Sussman ES 24A, ES30A, ES36A, HP30A Installation, Operation And Maintenance Manual

ES 24A Electric

Steam Generator

Installation, Operation and Maintenance Manual

Model No. ___________________________ Power Circuit Voltage ___________________

Boiler Serial No. __________________ Control Circuit Voltage __________________

National Board No ____________________ Amps ________ Phase ________ Cy ________

IMPORTANT:

This data file contains the National Board Registration Certificate

approving your generator. It must be kept near the generator at all times.

Products Covered by this Manual

KW Design Max. Work

Model Range Steam Rate BHP Pressure Pressure*

__________________________________________________________________________________________

24A 24 73 lbs./hr 2.44 100 PSIG 90 PSIG

__________________________________________________________________________________________

*Line water pressure must be a minimum of 10 PSIG higher than generator operating pressure or you will require high pressure water feed

w/motor and pump.

Installation

CAUTION

!

NOTE:

Standard minimum suggested clearance is 21 inches.

Reference heating element clearance requirements for particular boiler to allow for removal of elements.

Refer to National and all applicable Local Codes for specific installation requirements.

1.

The boiler should be mounted on a solid level foundation.

2.

All piping should be installed by a licensed plumber.

3.

When any type water feed other than a pump feed is used, the existing water supply pressure must be 10 PSIG

greater than boiler operating pressure to assure water supply maintains proper water level in boiler. Lack of

water can result in improper boiler operation. Keep feed water valves open at all times during normal operation.

4.

Connect steam line with customer supplied outlet valve to boiler steam outlet.

5.

During normal operation, keep drain valve closed.

6.

If pump and boiler are plumbed within 30 ft (pipe length), a minimum of two check valves are required on boiler to avoid damage to pump.

NOTE:

THE SAFETY VALVE SHALL NOT BE PLUMBED WITH A DRAIN

LINE SIZED LESS THAN THE OUTLET SIZE OF THE SAFETY VALVE.

A Division of Sussman-Automatic Corporation

43-20 34th Street, Long Island City, NY 11101•(718) 937-4500•1-800 238- 3535

Fax: (718) 937-4676

•

www.sussmanboilers.com•Email: seb@sussmancorp.com

PN 101167 5/12

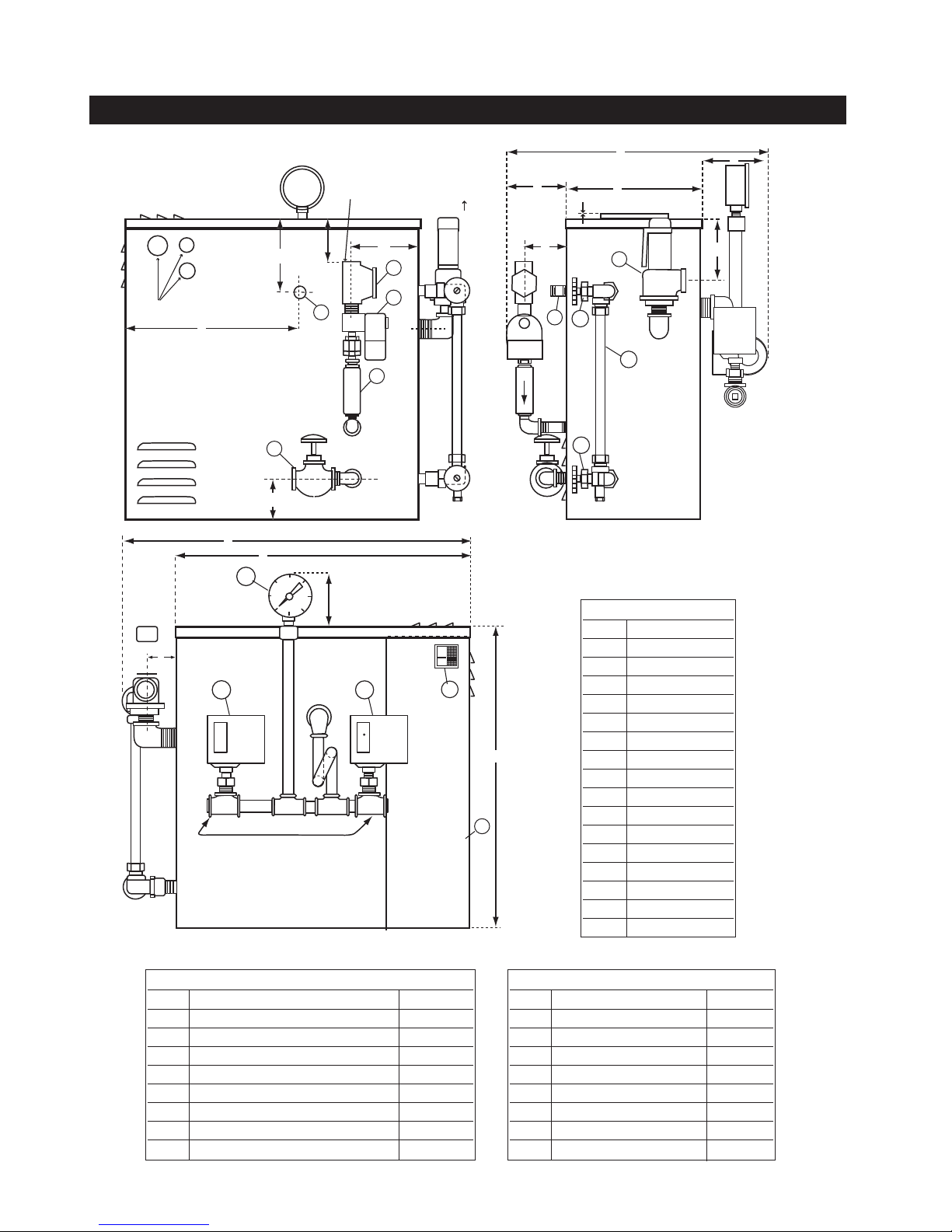

ES 24A Electric Steam Generator Installation, Operation and Maintenance Manual

1

/4 NPT Water Inlet

Connection

Electric Service Entrance

I

K

J

E

O

F

H

M

L

P

G

7

5

6B

6A

6A

1

2

3

4

5

A

B

C

8

10

9

12

11

Hi-Limit

Control

D

Operating

Control

_____________________________________________________________________________

Component Identification Dimensional Information

Dimensional Table

Item Models 24A

A25

B22

C17

D1

E 1611⁄16

F4

G2

H2

I3

J9

K2

L10

M4

N2

O8

P2

3

6

⁄1

1

(

)

⁄8

REF

13

(

)

⁄16

REF

3

⁄4

1

⁄16

15

⁄16

1

⁄2

1

⁄2

1

⁄8

1

⁄4

5

⁄16

5

⁄16

5

⁄8

3

⁄4

1

⁄2

Dimensional Table Model 24A

Item Description

11⁄4 NPT Strainer 93806

21⁄4 NPT 120V 60HZ Solenoid,1⁄4 OBIF. 99042

33⁄8 NPT Check Valve 99162

41⁄2 NPT Drain Valve 99178B

51⁄2 NPT Steam Outlet Nipple 100380

6A Gauge Glass Valve Set 99173C

6B Gauge Glass Tube 99074-1

1

7

⁄2 NPT 100PSIG S.Valve 99136

Dimensional Table Model 24A

Item Description

81⁄4 NPT Pressure Gauge 99197

9 Hi-Limit Pressure Control 99066

10 operating Pressur Control 99966

11 Access Panel -----12 Main On-Off Switch 92830

13 Probe Isolator 100378

14 Probe Spark Plug 90229

15 Probe 5 inch 99807F

2

ES 24A Electric Steam Generator Installation, Operation and Maintenance Manual

_____________________________________________________________________________

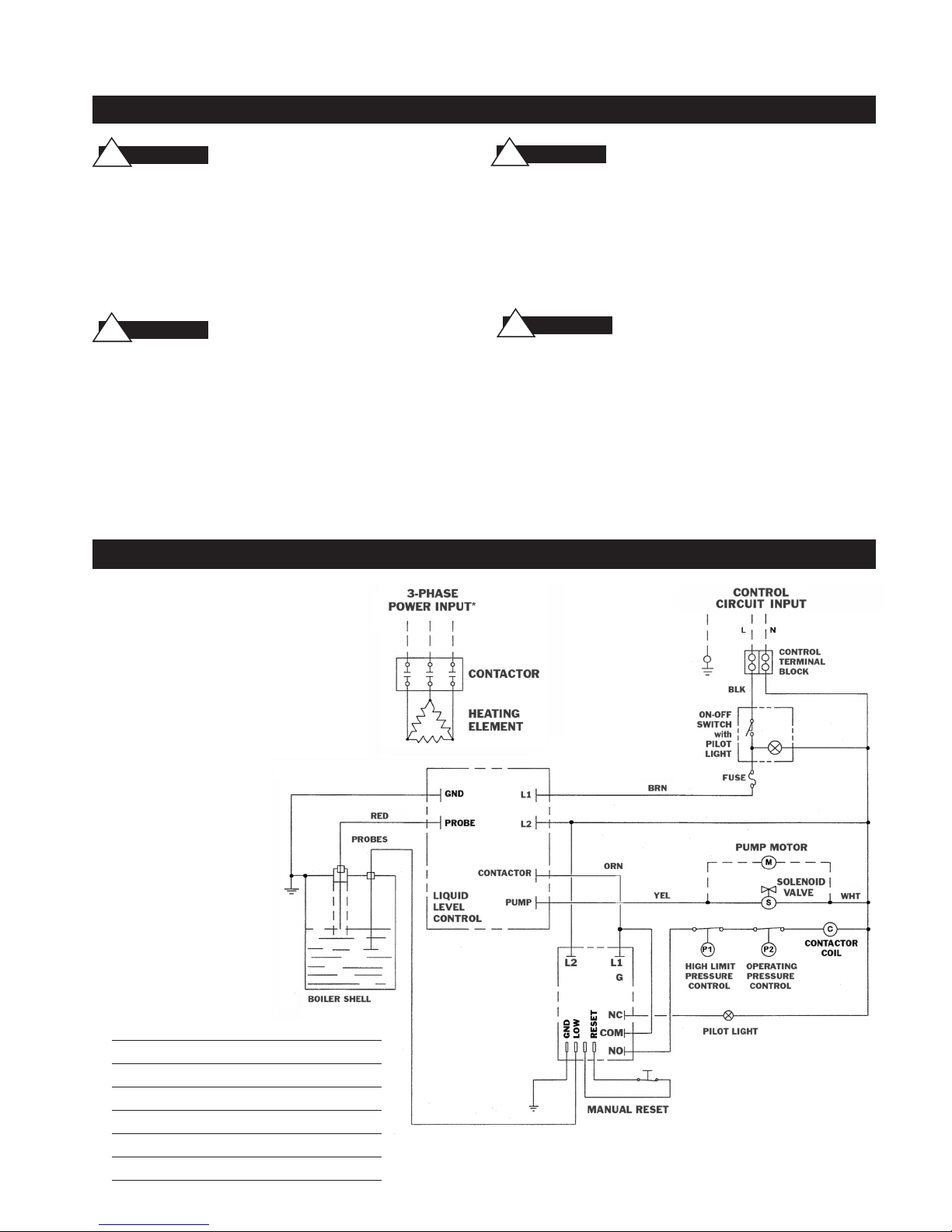

Wiring

CAUTION

!

Electric Code requirements to avoid shock. Use proper sized

wire. Power wiring to boiler should be in accordance with

Local and N.E.C. requirements following wiring diagram

supplied. Wire size specified adjacent to field wiring terminal block(s). Use 90˚ C copper wire only.

Purchaser should use a disconnect switch employing circuit breakers or fuses between the main power source and the boiler.

CAUTION

!

age because of plumbing water lines. Industrial type lightning/surge protectors should be installed according to the

manufacturer's recommendation at your service entrance.

Consult your contractor or electrical dealer.

1.

The unit is pre-wired and tested. Connect control circuit volt-

age at the control circuit terminal block.

2.

With the main power off, make sure that all wiring termina-

tions are tight to avoid arcing, carbonizing and/or overheating

of contacts.

Ground boiler according to National

Boilers are susceptible to lightning dam-

WARNING

!

modification of wiring systems voids the warranty and

may lead to dangerous operating conditions.

3.

Instructions for water feed control system (i.e. motor and

pump or solenoid feed).

a.

Check the voltage of the motor or solenoid before

making electrical connection.

WARNING

!

wired to the junction box provided.

c.

Motors rated greater than 1/3HP or are not 120VAC sin-

gle phase require the use of suitable motor starter.

d.

Amperage/Wire Size – For correct sizing refer to the label

on the boiler located next to the field wiring termi nals. This

label states the wire size (AWG or MCM), minimum temperature rating (90˚C) and conductor material (copper only).

Deviation from this information may result in improper or

unsafe boiler operation.

Substitution of components or

b.

The water feed circuit should be

Wiring Diagram Control Circuit ES-24A–PRI Electric Boilers

Typical Wiring Diagram 24A

Factory Wiring ___________

Field Wiring __ __ __ __ __

Note: *See Boiler Nameplate for

Input requirements

Electrical Parts List

39243B Heating Element 24kw 208v 3Ph

39243C Heating Element 24kw 240v 3Ph

39243F Heating Element 24kw 480v 3Ph

102206-1 Contactor 75 amp 3 pole 120v Coil

100412A Liquid Level Control Board 120v

90241MRT Auxiliary LWCO Board 120v

3

Loading...

Loading...