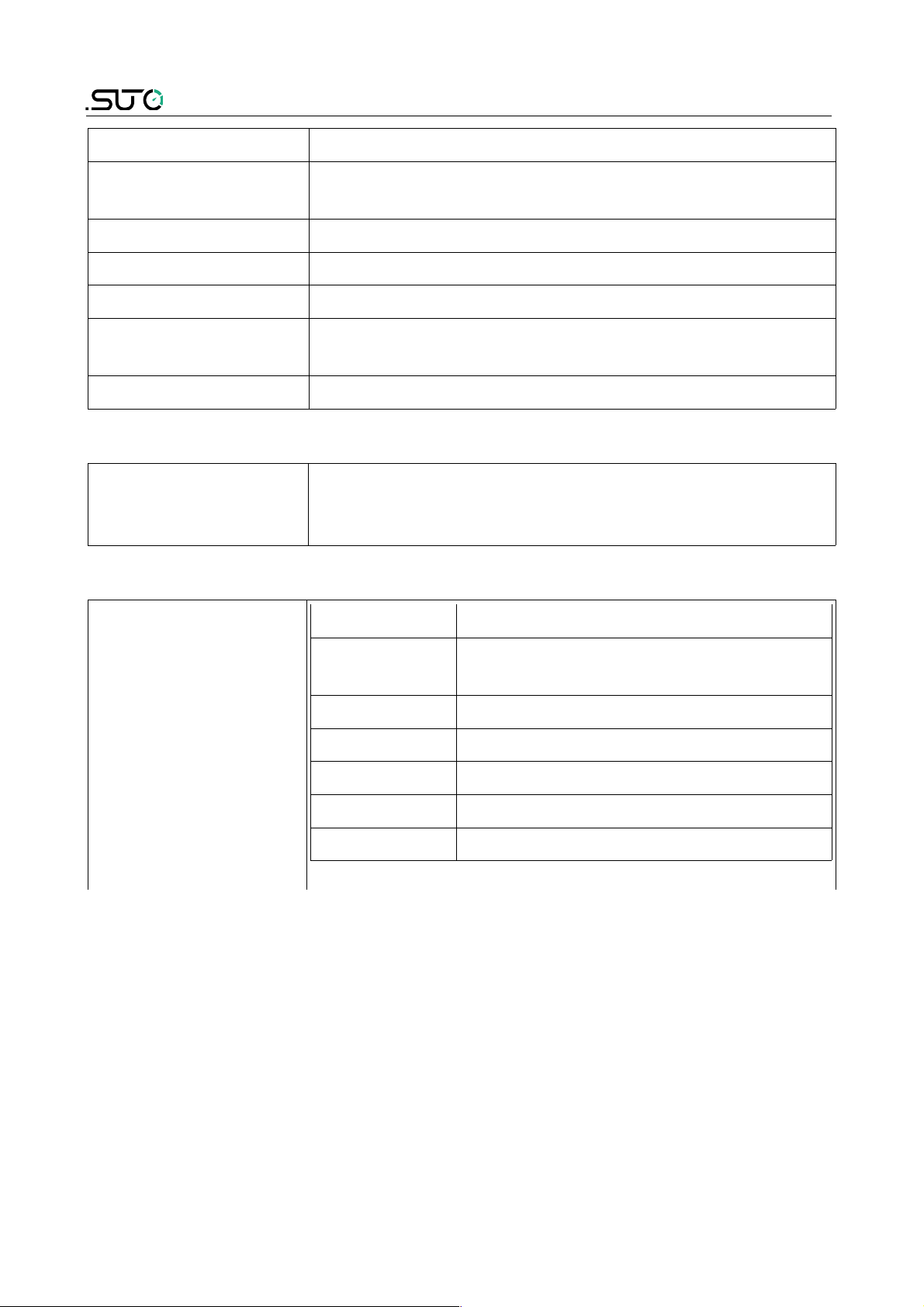

3D view of the S 600 and the isokinetic sampling device:

S 600 13

6. Installation on site

6. Installation on site

Please make sure that all components listed below are included in your

package.

Qty. Description Item No.

1 S 600 portable compressed air analyzer in a hand

carry case with handle and shoulder belt

P560 0600

1 USB OTG memory stick A554 0087

1 Operation and instruction manual PDF no P/N

1 Purge filter for pre-measurement (test kit) A554 0604

5 6mm Teflon hose adapter, stainless steal C219 0197

1 Power supply, 230 VAC / 24 VDC A554 0086

1 2 m Teflon hose, 6 OD x 4 ID mm, free adjustable C193 0002

1 1.5 m Teflon hose with quick connector A554 0003

The following items are included only if you have ordered the isokinetic

sampling device (A554 0600)

1 Isokinetic sampling device, including a flow sensor A554 0600

1 M12 connection cable for isokinetic sampling device A553 0134

If you need replacement materials for items in the preceding list or if

you need further useful accessories, please contact the manufacturer or

your local distributor.

6.1 Installation requirements

The device needs to be set up next to the measuring point. Please make

sure that the device is put on a flat surface. In case you are using the

additional isokinetic sampling devices, you must make sure that they

are also put on a flat surface next to the S 600.

The tubes should be not bended too strong and be installed with a big

curve radius to avoid turbulence in the air flow.

The isokinetic sampling device must be set up next to the S 600 to get

a straight and short connection. Please observe the following chapter,

connecting the isokinetic sampling device to the S 600.

Please connect the S 600 to the power during the measurement, and

make sure that the device is not turned off or plugged off during the

measurement because the data will then be lost and not saved.

14 S 600

6. Installation on site

ATTENTION!

If the device is not installed properly it may lead to

wrong measurement results.

• The device is designed to be operated indoors only. To use the

device outdoors, please protect the device from direct sunlight and

rain.

ATTENTION!

Before you connect the device to your point of

measurement, make sure that there is no rough

contamination like water/oil drops or heavy dust.

This may damage the sensor units. For this please

use the purge filter test kit.

Before you start the measurement, check your point of measurement:

1. Connect the purge filter test kit onto your measuring point first.

Open the purge valve on the test kit and purge air for a short

period.

2. Check the filter in the test kit to see if it shows high contamination

of water, oil or dust.

3. If the filter is contaminated severely, stop using the S 600 for

measurement because this may lead to serious damage to the

device. In case you are not sure, please contact the manufacturer.

S 600 15

6. Installation on site

ATTENTION!

Before connecting the

compressed air, make sure

that all protection caps are

opened/removed!

Remove the protection caps from all parts of both sides of the

instrument. If not removed, the device may get damaged and the risk

of bursting parts under high pressure can even lead to personal injuries.

All exhaust outlets will pass air during the measurement, if not, please

contact the manufacturer.

ATTENTION!

Always use the 6 mm Teflon hose adapter to

connect the teflon hoses to the S 600 and to the

isokinetic sampling device! You may damage the

device if not used.

Directly plugging and pulling the teflon hose more than once may lead

to particle contamination, which can affect the measurement. To avoid

this problem, please use the included adapter plugs and keep them on

your tubes.

16 S 600

6. Installation on site

6.2 Connection with the optional isokinetic sampling device

The picture above shows the S 600 setup with the isokinetic sampling

device connected. Please connect the isokinetic sampling device using

the teflon hose delivered with the device. On the next page you can

find the detailed description of the sampling device. Also you can find

which outlets of the sampling device need to be connected to which

input at the S 600.

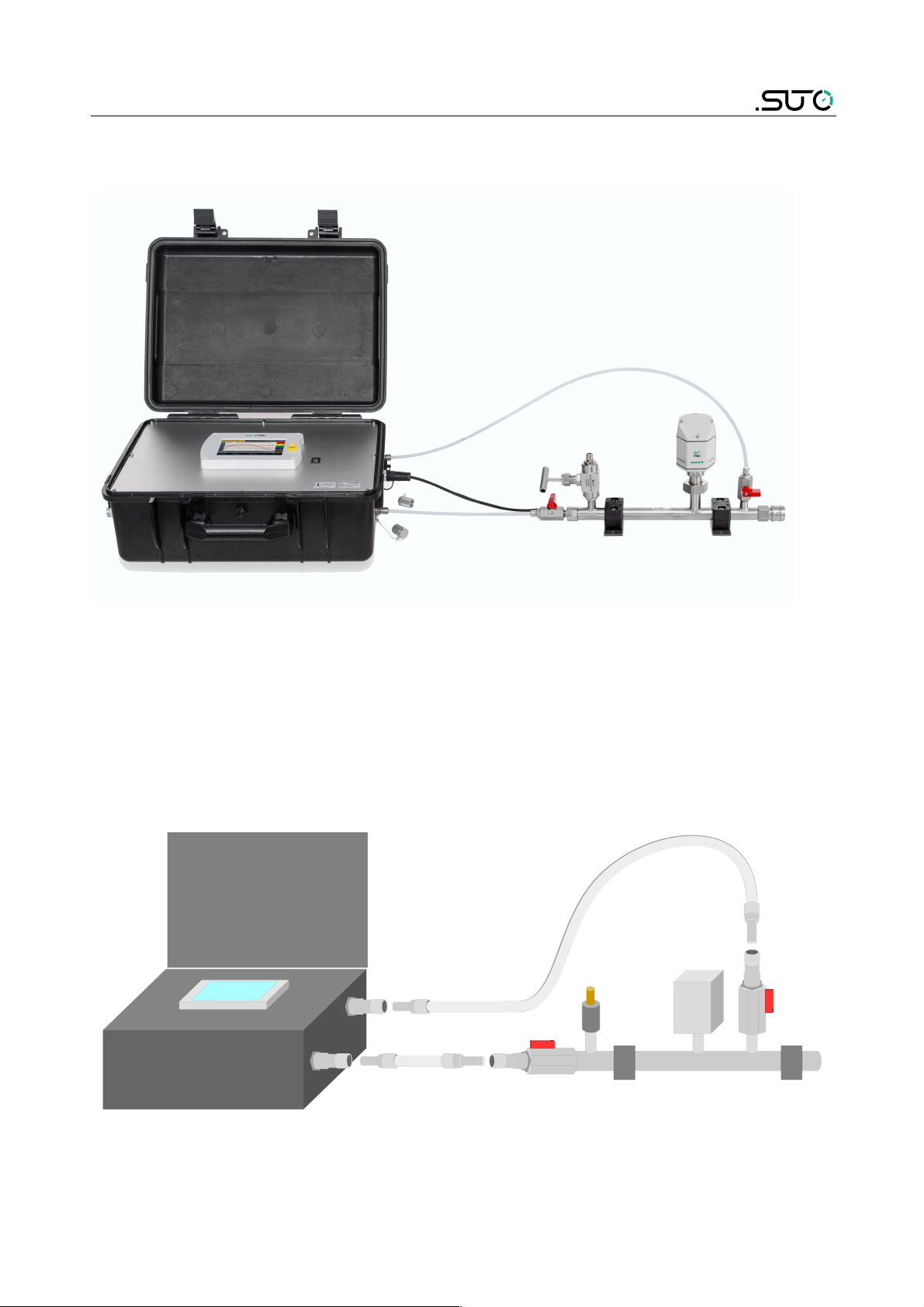

The following diagram helps you better understand the setup

connection.

S 600 17

6. Installation on site

1. Before connecting the S 600 to your compressed air, make sure

ball valve 2 and 4 are closed.

2. Close the needle valve 3.

3. The connection to your compressed air system is achieved through

the correct fitting (quick connector, teflon hose, etc.). Connect

your compressed air system to the inlet 1 using the correct

fitting.

4. Connect the outlet valve 2 to the inlet for dew point and oil

vapor measurement at the S 600 using a teflon hose.

5. Connect the isokinetic outlet 4 with the inlet for the particle

counting at the S 600.

6. Now open outlet valve 2 and 4 to start your measurementfollow

the instructions on the screen.

6.3 Connection without the isokinetic sampling device

Connect your compressed air system using two teflon hoses to the

corresponding inlets at the S 600. They are marked: Gas inlet Oil / Dew

point measurement and Gas inlet Particle measurement.

18 S 600

6. Installation on site

6.4 Electrical connections

The S 600 offers three types of electrical connections. The power

supply connector 1, the communication port for the isokinetic

sampling device 2 and an Ethernet port 3 to communicate with

network devices.

ATTENTION!

Only use the power supply which comes with the

S 600!

S 600 19

6. Installation on site

6.5 Compressed air connections (inlet and outlet)

The S 600 offers two compressed air inputs on the right side of the

housing. The inlets are shown on the picture above and are marked

respectively to their functions: Gas inlet Oil / Dew point measurement

and Gas inlet Particle measurement.

ATTENTION!

Permissible pressure!

Please observe the maximum permissible incoming

pressure. It must be in between 3 and 15 bar

overpressure. If the pressure exceeds this range, it

will damage the device. If the pressure is too low,

the volumetric flow will not be high enough which

will lead to wrong results.

20 S 600

6. Installation on site

In the picture below shows the left side of the housing where the gas

outlets can be found. The calibration outlets Gas outlet Dew point

measurement and Gas outlet Oil vapor measurement are used to

connect the internal sensors to references. These calibration outlets

must be opened all the time during compressed air is connected. Also

the other two outlets need to be opened before connected to the

compressed air.

Note!

All gas outlets of the

measurement device

must stay opened

during the complete

usage of the device.

S 600 21

7. Setup and configuration

7. Setup and configuration

The S 600 is configured ex-works and ready to work out of the box. The

S 600 provides a guided measurement procedure to guide you through

device setup for each measurement parameter. All these setup settings

are automatically saved into the device even after a power failure.

Note!

If you are facing problems setting up you device,

contact the manufacturer or your local dealer for

assistance.

8. Operation

After the S 600 gets

powered, the initialization

screen is displayed with an

active progress bar.

During initialization, the

device configures the

sensors and runs

initialization routines.

After the initialization is

completed, the date of the

last calibration is shown.

Click OK to proceed.

22 S 600

8. Operation

The value screen as shown

on the left appears.

Quick buttons or icon on the bottom bar are listed as follows:

• Graphic:To switch to the graphic view.

• Value: To switch to the value view.

• Menu: To access the operation sub-menus.

• The camera icon: To take a screenshot.

8.1 Value view

In this view, the S 600 shows all measured values in realtime.

To switch to the value

screen, click Value in the

bottom.

Note: During the first five minutes, the S 600 performs a purge process

to ensure any remaining particles in the system are blown out. During

this period, the counting numbers on the Particle pane appear green

and blink.

S 600 23

8. Operation

8.2 Graphic view

The graphic view is pre-configured in the factory, and you do not need

to change anything.

In case that you need to make changes, follow the instructions indicated

in the following figure.

8.3 Main menu

Access the main menu

by clicking Menu in the

bottom bar.

The screen with submenus is shown.

The main menu offers the access to the following sub-menus.

Guided

Measurement

To start the guided measurements, which lead you

through a complete measurement cycle. For more

24 S 600

8. Operation

information, see Chapter 9. Guided measurement.

Files To access the saved screenshots and the memory

usage as well.

Service info To show contact information for technical support.

System

settings

To perform general settings on date, time and

language and so on. To view information such as the

serial number.

Communication To perform field bus settings and configure

communication parameters

8.3.1 Files

The files menu shows all screenshots for you to view, export, and delete

them. You can also check the memory status.

8.3.2 Service Info

Shows contact information for technical support.

S 600 25

8. Operation

8.3.3 System Setting

You can perform general settings using this menu.

Password To set a password to protect the settings menu

from unauthorized access.

Back light To configure the brightness and the auto dimming

function of the screen.

Calibrate touch

screen

To calibrate the touch screen if it does not

respond to user inputs correctly or precisely, it

can be calibrated.

Language To select the interface language.

Date time To configure date and time.

26 S 600

8. Operation

Device info To view device information such as serial number.

System update To perform a system update.

Reset To restart the device (User settings will be

saved).

8.4 Icons in the status bar

USB memory stick is

connected. By pressing

the icon, the stick can

be disconnected.

System errors occur.

Press this icon to get

further information.

Calibration is overdue,

please. Contact the

manufacturer of your

local dealer.

The S 600 is connected

to a PC by the USB

cable.

Data logger status:

- STOP—Indicates that the data logger is not running.

- LOG—Indicates that the data logger is running.

9. Guided measurement

The S 600 provides a software-based guided measurement which takes

you through the complete measurement. This leads to a simplified

measurement process and prevents you from wrong measurements.

To start a guided measurement, do the following:

1. Click Menu > Guided measurement.

2. Select which type of measurement you want to perform.

S 600 27

9. Guided measurement

◦ Monitoring with programmed time out: It starts a

measurement with a user-programmed period of measurement

time. You can set the measurement time during the process of

measurement preparation. The system will then, after finishing

the programmed measurement duration, stop the measurement

automatically and save the data. This mode is ideally used for

audits where you must measure at several points. You can

program for each point a duration of e.g. 2 hours and then you

can compare the measurements.

◦ Monitoring with manual stop: It starts the measurement

without a programmed stop time. You can click it to start the

measurement and when you come back you can stop it. Then

you can decide if you want to save or delete the data. This can

be used to monitor changes in values.

3. Perform the guided measurement following the onscreen

instructions. For more information, see section 9.1 Steps for

guided measurement.

4. To view and manage the measurement files generated, click

Report Manager. For more information, see section 9.2 Reports

for guided measurements

28 S 600

9. Guided measurement

9.1 Steps for guided measurement

After you start a guided measurement, follow below steps to go through

the whole process.

1. An overview is given

about the selected

measurement types.

Click Yes to start.

2. The system asks if you

are using the isokinetic

sampling device, and

this will affect the

further steps and

instructions.

Select Yes if you have

the isokinetic sampling

device connected.

Otherwise, click No.

3. Input your data, which

will be then shown on

the report.

S 600 29

9. Guided measurement

4. Select your

compressed air class,

which will then select

the corresponding

alarms.

- CLASS 0: To

customize alarm

settings.

5. If you selected CLASS

0, enter the limit

values for each

measurement channel,

through which you

define different alarm

settings for the quality

management.

6. Enter how long the

measurement will take.

The longer it takes, the

more stabilized the

values will be and the

more exactly it will

represent the system

conditions.

30 S 600

9. Guided measurement

7. The system checks

whether the pressure is

in the valid range.

8. The system

performs the selfcalibration cycles and

cleans the internal

sensor components.

The following 3 steps only apply if you select Yes for the

isokinetic sampling device, otherwise skip the next 3 steps

1. The S 600 is now ready

for measurement.

Please read the

instructions shown on

the screen carefully.

Click Start.

S 600 31

9. Guided measurement

2. Follow the onscreen

instructions to proceed.

3. Perform Isokinetic

setup as instructed on

the screen.

Now the device is well set up and starts to measure data. The

remaining time is shown on the top left corner.

32 S 600

9. Guided measurement

During the measurement,

you can see the Data logger

status icon on the status bar

switched from STOP to LOG.

The remaining time is

displayed in the upper left

corner.

Please wait. The system will

stop the measurement

automatically.

When the measurement is

successfully completed, the

left screen appears. You can

choose discard or save the

measurement data.

9.2 Reports for guided measurements

After performing guided measurements, you can view and manage

measurement files through Guided Measurement > Report

Manager.

In the report screen:

• To view the

measurement results,

click on the file (not the

check box on the right).

A window appears

showing the PDF for your

preview.

• To copy, export , or

delete files, select the

file check boxes, and

then click the

corresponding button at

the bottom.

S 600 33

10. Optional accessories

10. Optional accessories

To purchase optional accessories, please contact the manufacturer or

your local dealer:

• Isokinetic sampling device, for particle sampling according to ISO

8573.

• Teflon hoses and sorts of adapters.

11. Maintenance

Use a moist fabric to clean the device. For the use in GMP areas, the

device must be disinfected through wipe disinfection. For more

information, please contact the manufacturer or your local dealer.

ATTENTION!

Please dry the device after cleaning using a clean

and dry fabric. Always take care, that the fabric for

cleaning is not to wet as water could get into the

device and lead to damage.

12. Disposal or waste

Electronic devices are recyclable material and do not

belong in the household waste.

The sensor, the accessories and its packing must be

disposed according to your local statutory requirements.

The dispose can also be carried by the manufacturer of the

product, for this please contact the manufacturer.

13. Warranty

SUTO provides a warranty for this product of 24 months covering the

material and workmanship under the stated operating conditions from

the date of delivery. Please report any findings immediately and within

the warranty time. If faults occur during the warranty time SUTO will

repair or replace the defective unit, without charge for labour and

material costs but there is a charge for other service such as transport

and packing costs.

Excluded from this warranty is:

• Damage caused by:

◦ Improper use and non-adherence to the instruction manual.

34 S 600

13. Warranty

◦ Use of unsuitable accessories.

◦ External influences (e.g. damage caused by vibration, damage

during transportation, excess heat or moisture).

• Sensor lifetime, which is determined by the operating hours

(6,000-hour sensor durability).

• Filter capacity, which is determined by the operating hours (8,640hour or 360-day lifetime).

The warranty is cancelled:

• If you open the measurement instrument without a direct request

written in this instruction manual.

• If repairs or modifications are undertaken by third parties or

unauthorized persons.

• If the serial number has been changed, damaged or removed.

• If the warranty sealing is removed or damaged.

Other claims, especially those for damage occurring outside the

instrument are not included unless responsibility is legally binding.

Warranty repairs do not extend the period of warranty.

ATTENTION!

Batteries have a reduced warranty time of 12

months.

S 600 35

SUTO iTEC GmbH SUTO iTEC (ASIA) Co., Ltd.

Werkstr. 2 Room 10, 6/F, Block B, Cambridge Plaza

79426 Buggingen 188 San Wan Road, Sheung Shui, N.T.

Germany Hong Kong

Tel: +49 (0) 7631 936889-0 Tel: +852 2328 9782

Fax: +49 (0) 7631 936889-19 Fax: +852 2671 3863

Email: sales@suto-itec.com Email: sales@suto-itec.asia

Website: http://www.suto-itec.com Website: http://www.suto-itec.com

All rights reserved © Modifications and errors reserved.

S600_im_en_2019-2

36 S 600

Loading...

Loading...