Sussman ES 18, ES 24, ES 72, ES 30, ES 36 Installation, Operation And Maintenance Manual

...

Sussman Boilers: ES, SSB & HU

Installation, Operation and Maintenance Manual

TABLE OF CONTENTS

Dimensional Information

& Component Identification. . . . . . . . . . . . . . . . 2

Dimensional & Clearing Specifications . . . . . . . . 3

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Installation

Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Pre-Operation Check. . . . . . . . . . . . . . . . . . . . . . 10

Pressure Controls, Operation & Testing . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Blowdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . 14

Auxilliary Low Water Cut Off . . . . . . . . . . . . . . . 14

Line Pressure Water Feed System

. . . . . . . . . . . . . 14

High Pressure Water Feed System . . . . . . . . . . . . 14

Condensate Return System . . . . . . . . . . . . . . . . . 14

Vacuum Breaker Systems . . . . . . . . . . . . . . . . . . 15

Automatic Blowdown System . . . . . . . . . . . . . . . 15

Blowdown Separators . . . . . . . . . . . . . . . . . . . . 15

Control Voltage Stepdown Transformer . . . . . . . . 15

Multistage Load Progressive Sequencers . . . . . . . 15

Condensate Return Systems. . . . . . . . . . . . . . . . 16

Blowdown Separator Tanks . . . . . . . . . . . . . . . . 17

Specification Charts . . . . . . . . . . . . . . . . . . . . . . 18

Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Gauge Glass Installation . . . . . . . . . . . . . . . . 20-21

Element Replacement . . . . . . . . . . . . . . . . . . . . . 22

Water Quality Information for Carbon

Steel Boilers . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Products covered by this manual:

Max

Series KW Range Steam Rate* BHP Design Pres.

Work Pres.

______________________________________________________________________

ES, HU 12-180 36-542 lbs/hr 1.2-18.4 0-100 psig 85 psig

SSB 12-180 36-542 lbs/hr 1.2-18.4 0-100 psig 85 psig

*Steam Rate- Steam @ 212 F with 50 F feed water

SSB Boilers have all wetted metal parts Stainless Steel and are

required to be operated on distilled, de-ionized or RO type

water having a minimum specific resistivity of 1 Megohm-cm.

ES & HU Boilers are of Carbon Steel construction and are not

to be operated on distilled, deionized or RO type water.

A Division of Sussman-Automatic Corporation

43-20 34th Street, Long Island City, NY 11101 • (718) 937-4500

1-800-238-3535 • Fax: (718) 937-4676 • email: seb@sussmancorp.com

www.sussmanboilers.com

Made in USA

PUR 101137 07/03

states a hazard which may

cause serious injury or death if

precautions are not followed.

signals a situation where

minor injury or product damage

may occur if you do not follow instructions.

IMPORTANT NOTE:

This highlights information that is especially relevant to a problem-free installation.

IMPORTANT NOTE:

As you follow these instructions, you will notice warning and caution symbols. This blocked information is important for the safe and efficient installation and operation of

electric boilers. These are two types of potential hazards that may occur during this installation and operation:

!

CAUTION

!

WARNING

Model No. ______________________

Boiler Serial No. _________________

National Board No. ______________

Safety Valve Set Pressure________

PSIG

Power Circuit Voltage ____________

Control Circuit Voltage ___________

Amps _____ Phase _____ HZ ______

IMPORTANT:

This data file contains the National

Board Registration Certificate approving your boiler.

It must be kept near the boiler at all times.

Sussman Boilers

Installation, Operation & Maintenance Manual

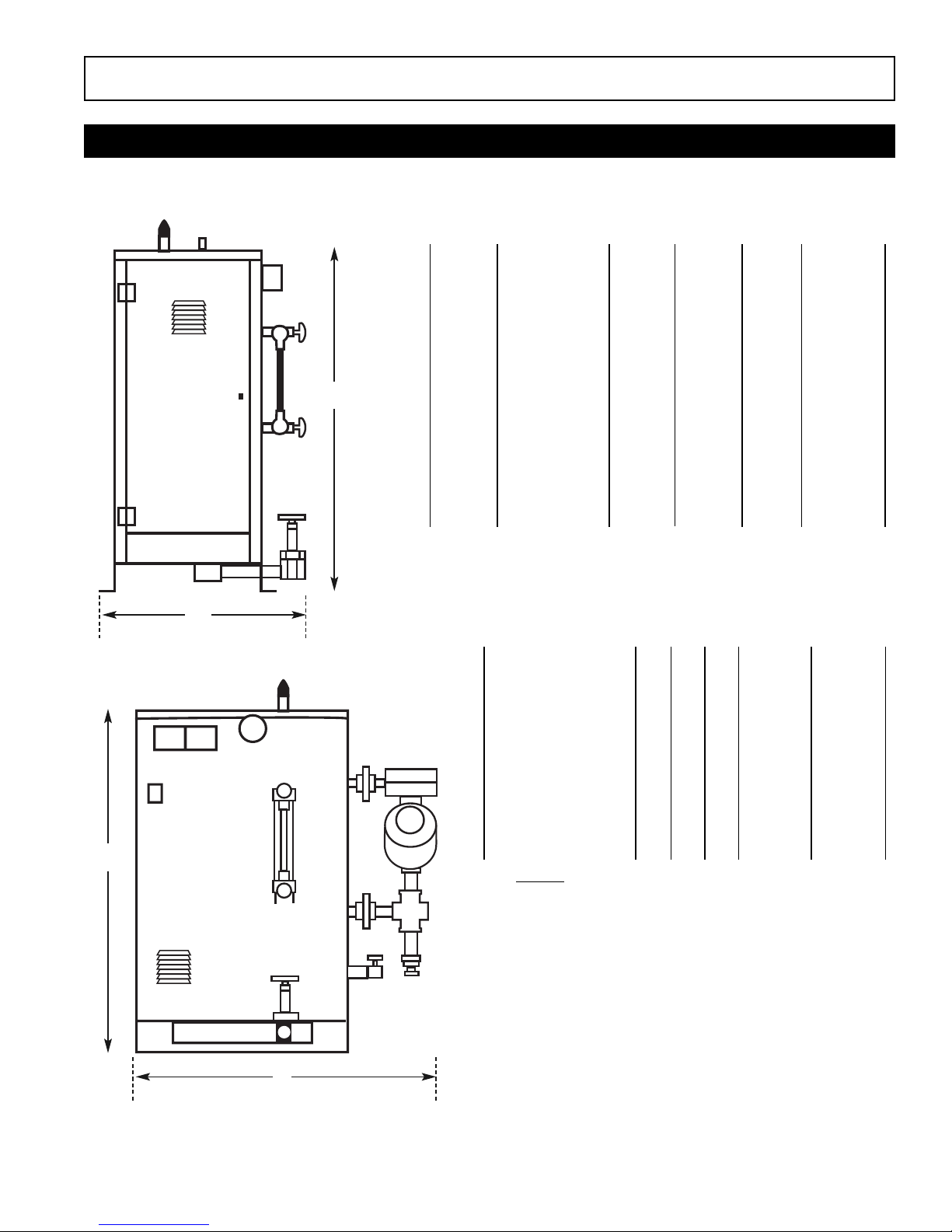

Dimensional Information & Component Identification

2

___________________________________________

WATER STEAM

MODEL H W L INLET OUTLET

___________________________________________

ES 12, 18; HU 40–55 36" 20" 28" 1/2” NPT 1/2”NPT

___________________________________________________

ES 24–72; HU 75–205 44" 23" 33" 1/2”NPT 1” NPT

___________________________________________________

ES 100; HU 310 59" 28" 34" 1/2”NPT 1 1/2”NPT

___________________________________________________

ES 135–180; HU 410–550 61" 30" 36" 1/2”NPT 2” NPT

___________________________________________________

SSB 12–18 36" 20" 28" 1/2”NPT 1/2”NPT

___________________________________________________

SSB 24–72 45" 27" 33" 1/2”NPT 1” NPT

___________________________________________________

SSB 80–100 59" 28" 34" 1/2”NPT 1 1/2”NPT

___________________________________________________

SSB 135–180 61" 30" 36" 1/2”NPT 2” NPT

___________________________________________

Allow minimum 21 inches clearance in front of door for servicing of heating

elements. Recommended clearance: 24 inches all around boiler for servicing.

H

H

L

W

Models: ES, HU, SSB

_______________________________________

SYMBOL ITEM ES12-18 ES24-72 ES100 ES135-180

_______________________________________

Height Overall Height 36" 44" 59" 61"

________________________________________________________________________

Length Overall Length 28" 33" 34" 38"

_________________________________________________________________________

Width Overall Width 20" 22" 26" 30"

_________________________________________________________________________

A Steam Outlet 6-1/4" 10" 8-1/4" 9"

_________________________________________________________________________

B Steam Outlet 10-1/4" 17" 17-1/4" 18-1/4"

_________________________________________________________________________

C M/M Drain Valve 5" 12" 17" 16-3/4"

_________________________________________________________________________

D M/M Drain Valve 6-1/2" 6" 6-1/4" 6-1/4"

_________________________________________________________________________

E Check Valve 14" 9" 17" 16-3/4"

_________________________________________________________________________

F PV Drain Valve 2-3/4" 2-1/4" 2-3/4" 2-3/4"

_________________________________________________________________________

G PV Drain Valve 6-1/4" 9-1/2" 7-3/4" 9-1/4"

_________________________________________________________________________

J Clearance 3-3/4" 3-1/2" 4" 4"

_________________________________________________________________________

K Check Valve 2-1/2" 2-3/4" 3" 3"

_________________________________________________________________________

M Door Width 8-3/4" 14" 12-3/4" 14-3/4"

_________________________________________________________________________

Allow 24 inches all around for servicing.

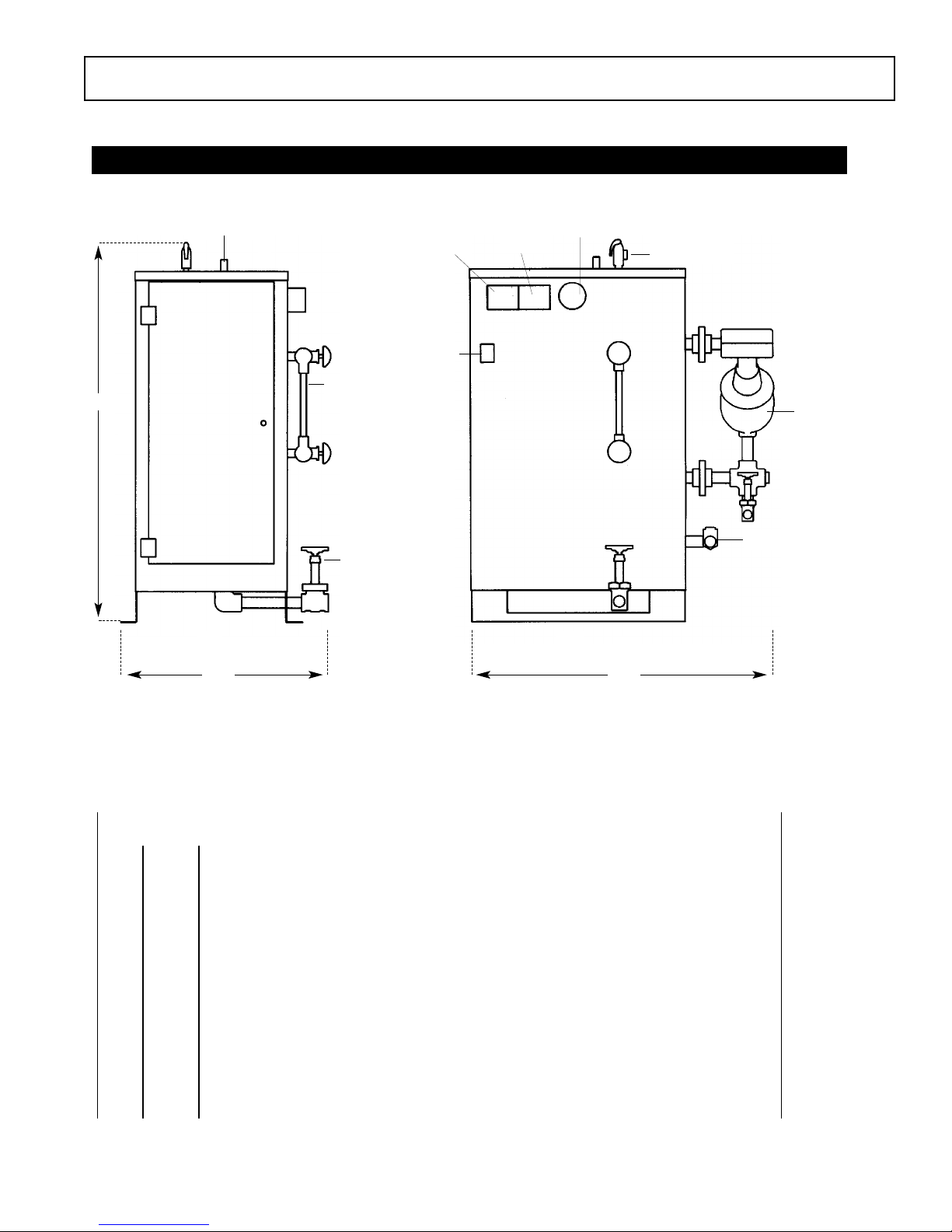

Sussman Boilers

Installation, Operation & Maintenance Manual

3

Dimensional & Clearance Specifications

Steam Outlet

High Limit

Pressure

Control

Operating

Pressure

Control

Pressure

Gauge

15 PSIG

Safety Valve

MM 150 Liquid

Level Control

(see note 3)

Water Feed Inlet

F

E

L

D

A

B

E

R

FrontLeft

Drain Valve

On/Off

Switch

Gauge Glass

Assembly

Height

Width Length

Side Elevation Front Elevation

Allow 24" all around for servicing.

__________________________________________________

Clearance from combustible surfaces

__________________________________________________

A

1" Clearance above top of boiler

_________________________________________________________________________

B

A Clearance from Front of boiler. Prefix "C" to numeral indicates acceptability for

closet or alcove installations; prefix acceptability for alcove installations but not

for closet installations.

_________________________________________________________________________

D

1" Clearance from back of boiler.

_________________________________________________________________________

EL

1" Clearance from left side of boiler.

_________________________________________________________________________

ER

16" Clearance from right side of boiler.

_________________________________________________________________________

F

C Indicates type of flooring: "NC" for non-combustible; "C" for combustible.

Numeral indicates minimum clearance below suspended units to combustible floor.

_________________________________________________________________________

G-

Total minimum free area in square inches of close ventilating openings.

_________________________________________________________________________

Sussman Boilers

Installation, Operation & Maintenance Manual

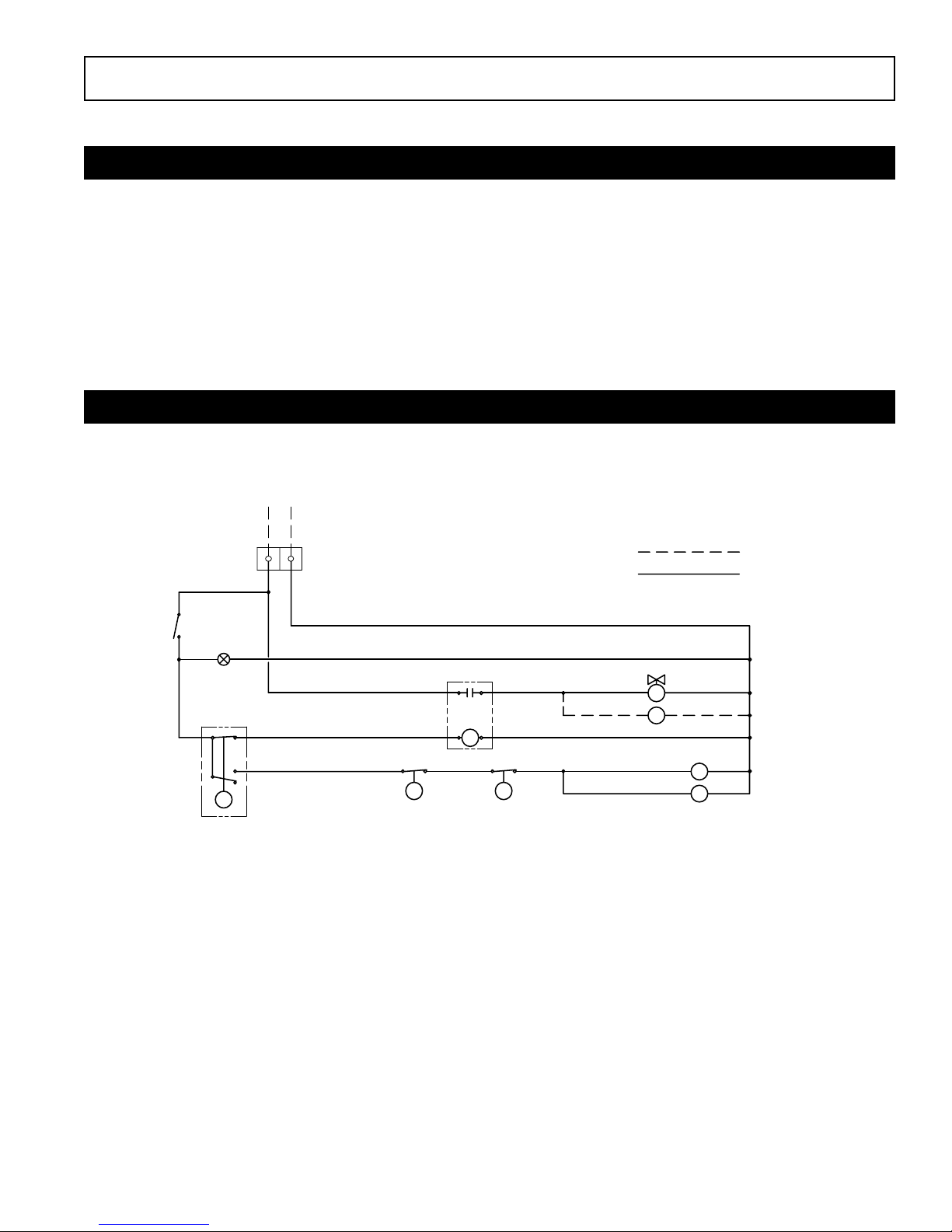

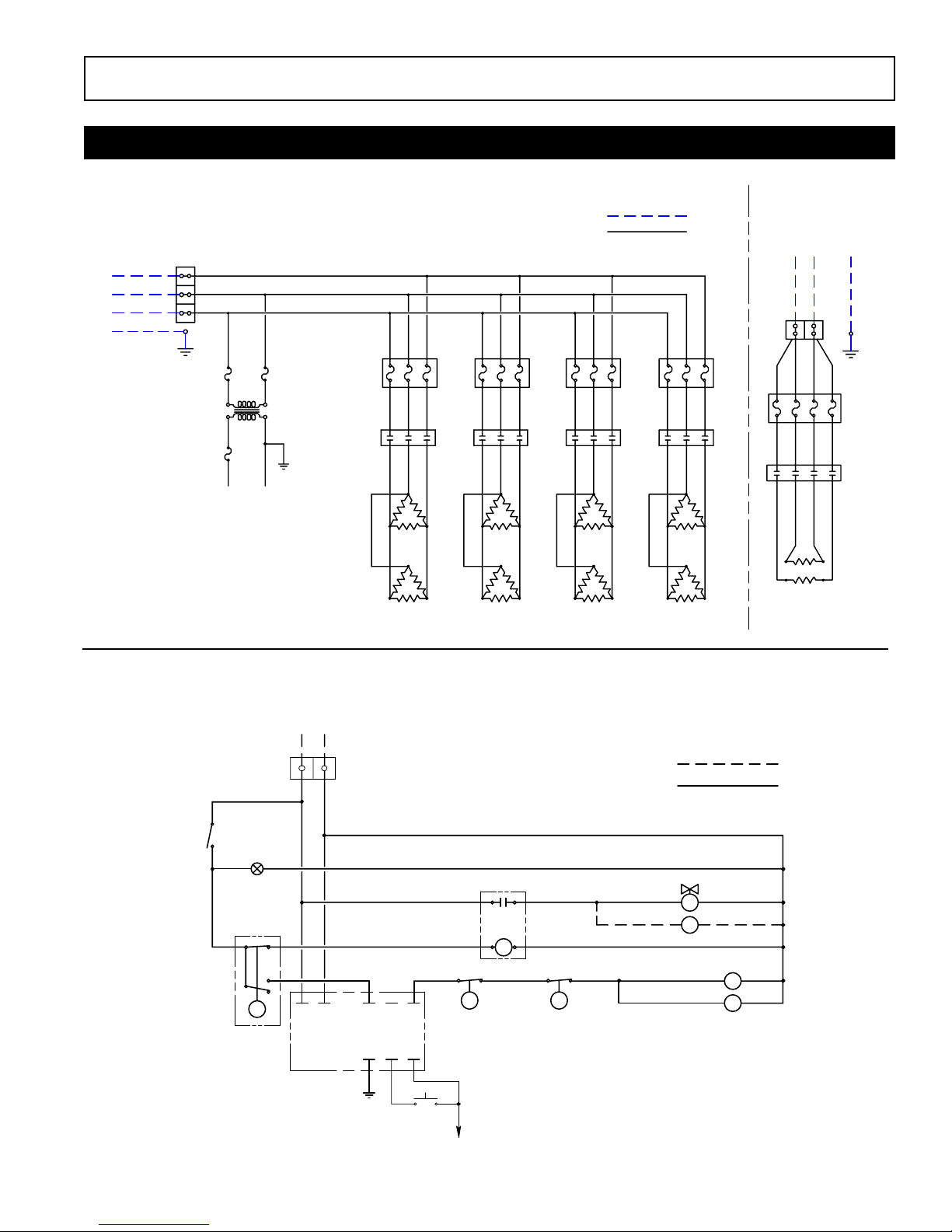

Typical Wiring Diagrams:

Wiring Diagram Control Circuit

4

a.

Three phase power circuit with separate 120Volt control circuit. (With singe phase power circuit insert.)

b.

Three phase power circuit with step down transformer.

c.

Detailed ES81017/81017MR auxiliary low water cut off wiring.

d.

Detailed SSB auxiliary low water cut off wiring.

e.

ES81600 Auto blowdown wiring diagram.

f.

Detailed sequencer package wiring diagram.

ES and SSB Electric Boilers

120V 1PH

INPUT

ON-OFF

SWITCH

PILOT

LIGHT

L

LIQUID

LEVEL

CONTROL

L

L1 L2

N

CONTROL

TERMINAL

BLOCK

P1

HIGH LIMIT

PRESSURE

CONTROL

R

RELAY

P2

OPERATING

PRESSURE

CONTROL

FIELD WIRING

FACTORY WIRING

SOLENOID VALVE

S

PUMP MOTOR

M

CONTACTORS

C1

C2

Sussman Boilers

Installation, Operation & Maintenance Manual

Wiring Diagram Control Circuit

5

ES Electric Boilers with Manual Reset- Auxiliary Low Water Cutoff

ES and SSB Electric Boilers

THREE PHASE

MAIN POWER

SUPPLY

L1

L2

L3

G

TRANSFORMER

NOTES:

1. Power Terminal Block only on boilers with two or more contactors

2. Power Fuses only on boilers rated 20 amperes and larger.

3. See Parts List for contactor and heating element information.

TB 1

(optional)

TO CONTROL

TERMINAL POWER BLOCK

(see note 1)

PILOT

LIGHT

480V

T1

120V

CIRCUIT

POWER FUSES

(see Note 2)

CONTACTORS C1 C2 C3 C4

HEATING

ELEMENTS

FIELD WIRING

FACTORY WIRING

FB1 FB2 FB3 FB4

H1 H3 H5 H7

H2 H4 H6 H8

SINGLE PHASE

MAIN POWER SUPPLY

L1 L2 G

TB

FB

C

H

120V 1PH

INPUT

N

L

ON-OFF

SWITCH

PILOT

LIGHT

L

LIQUID

LEVEL

CONTROL

L1

L2

AUX LWCO

PC BOARD

MANUAL RESET

CONTROL

TERMINAL

BLOCK

COM

C

RELAY

NC

NO

HIGH LIMIT

PRESSURE

HI

CONTROL

LO

TO

PROBE

R

P1

P2

OPERATING

PRESSURE

CONTROL

FIELD WIRING

FACTORY WIRING

SOLENOID VALVE

S

PUMP MOTOR

M

CONTACTORS

C1

C2

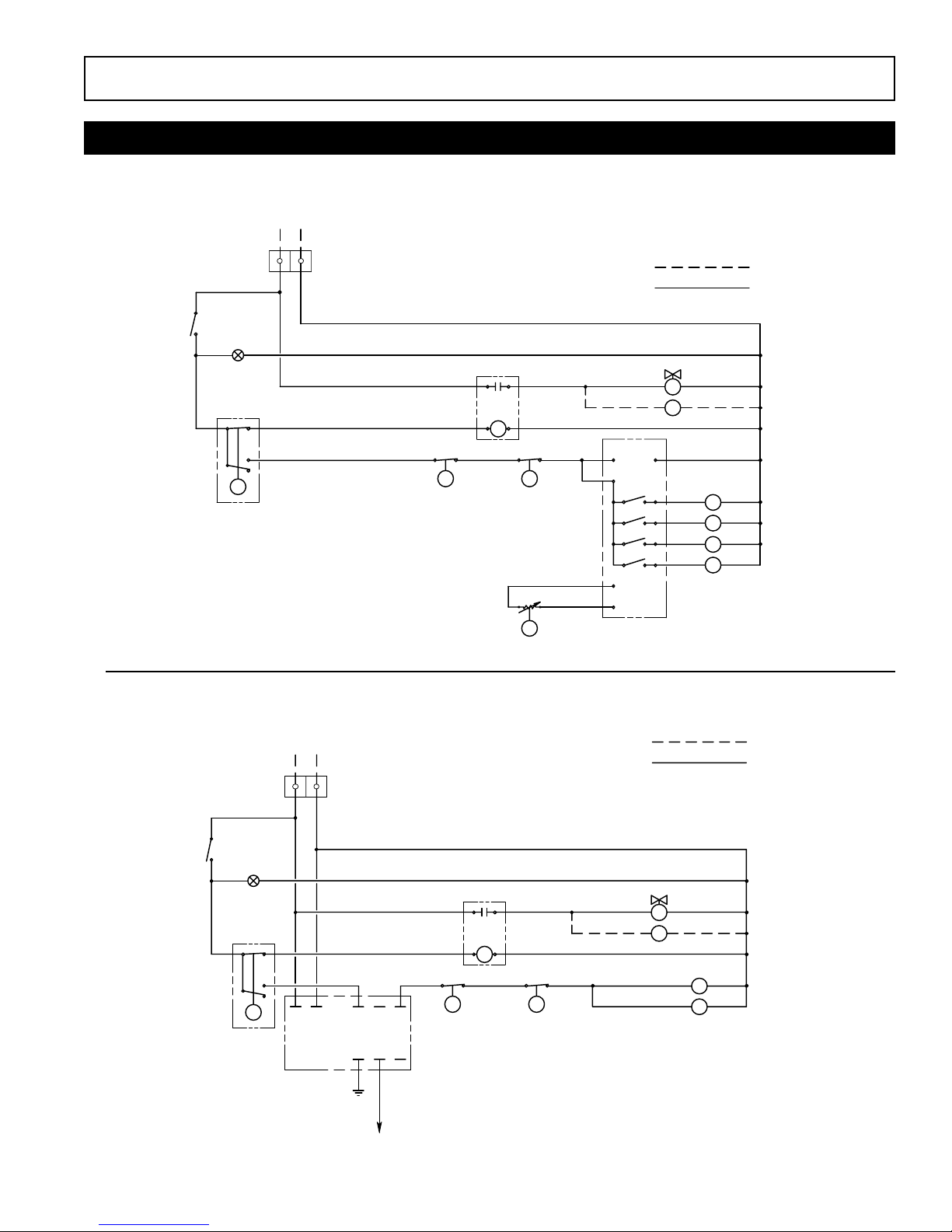

Sussman Boilers

Installation, Operation & Maintenance Manual

Wiring Diagram Control Circuit

6

ES Electric Boilers with Manual Reset- Auxiliary Low Water Cutoff

ES Electric Boiler with Auxiliary Low Water Cutoff

120V 1PH

INPUT

L N

CONTROL

TERMINAL

BLOCK

FIELD WIRING

FACTORY WIRING

ON-OFF

SWITCH

CONTROL

PILOT

LIGHT

L

LIQUID

LEVEL

L1 L2

RELAY

P1

HIGH LIMIT

PRESSURE

CONTROL

R

P2

OPERATING

PRESSURE

CONTROL

PROPORTIONING

PRESSURE CONTROL

P3

120V COM

M

135 OHM

COM

SEQUENCER

120V 1PH

INPUT

LN

CONTROL

TERMINAL

BLOCK

FIELD WIRING

FACTORY WIRING

S

M

1

2

3

4

SOLENOID VALVE

PUMP MOTOR

C1

C2

C3

C4

CONTACTORS

ON-OFF

SWITCH

PILOT

LIGHT

L

L1 L2 COM NC NO

LIQUID

LEVEL

CONTROL

AUX LWCO

PC BOARD

C HI LO

TO PROBE

RELAY

P1

HIGH LIMIT

PRESSURE

CONTROL

SOLENOID VALVE

S

PUMP MOTOR

M

R

C1

P2

OPERATING

PRESSURE

CONTROL

C2

CONTACTORS

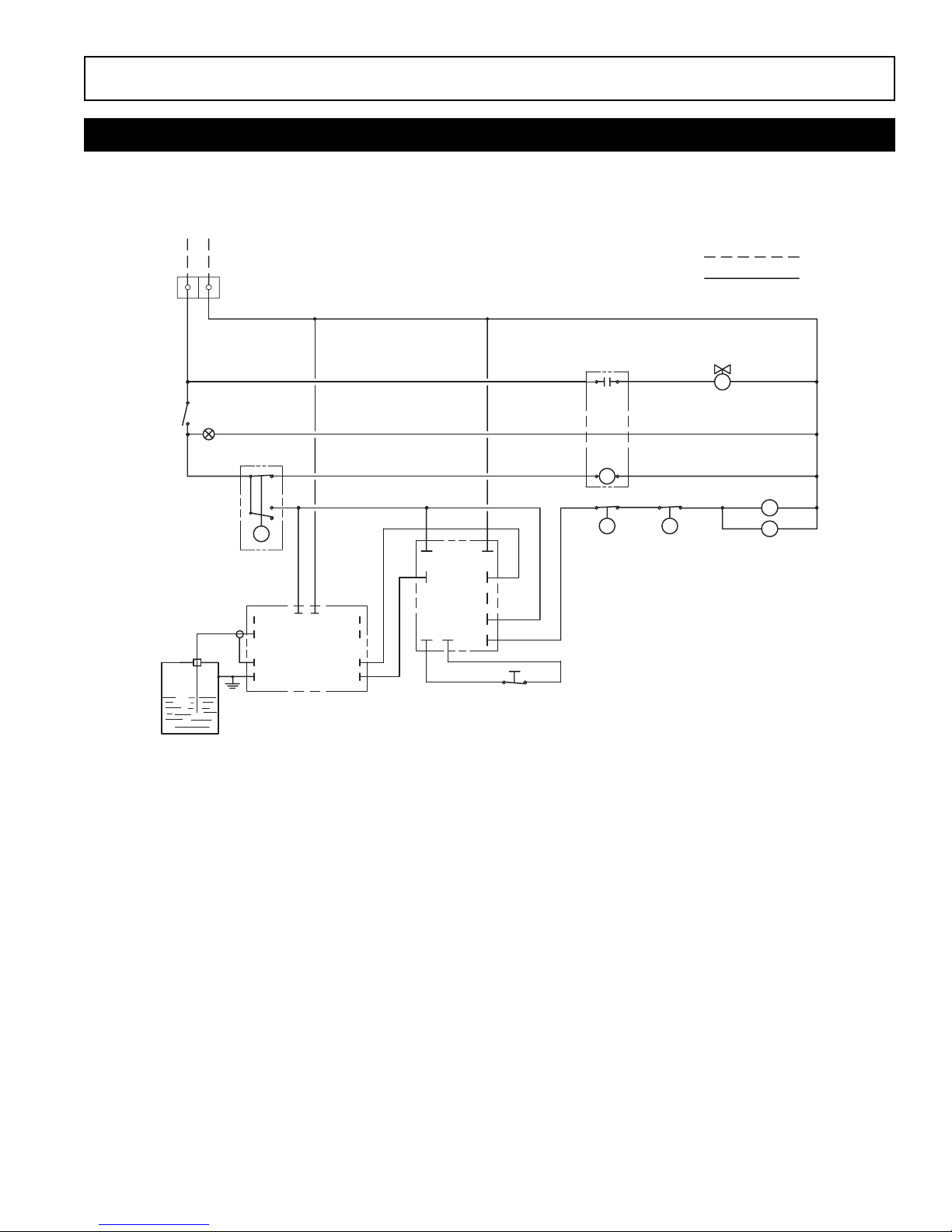

Sussman Boilers

Installation, Operation & Maintenance Manual

Wiring Diagram Control Circuit

7

ES and SSB Electric Boilers with Automatic Blowdown System

ES and SSB Electric Boilers with Automatic Blowdown System

ON-OFF

SWITCH

PILOT

LIGHT

L

LIQUID

LEVEL

CONTROL

120V 1PH

INPUT

L N

CONTROL

TERMINAL

BLOCK

T

7-DAY 24-HR

TIMER

ES81600

AUTOMATIC

BLOWDOWN SYSTEM

P1

HIGH LIMIT

PRESSURE

CONTROL

PROPORTIONING

PRESSURE CONTROL

R

RELAY

OPERATING

PRESSURE

CONTROL

TIME DELAY RELAY

P2

FIELD WIRING

FACTORY WIRING

D

PILOT LIGHT

2

OPEN

CLOSE

3

MOTORIZED

BLOWDOWN

VALVE

M

1

SOLENOID VALVE

S

PUMP MOTOR

CONTACTORS

C1

C2

ON-OFF

SWITCH

PROBE

120V 1PH

INPUT

Hot Leg

PILOT

LIGHT

Neutral

CONTROL

TERMINAL

BLOCK

LIQUID

LEVEL

CONTROL

L

L1 L2

LO

GUARD

GROUND

AUX LWCO BOARD

LWCO

LWCO

RELAY

R

P1

HIGH LIMIT

PRESSURE

CONTROL

FIELD WIRING

FACTORY WIRING

SOLENOID VALVE

P2

AUTOMATIC

PRESSURE

CONTROL

S

CONTACTORS

C1

C2

BOILER SHELL

Sussman Boilers

Installation, Operation & Maintenance Manual

Wiring Diagram Control Circuit

8

SSB Electric Boilers with Manual Reset, Auxiliary Low Water Cutoff

120V 1PH

INPUT

ON-OFF

SWITCH

PROBE

L N

PILOT

LIGHT

CONTROL

TERMINAL

BLOCK

LIQUID

CONTROL

L

LEVEL

LO

GUARD

GROUND

AUX LWCO BOARD

L1 L2

LWCO

LWCO

L1 L2

LLCO

NC

COM

RESET

NO

G

MANUAL RESET

RELAY

HIGH LIMIT

PRESSURE

CONTROL

R

P1

FIELD WIRING

FACTORY WIRING

P2

AUTOMATIC

PRESSURE

CONTROL

S

SOLENOID VALVE

C1

C4

CONTACTORS

BOILER SHELL

Loading...

Loading...