Sussman ES12-18, ES135-180, ES24-72, HU40-55, ES85-100 Installation, Operation And Maintenance Manual

...

ES & HU Installation, Operation

a nd Maintenance Manual

A Division of Sussman-Automatic Corporation

43-20 34th Street, Long Island City, NY 11101 • (718) 937-4500

1-800-238-3535 • Fax: (718) 937-4676 • email: seb@sussmancorp.com

www.sussmanboilers.com

PUR 101137

REV

5.18

Installation, Operation & Maintenance Manual

U S A

Designed, Engine ered

and Assembled in th e

Model No. _____________________________________

Boiler Serial No. _______________________________

National Board No. ___________________________

Safety Valve Set Pressure _______________ PSIG

Power Circuit Voltage _______________________

Control Circuit Voltage ______________________

Amps __________ Phase _________ HZ __________

Steam Outlet Valve Size _____________ NPT

Products covered by this manual:

_________________________________________________________________________________

KW Max Design Work

Series Range Steam Rate* BHP Pressure Pressure

_________________________________________________________________________________

ES, HU 12-180 36-542 lbs/hr 1.2-18.4 0-100 psig 85 psig

_________________________________________________________________________________

*Steam Rate: Steam at 212˚ F with 50˚ F feed water

ES and HU boilers are of Carbon Steel construction.

See page 23 for Water Quality Information.

TABLE OF CONTENTS

Dimensional Information and

Component Identification . . . . . . . . . . . . . . . . . 3

Dimensional & Clearing Specifications . . . . . . . . . 4

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Pre-Operation Check. . . . . . . . . . . . . . . . . . . . . . . . 8

Setting Pressure Controls . . . . . . . . . . . . . . . . . . . . 9

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Blowdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Digital Timer Operation Instructions . . . . . . . . . . 12

Timing Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Standard Equipment

Auxiliary Low Water Cut Off . . . . . . . . . . . . . . . . 14

Line Pressure Water Feed System . . . . . . . . . . . . . 14

Optional Equipment

High Pressure Water Feed System. . . . . . . . . . . . . 14

Condensate Return System. . . . . . . . . . . . . . . . . . 14

Vacuum Breaker Systems . . . . . . . . . . . . . . . . . . . 15

Automatic Blowdown System. . . . . . . . . . . . . . . . 15

Control Voltage Stepdown Transformer . . . . . . . . 15

Blowdown Separators . . . . . . . . . . . . . . . . . . . . . 15

Multistage Load Progressive Sequencers . . . . . . . . 15

Condensate Return Systems . . . . . . . . . . . . . . . . . 16

Blowdown Separator Tanks . . . . . . . . . . . . . . . . . 17

Specification Charts. . . . . . . . . . . . . . . . . . . . . . . . 18

Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Gauge Glass Installation . . . . . . . . . . . . . . . . . 20-21

Element Replacement . . . . . . . . . . . . . . . . . . . . . . 22

Water Quality Information. . . . . . . . . . . . . . . . . . 23

IMPORTANT NOTE:

As you follow these instructions, you will notice warning and caution symbols. This blocked information is important for the safe and efficient

installation and operation of electric boilers. These are two types of potential hazards that may occur during this installation and operation:

WAR N I N G

!

may cause serious injury or death if precautions

are not followed.

states a hazard which

CA U T I ON

!

minor injury or product damage may occur if you

do not follow instructions.

signals a situation where

2

IMPORTANT NOTE:

This highlights information that is especially

relevant to a problem-free installation.

Installation, Operation & Maintenance Manual

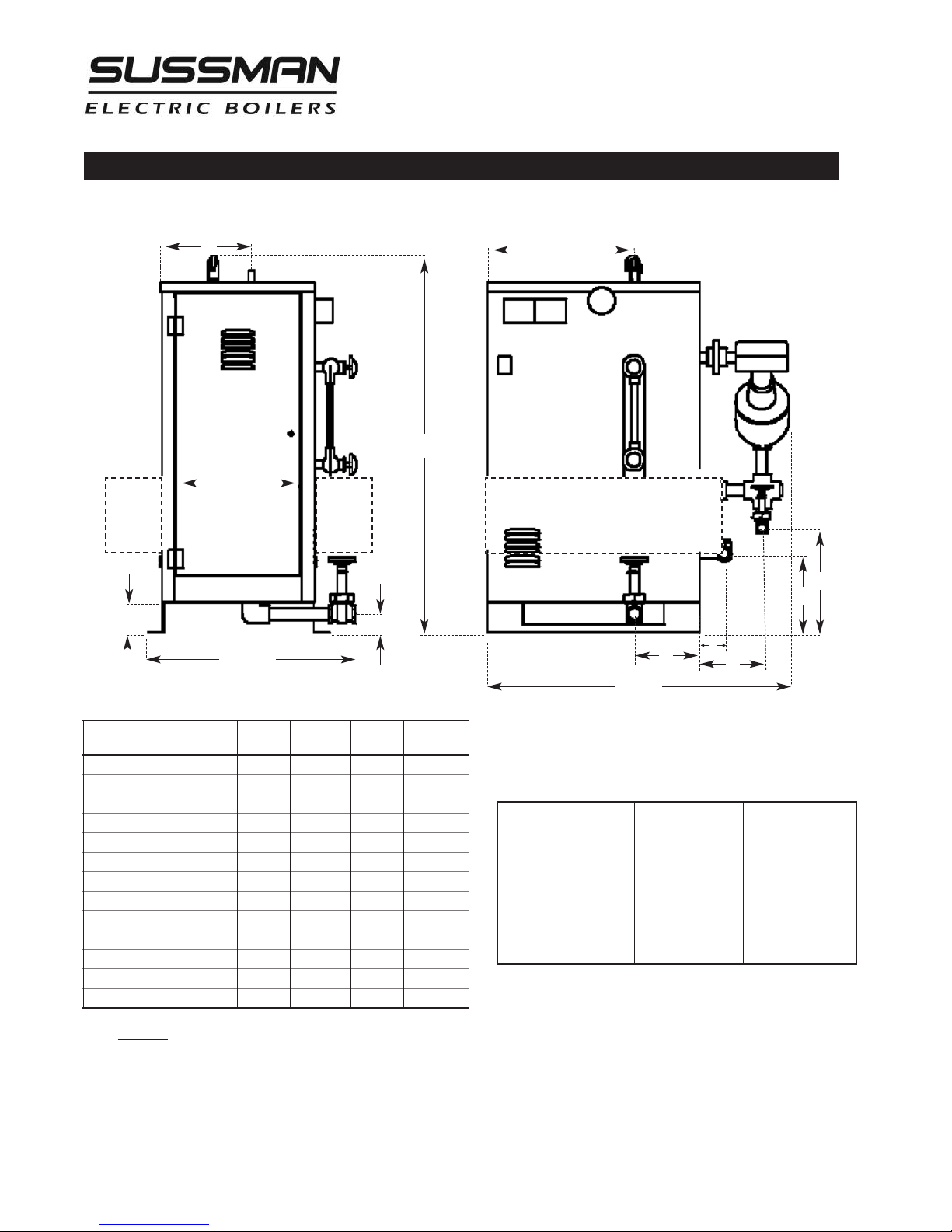

Dimensional Information & Component Identification

Models: ES, HU

A

B

Height

M

C

E

J

Width

F

G

K

D

Length

SYMBOL ITEM HU40-55 HU75-205 HU310 HU410-550

Height Overall Height 36" 46" 61" 61"

Length Overall Length 28" 33" 34" 36"

Width Overall Width 22" 22" 25"* 27"**

A Steam Outlet 6-1/4" 10" 8-1/4" 9"

B Steam Outlet 10-1/4" 17" 17-1/4" 18-1/4"

C M/M Drain Valve 5" 12" 17" 16-3/4"

D M/M Drain Valve 6-1/2" 6" 6-1/4" 6-1/4"

E Check Valve 14" 9" 17" 16-3/4"

F PV Drain Valve 2-3/4" 2-1/4" 2-3/4" 2-3/4"

G PV Drain Valve 6-1/4" 9-1/2" 7-3/4" 9-1/4"

J Clearance 3-3/4" 3-1/2" 4" 4"

K Check Valve 2-1/2" 2-3/4" 3" 3"

M Door Width 8-3/4" 14" 12-3/4" 14-3/4"

Allow minimum 36 inches clearance in front of doors for servicing of heating elements.

Recommended clearance: 24 inches other sides of boiler for servicing.

* ES100 Width shown is for 480 volts with one front mount fuse box, 208/240 volt that includes a front and back mounted fuse box is 30" wide

** ES135 -180 Width shown is for 480 volts with one front mount fuse box, 208/240 volt that includes a front and back mounted fuse box is 32" wide

All 480 volt ES100-180 include a front mounted box for fuses (shown as dotted lines)

All 208 and 240 Volt ES100-180 include a front and back mounted box for fuses (shown as dotted lines)

ES72 208 Volt includes a front mounted fuse box, overall width increases to 24"

ES12-18 ES24-72 ES85-100 ES135-180

MODEL 100 PSIG 15 PSIG 100 PSIG 15 PSIG

ES12-18, HU40-55

ES24-36, HU75-105 1”NPT 1”NPT

Steam Outlet Safety Valve Outlet

1

⁄

2

”

NPT

1

”

⁄

2

NPT

1

NPT

”

⁄

2

1

NPT

”

⁄

2

ES48, HU140 1”NPT 1”NPT 1” NPT

ES60-72, HU175-205 1”NPT 1”NPT 1” NPT 1” NPT

1

ES85-100, HU310 1

NPT 3”NPT 1”NPT 1

”

⁄

2

ES135-180, HU410-550 2”NPT 3”NPT 1”NPT 1

Water inlets for all ES & HU boilers are 1/2" NPT

Drains for all ES and HU boilers are 1" NPT

3

NPT

”

⁄

4

3

NPT

”

⁄

4

3

NPT

”

⁄

4

1

NPT

”

⁄

4

1

NPT

”

⁄

2

3

Installation, Operation & Maintenance Manual

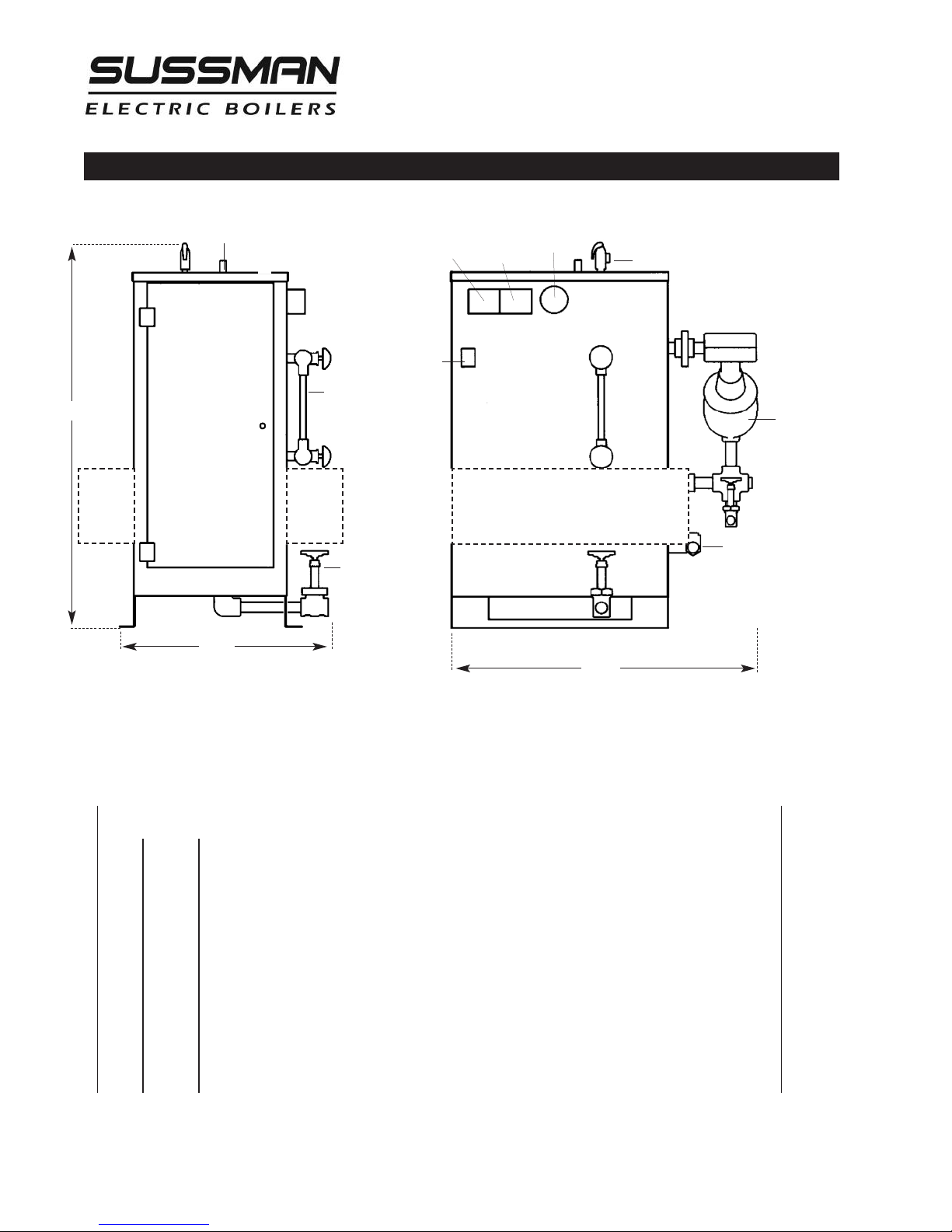

Dimensional & Clearance Specifications

Height

perating

Steam Outlet

A

Gauge Glass

Assembly

D

Drain Valve

Width

O

P

C

On/Off

Switch

ressure

ontrol

EL

High Limit

Pressure

Control

ressure

P

auge

G

Safety Valve

Liquid Level

Control

ER

Water Feed Inlet

F

Length

Left Side Elevation Front Elevation

Allow 24" all around for servicing, 36” in front of doors, minimum.

__________________________________________________

Clearance from combustible surfaces

__________________________________________________

A

_________________________________________________________________________

B

_________________________________________________________________________

D

_________________________________________________________________________

EL

_________________________________________________________________________

ER

_________________________________________________________________________

F

_________________________________________________________________________

G-

_________________________________________________________________________

All 480 volt ES100 - 180 include a front mounted box for fuses (shown as dotted lines)

All 208 and 240 Volt ES100 - 180 include a front and back mounted box for fuses (shown as dotted lines)

ES72 208 Volt includes a front mounted fuse box.

1" Clearance above top of boiler

A Clearance from Front of boiler. Prefix "C" to numeral indicates acceptability for

closet or alcove installations; prefix acceptability for alcove installations but not

for closet installations.

1" Clearance from back of boiler.

1" Clearance from left side of boiler.

16" Clearance from right side of boiler.

C Indicates type of flooring: "NC" for non-combustible; "C" for combustible.

Total minimum free area in square inches of close ventilating openings.

4

P1

C1

C2

C

3

C

4

P2

P2

P3

P3

(

See Note 6)

C1 C2 C3 C4

H1 H3 H5

H6

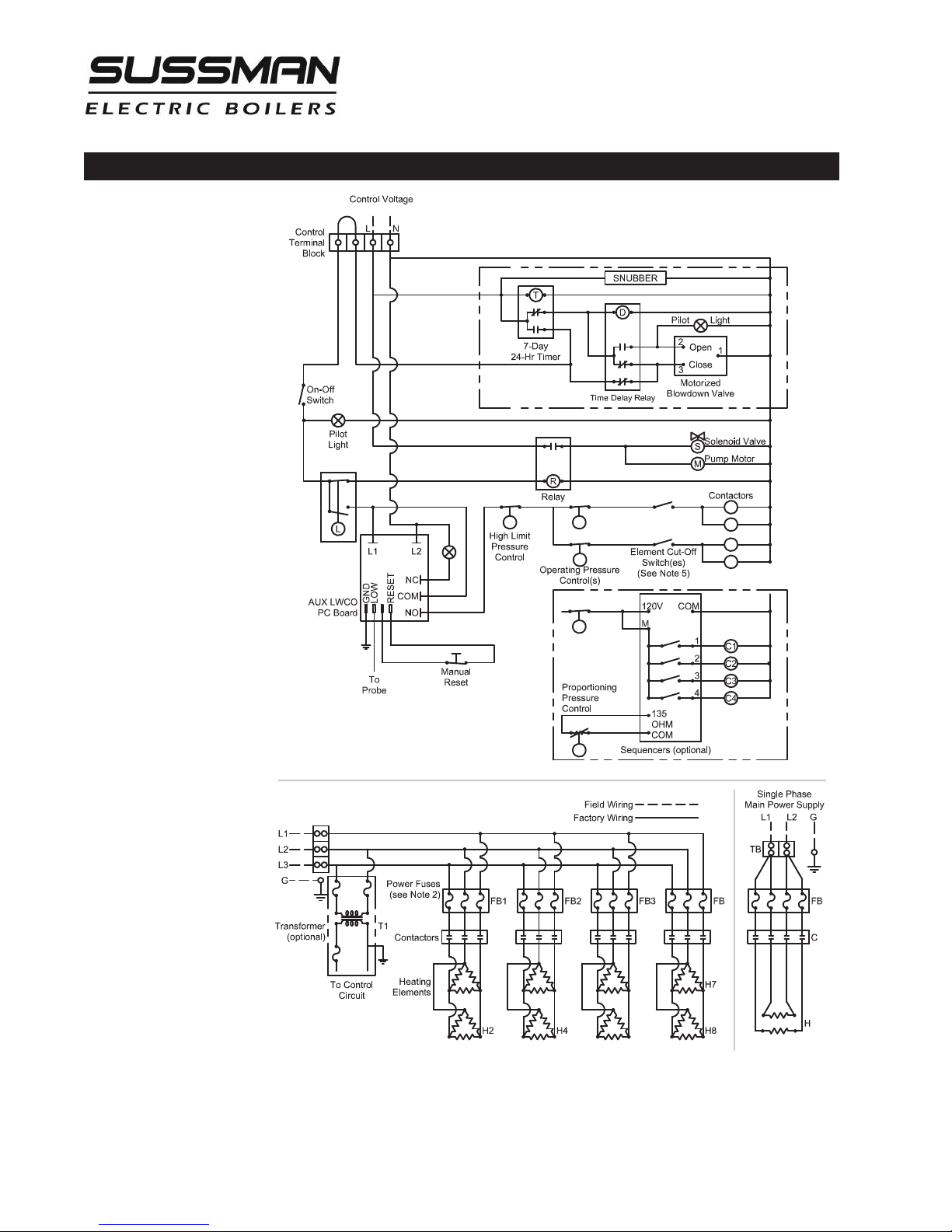

ES/SSB/CU 81600

Automatic Blowdown

System (optional)

Wiring Diagram

Power Circuit and

Control Circuit use

different voltage

Installation, Operation & Maintenance Manual

Three Phase Main Power Supply

NOTES:

1. Power Terminal Block only on boilers with two or more contactors.

2. On boilers with only one power contactor, connect power voltage to line side of contactor.

3. Power Fuses only on boilers rated 120 amperes and larger.

4. See Parts List for contactor and heating element information.

5. Element cut-off switches and second operating pressure control on ES/SSB 100-180 without sequencer

6. Refer to boiler nameplate for control and main power voltage

5

Installation

Installation, Operation & Maintenance Manual

REFER TO NATIONAL AND ALL APPLICABLE LOCAL

CODES FOR SPECIFIC INSTALLATION REQUIREMENTS.

1. The boiler should be mounted on a solid, level foundation.

2. The boiler should be located with suitable clearances, refer

to page 3 and Code requirements.

NOTE:

Allow a minimum of 36 inches clearance in front of

doors for servicing of heating elements. Recommended clearance: 24 inches other sides of boiler for servicing.

Piping

ALL PIPING SHOULD BE INSTALLED BY A

QUALIFIED LICENSED PLUMBER IN ACCORDANCE WITH NATIONAL AND LOCAL CODES.

1. When water feed is other than pump type the water

supply pressure must be 10 psig greater than boiler

operating pressure to assure water supply maintains

proper water level in the boiler. Insufficient water levels

can result in improper boiler operation. (Keep feed

water valves open at all times during normal operation.)

2. Connect steam line with a valve to boiler steam outlet

3. Do not install boiler in any location where water

could freeze.

4. Do not install boiler outdoors.

5. Do not install boiler near flammable or corrosive

materials.

6. Do not install boiler in a location where leakage

from the boiler tank or piping can damage to

adjacent areas or to lower floors of the structure.

Provide a floor drain and properly sloped floor

from the boiler towards the drain or install a suitably plumbed drain pan under the boiler.

NOTE:

ice higher than the maximum boiler pressure should be

plumbed on the steam outlet line; failure to do so can cause

heating element breakdown. See page 3 for steam outlet

valve size.

4. Provide for boiler drain connection, a daily blowdown is

5. Safety valve shall be plumbed according to local code.

NOTE:

sized less than the outlet size of the safety valve.

For best performance, a valve rated for steam serv-

required. A "Blowdown Separator Tank" may be

necessary, check with local code.

The safety valve shall not be plumbed with a line

6

Installation, Operation & Maintenance Manual

Wiring

ALL ELECTRICAL WIRING MUST BE PERFORMED BY A QUALIFIED ELECTRICIAN

IN ACCORDANCE WITH NATIONAL AND LOCAL ELECTRICAL CODES.

CA U T I ON

!

being supplied to the boiler matches the power voltage and

phase of the boiler. Connecting incorrect power supply can

damage boiler components or cause improper boiler operation. If the boiler power requirements do not match the

power to be supplied to the boiler the boiler must be

returned to the factory for conversion. Boilers cannot be

field converted.

ALL BOILERS ARE PRE-WIRED AND TESTED

PRIOR TO SHIPMENT.

1. Ground boiler according to National Electric Code

requirements to avoid shock.

2. Power wiring to boiler should be in accordance with

National and Local Electrical Code requirements following wiring diagram supplied. Use proper size wire. Wire

size is specified adjacent to field wiring terminals. This

label states the wire size [AWG or MCM], minimum

temperature rating (90 C) and conductor material

(copper only). Deviation from these requirements

may result in improper or unsafe boiler operation.

3. A disconnect switch employing circuit breakers or fuses

should be installed between the main power source and

the boiler. This disconnect switch should be located near

the boiler and clearly marked for easy access and identification should the boiler need to be turned off due to

an emergency.

Assure that the power voltage and phase

4. Boiler control circuit is 120 Volt*. Unless boiler has an

optional step down transformer, a separate 120 Volt

power feed wiring is required to be connected to the

control circuit terminal block. A 15 Amp circuit is

required for all boilers. If a 3/4 HP feed water motor

and pump assembly is connected to the boiler, then a

20 Amp circuit is required.

5. If a separate control circuit is used, it should be

connected to the control circuit terminal block.

6. Remote mounted water feed systems (i.e. condensate

return, motor and pump) should be connected to the

junction box provided on the outside of the boiler

jacket.

7. With main power off, make sure all wiring terminations are tight to avoid arcing, carbonizing or overheating of contacts.

CA U T I ON

!

damage due to water line connections. An industrial

type lightning/surge protector should be installed according to the manufacturer's recommendation at the service

entrance. Consult your contractor or electrical dealer.

WAR N I N G

!

cation of wiring system voids the warranty and may lead

to dangerous operating conditions.

Boilers are susceptible to lightning

Substitution of components or modifi-

7

Installation, Operation & Maintenance Manual

Pre-Operation Check (All Boilers)

LWCO/PUMP CONTROL OPERATION AND TESTING

1. All valves for incoming water supply are to be fully opened.

Main disconnect switch is to be in the "on" position. Boiler main

switch is to be in the "on" position. Since boiler will be empty

the pump or solenoid will be energized allowing the boiler to

fill with water. Control will automatically fill boiler to proper

operating water level and the pump/solenoid will be deenergized. Contactors will then energize, applying voltage to

the heating elements.

2. Pump switch operation – at this point water should be visible

approximately half way up the sight glass. Slowly open the drain

valve located at the bottom of the boiler. Water level in the

sight glass will begin to drop, allowing the low water cut

off/pump control to energize the feed water system. Close valve

for proper operation.

3. Low water cutout switch performance – open the drain valve

completely. Maintain this condition until water level falls within

the gauge glass enough to cause the low water cutout switch to

de-energize the heating elements. All of the contactors will be

in a de-energized or open state at this time. Close the drain

valve, water feed system will automatically refill the boiler and

the contactors will re-energize.

Pressure Controls, Operation and Testing

Boilers equipped with an auxiliary low water cut-off

control with a manual re-set button (required as

mandatory equipment is some states): once the correct

operating water level has been reached, it will be

necessary to depress the reset button in order for the

contactors to re-energize.

NOTE:

down system:

• For test 1 - the blowdown time clock must be in the

• For test 2 and 3 - in order for the drain valve to open

For boilers equipped with an automatic blow-

“run” mode before the boiler will automatically fill.

the blowdown clock must be in the “off” mode.

(See blowdown time clock insert) The automatic

blowdown indicator light will be on when the valve

is open. This light will remain on for the duration of

the blowdown cycle (a few seconds). It may be necessary to cycle the time clock from the “run” to

“off” mode several times.

NOTE:

All boilers are provided with one high limit pres-

sure control and at least one operating pressure control.

1. The high limit pressure control is equipped with a manual

reset feature. There is no subtractive differential scale with

this type of control

2. All pressure controls are equipped with an adjusting screw,

allowing for setting of desired operational and high limit

pressures. To reduce pressure setting, turn adjusting screw

in direction that allows indicator to point to a lower

pressure setting on the scale. To increase pressure setting

turn adjusting screw in direction that allows indicator to

point to a higher pressure on the scale

NOTE:

10% above the desired normal operating pressure (15 psig

boilers should be set to 13 psig)

3. Operating pressure controls, except low pressure (15 psig)

4. Operating pressure control check: Close steam outlet valve

It is recommended that the high limit control be set

types have a separate differential scale. Differential

indicates pressure below the main operating maximum

pressure, the pressure control will re-set. The differential set

point is adjusted in the same manner by turning the

adjusting screw in the desired direction to increase or

decrease the differential pressure value.

[supplied by customer] and adjust operating pressure

control to 20 psig (10 psig for low pressure boilers) and

the differential to 10 psig (Note: Low pressure boilers do

not have a differential setting). Set the high limit

pressure control to 30 psig (13 psig for low pressure

boilers). Switch boiler on to allow steam pressure to

build-up. Pressure gauge reading will increase and the

operating pressure control will de-energize the

contactor(s) when the pressure gauge indicates 20 psig

(10 psig for low pressure boilers). Open steam outlet

valve to bleed off pressure. When the pressure gauge

reading decreases below 10 psig (differential) (3 psig for

low pressure boilers) the operating pressure control will

re-energize the contactor(s).

5. High limit pressure control check: FOR TEST PURPOSES

ONLY! Set the high limit pressure control 10 psig (5 psig

for low pressure boilers) lower than the operating

pressure control. Close the steam outlet valve and switch

the boiler on to allow boiler to build pressure. When the

pressure gauge indicates the pressure at which the high

limit pressure control is set, the high limit pressure

control re-set button will pop-up and the control will deenergize the contactor(s). Open the steam outlet valve to

bleed off pressure. The contactor(s) should not reenergize on pressure drop. The contactor(s) should only

re-energize when the pressure has dropped and the high

limit pressure control reset button is depressed.

8

Loading...

Loading...