Sussman CU-360, CU-1000, CU-1250, CU-2000, CU-1400 Installation, Operation & Maintenance Manual

...Page 1

MrSteam

®

CU Series Steambath Generators

Installation,Operation & Maintenance Manual

!

CAUTION

TABLE OF CONTENTS

Before Installing . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

Steam Room Requirements . . . . . . . . . . . . . . . . . . . .2

Locating the Steambath Generator . . . . . . . . . . . . . .

3

Dimensional & Clearance Specifications . . . . . . . . . .

4

Selecting the Steambath Generator . . . . . . . . . . . . .

5

Installation

Plumbing, Water Supply, Steam Line, Steam Head,

Acrylic Shield . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Drain, Safety Valve

. . . . . . . . . . . . . . . . . . . . . . . . . .7

Electric . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Control Circuit Wiring Diagrams . . . . . . . . . . . . . . . .9-12

F1 Plus

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Control Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

Operating Temperature Sensor Installation . . . . . . . . . . . . . .

15

High Limit Operating Temperature Sensor Installation

. . . .

15

CU-HL Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Automatic Blowdown System

Kit Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Auxiliary Manual Reset Low Water Cutoff . . . . . . . . .19

P

rinciples of Operation . . . . . . . . . . . . . . . . . . . . . .20

Operating and Testing

Automatic Blowdown, F1 Plus Control, CU-HL . . . . .21

Warning Signs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

Pre-Operation Check . . . . . . . . . . . . . . . . . . . . . . . .22

Operation

Automatic Blowdown Instructions . . . . . . . . . . . .23

Manual Blowdown Instructions . . . . . . . . . . . . . .23

Maintenance Instructions . . . . . . . . . . . . . . . . . . . .24

24-hour and 7-day Time Switches . . . . . . . . . . . . . .25

Water Gauge & Gauge Glass Installation . . . . . . . .26

Use and Care . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Trouble Shooting . . . . . . . . . . . . . . . . . . . . . . . . . .28

Check

PC Boards, Probes, Steam Solenoid Valve,

F1 Plus Control, Heating Element . . . . . . . . . . . . .29

Element Replacement Instructions . . . . . . . . . . . . .30

CU 360 –CU 1400 . . . . . . . . . . . . . . . . . . . . . . . . .31

CU 2000 – CU 4500 . . . . . . . . . . . . . . . . . . . . . . . .32

Replacement Parts List . . . . . . . . . . . . . . . . . . . .33-34

A Division of Sussman-Automatic Corporation

43-20 34th Street, Long Island City, NY 11101

(718) 937-4500 • 1-800 767- 8326

Fax: (718) 472-3256 • Website: www.mrsteam.com

Email: slg@sussmancorp.com

signals a situation where injury or product damage

may occur if you do not follow instructions.

states a hazard may cause serious injury or death if

precautions are not followed.

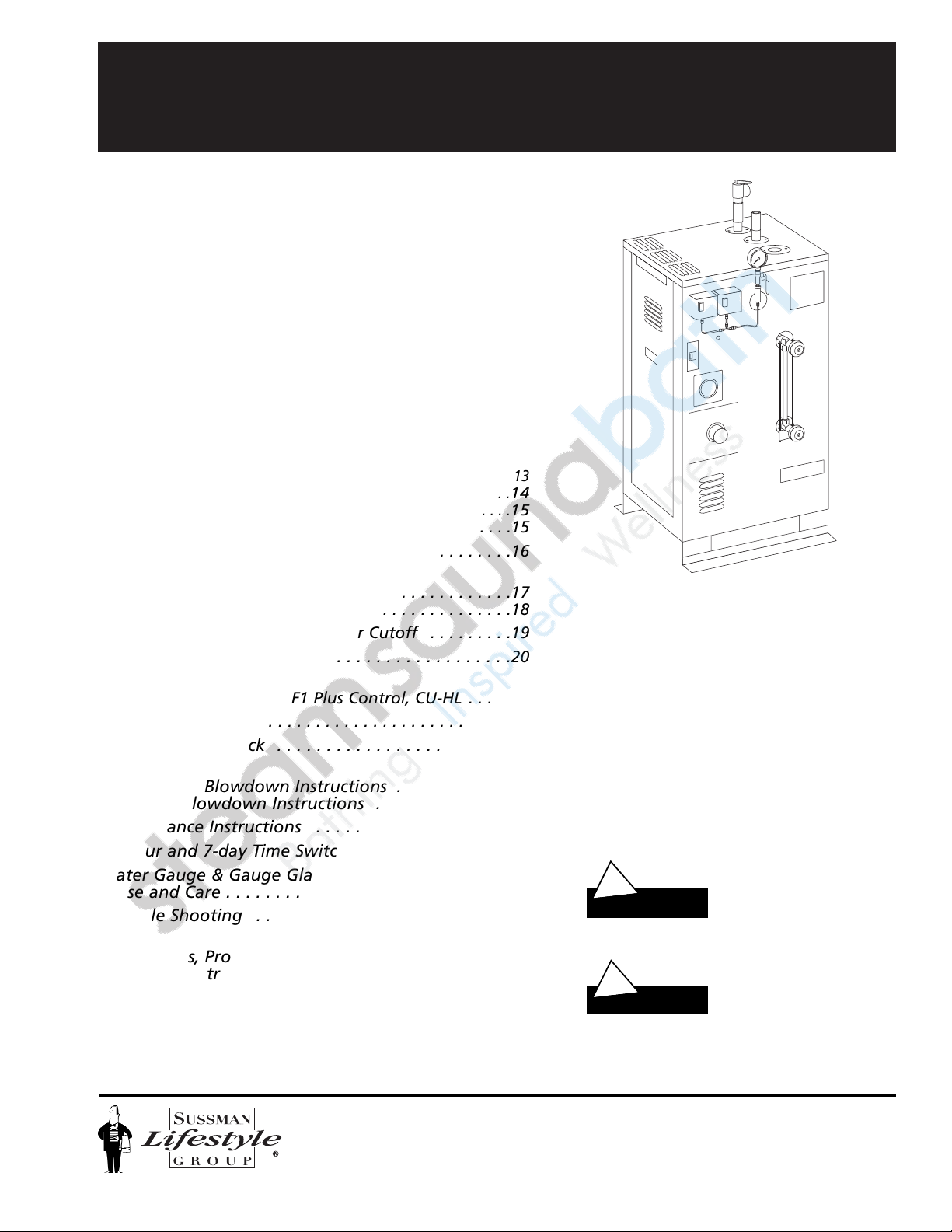

Typical CU Series Steambath Generator

(for illustrative purposes only)

_________________

IMPORTANT NOTE:

As you follow these instructions, you will notice

warning and caution symbols. This information is

important for the safe and efficient installation and

operation of this steam generator. There are two

types of potential hazards that may occur during this

installation and operation:

!

WARNING

PUR 100376 08/03

Western Regional Offices

9410 S. La Cienega Blvd. Los Angeles CA 90301

(310) 216-6565 • 1-800 727-8326

Fax: (310) 216-2944

MODELS:

CU-360 through

CU-4500

Page 2

IMPORTANT:

Take time to read these instructions thoroughly before installing or servicing. Although this

CU Steambath Generator has been qualified for shipment by MrSteam, the following must be reviewed for

proper and safe use.

1.

Verify that the model and accessories are as specified and ordered.

2.

Verify that the power voltage and control voltage at the site is suitable for the CU Steambath Generator.

3

.Verify the correct steam generator sizing by referring to the MrSteam sizing guide. See page 5.

4.

Do NO

T use black iron pipe or galvanized pipe for the steam line. Use brass pipe or copper tubing only, and in accor-

dance with National and local plumbing Codes.

5.

The physical size of the unit, clearance for plumbing servicing and its distance from the steam room must be all consid-

ered before selecting a location for the generator. See pages 4 & 5.

6

. The Manufacturer's Data Report is supplied with the generator.This is an important document and may be required by a

State or Provincial Agency. THIS DOCUMENT MUST BE SECURED IN

A SAFE LOCATION.

7.

Do not use or install unauthorized components, accessories or products on the generator or generator piping.

IMPORTANT:

The MrSteam F1 Plus System operating and high limit temperature controls are to be installed in accor-

dance with the specific instructions provided. See Note 7 below.

IMPORTANT:

The following general information should be used in conjunction with your architect, designer and con-

tractor in determining all factors necessary in providing a suitable and safe steam room environment for your bathers.

IMPORTANT:

Owners/operators should obtain a copy and familiarize themselves with the latest edition of the American

College Sports Medicine Health/Fitness Faculty Standards and Guidelines, or a similar resource and reference publication, and

refer to those guidelines for the proper and safe operation of a spa facility including steamrooms.

Steamroom construction information is available from the Tile Council of America, Inc. at (864) 646-8453 or www.tileusa.com

1.

Steam room must be completely enclosed, with full walls, door, floor and ceiling.

2.

It is recommended that a gasketed door be used for heat sealing and steam containment.Windows, skylights and the like

that are part of the steam room should be double paned. Only vapor sealed lighting fixtures approved for the application

should be used.

3.

If tile-type or other smooth surface flooring is used, provide suitable anti-skid strips or equivalent, to

prevent user slipping and injury.

IMPORTANT

4.

Walls and ceilings must be constructed with water-resistant, non-corrosive surface, such as tile, marble, molded acrylic, or

other non-porous material.The ceiling should be sloped to prevent dripping of condensate on bathers. If acrylic, fiberglass

or other non-heat resistant materials are used as part of the steamroom enclosure, see page 6, “Steamhead” and “Acrylic

Shield” for important additional details.

5.

Provide floor drains for condensate run-off and steamroom cleaning.

6.

Comply with all applicable National and local building and electrical Codes and confer with design consultants and con-

tractors for room construction details.

7.

The F1 Plus Temperature Control System is required operating equipment for each steam room.The

operating temperature control is to be set by the owner/operator to sense desired room temperature at the sensor location within the steam room. Installation of the F1 Plus System high limit room temperature sensor and control is mandatory to provide additional protection to the bathers.The steam room is to be operated in accordance with “Important”

information as noted above.

IMPORTANT:

Final selection of the steam room temperature setting is at the discretion of the owner/operator.

Before Installing

Steam Room Requirements

MrSteam CU Series

Installation, Operating & Maintenance Manual

2

!

CAUTION

!

CAUTION

Page 3

MrSteam CU Series

Installation, Operating & Maintenance Manual

Locating the Steam Generator Unit

3

MrSteam Installation

!

CAUTION

!

CAUTION

!

CAUTION

!

WARNING

1.

MrSteam®CU commercial steambath generators are designed to NEMA Type 1 requirements

and are intended for indoor use onl

y.They are to be located indoors in a dry, clean location

and are not to be subjected to moisture, condensate, hose wash down or the like.

2.

Do not install steambath generator outdoors or wherever environmental conditions may effect

the safety and/or performance of the generator.

3.

Do not install steambath generator in locations such as unheated attics or basements, or where

water could freeze.

4.

Do not install steambath generator near flammable or corrosive materials, or chemicals such as

gasoline, paint thinners, or the like. Installation in areas having high concentrations of chlorine

(such as pool equipment room) must be avoided.

5. IMPORTANT:

Select a location for steam generator in accordance with items 1-4 above and within 25 feet of the

steam room. Reference “Dimensional & Clearance Specifications

”

information on page 4. See page 5 for guidance if

generator is more than 25 feet from steam room.

6.

Install steambath generator on a solid and level surface. See Pages 4 and 5 for additional details.

7.

Provide access to the steambath generator for servicing. See page 4 for Dimensional & Clearance Specifications

8. IMPORTANT:

Steam line, safety valve and drain valve and plumbing, and steamheads become hot during operation

and remain hot after shutdown for a period of time. Provide appropriate protection, including insulating plumbing lines.

Avoid plumbing runs and steam head locations that can come in contact with service personnel and bathers. See page 6.

9.

Each steamhead must be located away from the bather seating areas and traffic patterns.

IMPORTANT:

A LOCKED

UTILITY ROOM THAT ONLY PERMITS ACCESS TO THE STEAM GENERATOR AND

ITS CONTROLS BY AUTHORIZED PERSONNEL AND IS NOT ACCESSIBLE TO THE GENERAL PUBLIC IS STRONGLY

RECOMMENDED.

!

WARNING

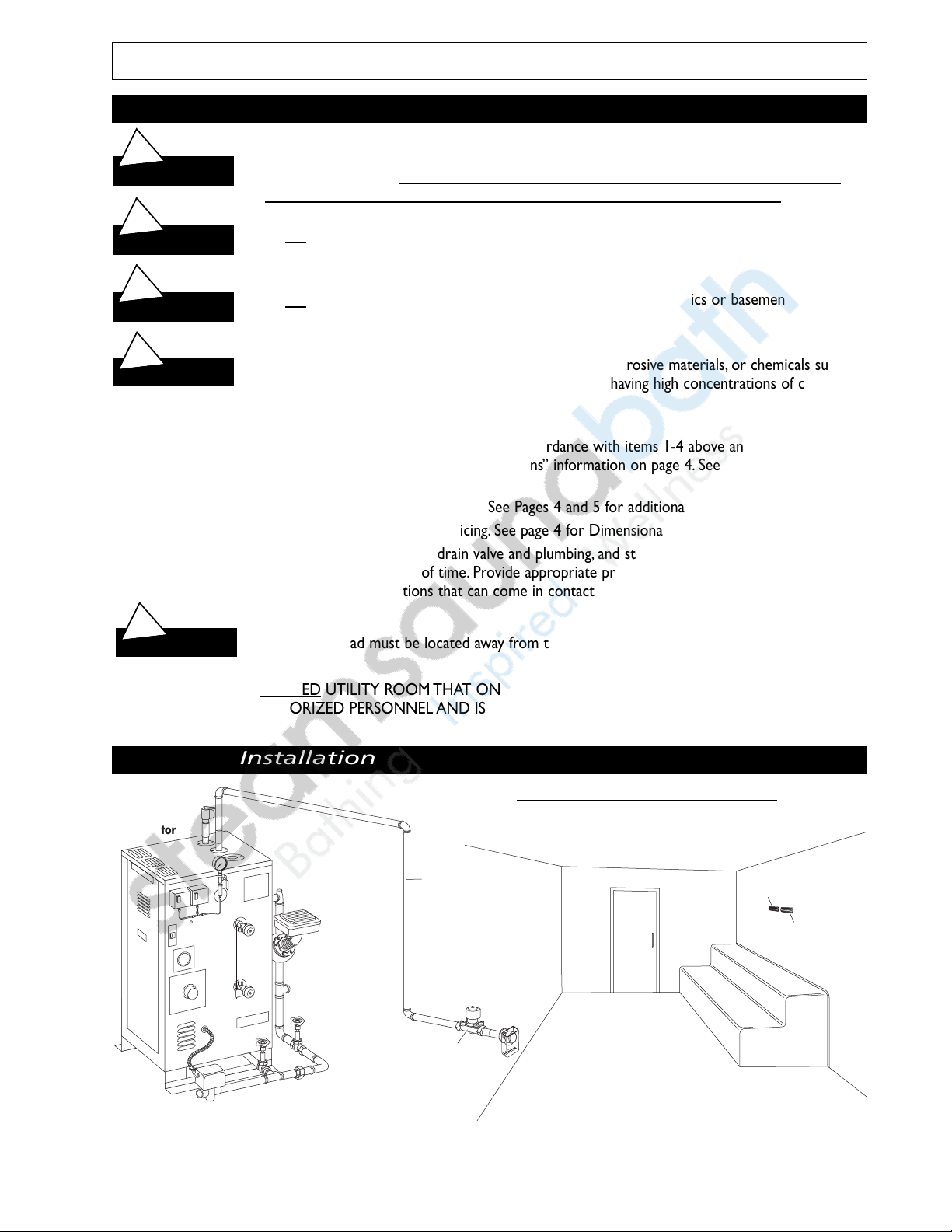

For Illustrative Purposes Only

NOTE:

For illustrative purposes only. Consult with qualified designer, architect or contractor

for steam room construction details, including location of steam head(s) and sensors.

Steam

Generator

Fully Insulated

Steam pipe

Steam Solenoid

F1 Plus Sensor

High Limit Sensor

Figure 1

STEAM ROOMUTILITY ROOM

Page 4

MrSteam CU Series

Installation, Operating & Maintenance Manual

Dimensional & Clearance Specifications

4

Figure 2: Typical Arrangement. For illustration purposes only

.

Refer to all notes below

NOTES for Figure 2:

1. IMPORTANT:

Allo

w minimum of 36" all around for servicing

2.

All dimensions are approximate. Refer to chart on Page 5.

3.

MM150 Liquid Level Control on CU-2000 and larger models only. CU-360 to CU-1400 have electronic liquid

level controls.

4. IMPORTANT:

Minim

um clearance from combustible surfaces.

Refer to Fig. 2 above for legend.

A

1" above top of CU generator

B

Front of CU generator suitable for alcove installation only.

D

1" from rear of CU generator.

E

L

1 " from left side of CU generator.

E

R

16" from right side of CU generator.

F

Type of flooring: "C", suitable for combustible flooring.

Steam Outlet

High Limit

Pressure

Control

Operating

Pressure

Control

Pressure

Gauge

15 PSIG

Safety Valve

MM 150 Liquid

Level Control

(see note 3)

MM 150 Drain Valve

Water Feed Inlet

F

E

L

D

A

B

E

R

FrontLeft

Drain Valve

On/Off

Switch

Gauge Glass

Assembly

Height

Width Length

Page 5

MrSteam CU Series

Installation, Operating & Maintenance Manual

5

Selecting a

MrS

team

CU Series Generator

The resultant calculated volume of the steam room determines the Model CU steambath generator required. Steam

room size and additional constructional factors affect model selected.

A.

To determine the steam room volume first multiply Length x Width x Height of the steam room.

_______________________________________________________________________________________________

Example:

A steam room 8' x 9' x 8' = 576 Cu.Ft. (volume).

Select the MrSteam Model which is the next larger volume. In this example, Model CU-750 is the correct selection.

Example:

2 Steam rooms each 6' x 10' x 7' x 2 rooms = 840 Cu. Ft. (volume).

In this example, Model CU-1000 is the correct selection.

NOTE:

Insure adequate consideration is given to assure that the CU unit selected is not undersized for the room.

_______________________________________________________________________________________________

B. NOTE:

Certain additional factors effect the correct sizing of the steambath generator:

1.

Construction materials such as glass or glass block, natural marble or other stones: Increase volume.

2.

Piping runs longer than 25 feet from the steambath generator to the steam room: Increase volume.

3.

Exterior walls and outside windows: Increase volume.

4.

Steam room with interior height in excess of 8 feet: Increase volume

_______________________________________________________________________________________________

C.

IMPORTANT:

The above selection guidelines are recommendations only. Al

ways consult with contractor

designer or architect. For general information, contact East Coast: 1-800-767-8326 or West Coast: 1-800-727-8326.

_______________________________________________________________________________________________

D.

IMPORTANT:

When specifying a CU Commercial Steambath generator the following is strongly recommend-

ed for best performance and user satisfaction.

1.

One CU steambath generator should service no more that two (2) steam rooms, each relatively similar in size and

construction.

2.

If two (2) steamrooms are serviced by one (1) CU generator, the combined resultant room volume of the two

rooms should not exceed 1000 cubic feet.

3.

Each room must be operated with the appropriate F1 Plus temperature control system inclusive of the room oper-

ating temperature control and the high-limit temperature control.

4.

In any case, the purchase and/or owner/operator must consult with a designer, architect, and/or consultant to

assure the proper specification of the steam generator.

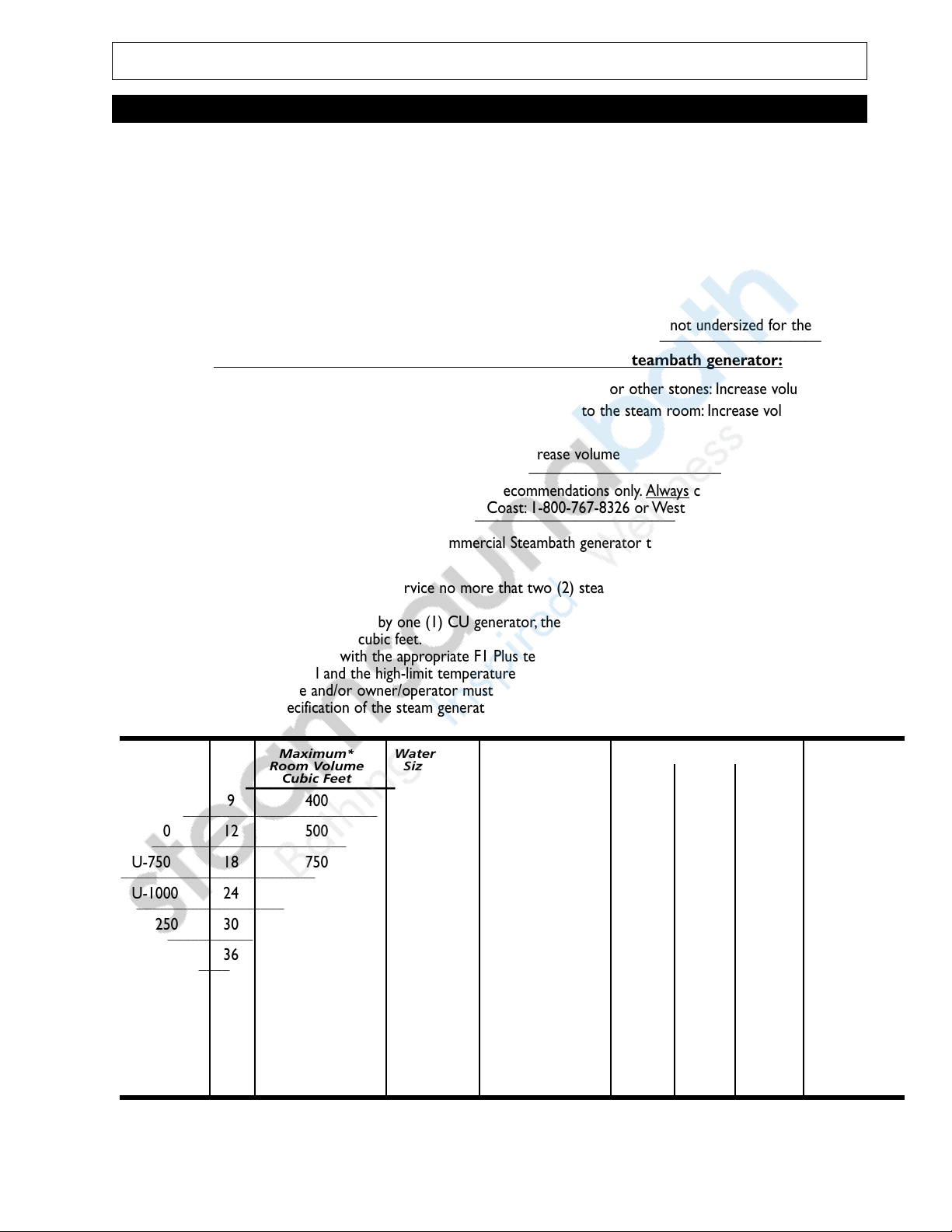

Model No. KW Maximum* Water Inlet Steam Generator Dimensions (inches) Shipping

Room Volume Size NPT Outlet Size, NPT Width Length Height Wt.Lbs.

Cubic Feet

_______________________________

CU-360 9 400 1/2" 1" 20 20 38 250

____________________________________________________________________________________________________

CU-500 12 500 1/2" 1" 20 20 38 250

____________________________________________________________________________________________________

CU-750 18 750 1/2" 1" 20 20 38 250

____________________________________________________________________________________________________

CU-1000 24 1000 1/2" 1" 20 30 38 270

____________________________________________________________________________________________________

CU-1250 30 1250 1/2" 1" 20 30 38 290

____________________________________________________________________________________________________

CU-1400 36 1400 1/2" 1" 20 30 38 300

____________________________________________________________________________________________________

CU-2000 48 2000 1/2" 1" 24 33 44 330

____________________________________________________________________________________________________

CU-2500 60 2500 1/2" 1" 24 33 44 380

____________________________________________________________________________________________________

CU-3000 72 3000 1/2" 1" 24 33 44 390

____________________________________________________________________________________________________

CU-4500 108 4500 3/4" 1-1/2" 28 34 59 625

* After taking into consideration all factors affecting resultant steam room volume, including materials of construction, distance from generator to steam room, interior height of steam room ceiling, outside/exterior walls and windows etc., select

proper Model CU generator. Consult with architect, designer and contractor before making final selection.

Page 6

MrSteam CU Series

Installation, Operating & Maintenance Manual

Installation

6

Plumbing

All plumbing shall be performed by a qualified licensed plumber and in accordance with applicable National and local Codes.

Water Supply

1.

Connect to hot or cold water line. A hot water line is preferable, however incoming hot water should not exceed 160° F.

IMPORTANT:

The low temperature setting on many hot water heaters provides 120°F water

2.

Provide a service shut off valve and water-line strainer in the water supply line upstream to the steambath generator

3.

Flush the inlet water line thoroughly before making connection to the steambath generator.

4.

Incoming water supply should be at least 25 psig and is not to exceed 100 psig.

5.

Install a back flow preventor as required by Code.

6.

Provide anti-water hammer device as required in accordance with Code.

7.

Use of unions in plumbing lines is strongly recommended.

8.

Recheck all factory and field plumbing connections for tightness.

Steam Line

1.

The F1 Plus steam solenoid valve should be plumbed as close as practical to the steam room using brass pipe or copper

tubing.

2.

Pitch the steam line a minimum of 1/4” per linear foot of run, towards the steam outlet on the generator, to avoid valleys

and trapping of condensate.

3.

Fully insulate steam lines with suitably-rated high temperature insulation.

4.

Install a suitable strainer or filter between the steam generator and steam solenoid valve.

5.

Use of unions in plumbing lines is recommended.

Steam Head (3/4” N.P.T.)

1.

For steam rooms constructed of tile, marble or similar non-porous heat-resistant materials for the enclosure, locate steam

head 12 inches above steam room floor and install MrSteam PN: CU-103412 acrylic shield on each steamhead.

IMPORTANT:

For Steam rooms using acrylic, fiberglass or other non-heat resistant materials used for steam room enclo-

sure, install each steam head 20-30 inches above the floor.

2.

Locate each steam head away from bather seating area and away from traffic patterns.

3.

Install each steam head with steam slot facing downward, towards floor. See Diagram A.

4. NOTE:

To preserve the steam head finish, do not use wrench or other tools to tighten. Use of proper thread sealant and

hand tightening is usually sufficient.

Acrylic Shield

1.

Place an Acrylic Shield (supplied) on each steamhead as shown.

Operation of the steamroom without an acrylic shield may expose users or surfaces to hot steam.

Do not operate steam room without an acrylic shield on each steamhead.

IMPORTANT:

Do not use with water soluble fragrance or fragrance containing emulsifiers or aldehydes.

Acrylic Shield damage may result. MrSteam oils are approved for use with this acrylic shield.

!

WARNING

Steam Supply Pipe

Steam Head

3/4"

1/4" minimum clearance

required for Acrylic Shield

Fill gap with silicone or

equal sealant as required

for moisture seal.

Finished interior face

of steam room wall

Use Teflon or equal

sealant on pipe threads

Diagram A

Steam Head

Acrylic Shield

Condensation Slot

(downward facing)

Page 7

Electric shock hazard. Disconnect all power supplies at the main disconnect

switch before proceeding. All electrical wiring must be installed by a qualified

licensed electrician in accordance with National and local Codes.

The steambath generator is factory wired and pre-tested before shipment. Electrical power supply details are provided on

the data plate secured to the generator and as part of this manual. Refer to applicable wiring and schematic information.

1.

Check power and control circuit voltage requirements on the data plate.

NOTE:

Separate 120 VAC line is not required if optional 120 VAC control transformer has been purchased and provided

as factory equipment.

2.

Use minim

um 90°

C insulated copper conductors only for field wiring, sized in accordance with National and local electric

Codes. Refer to Amperage Chart below.

3.

Connect suitably sized copper equipment grounding conductor in accordance with National and local electric Codes to

ground terminal provided.

4.

Install a separate dedicated circuit breaker or other approved overcurrent protection device between the incoming

electrical supply and the generator, in accordance with National and local electric Codes.

5. IMPORTANT:

With main disconnect switch off and no electric power entering the generator, tighten all e

lectrical

connections including all factory connections at the terminal block, fuse block, top and bottom of contactor and element

pins prior to energizing generator.

AMPERAGE CHART -

Indicates Total Ampere Draw of Specific CU Model at Voltage & Phase Specified

_______________________________

Model No. KW 208V/1 PH 208V/3 PH 240V/1 PH 240V/3 PH 480V/3 PH 600V/3 PH

_______________________________

CU-360 9 44 25 38 22 11 9

___________________________________________________________________________________________________

CU-500 12 58 34 50 29 15 12

___________________________________________________________________________________________________

CU-750 18 87 50 75 44 22 18

___________________________________________________________________________________________________

CU-1000 24 116 67 100 58 29 24

___________________________________________________________________________________________________

CU-1250 30 145 84 125 73 37 29

___________________________________________________________________________________________________

CU-1400 36 - 100 - 87 44 35

___________________________________________________________________________________________________

CU-2000 48 - 134 - 116 58 47

___________________________________________________________________________________________________

CU-2500 60 - 167 - 145 73 58

___________________________________________________________________________________________________

CU-3000 72 - 200 - 174 87 70

___________________________________________________________________________________________________

CU-4500 108 - 300 - 260 130 104

IMPORTANT:

Use minimum 90˚ C insulated copper conductors only for field wiring sized in accordance with

National and local electric Codes.

NOTE:

Consult factory for other voltage/phase combinations. CU generators are suitable for 50/60 hz. Standard control

circuit voltage for above V/PH combinations for United States, Canada and Mexico is 120 VAC. Exception: 220-240 VAC control

circuit voltage is provided on non-domestic product where power voltage is 220-240 V/3 PH, 380V/3PH, 415V / 3 PH, etc.

Electric

MrSteam CU Series

Installation, Operating & Maintenance Manual

7

Installation

(cont.)

!

CAUTION

Drain

In accordance with Code requirements, provide a drain line connection from the steambath generator drain valve(s).

If an Auto Blowdown is used, the drain line must be connected to the automatic blowdown valve. Refer to National and

local plumbing Codes for drain requirements, including receptor, trap, vent requirements and drain lines.

Safety Valve

Where permitted by Code, provide a connection for safety valve discharge.

DO NOT

connect a shut off valve or plug at the safety valve outlet.

DO NOT

reduce outlet size of safety valve discharge.

!

WARNING

Page 8

MrSteam CU Series

Installation, Operating & Maintenance Manual

Wiring

8

To avoid possible electric shock, the steambath generator shall be suitably

grounded in accordance with National Electric and local Codes. Disconnect all

power supplies at the main disconnect switch before proceeding.

1.

Electric wiring to the steambath generator must be in accordance with National Electrical and local wiring Codes

following wiring diagram supplied. Such wiring shall be done by a licensed electrician. See Amperage Chart and

Notes, Page 7.

2.

The unit is wired and pre-tested before shipment. Follow all instructions provided for safely and properly wiring

steambath generator and accessories.

Installer shall use a safety switch of adequate capacity employing suitably-

rated circuit breakers or fuses between main electrical power source(s)

and the generator. Location of safety switch to be in accordance with National and local

electric codes.

3.

IMPORTANT:

Insure all electrical connections are sufficiently tightened prior to energizing generator. See

Page 7, Item 5.

Substitution of components or modification of wiring systems voids

warranty and can lead to dangerous operating conditions.

4.

The F1 Plus Temperature Sensor and High Limit Temperature sensor(s) must be located inside the steam room.

Locate approximately 5 feet above the steam room floor, preferably away from steam heads.

5.

The F1 Plus steam solenoid valve(s) shall be located outside the steam room and shall be wired to the F1 Plus con-

troller(s) in accordance with wiring diagram provided. See applicable wiring diagrams included as part of this manual

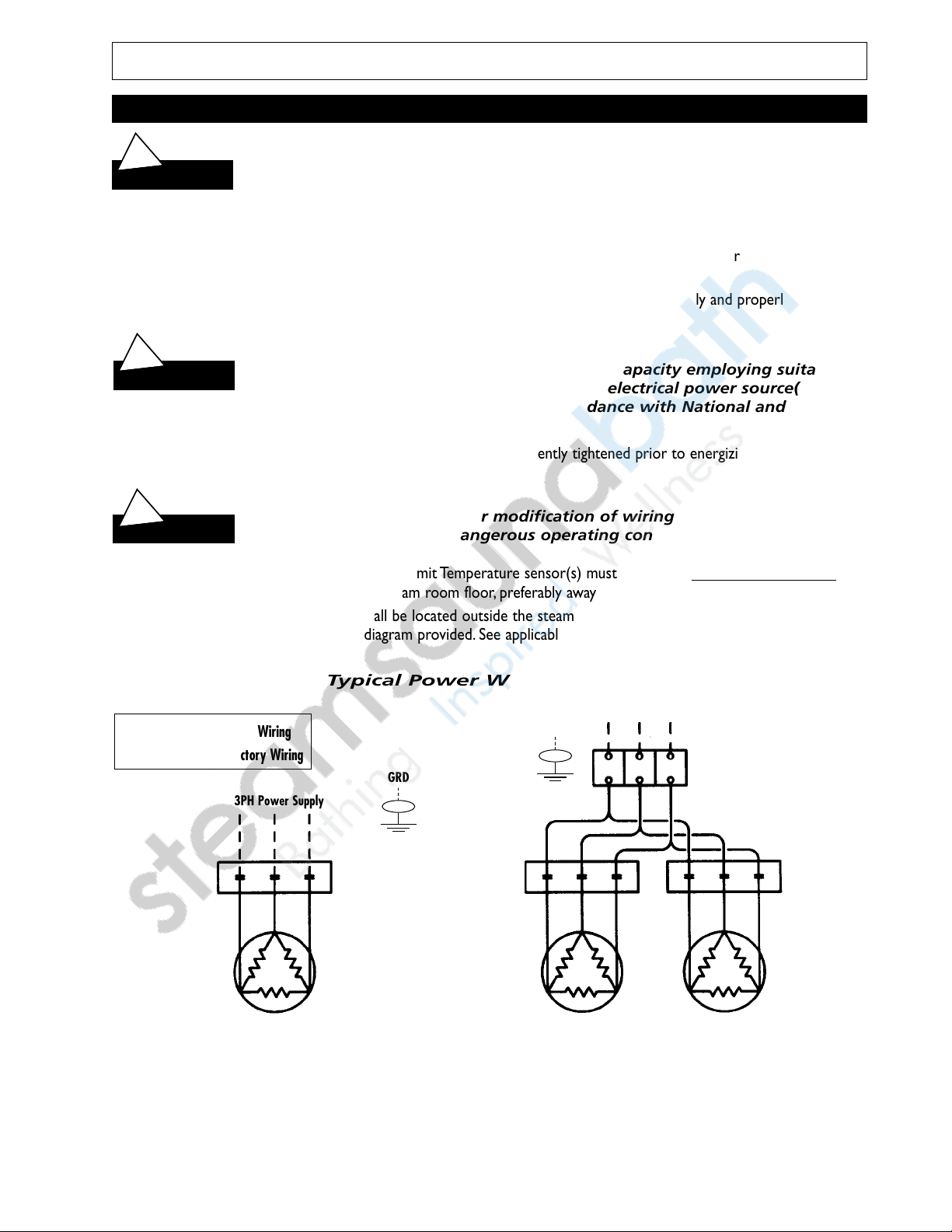

Typical Power Wiring Diagram

IMPORTANT:

Also refer to Control Circuit diagrams in this manual.

3PH Power Supply

Power Contactor

Heating Element

Diagram #1

Units with 1 Contactor (see note 1)

3PH Power Supply

Power Terminal Block

Power Contactors

Heating Elements

Diagram #2

Units with 2 or more Contactors (see note 1)

!

CAUTION

!

CAUTION

!

WARNING

GRD

GRD

__ __ __ __

Field Wiring

__________

Factory Wiring

Page 9

MrSteam CU Series

Installation, Operating & Maintenance Manual

Control Circuit Wiring Diagram

9

SEE PGS. 10 & 11 FOR DIAGRAMS

NOTES:

1.

Larger rooms may require two or more steam solenoid valves in parallel.

2.

When generator services two rooms, second room requires a set of F1 Plus solenoid valves and CU-HL.

IMPORTANT:

3.

F1 Plus sensors are intended to be field installed within the steam room at the location selected by the

designer/architect.

4.

Autoflush System 24 hr. timer and F1 Plus operating settings are at the discretion of the owner/operator.

IMPORTANT:

Owners/operators should obtain a copy and familiarize themselves with the latest edition of the American College Sports

Medicine Health/Fitness Faculty Standards and Guidelines, or a similar resource and reference publication, and refer to

those quide lines for the proper and safe operation of a spa facility including steamrooms. Steam room construction information is available from the Tile Council of America, Inc. at (864) 646-8453 or www.tileusa.com.

The F1 Plus Temperature Control System is required operating equipment for each steam room.

The operating temperature control is to be set by the owner/operator to sense desired room temperature at the sensor location within the steam room. Installation of the F1 Plus System high limit room temperature sensor and control is mandatory to provide additional protection to the bathers.The steam

room is to be operated in accordance with “Important” information as noted above.

IMPORTANT:

Final selection of the steam room temperature setting is at the decision of the owner/operator.

!

CAUTION

Page 10

MrSteam CU Series

Installation, Operating & Maintenance Manual

Control Circuit Wiring Diagram

10

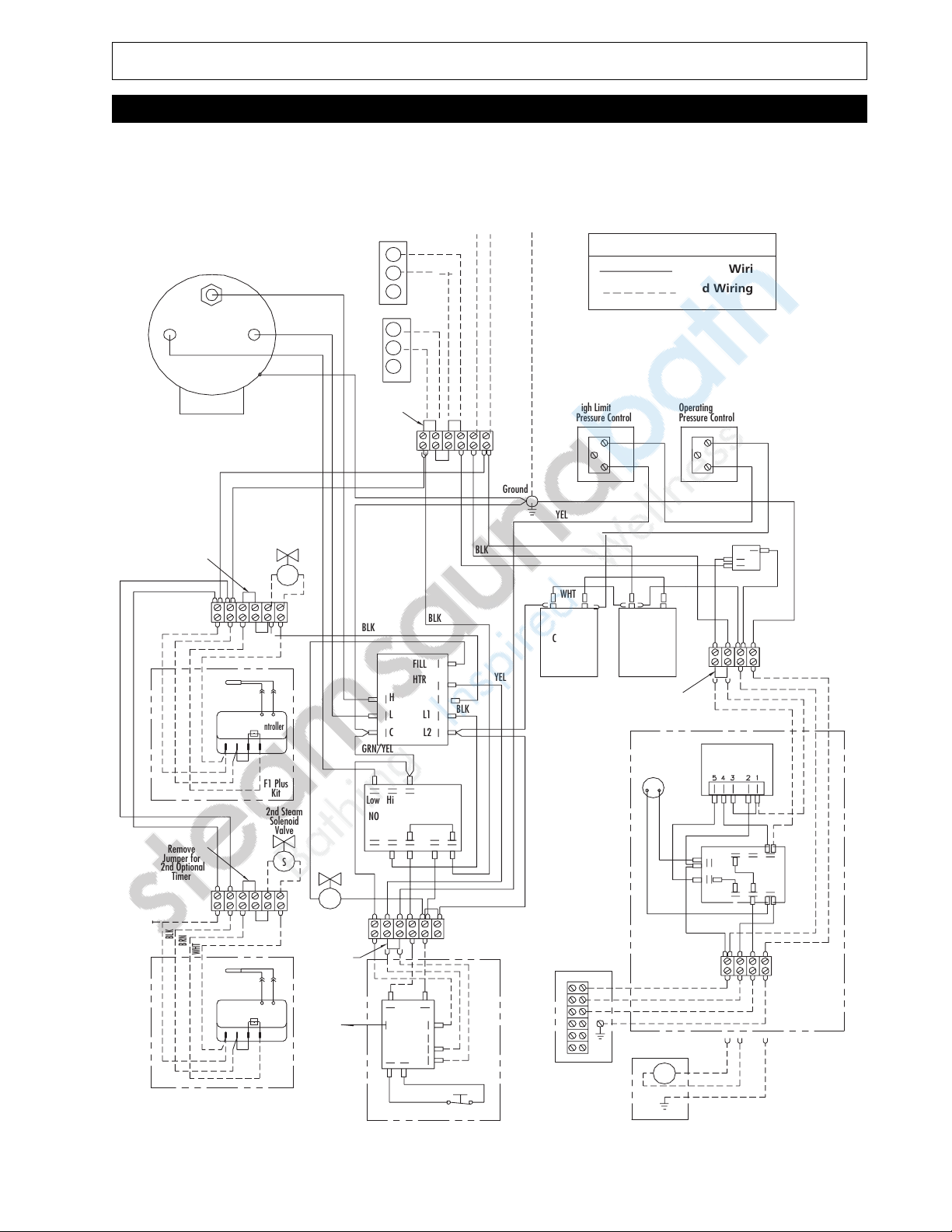

F1 Plus Temperature Control System and optional automatic blowdown assembly

For Models: CU-1000AB3, CU-1000AC3, CU-1250AB3, CU-1250AC3, CU-1400AB3, CU-1400AC3

120VAC Input

L N GND

LEGEND

Factory Wiring

Field Wiring

High Limit Operating

Pressure Control Pressure Control

High Probe

6" PUR

Rod

Low

9" Probe RED

Rod

High No Rod

Water

Probe

GRN/YEL

Top of Pressure Vessel

PINK

2nd CU-HL

R

B

W

CU-HL

R

B

W

Remove Jumper

for CU-HL

WHT

BLK

Steam

Solenoid

WHT

WHT

F1 Plus

Valve

S

BLK

BLK

FILL

HTR

H

L L1

C L2

GRN/YEL

Low High Com

NO NC COM Input

S

WHT

YEL

YEL

GRN

BLK

L1 L2

LLCO G

Side

NC

COM

Reset

Manual Reset

Auxiliary Low Water Cutoff (optional)

NO

Remove

Jumper for

Optional Timer

BLK

WHT

WHT

BLK

BRN

Sensor

Temperature Controller

F1 Plus

Kit

2nd Steam

Solenoid

Valve

Remove

Jumper for

2nd Optional

Timer

S

Water Feed

Solenoid Valve

WHT

BLK

BRN

Remove

Jumper for

AUX LWCO

Sensor

F1 Plus

Temperature Controller

Probe

2nd F1

Plus Kit

WHT

Ground

YEL YEL

ON/OFF Switch

BLK

BLK

YEL

WHT WHT

WHT

GRN/YEL

Contactor Contactor

GRN/YEL

YEL

WHT

Remove BR BLK

Jumper for

BLK

AutoFlush

WHT

Timer

Pilot Light

RED

BLK

PUR

BLU

Motorized

Blowdown

Valve (CU81600)

WHT

BLU

RED

GRN/YEL (optional)

S

BLU

Blowdown GRN/YEL

Valve

(CU81500)

BR

RED

WHT

Automatic

Blowdownc

Page 11

MrSteam CU Series

Installation, Operating & Maintenance Manual

Control Circuit Wiring Diagram

11

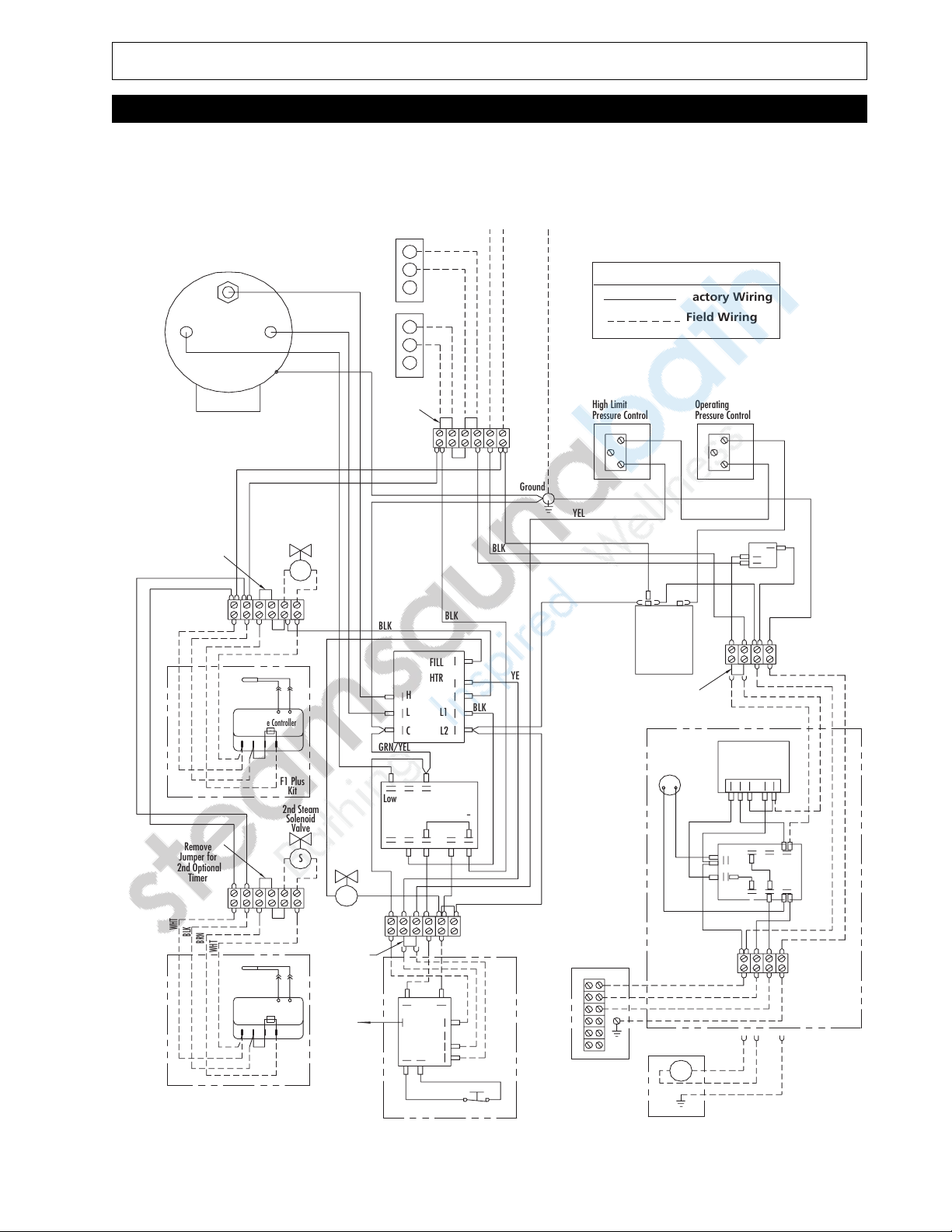

F1 Plus Temperature Control System and optional automatic blowdown assembly

For Models: CU-360A TO CU-750A, CU-1000AF3, CU-1250AF3, CU-1400AF3

120VAC Input

L N GND

LEGEND

Factory Wiring

Field Wiring

High Limit Operating

Pressure Control Pressure Control

High Probe

6" PUR

Rod

Low

9" Probe RED

Rod

High No Rod

Water

Probe

GRN/YEL

Top of Pressure Vessel

PINK

2nd CU-HL

R

B

W

CU-HL

R

B

W

Remove Jumper

for CU-HL

WHT

BLK

Steam

Solenoid

WHT

WHT

Valve

S

F1 Plus

BLK

BLK

FILL

HTR

H

L L1

C L2

GRN/YEL

Low High Com

NO NC COM Input

S

WHT

YEL

YEL

GRN

BLK

L1 L2

LLCO G

NC

COM

Reset

Manual Reset

Auxiliary Low Water Cutoff (optional)

NO

Remove

Jumper for

Optional Timer

BLK

WHT

WHT

BLK

BRN

Sensor

Temperature Controller

F1 Plus

Kit

2nd Steam

Solenoid

Valve

Remove

Jumper for

2nd Optional

Timer

S

Water Feed

Solenoid Valve

WHT

BLK

BRN

Remove

Jumper for

AUX LWCO

Sensor

F1 Plus

Temperature Controller

Side

Probe

2nd F1

Plus Kit

WHT

Ground

YEL YEL

ON/OFF Switch

BLK

BLK

WHT WHT

GRN/YEL

Contactor

GRN/YEL

YEL

WHT

Remove BR

Jumper for

BLK

AutoFlush

WHT

Timer

Pilot Light

RED

BLK

PUR

BLU

Motorized

Blowdown

Valve (CU81600)

WHT

BLU

RED

GRN/YEL (optional)

S

BLU

Blowdown

Valve

(CU81500)

BR

BLK

5 4 3 2 1

RED

WHT

GRN/YEL

Automatic

Blowdownc

Page 12

MrSteam CU Series

Installation, Operating & Maintenance Manual

Control Circuit Wiring Diagram

12

IMPORTANT:

1.

F1 Plus sensors are intended to be field installed within the steam room at the location selected by the designer/architect.

2.

Autoflush System 24 hr. timer and F1 Plus operating settings are at the discretion of the owner/operator.

IMPORTANT:

Owners/operators should obtain a copy and familiarize themselves with the latest edition of the

Models CU-2000 and higher with

F1 Plus Temperature Control System and

Optional Automatic Blowdown Assembly

Control Supply

120 Volts 1PH 60Hz

L N GND

2nd

CU-HL

CU-HL

Remove Jumper

for CU-HL

Ground

Control Terminal Block

1 2

R

5

3 4

103805

24-hr. Timer

8 1

T

5

7 6

4 2

99353

Delay Timer

ON/OFF Switch

with Pilort Light

LEGEND

F1 Plus Control Package

Sensor

Part No. 103731-1

2

Open

1

Close

3

103661

Blowdown Valve

120V F1 Plus

Electronic Temperature Controller

PN 103730

Red Black Orange

Optional CU 81600

AutoFlush System

Factory Wiring

Field Wiring

Steam Solenoid

Valve CU-99285A

Optional

Timer

Location

Terminal

Block

White Black

N

L

120 VAC Input

Side Probe

Water Feed

Solenoid Valve

P P

High Limit

Pressure Control

Operating

Pressure Control

S

C1

C2

Contactor

Typical F1 Plus

Page 13

MrSteam CU Steambath Generator can be used for one or two steam rooms.

Each room requires one F1 Plus Kit sized for the room.

F1 Plus Kit consists of:

• F1 Plus Control and Sensor

• CU-HL Room High Temperature Limit Control

• One or more Steam Solenoid Valves

• Acrylic Shield, one for each steamhead

MrSteam CU Series

Installation, Operating & Maintenance Manual

F1 Plus Kit Contents

13

F1 Plus Control (Front) F1 Plus Sensor CU-HL Hi Limit Control Acrylic Shield

110

112

108

106

104

102

100F

114

116

118

120

F1 Plus Control

(Back) Steam Solenoid Valve F1 Plus Sensor Cover Steam Head

CU-HL Sensor Cover

Page 14

MrSteam CU Series

Installation, Operating & Maintenance Manual

14

F1 Plus Control Installation

Hazard of Electric Shock. Disconnect all power supplies before making wiring connections.

NOTE:

Reference applicable wiring diagram.

1.

Remove 4" diameter blank cover located steam generator. Mount the F1 Plus faceplate on the back of the generator

cabinet with provided screws and nuts. For one room installation use the upper blank.

2.

Connect the control wires to the bottom of the terminal above the control. The terminals are coded with the wire

insulation color: White-Blank-Brown-skip-skip-White.

3.

Refer to applicable schematic for proper wire connections.

Control Panel Showing Control Panel Showing

One F1 Plus Control Two F1 Plus Controls

!

WARNING

Single Control Installation

ROOM TIMER STEAM SOLENOID

WHT

ROOM TIMER STEAM SOLENOID

VALVE

WHT

VALVE

F1 PLUS

F1 Plus Control

F1 PLUS

WHTBRNBLK

WHTBRNBLK

Terminal

Block

Double Control Installation

ROOM TIMER STEAM SOLENOID

WHT

ROOM TIMER STEAM SOLENOID

WHT

F1 PLUS

F1 PLUS

VALVE

WHTBRNBLK

VALVE

WHTBRNBLK

Blank

Page 15

MrSteam CU Series

Installation, Operating & Maintenance Manual

15

F1 Plus Operating Temperature Sensor Installation

• Locate sensor on a wall inside the steam room five (5) feet above the floor.

• Route sensor cable directly to F1 Plus Control.

• Do not splice the sensor cable.

• Do not route sensor cable inside conduit.

• Do not route sensor cable with power wiring, next to electric motors or any other location subject to electrical noise.

• Seal cable entrance to steam room with silicone.

• Protect sensor with bulb guard provided.

F1 Plus High Limit Operating Temperature Sensor Installation

Sensor Cable

3/8" hole

Silicone Sealant

(4) Mounting Screws

Bulb Guard

Sensor

Route Sensor Cable

directly to F1 Plus Control

Locate approximately

5 feet above

steam room floor

Locate approximately

5 feet above

steam room floor

Sensor Cable

Silicone Sealant

Sensor

Bulb Guard

(4) Mounting Screws

Page 16

MrSteam CU Series

Installation, Operating & Maintenance Manual

16

CU-HL Installation

NOTE: Reference applicable wiring diagram.

1.

Model CU-HL room temperature control unit must be installed outside the steam room. Consider the length of

capillary (20 ft) before mounting.

2

. Sensing bulb must be installed inside the steam room five (5) feet above the floor on a wall. It is recommended that

it not be located directly by above the steamhead.

3.

Remove screw above the dial and remove cover.

4.

Mount housing using mounting holes at the back of the control. Locate CU-HL where it is accessible to authorized

personnel only it is not to be accessible to the general public.

To Avoid Electric Shock. Do not install control unit inside steam room

or in any wet or damp location.

5.

Install sensing bulb INSIDE steam room five (5) feet above the floor on a wall. Avoid sharp bends or kinks in

capillary tubing. This could affect the controller’s performance and may result in unsafe operation. Excess capillary

should be very carefully coiled and placed beneath the control unit.

6

. Secure sensing bulb to the wall with the sensor bulb guard provided.

Hazard of Electric Shock. Disconnect all power supplies before

making wiring connections.

7.

Connect wiring to CU steambath generator. See applicable wiring diagram. Remove jumper next to 120v control

supply input of CU generator. Using AWG #14 or larger wire, connect terminals R and B of controller to the

terminals vacated by the jumper. Also connect ground wire from controller ground terminal to CU ground

terminal. Note: All factory ground wiring is color coded using green/yellow insulation:

8.

Set differential dial to maximum,“12”.

9.

Reassemble cover and screw.

10.

Set the thermostat knob of Model CU-HL to max 130°F or at the maximum temperature permitted by

jurisdiction.

!

WARNING

!

WARNING

Page 17

CU 81500 Kit for Soft Water Installations

• F1 Plus Control Panel

• Motorized Drain Valve Assembly #CU-81500

CU 81600 Kit for Hard Water Installations

• F1 Plus Control Panel

• Motorized Drain Valve Assembly #CU-81600

MrSteam CU Series

Installation, Operating & Maintenance Manual

17

Automatic Blowdown System Kit Contents

Front Back

CU-81500

Motorized Drain Valve

Front Back

CU-81600

Motorized Drain Valve

Page 18

MrSteam CU Series

Installation, Operating & Maintenance Manual

18

Hazard of Electric Shock. Disconnect all power supplies before

making wiring connections.

Note: Reference applicable wiring diagram.

1.

Remove blank cover and mount the Automatic Blowdown Control Panel on the front of the generator cabinet

with screws and nuts provided.

2.

Remove the jumper between Brown and Black from the terminal block above the panel.

3.

Connect the wires to the terminal block.

The terminals are coded with the wire insulation color: Brown-Black-White-Green.

4.

Plumb the motorized valve assembly to the generator drain valve.

5.

Install the valve cable in the knockout below the Automatic Blowdown Control Panel.

6.

Connect the wires to the terminal block at the bottom of the panel.

The terminals are coded with the wire insulation color.

CU81500:White-Blue-none-Green. CU81600:White-Blue-Red-Green

7.

Program the timer and set the clock (See page 25)

Automatic Blowdown System Kit Installation

!

WARNING

Terminal Block

in Steam Generator

Panel Interior

GRNWHTBRNBLK

CU AUTOFLUSH

GRNWHTBRNBLK

CU AUTOFLUSH

CU-81500

Motorized Drain Valve

CU-81600

Motorized Drain

Valve Assmbly

F1 Plus

Control Panel

Page 19

MrSteam CU Series

Installation, Operating & Maintenance Manual

Auxiliary Manual Reset Low Water Cutoff

19

Hazard of Electric Shock. Disconnect all power supplies before making

wiring connections.

NOTE: Reference applicable wiring diagram.

1.

Install the auxiliary low water cutoff pc board below the AUX LWCO terminal block inside the control panel

using screws provided.

2.

Remove jumper between Yellow and Yellow from terminal block.

3.

Connect the pc board wires to the terminal block. The terminals are coded with the wire insulation color:

Green-Yellow-Yellow-Black-White-none.

4.

Install manual reset button and connect wires to RESET terminals on pc board.

5.

Locate and punch out knockout on middle and back of generator.

6.

Remove 3/8” npt plug and install side probe.

7.

Install electrical junction box over the probe, connect probe wire and close junction box.

8.

Install other end of the probe cable in the knockout adjacent to Aux Lwco pc board.

9.

Connect probe wire to LLCO terminal on Aux Lwco pc board.

!

WARNING

Page 20

MrSteam CU Series

Installation, Operating & Maintenance Manual

20

MR STEAM CU Steambath Generators require two sources of electrical supply – power voltage and control voltage. Power

voltage is usually 208, 240, or 480 volt, single or three phase. Control voltage for generator suitable for operation with

these voltages is 120V, 1PH.

IMPORTANT:

See the generator nameplate for specific electrical supply requirements for your steam generator. A lighted ON/OFF switch activates the control circuit. MR STEAM CU Generators are equipped with automatic liquid level/low

water cut-off control. CU360 – CU1400 are equipped with a dual probe type electronic control. CU2000-CU4500 are

equipped with float type MM150 control (Refer to wiring diagrams.) When there is no water in the generator, the contactor is "OFF" and the water feed solenoid valve is "ON". The unit will start filling with water.When the water level has

reached approximately halfway up the gauge glass, the contactor(s) will be energized and, in turn, energize the heating element(s).The water solenoid will continue to feed water for a short time and then de-energize. Steam will be available within a few minutes.

The generator has an electronic high water level cut-off control. If water level rises near the top of the pressure vessel, the

contactor(s) and the water feed solenoid valve will de-energize to “OFF”.

When steam pressure reaches the operating pressure control setting, the pressure control will de-energize the

contactor(s). Operating pressure control is factory set at 5 psig.

IMPORTANT:

It is recommended that the steam generator not be operated higher than 5 PSIG.

Steam supply to the steambath is controlled by the F1 Plus Temperature Control System and the steam solenoid valve(s).

As the room temperature selected by the owner/operator decreases below the set point, the F1 Plus Control will energize

the steam solenoid valve(s) and allow steam to enter the steam room. Once the set temperature on the control is reached

at the sensor, the control will de-energize the steam valve, closing the valve and stopping the flow of steam into the steam

room.

The F1 Plus Kit is provided with CU-HL High Limit Room Temperature Controller. CU-HL monitors the room temperature inside the commercial steambath. If the room temperature exceeds the set point, Model CU-HL shuts off the power

to the CU Steambath Generator, shutting steam off. CU-HL can also send a signal to an audible alarm (provided by others).

The pressure in the generator will decrease slightly as steam leaves the generator and enters the steam room.The pressure

control will energize and de-energize the contactor(s), maintaining the set pressure. As the water level in the generator

decreases, the liquid level control will energize the water solenoid valve on and off and maintain proper water level.

IMPORTANT:

Owners/operators should obtain a copy and familiarize themselves with the latest edition of the American

College Sports Medicine Health/Fitness Faculty Standards and Guidelines, or a similar resource and reference publication,

and refer to those guidelines for the proper and safe operation of a spa facility including steamrooms.

The owner/operator has the responsibility to select a room operating temperature meeting guideline requirements for

steamrooms.

Important Optional Equipment

1.

Optional Automatic Blowdown Systems (CU81500, CU81600) have a 24-hour, 7-day timer that turns the steambath

generator ON and OFF. At the end of the "ON" cycle, the boiler is automatically blown down, discharging daily accumulation of minerals and salts which if not drained may affect steam generator performance and operation.

IMPORTANT NOTES:

a.

Automatic Blowdown System CU 81500 is intended for installation with soft water conditions.

b.

Automatic Blowdown System CU 81600 is intended for installations with hard water conditions and/or usage

exceeding 8 hours per day.

2.

An optional control circuit transformer provides control circuit voltage from the power supply voltage.

This option is in lieu of the need for a separate control circuit.

3.

An optional Auxiliary Manual Reset Low Water Cutoff serves as a back up to the standard liquid level control as

required in some jurisdictions.

Principles of Operation

Page 21

MrSteam CU Series

Installation, Operating & Maintenance Manual

Automatic Blowdown Operation and Testing

21

Burn Hazard. Pressurized Steam and Hot Water is discharged during blowdown.

1.

Turn the override switch to permanent ON (I).

2.

Turn the generator On/Off Switch to “ON”. On/Off Switch pilot light and generator should be “ON”. Motorized

drain valve should be closed. Autoblowdown light should be “OFF”.

3.

Turn the override switch to permanent OFF (0). On/Off Switch pilot light and generator should be “OFF”.

Autoblowdown light should be “ON” Motorized drain valve remains open for approximately 10 seconds.

4.

After10 seconds: Motorized drain valve closes. Autoblowdown light should be “OFF”. On/Off Switch pilot light and

generator remains “OFF”.

5.

Turn the override switch to automatic ( ).

1.

1. Set the F1 Plus thermostat knob to 100°F. Turn “ON” the CU steam generator.

2.

CU generator will heat up and produce steam in a few minutes then stop when steamroom temperature reaches

100˚F.

3

. Slowly turn the F1 Plus thermostat knob higher. The steam solenoid valve should open and allow steam to fill the

steamroom again.

4.

Turn the thermostat knob lower. Steam should stop.

5.

Set the F1 Plus thermostat to 100˚F or desired setting.

1.

Set the thermostat knob of CU-HL to max 130°F or to the temperature permitted by jurisdiction. Turn on the CU

steam generator.

2.

Slowly turn the thermostat knob of CU-HL lower. The CU steam generator should shut off at about the current

room temperature.

3.

Turn the thermostat knob of CU-HL back to max 130°F or to the temperature permitted by jurisdiction.

The CU steam generator should turn back on.

NOTE: The operating room temperature setting is determined by the owner/operator of

the facility. For guidance, refer to ASCM guidelines or equal reference.

!

WARNING

F1 Plus Control Operation Testing

CU-HL Operation and Testing

Page 22

MrSteam CU Series

Installation, Operating & Maintenance Manual

22

Pre-Operation Check

Low water Cutoff (LWCO) and Feed Control Operation and Testing

1. All valves for incoming water supply are to be fully opened. Main disconnect switch to be in "ON" position.

Generator switch to be in "ON" position. Since generator will be empty, water solenoid will be energized allowing

the generator to fill with water until proper level is reached.Then the contactors will energize and supply voltage to

heating elements.

2.

Water level control operation: At this point the water should be visible approximately half way up the sight

glass. Slowly open the drain valve located at bottom of the generator.The water level will fall allowing the low water

cutoff/water level control to energize the feed water system. Close the drain valve for proper operation.

3.

Low water cut-out switch performance.

Close water feed valve. Open the drain valve completely. Maintain this

condition until the water level falls within the gauge glass enough to cause the low water cutout switch to de-energize

the heating elements.All contactors will be in the de-energized state at this time. Close the drain valve. For automatic

re-setting type low water cutoff switches, feed system will return the water level to normal. For manual re-set the reset

button must be depressed to complete circuit.The generator is now qualified for proper low water cutout and normal

liquid-level operating conditions.

NOTE:

For automatic blowdown, turn timer off and on until water level is low enough to de-energize heaters.

Pressure Controls Operation and Testing

Steambath generators are provided with one hi-limit pressure control and at least one operating pressure control.

1.

All pressure controls are equipped with a screw allowing for setting of the desired operational and hi-limit

pressures.

2.

It is recommended that the hi-limit control be set at 8–10 psig maximum and the operating pressure control(s) shall

not be set above 5 psig.

Note:

Models CU360 - CU3000 are provided with one (1) automatic reset operating pressure control and one (1)

manual reset high limit pressure control. Models CU 4500 is provided with two (2) automatic reset operating

pressure controls and one (1) manual reset high limit pressure control.

3.

Pressure control operation check: Manually close the steam outlet valve. Switch the generator on to allow for

steam pressure build-up. Pressure gauge reading will build and the operating pressure control will shut off the generator at the pressure setting . Re-setting the operating pressure control is accomplished by manually bleeding off

pressure through the steam outlet valve and allowing the pressure to drop below the desired set point.

Warning Sign

The CU Steambath generator is provided

with a WARNING sign. This WARNING is

to be secured to the outside of the steam

room, on the steam room door or

adjacent to that door. It's location must be

such that all steam bathers are readily

made aware of the important information

contained in the sign.

Attention Guests:

1. Children under the age of 16 should not use the

Steamroom.

2. People who are pregnant, have heart disease, have a

coronary condition, have elevated blood pressure, are

in poor health, are being treated for any other medical

condition, or are using medication or drugs should not

use the steambath unless authorized by their physician.

3. Exit Steamroom immediately if you feel faint, dizzy,

sleepy, or otherwise uncomfortable.

4. Do not use the Steamroom if you have recently consumed alcohol.

5. Condensation and moisture may cause the Steamroom

floor and other surfaces to become slippery and dangerous. Use of proper footwear is recommended at all

times.

MrSteam

A Division of Sussman-Automatic Corporation

43-20 34th Street, Long Island City, NY 11101 • 1-800 767-8326

WARNING

!

Page 23

MrSteam CU Series

Installation, Operating & Maintenance Manual

23

Operation

With all power disconnected at main switch, insure all electrical and

mechanical connections are tight before energizing unit to prevent electrical

problems and mechanical leaks.

1.

Turn on water and electrical supply, power and control voltage suppliers.Turn unit switch to ON position; Switch light

will go ON and water level will reach operating level automatically.

2.

When proper operating level is reached (approximately half way up the gauge glass), the heating element(s) will be

energized. In approximately 20 minutes, steam will begin to be produced.

3.

Adjust the F1 Plus operating temperature control to the desired steam room setting at the sensor

(range 100°F – 120° F). Operating temperature is at the discretion of the owner/operator.

For user comfort, the F1 Plus operating control is provided with an adjustable

temperature range. The F1 Plus control will cycle automatically to maintain

the room operating temperature selected by the owner/operator at the sensor at the set

point temperature.

4.

If not supplied with an automatic blowdown system, the generator must be blown manually down daily. An optional

automatic blowdown assembly is recommended for daily maintenance. The steambath generator should be blown

down manually in accordance with manual blowdown instructions below. See below.

Blowdown is an essential part of operation. It is an excellent preventative maintenance procedure and will prolong steambath generator operation. Insure the following recommended blowdown schedule is established and followed daily:

1.

If blowdown is conducted manually, at the end of each working day while unit is still operating,

turn ON/OFF s

witch to the "OFF" position and close water supply valve. De-energize wall-mounted safety switch.

Open blowdown valve(s) SLOWLY.

IMPORTANT:

Pressure may still be in the generator.

2.

Discharge is complete when gauge glass shows no water. Unit has been effectively drained. Follow this

procedure:

a. Fully close the blowdown valve

b. Fully open water supply

c. Put ON/OFF switch in the "ON" position

d. Close wall-mounted safety switch

3.

When re-filling is complete (water feed solenoid valve de-energizes and water is visible to half-way level in gauge

glass), turn off generator unless further operation is required.

4.

If you have been supplied with a manual reset low water control, as required by some states, the reset button on the

control must be reset before unit will begin developing pressure. Do not push r

eset until unit has filled with water.

5.

More frequent blowdowns may be required in area with hard water or excessive usage. Please consult with factory.

Automatic Blowdown Systems drain the steambath generator every 24 hours (or more often if required or desired). It

also turns the generator "ON" and "OFF". Blowdown occurs after the timer turns the generator off. The blowdown pilot

light is energized during blowdown.To set the timer, refer to instructions on inside of element access door.

Use of chemical cleaning compounds voids warranty.

To provide for safe and low temperature blowdown, and to comply with

National and local plumbing and building Codes, it may be necessary to blowdown into an ASME Code blowdown separator tank, or to take other precautions to prevent

damage to building drain plumbing. Consult with a licensed plumber.

Automatic Blowdown Instructions

Manual Blowdown Instructions

!

CAUTION

!

CAUTION

!

CAUTION

!

CAUTION

Page 24

MrSteam CU Series

Installation, Operating & Maintenance Manual

24

Maintenance Instructions

To establish a good preventive maintenance program, we suggest that the site equipment foreman, engineer or

owner/operator familiarize themselves with these guidelines:

1. Daily blowdown

at max 5 PSIG operating pressure is recommended for best steambath generator

performance. In order to safeguard the heating element(s) within the steambath generator, the main wall

switch and the steambath generator switch shall both be placed in the OFF position

prior to blo

wing down

the generator. Blowdown instruction should then be followed as outlined in this manual. Do not use chemical

cleaning compounds in the steambath generator since the chemical agents may damage some of the generator

components.A daily blowdown will assist in prolonging product operation.

2.

Only after electric pow

er supplies have been disconnected at main disconnect switch,

a

monthly

inspection

should be made of all wiring. All electrical connections should be checked for tightness. A check

for steam and/or water leaks should be made and any loose fittings must be tightened immediately. Check heating

element flange bolts for tightness. Specific torque in 22 Ft. lbs. cold.

3. In hard water areas

, generators equipped with the McDonnell-Miller control (Models CU-2000 and

larger), should be checked for proper operation every four months or sooner. At the same time, a bottom

heating element should be removed and inspected. If scale has begun to form, all elements should be cleaned and

re-installed, using only new gaskets and bolts. The pressure control should also be removed to insure that the

bellows has not become clogged. (See trouble-shooting guide for instructions.) Check valves should be inspected

for leakage and proper operation.

4.

Generators equipped with level probes (Models CU 2000 - CU 1400) for maintaining operating water level and

probe for auxiliary low water cut-off protection need special consideration. In hard water areas, the probe

should be checked for chemical deposits and cleaned if necessary. This should be done every four months or

sooner. See the trouble-shooting manual for instructions.

Under an

y circumstances, only qualified service personnel should attempt the above

procedures. Always insure all electrical power supplies are disconnected at the main disconnect

switches to prevent electric shock. Always insure that pressure within steam generator is 0 PSIG (zero pressure)

whenever plumbing connections, including any factory-plumbed components, are being disconnected.

!

CAUTION

Page 25

MrSteam CU Series

Installation, Operating & Maintenance Manual

25

24-Hour and 7-day Time Switches

PROGRAMMING

For CU steam bath generators equipped with Automatic Blowdown Systems

CU 81500 and CU 81600, refer to the following instructions for time clock

operation and settings. Timer settings f

or blowdown operation are at the

discretion of the owner/operator

.

The weekly program dial shows the seven days of the week and AM/PM

imprints for each day.

The time switch is set by pushing the captive trippers to the outer ring position

for the entire period that the load is to be turned ON, i.e., 2 hours to each

tripper on the 7-day dial.When the tripper is pushed to the inside, the switch

is in the OFF position.

SETTING TIME

To set the current time and day of week, turn the minute hand clockwise. Do not set the

time by rotating “Outer” Dial.

Turn the minute hand clockwise until the day of the week and the time of day on the outer dial is aligned with the

triangle marker on the inner dial (two o'clock).

Example for 7-day program dial Monday 10:30 AM.Turn the minute hand clockwise until Monday 10:30 AM is

aligned with the triangle on the inner dial.The hour and minute hand will show exactly 10:30.

FOR MANUAL OVERRIDE

Manual override can be accomplished at the discretion of the owner/operator as follows.

3-WAY MANUAL OVERRIDE SWITCH

I= permanent ON

I

= automatic

O= permanent OFF

O

IMPORTANT:

It is recommended that for periodic and effective blowdown,

the override switch be set in the automatic setting.

Page 26

MrSteam CU Series

Installation, Operating & Maintenance Manual

Water Gauge & Gauge Glass Installation

26

IMPORTANT:

Only properly trained personnel should

install and maintain water gauge glass and connections.

Pressure in generator must be at zero before proceeding.

Remember to wear safety gloves and glasses during installation. Before installing, make sure all parts are free of chips

and debris.

1.

Apply Teflon tape or pipe dope to pipe threads. Install

top gauge fitting (fitting without a drain valve) into the

uppermost tapping. Wrench tighten the fitting until it is

snug and the glass outlet is pointing at five o'clock (about

1/8 turn from its final downward vertical position).

2. Install the bottom gauge fitting (the fitting with a drain

valve) until it is snug and the glass outlet is pointing directly

upward. Verify top and bottom fittings are threaded into

the tappings the same number of turns (distance A= distance B).

3. Remove glass packing nut, friction washer (or packing

gland, depending upon the model), and glass packing from

the fittings, and place them, in the same order, on to both

ends of the gauge glass. Push both packings about an inch

up the gauge glass.

4. Gently insert one end of the glass into the top gauge

fitting. Keeping the glass inside the top fitting, gently rotate

the top gauge fitting clockwise until vertically aligned with

the bottom gauge, then insert glass into bottom fitting until

glass bottoms out on the shoulder inside the bottom fitting.

5. Carefully raise glass about 1/1611 and slide lower glass

packing down until the glass packing contacts the lower

gauge fitting. DO NOT allow the glass to remain in contact

with any metal!

6. Carefully slide upper glass packing up as far as possible.

7. Hand tighten both glass packing nuts, then tighten

1/2 turn more by wrench.Tighten only enough to prevent

leakage. DO NOT OVER TIGHTEN! If any leakage should

occur, tighten slightly, a quarter turn at a time, checking

for leakage after each turn.

IMPORTANT:

Read all warnings and instructions before performing installation or maintenance.

Safety glasses and gloves should be worn at all times when working with

or examining water gauge glass and connections.

Pressure in generator to be at zero before proceeding.

Improper installation or maintenance of gauge glass and connections can cause immediate or delayed

breakage resulting in bodily injury and/or property damage.

!

WARNING

Top Gauge

Fitting

Guard Rail

Friction Washer

(or Packing Gland)

Bottom

Gauge

Fitting

Drain Valve

Vessel Wall

Gauge Glass

Glass Packing

Nut

Glass Packing

A

B

Page 27

MrSteam CU Series

Installation, Operating & Maintenance Manual

Use and Care

27

DO NOTs

DO NOT use glass if it contains any scratches, chips, or any other visible signs of damage.

DO NOT reuse any tubular glass or glass packings.

DO NOT subject gauge glass to bending or torsional stresses.

DO NOT over tighten glass packing nuts.

DO NOT allow glass to touch any metal parts.

DO NOT exceed the recommended pressure of the gauge or gauge glass.

DO NOT clean the gauge or gauge glass while pressurized or in operation.

DO's

DO verify proper gauge has been supplied.

DO examine gauge glass and packings carefully for damage before installation.

DO install protective guards and utilize automatic ball checks where necessary to help prevent

injury in case of glass breakage.

DO inspect the gauge glass daily, keep maintenance records, and conduct routine replacements.

DO protect glass from sudden changes in temperatures such as drafts, water spray, etc.

MAINTENANCE

Examine the gauge regularly for any signs of clouding, scratching, erosion, or corrosion.

The glass should be inspected daily until the need for replacement becomes apparent.

This will help establish the routine inspection and routine replacement schedules.

CLEANING

Use commercial non-abrasive glass cleaners to keep glass clean.

Use diluted acids such as Hydrochloric (muriatic) acid when regular cleaners do not seem to work.

Do not use wire brushes or any other abrasive materials which could scratch the glass.

INSPECTION

Examine the surface of the glass for scratches, corrosion, chips, cracks, surface flaws, or nicks.

To do this, shine a very bright concentrated light at an angle of about 45 degrees.

A defective glass will glisten as the light strikes imperfections.

Glass which appears cloudy or roughened, and will not respond to cleaning, should be replaced.

STORING

Keeping gauge glass in original packaging until ready to install.

Page 28

MrSteam CU Series

Installation, Operating & Maintenance Manual

28

To prevent risk of electric shock, trouble shooting

should be done only by a qualified licensed electrician

_______________________________________

Problem Probable Cause Suggested Remedy

_______________________________________

No water in generator Water supply is "OFF" Turn on water supply

_______________________________________________________

Clogged strainer Clean or replace strainer screen

_______________________________________________________

Control voltage disconnected Restore control voltage

_______________________________________________________

Defective ON/OFF control switch Check/replace control switch

_______________________________________________________

Defective water solenoid valve Check/replace water solenoid valve

_______________________________________________________

Defective PC Board Check/replace PC Board

_______________________________________________________

Water feed probe not functioning Check/replace water feed probe

(Models 360-1400)

and probe isolator

Add MM150

(Models CU2000 and higher)

_______________________________________

Generator does Power supply disconnected Restore power supply

not heat

_______________________________________________________

No water in generator See above

_______________________________________________________

Defective contactor Check/replace contactor

_______________________________________________________

Defective pressure control Check/replace control switch

_______________________________________________________

Defective PC Board Check/replace PC Board

____________________________________________________

LWCO not functioning Check/replace LWCO probe

_______________________________________________________

Defective heating element Check/replace heating element

_______________________________________________________

Hi-Limit pressure control tripped Clean out syphon tube

& reset pressure control

_______________________________________

Generator floods Water feed solenoid Reverse solenoid connection

installed backwards "A" towards generator

_______________________________________________________

Defective water solenoid valve Check/replace water solenoid valve

_______________________________________________________

Defective PC Board Check/replace board

_______________________________________________________

Water feed probe

(Models 360-1400)

Check/replace water feed probe

not functioning

_______________________________________________________

MM 150

(Models CU 2000 and higher)

Clean out pipes under MM 150

is clogged

_______________________________

Trouble Shooting

!

CAUTION

Page 29

MrSteam CU Series

Installation, Operating & Maintenance Manual

Check

29

PC Board - Models CU 360, CU 500, CU 750, CU 1000, CU 1400

1.

Turn the control voltage "ON" and measure the voltage across "L1" and "L2".The voltage should be approximately

110 VAC.

2.

On the water feed control, disconnect the wire from the "H" terminal and check the voltage across "L2" and

"FILL".The voltage should be approximately 110 volts (same as "L1" and "L2"). Connect a jumper between the "H"

and "C" terminals.The voltage between "L2" and "FILL" should be zero.

3.

On the LWCO (heat control), disconnect the wire from the "L" terminal.There should be no voltage between the

"L2" and "HTR" terminals. Connect the jumper between the "L" and "C" terminals.The voltage between "L2" and

"HTR" should be 110V.

_____________________________________________

Checking Low Water Cutout, Water Feed and High Water Cutout Probes

Models CU-360 through CU-1400 are equipped with two probes for low water cut-off (LWCO) and water feed

control. Failure to clean the probes may result in generator not operating, overflow or element failure.

Turn off all power supplies to steam bath generator and

release pressure to zero (0 psig) before removing probes.

1.

Probes are located in the top of the generator. Remove covers and disconnect wires from probes.

Note wire connections.

2.

Remove probes using a standard spark plug wrench. Care should be taken not to damage the porcelain insulation.

3.

Check probes for deposits. Use emery paper to clean probes.

4.

Remove and flush probe isolator (thoroughly) with water. If clogged, use a long piece of wire to remove

obstruction. Replace if necessary, center probe rod in isolator tube.

5.

Use teflon tape on probe threads and reinstall.

6.

After installation, make sure probe is not touching ground.With generator drained and probe wires

disconnected, there should be no resistance (X) between probe and ground. Check for leaks.

_____________________________________________

Steam Solenoid Valve

1.

Check voltage rating of solenoid valve (120 VAC for United States, Canada, Mexico; may be 220-240 VAC for other

countries).

2.

Check voltage across solenoid coil.

a. If there is voltage across coil and valve does not allow passage of steam, check for clogged valve. Clean out

line with bottle brush. If solenoid valve is still malfunctioning, the valve is defective and should be replaced.

b. If there is no voltage across coil, check room temperature control.

_____________________________________________

F1 Plus Control

1.

Check voltage rating of solenoid valve (120 VAC for United States, Canada, Mexico; may be 220-240 VAC for

other countries).

2

. Check voltage across solenoid coil.

a.

If there is voltage across coil and valve does not allow passage of steam, check for clogged valve. Clean out

line with bottle brush. If solenoid valve is still malfunctioning, the valve is defective and should be replaced.

b.

If there is no voltage across coil, check room temperature control.

_____________________________________________

Heating Element

1.

Check power voltage across heating element terminals. Refer to nameplate data for voltage rating.

Voltage should be as marked on nameplate.

2.

Using an ammeter, measure total current draw as per nameplate rating. (See also Amperage Chart, page 7)

Each leg should register about the same current reading.

3.

If there is more than one heating element, check amperes of each element. Each leg of the same element should

register about the same reading for that element. Reading may be different from other elements due to KW

(Kilowatt) rating of individual heating element.

!

CAUTION

Page 30

MrSteam CU Series

Installation, Operating & Maintenance Manual

Instructions for Element Replacement

30

Before installing your new element(s), be sure the low-water cut-off is operating

properly and the float chamber and water equalizer pipe are completely clear of sludge

or other foreign matter. If unit is probe equipped, check the condition for the probes.

Failure to do this may cause the immediate burn-out of the new element(s). All elements are thoroughly

checked before they are shipped. The manufacturer cannot be responsible for burn-outs caused by faulty or

plugged low-water cut-offs.

IMPORTANT:

Models CU 360-CU 1400 use probes for liquid level sensing and control. Model CU

2000 and higher use McDonnell-Miller MM 150.

The Water Equalizing Pipe can best be examined by opening the unions on either side and visually and manually

examining the piping with your fingers or probes to see if it is clean.

Read completely before starting work

1.

Disconnect steam generator from electric power supply at main safety switch or fuse panel, then turn switch

to OFF position.

2.

Close valve on incoming water line. Drain unit completely of water.

3.

Open generator door to expose heating element.

4.

Disconnect wire (electric) leads connecting element to main power system of unit.

IMPORTANT:

Wire connections to facilitate re-assembly (see wiring schematic).

Remove (6) 5/16" - 18 bolts from flange.

5.

Thoroughly clean unit flange of all foreign materials. Be certain no part of the old gasket remains on flange.

6.

Apply "Slick-Tite" gasket compound (or equal) to both surfaces of new gasket supplied with replacement element.

Install heating element with gasket between flanges. Be careful to align flange holes so wire connection terminals

on element assembly are in line with previously disconnected wire leads to facilitate easy connections.

NOTE:

Observe markings on element flange. Install elements “TOP” with marking on top.

7

.

Use only new bolts - do not use the old bolts. After all (6) flange bolts are tight, connect all wires to terminals.

Make certain wires are clean and bright to assure good electrical contact and nuts on screws are firmly secured.

Bolts should be tightened to a torque of 22 Ft.-Lbs.

8

.

Open the water valve so the water supply can reach the steambath generators feed mechanism.

9.

Put the main safety switch to the "ON" position.

10.