Sur-Gard System III Operating Manual

Sur-Gard System III

Multi-Platform

Digital Telephone Receiver

WARNING: This manual contains information on limitations regarding

product use and function and information on the limitations as to

liability of the manufacturer. The entire manual should be carefully read.

Operating Manual

version 1.8

Table of Contents

Section 1 - Introduction .................................... 1

1.1 System Overview ...................................1

1.2 Approvals ..............................................1

1.2.1 Industry Approvals ........................... 1

1.2.2 UL Manual Mode ............................. 1

1.3 Description (Hardware) ..........................2

1.3.1 BP3 Backplane ................................. 2

1.3.2 DC/DC-3 5V Power Converter .......... 2

1.3.3 PSU3 Power Supply Unit .................. 2

1.3.4 PSC3 Power Supply Controller .......... 2

1.3.5 CPM3 Central Processing Module .... 2

1.3.6 DRL3 Line Card ................................ 2

1.3.7 BP3X Interface Module ..................... 3

1.4 Receiver Setup and Operation ................ 6

1.5 Description (Operation) .........................6

1.5.1 Operation with Default Programming 6

1.5.2 Virtual Connectivity .......................... 6

1.5.3 Status Addressing ............................ 6

1.5.4 Automation Input/Output

(Port 1025) ...................................... 6

1.5.5 Compatibility ................................... 6

1.5.6 Automation Protocols ...................... 6

1.5.7 Data Byte Protocol ........................... 6

1.5.8 Acknowledgment of the Signal ......... 7

1.5.9 COM Responses .............................. 7

1.5.10 Automation Absent ........................ 7

1.5.11 System III SIA Internal Status Output 7

Section 2 - CPM3 Operating Modes .................. 8

2.1 Contrast Adjust ...................................... 8

2.2 Active Mode ..........................................8

2.3 Manual Mode ........................................8

2.4 Standby Mode .......................................8

2.5 System Trouble ......................................8

Section 3 - DRL3 Operating Modes .................. 9

3.1 DRL3 Standby Mode .............................. 9

3.2 Line Fault ...............................................9

3.3 CPM3 Error ............................................9

3.4 Data Reception ...................................... 9

3.5 Fault Data Message ................................9

3.6 Fault Call Message ..................................9

Section 4 - Programming/Operation .............. 10

4.1 Introduction .........................................10

4.2 System III Console Software .................10

4.3 Debug Programming ............................10

4.3.1 Debug Cable Connectivity .............. 10

4.3.2 Debug Software Setup .................. 10

4.3.3 Downloading Steps ........................ 11

4.4 Manual Programming ..........................11

4.4.1 Advanced Programming ................. 11

4.4.2 System functions ........................... 12

4.5 CPM3 Options .....................................12

Option [01]: IP Address .................................. 12

Option [02]: Subnet Mask Address .................12

Option [03]: Gateway Address........................ 12

Option [04]: Auto Update Time & Date...........12

Option [05]: Contrast Adjust ...........................12

Option [06]: Password Menu ......................... 12

Option [07]: COM1 Baud Rate ....................... 12

Option [08]: COM1 Data Bits ......................... 12

Option [09]: Parity .......................................... 12

Option [0A]: COM2 Format ............................ 12

Option [0B]: COM2 Baud Rate .......................12

OOption [0C]: COM2 Data Bits .....................12

Option [0D]: COM2 Parity .............................. 12

Option [0E]: TCP GUI ......................................13

Option [0F]: B32 Headers .............................. 13

Option [10]: Input RRLLL Digits ...................... 13

Option [11]: Output RRLLL Digits ................... 13

Option [12]: Heartbeat Timer ......................... 13

Option [13]: Mute Buzzer ..............................13

Option [14]: Receiver Number ....................... 13

Option [15]: Printer Test ..................................13

Option [16]: Mask PSU 1.................................13

Option [17]: Mask PSU 2.................................13

Option [18]: Mask DC A ..................................13

Option [19]: Mask DC B...................................13

Option [1A]: Mask DC A2 ................................13

Option [1B]: Mask DC B2 ................................13

Option [1C]: Mask Low Battery 1 ....................13

Option [1D]: Mask Low Battery 2 ...................13

Option [1E]: Mask Fan 1 Fail ............................13

Option [1F]: Mask Fan 2 Fail ............................13

Option [20]: Mask UPS AC 1 ..........................13

Option [21]: Mask UPS BAT 1 .........................13

Option [22]: Mask UPS AC 2 ..........................13

Option [23]: Mask UPS BAT 2 .........................13

Option [24]: Mask SG TCP 1 ...........................13

Option [25]: Mask SG Serial 1 .........................13

Option [26]: Mask SG TCP 2 ...........................13

Option [27]: Mask SG Serial 2 .........................13

Option [28]: Mask TCP 1 Printer .....................13

Option [29]: Mask Parallel 1 Printer ................13

Option [2A]:Mask Serial 1 Printer ....................13

Option [2B]: Mask TCP 2 Printer .....................13

Option [2C]: Mask Parallel 2 Printer ................14

Option [2D]: Mask Serial 2 Printer ..................14

Option [2E]: Number of Line Cards..................14

Option [2F]: Automation Mode .......................14

Option [30]: Printer Mode ...............................14

Option [32] Date Format .................................14

Option [33] Protocol ID ...................................14

Option [34] Time Correct.................................14

Option [35] Output Config(Future Use)............14

Option [36] CIS Enable (Future Use) ................14

Option [37] RBUS HighSpeed .........................14

Section 5 - Advanced Programming ............... 17

5.1 Profiles Introduction ............................17

5.2 Static Options: [00] - [2F] .................... 18

Option [00]: Reserved .....................................18

Option [01]: Line Card Number ......................18

Option [02]: Line Card Number Length ..........18

Option [03]: Internal messages RS-232 ..........18

Option [04]: 2-Way Audio Activation Time ......18

Option [05]: Pre-H.S. Duration .......................18

Options [06] to [08]: Reserved .......................18

Option [09]: First Ring Length ..........................18

Options [0A] to [0C]: Reserved .......................18

Option [0D]: Ring Select - Default [00] ...........18

Option [0E]: Backup Line Enable/Disable .........18

Option [0F-10]: Reserved ................................19

Option [11]: Hook-flash Enable/Disable ..........19

Option [12]: Caller Source ID Option ..............19

Option [13]: Caller Source to SG Computer ....19

Option [14]: Caller Source to printer ...............19

Options [15]: Reserved ...................................19

Option [16]: Format disabling Option ..............19

Option [17]: DMP User Length .......................19

Option [18]: Sur-Gard DTMF 4/3 Format

Output...........................................19

Option [19]: Fault Call Counter ........................20

Option [1A]: DNIS Input Sensitivity .................20

Option [1B]: Reserved .....................................20

Option [1C]: Busy Out ....................................20

Option [1D]: Reserved ....................................20

Option [1E]: Reserved .....................................20

Option [1F]: Debug Output .............................20

Option [20]: C.L.A.S.S. Field Data ....................20

Option [21] RBUS Speed ................................21

Options [22] - [26]: Internal Use Only ............21

Option [27]: Caller Source Process .................21

Options [28] - [29]: Reserved .........................21

Option [2A]: Hook-flash Delay ........................21

Options [2B] - [2C]: Reserved .........................21

Option [2D]: A.H.S. .........................................21

Options [2E] Reserved ....................................21

Options [2F] Online Time Out .........................21

Dynamic Options: [30] - [FF] .......................... 21

Options [30] - [3F]: 3/1 - 4/1 Digit 0-F ............21

Options [40] - [4F]: 3/2 - 4/2 Digit 0-F ............21

Options [50] - [5F]: 4/3 Digit 0-F .................... 22

Options [60] - [6F]: Printer Words .................. 22

Option [70]: Automation Common Event

Option [72]: SIA Option ..................................22

Option [73]: DSP Input and Ouput ................. 23

Option [74]: Equivalent Line Number ............. 23

Option [75]: Receiver Number .......................23

Option [76]: Accounts 3/x to 4/x .....................23

Option [77]: Digit Replace .............................. 23

Option [78]: Max Inter-digit ............................23

Option [79]: Max Inter-burst ...........................24

Option [7A]: 4 and 5 Digit Account Codes to

Option [7B]: 3 Digit Account Codes to Activate

Option [7C]: Alarm Codes to Activate 2-Way

Option [7D]: Audio Zone Code .......................24

Option [7E] Audio RS-232 .............................. 24

Option [7F]: Audio Format Enable ................... 24

Option 80: Kiss-Off to Hang-up Time .............24

Options [81] through [88]: Handshake

Option [89] to [90]: Handshake and Kiss-off

Option [91]: Inter-Handshake Duration .......... 25

Option [92]: Reserved .................................... 25

Option [93]: Min Audio Tone .......................... 25

Option [94]: Account Digit Stripping ...............25

Option [95]: 5-Digit Pulse ............................... 25

Option [96]: 4/1 Extended .............................. 26

Option [97]: 4/2 Extended .............................. 26

Option [98]: 3/1 Extend .................................. 26

Option [99]: Ademco Express .........................26

Option [9A]: Reserved .................................... 26

Option [9B]: Echo Canceller ............................26

Option [9C]: Acron RS-232 ............................. 26

Option [9D]: MODEM II RS-232 ....................26

Option [9E]: Scantronics Select ......................27

Option [9F]: Ademco High Speed RS-232 ......27

Option [A0]: 11 / 12-Digit DTMF (Acron or Scant-

Option [A1]: FBI RS-232 ................................. 27

Option [A2]: Digit Replace ..............................27

Option [A3]: D6500 RS-232 ........................... 27

Option [A4]: BFSK RS-232 .............................. 27

Option [A5]: Sescoa Super Speed ..................28

Option [A6]: ITI Adjust .................................... 28

Option [A7]: Silent Knight FSK2 RS-232 .......... 28

Options [A8] - [AF]: Dial-out Number For 2-way

Option [B0]: CCITT Audio Format Enable bits.. 29

Option [B1]: DMP Area BIN or DEC Option ... 29

Options [B2] - [FF]: Reserved .........................28

Code.............................................22

Activate 2-Way Audio ...................24

2-Way Audio ................................ 24

Audio ...........................................24

Selection....................................... 25

Duration .......................................25

ronics) ..........................................27

Audio Transfer .............................. 28

Glossary .......................................................... 30

Appendix A - Printer Words: Options [60-6F] . 33

Appendix B - System III Internal Status

Messages ........................................................ 35

Appendix C - TELCO Connector Pin-outs ........ 38

Appendix D - DEC-HEX-BIN Conversion Chart . 38

Appendix E - ASCII Character Chart ................ 39

Appendix F - DRL3 Communication Formats ... 40

GENERAL DESCRIPTION of the EQUIPMENT and CLASSIFICATION.

CLASSIFICATION

The SYSTEM III equipment is a CLASS 1, RACK-MOUNTED, (FIXED –

STATIONARY) EQUIPMENT, PLUGGABLE TYPE A USING A DETACHABLE POWER SUPPLY CORD, designed to be INSTALLED, OPERATED and MAINTAINED by SERVICE PERSONNEL ONLY. [persons

having appropriate technical training and experience necessary to

be aware of hazards to which they are exposed in performing a task

and of measures to minimise the danger to themselves or other

persons].

The equipment SYSTEM III is designed to be installed in

RESTRICTED ACCESS LOCATIONS within an environment that provides the Pollution Degree max 2 and OVERVOLTAGES CATEGORY II

- NONHAZARDOUS LOCATIONS, INDOOR ONLY.

The POWER SUPPLY CORD serves as a means of disconnection

from the MAINS. The OUTLET used to power the equipment shall

be installed near the equipment and shall be easily accessible. The

equipment must be connected to a socket-outlet with a protective

earthing connection! The INSTALLATION of the SYSTEM III equipment must provide a reliable earth connection and it shall respect

the local electrical wiring regulations.

IMPORTANT:

IT IS THE RESPONSIBILITY OF THE INSTALLER TO ENSURE THAT

THE SYSTEM III EQUIPMENT IS PROPERLY MOUNTED WITHIN A

METALLIC FIRE ENCLOSURE WITH A MINIMUM THICKNESS OF

1.5 MM AND THE FINAL ASSEMBLY IS COMPLIANT WITH ALL OF

THE APPLICABLE REQUIREMENTS FROM THE POINT OF VIEW OF

THE ACCESSIBILITY TO THE ENERGIZED PARTS (HAZARDOUS

VOLTAGES, TNV CIRCUITS, ETC.) AS THESE CHARACTERISTICS ARE

DEFINED WITHIN THE EN60950:2000 STANDARD.

THE EXTERNAL ENCLOSURE SHALL MEET ALL OF THE APPLICABLE

REQUIREMENTS FROM THE POINT OF VIEW OF PHYSICAL

REQUIREMENTS, E.G.: STEADY FORCE 250N, IMPACT AND STABILITY. THE EQUIPMENT MUST BE SECURED TO THE BUILDING

STRUCTURE BEFORE OPERATION; ALL WIRING AND INSTALLATION SHALL BE IN ACCORDANCE WITH ELECTRICAL CODES

ACCEPTABLE TO THE AUTHORITIES THAT HAVE JURISDICTION

WHERE THE EQUIPMENT IS INSTALLED, SERVICED AND OPERATED.

NOT MORE THAN 3 (THREE) ASSEMBLIES [EACH CONSISTING OF

2 (TWO) SYSTEM III EQUIPMENT] MOUNTED WITHIN THE SAME

RACK SHALL BE POWERED FROM THE SAME BRANCH CIRCUIT.

USE A DIFFERENT BRANCH CIRCUIT FOR ANY GROUP LARGER

THAN 3 (THREE) ASSEMBLIES.

Internal wiring shall be routed in a manner that prevents:

• excessive strain on wire and on terminal connections;

• loosening of terminal connections;

• damage of conductor insulation.

The wireways within the enclosure shall be smooth and free from

sharp edges. Wires shall be protected and routed so that they do

not come in contact with burrs, cooling fan or heatsinks which

could cause damage to the insulation of conductors. Holes in metal

shall have smooth well-rounded surfaces or shall be protected with

bushings.

The EXTERNAL ENCLOSURE shall be connected to the PROTECTIVE

EARTH GROUND. The external cabinet (RACK) must be secured to

the building structure before operation in a such a way to fully meet

the STABILITY REQUIREMENTS as per EN60950: 2000 conditions.

An adequate MARKING [visible before the door (cover)], NEXT TO

THE ACCESS DOOR (or cover) of the rack, with instructions for protection once the DOOR (or covers) IS (are) removed, stating that

“telephone cord is to be disconnected prior to opening the door” is

an example of an acceptable Marking), and it shall be provided by

the Installer.

An acceptable power supply cord (detachable), shall be used

accordingly to the local outlets and voltages. IT IS THE INSTALLER’S

RESPONSIBILITY TO PROVIDE AN APPROPRIATE ACCEPTABLE

POWER SUPPLY CORD.

CAUTION:

This product uses Lithium Batteries. Improper handling of lithium

batteries may result in HEAT GENERATION, EXPLOSION or FIRE,

which may lead to personal injuries.

Please ensure that the above precautions are strictly observed by

the related divisions including but not limited to sales, service, customers and (or) outside contractors.

THE EQUIPMENT SYSTEM III IS EQUIPPED WITH LITHIUM NON

REPLACEABLE BATTERY. DO NOT ATTEMPT TO REPLACE THE BATTERIES.

CONNECTION TO THE MAINS

1. Connect first the DETACHABLE POWER SUPPLY CORD to the

IEC 320 connector located on SYSTEM III equipment.

2. Connect all the telecommunications cord-sets to the appropriate connectors.

3. Be sure that the enclosure of the equipment SYSTEM III is fully

installed (covers, doors, etc.) in a such a way that HAZARDOUS

VOLTAGES and TNV Circuits will not be ACCESSIBLE when the

equipment will be connected to the MAINS and/or TELECOMMUNICATION NETWORK.

ATTENTION: THE INTERNAL POWER SUPPLIES ARE NOT SWAPPABLE! DISCONNECT POWER BEFORE ATTEMPTING TO CHANGE A

POWER SUPPLY!

In order to change the INTERNAL Power Supply, first DISCONNECT

the DETACHABLE POWER SUPPLY CORD from the socket outlet

used to provide power, and then, from the IEC320 Connector which

is mounted on the SYSTEM III equipment. Wait minimum 5 seconds

to allow the Capacitor (C8) within the unit to discharge. IF THE

FUSE IS SUSPECTED OF HAVING OPENED, a discharge path for the

involved Capacitor (C8) shall be provided.

Do not touch the HEATSINKS within the equipment: these are LIVE

PARTS and/or may present a hazard related to high temperatures.

In order to swap the boards USE THE PROVIDED PLASTIC HANDLES (INSERTERS, EXTRACTORS).

NO REPAIRS IN THE FIELD ARE ALLOWED. THE EQUIPMENT

SYSTEM III MUST BE RETURNED TO THE MANUFACTURER FOR

REPAIRS.

Section 1 - Introduction

The System III is a multi-platform digital telephone receiver

intended for remote monitoring of commercial fire and burglary systems.

The System III can monitor up to 24 telephone lines; receive

and process alarm data in up to 64 pre-programmed formats (profiles) per line card.

The System III real time clock and calendar stamps all

received alarm data which are then transmitted to a central

station computer via TCP/IP or RS-232 port; transmitted

directly to a printer using the parallel printer port; and

viewed on the LCD of the front panel. System configuration

and phone line profiles can be programmed using a PC with

System III Console Software or locally using the scroll buttons and LCD. Each rack can house up to 12 DRL3 cards.

Each telephone line is monitored by a DRL3 line card.

1.1 System Overview

• Patented Caller Identification (Call Display) capability

• Patent pending AHS (Automatic Handshake selection)

• Patented virtual configurations

• Non-volatile RAM on each DRL3 line card for programming and event buffer

• Flash download for software upgrades for the DRL3

line cards and the CPM3

• DSP technology (patent pending)

• Up to 64 different options set (profiles per line card)

• Up to 8 different handshakes per profile

• Large, easy to read LCD (Liquid Crystal Display)

• All modules function individually to help ensure

uninterrupted operation during hardware or software upgrades

• All cards are Hot Swappable. Printed circuit cards

can be removed and replaced without removing

power from the system or compromising the system performance

• 24 lines maximum per redundant receiver

• 512-event memory buffer on each individual line card

• Real-time clock

• One parallel printer port, two serial RS-232 ports

and 10/100BaseT connection per rack

• Operator Acknowledge

• Programmable serial ports configuration

• Continuous verification of the computer-receiver

links with the 'heartbeat' function

• Fast transmission of multiple alarms to the computer

and printer to ensure operator's quick response

• Telephone Line supervision

• Rack mount in standard 19 inch rack

For UL listed installations use MLR2-CL, MLR2-CM,

IMRAK 1400 or other equivalent listed enclosure.

1.2 Approvals

1.2.1 Industry Approvals

The System III is listed under the following UL standards:

• UL 864 Control Units for Fire-Protective Signaling

Systems

• UL 1610 Central Station Burglar Alarm Units

This equipment should be installed in accordance

with the requirements of NFPA72, NFPA70, UL827

and the authority having jurisdiction.

1.2.2 UL Manual Mode

For UL manual mode, each event will activate the

internal buzzer to be acknowledged manually. Each

event will also be sent automatically to the connected printer.

For Central Station applications, the signaling performance of each DACT (Digital Alarm Communication

Transmitter) shall be manually tracked. Failure to

receive a signal from a DACT over 24 hour period

shall be handled as a trouble signal.

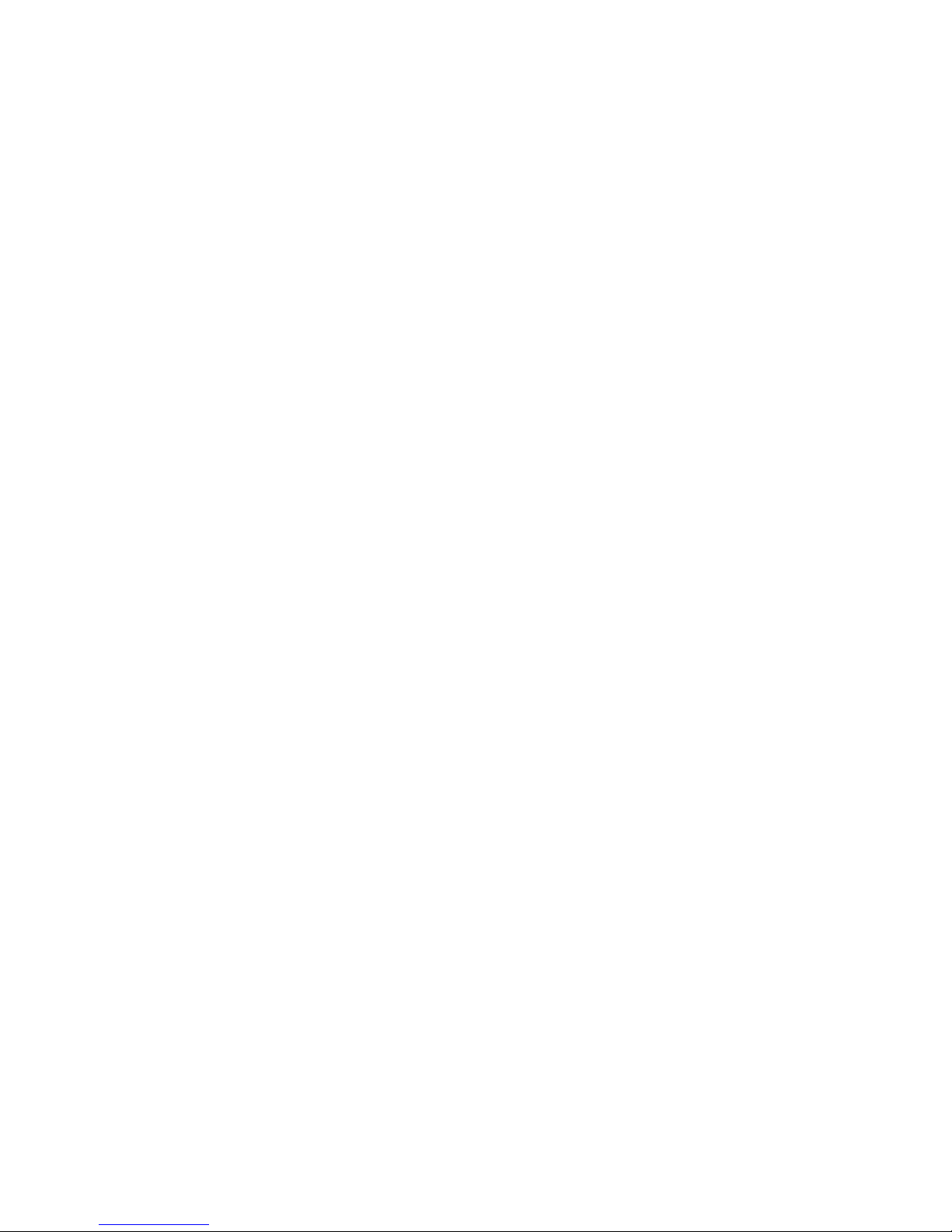

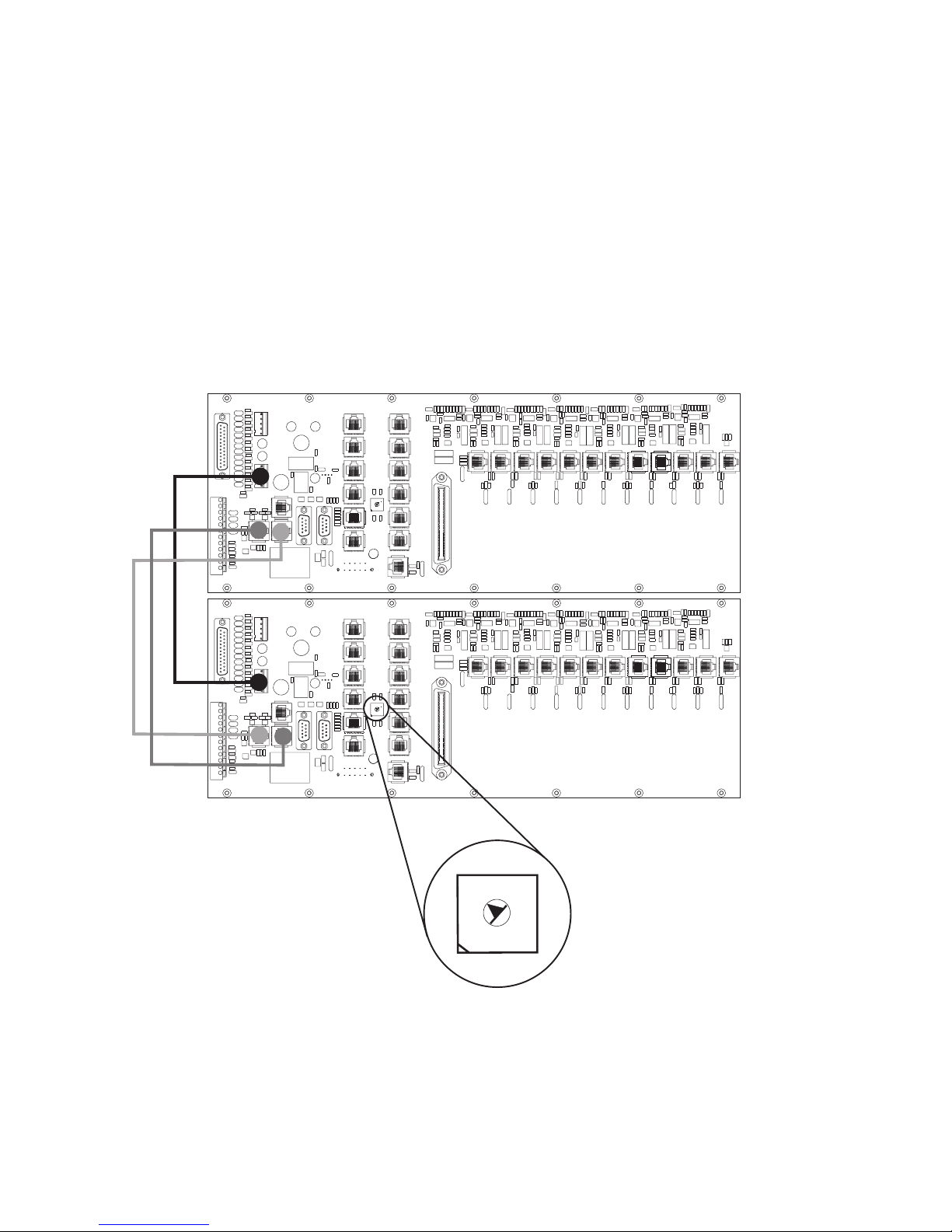

Figure 1-1, System III

1

1.3 Description (Hardware)

• Basic Configuration: The basic configuration consists of one 19" rack mounted chassis comprising

the following:

• BP3 Backplane provides interconnection of modules and communications interface

• CPM3 Module contains the CPU that controls all

communication to and from up to 24 line receiver

modules, printers, including 2 serial ports and an

Ethernet connection.

• PSU3 Power Supply Unit provides power to all

modules of the system.

• DRL3 Line Card: Each DRL3 line card monitors one

telephone line. Stores on the card up to 64 profiles

for data management including 8 different handshaking protocols. Each card has a 256-event

buffer, for short term retention of signals.

• DC/DC3 provides 5 V

the DRL3 line cards. A slot exists for a second DC/

DC3 voltage converter. In the event of a failure, the

redundant DC/DC3 can be removed/replaced without powering down the unit.

• PSC3 (Power Supply Controller) monitors the

states of the power and fan for each MLRF3.

• MLRF3: The metal rack of the System III that incorporates the LCD and BP3.

1.3.1 BP3 Backplane

The BP3 provides for interconnection of system

modules and racks; and provides communication

outputs as indicated in figure 1-6.

1.3.2 DC/DC-3 5V Power Converter

Each DC/DC3 converts 15VDC input from the PSU3

module and outputs the 5V

ules to function. A slot is provided for a second DC/

DC3 power supply to provide full redundancy for

DC power requirements. Power will remain ON if

5V

there are two DC/DC3 in the rack. The DC/DC3 is

also Hot Swappable if a working redundant DC/DC3

is in the same rack.

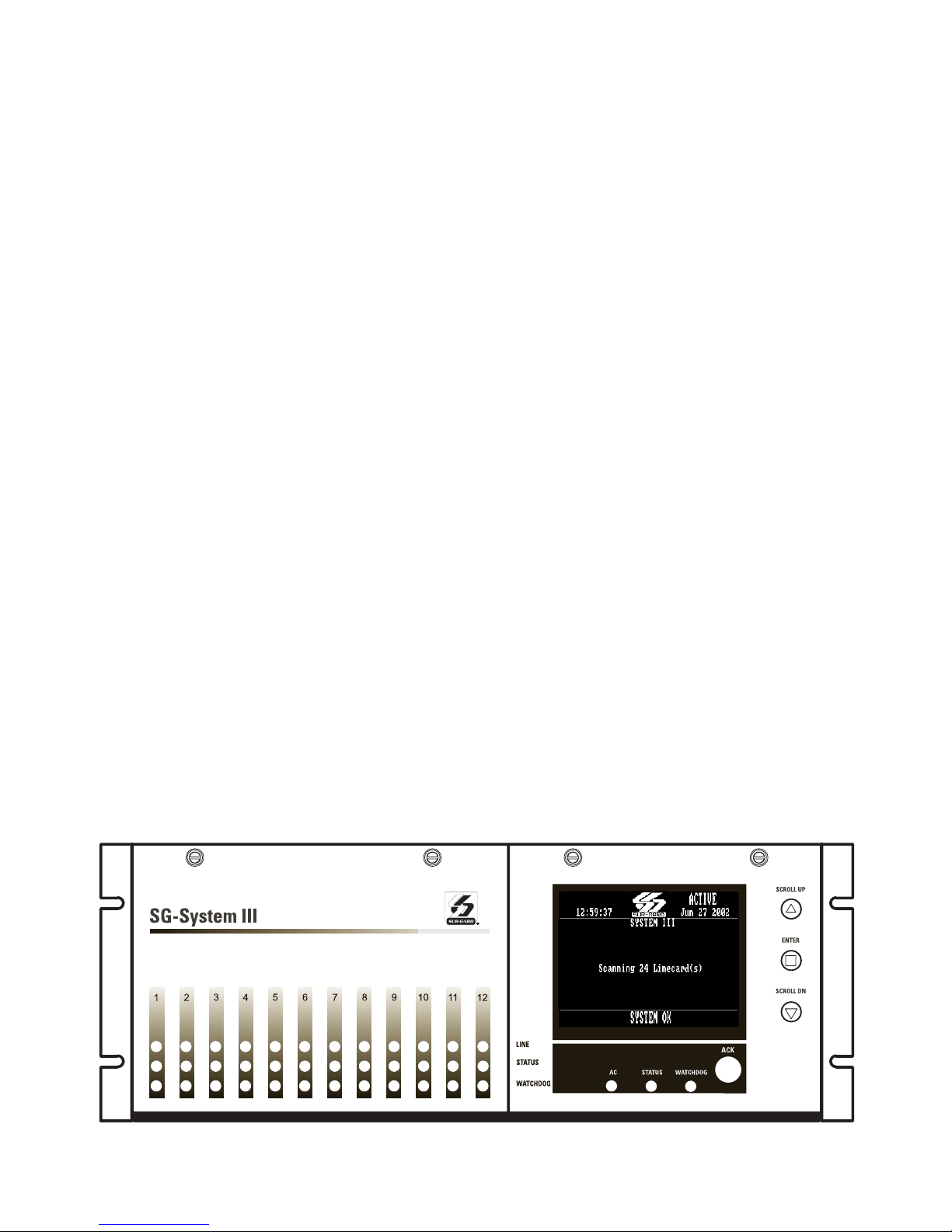

Fig ure 1-2

DRL3 Line Card

(12 cards per rack)

Line Card Debug Output

DC power output required for

DC required for all mod-

CPM3 PSC3 DC/DC3 B

PSU3

Fan (not shown)

located above PSU3

LCD

DC/DC3 A

UIB3

1.3.3 PSU3 Power Supply Unit

The PSU3 is the System III power supply. The

System III requires a 120VAC/60Hz input power

source. A power cord with a IEC connector is

required. The model System III CE requires a 240V

50Hz input power source.

NOTE: For UL installations use only 120VAC/60Hz to

power the SYSTEM III.

For UL installations use UL listed UPS Power Supply

for protective signaling systems and/or listed burglar alarm power supply, as applicable.

The model System III CE is not UL Listed.

Electrical Specifications:

System III

• Input voltage range: 120 V

AC

• Frequency: 60 Hz

• Input current: 2.5A max (RMS) @120 V

In 2-rack configurations a redundant PSU3 can be

inserted in the second shelf. In the event of a PSU3

failure, the redundant PSU3 automatically assumes

operation. These modules are Hot Swappable (can

be removed/replaced while the system is in operation) if a working redundant PSU3 is installed.

1.3.4 PSC3 Power Supply Controller

The PSC3 performs two functions. It provides the

high voltage required for backlighting to the LCD display. It also monitors the activity of the PSU3, DC/

DC3 power supplies and the power supply fan, and

reports their status to the CPM3 module.

1.3.5 CPM3 Central Processing Module

The CPM3 Central Processing Module collects system information and directs line card information to

the appropriate outputs. Along with it's built in scroll

buttons and large LCD message screen, the CPM3

features TCP/IP, parallel printer and two serial RS-232

ports for computer interface capability. The printer is

supervised for loss of power, off-line, paper out and

other trouble conditions. The communication link to

the computer through the RS-232 and TCP/IP port

can be monitored by the supervisory heartbeat test

transmissions.

1.3.6 DRL3 Line Card

The System III supports a maximum of 24 line cards.

Each DRL3 line card can monitor one telephone line

and act independently of the CPM3 module. Each

module is equipped with a 256-event non-volatile

memory to record events and corresponding telephone numbers. Calling source (Caller ID, ANI and

calling name) capability is built-in and telephone

numbers can be printed out, sent to automation and

stored in memory. Events and information stored in

memory may be printed at any time. Each line card

also features flash downloads through Ethernet or

serial port for fast software upgrades.

AC,

AC

2

The DRL3 receives ANI (Automatic Number Identification) and/or DNIS (Dialed Number Identification

Service) via the Telco connection. This information

allows the Sur-Gard expert format identification system to change options on the fly for each received

call. This eliminates dedicated line pool hardware.

The DNIS information is used in a look-up table,

which sets up virtual line pools to identify security

formats and extend account numbers. Standard

dialed number identification is supported up to 10

digits. Each dialed number would have formerly been

a line pool on conventional line cards.

1.3.7 BP3X Interface Module

(optional - one required per rack)

This 19” Rack mounted panel interfaces with the

System III Telco connector to provide 24 RJ-11 connectors for direct connection to telephone lines.

NOTE: On the BPX3 the B ports are the channels

used for two-way audio or back-up telephone line.

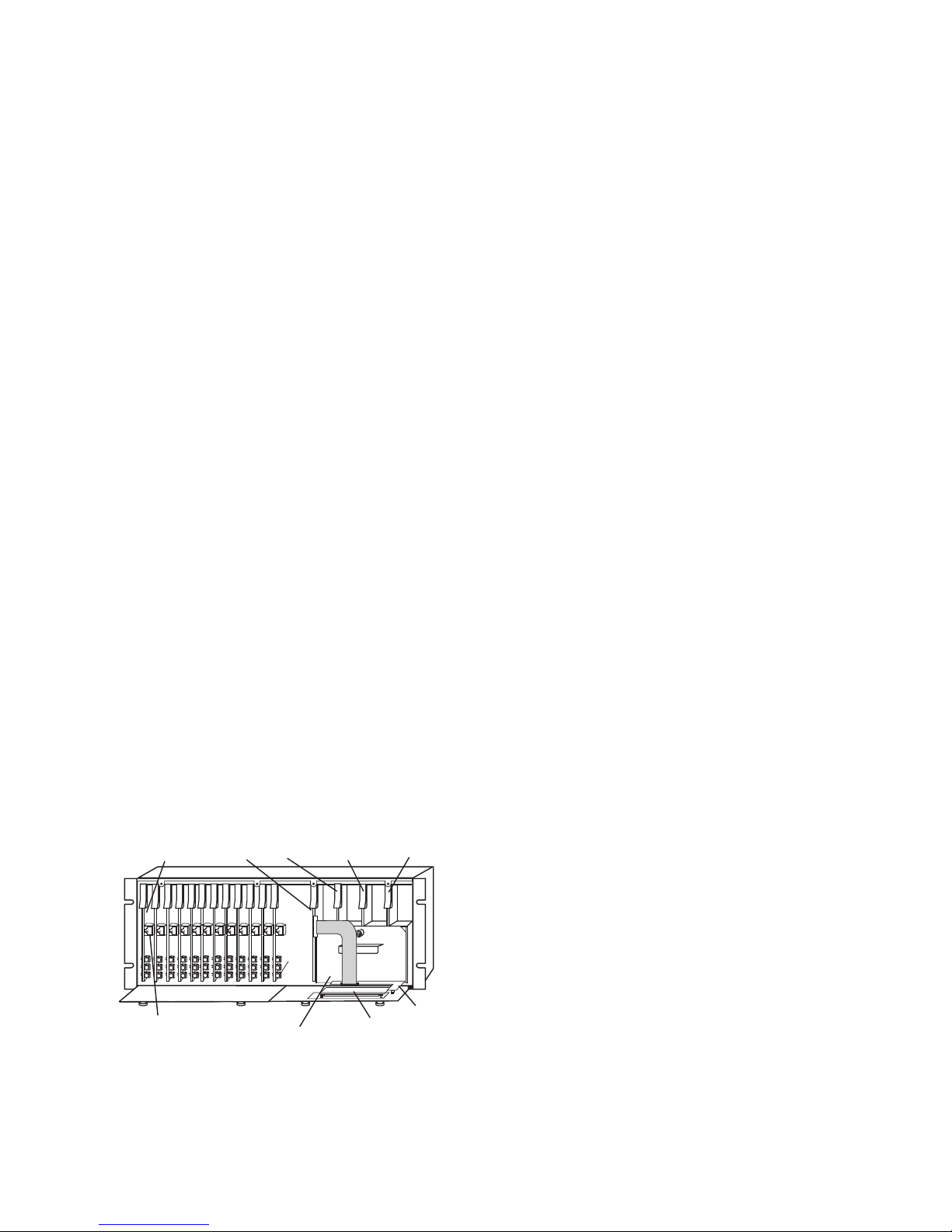

Figure 1-3 Front

A A

BP3X

B B

6 5 4 3 2 1

• Parallel Printer: A standard parallel printer output is located

on the back of the CPM3.

For UL Listed applications, the following UL listed printers

can be used with the System III:

- Sur-Gard CPU-1150 - DMP SCS-PTR

- Sur-Gard CPU DMP-206 - Seiko DPU-414

• Serial Printer

: A standard serial printer output is located on the

back of the MLRF3.

For UL Listed applications, the following UL listed printers can

be used with the System III: Seiko DPU-414

IMPORTANT: Do not use a printer cable that has only 1

common ground wire.

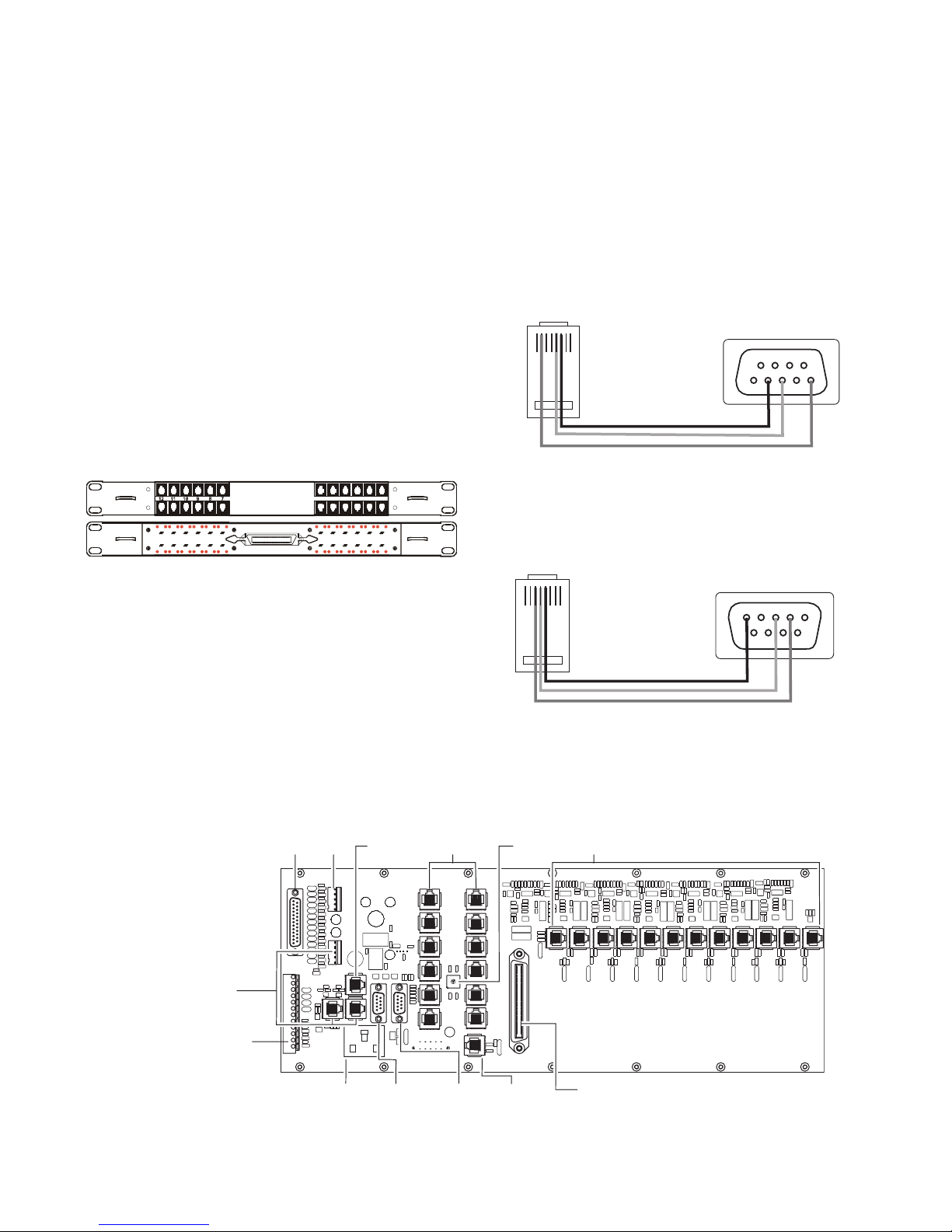

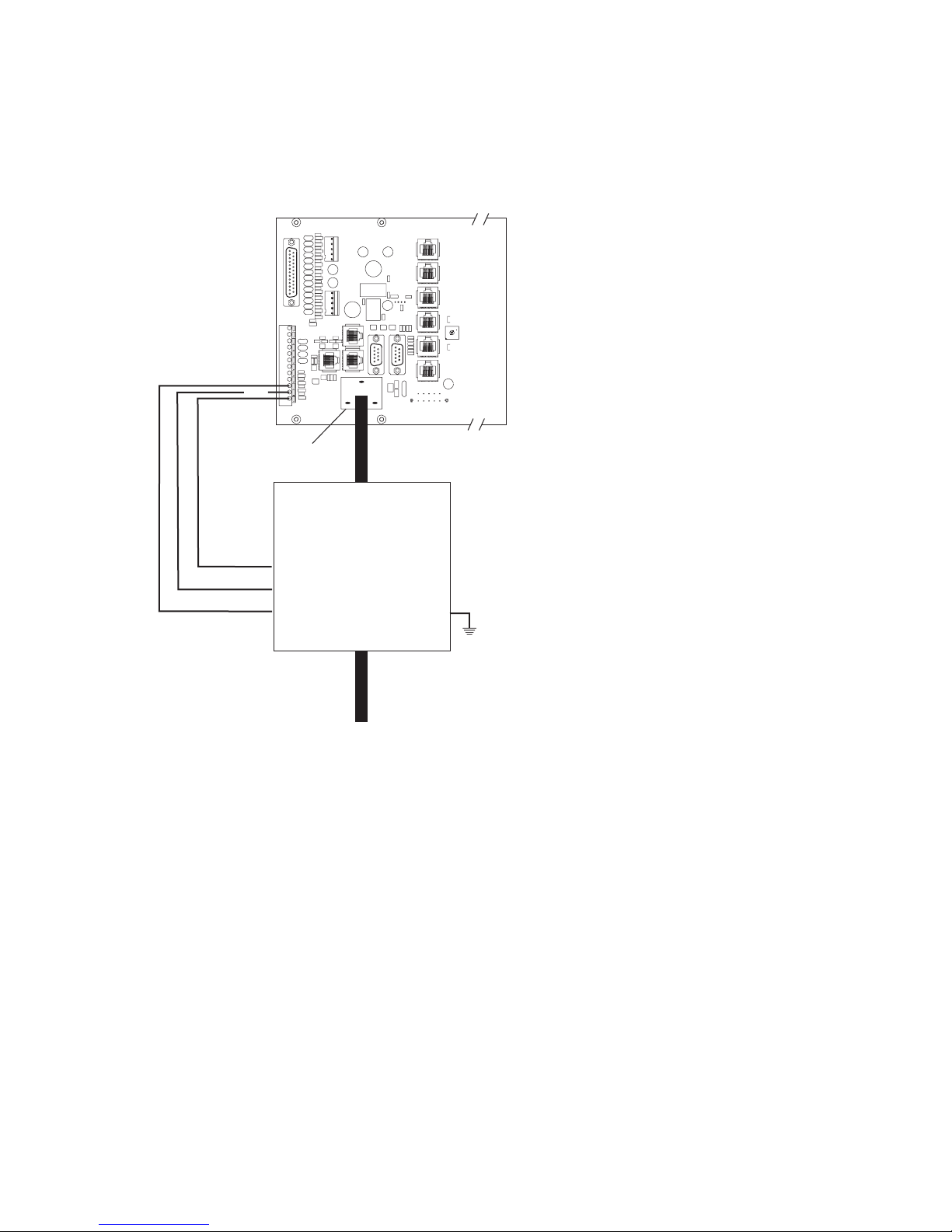

Figure 1-6, System III Wiring Diagram

* For Model System III CE:

- 240V

AC /50Hz

- System III CE is not UL Listed

**CAUTION: The ethernet

communication lines must be

connected first to an Approved

(acceptable to the local

authorities) type NID (Network

Interface Device) before leaving

the premises (e.g., UL

installations, UL60950 Listed

NID).

Connections for second

backplane

DB25

Parallel

Printer

Output

Not

Used

CPM3

Debug

Output

12 RJ-45

Connectors

Not Used

NOTE: Non-printable characters are replaced by a square

on the print out. Ensure that the printer is configured for

80 columns (System III only supports 80 columns).

• Connections for Redundant System III: Refer to Figure 1-7

System III Redundancy Wiring Diagram.

• CPM3 Debug Output: Connect the RJ-45 end of the debug

cable to the debug output jack.

Connect the female DB-9 connector to the serial port of a

computer (COM1 port - usually DB-9 male).

Figure 1-4 CPM3 Debug Cable

RJ45

1 2 3 4 5 6 7 8

Pin 2 to Pin 5

Pin 5 to Pin 3

Pin 6 to Pin 2

Back of DB9

• DRL3 Debug Output: Connect the RJ-45 end of the debug

cable to the debug output jack on the front of the line card.

Connect the female DB-9 connector to the serial port of a

computer (COM1 port - usually DB-9 male).

Figure 1-5 DRL3 Debug Cable

RJ45

1 2 3 4 5 6 7 8

Pin 3 to Pin 2

Pin 4 to Pin 3

Pin 5 to Pin 5

Back of DB9

• IEC Power Connector: Provides local power line connection

(cable is not supplied).

Shelf

Address

Switch

4

5

3

6

7

2

8

1

0

9

A

F

E

B

C

D

12 RJ-45

Connectors

Not Used

Note: All external

devices should be

mounted in the same

room as the receiver.

All circuits

are power

limited

976

8

54321

12345

689

7

See System III Supervised

UPS Connection Diagram for

details

Note: For UL Installations:

- AC input is 120V

- Do not connect to a receptacle

controlled by a switch.

AC / 60 Hz.

IEC Power

Connector

120Vac / 60 Hz*

2.5A

RS-232

Serial

Automation

Output

RS-232

Serial

Printer

Output

3

Ethernet**

Output

10/100 BaseT

25 Pair RJ-21 Supervised Telephone Lines

(Refer to Appendix C for pin out)

Note: Maintain 6.5mm (1/4") separation between

power limited and non-power limited circuits.

WARNING! To reduce the risk of electric shock the product is provided with a grounding type power supply IEC

recepticle. Connect product using an appropriate IEC

cable to a grounded recepticle.

• RS-232 Serial Automation Output: Provides serial connection to a local computer running automation software. A

straight through serial cable must be used.

• RS-232 Serial Printer Output: Provides serial connection to

a local computer or serial printer.

• 25 Pair Telco Connection: Connects directly to the local PBX

or to BP3X-3 (Refer to Appendix C for pinouts).

Figure 1-7, System III Redundancy Wiring Diagram

• Ethernet Output 10/100 BaseT: Traditional automation

communication is provided via port 1025 on the Ethernet

connection. This primary port is a Sur-Gard standard output

and provides Sur-Gard standard automation protocol output. All or a number of virtual receiver types can be mapped

to the Sur-Gard output.

CAUTION: The ethernet communication lines must

be connected first to an Approved (acceptable to

the local authorities) type NID (Network Interface

Device) before leaving the premises (e.g., UL

installations, UL60950 Listed NID).

All circuits are power limited

Use only the cables provided in the

System III Interconnect Pack. Failure

to do so may result in damage to the

unit. Using the provided RJ-45 patch

cables connect the Output of the

primary System III (shelf address 1)

to the Input of the redundant system

III (shelf address 2). Connect the

Output of the redundant System III to

the Input of the primary System III.

4

5

3

6

7

2

8

1

0

9

A

F

E

B

C

D

4

5

3

6

7

2

8

1

0

9

A

F

E

B

C

D

4

5

3

6

7

2

8

1

0

9

A

F

E

B

C

D

Use a small flat screw

driver to turn the shelf

address switch to 2 on

the second redundant

System III.

Shelf 1

Shelf 2

4

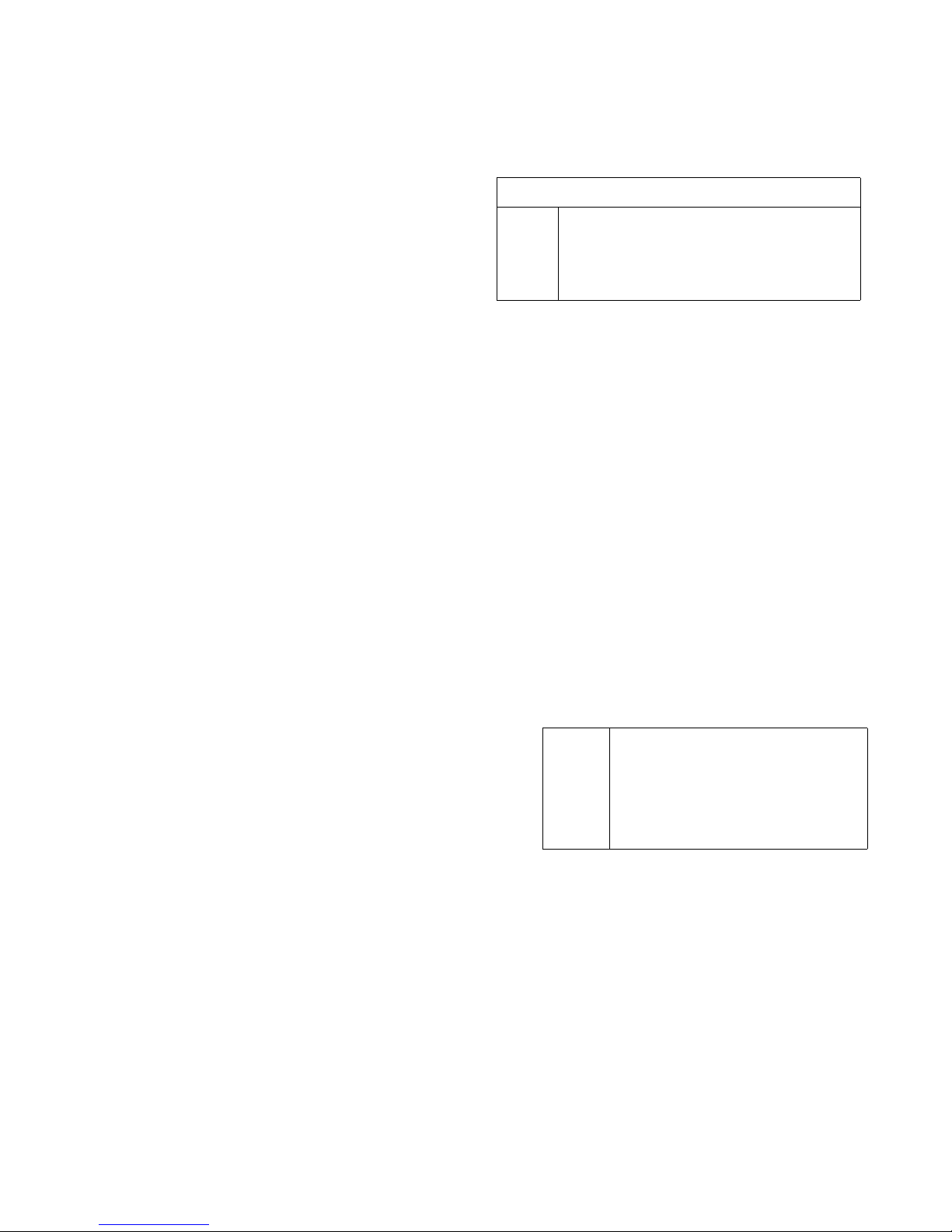

Figure 1-8, System III UPS Supervision Connection Diagram

SG-System III Backplane

12V , 25mA

DC

In2

In1

COM

For UL installations use

UL listed UPS

(uninterrupted power

4

5

3

6

7

2

8

1

0

9

A

F

E

B

C

D

supply) power supply for

protective-signaling

systems and/or listed

burglar alarm power

supply, as applicable.

IEC Power

Connector

For UL Installation of model SG-System III: UPS Output 120V /60Hz, 2.5A

For model System III CE (not UL Listed): UPS Output 240V 50Hz

AC Out

Note:

UPS connection is to

be made using dry

contact connections

provided by the UPS.

Common

UPS LOW BAT Normally Closed

UPS AC TROUBLE Normally Closed

AC In

For UL Installation of model SG-System III: UPS Output 120V /60Hz, 2.5A

For model System III CE (not UL Listed): UPS Output 240V 50Hz

UPS

EGND

WARNING:

To reduce the risk of electric shock the product is provided with

a grounding type power supply IEC receptacle. Connect product

using an appropriate IEC cable to a grounded receptacle.

AC

AC

AC

/

AC

/

5

1.4 Receiver Setup and Operation

DSC recommends testing the receiver before actual

installation. Becoming familiar with the connections

and setup of the unit on the workbench will make

final installation more straightforward.

The following items are required:

• IEC power supply cord

•One telephone line

• One or more dialer or digital control panel(s)

1. Unpack the components for the System III.

NOTE: Carefully unpack the receiver and inspect

for shipping damage. If there is any apparent damage, notify the carrier immediately.

2.Unscrew the front thumb screws and open the

front plates.

NOTE: Before inserting the CPM3 connect the ribbon cable from the UIB3 board. Before inserting

the PSC3 connect the LCD backlight.

3. Insert all the cards in the rack, in their appropriate

position (refer to figure 1-2). Connect the ribbon

cable of the front panel to the CPM3 before inserting it. Connect the backlight power connection to

the PSC3 then insert the PSC3.

4. Insert the PSU3 into the rack and fasten it properly.

5.Connect a telephone line to the proper line.

6. Connect the main power using a standard computer IEC cable (not supplied).

7. The LCD will power up and display internal troubles

(printer, computer, telephone line fault). The DRL3

that has the telephone line connected to it will have

its red LED off. If the LED is always on make sure the

telephone line is connected to the right port.

NOTE: Internal diagnostics may require more than

one minute during the power up sequence.

8.Send a signal from a control panel to the receiver.

The signal will be displayed on the LCD. Press the

[ACK] button to silence the buzzer and clear the

signal from the LCD.

1.5 Description (Operation)

1.5.1 Operation with Default Programming

Without any changes to the factory default programming, the receiver operates as indicated below:

• Answers incoming calls on the first ring

• Sends the following handshake order

1

2300 Hz

2

1400 Hz

3

Dual-tone

4

SIA FSK

5

ITI, Modem IIE/IIIa2

6

Modem II

• Receives all communication formats, except for 3/2,

3/1 checksum, SKFSK, 4/2 extended, and 4/2 checksum (see Option 95).

• The above formats can be manually selected

• Signals can be displayed on the debug output com-

puter as they are received. The signals are then sent

to the printer and computer connected to serial port

COM1 or to the 10/100BaseT connector. The default

event codes described in the DRL3 Library Decod-

ing and Event Codes Table will be used with the

Sur-Gard automation communication protocol to

send signals to the computer, if connected.

• If a computer is not connected press the [ACK]

button on the CPM3 to silence the buzzer and to

clear the alarm(s) from the LCD display.

1.5.2 Virtual Connectivity

Each receiver has one static IP address and a number

of associated ports. Internal socket programming

uses specific ports for expected tasks. The configuration management, done from the Console Software,

is located on port 1024. The System III Console software is provided for Windows 98/ME/NT/2000/XP,

which provides a graphical style menu for configuration management. Additional features are available

with the Console software including storage of virtual

receiver setups and configuration wizards.

NOTE: For Windows NT, user must be logged in as

Administrator or with administrator rights for

proper use of the Console Software.

1.5.3 Status Addressing

Line card status is reported via physical addressing.

Shelf and slot number are assigned automatically to

each line card. All device status information is in SurGard format. The reporting of status on this port,

automation output and printer will relate to physical

addressing.

1.5.4 Automation Input/Output (Port 1025)

Traditional automation communication is provided

via port 1025 on the Ethernet connection. This primary port is a Sur-Gard standard output and provides Sur-Gard standard automation output.

1.5.5 Compatibility

Central station automation software packages such as:

• MAS • DICE • SIMS II • GENESYS

• S.I.S. • IBS • MicroKey

support the System III Sur-Gard interface. Refer to

automation software specifications for compatibility.

NOTE: Automation connections are considered supplementary per UL864 Listing. Compatibility with the

automation software in a system used at a central

station is intended to be handled under a separate

UL1981 software and/or site certification evaluation.

1.5.6 Automation Protocols

The System III receiver sends a variety of protocols

to report signals to the central station computer via a

TCP/IP and/or RS-232 port. A complete list of protocols can be provided upon request.

1.5.7 Data Byte Protocol

The System III receiver uses a default configuration of

9600 Baud rate, 1-start bit, 8-data bits, 0-parity bits

and 1-stop bit structure, to transmit and receive signals

6

on the RS-232 port. This protocol can be programmed

on the receiver to enable different configurations.

1.5.8 Acknowledgment of the Signal

The System III receiver requires an acknowledgment

signal [ACK] (Hex 06) from the computer software

within 4 seconds for each message sent. Failure to

receive the [ACK] will result in 3 retransmissions of

the signal before indicating a communication failure.

During a communication failure the System III

receiver will cease transmitting except for the heartbeat. The same thing happens if the receiver receives

a [NAK] (Hex 15). In case of communication failure

with the computer, the System III receiver can store

up to 256 events per line card in the line card internal memory. Communication is resumed when the

first acknowledgment is received on the heartbeat;

all buffered information is then transmitted.

1.5.9 COM Responses

When the CPM3 sends an event to the computer, it

checks for 3 responses: ACK, NAK or Unknown/No

Response. An ACK tells the CPM3 the computer

automation got the event successfully. A NAK tells

the CPM3 the computer automation got the message but didn't understand it. The line card will

attempt to send the messages 25 times. If after 25

attempts it continually gets a NAK from the computer automation, the DRL3 will generate an internal

communication error. After 20 NAKs the CPM3 will

send an internal communication error event to the

printer. Any other response from the computer automation, including no response will cause the CPM3

to attempt to send the message again, up to 4

times. If after 4 attempts the CPM3 gets no

response or an unknown response, it will assume

nothing is connected and generate an alarm.

1.5.10 Automation Absent

When the computer is not responding to transmissions, the CPM3 will generate a 'SG-Serialx fail' or

'SG-TCP/IPx Fail' trouble. When a trouble occurs, the

CPM3 will continue to attempt to send a heartbeat

signal to the computer until it gets a response. The

System III receiver will make 4 attempts, then wait for

the next heartbeat period before making another 4

attempts. The typical heartbeat interval is 30 seconds.

Supervisory Heartbeat Signal Protocol (1)

00000

s

@

[DC4]

100000sssssssssss@ssss[DC4]

Receiver number (Real programmed number.

Never virtual).

Space Character.

Supervisory Signal.

Terminator, 14 Hex

This signal is used to supervise the communication

between the receiver and computer automation. It is

sent to the computer automation every 30 seconds

and is programmable from the receiver. The computer automation should acknowledge this signal

with an [ACK]. The CPM3 can be programmed to

send a heartbeat signal to the computer automation

once every 01-99 seconds to test the connection

between the CPM3 and the computer automation

(30 seconds is recommended). If a heartbeat fails to

get a response from the computer automation, the

CPM3 will immediately transmit the heartbeat again,

up to 4 attempts. The SG-System III, by default, will

output the automation signals via TCP/IP. If TCP/IP

fails it will switch to the Serial Automation output.

If the serial output fails, the CPM3 will switch to

manual mode, all signals will be displayed on the

LCD and will require a manual acknowledgement. To

re-establish connection with the TCP/IP a reset SG

fallback command must be generated from the Console software. If the line card buffers are full, the line

cards will stop answering calls.

1.5.11 System III SIA Internal Status Output

0

RR

LLL

0000

NYYZZ

[DC4]

0RRLLL[#0000|NYYZZZZ]

Protocol ID

Receiver number of the CPM3

Line card number, 000 signifies a

CPM3 Event.

System III account.

SIA Event

Terminator, 14 Hex

Refer to “CPM3 Internal Status Messages” on

page 35.

7

Section 2 - CPM3 Operating Modes

192.168.0.1

192.168.0.1

2.1 Contrast Adjust

To adjust the contrast press the Up and Enter buttons together to increase the contrast or press

Scroll Down and Enter together to decrease the contrast. This operation can be done at any time after

the power up sequence.

2.2 Active Mode

In active mode, the primary connection to the computer is via TCP/IP networking on the 10/100 BaseT

Ethernet connection for the automation computer. If

this fails, then the output will go via serial RS-232. A

command can then be sent through the System III

Console software to revert back to TCP/IP when the

connection is restored. The IP of the CPM3 is displayed on the screen.

Figure 2-1, Active Mode

192.168.0.1

2.3 Manual Mode

For manual mode, each event will activate the internal buzzer to be acknowledged manually. Each event

will be sent automatically to the connected printer

and displayed on the CPM3 LCD. Messages longer

than 80 characters will be displayed on two lines.

Once the signal is acknowledged, it will be cleared

from the screen.

Figure 2-2, Manual Mode

NOTE: The CPM3 will display a maximum of 5000

events which have not been acknowledged.

2.4 Standby Mode

When two CPM3s are present, one CPM3 will be in

active or manual mode, and the other CPM3 will be

in standby. If the active CPM3 fails, the standby unit

will automatically take over the control of the system. The IP of the CPM3 is displayed on the screen.

Figure 2-3, Standby Mode

192.168.0.1

2.5 System Trouble

When a trouble is present on the System III, the

message ‘SYSTEM TROUBLE’ will be displayed at the

bottom of the screen.

• To view which trouble is present, press the

SCROLL UP and SCROLL DN buttons simultaneously. (All signal must be acknowledged before

this is available.)

• To return to the main screen, press the SCROLL UP

and SCROLL DN buttons simultaneously, or wait

for timeout before this is available.

System Troubles are displayed as shown in Figure

2-4:

Figure 2-4, System Troubles

8

Section 3 - DRL3 Operating Modes

3.1 DRL3 Standby Mode

After start-up the line card enters the Standby mode

and monitors the telephone line and the CPM3.

Depending on the system's status, the following conditions will be displayed for each line card:

LED ON OFF FLASH-

LINE

(Red)

STATUS

(Yellow)

WATC H-

DOG

(Blue)

Line

Fau lt

On-line Off-line

Line Card

not functional

Line

Normal

* The number of flashes on the yellow LED

indicates the following errors:

1. CPM absent

2. Line card clock not set

3. EBUS command to disable the line card

was sent.

4. Printer or computer buffer full.

5. Checksum failed when downloading

Flash ROM files.

3.2 Line Fault

The DRL3 verifies the telephone line voltage. The

'Line Fault' LED will come ON when the voltage drops

below 12V

Printer:

Jul 17 1998-08:08:28-SS/OO-SG-RR-LLL-0000PHONE LINE TROUBLE

Computer:

0RRLLL[#0000¦NLTSSOO][DC4]

A hexadecimal number from 01 to 0C representing

the slot number of the line card will be sent for each

'00' shown above.

A hexadecimal number from 01 to 02 representing

the shelf number of the line card will be sent for each

'SS' shown above.

When the line condition returns to normal, the 'Line

Fault' LED will be shut OFF. The following information

will be transmitted to the printer and computer:

Printer:

Jul 17 1998-08:08:35-SS/OO-SG-RR-LLL-0000PHONE LINE RESTORE

Computer:

0RRLLL[#0000¦NLRSSOO][DC4]

NOTE: Additional line fault operation if Backup

Line option is enabled. See Backup Line option

(Option 0E) for explanation.

DC.

ING

N/A

*Error

condition

Line Card

functional

3.3 CPM3 Error

If the DRL3 cannot detect the CPM3 polling, the

DRL3 will start buffering incoming calls. Up to 512

alarm messages for the printer and computer will be

retained in the DRL3 event buffer. When the event

buffer is full, the line card will stop answering the

calls and the status LED will begin flashing. When the

CPM3 Error condition is corrected, the alarm messages in the event buffer will be transmitted to the

CPM3 with the corresponding time/date the alarm

has been received.

3.4 Data Reception

During data reception, the yellow STATUS LED will

turn on. The DRL3 decodes all information received

and stores the information in its Event Buffer. When a

valid signal is received, the DRL3 sends a kiss-off signal and transmits the decoded alarm signal to the

computer and to the printer through the CPM3. The

DRL3 will send each message it receives to the

printer for review by the system operator. Two messages may be sent to the printer to indicate reception problems: the 'Fault Data' (Invalid Report) and

'Fault Call' (Communication Fail).

3.4.1 Fault Data Message

When this problem is encountered, the following information is transmitted to the printer and the computer:

Printer:

Jun 25 1998-11:18:07-SS/OO-SG-12-234-0000INVALID REPORT

Computer:

012234[#0000¦NYNSSOO][DC4]

This output for account code '0000' indicates that

data has been received, but is not valid (for example,

there are unmatched rounds or incorrect parity).

3.4.2 Fault Call Message

When this problem is encountered, the following information is transmitted to the printer and the computer:

Printer:

Jun 25 1998-11:18:07-SS/OO-SG-12-234-0000COMMUNICATION FAIL

Computer:

012234[#0000¦NYCSSOO] [DC4]

This output indicates that a call was received, but no

data was detected. The call may have been a wrong

number, or the calling control panel was unable to

connect with the receiver's handshakes.

Computer message NACKed 25 consecutive times.

Printer message: Internal Comm. Error

Computer signal: RRLLL[#0000¦NRTSSOO][DC4]

9

Section 4 - Programming/Operation

4.1 Introduction

The System III can be programmed manually using

the front panel; from a local computer using the

Debug Output located on each line card behind the

front panel; or remotely using the TCP/IP network

and System III Console software. The Debug output

is intended as a testing and troubleshooting tool.

Manual programming allows the user to program all

of the System III options for remote and local operation. Manual programming does not support the

grouping of line cards into hunt groups or line pools.

4.2 System III Console Software

The System III Console software is intended to be

the primary method of programming the system,

refer to the System III Console User Manual for

details.

4.3 Debug Programming

The debug output is another method of accessing

the line card's programmed options and diagnostics

features. A debug cable is required to connect by

serial communication from the line card to a standard PC running Windows 95 or higher software.

NOTE: Debug programming only affects options in

profile “0”.

ALL PROGRAMMING WITH THE DEBUG SETUP IS

LOST WHEN THE SYSTEM IS POWERED DOWN OR

WHEN LINE CARDS ARE REBOOTED OR REMOVED

FROM THE RACK.

4.3.1 Debug Cable Connectivity

• Connect the RJ-45 end of the debug cable to the

debug jack on the front of the line card.

• Connect the female DB-9 connector to the serial

port of a computer.

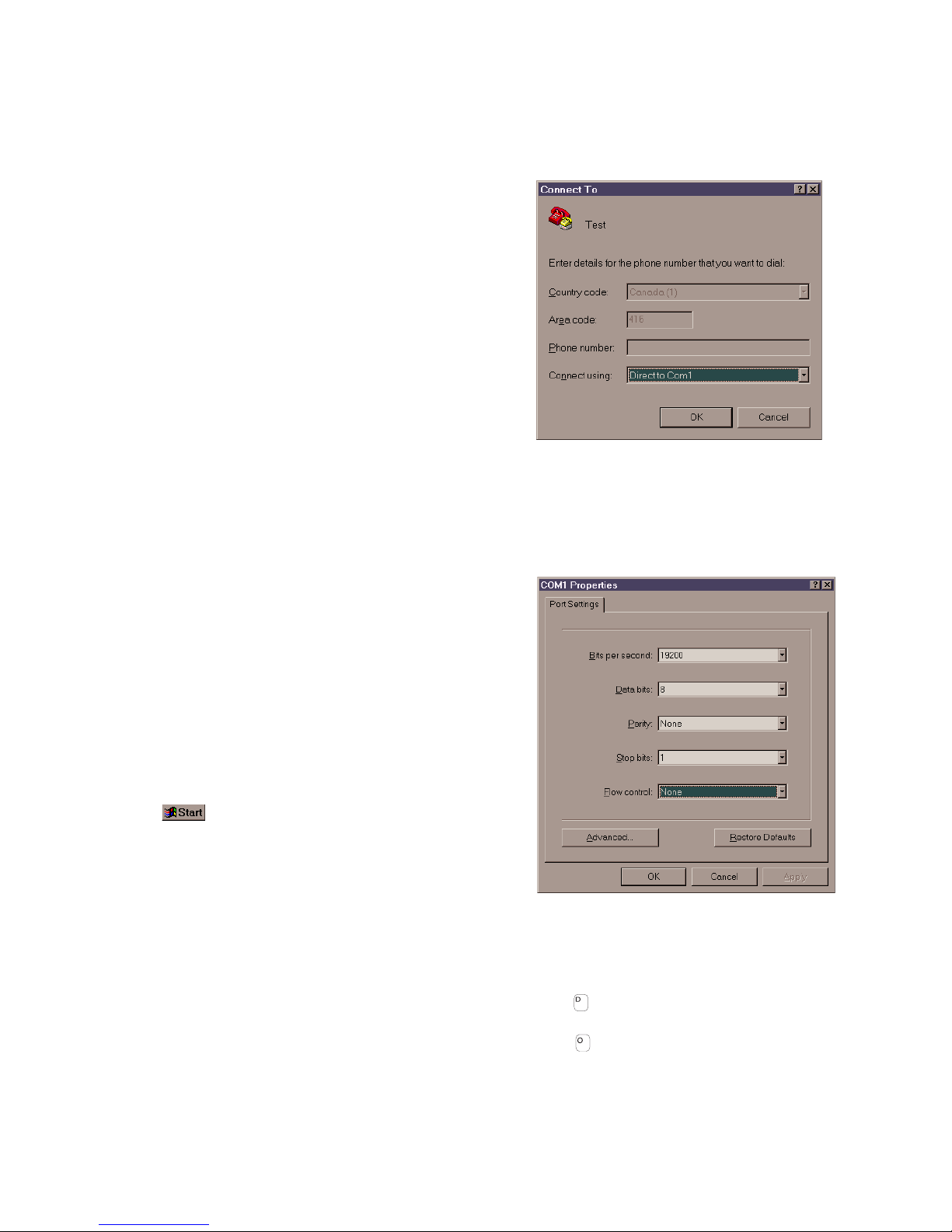

4.3.2 Debug Software Setup

• Using Windows 95 or higher, point and click on

the button.

•Then select Programs Accessories Commu-

nications HyperTerminal. Once in the Hyper-

Terminal window, point and click on the

'Hypertrm.exe' icon.

• A connection description window should appear. A

prompt should appear on the 'Name' category.

Type a name. Point and click on the 'OK' button.

• A phone number window should appear. Choose

the direct to COM port required for connection

and point and click on 'OK'.

Fig ure 4-1

• The COMx properties windows should appear. The

configuration should be:

Bits per second:

Data bits:

Parity:

Stop bits:

Flow control:

Fig ure 4-2

• Click on the 'OK' button after setting the configuration.

• The HyperTerminal window should appear. Press

any key. The debug menu will be displayed.

Keyboard Commands

• The key will initiate the download of a file to the

line card.

• The key will enable the user to dump the current programmed options of the line card or set an

option to a particular value.

19200

8

None

1

None

10

4.3.3 Downloading Steps

1. Press the key to initiate downloading of the

binary file. The HyperTerminal will display:

Ready to download.

CCCC

2. Point and click on 'Transfer' on the HyperTerminal

menu and access the 'Send File' category. The 'Send

File' window should appear.

Fig ure 4-3

3. Change the protocol to 'X-modem' and place the

correct path and file name of the binary file to be

downloaded.

4. Point and click on the [Send] button and the downloading status window should appear. The line card

will restart automatically after a successful download.

4.4 Manual Programming

The user interface consists of 3 buttons: the

Scroll Up button, the Scroll Down button, and the

Enter button. These buttons are used to access the

programming of the line cards and the CPM3, and to

view alarm and trouble messages in manual mode.

They are located on the right side of the screen.

Fig ure 4-4

The Configuration mode allows programming of the

various features and options available on the

System III. To enter the Configuration mode, press

the [Enter] button; the following screen will be displayed.

Enter the Master Access Code using the buttons; the

default Master Access Code is "CAFE" to change the

default Master Access Code.

When the access code is entered, the screen will display the Configuration Menu.

Figure 4-5, Configuration Menu

CPM Options allow the user to customize the operation of the system TCP/IP addressing, Passwords,

COM settings and other system functions are programmable here. Refer to the description of all CPM

options and their default settings.

4.4.1 Advanced Programming

The advanced programming menu allows the user to

change the options of a specific profile and line card.

The CPM3 will prompt the user to enter the line card

number, the profile number, and the option number.

When all the information is entered (the line card number, the profile number, and the option number), the

CPM3 will move to the option value segment and display

the current value of the option. The user can change the

value by pressing the up or down key. After the changing

the value, the CPM3 will display the following:

Line card Menu

0 Go to next Line card number

1 Go to next profile number

2 Go to next option number

3Save

The user can change multiple profiles and options per

line card. After all the modifications to options and profile are made, the user must Save in order for the

changes to take effect for each line card.

To exit from the menu, the user must press the Scroll Up

and Scroll Down keys simultaneously.

NOTE: The line card will need to be reset in order for

the options to take effect.

Programming Line Card Options:

• Cold boot Line Card

Resets the selected line card to the factory

defaults. This will also clear all the internal buffers.

Figure 4-6, Advanced Programming Menu

11

4.4.2 System functions

• Reset the CPM3

Restarts the CPM3. This is required to make the

changes to some options effective. For example,

the IP address.

•Date and Time

To set the date and time of the System III. This can

also be done from the Console software.

Figure 4-7. System Function Menu

Advanced Programming allows the user to customize line card profiles.

4.5 CPM3 Options

Option [01]: IP Address - Default [10.0.7.100]

Enter the IP Address of

the CPM3. Ensure that

the IP address programmed is unique to

the CPM3.

Option [02]: Subnet Mask

Address Default [255.255.0.0]

Enter the Subnet Mask

Address of the CPM3.

Option [03]:

Enter the Gateway Address of the CPM3 if required.

Option [04]: Auto Update Time & Date - Default [0]

This option allows the automation to update the SGCPM3’s time via the TCP/IP port. When enabled should

the CPM3 fail to get the time & date within 24 hours

period (started after the last update is received), it will

generate a status message to the printer and automation, following the internal trouble protocol. The Trouble

status on the CPM3 will not be affected. The SG-System

III Console time update function must be disabled when

using this feature or there is possibility that the CPM3

will not remain synchronized with the automation PC.

Printer message: "Time&Date Update Fail"

Automation message: 0RRLLL[#0000¦NRU0000]

Option [05]: Contrast Adjust - Default N/A

Allows the contrast of the message display screen to be

adjusted. Press the up or down button to adjust. The

contrast can also be adjusted from the main screen by

holding the up and enter buttons simultaneously to

increase the level, or by holding the enter and down buttons simultaneously to decrease the level.

Gateway Address - Default [0.0.0.0]

Option [06]: Password Menu - Default [CAFE]

Allows the System III

users and passwords to

be erased or changed.

Sixteen users with 4digit passwords are

available for use on the

System III. User 0 is the

Master user, and users 1

through F may be

assigned to individual

operators. The Master

user will provide access to all menus, while the operators

will not have access to the CPM3 settings. To erase a user,

program the password for that user to ‘FFFF’.

NOTE: User “0” cannot be erased.

Option [07]: COM1 Baud Rate - Default [9600]

Determines the baud rate at which the CPM3 will communicate to the automation software via serial port 1.

2400 9600

4800 19200

Option [08]: COM1 Data Bits - Default [8]

Determines the number of data bits used to communicate to the Automation Software connected on the serial

port 1. Choose a number from 7 through 9 to indicate 7,

8, or 9 data bits.

Option [09]: Parity - Default [0]

Determines the parity of the serial port 1.

0: no parity (default)

1: odd parity

2: even parity

NOTE: The number of stop bits can not be changed

and will always be 2.

Option [0A]: COM2 Format - Default [0]

This option affects how the COM2 Serial Port is supervised and how the data is formatted.

To disable the option set to [0].

To enable the printer messages to be outputted to a

serial printer via the COM2 set to [1].

To enable the printer messages to be outputted to a

computer via the COM2 port set to [2].

To enable SCADA interface through the COM2 set [3].

This setting is for FUTURE USE.

Option [0B]: COM2 Baud Rate - Default [9600]

Determines the baud rate at which the CPM3 will communicate to the Serial Printer connected on the serial

port 2:

2400 9600

4800 19200

OOption [0C]: COM2 Data Bits - Default [8]

Determines the number of data bits used to communicate to the Automation Software connected on the serial

port 2. Choose a number from 7 through 9 to indicate 7,

8, or 9 data bits.

Option [0D]: COM2 Parity - Default [0]

Determines the parity of the serial port 2.

0: no parity (default)

1: odd parity

2: even parity

NOTE: The number of stop bits can not be changed

and will always be 2.

12

Option [0E]: TCP GUI - Default N/A (Future Use)

Option [0F]: B32 Headers - Default [00]

Compatible with MAS B32 Automation Software through

TCP/IP. To enable, change to [01].

Option [10]: Input RRLLL Digits - Default [5]

Indicates the number of expected digits in the computer

message header from the line card. This must be the

same as Option [02] of the line cards +2.

Option [11]: Output RRLLL Digits - Default [5]

Indicates the number of digits the CPM3 will send in the

header to the automation output. This should be left as 5

unless the automation software does not support the

MLR2000 or System III output protocol.

NOTE: Ensure that option [02] in the DRL3 line cards

is programmed to match this entry. For example, if

CPM3 option [0F] is programmed with [04], then DRL3

option [02] must be set to, [02].

Option [12]: Heartbeat Timer - Default [30]

Determines at what time interval, in seconds, the heartbeat transmission will be sent to COM1 and TCP/IP port

1025. The heartbeat transmission is used to ensure that

communications through COM1 and TCP/IP are functioning normally. Enter a decimal number from 01

through 99 to determine the time interval between

heartbeat transmissions. Program this option as "00" to

disable the heartbeat transmission.

Option [13]: Mute Buzzer - Default [OFF] (Disabled)

A tone will sound when the System III receives an alarm

and is unable to forward the alarm message to COM1 or

TCP/IP. The tone may be silenced with this option. If

enabled, the buzzer will not sound when an alarm is

received and cannot be forwarded to COM1.

Option [14]: Receiver Number - Default [01]

The receiver number is used to identify the receiver

when communicating to the TCP/IP Automation, COM1

and the printer. To change the receiver number, enter a

new receiver number using the hexadecimal numbers

"01" to "FE".

Option [15]: Printer Test - Default [Off]

When this option is enabled, a test signal will be sent to

the printer at 05:00 and 17:00 hrs. This option is set to

"0" (OFF) by default.

Printer message:

26 Nov 2003 16:41:25 - 26 Nov 2003-16:41:25-00/00SG -01-000-0000--Printer Test Message

Option [16]: Mask PSU 1- Default [Off]

Some installation may not have the full System III configuration, Option 14 through 1E are used to enable or disable the supervision of the selected components. To not

report the trouble, turn the appropriate option ON.

NOTE: PSU 1 is the PSU3 installed in shelf 1

Option [17]:

NOTE: PSU 2 is the PSU3 installed in shelf 2

Option [18]:

DC A is the Right DC/DC3 located on the same shelf as

the CPM3 being programmed

Option [19]:

DC B is the Left DC/DC3 located on the same shelf as

the CPM3 being programmed.

Mask PSU 2- Default [On]

Mask DC A - Default [Off]

Mask DC B- Default [On]

Option [1A]: Mask DC A2 - Default [On]

DC A2 is the Right DC/DC3 located on the other shelf

from the CPM3 being programmed.

Option [1B]: Mask DC B2- Default [On]

DC B is the Left DC/DC3 located on other shelf from the

CPM3 being programmed.

Option [1C]:

DC/DCB Shelf 1 trouble mask. If set, DC/DCB Shelf 1

trouble conditions are not reported

Option [1D]:

DC/DCB Shelf 2 trouble mask. If set, DC/DCB Shelf 2

trouble conditions are not reported.

Option [1E]:

Fan Shelf 1 trouble mask. If set, Fan Shelf 1 trouble conditions are not reported.

Option [1F]:

Fan Shelf 2 trouble mask. If set, Fan Shelf 2 trouble conditions are not reported.

Option [20]:

UPS AC Shelf 1 trouble mask. If set, UPS AC Shelf 1 trouble conditions are not reported.

Option [21]:

UPS Battery Shelf 1 trouble mask. If set, UPS Battery

Shelf 1 trouble conditions are not reported.

Option [22]:

UPS AC Shelf 2 trouble mask. If set, UPS AC Shelf 2 trouble conditions are not reported.

Option [23]: Mask UPS BAT 2 - Default [On]

UPS Battery Shelf 2 trouble mask. If set, UPS Battery

Shelf 2 trouble conditions are not reported.

Option [24]: Mask SG TCP 1 – Default [Off]

SG TCP Shelf 1 trouble mask. If set, SG TCP shelf 1 trouble conditions are not reported.

Option [25]: Mask SG Serial 1 – Default [Off]

SG Serial Automation Shelf 1 trouble mask. If set SG

Serial automation shelf 1 trouble conditions are not

reported.

Option [26]: Mask SG TCP 2 – Default [On]

SG TCP Shelf 2 trouble mask. If set, SG TCP shelf 2 trouble conditions are not reported.

Option [27]: Mask SG Serial 2 – Default [On]

SG Serial Automation Shelf 2 trouble mask. If set, SG

Serial automation shelf 2 trouble conditions are not

reported.

Option [28]: Mask TCP 1 Printer - Default [Off]

SG TCP Printer Shelf 1 trouble mask. If set, SG TCP

Printer shelf 1 trouble conditions are not reported.

Option [29]: Mask Parallel 1 Printer - Default [Off]

SG Parallel Printer shelf 1 trouble mask. If set, SG Parallel

Printer shelf 1 trouble conditions are not reported.

Option [2A]:Mask Serial 1 Printer - Default [Off]

SG Serial printer shelf 1 trouble mask. If set, SG Serial

Printer Shelf 1 trouble conditions are not reported.

Option [2B]: Mask TCP 2 Printer - Default [On]

SG TCP Printer Shelf 2 trouble mask. If set, SG TCP

Printer Shelf 2 trouble conditions are not reported.

13

Mask Low Battery 1 - Default [On]

Mask Low Battery 2 - Default [On]

Mask Fan 1 Fail - Default [Off]

Mask Fan 2 Fail - Default [On]

Mask UPS AC 1 - Default [On]

Mask UPS BAT 1 - Default [On]

Mask UPS AC 2 - Default [On]

Option [2C]: Mask Parallel 2 Printer - Default [On]

SG Parallel Printer shelf 2 trouble mask. If set, SG Parallel

Printer Shelf 2 trouble conditions are not reported.

Option [2D]: Mask Serial 2 Printer - Default [Off]

SG Serial Printer Shelf 2 trouble mask. If set, SG Serial

Printer Shelf 2 trouble conditions are not reported.

Option [2E]: Number of Line Cards- Default [12]

Option [1F] is used to set the number of line cards

polled by the CPM3. Enter a number from 01 to 24 to

indicate how many line cards are to be polled by the

CPM3.

Option [2F]:

The TCP/IP connection is the primary output of the System III for automation computer alarms. It is estimated

that sockets may appear and disappear regularly as processes are terminated and reconstituted. After 5 seconds of socket loss, a socket loss is declared and

automation output is shifted to the next connection

level, which is the serial automation output connection.

First configuration: LOOP (0)

If both outputs are present, the CPM3 will send to the

TCP/IP until it fails, proceed to the serial until it fails, proceed back to the TCP/IP until it fails ... and so on. See

Automation out flow diagram 1.

Second configuration: FALL BACK (1)

If both outputs are present, the CPM3 will send to the

TCP/IP until it fails, proceed to the serial until it fails, and

will keep trying on the serial continuously, or until the

reset fallback command is generated from the console,

in which case it would go back to try the TCP/IP connection. See Automation out flow diagram 2.

Third Configuration: ALL (2)

The CPM3 will always send to all connected outputs. If

at least one output replies with a ACK, then the alarm is

considered as transmitted regardless if the other output

acknowledged it or not. This setting is NOT recommended. See Automation out flow diagram 3.

Fourth Configuration: IP Fall Back Mode (3)

The CPM3 A will send through its TCP/IP output until it

fails. If it fails the CPM3 B will sent through its TCP/IP

output. If it fails the CPM3 A will send the signals

through its serial output. If that fails the CPM3 B will

output through its serial output. See Automation out

flow diagram 4.

Fifth Configuration: Automatic SG-Fall Back (4)

This mode is similar to Fall Back except that when the

TCP/IP connection is restored the CPM3 will return to the

TCP/IP port to send events. This eliminates the need for

the Reset SG Fallback from the SG-System III Console.

Automation Mode - Default [1] (Fall Back)

Option [30]:

The printer outputs can be configured in a similar

approach as the automation outputs except that the

FALLBACK (1) option is not available.

Default Configuration: ALL (2)

NOTE: Order of sequence is TCP, Parallel and finally Serial.

DSC does NOT recommend changing the default setting.

Option [31]:

Determines the acknowledge wait time, in tenths of a

second, to be used for automation outputs before the

CPM3 will try again if no response is received within this

interval.

Enter a decimal number from 40 to 99 for 4.0 seconds

to 9.9 seconds.

Option [32] Date Format – Default [0]

Selects the format used to represent date for printer output. Format [1] represents US format is

MM/DD/YY . Format [0] International format is DD/MM/

YY.

Option [33] Protocol ID – Default [0]

When this option is programmed as ‘0’ the CPM3 will

output its internal messages in the following format:

0RRLLL[#AAAA|Nxxyy]

When this option is programmed as ‘S’ the CPM3 will

output its internal messages in the following format:

SRRLLL[#AAAA|Nxxyy]

S,0 (zero): protocol number

RR: Receiver number

LLL: Line number

AAAA: Account code, always 0000

Nxxyy: SIA event

Option [34] Time Correct – Default [000]

The CPM3 will synchronize its time with the SG-System

III console application PC. However in some

situations it may be desirable to automatically correct

the time of the CPM3. The CPM3 will update its time

once an hour. Valid values are -590 to +590;

value represents time in tenths of a second (i.e. 243

means 24.3 seconds).

Option [35] Output Config – Default [Local] (Future Use)

Option [36] CIS Enable – Default [0] (Future Use)

Enable the CIS protocol for automation outputs.

Option [37] RBUS HighSpeed – Default [1]

Sets the speed of the communication from the CPM3 to

the to the DRL3s.

NOTE: The option in the DRL3 must be set to the

same speed in order for communication to work. All

units must have the same speed. Once changed the

unit must be reset for the option to take affect.

Printer Mode- Default [2]

ACK Wait - Default [40]

14

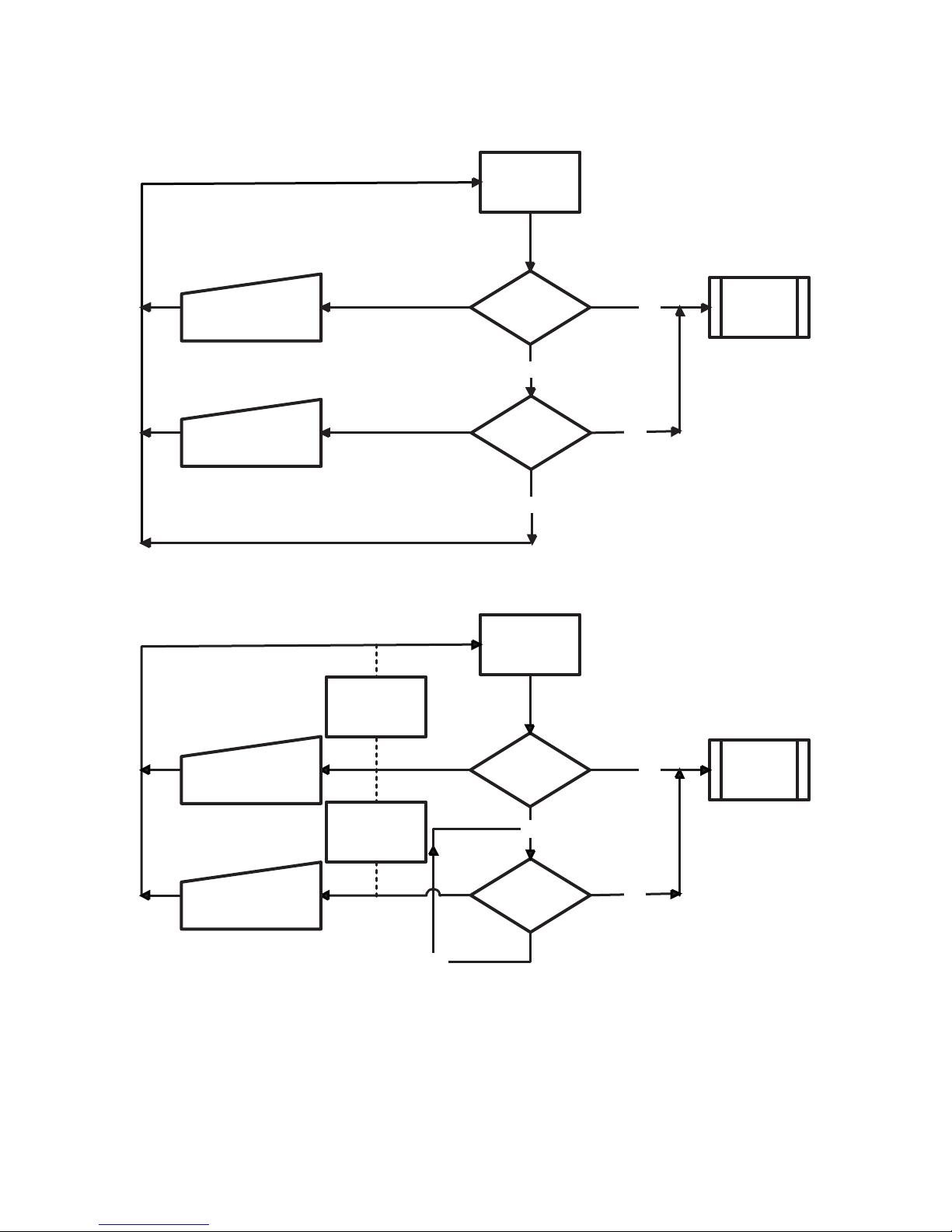

Flow Diagram for Automation LOOP Mode (0)

Power Up/Restart

Manual Re-start from

Console (Reset Fallback)

Manual Re-start from

Console (Reset Fallback)

Flow Diagram for Automation FALL BACK Mode (1)

Automatic Fall

Back mode (4)

CPM3 (A)

Ethernet Port

Active?

No

CPM3 (A) Serial

Port Active?

No

Power Up/Restart

Yes

Yes

Poll

Automation

Manual Re-start from

Console (Reset Fallback)

Manual Re-start from

Console (Reset Fallback)

Automatic Fall

Back mode (4)

No

CPM3 (A)

Ethernet Port

Active?

CPM3 (A) Serial

Port Active?

15

NoNo

Yes

Yes

Poll

Automation

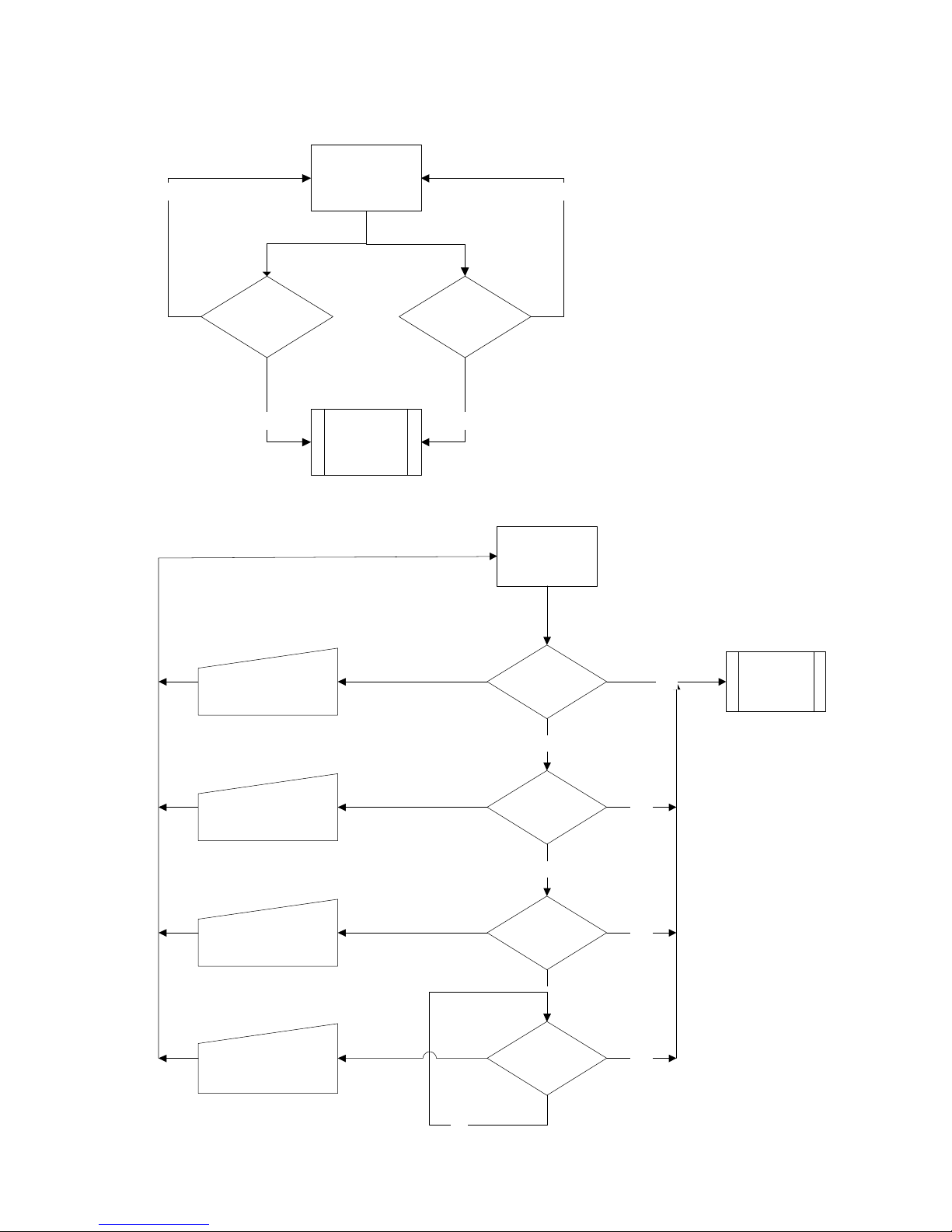

Flow Diagram for Automation ALL Mode (2)

Power Up/Restart

No No

CPM3 (A) Serial

Port Active?

Poll

Automation

Flow Diagram for Automation IP FALL BACK Mode (3)

Manual Re-start from

Console (Reset Fallback)

CPM3 (A)

Ethernet Port

Active?

YesYes

Power Up/Restart

CPM3 (A)

Ethernet Port

Active?

No

Yes

Poll

Automation

Manual Re-start from

Console (Reset Fallback)

Manual Re-start from

Console (Reset Fallback)

Manual Re-start from

Console (Reset Fallback)

No

16

CPM3 (B)

Ethernet Port

Active?

No

CPM3 (A) Serial

Port Active?

No

CPM3 (B) Serial

Port Active?

Yes

Yes

Yes

Section 5 - Advanced Programming

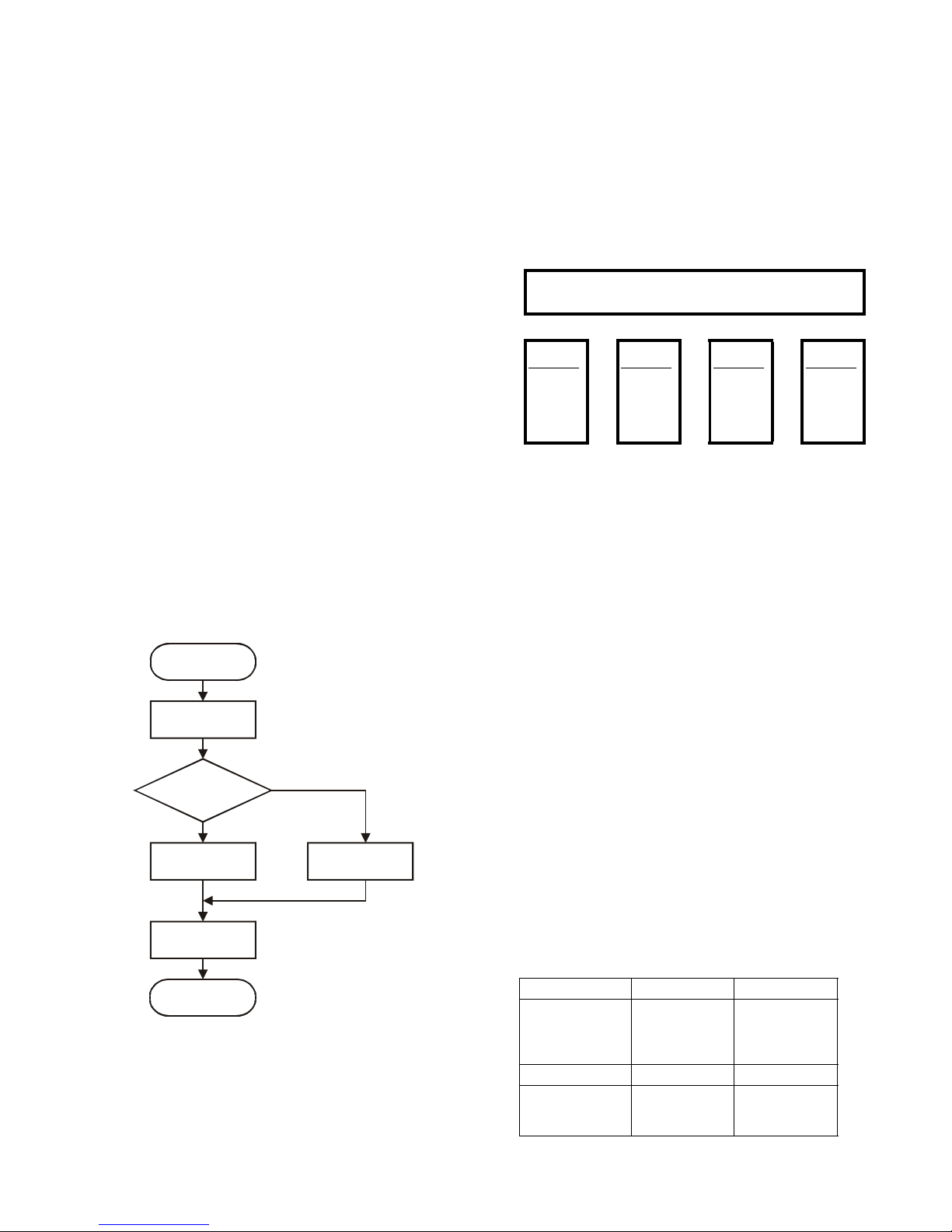

5.1 Profiles Introduction

The DRL3 'virtual receiver' will load unique 'profiles' in

order to effectively communicate with control panels. A profile is a set of pre-programmed line card

options unique for a particular DNIS number. The

'DNIS' will point to a particular profile, which will then

be loaded into the line card before the first handshake is sent. It is essential that the correct option

be programmed for a profile in order to correctly

communicate with the control panel. Each 'virtual

receiver' can have a maximum of 64 profiles. To

change the options for a particular profile, the System III Console software is provided. This software

will allow the user/operator to edit the profiles.

NOTE:DNIS (Dialled Number Identification Service).

This number represents the dialled number, or the

number being called. ANI: (Automatic Number

Identification). This number represents the source

of a call and allows the system to determine the

handshake protocol. Caller ID: This number identifies the source of a call. For the purpose of this document, Caller ID and ANI will be referred to as

Caller ID, but both can not be used at the same

time. Contact your provider to determine which

service is available.

DNIS or Caller ID can be used for profile selection.

Line Cards Identification Number Handling:

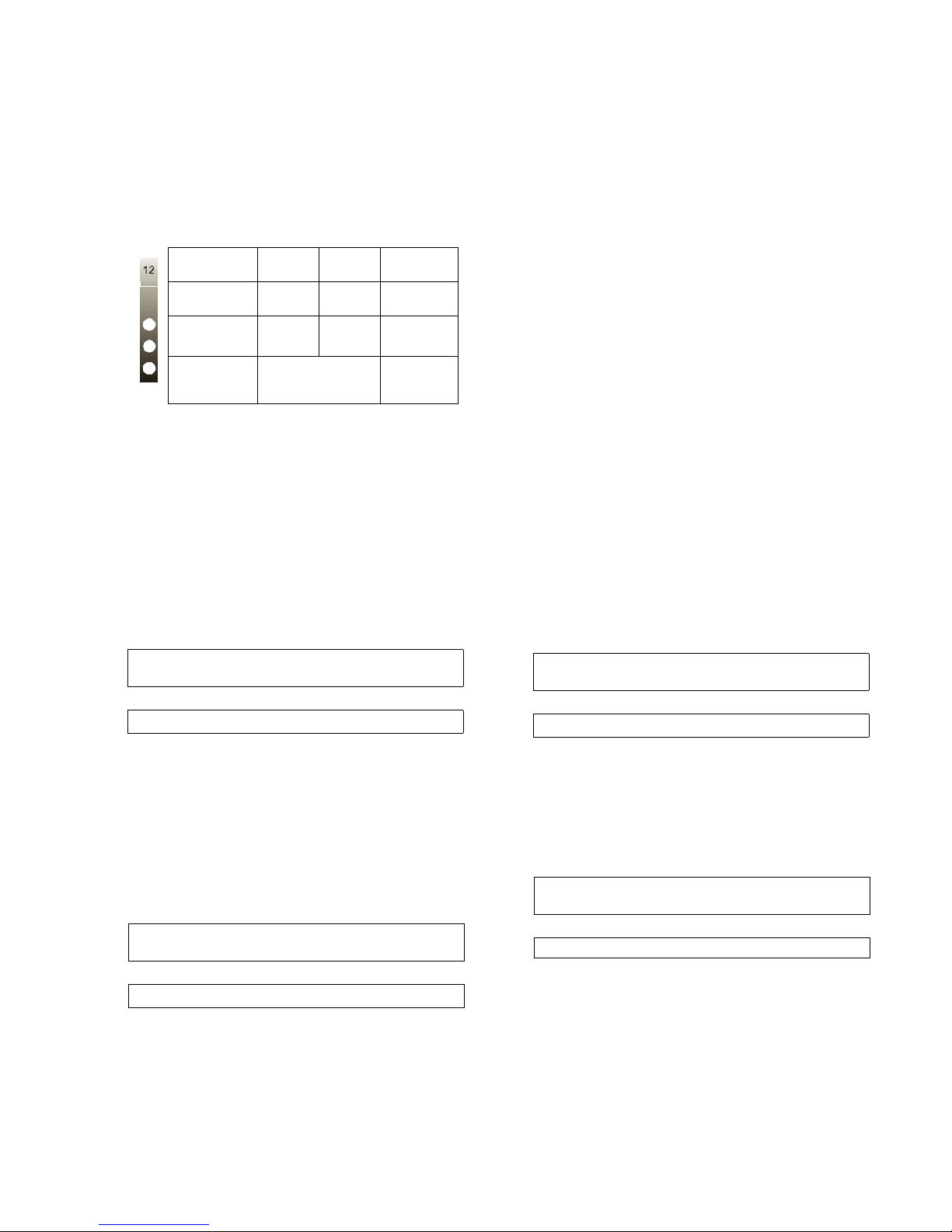

Figure 5-1, Call Processing Flowchart

Receive DNIS

or Caller ID

Send string to

Lookup Table

Corresponding

Profile?

YES

Point to Profile #

Use Options

from Profile

Done

Each profile is made up of Static Options and Dynamic

Options. The static options are the same for all profiles, but the dynamic options can be programmed

specifically per hunt groups, panel type, etc.

No

Use Profile 0

By receiving the DNIS or Caller ID, the appropriate

profile can be selected through a look-up table

"stored" on the line card.

Profile

0

Profile

1

Profile

2

(Default)

00

Static Options - identical for all profiles

2F

30

Dynamic

Options

30 Dynamic

Options

30 Dynamic

Options

unique

for each

profile

AF

AF AF AF

Profile 0 is the default. When no Caller ID or unknown

DNIS is received, or when the received number does

not point to a profile, the default will be used.

Profiles are used to reduce on-line time, and for specific customers or panel/format types, one can have

a profile with certain handshakes sent first. Also,

some formats require certain options, and this can

be pre-defined as well.

Profiles allow for a more customized system. Rather

than having a line card (or a receiver itself) devoted to

certain customers, the System III can "handle" any format at any time through the use of profiles. Each line

card holds its own look-up table that can be shared

through line pools, or shared within the entire receiver.

Two types of tables are available, but only one type can

be chosen. The first type, which consists of 10 000

entries, is used strictly with DNIS of up to 5-digits.

Table type 1:

DNIS receivedProfile # to be used

DNIS Received Profile# to be used

00001

00002

00003

...

99999

01

03

24

...

45

The second type is used if ANI-Caller ID and/or DNIS

are received, and can consist of up to 5,000 entries,

with Caller ID or DNIS of up to 10 digits.

Table type 2:

Caller ID Number Convert Data Profile

05 603000

05 603001

05 603002

05 603003

DNIS Number Convert Data Profile

12345

12346

1234

Not Used

Not Used

Not Used

Not Used

54321

54322

54333

Profile

~

63

30 Dynamic

Options

~

0

1

2

3

0

1

2

17

Loading...

Loading...